Page 1

PRO SERIES OPERATIONS & MAINTENANCE MANUAL

Page 2

PRO SERIES OPERATIONS MANUAL

Daktronics Automated Rigging System

Manufacturers contact info

7200 Rawson Road

Victor, New York 14564

tel 866-486-7835 585-924-5000

fax 585-924-0545

email sales@daktronics.com

daktronics.com/rigging

Copyright © 2013 Daktronics, Inc.

ED 17171 REV 5 17 July 2013

Page 3

Page 4

TABLE OF CONTENTS

01 Safety Information 1

Warning, cautions, and notes

Electrical safety—general warning

Included safety features

Compliance with regulations

EU declaration of conformity

02 General Information 5

Motor electronic variable frequency drive

Hoist assembly

Pro Series Controller (VAC)

Specications

USA VAC based models and applications

VAC—Single purchase

VAC—Double purchase

European VAC based models and applications

VAC—Single purchase

VAC—Double purchase

Dimensions of a standard unit

03 Theory of Operation 9

04 Administration 11

Password

Add user

Remove user

E-stops

Deadman

05 Manual 19

Motor selection

Motor info

Hoist info screen

Digital I/O screen

Speed

Set speed numerically

Icon selection

Up/Down

Batten position indicator

Upper target

TABLE OF CONTENTS i

Page 5

Current position

Alternate target

Lower target

Set/clear targets

Clear target

Setting targets

Move to postion

Auto up/down

Curtain control

Open target

Current position

Alternate target

Close target

Auto open/close

06 Grouping 29

Create group

Name

Modify group

Modify menu

Edit group

Trim motor

Joystick control

Rename group

Delete group

07 Cueing 35

Vocabulary

Load cue sheet

Delete cue sheet

Create cue sheet

Name

Set cue 00.00

Add Cue sheet

Number

Title

Motor/group

Target

Time/speed

More Actions

Create action

Delete action

Modify action

More cues

Delete cues

Modify cues

Run cues

i-Batten

Hide/show alert

Alert box functions

Clear fault

Bypass

Disable

ii

PRO SERIES OPERATIONS MANUAL

Page 6

08 Presets 53

Create preset

Name preset

Create

Order controls

Omit motor

Move in list

All

Target controls

Up/down

Keypad

UPR/LWR

Joystick

Delete preset

Modify preset

Modify screen

Run preset

Conrmpreset

Run screen

Pause screen

09 Setup 63

Motor selection

Batten setup

Restore factory setting

Bypass i-Batten safety

Conrm

Curtain setup

Rename

Speed

Set speed numerically

Up/down

Batten position indicator

Upper limit

Current position

Lower limit

Set/clear limits

Set upper/lower limits

Clear upper/lower limits

Move to position

Auto up/down

Icon selection

Icon management

Add category

Add icons

Delete icons

Category management

Edit category

Delete category

Curtain control

TABLE OF CONTENTS

iii

Page 7

Open target

Current position

Alternate target

Close target

10 Motor Restrictions 79

Disable motors

Enable motors

Order motors

11 E-Stop & Deadman Recognition 83

E-Stop display

Deadman display

12 View 87

View display

Numerical information

Individual display

Hoist info panel

Digital I/O panel

13 Troubleshooting 91

14 Warranty 93

15 Maintenance 95

Periodic Inspections

Recommended Supplies

System Maintenance

16 Cue Sheets 105

iv

Page 8

01 SAFETY INFORMATION

Warnings, cautions and notes

All Warning notes contained in this manual indicate information that may endanger personnel.

WARNING

The Daktronics rigging system is designed to raise and lower theatrical equipment under the rated hoist capacity

ONLY. This system is NOT designed to lift or lower personnel, and should never be used for that purpose.

Only trained and authorized personnel should be permitted to operate the Daktronics system. The unauthorized use,

alteration, or use for purposes other than those for which it was designed may cause injury to persons, damage to

the equipment, or create conditions which could lead to fatalities. All proper safety considerations must be observed.

While operating the Daktronics rigging system, a spotter must be used in conjunction with the user at all times. The spotter

must have a clear view of all moving elements while maintaining contact with the user. If an unsafe situation occurs, the

spotter must immediately signal the user to halt all movements until the environment is cleared of any person or obstruction.

All installation and maintenance involving the Daktronics drive unit itself or the main electrical control cabinets will

require trained personnel. Simple daily maintenance activities such as cleaning of the touchscreen and the VAC

workstation may be carried out by the operators, and in most cases will be all that is needed once installed.

Electrical Safety—General Warning

WARNING

Before working on any of the Vortek hoists, the main electrical disconnect must be

turned off and locked out according to OSHA regulations 29 CFR 1910.147.

The voltages used in the motor drive and master control panels can cause severe electrical

shock and/or burns. Extreme care is necessary at all times when working with the motor

drives. Only authorized personnel should carry out any installation, commissioning, or

maintenance of the electrical systems. All drive systems have been tuned at the factory

and will not require any additional alteration or adjustment by the owner’s personnel

unless specifically authorized by a Daktronics representative.

SAFETY INFORMATION

SAFETY INFORMATION

1

Page 9

Included Safety Features

i-Batten with Over-load and Under-load Protection

The i-Batten feature allows the authorized operator to preset sensitivity on the maximum and minimum

loads a specific Vortek hoist will encounter. If the system detects a load outside the set range, indicating

a possible problem, the unit will automatically stop all motion. It is strongly recommended that this feature

be used in order to prevent any injury to personnel or damage to equipment.

Emergency Stop

A red Emergency Stop mushroom head push button is located on each VAC control station. Pushing

the button will disable all motor drives connected through the specific VAC, and set all motor brakes.

This will stop all motion of the attached loads on each Vortek hoist immediately, and inhibit further

movement until reset.

The Emergency Stops should ONLY be used for real emergencies or when required to reset a motor fault

if indicated on the VAC touchscreen.

Vortek Back-Up brake

This secondary mechanical braking system is designed to hold the rated load in the improbable case of

a failure of the primary motor brake or gearbox. This system acts independently of any electrical inputs

on the system.

Compliance with Regulations

The Daktronics system complies with the relevant European directives required for the CE mark, including:

98/37/EC: Machinery Directive

73/23/EEC: Low Voltage Directive

89/336/EEC: Electromagnetic Compatibility

Independent reviews/tests in support of above compliance

EN55022 Class A Radiated and Conducted Emissions

EN61000-4-2 Electrostatic Discharge

EN61000-4-6 Conducted Susceptibility

EN60950, 60204 Safety Review

Airborne noise emissions

Continuous A-weighted sound pressure levels at distances 40 feet from the Vortek hoist module,

a typical distance for the operator VAC control unit to be located, do not exceed 70 decibels.

2

Page 10

EU DECLARATION OF CONFORMITY

Manufacturer's name and address:

Daktronics, 7200 Rawson Road

Victor, N.Y. 14564 USA

We declare under sole responsibility that the product:

Product Name:

Daktronics Automated Theater Rigging system

Product Description:

Automated Hoisting Equipment for theatrical venues

Product type/model:

Single Purchase: V_-12180, V_-1740, V_-14120, V_-2020, V_-0820, H_-22230, H_-4020,

EV_-0509, EV_-0607, EV_-0702, EV_-0901, EV_-0301, EH_-1012, EH_-1801

Double Purchase: V_-12180-2, V_-1740-2, V_-14120-2, V_-2020-2, V_-0820-2, H_-22230-2, H_-4020-2,

EV_-0509-2, EV_-0607-2, EV_-0702-2, EV_-0901-2, EV_-0301-2, EH_-1012-2, EH_-1801-2

*To reference the model list of pre-2009 hoist nomenclature, see Troubleshooting on p. 91.

Conforms to the following standard(s) :

EN 60204-1 Safety of Machinery/ Electrical Equipment for Machinery

EN 60950 (ITE) Information Technology Equipment

EN 55022 Class A Product Specific Emissions

EN 61000-4-2 Electrostatic Discharge

EN 61000-4-6 Conducted RF Susceptibility

Following the provisions of the EU Machinery Directive 98/37/EC, EU Low Voltage Directive

73/23/EEC, and EU EMC Directive 89/336/EEC.

SAFETY INFORMATION

3

Page 11

4

Page 12

02 GENERAL INFORMATION

WARNING

The Daktronics hoist system is an automated rigging system meaning that the load is not counter-weighted. Each

hoist can lift loads only up to the design capacity. Overloading will result in electrical overload protection shut

down of the hoist and possible damage to rigging components.

Each hoist system consists of an integral electric motor driven reducer, directly coupled to a cable drum, which

winds steel cables (wire ropes) leading over sheaves installed within the hoist assembly and along the structural

steel of the building. The cables support battens for attaching the load. The battens can be lowered to within the

specified trim above the stage floor to allow attachment of loads.

The Daktronics hoist system consists of three basic parts.

Motor electronic variable frequency drive

The Electronic Variable Frequency Drive and dynamic braking resistor for each motor is located in each Vortek

motorized hoist. A local control panel is located on each hoist for programming and diagnostics by factory

personnel. There is a reset-able circuit breaker located at each power point on the HV wireway. The rated

twist-locking plug on each unit acts as the main high voltage disconnect along with its corresponding CB.

The Vortek batten hoists are not designed to raise and lower people.

These hoists should NEVER be used for this purpose.

Hoist assembly (cable drum, load brake, limit switches and frame)

The Vortek hoist assemblies are mounted on the rigging steel at the top of the stage house. The gearmotor, helically

grooved cable drum, support bearing and frame structure are all factory assembled and tested. Maximum upper

height and minimum lower height are set by limit switches which are adjusted by factory-trained personnel during

installation and commissioning of the system. A position encoder is located at the brake end of each hoist motor,

attached directly to the motor shaft. Each hoist assembly is also equipped with a LOAD BRAKE, a unique safety

feature provided exclusively by Daktronics. This unit is designed to engage automatically when the load is being

lowered. This greatly reduces any possibility of a loaded batten to descend uncontrolled.

GENERAL INFORMATION

5

Page 13

Pro Series controller

Control of all hoists is possible from the Daktronics VAC console. The hoists can be controlled individually, and

operated at various speeds. Please see the Controls Operating portion of this manual for the operating procedures.

WARNING

If it is necessary to operate a hoist from a location where the operator's view of the moving

load is obstructed, a second person must be used to observe the load and communicate to

the operator.

Specifications

WARNING

THE FOLLOWING MODELS ARE VARIABLE SPEED AND DESIGNATED TO BE CONTROLLED THROUGH

THE VORTEK AUTOMATION CENTER (VAC

The Vortek hoist must only be used with a maximum load equal to the capacity stated for your

model below. Overloading the system may result in serious injury or an inoperable system.

®

). THE VAC IS A STAND ALONE AUTOMATION SYSTEM.

