Page 1

841 & 842

Seven Day Pulsed Output Electronic Timeswitches

110 Volt

INSTALLATION INSTRUCTIONS

The Model 841 & 842 Timeswitches must be installed

by a competent electrician and the installation should

conform to IEE Wiring Regulations.

Installation & Wiring

1. Slacken the four fi xing screws, one in each corner of the unit, and

carefully separate the front and rear portions. Unplug the ribbon cable

from the rear portion.

CAUTION: Do not allow either half of the unit to hang by the ribbon

cable as damage could be caused.

2. Remove the polystyrene packing piece from the top of the transformer.

It is marked ‘REMOVE’.

3. Select the desired fi xing position and observe the label ‘THIS WAY UP’

inside the rear portion. The two halves will only assemble correctly

one way round.

4. Four fi xing holes are provided for attaching the rear portion to the

wall or mounting surface.

Conduit box adaptors as shown below are available if required.

Part No.: 8/3223 Double Gang Surface Box Adaptor

Cable

Entry

Aperture

2 fi xings for

double gang

surface box

5. Surface cable entries to the units can be made from above, below or

from the left hand side. Conduit or recessed cable entry is through the

aperture in the rear moulding.

6. For surface cable entr y remove the appropriate knock-out and ensure

one of the two cable clamps is positioned correctly.

