Page 1

DakTicker®

KE-1010 Series

GEN II

Installation/Operation Manual

ED-15353 Rev 1 27 April 2007

Website: www.daktronics.com

Tel 866-343-3122 Fax 605-697-4444

nd

331 32

Ave PO Box 5128 Brookings SD 57006

Page 2

ED-15353

Product 1182

Rev 1 – 27 April 2007

Fill in the chart with specific information about this display so the details are readily

available when calling for service or replacement parts.

Information needed for technicians

and/or Customer Service

Location address of the display:

Model number of this display:

Version of software being used:

(Consult software for this information.)

Method of communication:

Network address:

Fill in the blanks

KE-1010

RS-422 or Ethernet

Copyright © 2003-2007

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered

by the copyrights hereon may be reproduced or copied in any form or by any means –

graphic, electronic, or mechanical, including photocopying, taping, or information storage and

retrieval systems – without written permission of the publisher.

DakTicker

®

and DataStreamer™ are trademarks of Daktronics, Inc.

Page 3

Table of Contents

Section 1: Introduction................................................................................................................. 1

1.1 Display Overview ...................................................................................................................1

1.2 Drawing References................................................................................................................2

1.3 Safety Precautions...................................................................................................................2

Section 2: Mechanical Installation..............................................................................................3

2.1 Support Structure Design ......................................................................................................3

2.2 Display Mounting...................................................................................................................4

Ceiling Mount ..................................................................................................................4

Wall Mount.......................................................................................................................4

Mounting Multi-section Tickers ....................................................................................5

Section 3: Power Installation.......................................................................................................7

3.1 Power Requirements ..............................................................................................................7

3.2 Power Cord - Grounding.......................................................................................................8

Section 4: Signal Installation.......................................................................................................9

4.1 Network Options ....................................................................................................................9

RS-422 Connections .........................................................................................................9

Ethernet Connections ....................................................................................................11

4.2 Section to Section Connections............................................................................................12

4.3 Master to Master Connections ............................................................................................12

4.4 Installation Checklist............................................................................................................13

4.5 Boot Up Sequence .................................................................................................................13

Section 5: Maintenance & Troubleshooting.............................................................................15

5.1 Display Maintenance............................................................................................................15

Controller Diagnostic LEDs..........................................................................................15

Visual Structural Inspection.........................................................................................16

5.2 Troubleshooting ....................................................................................................................16

5.3 Definitions..............................................................................................................................17

Section 6: Parts Replacement...................................................................................................19

6.1 Replacement Parts List.........................................................................................................19

6.2 Removing the Face Panel.....................................................................................................21

6.3 Instructions for Replacing Parts..........................................................................................22

LED Module Replacement............................................................................................22

Power Supply Replacement .........................................................................................23

Shift Card Replacement ................................................................................................23

Controller Replacement ................................................................................................24

Controller Address ........................................................................................................25

Table of Contents i

Page 4

Daktronics Exchange and Repair & Return Program ......................................................25

6.4

Exchange Program.........................................................................................................25

Repair & Return Program.............................................................................................26

Appendix A: Reference Drawings .................................................................................................27

Appendix B: Signal Converter .......................................................................................................29

Appendix C: Ethernet Configuration.............................................................................................35

ii

Table of Contents

Page 5

List of Figures

Figure 1: KE-1010 Display......................................................................................................................1

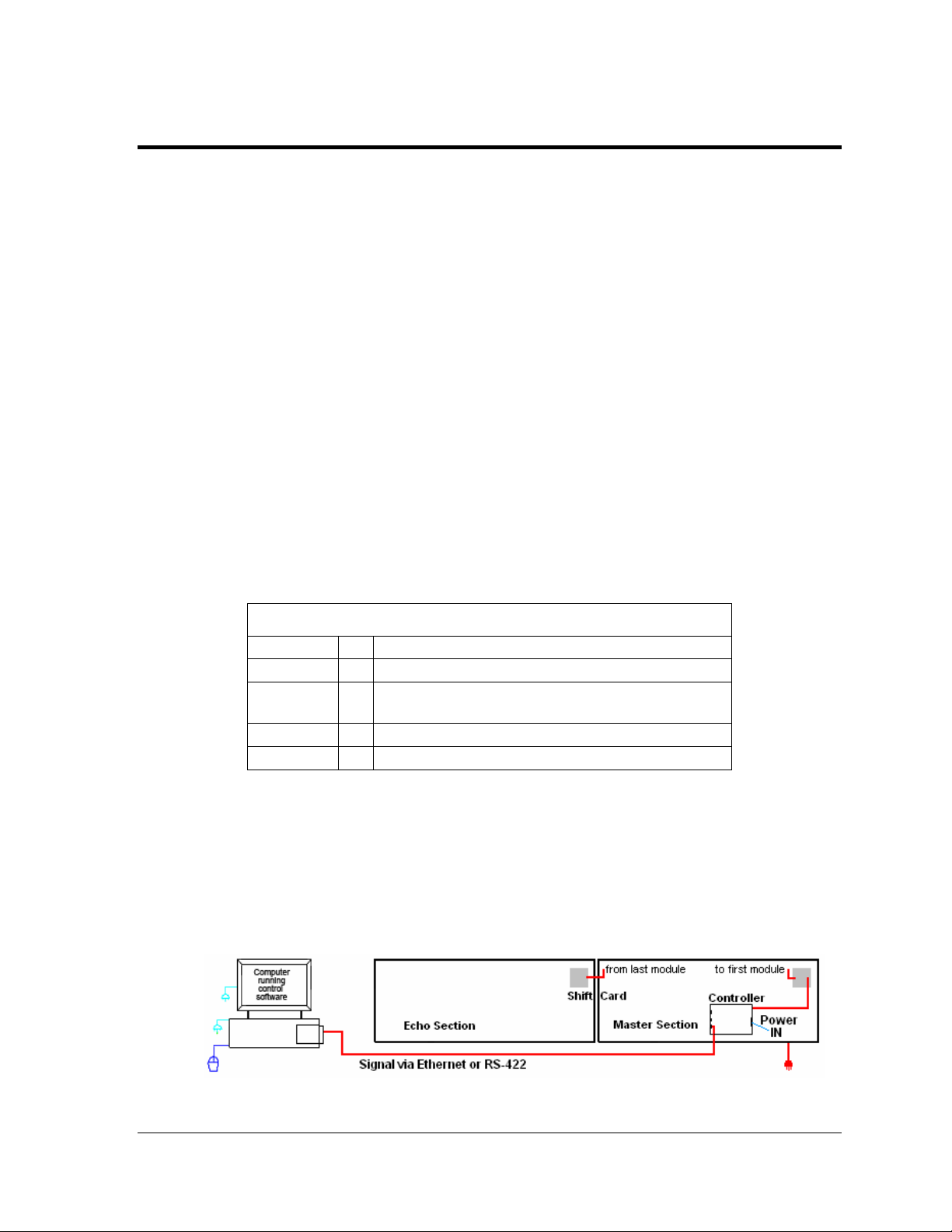

Figure 2: Basic Display Setup.................................................................................................................1

Figure 3: Front of 16 x 40 Module...........................................................................................................2

Figure 4: Drawing Label..........................................................................................................................2

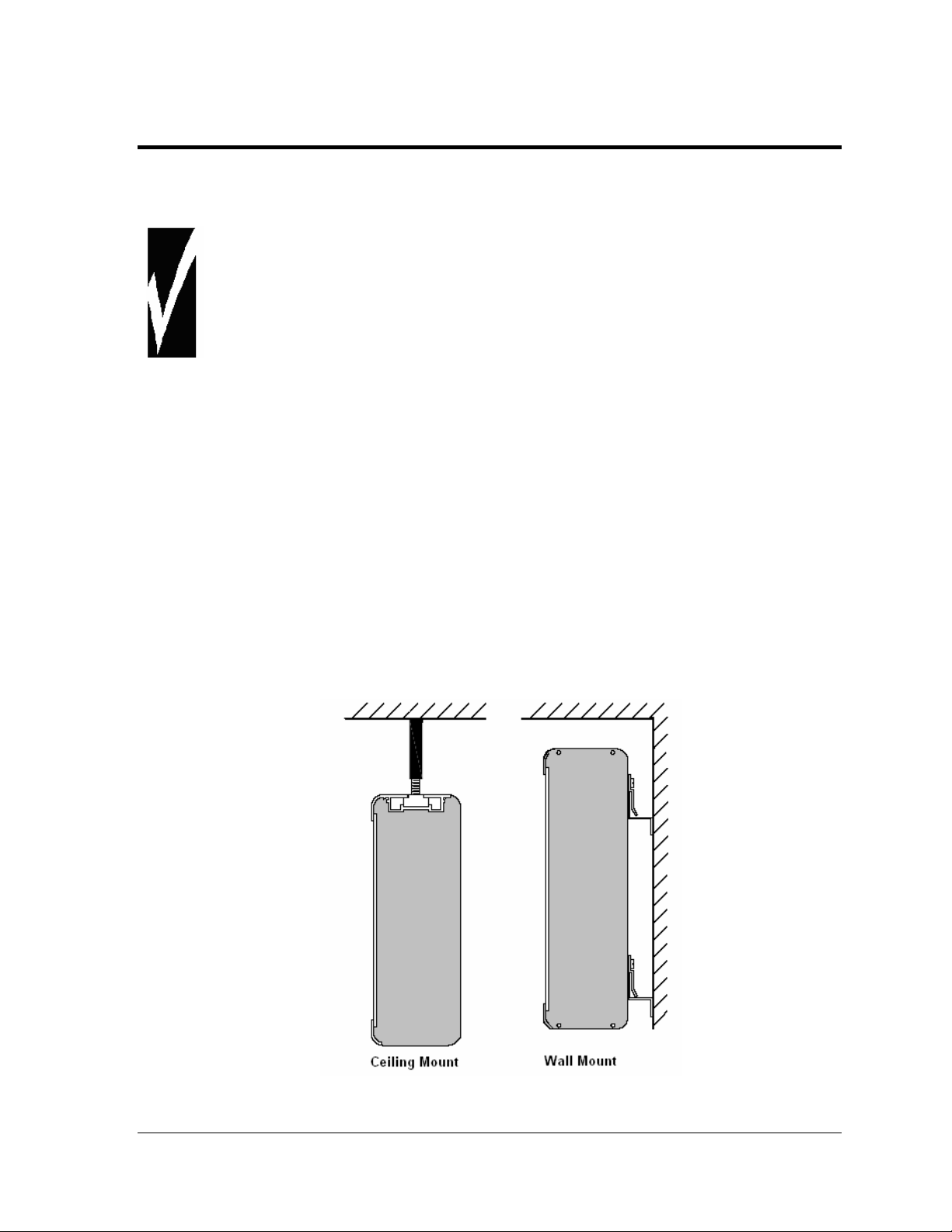

Figure 5: Mounting Options.....................................................................................................................3

