Page 1

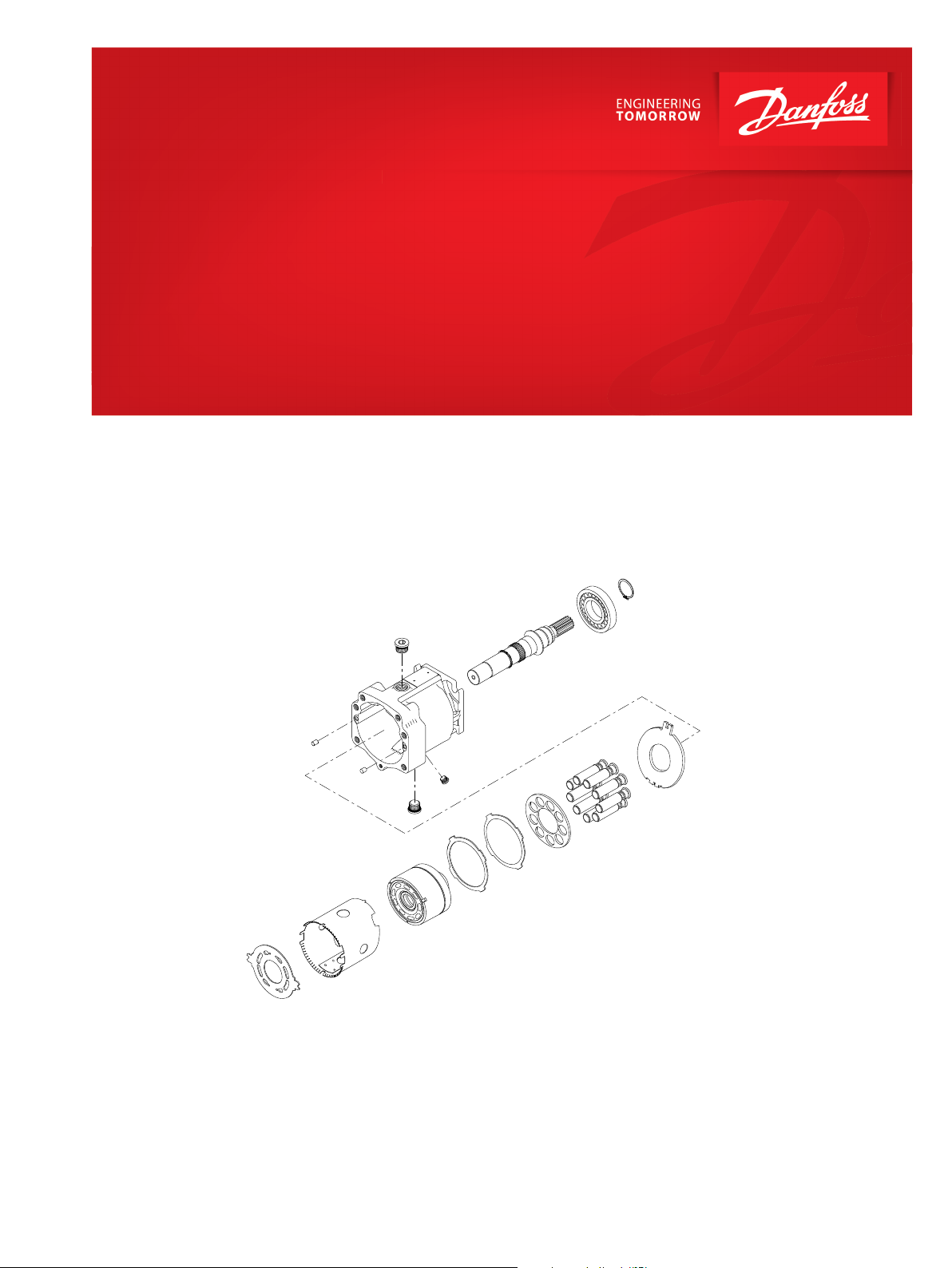

Parts Manual

Series 90 100cc

Axial Piston Motor

www.danfoss.com

Page 2

Parts Manual

Series 90 Motors, 100cc

Revision history Table of revisions

Date Changed Rev

January 2020 Removed obsolete option 0204

September 2018 Corrected o-ring quantities in the seal kit 0203

January 2018 Updated to Engineering Tomorrow 0202

2 | © Danfoss | January 2020 AX00000094en-000204

Page 3

Parts Manual

Series 90 Motors, 100cc

Contents

General information

Service Parts Identification............................................................................................................................................................4

Nameplate...........................................................................................................................................................................................4

Date code............................................................................................................................................................................................ 5

About service bulletins...................................................................................................................................................................5

Procedure to identify a part..........................................................................................................................................................5

Regional part numbers............................................................................................................................................................. 5

Example of a part identification (S90 100cc motor)....................................................................................................... 5

Adobe Acrobat 2-page viewing..................................................................................................................................................6

Order code.......................................................................................................................................................................................... 7

Common parts and special hardware

Common parts and special hardware CAA, CBA...................................................................................................................8

Special hardware CBC, CBE.........................................................................................................................................................12

Special hardware EAA, EBA, EFT............................................................................................................................................... 14

Special hardware EBB-EEH..........................................................................................................................................................16

Special hardware EFA-EFM.........................................................................................................................................................20

Special hardware EGL-JAB.......................................................................................................................................................... 24

Special hardware JAE-JCB...........................................................................................................................................................28

Special hardware LAB-NNN........................................................................................................................................................32

Special hardware PAA, PAB........................................................................................................................................................34

End cap

End cap 1-8, D, E............................................................................................................................................................................. 36

End cap F-Q......................................................................................................................................................................................40

End cap T, U......................................................................................................................................................................................44

End cap V, W, X................................................................................................................................................................................46

Loop flushing

Loop flushing B-W......................................................................................................................................................................... 48

Charge pressure setting

Charge pressure setting 00-N6................................................................................................................................................. 50

Shaft

Shaft C6-TJ........................................................................................................................................................................................54

Overhaul seal kit

Seal kit................................................................................................................................................................................................56

Service bulletin

SB-1988-018.....................................................................................................................................................................................57

SB-1988-023.....................................................................................................................................................................................59

SB-1989-020.....................................................................................................................................................................................61

SB-1998-007.....................................................................................................................................................................................64

SB-1999-036.....................................................................................................................................................................................66

SB-2000-047.....................................................................................................................................................................................68

SB-2001-011.....................................................................................................................................................................................69

SB-2002-048.....................................................................................................................................................................................70

SB-2003-010.....................................................................................................................................................................................71

©

Danfoss | January 2020 AX00000094en-000204 | 3

Page 4

MADE IN P. R. C.

Serial No. Fabr- Nr

C-01-16-23456

Model Code Typ

Model No.

90M100 NC 0 N 8 N 0

S1 W 00 EAA 00 00 N6

83023054

Ident-Nr

Parts Manual

Series 90 Motors, 100cc

General information

Service Parts Identification

Nameplate

The following information and procedure is used to identify the module group, item number,

manufacture date, part number, and part name of the parts included in the .

The parts listed include all parts which may be used when performing either “Minor Repairs”, “Major

Repairs” or “Conversions” on the .

Each unit will have a nameplate affixed to the housing. The nameplate will include the following

information:

Model Code

The Danfoss model code completely defines the specific unit and must be used when ordering parts to

service this product.

Model Number

The Danfoss model number is used by the factory in manufacturing. On repeat orders, a complete unit

can be ordered by the model number.

Serial Number

The Danfoss serial number is used to identify the manufacture date and the unit sequence in the build.

The serial number is also used to identify the units warranty time period.

The letter code indicates the location of original manufacture (assembly).

The first number (2 digits) indicates the year of manufacture. The second number (2 digits) indicates the

calendar week of manufacture.

The third number (5 digits) is a sequential number used to identify a specific unit.

4 | © Danfoss | January 2020 AX00000094en-000204

Page 5

Parts Manual

Series 90 Motors, 100cc

General information

Date code

About service bulletins

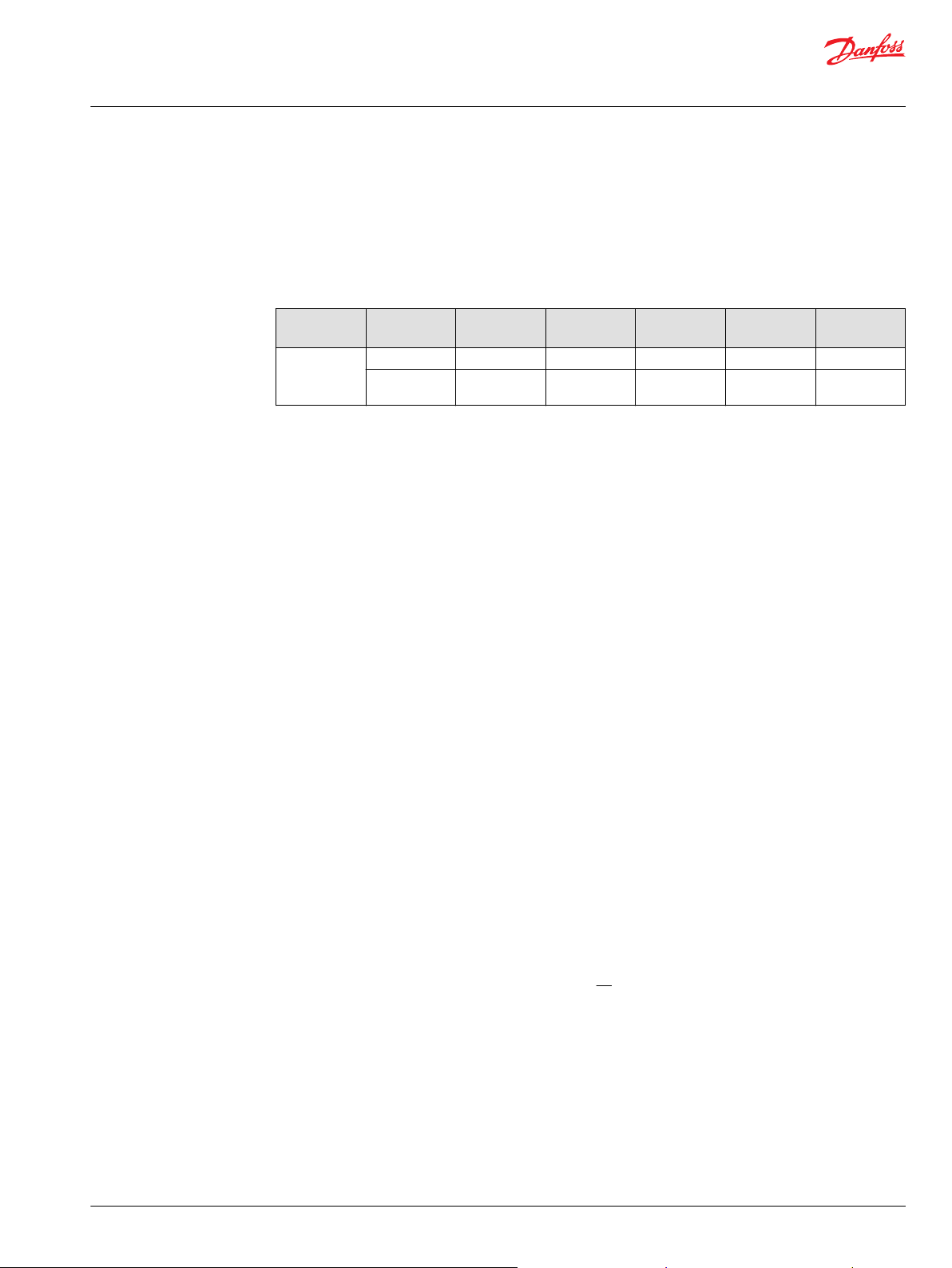

The date code is defined as the year and week of manufacture. The same item number may list more than

one part number. This indicates that there is more than one configuration for that item number. You will

see that there are different date codes for the different part numbers. Find the date code of your unit

from the nameplate to determine which service part number you need to order.

Example: The service part desired is item G30

Order Code Item Date Begin Date End Part Number Part Name Qty. per

80 G30 89-17 8000243 End cap gasket 1

G30 89-16 8000151 End cap gasket

(SB-1995-006)

Model/Kit

1

All units using this order code with a date code prior to 89-17 must use part number “8000151.” All units

with a date code of 89-17 and newer must use part number “8000243.”

A Service Bulletin Number (SB-_ _ _ _ - _ _ _) may follow the “Part Name” of the part you desire. You must

read that Service Bulletin prior to ordering that part. The information contained in these Service Bulletins,

as of the print date of this bulletin, are included at the end of this manual. Service Bulletins contain more

detailed information such as interchangeability, what additional parts are involved, etc. It is suggested

that you add additional Service Bulletins to this manual as you receive them.

Procedure to identify a part

The modular design of this product results in a simplified service parts list and part number identification

procedure.

The same item numbers are used for same part names on all units within a product type. A part number

that has another number following it in parentheses is done to make this a world wide manual.

Regional part numbers

Some part numbers are region specific and should be ordered accordingly.

As an example, the part number (example: 314583 (9008000-0118) will be used. The first number is sold

in Germany. The number in parentheses is sold in the United States. Customers would order

9008000-0118 if ordering the part in the United States.

Example of a part identification (S90 100cc motor)

The nameplate on a Series 90 motor has an Order Code of 90M100 NC 0 N 8 N 0 S1 W 00 EAA 00 00 N6.

Use the following procedures to determine the part number of the drive shaft used on this motor.

1. Referring to the shaft module in the Order code on page 7, the shaft option for this motor is

identified by the code “S1”. (90M100 NC 0 N 8 N 0

S1W 00 EAA 00 00 N6)

2. Referring to the Service Parts List, find the shaft group. Next find the order code that relates to this

unit,which is “S1”. The shaft is found to be item L100 and part number 11012429.

©

Danfoss | January 2020 AX00000094en-000204 | 5

Page 6

Parts Manual

Series 90 Motors, 100cc

General information

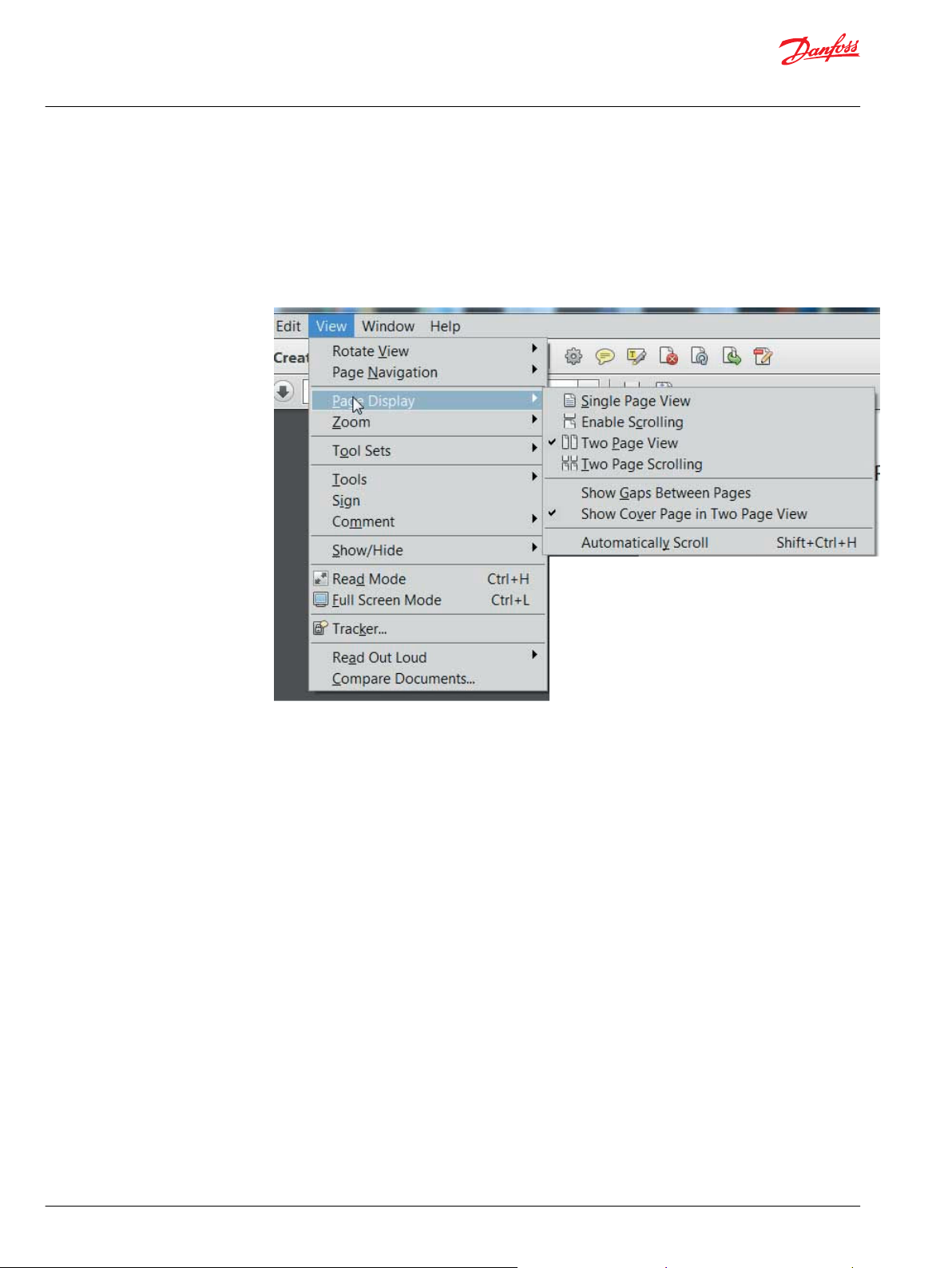

Adobe Acrobat 2-page viewing

While viewing manual in Adobe Acrobat, the following settings need to be applied to ensure proper

page display.

