Page 1

HOIST SYSTEM

INSTALLATION

GUIDE

Page 2

HOIST INSTALLATION MANUAL

Daktronics Automated Theatre Rigging System

Manufacturer contact

7200 Rawson Road

Victor, New York 14564

tel 866-486.7835 585-924-5000

fax 585-924-0545

email sales@daktronics.com

www.daktronics.com/rigging

Page 3

TABLE OF CONTENTS

Introduction

Warning and Compliance with Regulations ......................................2

Tool List and Hoist Overview ...........................................................3

Mechanical Installation

When the Hoists Arrive

Unloading Vortek Hoists ............................................................4

Proper Staging of Vortek Units ....................................................5

Uncrating Vortek Hoists .............................................................6

Using the Installation Blocks ............................................................6

Using Hoist Lifting Clips and Installing Backbone Stiffeners .................7

Attaching the Backbone Stiffeners and Installing the Hoist ...................8

Completing the Vortek Hoist Installation ...........................................9

Installing Vortek Loft Blocks ............................................................10

Routing the Lift Lines ....................................................................11

Terminating Wire Rope Cables ......................................................12

TABLE OF CONTENTS

1

Page 4

INTRODUCTION

This guide assists with the most common Daktronics installations and scenarios showing basic mechanical

layouts.

Each installation will have its own layout and drawings as specifi ed by the Architect and Theater Consultant

that works best for the theater involved. Refer to the drawings for specifi c information that may be needed.

If any questions arise, please contact Daktronics at:

585-924-5000

8am to 5pm, Monday through Friday EST/EDT

When calling please specify whether the question refers to an electrical or mechanical rigging issue.

Electrical Safety—General Warning

All Warning notes contained in this manual indicate information that may endanger personnel.

WARNING

WARNING

The voltages used in the motor drive and master control panels can cause severe electrical

shock and/or burns. Extreme care is necessary at all times when working with the motor

drives. Only authorized personnel should carry out any installation, commissioning, or

maintenance of the electrical systems. All drive systems have been tuned at the factory

and will not require any additional alteration or adjustment by the owner’s personnel

unless specifically authorized by a Daktronics representative.

Before working on any of the Vortek hoists, the main electrical disconnect must be

turned off and locked out according to OSHA regulations 29 CFR 1910.147.

Compliance with Regulations

The Vortek system complies with the relevant European directives required for the CE mark, including:

98/37/EC: Machinery Directive

73/23/EEC: Low Voltage Directive

89/336/EEC: Electromagnetic Compatibility

Independent reviews/tests in support of above compliance

EN55022 / Class A Radiated and Conducted Emissions

EN61000-4-2 / Electrostatic Discharge

EN61000-4-6 / Conducted Susceptibility

EN60950, 60204 / Safety Review

Standard products are ETL listed to the following UL Standards

UL508A - UL Standard For Industrial Control Panels

UL1340 - UL Standard For Hoists.

