Data sheet

Differential pressure controller (PN 16, 25, 40)

AFP 2 / VFG 22(1) – return and flow mounting, adjustable setting

Description

virtus.danfoss.com

The controller is a self-acting differential pressure

controller primarily for use in district heating

systems. Direct operated, reliable and high

precise controller closes on rising differential

pressure.

The controller has a control valve, an actuator

with one control diaphragm and spring for

differential pressure setting.

Further on two valve versions are available:

∙ VFG 22 with metallic sealing cone

∙ VFG 221 with soft sealing cone

Together with Danfoss intelligent electrical

actuator AMEi 6 intelligent optimization

functions are available:

∙ iSET-intelligent substation efficiency

optimization

∙ iNET-intelligent network balancing

Main data:

∙ DN 65-250

∙ kVS 60-800 m3/h

∙ PN 16, 25, 40

∙ Setting range:

0.1-0.35 bar / 0.1-1 bar / 0.5-1.5 bar /

/ 1-2.5 bar / 1.5-4 bar / 1-3 bar / 1.5-5 bar

∙ Temperature:

– Circulation water / glycolic water up to 30%:

2 … 150°C

∙ Connections:

– Flange

Ordering

Example 1:

Differential pressure controller,

return mounting, DN 65, kVS 60,

PN 16, metallic sealing, setting

range 1.5-4 bar, T

– 1× VFG 22 DN 65 valve

Code no: 065B5500

– 1× AFP 2 actuator

Code no: 003G5606

– 2× Impulse tube set AF

Code no: 00 3G1391

Products will be delivered

separately.

150 °C, flange

max

Impulse tube set AF

VFG 22 Valve (metallic sealing cone)

Picture

DN

(mm)

65 60

80 80 065B5501 065B5508 065B5515

100 160 065B5502 065B5509 065 B5516

125 250 065B5503 065B5510 06 5B5517

150 380 065B5504 0 65B5 511 06 5B5518

200 650 065B5505 065 B5512 06 5B5519

250 800 065B5506 06 5B5513 065B5520

k

VS

(m3/h)

Flanges acc. to EN 1092-1 150

VFG 221 Valve (soft sealing cone)

Picture

DN

(mm)

65 60

80 80 065B5522 065B5529 065 B5536

100 16 0 065 B5523 065B5530 065B5537

125 250 065B5524 065B5531 065B5538

150 380 065B5525 065B5532 065B5539

200 650 0 65B5526 065B5533 065B5540

250 800 065B5527 065B5534 065B5541

k

VS

(m3/h)

Flanges acc. to EN 1092-1 150

Connections

Connections

T

(°C)

T

(°C)

max.

max.

PN 16 PN 25 PN 40

065B5500 065B5507 06 5B5514

PN 16 PN 25 PN 40

065 B5521 065B5528 065B5535

Code No.

Code No.

© Danfoss | 2022.01 AI268355020467en-010304 | 1

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

Ordering (continuous)

