Page 1

Data sheet

Pressure independent balancing and control valve

AB‑QM DN 10‑250

The AB‑QM valve equipped with an actuator is a control valve with full authority and an automatic balancing function / f low limitation. Typical applications

are: Temperature control with permanent automatic balancing on terminal units (chillers, air‑handling units, fan coils, induction units, radiation panels and

heat exchangers).

Description

The precise flow control performance of the

AB-QM with a Danfoss actuator provides

increased comfort and lower Total Cost of

Ownership because of savings made on:

• Efficient energy transfer and minimal

pumping costs since there are no overflows

at partial loads because of the exact pressure

independent flow limitation.

• Smaller pump investments and lower energy

consumption as the pump head needed is

lower than in the traditional setup. With the

built in test plugs it is easy to troubleshoot

and find the optimal setpoint for the pump.

• Reduced movements of the actuator since the

built-in differential pressure controller ensure

the pressure fluctuations do not influence the

room temperature.

• Achieving a stable temperature in a room

leading to a lower average temperature at the

same comfort level.

• Minimal flow complaints, as the valve

performs as designed.

• Minimal blockage complains, as the

membrane design makes AB-QM less

susceptible to blockage than a cartridge type

construction.

• Trouble-free segmentation of the building

project. When sections of a project are

finished they can normally not be handed

over to the customer with a fully functional

HVAC installation. However the AB-QM with

a Danfoss actuator will automatically control

the flow, even when other parts of the

installation are still unfinished. It’s not needed

to adjust the AB-QM after finalisation of the

project.

• Commissioning costs, the costs are close

to zero because of a convenient setting

procedure without the need for flow charts,

calculations or measuring equipment. The

AB-QM valves can be set to a precise design

value even when the system is up and

running.

• Halved mounting costs as the AB-QM valve

covers two functions, Balancing & Control

© Danfoss | 2018.06

VD.A7.F7.02 | 1

Page 2

Data sheet AB‑QM DN 10‑250

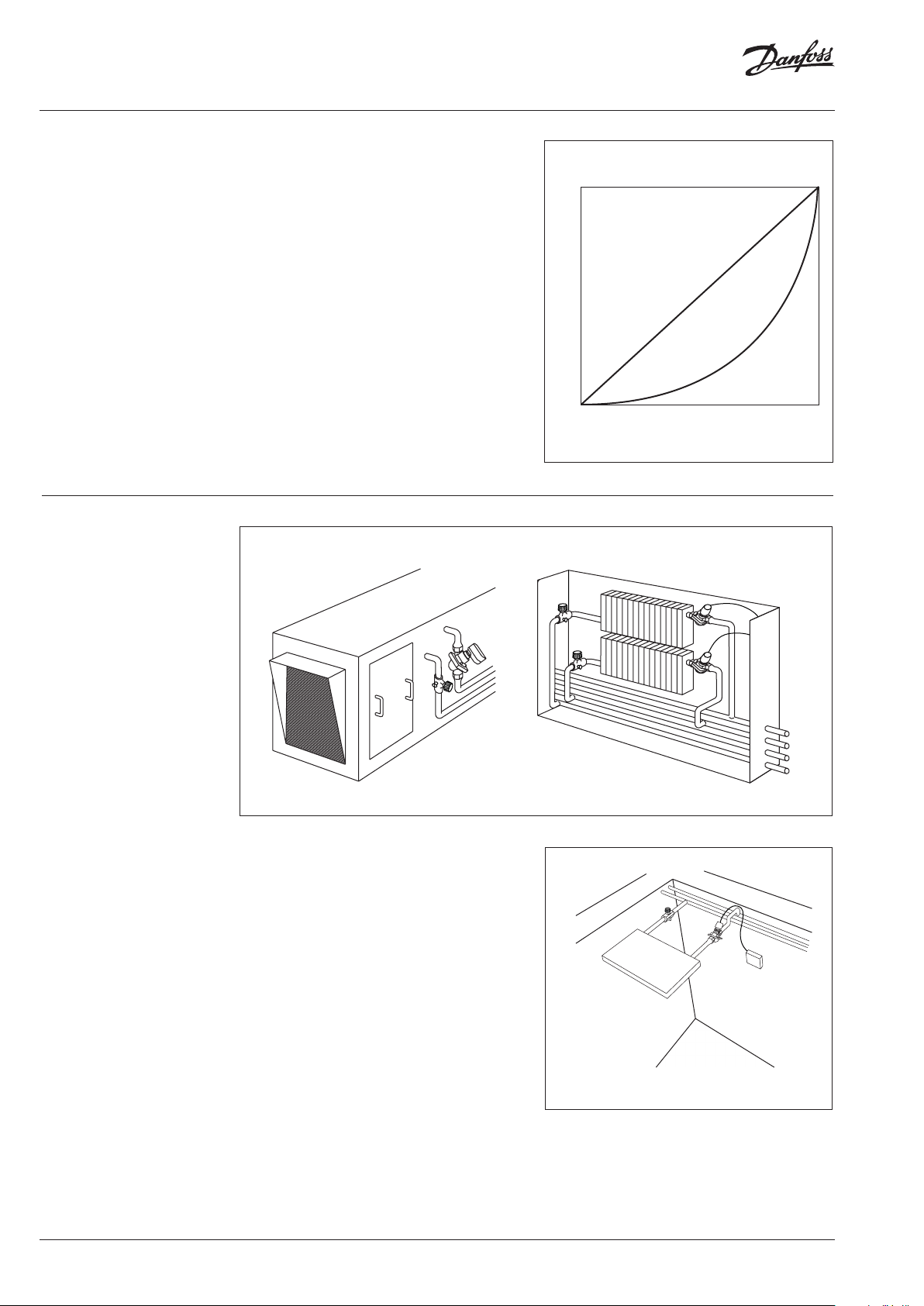

Control performance

Applications

- variable flow systems

The AB-QM has a linear control characteristic.

The AB-QM is pressure independent which

means that the control characteristic is

independent from the available pressure and is

not influenced by a low authority.

The flow limitation on the AB-QM is achieved

by limiting the stroke and the Danfoss actuators

calibrate to the stroke of the valves. This means

that the AB-QM keeps its linear characteristic

independent of the setting or differential

pressure.

Because of the predictable characteristic the

actuators on the AB-QM can be used to change

the response from linear to logarithmic (equal

percentage). That makes the AB-QM suitable

for all applications, including AHUs, where the

equal percentage characteristic is needed to

get a stable control loop. The actuators can be

switched from linear to logarithmic by changing

a DIP switch setting on the actuator.