1. Select “View” → “Page Display” → “Two Page View”

2. Select “View” → “Page Display” → “Show Cover Page in Two Page View”

6 | © Danfoss | January 2020 AX00000094en-000204

Page 7

9

0

M

0

1

0

N

C

0

N

8

S 1

0

N

0 0

W

2 4

0

N N

N

0 0

0

Series

Displacement

Not applicable

Not applicable

End cap

Not applicable

Not applicable

Not applicable

Shaft

Loop flushing

Not applicable

G L H W K

Special hardware features

Not applicable

Not applicable

Charge pressure setting

Type

Parts Manual

Series 90 Motors, 100cc

General information

Order code

©

Danfoss | January 2020 AX00000094en-000204 | 7

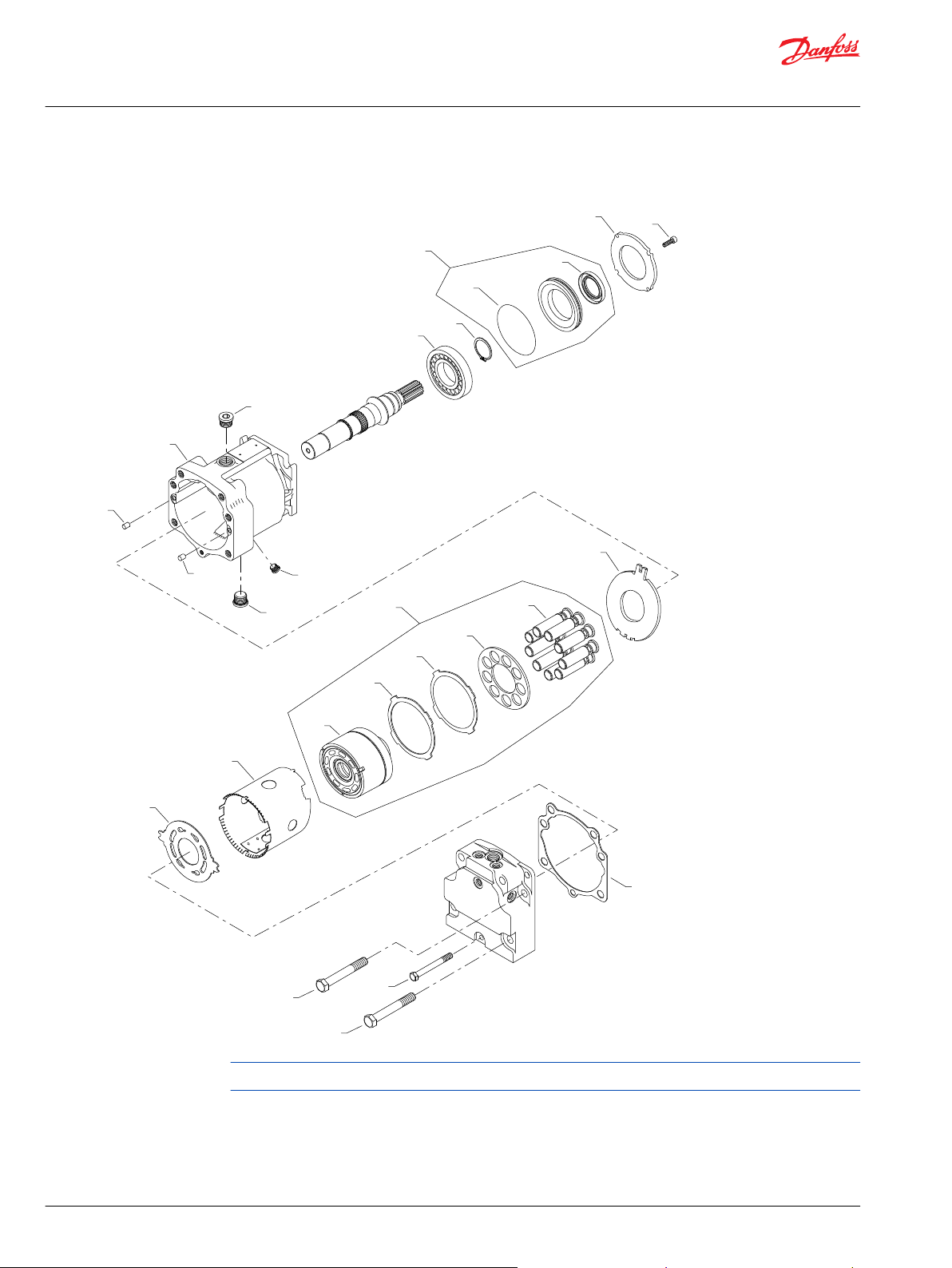

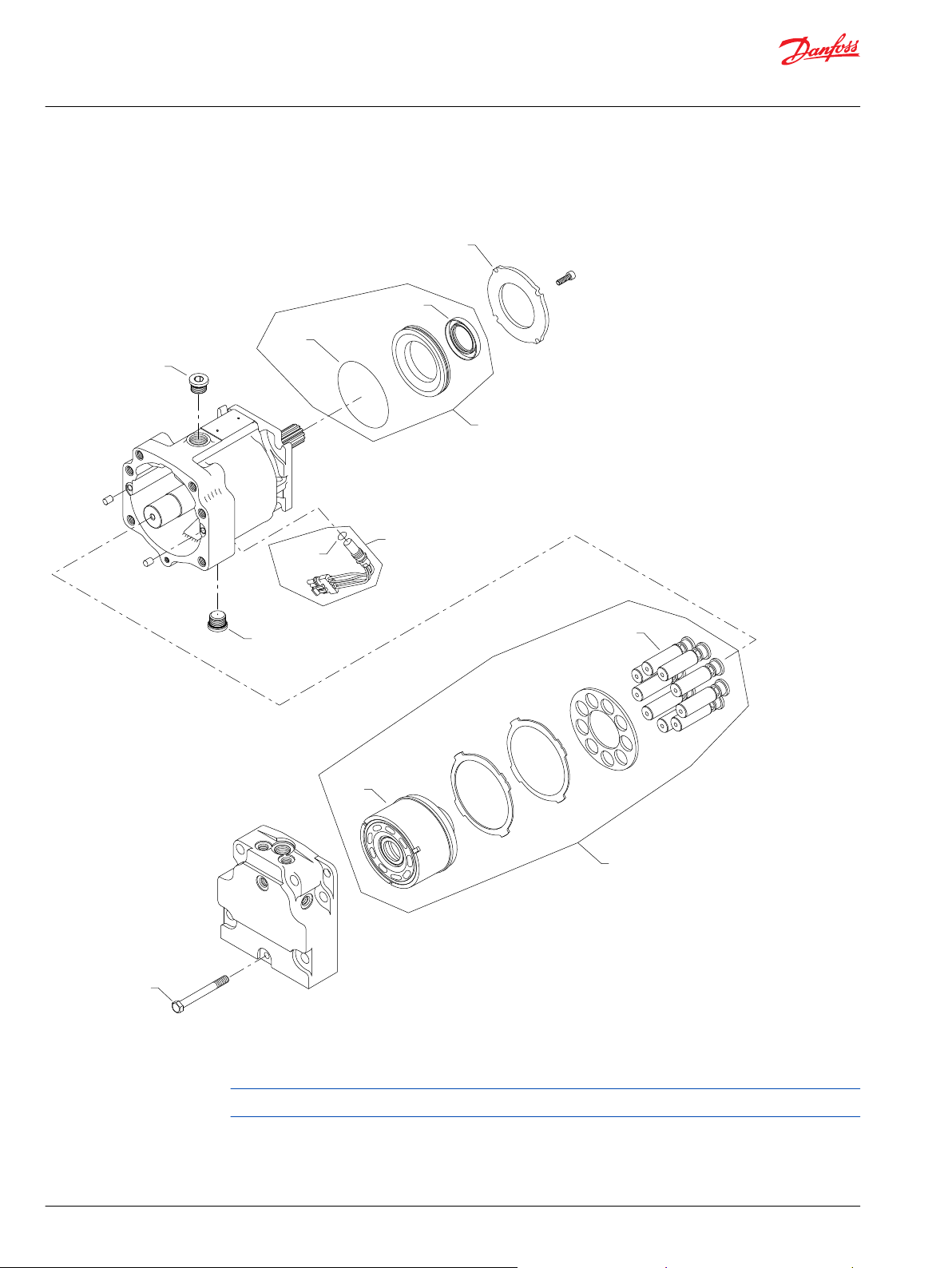

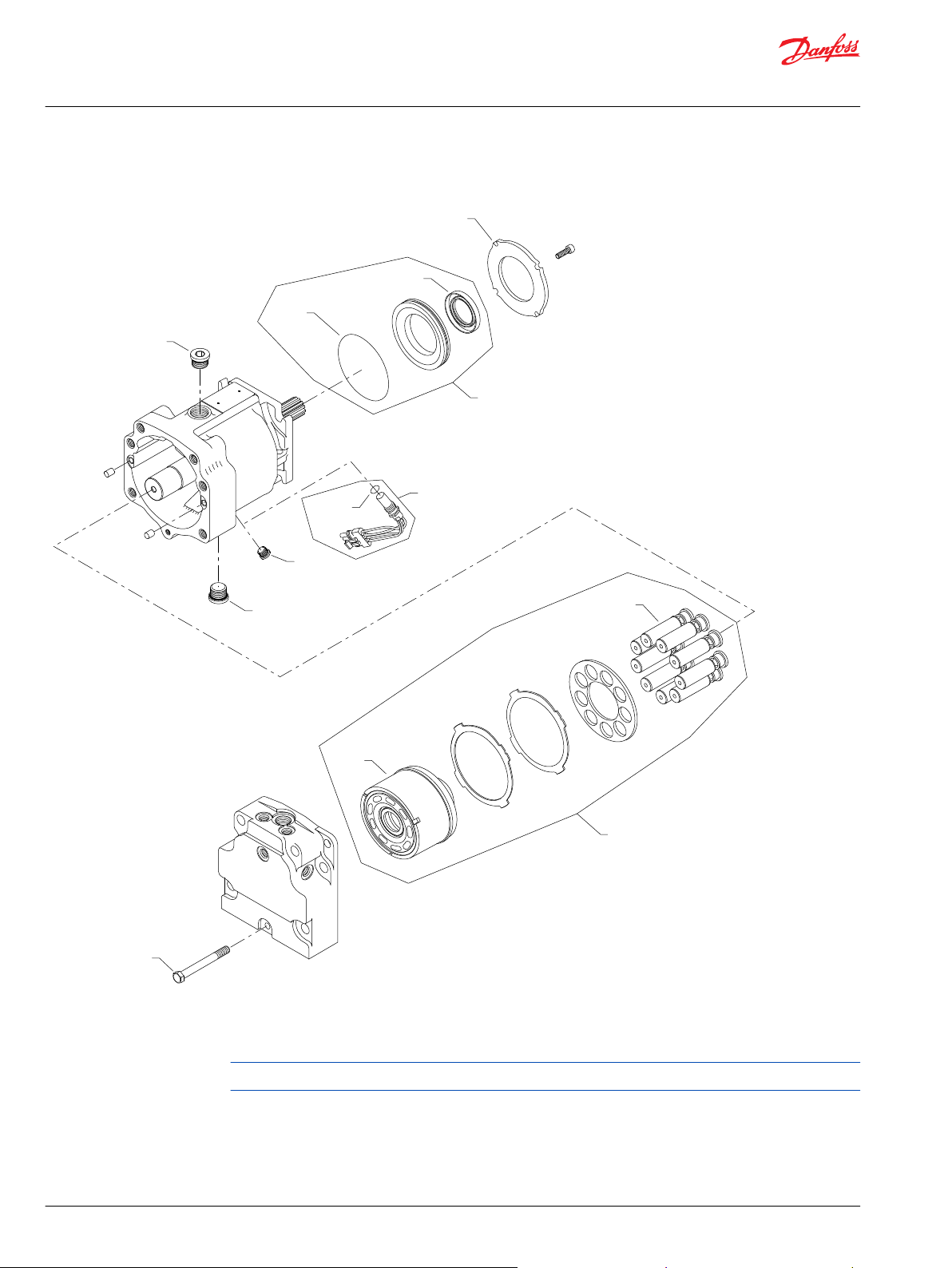

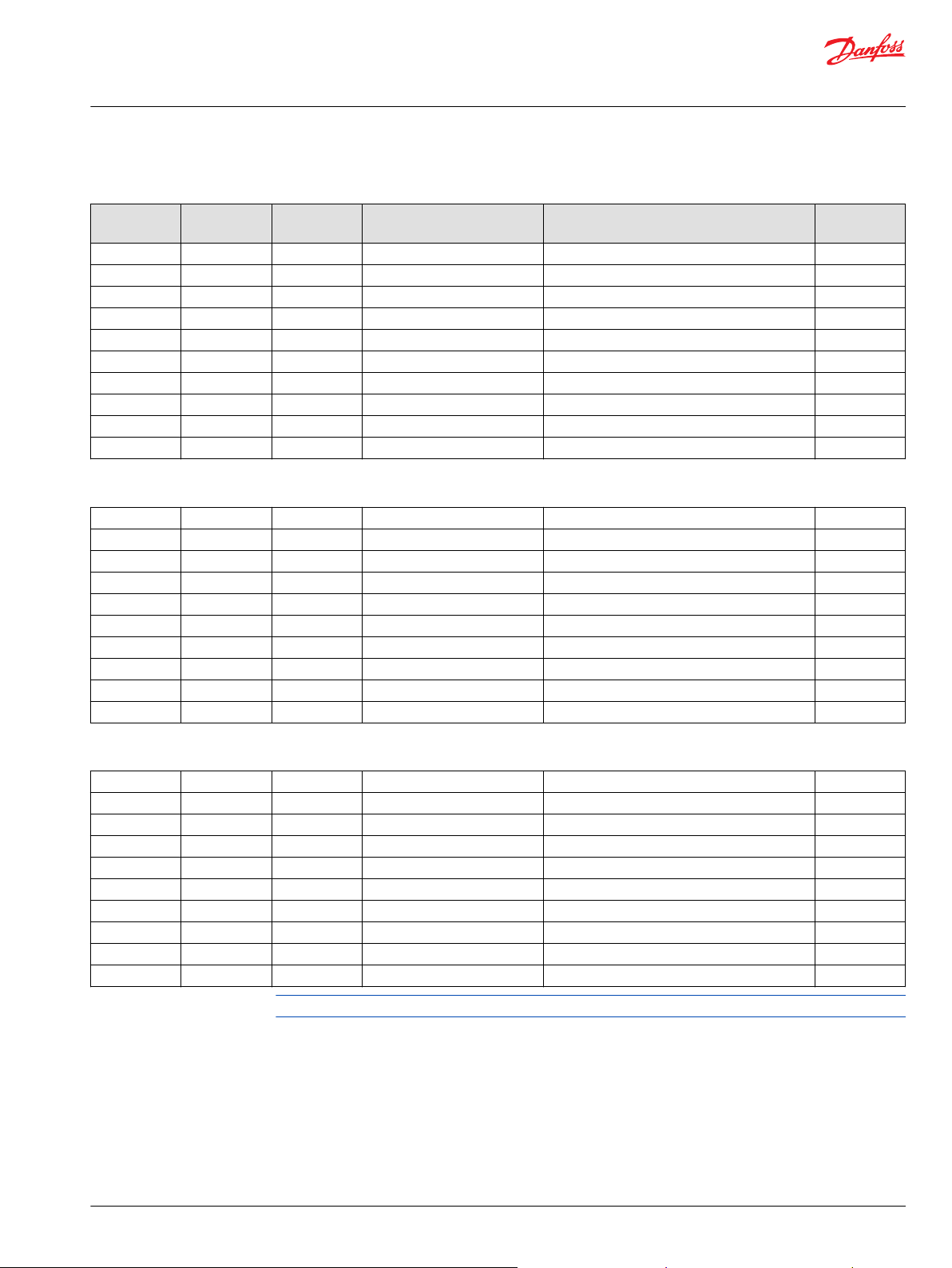

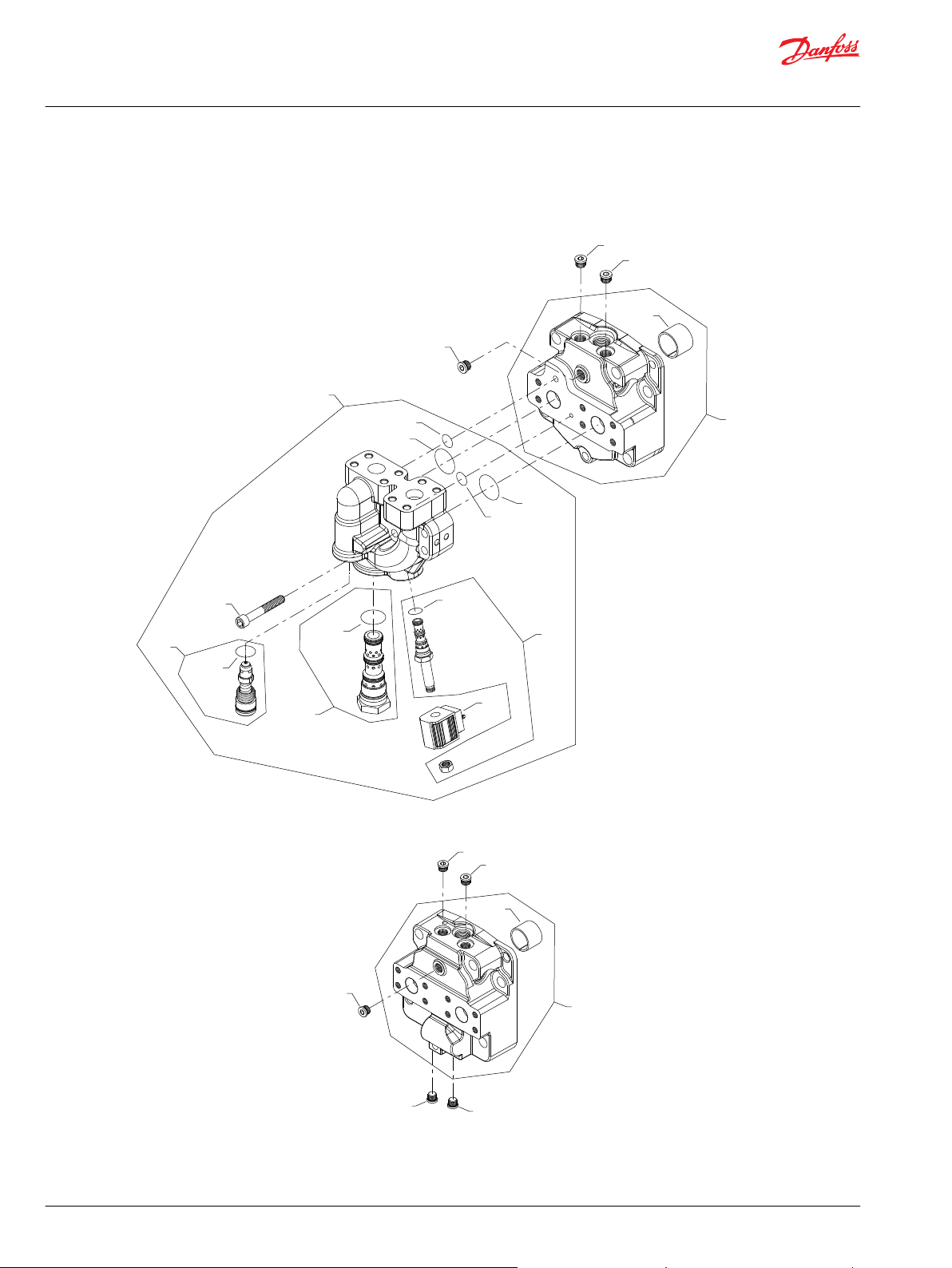

Page 8

B83

L20

L10

B10

B50

*G30

B50

G96

G90

B81

L50

L40

*L25

G90

L70

L60

D50

C50

C80

C20

QC04

C30

C40

C45

C05

B80

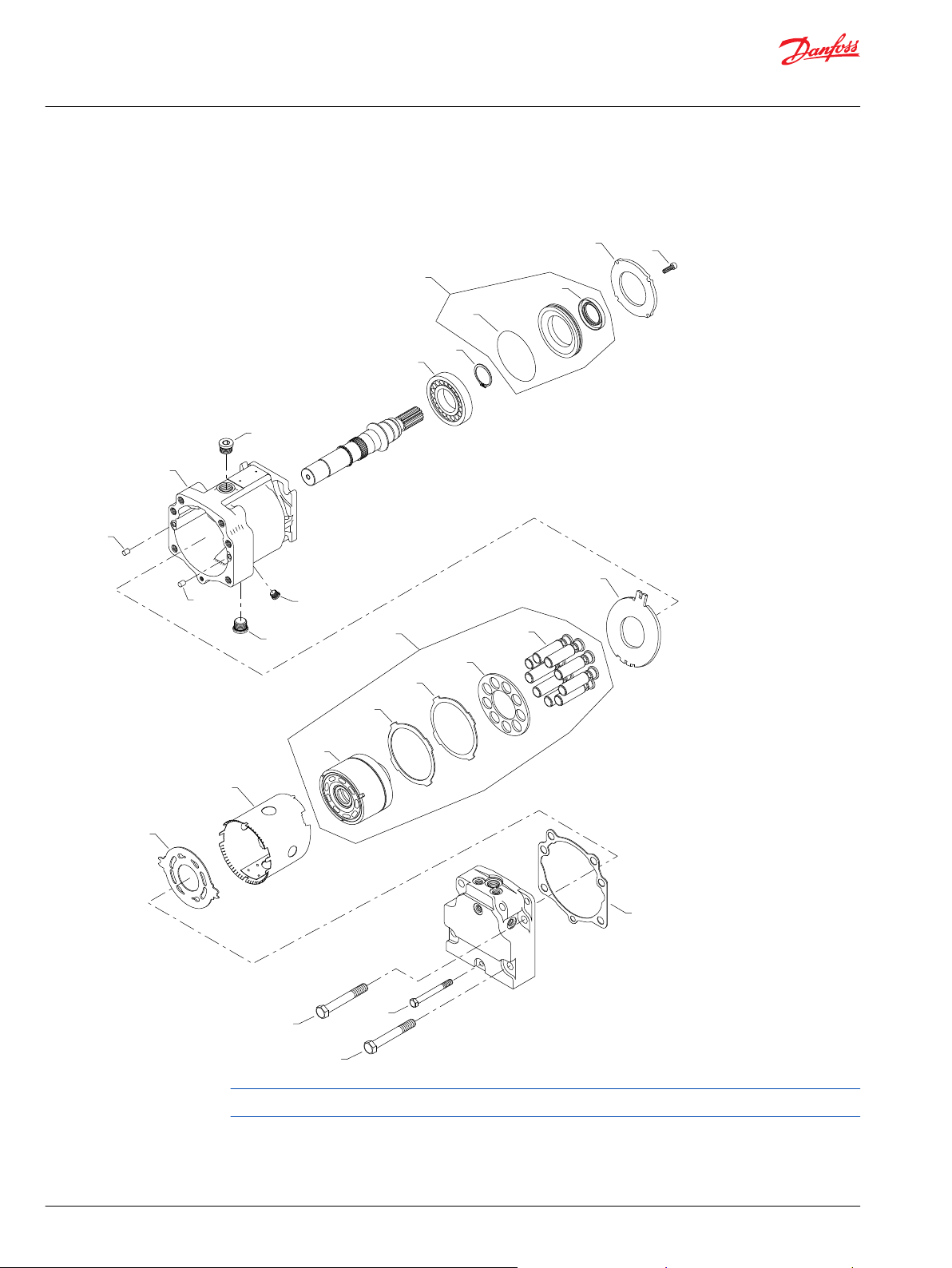

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

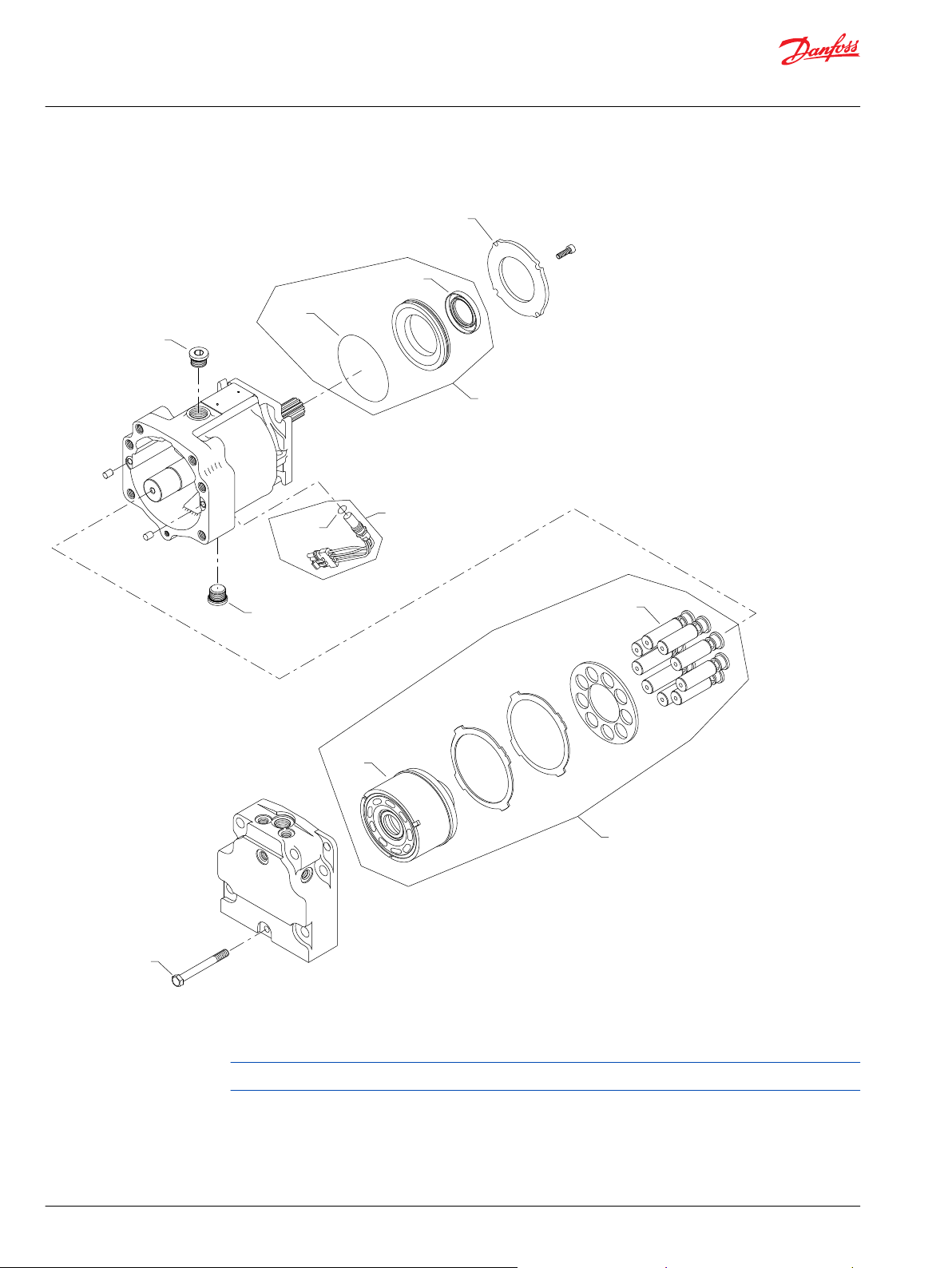

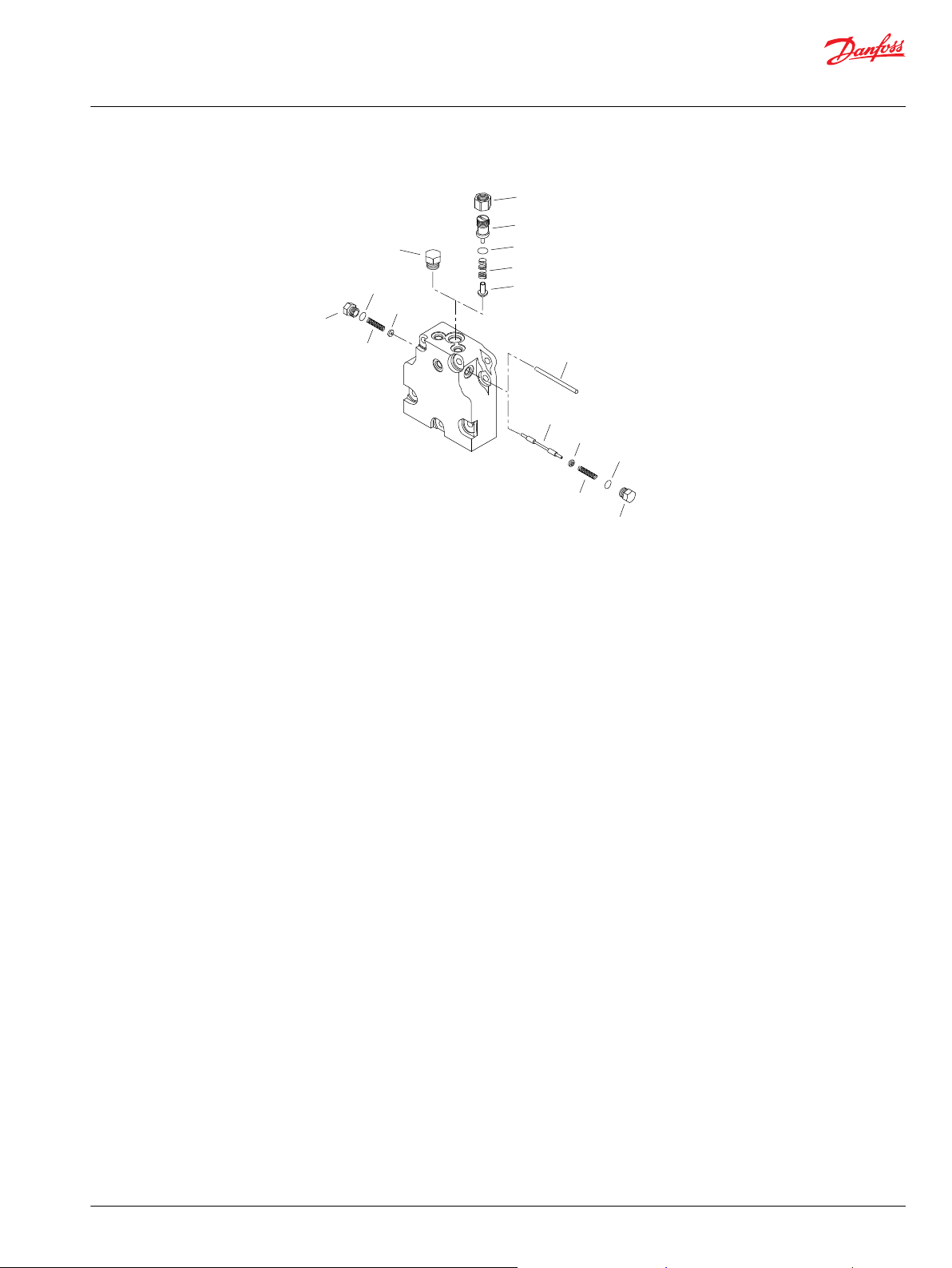

S90 100cc motor special hardware CAA, CBA

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

8 | © Danfoss | January 2020 AX00000094en-000204

Page 9

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

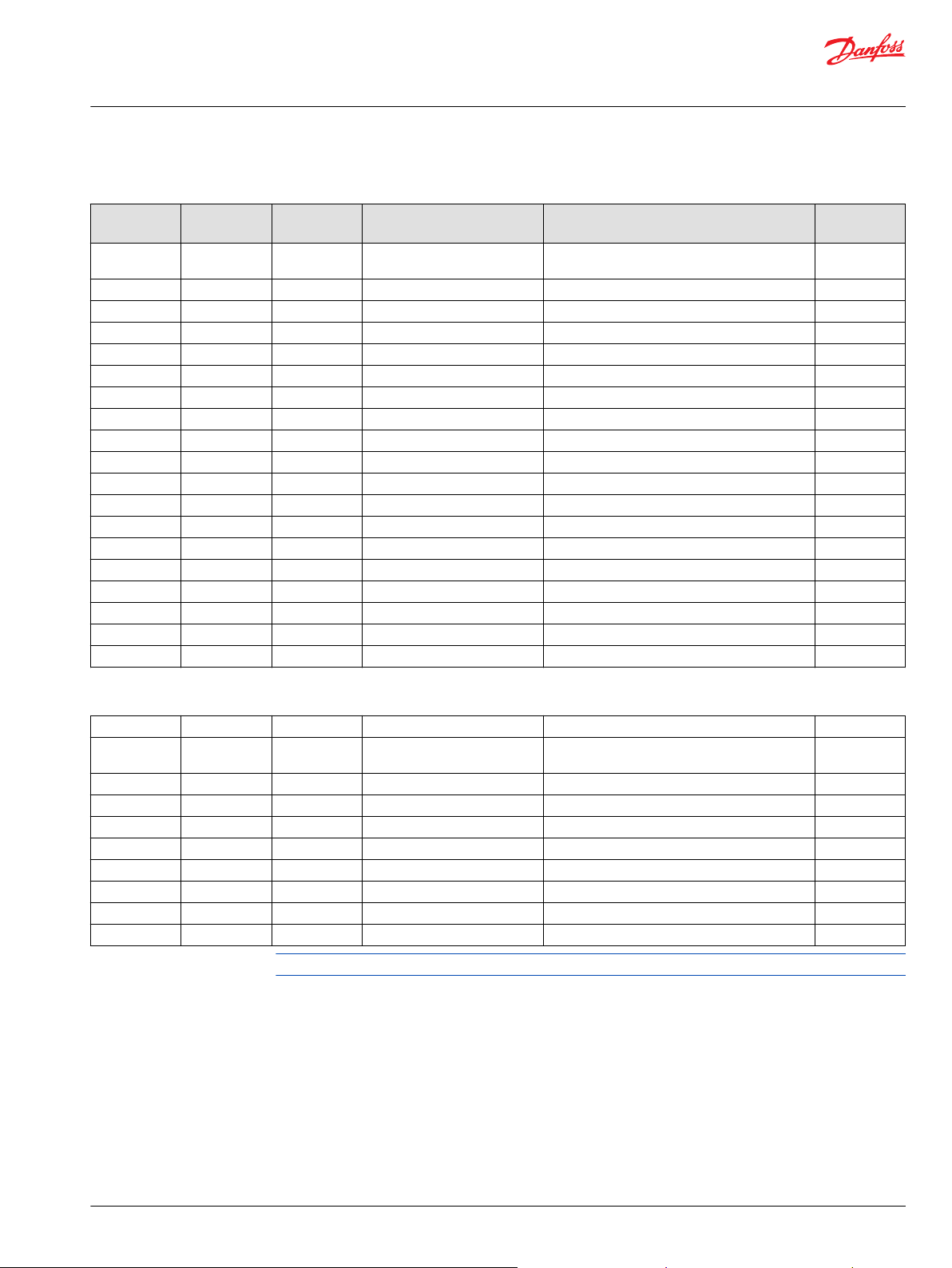

Common parts