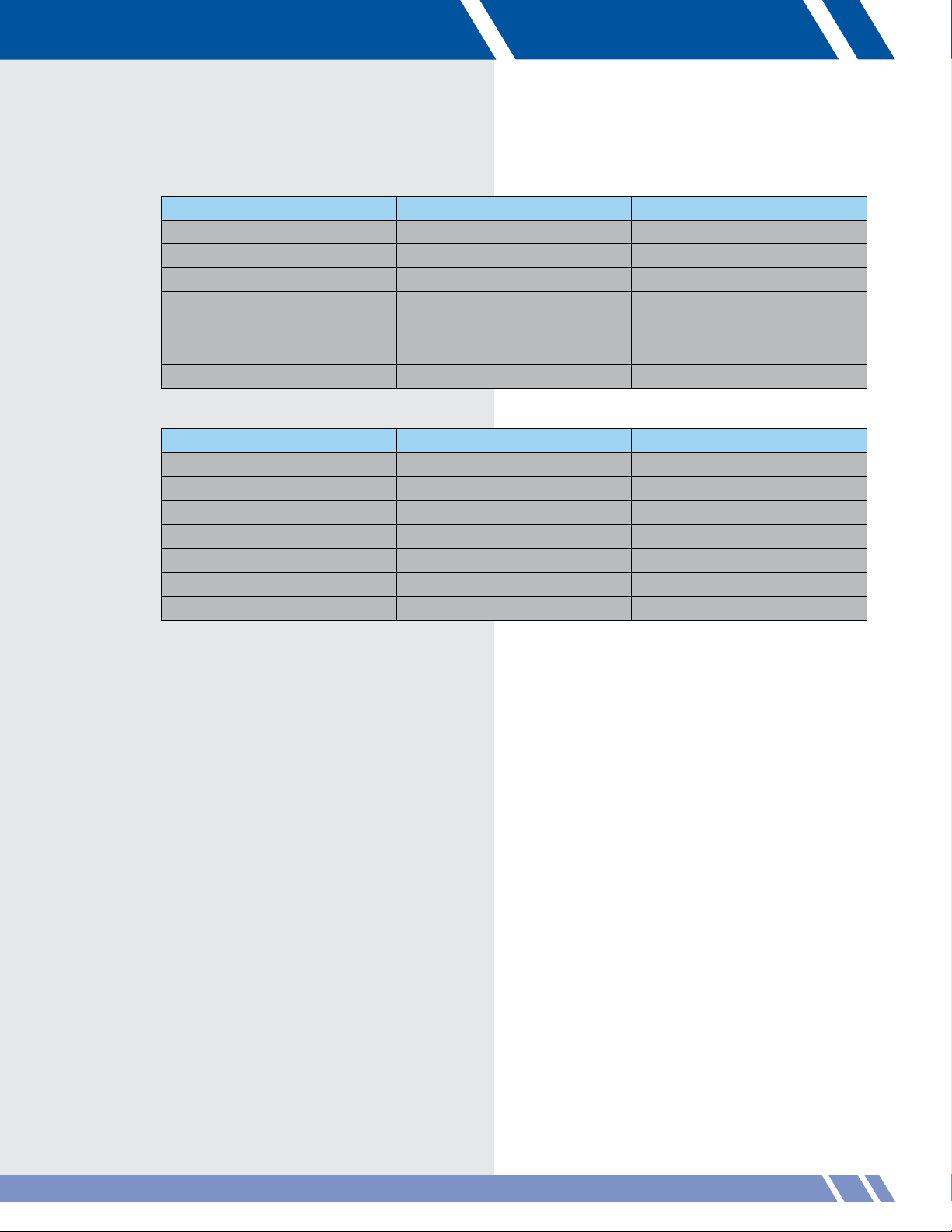

USA VAC® based models and applications

VAC - Single Purchase

MODEL NUMBER LOAD LBS (kg) SPEED FT/MIN (M/SEC)

V_-0820 0 - 800 (362) 0 - 20 (.1)

V_-12180 0 - 1200 (540) 0 - 180 (0.914)

V_-14120 0 - 1400 (635) 0 - 120 (.6)

V_-1740 0 - 1750 (790) 0 - 40 (0.203

V_-2020 0 - 2000 (900) 0 - 20 (0.101)

H_-22230 0 - 2200 (1000) 0 - 234 (1.2)

H_-4020 0 - 4000 (1814) 0 - 20 (.1)

VAC - Double Purchase

MODEL NUMBER LOAD LBS (kg) SPEED FT/MIN (M/SEC)

V_-0820 0 - 1600 (725) 0 - 10 (.05)

V_-12180-2 0 - 2400 (1080) 0 - 90 (0.457)

V_-14120 0 - 2800 (1270) 0 - 60 (.3)

V_-1740-2 0 - 3500 (1580) 0 - 20 (0.101)

V_-2020-2 0 - 4000 (1800) 0 - 10 (0.050)

H_-22230 0 - 4400 (2000) 0 - 117 (.6)

H_-4020 0 - 8000 (3628) 0 - 10 (.05)

Maximum travel distance is 65' (19.8 m) for Single Purchase Units, 32.5' (9.9 m) for Double Purchase Units.

6

Page 14

European VAC® based models and applications

VAC - Single Purchase

MODEL NUMBER LOAD kg SPEED M/SEC

EV_-0301 360 0.10

EV_-0509 500 0.9

EV_-0607 630 0.7

EV_-0702 790 0.2

EV_-0901 910 0.1

EH_-1012 1000 102

EH_-1801 1810 0.1

VAC - Double Purchase

MODEL NUMBER LOAD kg SPEED M/SEC

EV_-0301-2 720 0.05

EV_-0509-2 1100 0.45

EV_-0607-2 1260 0.35

EV_-0702-2 1580 0.01

EV_-0901-2 1820 0.05

EH_-1012-2 2000 0.06

EH_-1801-2 3620 0.05

Maximum travel distance is 65' (19.8 m) for Single Purchase Units, 32.5' (9.9 m) for Double Purchase Units.

Dimensions of Standard Unit

• Average weight of self-contained hoist module is 600 lb (272 kg)

• Height = 19.35" (49.15 cm)

• Length = 12' 9" (3.9 m)

• Width = 9" (22.9 cm) -- 6" (15.2 cm) centers can be achieved by positioning self-containing

hoist modules on opposite or opposing sides of the stage (stage right and stage left)

GENERAL INFORMATION

7

Page 15

8

Page 16

03 THEORY OF OPERATION

Each Vortek hoist is connected to the main high voltage power buss through a safety twist-locking plug. This plug

brings in the main 3-phase power that is connected to the motor drive and motor brake located in each hoist

assembly. Also connected to each Vortek hoist assembly through safety locking connectors are 24 V DC power,

E-Stop circuit, and a computer network cable.

The motor drive controls all movements of the hoist. Each drive on each hoist contains programming to identify

it to the network. This programming also includes but is not limited to maximum speed, acceleration, gear ratios

and soft limits. Each motor drive monitors an incremental encoder, limit switches, i-Batten™ safety feature and

emergency stop status. The incremental encoder is used for position control. The limit switches are used for

maximum up and down travel. i-Batten safety feature is used for the detection of both an underload or overload

condition. The emergency stop status is used to detect the operation of the emergency stop system.

Monitoring of each hoist is done over the network using a master drive. The master drive is located in the master

drive cabinet typically at stage level. Included in the master drive cabinet are the master drive and the network

hubs. A 24 V DC power supply that powers the network hubs and the E-Stop circuit is also located in the master

drive cabinet.

®

The main Daktronics Pro Series controller (VAC) is comprised of a Pentium

joysticks and E-Stop button. The VAC computer runs a proprietary Windows® based application that allows the

operator to perform manual and programmable functions to any or all of the hoists connected to the system. The

VAC is connected to the master drive and motor drives through an ArcNet™ based network operating at 2.5

Mbaud. During operation of the VAC, data is transmitted from the VAC computer through the network system to the

master drive and distributed to the appropriate hoist drive. Likewise, data is received from each hoist drive through

the master drive and to the VAC computer for display by the VAC operating software. The 24-volt dc E-Stop circuit

is also connected to the E-Stop button located on the front of the VAC.

class computer, touch screen, keyboard,

THEORY OF OPERATION

9

Page 17

10

Page 18

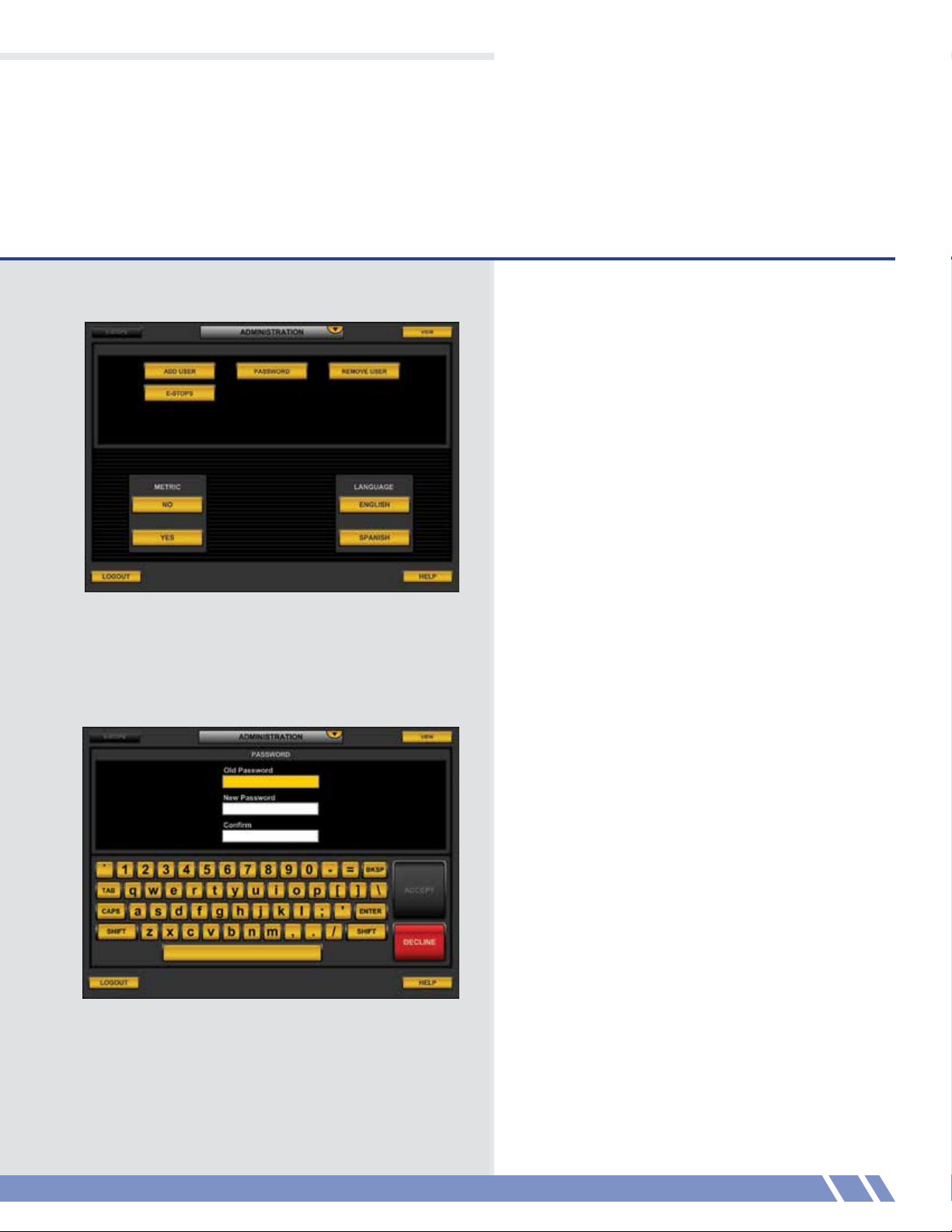

Figure 4.1: Administration screen

04 ADMINISTRATION

The administration module (Figure 4.1) allows the

user to change the system preferences according

to their security level.

An operator may change their password.

An administrator may add users, change their

password, or remove users at administrator

level and below.

The screen on the top shows the operator level

screen, while the screen on the bottom shows

the administrator level screen.

On-screen assistance can always be found by

touching HELP in the lower right corner.

Figure 4.2: Password screen

Password

Touch PASSWORD from the main menu to edit

your password for the system.

Before your password can be changed, you must

first enter your old password so the system can

verify your identity.

Select the next field to enter by touching the field

you wish to enter.

Enter your new password in the New Password

field (Figure 4.2) and the Confirm field.

When the Old Password is correct and the New

Password fields contain the same value, the ACCEPT

button will light. Touch ACCEPT to confirm the

change, or touch DECLINE to return to the main

menu without changing the password.

ADMINISTRATION

11

Page 19

Add user

From the main menu, Administrators may touch

ADD USER to insert profiles of new users into

the system. The New User screen (Figure 4.3)

will display.

A profile consists of the new user’s name, password

and user type (either Normal User, Administrator,

or Factory).

A complete profile (Figure 4.4) of the new user must

be entered before the Accept button will activate.

Touch ACCEPT to confirm the addition of the user.

Figure 4.3: New User screen

12

Figure 4.4: New User screen with a complete profile filled in.

Page 20

Figure 4.5: Remove User screen

Remove user

From the main menu, administrators may touch

REMOVE USER to delete profiles of users out of

the system. The Remove User screen (Figure 4.5)

will display.

Select a user by touching their name. After selection

the Accept button activates.

Touch ACCEPT to confirm the removal of the user

and return to the main menu.

