Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® Active Front End AFE 302

www.danfoss.com/drives

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Safety Symbols

1.3 Software Version

1.4 Approvals

1.5 Abbreviations

2 Safety Instructions and General Warning

2.1 Safety Regulations AFE 302

2.1.1 Disposal Instruction 6

2.1.2 High Voltage Warning 6

2.1.3 Safety Instructions 6

2.1.4 General Warnings 6

2.1.5 Before Commencing Repair Work 6

2.1.6 System Description 6

3 Crane System Design

3.1 Selection of Motor Voltage

4

4

4

4

4

5

6

6

8

8

3.1.1 Selection of AFE & LCL Filter 8

3.1.2 Selection of AFE for Different Applications 8

3.1.3 Selection of Output Filter (LC Filter) 8

3.1.4 Selection of Switching Frequency 8

3.1.5 Selection of LCL Filter 8

3.1.6 Crane Cable Concept 8

3.1.7 Grounding Concept 9

3.1.8 Cooling and Airflow 9

3.1.9 Selection of Transformer 10

3.2 Assembling the Frequency Converter System

3.2.1 Tools Required 11

3.2.2 General Tightening Torque Values 11

3.2.3 Exploded Views 11

3.2.4 MDCIC Connector Configuration 17

3.3 First Power Up/Commissioning Check List

3.4 E-House Design

3.4.1 Cables between AFE and LCL Filters 18

11

17

18

3.4.2 Cables to the Damping Resistors 18

3.5 Test with the Real System Transformer and Motors

3.5.1 Re-program the Frequency Converter Parameters 18

3.6 On-site Final Test

3.6.1 Change Parameters to Actual 18

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 1

18

18

Page 4

Contents Operating Instructions

3.6.2 Run with Full Load 18

3.7 AFE Emergency and Restore Procedures

3.7.1 Emergency Run when One Slave Unit is Damaged 18

3.7.2 Restoration after Slave Unit is Repaired 19

3.7.3 Emergency Run when Master Unit is Damaged 19

3.7.4 Restoration after Master Unit is Repaired 20

3.7.5 Emergency Run When More Than One Unit is Damaged 20

3.8 Manual Shut Down Sequence

3.9 Start-up Sequence

3.10 Shut-down Sequence

4 How to Install

4.1 Overall Typical Frequency Converter Configuration

4.2 Pre-installation

4.2.1 Planning the Installation Site 24

4.2.2 Receiving the Frequency Converter 24

4.2.3 Transportation and Unpacking 24

4.2.4 Lifting 26

4.2.5 Mechanical Dimensions 27

18

20

21

22

23

23

24

4.2.6 Weight Information 31

4.3 Mechanical Installation

4.3.1 Tools Needed 32

4.3.2 General Considerations 32

4.3.3 Terminal Locations 32

4.3.4 Mains Torque 33

4.3.5 Mains Connection 33

4.3.6 Screened Cables 33

4.4 Electrical Installation

4.4.1 Control Wires 36

4.4.2 Power Connections 36

4.4.3 Grounding 36

4.4.4 Electrical Installation, Control Terminals 37

5 Specifications

5.1 General Specifications

5.2 Mains Supply

32

35

38

38

42

6 How to Programme

6.1 Parameter Selection

6.2 Parameters: 0-** Operation and Display

6.3 Parameters: 4-** Limits/Warnings

2 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

43

43

44

48

Page 5

Contents Operating Instructions

6.4 Parameters: 5-** Digital In/Out

6.5 Parameters: 6-** Analog In/Out

6.6 Parameters: 7-** Controllers

6.7 Parameters: 8-** Communications and Options

6.8 Parameters: 14-** Special Functions

6.9 Parameters: 15-** AFE Information

6.10 Parameters: 16-** Data Read-outs

6.11 Parameters: 40-** Mains / Filter

6.12 Warnings/Alarm Messages

Index

49

52

53

54

57

59

62

64

65

71

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 3

Page 6

Introduction Operating Instructions

1

1 Introduction

1.1 Purpose of the Manual

1.1.1 How to Read these Operating

Instructions

Please read this manual carefully for proper use. Incorrect

handling of the frequency converter may cause improper

operation of the frequency converter or related equipment,

shorten lifetime or cause other troubles.

These Operating Instructions will help getting started,

installing, programming, and troubleshooting the AFE 302.

Chapter 1 Introduction, introduces the manual and informs

about the approvals, symbols, and abbreviations used in

this literature.

Chapter 2 Safety Instructions and General Warning, entails

instructions on how to handle the AFE 302 correctly.

1.3 Software Version

VLT® Active Front End AFE 302

Operating Instructions

Software version: 1.15

1.4 Approvals

Table 1.1 Compliance Marks: CE and C-Tick

Chapter 3 Crane System Design, describes the crane system

design associated with the frequency converters.

Chapter 4 How to Install, guides through the mechanical

and technical installation.

Chapter 6 How to Programme, describes how to operate

and programme the AFE 302 via the Local Control Panel

(LCP).

1.2

Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

4 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 7

Introduction Operating Instructions

1.5 Abbreviations

1

1

AFE Active Front End

AC Alternating current

AWG American Wire Gage

A Ampere/AMP

AMA Automatic Motor Adaptation

I

LIM

°C

DC Direct current

EMC Electro Magnetic Compatibility

ETR Electronic Thermal Relay

FC Frequency Converter

g Gram

Hz Hertz

HF High Frequency

ID Identification

IGBT Insulated Gate Biopolar Transistor

IP International Protection

IT Isolation Terra

kHz Kilohertz

kW Kilowatt

kWh Kilowatt-hour

LCP Local Control Panel

MW Megawatt

m Meter

uF Microfarad

mH Millihenry Inductance

mA Milliampere

MCM Thousand circular mils

ms Millisecond

min Minute

MCT Motion Control Tool

MDCIC Multi Drive Control Interface Card

NEMA National Electrical Manufacturers

Nm Newton Meters

I

M,N

f

M,N

P

M,N

U

M,N

par. Parameter

PELV Protective Extra Low Voltage

PCB Printed Circuit Board

PLC Programmable Logic Controller

PN Part Number

I

INV

Regen Regenerative terminals

RCD Residual Current Device

RPM Revolutions Per Minute

RMS Root Mean Square

s Second

SW Software

SMPS Switching Mode Power Supply

Current limit

Degrees Celsius

Association

Nominal motor current

Nominal motor frequency

Nominal motor power

Nominal motor voltage

Rated Inverter Output Current

n

s

I

VLT,MAX

I

VLT,N

T

LIM

THD Total Harmonic Distortion

THDi Total Harmonic Distortion in Current

THDu Total Harmonic Distortion in Voltage

V Volts

Synchronous Motor Speed

The maximum output current

The rated output current supplied by the

frequency converter

Torque limit

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 5

Page 8

Safety Instructions and Gen...

Operating Instructions

2 Safety Instructions and General Warning

22

2.1 Safety Regulations AFE 302

2.1.1 Disposal Instruction

Equipment containing electrical components

may not be disposed with domestic waste.

It must be separately collected with Electrical

and Electronic waste according to local and

currently valid legislation.

WARNING

When the AFE is on, the earth current from the AFE 302

frequency converter will exceed 3.5 mA. The earth cable

must have a good contact to the earth terminal 95. The

earth connection is done with the two separate cables.

The size of each cable needs to be a half of the mains

cable size in minimum.

2.1.5 Before Commencing Repair Work

2.1.2 High Voltage Warning

WARNING

The voltage of the AFE 302 is dangerous whenever the

frequency converter is connected to mains. Incorrect

installation or operation of the frequency converter may

cause damage to the equipment, serious personal injury

or death. The instructions in this manual must

consequently be observed, as well as applicable local

and national rules and safety regulations.

WARNING

Installation in high altitudes

At altitudes above 2,000 m, contact Danfoss regarding

PELV.

2.1.3 Safety Instructions

Make sure that the AFE 302 is properly connected

•

to earth.

Protect users against supply voltage.

•

Remember that the [Off] key on LCP is not a

•

safety switch. Pressing the [Off] key does not

disconnect the AFE 302 from the mains.

General Warnings

2.1.4

1. Switch off the entire system.

2. Wait until the DC-link capacitor is discharged

fully. See period of time on the warning label.

3. Disconnect DC bus terminals 88 and 89.

4. Disconnect the soft charge supply connector from

the soft charge board.

CAUTION

The source of the MDCIC connector (MK105) is the AC

voltage from the front end of the LCL filter. Make sure to

switch off the mains switch.

CAUTION

The source of the fan voltage is from an external 400 V.

Make sure to switch off the external fan voltage source

switch.

2.1.6 System Description

NOTICE

The grounded Delta mains are not used.

An Active Front End (AFE) is sometimes called an active

rectifier, in comparison with a passive rectifier such as the

diode bridge. The AFE consists of LCL filter and the

inverter unit.

WARNING

Touching the electrical parts may be fatal even after the

equipment is disconnected from the mains.

Before carrying out the maintenance, the frequency

converter must be disconnected from the mains. It will

avoid the electrical shock hazard.

Check the discharge time on the nameplate for the exact

waiting period. Otherwise wait at least 40 min.

6 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

The AFE main features are as follows:

sinusoidal input current and low harmonic

•

distortion in the mains

unity power factor

•

both rectifying and regenerating operation

•

constant regulated DC voltage

•

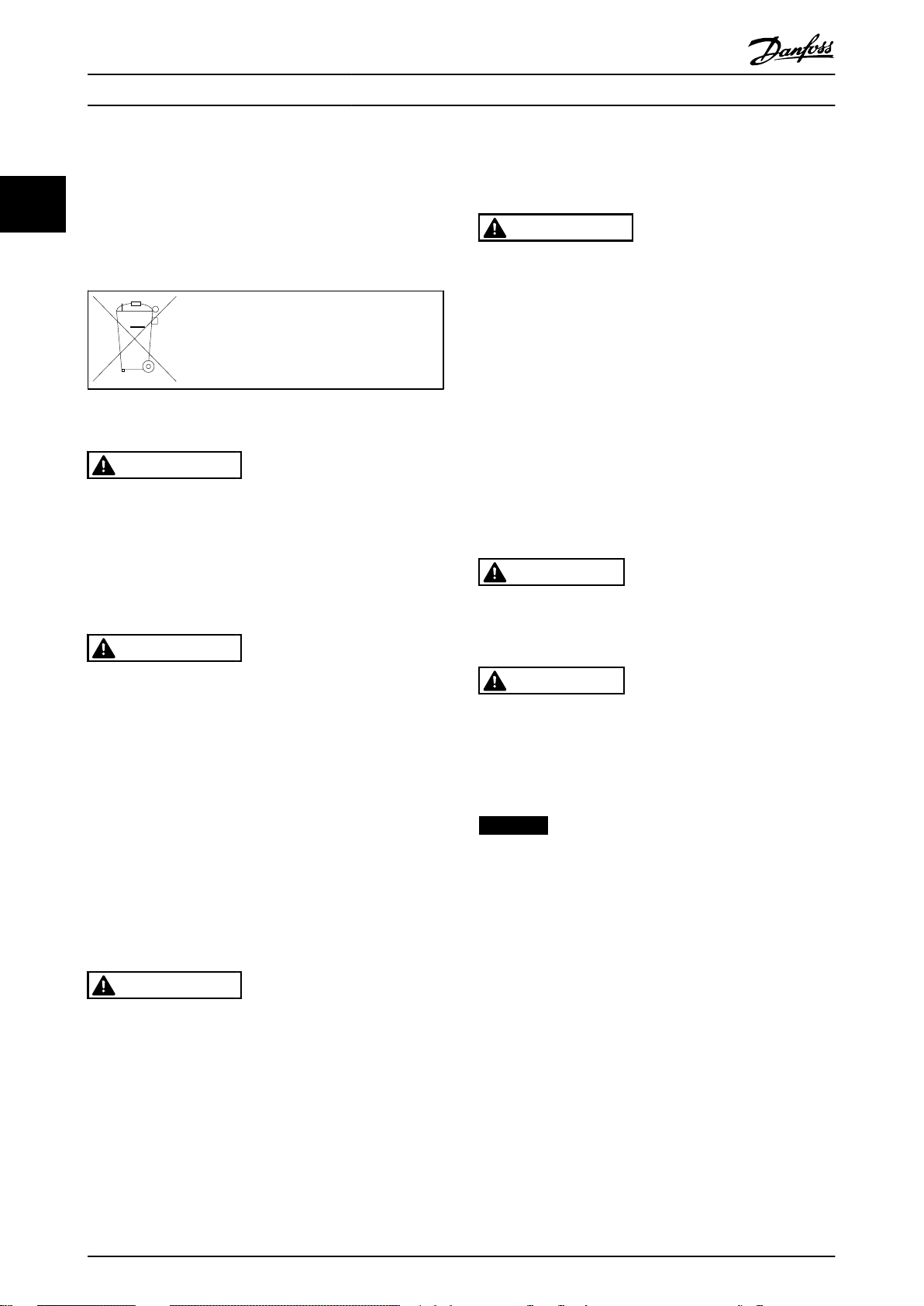

Illustration 2.1 shows the AFE system example.

At start-up, the AFE must detect the mains frequency and

phase to synchronize the operation.

Page 9

Transformer

AFE

Master Slave Slave

Control signals

130BA771.11

L

m

L

t

C

f

L

C

R

d

Safety Instructions and Gen... Operating Instructions

During the normal operation, the AFE DC-link voltage is

regulated to be constant. This means that the energy from

the decelerated motor is passed on to the mains as

regenerated electrical energy. A passive rectifier would

require a braking resistor to consume the surplus energy

as heat. The AFE is energy efficient for the application

where the motor deceleration is frequent. Also the brake

resistor space is saved.

The LCL filter allows the power flow. It also reduces the

ripple current of the fundamental frequency, switching

frequency, and their harmonics into the mains. A damping

resistor Rd is connected in series with the filter capacitor

Cf to stabilize the filter resonance.

The three inverter units are connected in parallel to

achieve the required power level. One AFE controller

regulates the three parallel-connected inverter units.

2 2

Illustration 2.1 Active Front End System Example

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 7

Page 10

Crane System Design

Operating Instructions

3 Crane System Design

The cable length is calculated as the sum of all

3.1 Selection of Motor Voltage

33

The AFE system is designed to regulate a DC voltage of

630x1.08=680 V. 690 V motors are suitable for this system.