Item Date Begin Date End Part Number Part Name Quantity per

B10 88-23 8200561 Housing (SB-1988-018 on page 57, SB-1999-036

on page 66, and SB-2003-010 on page 71)

B50 88-23 9004800-3708 Pin (SB-1988-018 on page 57) 2

B50 87-07 88-22 9004800-3116 Pin 2

B80 87-07 664524 (9005110-9000) Plug assembly 1

B81 87-07 664524 (9005110-9000) Plug assembly 1

C30 87-07 11067351 Slipper guide 1

C40 87-07 11057798 Slipper guide retainer 1

C45 87-07 11063829 Slipper guide retainer spacer 1

C50 87-07 8200237 Hold down tube 1

C80 88-23 324137 Valve plate (SB-2002-048 on page 70) 1

C80 87-07 88-22 8200103 Valve plate (SB-1988-018 on page 57) 1

D50 88-23 11136453 Thrust plate (SB-1988-018 on page 57) 1

G30 87-07 8200511 End cap gasket (SB-2001-011 on page 69) 1

G90 04-15 674424 (9007210-1617) Screw 6

G90 87-07 04-14 674424(9007210-1617) Screw (SB-2003-010 on page 71) 4

G95 87-07 04-14 675900 (9007210-1609) Screw (SB-2003-010 on page 71) 2

L10 87-07 5000506 Roller bearing 1

L20 87-07 9006300-0175 Retaining ring 1

L70 87-07 041160 (9007314-0605) Screw 4

Model/Kit

1

Order code: CAA

C05 94-14 519257 (11012434) Cylinder block assembly without speed ring 1

C20 94-14 8200031 Piston assembly, hollow (SB-1988-023 on page

59)

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510369 Cylinder block kit, without speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Parts continue to the next 2 pages.