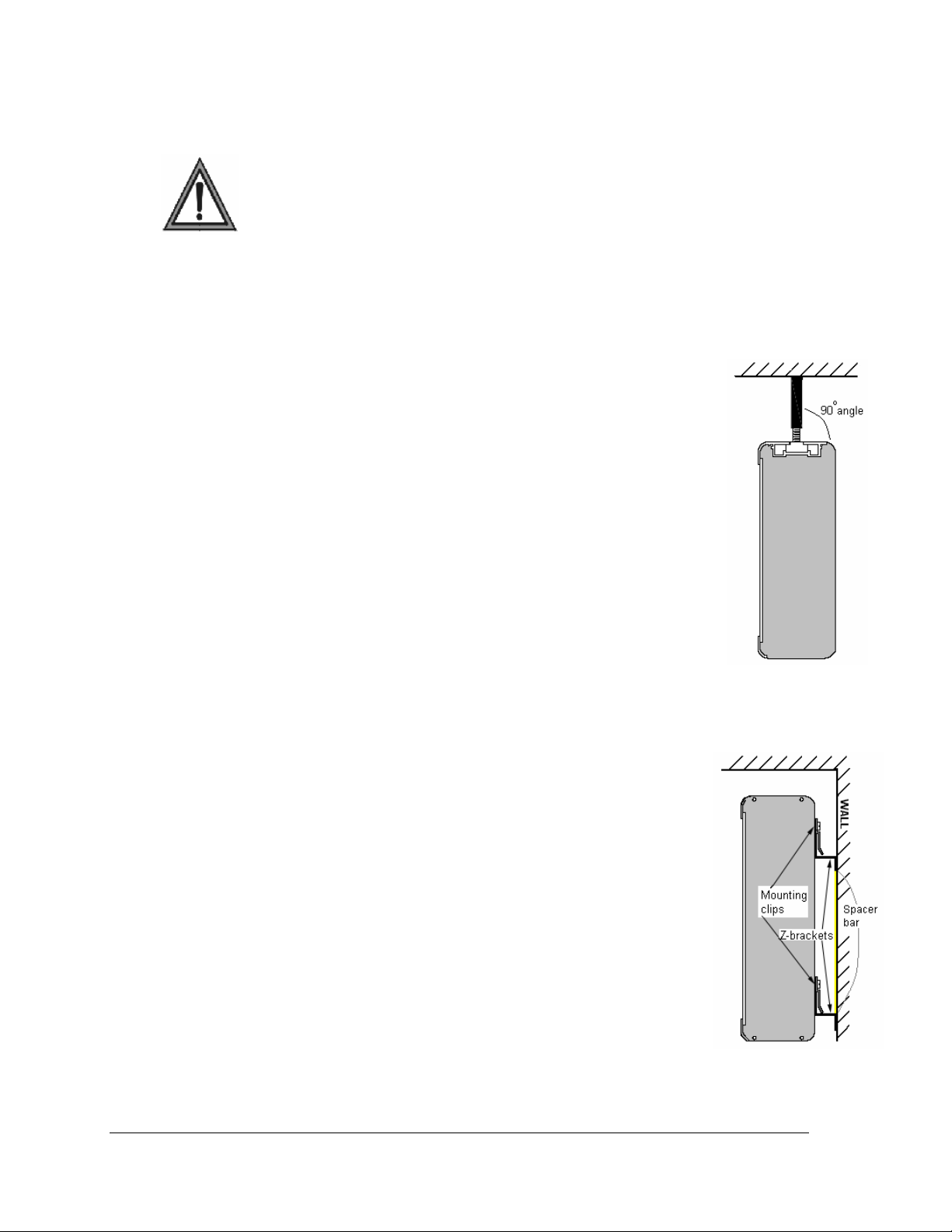

Figure 6: Ceiling Mount...........................................................................................................................4

Figure 7: Wall Mount...............................................................................................................................4

Figure 8: Master-Echo Installation Detail................................................................................................5

Figure 9: 16 and 24 High DakTickers Power Connection ......................................................................7

Figure 10: 16 High Twin DakTicker Power Connection..........................................................................7

Figure 11: Power Cord Connection ........................................................................................................8

Figure 12: RS-422 Signal Layout............................................................................................................9

Figure 13: Ethernet Signal Layout........................................................................................................11

Figure 14: Shift Board...........................................................................................................................12

Figure 15: Master to Echo Connection.................................................................................................12

Figure 16: Master to Master RS-422 Connection.................................................................................13

Figure 17: Controller with Diagnostic LEDs..........................................................................................15

Figure 18: Typical Label........................................................................................................................19

Figure 19: Removing the Face Panel...................................................................................................21

Figure 20: Detaching a Module.............................................................................................................22

Figure 21: Removing a Module.............................................................................................................22

Figure 22: Power Supply Wiring...........................................................................................................23

Figure 23: Shift Board...........................................................................................................................23

Figure 24: Display Controller ................................................................................................................24

Figure 25: RS-232 to RS-422 Signal Converter...................................................................................30

Figure 26: Flipped Cable (Reversed)....................................................................................................31

Figure 27: Straight Cable......................................................................................................................31

Figure 28: Network Cable Tester..........................................................................................................31

Figure 29: Signal Converter Enclosure.................................................................................................33

List of Figures iii

Page 6

Page 7

Section 1: Introduction

The Daktronics DakTicker™ KE-1010 displays are designed and manufactured for performance,

reliability, easy maintenance, and long life. To ensure the optimal performance of this display, the

manual explains the installation and maintenance of the KE-1010 displays. Sections 2, 3, and 4

provide mechanical, power, and signal installation instructions. Later sections include diagnostic and

parts replacement information, along with the instructions for obtaining parts from Daktronics

Customer Service. Definitions of terms are provided in Section 5.3. A DakTicker display is shown in

Figure 1.

Figure 1: KE-1010 Display

1.1 Display Overview

The DakTicker model number is described as follows:

KE-1010

HH

CCC

7.62

RG

The displays are offered as single-face (one-sided) units which may consist of a number of

separate sections. Two types of display sections are used, one called the “master” and the

other an “echo.” Master sections contain the controller board which receives information

from the computer. Echo displays do not contain a controller board and require a master

display to operate. Displays show information from a third party source, such as a wire

service, ticker input, or Internet service, and scroll these messages from right to left on the

display. A generic KE-1010 setup is illustrated in Figure 2.

KE-1010-HHxCCC-7.62-RG

= Indoor DakTicker display

= Number of pixels high (16 or 24)

Number of columns wide

=

(120, 160, 200, 240, 280, 320, 360, 400)

= Pixel spacing in millimeters

= Tri-color (Red, Green, and Amber)

Figure 2: Basic Display Setup

Introduction 1

Page 8

A module is the building block of the DakTicker display.

By placing modules side-by-side, a display of any length

can be designed and built. Individual modules can be

easily removed from the display, if required

modules consist of an array of LED (light emitting diode)

pixels that are available in several matrix sizes. The

height options include 16-pixels high and 24-pixels high

as well as a twin ticker with two separate sections of 16

pixels high. Text can be configured into one large font or

two to three lines of smaller fonts, as shown in Figure 1.

Tickers are available in tri-color (red, green and amber) characters.

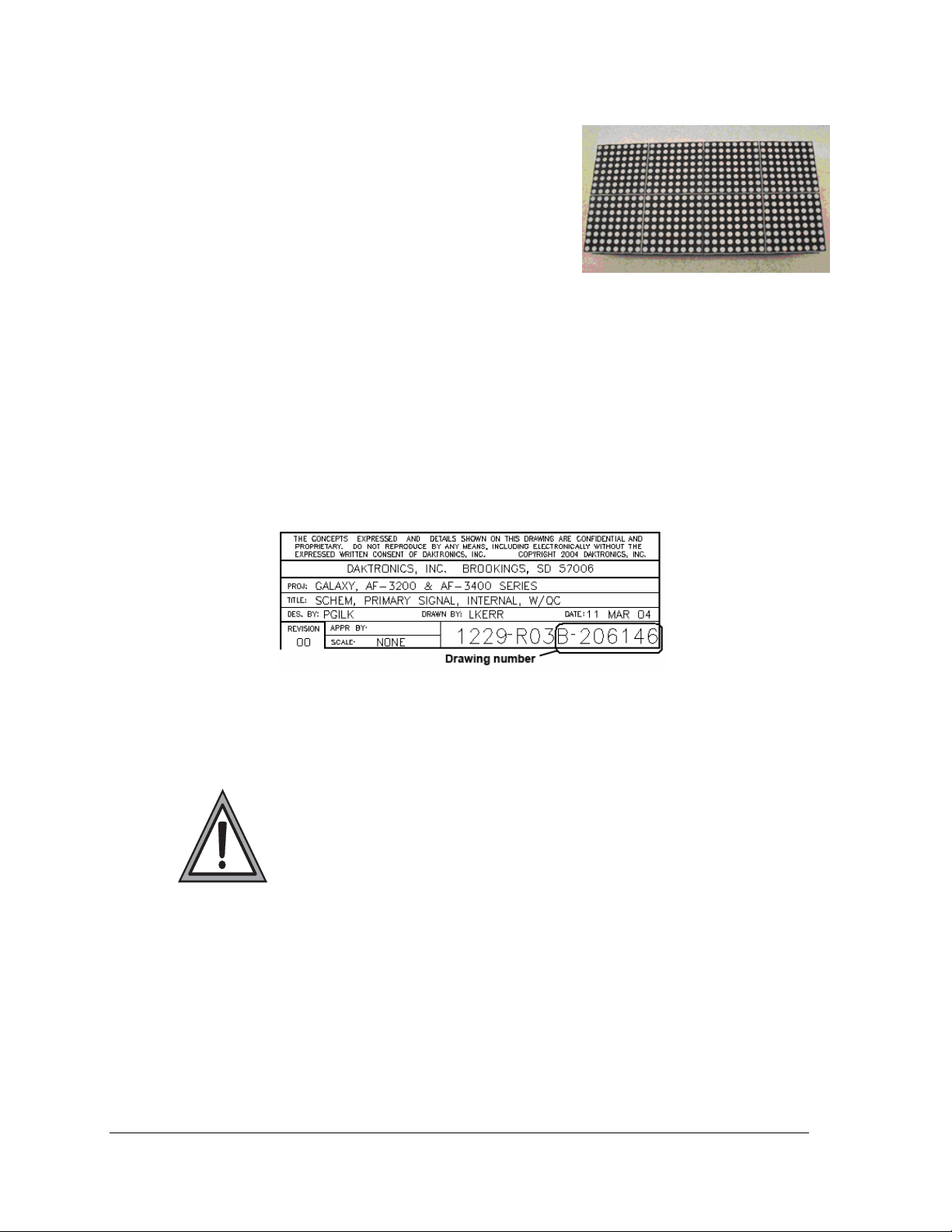

1.2 Drawing References

Drawings may be referenced at the beginning of a section and also within the text. The

reference number consists of the last set of digits and the letter preceding them on the

drawing label (Figure 4). The drawing number is located in the lower-right corner of the

drawing. In the example below, the drawing would be referred to as Drawing B-206146.

