Page 1

MS-2013 Portable

LED Scoreboard

Display Manual

ED-13145 Rev 8 – 16 April 2015

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4746

www.daktronics.com/support

Page 2

Page 3

ED-13145

Product 1192

Rev 8 – 16 April 2015

DAKTRONICS, INC.

Copyright 2007-2015

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retrieval systems – without written permission of the publisher.

All Sport® and PanaView® are trademarks of Daktronics, Inc. Other trademarks used in this manual are the property of their

respective owners.

Page 4

Page 5

Table of Contents

Section 1: Introduction ................................................................................................................. 1

1.1 Specifications Label................................................................................................................. 1

1.2 Scoreboard Controllers ........................................................................................................... 1

1.3 Resources .................................................................................................................................. 2

1.4 Daktronics Nomenclature ...................................................................................................... 2

1.5 Product Safety Approval........................................................................................................ 2

Section 2: Specifications ............................................................................................................. 3

Section 3: Mechanical Installation .............................................................................................. 5

3.1 Cart Assembly ......................................................................................................................... 5

3.2 Adjusting the Cart ................................................................................................................... 5

3.3 Optional Equipment Installation ........................................................................................... 6

Caption Kits ...................................................................................................................... 6

Scoreboard Cover ............................................................................................................. 6

Ad Panel ............................................................................................................................ 6

Section 4: Electrical Operation .................................................................................................... 7

4.1 Power & Signal Access ........................................................................................................... 7

4.2 Power ........................................................................................................................................ 7

4.3 Signal ........................................................................................................................................ 8

Connecting Signal Cable ................................................................................................. 8

Base Station & Radio Receiver Installation ................................................................... 9

Setting the Base Station Function ............................................................................ 9

Setting the Radio Receiver Channel ....................................................................... 9

4.4 Power-On Self-Test (POST) ................................................................................................. 10

Radio Settings ................................................................................................................. 10

Section 5: Battery Care & Charging .......................................................................................... 11

5.1 On-Board Charger ................................................................................................................. 11

Operation ........................................................................................................................ 13

Charger Troubleshooting Table ................................................................................... 13

Radio Interference .......................................................................................................... 14

5.2 Battery & Charging Safety ................................................................................................... 14

Personal Safety Precautions .......................................................................................... 14

DC Connection Precautions .......................................................................................... 15

Section 6: Scoreboard Troubleshooting .................................................................................. 17

6.1 Troubleshooting Table .......................................................................................................... 17

6.2 Component Location & Access ........................................................................................... 19

6.3 Replacing Digits .................................................................................................................... 20

Segmentation & Digit Designation .............................................................................. 20

6.4 LED Driver ............................................................................................................................. 21

Replacing a Driver ......................................................................................................... 21

Setting the Driver Address ........................................................................................... 22

6.5 Replacing Batteries ................................................................................................................ 22

6.6 Horn ........................................................................................................................................ 23

Table of Contents i

Page 6

6.7 Replacement Parts ................................................................................................................. 23

Section 7: Daktronics Exchange and Repair & Return Programs .......................................... 25

7.1 Exchange Program ................................................................................................................ 25

Before Contacting Daktronics ....................................................................................... 25

7.2 Repair & Return Program .................................................................................................... 26

Shipping Address ........................................................................................................... 26

7.3 Daktronics Warranty and Limitation of Liability ............................................................. 26

Appendix A: Reference Drawings .................................................................................................. 27

Appendix B: Daktronics Warranty and Limitation of Liability .................................................... 29

ii Table of Contents

Page 7

Figure 1: Specifications Label

Section 1: Introduction

This manual outlines specifications, installation, and operating procedures for the Daktronics portable

LED scoreboard model MS-2013. For additional information regarding the safety, installation,

operation, or service of this system, refer to the telephone numbers listed in Section 7. Project-specific

information takes precedence over any other general information found in this manual.

IMPORTANT SAFEGUARDS

Read and understand all instructions before beginning the installation process.

Toggle the power switch to "OFF" when not using the scoreboard.

Disconnect the batteries and turn the power switch "OFF" when servicing the

scoreboard.

Do not modify the scoreboard structure or attach any panels or coverings to the

scoreboard without the express written consent of Daktronics.

Do not disassemble control equipment or electronic controls of the display; failure to

follow this safeguard will make the warranty null and void.

Do not drop control equipment or allow it to get wet.

1.1 Specifications Label

Power specifications as well as serial and model number information can be found on an ID

label on the display, similar to the one shown in Figure 1.

Please have the assembly number, model number, and the date manufactured on hand when

calling Daktronics customer service to ensure the request is serviced as quickly as possible.

Knowing the facility name and/or job number will also be helpful.

1.2 Scoreboard Controllers

The MS-2013 scoreboard is designed for use with the battery-powered RC-100 handheld

controller. The MS-2013 may also be controlled via an All Sport® 1600 series control console,

which may be equipped with an optional radio transmitter and powered by its own battery

pack for an alternate wireless scoring solution. Both controllers use keyboard overlays (sport

inserts) to control multiple sports. Refer to the following manuals for operating instructions:

All Sport 1600 Series Control Console Operation Manual (ED-12462)

Remote Control System RC-100 All Sport Operation Manual (ED-15133)

These control console manuals are available online at www.daktronics.com/manuals.

Introduction 1

Page 8

Main Component Labels

Part Type

Part Number

Individual circuit board

0P-XXXX-XXXX

Assembly; a collection of

circuit boards

0A-XXXX-XXXX

Wire or cable

W-XXXX

Fuse

F-XXXX

Transformer

T-XXXX

Metal part

M-XXX

Fabricated metal assembly

0S-XXXXXX

Specially ordered part

PR-XXXXX-X

Figure 2: Daktronics Drawing Label

Figure 3: Typical Label

Accessory Labels

Component

Label

Termination block for

power or signal cable

TBXX

Grounding point

EXX

Power or signal jack

JXX

Power or signal plug

for the opposite jack

PXX

1.3 Resources

Figure 2 illustrates a Daktronics drawing

label. The drawing number is located in the

lower-right corner of a drawing. This

manual refers to drawings by listing the last

set of digits and the letter preceding them.

In the example, the drawing would be

referred to as Drawing C-1007804. Any

drawings referenced in a particular section

are listed at the beginning of it as shown below:

Reference Drawing:

System Riser Diagram ......................................................................................... C-1007804

Daktronics identifies manuals by the DD or ED number located on the cover page of each

manual. For example, this manual would be referred to as ED-13145.

1.4 Daktronics Nomenclature

Most components within this display carry a white label that lists

the part number of the unit. If a component is not found in the

Replacement Parts List in Section 6.7, use the label to order a

replacement. Figure 3 illustrates a typical label. The part number

is in bold.

Following the Replacement Parts List is the Daktronics Exchange Policy and the Repair &

Return Program. Refer to these instructions if replacing or repairing any display component.

1.5 Product Safety Approval

Daktronics outdoor scoreboards are ETL-listed, tested to CSA standards, and CE labeled.

Contact Daktronics with any questions regarding testing procedures.

2 Introduction

Page 9

Dimensions (Height, Width, Depth)

Display Only:

2'-10" H x 4'-4" W x 8" D

(864 mm, 1.32 m, 203 mm)

With Cart:

5'-2" H x 4'-4" W x 8" D

(1.57 m, 1.32 m, 203 mm)

Weight w/ Batteries & Cart

150 lb

(68 kg)

Digit Size

10" (254 mm)

Digit Color

Red

Watts

100 W

Power

120 VAC

or

24 V battery

Batteries

2 @ 12 V (each)

28 Amp/Hours

Amps per Line (Single Phase)

1 A

Driver Number & Address

A1 – 11

Section 2: Specifications

The table below lists all of the mechanical specifications, circuit specifications, and power

requirements for the MS 2013.

Note: Batteries require 12 hours to fully recharge and can operate for up to 14 hours of

normal use.

