Page 1

Data sheet

Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Features and Benefits

The AB-QM temperature control valve provides

pressure independent regulation of flow while

also providing flow limiting system balance. The

valve internally contains a unique differential

pressure regulator which automatically adjusts

to normal changes in system pressure from

valves opening and closing or changing of pump

speed. As a result of maintaining a constant

pressure for the temperature control valve, valve

authority is maintained at 100%. This allows

for precise interaction with the temperature

controller and unparalleled system operation

as indicated by assuring the highest possible

coil log mean temperature difference (∆T). The

valve is easily set and adjusted to provide the

precise flow required for each terminal unit.

Design calculation and commissioning effort

normally required for it's control and balance

valves are virtually eliminated because of the

built in automatic pressure control regulator. A

wide selection of actuators are available for the

AB-QM providing further control features for

the valve, making it an ideal selection for the

simplest of two position control strategies to the

precision required for modulating control and

variable speed pump optimization.

Features:

• AB-QM maintains a stable flow through its

range of operation unaffected by changes

in system differential pressure period. 100%

valve authority allows lower pump head

than traditional valves and reduces energy

consumption which increases ∆T

• Three required valve functions; temperature

control, balance and flow limitation in one

compact valve design

• Flow parameter is the only consideration,

reducing valve selection engineering

• Constant flow regulation limitation through

independent pressure balancing

• User adjustable flow setting for maximum

flow limitation

• Maintains linear characteristic of flow when

installed with a Danfoss proportional actuator.

Actuator options with equal percentage flow

characteristics.

Benefits:

• Flow will match the load

• Eliminate coil over flows

• Reduced installation time and materials

• Simple flow setting procedure; reduced time

involved for field commissioning

• Valve allows maximum coil and system

differential temperature drops for optimum

efficiency

• Operation costs reduced as much as 90 % or

more when properly applied with variable

speed pumping

• "Plug and Play" for quick setup for balancing

allowing immediate start up of unit

• Commissioning accomplished without use of

specialized equipment

• Compact design allows installations in areas

with limited space such as stand alone fan

coils

© Danfoss | 2022.03 AI194086469170en-US0401 | 1

Page 2

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

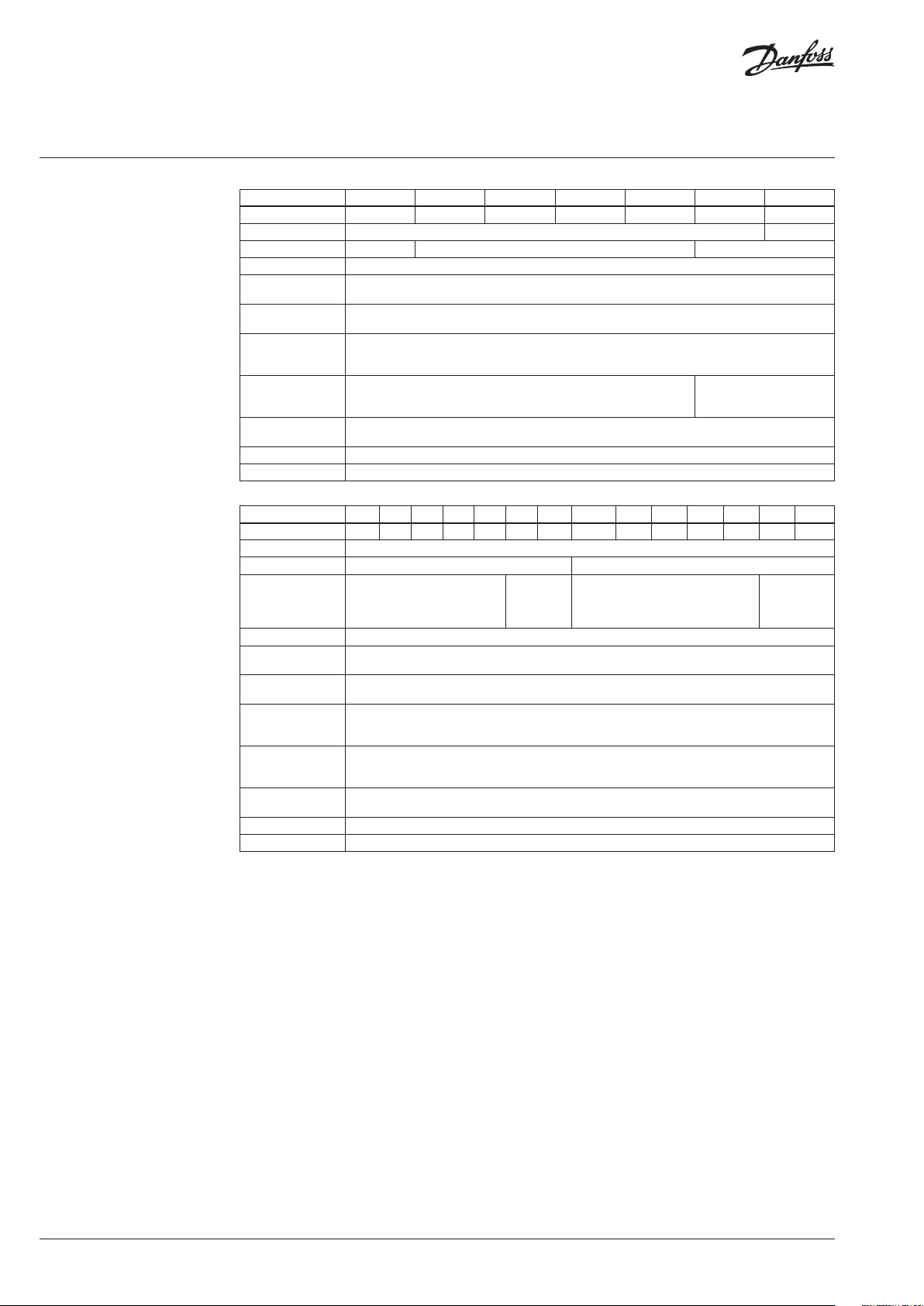

Technical Data:

Nominal Diameter ½” LF ½” HF ¾” HF 1” HF 1¼” H F 1½” 2”

Max flow (GPM) 1.2 5 7.5 12 17.5 33 55

Setting range

Diff. pressure (PSI)

1)

2), 3)

2.3-60 5-60 4.4-60

20 -100 % 40 -100 %

Connection Male NPSM

Control valve

characteristic

Control valve

accuracy

Linear

± 5% of set point

Max. differential

pressure

90 psi (6.2 bar)

(across the valve)

Max. close off

pressure (regardless

232 psi (16 bar) 250 psi (17.2 bar)

of actuator)

Medium

temperature

15 °F to 250 °F (−10 °C to 120 °C)

Allowable Fluid Water and secondary refrigerant additives such as glycol

Leakage Class 4, metal to metal

Nominal Diameter 2 ½” 3” 4” 5" 6” 8” 10" 2 ½” HF 3” HF 4” HF 5" HF 6" H F 8" HF 10" H F

Max flow (GPM) 85 120 165 395 640 830 1,235 110 176 260 485 830 1,100 1,60 0

Setting range

Diff. pressure (PSI)

Connection ANSI Flange (ANSI Standard B16.1)

1)

2), 3)

4.4-60 8.7– 60

ISO Flange &

Gasket (ISO

Flange EN

1092-2)

40 -100 %

ANSI Flange (ANSI Standard B16.1)

ISO Flange &

Gasket (ISO

Flange EN

1092-2)

Connection rating ANSI Class 125

Control valve

characteristic

Control valve

accuracy

Linear

± 5% of set point

Max. differential

pressure

90 psi (6.2 bar)

(across the valve)

Max. close off

pressure (regardless

232 psi (16 bar)

of actuator)

Medium

temperature

15 °F to 250 °F (−10 °C to 120 °C)

Allowable Fluid Water and secondary refrigerant additives such as glycol

Leakage Class 4, metal to metal

1)

Factory se tting of the valve is done at 100%.