9

©

Danfoss | January 2020 AX00000094en-000204 | 9

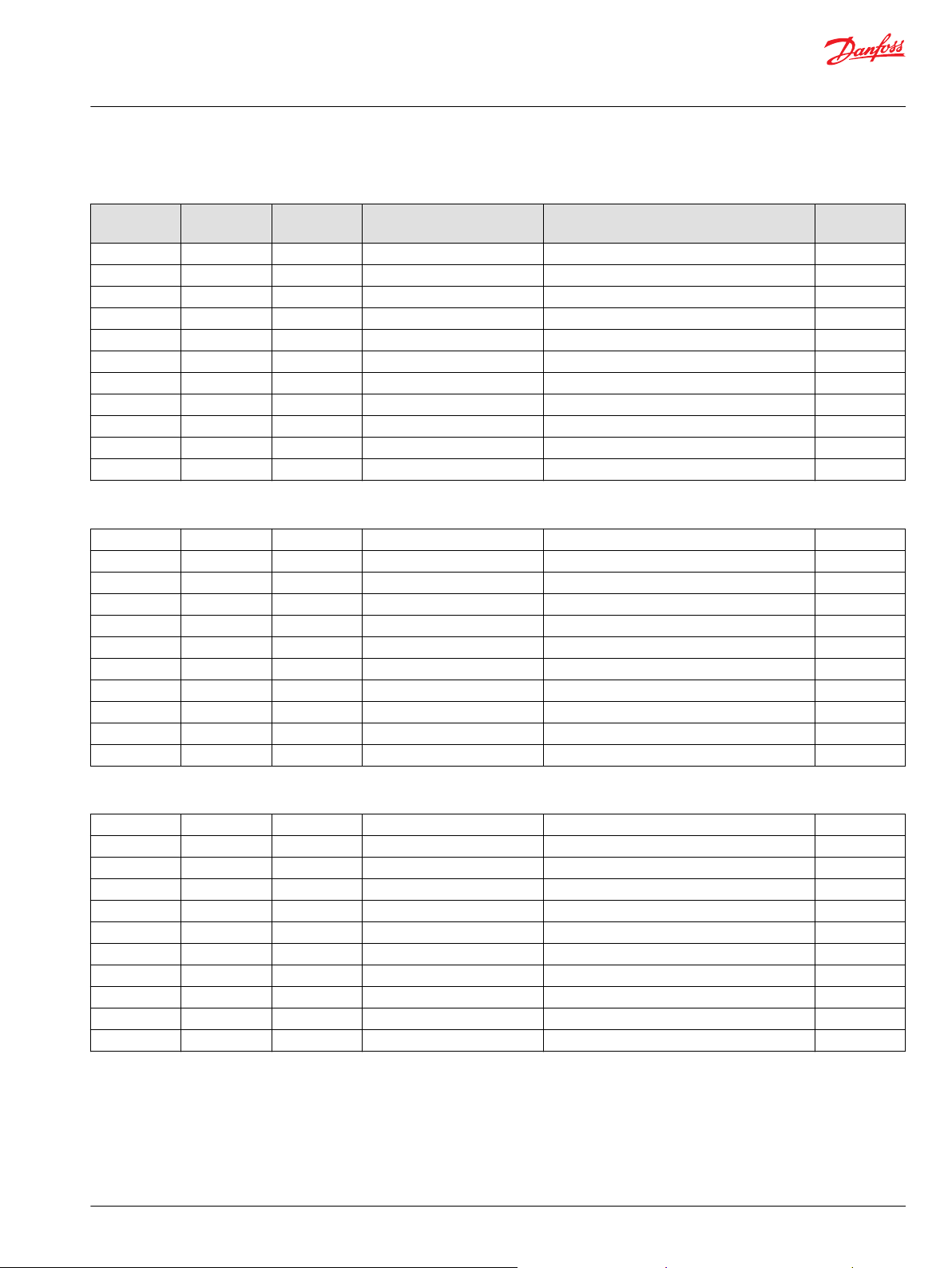

Page 10

B83

L20

L10

B10

B50

*G30

B50

G96

G90

B81

L50

L40

*L25

G90

L70

L60

D50

C50

C80

C20

QC04

C30

C40

C45

C05

B80

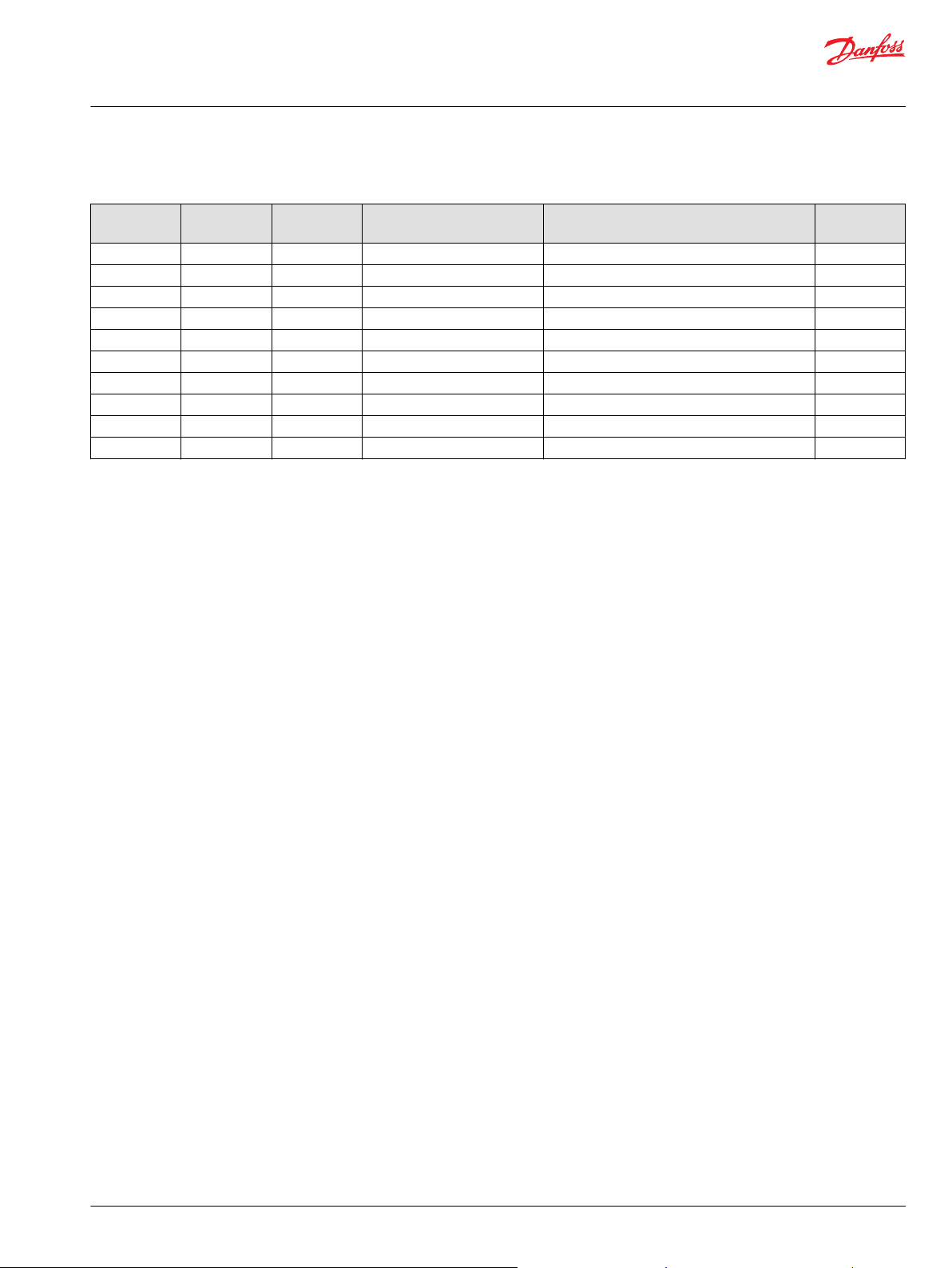

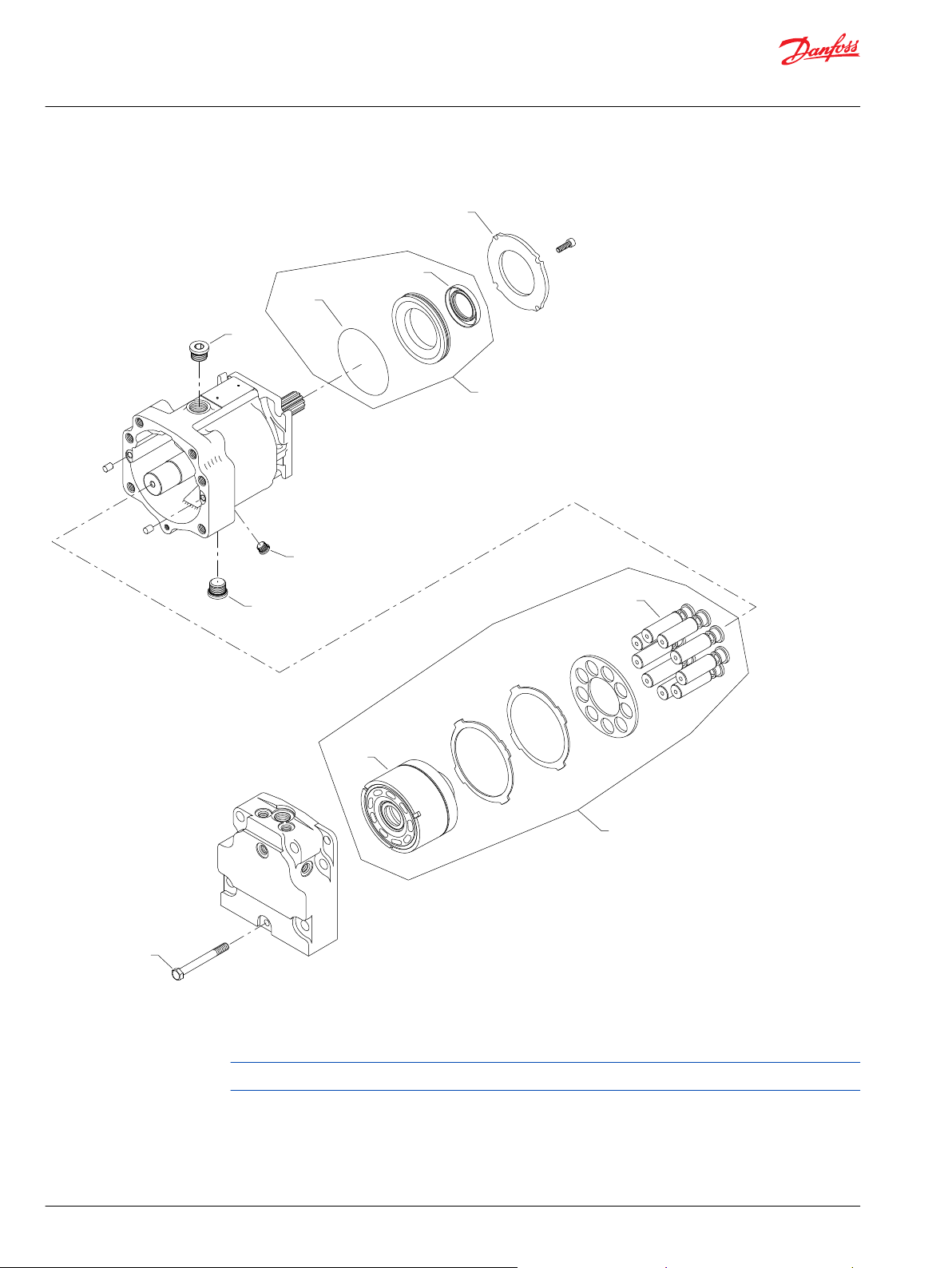

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

10 | © Danfoss | January 2020 AX00000094en-000204

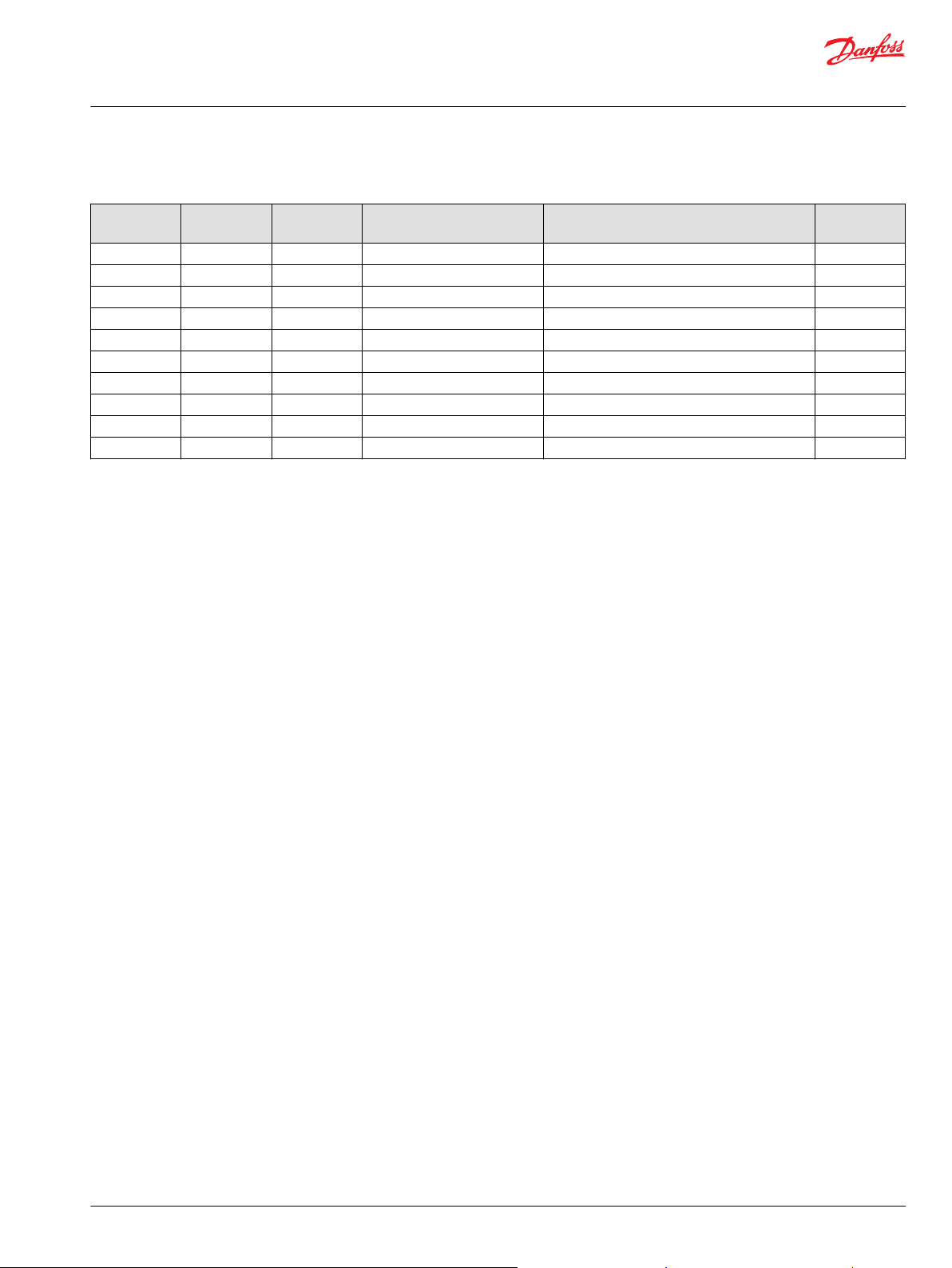

Page 11

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: CBA

Item Date Begin Date End Part Number Part Name Quantity per

C05 94-14 519257 (11012434) Cylinder block assembly without speed ring 1

C20 94-14 508080 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 11133858 Cylinder block kit, without speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 11

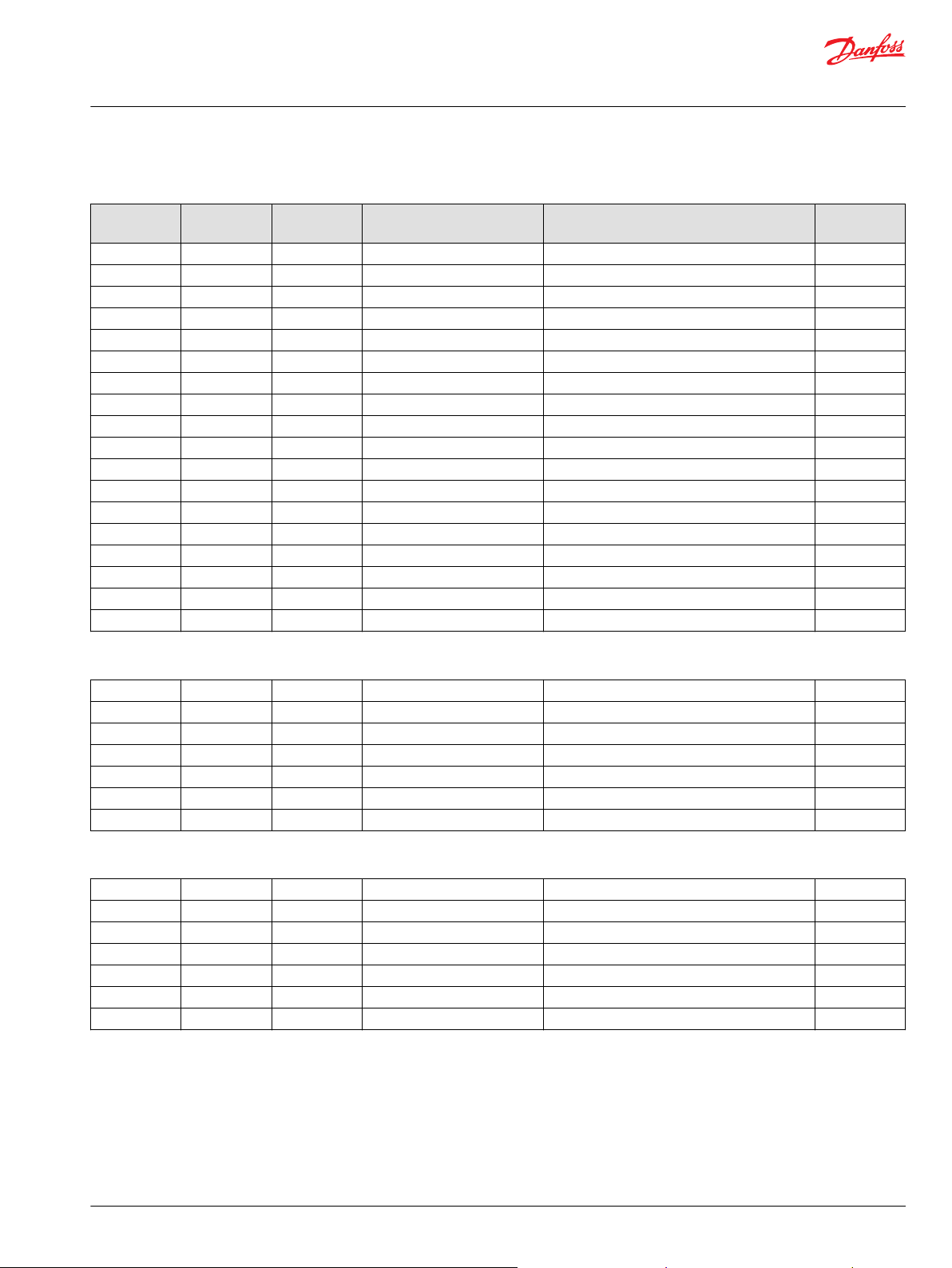

Page 12

B83

L60

C20

QC04

C05

L50

L40

*L25

B81

B80

*L25

L44

L42

L50

L60

C06

C20

QC04

G96

G96

B83

*QB83

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

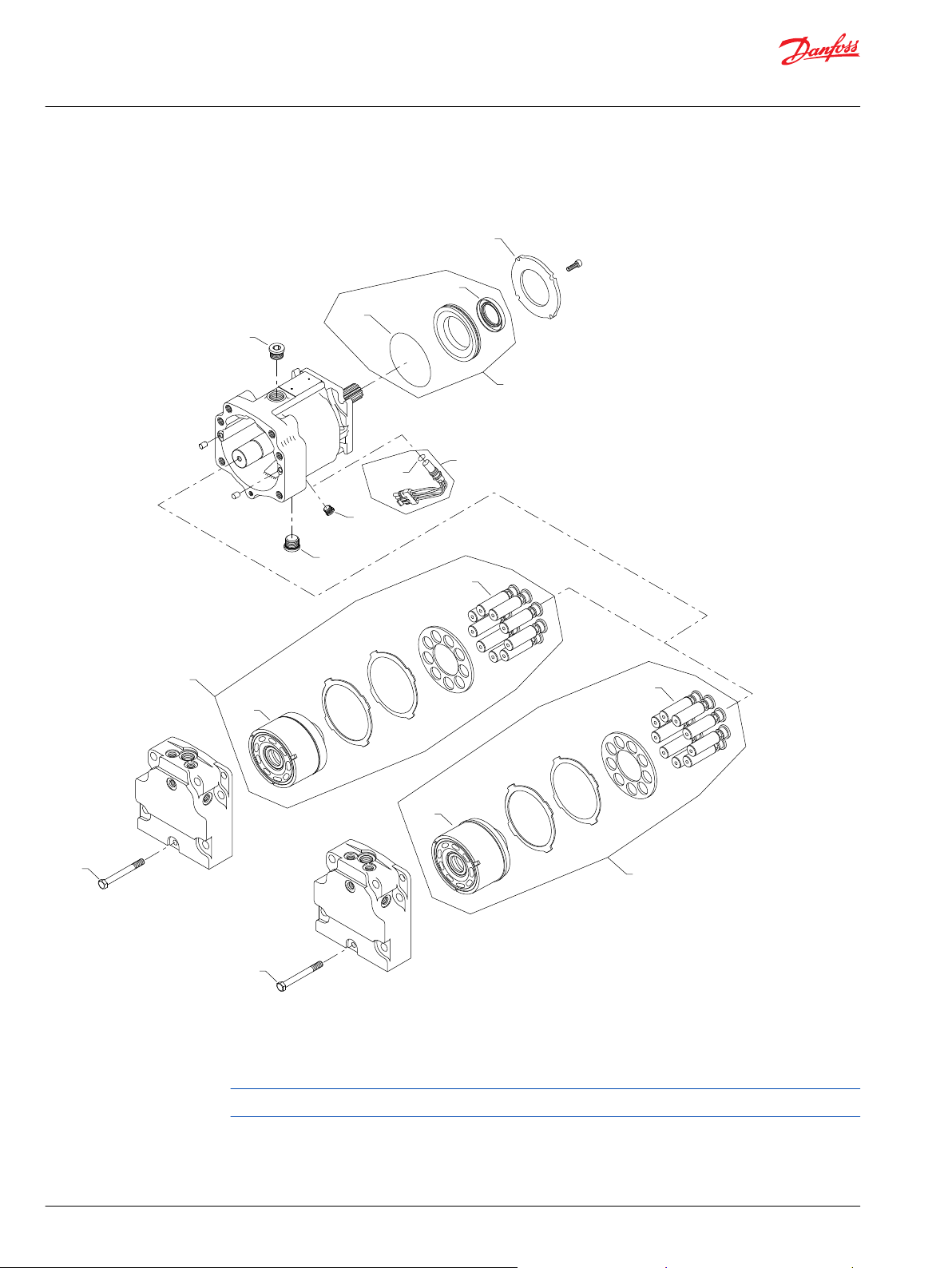

S90 100cc motor special hardware CBC, CBE

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

12 | © Danfoss | January 2020 AX00000094en-000204

Page 13

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: CBC

Item Date Begin Date End Part Number Part Name Quantity per

C05 94-14 519257 (11012434) Cylinder block assembly without speed ring 1

C20 94-14 508080 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 509487 Screw, M10 x 100 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 11133858 Cylinder block kit, without speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: CBE

C05 94-14 519257 (11012434) Cylinder block assembly without speed ring 1

C20 94-14 508080 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 509487 Screw, M10 x 100 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 11133858 Cylinder block kit, without speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 13

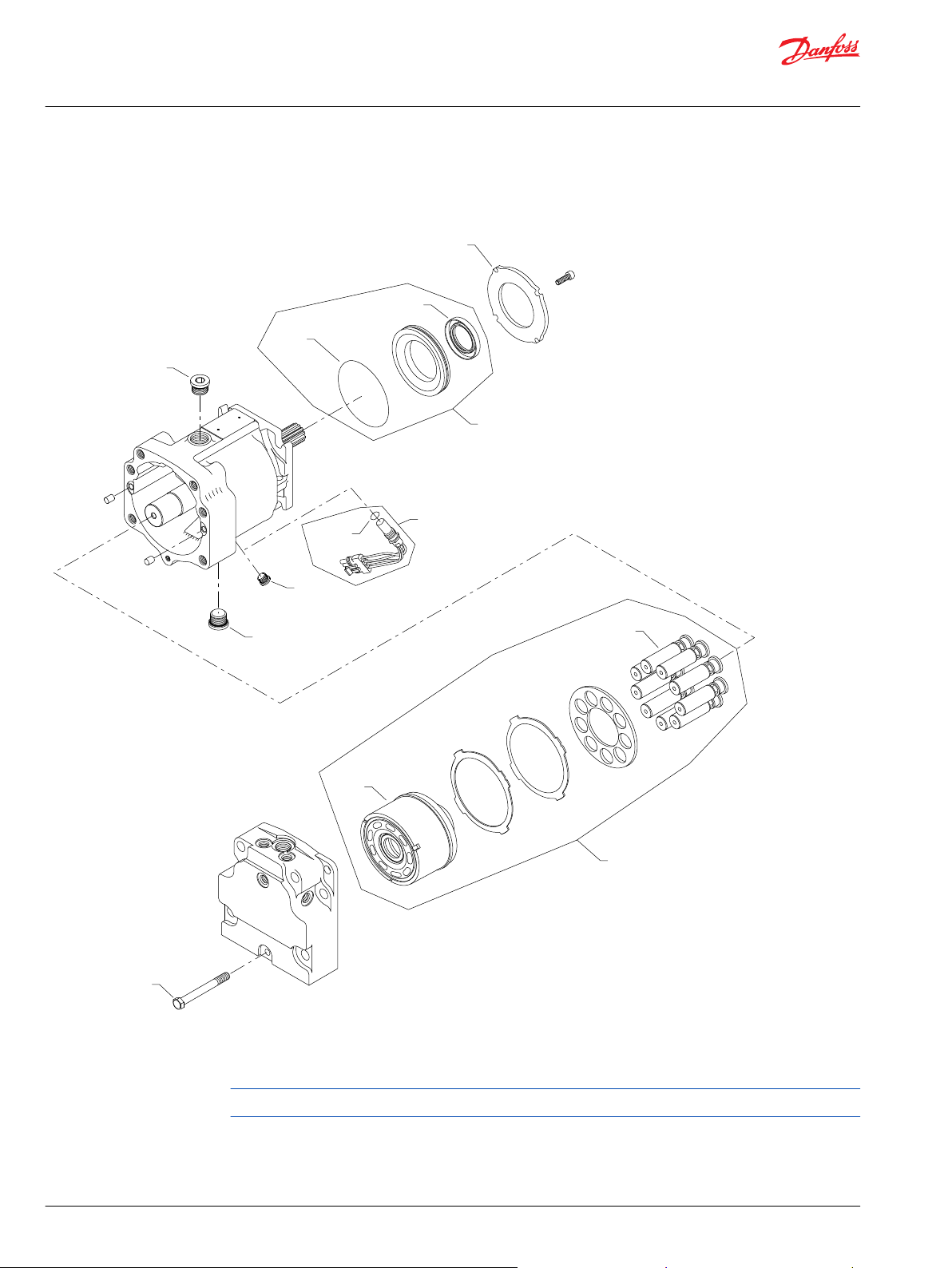

Page 14

L60

L50

L40

*L25

B81

C06

C20

QC04

G96

B83

*QB83

B80

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

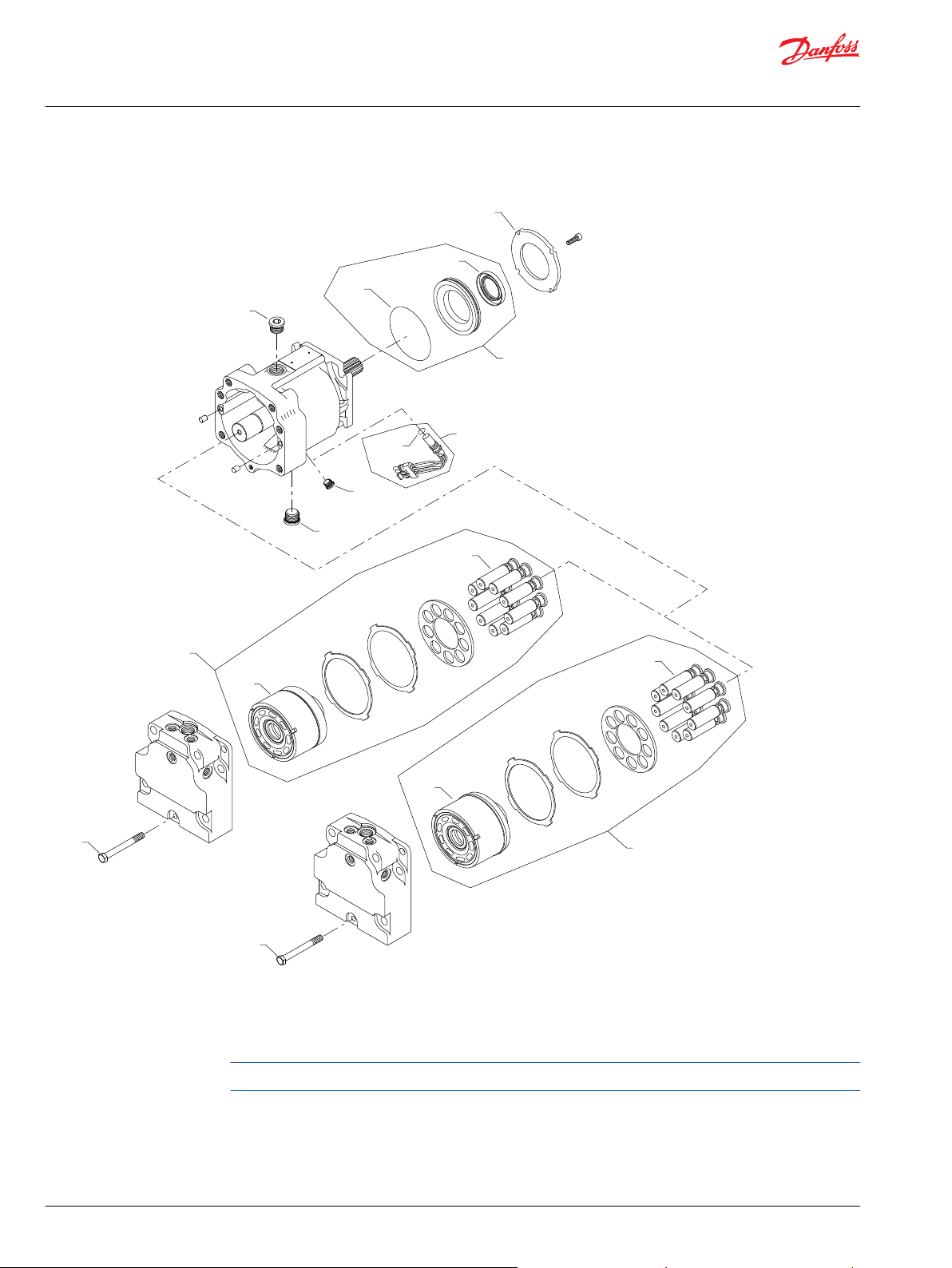

S90 100cc motor special hardware EAA, EBA, EFT

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

14 | © Danfoss | January 2020 AX00000094en-000204

Page 15

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EAA

Item Date Begin Date End Part Number Part Name Quantity per

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG12508 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit, with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: EBA

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG13408 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: EFT

C06 17-33 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 17-33 364000 Piston assembly 9