When the motors are used in the field weakening region

or with output filters, the motors with less than 650 V are

used.

3.1.1 Selection of AFE & LCL Filter

AFE systems are built up based on standard 690

•

V hardware.

Standard AFE hardware runs on 630 V mains

•

supply and DC-link voltage is 975 V.

Selection of AFE for Different

3.1.2

Applications

The frequency converter power size in the flux

•

application must be one or two sizes higher than

the application needed. Also, the frequency

converter should not be higher than two to

maintain a good resolution on current sensors.

The AFE electrical rating should be selected

•

based on the worst-case total power, including

the overload percentage, rather than a mere sum

of the motor power.

Example:

•

Hoist motors 500 kW @ 650 V - Hoist

drives 800 kW

Travel motors 8x50 kW @ 650 V - Travel

drive 500 kW

Trolley motors 4x55 kW @ 650 V Trolley drive 400 kW

AFE/LCL – 1,2 MW continuous, with a

175% overload for a maximum 1 min.

Selection of Output Filter (LC Filter)

3.1.3

The output filter is needed because of the long

•

motor cable configuration.

Output filters should be sized based on the

•

frequency converter's maximum output current.

The dU/dt filters can be used up to 100 m to

•

protect the motor. The sine-wave filters can be

used with any cable length (maximum of 1,000

m).

Above 150 m cable length it is recommended to

•

use a sine-wave filter.

•

parallel cables.

Filters must be designed to switching frequency

•

of the frequency converter. The resonance

frequency, f0, of the filter should be:

10×

f

out max

The resonant frequency must meet the following

•

equation, limited by the control frequency, f

f

con

f

<

0

6

Switching frequency [kHz]

1.5 3

2 4

2.5 5

3 6

3.5 7

4 4

5 5

6 6

7 7

Table 3.1 Frequencies

1) The control frequency is an internal hardware frequency.

Selection of Switching Frequency

3.1.4

It is recommended that the switching frequency of AFE

and motor drives shall be equal or an integer multiple of

each other.

Selection of LCL Filter

3.1.5

The AFE system is designed in conjunction with the

recommended Danfoss LCL filters in which the physical

size, power rating and electrical parameters of the filters

are optimized.

If non-Danfoss filters are used, system performance and

stability may be degraded.

Crane Cable Concept

3.1.6

To reduce the high frequency noise on the mains line and

to meet the EMC emission limits, the electromagnetic

coupling should be avoided and the following rules have

to be applied:

f

sw

≤

f

≤

0

3

:

con

Control frequency1) [kHz]

8 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 11

Crane System Design

Operating Instructions

1. Use the shielded cable between the sine-wave

filter and frequency converter.

2. Keep the unshielded cable away from the mains

cable. The two cables should not be run in

parallel.

3. If the installation requires to route the motor

cables and mains cables in parallel, keep a

distance of at least 45 cm between the two

cables. Separate the cables by placing them in

different cable trays or in different sections of a

cable tray.

4. Use continuous cable trays and avoid “laddertype” cable trays.

5. Route the motor cable along the metallic

grounded conductors such as cable trays, rails

from the building structure, pipes, etc.

Grounding Concept

3.1.7

Do the common grounding between AFE and

•

motor drives.

The output filters and LCL should have low

•

impedance grounding to the AFE and motor

frequency drives.

Ensure low impedance between entire crane

•

construction and the cabinets and the

transformer.

Use only one connection to the transformer.

•

NOTICE

The door fan(s) is required on the Rittal cabinet to

remove the heat losses from the frequency converter

and other components inside the enclosure. The total air

flow required must be calculated and the appropriate

fan can be selected. Rittal Therm software can calculate

the cooling air flow volume. If the frequency converter is

the only heat generating source in the enclosure, the

minimum airflow required at an ambient temperature of

45 °C for the D3 and D4 frame sizes is 391 m3/h (230

cfm). The minimum airflow required at an ambient

temperature of 45 °C for the E2 frame size is 782 m3/h

(460 cfm).

Airflow

Table 3.2 shows the necessary airflow over the heat sink.

Enclosure

protection Frame size

IP54/NEMA 12 F1, F2, F3 and

F4

IP00/Chassis D3 and D4

E2 P400T7

E2 P500P560T7

* Airflow per fan. Frame size F contain multiple fans.

Table 3.2 Heatsink Air Flow

Door

fan(s)/Top fan

airflow

525 m3/h (309

cfm)*

255 m3/h (150

cfm)

255 m3/h (150

cfm)

255 m3/h (150

cfm)

Heatsink

fan(s)

985 m3/h (580

cfm)*

765 m3/h (450

cfm)

1105 m3/h

(650 cfm)

1445 m3/h

(850 cfm)

3 3

Cooling and Airflow

3.1.8

Cooling

The cooling air can be channeled through the air ducts at

the top and bottom of the unit, through the back of the

unit, or through the combination of the both methods.

Duct cooling

The duct cooling kit is used to install IP00/chassis D and Eframe frequency converters in the Rittal TS8 enclosure.

See Installation of Duct Cooling Kit in Rittal enclosures, for

further information.

Back cooling

The D and E frame frequency converters can be mounted

in the Rittal cabinet where the cabinet backplate has

cutout, through which the back-channel cooling is

available.

NOTICE

The ideal cooling air is clean and dry. When the cooling

air is from outside, the filter mats and long air inlet may

be considered to prevent the dirty air problem. When

the application environment is humid, consider the

condensation of the frequency converter which may

require the drain outlet.

NOTICE

The fan runs for the following reasons:

1. AMA

2. DC Hold

3. Pre-Mag

4. The frequency converter current exceeds 60%

of its nominal current rating.

5. The heat sink temperature exceeds its limit. The

limit depends on the power size.

When the fan is activated, it will run for a minimum of

10 min.

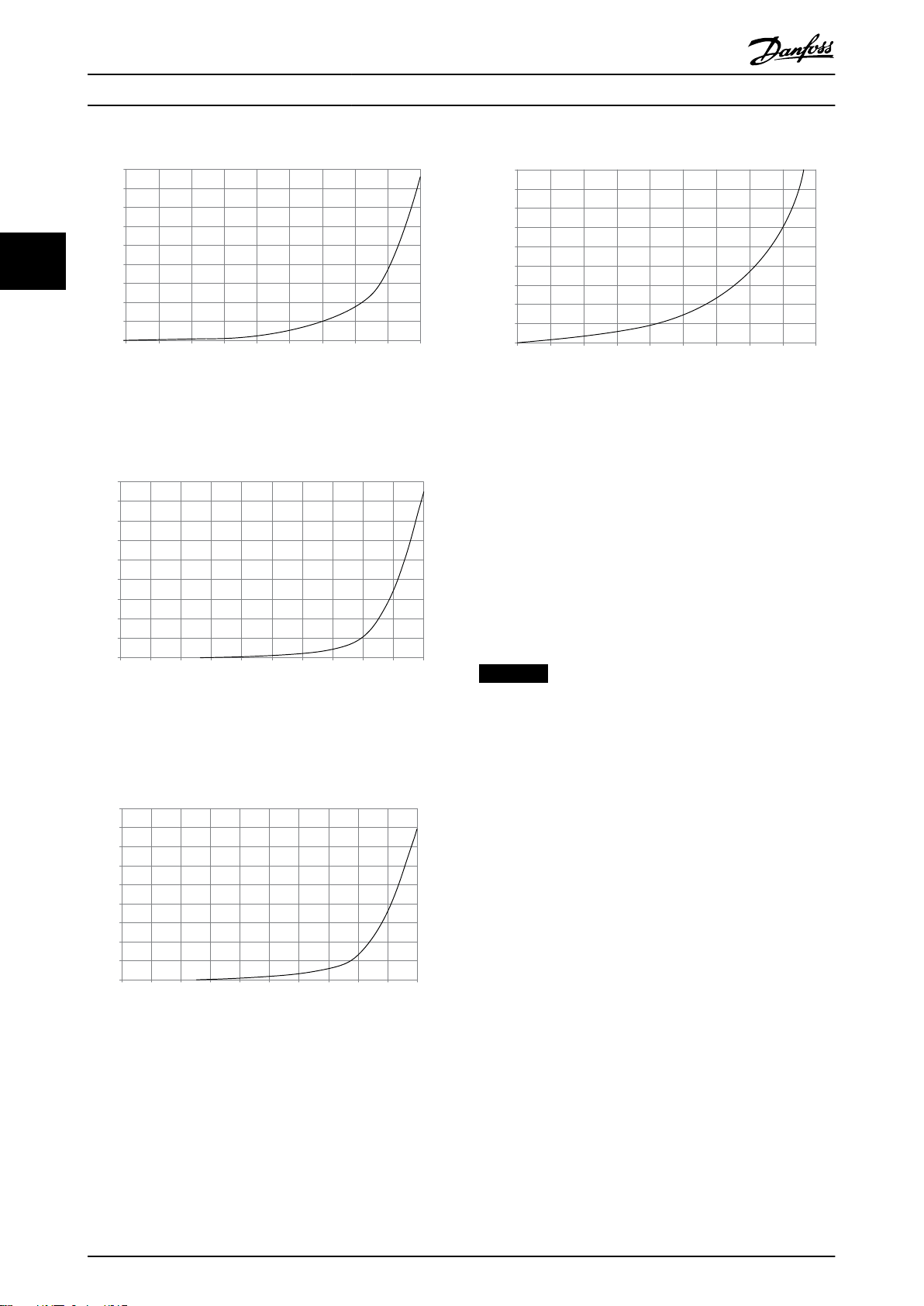

External ducts

If additional duct work is added externally to the Rittal

cabinet the pressure drop in the ducting must be

calculated. Use the charts below to derate the frequency

converter according to the pressure drop.

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 9

Page 12

90

80

70

60

50

40

30

20

10

0

0 0.5 4.9 13 27.3 45.9 66 89.3 115.7 147

(%)

(Pa)

Pressure Increase

Drive Derating

130BB007.10

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0 0.1 3.6 9.8 21.5 43.4 76 237.5 278.9

(Pa)

Pressure Change

130BB010.10

147.1

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 0.2 0.6 2.2 5.8 11.4 18.1 30.8 152.8 210.8

(Pa)

Pressure Change

130BB011.10

69.5

90

80

70

60

50

40

30

20

10

0

(%)

Drive Derating

0 25 50 75 100 125 150 175 225

130BB190.10

200

Pressure Change

Crane System Design Operating Instructions

33

Illustration 3.1 D frame derating vs. pressure change

frequency converter air flow: 450 cfm (765 m3/h)

Illustration 3.2 E frame derating vs. pressure change (small

fan), P355T7-P400T7

frequency converter air flow: 650 cfm (1105 m3/h)

Illustration 3.4 F1, F2, F3, F4 frame derating vs. pressure

change

frequency converter air flow: 580 cfm (985 m3/h)

Selection of Transformer

3.1.9

The output of the HT-transformer must be

•

specified for 630 V.

It is recommended to use 2 separate transformers

•

for 630 V and the 400 V and these transformers

should be physically separated. The 400 V

transformer must be close to or in the E-house to

have a short ground cable.

NOTICE

Danfoss reviews/evaluates the LCL filter design for each

application especially when the new transformer is used.

Illustration 3.3 E frame derating vs. pressure change (large

fan), P500T7-P560T7

frequency converter air flow: 850 cfm (1445m3/h)

10 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 13

Crane System Design Operating Instructions

3.2 Assembling the Frequency Converter

System

3.2.1 Tools Required

Operating Instructions for the FC Series.

Metric socket set 7–19 mm

Socket extensions 1/4" drive size, 4", 6" and 12"

Torx driver set T8-T50

Torque wrench 0.675–19 Nm (6–168 in-lbs)

Needle nose pliers

Magnetic sockets

Ratchet

Hex wrench set

Screwdrivers Standard and Phillips

Table 3.3 Tools Required

Additional Tools Recommended for Testing

Digital volt/ohmmeter (rated for 1200 V DC)

Voltmeter

Oscilloscope

Clamp-on style ammeter

Test cable PN 176F8766

Signal test board PN 176F8437

Power supply: 500-1000 V DC, 250 mA to supply external power

to 4 power cards and the control card.

Power supply : 24 V DC, 2 A for external 24 V power supply.

