Page 1

Data sheet

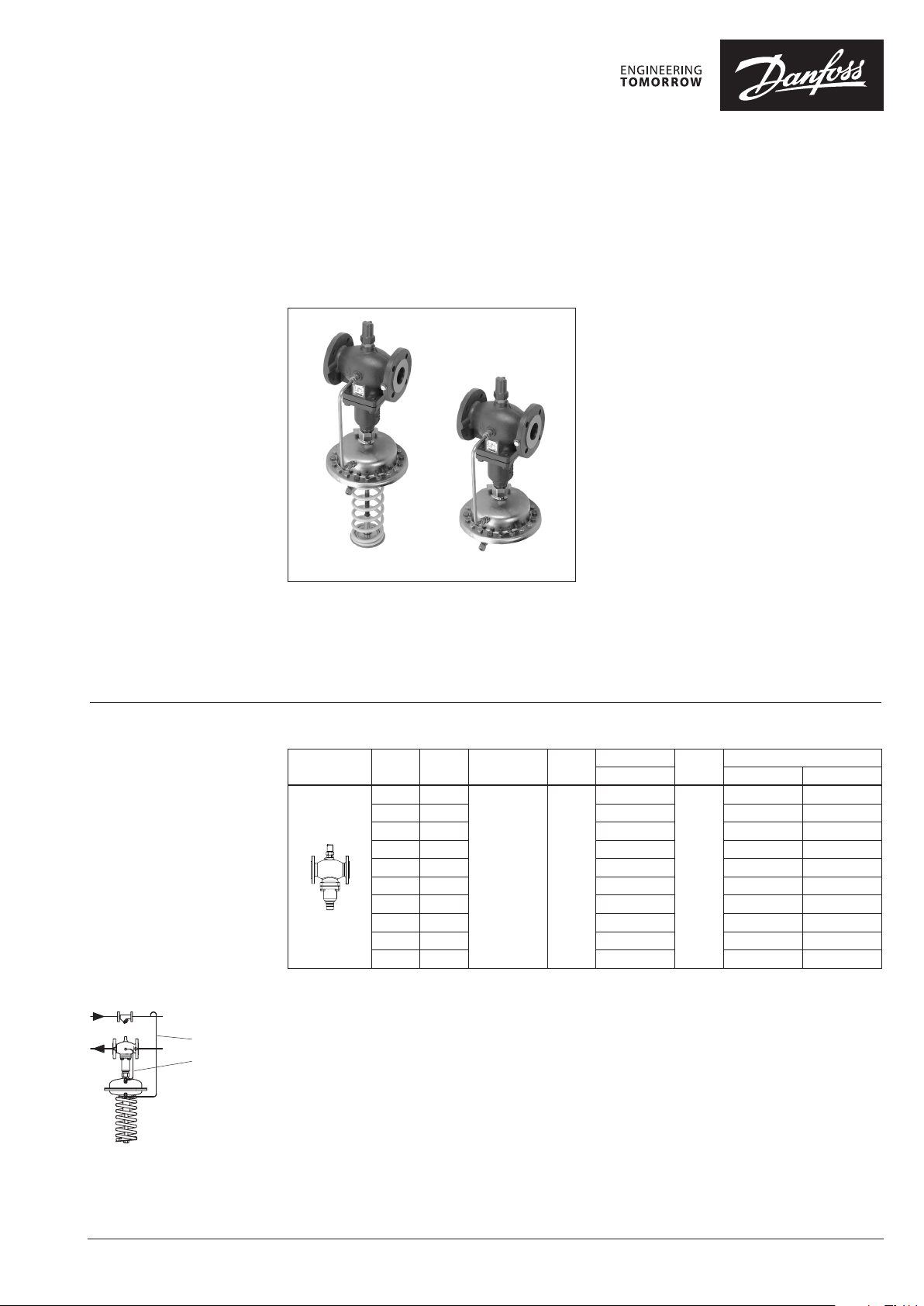

Differential pressure controller with flow limitation (PN 16, 25, 40)

AFPB / VFQ 2(1) – return mounting, adjustable setting

AFPB-F / VFQ 2(1) – return mounting, fixed setting

Description

Ordering

Example 1:

Differential pressure controller with

flow limitation; return mounting;

DN 15; kVS 4.0; PN 16; metallic

sealing; setting range 0.1- 0.7 bar;

t

150 °C; flange;

max

– 1× VFQ 2 DN 15 valve

Code no: 065B2654

– 1× AFPB actuator

Code no: 00 3G1017

– 1× AFPB DN 15 impulse tube

Code no: 003G1355

– 1× Impulse tube set AF

Code no: 003G1391

Products will be delivered separatly.

