Page 1

August 2011 compressors.danfoss.com - DEHC.EI.100.G6.02 / 520N0232 1/2

Instructions

Electronic Unit for BD35/BD50F Compressors,

101N0500, 12/24V DC & 100-240V AC 50/60Hz

The electronic unit is a multi voltage device. It can

be used in both 12V/24V DC and 100-240V AC

50/60Hz power supply systems. Max. voltage is

17V DC for a 12V DC system and 31.5V DC for

a 24V DC power supply system. Max. voltage is

265V AC and min. 85V AC for an AC power supply

system. Max. ambient temperature is 55°C. The

electronic unit has a built-in thermal protection

which is actuated and stops the compressor operation if the electronic unit temperature becomes

too high (100°C / 212°F on the PCB). Power

consumption is limited to 100W. See datasheet

BD50F for details.

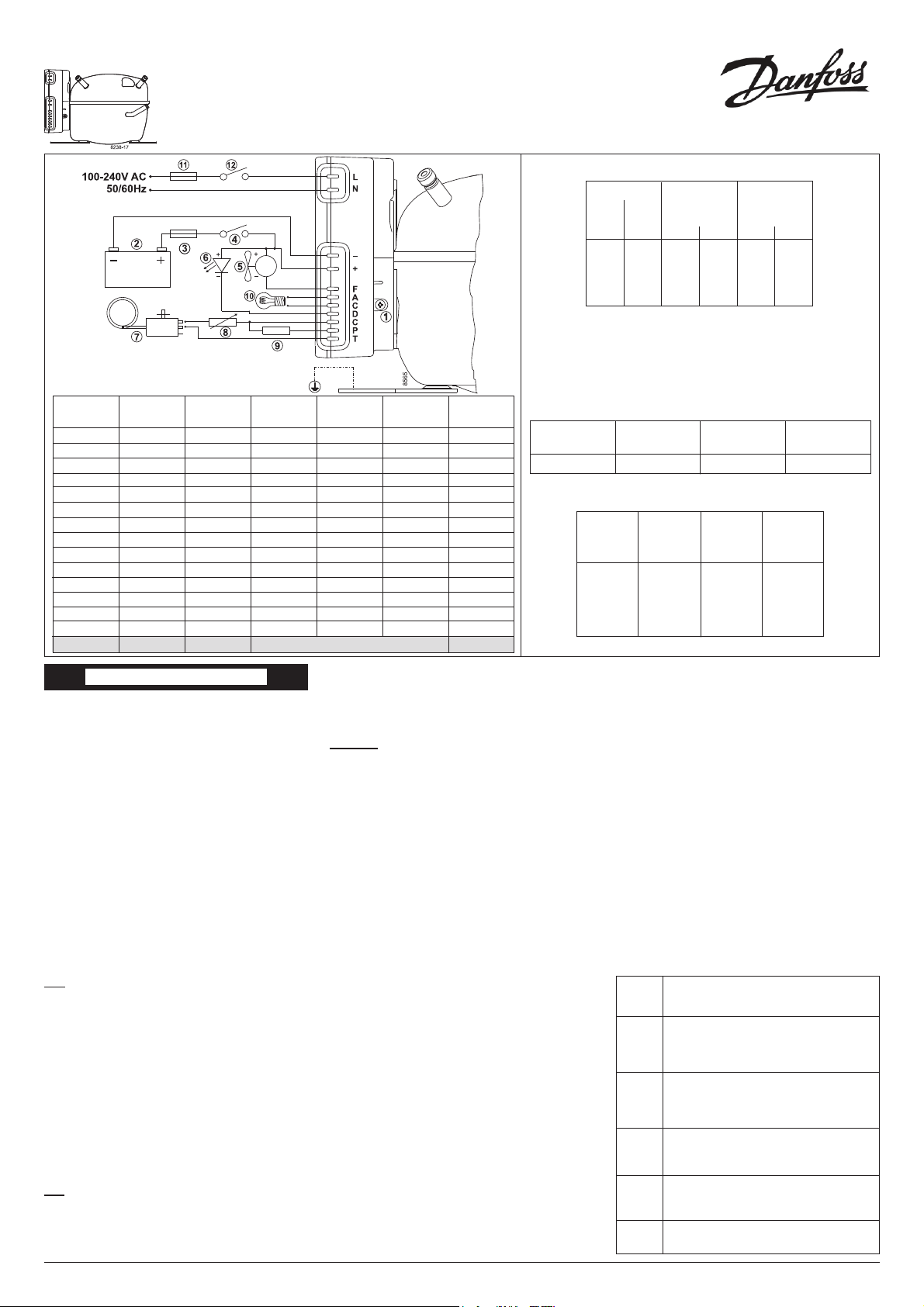

Installation (Fig. 1)

Connect the terminal plug from the electronic unit

to the compressor terminal. Mount the electronic

unit on the compressor by snapping the cover

over the screw head (1).

Power supply (Fig. 1)

DC: The electronic unit must always be connected

directly to the battery poles (2). Connect the plus

to + and the minus to -, otherwise the electronic

unit will not work. The electronic unit is protected

against reverse battery connection.

For protection of the installation, a fuse (3) must

be mounted in the + cable as close to the battery

as possible. It is recommended to use 15A fuses

for 12V and 7.5A fuses for 24V circuits. If a main

switch (4) is used, it should be rated to a current

of min. 20A. The wire dimensions in Fig. 2 must

be observed. Avoid extra junctions in the power

supply system to prevent voltage drop from affecting the battery protection setting.

AC: The wires must be connected to the terminal

marked L and N on the electronic unit. Nominal

voltages from 100 to 240 VAC 50/60Hz. Upper

safety cut-out limit = 270V AC and lower limit 80V

AC. A 4A fuse (11) must be mounted in the live

(L) cable to protect the installation.

If a main switch (12) is used, it should be rated to

a current of min. 6A. The wire dimensions must

be min. 0.75 mm2 or AWG 18.