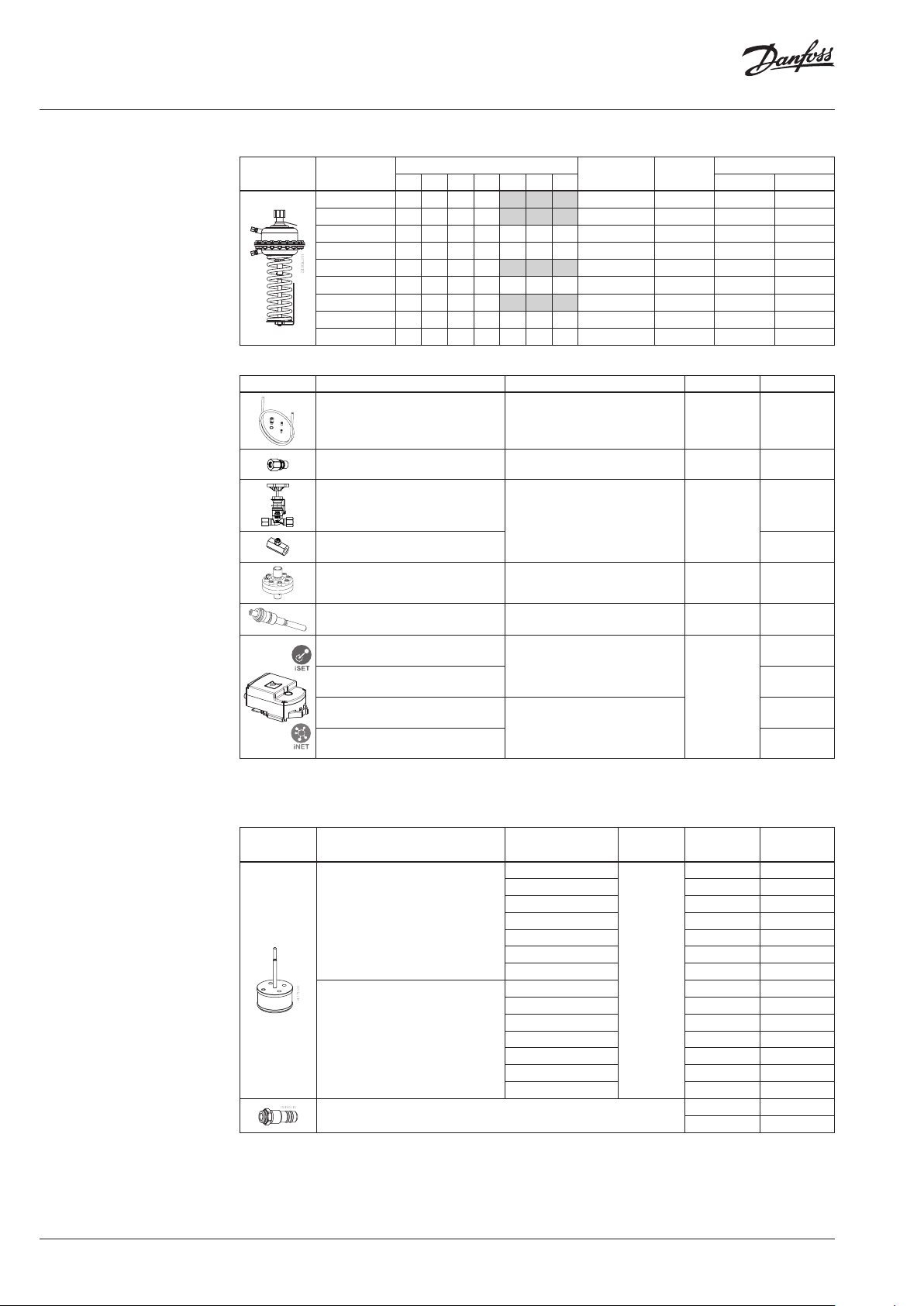

AFP 2 Actuator

Picture

Setting range

(bar)

1.5 -5

1-3

1.5 -4

1-2. 5

0.5-1.5

0.4-1.5

0.1-1

0.1-1

0.1-0.35

Possible combinations with DN

65 80 10 0 125 150 200 250

- - - 80 red 003G5604 003G5614

- - - 80 yellow 003G5605 003G5615

- - - 160 yellow 003G5608 003G5618

- - - 160 blue 003G5612 003G5622

Actuator size

(cm)

Spring

colour

160 black 1) 003G5606 003G5616

160 red 003G5607 003G5617

320 red 003G5609 003G5619

320 orange 003G5610 003G5620

640 yellow 003G5611 003G5621

Code No.

PN 16 PN 40

Accessories

Picture Type designation Description Connections Code No.