B83 17-33 KPPG16708 Speed sensor assembly 1

G96 17-33 307686 (9007210-1017) Screw, M10 x 80 1

L25 17-33 521722 Seal carrier assembly 1

L40 17-33 519021 Lip seal 1

L50 17-33 327627 (9004104-1540) O-ring 1

L60 17-33 516768 Retainer plate 1

QB83 17-33 085043 (9004201-3700) O-ring 1

QC04 17-33 8510395 Cylinder block kit with speed ring 1

Q210 17-33 11134055 Overhaul seal kit, standard 1

©

Danfoss | January 2020 AX00000094en-000204 | 15

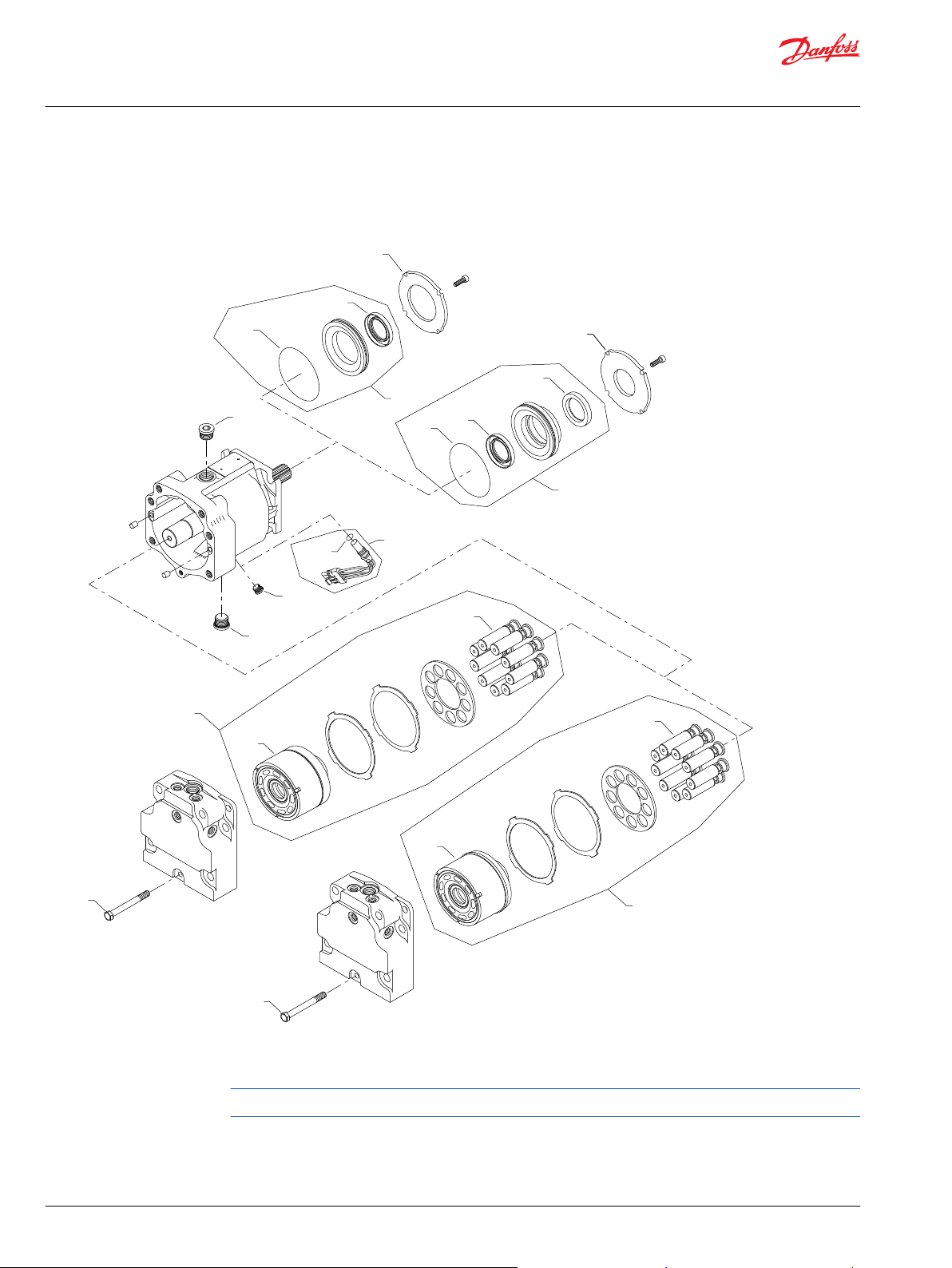

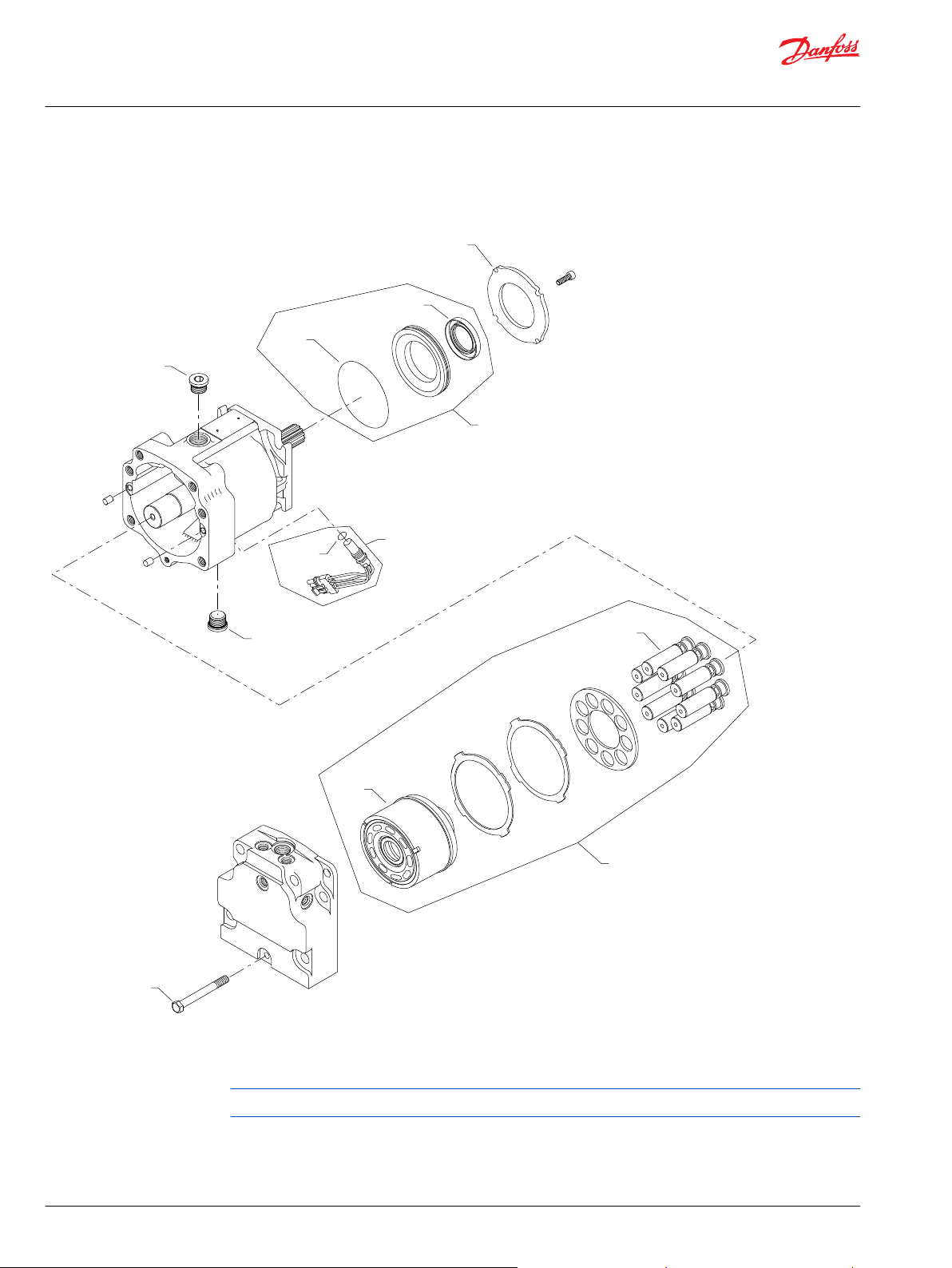

Page 16

L60

L50

L40

*L25

B81

B80

C06

C20

QC04

G96

B83

*QB83

B83

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware EBB-EEH

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

16 | © Danfoss | January 2020 AX00000094en-000204

Page 17

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EBB

Item Date Begin Date End Part Number Part Name Quantity per

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG14408 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: EBF

C06 15-30 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 15-30 364000 Piston assembly 9

B83 15-30 KPPG1A408 Speed sensor assembly 1

G96 15-30 307686 (9007210-1017) Screw, M10 x 80 1

L25 15-30 521722 Seal carrier assembly 1

L40 15-30 519021 Lip seal 1

L50 15-30 327627 (9004104-1540) O-ring 1

L60 15-30 516768 Retainer plate 1

QB83 15-30 085043 (9004201-3700) O-ring 1

QC04 15-30 8510395 Cylinder block kit with speed ring 1

Q210 15-30 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: EEA

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 17

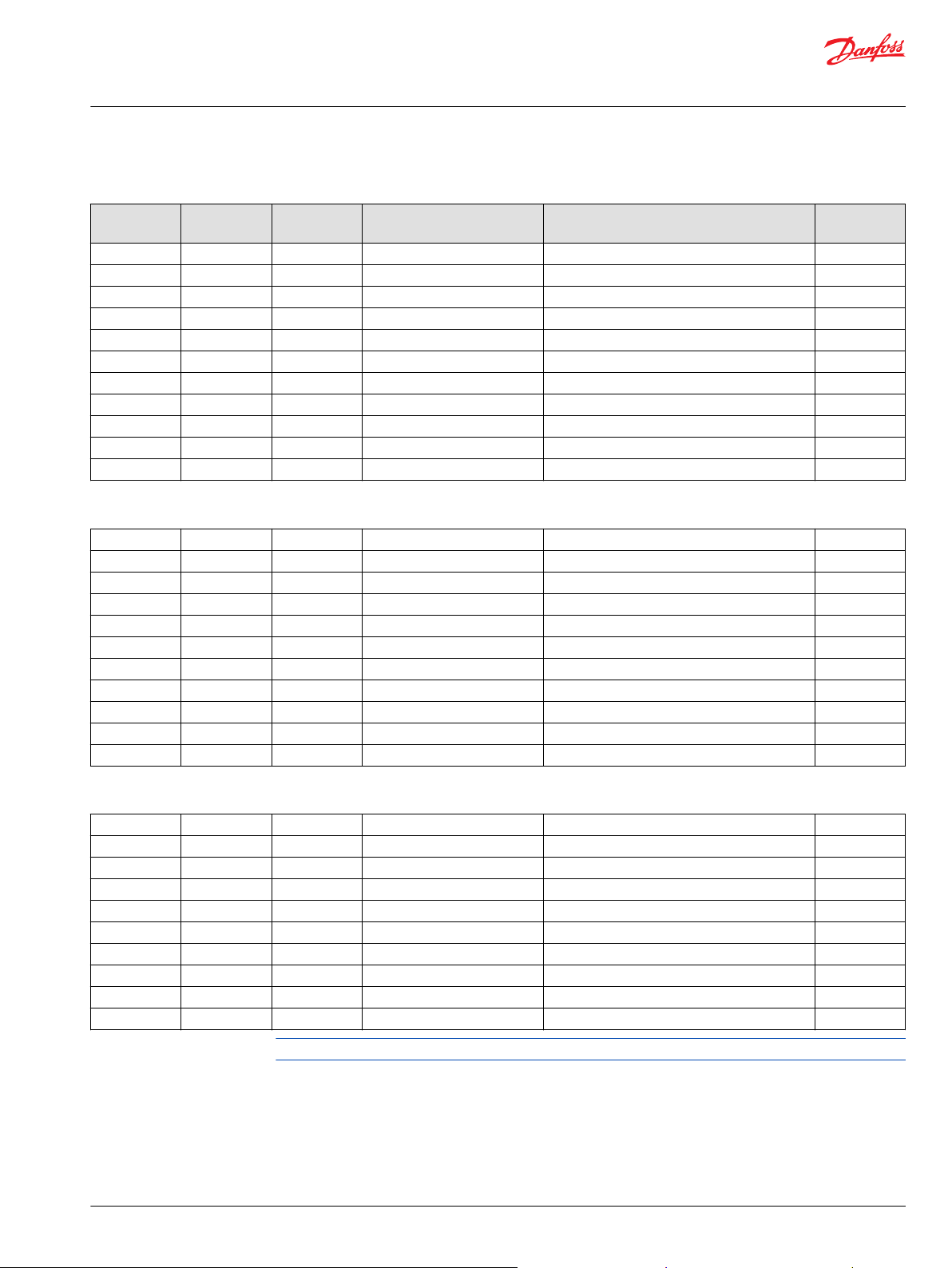

Page 18

L60

L50

L40

*L25

B81

B80

C06

C20

QC04

G96

B83

*QB83

B83

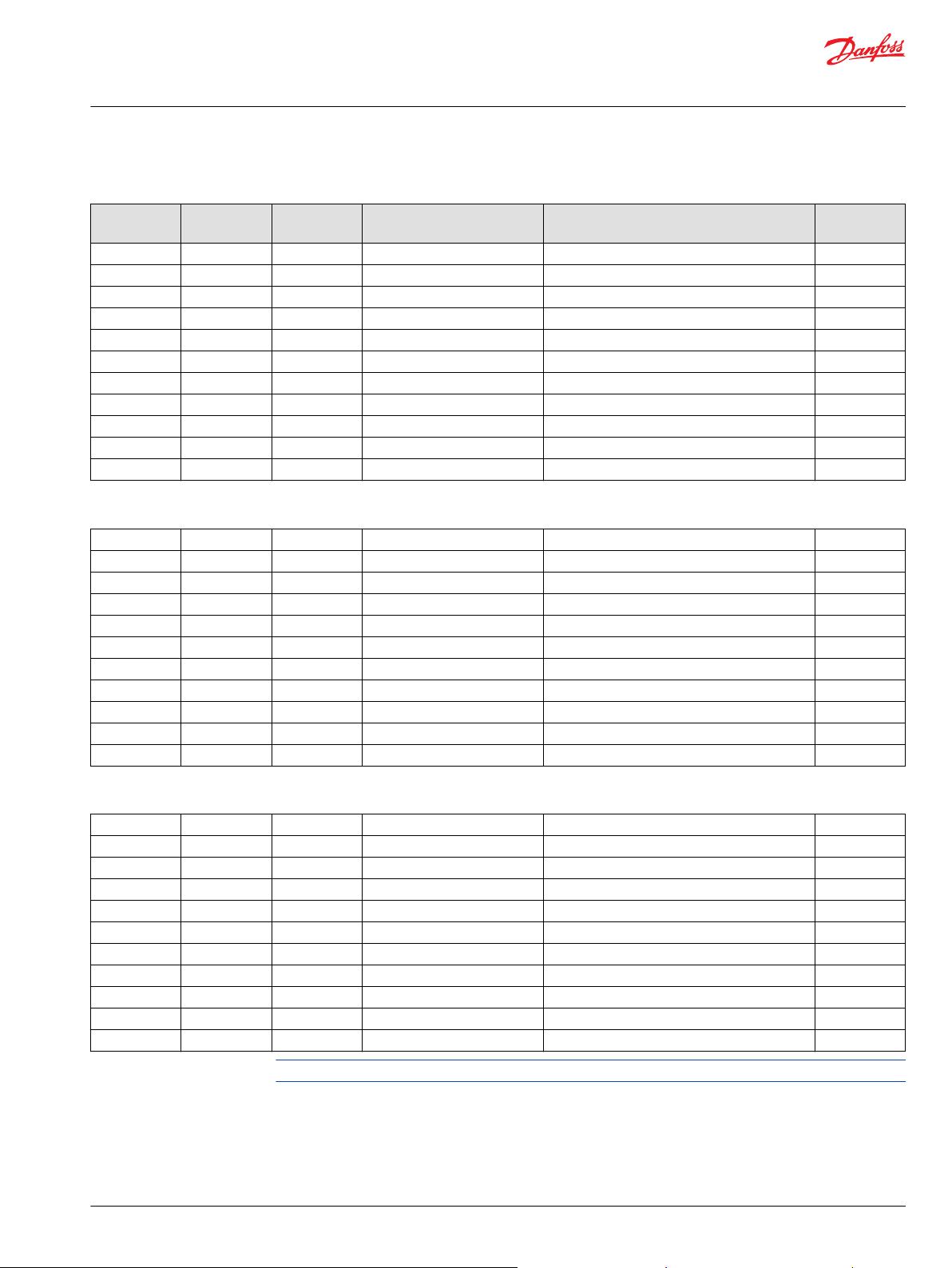

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

18 | © Danfoss | January 2020 AX00000094en-000204

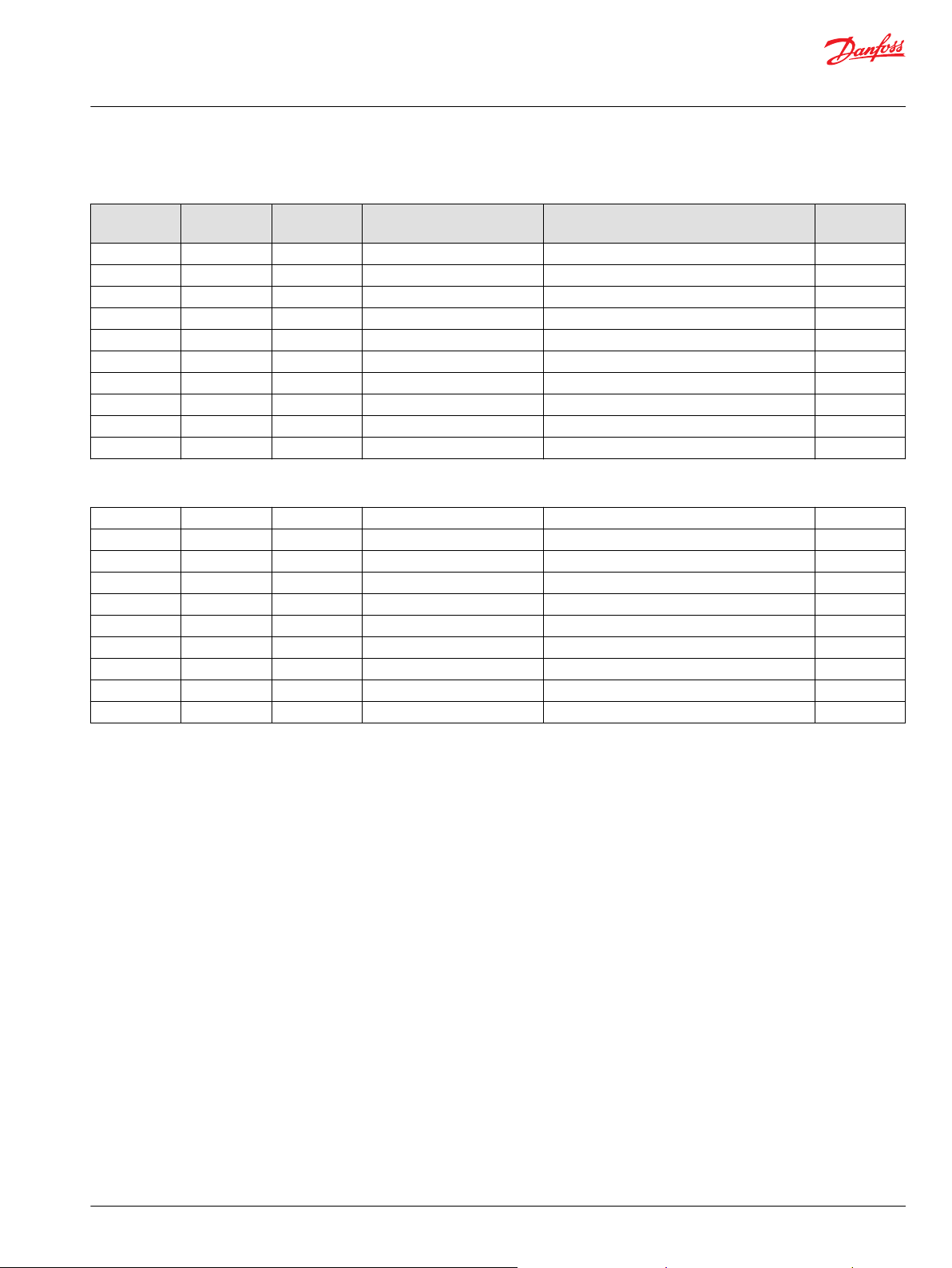

Page 19

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EEH

Item Date Begin Date End Part Number Part Name Quantity per

C06 14-15 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 14-15 364000 Piston assembly 9

B83 14-15 140644 Plug assembly 1

G96 14-15 307686 (9007210-1017) Screw, M10 x 80 1

L25 14-15 521722 Seal carrier assembly 1

L40 14-15 519021 Lip seal 1

L50 14-15 327627 (9004104-1540) O-ring 1

L60 14-15 516768 Retainer plate 1

QC04 14-15 8510395 Cylinder block kit with speed ring 1

Q210 14-15 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 19

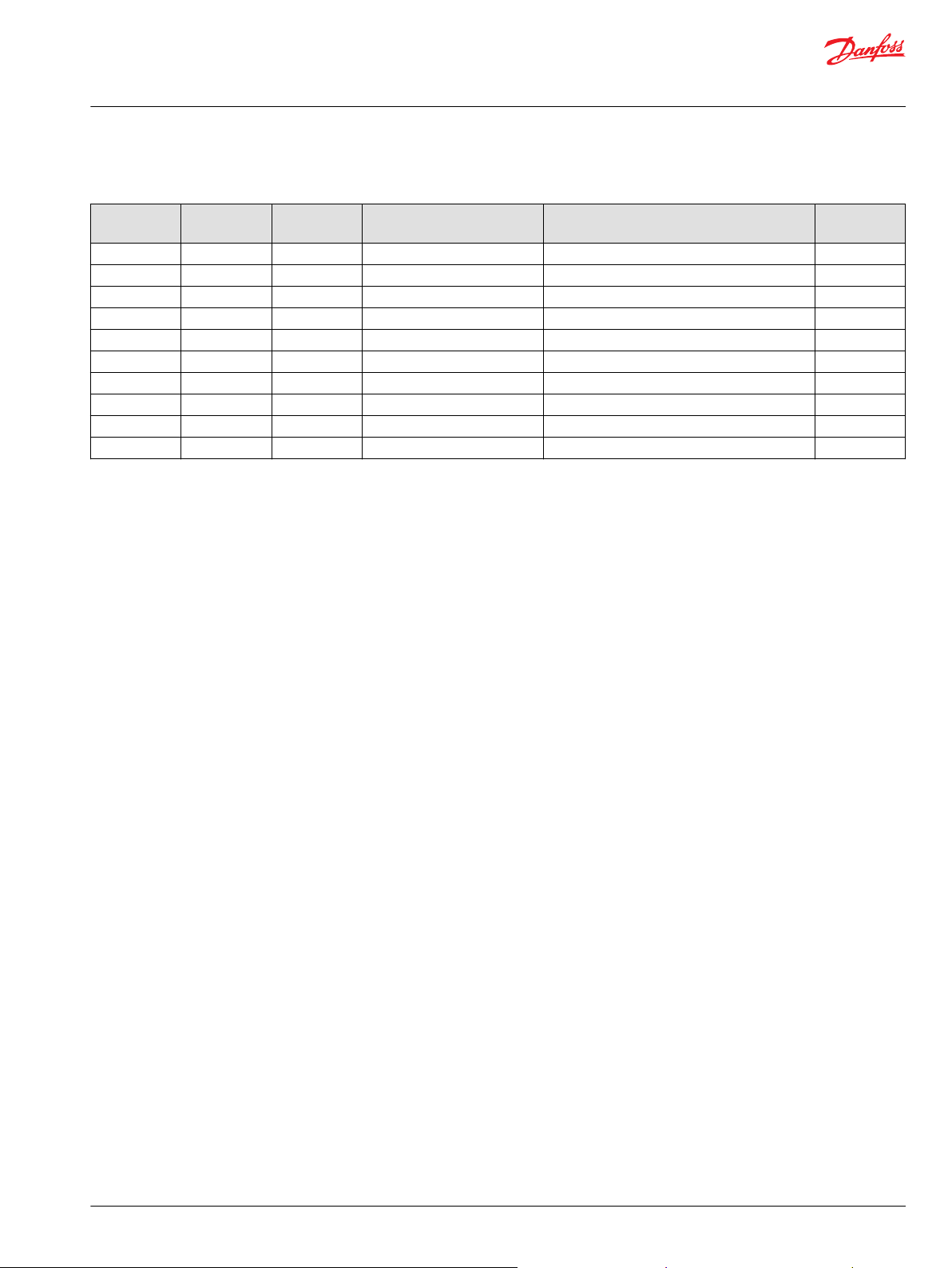

Page 20

L60

L50

L40

*L25

B81

C06

C20

QC04

G96

B83

*QB83

B80

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware EFA-EFM

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

20 | © Danfoss | January 2020 AX00000094en-000204

Page 21

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EFA

Item Date Begin Date End Part Number Part Name Quantity per

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG136 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: EFB