2

Page 5

Vortek® Hoist Installation Tool List

1. 9/16" Combination Wrench

2. 3/4" Combination Wrench

3. 3/8" drive 7/16" Socket

4. 3/8" drive 1/2" Socket

5. 3/8" drive 9/16" Deep Well Socket

6. 1/2" drive 3/4" Deep Well Socket

7. 3/8" drive torque wrench

8. 3/8" drive ratchet

9. 1/2" drive ratchet

10. 18" long 3/8" drive “wobble” extension or universal

11. 1/4" Allen Wrench

12. 3/32" Allen Wrench

13. Cordless drill with 3/8" drive attachment

14. Tape Measure

15. Metal Banding Cutter

16. Nicopress Tool

17. Cable Cutter

18. Electrical Tape

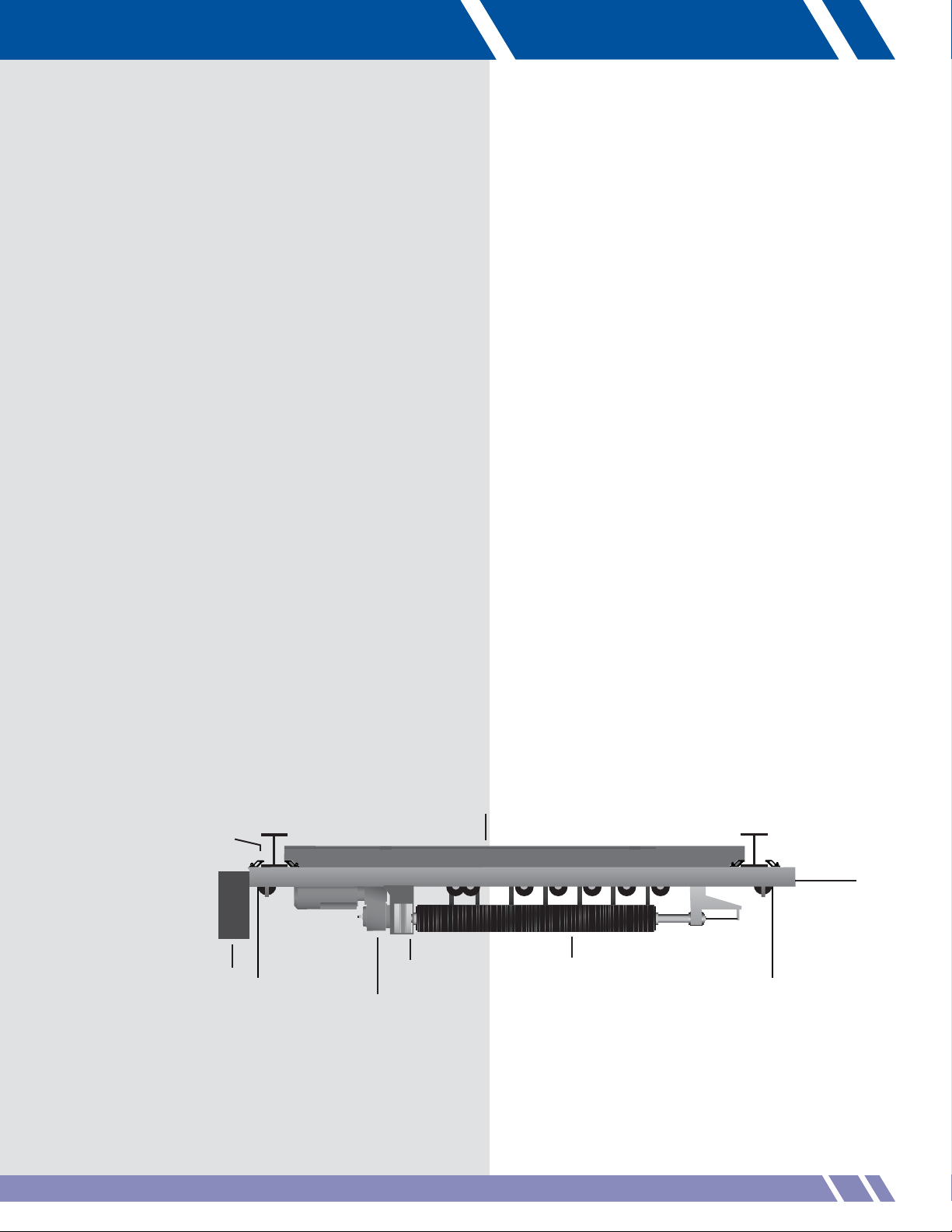

Basic Hoist Components

Beam clamps

ˇ

MOTOR

END

ˆ

Power panel

Cable drop

ˆ

Gearbox/Motor

Backbone stiffeners

ˇ

ˆ

Vortek load brake

ˆ

Drum

TAIL END

Cable drop

SAFETY INFORMATION

INTRODUCTION

Cables

out end

3

Page 6

MECHANICAL INSTALLATION

Unloading Vortek Hoists

When the truck(s) arrives with the Vortek hoists,

unloading and getting them situated for either

storage or immediate installation will make

the installation process much easier.

Each Vortek hoist crate has a packing sheet

(Figure 1) attached that specifi es what type of

unit it is and the quantities supplied. Be sure to note

the accessory box shipped together with the crates,

typically one or more per project.

Each crated Vortek hoist weighs approximately 1100

lbs. (500 kg) There are only two places where the

Vortek crates can be lifted with a forklift.

The fi rst lifting point is from the end (Figure 2) with

a forklift that has fork tines that are at least 41" long,

a maximum of 8-1/2" wide and 2" thick to use this

location.

Insert the forks completely into the slot. Raise the

forks and the rack to lift the crate.

The second lifting point is from the side (Figure 3).

When using this location, spread the forks as wide

as possible. Either side can be used to lift the crates.

The Vortek hoists are not balanced at

center so care must be taken when

moving the units.

Each Vortek crate will be labeled with the model

number and/or set number (Figure 4). Organizing

the hoists as they are unloaded may help during

installation.

Figure 1: Packing sheet and accessory box

Figure 2: Lift end of crate

Figure 3: Lift center of crate

Figure 4: Crate label

4

Page 7

Figure 5: Typical hoist layout

Figure 6: Nameplate

Figure 7: Model number label

Follow the layout plan in order to place the crates

in the right position. Figure 5 shows one possible

way the Vortek hoists might be installed.

The layout, nameplate and label on the side of the

crate identify model number placement within the

installation.

