1/1 Designed and manufactured by Secop for DANFOSS - DEHC.EI.100.E2.02 / 520N0556 August 2011

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifi cations already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Instructions

Electronic Unit Type 105N4220,

160-254V, AC 50-60Hz for BD150F Compressor

Example for compressor speed: external frequency multiplied by 10 (270 Hz ⇒ 2,700 rpm).

If a signal with a frequency according to a speed

above maximum is applied, the compressor

works at maximum speed.

If a DC signal is supplied immediately after

a frequency signal, the compressor speed is

locked until another frequency is applied or the

DC signal is removed.

5. Adaptive control

(AEO - Adaptive Energy Optimizer)

The compressor adjusts its speed in steps to

any increasing or decreasing cooling demand,

within the minimum and maximum speed limits.

If the thermostat switches the compressor ON:

After a 60-minute running time, the speed will

increase stepwise every 15 minutes, depending

on the latest speed used, until the maximum is

reached.

If the thermostat switches the compressor OFF:

After each ON, the compressor either restarts

with lower speed steps than the recently used,

until the minimum is reached, or increases its

speed stepwise, after a new 60-minute running

time.

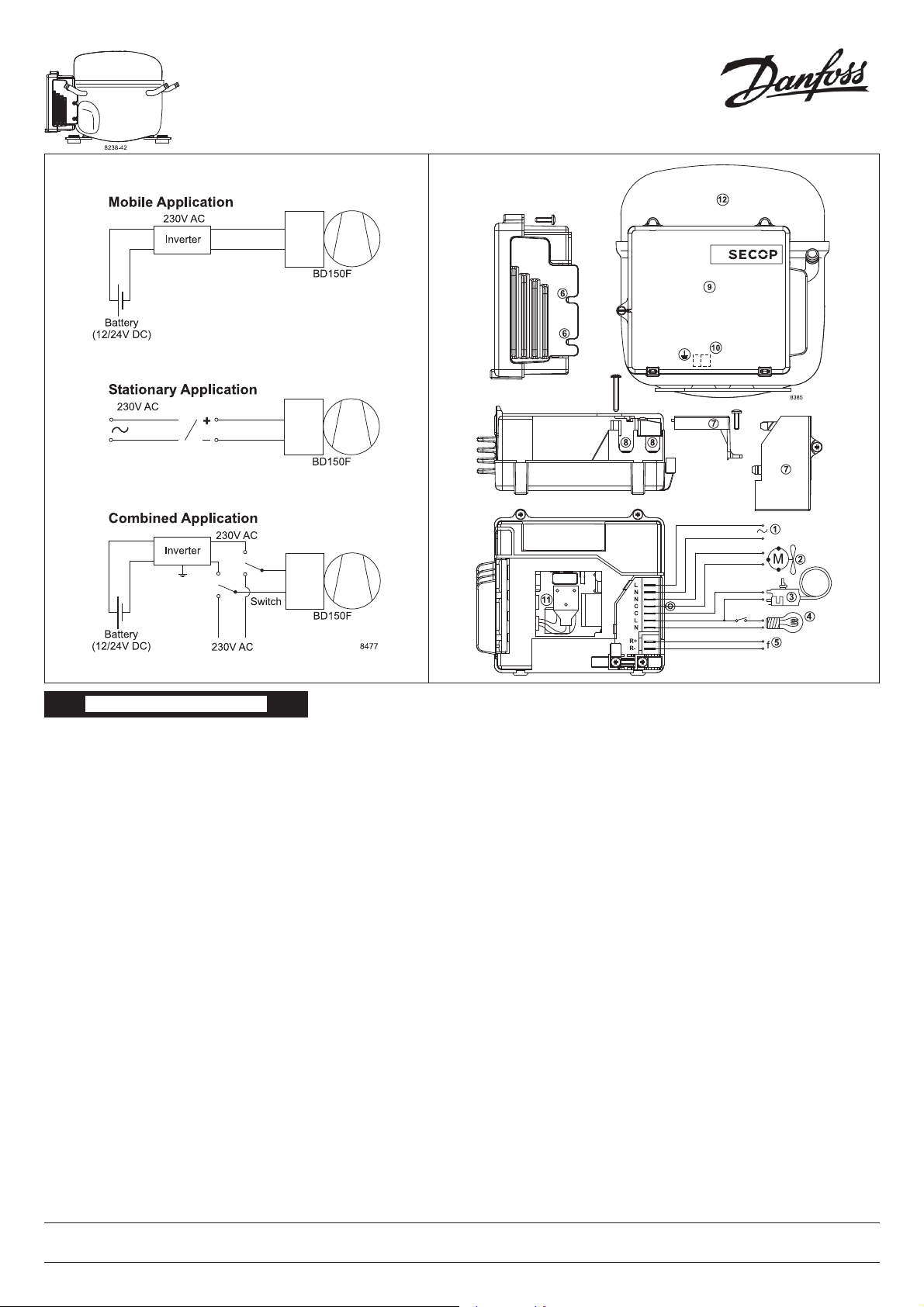

6. Earth connection

Earth connector to be applied to compressor

housing (10). The electronic unit is protected

by the electrical connection heatsink - toothed

washer - screw - compressor housing.

The electronic unit is working within a voltage

range of:

160-254V AC, 50- 60Hz or

12/24V DC with inverter

Max. allowable ambient temperature is 43°C.

The electronic is provided with a built-in thermal

protection which stops the compressor in case

of thermal overload.

Use with 12/24V DC battery in a mobile application is possible by means of an inverter, 12/24V

to 230V AC type, min. 300V peak voltage, min.

300W continuous power output. Examples of

application - see Fig. 1

1. Installation (see Fig. 2)

The connector (11) of the electronic unit (9) has

to be connected to the compressor (12) fi rst. The

total unit is then fi tted to the compressor housing

with two screws and toothed washers through the

recesses in the heatsink unit (6). All other terminals (except the earth connection under point 6)

and cord relief (8) are under the cover (7).

2. Power supply

Power supply L and N:

Power supply (1) is connected to L and N. Earth

connection is connected to terminal (10) on the

compressor housing (12).

3. Fan

Fan N and C:

A fan (2) can be connected to N and C. It will be

operated with power line voltage, and cut in and

out with the compressor if a conventional thermostat is used.

4. Thermostat connection (3) light connection (4)

The unit has 3 connec ti on options for thermostats.

4.1 Voltage signal application on-off (conventional thermostat)

Thermostats C, L and N:

Compressor control is an adaptive control, see

description under point 5.

4.2 Application of a thermostat provided with

DC signal out (min. 5V, max. 15V)

Signal input R+ and R- (5)

(fan operation not possible):

Connection with DC signal on-off to control unit,

with reinforced isolation in control unit (5).

The compressor unit runs in adaptive control

mode, see description under point 5.

4.3 Application of an electronic thermostat

with frequency output (min. 5V, max. 15V)

Signal input R+ and R- (5)

(fan connection not possible):

The refrigerator thermostat has to supply the

control unit (9) with a square signal (min. pulse

width 200 µs). The input terminals are reinforced

isolated. If the frequency is more than 100 Hz the

compressor goes into external reference control

mode. The compressor speed is con-trolled by

the external frequency (adaptive control is disabled). The control unit remains in this mode until

the power supply is disconnected. The compressor stops with an input signal below 198 Hz (min.

196 Hz, max. 199 Hz).

Compressor operation: if a frequency of above

203 Hz (min. 201 Hz, max. 205 Hz) is supplied,

the compressor starts.

Fig. 1

ENGLISH

Fig. 2

Loading...

Loading...