Page 1

VLT® drives for 690 V now available

down to smallest power sizes

Danfoss makes 690 V installations most cost ecient. The high performance frequency converters

now cover the complete 690 V power range from 1.4 MW down to 1.1 kW.

Danfoss presents the smallest 690 V

enclosure on the market below 7.5 kW

and extends the power range of its

IP 20 drives up to 75 kW with 4 new

enclosure sizes.

Now you can even control 690 V

motors down to 0.37 kW without

expensive over-dimensioned drives or

step down transformers.

Built on the powerful and reliable

VLT® platform, the drives oer system

designers, machine builders, and end

users the eciency enhancing benets oered by Danfoss’ single drive

concept for industrial applications.

Suitable for use on normal TN and IT

(isolated) grids, the IP 20 protected

drives are especially useful in installations within chemical, mining, water/

wastewater and marine applications.

65%

less cabinet space required.

Especially for power sizes

below 7.5 kW, Danfoss

offers a remarkable space

reduction in comparison to

other solutions.

D3h

C3

B4

Danfoss extends the power range of its IP 20 drives up to 75 kW with 4 new enclosure sizes

Feature Benet

Dedicated enclosure sizes down to 1.1 kW No need for large over-dimensioned drive

Operate motors down to 0.37 kW No need for step-down transformer

Smallest size and required space

Side-by-side mounting without derating Saves valuable panel space

Integrated harmonic lters (<40% THDi)

Integrated EMC lter (A1/EN 55011) with up to

150 m screened motor cable

Class 3C3 conformal coating (IEC 60721-3-3)

as standard

Full performance at 50° C ambient temperature

(D-frames 45° C)

Danfoss output lters Matching sinusoidial or du/dt lters

Complete range of 690 V drives up to 1.4 MW

A3

Cost for cabinet and installation

room reduced

Maintain mains quality without

external lters

Provide reliable operation of the installation

without additional external lters

Increase lifetime and reliability in harsh

environments

Secure operation without derating/

over-dimensioning

One drive series covers all

your systems needs

Facts about our products

Page 2

VLT® AutomationDrive frequency

converters can be individually

congured with additional safety

functions through special options and

accessories.

ATEX-certied thermistor input

The PTB ATEX-certied PTC Thermistor

option MCB 112 can be used to monitor

both Ex d and Ex e motors. It is certied

according to IEC 61508 for use in low

demand applications to protect motors

placed in Zones 1, 2, 21 and 22. The

option can be used as the sole protective device of an explosion-proof motor

operated by a frequency converter.

