Page 1

103E5

Electronic Timeswitch

for Controlling Hot Water and Heating

(Including Factory Replacement Units FRU)

Danfoss Heating

Installation and User Guide

Page 2

Index

Installation

Product speci cation 3

Installation 4-6

Wiring 6-9

Replacement 10-11

User

What is a timeswitch 12

Your timeswitch 13

Setting the clock 14

Factory preset programmes 15

Setting the programme - 24 hour 16

Setting the programme - 5/2 day 17

Running the programme 18

Temporary user overrides 19

Battery backup 20

INDEX

Contact details 24

2

®

Certification Mark

Danfoss can accept no responsibility for possible errors in catalogues, brochures, and other printed

material. All trademarks in this material are property of the respective companies. Danfoss and the

Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Page 3

Installation Instructions

Please Note:

This product should only be installed by a quali ed

electrician or competent heating installer, and should be

in accordance with the current edition of the IEEE wiring

regulations.

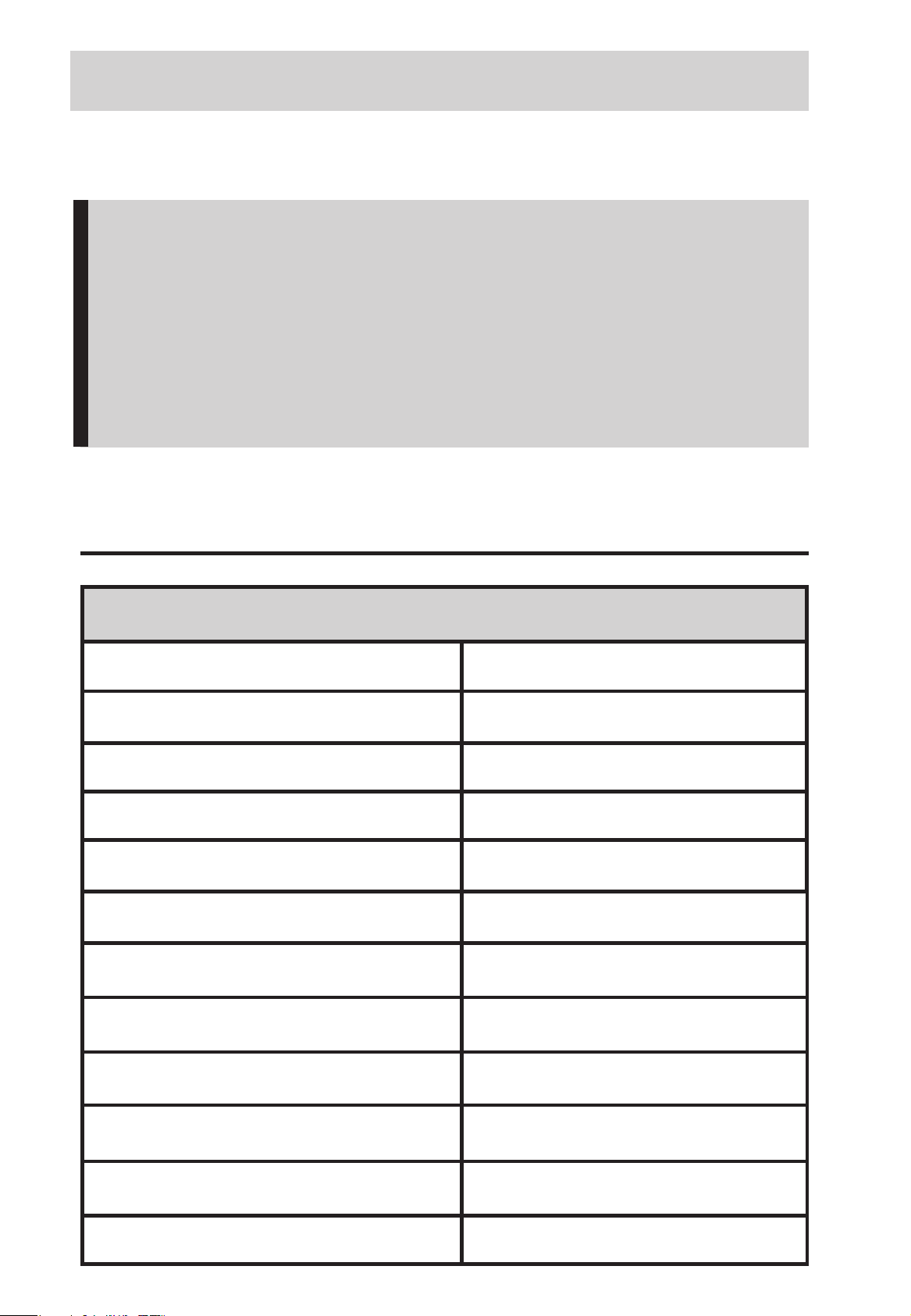

Product speci cation

Speci cation

Power supply 230 Vac ± 15%, 50 Hz

Switching action 1 x SPST, Type 1B

Switch rating 264 Vac, 50/60Hz, 3(1)A

Timing Accuracy ±1 min./month

Power Reserve Minimum 14 days

Enclosure Rating IP30

Max. Ambient Temperature 45°C

Dimensions, mm (W, H, D) 102 x 136 x 47

Speci cation

Design standard EN 60730-2-7

Control Pollution Situation Degree 2

Rated Impulse Voltage 2.5kV

Ball Pressure Test 75°C

3

Page 4

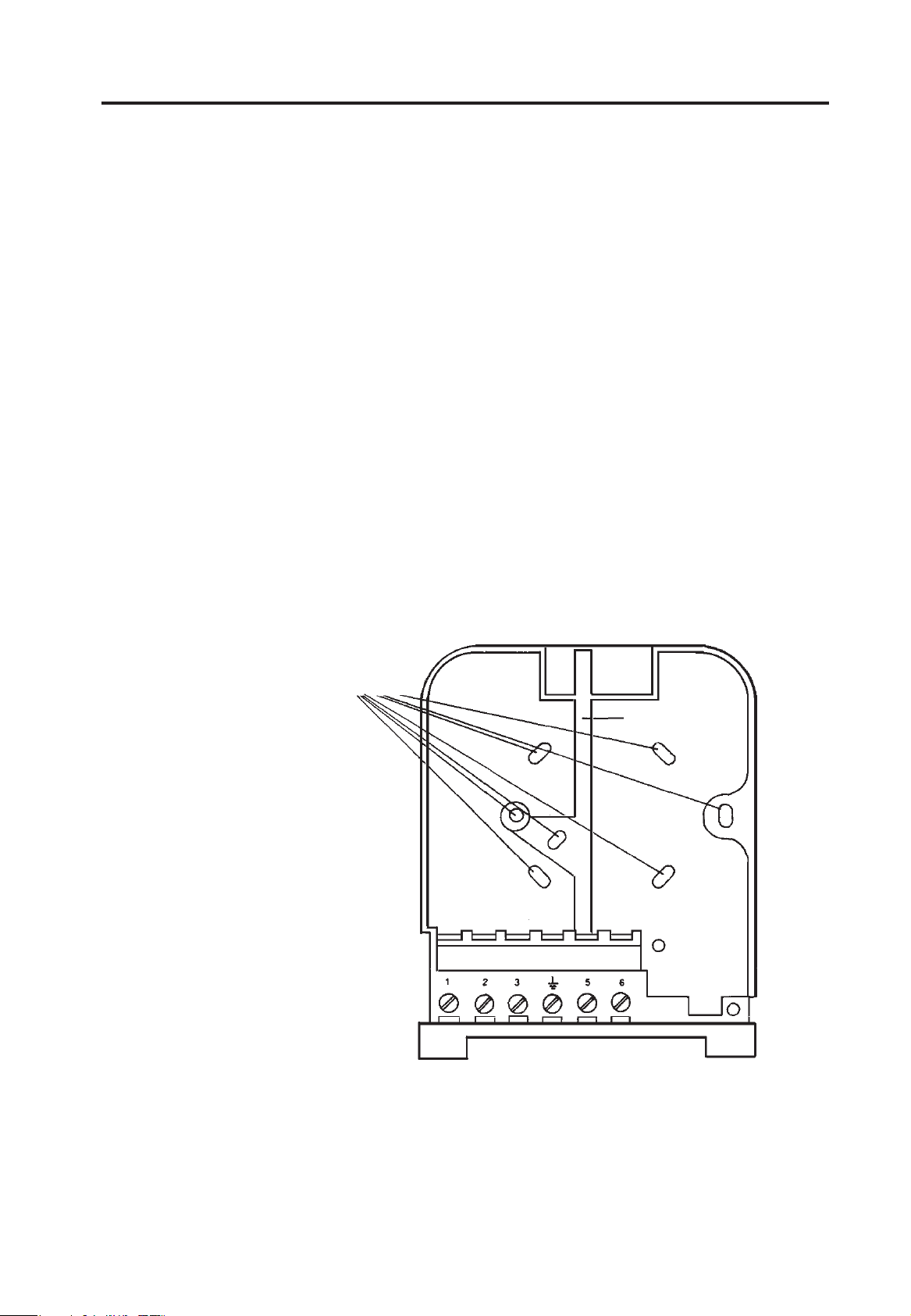

Installation

NB. For FRU units - go straight to point 6.

1. Loosen the xing screw in the base of the unit to release the

Wiring Cover.

2. Holding the unit face downwards, press rmly in the

centre of the wallplate and slide it apart and lift it from the

module.

3. Fix the wallplate and terminal block to the wall, or plaster

box, as required. Ensure that the screw heads do not

protrude beyond the vertical centre rib of the wallplate,

Installation

or this will prevent the module correctly locating onto the

wallplate.