Specifications 3

Page 10

Page 11

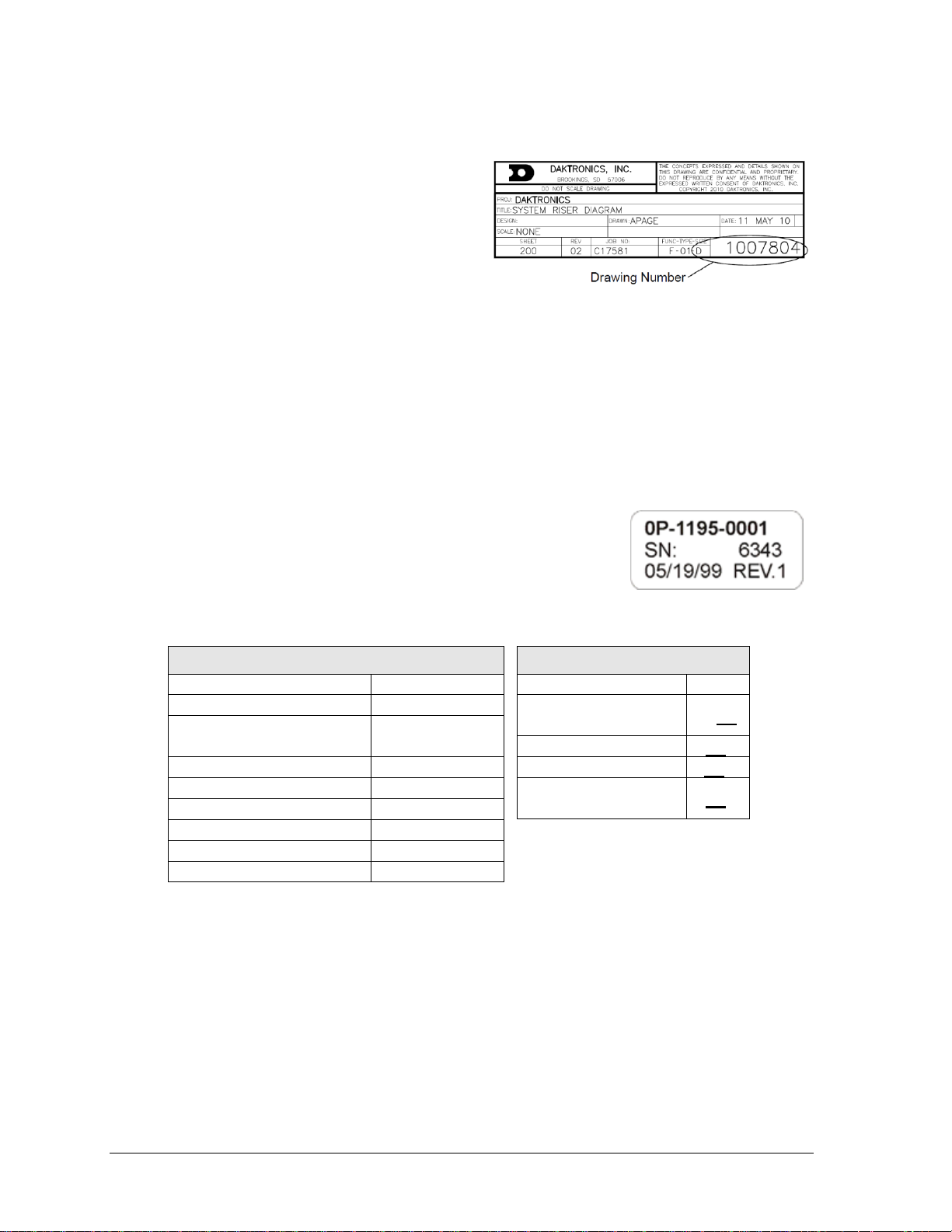

Figure 4: Cart Assembly, Side View

Section 3: Mechanical Installation

Mechanical installation involves assembly of the cart. The scoreboard itself requires no assembly or

permanent installation. Some assembly is required, however, for certain scoreboard options.

3.1 Cart Assembly

Reference Drawings:

Mechanical Specifications, MS-2013 .................................................................... A-159886

Cart Assembly ....................................................................................................... A-159889

The display cart, as shown in Figure 4, comes standard

with two wheels, but may use four if ordered. Open the

cart kit and verify the following pieces are included:

T-stands @ 2

Axle tubes @ 4

10" wheels @ 2 (or 4)

1

/2"-13 x 3 1/2" bolts @ 2 (or 4)

1

/2" flat washers @ 2 (or 4)

5

/16" diameter pins with clips @ 6

A 3/4" wrench will be needed to attach the wheels.

Refer to Drawing A-159889 in Appendix A and the

following instructions to assemble the cart:

1. Insert the axle tubes into the T-stands, and secure them with pins and retaining clips.

2. Mount the scoreboard by inserting the two T-stands into the larger tube attachments

on the sides of the scoreboard, and secure the stands with pins and retaining clips.

(The tubes mounted on either side of the scoreboard are permanent attachments; do

not remove them during cart disassembly.)

3. Mount the first wheel to one end of the T-stand, using a washer as a spacer, and

secure the wheel with an axle bolt. Repeat the process for the second wheel, and

tighten the bolts with a 3/4" wrench.

Note: Two more optional wheels may be installed on the opposite T-stand.

3.2 Adjusting the Cart

Drawing A-159886 in Appendix A shows the two axle positions that may be used with the

cart. The extended axle position provides maximum stability and is recommended for any

situation in which the scoreboard is raised. Use the narrow axle position (and lowest height)

to move the scoreboard through doorways and for storage. The drawing also illustrates front

profiles of the scoreboard in transport position and at maximum viewing height.

Mechanical Installation 5

Page 12

There are three height-adjustment holes in the support tubes on the sides of the scoreboard.

Raise the scoreboard for viewing by removing the pins and retaining clips, sliding the

scoreboard upward on the T-stands and reinserting the pins in the appropriate holes. Lower

the scoreboard for storage or transportation. It may be helpful to have one person lift the

scoreboard while another person adjusts the locking pins.

Caution! Do not raise the scoreboard in high winds or transport the scoreboard in the raised

position. These actions increase the likelihood of tipping over and damaging the scoreboard.

3.3 Optional Equipment Installation

Reference Drawings:

Caption Options, MS-2013 .................................................................................... A-159890

Cover Installation- MS-2013 .................................................................................. A-160060

Ad Panel Installation, MS-2013.............................................................................. A-160057

Caption Kits

The MS-2013 is shipped as a generic multisport scoreboard with a standard clock/score

caption arrangement. The face of the scoreboard displays game time, home and guest scoring,

and period. Four optional caption kits give the scoreboard added versatility:

Custom Team Names

Baseball/Softball Mode

Segment Timing Mode

Volleyball Mode

The aluminum caption panels are applied to the scoreboard face with hook-and-loop fastener

strips. They can be easily removed and replaced for various events, leaving the hook strips

attached to the face of the scoreboard. Refer to Drawing A-159890 in Appendix A for an

illustration of the various caption configurations.

Scoreboard Cover

The aluminum cover protects the MS-2013 during transportation and storage. Flanges on the

cover fit into slots on either side of the scoreboards, and the cover simply slides into place

using handles on the front. Drawing A-160060 in Appendix A illustrates the cover installation.

Note: If a radio antenna is installed on the face of the scoreboard it is highly recommended

to remove the antenna before installing or removing the cover. Refer to Section 4.3 for

more information about radio installations.

Ad Panel

A custom advertising/school logo panel may be added to the MS-2013. Threaded inserts in the

top of the scoreboard cabinet allow attachment using only three screws. The 12" H x 52" W

(305 mm, 1.32 m) aluminum panel runs the full width of the scoreboard. Drawing A-160057 in

Appendix A illustrates the ad panel installation.

6 Mechanical Installation

Page 13

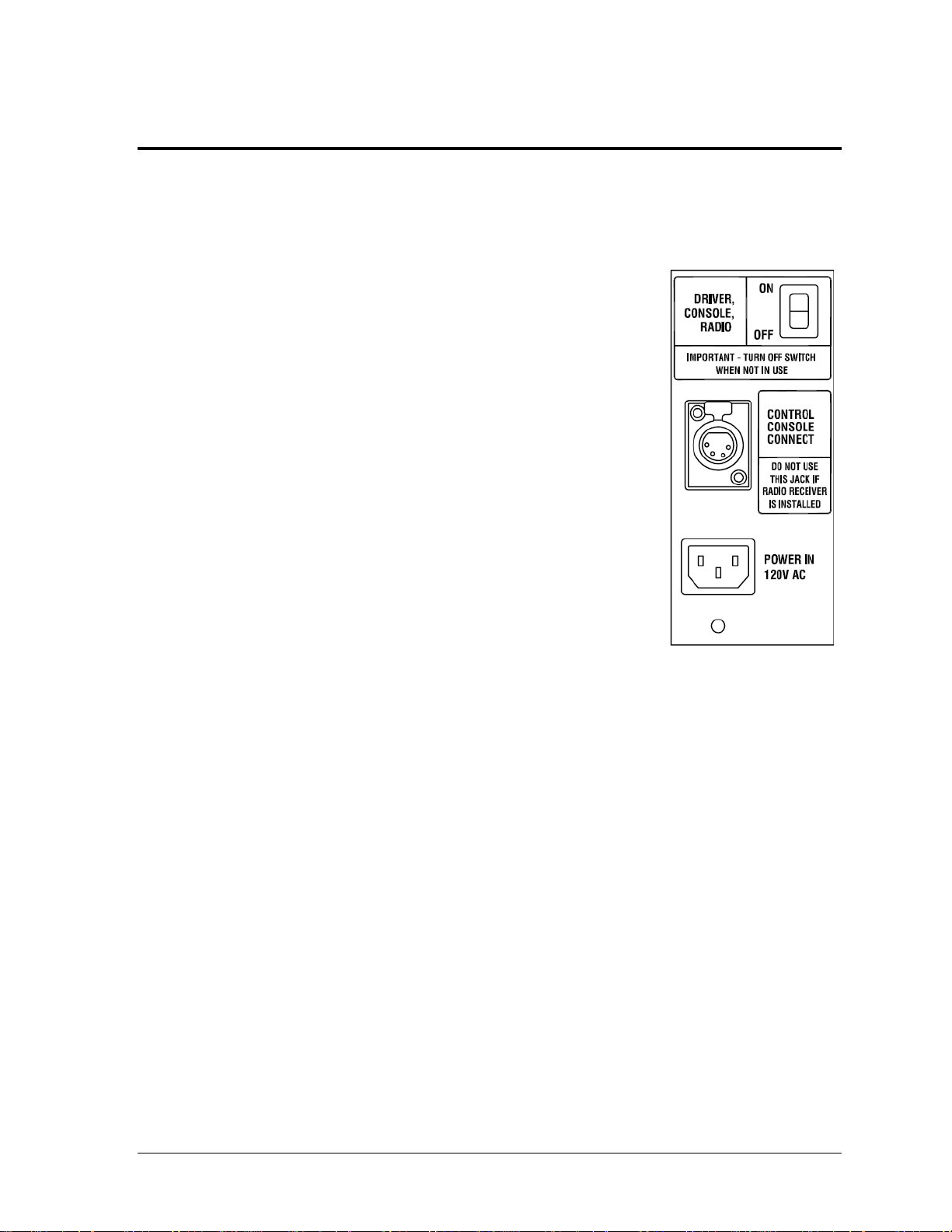

Figure 5: Control Panel

Section 4: Electrical Operation

The MS-2013 can be powered by two different electrical systems: a standard 120 VAC power source

and/or enclosed lead-acid batteries.