Universal residual

current monitoring

The RCMB20/35 external fault current

monitoring module reliably detects

insulation faults in drives systems

operating on IT or TN mains. In addition

to usual protection against sudden

insulation faults, this module supports

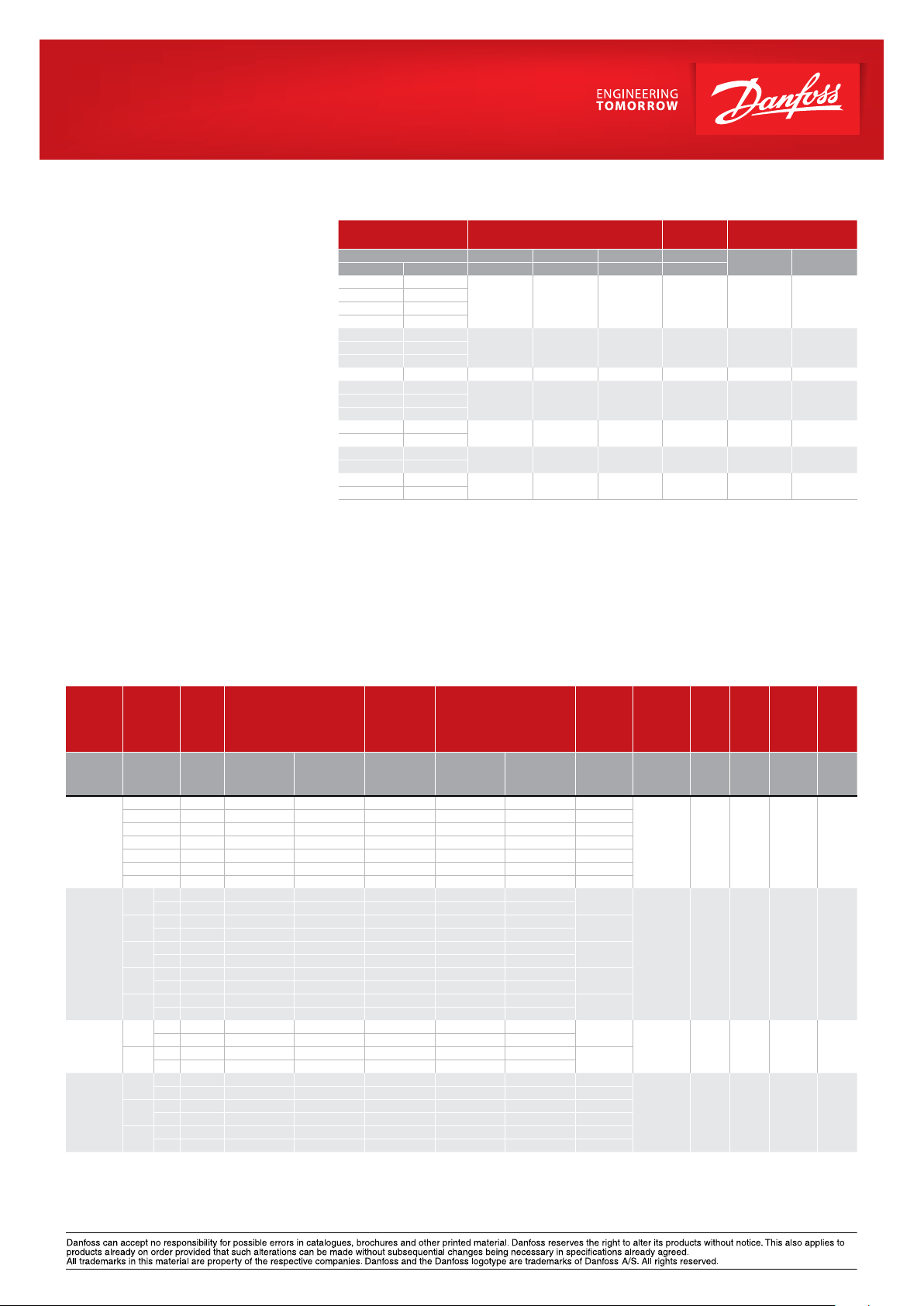

Ordering numbers: Sine Wave Filters

VLT® ratings Filter current rating

690 V @50 Hz @60 Hz @10 0 Hz

kW Current (A) A A A kHz

1.1 1.6

1.5 2.2

2.2 3.2

3.0 4.5

4.0 5.5

7.5 10

11 13 13 12 9 3 130B 3195 130B 3196

15 18

22 27

30 34

37 41

45 52

55 62

75 83

90 100

preventive maintenance by detecting

gradual insulation deterioration in the

4.5 4 3 4 130B7335 13 0B7356

10 9 7 4 130 B728 9 130B73245.5 7. 5

28 26 21 3 13 0B 4112 130 B411318. 5 22

45 42 33 3 13 0B 4114 13 0B 4115

76 72 57 3 13 0B 4116 1 30B4117

115 109 86 3 13 0B 4118 130 B4 119

unexpected and expensive machine

standstills.

equipment in advance, avoiding

Switching

frequency

Part-No .

IP 00 IP 20/23

Technical data

Enclosure

IP 20 [kW]

A3

P11K

P15K

P18K

B4

P22K

P30K

P37K

C3

P45K

N55K

D3h

N75K

N90K

Typ ical

shaft

output

P1K1 1.1 1.6 2.6 1.9 1.4 2.3 44

P1K5 1.5 2.2 3.5 2.6 2.0 3.2 60

P2K2 2.2 3.2 5.1 3.8 2.9 4.6 88

P3K0 3 4.5 7. 2 5.4 4.0 6.5 120

P4K0 4 5.5 8.8 6.6 4.9 7. 9 160

P5K5 5.5 7.5 12 9 6.7 10.8 220

P7K5 7. 5 10 16 12 9.0 14. 4 300

HO 11 13 20.8 15. 5 12.5 20.1

NO 15 18 19. 8 21.5 17. 4 19.1

HO 15 18 28.8 21.5 17.4 2 7.8

NO 18. 5 22 24.2 26.3 21. 2 23.3

HO 18. 5 22 35.2 26.3 21.2 33.9

NO 22 27 29.7 32.3 26.0 28.6

HO 22 27 43.2 32.3 26.0 41.6

NO 30 34 37.4 40.6 32.8 36.0

HO 30 34 51 40.6 32.8 49.2

NO 37 41 45.1 49. 0 39.5 43.5

HO 37 41 61.5 49 39.5 59. 3

NO 45 52 57. 2 62.2 50.1 55.1

HO 45 52 78 62. 2 50.1 75.2

NO 55 62 68.2 74.1 59.8 65.8

HO 55 73 110 87 77. 0 96.3 1057

NO 75 86 95 103 87.0 95.7 1204

HO 75 86 129 103 87. 0 130 .5 120 5

NO 90 108 119 129 109.0 119 .9 1477

HO 90 108 16 2 129 109.0 163 .5 1480

NO 110 131 144 157 128. 0 14 0.8 179 8

VLT® power rating: Power ratings correspond to both HO and NO ratings.

Output current

150% for 1 min (HO)

110% for 1 min (NO)

160% for 1 min

(HO for A3)

Continuous

(3x551-690 V)

[A]

Intermittent

(3x551-690 V)

[A]

Output

power

Continuous

kVA 690 V AC

[kVA]

Max input

current

Continuous

(3x551-690 V)

[A]

Intermittent

(3x551-690 V)

[A]

Estimate d

loss at

rated

maximum

load

[W]

228

285

335

375

480

592

720

Eciency Height Width Depth

Of back

Of back

plate

[mm]

Without

option

A/B [mm]

plate

[mm]

0.96 268 130 205 6.6

0.98 520 230 242 23.5

0.98 550 308 333 35

0.98 909 250 375 62

Max

weight

[kg]

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80

www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFP.300.A4.02 VLT® is a trademark of Danfoss A/S PE-MMSC 2014.09

Loading...

Loading...