– 1× Copper tube Ø10 × 1 × 1500 mm

Impulse tube set AF

Compression fitting

2)

Shut off valve

Static throt tle valve 065B2909

Dynamic throttle valve

3)

– 1× compression fitting for imp.

tube connection to pipe (G ⁄)

– 2× socket

For impulse tube Ø10 connections

to controller

For impulse tube Ø10 –

For impulse tube Ø10 /

connection to pressure actuator

– 003G1391

G⁄ 00 3G1468

G⁄ 003G177 1

00 3G1401

Adapter new AFP 2old VFG DN 15 -250 0 03G17 80

AMEi 6 iSET

el actuator 230 V

AMEi 6

iSET

el actuator 24 V

AMEi 6 iNET

el actuator 230 V

AMEi 6 iNET

el actuator 24 V

1)

Combination w ith AMEi 6 not possible

2)

Consist of a nippl e, compression ring and nut

3)

Available in 2022

Service kits

Picture Typ e

Pressure control

inser t VFG/Q/22

Pressure control

ins ert V FG/Q/ 221

Pressure stuffing box VFG/Q /221

Intelligent p actuator with iSET

function

Intelligent p actuator with iNET

function

k

VS

(m3/h)

60

PN DN Code No.

65 003G1800

80 80 0 03G1801

160 100 003G18 02

250 125 003G1803

380 150 0 03G180 4

650 200 0 03G1805

800 250 003 G1806

60 65 0 03G1807

16/2 5/40

80 80 00 3G1808

160 100 003G18 09

250 125 00 3G1810

380 150 0 03G1 811

650 200 00 3G1812

800 250 0 03G1813

65 -125 003G1730

150-250 003G1731

082G4300

082G4301

082G4302

082G4303

2 | AI268355020467en-010304 © Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

Technical data

Valve

Nominal diameter DN 65 80 100 125 150 200 250

kVS value

Leakage acc. to standard

IEC 534 (% of kVS)

Nominal pressure PN 16, 25, 40

Max. differential

pressure

Pressure relieve system Chamber relieved

Media Circulation water / glycolic water up to 30%

Media pH Min. 7, max. 10

Media temperature VF G 22(1) °C 2 … 150

Connections Flange

Materials

Valve body

Valve seat Stainless steel, mat. No. 1.4021

Valve cone Stainless steel, mat. No. 1.4021

Sealing

VFG 22 ≤ 0.03 ≤ 0.05

VFG 221 ≤ 0.01

PN 16

PN 25, 40 20

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN-GJS-400(GGG-40.3)

PN 40 Cast steel GP240GH (GS-C 25)

VFG 22 Metal

VFG 221 EPDM

m3/h

bar

60 80 160 250 380 650 800

16

15 12 10

AFP 2 Actuator

Actuator size cm

Max. operating pressure bar 16, 4 0

Diff. pressure setting ranges and

spring colours

For valve DN 6 5-125 65-2 50 65-125 65 -125 65-250 65-2 50

Materials

Actuator housing Steel, mat. No. 1.0345, zinc plated

Control diaphragm EPDM

1)