2)

Regardless of t he flow limitations valve can mo dulate till 0.1% of the nomina l flow.

3)

∆p = (P1–P3) min~max

According suitabili ty and usage especiall y in not oxygen tight syste ms please mind the instructio ns given by the coolant produce r.

Available AB- QM valves with low minimum p in sizes ⁄” to 1⁄”.

Contact Danfoss f or further informati on.

2 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 3

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

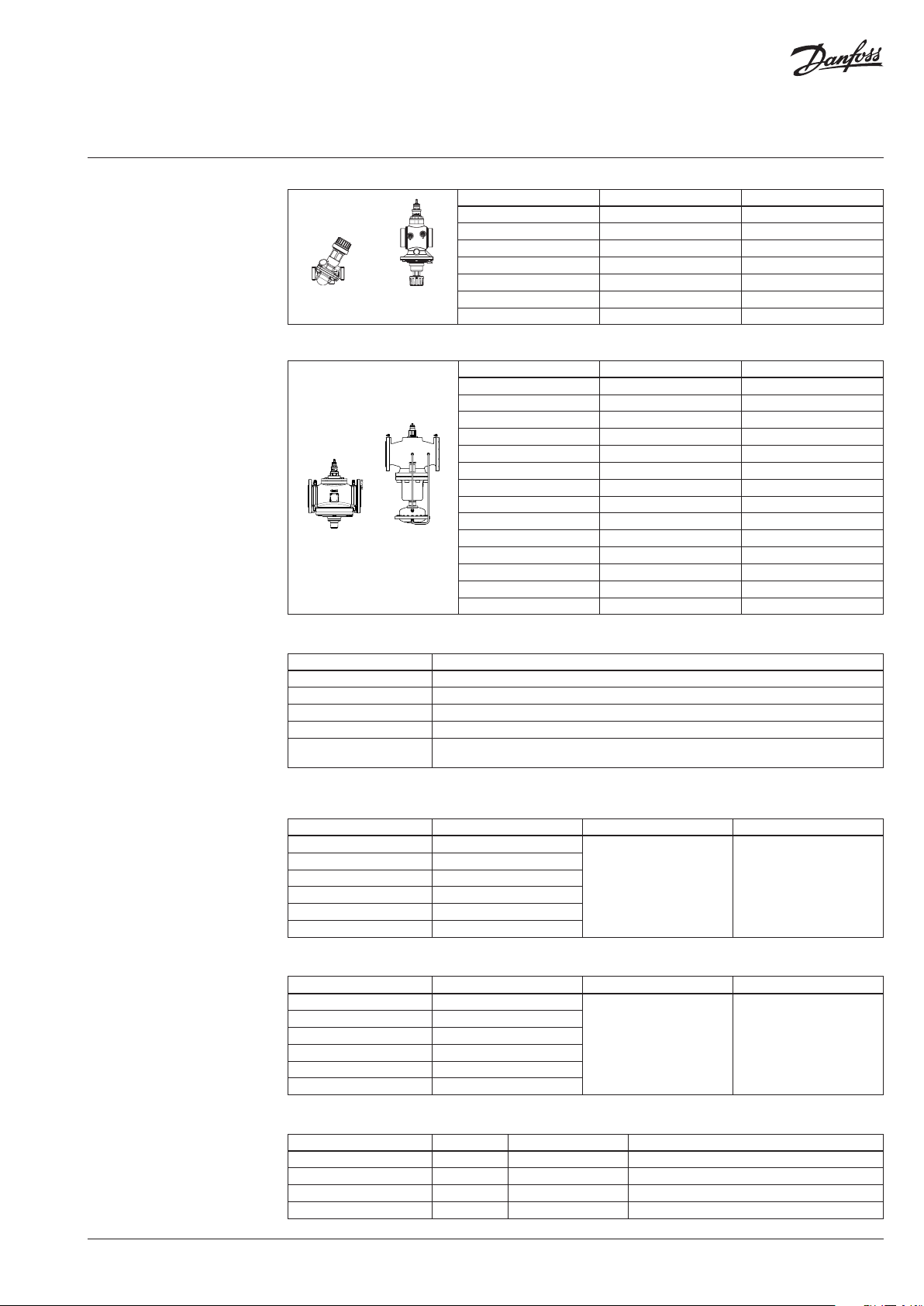

Ordering Information:

Code No. Size Max. Flow (GPM)

003Z1321 ½“ LF 1.2

003Z1332 ½“ HF 5

003Z1333 ¾“ HF 7.5

00 3Z1334 1“ HF 12

00 3Z1335 1 ¼“ HF 17. 5

AB-QM (⁄" - 1⁄")

Without P/T Plug s

Contact Danfoss f or lower p valve bodies i n sizes from ⁄" to 1 ⁄”

AB- QM (2⁄"-4")

With P/T Plugs

AB -QM (1⁄"-2 ")

With P/T Plugs

AB- QM (5"- 6")

With P/T Plugs

003Z0780 1 ½“ 33.0

003Z0781 2" 55.0

Code No. Size Max. Flow (GPM)

003Z0783 2½" 85

003Z0784 3" 120

003Z0785 4" 165

003Z0905 5" 395

003Z0906 6" 640

003Z0707 8" 830

003Z0708 10" 1235

003Z0983 2½” H F 11 0

003Z0984 3" HF 176

003Z0985 4" HF 260

003Z0 915 5" HF 485

003 Z0916 6" HF 830

00 3Z07 17 8" HF 110 0

003 Z0718 10" H F 1600

Accessories

Code No. Description

003Z0695 Brass handle for AB- QM 1½" thru 4", required if without assembled motor ac tuator

003Z0696 Brass handle for AB- QM 5" thru 6", required if without assembled motor actuator

003Z0697 Brass handle for AB -QM 8" thru 10", required if without assembled motor actuator

003Z0230 Brass shut-off & protection cap, Max 232psi (16 bar) (for use with ½” to 1¼” AB-QM valve)

003Z0236

Note: For insulation k its contact Danfoss

Locking Ring - installed to inhibit the unintentional changing of the AB- QM valve setting, 5pcs.