Screw xing holes

(screwheads MUST

NOT protrude above

centre rib)

Vertical centre rib

4

Wallplate & Terminals

4. Surface cables can only enter from below the unit. Cut

an appropriate cable aperture in the wiring cover. If the

wallplate is mounted on a plaster box, cables can enter

from the rear below the terminal block.

Page 5

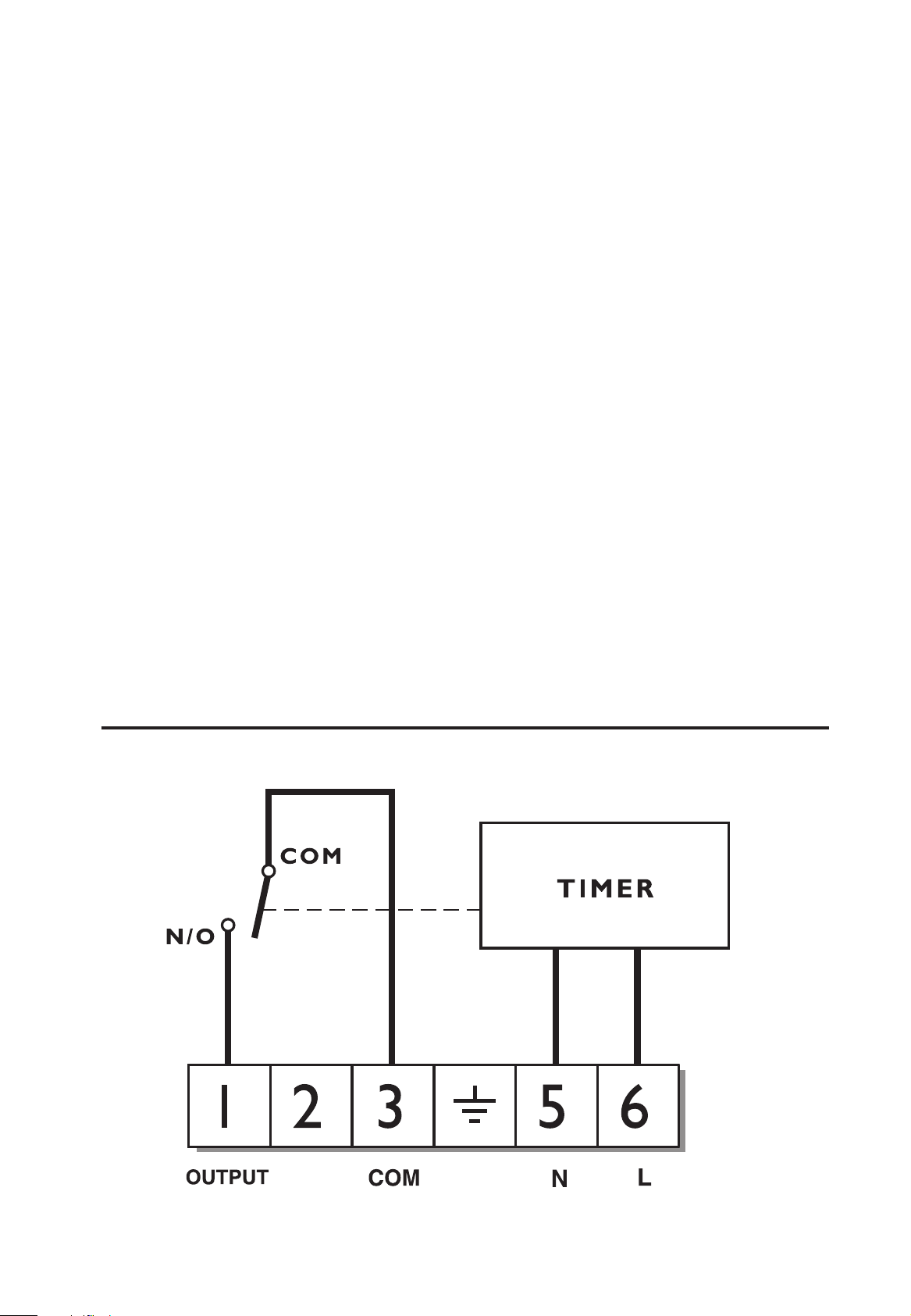

5. Electrical connections are simpli ed by using a Wiring

Centre. However, if this is not used, the wallplate terminal

identi cation is as shown.

LOAD

ON SPARE COM N L

123 5 6

Mains Supply

(via 3 amp. fuse)

If the system being controlled is 230 Vac then terminals

3 and L must be linked with insulated cable capable of

carrying full load current. Whilst the unit does not require

an earth connection, a terminal is provided on the wallplate

for earth continuity purposes.

6. Referring to the wiring diagrams on page 6-9, connect the

unit as shown.