4.1 Power & Signal Access

Power and control connections for the MS-2013 are located in a

compartment on the rear of the scoreboard (Figure 5).

To open the rear compartment, turn the adjustable latch a quarterturn to the left. To close, shut the access door and turn the latch to

the right. If the latch will not engage because it is too tight, make

several turns to the left, and then turn back to the right to latch

and tighten.

The compartment is also designed for storage of the control

equipment. The compartment door can be closed with the power

and signal cords extending through the slot below the door.

Note: If the scoreboard came with a 100' (30.5 m) signal cable,

there will be two hooks on the rear of the scoreboard which

the cable may be wrapped around for storage.

4.2 Power

Reference Drawings:

Schematic: MS-2013-11 ........................................................................................ A-158030

Electrical Specifications, MS-2013 ........................................................................ A-159887

Battery Service, MS-2013 ..................................................................................... A-159891

Power for the scoreboard is provided in two ways: via standard 120 VAC line, or by means of

two sealed lead-acid DC batteries. Daktronics supplies two 12 V Panasonic® batteries (Model

LC-X1228P), rated at 28 ampere hours (A/H) as original equipment. Refer to Section 5 for

information on battery care and use of the on-board battery charger.

The provided 8' (2.4 m) 120 VAC power cord plugs directly into the POWER IN 120V AC

receptacle, located in the rear compartment on the back panel of the scoreboard (Figure 5).

Any time 120 VAC power is connected, the internal charger operates; however, the system

will not overcharge the batteries. When the power cord is not connected, the system runs on

battery power.

The MS-2013 is shipped ready for use. The battery charger is factory-mounted in the

scoreboard, and all internal wiring is in place and connected to the driver and batteries.

Electrical Operation 7

Page 14

The ON/OFF control switch (Figure 5) activates power to the internal scoreboard

components, as well as to the radio receiver or control console.

Turn the switch to ON for scoreboard operation.

At all other times, keep the switch in the OFF position.

Whether or not the scoreboard is operational, its batteries will continue to discharge any time

the switch is in the ON position. Leaving the switch ON when the unit is not in use could

completely discharge and damage the batteries.

Refer to Drawing A-159887 in Appendix A for component locations and illustrations of

internal and external wiring. Drawing B-158030 provides a detailed wiring schematic of

internal scoreboard components for advanced troubleshooting.

Daktronics recommends that the scoreboard remains plugged in to a 120 VAC power source

during storage. Battery life is enhanced by keeping the batteries fully charged. Typically,

batteries will be fully charged in about 12 hours and will give about 14 hours performance on

a full charge.

4.3 Signal

Reference Drawings:

System Riser Diagrams- MS-2013-11 ................................................................... A-160237

The MS-2013 can receive control signal three different ways, described below. Refer also to

Drawing A-160237 in Appendix A for diagrams of each of these control setups.

Setup 1 (Standard): A wireless RC-100 handheld controller communicates with a

radio base station installed inside the scoreboard.

Setup 2 (Optional): A 4-pin cable connects the scoreboard directly to the All Sport.

The cable transmits signal output to the scoreboard and power input to the controller.

Setup 3 (Optional): A control console equipped with radio transmitter and its own

battery pack or a separate power cord communicates with a radio receiver installed

inside the scoreboard.

Connecting Signal Cable

If the scoreboard was ordered with a wired control console, simply plug the signal cable into

the jack labeled CONTROL CONSOLE CONNECT (Figure 5) Attach the mating plug to the

modified power cord from the All Sport controller. Extension cables are also available from

Daktronics if more than the 100' (30.5 m) of control cable provided is needed.

8 Electrical Operation

Page 15

Base Station & Radio Receiver Installation

Reference Drawings:

Radio Receiver Installation, MS-2013 ................................................................... A-160015

Base Station: Outdoor Installation ......................................................................... A-236394

System Riser Diagram: RC-100- MS-2013 ........................................................... A-244926

Installation Drawing; Outdoor Scbd Gen VI Radio Receiver ............................... A-1109181

The RC-100 base station and All Sport radio receiver are typically held in place with

adhesive-backed, hook-and-loop fastener strips, and when ordered as original equipment

may already be installed. The only installation required is attachment of the radio antenna,

which may have been shipped separately to prevent damage.

If the base station or receiver is not already installed:

1. Access the inside of the scoreboard by removing the three (3) screws securing the rear

access panel and swinging it open.

2. Position the unit inside the scoreboard so the antenna connector can extend through

the hole in the upper-right corner on the front of the scoreboard.

3. Remove the backing from the fastener strips on the unit.

4. Insert the antenna jack through the hole, and then firmly press the unit against the

interior front panel, sticking the fastener's adhesive to the sheet metal.

5. Route and connect the cable protruding from the bottom of the unit to the mating 6-

pin jack directly on the LED driver.

Note: For models built prior to April 2015, the radio cable will connect to the 5-pin

jack labeled “J45” coming from the LED driver.

6. Close and secure the rear access panel.

7. From the front face of the scoreboard, note that the antenna connector now protrudes

through the panel.

a. Install and tighten the lock washer and nut on the antenna connector.

b. Mount the external antenna on the connector, turning the nut on the antenna

until it is snug.

c. Rotate the antenna so that it is pointing straight upward (it should look like a

capital “L” when viewed from the side).

Setting the Base Station Function

The base station is preset to Function 2 or 5, Channel 1. If the default settings do not appear to

work, refer to Drawings A-236394 and A-244926 for instruction on changing these settings.

For more information, refer to the RC-100 manual listed in Section 1.1.

Setting the Radio Receiver Channel

The radio receiver is preset to Channel 1. If there are other scoreboards in the facility

operating with radio signal, each scoreboard receiver must be set to a different channel

number (typically starting with 1 and numbering consecutively). Refer to Drawing A-1109181.

Refer to the Gen VI Radio Installation Manual (DD2362277) for more information.

This manual is available online at www.daktronics.com/manuals.