100 %

a

t

s

n

o

c

s

For any given 100 % setting

LIN setting stays constant at any available pressure

0

G

O

L

y

a

t

s

g

n

i

t

t

e

s

0 10 V

e

r

u

s

s

e

r

p

e

l

b

a

il

a

v

a

y

n

a

t

a

t

n

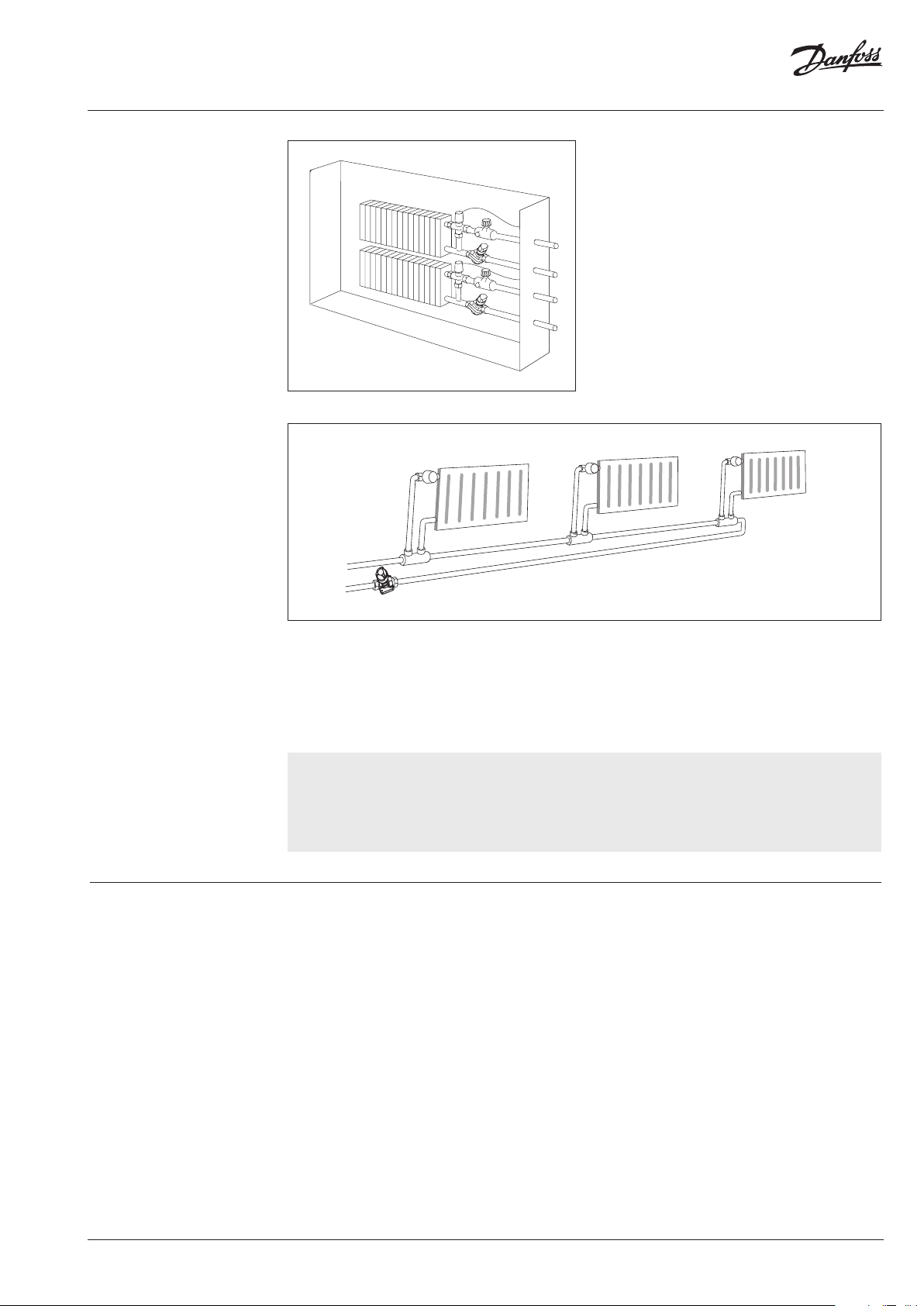

Air handling unit (AHU) / fan coil unit (FCU)

An AB-QM with a Danfoss actuator is used

as a control valve for terminal units, like an

AHU (Air Handling Unit), FCU (Fan Coil Unit) or

radiation panel. The AB-QM ensures and control

the required flow on every terminal unit and

maintains hydronic balance in the system.

Because of the integrated differential pressure

controller the control valve always has 100 %

authority and therefore offers always stable

control. At partial load there is no overflow,

contrary to conventional solutions, because the

AB-QM will always limit the flow to exactly what

is needed. By installing the AB-QM the whole

system is divided in completely independent

control loops.

There is a full range of Danfoss actuators

available for the AB-QM, suitable for every

control strategy. Actuators are available for

On/Off, 0-10 Volt, 4-20 mA or floating point.

Radiation panel

2 | © Danfoss | 2018.06

VD.A7.F7.02

Page 3

Data sheet AB‑QM DN 10‑250

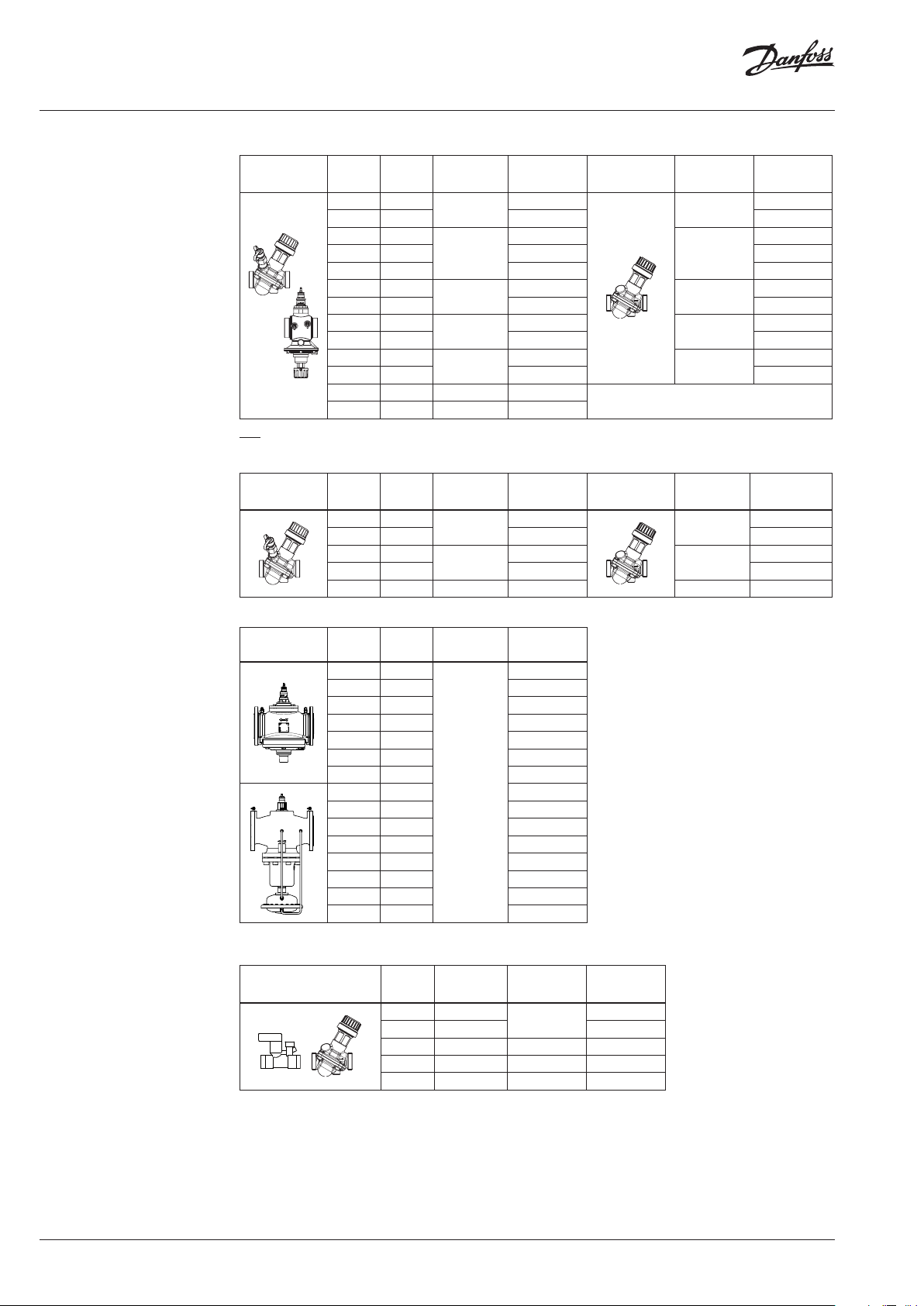

Applications

- constant flow systems

Easy implementation

In constant flow system with FCUs or in a one

pipe heating system the AB-QM can be installed

as an automatic balancing valve in every riser.