Administrators may only delete Administrators and

Operator level users. Administrators can not delete

Factory level users.

Figure 4.6: E-Stops screen awaiting selection.

E-Stops

From the main menu, administrators may touch

E-STOPS to edit the names of multiple E-Stops for

the system. The reason to do this is to specify the

location of the activated E-Stop.

Select an E-Stop by touching its name.

13ADMINISTRATION

Page 21

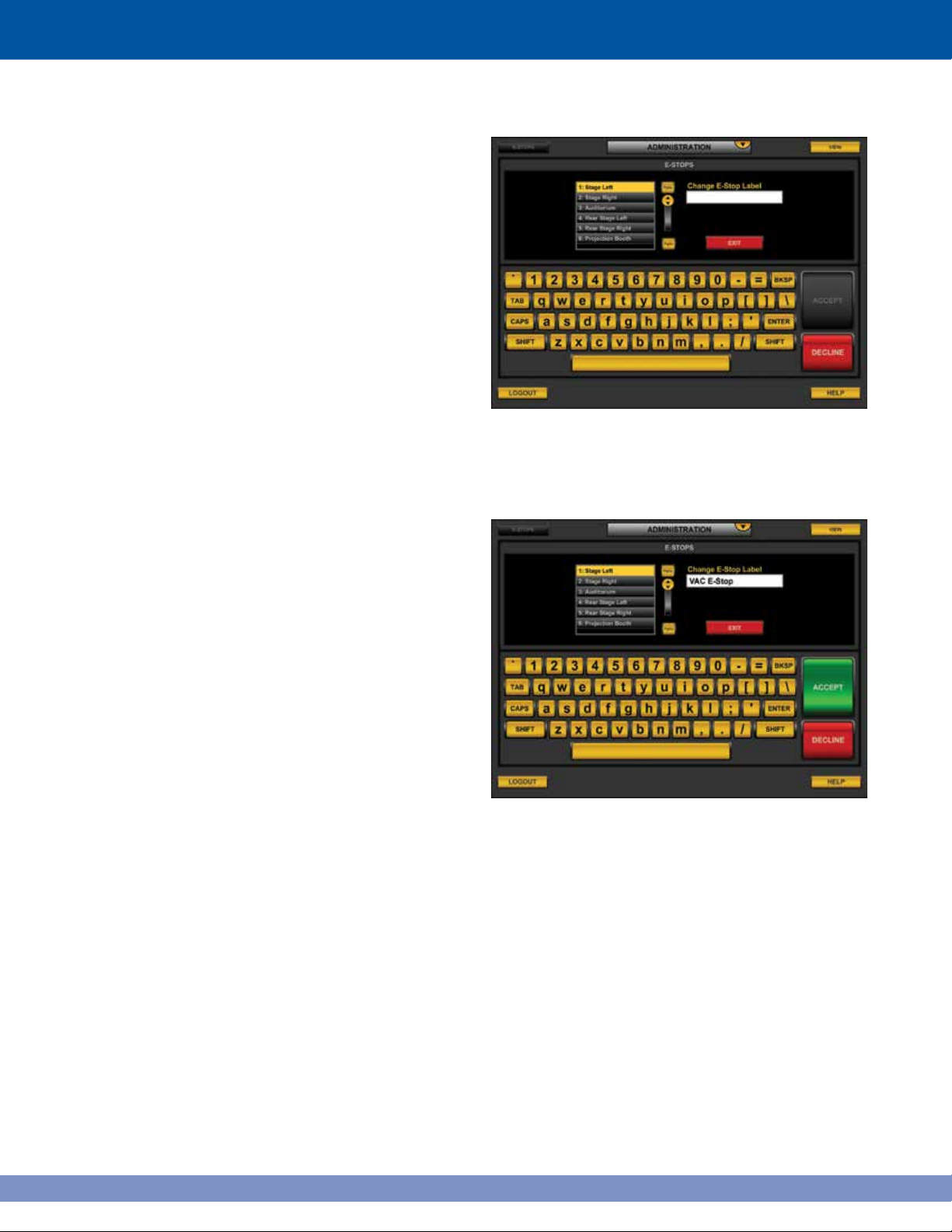

After selection the Change E-Stop Label field activates.

Type a new name for the E-Stop and touch ACCEPT

to confirm the new name.

Figure 4.7: E-Stops screen awaiting the new name

14

Figure 4.8: E-Stops screen.

Page 22

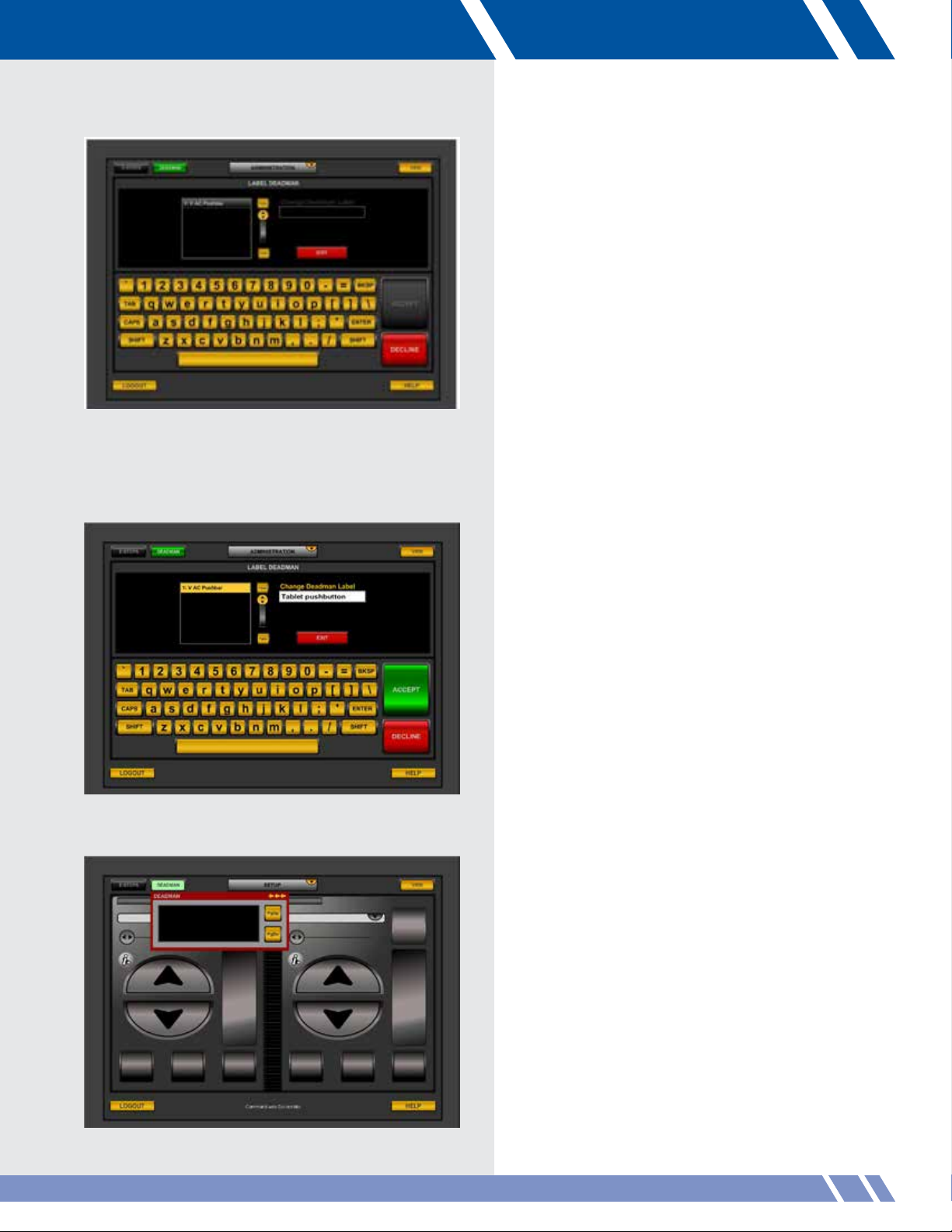

Figure 4.9 Label Deadman screen

Deadman

From the Administration module, (Figure 4.9)

administrators may touch LABEL DEADMAN to

edit the names of one or more Deadman switches

for the system (Optional). This will help identify the

Deadman switch location where multiple Deadman

switches are required.

Select a Deadman switch to edit

After selecting a Deadman switch to edit, the Change

Deadman Label field activates. Type a new name for

the Deadman switch and touch ACCEPT to confirm

the new name (Figure 4.10).

Figure 4.10: Change Deadman Label field

Figure 4.11: Deadman open window

Upon pressing the DEADMAN button, a window will

open (Figure 4.11).

ADMINISTRATION 15

Page 23

This window will list the name of any Deadman

switch that is not depressed (Figure 4.12).

The Deadman button will change from red to green

when the DEADMAN switch is pressed, allowing

movement (Figure 4.13).

Figure 4.12: Deadman switches not tripped

All hoist movement will be inhibited and each

move initiating button will be grayed out and

unusable until the Deadman switch(s) is

depressed (Figure 4.14).

16

Figure 4.13: Green button allows movement

Figure 4.14: Hoist movement inhibited

Page 24

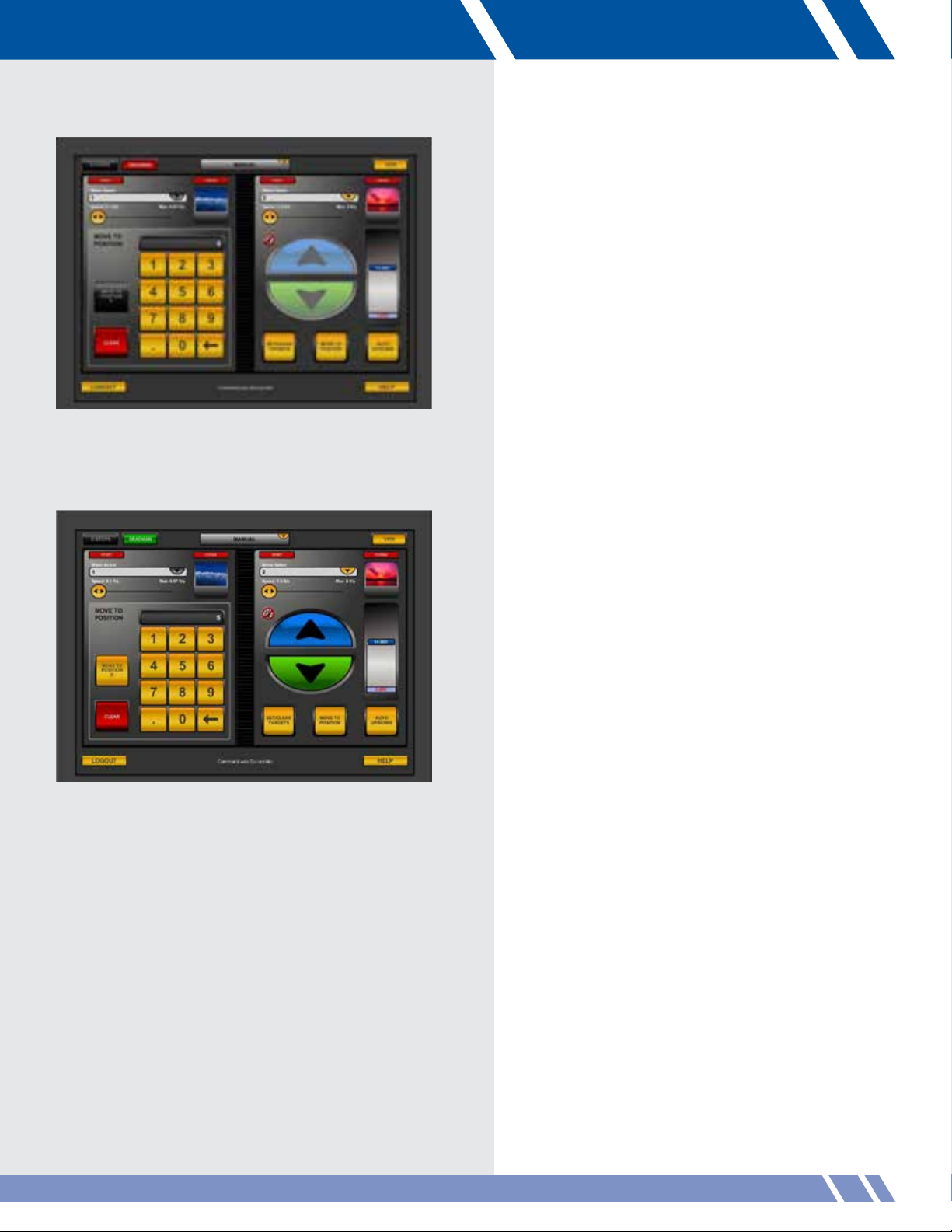

Figure 4.15: Move to Position control disabled

Move to Position control is also disabled while

the Deadman switch is not pressed (Figure

4.15)

.