Table 3.4 Additional Tools

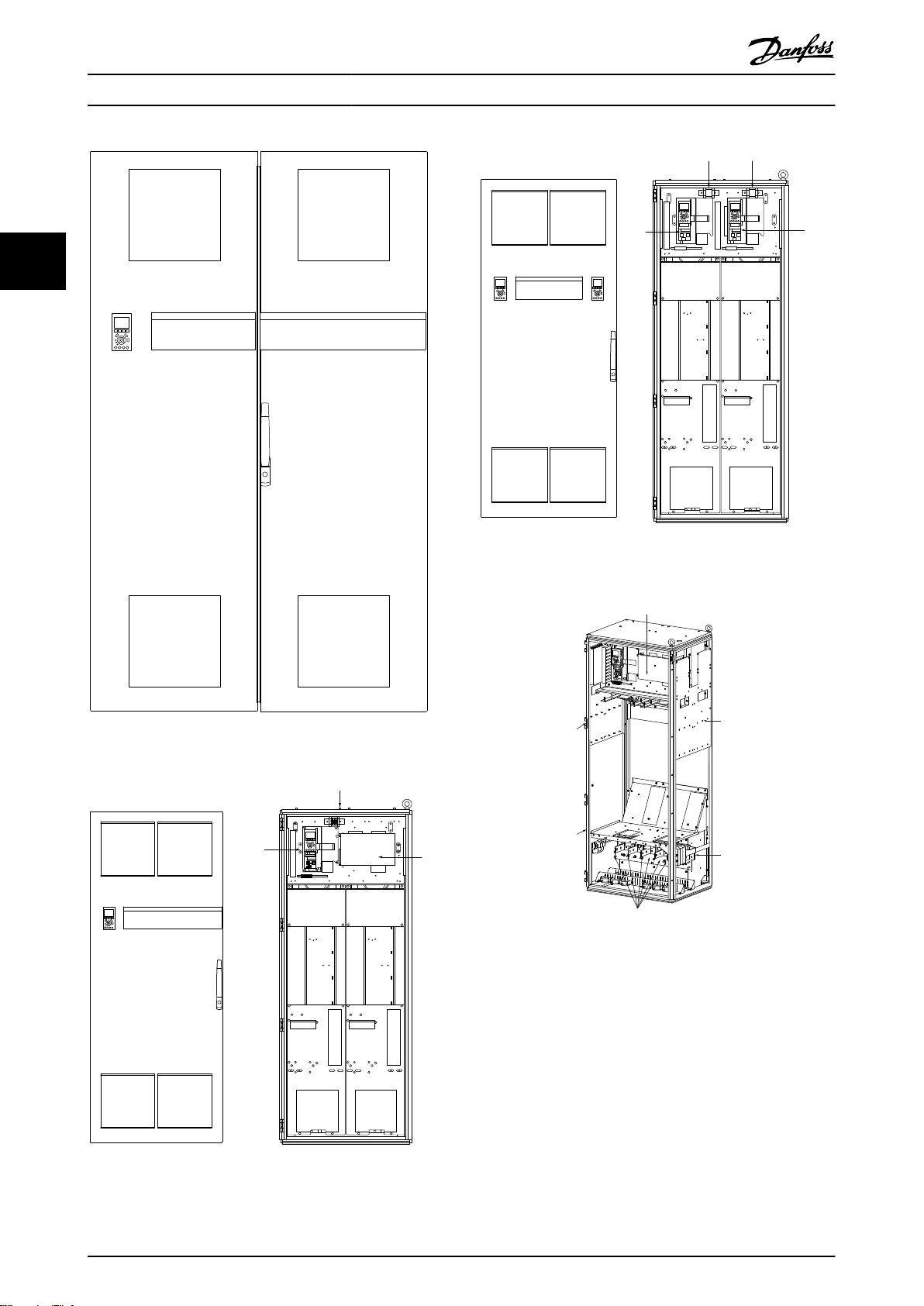

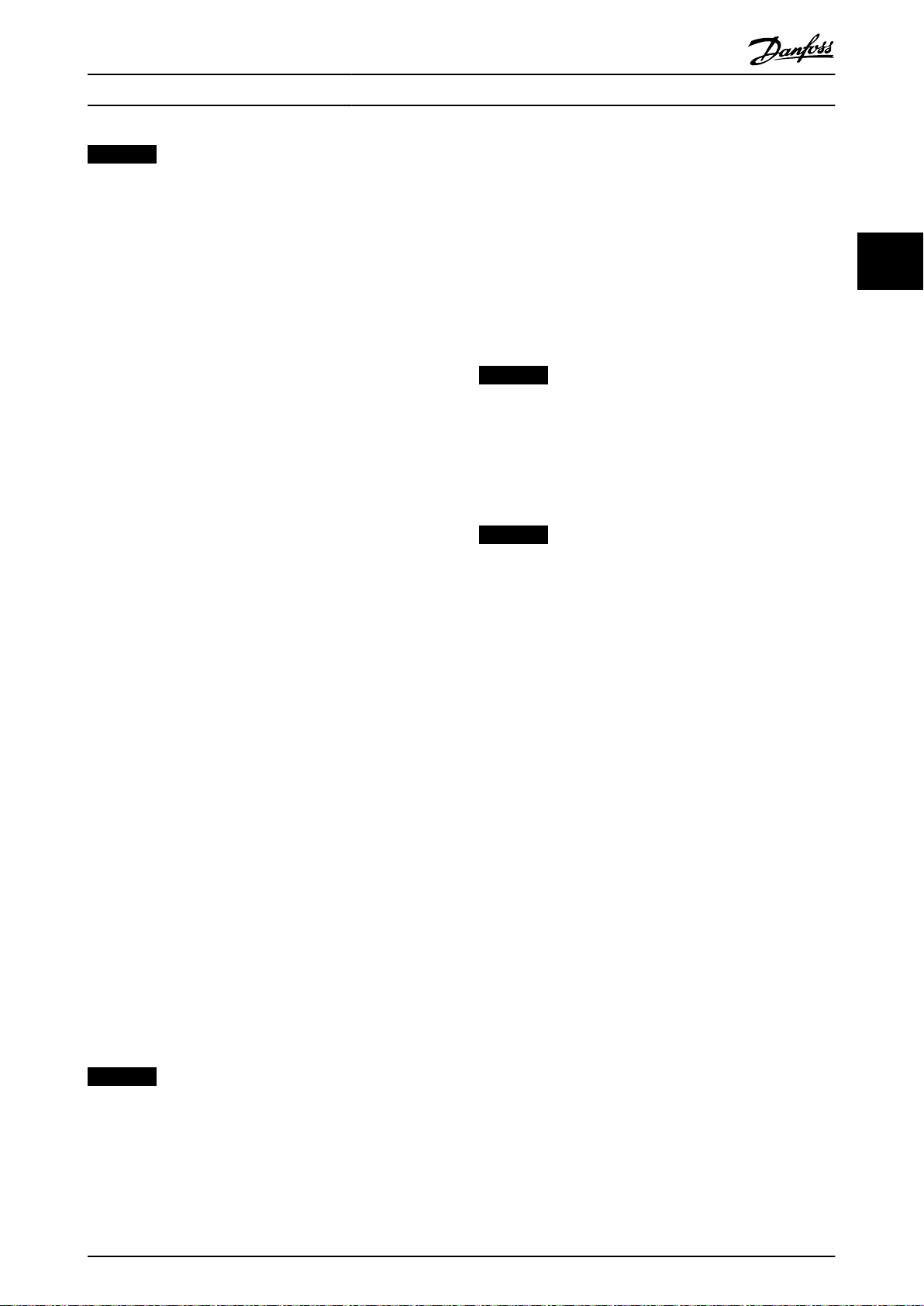

3.2.3

Exploded Views

Number Terminal and component description

1 Fan Voltage Supply (FVS)

2 Soft Charge Board (SC)

3 FVS Fuse (TB10)

4 SC Fuse (TB11)

5 Aux Fan Fuse

6 Fan Fuse

7 SMPS Fuse

8 Mains Terminals (R, S, T)

9 Aux Relay (TB12)

01 02 03 04 05 06

10 VSYNC (TB13) (Only for AFE Cabinet)

01-R, 02-S, 03-T

11 Control Card

12 MDCIC

13 Control Panel (Check the enlarged view)

14 DC Terminals (DC+ and DC-)

15 DC Bus Fuses

Table 3.6 Legend for Illustration 3.6 to Illustration 3.18

The rated voltage and maximum current magnitudes for

the AUX relay and VSYNC terminals are as follows:

AUX Relay: 240 V AC 2 A

VSYNC: 630 V 1 A

NOTICE

The control circuit including the control card terminal is

PELV isolated and it is also isolated from the power

circuit galvanically.

3 3

General Tightening Torque Values

3.2.2

Table 3.5 tabulates the tightening torque values. The

tightening toque values for the rectifier and IGBT modules

are referred to in the instruction within the spare kits.

Shaft size Driver size

Torx/hex

M4 T-20/7 mm 10 1.0

M5 T-25/8 mm 20 2.3

M6 T-30/10 mm 35 4.0

M8 T-40/13 mm 85 10

M10 T-50/17 mm 170 19

M12 18 mm/19 mm 170 19

Table 3.5 Torque Values

Torque [in-

lbs]

Torque [Nm]

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 11

Page 14

130BA667.10

130BA664.10

9,10

11

12

130BT258.10

9 9

11

11

130BA663.10

1

2

8

2

4

13

Crane System Design Operating Instructions

33

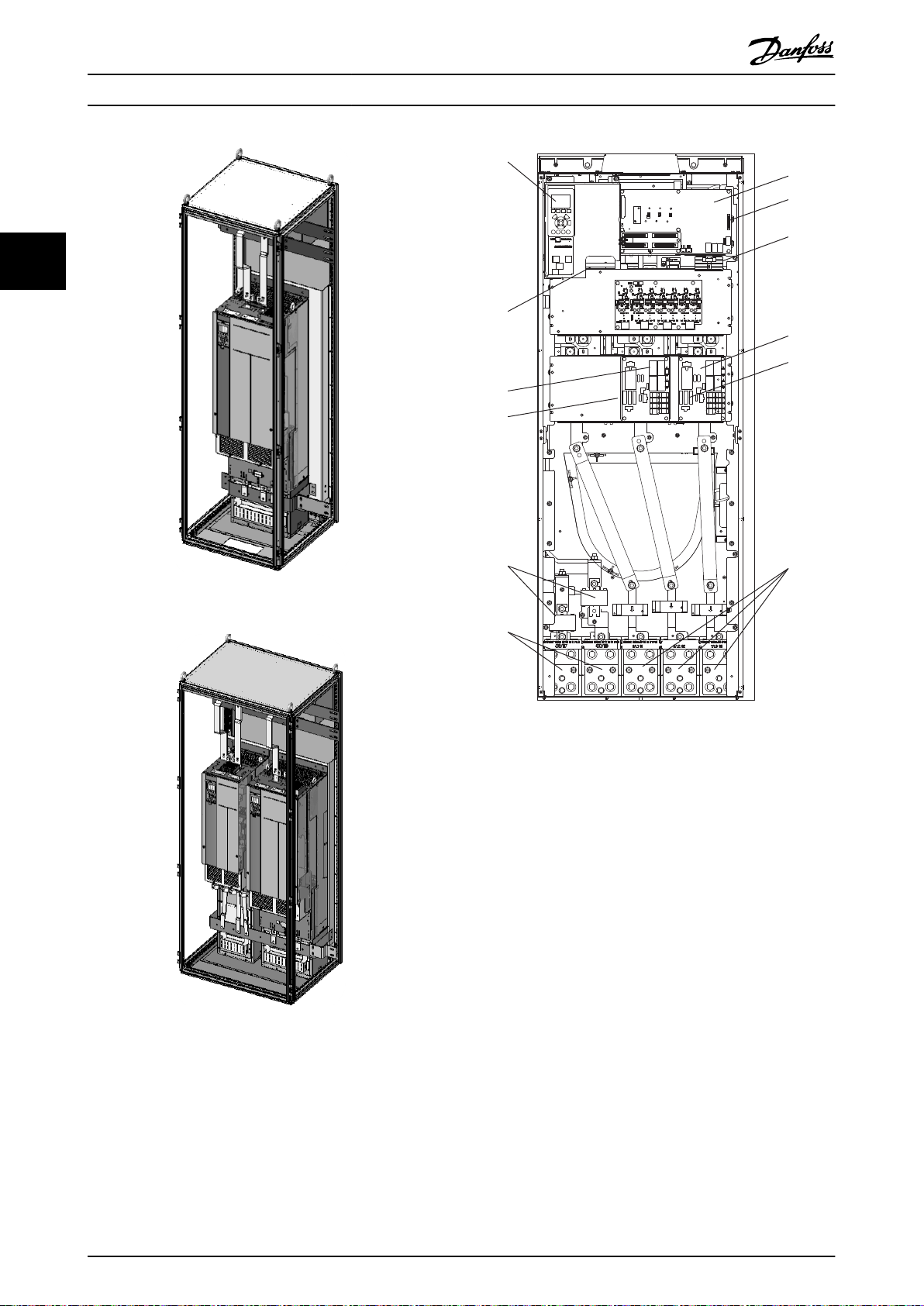

Illustration 3.7 Outside- and Inside View

Illustration 3.5 Front Door View

Illustration 3.8 800 mm Cabinet Skeleton View

Illustration 3.6 800 mm Cabinet Front Door and its Inside

Views (One Drive Case)

