Data sheet

Differential pressure relief controller (PN 16, 25, 40)

AFPA / VFG 2(1)

Description

Ordering

Example 1:

Differential pressure relief

controller;

DN 15; kVS 4.0; PN 16; metallic

sealing; setting range 0.15-1. 2 bar;

T

150 °C; flange;

max

– 1× VFG 2 DN 15 valve

Code no: 065B2388

– 1× AFPA actuator

Code no: 003G

– 2× Impulse tube set AF

Code no: 003G1391

Products will be delivered separatly.

1021

The controller is a self-acting differential pressure

relief controller primarily for use in district

heating systems. The controller is normally

closed and opens on rising differential pressure.

VFG 2 Valves (metallic sealing cone)

Picture

DN

(mm)

15 4.0

20 6.3 065B2389 065B2402 06 5B2412

25 8.0 0 65B2390 065B2403 06 5B2413

32 16 065B2391 065B2404 065B2414

40 20 065B2392 065B2405 0 65B2 415

50 32 065B2393 065B2406 0 65B2416

65 50 065B2394 065B2407 065 B2417

80 80 065B2395 065B2408 0 65B2418

100 125 065B2396 065B2409 065 B2419

125 160 065B2397 06 5B2410 065B2420

150 280 065B2398

200 320 065B2399 – 065B2422

250 400 065B2400 – 065B2423

k

VS

(m3/h)

Connections

Flanges acc. to

EN 1092-1

T

(°C)

150

The controller has a control valve, an actuator

with one control diaphragm and spring for

differential pressure setting.

Further on two valve versions are available:

– VFG 2 with metallic sealing cone

– VFG 21 with soft sealing cone

Main data:

∙ DN 15 -250

∙ kVS 4.0-400 m3/h

∙ PN 16, 25, 40

∙ Setting range:

– 0.05-0.3 bar / 0.1-0.6 bar / 0.15-1.2 bar /

0.5-2.5 bar / 1-5 bar

∙ Temperature:

– Circulation water / glycolic water up to 30 %:

2 … 150/200 °C

∙ Connections:

– Flange

max

Code No.

PN 16 PN 25 PN 40

065B2388

T

(°C)

200

150

max

1)

Code No.

065B2401 06 5B 2411

– 065B2421

Impulse t ube set AF

© Danfoss | 2018.10

150 280 –

200 320 – – On request

250 400 – – On request

1)

at temperature s above 150 °C only with sea l pots (see Accessories)

200

1)

– On request

VD.CA.N7.02 | 1

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

Ordering (continuous)

Example 2:

Differential pressure relief

controller;

DN 15; kVS 4.0; PN 25; metallic

sealing; setting range 0.15-1.2 bar;

T

200 °C; flange;

max

– 1× VFG 2 DN 15 valve

Code no: 065 B2401

– 1× AFPA actuator

Code no: 003G

– 2× Impulse tube set AF

Code no: 003G1391

– 2× Seal pot V1

Code no: 003G1392

Products will be delivered separatly.

Seal pot s V1

1021

Impulse tube

set AF

VFG 21 Valves (soft sealing cone)

Picture

Note: othe r valves available on special r equest.

DN

(mm)

15 4.0

20 6.3 065B2503

25 8.0 065B2504

32 16 065B2505

40 20 065B2506

50 32 065B2507

65 50 065B2508

80 80 065B2509

100 125 0 65B2510

125 160 0 65 B25 11

150 280 065B25 12

200 320 065 B2513

250 400 06 5B2514

k

VS

(m3/h)

T

max

(°C)