When the Deadman switch is depressed, control

functionality will be restored, and grayed out buttons

will once again be available. This function applies to

all modules when the Deadman feature is enabled.

(Figure 4.16).

Figure 4.16: Deadman functionality restored

17ADMINISTRATION

Page 25

18

Page 26

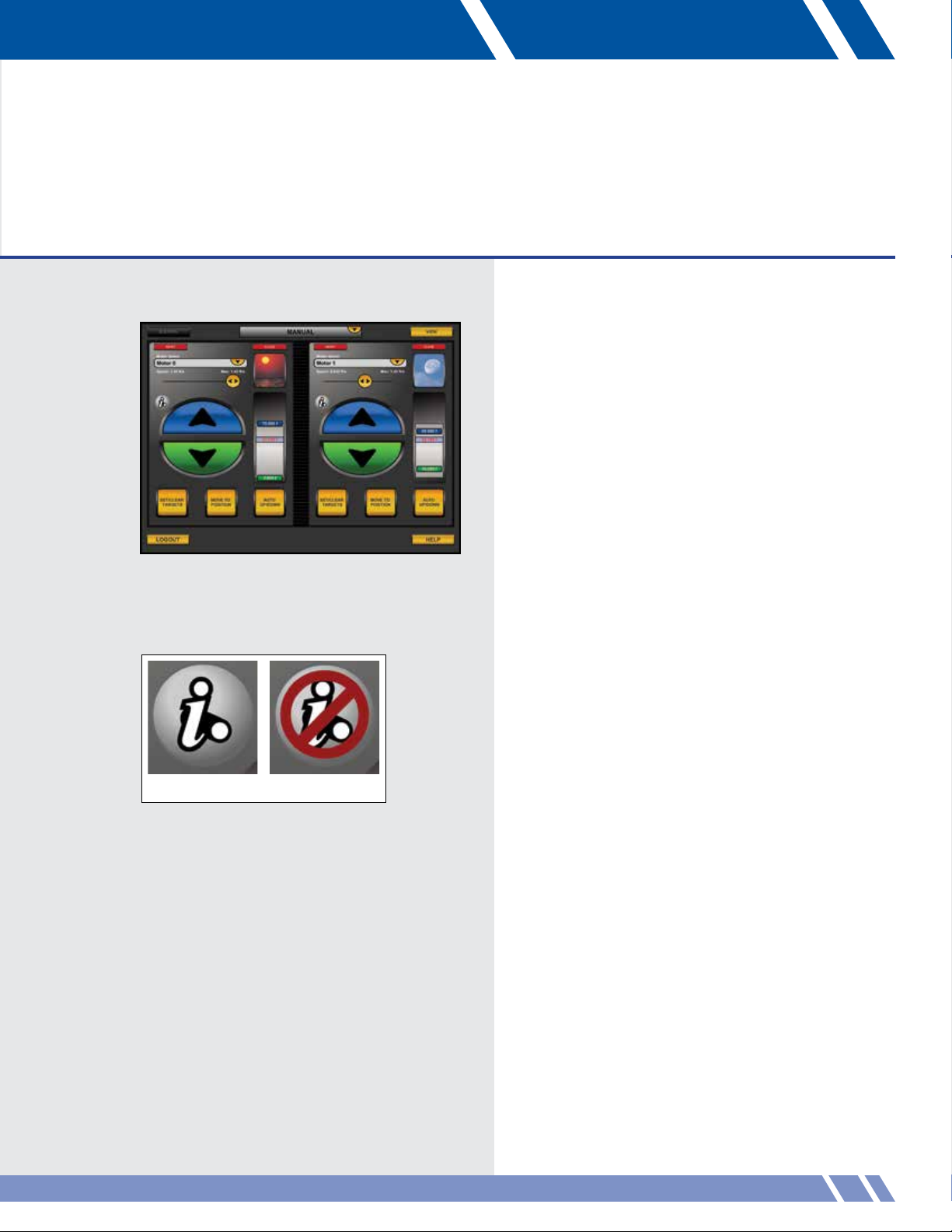

Figure 5.1: Manual screen

05 MANUAL

The Manual module (Figure 5.1) has two controllers,

each of which controls a motor, group or curtain.

After selecting which element to control, its speed,

position, targets or icon may be changed.

Additionally, the controllers display the state of the

i-Batten safety feature. If a weight change for the

batten is detected, the Vortek will stop the motor from

moving until the batten weight returns to normal.

If the safety feature is disabled for a motor or group,

the controller will display a red slash over the i-Batten

logo (see Figure 5.2).

On-screen assistance can always be found by

touching HELP in the lower right corner.

Enabled Disabled

Figure 5.2: i-Batten status

19MANUAL

Page 27

Motor selection

Select a motor by touching the yellow drop

down button at the top of the menu as shown

in Figure 5.3.

The dropdown menu expands to show a list of all

available motors, with grouped motors shown in

blue (Figure 5.4).

Move through the list by using the:

• Slider

• PgUp

• PgDn

Figure 5.3: Motor Select button

Touch the name of the desired motor or group to

select it. It will highlight and both MOTOR INFO

and CONFIRM will activate (Figure 5.5).

Touch CONFIRM to verify the selection. If there’s a

need to find out more detailed information about

the selected motor, touch MOTOR INFO.

Before touching CONFIRM, change the

selection by touching a different motor name.

Figure 5.4: Motor Select screen

Figure 5.5: Motor selected

20

Page 28

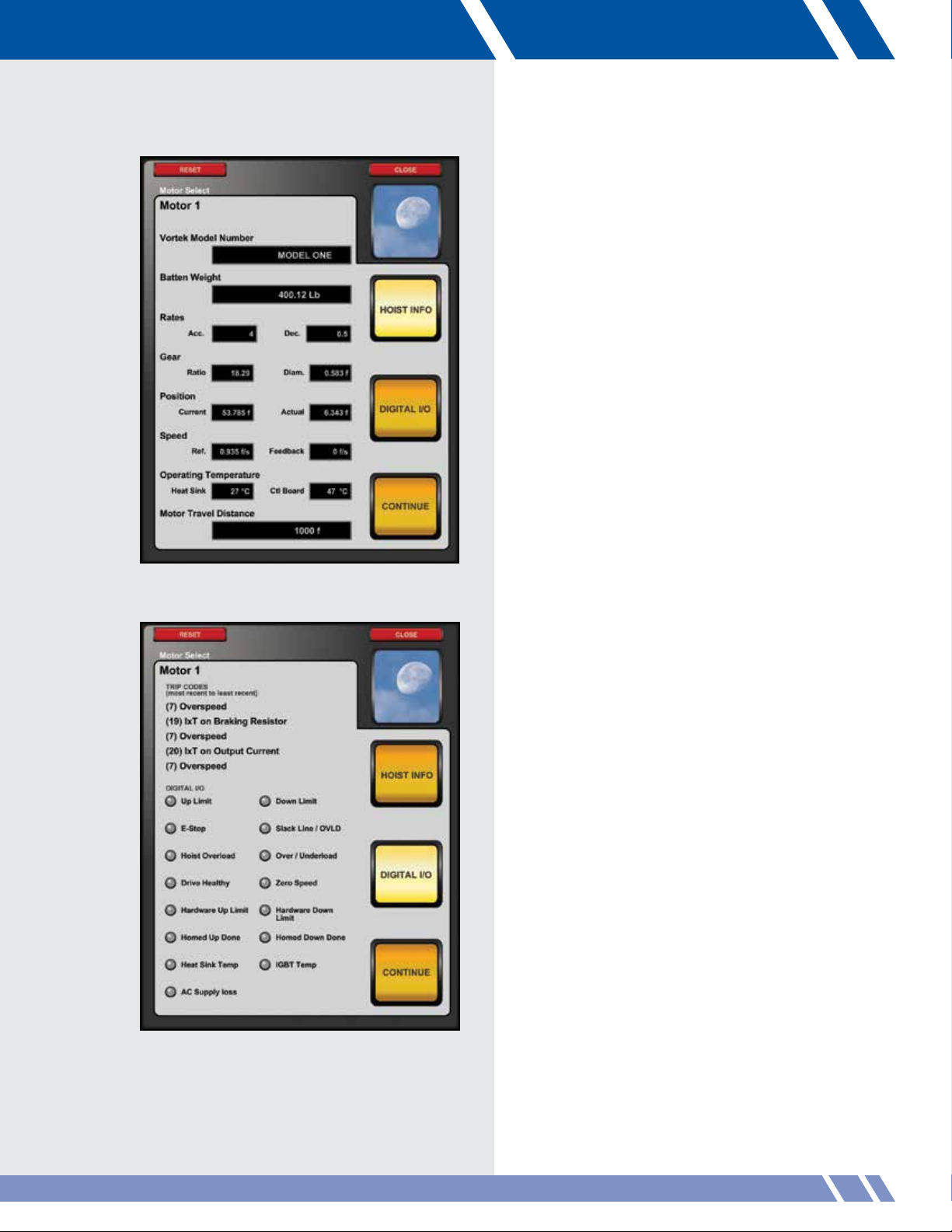

MOTOR INFO

When the MOTOR INFO button is touched, the

Hoist Info screen is displayed (Figure 5.6).

Hoist Info screen

This screen has details about the

• Batten Weight

• Acceleration Rates

• Gear Ratio and Diameter

• Batten Position

• Motor Speed

• Operating Temperature

• Travel Distance

Touch the DIGITAL I/O button to display

the Digital I/O screen (Figure 5.7) or touch

CONTINUE to return to the normal display.

Figure 5.6: Hoist Info screen

Figure 5.7: Digital I/O screen

Digital I/O screen

This screen displays:

• The last five trip codes

• Whether the motor is at the

Upper / Lower Limit

• Whether an E-Stop is engaged

• Whether an Overload or Underload

has occurred

• Whether the motor is healthy

• Whether the motor is not moving

• Whether the hardware Upper / Lower

Limit is reached

• Whether a Homed Up / Down command

has been completed

• Whether extreme operating temperatures

have been encountered.

• Whether the motor’s power has been lost

Touch the HOIST INFO button to display the

Hoist Info screen or touch CONTINUE to

return to the normal display.