12 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 15

130BA665.10

8

Crane System Design Operating Instructions

3 3

Illustration 3.9 800 mm Lower Front End View

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 13

Page 16

1

3

3

8

4

2

5

6

7

4

13

130BA666.10

Crane System Design

Operating Instructions

33

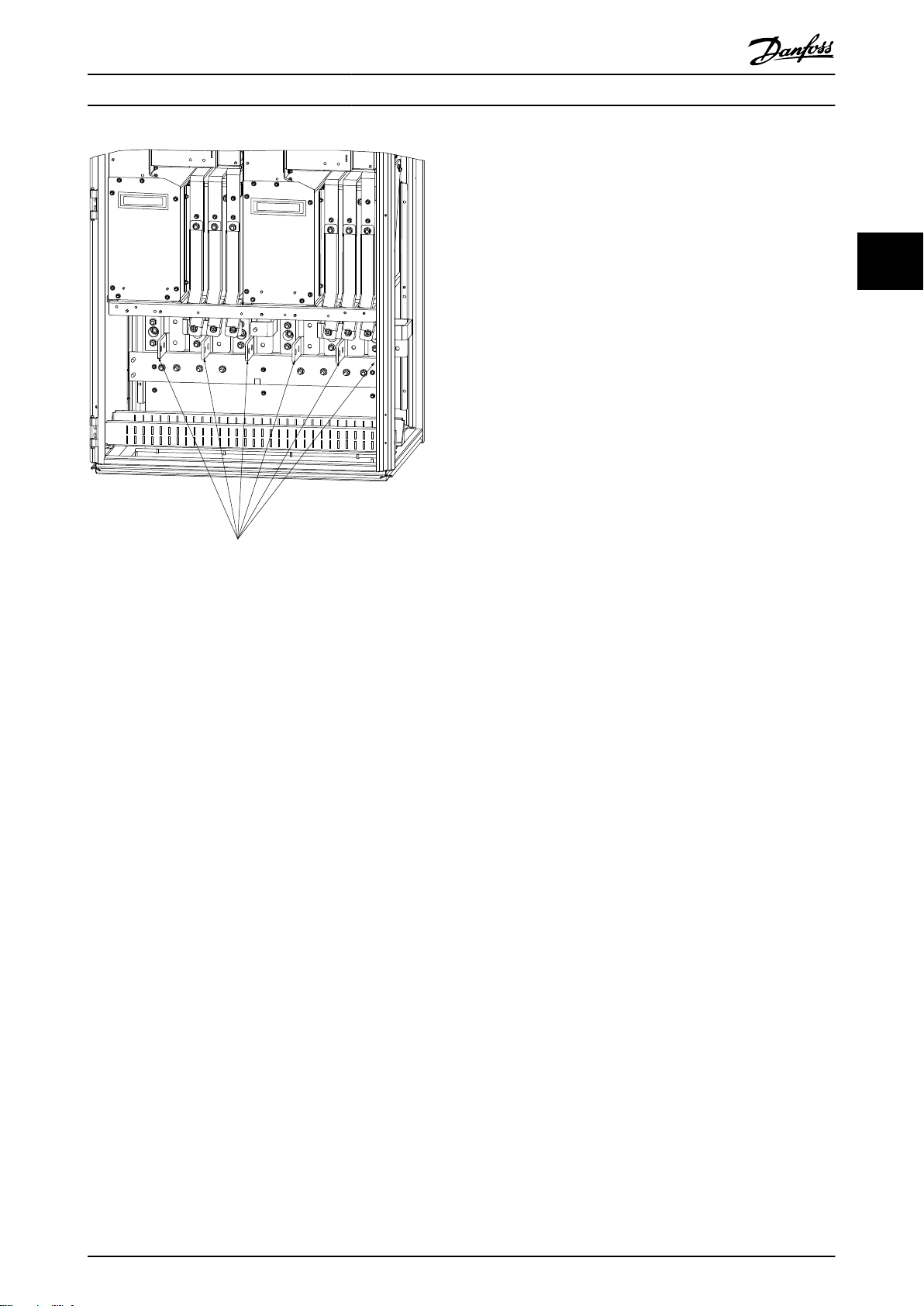

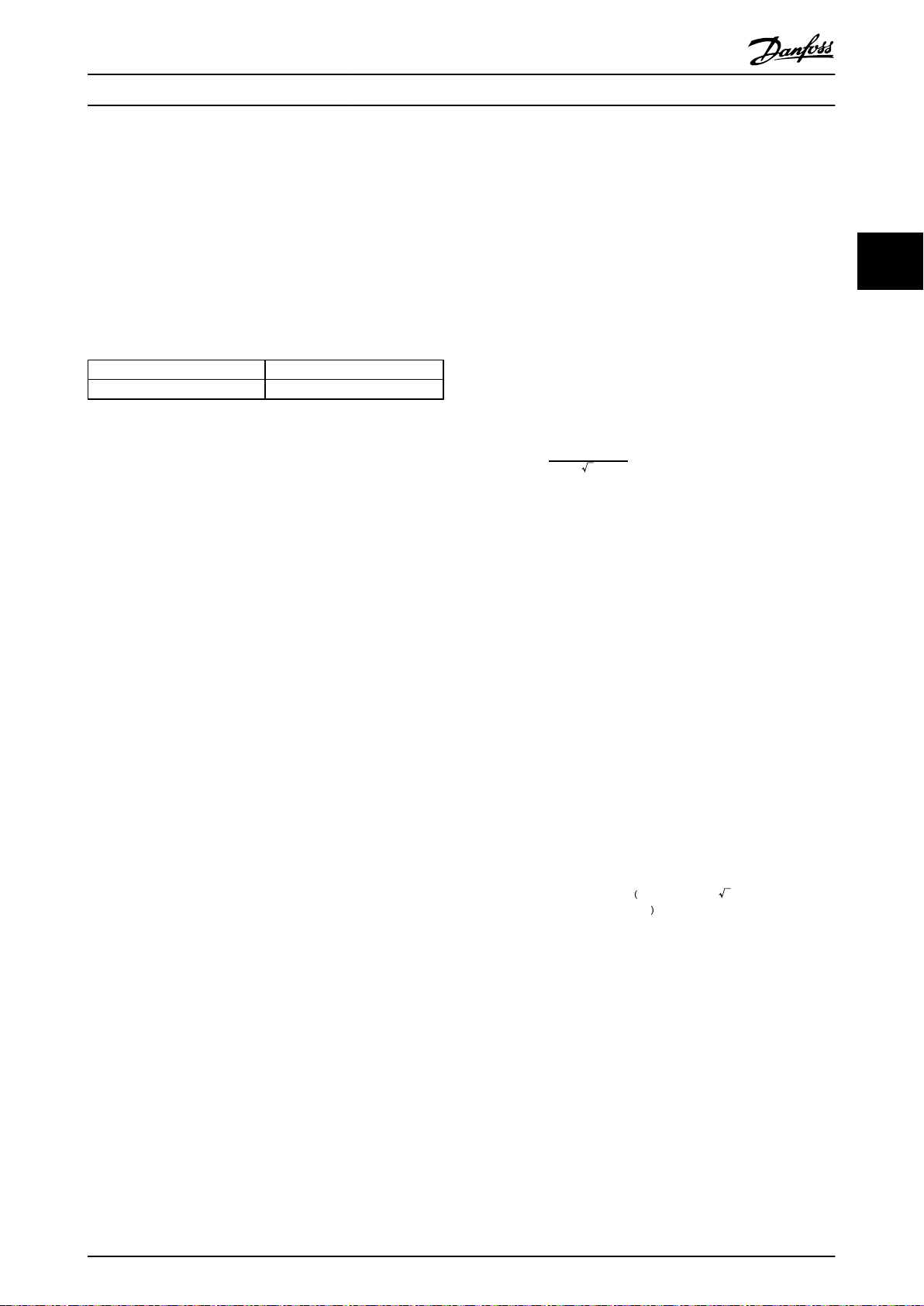

Illustration 3.10 1200 mm Cabinet Exploded View

14 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 17

1

2

3

4

130BD818.10

9,10

12

11

5, 6, 7

130BD819.10

130BD820.10

3

4

4

8

8

130BT254.10

130BT255.10

12

13

18

19

27

29

32

33

20

33

64

Life Stop

55

12

13

18

19

27

29

32

33

20

33

64

Life Stop

55

Crane System Design Operating Instructions

3 3

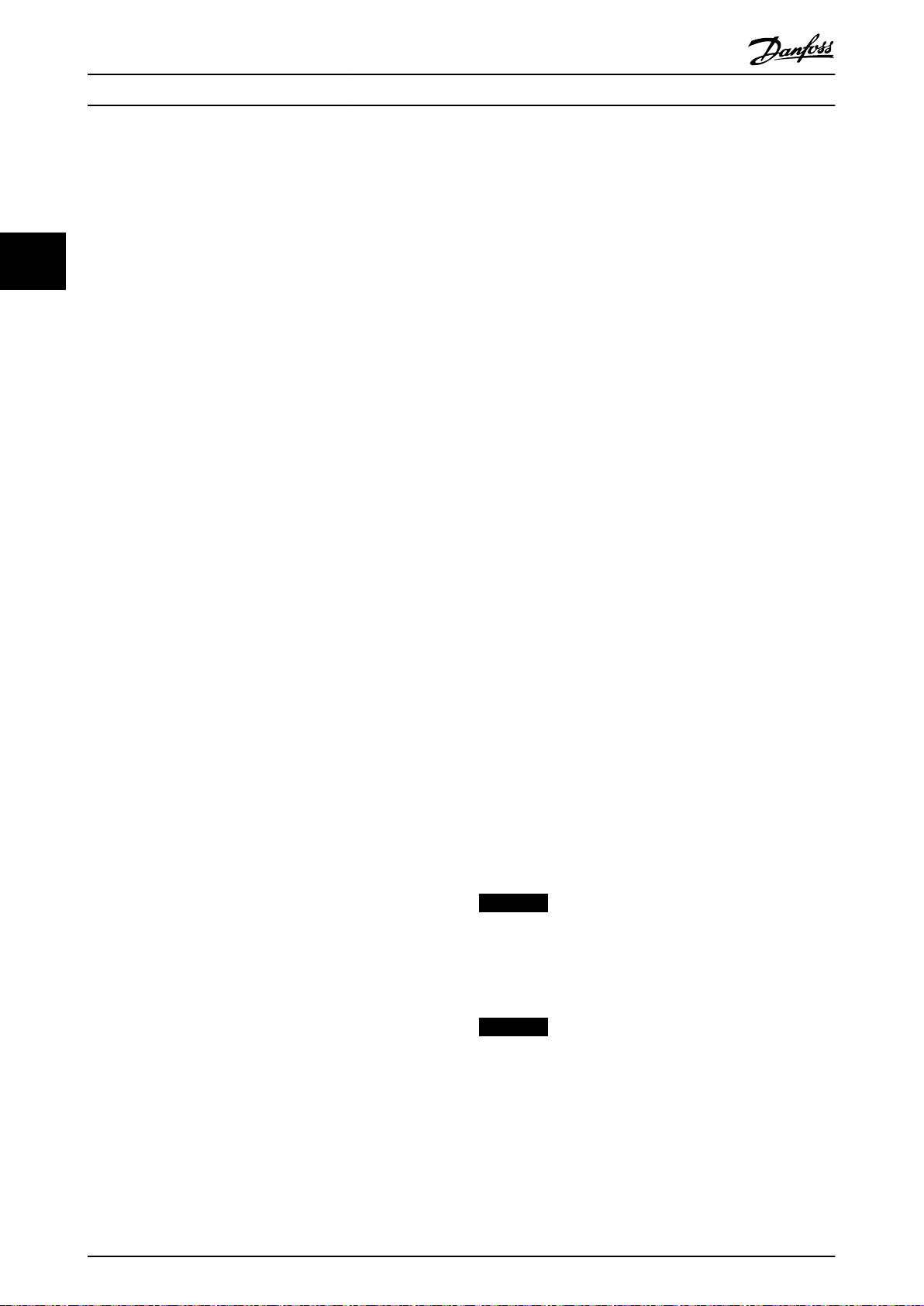

Illustration 3.13 1600 mm Cabinet Exploded View

Illustration 3.11 1600 mm Cabinet Exploded View

Illustration 3.14 One-drive Configuration Control Panel View

Illustration 3.15 Two Independent Drive Configuration Control

Panel View

Illustration 3.12 1600 mm Cabinet Exploded View

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 15

Page 18

130BD836.10

130BD837.10

-C-

-C-

12

10

6, 7

2

4

8

11

9

1

3

15

14

130BD871.10

Crane System Design Operating Instructions

33

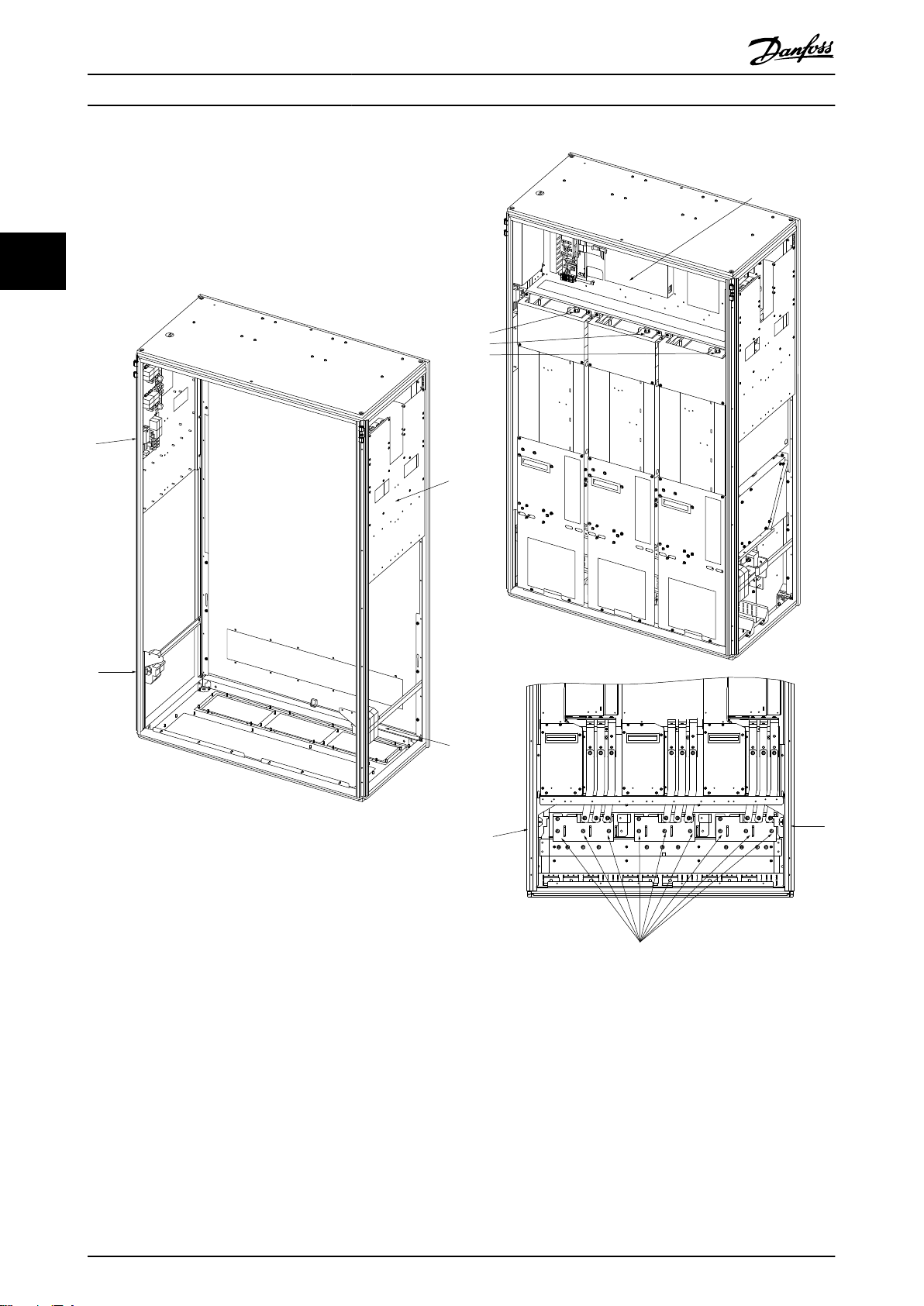

Illustration 3.16 600 mm Drive Cabinet

Illustration 3.18 AFE E-frame Drive Open View

Illustration 3.17 800 mm Drive Cabinet

16 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 19

Crane System Design

Operating Instructions

3.2.4 MDCIC Connector Configuration

The MDCIC board has the four connectors. The ribbon

cables from the power units will be connected from FK100

to FK103.