Electrical Operation 9

Page 16

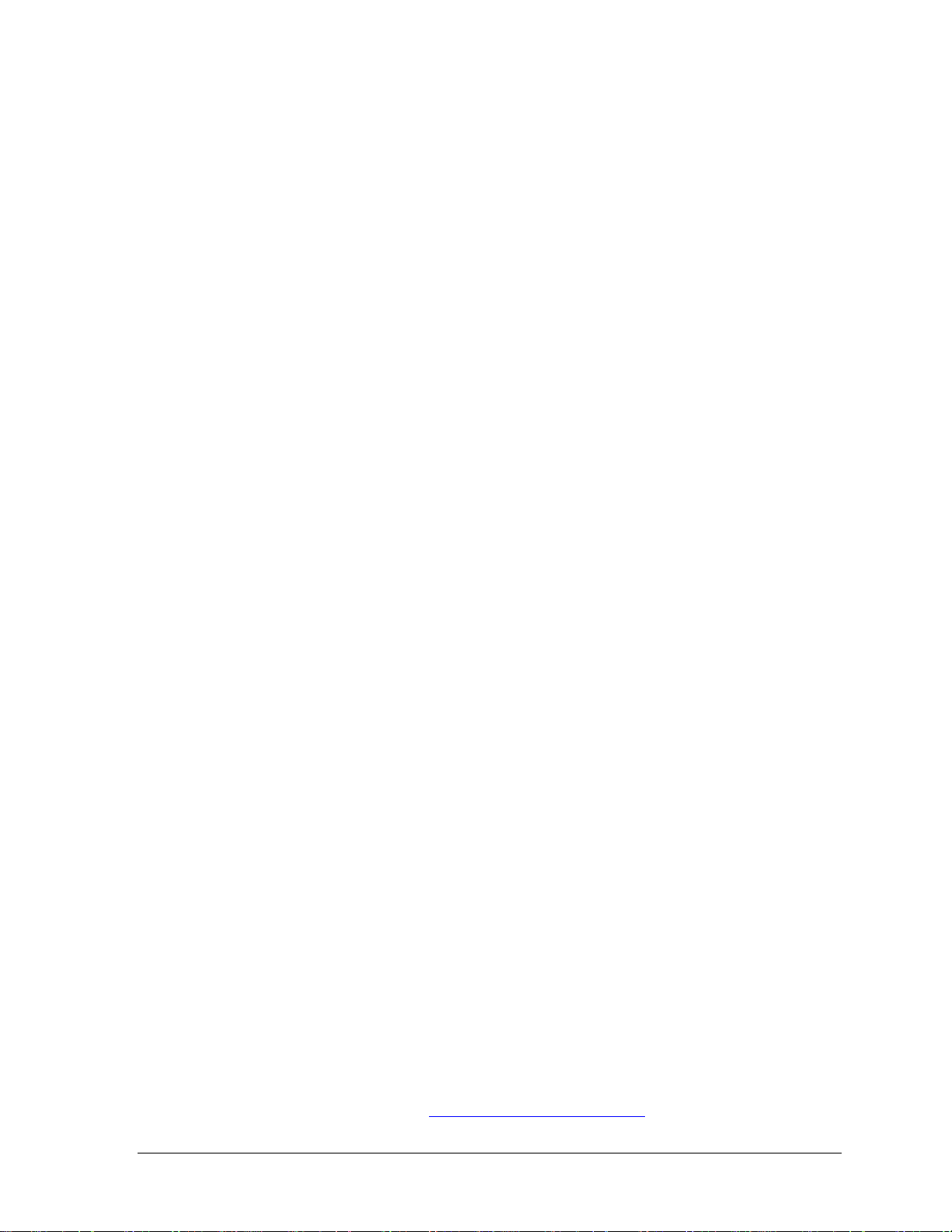

Figure 6: Digit Segment POST

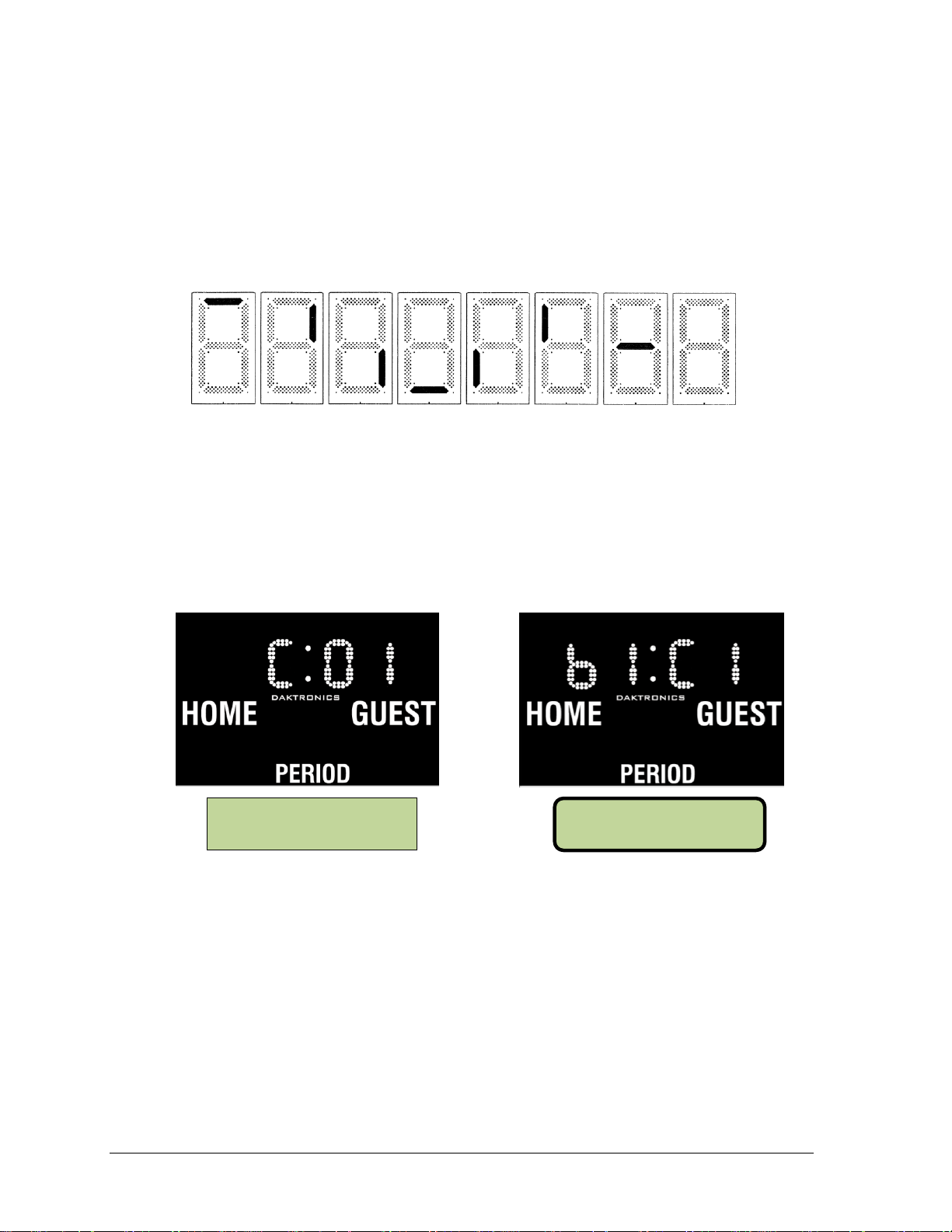

RC-100 (Channel)

All Sport Radio (Broadcast & Channel)

Figure 7: Radio Settings

RA DI O S ETT I NGS

BC AST 1 CH AN 0 1

CONNECTI NG VI A

CH ANN EL O 1

4.4 Power-On Self-Test (POST)

The scoreboard performs a self-test each time that power is turned on and the control console

is powered off or not attached to the scoreboard. If the control console is attached and

powered on, the self-test does not run, and data from the control console is displayed on the

scoreboard after a brief period of time. Each scoreboard self-test pattern will vary depending

on the scoreboard model, the number of drivers, and types of digits. Figure 6 shows an

example of the LED bar test pattern that each digit performs.

Radio Settings

With an RC-100 base station installed, the channel settings (“C 01”) will be displayed in the

clock digits (Figure 7) during the POST. If an All Sport radio receiver is installed, both the

broadcast setting (“b1”) and the channel setting (“C1”) will be displayed. These values must

match the settings in the controller (refer to appropriate manual in Section 1.1).

10 Electrical Operation

Page 17

Charger Power Specifications

Outputs: two individual isolated outputs with

a combined rating as follows:

When charging:

When maintaining

6 A at 12 VDC

0.1 A at 13.3 VDC

Maximum recommended battery size:

For recharging:

Maintenance only

Up to 150 A/H

Up to 350 A/H

Input:

Rated AC voltage

Current draw

100-140 VAC, 50-60 Hz

1.6 A at full output

Figure 8: ChargePro Charger

Section 5: Battery Care & Charging

This section describes care and operation of the MS-2013 on-board battery charging system.

5.1 On-Board Charger

Reference Drawing:

Electrical Specifications. MS-2013 ........................................................................ A-159887

On a full charge, the two internal batteries provide enough power for approximately 14 hours

of normal operation. Keeping the batteries charged will help extend their life. Be sure that the

batteries are fully charged before storing the scoreboard during the off-season; storing the

scoreboard with a discharged battery can contribute to early battery failure. Daktronics

recommends keeping the scoreboard plugged in to a 120 VAC receptacle during storage.

The Guest® ChargePro on-board battery charger is designed both to recharge the batteries of

the scoreboards and to extend battery life in applications where scoreboard and batteries are

stored for long periods of time. The charger is located in the cabinet interior, attached to the

right side of the scoreboard back sheet (as viewed with the rear access panel open). The

charger is connected to the transformer next to the driver enclosure, and to the batteries.

Refer to Drawing A-159887 in Appendix A.

The charger, shown in Figure 8, is fully automatic and can

be connected to the twin 12 V lead-acid batteries

indefinitely without risk of overcharging. The 28 A/H

batteries provided with the scoreboard will typically be

fully recharged after about 12 hours.

The ChargePro is a three-stage, "smart" charger, and its

regulated output recharges the battery in the safest, fastest

way possible. Once a battery has been recharged, the

ChargePro supplies just enough electricity to compensate

for the charge a battery loses during storage. Unlike most

automotive "trickle" chargers, the unit will not boil off the

electrolyte in a lead-acid battery when left unattended.

Battery Care & Charging 11

Page 18

Scoreboard

Operating Condition

High Charge

Red ON

Green OFF

When just the red LED is on, it indicates that the batteries

are discharged and the charger is recharging them at the

BULK rate of 6 A (stage 1).

While the red LED is on, the voltage measured (with the

charger on) should be 11.8–14 V.

If the red LED stays on for more than 48 hours, refer to the

Charger Troubleshooting Table.

Medium Charge

Red ON

Green ON

When both the green and the red LEDs are on, the unit is

charging at an ABSORPTION rate of 2-6 A (stage 2).

This mode of charging gradually "tops off" the batteries

and reduces harmful sulfating.

While both LEDs are on, the voltage measured (with the

charger on) should be approximately 14 V.

If both LEDs stay on longer than 48 hours, refer to the

Charger Troubleshooting Table.

Float Charge

Red OFF

Green ON

When just the green LED is on, the unit is charging at a

FLOAT rate of less than 2 A (stage 3). The batteries are now

90 percent charged and ready for use.

This "float" charging current will gradually decrease to as

low as 0.1 A over the next day as the batteries reach 100

percent charge. They will now be kept at full charge without

overcharging.

If the green LED stays on and the battery is known to be low,

refer to the Charger Troubleshooting Table.

To operate the charger, simply plug the scoreboard's power cord into a standard 120 VAC,

60 Hz outlet. Red and green LED indicators on the charger, visible through holes on the

exterior back panel, indicate the recharging status. A label at this location also describes

charging levels.

Note: When the batteries are connected, they will continuously supply power to the

driver, even if the digits are blank. Make sure that the unit is switched ON only during

an event or when testing. At all other times, the switch should be in the OFF position.

The table below describes how the charger indicators operate:

12 Battery Care & Charging

Page 19

Problem

Cause

Solution

The charger does not seem

to be charging.

One or more defective/

damaged cells

One or more loose wire

connections

Charger has reduced its

output voltage due to a DC

overload or a DC short.

The internal AGX 15 A DC

output fuse has blown.

Test batteries and

replace if necessary

(see Section 6.5).