MANUAL 21

Page 29

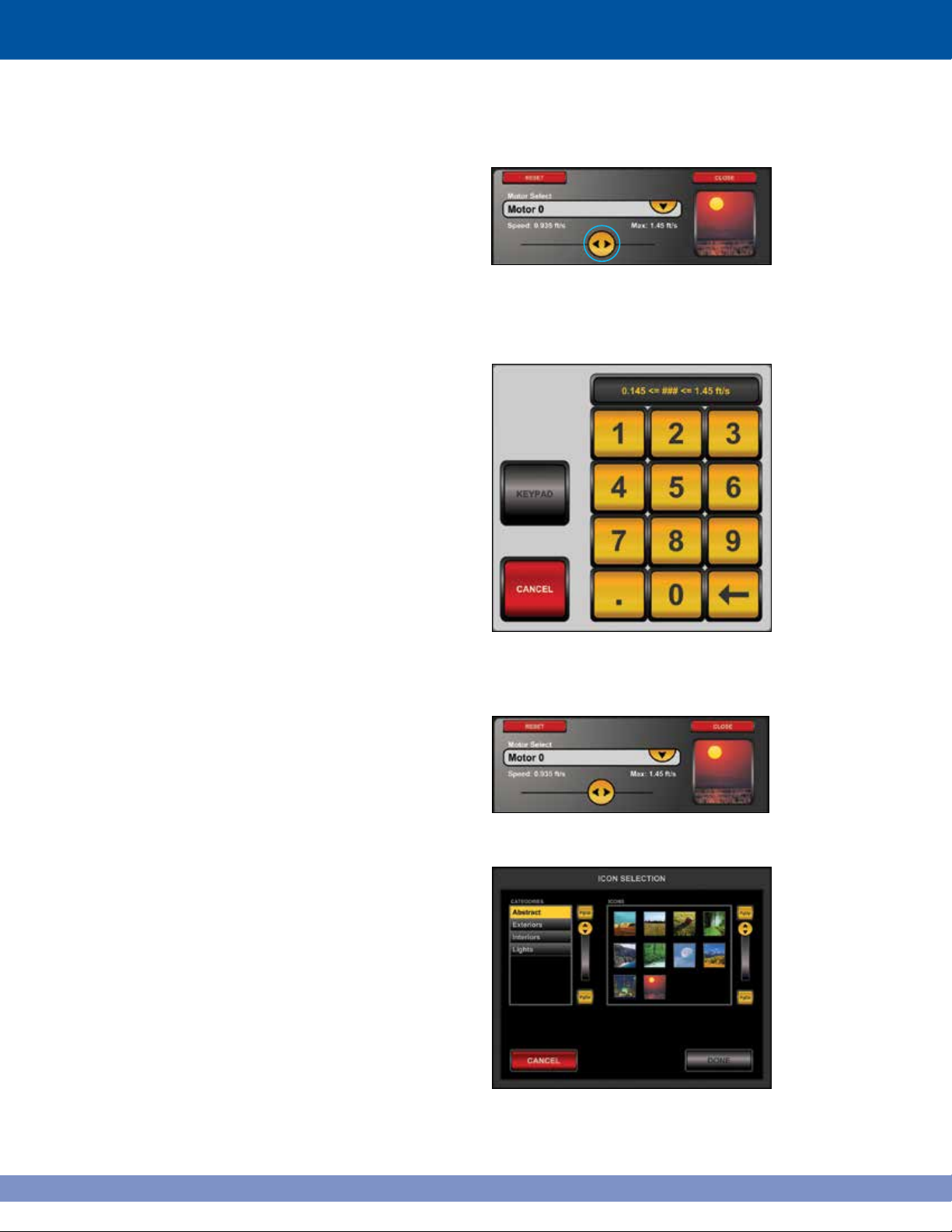

SPEED

The speed button is located under the Motor Select

dropdown menu (Figure 5.8). To change the speed,

touch and hold down the speed button. Slide it to the

right to increase the speed of the selected motor, or

left to decrease the speed.

Above the button, the current speed is shown on the

left, while the maximum speed of the selected motor

is shown on the right.

Set Speed Numerically

Touch the speed button twice quickly (double-click)

to adjust the speed with greater accuracy,

The controller will display a keypad for manual entry

(Figure 5.9). Enter the new speed value and touch

KEYPAD to confirm the entered value.

Figure 5.8:

Speed button

Icon Selection

The button for icon selection is located to the right of

Motor Select (Figure 5.10). The icon for the selected

motor appears here.

To change the icon, double-click the icon to display

the Icon Selection panel (Figure 5.11).

Select a category by touching its name in the

category list. The different icons available will

display in the box on the right. Use the scroll bar

to navigate through the icons. Choose an icon by

touching it.

Touch DONE to confirm the selection, or CANCEL

to leave the function without changing the icon.

Figure 5.9: Enter speed numerically

Figure 5.10: Icon Selection button

22

Figure 5.11: Icon Selection

Page 30

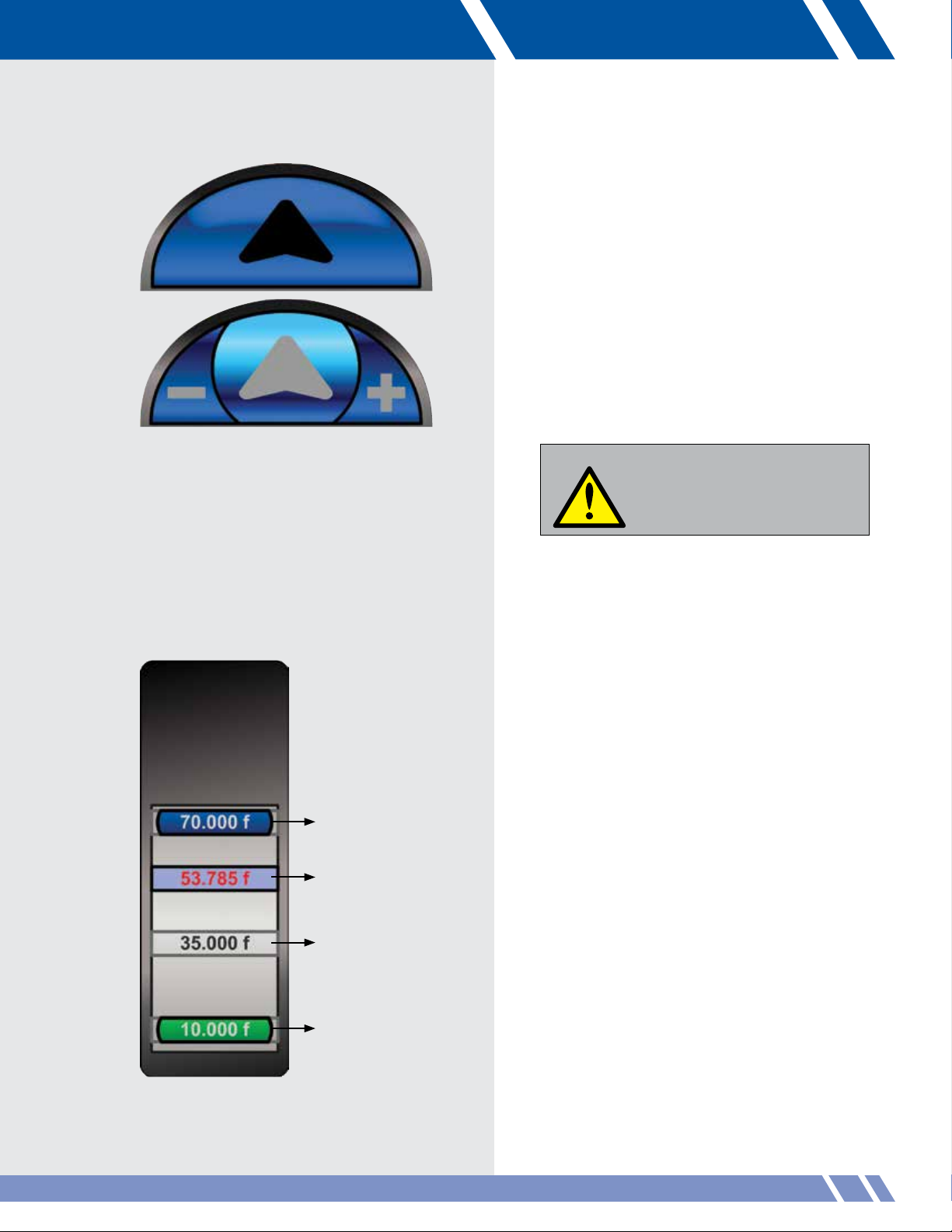

UP / DOWN

These buttons raise or lower the batten. They

are colored blue for up and green for down.

To move the motor, touch and hold an arrow

key. When pressed, they divide into three areas

(Figure 5.12).

Touch the MINUS (-) to decrease the

speed, or to PLUS (+) to increase it while the

motor is moving. The motor will stop moving

when the button is no longer touched or the

motor has reached its pre-set target position.

Figure 5.12: Up arrow depressed

Upper target

Current position

Alternate target

WARNING

If any problems arise during any hoist

motions, depress the Emergency

Stop button located below the

monitor immediately and all hoist

movements will stop.

BATTEN POSITION INDICATOR

This displays the batten position visually and

numerically relative to its upper and lower target

height. The batten upper and lower target values

along with alternate targets (if any exist) are also

displayed (Figure 5.13).

Upper target

This dark blue button shows the value for the

upper target.

Current position

This light blue bar shows the position of the

batten in relation to the targets. As the batten

moves, this display will move as well.

Figure 5.13: Batten indicator

Lower target

Alternate target

This gray box is another target position.

The VAC allows three of these per motor.

Lower target

This green button shows the value for the

lower target.

MANUAL

23

Page 31

SET / CLEAR TARGETS

To set or change the targets, touch SET /

CLEAR TARGETS (Figure 5.14). The screen will

display the Set/Clear Targets panel (Figure 5.15).

Clear Target

Touch the desired CLEAR button to clear a target

(Figure 5.15). The CLEAR button touched will

change to read CONFIRM. Touch this button to confirm

clearing the target.

Note: Clearing an upper (or lower) target resets

its value to the upper (or lower) limit.

Setting Targets

Touch SET TARGETS. The Set Targets panel displays

(Figure 5.16). Select which target to set from the

dropdown menu

(Figure 5.16a).

Enter a new value

for the target

with the keypad.

Touch KEYPAD to

confirm the new

value.

Alternately, touch

CURRENT to

use the current

position of the

batten as the target.

After entering a new target or using the

current batten position, touch CONTINUE

to return to the main screen.

Figure 5-16a: Dropdown menu

Figure 5.14:

Figure 5.15: Set/Clear Targets panel

Set/Clear Targets button

A limit is the operational boundary of a motor.

A motor can not move outside its limits, which

are set by an administrator.

A target is a preset motor position that may be

set within the limits set by the administrator.

24

Figure 5.16: Set Targets panel

Page 32

Figure 5.17:

Move To Position button

MOVE TO POSITION

To move a batten to a specific height, touch

MOVE TO POSITION (Figure 5.17).

The controller will display a new panel with a

keypad (Figure 5.18). Enter the desired height using

the keypad. Set the speed for the move by using the

speed button and touch MOVE. The motor will move

to the target and stop.

While the motor is moving, the Move To Position

button will be changed to read Stop. The STOP

button will slow and halt the motor prior to

reaching its target.

Figure 5.18: Move To Position panel

Figure 5.19: Auto Up/Down button

Upper target

Alternate target

Alternate target

Alternate target

Lower target

Auto Up / Down

To move the motor to its upper,blower or alternate

targets, touch AUTO UP / DOWN (Figure 5.19).

The controller will display a new panel with

between two and five buttons (Figure 5.20):

• Upper target

• Lower target

• Alternate targets (if any)

• CANCEL (not shown)

To move to a target, set the speed using the speed

button, then touch and hold either of the target

buttons for three seconds.

When the motor begins moving, the CANCEL

button will change to STOP. Touch STOP to halt

the motor's movement.

During any hoist movements, in an emergency,

press the Emergency Stop button.

Figure 5.20: Auto Up/Down panel

MANUAL

25

Page 33

Curtain control

If the controller is set to control a curtain, the display

will look like Figure 5.21.

The Up / Down buttons will change to Open / Close

buttons (Figure 5.22). These function the same as

the Up / Down buttons.

Figure 5.21: Curtain controller

Open target

This dark blue button shows the value for the upper

target. Blue vertical line shows the curtain position

at the upper target.

Current position

This light blue bar shows the value of the curtain’s

current position. As the curtain moves, this red

curtain graphic will move as well.

Alternate target

Alternate target positions are shown with gold

vertical bars.

Close target

This green button shows the value for the lower

target. Green vertical lines show the curtain

position at the lower target.

Figure 5.22: Open arrow depressed

Open target

Current position

Close target

Figure 5.23: Curtain indicator

26

Page 34

Figure 5.24: Auto Open/Close button

Open target

Alternate target

Alternate target

Auto Open / Close

To move the motor to its upper, lower or

alternate targets, touch AUTO OPEN /

CLOSE (Figure 5.24).

The controller will display a new panel

with 2 to 5 buttons (Figure 5.25):

• Open target

• Close target

• Alternate targets (if any)

• CANCEL (not shown)

To move to a target, set the speed using the speed

button, then touch and hold either of the target

buttons for three seconds.

When the motor begins moving, the CANCEL

button will change to STOP. Touch STOP to halt

the motor's movement.