AFPB AFPB- F

The controller is a self-acting differential pressure

controller with flow limitation primarily for use in

district heating systems. The controller closes on

rising differential pressure or when set max. flow

is exceeded.

VFQ 2 Valves (metallic sealing cone)

Picture

Note: othe r valves available on special r equest.

1)

At temperat ures above 150 °C only with seal pots (see Accessori es)

DN

(mm)

15 4.0

20 6.3 065B2655 065B2668 065B2678

25 8.0 065B2656 065B2669 065B2679

32 16 065B2657 065B2670 065B2680

40 20 065B2658 065B2671 065B2681

50 32 065B2659 065B2672 065B2682

65 50 065B2660 065B2673 065B2683

80 80 065B2661 065B2674 065B2684

100 125 065B2662 065B2675 065B2685

125 160 065B2663 065B2676 065B2686

k

VS

(m3/h)

Connections

Flanges acc. to

EN 1092 -1

T

(°C)

150

The controller has a control valve with adjustable

flow restrictor, an actuator with one control

diaphragm and spring for differential pressure

setting.

Further on two valve versions are available:

– VFQ 2 with metallic sealing cone

– VFQ 21 with soft sealing cone (on special

request)

Main data:

∙ DN 15 -125

∙ kVS 4.0 -160 m3/h

∙ Flow range: 0.05-120 m3/h

∙ PN 16, 25, 40

∙ Setting range: 0.1-07 bar/0.15-1.5 bar

∙ Temperature:

– Circulation water/glycolic water up to 30 %:

2 … 150/200 °C

∙ Connections:

– Flange

max.

Code No.

PN 16 PN 25 PN 40

065B2654

T

(°C)

200

max.

1)

Code No.

065B2667 065B2677

Impulse tube set AF

Impulse t ube AFPB

© Danfoss | 2018.10 VD.AC.B7.02 | 1

Page 2

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

Ordering (continuous)

Example 2:

Differential pressure controller with

flow limitation; return mounting;

DN 15; kVS 4.0; PN 25; metallic

sealing; setting range 0.1- 0.7 bar;

t

200 °C; flange;

max

– 1× VFQ 2 DN 15 valve

Code no: 065B2667

– 1× AFPB actuator

Code no: 00 3G1 017

– 1× AFPB DN 15 impulse tube

Code no: 003G1355

– 1× Impulse tube set AF

Code no: 003G1391

– 1× Seal pot V1

Code no: 003G1392

Products will be delivered separatly.

Seal pot V1

Impulse tube set AF

Impulse t ube AFPB

AFPB(-F) Actuators

Picture

∆p setting range

(bar)

0.1 – 0.7

0.15 – 1.5 003 G1016

0.2

0.5 003 G1027

Max. operat. pressure Code No.

25

25

Accessories

Picture Type designation For controller

Impulse tubes

(Stainless steel)

Picture Type designation Description Ordering number Code No.

Impulse tube set AF

Seal pot V1

Compression fitting

port B

Combination piece KF3

3)

port A

Combination piece KF2

1)

2)

AFPB

– 1× Copper tube

Ø10 × 1 × 150 0 mm

– 1 × compression fitting for imp.

tube connection to pipe (G 1/)

– 2 × socket

Capacit y 1 liter; with compression

fittings for imp. tube Ø10

For impulse tube Ø10 connections

to controller

For combination with pressure

actuators. Electrical actuator

connected on side (port B)

only for ON/OFF function

For combination with thermostat side connection to port B

DN

(mm)

15

20

25

32

40 003G1359

50 00 3G1360

65

80

100 00 3G1363

125 0 03G136 4

G 11//2× G 11/

PN Code No.

16, 25, 40

–

G 1/ 003G1468

00 3G1017

003 G1026

00 3G1355

00 3G1357

00 3G1361

003G1391

003G1392

00 3G1441

00 3G1440

Shut off valve

Throttle valve 065B2909

1)

Seal pot has to b e used on impulse tubes alwa ys when Tmax ≥ 150 °C

2)

Consist of a nipple , compression ring and nut

3)

Port A - for conn ection of any type of ac tuator

For impulse tube Ø10 –

00 3G1401

Service kits

Picture Type designation For valve

Valve insert VFQ 2

Stuffing cone (with EPDM O -rings) 003G1464

DN

(mm)

15 4.0 065B2796

20 6.3 065B2797

25 8

32 16

40 20

50 32

65 50

80 80

100 125

125 160

k

VS

(m3/h)

Code No.