Reference drawings are inserted or listed in Appendix A.

. KE-1010

Figure 3: Front of 16 x 40 Module

Figure 4: Drawing Label

1.3 Safety Precautions

• Read and understand these instructions before installing.

• Be sure that the display is properly grounded.

• Disconnect power when servicing the display.

• Do not modify the display structure or attach any panels or coverings to

the display without the written consent of Daktronics.

2

Introduction

Page 9

Section 2: Mechanical Installation

Mechanical installation includes both support structure design and mounting methods. Two

mounting methods are explained in this section, wall mount and ceiling mount.

• Daktronics engineering staff must approve any changes made to the displays. If any

modifications are made, detailed drawings of the changes must be submitted to

Daktronics for evaluation and approval or the warranty may be void.

• Daktronics is not responsible for the installations or the structural integrity of support

structures installed by others.

Reference Drawings:

Shop Drawings ............................................................................................Listed in Appendix A

Mounting Drawing, Ceiling, KE-1010 ............................................................. Drawing A-118572

Shop Dwg, Horiz. Wall Mount, Gen II KE-1010 ............................................. Drawing A-234483

2.1 Support Structure Design

DakTicker KE-1010 displays are generally mounted on the wall or from the ceiling. Support

structure design depends on mounting methods, display size, and weight. (Figure 5). The

structure design is critical and should be done only by a qualified individual. It is the

customer’s responsibility to ensure that the structure and the connectors are adequate. Refer

to the Shop Drawings listed in Appendix A for dimensions and mounting clip locations.

Attaching or hanging anything from the display will render the warranty null and void.

Figure 5: Mounting Options

Mechanical Installation 3

Page 10

2.2 Display Mounting

• It is the customer’s responsibility to ensure that the installation will meet local

standards.

• The mounting hardware must be capable of supporting all components to be

mounted.

Daktronics recommends either a wall mount or hanging mount method (Figure 5).

Remember to have all mounted displays inspected by a qualified structural engineer.

Ceiling Mount

Splice bars, provided by Daktronics, have 3/8"-16 UNC holes that can be used

to secure the ticker displays from a ceiling or other overhead structure. Use the

middle hole only when using the splice bars for mounting. Daktronics does

not provide the ceiling mounting supports. To hang a ticker, refer to Drawing

A-118572 and the following instructions:

1. Determine and mark the locations where the ceiling mounting

supports will attach to the overhead structure. The supports, when

installed, should form a 90-degree angle with the top of the display

(Figure 6).

2. Install the supports. Qualified personnel must approve the ceiling

mounting supports. Daktronics is not responsible for ceiling mounting.

3. Secure the splice bars to the supports.

4. Carefully hang each display by fitting the channel on the top of the

display over the splice plates and slide it into place (refer to Drawing

A-118572). When multiple sections are used, each joint between

displays must have hanging support.

Figure 6: Ceiling Mount

4

Wall Mount

The wall mount method includes the installation of Z-brackets to hold the

mounting clips attached to the back of the displays. Refer to Figure 7.

1. Determine the desired location of the top of the ticker display. Refer

to Drawing A-234483.

2. From the desired location for the top of the display, measure down

the distance listed in the chart following or Drawing A-234483. This

is the height location where the bottom Z-bracket is going to be

attached to the wall.

3. Determine the desired location of the end of the ticker display.

Measure from this point 3/4” in toward the display body if the

display has an endcap, or 1/2” if an endcap is not present.

4. Mount the bottom Z-bracket at this location.

5. Once the bottom Z-bracket is mounted place the metal spacers

(provided by Daktronics) on top of the bottom Z-bracket. Be sure the

arrow points up.

6. Mount the top Z-bracket so that the bottom of the bracket touches the

top of the spacer and the ends align with the bottom bracket.

Figure 7: Wall Mount

Mechanical Installation

Page 11

Display Distance From Display Top To

Bottom Bracket Attachment Point

KE-1010-16x***-7.62 0’-10 ¼” (260 mm)

KE-1010-24x***-7.62 0’-13 ¼” (337 mm)

KE-1010-2-16x***-7.62 0’-17 ¼” (438 mm)

Mounting Multi-section Tickers

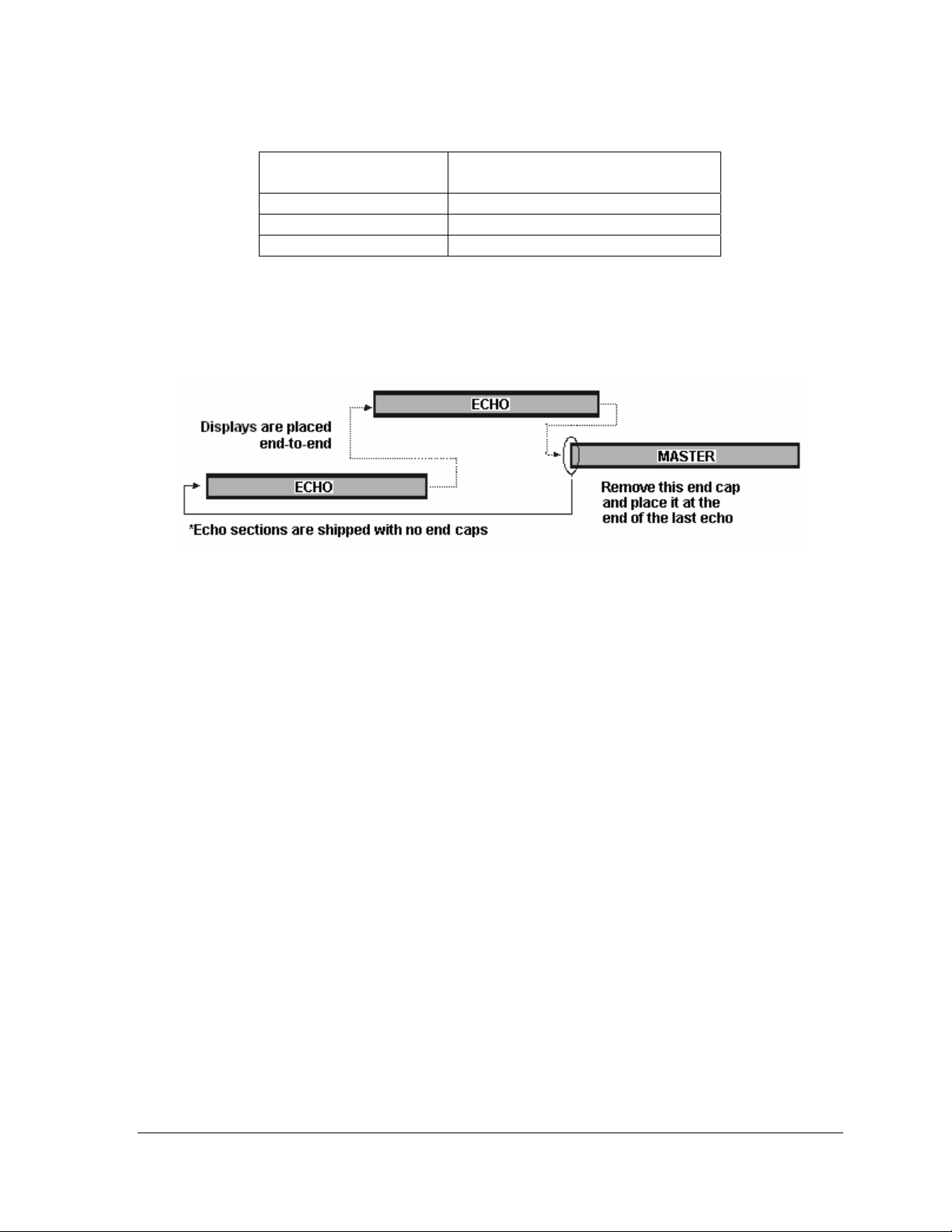

The echo sections are shipped without end caps. Remove the left outer end cap from the

master ticker and attach it to the left-most echo ticker (refer to Figure 8).

Figure 8: Master-Echo Installation Detail

1. Before attempting to connect the sections, check their mounted alignment in relation

to each other. If the alignment is off, then adjust the mounting clips on the back of

the tickers.

2. Hang each section according to the appropriate mounting directions.

3. Refer to Section 3 for routing power and Section 4 for signal installation to each

section.

4. Slide the sections together.

5. Slide the splice bar over the joint(s) between the displays.

6. Tighten the screws (provided in the splices) using a 3/16" hex wrench.

Mechanical Installation 5

Page 12

Page 13

Section 3: Power Installation

• Only a qualified individual should terminate power and signal cable at this Daktronics

display.

• All proposed changes must be approved by Daktronics engineering staff or the

warranty will be rendered null and void.

Reference Drawings:

Power Specs, GEN II, KE-101

Shop Drawings........................................................................................................in Appendix A

Schematics..............................................................................................................in Appendix A

3.1 Power Requirements

The displays accept a universal input voltage of 100-240 VAC at 50-60 Hz. Refer to the

following table and the drawings referenced at the beginning of the section for voltage and

current requirements. The displays are sufficiently powered by a 100-240 VAC single-phase

outlet. Refer to Drawing A-234168 for the power specifications for individual DakTicker

display sizes.