150 Flanges acc. to EN 1092-1

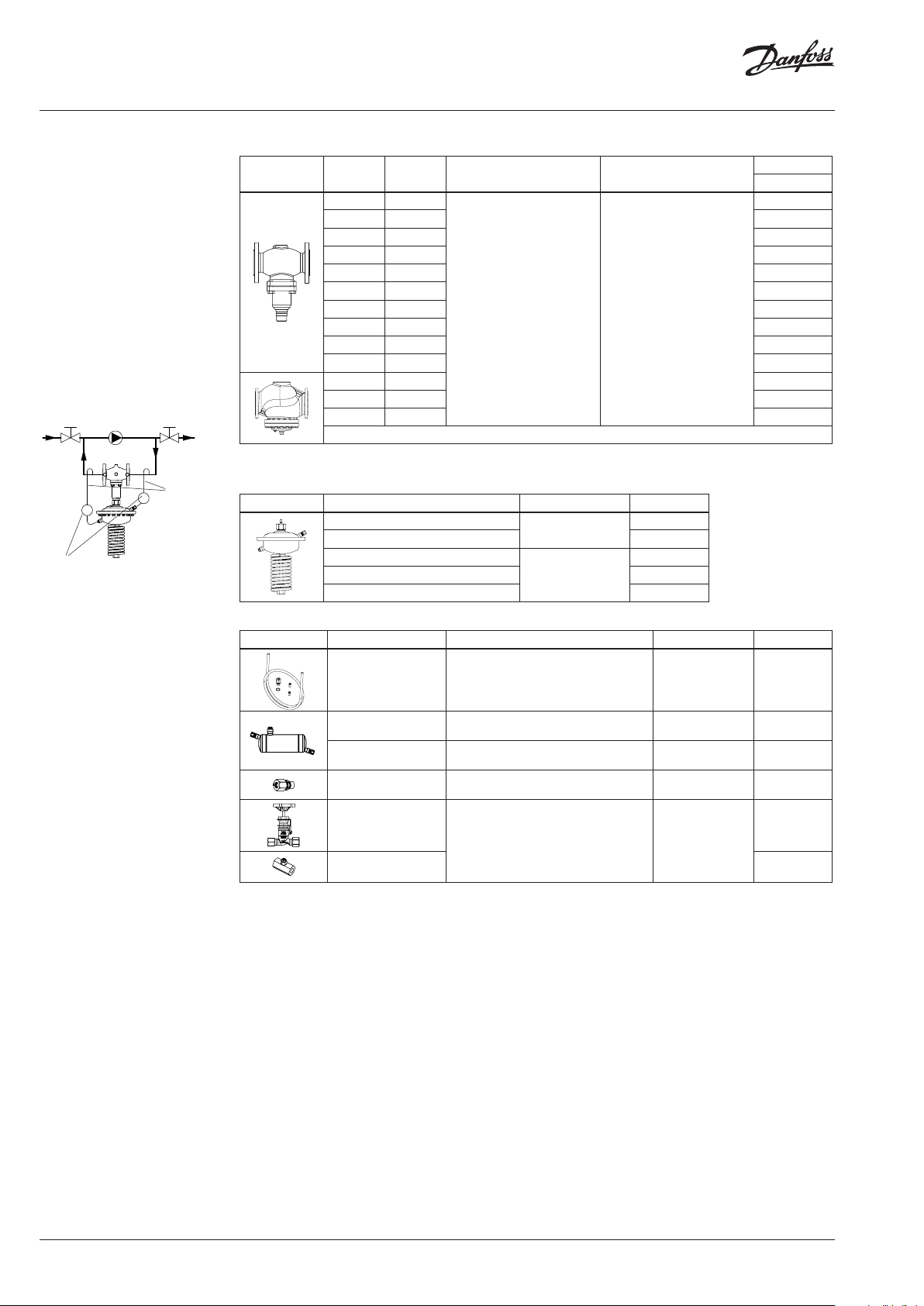

AFPA Actuators

Picture ∆p setting range (bar) for DN Code No.

1-5

0.5-2.5 003 G1020

0.15 -1.2

0.1-0.6 003G10 22

0.05-0.3 003 G1023

15-125

15-2 50

Connections

003 G1019

003 G1021

Code No.