For one power unit configuration, the part 176F9091 which

consists of the DC/DC converter and the ribbon cable is

connected to FK101. It generates an isolated 5 V from an

internal 24 V for the RS-485 communication.

FK100 (Master) FK102 (Slave 2)

FK101 (Slave 1) FK103 (Slave 3)

Table 3.7 MDCIC Port Layout

3.3 First Power Up/Commissioning Check

List

The following measurement equipment are recommended:

Voltage meter (1 kV AC/DC env. Cat III)

•

Current clamp min. 2 kA

•

Harmonic analyzer, only for commissioning

•

Check list

Check fan voltage supply (3x400 V).

•

Verify that system is not powered.

•

Verify the system is grounded to earth.

•

all AFEs and frequency converters

-

all motors

-

all filters

-

the whole crane construction

-

HT transformer

-

Check that there are no earth faults or short

•

circuits at the motor cables and motors.

Check that the DC discharge resistor is connected

•

right and not shorted.

Verify phase sequence and continuity for the

•

voltage sensing on the AFE as described below.

Make sure that power is not applied.

-

Manually close input contactor between

-

AFE and LCL filter.

Unplug the MK105 connector on the

-

MDCIC.

Measure MK105 of MDCIC harness to

-

the input phases.

Red wire of MK105 to phase R.

-

White wire of MK105 to phase

-

S.

Black wire of MK105 to phase

-

T.

-

All should be <0.2Ω.

Open the input contactor between AFE and LCL

•

filter.

Verify that the mains voltage is 630 V RMS and

•

balanced.

Apply power to the LCL filter and verify that the

•

rms current magnitude measured between the

line and delta connection point is approximately

same as the value using the following formula:

630×314 ×C×3

i

=

capacitance, delta value.

Leave the AFE main contactors open and disallow

•

the AFE start signal in the PLC.

Soft charge the system but do not enable the

•

main contactor.

Let the softcharge circuit active for about 5min.

•

Check the voltage at the AFE Mains side when

•

the AFE is powered up by softcharge. The voltage

between all phases should be 0 V. Also the

voltage between the phases L1/L2/L3 and earth

should be 0 V. Please call Danfoss service if you

can measure a voltage greater then 10 V here.

Do not switch on the mains contactors if you

measure a voltage more than 10 V here.

Verify that the LCP readings for the DC-link

•

voltage from all the AFE and inverter drives are

within ±2% of the value measured with the

voltage meter. The estimated DC-link voltage

value at 630 V mains voltage with no load is as

follows:

890

V

+5 / − 10% =

DC

= 630× 1,414+ 5 / −10%

Download all the AFE and frequency converter

•

settings with MCT 10 Set-up Software.

1. Capacitance value of the LC filter in the

2. Set the right LCL filter values in the AFE,

3. Set the right mains values in the AFE.

4.

5. Total system capacitance par. 7-60 must

, where C is the LCL filter

3

V

mains_LL_RMS

inverter drive must be star equivalent.

the capacitance value of the LCL filter

shall be entered as delta equivalent.

Parameter group 4-** Output Limits AFE

– use factory settings.

be programmed with a sum of the DClink capacitance x 0,9.

× 2+5 / −10 %

3 3

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 17

Page 20

Crane System Design

6.

Use parameter group 7-** Controllers as

follows:

Parameter 7-61 DC-Link

•

Reference is 975 V.

Parameter 7-62 DC-Link PI

•

33

Switch Crane off.

•

Program the PLC to the normal start-up

•

sequence.

Switch Crane on.

•

The AFE starts, but not any of the inverters, and

•

verify that the AFE and inverter LCP readings are

975 V DC and that they are within ±2% of a

calibrated voltage meter.

Check if all fans are running after closing the

•

mains contactor.

Start checking inverters and motors.

•

Save all parameter settings with MCT 10 Set-up

•

Software.

For the crane commissioning, measure THDu and

•

THDi of the 630 V and 400 V terminals and

document the results in the commissioning

certificate.

Verify that the THD levels of the 400 V terminal

•

are complied to EN 61000-3 or other country

specified harmonic requirements.

3.4

E-House Design

Proportional Gain (Kp) is

calculated internally based on

the power size and DC

capacitance in parameter 7-60

DC-Link Total Capacity.

Recommend to use the default

value. The wrong setting could

cause the unstable DC voltage

regulation.

Parameter 7-63 DC-Link PI

•

Integral Time (Ti) is 5 ms in

default.

3.4.1 Cables between AFE and LCL Filters

The cables should be as short as possible.

•

The connection must be made with shielded

•

cables.

The synchronization voltage cable which is connected to

the AFE-MDCIC board MK105 must be separated from all

power cables. The distance needs to be at least 50 cm

from other power cables.

3.4.2

Cables to the Damping Resistors

Operating Instructions

3.5

Test with the Real System Transformer

and Motors

3.5.1 Re-program the Frequency Converter

Parameters

Set the mains voltage, mains frequency, the

•

transformer values, LCL filter values, and DC

capacitance.

3.6 On-site Final Test

3.6.1 Change Parameters to Actual

Set actual cable length.

•

Check encoder wiring and encoder direction.

•

Optimize ramp time shapes.

•

Save parameter settings in the LCPs.

•

Run with Full Load

3.6.2

Check that AFE input voltage is stable. The

•

voltage waveform does not need to be

sinusoidal.

Check that DC-link voltage is stable.

•

3.7

AFE Emergency and Restore Procedures

Chapter 3.7.1 Emergency Run when One Slave Unit is

Damaged to chapter 3.7.4 Restoration after Master Unit is

Repaired describe how to set up an emergency run and

how to restore the drive for the case where one of the

three units are damaged. Chapter 3.7.5 Emergency Run

When More Than One Unit is Damaged describes the case

where the multiple units are damaged.

Emergency Run when One Slave Unit

3.7.1

is Damaged

NOTICE

The mains synchronization voltage is always connected

to the MDCIC board. Make sure that the mains power

switch is off before opening the frequency converter

cabinet.

NOTICE

The power is reduced to two thirds of the original.

1. Switch Crane off.

2. Switch the circuit breaker in front of the

damaged AFE power unit off.

3. Check the DC-link voltage with a voltage meter at

the terminals before and after the DC fuses.

The cables should be as short as possible.

18 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 21

Crane System Design

Operating Instructions

NOTICE

Do not touch until the DC voltage is below 10 V.

4. Disconnect the DC-link fuses of the damaged

power unit and AC connection.

5. Disconnect the softcharge connector on the

softcharge board of the damaged power unit.

6. Disconnect the ribbon cable, from the damaged

AFE power unit, on the MDCIC card.

7. If the removed connector is at Inverter 2 position,

move the ribbon cable at Inverter 3 position to

Inverter 2.

8.

Turn the key switch to AFE emergency mode.

9. Switch Cane on.

10. Check on the AFE LCP if it is in set-up 2. The setup shift at the AFE is done with terminal 32 at

AFE control card. Terminal 32 = 0 means set-up 1,

Terminal 32 = 1 means set-up 2.

11. A warning 78 (power unit set-up) may come up

at the AFE LCP.

12. Switch Crane off.

13. Wait at least 20 s. All LCPs must be completely

off.

14. Switch Crane on.

15. The warning 78 disappears and the warning 77

(Reduced power mode) appears on LCP.

16. The AFE can run with two units with a reduced

power.

Restoration after Slave Unit is

3.7.2

Repaired

1. Switch Crane on but do not run any frequency

converter.

2.

Turn the key switch to AFE normal mode.

3. A warning 78 appears on AFE LCP.

4. Check on the AFE LCP if it is in set-up 1. The setup shift at the AFE is done with terminal 32 at

AFE control card. Terminal 32 = 0 means set-up 1,

Terminal 32 = 1 means set-up 2.

5. Switch Crane off.

6. Check the DC-link voltage with a voltage meter at

the terminals before and after the DC fuses.

NOTICE

Do not touch until the DC voltage is below 10 V.

7. Bring back the ribbon cables on the MDCIC card

in the original set-up (AFE Master to Inverter 1,

AFE Slave left to Inverter 2, AFE Slave right to

Inverter 3).

8. Connect the softcharge connector on the

softcharge board.

9. Connect the DC-link fuses and AC connection.

10. Switch on the circuit breaker in front of the AFE.

11. Switch Crane on.

12. The AFE runs now with all 3 power units.

3.7.3 Emergency Run when Master Unit is

Damaged

NOTICE

The power is reduced to two thirds of the original.

1. Switch Crane off.

2. Switch the circuit breaker in front of the

damaged AFE power unit off.

3. Check the DC-link voltage with a voltage meter at

the terminals before and after the DC fuses.

NOTICE

Do not touch until the DC voltage is below 10 V.

4. Disconnect the DC-link fuses of the damaged

power unit and AC connection.

5. Disconnect the softcharge connector on the

softcharge board of the damaged power unit.

6. Disconnect the ribbon cable from the Inverter 1

position at the MDCIC.

7. Unplug the ribbon cable at Inverter 3 position on

the MDCIC card and plug it at Inverter 1 position.

8. Plug this ribbon cable (what you plugged out

from Inverter 3) on the connector Inverter 1. Now

the right power unit will be the AFE Master.

9.

Turn the key switch to AFE emergency mode.

10. Switch Crane on.

11. Check on the AFE LCP if it is in set-up 2.

12. A warning 78 may appear on AFE LCP.

13. Switch Crane off.

14. Wait at least 20 s. All LCPs must be completely

off.

15. Switch Crane on.

16. The warning 78 disappears and the warning 77

appears on LCP.

17. The AFE can run with two units with a reduced

power.

3 3

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 19

Page 22

Crane System Design Operating Instructions

3.7.4 Restoration after Master Unit is

Repaired

1. Switch Crane on but do not run any frequency

converter/motor.

2.

33

Turn the key switch to AFE normal mode.

3. A warning 78 appears on AFE.

4. Check on the AFE LCP if it is in set-up 1 (see

attached file LCP.pdf). The set-up shift at the AFE

is done with terminal 32 at AFE control card.

Terminal 32 = 0 means set-up 1, Terminal 32 = 1

means set-up 2.

5. Switch Crane off.

6. Check the DC-link voltage with a voltage meter at

the terminals before and after the DC fuses.

3. Power up.

4. Power cycle.

NOTICE

Do not touch until the DC voltage is below 10 V.

7. Bring back the ribbon cables on the MDCIC card

in the original set-up (AFE Master to Inverter 1,

AFE Slave left to Inverter 2, AFE Slave right to

Inverter 3).

8. Connect the softcharge connector on the

softcharge board.

9. Connect the DC-link fuses an AC connection.

10. Switch on the circuit breaker in front of the AFE.

11. Switch Crane on.

12. The AFE runs now with all 3 power units.

Emergency Run When More Than

3.7.5

One Unit is Damaged

When multiple units are damaged, an emergency run with

a minimum of one unit can be performed. The procedure

of setting up the emergency run and restoring from the

emergency run can be referred to in

chapter 3.7.1 Emergency Run when One Slave Unit is

Damaged to chapter 3.7.4 Restoration after Master Unit is

Repaired.

The following issues are considered:

1. In an emergency run, the door fan may not be in

operation. It is recommended that the emergency

configuration is only for a temporary usage.

2. An emergency run may cause the overcurrent

alarm at start-up because the start-up current

may be high for the number of units used. The

switching frequency (parameter 14-01 Switching

Frequency) may need to be increased from 1.5

kHz to 2 or 2.5 kHz.

3.8

Manual Shut Down Sequence

Stop all motor drives.

•

switch off the AFE start signal.

•

Open the mains contactor

•

Switch off the HT transformer if necessary

•

In emergency, command the AFE to stop and

•

open the AFE contactor, or pull the safe stop and

open the AFE contactor.

(176F9091) needs to be connected at

FK101 to have the RS-485 communication.

3a The warning message W78 (Power Unit

Setup) appears on LCP.

3b

Change the number of the units in

parameter 14-59 Actual Number of

Inverter Units.

4a The warning message W77 (Reduced

Power Mode) appears on LCP.

4b The power is reduced to the original

power multiplied by the number of

active units over the original number of

the units.

The key procedure of an emergency run is as follows:

1. Disconnect AC and DC sides of the damaged

units.

2. Change the connector position at MDCIC.

2a The ribbon cables at the MDCIC are

connected from FK100 (Master)

following FK101, FK102, and FK103. You

do not skip the terminal sequence.

2b You can go down to one unit. When

one master unit is used, the part

20 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 23

Auxiliary Hardware

Actions

AFE Drive Control PLC

: Assume that the AFE contactors

and SC contactor are open

prior to this start-up sequence.

Start-up Sequence

Crane ON

Contactor LCL cabs ON

2 sec Delay

Send close signal to

the SC contactor.

Receive "Soft Charge

Ready" signal within

20sec?

Protection Mode

due to the Start-up

Failure

No

Wait for 1 second

to have the DC capacitors

charged further.

Yes

Send the open signal

to the SC contactor.

Wait for 1 second

to make sure that the

S/C contactor is open.

Send the close signal

to the AFE contactors.

Wait for 0.5 second

to have the DC capacitors

charged fully.

Send the "Run"

signal to the AFE drive.

Receive "DC-Link

on Ref" signal from

AFE within 5 sec?

End of Start-up

Sequence

No

No

Yes

Yes

Protection Mode

due to the Start-up

Failure

3rd Try?

:The waiting period can be substituted

by the contactor status signal.

: Assume that the AFE contactors

are fully engaged within 2seconds.

:The waiting period can be substituted

by the contactor status signal.

: Assume that the SC contactor is

disengaged within 0.5sec.

The DC capacitor discharge

is negligble.

130BA783.12

Abbreviations:

AFE: ACtive Front End

CC: Control Card

PC: Power Card

PLC: Programmable Logic Controller

SC: Soft Charge

When the DC voltage is within

the target range, "DC-link on

Ref" signal is on.

The AFE drive is active.

DC voltage is going

up to the desired level.

The AFE contactors

are closed.

The SC contactor

is open.

Charge the DC bus

through the SC circuit.

The SC contactor

is closed.

When the PC becomes

active, "Soft Charge Ready"

signal is ON.