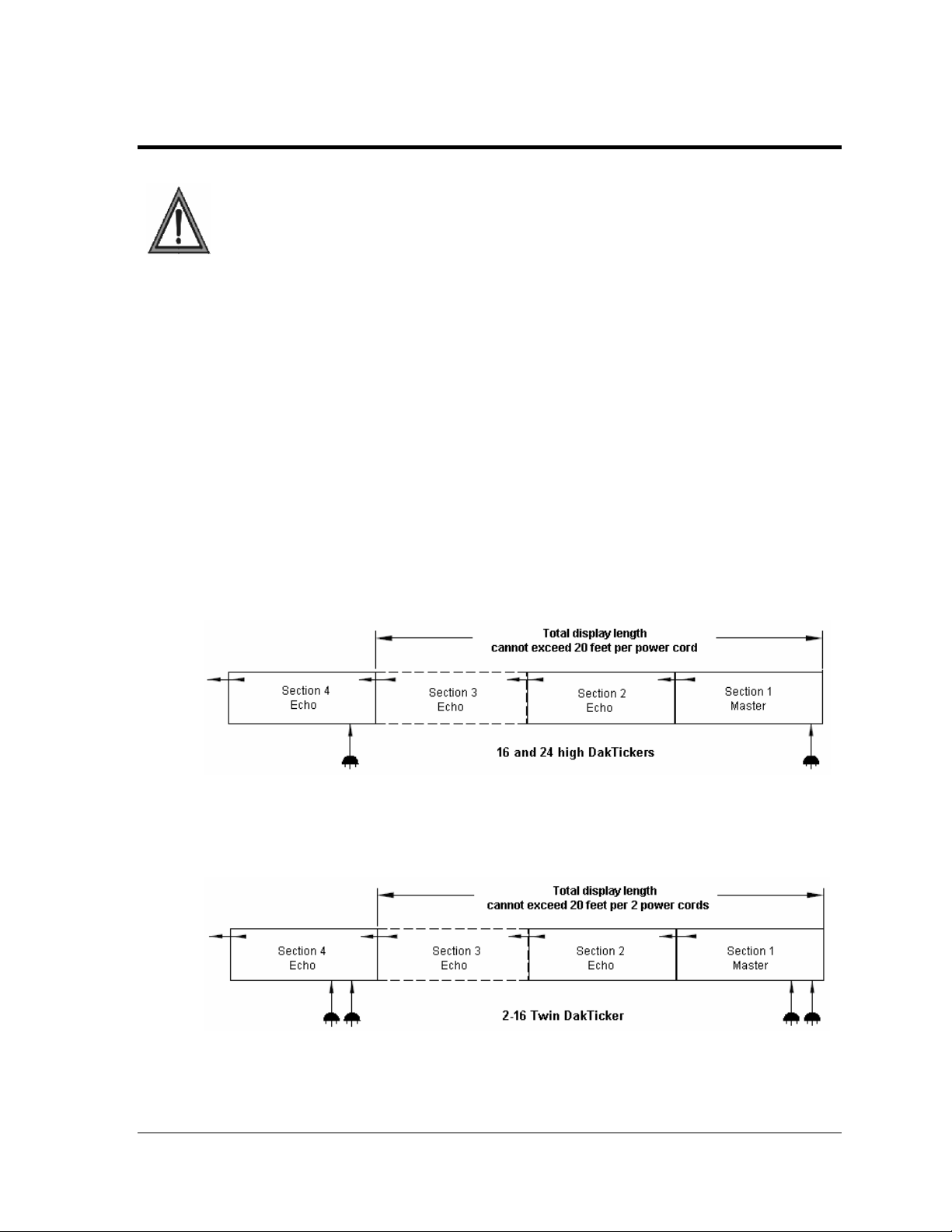

No more than two additional sections may be powered from one powered section. Total

display length powered from one section is not to exceed 20 feet (6.1 M).

*-16x***, 24x***, 2-16*** .................................... Drawing A-234168

Figure 9: 16 and 24 High DakTickers Power Connection

Figure 10: 16 High Twin DakTicker Power Connection

Power Installation 7

Page 14

Power Specifications for Tickers with Multiple Sections

# of Phases 16 and 24 High Twin 16 High

Amps Per Line

(100-240VAC)

Max Watts

6.9 (Sum of 3 Sections) 13.8 (Sum of 3 Sections)

825 Watts (Sum of 3 Sections) 1650 Watts (Sum of 3 Sections)

Voltage – Secondary

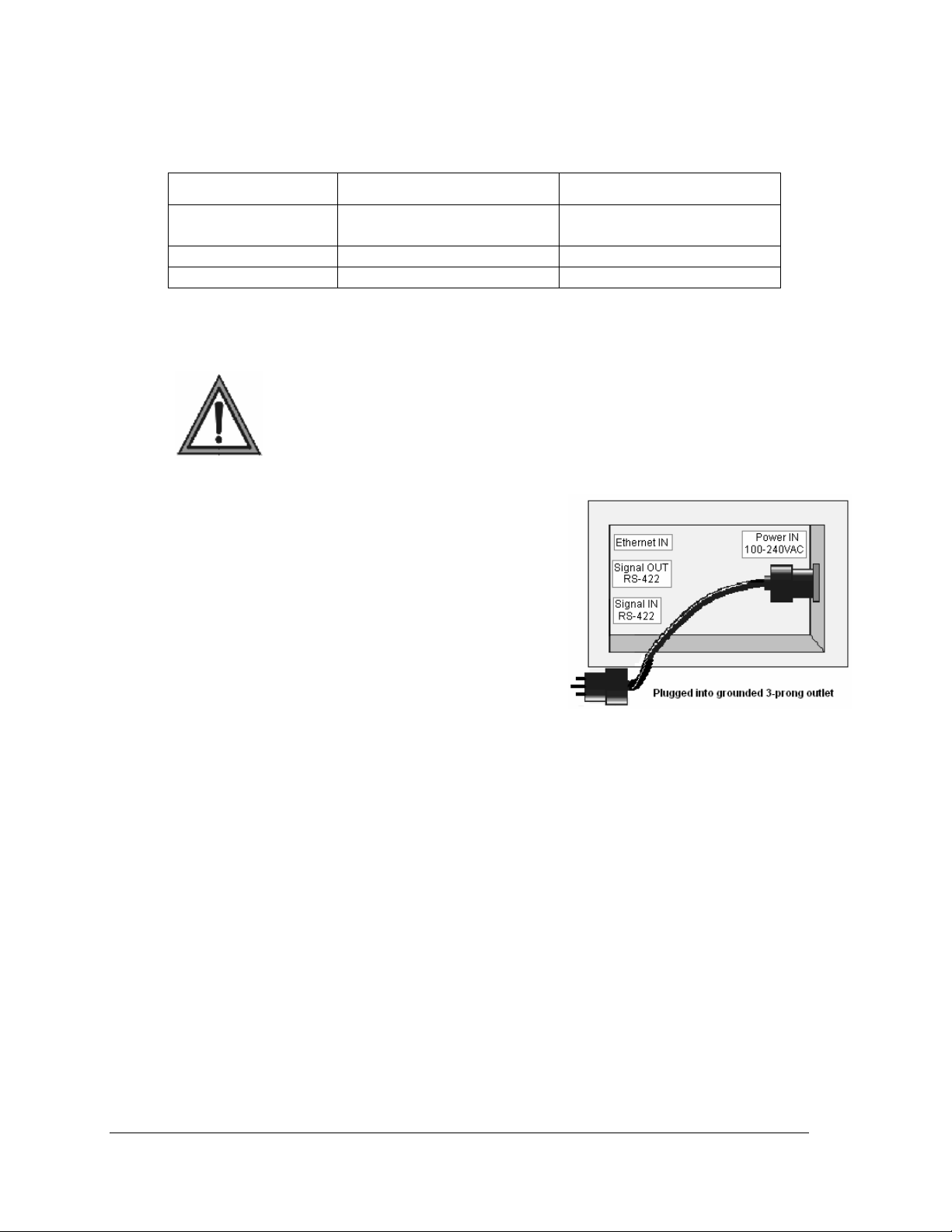

3.2 Power Cord - Grounding

Note: Most products are equipped with a 3-wire grounding-type

plug—a plug having a third (grounding) pin. This plug will only fit into

a grounding-type power outlet. This is an essential safety feature. If

the correct outlet is not available for this plug, contact a qualified

of the grounding-type plug.

The DakTicker displays are each supplied with a sixfoot long removable power cord. The socket-outlet

should be available near the equipment and easily

accessible. Plug the power cord into the socket on the

back of the display, as shown in Figure 11.

Note: No more than two additional display sections can

be powered from this section. Total length of the

display cannot exceed 20 feet (6.1 M)

If proper grounding methods are not followed, the

warranty will be void.

electrician to replace the obsolete outlet. Do not defeat the purpose

5VDC 5VDC

Figure 11: Power Cord Connection

8

Power Installation

Page 15

Section 4: Signal Installation

To display messages on a KE-1010 display, signal is sent from the computer to the ticker via one of

two possible network systems: RS-422 or Ethernet. Signal is received by the controller board inside

the master section of the ticker. The controller board processes the data and relays it to the shift card.

The shift card relays signal to the modules, then the appropriate LEDs create the messages which

scroll across the ticker display.

Reference Drawings:

Concept System Riser Diagram TCP/IP......................................................... Drawing A-229840

Concept System Riser Diagram RS-422........................................................ Drawing A-229912

Schematics..............................................................................................................in Appendix A

4.1 Network Options

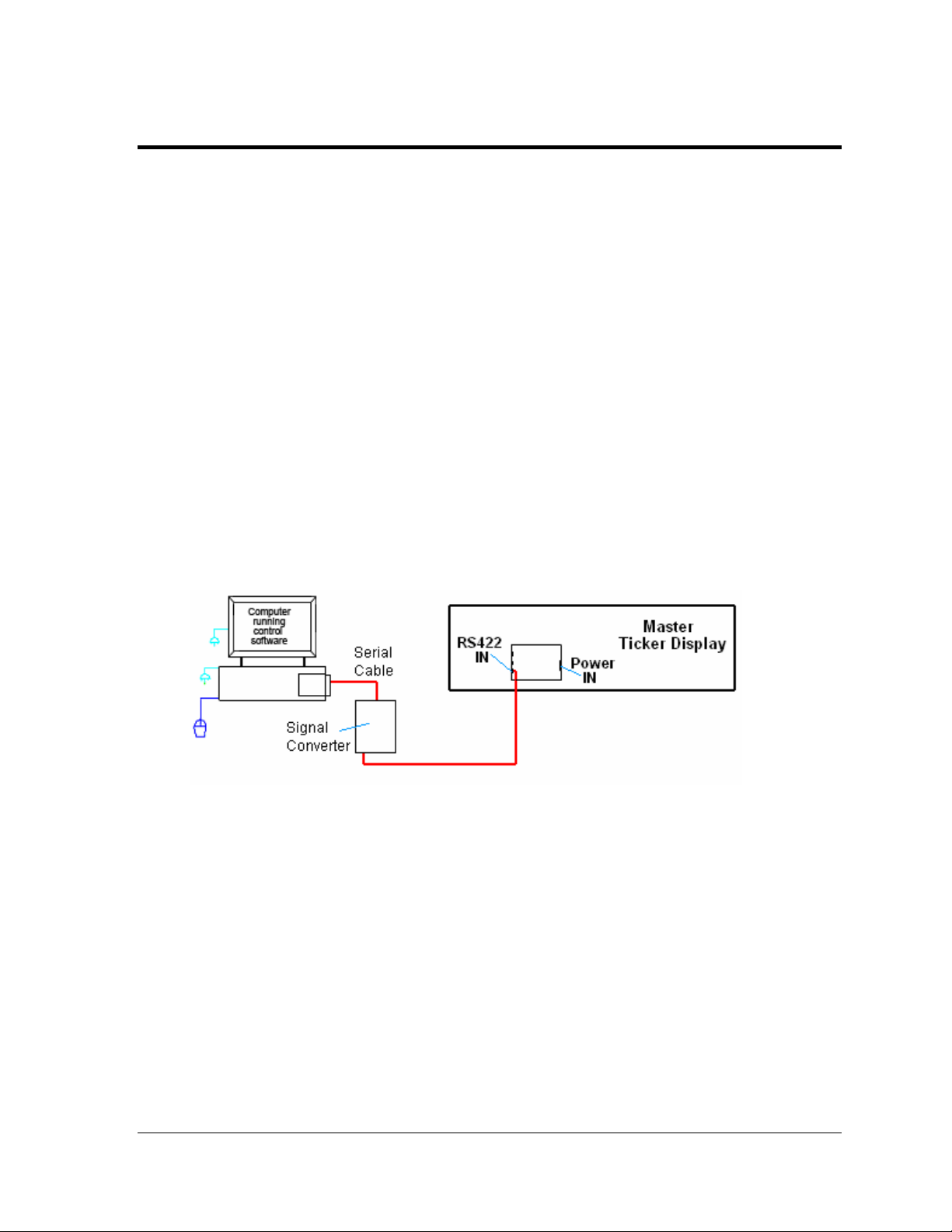

RS-422 Connections

An RS-422 communication system requires a signal converter to change the computer’s RS232 output into RS-422 signal for the controller. The typical maximum cable length is 1.2km

(approximately 4,000 feet). Refer to Appendix B for information on the signal converter.