NB: Earth connection can be used if required.

General: Both the AC and the DC power supply

can be connected to the electronic unit at the

same time. In this case, AC will be preferred power

supply source. If the AC power supply is disconnected or drop below 85V AC on a 12V DC supply

system, a time delay of 1 min. will be activated

before the compressor continues on DC power

supply. If AC power supply is re-established there

will be no delay in compressor operation.

Battery protection (Fig. 1)

The compressor stops and restarts again according to the designated voltage limits measured on

the + and - terminals of the electronic unit.

The standard settings for 12V and 24V power

supply systems appear from Fig. 3.

Other settings are optional if a connection which

includes a resistor (9) is established between

terminals C and P. See manual.

Thermostat (Fig. 1)

The thermostat (7) is connected between the terminals C and T. Without any resistor in the control

circuit, the compressor will run with a fi xed speed

of 2,000 rpm when the thermostat is switched on.

Other fi xed compressor speeds in the range between 2,000 and 3,500 rpm can be obtained when

a resistor (8) is installed to adjust the current (mA)

of the control circuit. Resistor values for various

motor speeds appear from Fig. 5.

Fan (optional, Fig. 1)

A fan (5) can be connected between the terminals

+ and F. Connect the plus to + and the minus to

F. Since the output voltage between the terminals

+ and F is always regulated to 12V,

a 12V fan must be used for both 12V and 24V

power supply systems.

Fig. 1

Optional battery

protection settings DC

Fig. 4

ENGLISH

The fan output can supply a continuous current

of 0.5A

avg

. A higher current draw is allowed for 2

seconds during start.

Lamp (optional, Fig. 1)

A 12V DC 5 Watt lamp (10) can be connected

between the terminals A and C. The output voltage between the terminals A and C is always

regulated to 12V DC. A 12V DC lamp must be

used for both 12V and 24V power supply systems.The lamp output can supply a continuous

current of 0.5A

avg

.