Check and tighten all

connections.

Remove the source of

the overload or short.

Contact Daktronics

Customer Service for

replacement.

It seems to take a long time

to recharge the batteries in

hot weather.

The charger has

overheated due to poor air

circulation and has

reduced its output.

Consider moving the

scoreboard to a shaded

location.

The red LED is always on.

or

The green LED never

comes on.

A dead short or an

overload

One or more bad cells in

battery

Too many batteries, or

battery is too large

A heavy DC load on the

battery while charging

Perform charger test:

1. Unplug the AC cord.

2. Remove the black

charger output wire

from the battery.

3. When AC power is

reapplied, only the

green LED should turn

on. If not, replace the

charger.

The green LED says on, but

the batteries do not charge.

Check charger's output

fuses.

If connections are

good, contact

Daktronics Customer

Service for

replacement.

Both the red and green

LEDs stay on all the time.

The battery is damaged or

unable to reach full charge.

Check electrolyte. Test/

replace the battery (see

Section 6.5).

Operation

If the ChargePro encounters a DC overload (excessive demand), it will reduce its output

voltage to a safe level to prevent damage. If the positive and negative connectors are touched

together, creating a short, the charger will instantly reduce its output voltage to nearly 0 V.

When the overload is removed, the charger automatically resumes normal operation.

If the in-line 10 A, 32 VDC fuse in either cable blows due to improper connection to a battery,

replace the fuse with an identical 10 A fuse only (Daktronics part # F-1006). Never replace a

blown fuse with a higher-value fuse.

The charger is waterproof, but the AC plug and DC bolt-type connectors should be kept dry.

It is normal for the charger to become warm during operation; consequently, it should not

contact any surface other than the scoreboard cabinet.

Charger Troubleshooting Table

Battery Care & Charging 13

Page 20

A DC component is

continuously drawing 3 A

or more, holding the

charger in its absorption

stage.

Disconnect any

accessories while

charging. If conditions

on board force the

charger to stay in

absorption stage for

several days, battery

damage may occur.

When AC power is applied,

neither LED turns on.

Confirm that all AC power

is available.

Internal failure

Reset AC power.

Contact Daktronics

Customer Service for

replacement.

The ground fault circuit

(GFCI) trips when charger is

on.

Problem with the AC outlet

Defective or oversensitive

charger

Check all connections

at the AC outlet.

Try a different outlet, or

replace the charger.

Radio Interference

The on-board battery charger generates and can radiate radio frequency energy. The

equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to FCC rules, Part 15.

With proper installation, there should be no interference with any radio communications,

either with the scoreboard's own receiver or other radio-controlled devices in the immediate

area. However, if it is determined that this device may be the cause of radio interference, try

to correct the interference with one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment to an AC outlet on a circuit different from the receiver.

5.2 Battery & Charging Safety

Note: The following lists are general safety instructions when working with lead-acid

batteries. Some of the safety considerations are not applicable to the sealed batteries provided

with the MS-2013 as those batteries are self-contained and cannot be opened, and they are

safer than automotive batteries that require servicing. Exercise caution, however, when

working with any lead-acid battery.

Personal Safety Precautions

Someone should be within range of your voice or close enough to come to your aid

Have plenty of fresh water and soap nearby in case battery acid contacts your skin,

Wear complete eye protection and clothing protection. Avoid touching your eyes

14 Battery Care & Charging

If battery acid does contact skin or clothing, wash immediately with soap and water.

when you work near a lead-acid battery.

clothing, or eyes.

while working near the battery.

If you get acid in your eye, immediately flood the eye with running cold water for at

least 10 minutes, and get medical attention immediately.

Page 21

NEVER smoke or allow a spark or flame near the battery.

Be extra cautious while servicing the scoreboard to reduce the risk of dropping a tool

onto the battery. It might spark or short-circuit the battery or another electrical part,

which could cause an explosion.

Remove all personal metal items such as rings, watches, and other jewelry when

working with a lead-acid battery. A lead-acid battery can produce a short-circuit

current high enough to weld a ring or similar item to metal, causing severe burns.

Use the charger for charging LEAD-ACID batteries only. It is not intended to

recharge common dry cell batteries, which may burst and cause injury to people and

damage to property.

NEVER charge a frozen battery.

DC Connection Precautions

1. Check the polarity markings on the battery.

2. Attach the positive ring terminals (red or white wires with fuse) from each cable on

the charger to the positive (+) terminals of the batteries.

3. Attach the negative ring terminals (black wires) from each cable on the charger to the

negative (-) terminals of the batteries.

4. When disconnecting the charger, first disconnect (unplug) the AC power cord, then

remove the negative ring terminal from the battery's negative (-) terminal, and

remove the positive ring terminals last.

Battery Care & Charging 15

Page 22

Page 23

Problem

Possible Cause

Solution/Items to Check

Scoreboard doesn’t light

and console doesn’t work

No power to the scoreboard

Check that the scoreboard is

receiving 120 VAC power.

There may be a problem with the

batteries/charger. Refer to the

Charger Troubleshooting Table in

Section 5.

No power to console

Ensure the console is plugged into

the J31 jack labeled CONTROL

CONSOLE CONNECT or a 120

VAC power supply.

Exchange the console with a

working one, and enter the correct

sport code and/or radio settings to

test. Replace console if necessary.

Scoreboard digits don’t light,

but console works

No wired signal from console

Check that the scoreboard is

receiving 120 VAC or battery power.

Check that the red DS5 (or DS2)

LED on the driver lights up when

sending commands from the control

console (see Section 6.4).

No radio signal from console

Cycle power to the scoreboard and

watch for radio settings (see

Section 4.4).

Section 6: Scoreboard Troubleshooting

IMPORTANT NOTES:

1. Always disconnect power before doing any repair work on the scoreboard.

2. Permit only qualified service personnel to access internal display electronics.

3. Disconnect power when not using the scoreboard.

6.1 Troubleshooting Table

The table below lists potential problems with the scoreboard and indicates possible causes

and corrective actions. This list does not include every symptom that may be encountered,

but it does present several of the most common situations that may occur.

Many of the solutions offered below provide references to other sections within this manual

or to supplemental product manuals with further detail on how to fix the problem.

If a problem occurs that is not listed or that cannot be resolved using the solutions in the

following table, contact Daktronics using the information provided in Section 7.

Scoreboard Troubleshooting 17

Page 24

Problem

Possible Cause

Solution/Items to Check

Check that the green POWER and

amber RADIO IN RANGE indicators

on the radio receiver in the

scoreboard light up when the control

console is powered on. Keep the

console between 20-30' (6-9 m) from

the scoreboard.

Move the console 20-30' (6-9 m)

from the scoreboard and test again.

Verify that both the console and

scoreboard antennas are securely

tightened and in a vertical position.

Replace the radio receiver.

No signal to driver

Check that the scoreboard is

receiving 120 VAC or battery power.

Check that the red DS2 (or DS2)

LED on the driver lights up when

sending commands from the control

console (see Section 6.4).

Exchange the driver with a working

one of the same part #. Replace if

necessary (Section 6.4).

No power to driver

Check that the red DS8 (or green

DS1) LED on the driver is always lit

up when the scoreboard is powered

on (see Section 6.4).

Scoreboard digits light, but

not in the correct order

Incorrect sport code

Ensure the correct sport code is

being used for the scoreboard

model. Refer to the appropriate

control console manual.

Incorrect driver address

Check that the scoreboard driver is

set to the correct address (see

Section 6.4)

Scoreboard digits light,

console works, but no

display on scoreboard

No wired signal from console

(See solution on previous page)

No radio signal from console

(See solution on previous page)

Bad/damaged field wiring

Check that the red DS5 (or DS2)

LED on the driver lights up when

sending commands from the control

console (see Section 6.4)

Scoreboard works, but some

LEDs always stay on

Short in digit circuit

Exchange the digit with a working

one of the same part # to verify the

problem. Replace if necessary (see

Section 6.3).

Scoreboard works, but some

LEDs do not light or they

blink

Bad connection

Verify the connector on the back of

the digit circuit board is secure (see

Section 6.3).

18 Scoreboard Troubleshooting

Page 25

Problem

Possible Cause

Solution/Items to Check

Bad digit or driver

Exchange the digit/driver with a

working one of the same part # to

verify the problem. Replace if

necessary (see Section 6.3 for

digits or Section 6.4 for drivers).

Scoreboard works, but some

digits do not light

Bad digit or driver

(see solution above)

Incorrect sport code

(see solution on previous page)

Incorrect driver address

(see solution on previous page)

Wrong console controlling

scoreboard

Another console’s radio signal could

be transmitting to the scoreboard.

An example would be football and

baseball scoreboards that are within

1500' (457 m) of each other.

Radio interference

There may be other radio

transmissions in the area that

overpower the console. If it is not

possible to disable the interfering

device, It may be necessary to run a

wired signal connection instead.

6.2 Component Location & Access

Reference Drawing:

Electrical Specifications, MS-2013 ........................................................................ A-159887

In the MS-2013, the entire back panel is hinged on the right side (as viewed from the rear). To

gain access to the internal scoreboard components, simply remove the three screws securing

the back panel to the scoreboard cabinet, and swing it open. Drawing A-159887 in Appendix

A illustrates the back panel open and all of the internal components exposed.

Note: Disconnect power before servicing the scoreboard! Also turn power OFF when the

scoreboard is not in use. In addition to discharging the scoreboard batteries, prolonged

power-on may shorten the life of some electronic components.