Refer to Figure 12 for an overview of this communication layout.

Figure 12: RS-422 Signal Layout

To connect RS-422 signal, follow these steps:

1. Plug the serial cable’s 25-pin connector into the signal converter.

2. Plug the 9-pin connector into the RS-232 COM port to be used.

3. Plug the signal converter’s power cord into a grounded outlet.

Note: The signal converter requires a specific supply voltage of 120 or 240 VAC.

4. Plug a flipped 6-conductor RJ11 cable into the “RS-422 OUT” of the signal converter

and the opposite end into the “RS-422 IN” of the master section.

5. Plug the ticker’s power cord into a 100-240 VAC grounded outlet.

Signal Installation 9

Page 16

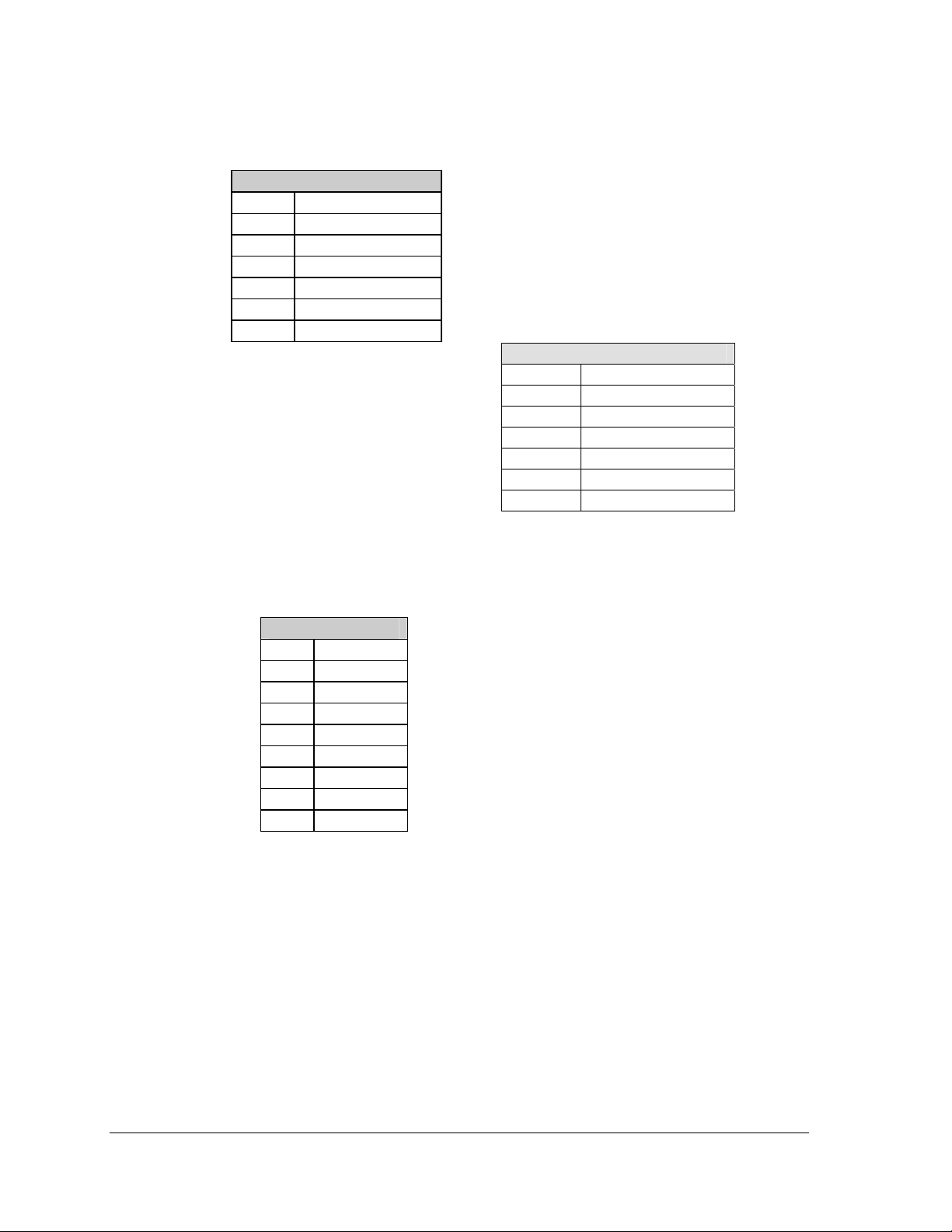

RS-422 Pin-outs

The controller’s RS-422 jacks have the following pin-outs:

Signal Converter Pin-outs

The signal converter has two RS-422 output jacks, with the following pin-out:

INPUT (J4)

RJ11 Function

1 N.C.

2 D1OUT-P

3 D1OUT-N

4 D1IN-P

5 D1IN-N

6 N.C.

OUTPUT (J5)

RJ11 Function

1 N.C.

2 D2OUT-N

3 D2OUT-P

4 D2IN-N

5 D2IN-P

6 N.C.

OUTPUT

RJ45 Function

1 N.C.

2 CHGND

3 TX.A-N

4 TX.A-P

5 RX.A-N

6 RX.A-P

7 CHGND

8 N.C.

10

Signal Installation

Page 17

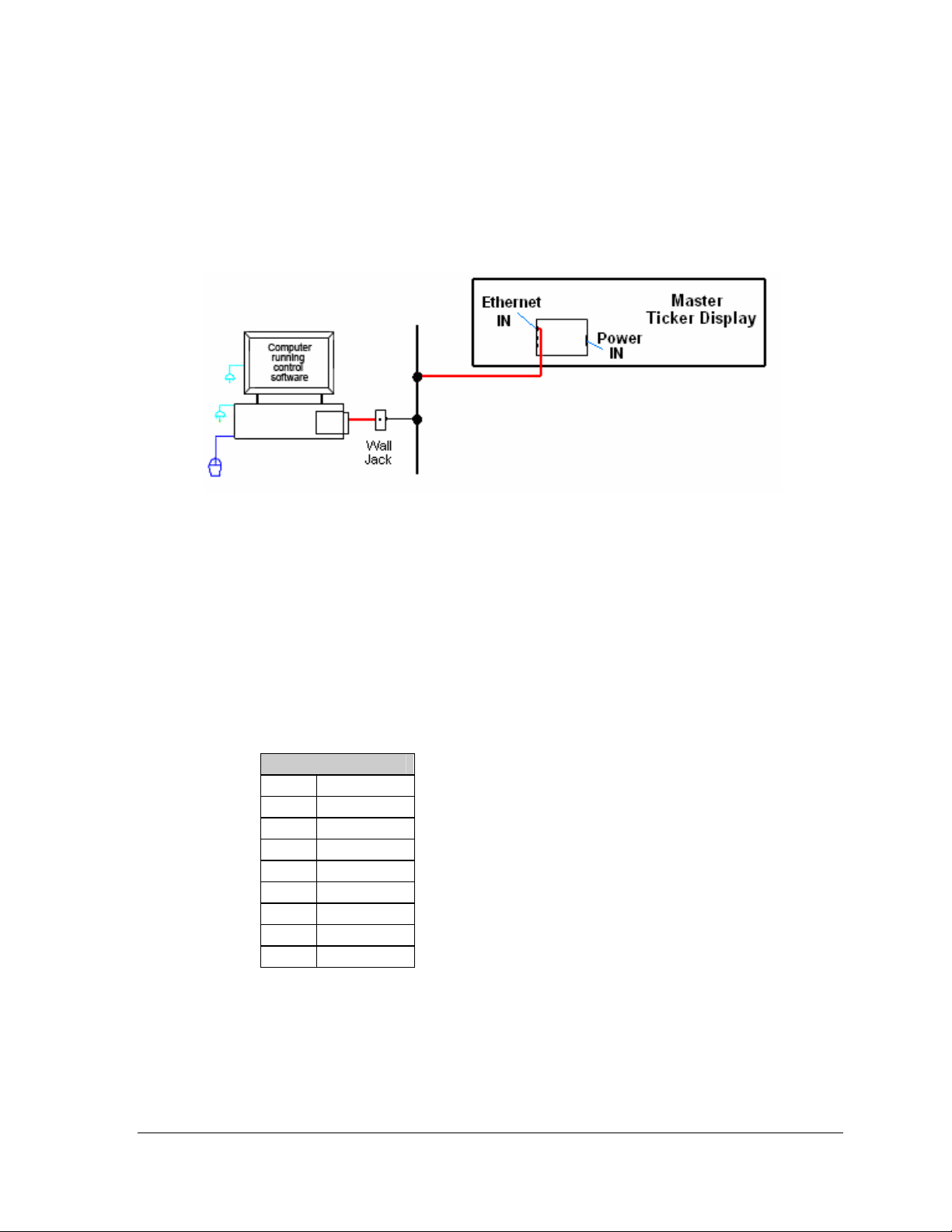

Ethernet Connections

For DakTickers using an Ethernet system for communication, a network connection will be

made from the network hub or switch to the master section. The Cat-5/Cat-5E cable has a

typical maximum length of 100 meters (approximately 300 feet). The controller has an

onboard Ethernet port with a default address that will need to be reconfigured to an address

on the local network. Refer to Appendix C. The default address is 172.16.192.27.

Figure 13: Ethernet Signal Layout

Follow these steps to set up the Ethernet system:

1. Plug the computer into a network hub.

2. Plug the network cable into a network hub or switch.

3. Plug the other end of the RJ45 network cable into the jack labeled “Ethernet IN” on

4. Plug the ticker’s power cord into a 100-240 VAC grounded outlet.

Ethernet Pin-outs

The controller’s Ethernet input jack has the following pin-out:

the controller in the master section.