(for use with ½" to 1¼" AB-QM valve)

MNPT THREADED TAILPIECE KIT (two kits required per valve)

Code No. Size Connection Type Description

003Z0282 ½”

003Z0283 ¾”

003Z0284 1"

003Z0285 1¼"

003Z0286 1½"

003Z0287 2"

NPT (Male)

One Nut + One Tailpiece +

SWEAT TAILPIECE KIT (two kits required per valve)

Code No. Size Connection Type Description

003Z0292 ½”

003Z0293 ¾”

003Z0294 1"

003Z0295 1¼"

003Z0296 1½"

003Z0297 2"

Sweat (Female)

One Nut + One Tailpiece +

ISO FLANGES & GASKETS, for 8” & 10” VALVES (2pcs per valve)

Code No. Size Connection Type Description

D2576-16-200 8” ISO PN 16 ISO flat face slip on weld f lange, EN 1092-2

GASKET AB-QM 8 ” 8” Gasket 8" gasket for ISO flange

D2576-16-250 10" ISO PN 16 ISO flat face slip on weld flange, EN 1092-2

GASKET AB-QM 10" 10 " Gasket 10" gasket for ISO flange

One Gasket

One Gasket

AI194086469170en-US0401 | 3© Danfoss | 2022.03

Page 4

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

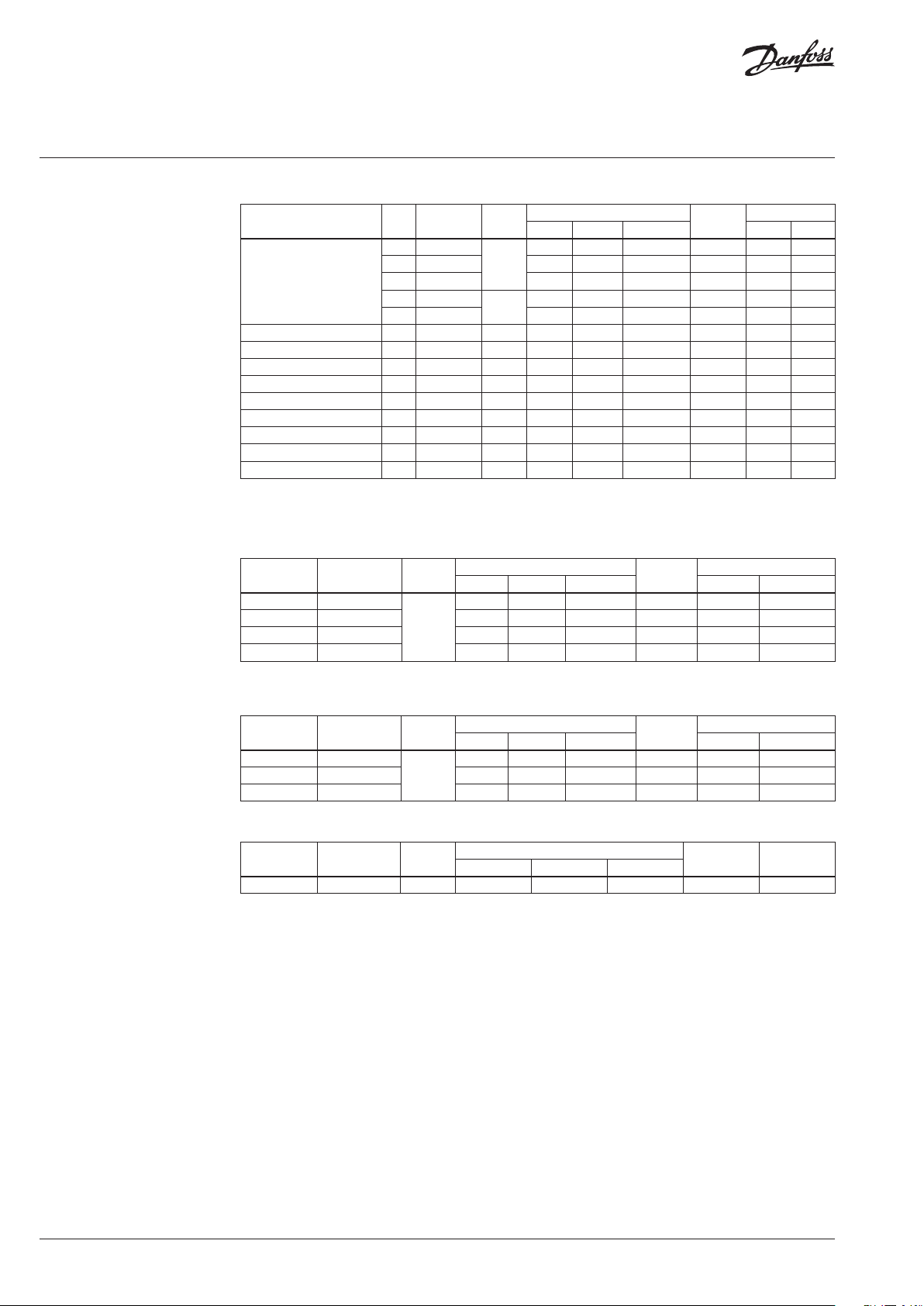

Electric Actuator

Selection Information:

Refer to electric actuator data

sheet for further information.

For Valve Sizes ½" to 1¼"

Style Note Code No. Power

3)

08 2F1150

ABN A5

AMI 120 NL-1

3)

08 2F1151 • •

3)

082F1154 • • •

3)

08 2F1156

3)

08 2F1157 • •

2)

082H5003 24Vac • •

24Vac

120 Vac

AMV 120 NL-1 082H5005 24Vac • •

AME 13 SU-1

AME 13 SD-1

ABNM A5 (Equal Percentage)

ABNM A5 (Equal Percentage)

ABNM A5 (Linear)

ABNM A5 (Linear)

1)

082H5006 24Vac • • • •

2)

082H5007 24Vac • • • •

3)

08 2F1163 24Vac • •

3)

08 2F116 0 24Vac • •

3)

08 2F116 5 24Vac • •

3)

08 2F1161 24Vac • •

AME 120 NLX-1 082H5004 24Vac • •

1)

Included required 003Z3960 adap ter

2)

Included req uired spacer 003Z02 57

3)

Require cable o rdered as separate Code no.

Input Signal

On/Off

Floating

Modulating

Feedback

• •

• •

For Valve Sizes 1½" to 4"

Style Code No. Power

On/Off Floating Modulating Up Down

AME435 QM 08 2H017 1

AMV 435 082H0162 • •

AME 25SU

AME 25SD

1)

Adapter requi red, ordered separately. Part # 0 03Z0694

1)

082H3041 • • • •

1)

082H3038 • • • •

24Vac

Input Signal

• •

Position

Feedback

Position

Safety Function

Safety Function

Up Down

For Valve Sizes 5" to 6"

Style Code No. Power

On/Off Floating Modulating Up Down

AM E 655-1 082H 5010

AME 658 SD-1 08 2H 5011 • • • •

24Vac

Input Signal

• • •

Position

Feedback

AME 658 SU-1 08 2H5012 • • • •

Safety Function

For Valve Sizes 8” to 10”

Style Co de No. Power

On/Off Floating Modulating

Input Signal

AM E 685 -1 0 82H5 013 24Vac • • •

Digital actu ators available, refer to N ovocon series data sheet for ABQM va lves for further inform ation.

