Page 1

Instruction Bulletin

Series 90 Intrinsically Safe Control

Installation, Maintenance

Intended Use

This line of Intrinsically Safe Pressure Control Pilots receives a low current input signal from a variety of machine controllers and

converts the current signal into a proportional differential pressure signal suitable to control larger hydraulic equipment in hazardous

locations. The Intrinsically Safe Controls can be added to a Series 90 pump as a standard option or purchased separately.

Danfoss offers five different models of Intrinsically Safe Pressure Control Pilots to accommodate a variety of standard industrial

process controllers. Various combinations of hydraulic nozzle sizes and coil resistances yields a relationship between electrical current

(input) and hydraulic differential pressure (output).

Refer to the Unit Specifications tables on pages three and four for proper selection.

Installation

Mechanical installation

Ensure that the four supplied O-rings are in place on the bottom of the unit. These pressure control pilots are fastened to the second

stage of the control with four M5 x 0.8 x 16 mm socket head screws. Torque to 5 Nm (44 in-lb).

Electrical Installation

A Mil-Spec Connector (MS3102C-14S-2P) provides the means for electronic signal input to the device. Proper selection of the mating

connector to ensure safe operation in a hazardous environment is required (Recommended MS3108E-14S-S, Danfoss Kit number

K08106). A suppression circuit is incorporated in the PCP torque motor cover but by itself does not insure intrinsic safety. An additional

safety barrier used to connect intrinsically safe circuits with non-intrinsically safe circuits must be connected in series between the

PCP and controller. The safety barrier and electrical controller must be isolated from the hazardous area either through use of a purge

enclosure or mounted in a safe area. The intrinsically safe device enclosure grounding terminal must be connected to a robust chassis

ground. The connection must be in accordance with applicable standards where required.