INPUT (J6)

RJ45 Function

1 TX+

2 TX3 RX+

4 EPWR+

5 EPWR+

6 RX7 EPWR8 EPWR-

Signal Installation 11

Page 18

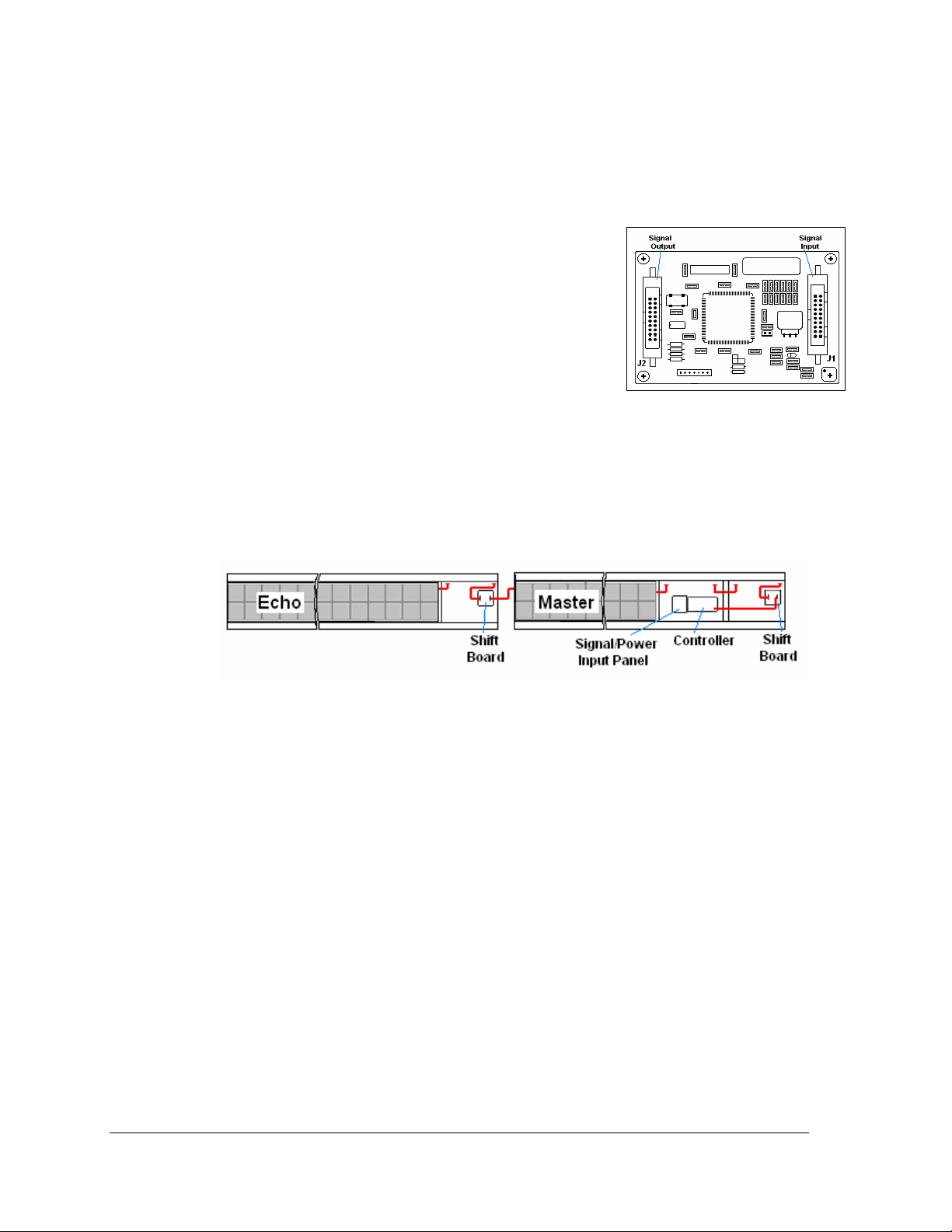

4.2 Section to Section Connections

The signal between the master and echo sections is connected using 20-pin ribbon cables

between the shift board and the last module of the previous section (Figure 15). Follow these

steps to connect display sections.

1. Carefully hang the echo section(s) as described in

Section 2.2. Do not yet slide the sections together.

2. A ribbon cable should already be plugged into the

“Signal In” jack on the shift board (Figure 14) of the first

echo section. If it isn’t, do so at this time.

3. Plug one end of the ribbon cable into the “Out” jack on

the back of module A101 (the left end module) of the

master section.

4. If an echo section is present, plug P42/P43 of the echo

section into J42/J43 of the master section to complete

the interconnection of power. Repeat this for additional sections. Note: Total display

length cannot exceed 20 feet per power cord.

5. The connection for a master to one echo is shown in Figure 15. Repeat steps 1 though

3 to connect and hang each consecutive echo ticker. All other internal wiring

between modules has been done by Daktronics.

Figure 14: Shift Board

Figure 15: Master to Echo Connection

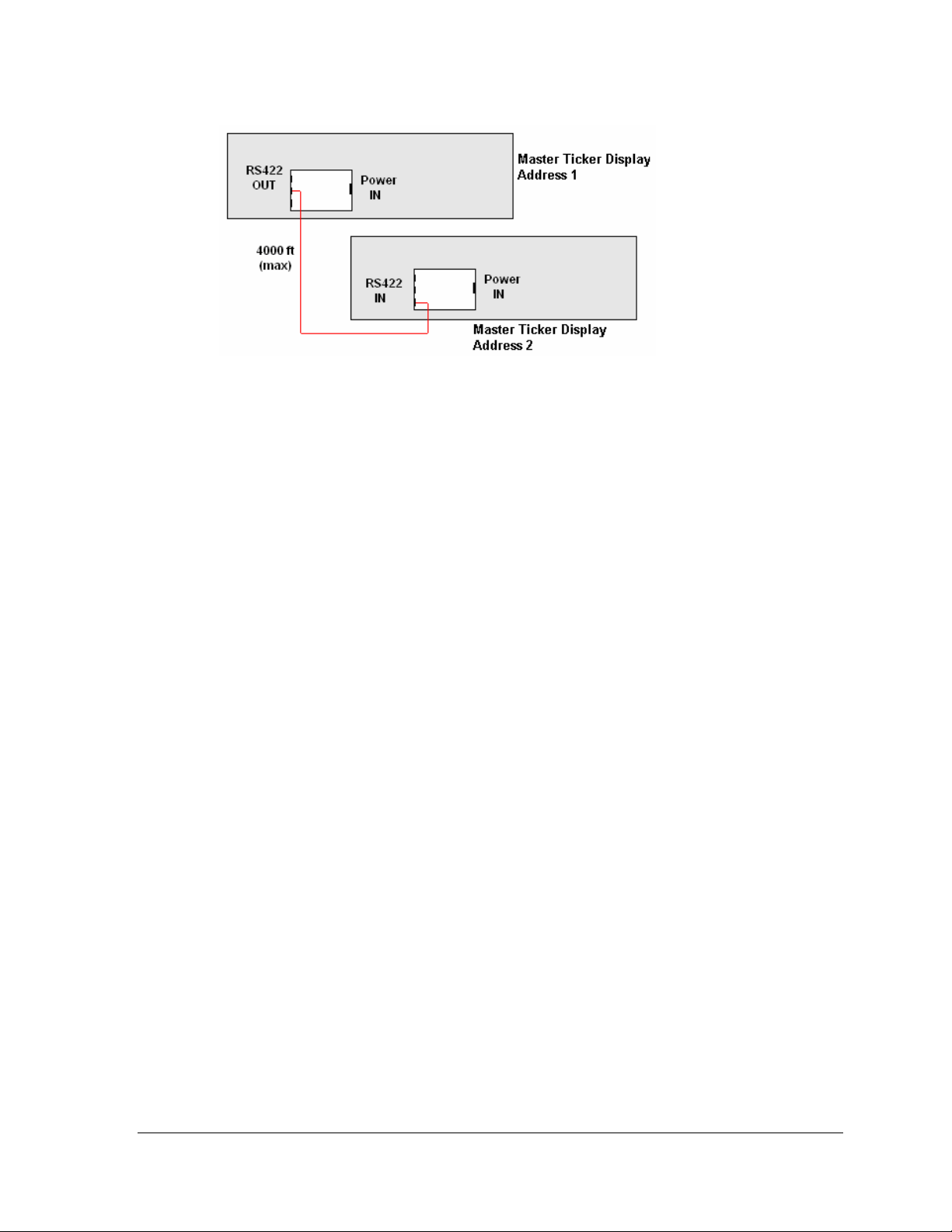

4.3 Master to Master Connections

In some cases, more than one master display is used instead of the master-echo

configuration. In this case, signal can be transmitted between master displays using a flipped

6-conductor RJ11 cable running RS-422. To connect multiple master displays:

1. Signal into the first display can be either RS-422 or Ethernet.

2. Connection between displays will always be RS-422. Connect from RS-422 OUT on

the first display to RS-422 IN on the second display (Figure 16).

3. Master displays connected in this way will need to have different addresses set on

each controller.

12

Signal Installation

Page 19

Figure 16: Master to Master RS-422 Connection

4.4 Installation Checklist

After installation is complete, go over these steps to make sure that the display is properly

connected and ready to operate correctly.

1. Carefully check the voltage between the hot lines and neutral. Normal voltage range

is between 100 VAC and 240 VAC.

2. If problems arise with the voltage, check with a local electrician or power company.

3. Plug the power cord(s) from the ticker(s) into a grounded 100-240 VAC single-phase,

grounded outlet(s).

4. Turn power ON to the outlet(s).

4.5 Boot Up Sequence

Each time the KE-1010 is powered up, the following information is shown on the display

face. The Xs represent numbers that will change according to the specific installation.

• DakTicker by Daktronics

• ED10288

• REV X

• ADDRESS XX

• IP Address

Signal Installation 13

Page 20

Page 21

Section 5: Maintenance and Troubleshooting

This section covers the basic maintenance needed to keep the display operating effectively. Also

included are diagnostic and troubleshooting information to pinpoint display problems and provide

solutions. Following this are definitions of terms used in the manual.

• Disconnect power before any repair or maintenance work is done on the display!

• Qualified service personnel must make any access to internal display electronics.

• Disconnect power when the display is not in use.

5.1 Display Maintenance

Controller Diagnostic LEDs

The ticker controller has four LEDs that indicate whether the controller is functioning

properly. Note that the transmit and receive LEDs will toggle on and off a few times when

the controller is first establishing communication.

LED Name Label Indication

Power PWR On constantly when operating correctly.

Run RUN Blinks at a rate of every half second when power is on.

Receive RXD Flashes each time data is received.

Transmit TXD

Flashes when sending data from the controller to the

computer. Most of the time, this LED is off.