Position

Feedback

Function

Safety

1)

4 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 5

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Application:

The AB-QM is a versatile device that can

be used as an actuated or non-actuated

balance valve / flow limiter. With an actuator

mounted to the AB-QM valve, the assembly is

a pressure independent control valve. Utilizing

a proportioning controller, the AB-QM creates

a robust and stable energy management sub

system using only the required flow and energy

to offset facility heat transfer gains and losses.

The integrated AB-QM differential pressure

regulator virtually eliminates the problem

of fluctuating pressures on control valve

performance. The AB-QM regulator immediately

reacts to all changes in system pressure creating

the stability to make the valve flow and control

predictable and controllers and valves work as

intended. Energy is saved taking advantage of

the greatly reduced amount of flow required

for heat transfer of full valve authority for an

air handling unit (AHU), fan coil, etc. With the

AB-QM the required design flow to the AHU is

met, subsequently simplifying the balancing

of the system. Air handling units react quickly

to changes in the building load and simple

proportional control will not accurately

regulate these systems. Using control integral

action to adjust for this requires skill and extra

commissioning to properly match the required

setting to the applications, sometimes over

several seasons of operation. The AB-QM

differential pressure regulator acts as an extra

sub-master controller and makes tuning the

main controllers easier and less time consuming.

Smaller building HVAC sub-systems such as

fan coil units, or terminal unit heating coils and

newer modern designs such as chilled beams

or radiant cooling panels greatly benefit from

AB-QM application even when applied with

simple thermostatic operation. No pressure

calculations are required, valve authority doesn't

need to be calculated and no calculations

have to be performed to pre-set a balancing

valve. If extra flow is determined to be required

while tuning the installation, it's easy for the

commissioning agent to reset the AB-QM for

any flow up to the rated range of the valve.

The HVAC units and controllers will benefit

from greatly enhanced ability to control, with

no overflow. AB-QM allows hydronic HVAC

systems to achieve the green and sustainable

performance envisioned by their designers and

owners. Owners benefit in significant reductions

in commissioning time, energy cost in operation

from reduced flow and reduced complaints

associated with improper temperatures within

the building.

Minimum Pressure Drop

To verify that an installation functions according

to the design specifications checking the critical

valve in the installation is needed . The critical

valve is the furthest valve away on the branch

or loop and has the lowest available differential

pressure. The AB-QM maintains a constant

differential pressure across temperature control

valve and any excess pressure will automatically

be throttled by the regulator. If there is not

enough differential pressure the valve cannot

reach the set flow. Therefore the critical valve

must have the minimum differential pressure for

the pressure regulator to properly operate, all

prior AB-QM valves will function properly.

AI194086469170en-US0401 | 5© Danfoss | 2022.03

Page 6

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

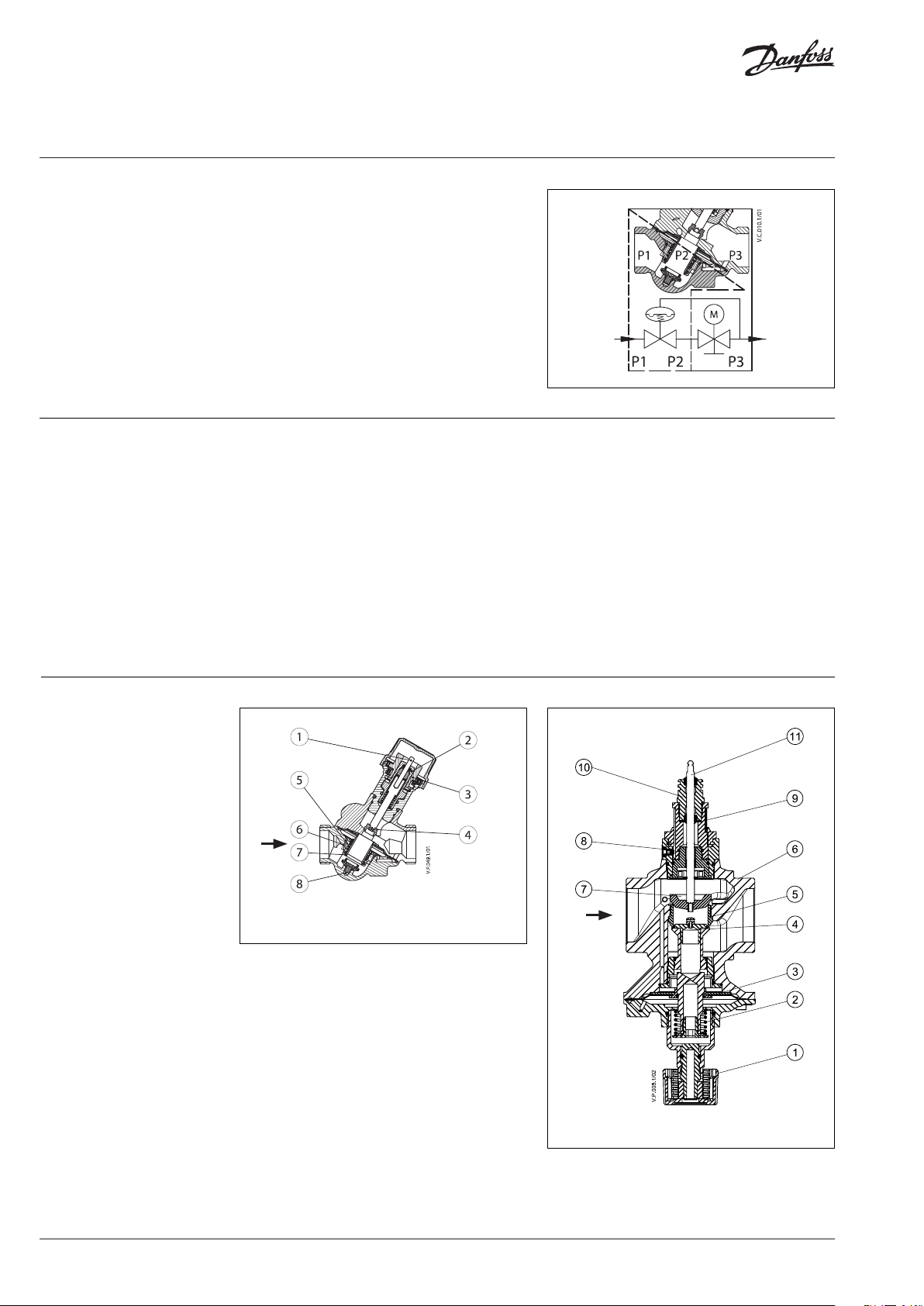

Function

Differential Pressure

Regulator

The AB-QM combines aspects of both a

differential pressure controller for balancing and

a temperature control into a single valve.