LED (optional, Fig. 1)

A 10mA light emitting diode (LED) (6) can be

connected between the terminals + and D. If the

electronic unit records an operational error, the

diode will fl ash a number of times. The number of

fl ashes depends on what kind of operational error

was recorded. Each fl ash will last ¼ second. After

the actual number of fl ashes there will be a delay

with no fl ashes, so that the sequence for each error recording is repeated every 4 seconds.

24V max.

Voltage

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

31.5

24V cut-in

V

22.7

22.9

23.2

23.4

23.7

23.9

24.2

24.5

24.7

25.0

25.2

25.5

25.7

26.0

24V cut-out

V

21.3

21.5

21.8

22.0

22.3

22.5

22.8

23.0

23.3

23.6

23.8

24.1

24.3

24.6

12V max.

Voltage

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

12V cut-in

V

10.9

11.0

11.1

11.3

11.4

11.5

11.7

11.8

11.9

12.0

12.2

12.3

12.4

12.5

10.9

12V cut-out

V

9.6

9.7

9.9

10.0

10.1

10.2

10.4

10.5

10.6

10.8

10.9

11.0

11.1

11.3

9.6

Resistor

(9) kΩ

0

1.6

2.4

3.6

4.7

6.2

8.2

11

14

18

24

33

47

82

220

Number

of

fl ashes

Error type

Thermal cut-out of electronic unit

(If the refrigeration system has been too hea vi ly

loaded or if the ambient temperature is high, the

electronic unit will run too hot).

5

Minimum motor speed error

(If the refrigeration system is too heavily loaded,

the motor cannot maintain minimum speed

1,850 rpm).

4

Motor start error3

(The rotor is blocked or the differential pressure

in the refrigeration system is too high (>5 bar)).

Fan over-current cut-out2

(The fan loads the electronic unit with more

than 1A

peak

).

1

Battery protection cut-out

(The voltage is outside the cut-out setting).

Fig. 3

24V cut-out

V

22.8

12V cut-in

V

11.7

24V cut - in

V

24.2

12V cut-out

V

10.4

Standard battery protection settings DC

Compressor speed

Electronic

unit

101N0500

Motor

speed

rpm

2,000

2,500

3,000

3,500

Resistor

(8) Ω

(calculated)

0

277

692

1523

Contr.circ.

current

mA

5

4

3

2

Fig. 5

Fig. 2

Wire dimensions DC

*Length between battery and electronic unit

Max length*

24V DC

operation

ft. m

16 5

26 8

39 12

66 20

Size

AWG Cross

section

Gauge mm

2

12 2.5

12 4

10 6

8 10

Max length*

12V DC

operation

ft. m

8 2.5

13 4

20 6

33 10

Wire dimensions AC

Cross section min. 0.75 mm2 or AWG 18

Page 2

2/2 Designed and manufactured by Secop for DANFOSS - DEHC.EI.100.G6.02 / 520N0232 August 2011

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifi cations already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