7. Find out from the user whether the unit is required to

operate in 24-hour mode (factory preset) or weekday/

weekend mode (5/2 day). To convert to 5/2 day mode

remove the small two-way connector from the pins towards

the left of the recess on the rear of the module, then press

the SELECT/ADVANCE/+/- buttons all at the same time to

RESET the unit.

8. Ensure all dust and debris are cleared from the area. Plug

the module into the wallplate by locating it onto the

wallplate and, when ush with it, sliding it down, ensure

the hook at the top of the wallplate engages with the slot

at the back of the module.

Installation

9. Before setting the programme, check the unit and circuit.

Press the SELECT button until the bar in the display lines up

with the word ON. Adjust the remote thermostats to check

the system operates correctly.

5

Page 6

10. Then press the SELECT button until the bar lines up with

the word OFF and check the system does not operate.

11. When the circuit check has been completed, replace the

wiring cover and tighten the xing screw. Cut any cable

aperture in the wiring cover which may be necessary to

accommodate surface mounted cables.

12. Finally set time of day and programmes required, noting

that the unit is supplied with a pre-set programme, as

stated on Page 14.

Wiring

Wiring

6

103, 103E5

Page 7

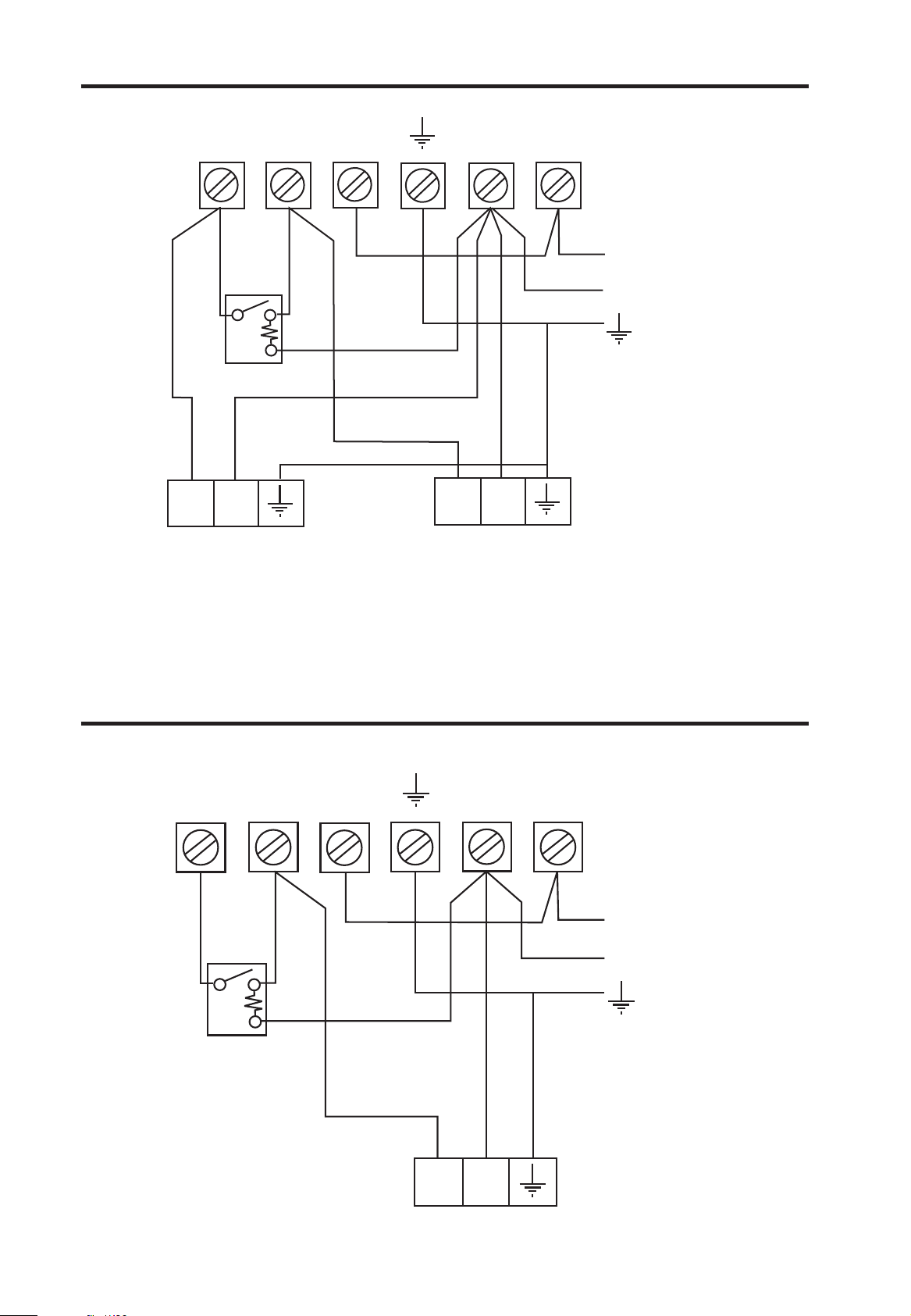

Typical Gravity DHW with pumped heating

COM

L N

1

ROOM