Figure 17: Controller with Diagnostic LEDs

Maintenance and Troubleshooting 15

Page 22

Visual Structural Inspection

At least once a year, check the display to make sure that the structure and components are in

good condition. Inspect the paint and cabinet for corrosion. Make sure that fasteners are

tight; if not, tighten or replace as required.

5.2 Troubleshooting

This chart lists some symptoms that may be encountered with the ticker displays. For each

symptom, possible causes and corrective actions are indicated. This list does not include

every possible problem but does represent some of the more common situations that may

occur.

Symptom/Condition Possible Cause/Remedy

A single pixel on the display will not light. • Check signal connection.

One or more LEDs will not turn off. • Check signal connection.

Section of display is not working. • Check power to the section.

Display is garbled or sequence is shifted. • Check the data settings on the computer.

A group of modules does not work. • Check for output from power supplies.

Entire display does not work. • Check 100-240 VAC input power to 1st section.

Data feed or software is not operating

properly.

Display resets and restarts. • Reduce the amount of amber pixels used.

• Replace the module.

• Replace the module.

• Check for input power to the module.

• Replace ribbon cable.

• Replace/move the first module not working.

• Replace/move the last working module of the

previous section.

• Check power supply.

• Replace shift card.

• Replace the controller.

• Check signal connections.

• Refer to the data feed manual.

• Reboot power to the section.

• Check/replace ribbon cable.

• Replace/move the first module not working.

• Replace/move the last working module of the

previous section.

• Check signal connections.

• Check all signal connections.

• Check PC/Feed setting for proper orientation.

• Replace controller.

• Refer to data feed manual.

• Check signal connection feed to display.

• Contact data feed/software provider.

• Remove inverted text.

16

Maintenance and Troubleshooting

Page 23

5.3 Definitions

Cabinet: The metal frame of the display (back, bottom, top); may also include the end caps.

Column: A vertical line of pixels.

Controller: The component i

the computer’s ticker feed.

End Cap: A metal plate that covers each end of a ticker.

Ethernet: A standard communication interface that utilizes a local area network (LAN). The

m

aximum cable length is 300 feet (100 meters).

Face Panel: The tra

LED: (Light

the ticker display.

Module: A 16 x 40 or 24 x 40 array of LEDs. Modules m

display unit.

Pixel: A single p

RS-232: A sta

meters).

RS-422: A st

feet (1.2 kilometers).

Row: A horizont

Shift Board: R

ticker sections.

Signal Converter: A Dakt

The signal converter is connected to the control PC via a straight through serial cable.

Emitting Diode) A low energy, high intensity lighting unit that shows the text on

oint of light on a display. On the KE-1010, a pixel consists of one LED.

ndard PC communication type with a maximum cable length of 25 feet (7.6

andard differential communication type with a maximum cable length of 4,000

al line of pixels.

elays the signal from the controller board to the first module and then between

n the master section that receives and interprets the data from

nsparent polycarbonate panel that sits in front of the modules.

ay be individually removed from the

ronics supplied unit that converts the data from RS-232 to RS-422.

Maintenance and Troubleshooting 17

Page 24

Page 25

Section 6: Parts Replacement

• Disconnect power before any repair or maintenance work is done on the display!

• Qualified service personnel must make any access to internal display electronics.

• Disconnect power when the display is not in use.

DakTicker displays are built for long-term reliable operation; however, on occasion parts may need

to be replaced. (Components within the displays are not field repairable.) To access internal

components, modules may easily be removed. This section provides instructions for removing

modules and replacing basic components.

Reference Drawings:

Component Layout Drawings.................................................................Inserted into Appendix A

Shop Drawings............................................................................................. Listed in Appendix A

Schematics................................................................................................... Listed in Appendix A

6.1 Replacement Parts List

The following part labeling formats might be found on various Daktronics drawings. These

part numbers can be used when requesting replacement parts from Daktronics Customer

Service.

• “TB__” denotes a termination block for power or signal cable.

• “F__” denotes a fuse.

• “E__” denotes a grounding point.

• “J__” denotes a power or signal jack.

• “P__” denotes a power or signal plug for the opposite jack.

• “0P-_ _ _ _-_ _ _ _” shows an individual circuit board, such as the internal shift card.

• “0A-_ _ _ _-_ _ _ _” indicates an assembly, such as a circuit board and the plate or

bracket to which it is mounted. A collection of circuit boards working as a single unit

may also carry an assembly label.

• “W-_ _ _ _” represents a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances, such as ribbon cables.

Most circuit boards and components within this display carry a

label that lists the part number of the unit. If a circuit board or

assembly is not listed in the Replacement Parts List, use the

label to order a replacement. A typical label is shown in Figure

18 with the part number in bold.

Figure 18: Typical Label

Parts Replacement 19

Page 26

Consult this list for the Daktronics part number for basic display components. Refer to

Section 6.4 for inst

ructions on obtaining parts from Daktronics.

Part Description Daktronics Part #

Controller Board (16-high, RS-422 Input) 0P-1182-0011

Controller Board (16-high, RS-422 or Ethernet Input) 0P-1182-0022

Controller Board (24-high, RS-422 or Ethernet Input) 0P-1182-0023

Shift Board (16-high) 0P-1182-0012

Shift Board (24-high) 0P-1182-0019

Module; 16x40 Super Bright Red-Green 0P-1182-0014

Module; 24x40 Super Bright Red-Green 0P-1182-0018

Signal Converter; RS232 to RS-422, 120V 0A-1127-0255

Serial Cable, DB9 to DB25, from PC to Signal Converter W-1249

Ribbon Cable; 20 Cond. 28 AWG (Between Modules) W-1357

Ribbon Cable; 20 Cond. 28 AWG

(Controller to shift card and shift card to module)

Power Supply; +5VDC A-1632

Power Cord; 3-Prong 120VAC W-1181

Splice Bar EN-1772

Mounting Clip, KE-1010-**x***-7.62 0M-233464

Suction Cup, 2 ¼” Dia. HS-1338

Filter; RFI Line Z-1014

Face Panel; 16x240 0A-1182-0015

Face Panel; 16x320 0A-1182-0016

Face Panel; 16x400 0A-1182-0017

Z-Mounting, GEN II, KE-1010-**x120-7.62 0M-233463

Z-Mounting, GEN II, KE-1010-**x160-7.62 0M-234569

Z-Mounting, GEN II, KE-1010-**x200-7.62 0M-234704

Z-Mounting, GEN II, KE-1010-**x240-7.62 0M-234712

Z-Mounting, GEN II, KE-1010-**x280-7.62 0M-234719

Z-Mounting, GEN II, KE-1010-**x320-7.62 0M-234723

Z-Mounting, GEN II, KE-1010-**x360-7.62 0M-234728

Z-Mounting, GEN II, KE-1010-**x400-7.62 0M-234733

Z-Mounting, GEN II, KE-1010-24x***-7.62 0M-235529

DataStreamer Manual ED-13649

W-1387

20

Parts Replacement

Page 27

6.2 Removing the Face Panel

The internal components of the KE-1010 displays may be accessed after the face panel and

modules are removed. Refer to Figure 19 for a visual diagram of the steps involved in

removing the face panel. Never attempt to lift the entire display or carry the face panel using

the suction cups.

To remove the face panel:

1. Disconnect power to the display.

2. Using the suction cups provided with the display, slide the face panel up toward the

top of the display (Figure 19).

3. Pivot the bottom edge of the panel out of the support groove. The face panel should

now be free of the display cabinet.

4. Carefully remove the face panel. The LED modules will now be accessible.

5. Remove the appropriate module to access the internal electronic components.

To replace the face panel, follow the previous steps in reverse order.

Note: When replacing the face panel, it may be slightly wavy and not slide neatly down into

the groove. If the face panel is not easily reinserted, then start at one end of the display and

gently press your hand against the bottom edge of face panel to slide it into the bottom

support groove.

Figure 19: Removing the Face Panel

Parts Replacement 21

Page 28

6.3 Instructions for Replacing Parts

LED Module Replacement

To remove and replace an LED module:

1. Disconnect the main supply power to the section

being serviced.

2. Remove the face panel as described in Section 6.2.

3. Each module is held in place by 5/16”hex nuts at

six locations. Remove the securing nuts (refer to

Figure 20).

4. Carefully lift the module out of the display. Note:

All power and signal cables are still connected

(Figure 21).

5. Disconnect the cables from the back of the module,

noting their location. The module is then no longer

attached to the display.

6. Follow the previous steps in reverse order to

reattach a module. Refer to the Schematic for

additional wiring information.

Figure 20: Detaching a Module

22

Figure 21: Removing a Module

Parts Replacement

Page 29

Power Supply Replacement

Power to the LED modules is provided by +5 VDC power supplies. To remove a power

supply:

1. Disconnect the main supply power to the section requiring service.

2. Remove the face panel per Section 6.2.

3. Remove the LED module in front of the failed power supply. Refer to the

appropriate Component Layout Drawing for the location of the power supplies.

4. The plate is secured to the back sheet by two (2) #6 nuts. Remove the #6 nuts to

remove the plate with the power supply. Lift the power supply and plate out of the

display.

5. Each power supply is attached to a

mounting plate by two (2) M4x8MM

metric screws. Using a #1 Philips

screwdriver, remove the screws to free

the power supply.

6. Disconnect all power supply wires,

noting their connections (Figure 22). The

power supply is now ready for

replacement.

7. Follow the previous steps in reverse

order to reattach the new power supply.

Figure 22: Power Supply Wiring

Shift Card Replacement

The shift cards are used to relay signal from the controller to the modules or from the last

module of the previous section to the LED modules in the next section. One shift card is

located in the right end of each KE-1010 section (both master and echo). To replace a shift

card:

1. Disconnect the main supply power to the

section requiring service.

2. Remove the face panel per Section 6.2.

3. Remove the last module in the right end

of the selected ticker section.

4. Remove signal cables from the shift card,

noting the correct connections (Figure

23).

5. The card is attached to the inside of the

display with four #6-32 hex-head screws.

Remove the attaching screws and

carefully lift the card from the display.

6. If a jumper is present, make sure it is in

the same location as the board being replaced.

7. Follow the previous steps in reverse order to attach a new shift card. Refer to the

appropriate display Schematics for wiring information.

Figure 23: Shift Board

Parts Replacement 23

Page 30

Controller Replacement

The controller is mounted inside the master display on the back of the cabinet (Figure 24). It

is typically located behind the second module from the right end. The display controller

receives information from the ticker input, interprets it, and activates

LEDs. The controller has a set of eight switches, the first four of which are used to set the

hardware address using standard binary code. Refer to the following section for instructions

on setting the address. Display controllers are found only in master displays.