Scoreboard Troubleshooting 19

Page 26

Figure 9: Digit Assembly

6.3 Replacing Digits

LEDs are embedded in a circuit board that is

mounted to the back of a single face panel,

as shown in Figure 9. Do not attempt to

remove individual LEDs. In the case of a

malfunctioning LED or digit segment,

replace the entire digit circuit board.

To replace a digit circuit board:

1. Open the back panel as described in

Section 6.2.

2. Disconnect the power/signal plug

from the back of the digit by

squeezing together the locking tabs

and pulling the connector free.

3. Use a

4. Position a new digit over the studs, making sure the rubber side of the rubber-backed

5. Tighten the nuts.

6. Reconnect the power/signal connector.

7. Close and secure the back panel, then power up and test the scoreboard to see if

9

/32" nut driver to remove the

nuts securing the digits to the inside

of the panel, and then lift the digit

off the standoff studs.

spacer is facing the digit circuit board.

Note: This is a keyed connector and it will attach in one way only. Do not attempt to

force the connection.

changing the digit has resolved the problem.

20 Scoreboard Troubleshooting

Segmentation & Digit Designation

Reference Drawings:

Segmentation, 7 Segment Bar Digit ........................................................................ A-38532

Electrical Specifications, MS-2013 ........................................................................ A-159887

In each digit, certain LEDs always go on and off together. These groups of LEDs are called

segments. Drawing A-38532 in Appendix A details which connector pin is wired to each

digit segment and the wiring color code used throughout the scoreboard.

Drawing A-159887 in Appendix A indicates the driver connectors controlling the digits.

The numbers shown in the upper half of a digit indicate which driver connector is wired to it.

Page 27

LED

Function

Operation

Summary

DS1

Radio/

RS-232 RX

Blinking

or off

DS1 will be blinking when the driver is receiving radio signal

and off when there is no signal.

DS2

Status

Blinking

DS2 will be blinking at one second intervals to indicate the

driver is running.

DS5

Signal RX

Blinking

or off

DS5 will be blinking when the driver is receiving current loop

signal and off when there is no signal.

DS8

Power

Steady on

DS8 will be on and steady to indicate the driver has power.

LED

Color

Function

Operation

Summary

DS1

Green

Power

Steady on

DS1 will be on and steady to indicate the driver

has power.

DS2

Red

Signal RX

Steady on

or blinking

DS2 will be on or blinking when the driver is

receiving a signal and off when there is no signal.

DS3

Amber

Status

Blinking

DS3 will be blinking at one second intervals to

indicate the driver is running.

6.4 LED Driver

The LED driver performs the task of switching digits on and off within the scoreboard.

LED drivers are located inside of a driver enclosure. Refer to Drawing A-159887 in Appendix

A to view the location and components of the driver enclosure.

When troubleshooting driver problems, several LEDs provide diagnostic information.

The number of LEDs and their function depends on the driver type.

Note: While it is necessary to have the scoreboard powered on to check the LED

indicators, always disconnect scoreboard power before servicing.

16-Column “Gyrus” Drivers

16-Column Drivers (prior to April 2015)

Replacing a Driver

1. Open the back panel as described in Section 6.2.

2. Remove the metal cover of the driver enclosure to expose the driver components.

3. Disconnect all connectors from the driver by squeezing together the locking tabs and

pulling the connectors free. It may be helpful to label the cables to know which cable

goes to which connector when reattaching the driver.

4. Remove the screws or nuts securing the driver to the inside of the enclosure.

5. Carefully lift the driver from the display and place it on a clean, flat surface.

6. Position a new driver over the screws and tighten the nuts.

7. Reconnect all power/signal connectors. Note that the connectors are keyed and will

attach in one way only. Do not attempt to force the connections.

8. Ensure the driver is set to the correct address (refer to Setting the Driver Address).

9. Close and secure the back panel, then power up and test the scoreboard to see if

changing the driver has resolved the problem.

Scoreboard Troubleshooting 21

Page 28

Figure 10: Driver Address Dials

Figure 11: Driver Address Dip Switch (prior to April 2015)

Setting the Driver Address

Since the same LED drivers can be used for many

scoreboard models, each driver must be set to receive

the correct signal input, or address, for the model

being used.

The MS-2013 will always be set to address 11.

Addresses are set through the S2 (L) and S3 (H) rotary

switches on the driver (Figure 10) using a small

flathead screwdriver. For address 11, set the

H switch to “0” and the L switch to “B”.

Note: For models built

prior to April 2015, the

driver address was set

via the S1 dip switch

(Figure 11) using a pen or

small, pointed object. For

address 11, set switches 1,

2, and 4 to ON.

6.5 Replacing Batteries

Reference Drawings:

Battery Service, MS-2013 ...................................................................................... A-159891

As the batteries age, they may lose capacity to sufficiently operate the scoreboard, even on a

full charge. When replacement becomes necessary, Daktronics recommends the same brand

battery installed as original equipment. Similar batteries may be used as long as they meet the

specifications for the scoreboard. If a different brand must be used, be sure that the terminals

are oriented the same as in the original to ensure a proper connection. Refer to Section 6.7 for

Daktronics replacement part numbers for batteries and fuses.

Drawing A-159891 in Appendix A illustrates battery service. Mounting brackets hold the

batteries in place at the bottom of the scoreboard. The bracket is designed to hold batteries

measuring 7" high, 6.5" wide, and 5" deep (178 mm, 165 mm, 127 mm). The bracket will not

support a battery of different dimensions.

To replace the batteries:

1. Open the back panel as described in Section 6.2.

2. Use a

3. Remove the screws securing the wires to the battery terminals.

4. Remove the battery from the scoreboard.

5. Reverse the procedure to install new batteries.

22 Scoreboard Troubleshooting

3

/8" socket or nut driver to unfasten the four nuts securing each battery bracket

to the scoreboard studs and remove the brackets.

Page 29

Description

Daktronics Part No.

12 VDC Horn Assembly

0A-1072-0023

Driver, 16-col outdoor LED

0A-1782-0100

Battery Monitor (Circuit Board)

0P-1192-0097

Digit, 10" red, 7-segment

0P-1192-0251

Battery; 12V, 28 A/H sealed lead-acid (Panasonic Model LC-X1228P)

BT-1023

Battery Charger; dual 12 or 24V, 3 A (Guest ChargePro Model 2607)

BT-1022

Fuse, AGC-10, 10A, 250 V glass tube

F-1006

Fuse, MDL-7, 7.5 A, 250 V glass tube

F-1031

Washer, ½ flat

HC-1095

Wheel Bolt, ½ -13 x 3 ½”

HC-1363

Wheel, 10x1.75, semi-pneumatic, 1/2" axle

RA-1007

Transformer, sec. 24 V @4A, pri. 115/230V, 50/60 Hz

T-1043

Power cord, 360º rotating, 8'

W-1181

Fuse holder

X-1287

Figure 12: Horn Mounting Detail, Side View

Important Notes:

During service, do not allow the battery terminals to touch any metal surface.

The batteries in these products contain lead. Do not dispose of the batteries in a

6.6 Horn

Reference Drawing:

Electrical Specifications, MS-2013 ........................................................................ A-159887

A 12 V buzzer horn is mounted in the upper-left

corner of the front face panel (as viewed from the

front). Drawing A-159887 in Appendix A shows

the horn location from the front as well as when

accessing internal components from the rear.

To replace a horn, simply disconnect the cable

running to it, and then remove the single nut and

washer holding the horn to the mounting bracket

(Figure 12).

Note: The horn volume is set at maximum during manufacturing and is not adjustable.

When reinstalling, make sure the terminal wires are connected correctly.

Improper connection may result in injury or damage to scoreboard components.

municipal waste system at the end of their useful life. Doing so may be a violation of

local, state, or federal environmental regulations. Please return the batteries to a

battery recycling center or battery retailer.

6.7 Replacement Parts

Refer to the following table for standard and optional replacement parts.

Scoreboard Troubleshooting 23

Page 30

Page 31

Market Description

Customer Service Number

Schools (including community/junior colleges), religious

organizations, municipal clubs and community centers

877-605-1115

Universities and professional sporting events, live events

for auditoriums and arenas

866-343-6018

Section 7: Daktronics Exchange and Repair &

Return Programs

7.1 Exchange Program

The Daktronics Exchange Program is a service for quickly replacing key components in need

of repair. If a component fails, Daktronics sends a replacement part to the customer who, in

turn, returns the failed component to Daktronics. This decreases equipment downtime.

Customers who follow the program guidelines explained below will receive this service.

Before Contacting Daktronics

Identify these important numbers:

Display Serial Number: _________________________________________________________

Display Model Number: _________________________________________________________

Job/Contract Number: __________________________________________________________

Date Installed: _________________________________________________________________

Daktronics Customer ID Number: ________________________________________________

To participate in the Exchange Program, follow these steps:

1. Call Daktronics Customer Service.

2. When the exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part being replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. The defective or unused parts must be returned to Daktronics within 5 weeks of

initial order shipment.

If any part is not returned within five (5) weeks, a non-refundable invoice will be

presented to the customer for the costs of replenishing the exchange parts inventory

with a new part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of

nature or causes other than normal wear and tear.

Daktronics Exchange and Repair & Return Programs 25

Page 32

7.2 Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Refer to the appropriate market phone number in the chart on the previous page.

Fax: 605-697-4444

2. Receive a case number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend using packing ‘peanuts’

when shipping.