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG136 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: EFJ

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG176 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 21

Page 22

L60

L50

L40

*L25

B81

C06

C20

QC04

G96

B83

*QB83

B80

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

22 | © Danfoss | January 2020 AX00000094en-000204

Page 23

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EFM

Item Date Begin Date End Part Number Part Name Quantity per

C06 14-36 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 14-36 364000 Piston assembly 9

B83 14-36 KPPG12730A Speed sensor assembly 1

G96 14-36 307686 (9007210-1017) Screw, M10 x 80 1

L25 14-36 521722 Seal carrier assembly 1

L40 14-36 519021 Lip seal 1

L50 14-36 327627 (9004104-1540) O-ring 1

L60 14-36 516768 Retainer plate 1

QB83 14-36 085043 (9004201-3700) O-ring 1

QC04 14-36 8510395 Cylinder block kit with speed ring 1

Q210 14-36 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 23

Page 24

B83

L60

C20

QC04

C05

L50

L40

*L25

B81

C06

C20

QC04

G96

G96

B83

*QB83

B80

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware EGL-JAB

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

24 | © Danfoss | January 2020 AX00000094en-000204

Page 25

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: EGL

Item Date Begin Date End Part Number Part Name Quantity per

C06 10-34 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 10-34 364000 Piston assembly 9

B83 10-34 KPPG16719 Speed sensor assembly 1

G96 10-34 307686 (9007210-1017) Screw, M10 x 80 1

L25 10-34 521722 Seal carrier assembly 1

L40 10-34 519021 Lip seal 1

L50 10-34 327627 (9004104-1540) O-ring 1

L60 10-34 516768 Retainer plate 1

QB83 10-34 085043 (9004201-3700) O-ring 1

QC04 10-34 8510395 Cylinder block kit with speed ring 1

Q210 10-34 11134055 Overhaul seal kit, standard 1

Order code: EHD

C06 94-14 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG16408 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 8510395 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: GTA

C05 14-26 519257 (11012434) Cylinder block assembly 1

C20 14-26 364000 Piston assembly 9

B83 14-26 140644 Plug assembly 1

G96 14-26 307686 (9007210-1017) Screw, M10 x 80 1

L25 14-26 521722 Seal carrier assembly 1

L40 14-26 519021 Lip seal 1

L50 14-26 327627 (9004104-1540) O-ring 1

L60 14-26 516768 Retainer plate 1

QC04 14-26 8510370 Cylinder block kit 1

Q210 14-26 11134055 Overhaul seal kit, standard 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 25

Page 26

B83

L60

C20

QC04

C05

L50

L40

*L25

B81

C06

C20

QC04

G96

G96

B83

*QB83

B80

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

26 | © Danfoss | January 2020 AX00000094en-000204

Page 27

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: JAB

Item Date Begin Date End Part Number Part Name Quantity per

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 27

Page 28

L60

L50

L40

*L25

B81

B80

C20

QC04

G96

B83

C05

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware JAE-JCB

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

28 | © Danfoss | January 2020 AX00000094en-000204

Page 29

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: JAE

Item Date Begin Date End Part Number Part Name Quantity per

C05 15-44 519257 (11012434) Cylinder block assembly 1

C20 15-44 364000 Piston assembly 9

B83 15-44 140644 Plug assembly 1

G96 15-44 307686 (9007210-1017) Screw, M10 x 80 1

L25 15-44 521722 Seal carrier assembly 1

L40 15-44 519021 Lip seal 1

L50 15-44 327627 (9004104-1540) O-ring 1

L60 15-44 516768 Retainer plate 1

QC04 15-44 8510370 Cylinder block kit 1

Q210 15-44 11134055 Overhaul seal kit, standard 1

Order code: JAF

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: JAH

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 29

Page 30

L60

L50

L40

*L25

B81

B80

C20

QC04

G96

B83

C05

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

30 | © Danfoss | January 2020 AX00000094en-000204

Page 31

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: JCB

Item Date Begin Date End Part Number Part Name Quantity per

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 31

Page 32

B83

L60

C20

QC04

C05

L50

L40

*L25

B81

C06

C20

QC04

G96

G96

B83

*QB83

B80

(NNN)

(LAB & LAC)

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware LAB-NNN

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

32 | © Danfoss | January 2020 AX00000094en-000204

Page 33

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: LAB

Item Date Begin Date End Part Number Part Name Quantity per

C06 94-14 11012436 Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 KPPG14408 Speed sensor assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QB83 94-14 085043 (9004201-3700) O-ring 1

QC04 94-14 11135418 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: LAC

C06 94-14 11012436 Cylinder block assembly with speed ring 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 11135418 Cylinder block kit with speed ring 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Model/Kit

Order code: NNN

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

©

Danfoss | January 2020 AX00000094en-000204 | 33

Page 34

B83

L60

C20

QC04

C05

L50

L40

*L25

B81

C06

C20

QC04

G96

G96

B83

*QB83

B80

(PAA)

(PAB)

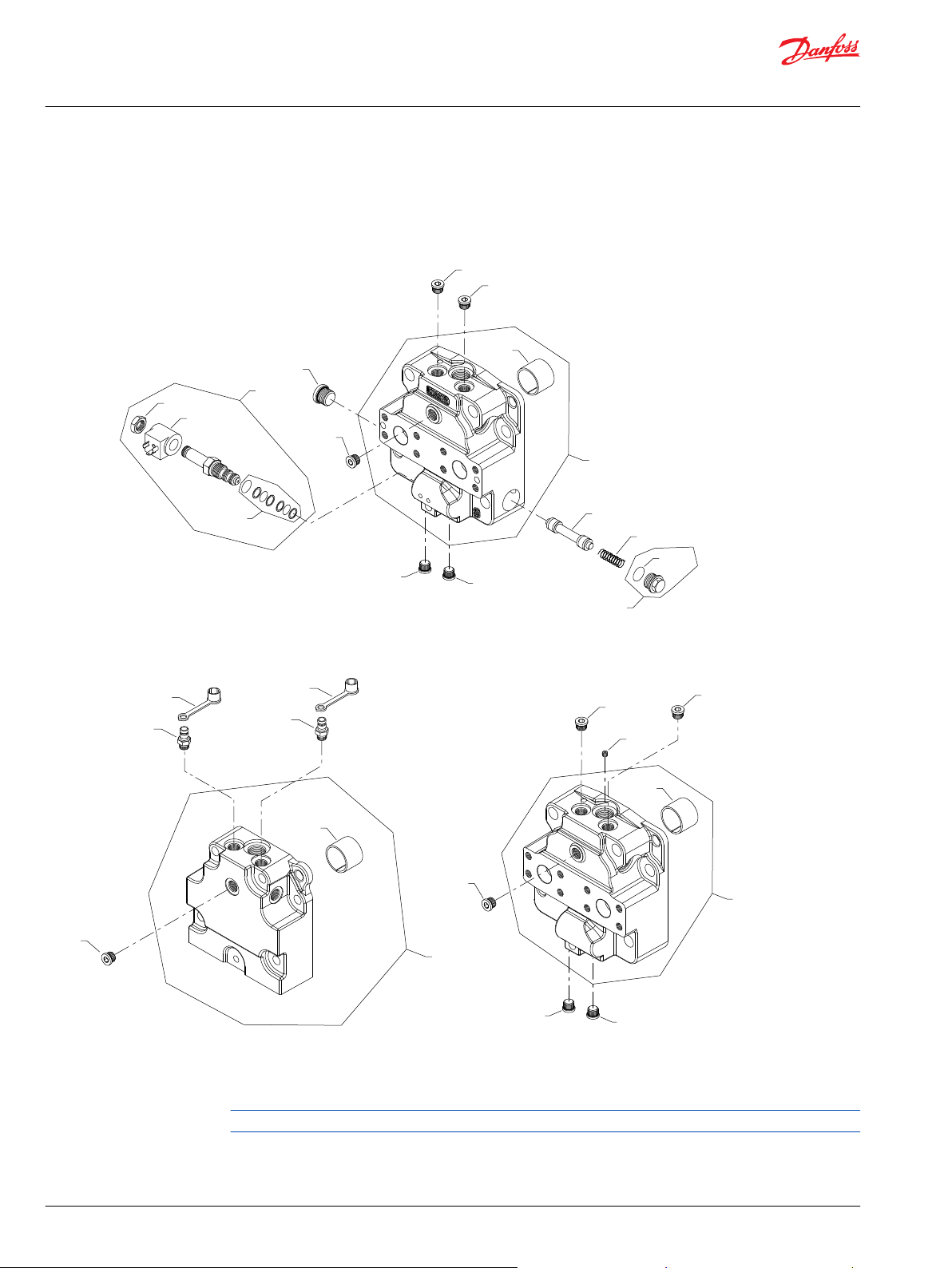

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

S90 100cc motor special hardware PAA, PAB

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

34 | © Danfoss | January 2020 AX00000094en-000204

Page 35

Parts Manual

Series 90 Motors, 100cc

Common parts and special hardware

Order code: PAA

Item Date Begin Date End Part Number Part Name Quantity per

C05 94-14 519257 (11012434) Cylinder block assembly 1

C20 94-14 364000 Piston assembly 9

B83 94-14 140644 Plug assembly 1

G96 94-14 307686 (9007210-1017) Screw, M10 x 80 1

L25 94-14 521722 Seal carrier assembly 1

L40 94-14 519021 Lip seal 1

L50 94-14 327627 (9004104-1540) O-ring 1

L60 94-14 516768 Retainer plate 1

QC04 94-14 8510370 Cylinder block kit 1

Q210 94-14 11134055 Overhaul seal kit, standard 1

Order code: PAB

C06 10-16 11093925 (11012435) Cylinder block assembly with speed ring 1

C20 10-16 364000 Piston assembly 9

B83 10-16 KPPG16719 Speed sensor assembly 1

G96 10-16 509487 Screw, M10 x 100 1

L25 10-16 521722 Seal carrier assembly 1

L40 10-16 519021 Lip seal 1

L50 10-16 327627 (9004104-1540) O-ring 1

L60 10-16 516768 Retainer plate 1

QB83 10-16 085043 (9004201-3700) O-ring 1

QC04 10-16 8510395 Cylinder block kit with speed ring 1

Q210 10-16 11134055 Overhaul seal kit, standard 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 35

Page 36

G04

G70

G04

G20

G70

G80

G81

G20

G04

G70

G20

G51

G50

G51

G50

G51

G50

(1, 8 & D)

(3 & 7)

(E)

Parts Manual

Series 90 Motors, 100cc

End cap

S90 100cc motor end cap 1-8, D, E

Parts configuration

* Included in overhaul seal kit Q210

36 | © Danfoss | January 2020 AX00000094en-000204

Page 37

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: 1

Item Date Begin Date End Part Number Part Name Quantity per

G04 90-20 8200581 End cap assembly, twin (SB-1988-018 on page

57, SB-1989-020 on page 61, SB-1998-007 on

page 64)

G20 87-02 11017304 (8700030) Journal bearing 1

G50 87-02 140644 Plug assembly 1

G51 87-02 140644 Plug assembly 1

G70 87-02 140644 Plug assembly 1

Order code: 3

G04 90-20 8200582 End cap assembly, axial (SB-1988-018 on page

57, SB-1989-020 on page 61, SB-1998-007 on

page 64)

G20 87-02 11017304 (8700030) Journal bearing 1

G50 87-02 140644 Plug assembly 1

G51 87-02 140644 Plug assembly 1

G70 87-02 140644 Plug assembly 1

Model/Kit

1

1

Order code: 7

G04 90-20 8200582 End cap assembly, axial (SB-1988-018 on page

57, SB-1989-020 on page 61, SB-1998-007 on

page 64)

G20 87-02 11017304 (8700030) Journal bearing 1

G50 87-02 140644 Plug assembly 1

G51 87-02 140644 Plug assembly 1

G70 87-02 140644 Plug assembly 1

Order code: 8

G04 90-20 8200581 End cap assembly, twin (SB-1988-018 on page

57, SB-1989-020 on page 61, SB-1998-007 on

page 64)

G20 87-02 11017304 (8700030) Journal bearing 1

G50 87-02 140644 Plug assembly 1

G51 87-02 140644 Plug assembly 1

G70 87-02 140644 Plug assembly 1

Parts continue to the next 2 pages.

1

1

©

Danfoss | January 2020 AX00000094en-000204 | 37

Page 38

G04

G70

G04

G20

G70

G80

G81

G20

G04

G70

G20

G51

G50

G51

G50

G51

G50

(1, 8 & D)

(3 & 7)

(E)

Parts Manual

Series 90 Motors, 100cc

End cap

Parts configuration

* Included in overhaul seal kit Q210

38 | © Danfoss | January 2020 AX00000094en-000204

Page 39

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: D

Item Date Begin Date End Part Number Part Name Quantity per

G04 99-09 11064118 End cap assembly, twin 1

G20 99-09 11017304 (8700030) Journal bearing 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

Order code: E

G04 95-17 8200562 End cap assembly, twin (SB-1998-007 on page

64)

G20 95-17 11017304 (8700030) Journal bearing 1

G50 95-17 140644 Plug assembly 1

G51 95-17 140644 Plug assembly 1

G70 95-17 140644 Plug assembly 1

G80 95-17 664524 (9005110-9000) Plug assembly 1

G81 95-17 664524 (9005110-9000) Plug assembly 1

Model/Kit

1

©

Danfoss | January 2020 AX00000094en-000204 | 39

Page 40

G04

G20

G70

G51

G50

G24

G22

G21

G31

G23

G29

G59

G04

G70

G50

G57

G51

G58

G20

G04

G70

G51

G50

G29

G59

G57

G20

M200

QM36

QM34

G32

(F)

(G & Q)

(M)

Parts Manual

Series 90 Motors, 100cc

End cap

S90 100cc motor end cap F-Q

Parts configuration

Generic coils shown.

40 | © Danfoss | January 2020 AX00000094en-000204

Page 41

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: F

Item Date Begin Date End Part Number Part Name Quantity per

G04 99-09 507659/P End cap assembly, axial ports 1

G20 99-09 11017304 (8700030) Journal bearing 1

G21 99-09 507587 Spool 1

G22 99-09 507534 Spring 1

G23 99-09 511926 Plug assembly 1

G24 99-09 012559 O-ring 1

G29 99-09 140644 Plug assembly 1

G31 99-09 315325 Plug assembly 1

G32 99-09 784942/P Solenoid valve. 12v 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G59 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

M200 99-09 785196 Coil, 12v, DIN connector 1

QM34 99-09 11144220 Solenoid seal kit 1

QM36 99-09 11144221 Coil nut 1

Model/Kit

Order code: G

G04 98-02 11064118 End cap assembly, twin metric ports 1

G20 98-02 11017304 (8700030) Journal bearing 1

G50 98-02 8700127 Diagnostic receptacle 1

G51 98-02 8700127 Diagnostic receptacle 1

G57 98-02 8700128 Dust cover 1

G58 98-02 8700128 Dust cover 1

G70 98-02 140644 Plug assembly 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 41

Page 42

G04

G20

G70

G51

G50

G24

G22

G21

G31

G23

G29

G59

G04

G70

G50

G57

G51

G58

G20

G04

G70

G51

G50

G29

G59

G57

G20

M200

QM36

QM34

G32

(F)

(G & Q)

(M)

Parts Manual

Series 90 Motors, 100cc

End cap

Parts configuration

Generic coils shown.

42 | © Danfoss | January 2020 AX00000094en-000204

Page 43

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: M

Item Date Begin Date End Part Number Part Name Quantity per

G04 98-02 11133008 End cap assembly, axial metric ports 1

G20 98-02 11127356 Journal bearing 1

G29 98-02 140644 Plug assembly 1

G50 98-02 140644 Plug assembly 1

G51 98-02 140644 Plug assembly 1

G57 98-02 517100 Orifice plug 1

G59 98-02 140644 Plug assembly 1

G70 98-02 140644 Plug assembly 1

Order code: Q

G04 98-02 11064118 End cap assembly, twin metric ports 1

G20 98-02 11017304 (8700030) Journal bearing 1

G50 98-02 8700127 Diagnostic receptacle 1

G51 98-02 8700127 Diagnostic receptacle 1

G57 98-02 8700128 Dust cover 1

G58 98-02 8700128 Dust cover 1

G70 98-02 140644 Plug assembly 1

Model/Kit

©

Danfoss | January 2020 AX00000094en-000204 | 43

Page 44

G04

G20

G70

G51

G50

G29

G33

G31

G24

G23

G22

G21

G59

G04

G70

G51

G50

G24

G22

G21

G31

G23

G29

G59

G20

G32

M200

QM36

QM34

(T)

(U)

Parts Manual

Series 90 Motors, 100cc

End cap

S90 100cc motor end cap T, U

Parts configuration

44 | © Danfoss | January 2020 AX00000094en-000204

Generic coils shown.

Page 45

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: T

Item Date Begin Date End Part Number Part Name Quantity per

G04 99-09 513899/P End cap assembly, axial ports 1

G20 99-09 11017304 (8700030) Journal bearing 1

G21 99-09 507587 Spool 1

G22 99-09 507534 Spring 1

G23 99-09 511926 Plug assembly 1

G24 99-09 012559 O-ring 1

G29 99-09 140644 Plug assembly 1

G31 99-09 315325 (9005110-8700) Plug assembly 1

G33 99-09 327007 (9005110-4400) Plug assembly 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G59 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

Model/Kit

Order code: U

G04 99-09 516298/P End cap assembly, axial 1

G20 99-09 11017304 (8700030) Journal bearing 1

G21 99-09 507587 Spool 1

G22 99-09 507534 Spring 1

G23 99-09 511926 Plug assembly 1

G24 99-09 012559 O-ring 1

G29 99-09 140644 Plug assembly 1

G31 99-09 315325 Plug assembly 1

G32 99-09 517171/P Solenoid valve, 12v 1

G59 99-09 140644 Plug assembly 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

M200 99-09 517167 Coil, 12v, Weather-Pack 1

QM34 99-09 11144220 Solenoid seal kit 1

QM36 99-09 11144221 Coil nut 1

©

Danfoss | January 2020 AX00000094en-000204 | 45

Page 46

G100

SR1

ST1

S100

SR1A

G04

G20

G70

G51

G50

SDR1

SPA1

SPB1

SL01

ST1A

SE2

SE1

SE1A

G04

*G20

G70

G51

G50

G29

G59

(V)

(W & X)

Parts Manual

Series 90 Motors, 100cc

End cap

S90 100cc motor end cap V-X

Parts configuration

46 | © Danfoss | January 2020 AX00000094en-000204

Page 47

Parts Manual

Series 90 Motors, 100cc

End cap

Order code: V

Item Date Begin Date End Part Number Part Name Quantity per

G04 98-02 518212/P End cap assembly, axial ports 1

G20 98-02 11017304 (8700030) Journal bearing 1

G50 98-02 140644 Plug assembly 1

G51 98-02 140644 Plug assembly 1

G70 98-02 140644 Plug assembly 1

G100 98-02 9007300-4432 Screw 6

S100 98-02 518083 Valve housing assembly 1

SDR1 98-02 518149 O-ring 1

SE1 98-02 518961 Solenoid pilot valve 1

SE1A 98-02 516735 Seal ring 1

SE2 98-02 520344 Coil, 12v 1

SL01 98-02 518149 O-ring 1

SPA1 98-02 516756 O-ring 1

SPB1 98-02 516756 O-ring 1

SR1 98-02 516970 Valve 1

SR1A 98-02 518151 O-ring 1

ST1 98-02 518052 Bypass valve 1

ST1A 98-02 518150 O-ring 1

Model/Kit

Order code: W

G04 99-09 519388/P End cap assembly, axial ports 1

G20 99-09 11017304 (8700030) Journal bearing 1

G29 99-09 140644 Plug assembly 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G59 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

Order code: X

G04 98-02 11040386 End cap assembly, axial ports 1

G20 98-02 11017304 (8700030) Journal bearing 1

G29 99-09 140644 Plug assembly 1

G50 99-09 140644 Plug assembly 1

G51 99-09 140644 Plug assembly 1

G59 99-09 140644 Plug assembly 1

G70 99-09 140644 Plug assembly 1

©

Danfoss | January 2020 AX00000094en-000204 | 47

Page 48

H50

H20

*H90

H30

H55

H50

H55

H20

*H90

H30

H10

H50

H20

*H90

H30

H55

H10

H50

H50

H10

*QH50

*QH50

H10

H50

H55

H20

*H90

H30

H30

H20

H30

H20

H600

H500

(B)

(C)

(N)

(W)

(B)

(C)

(N)

(W)

Parts Manual

Series 90 Motors, 100cc

Loop flushing

S90 100cc motor loop flushing B-W

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

48 | © Danfoss | January 2020 AX00000094en-000204

Page 49

Parts Manual

Series 90 Motors, 100cc

Loop flushing

Order code: B

Item Date Begin Date End Part Number Part Name Quantity per

H10 00-14 516301 Loop flushing spool 1

H20 00-14 517438 Spring guide 2

H30 00-14 517439 Spring 2

H50 00-14 517436 Spring cartridge assembly 2

H55 00-14 140644 Plug assembly 1

H90 00-14 085043 (9004201-3700) O-ring 2

Order code: C

H10 03-16 519242 Loop flushing spool 1

H20 03-16 517438 Spring guide 2

H30 03-16 517439 Spring 2

H50 03-16 517436 Spring cartridge assembly 2

H55 03-16 140644 Plug assembly 1

H90 03-16 085043 (9004201-3700) O-ring 2

Model/Kit

Order code: K

H10 89-38 365544 (8800550) Shuttle spool 1

H50 89-38 518016 Plug assembly 2

H300 89-38 513596 Spring guide assembly (SB-2000-047 on page

68)