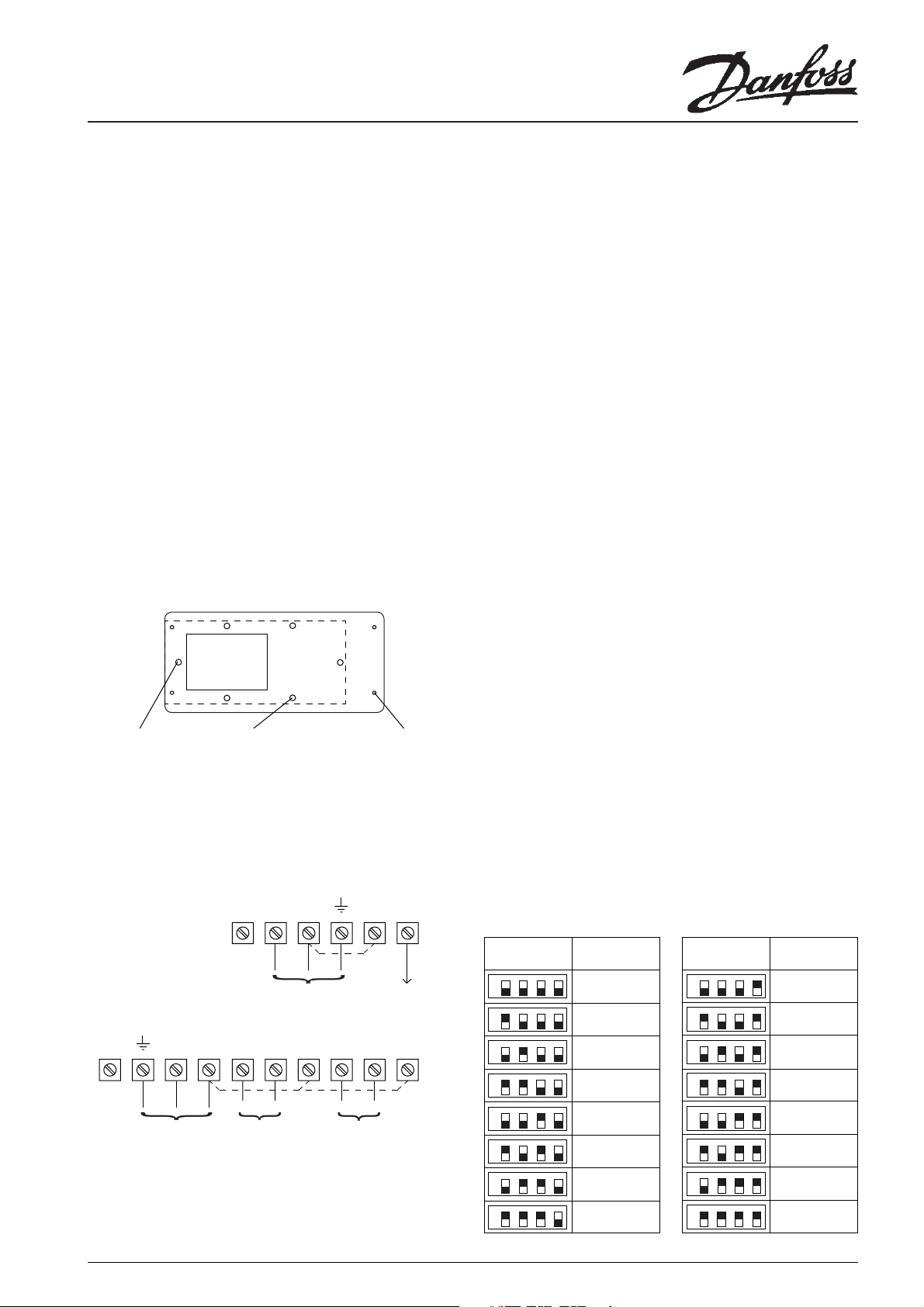

7. Connections to the units should be made as shown below.

MODEL 841

Spare N L 1 2

Alternative 4 fi xings

for double gang

surface box

4 fi xings for Mark

8 Timeswitch

In the case of Model 842 terminals 1, 2 and 3 (if required) should be

connected to the load controlled by Channel 1 and terminals 4, 5 and

6 (if required) to the load controlled by Channel 2.

8. The unit is supplied set for a 5 second single pulse output. If a multi

pulse output is required, proceed as described in paragraph 10 (b). If a

number of pulses or the pulse duration is required to be different from

supplied, proceed as described in paragraph 11(b).

9. Upon completion of wiring plug in the ribbon cable ensuring the

polarised plug is fully inserted into the socket. Refi t the front half of the

timeswitch ensuring correct alignment and that no cables are trapped

before re-tightening the screws.

10. TO CHANGE FROM SINGLE TO MULTI PULSE OUTPUT

(a) Remove the front portion of the unit as described in ‘Installation

and Wiring’ paragraph 1.

(b) A push/pull switch is provided on the rear of the printed circuit

board inside the front portion of the unit.

With the switch pulled out (as supplied) this provides a single pulse

output. Push the switch in to achieve a multi pulse output (½ second

on followed by ½ second off).

On Model 842 a push/pull switch is provided for each channel to enable

different types of pulsed output if required. The switch relating to each

channel is clearly marked.