The AB-QM limits the flow to the set value, thus

automatically achieving hydronic balance in the

system.

There are numerous applications in which AB‑QM can be used. Every time you need an automatic

flow limiter or a control valve you can take advantage of the cost‑saving properties of the AB‑QM.

That includes systems with (floor) heating/cooling, concrete core activation or radiation panels.

Note: For more application examples please contact your local Danfoss organization.

• No Kv or authority calculations needed. Flow

is the only parameter to be considered when

designing.

• The AB-QM always fits the application

because the maximum setting of the AB-QM

corresponds with international standards for

flow velocity in pipes.

• The AB-QM can be used for all HVAC

applications since it can have a linear or

logarithmic characteristic when combined

with thermal electric or gear actuators.

• Easy commissioning. No specialized staff or

measuring equipment needed.

• Easy trouble shooting.

• Fast start-up because AB-QM valves don’t

need to be flushed or de-aired before use.

• Trouble-free segmentation of the building

project. The AB-QM will automatically control

the flow, even when parts of the installation

are still unfinished. It’s not needed to adjust

the AB-QM after finalisation of the building

project.

• Compact design, essential when only limited

space is available. For example in fan-coil

units.

VD.A7.F7.02

© Danfoss | 2018.06 | 3

Page 4

Data sheet AB‑QM DN 10‑250

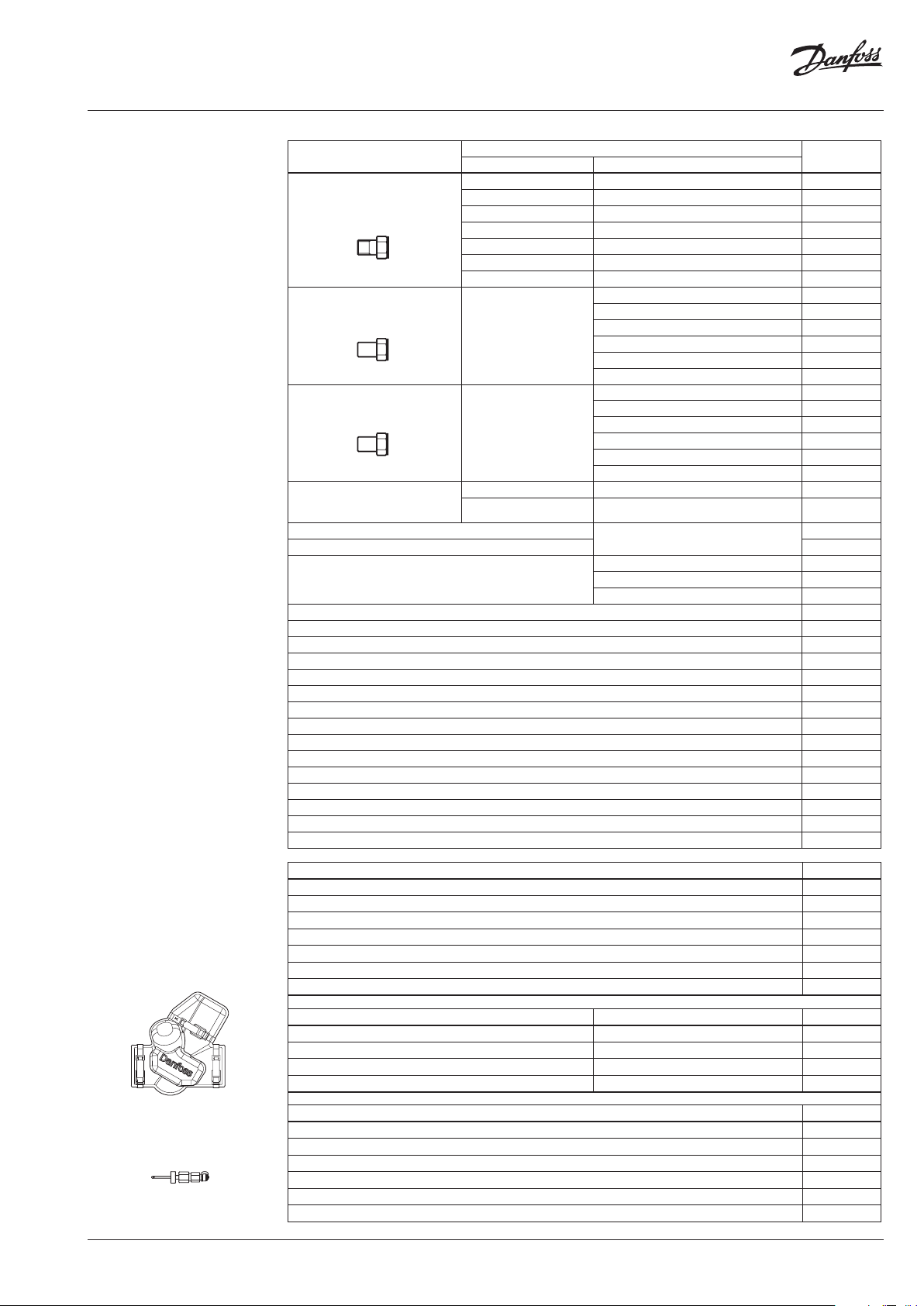

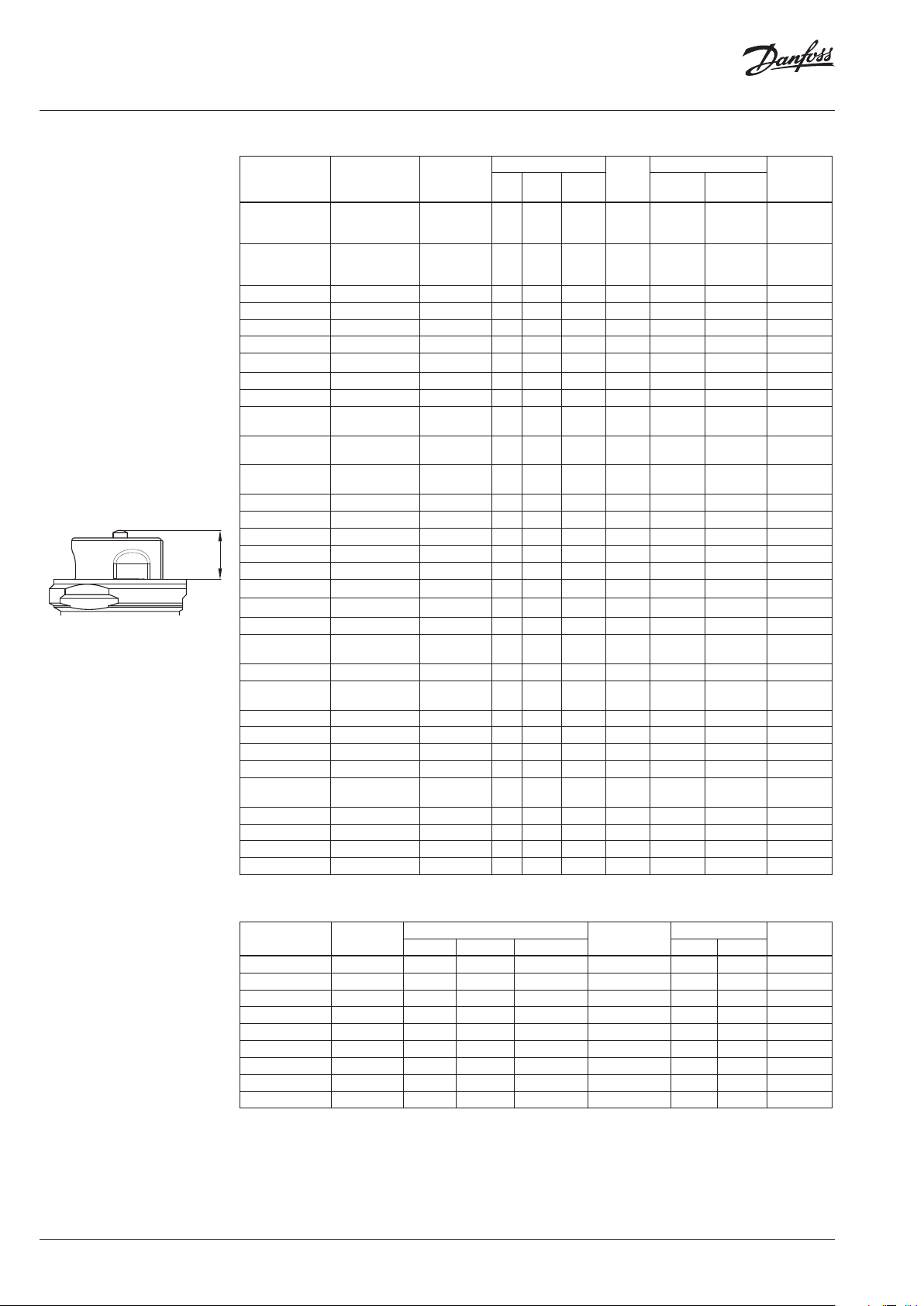

Ordering

AB‑QM threaded version (with test plugs and without test plugs)

Picture DN

10 LF 150

15 LF 275

15 HF 1,135 003Z1222

20 HF 1,70 0 00 3Z1223

25HF 2,700 003Z1224

32 HF 4,000 003Z1225

Note: AB‑ QM DN 10‑32 acts as a normally ope n valve.

Q

10 275 003 Z1211 00 3Z1201

15 450 003 Z1212 00 3Z1202

20 900

25 1, 700

32 3,200

40 7,500 G 2A 003Z0770

50 12,500 G 2 ½A 003Z0771

nom.

(l/h)

Ext. thread

(ISO 228/1)

G ½A

G ¾A

G 1A

G 1 ¼A

G 1 ½A

Code No. AB‑QM

00 3Z1261

00 3Z1262

00 3Z1213

00 3Z1214

00 3Z1215

AB‑QM (D N 10‑32) can not be upgra ded to AB‑QM

with test plugs!