Once out of the crate, Vortek Classic hoists are

virtually indistinguishable from each other except

for the nameplate on top of the electronics cabinet

(Figure 6).

Each hoist with Pro Series or M Series controller

has a pre-programmed network address and a

set number that is attached to the side of the hoist

(Figure 7). Please refer to the set plan layout for

the proper location.

If the wrong type of unit is installed in a

position that is specifi ed for another, it will

have to be uninstalled and moved to the

correct position.

INSTALLATION

5

Page 8

Uncrating the Vortek Hoist

The wooden shipping container is a two-piece

unit. The top portion that consists of the top,

ends, and sides are one unit (Figure 8). There

is a bottom skid that the Vortek hoist rides on.

Simply clip the banding and lift the top portion

of the crate off for easy unpacking.

Please return the shipping crates

to Daktronics for re-use.

Cut the remaining banding and remove the

poly sheeting from the hoist (

Figure 9). There

will be either two backbone stiffeners loosely

attached on top of the unit or two extra beam

clamp assemblies pre-installed at the factory.

This will depend on a two or three-beam

installation.

Using the Installation Blocks

Figure 8: Lift crate top off bottom skid

Daktronics offers optional installation blocks

that will assist in lifting and mounting the Vortek

hoists. These may be purchased from Daktronics

if needed. Figure 10 illustrates mounting of

the installation blocks.

The installation blocks go on the offstage side

and the onstage side of the steel beams. This

allows the space for the backbone stiffeners to

be placed into the backbone channel.

The installation blocks require a minimum of 9"

of adjacent space on the steel beams as the

hoist is lifted into place (Figure 11).

Figure 9: Cut banding and remove sheeting

Figure 10: Installation block with pivoting sheave and fixed sheave

Figure 11: Maintain spacing between steel beams

6

Page 9

Figure 12: Set clip into the backbone channel

Figure 13: Lift line attached to clip

Figure 14: Beam clamps with hoist

Figure 15: Rod through beam clamp

Using Hoist Lifting Clips

Daktronics supplies hoist lifting clips with each

hoist installation. The hoist lifting clips install

into the backbone to connect the hoist to the

lifting cables.

Figure 12 shows a clip in the backbone

channel prior to being rotated into the proper

lifting position then locked into the channel.

Verify that the bolts are set and the clip can

not slip out of the backbone channel. Prior to

lifting, torque the bolts to 10ft/lb to secure

the clips.

Directly attach lift lines to the hoist lifting clip

with a 3/16" thimble and Nicopress swage

(Figure 13).

Each installation is unique. Pre-measure the wire

rope to be sure to have enough to go the total

distance of the lift.

Attaching the Backbone Stiffeners

Most Vortek hoist installations require the use

of backbone stiffeners. There may, however,

be three sets of beam clamps instead. Refer to

Figure 14. For 3-beam installations, skip the

following steps and begin mounting the hoist.

For 2-beam installations, there will be two

aluminum backbone stiffeners located on top of

the hoist with two 3/8" threaded rods, 4 nuts

and two steel clamps. Assemble them to the

hoist as follows:

1. Turn the backbone stiffener on edge with

the chamfered corner down and towards

the beam clamps then slide under the

center lip of the backbone. Repeat

this process for the opposing side.

2. Run the threaded rod through the beam

clamp while threading the nut onto the lead

end (Figure 15). Continue pushing the

rod into the hole on the backbone stiffener

and start threading the second nut onto the

lead end. The threaded rod will run into

and through the second beam clamp.

INSTALLATION

INSTALLATION

5

7

Page 10

3. Tighten both nuts onto the backbone

stiffener as shown. Make sure the threaded

rod is centered across the backbone so

that it does not stick out of either side of

the beam clamps (Figure 16).

If the beam clamps on the power panel

end of the hoist are installed in the very

fi rst position, the installation blocks and

lifting clips may have to be used on the

inside of the support I-beams. In this

situation, the backbone stiffeners will have

to be installed after the hoist is lifted and

partially clamped in place.

4. To hold the tops of the backbone stiffeners

together, place a clamp onto a single side

and slide it 6" past the end of the second

channel. Repeat for the other end of the

stiffeners with the 2nd clamp (Figure 17).

Do not tighten the set screw on these clamps at

this time.

Figure 16: Tighten both nuts to backbone

stiffener

Mounting the Vortek Hoist

The hoist weighs approximately 650 lb

(295 kg) out of the crate. Take precautions

when lifting, making sure that the area is

roped off and unnecessary personnel are

away from the area.

• Once the installation blocks are mounted and

tightened and the hoist lifting clips are securely

in place on the hoist backbone, lift the hoist

out the skid just a few inches.