' STAT

23

LINK

CALL

N

BOILER

TERMINALS

56

L N

103E5

TERMINALS

L

MAINS

SUPPLY

N

FUSED

3 AMP

PUMP

TERMINALS

Typical control of Pump for Central Heating on a Solid

Fuel System

3

LINK

5

6

103E5

TERMINALS

L

MAINS

SUPPLY

N

FUSED

3 AMP

COM

1

ROOM

' STAT

2

CALL

N

Wiring

L N

PUMP

TERMINALS

7

Page 8

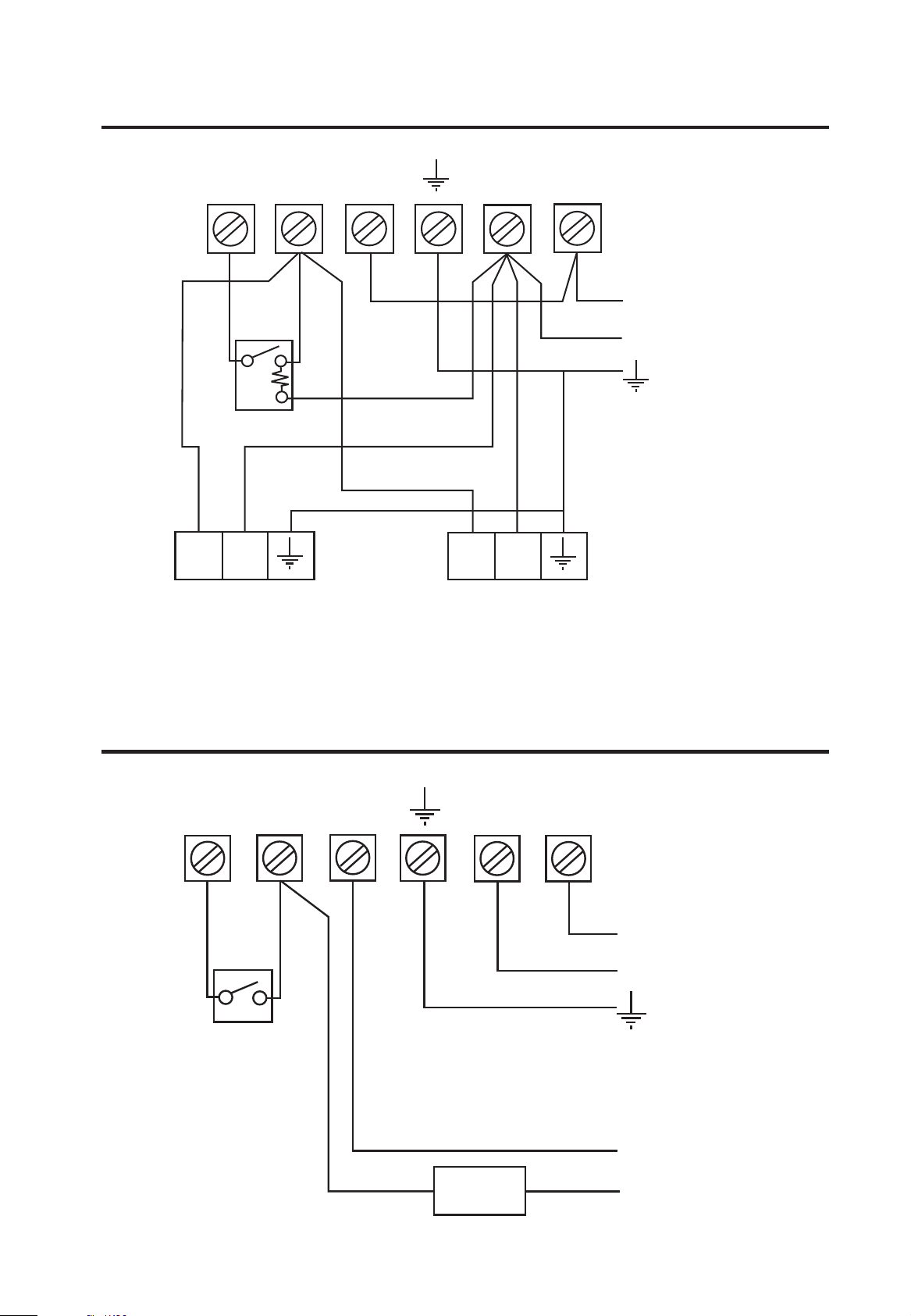

Typical Heating Only system, Boiler and Pump

control

1

COM

L N

ROOM

' STAT

23

LINK

CALL

N

BOILER

TERMINALS

56

L N

103E5

TERMINALS

L

MAINS

SUPPLY

N

FUSED

3 AMP

PUMP

TERMINALS

Typical control of Low Voltage System requiring

voltage free contacts

1

2

3

56

103E5

TERMINALS

Wiring

COM

LOW

VOLTAGE

ROOM

' STAT

CALL

L

N

MAINS

SUPPLY

FUSED

3 AMP

8

LOAD

LOW

VOLTAGE

SUPPLY

Page 9

Typical control of Heating when provided by

Combination type Boiler

COM

1

ROOM

' STAT

23

CALL

N

INPUT

OUTPUT

56

103E5

TERMINALS

NL

COMBI BOILER

TERMINALS

L

N

MAINS

SUPPLY

FUSED

3 AMP

Typical Heating & Hot Water control system using 3 port

mid-position valve

ROOM

' STAT

WHITE

OR

BROWN

1

BLUE

23

CYL.

' STAT

N

SAT

GREY

LINK

COM

CALL

RED OR

ORANGE

56

103E5

TERMINALS

BOILER &

PUMP

TERMINALS

L

N

MAINS

SUPPLY

FUSED

3 AMP

Wiring

MID-POSITION VALVE

L N

9

Page 10

should be terminated

required where these discon-

An additional terminal block is

nected leads (or pairs of leads)

MAINS SUPPLY

(via 3 amp fuse)