P1 Available Pressure

P2 Regulated inlet pressure to temperature

control valve

P3 Exit pressure of valve

Flow enters the valve through the differential

pressure regulator, which maintains a constant

pressure difference across the temperature

control valve orifice. As entering pressure

increases or decreases in reaction to changes

in flow and pump speed in the piping system,

the regulator diaphragm is balanced with the

force of the spring keeping a constant pressure

difference (P2-P3) between the water entering

the temperature control valve and the leaving

side of the valve. As a result the differential

pressure across the temperature control valve

(P2-P3) is at a constant level.

A nominal 5 psi differential is required from P1

to P3 for the valve and flow regulator operation.

The regulator controls the range of system

differential pressure to 60 psi (140 FOH). Under

normal system operation such as in variable

speed pumping, as system flow is reduced,

controlled pump speed reduces the system

differential pressure (head) of the pump. In

constant speed pumping applications reductions

in system flow may result in increased system

differential pressure (head) of the pump.

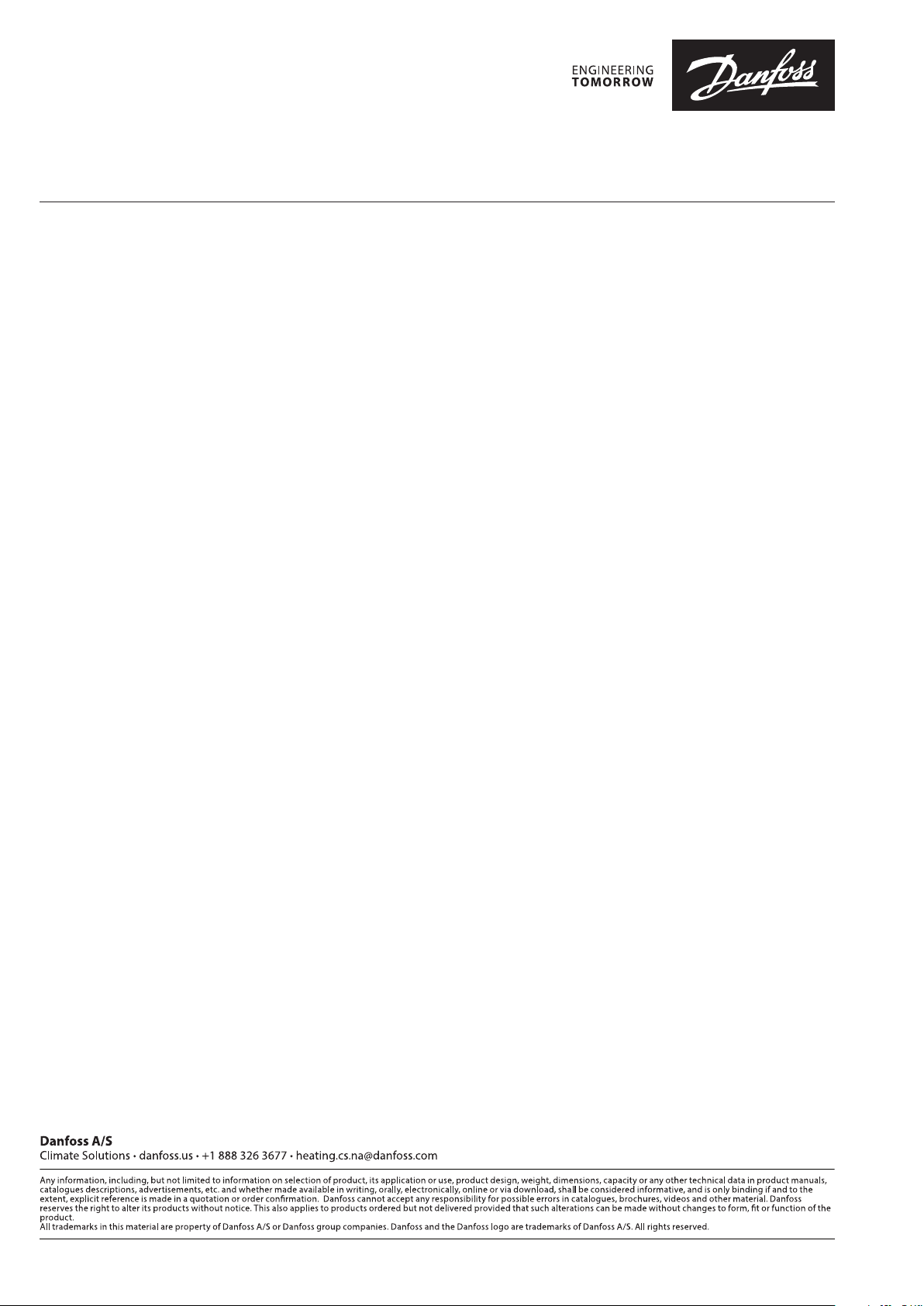

Valve Operation / Design

AB-QM ⁄" - 1⁄ "

1. Stuffing box

2. Spindle

3. Plastic ring

4. Control valve plug

5. Diaphragm

6. Regulator spring

7. Regulator cone

8. Regulator seat

AB-QM 1⁄" - 2 "

1. Shut off screw

2. Main spring

3. Membrane

4. DP cone

5. Seat

6. Valve body

7. Control valves cone

8. Locking screw

9. Scale

10. Stuffing box

11. Spindle

AB-QM ⁄"- 1⁄"

AB-QM 1½"- 2"

6 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 7

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Valve Operation / Design

(continuous)

AB-QM 2½"- 4"

1. Shut off screw

2. Main spring

3. Membrane

4. DP cone

5. Seat

6. Valve body

7. Control valve cone

8. Locking screw

9. Scale

10. Stuffing box

11. Spindle

AB-QM 5"-6"

1. Valve body

2. Valve seat

3. DPC cone

4. Cv cone

5. Controller casting

6. Rolling diaphragm

7. Adjusting screw

8. Bellow for pressure relief

on DPC cone

AB-QM 2½"- 4"

AB-QM 5"-6"

AB -Q M 8”-10 ”

1. Valve body

2. Valve seat

3. DPC cone

4. CV cone

5. Controller casting

6. Rolling diaphragm

7. Adjusting screw

8. Bellow for pressure relief on

DPC cone

P1

AB -QM 8 "-10"

P3

AI194086469170en-US0401 | 7© Danfoss | 2022.03

Page 8

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Control Valve Flow

Coefficient and

Characteristic, Cv

Flow Adjustment

STROKE

½"-11⁄" Sizes

Valve Stem Travel

100%

Q, C

The globe style temperature control valve has

a linear characteristic allowing for application

flexibility. The adjustment to the maximum

flow alters the stem travel of the valve, yet

this adjustment of the stem travel does not

compromise the control performance. On-Off

controls will cycle between full and no flow

positions, and proportional control actuators

upon reset will self calibrate to the new adjusted

stem travel, and still utilize the entire input signal

range. Maintaining a linear characteristic allows

for the predictability required to characterize the

control signal when needed in an application.