QH50 87-07 085043 (9004201-3700) O-ring 2

Order code: N

H10 89-38 8800668 Loop flushing spool, defeated 1

H10 87-07 89-37 308486 (8800021) Loop flushing spool, defeated (SB-1989-020 on

page 61)

H50 87-07 140644 Plug assembly 2

H50A 87-07 085043 (9004201-3700) O-ring 2

Order code: W

H10 89-38 365544 (8800550) Shuttle spool 1

H10 89-38 89-37 674473 (8800069) Loop flushing spool (SB-1989-020 on page 61) 1

H20 87-07 89-37 674481 (8800265) Spring guide (SB-1989-020 on page 61) 2

H30 87-07 89-37 8800067 Spring (SB-1989-020 on page 61) 2

H50 87-07 89-37 674507 (9005475-0069) Plug assembly (SB-1989-020 on page 61) 2

H500 17-33 11160971 Plug/spring assembly 1

H600 17-33 11160971 Plug/spring assembly 1

QH50 87-07 085043 (9004201-3700) O-ring 2

2

1

©

Danfoss | January 2020 AX00000094en-000204 | 49

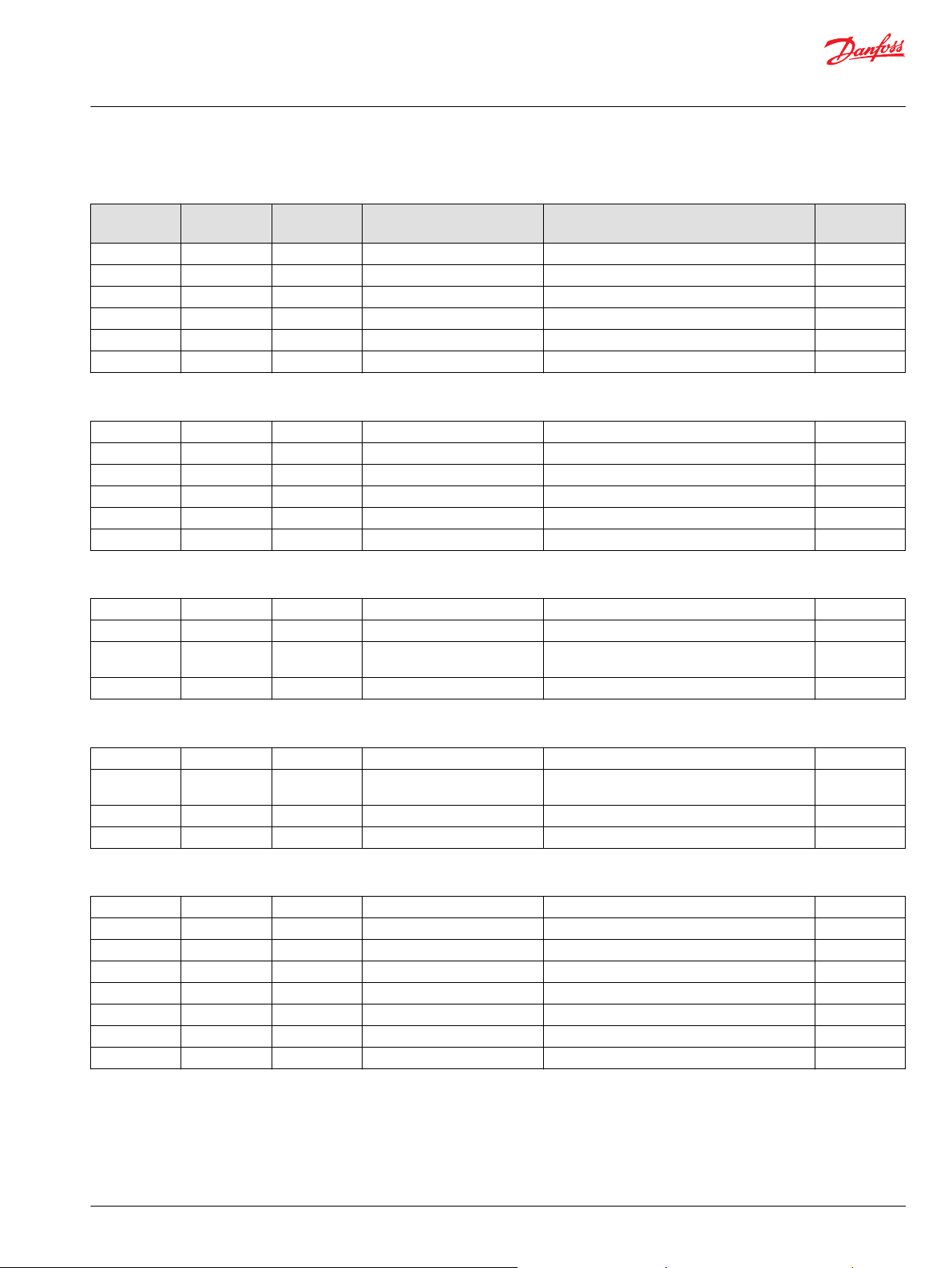

Page 50

K10

*K50

*K51

QK10

*K50

*K50

QK10

(00)

(20 & 24)

(A0-N6)

Parts Manual

Series 90 Motors, 100cc

Charge pressure setting

S90 100cc motor charge pressure setting 00-N6

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

50 | © Danfoss | January 2020 AX00000094en-000204

Page 51

Parts Manual

Series 90 Motors, 100cc

Charge pressure setting

Order code: 00

Item Date Begin Date End Part Number Part Name Quantity per

K10 89-44 001537 (9005100-8700) Plug assembly 1

K50 89-44 001149 (9004201-6200) O-ring 1

Order code: 20-24

K000 90-20 8510012 Adjustable charge relief valve kit (SB-1989-020 on

page 61)

K50 90-20 001149 (9004201-6200) O-ring 1

Order code: A0

QK10 98-19 8510253 Cartridge CPRV kit, 13 bar, 11 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: A3

QK10 98-19 8510256 Cartridge CPRV kit, 13 bar, 16 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Model/Kit

1

Order code: E4

QK10 98-19 8510261 Cartridge CPRV kit, 16 bar, 4 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: E6

QK10 98-19 8510252 Cartridge CPRV kit, 16 bar, 7 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: F0

QK10 98-19 8510259 Cartridge CPRV kit, 16 bar, 11 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: F3

QK10 98-19 8510262 Cartridge CPRV kit, 16 bar, 16 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Parts continue to the next 2 pages.

©

Danfoss | January 2020 AX00000094en-000204 | 51

Page 52

K10

*K50

*K51

QK10

*K50

*K50

QK10

(00)

(20 & 24)

(A0-N6)

Parts Manual

Series 90 Motors, 100cc

Charge pressure setting

Parts configuration

Generic end cap used to show part location only

* Included in overhaul seal kit Q210

52 | © Danfoss | January 2020 AX00000094en-000204

Page 53

Parts Manual

Series 90 Motors, 100cc

Charge pressure setting

Order code: G0

Item Date Begin Date End Part Number Part Name Quantity per

QK10 98-19 8510260 Cartridge CPRV kit, 16 bar, 22 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: G3

QK10 98-19 8510263 Cartridge CPRV kit, 16 bar, 27 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Order code: N4

QK10 98-19 8510255 Cartridge CPRV kit, 13 bar, 4 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

Model/Kit

Order code: N6

QK10 98-19 11097072 Cartridge CPRV kit, 13 bar, 7 L/min 1

K50 98-19 001149 (9004201-6200) O-ring 1

K51 98-19 085043 (9004201-3700) O-ring 1

©

Danfoss | January 2020 AX00000094en-000204 | 53

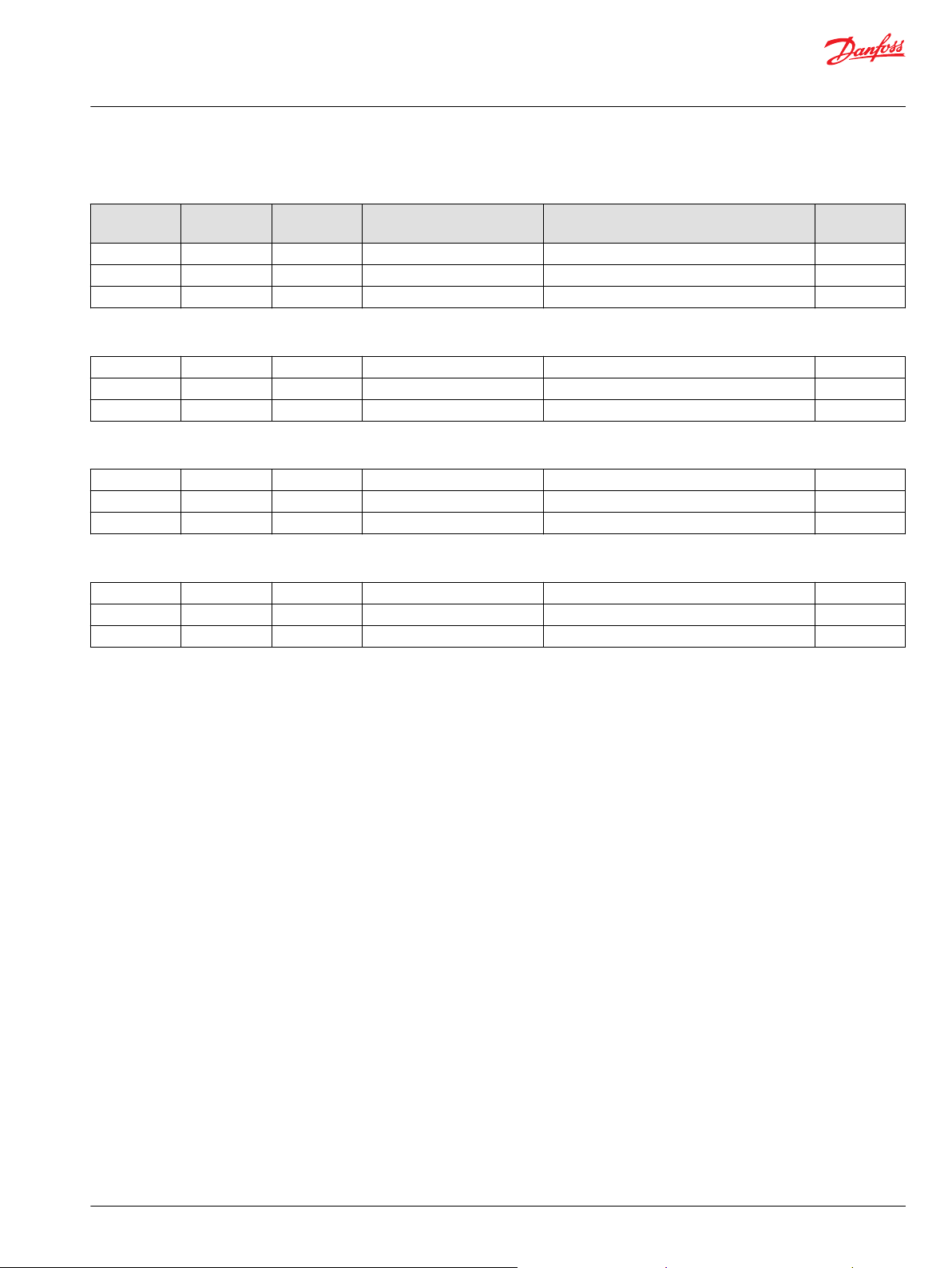

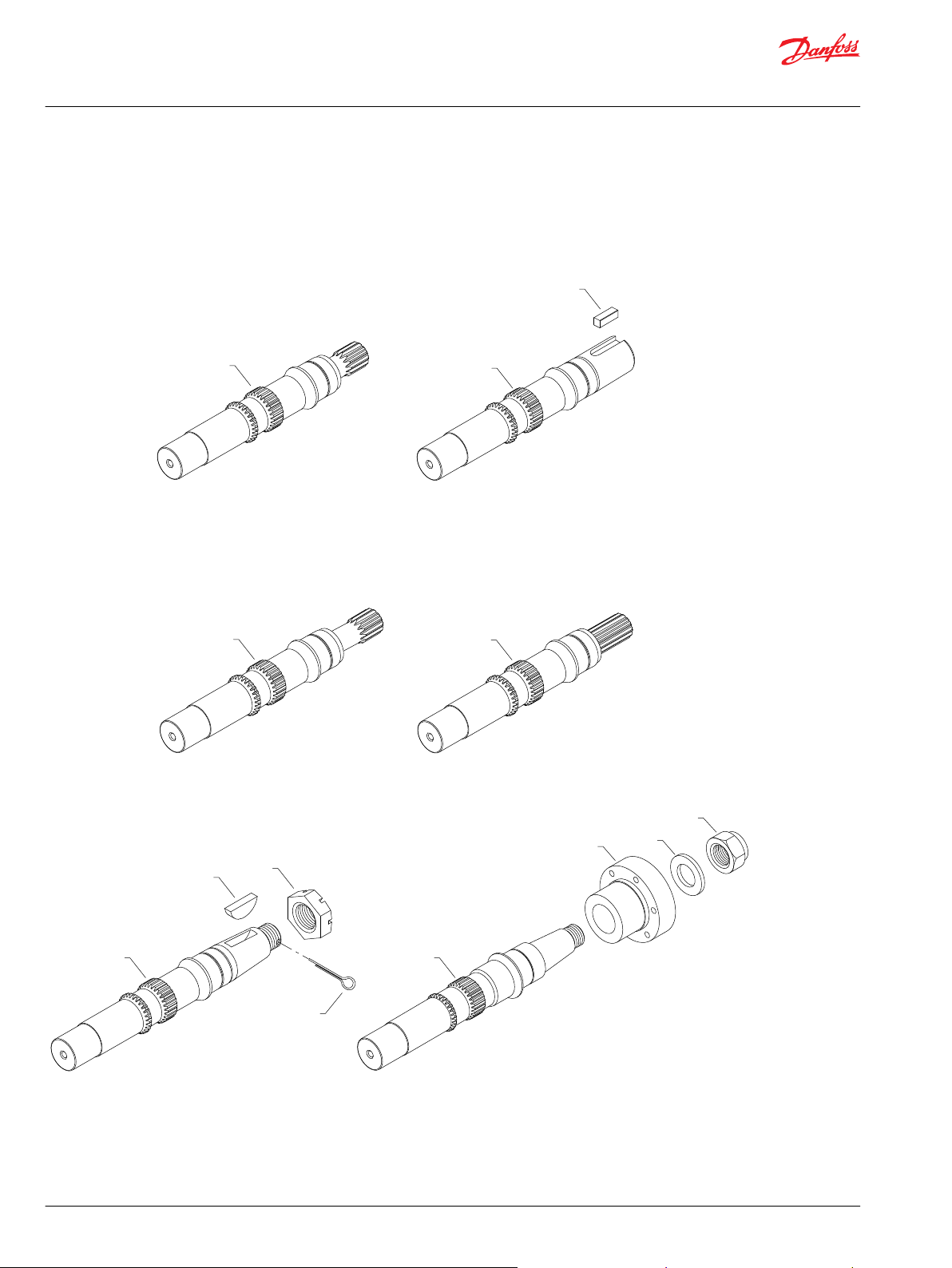

Page 54

L100

L100

L80

L100

L100

L100

L80

L90

L61

L100

L500

L200

L90

(C6, C7, F1, G7, S1)

(K3)

(L1)

(S5)

(T2)

(TJ)

Parts Manual

Series 90 Motors, 100cc

Shaft

S90 100cc motor shaft C6-TJ

Parts configuration

54 | © Danfoss | January 2020 AX00000094en-000204

Page 55

Parts Manual

Series 90 Motors, 100cc

Shaft

Order code: C6

Item Date Begin Date End Part Number Part Name Quantity per

L100 87-07 11045036 Shaft, 21 tooth spline, 16/32 1

Order code: C7

L100 87-07 8200591 Shaft, 23 tooth spline, 16/32 1

Order code: F1

L100 87-07 8200597 Shaft, 13 tooth spline, 8/16 1

Order code: G7

L100 05-21 8200591 Shaft, 23 tooth spline, 16/32 1

Order code: K3

L100 87-07 11012428 Shaft, straight key 1

L80 87-07 9003261-3724 Key, .375 x 1.5 1

Model/Kit

Order code: L1

L100 10-15 11081469 Shaft, 27 tooth spline, 12/24, special length 1

Order code: S1

L100 87-07 11012429 Shaft, 14 tooth spline, 12/24 1

Order code: S5

L100 87-07 11014534 Shaft, 17 tooth spline, 12/24 1

Order code: T2

L100 87-02 11014535 Shaft, tapered 1

L61 87-02 9004600-1230 Cotter pin 1

L80 87-02 9003310-3724 Woodruff key, .3730 x 1.5 1

L90 87-02 5000606 Slotted nut 1

Order code: TJ

L90 97-47 504060 Nut 1

L100 97-47 511785 Shaft, tapered 1

L200 97-47 511462 Flange coupling 1

L500 97-47 511627 Washer 1

©

Danfoss | January 2020 AX00000094en-000204 | 55

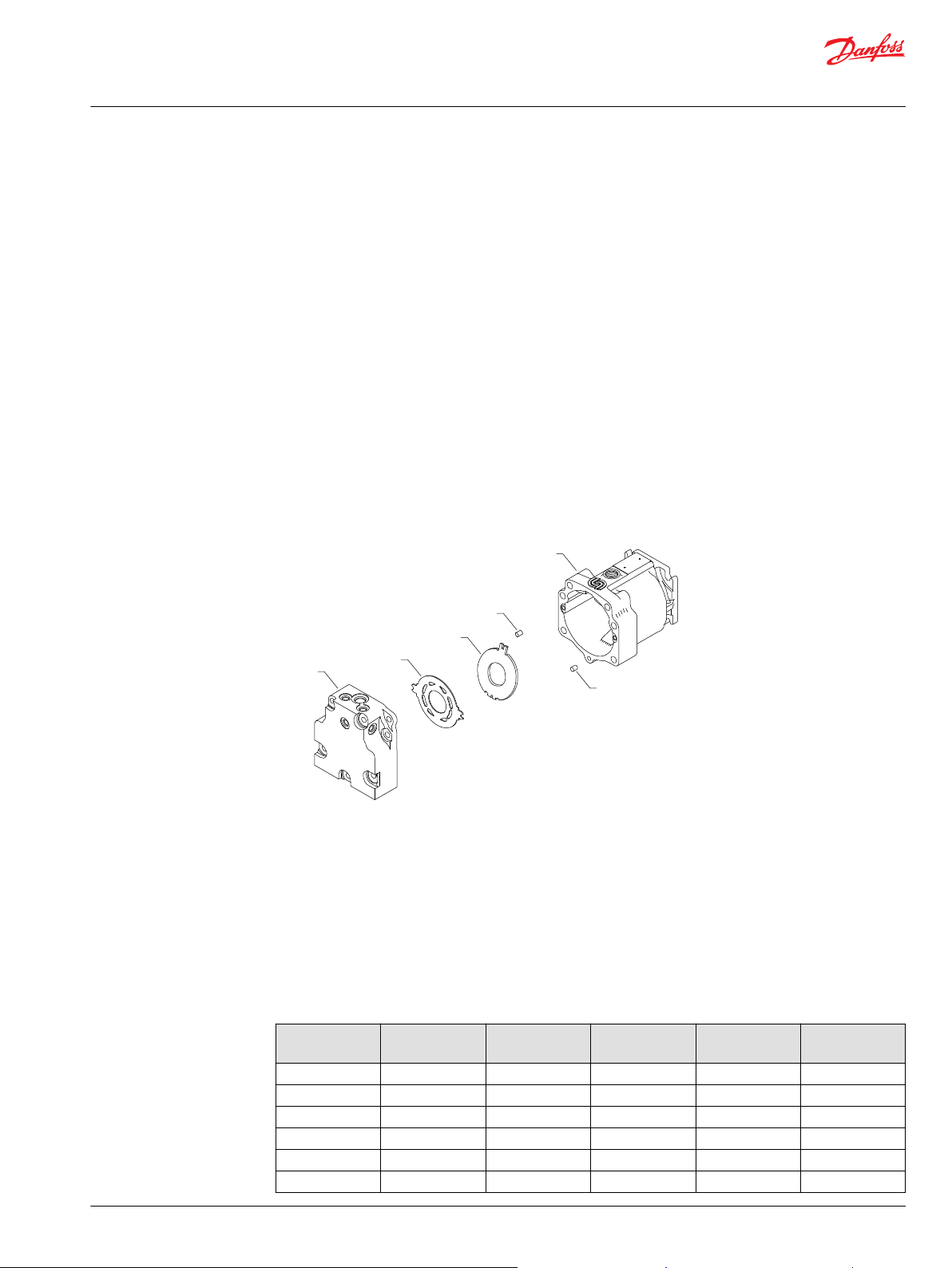

Page 56

Parts Manual

Series 90 Motors, 100cc

Overhaul seal kit

S90 100cc motor seal kit

Item Date Begin Date End Part Number Part Name Quantity per

Q210 87-07 11134055 Overhaul seal kit, 90M100, standard 1

G30 87-07 8200511 End cap gasket (SB-2001-011 on page 69) 1

K51 87-07 085043 (9004201-3700) O-ring 1

K50 89-44 001149 (9004201-6200) O-ring 1

L25 87-07 521722 Seal carrier assembly 1

QB83 87-07 085043 (9004201-3700) O-ring 1

QH50 87-07 085043 (9004201-3700) O-ring 2

Model/Kit

56 | © Danfoss | January 2020 AX00000094en-000204

Page 57

D50

B10

B50

C80

G04

B50

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-1988-018

Products affected

Series 90 fixed motors

Subject

Dowel pin change

Description

A product change has occurred on Series 90: 75cc and 100cc fixed displacement motors.

The dowel pins (item B50) have increased in diameter from 1/4” to 3/8”. With this change, the dowel pin

hole diameters in the end cap (item G04), housing (item B10), and the valve plate (item C80) have also

changed. In addition, the thrust plate (item D50) in the 100 cc fixed displacement motor has also

changed to fit the new housing.

This change creates spare parts non-interchangeability among all of the above mentioned parts. All of

the affected parts remain available for the repair of any vintage Series 90 fixed motor. Refer to the date

code portion of the serial number on the name plate of the motor being repaired when ordering parts.