AB‑QM industry pack (with test plugs and without test plugs)

Picture DN

10 LF 150

10 275 00 3Z1711 00 3Z1701

15 LF 275

15 450 003 Z1712 00 3Z1702

20 900 G 1A 00 3Z1713 G 1A 003Z1703

Q

nom.

(l/h)

Ext. thread

(ISO 228/1)

G ½A

G ¾A

Code No. AB‑QM

00 3Z1761

00 3Z1762

Ext. thread

(ISO 228/1)

G ½A

G ¾A

G 1A

G 1 ¼A

G 1 ½A

Ext. thread

(ISO 228/1)

G ½A

G ¾A

Code No.

00 3Z1251

00 3Z1252

003Z1203

00 3Z1204

003Z1205

Code No.

00 3Z1751

00 3Z1752

AB‑QM flanged version

Picture DN

50 12,500

65 20,000 003Z0773

65 HF 25,000 003Z0793

80 28,000 00 3Z0774

80 HF 40,000 003Z0794

100 38,000 0 03Z0775

100 H F 59,000 003Z0795

125 90,000 003Z0705

125 HF 110,000 003Z0 715

150 145,000 0 03Z0706

150 HF 190,000 0 03Z0716

200 200,000 003Z0707

200 HF 270,000 0 03Z 0717

250 300,000 003Z0708

250 HF 370,000 0 03Z0718

Q

(l/h)

nom.

Flange

connection

PN 16

Code No.

003Z0772

Set‑pack (one MSV-S and one AB-QM without test plugs)

Picture DN

15 LF 275

15 450 00 3Z1242

20 900 G 1 A 0 03Z124 3

25 1,70 0 G 1 ¼ A 003Z124 4

32 3,200 G 1 ½ A 003 Z1245

Q

(l/h)

nom.

Ext. thread

(ISO 228/1)

G ¾ A

Code No.

003Z1238

4 | © Danfoss | 2018.06

VD.A7.F7.02

Page 5

Data sheet AB‑QM DN 10‑250

Ordering (continuous)

Accessories & spare parts

Typ e

Union connection

(C W617N )

(1 pc s.)

Tailpiece welding

(W. Nr. 1.0308)

(1 pc s.)

Tailpiece welding - INOX

(W. Nr. 1.4404)

(1 pc s.)

Tailpieces for soldering

(CW614N)

(2 nuts, 2 gaskets, 2 soldering plugs

Shut-off & protection piece (max. closing pressure 16 bar)

Shut-off - plastic (max. closing pressure 1 bar) 003Z0240

Handle AB-QM

(necessar y accessory if installing valve without actuator)

Adapter for AB-QM DN 10, G ½ internal thread for AB- QM, G 3/8 internal thread (1 pcs.)

Adapter for AB-QM DN 15, G ¾ internal thread for AB-QM, G ¾A ex ternal thread (1 pcs.)

Adapter for AB-QM DN 20, G 1 internal thread for AB -QM, G 1A external thread (1 pcs.)

Adapter for AB-QM DN 25, G 5/4 internal thread for AB-QM, G 5/4A external thread (1 pcs.)

Adapter AMV(E) 25/35 (AB-QM DN 40-100, 2nd. generation)

Adapter AME 435 for AB-QM DN 40-100 (1st. generation)

Locking ring AB- QM DN10-32 (5 pcs.)

