Page 1

Data Sheet

Actuator Type ABNM-LOG/LIN for AB-QM, 0-10

V Proportional

Application

Function

The ABNM actuator is a thermoelectric actuator

for opening and closing valves in the fields of

heating, ventilation and air conditioning systems

(HVAC).

The actuator mechanism of the ABNM actuator

uses a positive temperature coefficient (PTC)

resistorheated wax element and a compression

spring. The wax element is heated by applying

the operating voltage and moves the integrated

piston. The force generated by this movement is

transferred to the piston, thus opening or closing

the valve.

The closing force of the compression spring (100

N actuating force) is matched to the closing force

of the valves and keeps the valve closed when

de-energized. When the control voltage is

applied (0-10 V), the wax element is heated under

electronic control. The actuator provides active

regulation in a defined range (see characteristic

curve between 0.5 V and 10 V).

In the range of 0 – 0.5 V, the actuator remains in a

quiescent state in order to ignore ripple voltage

occurring in long cables. The relation between

control voltage and actuator travel is balanced by

optical path measurement, allowing very

accurate positioning. When the control voltage is

outside of the active range, the valve is kept

closed by the closing force of the compression

spring.

Control is done by a 0-10 V signal, which is

provided either by a room thermostat or, in most

cases, by a central direct digital control (DDC)

system. The actuator converts the 0-10 V signal

into a proportional actuator travel, which can be

either linear (ABNM LIN) or logarithmic (ABNM

LOG).

Ideal use in heating/cooling systems and in

▪

combination with central direct digital

control (DDC) systems in building

management systems (BMS).

ABNM LOG for actuating valves controlling

▪

the flow of liquid to air heat exchanges, e.g.

cooling fan coils or air handling units.

ABNM LIN for actuating valves controlling

▪

the flow of liquid to liquid heat exchangers.