Signal characterization is optimally done in the

v

controller, but may be done through an available

actuator which allows matching to the terminal

unit characteristic.

≠

h

10%

h+ 2 mm, DN 10-20

h+ 4 mm, DN 25-32

②

①

③

④

⑤

8 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 9

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Flow Adjustment

(continuous)

1 ½"-4" Sizes

Max 25Nm

Note: 1 turn = 10%

For 1⁄" to 4" Valves:

Requires adjustment with crescent wrench or allen key.

5"-10" Sizes

+

–

Setting 60%

+

Note: 1 turn = 5.0 %

The setting of the flow limitation requirement

of the valve is based upon a percentage of the

maximum flow for the valve body.

Example:

Required flow rate:

100 GPM

Selected valve size:

4" Maximum flow (Q

Therefore, 100/165 = 0.6 -> 60 %

Set the valve to 60 % to achieve 100 GPM

through the valve.

Danfoss recommends a presetting range from

20 % to 100 %. Factory presetting is 100 %.

By turning the grey collar counter clockwise

would increase while clockwise would decrease

the flow. When valve is set to 80 % or more the

red line becomes visible.

)= 165 GPM

max

–

AI194086469170en-US0401 | 9© Danfoss | 2022.03

Page 10

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Valve Authority

Valve authority can be generally defined as a

measure of the change in differential pressure

across a control valve during operation. This

value is calculated by dividing the pressure drop

of the control valve (∆p

pressure drop of the control valve (∆p

system (∆p

coil, and other devices that become part of the

) it serves e.g. the pipes, fittings,

System

) by the sum of the

Valve

Valve

) and

system.

p

A

Valve

pp

SystemValve

The calculated result is expressed as a percent

ratio, with 100 % authority being an ideal

scenario achieved in laboratory conditions.

Within a lab, a constant differential pressure

is maintained across the control valve and

as a result an equal or linear relationship is

achieved between the flow requirements and

control valve's position. In reality in meeting the

output requirements in a variable flow system

the resulting reaction between the terminal

and the control valve performance can be less

than ideal. The dynamic variations (∆p) within

the entire system e.g. other actuating control

valves, create fluctuations to the differential

pressure across the control valve resulting in a

lower valve authority percentage. The lower the

valve authority, the worse the controllability is

between the terminal and control valve resulting

in inconsistent room temperature.

The interaction of ∆p

can significantly hinder the control valve's

on the control valve

System

effectiveness. The design of the AB-QM's internal

differential pressure regulator address this by

counteracting the inlet ∆p

as a result a constant differential pressure across

fluctuations, and

System

the control valve is achieved.

With a constant differential pressure across the

inlet and outlet of the control valve portion of

the AB-QM, a more ideal scenario is approached.

The result is the AB-QM valve assembly operates

at 100 % valve authority.

10 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 11

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Typical Specification

Revised Construction Specifications Institute

standard numbering is utilized. The Specifier

is advised to coordinate product provisions

with other speciality specification areas as

more than one may apply. The model for this

specification and suggested placement is based

on the "Unified Facilities Guide Specifications"

downloadable form the Whole Building

Design Guide web site (www.wbdg.org) and

found under the "Documents & References"

specifications library. The WBDG web site

is offered as an assistance to the building

community by the National Institute of Building

Sciences (NIBS) through funding support of

several US government agencies.

SECTION 23 09 13

INSTRUMENTATION AND CONTROL DEVICES

FOR HVAC

PART 2 PRODUCTS

2.5 Automatic Control Valves

Valves shall have stainless-steel stems and

stuffing boxes with extended necks to clear the

piping insulation. Valves bodies shall meet ASME

B16.34 or ASME B16.15 pressure and temperature

class ratings based on the design operating

temperature and 150 percent of the system

design operating pressure.

Unless otherwise specified or shown, valve

leakage shall meet FCI 70-2 Class IV leakage

rating (0.01 percent of valve Kv). Unless otherwise

specified or shown, valves shall be two way

pressure independent globe-style bodies. Unless

otherwise specified:

a. bodies for valves 2 inches and smaller shall be

brass or bronze, with union ends

b. bodies for valves 2 to 3 inches shall be of

brass, bronze or iron.

c. bodies of valves 2½ inches and larger shall be

provided with flanged-end connections

d. valve and actuator combination shall be

normally open or normally closed as shown

2.5.7 Two-Way Pressure Independent Globe

Valves

Two-way modulating valves used for liquids.

The valve shall be two way globe style with

integrated differential pressure control regulator.

Where indicated modulating proportional valve

application shall utilize controller or actuator to

match required control signal to complement

controlled coil heat transfer characteristic for

linear control, the valve shall:

a. provide integrated pressure regulator;

regulator to control pressure across control

valve orifice

b. provide regulator incorporating EPDM

diaphragm, stainless steel spring and pressure

control disc. Pressure control seat shall be

brass construction with vulcanized EPDM

c. provide counterbalance of supply pipe

pressure to return pipe pressure across

diaphragm to prevent diaphragm damage

when control valve is closed

d. provide user adjustable maximum flow within

valve control range; Adjustment method shall

indicate percentage of valve flow range and

utilize spring locked method of adjustment

e. regulate internal control valve differential

pressure to provide 100 % control valve

authority

f. shall have linear flow characteristic

g. provide back seated globe design to allow

service of packing under pressure without

leakage

h. provide entering to leaving (P1-P3) pressure

control across valve ½" in size from 2.3-60 PSI

i. provide entering to leaving (P1-P3) pressure

control across valves ½"-1¼" in size from

5-60PSI

j. provide entering to leaving (P1-P3 pressure

control across valves 1½"-10" in size from

4-60PSI

k. provide entering to leaving (P1-P3) pressure

control across valves 2.5”HF -10”HF in size

from 8.7-60PSI

l. provide union connections

m. utilize stainless steel internal trim with brass

globe seat

n. utilize threaded actuator connection

o. flow requirements shall be sized to provide

nominal body selection no more than one

size smaller to corresponding nominal pipe

connection

a. ½" bodies shall be utilized for ½" pipe and

may be utilized for ¾" pipe connection and

flow less than 5 GPM

b. ¾" bodies may be utilized for ¾" pipe and

may be applied to 1" pipe connection with

flow less than 7.5 GPM

c. 1" bodies may be utilized for 1” pipe and

may be applied to 1¼" pipe connection

with flow less than 12 GPM

d. 1¼"bodies may be utilized for 1¼" and

may be applied to 1½" pipe connection

with flow less than 17.5 GPM

e. 1½" bodies may be utilized for 1½" pipe

and may be applied to 2" pipe connection

with flows less than 33 GPM

f. flows less than 55 GPM may use 2" bodies

g. flows less than 85 GPM may use 2½" bodies

h. flows less than 120 GPM may use 3" bodies

i. flows less than 165 GPM may use 4" bodies

j. flows less than 395 GPM may use 5"bodies

AI194086469170en-US0401 | 11© Danfoss | 2022.03

Page 12

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Typical Specification

(continuous)