MO-

TOR

N

SWITCH

LIVE

LIVE

10

LOAD

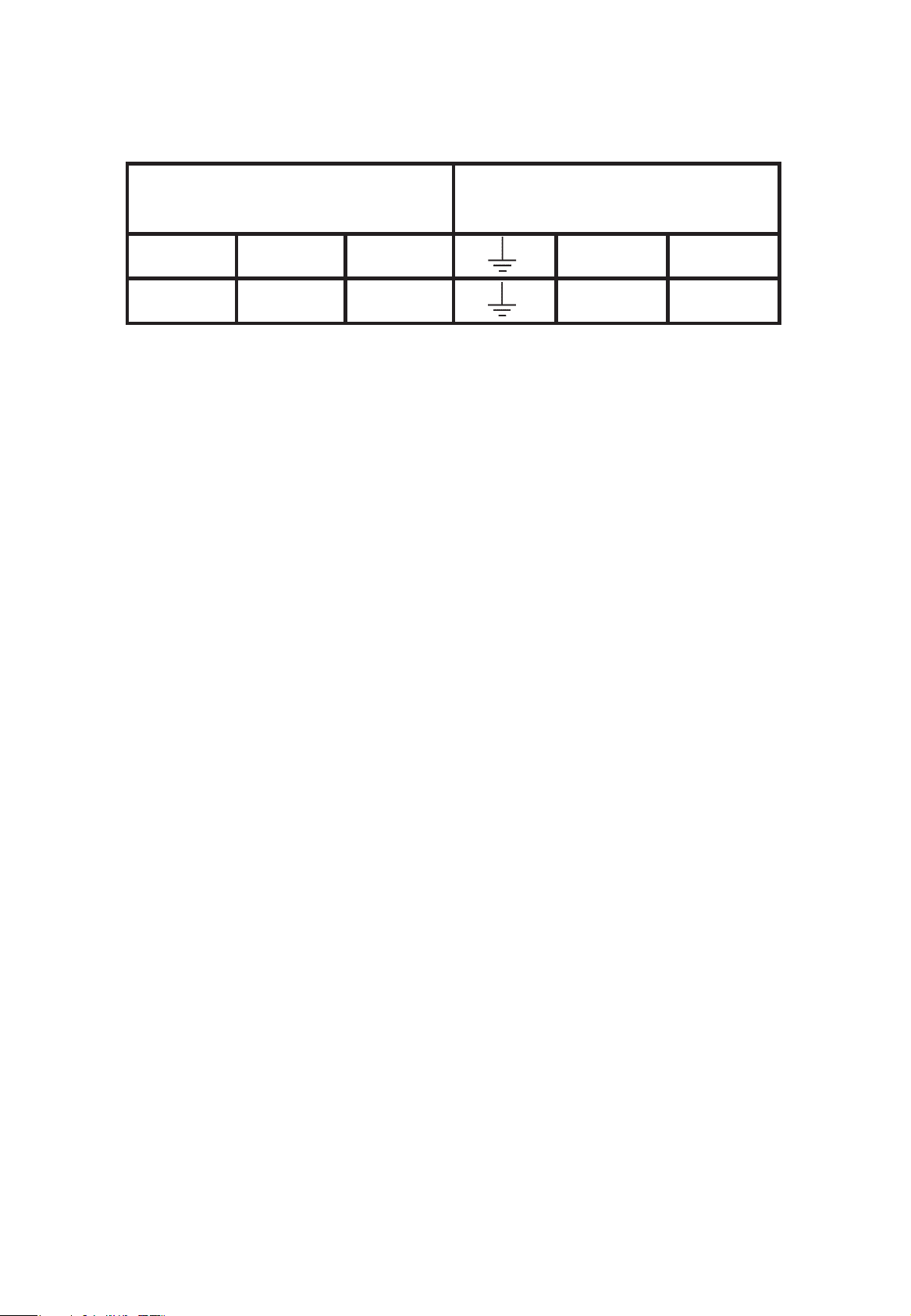

Replacement

ON SPARE COM

DANFOSS RANDALL

103E5

1 2 3 5 (N) 6 (L) A B C D

RANDALL 103, 103E, 103E7 1 2 3 5 6

RANDALL 3020 4 2 - 1,7 6 3 5

RANDALL TSR2 4 5 - 3 1,2 6 7

GRASSLIN 45, 45A, 45E 4 - 3 2 1

4 2 3 N L,1 5

HORSTMANN 424 EMERALD

& PEARL AUTO RANGE

413 NL256

LOAD - - N L

HORSTMANN 423 PEARL,

EMERALD & TOPAZ

SANGAMO S254 Form 2S408

LOAD -

SANGAMO S409 Form 8 2 1 6 3,N 5,L

Form 5, S251 Form 2

SANGAMO S610 F2, S611 F2,

S612 F2, S408 F4, S408 F6,

S253 F2, S255 F2

SANGAMO/RANDALL SET 1 4 2 5 N L

SMITHS IND. MKI, MKII P3 P1 P2 N L

Page 11

4,5 3 - 1 2 6

SMITHS IND.

CENTROLLER 30

4,5 3 - 1 2

SMITHS IND.

CENTROLLER 40

734 21891011

LOAD - LINE N L

SWITCHMASTER 300 1 2 4 N L 3

TOWERCHRON TC

VENNER

VENNERETTE MKIIA

1-4 23

VENNER

VENNERETTE MKIVA

VENNER VENNERON VEN-

4-1 32

NERON P

Replacement

11

Page 12

The text below has been edited and approved by the Plain

English Campaign, who has issued a Crystal Mark to be

displayed with it.

What is a programmer?

... an explanation for householders.

Programmers allow you to set ‘On’ and ‘O ’ time periods.

Some models switch the central heating and domestic hot

water on and o at the same time, while others allow the

domestic hot water and heating to come on and go o at

di erent times.

Set the ‘On’ and ‘O ’ time periods to suit your own lifestyle.

On some programmers you must also set whether you want

the heating and hot water to run continuously, run under the

chosen ‘On’ and ‘O ’ heating periods, or be permanently o .

The time on the programmer must be correct. Some types

have to be adjusted in spring and autumn at the changes

What is a programmer?

between Greenwich Mean Time and British Summer Time.

You may be able to temporarily adjust the heating

programme, for example, ‘Override’, ‘Advance’ or ‘Boost’. These

are explained in the manufacturer’s instructions.

The heating will not work if the room thermostat has switched

the heating o . And, if you have a hot-water cylinder, the