PN 16

065B2502

Accessories

Picture Type designation Description Connections Code No.

– 1× Copper tube Ø10 × 1 × 1500 mm

Impulse tube set AF

Seal pot V1

Seal pot V2

Compression fitting

Shut off valve

Throttle valve 065B2909

1)

Seal pot has to be us ed on impulse tubes always w hen T

2)

Consist of a nipple , compression ring and nut

1)

1)

– 1 × compression fitting for imp. tube

connection to pipe (G ⁄)

– 2 × socket

Capacit y 1 liter; with compression fittings

for imp. tube Ø10

Capacit y 3 liter; with compression fittings

for imp. tube Ø10, for actuator size 630 cm

For impulse tube Ø10 connections to

2)

controller

For impulse tube Ø10 –

≥ 150 °C

max

2

– 003G1391

– 003G1392

– 003G1403

G ⁄ 003G1468

00 3G1401

2 | © Danfoss | 2018.10

VD.CA.N7.02

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

Ordering (continuous)

Technical data

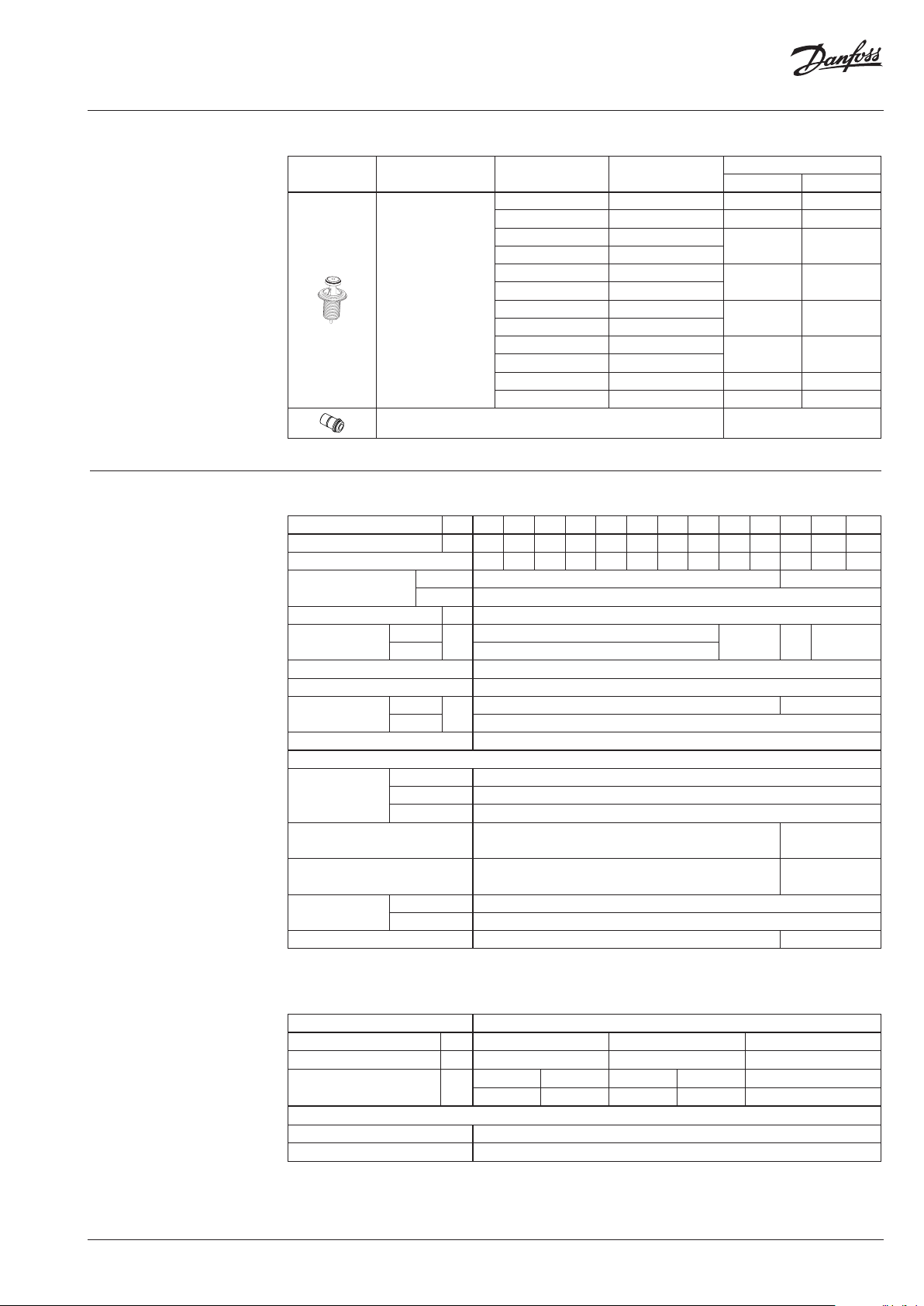

Service kits

Picture Type designation

Valve insert

Stuffing cone (with EPDM O-rings) 003G1464

DN

(mm)

15 4.0 065B2796 065B2790

20 6.3 065B2797 065B2791

25 8

32 16

40 20

50 32

65 50

80 80

100 125

125 160

150 280 065B2964 065B2966

250 400 065B2965 –

k

VS

(m3/h)

Code No.

for VFG 2 for VFG 21

065B2798 065B2792

065B2799 065B2793

065B2800 0 65B2794

065B2801 065B2795

Valve

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125 150 200 250

kVS value

Cavitation factor z 0.6 0.6 0.6 0. 55 0.55 0.5 0.5 0.45 0.4 0.35 0.3 0.2 0.2

Leakage acc. to standard

IEC 534 (% of kVS)

Nominal pressure PN 16, 25, 40

Max. differential

pressure