Stroke limiter - TWA (5 pcs. in a bag)

Adapter AME 13 SU for AB-QM (1st. generation)

Adapter AME 13 SU for AB-QM (2nd. generation)

Adapter for ABNM A5

Spacer AMI 140

Stem heater for AB-QM DN 40-100 / AME 15 QM

Stem heater for AB-QM DN 40-100 / AME 435 QM

Stem heater for AB-QM DN 125, 150 / AME 55 QM

To pipe To val ve

R / DN 10 003Z0231

R / D N 15 003Z0232

R / DN 20 003Z0233

R 1 DN 25 003Z0234

R 1 / DN 32 0 03Z0235

R 1/

R 2

Weld.

Weld.

12×1 mm DN 10

15×1 mm DN 15 06 5Z7017

Comments

Code No.

DN 40

DN 50

DN 15 003Z0226

DN 20 003Z0227

DN 25 003Z0228

DN 32 003Z0229

DN 40

DN 50

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50

DN 10 -32

DN 40 -100

DN 125-15 0

DN 200 -250

003Z0279

003Z0278

003Z0270

003Z0276

00 3Z1271

00 3Z1272

003Z1273

00 3Z1274

00 3Z1275

00 3Z1276

065 Z7016

003Z1230

003Z0695

003Z0696

003Z0697

003Z3954

003Z3955

003Z3956

003Z3957

003Z0694

06 5Z0313

00 3Z1236

00 3Z1237

003Z3959

003Z3960

082 F1072

003Z0257

06 5B2171

065Z0 315

065Z7022

VD.A7.F7.02

Typ e

AB-QM heating insul. cap DN 10

AB-QM heating insul. cap DN 15 003Z4731

AB-QM heating insul. cap DN 20 003Z4732

AB-QM heating insul. cap DN 25 003Z4733

AB-QM heating insul. cap DN 32 003Z4734

AB-QM heating insul. cap DN 40 003Z4735

AB-QM heating insul. cap DN 50 003Z4736

Typ e Comments Code No.

Refrig. insulation ABQM DN 15_ABNM/T WA-Z DN 15 003Z4787

Refrig. insulation ABQM DN 20_ ABNM/TWA-Z DN 20 003Z478 8

Refrig. insulation ABQM DN 25_ ABNM/TWA-Z DN 25 003Z478 9

Refrig. insulation ABQM DN 32_ABNM/ TWA-Z DN 32 0 03Z4790

Typ e

Set of needle plug (1 pcs.)

Set of ext. plug (1 pcs.)

Set of measuring needle (1 pcs.)

Elbow test plug extension (1 pcs.)

Straight test plug extension (1 pcs.)

Straight plug extension set (1 pcs.)

Code No.

003Z4730

Code No.

003Z0100

003 Z0106

003 Z0107

003Z3944

003Z3945

003Z3946

© Danfoss | 2018.06 | 5

Page 6

Data sheet AB‑QM DN 10‑250

Ordering (continuous)

Closing point (measure)

for DN 10‑32

Information regarding safety function is

relevant only for AB‑QM valves.

1)

Size AB‑Q M: DN 10LF ‑ DN 20 ena bles

setting to 120%; DN 25 ‑ 32 enable s

setting up to 6 0%

2)

Requires 003Z3960 adapter

3)

Requires spacer 003Z0257

4)

Cable needs to b e ordered as separate

cod e nr.

5)

Feedback signal over field bus

The code no. lis ted are for actuators with

standard cable lengths when cables are

included, others lengths are available

referring to da ta sheet for actuators.

For Valve Sizes DN 10 ‑ 32

Typ e Note Power

NovoCon® S

NovoCon® S CO6,

Ene rgy, I/O

AME 110 NL 24 VAC

AME 120 NL 24 VAC

AME 110 NLX 24 VAC

AME 13 SU

AME 13 SD

ABNM A5 NC LOG 5 mm stroke

ABNM A5 NC LOG 6.5 mm stroke

ABNM A5 DC NC

LOG

ABNM A5 DC NO

LOG

ABNM A5 NO

LOG

ABNM A5 NC LIN 5 mm stroke

ABNM A5 NC LIN 6.5 mm stroke

ABNM A5 NO LIN 6.5 mm stroke

AMV 110 NL 24 VAC

10.4±0.3

AMV 120 NL 24 VAC

AMV 13 SU

AMV 13 SD

TWA-Z NC

TWA-Z NC

ABN A5 NC 5 mm stroke

ABN A5 NC

ABN A5 NO 5 mm stroke

TWA-Z NO

AMI 140

TWA-Z NC

TWA-Z NC

ABN A5 NC 5 mm stroke

ABN A5 NO 5 mm stroke

TWA-Z NO

AMI 140

BACnet &

Modbus

communication

BACnet &

Modbus

communication

2), 3)

3)

4)

6.5 mm stroke

6.5 mm stroke

6.5 mm stroke

4)

2), 3)

3)

1)

Halogen free

1)

cable

5 mm stroke,

End-switch

1)

3)

1)

Halogen free

cable

1)

3)

4)

4)

4)

1)

4)

4)

4)

4)

4)

4)

4)

4)

4)

4)

24 VAC /DC

24 VAC /DC

24 VAC

24 VAC

24 VAC

24 VAC

24 VDC

24 VDC

24 VAC

24 VAC

24 VAC

24 VAC

24 VAC

24 VAC

24 VAC /DC

24 VAC /DC

24 VAC /DC

24 VAC /DC

24 VAC /DC

24 VAC /DC

24 VAC

230 VAC

230 VAC

230 VAC

230 VAC

230 VAC

230 VAC

Input Signal

On/

Float. Modul. Up Down

Off

Output

Signal

•

•

• •

5)

5)

Safety Function

Selectable

Selectable

•

•

• •

• • •

• • •

• •

• •

• •

• •

• •

• •

• •

• •

•

•

• • •

• • •

• •

• •

• •

• •

• •

• •

•

• •

• •

• •

• •

• •

•

Code No.

Selectable

003Z8504

Selectable 003Z8503

082H8057

082H8059

082H8060

082H3044

082G3006

08 2F116 0

08 2F116 2

08 2F116 6

08 2F1167

08 2F116 3

08 2F1161

08 2F116 4

08 2F116 5

082H8056

082H8058

082H3043

082G3004

08 2F1262

082F1380

08 2F115 0

082F1154

08 2F1151

08 2F1260

082H8048

08 2F1266

082F1382

08 2F1152

08 2F1153

08 2F1264

082H8049

* Adapter requ ired for 2nd gen valve.

Part# 003Z0694

**Available batte ry backup assembly f or

safety f unction, AM‑PBU25, 08 2H7090,

one per four A ME 435 QM actuators

AB‑QM D N 65‑100 with AME 25 SD has

limited flo w to 90% of Q

Actuators f or valves DN 40‑100 are

nom

delivered without cables.

6 | © Danfoss | 2018.06

For Valve Sizes DN 40 ‑ 100

Typ e Power

AME 435 QM 24 VAC /DC

AMV 435 24 VAC /DC

AMV 435 230 VAC

AME 25 SU* 24 VAC

AME 25 SD* 24 VAC

AMV 25 SD* 24 VAC

AMV 25 SU* 24 VAC

AMV 25 SD* 230 VAC

AMV 25 SU* 23 0 VAC

Input Signal

On/Off Floating Modulating Up Down

Output Signal

(0 ‑10VD C)

Safety Function

• • •** •**

• •

• •

• • • •

• • • •

• •

• •

• •

• •

Code No.