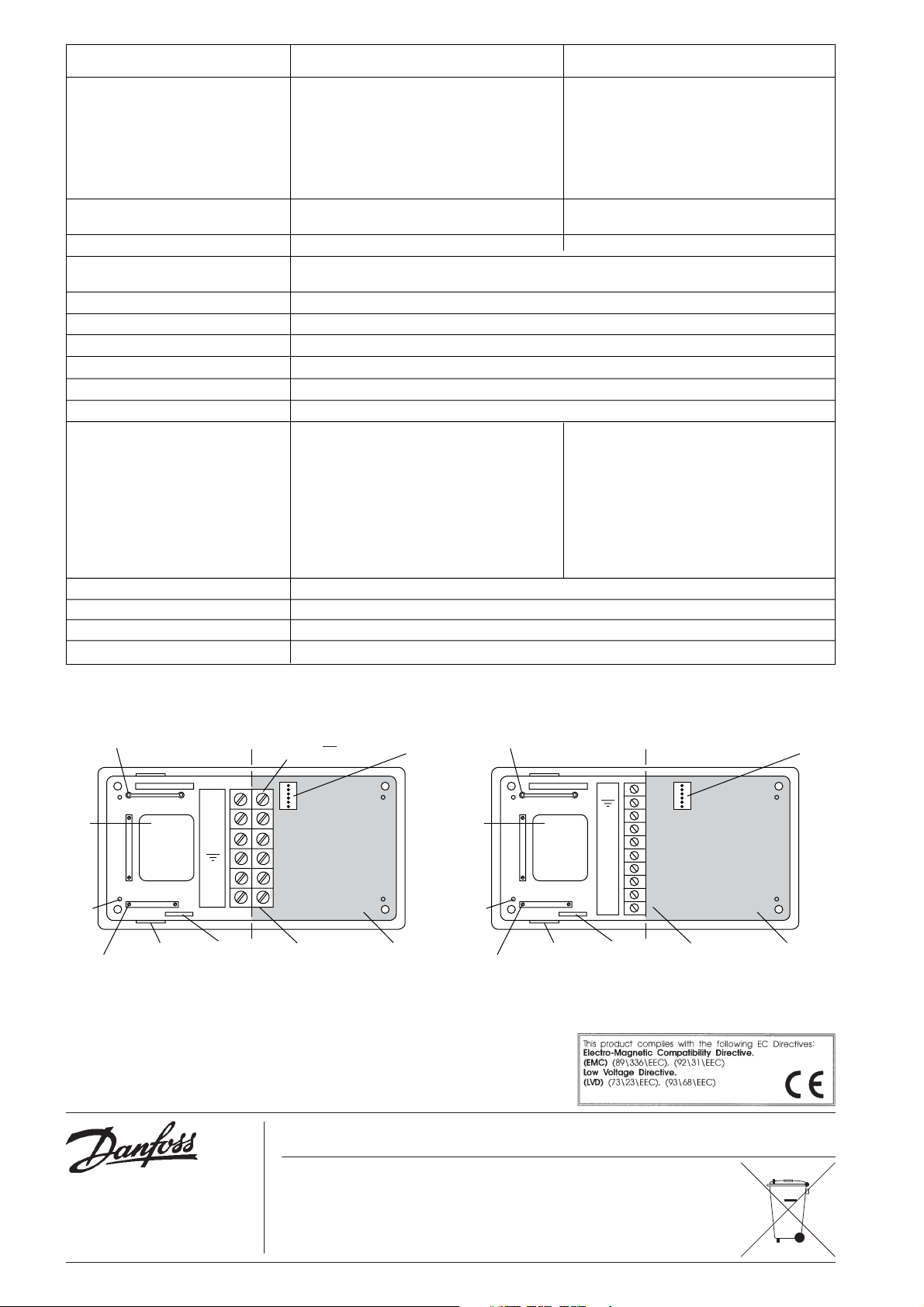

11. RESETTING OF SWITCHING DURATION

(a) Remove the front portion of the unit as described in ‘Installation

and Wiring’ paragraph 1.

(b) The bank of four miniature rocker switches is mounted on the

printed circuit board inside the front portion of the unit.

When switch no. 1 is ‘on’ 1 second duration is set.

When switch no. 2 is ‘on’ 2 seconds duration is set.

When switch no. 3 is ‘on’ 4 seconds duration is set.

When switch no. 4 is ‘on’ 8 seconds duration is set.

When all 4 switches are ‘on’ the duration is

1 + 2 + 4 + 8 = 15 seconds.

Any combination of the 4 switches may be selected to set from 1 to

15 seconds in increments of 1 second.

If all 4 switches were ‘off’ there would be no output and so this setting

should be avoided.

EXAMPLES

Link for 110V

control circuit

110V, 50 Hz

Mains Supply

Output

(LOAD)

MODEL 842

Spare N L 6 5 4 3 2 1

Link for

110V

control

circuit(s)

OFF ON

Channel 2

110V, 50 Hz

Mains Supply

OFF ON

Channel 2

If the control circuit(s) are to operate at 110V then terminals L & 1

(Model 841) and terminals L, 1 and 4 (Model 842) must be linked,

ensuring that the cable is sheathed and of a size to carry the required

load current.