065B2798

065B2799

065B2800

065B2801

2 | VD.AC.B7.02 © Danfoss | 2018.10

Page 3

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

2

Technical data

Valve

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125

kVS value

Range

of max.

flow

setting

pSPp

0.2 0 .1

1)

0.5 0.3

1.0 0.5

SISTEM

0.1/0.2/0.5 from

p

0.1

0.2

0.5

b

Cavitation factor z 0.6 0.6 0.6 0. 55 0.55 0.5 0.5 0.45 0.4 0.35

Leakage acc. to

standard IEC 534 (% of kVS)

Nominal pressure PN 16, 25, 40

Min. differential pressure

Max. differential pressure

PN 25, 40 20

Media Circulation water/glycolic water up to 30 %

Media pH Min. 7, max. 10

Media temperature

VFQ 21 2 … 150

Connections Flange

Materials

Valve body

Valve seat Stainless steel, mat. No. 1.4021

Valve cone Stainless steel, mat. No. 1.4404

Sealing

Pressure relieve system Bellows (Stainless steel, mat. No. 1.4571)

1)

Max. flow rate depends o n the differential pressur e over the system (dp System). System is part of the a pplication where dif ferential

pressure is controll ed by AFPB(-F) and for this part the re sistance is well known/defined .

Flow rates in table are sp recified for 3 diffe rent situations.

pSP = p

∆pSP -diff erential pressure set point

∆p

SYSTEM

∆pb -diff erential pressure over flow re strictor

2)

Depends o n the flow rate and valve kVS ; For Q

3)

at temperature s above 150 °C only with sea l pots (see Accessories)

+ p

System

b

-system dife rential pressure

m3/h

4.0 6.3 8.0 16 20 32 50 80 125 160

0.05 0.15 0.25 0.4 0.6 0.9 2 3.5 6.5 11

to 1.4 2.1 2.5 5 6.5 10 16 25 40 50

m3/h

to 2 3 4 7 11 16 28 40 63 80

to 3 4.5 6 10 16 24 40 58 90 12 0

VFQ 2 ≤ 0.03

VFQ 21 ≤ 0.01

2)

3)

PN 16 16

VFQ 2

bar

°C

see remark

2 … 150/2 … 200

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN-GJS-400(GGG- 40.3)

PN 40 Cast steel GP240 GH (GS-C 25)

VFQ 2 Metal

VFQ 21 EPDM

= Q

–> p

set

max

≥ 0.5 bar; For Q

min

< Q

–>

set

max

Q

p

min

p

b

k

VS

15

Actuator

Typ e AFPB AFPB-F

Actuator size cm

Max. operational pressure PN 25

Diff. pressure setting ranges and spring

colours

Materials

Actuator housing Steel, mat. No.1.0338, zinc plated

Control diaphragm EPDM (Rolling; fibre enforced)