Alternate target

Close target

Figure 5.25: Auto Open / Close panel

MANUAL

27

Page 35

28

Page 36

Figure 6.1: Grouping screen

06 GROUPING

Multiple motors may be set to act in unison by

using the Grouping module (Figure 6.1). This is

useful for assuring that multiple battens holding the

same set will move together simultaneously.

Although a group is always two or more motors,

Daktronics treats them as one motor in the Manual,

Setup and Cueing modules.

On-screen assistance can always be found by

touching HELP in the lower right corner.

GROUPING

29

Page 37

CREATE GROUP

The Create function has two motor lists, the Motors

list and the Group Motors list (Figure 6.2). Move

through either list by using the scroll button, PgUp or

PgDn.

To add a motor to the group, touch its name in

the available motor list. The motor is immediately

removed from the available list and is displayed

in the group motor list.

To remove a motor from the group, touch its name

in the group motor list. The motor is immediately

removed from the group motor list and is

displayed back in the available list.

On the left is a list of the all available motors (in

alpha-betical order). A motor that is disabled or

part of another group will not appear here. On

the right is a list of all motors selected to be

grouped, which is empty at this point.

Touch CANCEL to go back to the main screen

without creating the group.

When all of the desired motors are shown in

the group motor list, touch DONE to name the

new group.

Figure 6.2: Create function.

30

Figure 6.3: Motors added to group

Page 38

Figure 6.4: Naming a new group

NAME

The group motor list is now deactivated to show

that it can not be changed at this point (Figure

6.4). The group can be changed later with the

Modify function.

Type a name for the new group using the VAC

keyboard. A group name can only be made of

letters and numbers. Typing a name activates

the DONE button.

After entering the name, touch DONE to confirm

and create the new group. The screen will change

back to the main grouping screen and then the

message Group created will display in the

status message area.

MODIFY GROUP

The Modify function displays a list of groups on

the left hand side (Figure 6.5). Select a group to

work with by touching its name. The Continue

button will activate. Touch this to begin modifying

the selected group.

Figure 6.5: Modify function

GROUPING

31

Page 39

MODIFY MENU

The selected group name appears on the left

above the editing choices (Figure 6.6).

Touch EDIT to add or remove motors from the

group, TRIM to change an individual motor

position, RENAME to change the group name

or EXIT to return to the main screen.

EDIT GROUP

A list of all available motors (in alphabetical order)

is on the left (Figure 6.7). A motor that is disabled

or part of another group will not appear here. On

the right is the list of motors in the selected group.

To add a motor to the group, touch its name in

the available motor list. The motor is immediately

removed from the available list and is displayed

in the group motor list.

To remove a motor from the group, touch its name

in the group motor list. The motor is removed from

the group motor list and is displayed back in the

available list.

Touch CANCEL to go back to the main menu

without editing the group.

Touch DONE to confirm the edits to the selected

group and return to the Modify menu.

Figure 6.6: Edit menu

Figure 6.7: Edit function

32

Page 40

Figure 6.8: Trim motor

Figure 6.9: Trim controls activated

Trim motor

To change the position of an individual batten

within a group, use the Trim function.

Select a motor to trim from the list of grouped

motors on the left (Figure 6.8).

The trimming controls activate after a motor has

been selected (Figure 6.9).

The up and down arrow buttons will move the

batten at minimum speed. Touch and hold an

arrow button to begin moving the selected motor.

The motor will stop moving when the button

is released.

Touch EXIT to return to the Edit menu.

Joystick control

The joystick provides faster trimming speed.

To control the motor with the left joystick, touch

JOYSTICK under the arrow buttons (Figure 6.9).

The button will change to read FINISHED and all

other screen controls are deactivated. The left joystick

is now activated to move the selected motor. The

motor speed increases as the joystick moves farther

from center. Push the joystick forward for the up

direction and backwards for the down direction.

When the batten is in the correct position, touch

FINISHED to activate the rest of the controls and

deactivate the joystick.

GROUPING

33

Page 41

Rename group

Type a name for the new group using the VAC

keyboard (Figure 6.10). A group name can only

be made of letters and numbers. Typing a name

activates the ACCEPT button.

Touch ACCEPT to confirm the name and return

to the Edit menu.

Touch CANCEL to return to the Edit menu without

renaming the group.

DELETE GROUP

The list of groups is on the left. Select a group

by touching its name in the list. When a group is

selected, its motors display in the group motor list

on the right (Figure 6.11). This list is only to help

select the correct group for deletion. Selecting a

group also activates the DELETE button.

To permanently remove the group, touch DELETE.

To return to the main screen with no changes,

touch CANCEL.

Figure 6.10: Rename function

34

Figure 6.11: Delete function

Page 42

Figure 7.1: Cueing screen

Cue Sheet Breakdown:

1. Cue Sheet

2. Cue Lists A,B,C (Can be new shows or segments of one show).

3. Cues (Individual cues within a Cue List)

4. Cue Actions (Individual actions within a Cue)

Each cue is made of actions, called cue actions. These cue actions move motors, set timing for cues or keep notes.

Each cue action has a:

07 CUEING

This module works with cues. Cues are commands for

the Vortek hoists to carry out. The most common cue

is to move a motor or group, but there are others as

well. A set of cues for a show is called a cue sheet.

Each cue sheet is named for the show. For example,

the set of cues for a production of Annie is called the

Annie cue sheet.

The first menu for cueing is similar to the main menus

in the Grouping and Presets module. These choices

manage cue sheets (Figure 7.1). Touch CREATE

CUE SHEET to create a new show, or touch LOAD

CUE SHEET to work with an existing one. Touch

DELETE CUE SHEET to remove a cue sheet entirely.

On-screen assistance can always be found by touching

HELP in the lower right corner.

CUE SHEET VOCABULARY

Number The cue number sets the order of the cue in the cue sheet. Lower numbered cues run before higher

•

numbered cues. The cue number must be between 0.01 and 99.99. Cue 0.00 is always the initial staring

cue programmed into a cue list.

Title The title is only for describing a cue. For example, it may say “Act II Scene 3.”

•

• Motor/Group This motor/group will be moved by the cue action.

• Target The cue target is the destination for the motor/group.

• Time/Speed The time/speed value is how much time it will take to travel or how fast the motor will travel.

• Note A description of the cue action. For example, it may say “Motor 0 to upper limit.”

• Next This describes the link between this cue action and what follows.

CUEING

35

Page 43

LOAD CUE SHEET

The list of available cue sheets is shown in the center

of the screen (Figure 7.2). Select a cue sheet by

touching its name in the list. When one is selected,

the ACCEPT button will light up.

After selecting, touch ACCEPT to confirm the

selection and load the cue sheet. To return to the

first screen without loading a show, touch CANCEL.

DELETE CUE SHEET

Select a cue by touching its name in the list (Figure

7.2). When one is selected, the DELETE button is

activated (Figure 7.3).

To permanently remove the show, touch DELETE.

To return to the main screen with no changes,

touch CANCEL.

CREATE CUE SHEET

Name

After selecting CREATE CUE SHEET from the first

menu, type a name for the new show using the Pro

Series keyboard or the virtual keyboard (Figure

7.4). A show name can only be made of letters

and numbers (25 max). Typing a name activates the

ACCEPT button.

After entering the name, touch ACCEPT to confirm it.

Touch DECLINE to go back to the first menu without

creating the new cue sheet.

Set Cue 00.00

The starting position of all the motors needs to

recorded when a new show is created. It is important

that the motors start in the correct positions because

all motor movement is based from this starting point.

The starting position for the motors is Cue 00.00.

Modify > Cue Zero screen (Figure 7.5). Touch USE

MANUAL SCREEN to adjust the motors with the

Manual Screen. On the Manual Screen page, touch

CLOSE to return to Cueing. Touch SET CUE 00.00 to

record the initial motor positions for the show.

Figure 7.2: Load Cue Sheet function

Figure 7.3: Delete cue sheet

Figure 7.4: Name cue sheet function

36

Figure 7.5: Set cue 00.00 screen

Page 44

Figure 7.6: Manual screen

If the motors are not in their correct position, touch

MANUAL SCREEN. The VAC will display the

Manual Screen (Figure 7.6). Us the controllers

on this screen to move the motors to the correct

positions. (For more information see the Manual

chapter.)

.

There are three cue sheets per show: A, B and C.

The initial screen for a new show with no existing

cues is shown (Figure 7.7). At any point the

operator may view or edit the other sheets, simply

touch the desired tab or the sheet itself.

Cue Sheet B initial screen is illustrated (Figure 7.8)

with no existing cues.

Figure 7.7: Newly cue sheet

Figure 7.8: Cue Sheet B initial screen

CUEING

37

Page 45

Cuesheet: / A / B / C /

Number Title / Motor - Group / Action Target Speed / Time Next

Show Name:

Cuesheet: / A / B / C /

Number Title / Motor - Group / Action Target Speed / Time Next

A00.00 Initial Motor Setup

A01.00 Cue 1

A01.00.0 Motor 0 UPPER 1.4 ft./sec. AND

A01.00.1 Motor 1 LOWER 15 sec. END

A02.00 Cue 2

A02.00.0 Motor 0 LOWER 1.4 ft./sec. AND

A02.00.1 Motor 3 15' 6" 12 sec. END

Show Name: Example Cuesheet

Figure 7.9 is an example of a blank cue sheet

(additional copies can be found later in this manual).

Figure 7.10. shows an example of one of the cue

lists within the cue sheet showing three cues filled in

(cues 0,1 and 2) and their associated actions (cue

1.00 three actions, cue 2.00 one action).

The very first cue (00.00) for this show is the starting

position for all the motors. The programmable cues

start with the second line.

Cue 1.00 has three cue actions: moving Motor 0,

Motor 1 and Motor 2. Each motor will move to either

their upper or lower target (see the Manual chapter

to see how to set this). Each action will move at 1.4

feet per second.

The Next column displays either AND or END. The

rule is: If there are more actions in this cue, the Next

value is AND. If there are no more actions in this

cue, the Next value is END.

Figures 7.11 and 7.12 show a fictional stage with

battens at random positions like they might be at the

start of creating a new show. The upper and lower

limits are set by the administrator.

Use the manual screen to set upper and lower targets

for the three motors in the motor list. Move the motors

to a point in between their upper and lower targets

for the starting position.

Figure 7.9: Blank cue sheet

Figure 7.10: Cue sheet for new show

C EILING

UPPER LIMIT

M2

M0

FRONT BACK

M1

LOWER LIMIT

STAGE

Figure 7.11: Battens at random positions, viewed

from stage left

C EILING

UPPER LIMIT

UPPER TARGET

FRONT BACK

Figure 7.12: Battens ready to set Cue 00.00, viewed

from stage left

M0

M1

STAGE

M2

LOWER TARGET

LOWER LIMIT

38

Page 46

Figure 7.13: Cue number screen

ADD CUE

Number

Return to Cue List A, touch ADD to begin the

process to add a new cue. The first screen allows

the operator to enter a cue number for the new cue.

Enter the cue number by touching the buttons on

the keypad (Figure 7.13). The ACCEPT button

will activate when an entry has been made.

Touch ACCEPT to confirm your entry, or touch

CANCEL to return to the main menu without

creating a cue (Figure 7.13).

Note: When the cue will be “01.00” it is not

necessary to enter the leading zero, the decimal

point or the decimal numbers.

Title

Enter the cue title by using the Daktronics

keyboard or the virtual keyboard (Figure 7.14).

The ACCEPT button will activate when an entry

has been made.

Touch ACCEPT to confirm the entry, or touch

DECLINE to return to entering the cue number.

Note: When adding a cue, the CANCEL

or DECLINE buttons will step backwards.

Figure 7.14: Enter cue title

CUEING

39

Page 47

Motor/Group

There are two kinds of cue actions: those that

command motors to move and those that do not.

To command a motor to move:

Select the Motor from the list for the first action of a

new cue (Figure 7.15). The CONFIRM button will

activate when a selection has been made. When

the motor group actions are set, touch CONFIRM to

continue.

Touch NO MOVE to command no action, or touch

CANCEL to return to entering the cue title.

Touch NO MOVE to see the options available

(Figure 7.16).

There are two No Move commands.

• A WAIT command will pause for a specified

amount of time before the next action is run.