If, however, the control circuit(s) are operating at other than 110V then

no link(s) shall be fi tted and in the case of Model 841 both terminals 1

and 2 should be connected to the load.

Slider Switch Posi-

tions

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

4

4

4

4

4

4

4

4

‘ON’

Duration

NONE

Do Not Use

1 second

2 seconds

3 seconds

4 seconds

5 seconds

(As supplied)

6 seconds

7 seconds

Slider Switch Posi-

tions

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

23

1

ON

OFF

‘ON’

Duration

4

8 seconds

4

9 seconds

4

10 seconds

4

11 seconds

4

12 seconds

4

13 seconds

4

14 seconds

4

15 seconds

1

Page 2

Technical Specifi cation Model 841 Model 842

Max. current rating of output 15A at 110 Vac 3A* (at 110 Vac on each channel.

* If set as multi pulse output giving 15 pulses

per event 200 times per week, rating reduces

to 1A at 110 Vac

Conversely if set as single pulse at 100 events

per week, rating increases to 5A at 110 Vac

Output contacts Enclosed single pole single throw (SPST) Enclosed single pole double throw (SPDT)

Type B voltage free on each channel Type B

Mains supply required 110 V (+/-10%) AC 50/60 Hz 100V (+/-10%) AC 50/60 Hz

Battery reserve Retains memory settings for a period of 3 months during mains power failure (once battery is

fully charged)

Temperature Rating 0°C to 45°C

Enclosure Rating IP30

Max Ambient Temperature 45°C

Overall Dimensions 210mm wide, 115mm high, 50mm deep

Max. No. of programmable operations 200 which may be freely allocated throughout the 7 days

Setting and Running Accuracy +/- 1 min and +/- 1 min/month

Mode of operation Provides either a continuous or interrupted Provides either continuous or interrupted pulse

pulse (½ second ‘ON’ followed by ½ second (½ second ‘ON’ followed by ½ second ‘OFF’)

‘OFF’) for a duration of between 1-15 seconds on each channel for a duration of 1-15

at each programmed event. seconds at each programmed event.

The unit leaves the factory set for a single The unit leaves the factory with both channels

pulse of 5 seconds duration. This can be reset set for a single pulse of 5 seconds duration.

if required (see paragraphs 10 and 11 overleaf) Either or both of these can be reset

independently of each other to give differing

outputs (see paragraphs 10 and 11 overleaf).

Control Pollution Situation Degree 2

Software Classifi cation Class A

Rated Impulse Voltage 2.5kV

Ball Pressure Test 75°C

Aperture

for

cable

entry

4 fi xing

holes

2 cable

clamps

Alternative position

for cable clamp

THIS WAY UP

3 knockouts for

surface cable

entry

MODEL 841 MODEL 842

Spare

N

L

1

2

Rating and

model label

Do not slacken the

C/L

screws on this side of

the terminal block

Terminal block Do not route

Danfoss Randall can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss Randall reserves

the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without

subsequent changes being necessary in specifi cations already agreed.

Polarised

plug

surface mounted

cables through

shaded area

Aperture

for

cable

entry

4 fi xing

holes

2 cable

clamps

Alternative position

for cable clamp

THIS WAY UP

3 knockouts for

surface cable

entry

Spare

N

L

6

5

4

3

2

1

Rating and

model label

C/L

Polarised

plug

Terminal block Do not route

surface mounted

cables through

shaded area

Danfoss Randall Ltd,

Ampthill Road,

Bedford MK42 9ER

Tel: (01234) 364621 Fax: (01234) 219705

Email: danfossrandall@danfoss.com

Website: www.danfoss-randall.co.uk

2

Part No: 3262 Issue 5 12/05

Loading...

Loading...