bar

2

250

0.1-0.7 0.15-1.5 0.2 0.5

yellow red fixed setting

VD.AC.B7.02 | 3© Danfoss | 2018.10

Page 4

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

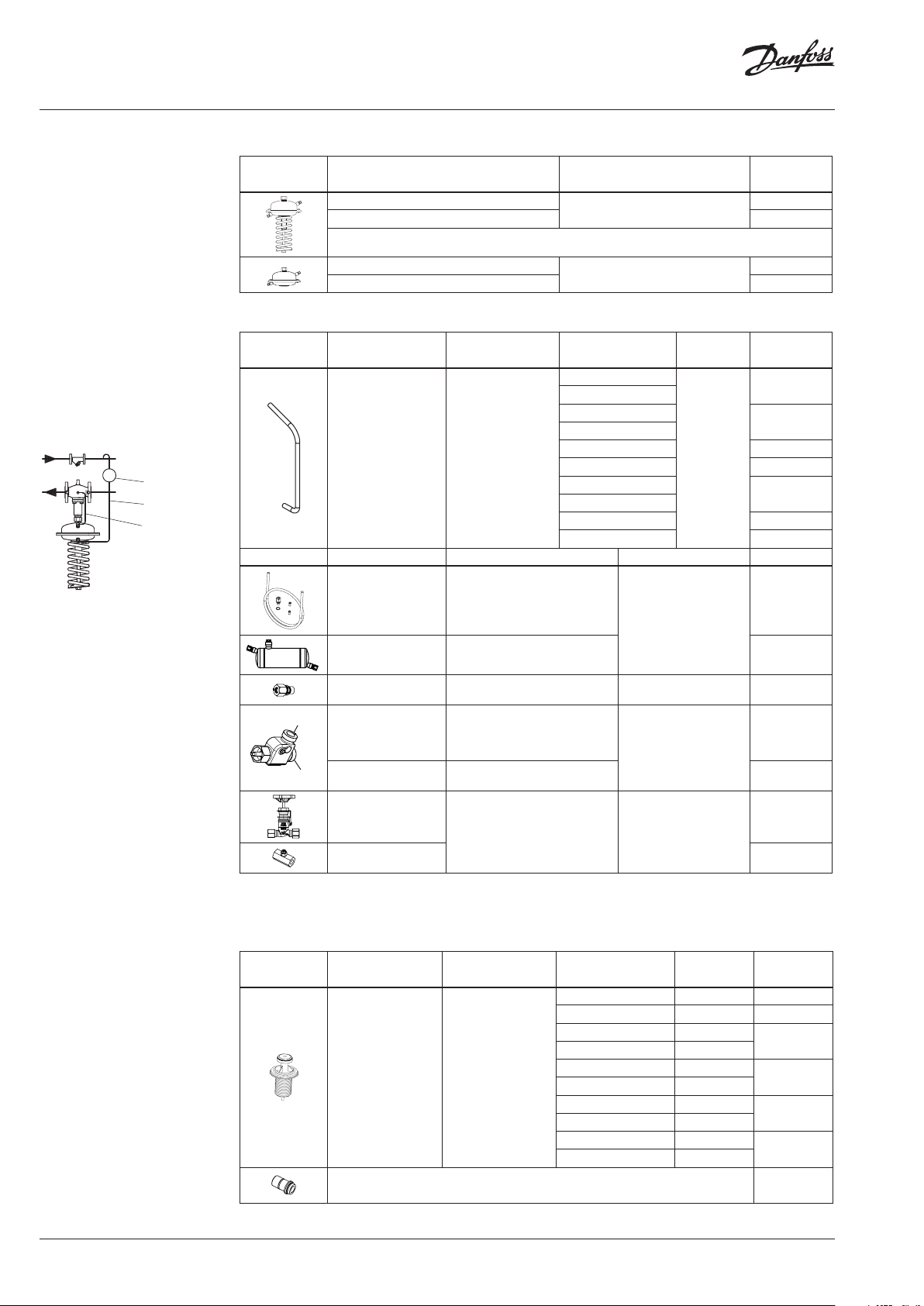

Application principles

AFPB controller must be installed in

the return pipe only.

Direct-connected heating system Indirectly connected heating system

Combinations

Example:

Differential pressure and

temperature controller with f low

limitation; return mounting; DN

15; kVS 4.0; PN 16; metallic sealing;

setting range 0.1-0.7 bar; t

°C; flange;

max

150

– 1× VFQ 2 DN 15 valve

Code no: 065B2654

– 1× AFPB actuator

Code no: 00 3G1017

– 2× Impulse tube set AF

Code no: 003G1391

– 1× AFT06 thermostat

Code no: 065-4390

– 1× Combination piece KF2

Code no: 003G14 40

Products will be delievered

separatelly.

Note:

For AFT 06 thermostat data see

relevant data sheet

AFT 06/KF2/AFPB/VFQ 2

– Differential pressure and temperature controller with

flow limitation, adjustable setting.