Media Circulation water / glycolic water up to 30 %

Media pH Min. 7, max. 10

Media temperature

Connections Flange

Materials

Valve body

Valve seat Stainless steel, mat. No. 1.4021

Valve cone Stainless steel, mat. No. 1.4404

Sealing

Pressure relieve system Bellows (Stainless steel, mat. No. 1.4571) Diaphragm (EPDM)

1)

at temperature s above 150 °C only with sea l pots (see Accessories)

2)

on request

PN 16

PN 25, 40 20

VFG 2

VFG 21 2 … 150

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN-GJS-400(GGG-40.3)

PN 40 Cast steel GP240GH (GS-C 25)

VFG 2 Metal

VFG 21 EPDM

m3/h

4.0 6.3 8.0 16 20 32 50 80 125 160 280 320 400

VFG 2 ≤ 0.03 ≤ 0.05

VFG 21 ≤ 0.01

bar

°C

16

2 … 150 / 2 … 200

15 12 10

1)

2 … 150 (200 2))

Stainless steel,

mat. No. 1.4313

Stainless steel,

mat . No. 1.4021

VD.CA.N7.02

Actuator

Typ e AFPA

Actuator size cm

Max. operating pressure bar 25 25 16

Diff. pressure setting ranges

and spring colours

Materials

Actuator housing Steel, mat. No. 1.0338, zinc plated

Control diaphragm EPDM (Rolling; fibre enforced)

2

bar

80 250 630

silver yellow silver yellow yellow

1-5 0.5-2.5 0.15 -1.2 0.1-0.6 0.05-0.3

© Danfoss | 2018.10 | 3

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

Application principles

Differential pressure control for a pump in bypass

Installation position DN 15-80 T

The controllers can be installed in any position.

DN 15-80 T

≤ 120 °C

max

≤ 120 °C

max

DN 15-80 T

> 120 °C; DN 100-250

max

The controllers can be installed in horizontal

pipes only, with a pressure actuator oriented

downwards.