A WAIT may be placed anywhere in a cue.

After selecting a wait, the VAC will display

a keypad to enter the amount of time to

wait before running the next action.

• A FOLLOW command can only be the last

action in a cue and tells the VAC controller to

execute the following cue immediately.

Figure 7.15: Select Motor

A WAIT command will pause for a specified

amount of time before the next action is run. If the

WAIT is in the middle of a cue, it begins timing with

the previous action. After timing is complete, the next

set of actions begins. This is easier to grasp with an

example cue sheet.

Cue 1.00, First Cue

0 Motor 0 UPPER 15 sec. AND

1 Motor 1 UPPER 15 sec. AND

2 WAIT 20 sec. AND

3 Motor 0 LOWER 25 sec. AND

4 Motor 1 LOWER 25 sec. END

The WAIT starts timing when Motor 0 and Motor 1

begin moving. Because the WAIT time is 5 seconds

longer than the amount of time to move the motors,

both motors are available to be moved in the

following actions.

Figure 7.16: No Move menu

40

Page 48

Figure 7.18: Target screen

Figure 7.19: Time screen

TARGET

Figure 7.18 shows the Target screen. The

boundaries for the target are displayed in the keypad

window. If targets are defined for a selected motor,

they are displayed on the keypad.

A blue target is the upper target, a green target is

the lower target. These are special because if the

upper target or lower target for a motor is changed,

then the target value for cues that use those values is

affected. Yellow target buttons do not have this.

Instead of entering a target, touch CANCEL to

return to selecting a motor/group for this action.

TIME/SPEED

The time/speed of the action can be set by entering

a desired time to complete the move or a speed

value for the motor.

The boundaries for Time entry are displayed in the

keypad window. To enter a time value:

• Enter a value by touching the keys on the

screen and KEYPAD will activate. Touch

KEYPAD to confirm your entry. The screen

displays the boundaries for the time value

as shown in Figure 7.19.

• Touch MINIMUM to use the minimum

amount of time for the action. The minimum

value is shown on the MINIMUM button.

Touch CANCEL to return to entering the target value.

The cue action’s motor can also be controlled by

speed. Touch the SPEED button in the upper right

corner of the panel to enter a speed value

(Figure 7.20).The boundaries are shown in the

keypad or the maximum speed value can be chosen.

To enter a speed value:

• Enter a value by touching the keys on the

screen and KEYPAD will activate. Touch

KEYPAD to confirm your entry. The screen

displays the boundaries for the speed value

as shown in Figure 7.20.

• Touch MAXIMUM to use the motor’s

maximum speed. This value is shown

on the MAXIMUM button.

Touch CANCEL to return to entering the target value.

Figure 7.20: Speed screen

CUEING

41

Page 49

MORE ACTIONS

Figure 7.21 shows the More Actions menu, which asks

the operator if additional actions to the cue sheet are

desired. Touch YES to create another cue. Touch NO to

stop entering cues. Touch CANCEL to return to the Main

menu.

Add Action

Touch ADD ACTION button to add a new action to the

cue. Figure 7.22 illustrates the new action screen.

Touch the grey arrow where the new action cue is to

be placed.

When arrow is highlighted indicating desired

location, touch ACCEPT to move forward with

adding a new cue (Figure 7.23).

Figure 7.21: More actions screen

42

Figure 7.22: New Action screen

Figure 7.23: Action screen with arrow selected

Page 50

Figure 7.24: Motor screen

After touching ACCEPT, the Motor/Group screen

displays (Figure 7.24) indicating additional cue

action is being added.

A motor can not be selected if:

• It is used earlier in the cue.

• The amount of power needed to move

the motor would exceed the capacity

for the group.

Choose a motor and touch CONFIRM. When all the

data is entered, the Modify Cue screen displays.

Delete Action

From the Modify Cue screen (Figure 7.25), select a

cue by touching it. The four options for editing cues

appears. Figure 7.26 illustrates the Modify Cue

screen.

If desired, select the action to delete and touch

DELETE to remove a cue action. A highlighted box

will appear around the selected cue action. Touch

ACCEPT to permanently remove the selected cue

action (Figure 7.27).

Figure 7.25: Modify Cue screen

Figure 7.26: Modify Cue screen with cue selected

Figure 7.27: Delete Action screen with action selected

CUEING

43

Page 51

Modify Action

From the Modify Action screen (Figure 7.26), touch

MODIFY to edit the values in the cue. Figure 7.28

shows the Modify Action screen.

Touch the value that is to be changed and the

appropriate screen will display, allowing the

desired changes.

If an action contains a motor used later in the cue,

its target or time/speed can not be modified. The

later cue depends on the earlier action’s completion

and the only way to assure this is to eliminate the

ability to modify it.

Note: If the motor/group changes, then the target and

time/speed must change. If the target changes, then the

time/speed must change.

MORE CUES

Figure 7.29 shows the More Cues screen. Touch

YES to add more cue actions, or touch NO to stop

entering cues.

When YES is selected, enter the motor/group for the

next cue action. The number and title are the same

throughout a cue, so if more actions are added, the first

two values are not entered again. Enter the information

for the remaining cue actions.

Figure 7.30 shows the Loaded show screen. Four

options are available: DELETE, MODIFY, ADD or RUN.

Figure 7.28: Modify Action screen

Figure 7.29: More Cues screen

44

Figure 7.30: Loaded show displayed

Page 52

Figure 7.31: Delete Cue screen

Figure 7.32: Delete Cue selected

Delete Cues

Touch the DELETE button. Figure 7.31 shows the

Cues loaded. Touch a cue to select it.

Figure 7.32 shows the Cue selected. Touch DELETE

to remove the cue and permanently erase it. Touch

EXIT to clear selection.

Modify Cues

Touch MODIFY from the Load Cue Sheet screen

(Figure 7.30). Four choices are displayed on the

Modify > Menu (Figure 7.33): Select the Cue Sheet

for action (Figure 7:34) ADD ACTION, DELETE

ACTION, MODIFY ACTION or CLEAR are the

options.

Figure 7.33: Modify Cue screen

Figure 7.34: Modify Cue screen with cue selected

CUEING

45

Page 53

Run Cue

Touch RUN on the main menu (Figure 7.30) and the

Run Cue screen will display (Figure 7.35).

Touch a cue in the list to select it for executing.

After selection touch ACCEPT to confirm the

selection.

Figure 7.36 illustrates the Cue Setup screen. To move

the motors to their positions before the selected cue is

run, touch SETUP.

Figure 7.35: Run screen

46

Figure 7.36: Setup screen for cue 1.00

Page 54

Figure 7.37 shows the setup running for the

selected cue.

The motors being moved into position and the status

of the operation are shown in the Setup window.

Figure 7.37: Setting up screen

WARNING

If any problems arise during

any hoist motions, depress the

E-Stop button located below the

monitor immediately and all hoist

movements will stop.

After the setup is completed, the cue is ready to run

(Figure 7.38).

The cue is being executed (Figure 7.39).

Touch RUN CUE to start the cue, or touch

DIFFERENT CUE to change the selected cue. The

Run Cue screen will display (Figure 7.35) to select

another cue.

Figure 7.38: Run motors screen

Figure 7.39: Running screen for Cue 01.00

CUEING

47

Page 55

The screen indicates when cue is complete

(Figure 7.40).

While the cue is running the operator may stop it

by touching PAUSE (Figure 7.41).

After a cue is paused, touch RESUME to continue,

or RESTART to set up the cue to run again.

After a cue is run, the display will highlight the

next cue to be run.

Figure 7.40: Screen showing Cue 1 completed

48

Figure 7.41 Screen showing Cue 1 paused

Page 56

Figure 7.42: The i-Batten system detecting a problem

Figure 7.43 ALERT button

Figure 7.44: Gold arrows

I-BATTEN

The i-Batten system monitors changes in batten load.

If i-Batten detects an overload or underload condition

on a batten during a cue, the i-Batten fault screen

will appear (Figure 7.42).

The top section of the alert box has the list of faulted

motors which are selectable by touching them. The

bottom section has optional controls for recovering

from the motor faults. All cue actions containing

faulted motors are highlighted red and change back

to a normal display when the faults are cleared.

Hide/Show Alert

The alert box will obscure the cue sheet when

it appears. To hide the alert box, either:

• Touch the ALERT button in the upper left

corner (Figure 7.43).

• Touch the three gold arrows in the upper

right corner of the alert box (Figure 7.44).

When the alert box is hidden, the ALERT

button flashes. To show the alert box, touch

the ALERT button.

Figure 7.45: Motor 0 is selected and the controls activate

Figure 7.46: Options for Clear Fault function

ALERT BOX FUNCTIONS

Select one of the faulted motors by touching its

name in the list. After selection, the controls will

activate (Figure 7.45).

Note: Make sure the selected batten has been

physically cleared of any obstruction BEFORE

clearing the fault. Otherwise, the i-Batten system

will fault when the batten is moved again.

Clear Fault

To clear a fault touch CLEAR FAULT to continue

(Figure 7.46).

A batten with a low sensitivity setting may trigger the

i-Batten system. If the batten isn’t physically obstructed

but is faulting, adjust the sensitivity higher by moving

the Sensitivity button to the right.

CUEING

49

Page 57

When the motor’s sensitivity is changed, the

ADJUST button will activate (Figure 7.47).

Touch ADJUST to confirm change.

Touch FINISH MOVE to complete the move in

which the batten faulted (Figure 7.48).

To clear the fault without finishing the move, hide

the Alert box by touching the ALERT button. This will

clear the fault without moving the batten. When the

box is displayed again, the fault will be cleared.

The Clear Fault function works for one move only. A

motor that keeps overloading or underloading may

need to have the i-Batten function bypassed or its

sensitivity adjusted.

Figure 7.47: Sensitivity has been adjusted

Figure 7.48: Motor 0 fault is cleared. Cues with

Motor 0 return to normal display.

Bypass

To bypass the i-Batten Safety feature and complete

a move, select a motor by touching its name in the

list. Touch BYPASS and the panel will display a

CONFIRM button (Figure 7.49). Touch CONFIRM

and FINISH MOVE. Bypassed motors display an

i-Batten Safety Off icon at the left of cue actions

where the motor is used as illustrated in Figure 7.50.

This will disable the i-Batten safety feature for this

motor. i-Batten can be re-enabled only from the Setup

module which requires Administrator privileges.

WARNING

Bypassing the i-Batten safety feature

will remove the ability of the VAC

to report a faulted condition

during operation.

Figure 7.49: From the alert box, BYPASS selected.

50

Figure 7.50: Cue action 2.00 with the safety feature

bypassed

Page 58

Figure 7.51: Selecting DISABLE from the alert box

Figure 7.39: Screen showinleted

Disable

To disable a motor so that it doesn’t move again,

select it by touching its name in the Faulted Motor

list, then touch DISABLE. Touch CONFIRM to

continue/disable the motor (Figure 7.51).

Cues with disabled motors are displayed in red text

(Figure 7:52).

Note: Once a motor is disabled, it will not move

again and can only be enabled by an administrator

using the Motor Restrict module.

Figure 7.52: Cue actions with disabled motors display in

red, such as Cue 3.00, Cue action 0 above.

CUEING

51

Page 59

52

Page 60

Figure 8.1: Presets module

08 PRESETS

To move one or all of the battens to preset positions

sequentially use the Presets module (Figure 8.1).

This is useful for setting up the stage in different

configurations that may be used over and over

again. A preset may be run to configure the stage for

band or choral concerts, or to raise all

the battens for maintenance purposes

On-screen assistance can always be found by

touching HELP in the lower right corner.

.

PRESETS

53

Page 61

CREATE PRESET

Name Preset

After selecting CREATE PRESET from the main menu,

type a name for the new preset using the Daktronics

keyboard or the virtual keyboard (Figure 8.2). A

preset name can only be made of letters and numbers

(max 25). Typing a name activates

the ACCEPT button.

After entering the name, touch ACCEPT to confirm it.

Touch DECLINE to go back to the main menu without

creating the preset.

A preset contains two pieces of information for

every motor: when it is moved and where it is

moved to (Figure 8.3). The motors move sequentially

in the listed order. The target value on the right column

is the position the motor will be moved to.

Note: Motors will move at the factory default speed.