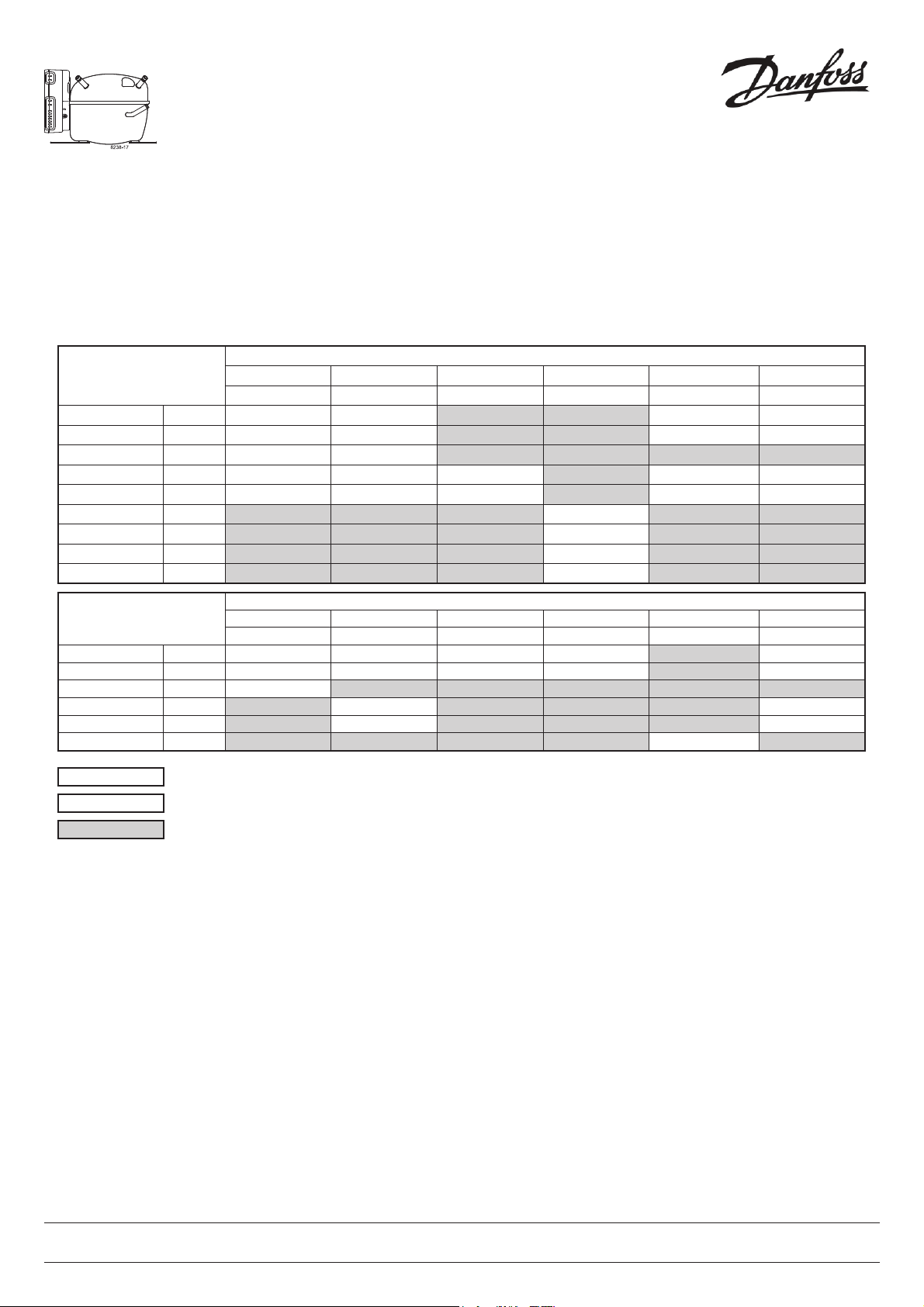

Instructions

Electronic Units for BD Compressors

VDE/UL Approvals for BD Compressors

Approved Compressor - Electronic Unit Combinations

Compressors Electronic Units

Standard EMI High start High speed AEO AEO EMI

101N0210 101N0220 101N0230 101N0290 101N0300 101N0320

BD35F mm 101Z0200

UL UL UL

BD35F inch 101Z0204

UL UL UL

BD35K (R600a) 101Z0211

BD50F mm 101Z1220

UL UL UL UL

BD50F inch 101Z0203

UL UL UL UL

BD80F mm 101Z0280

BD250GH 101Z0400

BD250GH Twin 101Z0500

BD100CN (R290) 101Z0401

Compressors Electronic Units

Solar AC/DC converter Automotive Automotive Telecommunication Extended EMI

101N0400 101N0500 101N0600 101N0630 101N0730 101N0900

BD35F mm 101Z0200

UL VDE/UL

BD35F inch 101Z0204

UL VDE/UL

BD35K (R600a) 101Z0211

BD50F mm 101Z1220

VDE/UL

BD50F inch 101Z0203

VDE/UL

BD250GH (48V) 101Z0402

UL

VDE/UL

= Combination possible, VDE or UL approval

= Combination possible, but no approval

= Combination not possible

Loading...

Loading...