water heating will not work if the cylinder thermostat detects

that the hot water has reached the correct temperature.

Please note: A timeswitch is a single channel programmer. It will

allow you to set your system’s On and O periods.

12

Page 13

User Instructions

Your timeswitch

Your 103E5 timeswitch controls your hot water and heating

together, turning them on and o at the same times

.

The 103E5 can provide 3 ON periods and 3 OFF periods each day

and can o er either 24 hour control (same programme for each

day of the week) or 5/2 day control (one set of programmes for

weekdays and a di erent set for weekends)

-

+

PROGRAMME

Overview

13

Page 14

Before you start

Open the ap on the front of

the unit.

Press all four buttons

(SELECT / ADVANCE / + / -)

at the same time

This will reset the unit, reinstate the

preset programmes and set the time to

12:00pm on Monday.

-

+

PROGRAMME

Setting the clock

Press PROGRAMME once

Use + and – buttons to set the

correct time

When time is correct press

PROGRAMME again.

Setting the time & the programme

In 24 hour mode this will take you

straight to programming mode,

where you can select your own ON

-

+

+

PROGRAMME

-

PROGRAMME

14

and OFF times.

In 5/2 day mode this will rst allow you to programme the

correct DAY. To do this:

use the + or – buttons to select the correct day

press PROGRAMME again to enter RUN mode

Page 15

Factory Presets

The unit is supplied with the following preset programme

which will be active after the unit has been reset.

Mon-Fri or All

days in 24hr mode

1st ON 6.30am 7.30am

1st OFF 8.30am 10.00am

2nd ON 12.00pm 12.00pm

2nd OFF 12.00pm 12.00pm

3rd ON 5.00pm 5.00pm

3rd OFF 10.30pm 10.30pm

N.B. 2nd ON and 2nd OFF are set to the same time. These 2

(5/2day mode only*)

Sat-Sun*

times are ignored by the programme therefore the heating will

just come on once in the morning and once in the evening. If

you want the heating to come on in the middle of the day set

the 2nd ON and 2nd OFF to the times you require.