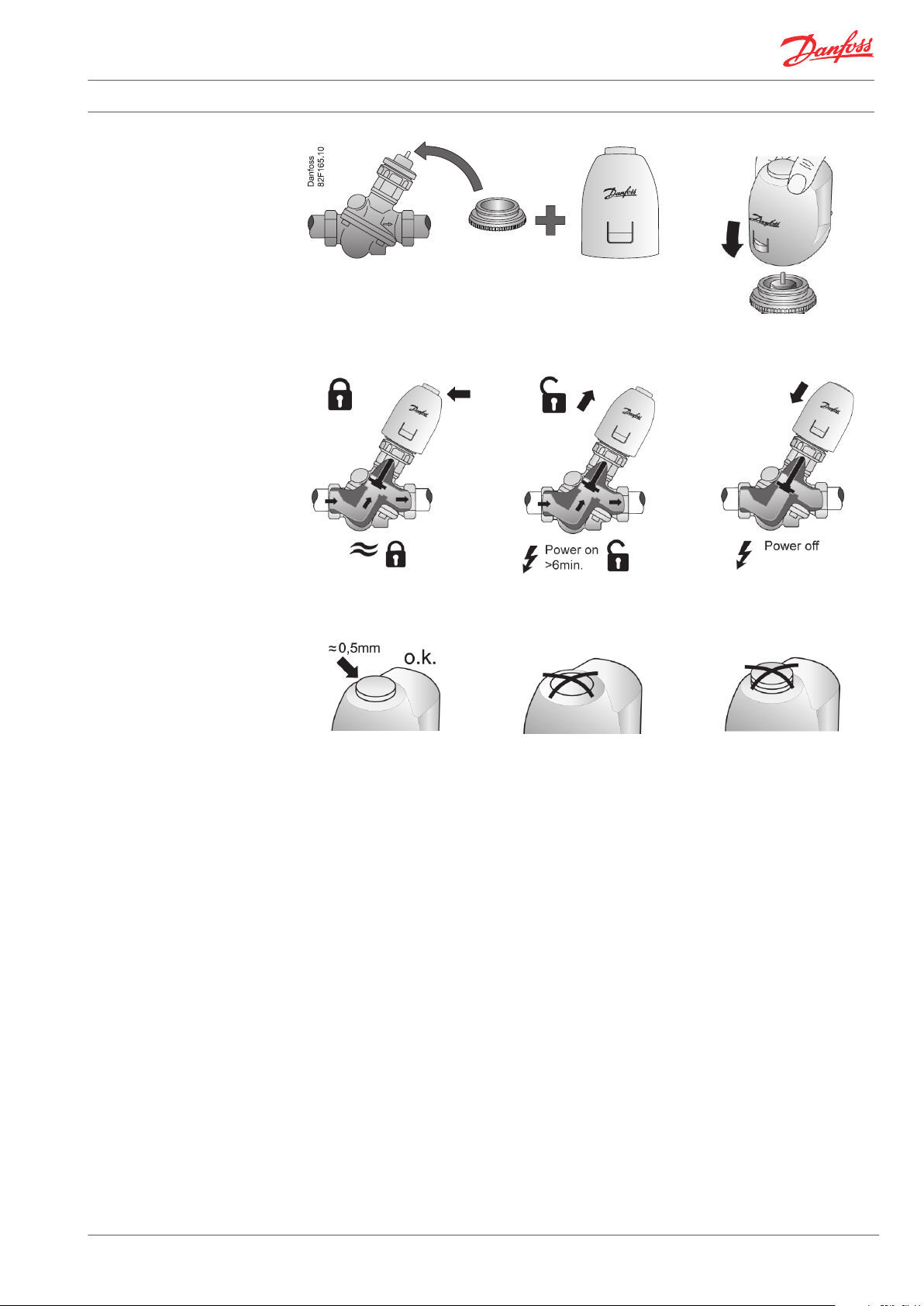

First open function (for NC only)

In its delivery condition, the ABNM is kept open

when de-energized due to the first open function

(filling). This enables heating/cooling operation

during the carcass construction phase even when

the electric wiring is not yet complete. During the

later electrical start-up, the first open function is

unlocked by applying the operating voltage for

more than 6 minutes and the ABNM will then be

completely operable.

Automatic calibration

During the electrical start-up the valve closing

point is detected. This ensures an optimum

match with the specific valve used.

Function display

The function display (all-round display) of the

ABNM shows at the first glance whether the valve

is “open” or “closed”.