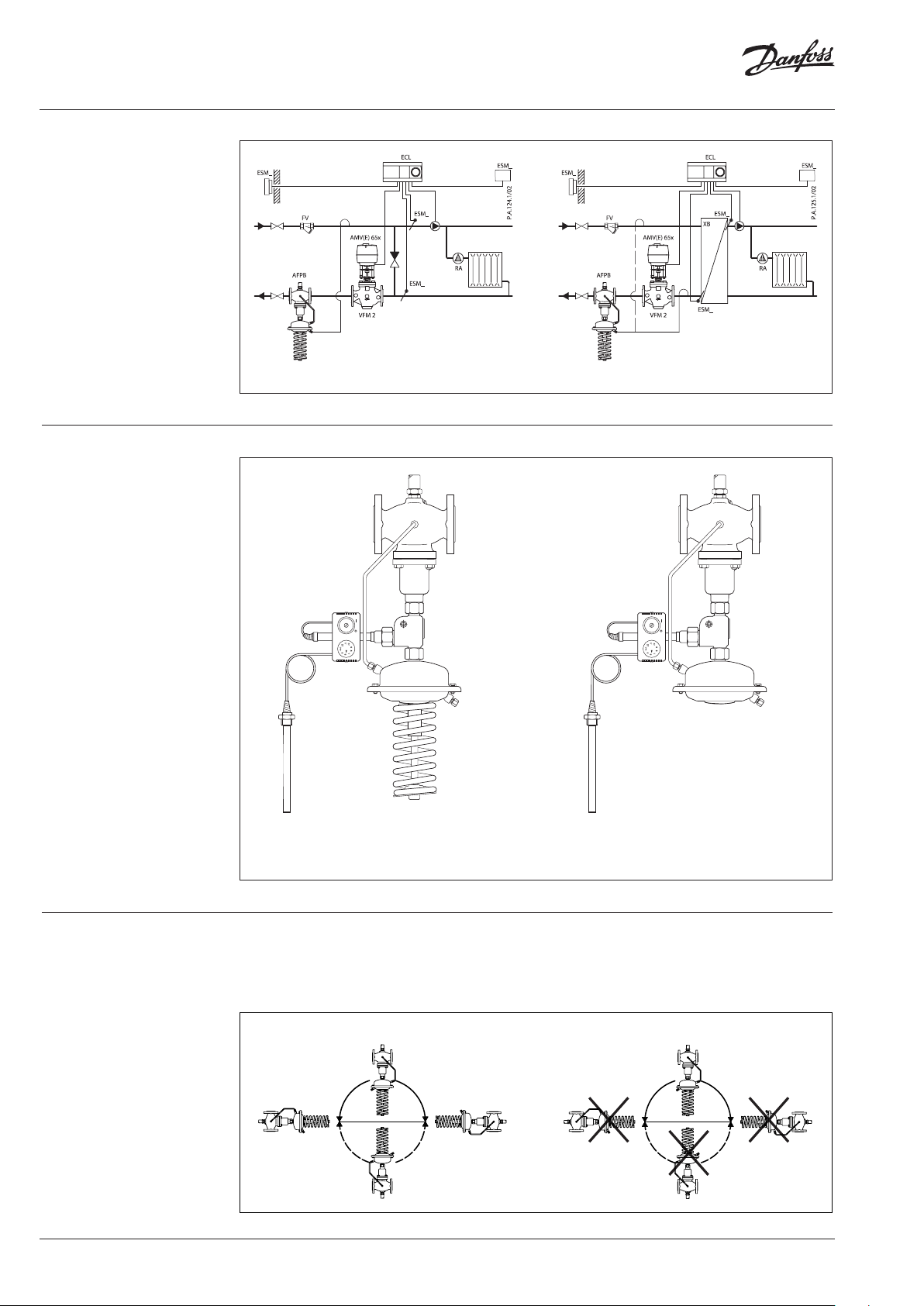

Installation positions DN 15-80 T

The controllers can be installed in any position.

DN 15-80 T

≤ 120 °C

max

≤ 120 °C

max

AFT 06/KF2/AFPB-F/VFQ 2

– Differential pressure and temperature controller with

flow limitation, fixed setting.

DN 15-80 T

The controllers can be installed in horizontal

> 120 °C; DN 100-125

max

pipes only, with a pressure actuator oriented

downwards.

DN 15-80 T

> 120 °C; DN 100-125

max

4 | VD.AC.B7.02 © Danfoss | 2018.10

Page 5

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

Pressure temperature

diagram

Working area is below P-T line

and it ends at Tmax for each

valve

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 16

EN - GJL- 250

(GG -25)

PN 25

EN-GJS- 400

(GGG-40.3)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-1)

VD.AC.B7.02 | 5© Danfoss | 2018.10

Page 6

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

Sizing

– Directly connected heating

system

Example 1

Motorised control valve (MCV) for mixing circuit

in direct-connected heating system requires

differential pressure of 0.3 bar (30 kPa) and flow

less than 1800 l/h.

Given data:

Q

= 1.8 m3/h (1800 l/h)

max

p

= 0.7 bar (70 kPa)

min

1)

p

= 0.1 bar (10 kPa)

circuit

p

= 0.3 bar (30 kPa) selected

MCV

2)

p

= 0.1 bar (10 kPa) assumption

b

Remark:

1)

∆p

corresponds to the r equired pump pressure in t he heating

circuit

circuit and is not to b e considered when sizing the AFPB .

2)

pb is differe ntial pressure over flow restri ctor.

The differential pressure set value is:

p

p

= pb + p

set value

= 0.4 bar (40 kPa)

set value

= 0.1 + 0.3

MCV

The total pressure loss across the controller is:

p

= p

AFPB

p

= 0.4 bar (40 kPa)

AFPB

min

− p

= 0.7 − 0.3

MCV

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

pp

bAFPB

8.1

1.04.0

kv = 3.3 m3/h

Solution:

The example selects AFPB/VFQ 2 DN 15; kVS value

4.0; with differential pressure setting range

0.1-0.7 bar; flow setting range 0.05-1.4 m3/h.