Combination w ith AMEi 6 not possible

2

80 160 320 640

red yellow black 1)red yellow blue red orange yellow

bar

1.5 -5 1-3 1.5-4 1-2.5 0.5-1.5 0.1-1 0 .4-1. 5 0.1-1 0.1-0.35

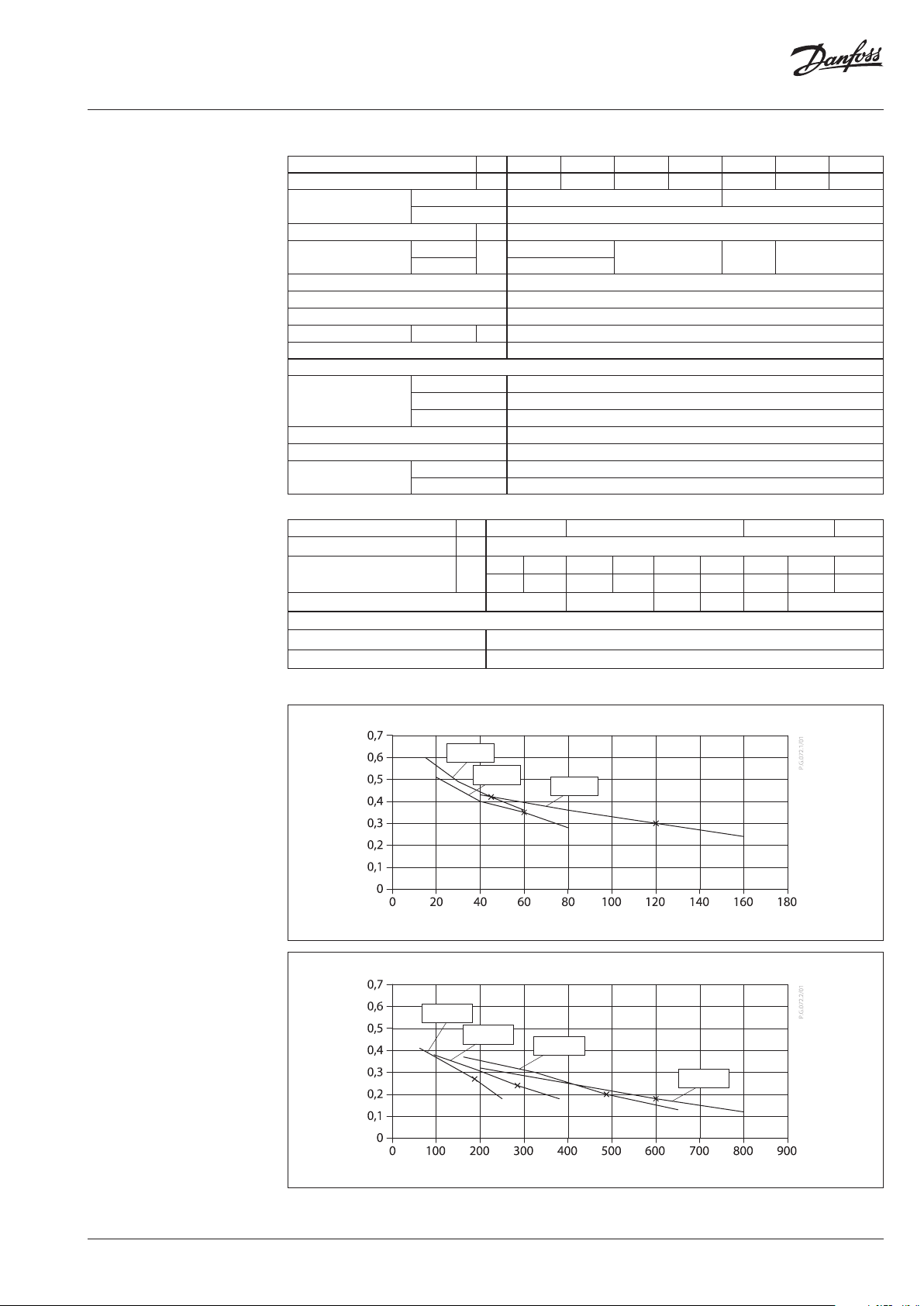

DN 65

DN 80

cavitation factor z

DN 100

flow (m3/h)

DN 12 5

DN 150

DN 200

DN 250

cavitation factor z

flow (m3/h)

AI268355020467en-010304 | 3© Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

p

at z = 0,2 ... 0,6 [bar]

Inlet pressure bar p [bar]

z =

Example :

Operating area

Maximum allowed differential pressure over the controller (p

max

T = 90°C

T = 100°C

T = 110°C

[bar]

max

p

) at different cavitation factors (z)

max

p = 6 bar

T = 140°C

z = 0,4

= 1,35 bar

p

max

T = 80°C

T = 130°C

T = 140°C

T = 150°C

Application principles

– Return mounting

– Flow mounting

Direct-connected heating system Indirectly connected heating system

Direct-connected heating system

Indirectly connected heating system

4 | AI268355020467en-010304 © Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

Installation position

The controllers can be installed in any position.