© Danfoss A/S, 2021

11129582 • AN152886481060en000303 •

February 2021

1

Page 2

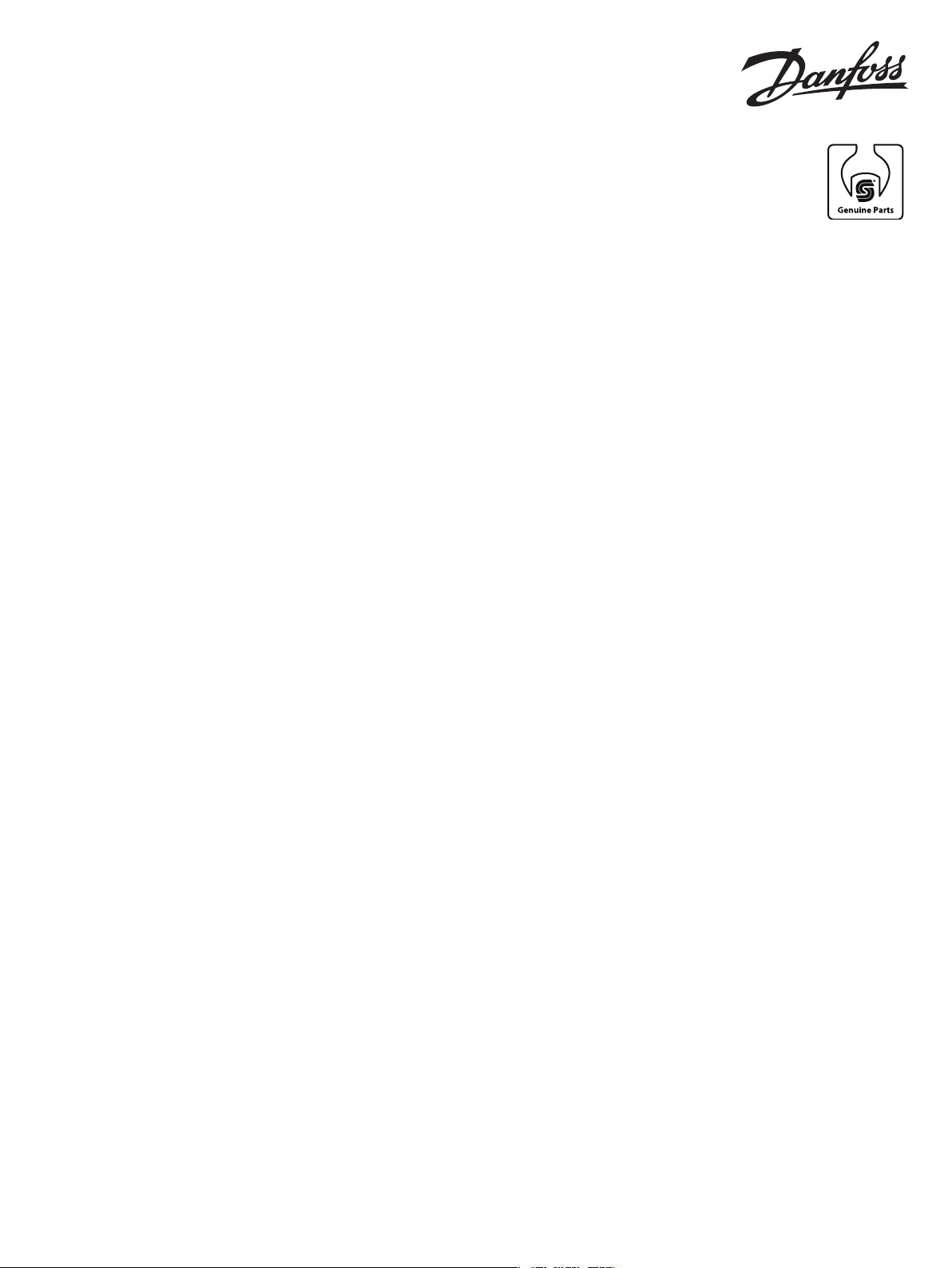

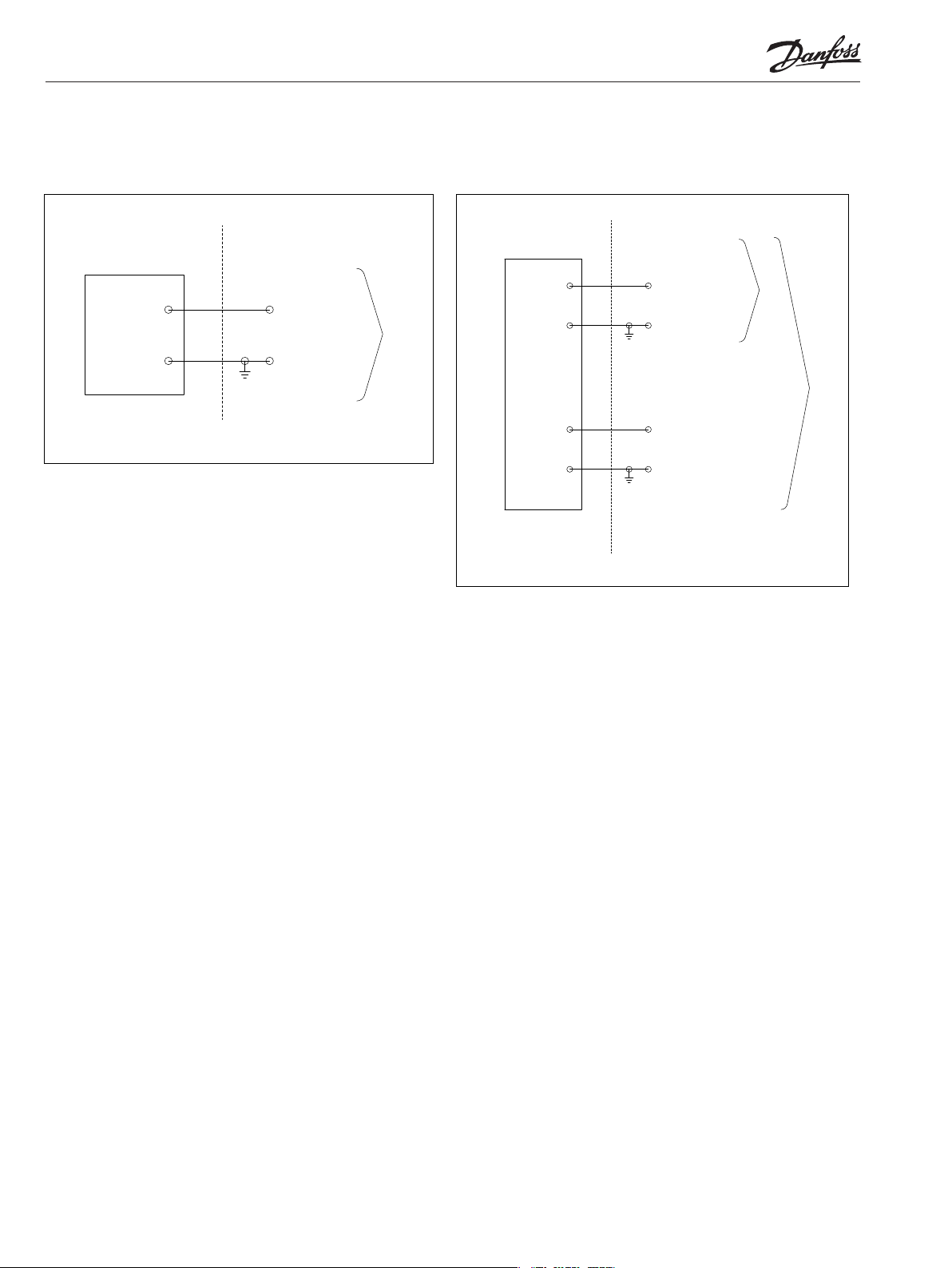

Refer to the following wiring diagrams for proper connections.

Wiring diagram for 11101116 Wiring diagram for 11101126, 11101118, 11101115, 11101106

Hazardous location

A

PCP

B

Exi Cl I, Div 1, Gp CD T4

Ex ia / AEx ia IIB T4 Ga

FM12ATEX0031X II 1 G Ex ia IIB T4 Ga

IECEx FMG 15.0008X Ex ia IIB T4 Ga

Non-hazardous location

V = 16.0 V

I = 110mA

P = 440mW

C = 0.4 µF

L = 0 mH

Adjustment

No adjustment is possible.

Do not attempt to disassemble or adjust the control.

Hazardous location

A

B

Single coil

PCP

C

D

Exi Cl I, Div 1, Gp CD T4

Ex ia / AEx ia IIB T4 Ga

FM12ATEX0031X II 1 G Ex ia IIB T4 Ga

IECEx FMG 15.0008X Ex ia IIB T4 Ga

Non-hazardouz location

V = 8.6 V

I = 250mA

P = 537.5mW

C = 0.4 µF

L = 0 mH

V = 8.6 V

I = 250mA

P = 537.5mW

C = 0.4 µF

L = 0 mH

Single coil

Dual coil

Putting into service

For instructions on putting a pump with the Intrinsically Safe Control in service, refer to Initial Startup Procedure in the Series 90 Pumps

Service Manual, AX152886483063.

Prior t

o installation, inspect packaging and unit for any damage. Do not continue installation if unit has visible signs of damage.

Danfoss is not responsible for the design of the control input circuit outside of the installed Mil-Spec connector. Proper design

on the entire system as noted in the applicable standards is required for safe usage in hazardous environments.

The condition of use

The EDC is designed to be controlled from a DC current source or voltage source. Pulse width modulation (PWM) is not required. But, if

a PMW signal is used, use a carrier frequency between 200 Hz and 4000 Hz. Do not use a pulse current of more than 120% of that

required for full output(refer to unit specifications below).

2

11129582 • AN152886481060en000303 •

February 2021

© Danfoss A/S, 2021

Page 3

A

C

Single coil

P108 686E

Unit specification tables

Pulse Width Modulation

(PWM) The PCP is designed to be controlled from a dc current source or voltage source. If a PWM signal is used, do not use a pulse

current of more than 120% of that required.

