Page 1

Unit Specication

11028312

Hall Eect Pulse Pickup

3500 Annapolis Lane North, Minneapolis, MN 55447

Telephone: (763) 509-2084 Fax: (763) 559-0108

GENERAL DESCRIPTION

The 11028312 is a sealed xed position, Hall eect pulse pickup. It is intended to be mounted in the case of a 51 series cartridge

motor in conjuction with a target ring mounted on the block of the motor. The 11028312 is designed to be powered directly from

a battery on either 12 or 24 V systems. This device will be used for speed detection and has limited wire fault detection. Unit has

gold plated contact terminals.

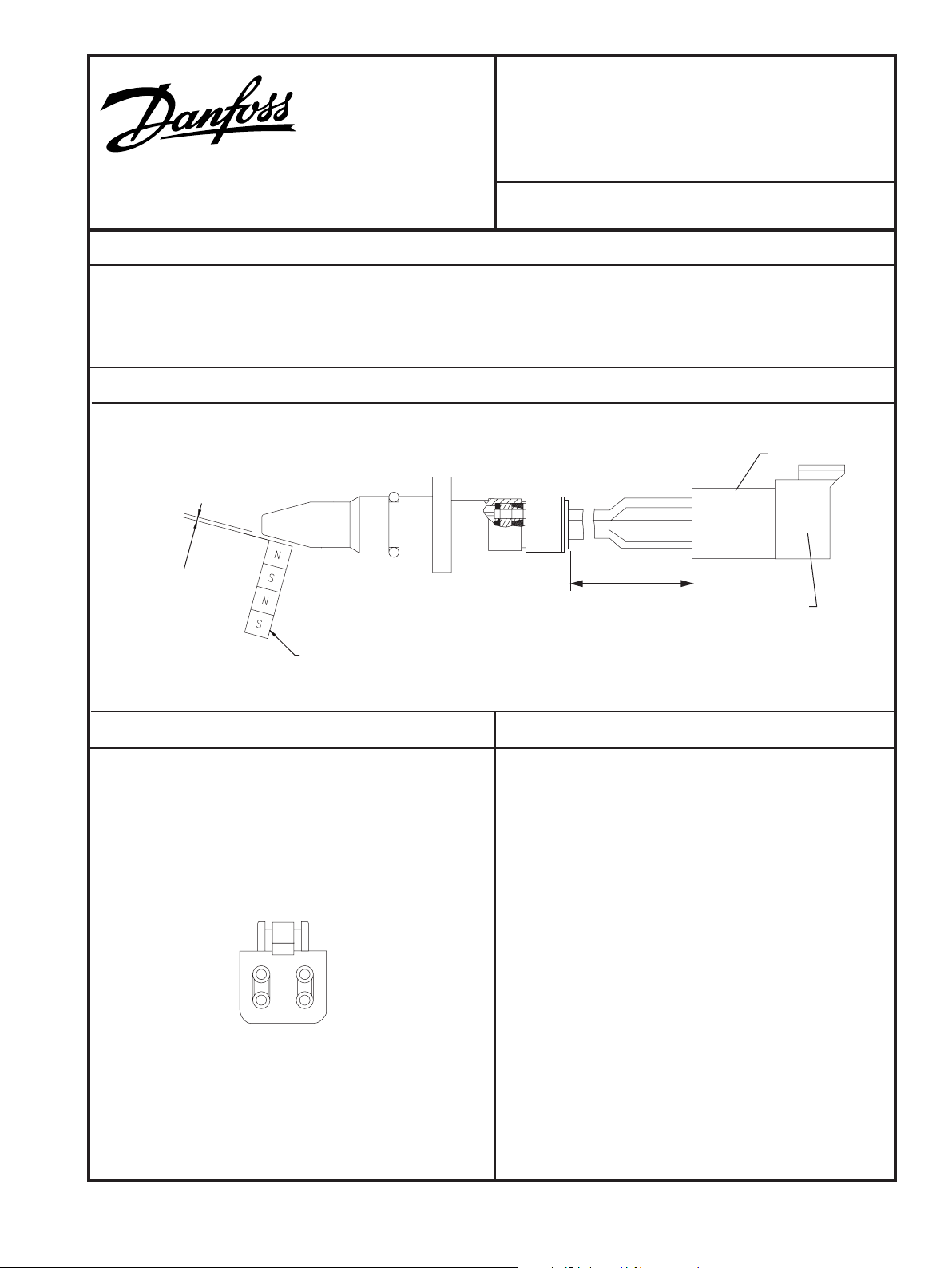

DIMENSIONS

Dimensions of the 11028312 Hall Eect Pulse Pickup.

ISSUE: 1 DATE: June 2007

Receptacle

Red

White

Black

Gap to Speed Ring

Speed Ring

ELECTRICAL CONNECTION

Pin orientation of the mating 4 pin Deutsch® Plug DT Series

connector. (Danfoss part number 11028348).

Red wire: Power+

White wire: Speed

1

2

3

Black wire:

Ground Common

4

No connection

2463

Variable

Electrical connection

with gold plated

contact terminals

ELECTRICAL CHARACTERISTICS

Supply voltage

Battery 7 t

Output voltage in high state

Supply voltage minus 0.5 Vdc

Output voltage in low state

0.5 Vdc, maximum (no load)

M

aximum frequency

15 kHz

M

aximum operation current

20 mA at 1

Load

15 kΩ to both g

Peak reverse voltage

-32 Vdc con

o 32 Vdc

, minimum (no load)

kHz

round and supply

tinuous

2462

Peak transient voltage

±300 Vdc for 2 ms

±200 Vdc for 100 ms

© Danfoss, 2013-09 11029282 • Rev-AA • Jun 2007 1

Copyright 2007, Sauehange.

Page 2

INSTALLATION

Speed Sensor

2464

1. Insert PPU housing, align the hole in mounting ange with mounting hole in block housing.

2. Installation torque is 8 ± 1 N.m (5.9 ± 0.7 ft.lb) for bolt M6X12.

Pulse Pickup installation drawing for directional conical end models, 51 cartridge only.

TROUBLESHOOTING

Tool required to perform the following steps: a volt-ohm-millimeter (VOM) set to read DC volts.

1. Ensure the pulse pickup is installed correctly. See Installation, on this page.

2. Check for pr

3. Check for speed output using a VOM across the black and white connections (pins 3 and 2). Turn pump or motor very slowly

by hand or check output just as the prime mover is coming to a stop. Note a voltage pulse at meter. It will likely be dicult to

read exactly, therefore simply note a pulse (approximately 60 pulses per revolution). If there is no indication of a pulse, replace

the pulse pickup.

oper supply voltage (7 to 32 Vdc) with a VOM across the red and black connections (pins 1 and 3).

© Danfoss, 2013-09 11029282 • Rev-AA • Jun 2007 2

Loading...

Loading...