08 2H017 1

082 H0162

082 H0163

082H3041

082H3038

082H3036

082H3039

082H3037

082H3040

VD.A7.F7.02

Page 7

Data sheet AB‑QM DN 10‑250

Ordering (continuous)

* Available bat tery backup assembl y for

safety f unction, AM‑PBU25, 08 2H7090,

one per two A ME 55 QM actuators

For Valve Sizes DN 125‑150

Typ e Power

AME 55 QM 24 VAC

AME 655 24 VAC /DC

AME 655 230 VAC/DC

AME 658 SU 24 VAC/ DC

AME 658 SU 2 30 VAC/ DC

AME 658 SD 24 VAC/ DC

AME 658 SD 230 VAC/ DC

Input Signal

On/Off Floating

• • • •* •*

• • •

• • •

• • • •

• • • •

• • • •

• • • •

Modulating

Output Signal

(0 ‑10VD C)

Safety Function

Up Down

Code No.

082H3078

082G3442

082G3443

082G3450

082G3451

082G3448

082G3449

For Valve Sizes DN 200‑250

** Available batte ry backup assembly f or

safety f unction, AM‑PBU25, 08 2H7090,

one per AME 85 Q M actuator

Actuators f or valves DN 125‑250 are

delivered without cables.

Typ e Power

AME 85 QM 24VAC

Input Signal

On/Off Floating

• • • •** •**

Modulating

Output Signal

(0 ‑10VD C)

Closing pressure f or AB‑QM on all above a ctuators is 16 bar.

More information regarding the actuators can be found in the individual data sheets.

Safety Function

Up Down

Code No.

08 2G1453

Technical data

AB‑QM (threaded version)

Nominal diameter DN 10 L F 10 15 LF 15 15 HF 20 20 HF 25 25 HF 32 32 HF 40 50

Q

Flow range

Setting range

Diff. pressure

3), 5)

nom

Q

high

1), 2)

∆p

∆p

Pressure stage PN 16

Control range 1:1000

Control valve’s characteristic Linear (could be converted by actuator to equal percentage)

Leakage rate with recommended actuators No visible leakage max. 0.05 % of Q

For shut off function Acc. to ISO 5208 class A - no visible leakage

Flow medium

Medium temperature

Storage and transport temp. – 40 … 70

Stroke mm 2.25 4 2.25 4 4.5 10

Connection

ext. thread (ISO 228/1) G ½ A G ¾ A G 1 A G 1¼ A G 1½ A G 2 A G 2½ A

actuator M30 × 1.5 Danfoss standard

Materials in the water

Valve bodies DZR Brass (CuZn36Pb2As - CW 602N)

Membranes and O-rings EPDM

Springs W.Nr. 1.4568, W.Nr. 1.4310

Cone (Pc) W.Nr. 1.4305

Seat (Pc) EPDM W.Nr. 1. 4305

Cone (Cv) CuZn40Pb3 - CW 614N

Seat (Cv) DZR Brass (CuZn36Pb2As - CW 602N) W.Nr. 1.4305

Screw Stainless Steel (A2)

Flat gasket NBR

Sealing agent

(only for valves with test plugs)

Materials out of the wate r

Plastic parts PA POM

Insert parts and outer screws CuZn39Pb3 - CW 614N; W.Nr. 1.4310; W.Nr. 1.4401 -

1)

Factory se tting of the valve is done at no minal setting range.

2)

Regardless o f the setting, the valve can mo dulate below 1 % of set flow.

3)

When set above 100 % , minimum starting pressu re needed is higher, see figu res in the ().

4)

Actuator wit h compatible stroke must be se lected.

5)

At min diffe rential pressure valve reache s at least 90% of nominal f low. Declaration of perf ormance is available upo n request.

*) If the medium te mperature is below 2°C fo r AB‑QM DN10‑32 refrig. insulatio n must be used to cover both the valve and a ctuator: Code 003Z4787‑003Z4790. For AB‑QM DN40 ‑100

stem heaters m ust be used: Code 065B2171, 065Z0315 or 065Z7022.

According suitabil ity and usage especia lly in not oxygen tight sy stems please mind the instruc tions given by the coolant pro ducer.

Pc ‑ pressure control ler part

Cv ‑ Control valve part

(100 %)

3)

min

max

1)

l/h

kPa

150 275 275 450 1,135 900 1,70 0 1,700 2,700 3,200 4,000 7,500 12,500

180 330 330 540 1,2504)1,080 1,8704)1,8704)2,9704)3,5204)4,4004)7,500 12,500

% 20-120 20 -110 20-120 2 0-110

4)

16 (18) 35 (40) 16 (18) 35 (4 0) 20 (25) 35 (40) 25 (30) 35 (40) 30

600

Water and water mixture for closed heating and cooling systems according to plant type I for DIN EN 14868.

plant Type II for DIN EN 14868 appropriate protective measures are taken.

°C

(-10*) + 2 … 120

The requirements of VDI 2035, part 1 + 2 are observed.

40 -100

nom

When used in

Grey iron

EN-GJL-250 (GG25)

CuZn40Pb3 - CW 614N,

W.Nr. 1.4305

Dimethacrylate Ester

VD.A7.F7.02

© Danfoss | 2018.06 | 7

Page 8

Data sheet AB‑QM DN 10‑250

Technical data (continuous)

AB‑QM (flanged version)

Nominal diameter DN 50 65 65 HF 80 80 HF 10 0 100 HF

Q

Flow range

Setting range

Diff. pressure

3) ,5)

nom

Q

high

1), 2)

∆p

∆p

Pressure stage

Control range Acc. to standard IEC 534 control range is high as Cv charac teristic is linear. (1:1000)

Control valve’s characteristic Linear (could be converted by actuator to equal percentage)

Leakage rate with recommended

actuators

For shut off function

Flow medium

Medium temperature

Storage and transport temp. –40 … 70

Stroke

Connection

flange PN 16

actuator Danfoss standard

Materials in the water

Valve bodies Grey iron EN-GJL-250 (GG25)

Membranes/ Bellow EPDM

O-rings EPDM

Springs W.Nr. 1.4568, W.Nr. 1.4310

Cone (Pc) CuZn40Pb3 - CW 614N, W.Nr. 1.4305

Seat (Pc) W.N r. 1.4305

Cone (Cv) CuZn40Pb3 - CW 614N

Seat (Cv) W.N r. 1.4305

Screw Stainless Steel (A2)

Flat gasket NBR

1)

(100 %)

12,500 20,000 25,000 28,000 40,000 38,000 59,000

min

max

12,500 20,000 25,000 28,000 40,000 38,000 59,000

l/h

%

kPa

30 60 30 60 30 60

40 -100

600

PN 16

max. 0.05 % of Q

nom

Acc. to ISO 5208 class A - no visible leakage

Water and water mixture for closed heating and cooling systems according to plant type

I for DIN EN 14868. When used in plant Type II for DIN EN 14868 appropriate protective

measures are taken. The requirements of VDI 2035, part 1 + 2 are observed.

°C

mm

10 15

−10 ... +120

1)

Factory set ting of the valve is done at

nominal setting range.

2)

Regardless of the set ting, the valve

can modulate b elow 1 % of set flow.

3)

When set above 100 %, minim um

starting pre ssure needed is higher,

see figure s in the ().

4)

In case AB‑QM is used ab ove 400 kPa

differential pressure contact D anfoss

design center to assur e proper

design.