k. flows less than 640 GPM may use 6" bodies

l. flows less than 836 GPM may use 8” bodies

m. flows less than 1232 GPM may use 10”

bodies

n. flows less than 110 may use 2 1/2”HF bodies

o. flows less than 176 may use 3”HF bodies

p. flows less than 260 may use 4”HF bodies

q. flows less than 484 GPM may use

5”HF bodies

r. flows less than 836 GPM may use

6”HF bodies

s. flows less than 1100 GPM may use

8”HF bodies

t. flows less than 1629 GPM may use

10”HF bodies

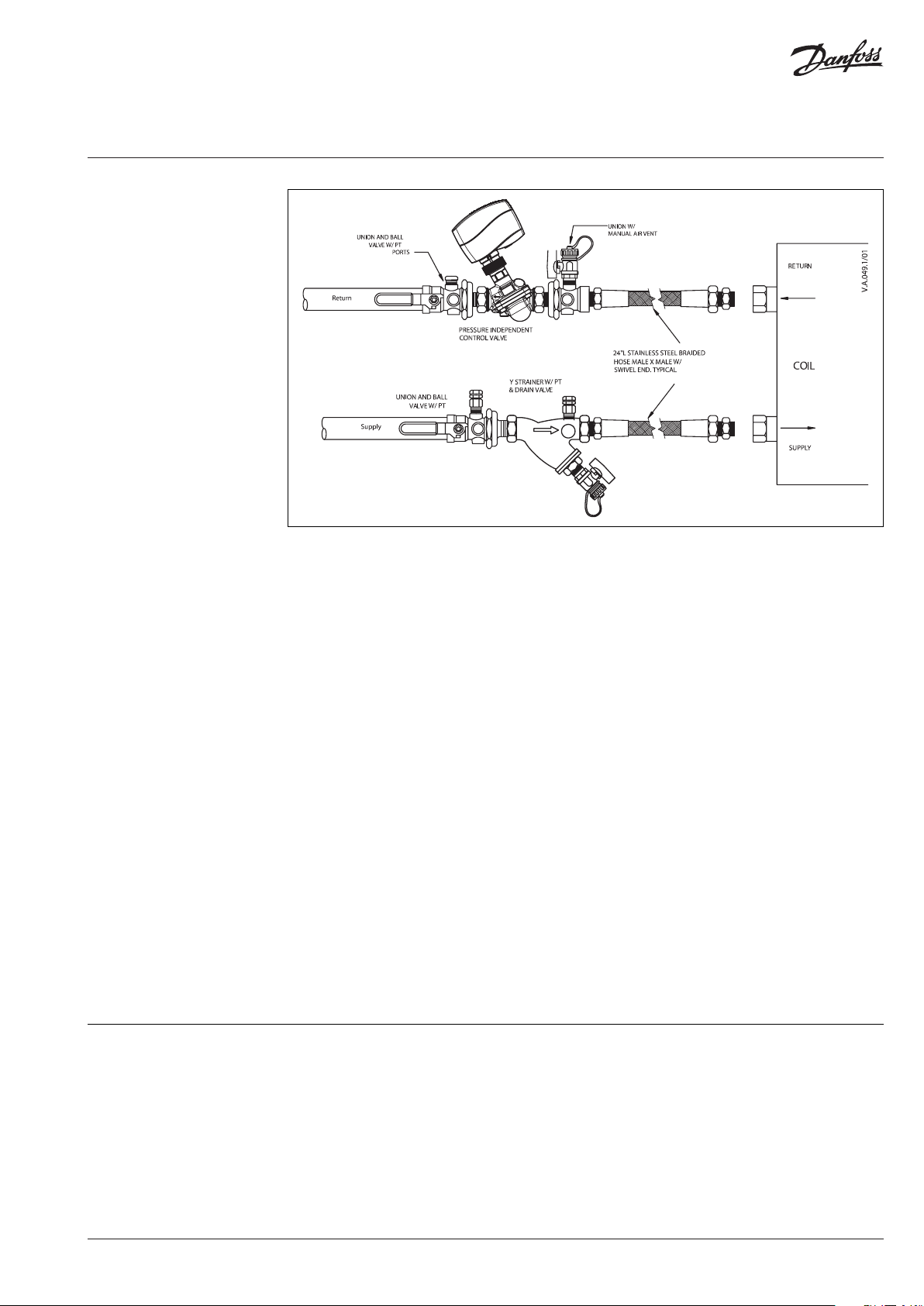

2.5.8 Duct-Coil and Terminal-Unit-Coil; Hot

and Chilled Water Systems

Control valves utilized for controlled flows shall

be proportionally modulated. Control valve shall

be integrated into coil assembly package. Coil

assembly package shall conform to requirements

of other common valves as specified in Section

23 05 15 Common Piping For HVAC. Coil

assembly package shall:

a. provide integrated ball valve and wye pattern

strainer. Strainer shall be #20 mesh. Strainer

valve shall provide pressure and temperature

measurement port with integrated positive

shutoff gland seal. Strainer valve shall have

plugged ¼" female NPT accessory port.

Strainer valve shall provide integrated ¼"

ball drain valve with cap and common hose

connection. Strainer valve shall provide

integrated union connection and tailpiece.

Strainer valve shall be provided to match flow

requirements for connected control valve.

b. provide union connection entering and

leaving piping of coil. Union connection

fitting shall include three accessory ¼" female

NPT tapped ports for test and other HVAC

devices. Provide pressure and temperature

measurement ports with integrated positive

shutoff gland seal in unions entering and

leaving coil. Provide manual air vent in union

leaving coil. Provide ¼" threaded plugs in

all unused union ports. Provide union nut,

tailpiece and o-ring seal, or appropriate

connectors to flexible piping.

c. provide ball shutoff valve with integrated

union. Valve shall provide pressure and

temperature measurement port with

integrated positive shutoff gland seal. Valve

shall have plugged ¼" female NPT accessory

port. Provide union nut, tailpiece and o-ring

seal, or appropriate connectors to flexible

piping.

d. provide flexible piping for connection to coil.

Piping shall be configured such that unions

are hard mounted to coil either directly or

with elbows as appropriate to allow straight

flexible connection without ninety degree

change in direction. Flexible pipe shall be

mounted between coil union and control

valve or strainer valve.

12 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 13

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Dimensions

AB-QM ½"-1 ⁄"

1

H

2

H

L

1

Dimensions, inches (mm)

Valve t ype

½” LF

½” HF 3.18 (81)

¾”

¾” HF 3.26 (83)

1” HF

1¼” H F

L

2.56

(65)

3.23

(82)

4.09

(104)

5.12

(130 )

1

L1 + tailpieces

MNPT F. Solder

4.69

(119 )

5.6

(142)

6.82

(173 )

8.12

(206)

L

1.8

(45)

2.2

(56)

2.8

(71)

3.5

(90)

* Dimensions sho wn are approximated and sho uld be verified.