Pressure temperature

diagram

Working area is below P-T line and it

ends at T

for each valve

max

PN 25

PN 16

EN - GJL- 250

(GG -25)

150

150

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

150

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-1)

EN-GJS-400

(GGG-40.3)

AI268355020467en-010304 | 5© Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

( )

=−=−=

Sizing Example:

The application demands a maximal flow of

25m3/h and has a motorized control valve (MCV)

that needs a control of a pressure drop 0.4 bar.

The minimal differential pressure available over

MCV and AFP is 0.7 bar.

Given D ata:

Q

= 25 m3/h

max

p

= 0.7 bar

min

p

= 0.4 bar

MCV

The total pressure across the controller is:

MCVminAFP

kPa 30bar 0.30.40.7ΔpΔpΔp

Calculate the kv value:

AFP

25

0.3

Q

max

k

v

p

The first bigger kVS to 45.6 m3/h is 60 m3/h and

gives VFG DN 65.

The available setting range to control 0.4 bar is

0.1-0.7 bar and is available for DN 65.

Solution:

AFP 2 0.1-0.7

VFG 22 (221) DN 65 kVS 60

3

hm 45.6

∆p

∆p

AFP

∆p

MCV

min

6 | AI268355020467en-010304 © Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

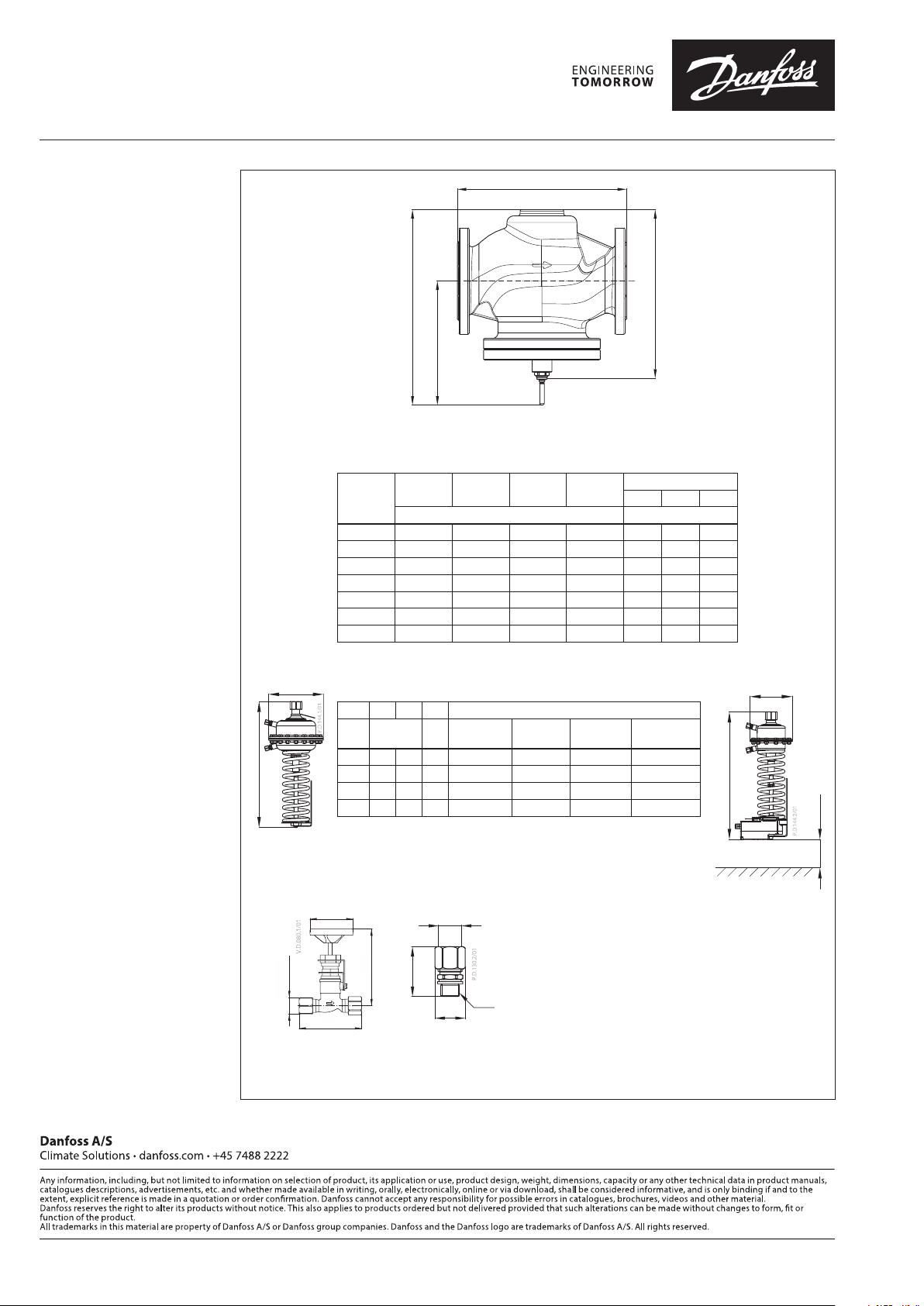

Design

1. Valve body

2. Valve seat

3. Pressure control insert

4. Pressure actuator

5. Pressure control cone

6. Pressure stuffing box

7. Cover

8. Impulse tube connection

9. Diaphragm

10. Diaphragm excess pressure

safety valve

11. Differential pressure setting

spring

12 . Differential pressure setting

nut

13. Setting scale

14 . Setting indicator

15. Union nut

16. Impulse tube

Function

The differential pressure control is achieved by

maintaining a constant differential pressure over

the control valve/application.

The differential pressure over the control valve is

lead to the pressure actuator diaphragm through

the impulse tubes.

The opening/closing of the pressure control cone

is performed by changing differential pressure

over the diaphragm.