Accepting the preset times

If you are happy to use the settings above, you don’t need to

do anything else.

To accept the presets press the PROGRAMME button until the

colon in the display begins to ash.

Factory preset programmes

Your unit is now in RUN mode.

15

Page 16

Programming event times in 24 hour mode

You can programme your timeswitch to come on and go o up to

3 times each day, to suit your requirements.

Press PROGRAMME until 1 (Event

1

1) shows along the top of the

display.

Use the + and - buttons to set the

time you want your system to rst

come on in the morning

Press PROGRAMME again to move to the next step (Event

2)

Use the + and - buttons to set the time you want your

system to rst go o .

Continue using the PROGRAMME and +/- buttons in this

way to set the ON/OFF times for events 3-6 (2nd ON/OFF

& 3rd ON/OFF).

N.B. It is not possible to programme times out of sequence.

If you do not press a button at all for 3 or 4 minutes the unit

will automatically return to RUN mode.

Programming the unit - 24 hour mode

16

Page 17

Programming event times in 5/2 day mode

You can programme your timeswitch to come on and go of up

to 3 times each day, to suit your requirements, with one set of

programmes for weekdays and a di erent set of programmes for

the weekend.

Weekdays (MOTUWETHFR)

Press PROGRAMME until 1 (Event 1)

1

shows along the top of the display

and MOTUWETHFR shows along

the bottom.

Use the + and - buttons to set the time you want your

system to rst come on in the morning.

Press PROGRAMME again to move to Event 2

Use the + and - buttons to set the time you want your

system to rst go o .

Continue using the PROGRAMME and +/- buttons in this

way to set the ON/OFF times for events 3-6 for weekdays.

Weekend (SASU)

Press PROGRAMME again until 1

(Event 1) shows along the top of the

display and SASU shows along the

bottom of the display.

Use the PROGRAMME and +/- buttons to set the ON/

OFF times for the weekend.

If at any time you wish to return to the factory preset

programme, press SELECT / ADVANCE / + / - buttons together

at the same time to reset the unit.

N.B. It is not possible to programme times out of sequence.

Programming the unit - 5/2 day mode

17

Page 18

Running your programme

ON

y

O

n

AUTO

s

The 103E5 controls your hot water and heating together, turning

them on and o at the same times.

To run the central heating and hot water programme press the

SELECT button.

As you press SELECT a bar on the display will move between

ON, OFF, ALLDAY and AUTO

OFF = the hot water/heating will not come on

AUTO = the hot water/heating will come on and

ALLDAY = the unit will come on at the rst

RUN mode

ON = the hot water/heating will remain on

= the hot water/heating will remain on

constantly

constantl

FF = the hot water/heating will not come o

= the hot water/heating will come on and

o o according to the programmed time

go o according to the programmed times

LLDAY = the unit will come on at the rst

programmed ON and will remain on until the last

programmed ON and will remain on until the last

programmed OFF

programmed OFF

18

Select the option you require, depending on your

circumstances, time of year, etc.

Page 19

Temporary User Overrides

Sometimes you may need to change the way you use your

timeswitch temporarily, i.e due to unusually cold weather. The

103E5 has two convenient overrides which can be selected

without a ecting the set programme.

Override

buttons

+1HOUR

Press +1HOUR once if you need an extra hour of

operation

If the system is o it will come on for an hour. If it is already

on it will add an extra hour so the system stays on for an

extra hour.

To cancel the override press +1HOUR again.

ADVANCE (only during AUTO mode)

Press the ADVANCE button once to advance to the next

programmed event.

Override buttons

If the system is on it will go o . If it is o it will come on. The

set programme will resume at the next programmed ON/

OFF time.

To cancel the override press ADVANCE again.

19

Page 20

Battery backup

In the event of a power cut, the built-in lithium battery will

keep your time and programme settings for up to 15 days.

After 15 days without mains power the unit will switch o

and two dots will show in the display. However all your

programmed on/o times will be remembered.

When the mains power is restored, the unit will need to be

reactivated by pressing the PROGRAMME button, and the

time and day will need to be set (see page 14).

Battery backup

20

Page 21

212223

Page 22

Page 23

Page 24

Still having problems?

Call your local heating engineer:

Name:

Tel:

For problems relating to your heating controls ...

Visit our website:

www.heating.danfoss.co.uk

Email our technical department:

ukheating.technical@danfoss.com

Call our technical department

01234 320 256

(9:00-5:00 Mon-Thurs, 9:00-4:30 Fri)

For a large print version of these instructions

please contact the Marketing Services

Department on 01234 364 621.

24

Danfoss Randall Ltd

Ampthill Road

Bedford

MK42 9ER

Tel: 01234 364621

Fax: 01234 219705

Part No 2468v05 Issue 5 01/15

Loading...

Loading...