Danfoss Heating Solutions VDSKF202 © Danfoss 10/2011 1

Page 2

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

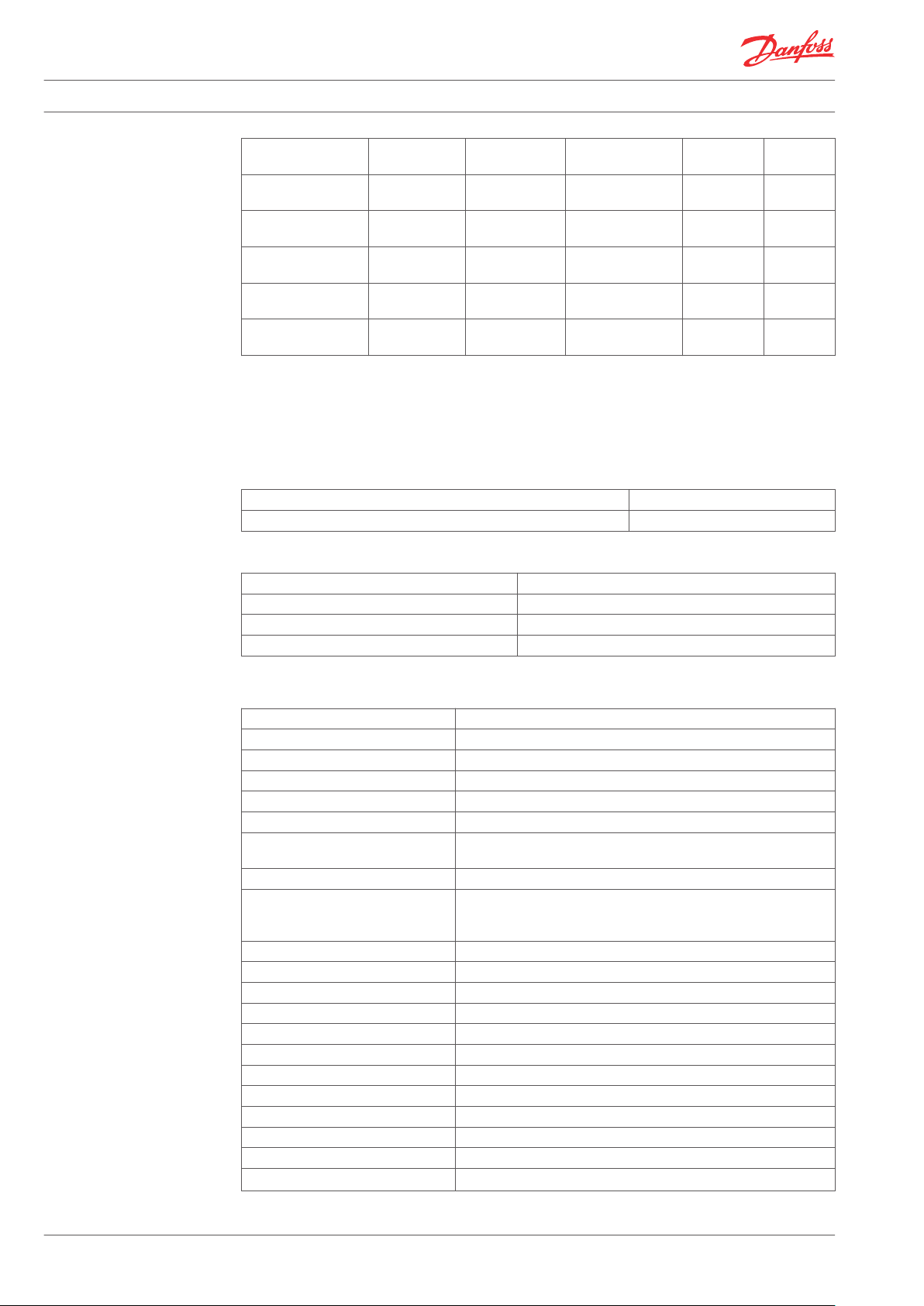

Code Nos. and Technical

Data

Accessories

Type Supply voltage Control voltage Valve function

ABNM LOG with

VA50 adapter

ABNM LOG with

VA50 adapter

ABNM LIN with

VA50 adapter

ABNM LOG without

adapter

ABNM LIN without

adapter

* Halogen free

Note: For theft protection order 082F1091

Valve adapters

Connection Code no.

Danfoss AB-QM VA50 082F1075

Cable (halogen free)

Length Code no.

1 meter 082F1081

5 meter 082F1082

10 meter 082F1083

24 V AC 0-10 V DC

24 V AC 0-10 V DC

24 V AC 0-10 V DC

24 V AC 0-10 V DC

24 V AC 0-10 V DC

NC (normally

closed)

NC (normally

closed)

NC (normally

closed)

NC (normally

closed)

NC (normally

closed)

Cable*

length

1 m 082F1191

5 m 082F1192

1 m 082F1193

no 082F1198

no 082F1199

Code no.

Data

Version Closed when de-energized

Voltage 24 VAC 50/60 Hz (-10% to +20%)

Max. inrush current <300 mA during approx. 2 min.

Operating current 90 mA

Operating power 0.4 W

Control voltage 0-10 V DC

Proportional conversion range of

control voltage

Input resistance 100 kΩ (also 10 kΩ factory setting, if ordered)

Actuator travel In the range 0.5-10V the actuator proportional controls (LOG or

Average actuation delay 30 s/mm

Actuating force 100 N +/- 5%

Operating temperature 0 - 60 °C

Fluid temperature 0 - 100 °C

Storage temperature -25 to 65 °C

Ambient temperature 0 to 60 °C

Relative humidity max. 80%

Degree/class of protection IP54 (only when connected to cable)/Safety extra-Iow voltage

CE conformity according to 60730

Housing/housing colour Polyamid/white RAL 9003

Weight 100 g without adapter and cable

Connecting cable/cable length

0.5-10 V DC

LIN) a 0-4 mm stroke, starting from the closing point of the

valve. The stroke is mechanically limited at 4.5 mm.