4. Enclose:

name

address

phone number

the case number

a clear description of symptoms

Shipping Address

Daktronics Customer Service

[Case #]

201 Daktronics Drive, Dock E

Brookings, SD 57006

7.3 Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix B. The Warranty

is independent of Extended Service agreements and is the authority in matters of service,

repair, and display operation.

26 Daktronics Exchange and Repair & Return Programs

Page 33

Appendix A: Reference Drawings

Drawing Title Drawing Number

Segmentation, 7 Segment Bar Digit ........................................................................................... A-38532

Schematic: MS-2013-11 ........................................................................................................... B-158030

Mechanical Specifications, MS-2013 ........................................................................................ A-159886

Electrical Specifications, MS-2013 ........................................................................................... A-159887

Cart Assembly, MS-2013 .......................................................................................................... A-159889

Caption Options, MS-2013 ....................................................................................................... A-159890

Battery Service, MS-2013 ......................................................................................................... A-159891

Radio Receiver Installation- MS-2013 ...................................................................................... A-160015

Ad Panel Installation, MS-2013 ................................................................................................. A-160057

Cover Installation- MS-2013 ..................................................................................................... A-160060

System Riser Diagrams- MS-2013-11 ...................................................................................... A-160237

Base Station: Outdoor Installation ............................................................................................ A-236394

System Riser Diagram: RC-100- MS-2013............................................................................... A-244926

Installation Drawing; Outdoor Scbd Gen VI Radio Receiver .................................................. A-1109181

Reference Drawings 27

Page 34

Page 35

Page 36

'$7(5(9 %<

'$7(5(9 %<

'$7(5(9 %<

'$7(5(9 %<

'$7(5(9 %<

5(3/$&('$:,7+:5(029('3$57180%(56

'$7(5(9 %<

0$5 5$$

)(% =6:

)520/(''5,9(5

3(5(&&255(&7('6:,7&+180%(5127$7,2121

'$7(5(9 %<

'5,9(532:(56:,7&+

'$7(5(9 %<

'$7(5(9 %<

Page 37

Page 38

DAKTRONICS

PERIOD

GUESTHOME

DAKTRONICS

CONNECT

CONSOLE

120V AC

POWER IN

CONTROL

OFF

ON

DRIVER,

CONSOLE,

RADIO

IMPORTANT NOTICE

RECYCLE THE BATTERIES

CONNECT

CONSOLE

WHEN NOT IN USE

IMPORTANT - TURN OFF SWITCH

120V AC

POWER IN

CONTROL

OFF

ON

DRIVER,

CONSOLE,

RADIO

CHARGE STATUS LIGHTS

THE CONCEPTS EXPRESSED AND DETAILS SHOWN ON THIS

DRAWING ARE CONFIDENTIAL AND PROPRIETARY. DO NOT

REPRODUCE BY ANY MEANS WITHOUT THE EXPRESS

WRITTEN CONSENT OF DAKTRONICS, INC.

COPYRIGHT 2015 DAKTRONICS, INC.

DAKTRONICS, INC.

AV

DRAWN: DATE:

SHEET JOB NO:REV

SCOREBOARDS

ELECTRICAL SPECIFICATIONS- MS-2013

A VANBEMMEL 11 DEC 01

P1192 R

04 A

1=20

AVB

159887

07

Page 39

Page 40

DAKTRONICS

GUESTHOME

SET INNING

SETS WON SETS WON

OUTBALL STRIKE

GUEST

PERIOD

DAKTRONICS DAKTRONICS

HOME GUEST

DAKTRONICS

DAKTRONICS

PERIOD

GUESTHOME

THE CONCEPTS EXPRESSED AND DETAILS SHOWN ON THIS

DRAWING ARE CONFIDENTIAL AND PROPRIETARY. DO NOT

REPRODUCE BY ANY MEANS WITHOUT THE EXPRESS

WRITTEN CONSENT OF DAKTRONICS, INC.

COPYRIGHT 2014 DAKTRONICS, INC.

DAKTRONICS, INC.

AV

DRAWN: DATE:

SHEET JOB NO:REV

OUTDOOR LED DIGIT SCOREBOARDS

CAPTION OPTIONS- MS-2013

A VANBEMMEL 10 DEC 01

P1192 R

08 A

1=20

AVB

159890

01

DATE:REV BY:

01 17 JUL 14 KDD

REPLACED 'GAMES WON' AND 'GAME' WITH

'SETS WON' AND 'SET'

REMOVED 'INTERVAL' CAPTION

Page 41

THE CONCEPTS EXPRESSED AND DETAILS SHOWN ON THIS

DRAWING ARE CONFIDENTIAL AND PROPRIETARY. DO NOT

REPRODUCE BY ANY MEANS WITHOUT THE EXPRESS

WRITTEN CONSENT OF DAKTRONICS, INC.

COPYRIGHT 2015 DAKTRONICS, INC.

DAKTRONICS, INC.

AV

DRAWN: DATE:

SHEET JOB NO:REV

SCOREBOARDS

BATTERY SERVICE- MS-2013

A VANBEMMEL 11 DEC 01

P1192 R

04 A

1=16

AVB

159891

04

Page 42

HOME GUEST

PERIOD

DAKTRONICS

NOTES:

IF THERE ARE TO BE MULTIPLE SCOREBOARD RECEIVERS AND MULTIPLE CONTROL CONSOLES

OPERATING IN THE AREA, REFER TO RADIO INSTALLATION MANUAL(S) TO CHANGE THE CHANNEL

NUMBER ON THE RECEIVER PRIOR TO INSTALLING.

REMOVE THE THREE SCREWS SECURING THE BACK OF THE MS-2013, AND SWING IT OPEN.

THE CONCEPTS EXPRESSED AND DETAILS SHOWN ON THIS

DRAWING ARE CONFIDENTIAL AND PROPRIETARY. DO NOT

REPRODUCE BY ANY MEANS WITHOUT THE EXPRESSED

WRITTEN CONSENT OF DAKTRONICS, INC.

COPYRIGHT 2012 DAKTRONICS, INC.

DAKTRONICS, INC.

AV

DRAWN: DATE:

SHEET JOB NO:REV

RADIO RECEIVER INSTALLATION- MS-2013

A VANBEMMEL 12 DEC 01

P1192 R

10 A

1=16

AVB

160015

06

LOCATE THE HOLE INSIDE THE

FRONT OF MS-2013 WHERE THE

ANTENNA IS TO BE MOUNTED.

EXTERNAL ANTENNA ON OUTSIDE

FACE OF SCOREBOARD.

ANTENNA PART NUMBER AND SIZE

WILL VARY.

NUT

TOOTH LOCK WASHER

RADIO

RECEIVER

DATE:REV BY:

06 2 MAR 15 KCS

UPDATED VIEWS WITH GYRUS DRIVER AND HARNESS.

ADDED LEGACY VIEW

DATE:REV BY:

01 17 FEB 03 TWEBER

MIRRORED LOCATION OF HORN FROM THE

RIGHT SIDE TO THE LEFT SIDE OF THE

DISPLAY

DATE:REV BY:

02 16 MAY 03 SAL

ADDED VISUAL DIAGRAM FOR THE RADIO

CONNECTOR. MOVED POWER/SIGNAL CABLE

TO THE WRITE LOCATION

DATE:REV BY:

03 26 FEB 07 MJK

MOVED POWER SIGNAL COMPARTMENT

DOWN 4"

LEGACY VIEW

GYRUS VIEW

W-2913

USE THE 2 PIECES OF VELCRO,

REMOVE BACKING AND APPLY

Page 43

Page 44

Page 45

DAKTRONICS

PERIOD

DAKTRONICS

GUESTHOME

DAKTRONICS

HOME GUEST

PERIOD

Page 46

EXTERNAL ANTENNA

ON OUTSIDE FACE

OF SCOREBOARD.

ANTENNA PART

NUMBER AND SIZE

WILL VARY.

TX RX IN TX RX

CL / RS232 RANGE CAN

Page 47

$9

DAKTRONICS

HOME GUEST

PERIOD

'$7(5(9 %<

$35 -)/

83'$7('5&+$1'+(/'3$57180%(5

83'$7('%2$5'(5$1'7,7/(%/2&.

'$.7521,&6,1&

7+(&21&(376(;35(66('$1''(7$,/66+2:1217+,6

'5$:,1*$5(&21),'(17,$/$1'35235,(7$5<'2127

5(352'8&(%<$1<0($16:,7+2877+((;35(66('

:5,77(1&216(172)'$.7521,&6,1&

&23<5,*+7'$.7521,&6,1&

5$',2/,1.

6<67(05,6(5',$*5$05&06

'5$:1 '$7(

.%,(5%$

.%,(5%$ -81

121(

6+((7 -2%125(9

3 5

$

Page 48

THE CONCEPTS EXPRESSED AND DETAILS SHOWN ON THIS

DRAWING ARE CONFIDENTIAL AND PROPRIETARY. DO NOT

REPRODUCE BY ANY MEANS WITHOUT THE EXPRESSED

WRITTEN CONSENT OF DAKTRONICS, INC.

COPYRIGHT 2012 DAKTRONICS, INC.

DAKTRONICS, INC.

AV

DRAWN: DATE:

SHEET JOB NO:REV

ALL SPORT RADIO

INSTALLATION DRAWING; OUTDOOR SCBD GEN VI RADIO RECEIVER

MMILLER 07 AUG 12

P1110 F

01 A

NONE

MMILLER

1109181

03

FUNC CHAN BCAST

0

1

2

3

4

5

6

7

8

0

1

2

3

4

5

6

7

8

0

1

2

3

4

5

6

7

8

- RADIO SETTING FROM FACTORY IS F=1, B=1, C=1. IF THIS SETTING IS

FINE FOR YOUR FACILITY LAYOUT, INSTALL RADIO INTO DISPLAY.