Contact With Water

Body Brass CuZn36Pb2As - CW 617N;

O-Ring EPDM

Spring W.Nr.1.4568, W.Nr 1.4310; Stainless steel

Cone (Pc) W.Nr.1.4305; Stainless steel

Seat (Pc) EPDM

Plug (Cv) CuZn40Pb3 - CW 614N; Wrought copper

Seat (Cv) CuZn40Pb2 - CW 617N; Die forged brass

Screw Stainless steel (A2)

Flat NBR

Sealing Agent Dimethacrylate Ester

Dezinc resistant brass

b

L

2

Weight

2

H

1

3. 11 (7 9)

3.18 (81)

3.5

(88)

4.02

(102)

H

2

0.98

¾” NPSM 1.06 (0.50)

(25)

1.3

(33)

1.65

(42)

1.97

(50)

1” NPSM 1.43 (0.65)

1¼” N PSM 3. 20 (1.45 )

1½” N PSM 4. 87 (2.20)

lb (kg)

b

4

H

3

H

L

3

ABN A5, ABNM A5 + AB -QM

AMV (E) 120 NL(X)-1+ AB-QM

AMI 120 NL-1 + AB-QM

Valve t ype

Dimensions, inches (mm)

L L H H

½” 4. 33 (110 ) 4.57 (116) 4.25 (108) 5. 55 (141)

¾” 4.7 2 (120 ) 4.92 (12 5) 4 .41 ( 112) 5. 63 (143)

1” 5. 59 (142) 5.59 (142) 4. 88 (124) 6.10 (15 5)

1¼” 6.0 6 (154) 6. 30 (160) 5.35 (136) 6.54 (16 6)

L

4

AI194086469170en-US0401 | 13© Danfoss | 2022.03

Page 14

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Dimensions (continuous)

AB-QM 1½"-2"

L

2

1

H

b

2

H

AME(V) 435 QM + AB- QM

3

H

Dimensions, inches (mm)

Valve t ype

1½” 4. 33 (110 ) 8 .3 0 ( 211) 7.28 (18 5) 7.69 (170 ) 6. 65 (174 ) 11.02 (280) 1½ - 11½ 13.22 (6.9 )

2” 5.11 (13 0) 9.40 (239) 8.70 (221) 7. 69 (17 0) 6.6 5 (174) 11.02 (280) 2 - 11½ 17.19 (7. 8)

L

L +

NPT

Tailpieces

L +

Solder

Tailpieces

H H H

b

(NPSM

thread)

Contact With Water

Body Ductile iron EN-GJL-250 (GG25)

Membrane EPDM

Diaphragm EPDM

O-Ring EPDM

Springs W.Nr.1.4568, W.Nr.1.4310;

Cone (Pc) CuZn40Pb3 - CW 614N, W.Nr.1.4305;

Seat (Pc) W.Nr.1.4305; Stainless Steel

Cone (Cv) CuZn40Pb3 - CW 614N;

Seat (Cv) W.Nr.1.4305; Stainless steel

Screw Stainless Steel (A2)

Flat Gasket NBR

Stainless Steel

Wrought copper, Stainless steel

Wrought copper

Weight

lb (kg)

14 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 15

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Dimensions (continuous)

AB-QM 2½"-4"

1

H

a

2

H

3

H

L

1

Valve t ype

2½” & 2½” HF 11 .42 (2 90) 8.66 (220) 6. 77 (17 2)

3" & 3”HF 12 .20 (310) 8.85 (225) 6. 96 (17 7)

4" & 4”HF 13 .78 (350) 9.44 (24 0) 7. 36 (187)

Dimensions, inches (mm)

L H H H

Contact With Water

Valve bodies Grey cast iron A4 8 No.35A

Membranes EPDM

Bellows EPDM

O-rings EPDM

Springs ASTM-631, ASTM-301

Cone (Pc) C37710. ASTM -303

Seat (Pc) ASTM-303

Cone (Cv) C37710

Seat (Cv) ASTM-303

Screw Stainless Steel (A2)

Flat NBR

AME(V) 435 QM + AB-QM

(ANSI, B16.1)

12. 99 (3 30)

13.18 (335)

13.77 (350)

7.0 8 (18 0) 83.77 (38)

7.4 8 (19 0) 99.20 (45)

9.05 (230) 125.66 (57)

a

Weight

lb (kg)

AI194086469170en-US0401 | 15© Danfoss | 2022.03

Page 16

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Dimensions (continuous)

AB-QM 5" AB-QM 6"

1

H

a

2

H

1

H

a

2

H

L

1

3

H

AME 655-1, AME658-1 + AB-QM 5"

Valve t ype

L

1

Dimensions, inches (mm)

H

1

H

2

AME 655-1, AME658-1 + AB-QM 6"

H

3

5” & 5” HF 15.74 (400 ) 10 .70 (272) 20.39 (518) 19.9 6 (507)

6” & 6” HF 18. 89 (48 0) 12 .12 (3 08) 18. 30 (465) 20.39 (518) 3 04. 23 (138)

L

1

a (Flange)

(ANSI, B16.1)

-

Weight

lb (kg)

187. 39 ( 85)

3

H

Contact With Water

Body Grey cast iron A48 No. 35A

Membrane EPDM

Diaphragm EPDM

O-ring EPDM

Springs ASTM-316N

Cone (Pc) ASTM-316L

Seat (Pc) ASTM- 420

Plug (Cv) ASTM-316L

Seat (Cv) ASTM-420

Screw ASTM-1055

Flat Gasket Non asbestos

16 | AI194086469170en-US0401 © Danfoss | 2022.03

Page 17

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

Dimensions (continuous)

AB-QM 8" & 10"

1

H

2

H

3

H

a

L

1

Valve t ype

L

1

Dimensions, inches (mm)

H

1

8” & 8” HF 23.62 (600) 19.01 (4 83) 19. 01 (483)

10" & 10” HF 28.74 (730) 15 .62 ( 533) 20.98 (533)

Contact With Water

Body Ductile iron EN-GJL-250 (GG25)

Membrane EPDM

Diaphragm EPDM

O-ring EPDM

Springs W.Nr.4310; Stainless Steel

Cone (Pc) W.Nr.1.4021; Stainless Steel

Seat (Pc) W.Nr.1.4027; Stainless Steel

Cone (Cv) W.Nr.1.4021; Stainless Steel

Seat (Cv) W.Nr.1.4027; Stainless Steel

Screw W.Nr.1.1181; Stainless Steel

Flat Gasket Non asbestos

AME 685-1 + AB-QM 8" , 10"

a (Flange)

H

2

H

24. 33 (618)

27. 87 (7 08 )

(EN 1092-2)

3

13.38 (340) 482.81 (219)

15.94 (405) 753.98 (342)

Weight

lb (kg)

AI194086469170en-US0401 | 17© Danfoss | 2022.03

Page 18

Data sheet Pressure Independent Control Valve AB‑QM,

½” thru 2”

2½” thru 4”

5” thru 10” Valve Size

© Danfoss | DCS-SGDPT/SI | 2022.0318 | AI194086469170en-US0401

Loading...

Loading...