Coil resistance

Electrical Characteristics

Single Coil

Coil Resistance

Dual Coil

Coil Resistance

Positive voltage to pin

A produces a pressure

Phasing

rise at output port C1

Positive voltage to pin

B produces a pressure

rise at output port C2

AB

Dual coil

B

D

Model Number

11101126 11101118 11101116 11101115 11101106

A-B 23 Ω at 70° F,

A-B 29 Ω at 200° F

A-B 23 Ω at 70° F,

A-B 29 Ω at 200° F

Positive voltage to pin

A produces a pressure

rise at output port C1

Positive voltage to pin

B produces a pressure

rise at output port C2

A-B 106 Ω at 70° F,

A-B 130 Ω at 200° F

Positive voltage to pin

A produces a pressure

rise at output port C1

Positive voltage to pin

B produces a pressure

rise at output port C2

A-B 20 Ω at 70° F,

A-B 25 Ω at 200° F

C-D 16 Ω at 70° F,

C-D 20 Ω at 200° F

Positive voltage to

pin A or C produces a

pressure rise at output

port C1 Positive

voltage to pin B or D

produces a pressure

rise at output port C2

A-B 20 Ω at 70° F,

A-B 25 Ω at 200° F

C-D 16 Ω at 70° F,

C-D 20 Ω at 200° F

Positive voltage to

pin A or C produces a

pressure rise at output

port C1 Positive

voltage to pin B or D

produces a pressure

rise at output port C2

Current/Voltage Range

Scale Factor

© Danfoss A/S, 2021

up to 145 mA at 3.90

Vdc (linear range)

0.165 ± 0.013 Bar/mA

2.4 ± 0.2 psid/mA

11129582 • AN152886481060en000303 •

up to 190 mA at 4.75

Vdc (linear range)

0.079 ± 0.007 Bar/mA

1.15 ± 0.1 psid / mA

4 mA at 0.50 Vdc

to 20 mA at 2.2 Vdc

(linear range)

0.379 ± 0.034 Bar/mA

5.5 ± 0.5 psid / mA

February 2021

up to 205 mA at 4.50

Vdc (linear range)

0.101 ± 0.010 Bar/mA

1.47 ± 0.15 psid / mA

up to 170 mA at 4.50

Vdc (linear range)

0.054 ± 0.006 Bar/mA

0.78 ± 0.08 psid / mA

3

Page 4

Unit specification tables

Hydraulic Fluid

Oil Viscosity must be in the 40 – 6000 SSU [cSt] range.

Oil Cleanliness of ISO 4406 class 22/18/13 (SAE J1165) or better, under normal operating conditions.

For detailed information on lubricants and cleanliness refer to Hydraulic Fluids and Lubricants BC1528864845240463, and Design

Guidelines for Hydraulic Fluid Cleanliness BC152886482150.

Hydraulic Characteristics

Model Number

11101126 11101118 11101116 11101115 11101106

Maximum supply pressure:

69 bar

1000 psid

69 bar

1000 psid

69 bar

1000 psid

69 bar

1000 psid

69 bar

1000 psid

Recommended range:

Maximum return pressure:

Maximum internal leakage:

at 500 psid supply

Maximum linear psid output

pressure:

Load flow: the output

dierential flow across a 100

psid load pressure drop at

maximum current:

27.6 - 41.4 bar

400 - 600 psid

13.8 bar

200 psid

3.41 lpm

0.90 gpm

24.1 bar at

34.5 bar supply

350 psid at

500 psid supply

>0.738 l/m

> 45 cim

20.7 - 34.5 bar

300 - 500 psid

13.8 bar

200 psid

2.46 lpm

0.65 gpm

15.2 bar at

20.7 bar supply

220 psid at

300 psid supply

>0.0492 l/m

> 30 cim

20.7 - 34.5 bar

300 - 500 psid

13.8 bar

200 psid

2.46 lpm

0.65 gpm

15.2 bar at

20.7 bar supply

220 psid at

300 psid supply

>0.0492 l/m

> 30 cim

34.5 - 41.4 bar

500 - 600 psid

13.8 bar

200 psid

2.46 lpm

0.65 gpm

21.4 bar at

34.5 bar supply

350 psid at

500 psid supply

>0.738 l/m

> 45 cim

20.7 - 34.5 bar

300 - 500 psid

13.8 bar

200 psid

2.46 lpm

0.65 gpm

13.8 bar at

20.7 bar supply

220 psid at

300 psid supply

>0.0492 l/m

> 30 cim

4

11129582 • AN152886481060en000303 •

February 2021

© Danfoss A/S, 2021

Page 5

Maintenance, Overhaul, and Repair

Caution

Part of the enclosure is constructed from plastic. To prevent the risk of electrostatic sparking the plastic surfaces should only be cleaned

with a damp cloth.