OR

OPEN RADIO CASE BY REMOVING 4 PHILIPS HEAD SCREWS.

ALWAYS LEAVE FUNCTION = 1, BUT CHANGE THE CHANNEL AND BCAST

DIALS AS NEEDED. USE SMALL FLAT HEAD SCREW DRIVER.

GREEN - POWER LED

RED - DATA LED

AMBER - STATUS LED

FACE SHEET

RADIO RECEIVER

RADIO PREPARATION

REMOVE THE SUPPLIED VELCRO

STRIPS FROM THE RADIO

"D" HOLE PUNCH IN

SCOREBOARD PANEL.

EXTERNAL ANTENNA

ON OUTSIDE FACE

OF SCOREBOARD.

ANTENNA PART

NUMBER AND SIZE

WILL VARY.

NUT

TOOTH LOCK

WASHER

FACE SHEET

CONNECTOR

LABELED "J45"

**OUTDOOR SCOREBOARDS ONLY**

DATE:REV BY:

01 27 MAR 14 KDD

PER EC-13907, ADDED OUTDOOR SCBD ONLY NOTE

DATE:REV BY:

02 26 NOV 14 KDD

ADDED "REMOVE VELCRO" NOTES

GYRUS VIEW

DATE:REV BY:

03 18 FEB 15 BJG

ADDED GYRUS VIEW

UPDATED RADIO RECEIVER AND LEGACY VIEWS

LEGACY VIEW

W-2913

6 -PIN PLUG

Page 49

Appendix B: Daktronics Warranty and Limitation

of Liability

Daktronics Warranty and Limitation of Liability 29

Page 50

Page 51

DAKTRONICS WARRANTY & LIMITATION OF LIABILITY

This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the Equipment. By accepting delivery of the

Equipment, Purchaser agrees to be bound by and accept these terms and conditions. Unless otherwise defined herein, all terms within the Warranty shall have the

same meaning and definition as provided elsewhere in the Agreement.

DAKTRONICS WILL ONLY BE OBLIGATED TO HONOR THE WARRANTY SET FORTH IN THESE TERMS AND CONDITIONS UPON RECEIPT OF FULL PAYMENT FOR THE

EQUIPMENT.

1. Warranty Coverage

2. Exclusion from Warranty Coverage

A. Daktronics warrants to the original end-user that the Equipment will be free from Defects (as defined below) in materials and

workmanship for a period of one (1) year (the “Warranty Period”). The Warranty Period shall commence on the earlier of: (i) four weeks from the date

that the Equipment leaves Daktronics’ facility; or (ii) Substantial Completion as defined herein. The Warranty Period shall expire on the first anniversary

of the commencement date.

“Substantial Completion” means the operational availability of the Equipment to the Purchaser in accordance with the Equipment’s specifications,

without regard to punch-list items, or other non-substantial items which do not affect the operation of the Equipment.

B. Daktronics’ obligation under this Warranty is limited to, at Daktronics’ option, replacing or repairing, any Equipment or part thereof that is found by

Daktronics not to conform to the Equipment’s specifications. Unless otherwise directed by Daktronics, any defective part or component shall be

returned to Daktronics for repair or replacement. This Warranty does not include on-site labor charges to remove or install these components.

Daktronics may, at its option, provide on-site warranty service. Daktronics shall have a reasonable period of time to make such replacements or repairs

and all labor associated therewith shall be performed during regular working hours. Regular working hours are Monday through Friday between 8:00

a.m. and 5:00 p.m. at the location where labor is performed, excluding any holidays observed by either Purchaser or Daktronics.

C. Daktronics shall pay ground transportation charges for the return of any defective component of the Equipment. All such items shall be shipped by

Purchaser DDP Daktronics; designated facility. If returned Equipment is repaired or replaced under the terms of this warranty, Daktronics will prepay

ground transportation charges back to Purchaser and shall ship such items DDP Purchaser’s designated facility; otherwise, Purchaser shall pay

transportation charges to return the Equipment back to the Purchaser and such Equipment shall be shipped Ex Works Daktronics designated facility. All

returns must be pre-approved by Daktronics before shipment. Daktronics shall not be obligated to pay freight for any unapproved return. Purchaser

shall pay any upgraded or expedited transportation charges.

D. Any replacement parts or Equipment will be new or serviceably used, comparable in function and performance to the original part or Equipment, and

warranted for the remainder of the Warranty Period. Purchasing additional parts or Equipment from the Seller does not extend the Warranty Period.

E. Defects shall be defined as follows. With regard to the Equipment (excepting LEDs), a “Defect” shall refer to a material variance from the design

specifications that prohibit the Equipment from operating for its intended use. With respect to LEDs, “Defects” are defined as LED pixels that cease to

emit light. The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for partial LED pixel degradation nor does

the limited warranty provide for the replacement or installation of communication methods including but not limited to, wire, fiber optic cable, conduit,

trenching, or for the purpose of overcoming local site interference radio equipment substitutions.

EXCEPT AS OTHERWISE EXPRESSLY SET FORTH IN THIS WARRANTY, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, DAKTRONICS DISCLAIMS

ANY AND ALL OTHER PROMISES, REPRESENTATIONS AND WARRANTIES APPLICABLE TO THE EQUIPMENT AND REPLACES ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, ACCURACTY OR QUALITY OF DATA. NO ORAL OR WRITTEN INFORMATION, OR ADVICE GIVEN BY THE COMPANY, ITS AGENTS OR

EMPLOYEES, SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS LIMITED WARRANTY.

THIS LIMITED WARRANTY IS NOT TRANSFERABLE.

The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for:

A. Any damage occurring, at any time, during shipment of Equipment unless otherwise provided for in the Agreement. When returning Equipment to

Daktronics for repair or replacement, Purchaser assumes all risk of loss or damage, and agrees to use any shipping containers that might be provided by

Daktronics and to ship the Equipment in the manner prescribed by Daktronics;

B. Any damage caused by the improper installation, adjustment, repair or service of the Equipment by anyone other than personnel of Daktronics or its

authorized repair agents;

C. Damage caused by the failure to provide a continuously suitable environment, including, but not limited to: (i) neglect or misuse, (ii) a failure or

sudden surge of electrical power, (iii) improper air conditioning, humidity control, or other environmental conditions outside of the Equipment’s

technical specifications such as extreme temperatures, corrosives and metallic pollutants, or (iv) any other cause other than ordinary use;

D. Damage caused by fire, flood, earthquake, water, wind, lightning or other natural disaster, strike, inability to obtain materials or utilities, war,

terrorism, civil disturbance or any other cause beyond Daktronics’ reasonable control;

Copyright © Daktronics, Inc. SL-02374 Rev 12 27Jun14 Page 1 of 2

Page 52

DAKTRONICS WARRANTY & LIMITATION OF LIABILITY

E. Failure to adjust, repair or replace any item of Equipment if it would be impractical for Daktronics personnel to do so because of connection of the

Equipment by mechanical or electrical means to another device not supplied by Daktronics, or the existence of general environmental conditions at the

site that pose a danger to Daktronics personnel;

3. Limitation of Liability

4. Assignment of Rights

5. Governing Law

6. Availability of Extended Service Agreement

F. Any statements made about the product by any salesperson, dealer, distributor or agent, unless such statements are in a written document signed by

an officer of Daktronics. Such statements as are not included in a signed writing do not constitute warranties, shall not be relied upon by Purchaser and

are not part of the contract of sale;

G. Any damage arising from the use of Daktronics products in any application other than the commercial and industrial applications for which they are

intended, unless, upon request, such use is specifically approved in writing by Daktronics;

H. Any performance of preventive maintenance;

J. Third-party systems and other ancillary equipment including without limitation front-end video control systems, audio systems, video processors and

players, HVAC equipment, batteries and LCD screens;

K. Incorporation of accessories, attachments, software or other devices not furnished by Daktronics; or

L. Paint or refinishing the Equipment or furnishing material for this purpose.

Daktronics shall be under no obligation to furnish continued service under this Warranty if alterations are made to the Equipment without the prior

written approval of Daktronics.

It is specifically agreed that the price of the Equipment is based upon the following limitation of liability. In no event shall Daktronics (including its

subsidiaries, affiliates, officers, directors, employees, or agents) be liable for any special, consequential, incidental or exemplary damages arising out of or

in any way connected with the Equipment or otherwise, including but not limited to damages for lost profits, cost of substitute or replacement

equipment, down time, lost data, injury to property or any damages or sums paid by Purchaser to third parties, even if Daktronics has been advised of

the possibility of such damages. The foregoing limitation of liability shall apply whether any claim is based upon principles of contract, tort or statutory

duty, principles of indemnity or contribution, or otherwise.

In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising out of or in connection with

this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by the Purchaser. The Purchaser’s remedy in any

dispute under this Warranty shall be ultimately limited to the Purchase Price of the Equipment to the extent the Purchase Price has been paid.

The Warranty contained herein extends only to the original end-user (which may be the Purchaser) of the Equipment and no attempt to extend the

Warranty to any subsequent user-transferee of the Equipment shall be valid or enforceable without the express written consent of Daktronics.

The rights and obligations of the parties under this warranty shall not be governed by the provisions of the United Nations Convention on Contracts for

the International Sales of Goods of 1980. Both parties consent to the application of the laws of the State of South Dakota to govern, interpret, and