3 x 0.22 mm2 PVC, white, halogen free/1 meter, 30 g

2 VDSKF202 © Danfoss 10/2011 Danfoss Heating Solutions

Page 3

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

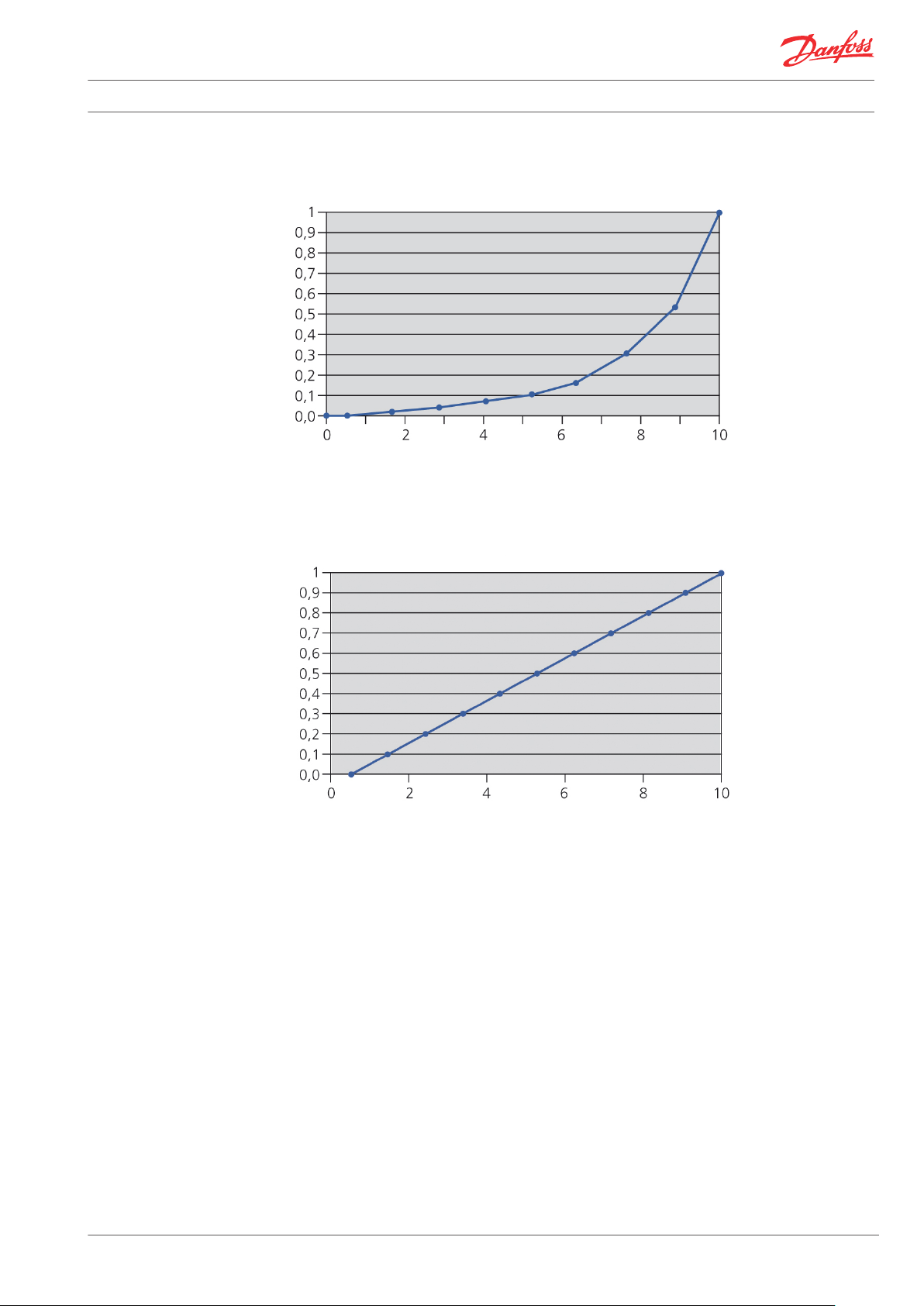

Characteristic Curves

ABNM-LOG, transformation curve

Relative stroke

Input signal (volt)

ABNM-LIN, transformation curve

Relative stroke

Input signal (volt)

ABNM actuator

The actuator converts the 0-10 V signal into a

proportional actuator travel of 0-4.5 mm.

Danfoss Heating Solutions VDSKF202 © Danfoss 10/2011 3

Page 4

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

Dimensions Connections

Transformer Calculation of max. cable length (copper cable)

Rule-of-the-thumb formula for dimensioning

transformer:

P

transformer

= 6 W x number of ABNM actuators L = K x A / n

A: Conductor cross-section in mm

2

n: Number of ABNM actuators

K: Constant for copper (269 m/mm2)

L: Cable length in m

4 VDSKF202 © Danfoss 10/2011 Danfoss Heating Solutions

Page 5

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

Installation

Danfoss AB-QM VA50, code no. 082F1075

1. Screw the suitable valve adapter on the

valve by hand.

2. The actuator is mounted on the adapter

ring. ABNM can be mounted in 360°.

Danfoss Heating Solutions VDSKF202 © Danfoss 10/2011 5

3. Switch on the power supply.

Page 6

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

6 VDSKF202 © Danfoss 10/2011 Danfoss Heating Solutions

Page 7

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

Danfoss Heating Solutions VDSKF202 © Danfoss 10/2011 7

Page 8

Data Sheet Actuator Type ABNM-LOG/LIN for AB-QM, 0-10 V Proportional

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

8 VDSKF202 © Danfoss 10/2011 Danfoss Heating Solutions

Loading...

Loading...