5)

At min differential p ressure valve

reaches at lea st 90% of nominal

flow. Declarat ion of performance is

available upon request.

Pc ‑ pressure controll er part

Cv ‑ Control valve part

Nominal diameter DN 12 5 125 H F 150 150 H F 200 200 HF 250 250 HF

Flow range

Setting range

Diff. pressure

3),

4),

5)

Q

nom

Q

high

2)

∆p

∆p

(100 %)

3)

min

max

1)

90,000 110,000 145,000 190,000 200,000 270,000 300,000 370,000

l/h

100,000 120,000 160,000

209,000

% 40 -110

40 (60) 60 (80) 40 (60) 60 (80) 45 (65) 60 (80) 45 (65) 60 (80)

kPa

220,000

600

300,000 330,000 407,000

Pressure stage PN 16

Control range 1:1000

Control valve’s characteristic Linear (could be converted by actuator to equal percentage)

Leakage rate with recommended

actuators

max.0.01 % of Q

nom

Water and water mixture for closed heating and cooling systems according to plant type

Flow medium

I for DIN EN 14868. When used in plant Type II for DIN EN 14868 appropriate protective

measures are taken. The requirements of VDI 2035, part 1 + 2 are observed.

Medium temperature

Storage and transport temp. –40 … 70

°C

−10 ... +120

Stroke mm 30

Connection

flange PN 16

actuator Danfoss standard

Materials in the water

Valve bodies Grey iron EN-GJL-250 (GG25)

Membranes/ Bellow W.Nr.1.4571 EPDM

O-rings EPDM

Springs W.Nr.1.4 401 W.Nr.1.4310

Cone (Pc) W.Nr.1.4404NC W. Nr.1.4021

Seat (Pc) W.Nr.1.4 027

Cone (Cv) W.Nr.1.4404NC W. Nr.1.4021

Seat (Cv) W.Nr.1.4 027

Screw W.Nr.1.1181

Flat gasket Graphite gasket Non asbestos

8 | © Danfoss | 2018.06

VD.A7.F7.02

Page 9

Data sheet AB‑QM DN 10‑250

Design

1. Spindle

2. Stuffing box

3. Pointer

4. Control valve’s cone

5. Membrane

6. Main spring

7. Hollow cone (pressure

controller)

8. Vulcanized seat (pressure

controller)

AB‑QM DN 10‑32

Δp = (P1‑P3)

ΔpCv = (P2‑ P3)

Function:

The AB-QM valve consists of

two parts:

1. Differential pressure

controller

2. Control valve

1. Shut off screw

2. Main spring

3. Membrane

4. DP cone

5. Seat

6. Valve body

7. Control valves cone

8. Locking screw

9. Scale

10. Stuffing box

11. Spindle

1. Differential pressure controller DPC

The differential pressure controller maintains a

constant differential pressure across the control

valve. The pressure difference pCv(P2-P3) on

the membrane is balanced with the force of the

spring. Whenever the differential pressure across

the control valve changes (due to a change in

available pressure, or movement of the control

valve) the hollow cone is displaced to a new

position which brings a new equilibrium and

therefore keeps the differential pressure at a

constant level.

2. Control valve Cv

The control valve has a linear characteristic. It

features a stroke limitation function that allows

adjustment of the Kv value. The percentage

marked on the scale equals the percentage of

100 % flow marked on the pointer. Changing

the stroke limitation is done by lifting the

blocking mechanism and turning the top of the

valve to the desired position, showed on the

scale as a percentage. A blocking mechanism

automatically prevents unwanted changing of

the setting.

P3P1

VD.A7.F7.02

AB‑QM DN 50 ‑100

AB‑QM DN 40, 50

© Danfoss | 2018.06 | 9

Page 10

Data sheet AB‑QM DN 10‑250

Design (continuous)

1. Valve body

2. Valve seat

3. DPC cone

4. CV cone

5. Controller casting

6. Rolling diaphragm

7. Adjusting screw

8. Bellow for pressure relief on

DPC cone

P1 P3

AB‑QM DN 125

P1

P3

AB‑QM DN 150

1. Valve body

2. Valve seat

3. DPC cone

4. CV cone

5. Controller casting

6. Rolling diaphragm

7. Adjusting screw

8. Bellow for pressure relief on

DPC cone

P1

P3

10 | © Danfoss | 2018.06

AB‑QM DN 200, 250

VD.A7.F7.02

Page 11

Data sheet AB‑QM DN 10‑250

Sizing

Thread version Flange version

VD.A7.F7.02

© Danfoss | 2018.06 | 11

Page 12

Data sheet AB‑QM DN 10‑250

Sizing (continuous)

Example 1: Variable flow system

Given:

Cool requirement per unit : 1000 W

Flow temperature in the system: 6 °C

Return temperature in the system: 12 °C

Required - control and balancing valves:

AB-QM and actuators type for BMS system.

Solution:

Flow in the system: Q (l/h)

Q = 0.86×1000/(12−6 ) = 143 l/h

Example 2: Constant flow system

Given:

Cool requirement per unit : 4000 W

Flow temperature in the system : 6 °C

Return temperature in the system : 12 °C

Required - automatic flow limiter:

AB-QM and presetting.

Solution:

Flow in the system : Q (l/h)

Q = 0.86 × 4000 / ( 12 − 6 ) = 573 l/h

Selected:

AB-QM DN 10 mm with Q

on 143/275 = 0.52 = 52 % of nominal opening.

= 275 l/h presetting

nom

Actuators: AMV 110NL - 24 V

Remarks:

required minimum differential pressure across

the AB-QM DN 10: 16 kPa.

Selected:

AB-QM DN 20 mm with Q

presetting on 573/900 = 0.64 = 64 % of

= 900 l/h

nom

maximum opening.

Remarks:

required minimum differential pressure across

the AB-QM DN 20: 16 kPa.

Example 3: Sizing AB‑QM according pipe

dimension

Given:

Flow in system 1.4 m3/h (1400 l/h = 0.38 l/s), pipe

dimension DN 25 mm

Required - automatic flow limiter:

AB-QM and presetting.

Solution:

In this case we can selected AB-QM DN 25 mm

with Q

= 1700 l/h

nom

In this case it will be recommended to check

the maximum velocity in the pipe. For this we

calculate velocity in the pipe for condition:

DN 25 mm – Di 27.2 mm

Dimension and condition acceptable, velocity

below 1.0 m/s.

Presenting on the valve AB-QM DN 25 mm

1400/1700 = 0.82 = 82 % of nominal opening.

Remarks:

required minimum differential pressure across

the AB-QM DN 25: 20 kPa.

12 | © Danfoss | 2018.06

VD.A7.F7.02

Page 13

Data sheet AB‑QM DN 10‑250

Measuring differential

pressure / Trouble shooting

Blue

Red

Blue

Red

Δp

cv

Blue

Δp

cv

DN 10-250

Δp

= (P1‑ P3)

min

min

p

cv

The AB-QM (DN 10-250) features test plugs that allow measuring of the differential pressure over the

control valve (dpcv) either differential pressure over the whole valve (dpv). If the pressure difference

(dpv) exceeds the minimal required pressure the dp controller is operational and the flow limitation is

achieved. For detailed information how to measure the flow on AB-QM DN 40-250 please refer to Flow

checker document and for detailed explanation how to do pump optimisation please refer to Pump

optimisation document. Verifying the pressure can be done by using for example Danfoss PFM device

(for more details please refer to AB‑QM Tech Note).