Crane System Design Operating Instructions

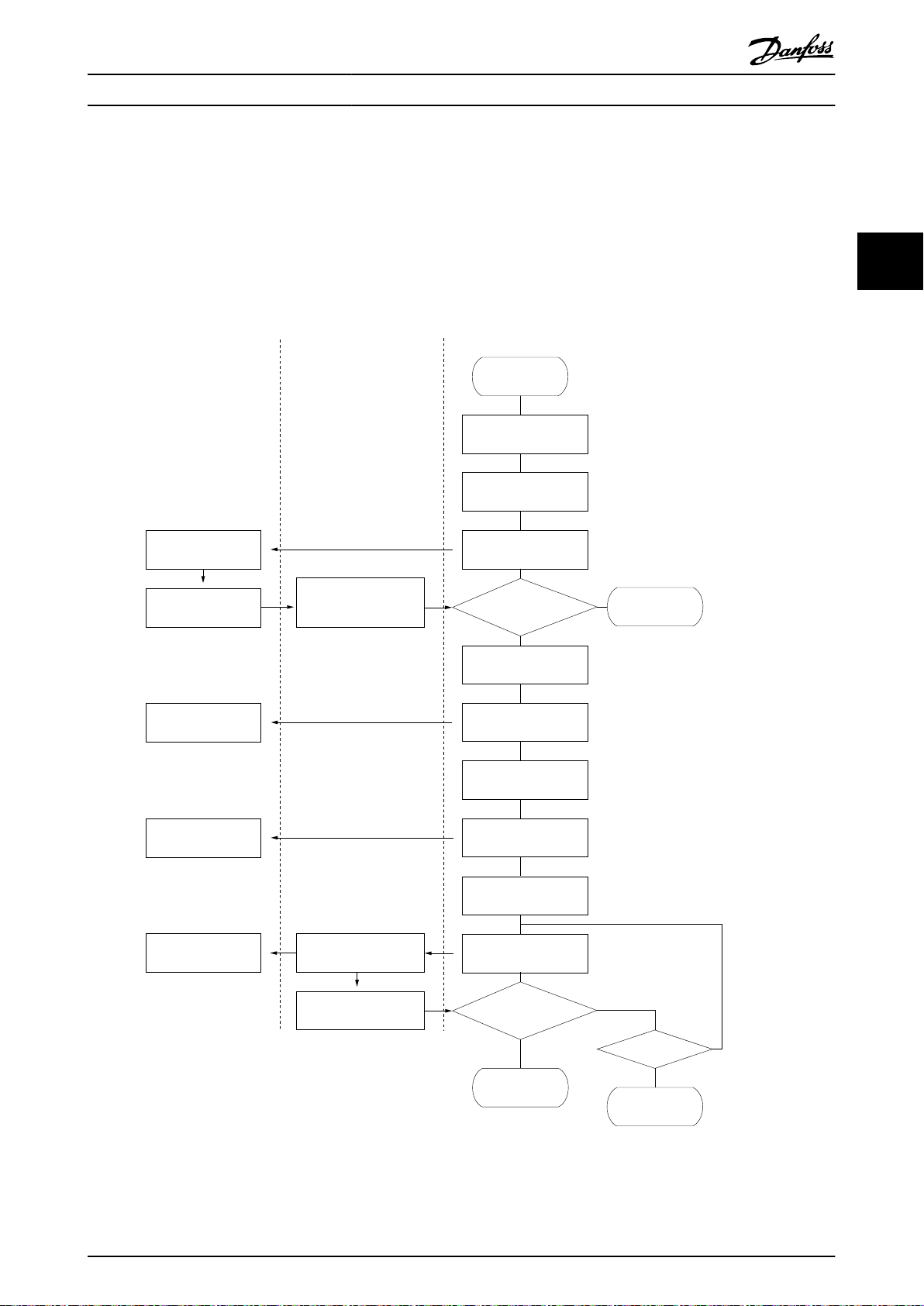

3.9 Start-up Sequence

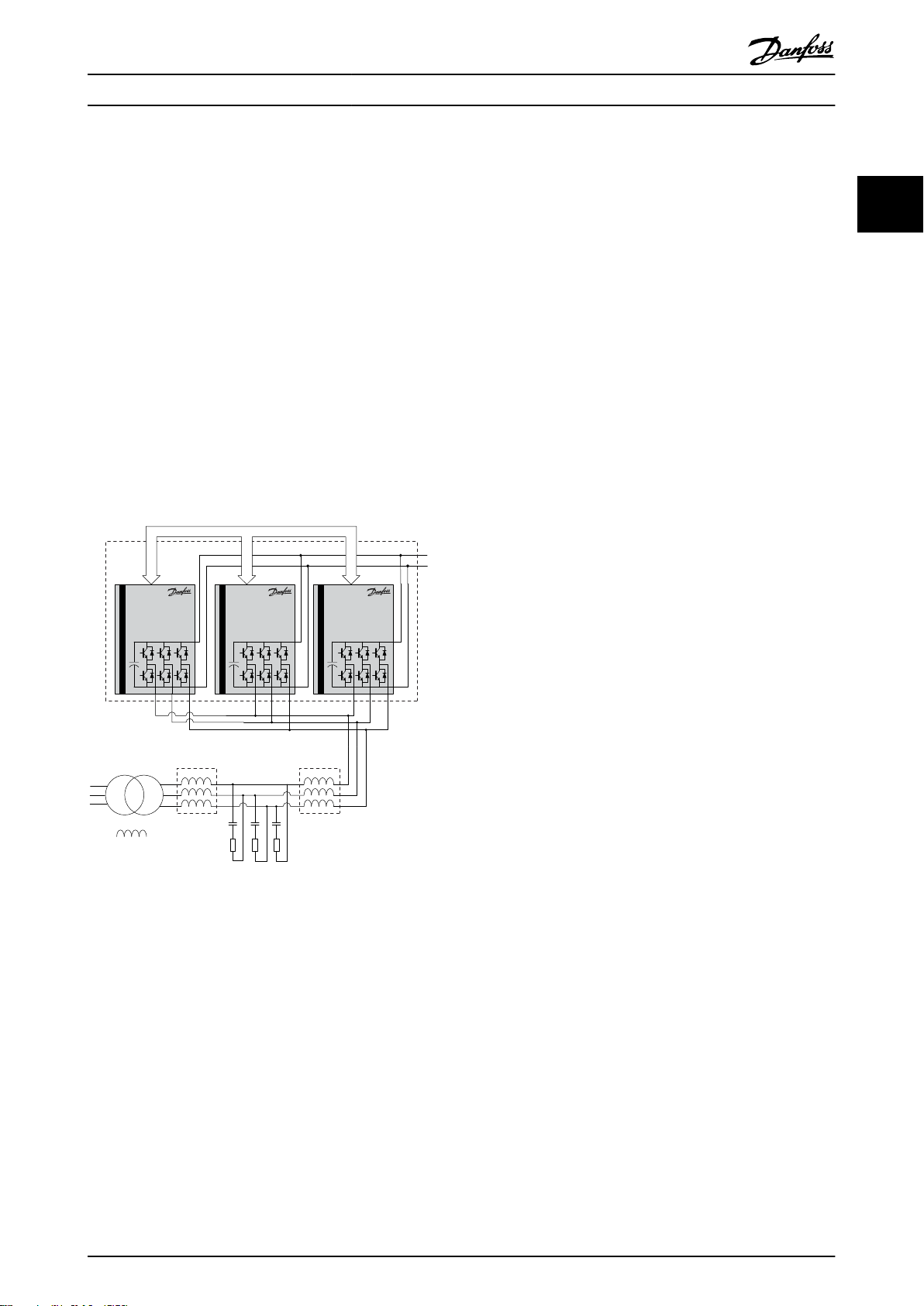

Illustration 3.19 shows the typical AFE start-up sequence flow chart. The flow chart describes the interaction among Auxiliary

Hardware, AFE Frequency Converters, and Liebherr Control PLC. The arrowed lines indicate the flow of the actions. The

Liebherr PLC expects to receive the “Control Ready” and “Ready” signals from the AFE frequency converter and it will send

“Run” signal to AFE frequency converter. The waiting periods and the number of tries are tentative. The “Control Ready”

signal is on when the power in Control Card is on. The meaning of the "Ready" signal in the AFE frequency converter is

different from the one in the standard frequency converter. The “Ready” signal in the AFE frequency converter is on when

the DC voltage is boosted to the level where the AFE regulation is enabled.

3 3

Illustration 3.19 Start-up Sequence Flow Chart

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 21

Page 24

Send Open signals to

the AFE and Mains

contactors.

AFE/Inverter DrivesAuxiliary Hardware

Actions

Control PLC

130BA775.11

End of Stop

Sequence

Stop Sequence

Wait for 1sec.

Send INV Stop signals

to all the inverters

All the inverters control

to reduce the speed

to zero, if it is not zero.

Send AFE Stop signals

to the AFE.

AFE is deactive.

DC voltage level is

down to zero

DC voltage level

is reduced.

Open the contactor.

The motor speed is

reduced to zero.

"Running" signal is o

when the speed is zero.

"Running" o?

Yes

No

Wait for 5min?

No

Protection Mode

Yes

The DC capacitor can be discharged

with the external resistor, which

expedites the discharge process.

: The wait period is tentative.

Crane System Design Operating Instructions

3.10 Shut-down Sequence

It is recommended to send a STOP signal to the AFE before shutting down the power.

33

Illustration 3.20 Shut-down Sequence Flow Cart

22 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 25

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

Inv #1

Inv #2

Inv #3

Inv #4

RST

LCL Filter

Fuse

Disconnect

Main PC

Sub PC1

Sub PC2

CT

CT

CT

gate signals

* Control gate signals

* Detect currents.

* Measure DC voltage.

* Control fans.

* Control gate signals

* Detect currents.

* Control fans.

* Control gate signals

* Detect currents.

* Control fans.

gate signals

gate signals

444444

MDCIC

FC302

CC

44

MDCIC Functions:

* Distribute the gate signals.

* Combine the current signals and

send it as a total rec current.

Detect the overcurrent (IMAX1)

per module per phase.

* Detect the main voltage phase to

synchronize AFE (Only for AFE)

Voltage

Detection

Fan

Volt

Soft

Charge

Soft

Charge

AFE #3

Contactor

Fuse:

AFE #2

Contactor

AFE #1

Contactor

Soft

Charge

Soft

Charge

Soft

Charge

Soft

Charge

SC Wire Fuse

Fuse:

Fuse:

IM

Trolley

Travel

Fuse

Fuse

Fuse

Fuse

Fuse

Fuse

PC

PC

PC

PC

Soft

Charge

Fan

Volt

Fan

Volt

Fan

Volt

Fan

Volt

Fan

Volt

Fan

Volt

Fan Volt Wire Fuse

SC Contactor

Hoist Master

Abbreviations:

AFE: Active Front End

CC: Control Card

MDCIC: Multi-Drive Control

Interface Card

PC: Power Card

Fan Volt Supply

400V Contactor

400V

630V

Boom

Switch

IM

Hoist Master

IM

IM

IM

130BA683.10

How to Install Operating Instructions

4 How to Install

This chapter covers mechanical and electrical installations to and from power terminals and control card terminals.

4.1 Overall Typical Frequency Converter Configuration

4 4

Illustration 4.1 Typical System Overview

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 23

Page 26

130BB639.10

A

B

How to Install Operating Instructions

The typical 1.2 MW LCL filter components are described

below:

1. Lc choke 100 uH

2. Lm choke 29 uH

3. Capacitor 10x 40 uF in delta, 30 pieces

4.

Resistors 90 mΩ 4000 W, 3 pieces

Transportation and Unpacking

4.2.3

Illustration 4.2 and Illustration 4.3 show the front and side

views of the frequency converter, shipping crate, respectively.

The unpacking procedure is as follows:

4.2 Pre-installation

44

4.2.1 Planning the Installation Site

Before performing the installation it is important to plan

the installation of the frequency converter. Neglecting this

may result in extra work during and after the installation.

Select the best possible operation site by considering the

followings:

Ambient operating temperature

•

Installation method

•

Cooling method

•

Position of the frequency converter

•

Cable routing

•

Power source supply configuration

•

Motor current rating with respect to the

•

frequency converter maximum current magnitude

Fuse arrangement, either built-in fuses or the

•

properly rated external fusees

Receiving the Frequency Converter

4.2.2

1. Remove clips from one long side panel (A) and all

around the top.

2. Remove the long side panel (A).

3. Remove the top panel (B).

4. Remove clips from one short side panel (C).

5. Remove the short side panel (C)

6. Remove the rest of the clips.

7. Remove the final two panels.

NOTICE

The package includes the plinth at the bottom of the

frequency converter. The plinth allows proper cooling of

the frequency converter during the shipment.

When receiving the frequency converters, please inspect

the frequency converters for any damage which may occur

during the transportation. When the damage is noticed,

please contact the shipping company immediately to claim

the damage and let Danfoss know the situation to work

for the corrective action.