Settings Differential pressure setting

Differential pressure setting is being done by the

adjustment of the setting spring for diff. pressure

control. This is done by rotating the differential

pressure setting nut. Set differential pressure

should be checked by observing the pressure

indicators.

When differential pressure over the control valve:

a) rises, the pressure control cone takes over

the exceeded differential pressure by closing,

until set differential pressure over the control

valve/application is reached.

b) drops, the pressure control cone compensates

the missing differential pressure by opening,

until set differential pressure over the control

valve/application is reached.

The pressure actuator diaphragm is equipped

with excess pressure safety valve to protect

diaphragm from the damages caused by too

high differential pressure.

AI268355020467en-010304 | 7© Danfoss | 2022.01

Data sheet Differential pressure controller AFP 2 / VFG 22(1) (PN 16, 25, 40)

Dimensions

L

V

H

B

H

VFG 22(1) DN 65-250

VFG 22, VFG 221 Valves

Weight

PN 16 PN 25 PN 40

DN

L B H H

V

mm kg

65 290 245 370 285 24 24 27

80 310 24 0 365 290 29 29 32

100 350 275 42 5 350 47 48 53

125 400 270 435 370 60 60 68

150 480 330 520 460 105 106 121

200 600 365 610 550 204 206 235

250 730 420 680 620 343 350 404

A

H

ØA

Ø60

SW 22

78

Shut off valve

AFP 2 Actuator

Size ØA HAH

(cm2)

mm

AI

AFP 2 PN 16

80 17 5 490 590 9 11 .5 16 18. 5

160 230 510 610 11 .5 14 23.5 26

320 300 510 610 15 17. 5 35.5 38

640 300 630 730 38 40.5 58 60.5

Total installation heig ht of the controller (VFG 22(1) valve + AFP 2 pressure

actuator) is sum of HV and HA (H

)

AI

Ø10

110

40

G⁄

SW19

Compression fitting

Weight [kg]

AFP 2 PN 16

+ AMEi 6

AFP 2 PN 40

AFP 2 PN 40

+ AMEi 6

ØA

AI

H

AMEi 6 intellig ent

actuator wit h iSET/ iNET

functionality should be

ordered sep arately

min. 250

© Danfoss | DCS-SGDPT/SI | 2022.018 | AI268355020467en-010304

Loading...

Loading...