VD.A7.F7.02

© Danfoss | 2018.06 | 13

Page 14

Data sheet AB‑QM DN 10‑250

Presetting

The calculated flow can be adjusted easily

without using special tools.

To change the presetting (factory setting is

100%) follow the four steps below:

① Remove the blue protective cap or the

mounted actuator

② Raise the grey pointer

③ Turn (clock wise to decrease) to the new

presetting

④ Press grey pointer back into lock position.

After click presetting is locked.

DN 10-32

>10 0 %

h

100 %

The presetting scale indicates values from 100 %

flow to 0 %. Clock wise turning would decrease

the flow value while counter clock wise would

increase it.

If the valve is a DN 15 then the nominal flow

= 450 l/h =100 % presetting. To set a flow of

270 l/h you have to set: 270/450 = 60 %.

Danfoss recomends a presetting/flow from 20 %

to 100 %. Factory presetting is 100 %.

≠

h

10 %

h+ 2 mm, DN 10-20

h+ 4 mm, DN 25-32

①

Scale +90 %

②

③

④

14 | © Danfoss | 2018.06

VD.A7.F7.02

Page 15

Data sheet AB‑QM DN 10‑250

Presetting (continuous)

DN 40 -100

Note: 1 turn = 10 %

DN 125-250

Max 25Nm

+

–

+

Note:

1 turn = 5 %

Service DN 10‑32

For the service shut off function, it is

recommended to install the valve in the supply

water pipe.

Valves are equipped with plastic protection cap.

When closing against higher differential pressure

please use accessory - shut-off & protection

piece (003Z1230) or set the value to 0 %.

Installing AB-QM valve is mono-directional meaning that

the valve operates when arrow on the valve body

is aligned with flow direction. When this rule is

disobeyed the valve acts like variable orifice that

cause water hammer at sudden closing when

available pressure has increased or valve have

been set to lower value.

Setting 60 %

–

DN 40‑10 0

For the service shut-off function, the valve can

be installed in either supply or return pipe.

Valves are equipped with manual shut-off for

isolating function up to 16 bar.

DN 125‑250

For the service shut-off function, the valve can

be installed in either supply or return pipe.

For shut-off set the valve to 0%.

VD.A7.F7.02

In case when system condition allows backflows

it is strongly recommended to use backflow

preventer in order to avoid possible water

hammer that can damage the valve as well as

other elements in the system.

© Danfoss | 2018.06 | 15

Page 16

Data sheet AB‑QM DN 10‑250

Tender text

The pressure independent balancing and control valve which means that the control characteristic is

independent from the available pressure. The precise flow control performance of the AB-QM with

a Danfoss actuator provides increased comfort and superior Total Cost of Ownership. The AB-QM

ensures and control the required flow on every terminal unit and maintains Hydronic balance in the

system.

AB-QM has following features:

• Flow limitation function

• Modulating below 1% of set flow, regardless of the setting,

• Authority of 1 at all settings

• Able to close against 16 bar of differential pressure.

• Linear control characteristic

• Scale in percentage of flow

• Control ratio 1:1000

• Test plugs for pump optimization and flow verification for DN 10-250. Available in the range from

DN 10 – 250 from one supplier.

• Characteristic changed from linear to equal percentage characteristic at all sizes by adjusting

actuator settings.

• Lockable setting

• Leakage rate of no visible leakage for DN 10 - DN 20 in combination with recommended actuator

• Leakage of 0.05 % of the Qnom for DN 25 - DN 100 in combination with recommended actuator

• Leakage of 0.01 % of the Qnom for DN 125 - DN 250 in combination with recommended actuator

16 | © Danfoss | 2018.06

VD.A7.F7.02

Page 17

Data sheet AB‑QM DN 10‑250

Dimensions

1

H

2

H

L

1

b

L

L

2

2

L

3

AB‑QM D N 10‑32

5

H

L

7

AB‑QM + N ovo Con™

L

4

AB‑QM + T WA‑Z

3

H

L

5

AB‑QM + ABNM

4

H

L

6

AB‑QM + AM V (E) 110 NL

AB‑QM + A MI 14 0

Typ e

L1L2L3L4L5L6L7H1H2H3H4H5H

mm

DN 10 53 36 79 92 104 10 9 119 69 20 100 104 13 8 14 0 G ½ 0.38

DN 15 65 45 79 98 110 116 126 72 25 102 108 141 143 G ¾ 0.48

DN 20 82 56 79 107 120 125 134 74 33 105 112 143 145 G 1 0.65

DN 25 10 4 71 79 124 142 142 149 82 42 117 124 155 153 G 1 ¼ 1.45

DN 32 130 90 79 142 154 160 167 93 50 128 136 166 164 G 1 ½ 2.21

6

b

(ISO 228/1)

Valve weight

(kg)

6

H

VD.A7.F7.02

A

AB‑QM DN 10‑50

DN

10

15

20

25

32

40

50

Union connection A*

mm

105

120

143

174

207

200

244

* Length is decrea sed with installation due to def ormation of the gasket.

Tailpiece welding A*

mm

- 87

139 109

166 -

188 -

214 -

204 -

234 -

Tailpieces for soldering A*

mm

© Danfoss | 2018.06 | 17

Page 18

Data sheet AB‑QM DN 10‑250

Dimensions (continuo us)

1

H

2

H

L

1

b

AB‑QM AB‑QM D N 40, 50 + AME 435 QM

Typ e

1

1

H

2

3

mm (ISO 228/1) (kg)

b Weight

L

H

H

DN 40 110 170 174 280 G 2 6.9

DN 50 130 17 0 174 280 G 2 ½ 7.8

3

H

3

H

1

H

a

2

H

L

1

AB‑QM DN 50 ‑100 + AME 435 QM

AB‑QM

Typ e

L1H1H2H

mm

3

DN 50 230 170 174 280 165 14. 2

DN 65 290 220 172 330 185 38.0

DN 80 310 225 177 335 200 45.0

DN 10 0 350 240 187 350 220 5 7.0

a

(EN 1092-2)

Weight

(kg)

18 | © Danfoss | 2018.06

VD.A7.F7.02

Page 19

Data sheet AB‑QM DN 10‑250

Dimensions (continuo us)

1

H

1

H

a

a

2

H

L

1

2

H

L

1

AB‑QM DN 125 AB‑QM DN 150

3

H

3

H

VD.A7.F7.02

AB‑QM DN 125 + AME 55 QM

Typ e

DN 125 400 272 518 507 250 85.3

DN 150 480 308 465 518 285 138

L1H1H2H

AB‑QM DN 150 + AME 55 QM

mm (EN 1092-2) (kg)

3

a Weight

© Danfoss | 2018.06 | 19

Page 20

Data sheet AB‑QM DN 10‑250

Dimensions (continuo us)

1

H

2

H

3

H

a

L

1

AB‑QM DN 200, 250 + AME 85 QMAB‑QM DN 200, 250

Typ e

L1H1H2H

mm (EN 1092-2) (kg)

3

DN 200 600 434 483 618 340 219

DN 250 730 430 533 708 405 342

a Weight

20 | © Danfoss | DHS-SRMT/SI | 2018.06

VD.A7.F7.02

Loading...

Loading...