Illustration 4.2 Package Front View

24 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 27

130BB640.10

C

How to Install Operating Instructions

4 4

Illustration 4.3 Package Side View

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 25

Page 28

F1

1

F3

2

130BA658.10

1

F2

2

130BA659.10

F4

How to Install Operating Instructions

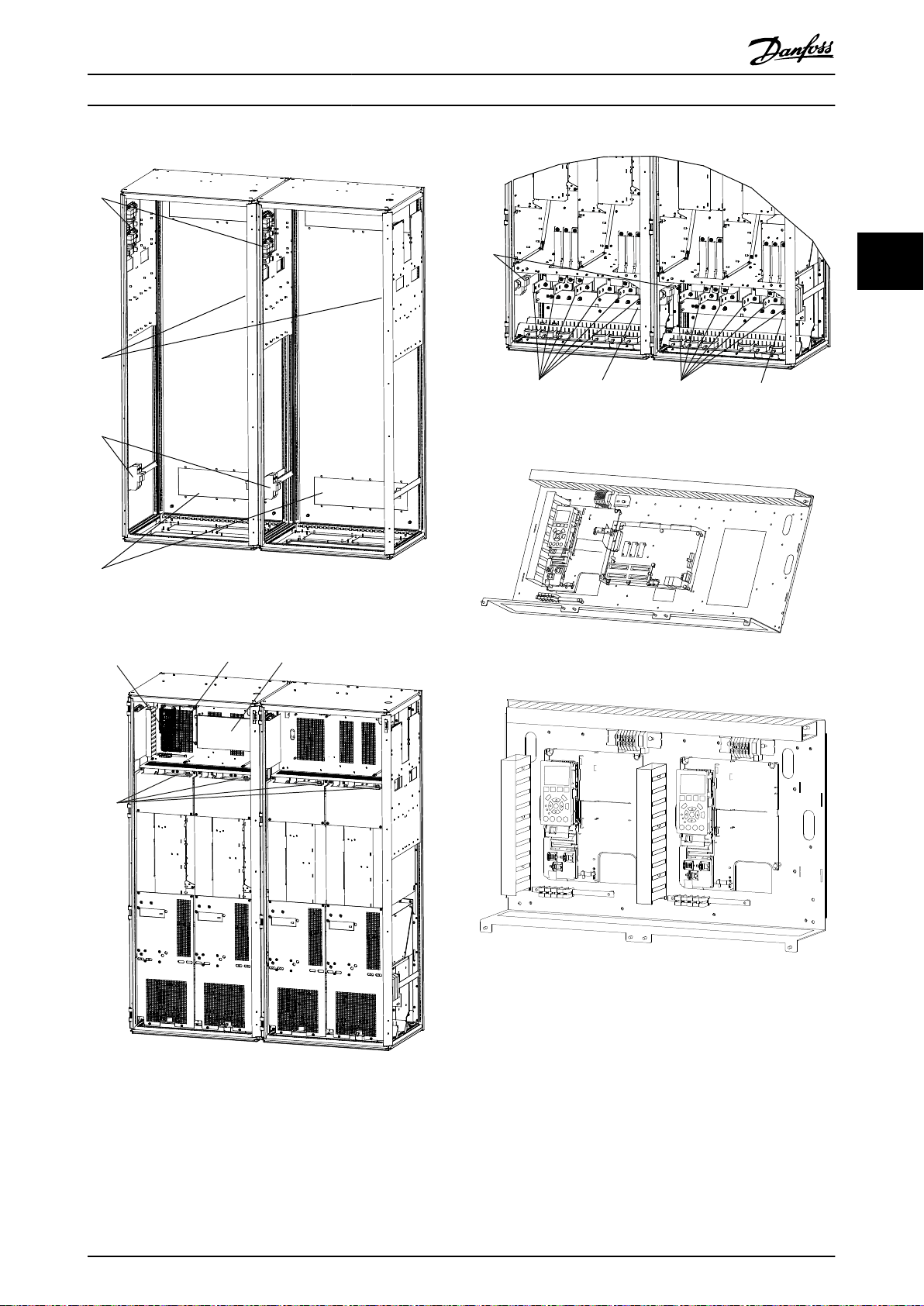

4.2.4 Lifting

Illustration 4.4 and Illustration 4.5 show the main load carrying points (1 and 2 in the illustrations) of the F-frame cabinets.

Lift the cabinets with all the lifting eyes and/or use a bar to avoid bending the lifting holes of the frequency converters. The

same principle is applied for the AFE cabinets.

44

Illustration 4.4 Main Load Carrying Points

Illustration 4.5 Main Load Carrying Points

NOTICE

The lifting cable angle should be 60° or greater. The spreader bar is an acceptable way of lifting. A spreader bar is an

acceptable way to lift the F Frame.

26 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 29

ADD 3MM

BETWEEN

TWO CABINET

TO ACCOUNT

FOR GASKET

ADD 3MM

BETWEEN

TWO CABINET

TO ACCOUNT

FOR GASKET

1296.0

ALL CABINET

2003.4

ALL CABINET

597.0 797.0

65.5

0.0

CABINET

BACK

WALL

CABINET

BACK

WALL

CABINET

BACK

WALL

73.0

338.4

540.5

61.1

CABINET FRAME 0.0

68.8

536.0

61.0

CABINET FRAME 0.0

65.5

0.0

140.8

392.7

426.7

678.7

736.0

102.0

695.0

2X 81.4

294.0

2X 219.4

493.5

540.5

CABLE

OPENING

CABLE

OPENING

CABLE

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

2078.4

ALL CABINET

WITH LIFT

BRACKET

1197.0

605.6

635.2

65.5

0.0

61.0

CABINET FRAME 0.0

140.8

430.8

464.8

754.7

788.7

1078.7

89.7

1084.0

1136.0

3X 81.4

3X 222.8

294.0

493.5

540.5

BACK CHANNEL

AIR IN

CABINET

AIR OUT

CABINET

AIR IN

600MM CABINET

BOTTOM VIEW

800MM CABINET

BOTTOM VIEW

1200MM CABINET

BOTTOM VIEW

SEE VIEW A

VIEW A

BACK CHANNEL

AIR OUT

X

130BA661.10

1597.0

2078.4

CABLE

OPENING

AIR INLET

OPENING

2X 61.0

2X 102.0

2X 695.0

2X 736.0

2X 678.7

2X 426.7

2X 392.7

2X 140.8

CABINET FRAME 0.0

0.0

CABINET

BACK

WALL

4X 65.6

4X 81.4

4X 219.4

2X 294.0

2X 493.5

4X 540.5

AIR INLET

OPENING

AIR INLET

OPENING

AIR INLET

OPENING

CABLE

OPENING

130BD821.10

How to Install Operating Instructions

4.2.5 Mechanical Dimensions

4 4

Illustration 4.6 Dimensions

Illustration 4.7 Dimensions 1600 mm Cabinet

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 27

Page 30

DOOR SWING

583.5591.5

783.5

583.5

AIR OUTLET

OPENING

114.0

0.0

122.0

298.5

475.0

483.0

415.5

0.0

423.5

567.5

575.5

BLOCKED

600MM CABINET

98.5

0.0

113.0

269.3

281.9

800MM CABINET 1200MM CABINET

BLOCKED

BLOCKED

96.7

0.0

91.0

366.4

422.4

681.9

706.0

AIR OUTLET

OPENING

98.5

0.0

113.0

269.3

281.9

101.1

0.0

99.7

395.1

462.7

759.2

826.8

1074.7

1093.7

130BA662.10

AIR OUTLET

OPENING

How to Install Operating Instructions

44

Illustration 4.8 Door Swing View and Back View

28 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 31

130BD822.10

0.0

2X 98.5

2X 113.0

2X 269.3

2X 281.9

0.0

2X 91.0

2X 96.7

2X 366.4

2X 422.4

2X 681.9

2X 706.0

2X 783.5

2X AIR OUTLET

OPENING

BLOCKED BLOCKED

How to Install Operating Instructions

4 4

Illustration 4.9 1600 mm Cabinet Door Swing View

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 29

Page 32

130BA445.10

225

64

1320

585

269

156

23

25

498

539

1547

1502

160

1043

14

184

184

184

139

304

2X13

(2.5)

(23.0)

(52.0)

(6.2)

(19.5)

(10.6)

(21.2)

(60.9)

(5.5)

(12.0)

(7.3) (7.3)

(0.5)

(1.5)

120

(4.7)

25

(1.0)

(59.1)

(41.1)

(6.3)

(8.9)

225

(8.9)

(1.0)

25

(1.0)

(0.9)

27

(1.0)

13

(0.5)

E2

D

E

D

E

IP00 / CHASSIS

How to Install Operating Instructions

44

Illustration 4.10 Dimensions E-frame IP00 Drive

30 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 33

How to Install Operating Instructions

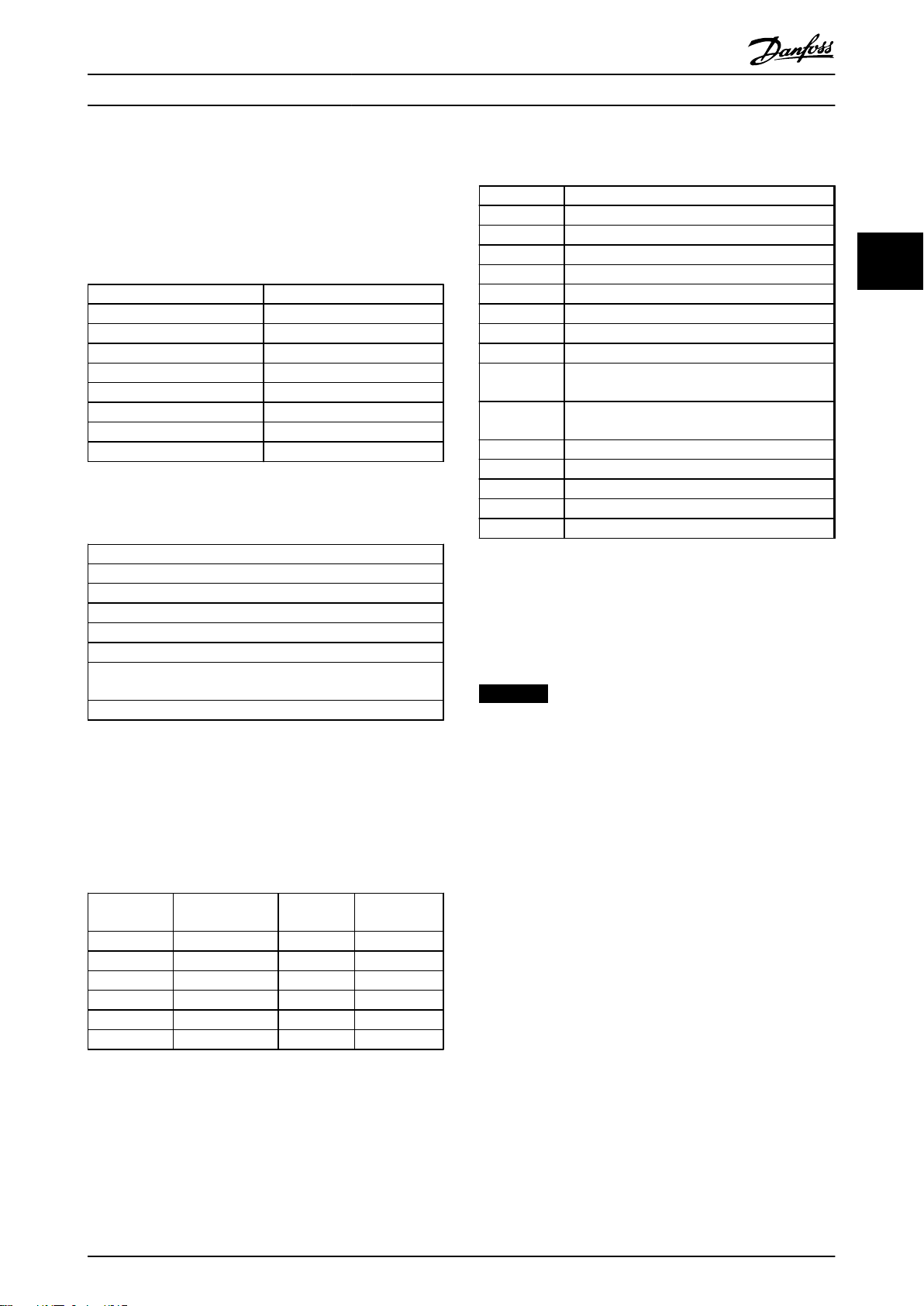

4.2.6 Weight Information

Crate

length

Table 4.1 Weight Based on Shipping Package Crate Size

Crate weight Cabinet weight Cabinet content

weight

[mm] [kg] [lbs] [kg] [lbs] [kg] [lbs] [kg] [lbs]

600 120 252 57 126 159 351 336 729 Cabinet and D frame frequency converter

800 130 273 76 168 306 675 512 1116 Inverter modules Qty. 2

1200 160 336 115 253 459 1012 734 1601 Inverter modules Qty. 3

1200 160 336 115 253 318 701 593 1290 600 mm cabinet qty. 2, D vrame

1600 260 546 153 337 612 1349 1025 2232 2 x 800 mm cabinet with inverter modules

2000 320 672 191 421 765 1687 1276 2780 1200 mm cabinet with inverter modules

2400 380 798 229 505 918 2024 1527 3327 2 x 1200 mm cabinet with inverter

2800 440 924 267 590 1071 2361 1778 3875 1200 mm cabinet with inverter modules

Total package

weight

Package contents

frequency converters qty. 2

qty. 2, 1600 mm cabinet with inverter

modules qty. 4

qty. 3, 800 mm cabinet with inverter

modules qty. 2

modules qty. 3, 1600 mm cabinet with

inverter modules qty. 4 800 mm cabinet

with inverter modules qty. 2

qty. 3, 2 x 800 mm cabinet with inverter

modules qty. 2

4 4

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 31

Page 34

122.5 [4.82]

.0 [.00]

178.0 [7.01]

233.5 [9.19]

363.5 [14.31]

419.0 [16.50]

474.5 [18.68]

722.5 [28.44]

778.0 [30.63]

833.5 [32.82]

963.5

[37.93]

1019.0

[40.12]

1074.5

[42.30]

1382.0 [54.41]

1452.0 [57.17]

1522.0 [59.92]

1737.5 [68.41]

1807.5 [71.16]

1877.5 [73.92]

2093.0 [82.40]

2163.0 [85.16]

2233.0 [87.91]

2581.9 [101.65]

2641.9 [104.01]

2701.9 [106.37]

2906.9 [114.44]

2966.9 [116.81]

3026.9 [119.17]

297.5 [11.71]

.0

[.00]

328.3

[12.93]

.0

[.00]

380.3 [14.97]

252.1 [9.93]

.0 [.00]

127.5 [5.02]

265.6 [10.46]

300.1

[11.82]

349.1

[13.74]

383.6

[15.10]

432.6

[17.03]

467.1 [18.39]

865.6[34.08]

900.1

[35.44]

949.1

[37.37]

983.6

[38.72]

1032.6

[40.65]

1067.1[42.01]

1365.1 [53.75]

1480.1 [58.27]

1595.1 [62.80]

1729.8 [68.10]

1844.8 [72.63]

1959.8 [77.16]

2094.4 [82.46]

2209.4 [86.99]

2324.4 [91.51]

2553.3 [100.53]

2668.3 [105.05]

2783.3 [109.58]

2906.2 [114.42]

3021.2 [118.95]

3136.2 [123.47]

600MM CABINET

TROLLEY/

TRAVEL

U,V,W

1200MM CABINET

AFE

R,S,T

800MM CABINET

HOIST 1&2

UVW

224.8

[8.85]

.0

[.00]

395.1 [15.56]

EARTH

GROUND BUS

(AFE/HOIST 1&2)

FASTENER TORQUE: M10 19 NM (14 FT-LB)

+DC/118 -DC/117

CH22

FASTENER TORQUE: M10 19 NM (14 FT-LB)

+DC/118 -DC/117

FASTENER TORQUE: M10 19 NM (14 FT-LB)

U/T196 V/T2 97 W/T3 98

FASTENER TORQUE: M10 19 NM (14 FT-LB)

U/T196 V/T2 97 W/T3 98

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

R/L1 91 S/L2 92 T/L3 93

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

R/L1 91 S/L2 92 T/L3 93

FASTENER TORQUE: M10 19 Nm (14 FT-LB)

R/L1 91 S/L2 92 T/L3 93

130BA660.10

How to Install Operating Instructions

4.3 Mechanical Installation

The installation of the frequency converters must be

prepared carefully. Review the mechanical drawings for the

space requirement.