If other differential pressure is assumed than pb

= 0.1 bar, in order to maintain the kVS value, the

flow has to be adjusted using the flow restrictor

screw. The new set value (Q-setting) of the

assumed differential pressure

(p

= 0.2 bar) is calculated according to

b NEW

formula:

p

b

Q

setting

p

Q

max

NEW b

∆p

Q

max

min

AFPB

∆p

b

∆p

AFPB

∆p

MCV

∆p

circuit

6 | VD.AC.B7.02 © Danfoss | 2018.10

Page 7

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

bAFPB

Sizing (continuous)

– Indirectly connected heating

system

Example 2

Motorised control valve (MCV) for indirectly

connected heating system requires differential

pressure of 0.3 (30 kPa) bar and flow less than

130 0 l/ h.

Given data:

Q

= 1.3 m3/h (1300 l/h)

max

p

= 1.0 bar (100 kPa)

min

p

p

p

Remark:

1)

pb is differe ntial pressure over flow restri ctor

= 0.05 bar (5 kPa)

exchanger

= 0.3 bar (30 kPa) selected

MCV

1)

= 0.2 bar (20 kPa) assumption

b

The differential pressure set value is:

p

p

p

= pb + p

set value

= 0.2 + 0.05 + 0.3

set value

= 0.55 bar (55 kPa)

set value

exchanger

+ p

MCV

The total pressure loss across the controller is:

p

= p

AFPB

p

= 1.0 − 0.05 − 0.3

AFPB

p

= 0.65 bar (65 kPa)

AFPB

min

− p

exchanger

− p

MCV

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

pp

3.1

2.065.0

kv = 1.9 m3/h

Solution:

The example selects AFPB/VFQ 2 DN 15; kVS value

4.0; with differential pressure setting range

0.1-0.7 bar; flow setting range 0.05-2.0 m3/h.

If other differential pressure is assumed than pb

= 0.2 bar, in order to maintain the kVS value, the

flow has to be adjusted using the flow restrictor

screw. The new set value (Q-setting) of the

assumed differential pressure

(p

= 0.1 bar) is calculated according to

b NEW

formula:

p

b

Q

setting

p

Q

max

NEW b

∆p

Q

max

min

AFPB

∆p

b

∆p

AFPB

∆p

MCV

∆p

exchanger

VD.AC.B7.02 | 7© Danfoss | 2018.10

Page 8

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

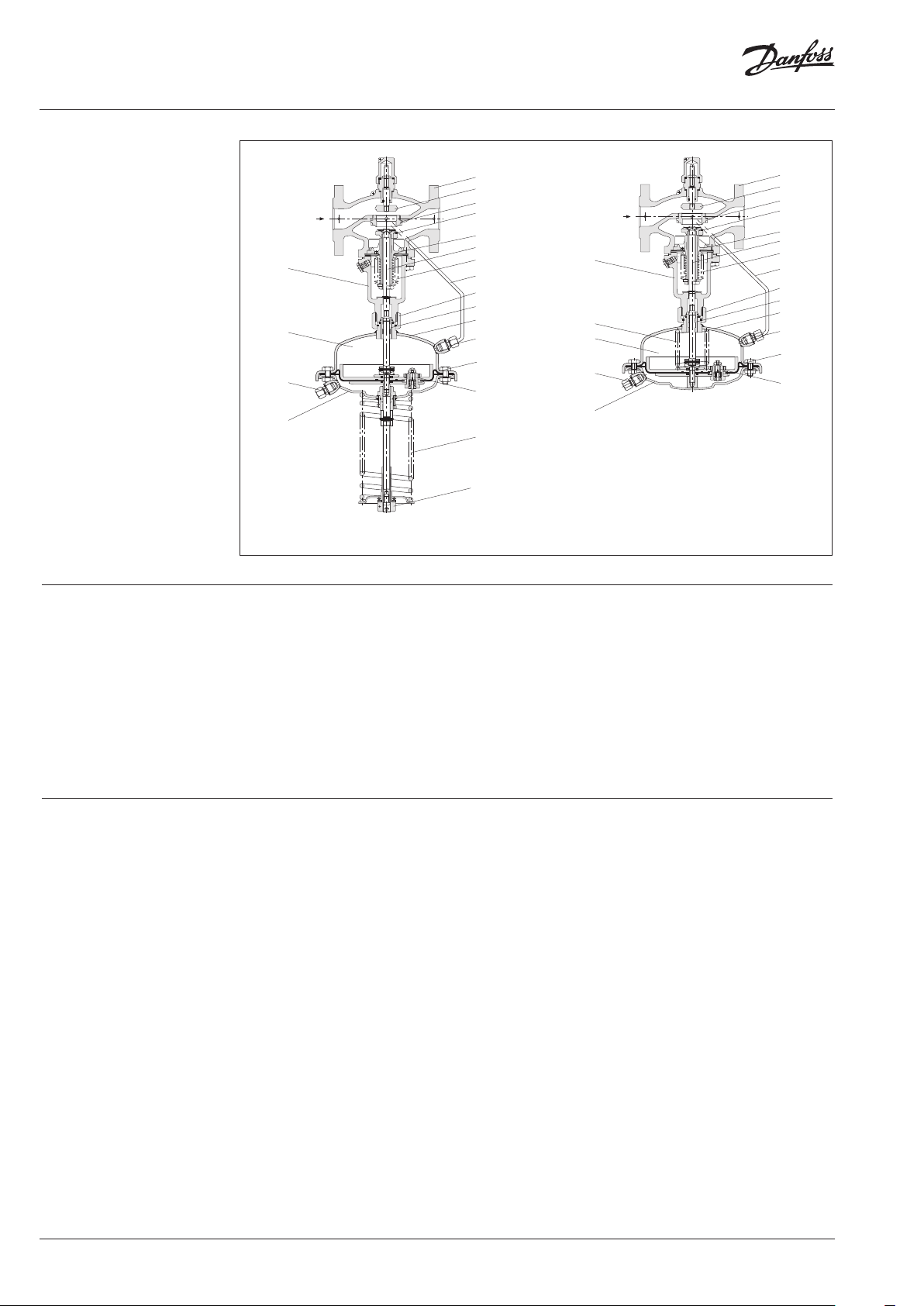

17

15

16

19

18

10

11

18

20

9

2

13

17

15

16

19

18

10

11

18

20

12

9

2

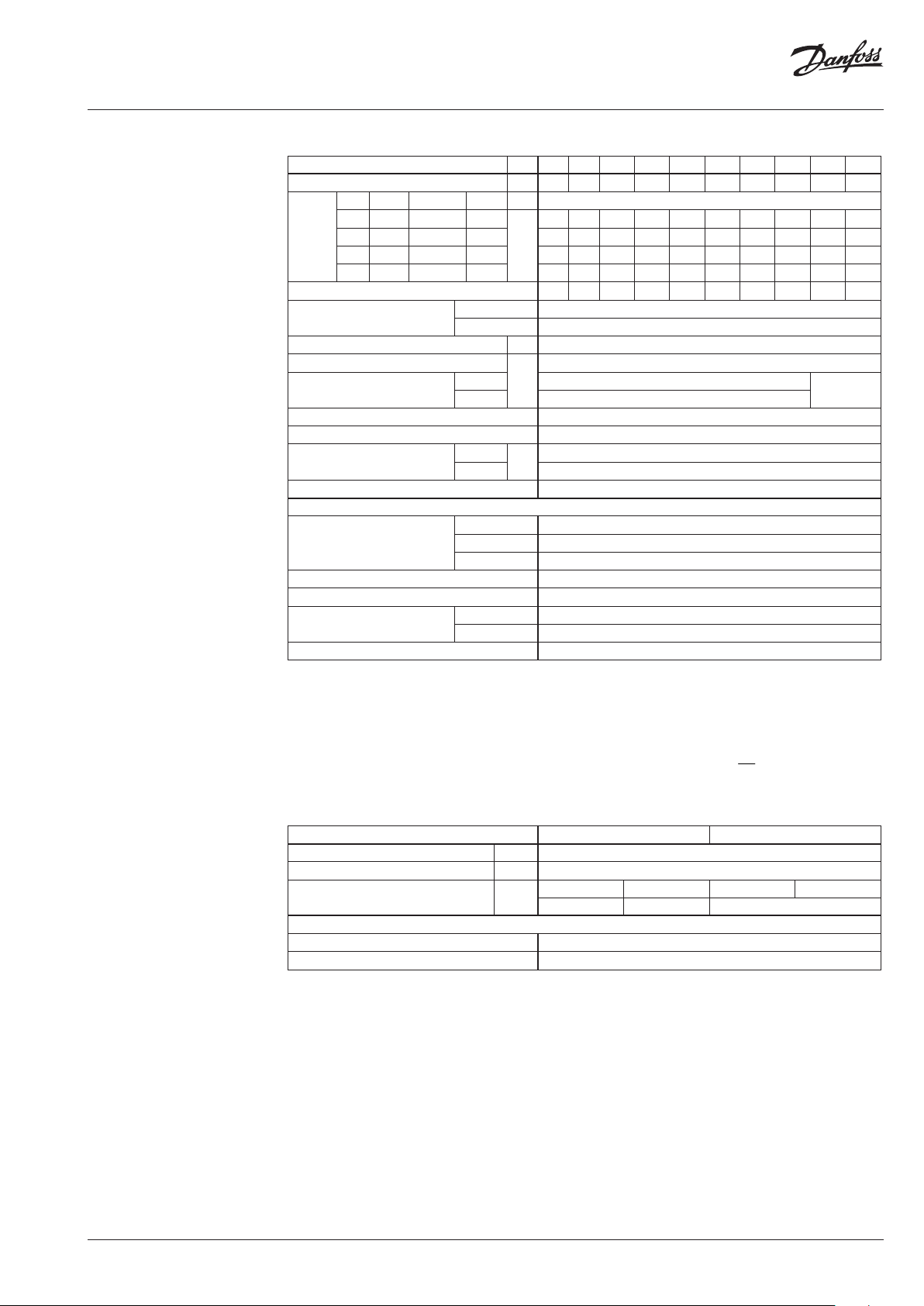

Design

1. Valve body

2. Cover

3. Adjustable flow restrictor

4. Valve seat

5. Valve insert

6. Pressure relieved valve cone

7. Valve stem

8. Bellows for pressure relief of

valve cone

9. Actuator

10. Control diaphragm for

differential pressure and flow

control

11. Excess pressure safey valve

12. Built in spring for differential

pressure and flow control

13. Setting spring for diff.

pressure control

14. Adjuster for diff. pressure

setting, prepared for sealing

15. Stuffing cone

16. Union nut

17. Impulse tube

18. Compression fitting for

impulse tube

19. Upper casing of diaphragm

20. Lower casing of diaphragm

AFPB/VFQ 2 DN 15 – 125

1

3

4

6

5

7

8

AFPB-F/VFQ 2 DN 15 – 125

14

1

3

4

6

5

7

8

Function

Pressure changes from flow and return pipes are

being transferred through the impulse tubes

to the actuator chambers and act on control

diaphragm for diff. pressure and flow control.

Controller is equipped with excess pressure

safety valve, which protects control diaphragm

for diff. pressure and flow control from too high

differential pressure.

The diff. pressure is controlled by means of

setting spring for diff. pressure control. Control

valve closes on rising differential pressure and