DN 15-80 T

> 120 °C; DN 100-250

max

4 | © Danfoss | 2018.10

VD.CA.N7.02

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

Pressure temperature

diagram

Working area is below P-T line

and it ends at T

for each valve

max

PN 16

EN - GJL- 250

(GG -25)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 25

EN-GJS- 400

(GGG-40.3)

Sizing

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-1)

Given data:

Q

= 4.5 m3/h

max

p

=1.4 b ar

AFPA

Nominal pressure PN 16

kv value is calculated according to formula:

Q

k

max

v

p

AFPA

5,4

4,1

kv = 3.8 m3/h

VD.CA.N7.02

Solution:

The example selects AFPA VFG 2 PN 16 DN 15,

kVS value 4.0 with differential pressure setting

range 0.5-2.5 bar.

© Danfoss | 2018.10 | 5

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

10

11

12

1

16

14

15

13

19

20

92

Design

1. Valve body

2. Cover

3. Valve seat

4. Valve insert

5. Pressure relieved valve cone

6. Valve stem

7. Bellows for pressure relief of

valve cone

8. Actuator

9. Diaphragm for pressure relief

of valve cone

10. Control diaphragm for

differential pressure control

11. Setting spring for diff.

pressure control

12. Adjuster for diff. pressure

setting, prepared for sealing

13. Stuffing cone

14. Union nut

15. Compression fitting for

impulse tube

16. Upper casing of diaphragm

17. Lower casing of diaphragm

18. Valve body extension

19. Shut off valve for water filling

20. Closing plug

5

8

15

17

AFPA / VFG 2 DN 15 – 125

3

6

4

7

2

VFG 2 DN 150-250, T

max

150 °C

VFG 2 DN 150-250, T

max

18

9

2

200 °C

Function

The pressures in front and behind of the control

valve are being transferred through the impulse

tubes to the actuator chambers and act on

control diaphragm for diff. pressure control.

The controller became normally closed after

commissioning (stretching the spring). It opens

on rising differential pressure and closes on

falling differential pressure to maintain constant

differential pressure.

Settings Differential pressure setting

Differential pressure setting is being done by the

adjustment of the setting spring for differential

pressure control. The adjustment can be done by

means of spring for differential pressure setting

and pressure indicators.

6 | © Danfoss | 2018.10

VD.CA.N7.02

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

240

Ø 89

298

Ø 140

Dimensions

L

L

H

B

H

B

VFG DN 15-125 VFG DN 150-250

L

1

H

1

B

VFG DN 150-250

with valve body extension up to 200 °C

VFG 2, VFG 21 Valves

DN 15 20 25 32 40 50 65 80 100 125 150 200 250

L

B 213 213 239 239 241 241 276 276 381 3 81 326 354 401

H 267 267 304 304 323 323 370 370 505 505 505 591 661

Weight

B

1

H

1

Weight (valve

with body

extension)

PN 16 / 25

PN 40 30 32.5 60.5 69 141 253 333

PN 16 / 25

PN 40 179 336 505

130 150 160 180 200 230 290 310 350 400 480 600 730

mm

kg 7.5 8.5 10 12 15 18

mm

kg

27. 5 30 58 68 115 185 323

620 852 11 99

799

154 301 469

1089

1459

VD.CA.N7.02

A

H

AFPA Actuator

Actuator size cm280 250 630

A mm 172 263 380

H mm 430 470 520

Weight kg 7. 5 13 28

Seal pot V1

Seal pot V2

ø60

110

SW 22

78

Ø10

40

SW19

Shut off valve Compression fitting

© Danfoss | 2018.10 | 7

G⁄

Data sheet Differential pressure relief controller AFPA/VFG 2(1) (PN 16, 25, 40)

8 | © Danfoss | DHS-SRMT/SI | 2018.10

VD.CA.N7.02

Loading...

Loading...