Crane or other lifting aid to place the frequency

•

converter in position

4.3.2 General Considerations

4.3.1 Tools Needed

Ensure the proper space at the top and bottom of the

frequency converter, allowing enough air circulation and

Space

To perform the mechanical installation the following tools

44

are needed:

cable accessibility.

Wire access

Ensure that the proper cable access space is present.

Tape measure

•

Wrench with metric sockets (7-19 mm)

•

Extensions to wrench

•

Lifting bar to lift the unit (rod or tube Ø 20 mm)

•

When the IP00 D or E frame frequency converters are

mounted on the Rittal cabinet, the cables to the frequency

converter must be secured to the back panel of the

cabinet. For example, the cable clamps can be used.

able to lift minimum 400 kg.

Terminal Locations

4.3.3

Illustration 4.11 Terminals for the Typical Crane System

32 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 35

How to Install

Operating Instructions

4.3.4 Mains Torque

Table 4.2 tabulates the tightening torque values for the

mains and DC bus terminals.

Enclosure Terminal Torque Value Bolt size

E, F Mains,

DC bus

Table 4.2 Torque Values for Mains and DC Bus Terminals

19 Nm (168 inlbs)

M10

4.3.5 Mains Connection

The mains cables must be connected at the terminals 91,

92 and 93. The ground cable is connected at the terminal

94.

Terminal No. Function

91, 92, 93

94

Table 4.3 Mains Connection

Power (3x525-690 V

AC)

P400-P560 4x240 (4x500 MCM)

P630-P800 8x150 (8x300 MCM)

P900-P1M2 12x150 (12x300 MCM)

P1M4-P1M6 16x150 (16x300 MCM)

Table 4.4 Mains Cable Size

Mains R/L1, S/L2, T/L3

Ground

Max. Cable Size (mm2 (AWG))

NOTICE

Check the name plate to ensure that the mains voltage

of the AFE matches the power supply of the crane.

Ensure that the power supply can supply the necessary

current to the frequency converter.

Ensure that the fuses have the correct current and voltage

rating.

Screened Cables

4.3.6

WARNING

Danfoss recommends using screened cables between the

LCL filter and the frequency converter. Unshielded cables

can be used between transformer and LCL filter input

side.

It is important that screened and armoured cables are

connected in a proper way to ensure the high EMC

immunity and low emissions.

The connection can be made using either cable glands

or clamps

EMC cable glands: Generally, available cable

•

glands can be used to ensure an optimum EMC

connection.

EMC cable clamp: Clamps allowing easy

•

connection are supplied with the frequency

converter.

4.3.7 Fuses

It is recommended to use fuses and/or circuit breakers on

the supply side as protection in case of component breakdown inside the frequency converter (first fault).

NOTICE

This is mandatory to ensure compliance with IEC 60364

for CE or NEC 2009 for UL.

WARNING

Protect personnel and property against the consequence

of component break-down internally in the frequency

converter.

Branch circuit protection

To protect the installation against electrical and fire hazard,

all branch circuits in an installation, switch gear, machines

etc., must be protected against short-circuit and

overcurrent according to national/international regulations.

NOTICE

The recommendations do not cover branch circuit

protection for UL.

Short-circuit protection

Danfoss recommends using the fuses/circuit breakers

mentioned below to protect service personnel and

property in case of component break-down in the

frequency converter.

Overcurrent protection

The frequency converter provides overload protection to

limit threats to human life, property damage and to avoid

fire hazard due to overheating of the cables in the installation. The frequency converter is equipped with an

internal overcurrent protection (parameter 4-18 Current

Limit) that can be used for upstream overload protection

(UL-applications excluded). Moreover, fuses or circuit

breakers can be used to provide the overcurrent protection

in the installation. Overcurrent protection must always be

carried out according to national regulations.

The following tables list the recommended rated current.

Recommended fuses are of the type gG for small to

medium power sizes. For larger powers, aR fuses are

recommended. Circuit breakers must be used, provided

they meet the national/international regulations and they

4 4

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 33

Page 36

How to Install

Operating Instructions

limit the energy into the frequency converter to an equal

or lower level than the compliant circuit breakers.

If fuses/circuit breakers according to recommendations are

selected, possible damage on the frequency converter is

mainly limited to damage inside the unit.

4.3.8 High Power Fuses

44

The fuses below are suitable for use on a circuit capable of

delivering the Short Circuit Current Rating (SCCR) of

100,000 Amps (symmetrical).

525-690 V, frame sizes D, E and F

Size/Type

P630P900

P1M0 170M7082 2000 A, 700 V 20 695 32.2000

P1M2P1M4

P1M6 170M7084 3000 A,700 V

Table 4.5 Frame Size F, Line Fuses, 525-690 V

Size/Type

P630P1M6

Table 4.6 Frame Size F, Inverter Module DC Link Fuses, 525-690 V

*170M fuses from Bussmann use the -/80 visual indicator, -TN/80

Type T, -/110 or TN/110 Type T indicator fuses of the same size and

amperage may be substituted for the external use.

Bussmann

PN*

170M7081 1600 A, 700 V 20 695 32.1600

170M7083 2500 A, 700 V 20 695 32.2500

Bussmann

PN*

170M8611 1100 A,

Rating Siba

Rating Siba

20 781 32. 1000

1000 V

Supplementary fuses

Frame size

D, E and F KTK-4 4 A, 600 V

Table 4.7 SMPS Fuse

Size/Type

P37K-P400,

525-690 V

P500-P1M6,

525-690 V

Table 4.8 Fan Fuses

Bussmann PN Rating

FWC-20A-10F 20 A, 600 V

Table 4.9 Fan Voltage/Softcharge Fuse

Bussmann PN* Rating

Bussmann PN* LittelFuse Rating

KTK-4 4 A, 600 V

KLK-15 15 A, 600 V

34 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 37

Switch Mode

Power Supply

Analog Output

Interface

relay1

* relay2

ON=Terminated

OFF=Open

130BD835.10

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

37 (D IN)

18 (D IN)

20 (COM D IN)

10Vdc

15mA 130/200mA

+ - + -

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10Vdc

0/-10Vdc -

+10Vdc

+10Vdc

0/4-20 mA

0/-10Vdc -

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4-20mA

OFF=0/-10Vdc +10Vdc

400Vac, 2A

P 5-00

21

ON

S801

*

*

3 Phase

power

input

91 (L1)

92 (L2)

93 (L3)

PE

95

DC+

DC-

How to Install Operating Instructions

4.4 Electrical Installation

4 4

Illustration 4.12 Diagram showing all electrical terminals without options.

A = analog, D = digital

Terminal 37 is used for Safe Stop. For instructions on Safe Stop installation please refer to the VLT® Frequency Converters - Safe

Torque Off Operating Instructions.

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 35

Page 38

130BT340.10

How to Install Operating Instructions

4.4.1 Control Wires

Connect the shields to ground in a proper way to ensure

optimum electrical immunity.

Connect the wires as described in the Operating

Instructions for the frequency converter. Remember to

connect the shields in a proper way to ensure optimum

electrical immunity.

44

the fuses section. Always ensure that proper fusing is

made according to the local regulation.

4.4.3 Grounding

The following basic issues need to be considered when

installing a frequency converter to obtain electromagnetic

compatibility (EMC):

Safety grounding: The frequency converter could

•

have a high leakage current. It must be grounded

appropriately for safety reasons. Apply local

safety regulations.

High-frequency grounding: Keep the ground wire

•

connections as short as possible.

Connect the frequency converters to the ground with the

lowest possible conductor impedance. The lowest possible

conductor impedance is obtained by keeping the

conductor short and by using the large possible cross

section conductors.

The metal cabinets of the different devices are mounted

on the cabinet rear plate using the lowest possible HF

impedance. This avoids having different HF voltages for

the individual devices and avoids the risk of radio

interference currents running in connection cables that

may be used between the devices. The radio interference

will have been reduced.

Use the fastening bolts of the devices as HF connection to

the rear plate. It is necessary to remove insulating paint or

similar from the fastening points.

Illustration 4.13 Control Cable Installation

Power Connections

4.4.2

Cabling and fusing

NOTICE

Cables General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. Copper (75°C) conductors are

recommended.

The power cable connections are situated as shown below.

The size of the cable cross section is determined according

to the frequency converter's current rating and the local

regulation requirement.

For protection of the frequency converter the correctly

rated fuses must be used or the unit must be with built-in

fuses. The recommended fuses can be seen in the tables in

36 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 39

130BA150.10

9 - 10 mm

(0.37 in)

130BT312.10

130BT306.10

How to Install Operating Instructions

4.4.4 Electrical Installation, Control

Terminals

To connect the cable to the terminal:

1. Strip insulation of 9-10 mm

2.

Insert a screwdriver1) in the square hole.

3. Insert the cable in the adjacent circular hole.

4. Remove the screwdriver. The cable is now

mounted to the terminal.

To remove the cable from the terminal:

1.

Insert a screw driver1) in the square hole.

2. Pull out the cable.

1)

Max. 0.4 x 2.5 mm

Wiring to Control Terminals

4 4

Illustration 4.14 Strip Isolation

Illustration 4.15 Insert Screwdriver and Cable

Illustration 4.16 Control Cable Terminals

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 37

Page 40

Specifications Operating Instructions

5 Specifications

5.1 General Specifications

Mains supply (L1, L2, L3)

Supply voltage 525-690 V -10/+5%

Mains voltage low/mains drop-out:

During low mains voltage or a mains drop-out, the frequency converters continues until the intermediate circuit voltage drops

below the minimum stop level, which corresponds typically to 15% below the drive's lowest rated supply voltage. Power-up and

full torque cannot be expected at mains voltage lower than 10% below the frequency converter’s lowest rated supply voltage.

55

Supply frequency 50/60 Hz ±5%

Max. imbalance temporary between mains phases 3.0% of rated supply voltage

True Power Factor (λ) ≥0.9 nominal at rated load

Displacement Power Factor (cos ϕ) near unity (> 0.98)

Switching on input supply L1, L2, L3 (power-ups) maximum 1 time/2 min.

Environment according to EN60664-1 over-voltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not more than 100.000 RMS symmetrical Amperes, 500/600/690 V

maximum.

Torque characteristics

Overload torque (constant torque) maximum 150% (typical)/175% (1.2 MW and above) for 60 s

1) Percentage relates to the nominal torque.

1)

Digital inputs

Programmable digital inputs 4 (6)

Terminal number 18, 19, 271), 29, 32, 33,

Logic PNP or NPN

Voltage level 0-24 V DC

Voltage level, logic'0' PNP < 5 V DC

Voltage level, logic'1' PNP > 10 V DC

Voltage level, logic '0' NPN

Voltage level, logic '1' NPN

Maximum voltage on input 28 V DC

Pulse frequency range 0-110 kHz

(Duty cycle) Minimum pulse width 4.5 ms

Input resistance, R

i

2)

2)

> 19 V DC

< 14 V DC

approx.4 kΩ

38 Danfoss A/S © Rev. 05/2014 All rights reserved. MG33X402

Page 41

Mains

Functional

isolation

PELV isolation

DC-Bus

High

voltage

Control

+24 V

RS-485

18

37

130BD834.10

Specifications Operating Instructions

Safe stop Terminal 373) (Terminal 37 is fixed PNP logic)

Voltage level 0-24 V DC

Voltage level, logic'0' PNP < 4 V DC

Voltage level, logic'1' PNP >20 V DC

Nominal input current at 24 V 50 mA rms

Nominal input current at 20 V 60 mA rms

Input capacitance 400 nF

All digital inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

1) Terminals 27 and 29 can also be programmed as output.

2) Except safe stop input Terminal 37.

3) See for further information about terminal 37 and Safe Stop.

Analog inputs

Number of analog inputs 2

Terminal number 53, 54

Modes Voltage or current

Mode select Switch S201 and switch S202

Voltage mode Switch S201/switch S202 = OFF (U)

Voltage level -10 to +10 V (scaleable)

Input resistance, R

i

approx. 10 kΩ

Max. voltage ±20 V

Current mode Switch S201/switch S202 = ON (I)

Current level 0/4 to 20 mA (scaleable)

Input resistance, R

i

approx. 200 Ω

Max. current 30 mA

Resolution for analog inputs 10 bit (+ sign)

Accuracy of analog inputs Max. error 0.5% of full scale

Bandwidth 100 Hz

The analog inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

5 5

Illustration 5.1 PELV Isolation of Analog Inputs

MG33X402 Danfoss A/S © Rev. 05/2014 All rights reserved. 39

Page 42

Specifications

Digital output

Programmable digital/pulse outputs 2

Terminal number 27, 29

Voltage level at digital/frequency output 0-24 V

Maximum output current (sink or source) 40 mA

Maximum load at frequency output 1 kΩ

Maximum capacitive load at frequency output 10 nF

Minimum output frequency at frequency output 0 Hz

Maximum output frequency at frequency output 32 kHz

Accuracy of frequency output Maximum error: 0.1 % of full scale

Resolution of frequency outputs 12 bit

55

1) Terminal 27 and 29 can also be programmed as input.

The digital output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

Analog output

Number of programmable analog outputs 1

Terminal number 42