opens on falling differential pressure to maintain

constant differential pressure. Flow volume is

limited by means of the flow restrictor.

Settings Differential pressure setting

8 | VD.AC.B7.02 © Danfoss | 2018.10

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

Differential pressure setting is being done by the

adjustment of the setting spring for diff. pressure

control. The adjustment can be done by means

of adjuster for diff. pressure setting and pressure

indicators.

Page 9

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

A

ø89

Dimensions

L

2

B

H

B

VFQ DN 15-125

VFQ 2, VFQ 21 Valves

DN 15 20 25 32 40 50 65 80 100 12 5

L

B 213 213 239 239 241 241 276 276 381 381

B

2

H 337 337 3 74 374 393 393 440 440 575 575

PN 16/25

Weight

PN 40 31 34 63 72

130 150 16 0 180 200 230 290 310 350 400

mm

124 124 135 13 5 152 152 16 4 164 194 194

kg 8 9 10 .5 12 .5 15.5 18 .5

28.5 31 61 71

ø60

AFPB Actuator

110

78

Ø10

mm

2

250

263

SW 22

H

Actuator size cm

Ø A

H 457

Weight kg 9

Shut off valve

AFPB-F Actuator

H

A

Actuator size cm

Ø A

H 160

Weight kg 9

240

Seal pot V1

2

250

mm

263

Comb. piece KF2, KF3

40

G⁄

SW19

Compression fitting

VD.AC.B7.02 | 9© Danfoss | 2018.10

Page 10

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

10 | VD.AC.B7.02 © Danfoss | 2018.10

Page 11

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

VD.AC.B7.02 | 11© Danfoss | 2018.10

Page 12

Data sheet Differential pressure controller with flow limitation AFPB(-F) / VFQ 2(1) (PN 16, 25, 40)

© Danfoss | DHS-SRMT/SI | 2018.1012 | VD.AC.B7.02

Loading...

Loading...