Figure 8.2: Name preset virtual keyboard.

Note: Grouped motors cannot be moved in

a preset.

54

Figure 8.3: Example preset.

Page 62

Figure 8.4: Create screen

Create

On the left side of the screen, the Order controls

determine in what order the motors are moved; on

the right side, the Target controls, specify where a

motor will move to (Figure 8.4).

In a new preset, the default order is determined

at commissioning and usually runs from downstage to

upstage. The default target for a motor is its current

position.

Order controls

Figure 8.5: Order controls

Target controls

Order Controls

The Order controls (Figure 8.5) change the motor

sequence, remove motors from the preset or add all

omitted motors back into the preset.

PRESETS

55

Page 63

Omit Motor

In some presets, not every motor is used. To

remove a motor from the list, select it and touch

OMIT MOTOR.

The motor name will deactivate to show that it

will not move in the preset (Figure 8.6).

Move in List

To change the sequence in which the motors move,

select the motor and touch the MOVE IN LIST button.

Choose a new list position for the motor by touching

one of the grey arrows that appear (Figure 8.7).

MOVE IN LIST changes to read ACCEPT.

Touch ACCEPT to confirm the new list position. The

order list displays the updated order (Figure 8.8).

Figure 8.6: Motor 0 is omitted.

Figure 8.7: Change position arrows

All

To add all omitted motors back into the order list,

touch ALL. When omitted motors are added, check

to make sure the target values are correct.

Target controls

Select a motor from the list by touching its name.

Now the top of the Target controls will display

the name of the selected motor (Figure 8.9).

Figure 8.8: After position is changed

UPR (upper limit)

Up

Keypad

Down

LWR (lower limit)

56

Figure 8.9: Target controls

Joystick

Page 64

Figure 8.10: Up arrow depressed

Up/Down

Touch and hold either button to move the motor in

that direction. As the motor moves, its target value

moves as well.

When either of the arrows are pressed, they divide

into three areas (Figure 8.10). Push the minus (-) to

decrease the speed, or plus (+) to increase it while

the motor is moving.

The motor will stop moving when your finger leaves

the button or the motor has reached its limit.

Keypad

To enter the target value manually, touch the

KEYPAD button and a keypad will display (Figure

8.11). The keypad displays the boundaries for the

target value.

Touch CHANGE to confirm the new target value or

CANCEL to return to the main Preset screen without

changing the target.

Figure 8.11: Keypad showing boundaries

Figure 8.2: UPR button shows the upper limit is 100;

LWR button shows the lower limit is 3.

UPR / LWR

Touch UPR or LWR to use the value of the upper

limit or lower limit as displayed on the button

(Figure 8.12).

WARNING

If any problems arise during

any hoist motions, depress the

Emergency Stop button located

below the monitor immediately and

all hoist movements will stop.

PRESETS

57

Page 65

Joystick

To control the motor (and change the target value)

with the left joystick, touch the JOYSTICK button

under the arrow buttons.

The button will change to read FINISHED and all

other controls are deactivated (Figure 8.13). The

Vortek is now ready to move the motor with the left

joystick. The motor will move faster the farther you

push the joystick away from center.

When the batten is in the correct position, touch

FINISHED to activate the rest of the controls and

deactivate the joystick. The position of the motor

will now be used for the preset target.

Figure 8.13: Target controls are deactivated while

the joy-stick is used to set the target value.

DELETE PRESET

The list of presets is on the left of the screen(Figure

8.14). Select a preset by touching its name in the

list. The ACCEPT button is activated after selection.

To permanently remove the preset, touch ACCEPT.

To return to the main screen with no changes,

touch EXIT.

Figure 8.14: Delete preset

58

Page 66

Figure 8.15: Modify preset

MODIFY PRESET

The list of presets is on the left of the screen (Figure

8.15). Select a preset by touching its name in the

list. The ACCEPT button is activated after selection.

Select a preset from the list by touching its name.

Touch ACCEPT to change the preset or touch EXIT

to return to the main Preset screen without change.

Modify screen

This screen works like the Create screen in the

Create Preset function (Figure 8.4). When

modifications are complete, touch DONE to

save the modified preset (Figure 8.16).

Figure 8.16: Modify screen

PRESETS

59

Page 67

RUN PRESET

The list of presets is on the left (Figure 8.17). Select

a preset by touching its name in the list. The ACCEPT

button is activated after selection.

To execute the preset, touch ACCEPT. To return to

the main Preset screen, touch EXIT.

Confirm Preset

The system will ask you to confirm that you have

chosen the correct preset before the preset will run

(Figure 8.18). Touch CONTINUE to move forward.

Figure 8.17: Run preset

60

Figure 8.18: Confirm preset

Page 68

Figure 8.19: Run screen

Run screen

At the run screen (Figure 8.19) there are

two options:

• To run the selected preset, touch START.

• To cancel this function and return to the

main Presets screen, touch EXIT.

Touch START to run the preset. The first motor of

the preset will begin moving to its target (Figure

8.20) while the PAUSE and STOP/CANCEL

buttons activate.

Touch PAUSE while the preset is running to stop

the motor.

Touch STOP/CANCEL to stop running the preset

and return to the main Presets screen.

Figure 8.20: Preset running.

PRESETS

61

Page 69

Pause screen

While the preset is paused (Figure 8.21), touch

START to continue running the preset or touch

STOP/CANCEL to halt the preset where it is

and return to the main menu.

Figure 8.21

62

Page 70

Figure 9.1: Setup module

09 SETUP

The Setup module is very similar to the

Manual module but with two differences. The Setup

module (Figure 9.1)works with limits (instead of

targets) and has the controls to calibrate the i-Batten

safety feature.

The Setup module has two controllers, each of which

controls a motor, group or curtain. After selecting a

motor, its name, speed, position, limits

or icons may be changed.

If the safety feature is disabled for a motor or group,

the controller will display a red slash over the i-Batten

logo (Figure 9.2).

If a weight change for the batten is detected, the

motor will stop moving until the batten weight returns

to normal.

Enabled Disabled

Figure 9.2: i-Batten status

SETUP

63

Page 71

MOTOR SELECTION

Select a motor by touching the yellow button at the

top of the controller as shown in Figure 9.3.

The bar with the current motor expands to show a

list of all available motors, with grouped motors

shown in blue (Figure 9.4).

Move through the list by using the:

• Slider

• PgUp

• PgDn

Figure 9.3: Motor Select button

Touch the name of the desired motor or group to

select it. It will highlight and CONFIRM will activate

(Figure 9.5).

Touch CONFIRM to verify selection.

Note: Before touching CONFIRM, the operator

may change the selection by touching a different

motor name.

Figure 9.4: Motor Select screen

Figure 9.5: Motor selected

64

Page 72

Figure 9.6: Modify Motor screen

Batten Setup

After selecting a motor, touch BATTEN SETUP

to "teach" the i-Batten safety feature. This system

detects when a batten's weight changes, such as

when it gets obstructed during a move, and

disables it as a safety precaution.

This safety feature is bypassed in Batten Setup mode

to allow you to attach curtains and scenery to the

batten. The process for Batten Setup is:

1. Choose a motor and confirm it. Three

options are displayed: BATTEN SETUP,

RENAME and CONTINUE (Figure 9.6).

Touch BATTEN SETUP. A new panel is

displayed (Figure 9.7).

2. Use the Up/Down arrows or the

joystick to lower the batten until it is

a comfortable height to work with.

Tie curtains or scenery to the batten.

3. Move the batten up until the attachment

is completely off the floor. This is the

lowest point the batten will travel to.

Touch SET LOWER LIMIT.

4. Move the batten up until it is at the

highest point you wish.

Touch SET UPPER LIMIT.

Figure 9.7: Batten Setup screen

SETUP

65

Page 73

5. Set the maximum speed of the motor using

the slider control (Figure 9.8).

Depending on what is attached to the batten,

you may wish to limit how fast the motor can

move. By dragging the slider change the

motor’s maximum speed can be changed.

6. The i-Batten sensitivity value determines how

much the batten’s weight must change to

register a fault.

Touch SET SENSITIVITY (Figure 9.9) to

display a keypad to enter the sensitivity value

(Figure 9.10). After entering the sensitivity,

i-Batten system is ready for the teach setup.

Figure 9.8: Maximum speed slider

Figure 9.9: Set Sensitivity button

WARNING

66

The cables are rated for 420 lbs.

of support. Overloading the batten

could cause the cables to break.

Figure 9.10: Sensitivity keypad

Page 74

Figure 9.11: Teach Down panel

7. Touch TEACH DOWN. A new panel displays

(Figure 9.11).

To teach the i-Batten System, the batten must

travel for a length of time. The proper way to

ensure the motor has enough time to travel

is to start at the opposite limit. At this point

in the instructions, the batten is at the upper

limit so the i-Batten is is ready to be taught

down. Touch TEACH DOWN.

The batten will start travelling downward.

In an emergency, touch STOP to halt the

motor's movement and suspend the

teaching. Touch UPPER LIMIT and

teach the i-Batten again.

When the i-Batten system is successfully

taught, the batten will automatically stop.

Touch CONTINUE. Return to the Batten

Setup screen.

8. On the Batten Setup screen (Figure 9.7),

touch TEACH UP. A new panel displays

(Figure 9.12).

Touch LOWER LIMIT to move the batten to

its lower limit and ensure it has enough room

to be taught. When the batten has reached

its lowest point, touch TEACH UP.

The batten will start travelling up. Touch

CONTINUE when the batten has stopped

moving.

i-Batten teaching is now complete for this motor.

Figure 9.12: Teach Up panel

WARNING

Because this is an automatic

procedure, the area underneath the

batten must be clear of people and

obstructions before this operation is

attempted. During this procedure the

i-Batten safety feature is off.

SETUP

67

Page 75

Additionally, from the Batten Setup screen you may:

Restore Factory Settings

Touch RESTORE FACTORY SETTINGS (Figure

9.13) to return all settings for this motor to the

factory installed specification. This is useful for

resetting the maximum speed to its factory setting.

Bypass i-Batten Safety

Touch BYPASS (Figure 9.14) to enable/disable

the i-Batten safety feature for this batten.

Figure 9.13: Restore Factory Settings button

Figure 9.14: i-Batten Safety is on.

Touch BYPASS to turn it off.

Confirm

Touch CONFIRM to complete the batten setup

(Figure 9.15).

Figure 9.15: Confirm button

68

Page 76

Figure 9.16: Curtain setup panel

Curtain Setup

If the selected motor controls a bi-part curtain then

the display will be different. Note that the symbols

on the blue and green buttons have changed from

arrows to open and close icons. Curtain Setup mode

allows only for the setting of open and close limits

and maximum speed for the curtain.

Figure 9.17: Rename panel

Rename

To rename a motor, touch RENAME on the Modify

Motor screen (Figure 9.16). The Rename panel will

display (Figure 9.17).

Enter a new name by using the VAC keyboard.

Names can only contain letters and numbers (max

25 characters) and must be unique. Renaming is

not an option if the motor is part of a group.

Touch CONFIRM to change the name of the motor

to the entered name.

SETUP

69

Page 77

SPEED

The speed button is located under the Motor

Select dropdown menu (Figure 9.18). To change the

speed, touch and hold down the speed button. Slide

it to the right to increase the speed of the selected

motor, or left to decrease the speed.

Above the button, the current speed is shown on the

left, while the maximum speed of the selected motor

is shown on the right.

Set Speed Numerically

To adjust the speed with greater accuracy,

touch the speed button twice quickly (double-click).

The controller will display a keypad for manual entry

(Figure 9.19). Enter the new speed value and touch

USE KEYPAD ENTRY to confirm the entered value.

Figure 9.18: Speed button

UP/DOWN

These buttons raise or lower the batten. They

are colored blue for up and green for down.

To move the motor, touch and hold an arrow

key. When pressed, they divide into three

areas (Figure 9.20).

Press minus (-) to decrease the speed, or to

plus (+) to increase it while the motor is moving.

The motor will stop moving when the button is no

longer pressed or the motor has reached its limit.

Figure 9.19: Enter speed numerically

Figure 9.20: Up arrow depressed

70

Page 78

Upper limit

Current position

Lower limit

BATTEN POSITION INDICATOR