No other maintenance is required.

For overhaul or repair return to:

Danfoss Power Solutions

2800 East 13th Street

Ames IA, 50010

A List of Standards to which the Product

was Assessed

For the U.S.

FM3600: 2011; FM3610: 2010; FM3810: 2005; ANSI/IEC 60529: 2004; ANSI/ISA 60079-0: 2009; ANSI/ISA 60079-11: 2011;

For Canada

CAN C22.2 No. 157-92:1992; C22.2 No. 1010.1:2012; CSA-C22.2 No. 60529:2005; CAN/CSA E60079-0:2011; CAN/CSA E60079-11:2011

For ATEX

EN60079-0:2012; EN60079-11:2012; En 60529:1991+Amendment :2000

For IEC

IEC 60079-0:2011 Edition 6; IEC 60079-11 Edition 6

Labels

11101126, 11101118, 11101115, 11101106

Intrinsically Safe / Sécurité intrinséque

Exi, Cl I, Div 1, Gp CD T4

Ex ia / AEx ia IIB

FM12ATEX0031X II 1 G Ex ia IIB T4 Ga

IECEx FMG 15.0008X Ex ia IIB T4 Ga

Install per control drawing: DWG00019588

MODEL NO.

XXXXXXXXXXX

DANFOSS POWER SOLUTIONS (US) COMPANY, 2800 E. 13th St. Ames, IA 50010

Input: 8.6 VDC; 250mA

11101116

Intrinsically Safe / Sécurité intrinséque

Exi, Cl I, Div 1, Gp CD T4

Ex ia / AEx ia IIB

FM12ATEX0031X II 1 G Ex ia IIB T4 Ga

IECEx FMG 15.0008X Ex ia IIB T4 Ga

Install per control drawing: DWG00019589

MODEL NO.

XXXXXXXXXXX

DANFOSS POWER SOLUTIONS (US) COMPANY, 2800 E. 13th St. Ames, IA 50010

Input: 16 VDC; 110mA

T4 Ga

2809

IP66

Made in USA

S/N: A123456789

T4 Ga

2809

IP66

Made in USA

S/N: A123456789

© Danfoss A/S, 2021

11129582 • AN152886481060en000303 •

February 2021

5

Page 6

Danfoss A/S

Teleph

EU DECLARATION OF CONFORMITY

Danfoss A/S

Danfoss Power Solutions

declares under our sole responsibility that the

Product: Pressure Controlled Pilot Valve

Models: 11101106, 11101115, 11101118, 11101126, and 11101116

Description: Receives a low current input signal from a variety of machine controllers and converts the

current signal into a proportional differential pressure signal suitable to control larger

hydraulic equipment

DK-6430 Nordborg

Denmark

CVR nr.: 20 16 57 15

one: +45 7488 2222

Fax: +45 7449 0949

2809

Ex ia IIB T4 IP 66

FM12ATEX0031X

II 1 G

covered by this decl aration is in conformity with the following directive(s), standard(s) or other

normative document(s), provided that the product is used in accordance with our instructions.

Directive Title

2014/34/EU Equipment for Potentially Explosive Atmospheres (ATEX)

Reference Number Title

EN 60079-0:2012 + A11:2013 Explosive Atmospheres – Part 0: Equipment – General requirements

EN 60079-11:2012 Explosive Atmospheres – Part 11: Equipment protection by intrinsic safety “i”

EN 60529:1991 + A1:2000 Degrees of Protection Provided by Enclosures (IP Code)

Notes:

The pressure controlled pilo t valve must be used in accordance with its specifications, especially (but not

limited to) electrical, pressure, temperature, shock, and vibration limits.

FM Approvals, Ltd. Notified Body n o.:

2809

6

Date Issued by Date Approved by

Signature

Name

Title

Danfoss only vouches for the correctness of the English version of this declaration. In the event of the declarationbeing translated into any other

language, the translator concerned shall be liable for the correctness of the translation

11129582 • AN152886481060en000303 •

Signature

Name

Title

February 2021

© Danfoss A/S, 2021

Loading...

Loading...