Models affected

All 95-3xxx (75 cc) and 96-3xxx (100cc) series 90 fixed displacement motors

Serial numbers

Series 90: 75 cc fixed motors, 95-3xxx, changed at serial number A-88-43-xxxxx.

Series 90: 100 cc fixed motors, 96-3xxx, changed at serial number A-88-23-xxxxx.

Part numbers affected

Item* Quantity per

©

Danfoss | January 2020 AX00000094en-000204 | 57

G04 (axial) 1 8100233 8100306 8200123 8200152

G04 (twin) 1 8100232 8100279 8200122 8200151

C80 1 8100095 8100278 8200103 8200134

D50 1 No Change No Change 8200014 8200167

B50 2 9004800-2512 9004800-3708 9004800-3116 9004800-3708

B10 1 8100252 8100465 8200099 333641

motor

75 cc Prior to

88-43

75 cc From 88-43 100 cc Prior to

88-23

100 cc From

88-23

Page 58

Parts Manual

Series 90 Motors, 100cc

Service bulletin

Parts disposition

Non-interchangeable

58 | © Danfoss | January 2020 AX00000094en-000204

Page 59

Welded Piston

Assembly

Hollow Piston

Assembly

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-1988-023

Products affected

Series 90 pumps and motors

Subject

Piston improvement

Description

Product Information Bulletin PIB-8801 (March, 1988) announced the incorporation of fabricated (welded)

piston assemblies, replacing non-fabricated (hollow) piston assemblies, in the cylinder blocks of all Series

90 pumps and motors. This change increases the overall efficiency of the Series 90 product line.

To simplify service parts inventory for all Series 90 units, only individual welded piston assemblies will be

available as spare parts. The hollow pistons will be obsoleted. Part numbers for individual welded piston

assemblies are listed in this bulletin.

Since all Series 90 pumps and motors have nine (9) pistons, welded pistons being used to replace hollow

pistons during repair MUST be install in the cylinder block symmetrically, in multiples of three (3).

When replacing hollow pistons with welded pistons, it is mandatory that the welded pistons be

incorporated symmetrically in multiples of three.

Models affected

All series 90 pumps and motors: 93-xxxx, 94-xxxx, 95-xxxx, and 96-xxxx pumps

Serial numbers

Welded pistons will be incorporated into all series 90 pumps and motors by the end of the first quarter of

1998.

Part numbers affected

Part number Description

706101 Piston assembly, welded - 42 cc

367672 Piston assembly, welded - 55 cc

708230 Piston assembly, welded - 75 cc

364000 Piston assembly, welded - 100 cc

©

Danfoss | January 2020 AX00000094en-000204 | 59

Page 60

Parts Manual

Series 90 Motors, 100cc

Service bulletin

Parts disposition

Interchangeable

60 | © Danfoss | January 2020 AX00000094en-000204

Page 61

A

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-1989-020

Products affected

Series 90 fixed displacement motors

Subject

Incorporation of adjustable charge relief valve

Description

As a product improvement, Danfoss is incorporating an externally adjustable charge relief valve on all

series 90 fixed displacement motors. This design replaces the previous shimmed relief valve. The new

design valve provides a range of pressure adjustment from 10 to 32 bar.

The diameter of the loop flushing shuttle spool increases from .25” (6.35mm) to .375” (9.53mm) at the

same incorporation date as the charge relief valve change.

This is a non-interchangeable change. Adjustable style charge relief valves can not be added to motors

manufactured before this incorporation date. Old style end caps, which house the charge relief and loop

flushing valves, will not be available as service parts. If new end caps are required, new style charge relief

and loop flushing parts must also be installed.

Charge relief valve adjustment procedures can be found in the Series 90 Service Manual (BLN- 9947 Rev.

B). Charge pressure increases/decreases at the rate of 78 psi (5.4 bar) per turn clockwise/

counterclockwise.

The new style charge relief plug protrudes from the motor end cap approximately .63” (16mm) farther

than the shimmed design. New dimensions from the center line to the top of the charge relief valve plug

are shown below.

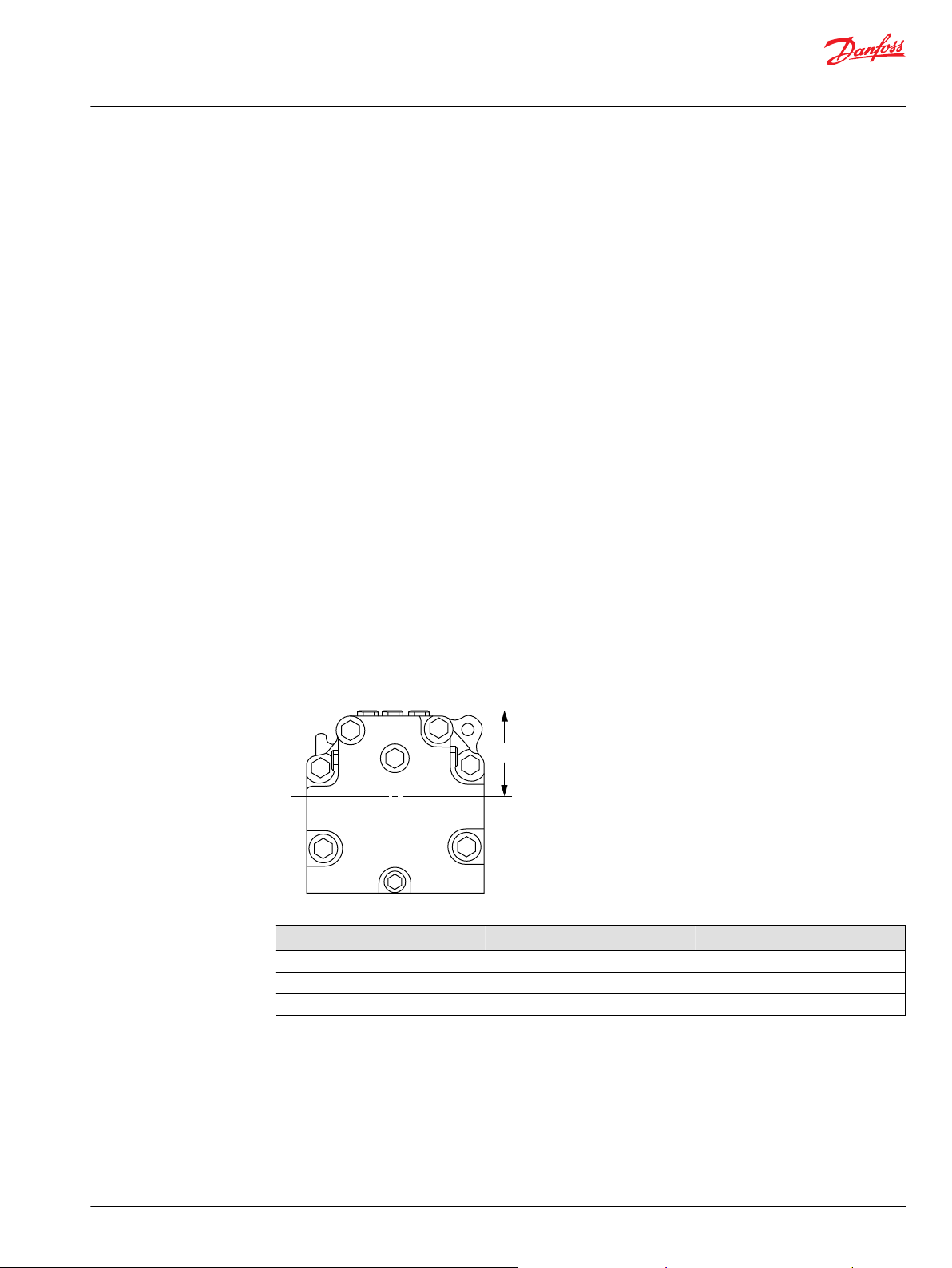

Size Non-adjustable dimension (A) Adjustable dimension (A)

55cc 82.3 mm [3.24 in] 98.3 mm [3.87 in]

75cc 88.9 mm [3.50 in] 105 mm [4.13 in]

100cc 92.5 mm [3.64 in] 108.5 mm [4.27 in]

Models affected

All94-3xxx, 95-3xxx, and 96-3xxx fixed displacement motors

Series numbers

All 55cc motors (94-3xxx) will change at s/n A-89-38-xxxxx

All 75cc motors (95-3xxx) will change at s/n A-89-44-xxxxx

©

Danfoss | January 2020 AX00000094en-000204 | 61

Page 62

Parts Manual

Series 90 Motors, 100cc

Service bulletin

All 100cc motors (96-3xxx) will change at s/n A-90-20-xxxxx

Part numbers affected

Charge relief and loop flushing hardware for old vintage motors can be found in the Series 90 Parts

Manual (520L0890). The new part numbers are as follows:

New charge relief and loop flushing hardware

Item Part number Description Quantity

K90 9003575-0101 Nut 1

K10 8800488-1000 Plug assembly 1

K50 9004201-6200 O-ring 1

K70 8800476 Spring 1

K80 8800449 Poppet 1

K000 9005100-8700 Plug assembly 1

H10 8800550 Shuttle valve spool 1

H20 8800551 Washer 2

H30 364950 Spring 2

H40 9004201-3700 O-ring 2

H50 9005475-0097 Plug assembly 2

H10 8800552 Loop flushing spool,

defeated

1

New end caps

Part number Description

8000196 Twin port - 55 cc

8000197 Axial port - 55 cc

8100373 Twin port - 75 cc

8100374 Axial port - 75 cc

8200188 Twin port - 100 cc

8200189 Axial port - 100 cc

62 | © Danfoss | January 2020 AX00000094en-000204

Page 63

H20W

H30W

H40W

H50W

H68W

H66W

H64W

H62W

H60W

H20W

H30W

H50W

H40W

H10W

K000

H10N

Parts Manual

Series 90 Motors, 100cc

Service bulletin

Parts disposition

Non-interchangeable

©

Danfoss | January 2020 AX00000094en-000204 | 63

Page 64

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-1998-007

Products affected

Series 90 55cc, 75cc, and 100cc fixed displacement motors, and 55cc and 75cc variable displacement

motors

Subject

Charge relief seat

Description

Danfoss has initiated a change to the end caps used on series 90 55cc, 75cc, and 100cc fixed

displacement motors, and the series 90 55cc and 75cc variable displacement motors.

Currently, the end caps used on these motors contain a pressed in insert, which serves as a seat for the

charge pressure relief valve assembly. The insert was originally introduced to provide a suitable wear

surface for the charge pressure relief valve poppet.

Since the original design, a number of changes to the charge pressure relief valve design have reduced

the severity of the wear characteristics between the poppet and relief seat. These changes have now

made it possible to remove the insert from the end cap assembly. The design of the motor end cap has

been modified in a manner that allows the charge relief poppet to seat directly against the casting

machined surface.

The removal of the insert was initially introduced with the series 90 130cc motors in 1995, and with this

change a more uniform product family is achieved.

To aid in identifying and tracking this change, Danfoss has released new end cap part numbers. The new

end cap is directly interchangeable with the previous end cap and with adjustable charge pressure relief

valve components. The previous end cap part numbers will no longer be available as service parts. Page 2

of this bulletin provides part number cross-reference information.

Models affected

All 94-3xxx, 943xxxx, 95-3xxx, 953xxxx, 96-3xxx, and 963xxxx fixed displacement motors.

All 94-4xxx, 944xxxx, 95-4xxx, 954xxxx variable displacement motors.

Serial numbers

Change became effective with s/n A-98-34-xxxxx and beyond.

64 | © Danfoss | January 2020 AX00000094en-000204

Page 65

Parts Manual

Series 90 Motors, 100cc

Service bulletin

Part numbers affected

Motor type Displacement Order code Porting Split flange

thread

Fixed 55 cc D Twin Metric 8000417 8000593

Fixed 55 cc 1 & 8 Twin English 8000196 8000594

Fixed 55 cc 3 & 7 Axial English 8000197 8000596

Variable 55 cc R Twin Metric 8000356 8000598

Variable 55 cc 1 & 8 Twin English 8000335 8000599

Fixed 75 cc D Twin Metric 8100576 8100731

Fixed 75 cc 1 & 8 Twin English 8100373 8100733

Fixed 75 cc 3 & 7 Axial English 8100374 8100734

Variable 75 cc 1 & 8 Twin English 8100442 8100737

Fixed 100 cc E Twin English 8200319 8200407

Fixed 100 cc 1 & 8 Twin English 8200188 8200408

Fixed 100 cc 3 & 7 Axial English 8200189 8200409

Prior to 98-34 Current

Parts disposition

Interchangeable

©

Danfoss | January 2020 AX00000094en-000204 | 65

Page 66

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-1999-036

Products affected

Series 90 100cc fixed displacement motors

Subject

Motor housing change

Description

Danfoss has introduced a design change to the motor housings used on all series 90 100cc fixed

displacement motors. The housing strength has been increased in the area of the casting ribs, by

increasing the size of the rib. This change will reduce the potential for cracking the rib of the housing

when tightening the two shorter end cap bolts.

To assist in identifying this change, Danfoss has released a new housing part number. The new housing is

completely interchangeable with the previous housing. The previous housing has been obsoleted and is

no longer available

Models affected

All 96-3xxx, and 963xxxx fixed displacement motors.

Serial numbers

Danfoss Ames Production - Effective on motor serial number A-99-44-xxxxx.

Danfoss Neumunster Production - Effective on motor serial number N-99-45-xxxxx.

Danfoss Shanghai Production- effective during the fourth quarter of 2000.

Part numbers affected

Description Previous Housing New Housing

motor housing - MF 8200230 8200447

66 | © Danfoss | January 2020 AX00000094en-000204

Page 67

Parts Manual

Series 90 Motors, 100cc

Service bulletin

Parts disposition

Interchangeable

©

Danfoss | January 2020 AX00000094en-000204 | 67

Page 68

Spring seat

Spring

Spring assembly

Old design New design

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-2000-047

Products affected

Series 90 42cc, 55cc, 75cc, and 100cc fixed displacement motors, and 55cc and 75cc variable

displacement motors

Subject

Loop flushing spring and spring seat change

Description

As a product improvement, Danfoss has changed the design of the spring and spring seat for the series

90 42cc, 55cc, 75cc, and 100cc fixed and variable displacement motors. The old design used a separate

spring and spring seat. The new design incorporates the two parts into a one piece assembly. This makes

the assembly of the spring and spring seat onto the spool much easier than the previous design.

Since the new spring assembly has a high spring rate than the previous spring, this is an interchangeable

change only if both springs and spring seats are replaced at the same time. Danfoss has issued a new part

number for the spring assembly. The previous spring seat and spring remain valid service parts since they

are used on other Danfoss products.

Models affected

All 93-3xxx, 933xxxx, 94-3xxx, 943xxxx, 95-3xxx, 953xxxx, 96-3xxx, and 963xxxx fixed displacement

motors with loop flushing options of A, B, or C.

All 94-4xxx, 944xxxx, 95-4xxx, and 954xxxx variable displacement motors with loop flushing options of A,

B, or C.

Serial numbers

Danfoss Ames, IA production - Change effective at serial number A-02-03-xxxxx.

Danfoss Neumunster, Germany production - Change effective at serial number N-01-08-xxxxx..

Part numbers affected

Previous spring seat Previous spring New spring assembly

8800551 4350286 513596

Parts disposition

Interchangeable

68 | © Danfoss | January 2020 AX00000094en-000204

Page 69

For both twin and axial

port end cap

For axial port

end cap

For twin port

end cap

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-2001-011

Products affected

Series 90 55cc, 75cc, and 100cc fixed displacement motors

Subject

Change to end cap gasket material

Description

The end cap gasket material has changed. Danfoss has issued new end cap gasket part numbers. The

previous part numbers are obsolete. They are no longer available for service.

Models affected

All 94-3xxx, 943xxxx, 95-3xxx, 953xxxx, 96-3xxx, and 963xxxx fixed displacement motors.

Serial numbers

Danfoss Ames, IA production - Change effective at s/n A-01-19-xxxxx.

Danfoss Neumunster, Germany production - Change effective at s/n N-01-19-xxxxx..

Part numbers affected

Frame size Mounting flange (end cap

porting)

55 cc SAE (all), cartridge (axial) 8000167 8000721

55 cc Cartridge (twin) 8000603 8000720

75 cc SAE (all), cartridge (axial) 8100311 8100875

75 cc Cartridge (twin) 8100749 8100874

100 cc SAE (all) 8200102 8200511

Previous end cap gasket New end cap gasket

Parts disposition

Interchangeable

©

Danfoss | January 2020 AX00000094en-000204 | 69

Page 70

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-2002-048

Products affected

Series 90 55cc pumps and motors, and 75 - 100 cc motors

Subject

Consolidation of valve plate part numbers

Description

Danfoss has consolidated the part numbers for some of the series 90 pump and motor valve plates. Our

plant in Germany has been producing the valve plates for series 90 pumps and motors since August 7,

2001. The U.S. plant has its part number for these valve plates as the German plant has its part number.

The U.S. plant will now use the German part number. This obsoletes the U.S. part numbers. Since the

parts are the same, the part number are interchangeable.

Models affected

All series 90 75 cc pumps and motors, 75 cc motors, and 100 cc motors.

Serial numbers

This change became effective at serial number A-02-46-xxxxx.

Part numbers affected

Description Old part number New part number

Valve plate, 75 cc pump 8000071 314427

Valve plate, 75 cc motor 8000132 329748

Valve plate, 75 cc motor 8100278 323766

Valve plate, 100 cc motor 8200134 324137

Parts disposition

Non-interchangeable

70 | © Danfoss | January 2020 AX00000094en-000204

Page 71

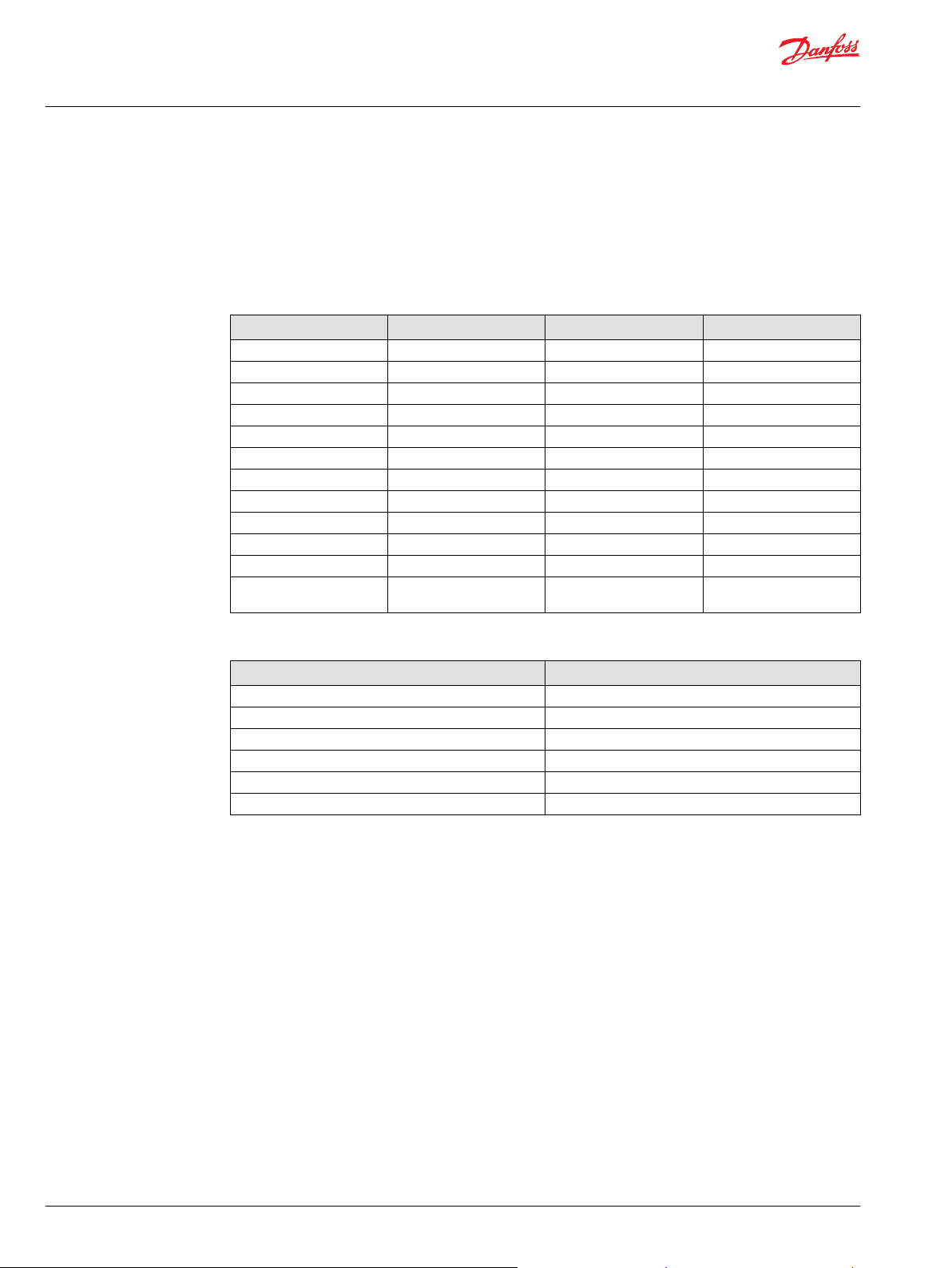

G96

G90

G95

Parts Manual

Series 90 Motors, 100cc

Service bulletin

SB-2003-010

Products affected

Series 90 100cc fixed displacement motors

Subject

Housing change to accept long screws

Description

Danfoss has changed the housing used in series 90 100 cc fixed motors. Material was added at the area of

the two shorter end cap mounting screws (G95). The hole for these screws is now deeper to accept the

longer screw (G90) that is used for the other four large end cap mounting screws. The six larger screws

will have the same stretch and therefore the same clamping force for the gasket sealing area. The smaller

end cap mounting screw (G96) remains the same. The “old” housing and the short screws will become

obsolete and no longer available for service.

Models affected

All series 90 100 cc fixed displacement motors

Serial numbers

US production started on 5 April 2004 (serial number A-04-15-xxxxx)

Part numbers affected

Description Old part number New part number

Housing 8200447 8200509

Screw (G95) 9007210-1609 9007210-1617

Parts disposition

Non-interchangeable

©

Danfoss | January 2020 AX00000094en-000204 | 71

Page 72

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and