Figure 24: Display Controller

To replace a controller:

1. Disconnect the main supply power to the master section.

2. Remove the face panel per Section 6.2.

3. Remove the two LED modules on the right end of the master section.

4. Remove all power and signal cables to the controller, noting their connections.

(Signal to the controller may also be connected from the back of the display.)

5. The controller is attached to the inside of the display with four #6-32 hex-head

screws. Remove the attaching screws and carefully lift the controller from the

display.

6. Follow the previous steps in reverse order to attach a new controller. Refer to the

appropriate display Schematic for wiring information.

Note: Be sure to set the new controller’s address to the same settings as the one it is

replacing. Refer to the following information.

the corresponding

24

Parts Replacement

Page 31

Controller Address

The controller has a set of “DIP” switches or address switches, as shown in Figure 24. These

switches set the hardware address for the display system. When replacing a controller board,

be sure to set the DIP switches on the new controller to the same address configuration as the

controller which was removed.

Note: DIP Switches 1-4 are used for addressing, while swit

6, and 8 are not used.

Switch 7 Switch 4 Switch 3 Switch 2 Switch

Off Off Off Off Off 0

Off Off Off Off On 1

Off Off Off On Off 2

Off Off Off On On 3

Off Off On Off Off 4

… … … … … …

Off On On On Off 14

Off On On On On 15

ch 7 enables test mode. Switches 5,

1

Address

On Off Off Off Off Test Mode

6.4 Daktronics Exchange and Repair & Return Program

To serve customers’ repair and maintenance needs, Daktronics offers both an Exchange

Program and a Repair & Return Program.

Exchange Program

Daktronics unique Exchange Program is a quick service for replacing key parts in need of

repair. If a part requires repair or replacement, Daktronics sends the customer a replacement,

and the customer sends the defective part to Daktronics. This decreases display downtime.

Before Contacting Daktronics

Insert important part numbers here:

____________________________________________________________

____________________________________________________________

____________________________________________________________

Fill in these numbers before calling Customer Service:

Display Serial Number: _____________________________________________

Display Model Number: _______KE-1010 DakTicker 7.62 mm

Contract Num

ber: ___________________________________________________

Date Installed: ______________________________________________________

Location of Disp

Daktronics Customer ID Num

lay: _________________________________________________

ber: _____________________________________

____________

Parts Replacement 25

Page 32

To participate in the Exchange Program, follow these steps:

1. Call Daktronics Custom

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the part which is being replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out

c. Shi

3. A charge will be m

service agreement is in place.

In most circumstances, the replacement part will be invoiced at

4. If the replacem

working days or the full purchase price will be charged.

If the equipment is still defective after the exchange was made, please contact

Customer Service immediately. Daktronics expects immediate return of an exchange

part

if it does not solve the problem. The company also reserves the right to refuse

parts that have been damaged due to acts of nature or causes other than normal wear

and tear.

and attach the enclosed UPS shipping document.

p the part to Daktronics.

ent part does not solve the problem, return the part within 30

er Service: 866-343-3122

ade for the replacement part immediately, unless a qualifying

the time it is shipped.

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Phone: 866-343-3122 Fax: 605-697-4444

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item

Electronic components, such as printed circuit boa

antistatic bag before boxing. Daktronics does not recommend Styrofoam peanuts in

packaging.

4. Enclose:

• your name

• address

• phone number

• the RMA number

• a clear description of symptoms

Shipping Address

Daktronics Customer Service

PO Box 5128

331 32nd Avenue

Brookings, SD 57006

carefully to prevent damage during shipment.

rds, should be placed in an

26

Parts Replacement

Page 33

Appendix A: Reference Drawings

Drawings are inserted here according to this list, with generic drawings first, followed by

Component Layout, Schematic, and Shop Drawings. Under each category, drawings are inserted by

matrix size.

General Drawings

Mounting Drawing, Ceiling, KE-1010-16x***-2.1

Shop DWG, Mounting, GEN II, Splice Bar, KE-1010

Concept System Riser Diagram TCP/IP

Concept System Riser Diagram RS/422

Mounting Clip, GEN II, KE-1010-**x***-7.62

Power Specs, Gen II, KE-101*-16x***,24x***, 2-16x***

Shop DWG, Horiz Wall Mount, GEN II KE-1010 Ticker

Shop DWG, Vert Wall Mount, GEN II

Drawings listed by matrix size:

Component Layout, KE-1010-16x***-7.62............................................................. Draw

Component Layout, KE-1010-24***-7.62

Component Layout, KE-1010-2-16x***-7.62

Schematic: GEN II, KE-101*-**x120-7.62-RG

Schematic: GEN II, KE-101*-**x160-7.62-RG

Schematic: GEN II, KE-101*-**x200-7.62-RG

Schematic: GEN II, KE-101*-**x240-7.62-RG

Schematic: GEN II, KE-101*-**x280-7.62-RG

Schematic: GEN II, KE-101*-**x320-7.62-RG

Schematic: GEN II, KE-101*-**x360-7.62-RG

Schematic: GEN II, KE-101*-**x400-7.62-RG

Shop DWG, GEN II, KE-1010-16x120/160/200/240

Shop DWG, GEN II, KE-1010-16x280/320/360/400

Shop DWG, GEN II, KE-1010-2-16x280/320/360/400

Shop DWG, GEN II, KE-1010-2-16x120/160/200/240

Shop DWG, GEN II, KE-1010-24x120/160/200/240

Shop DWG, GEN II, KE-1010-24x280/320/360/400

................................................... Drawing A-118572

............................................ Drawing A-118728

............................................................... Drawing A-229840

............................................................... Drawing A-229912

......................................................... Drawing A-233464

........................................ Drawing A-234168

........................................ Drawing A-234483

KE-1010-24x*** ......................................... Drawing A-234529

ing A-302699

.............................................................. Drawing A-302700

......................................................... Drawing A-302701

....................................................... Drawing B-234114

....................................................... Drawing B-234115

....................................................... Drawing B-234122

....................................................... Drawing B-233964

....................................................... Drawing B-234634

....................................................... Drawing B-234635

....................................................... Drawing B-234636

....................................................... Drawing B-234637

............................................. Drawing B-237159

............................................. Drawing B-118077

.......................................... Drawing B-210277

.......................................... Drawing B-237160

............................................. Drawing B-237161

............................................. Drawing B-214329

Reference Drawings 27

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Appendix B: Signal Converter

Signal Converters and Loop-back Testing for Direct Connections

The following table gives the typical state of the signal converter when the LEDs are either on or off.

Refer t

o Figure 25 for an illustration of the signal converter and the location of the various

components.

LEDs Typical States Troubleshooting

ON Signal Converter (SC) is receiving power

Power

TX

RX

TX/RX

OFF

On Steady

OFF

Steady

Brief

Flicker

ON Steady

OFF

Steady

Brief

Flicker

ON Steady

Signal Converter is not receiving power Check power/Replace fuse

Internal 1 AMP fuse is bad Replace fuse

Signal Converter is not connected to a

serial port

1. Serial port or serial cable is bad

2. Computer COM port is in sleep mode

Normal state, Signal Converter is not

transmitting data

SC is transmitting data

1. Field cabling between Signal Converter

and display is bad

2. Is connected to display output jack or

terminated incorrectly

3. Bad COM port is on display controller

Normal state, Signal Converter is not

receiving data

SC is receiving data

(If serial cable is connected) Bad Signal

Converter

Connect to open computer

COM port

1. Try another port or replace

serial cable

2. Communicate with display

1. Eliminate cabling by

disconnecting wire/cable

from SC to dis

2. Check connections and

terminations

3. Eliminate by disconnecting

wire/cable to display

controller

Replace Signal Converter

play controller

Signal Converter 29

Page 58

RS-422 Wire Signal Converter

The

following tables list the jack pin-outs for a wire signal converter:

PIN OPERATIO

Figure 25: RS-232 to RS-422 Signal

Converter

PIN OPERATION

1

2

3

4

5

6

J1 – 25 Pin DB-F

PIN OPERATION

2

3

7

J4 and J5 –

Phoenix

GND

1

RX-P (in)

2

RX-N (in)

3

TX-P (out)

4

TX-N (out)

5

GND

6

J2 and J3 –

RJ/11

GND

TX-N (out)

TX-P (out)

RX-N (in)

RX-P (in)

GND

TX-P (out)

RX-P (in)

GND

N

30 Signal Converter

Page 59

RS-422 Loop-Back Test (Indoor/Outdoor Displays)

All indoor displays and some outdoor displays (AE-3010, AF-3010, AF-3020, and X-1000) use

RJ11 plugs or connectors. In those cases, a “Network Cable Tester” is provided to conduct

the test.

The network cable tester is used to test for two things:

• verify that a flipped RJ11 cable is being used.

• verify that a good connection is made from a computer or signal converter.

The use of a flipped (reversed) or straight cable can be determined visually. Use the figures

below as a guide, or use the Network Cable Tester box for assistance.

Figure 26: Flipped Cable (Reversed)

Figure 27: Straight Cable

1. Plug one end of the flipped cable into the output from the computer or signal

converter.

2. Plug one end of the flipped cable into J2 (Loopback Connector) on the network cable

tester box.

3. When both ends are

connected, perform the loopback test using the Venus 1500

software as described in

Section 1.4.

Figure 28: Network Cable Tester

Signal Converter 31

Page 60

Electrical and Signal Information

WARNINGS:

• Never inst

• Never touch uni

been disconnected at the network interface.

• Avoi

There may be a remote risk of electrical shock from lightning.

• To reduce the risk of fire, use only 26AWG or larger telecommunication line cord.

• This product is to be used with UL and c-UL listed computers.

Electrical Ratings

The Signal Converter is rated for either 120 or 240 VAC power in and a maximum draw of 5

watts. Refer to the parts descriptions in Section 2.3.

Power Disconnect

The power cord serves as the disconnect device and the socket outlet must be installed near

the equipment and must be easily accessible.

Parts Listing

The following parts may need replacing during the life of the component.

Servicing should be conducted by qualified personnel only.

all telephone wiring during a lightning storm.

nsulated telephone wires or terminals unless the telphone line has

d using a telephone (other than a cordless type) during an electrical storm.

Part Description Part Number

RS-232-422 Signal Converter, 120 V 0A-1127-0255

RS-232-422 Signal Converter, 240 V 0A-1127-0257

Fuse; AGC-1, 1A, Glass Tube 250 V F-1019

6 Pin Fem, 5 mm, TB Mate, Screw P-1051

Environmental Rating

The signal converter is made for indoor operations and is rated for indoor use only.

32 Signal Converter

Page 61

Mounting Instructions

The signal converter can be either wall or table mounted. Do not mount the signal converter

from the ceiling or the underside of a table.

To mount the signal converter, refer to drawing B-200645. Secure the signal converter using a

screw through the mounting holes at the back of the enclosure. Do not fully tighten the

screws.

Figure 29: Signal Converter Enclosure

Signal Converter 33

Loading...

Loading...