• Double check that all connections are secure

at the installation blocks and hoist lifting clips.

Make sure that the cables do not get caught

on anything as the hoist is raised.

• When lifting the hoist to the level of the

I-beams, stop just short so that the beam

clamps can be adjusted for the spacing

of the I-beams (Figure 18). Raise the

hoist into position so the backbone is

about 1/2" below the I-beams and start

tightening the clamps using the 9/16"

socket and cordless drill set at MINIMUM

torque.

Figure 17: Clamp on backbone stiffener

Figure 18: Clamp on I-beam

8

Page 11

Figure 19: Secure I-beam clamps

Figure 20: Beam clamps

Tighten the clamps until they just contact

the top of the lower fl ange of the I-beam.

At this point, the lifting cables can be

slackened slightly. It is helpful to use a

cordless drill with a wobble extension drive

and socket to tighten beam clamps. Spread

a light lubricant on the bolt threads and

channels before tightening the bolts.

• Confi rm the placement of the hoist, and

make any fi nal adjustments by sliding the

hoist upstage or downstage on the I-beam

as needed.

For some installations, this may be the

technique needed to fi t hoists into areas

without enough room to use the installation

blocks.

If the backbone stiffeners were not

installed earlier, please do so now.

• With placement confi rmed, tighten the

beam clamps fi rst by alternating between

the two clamps until the hoist backbone

is contacting the I-beam. Repeat for the

onstage set of beam clamps (Figures 19

and 20).

Figure 21: Tighten clamps to the backbone

Figure 22: Installed hoist

• Tighten the beam clamp bolts to 17-20 ft/lb

maximum.

As the beam clamps are tightened, the

backbone stiffeners are drawn onto the

I-beam for additional support. The threaded

rod bends and applies constant pressure

to the backbone stiffeners to minimize

vibration and noise.

• When all beam clamps are tightened and

torqued to the proper specifications, the

5/16 x 18 socket head screws on the

sliding beam clamps must be tightened

to 10 ft/lb, securing the clamps to the

backbone (Figure 21).

• With the hoist in place on the I-beam,

tighten the set screws on the two backbone

stiffener clamps.

Upon completion, the installed Vortek hoist will

look similar to Figure 22.

INSTALLATION

9

Page 12

Installation of Loft Blocks

Two types of Vortek loft blocks, multi-line

and single line (Figure 23), mount to the

I-beams using aluminum clamps as shown

in Figure 24.

1. Determine the center of each hoist (4.5"

from the edge of the hoist) and snap a

chalk line to the other side of the stage on

each beam position confirming that it is the

same location at the hoist center (Figure

25).

All multi-line loft blocks will mount on the

beams closest to the hoist. The single line

block will mount on the beam furthest

away.

2. Mount the loft blocks by aligning the

grooved drop sheave with the hoists’

centerline and tighten the beam clamps.

Repeat this process for all loft blocks

(Figure 26).

Figure 23: Multi-line and single line

loft blocks

Figure 24: Loft Block with clamps

10

Figure 25: Verify center hoist line

Figure 26: Center sheave

Page 13

Figure 27: Alternating hoist layout

Multi-line block

Dead-off

Single line sheave

Due to wider I-beam fl ange on some

installations, the Loft Blocks may contain a

spacer located against the inside surface of the

Loft Block hooks. These spacers will rest against

the I-beams once tightened. Some adjustment

may be necessary to center the cable drop

under the main web of the beam.

Figure 27 shows alternating hoists in one

possible layout. In this configuration, it may be

easier to install the opposing loft blocks prior

to installing the adjacent hoist. Some Vortek

hoist configurations maximize lifting capacities

by using double purchased loft blocks. A “2”

after the model number, such as P-12180-2 or

S2020-2 will designate these Vortek hoists.

Figure 28 is a double purchase multi-line

loft block, single line sheave at the batten

connection and a dead-off attachment point at

the I-beam.

Batten attachment point

Figure 28: Double purchase block

Figure 29: Attaching lift line wire rope

Routing the Lift Lines

The Vortek hoists have up to 7 lift lines per

batten. Depending on the installation, all lift

lines may come out of the end of the hoist or

there may be one or two cables coming directly

out of the bottom of the unit at either end.

The order of the lift lines coming out of the

end of the hoist start being the shortest lift line

(closest loft block) and the longest lift line is

farthest from the center of the hoist (farthest loft

block). Daktronics ships all wire ropes equal to

the longest length.

Figure 29 illustrates a unit with 5 lines: 2 lines

drop directly out of the hoist and 3 lines come

out of the onstage end. Lift lines 3,4 and 5

come out of the end (L. to R.) as shown.

When running the lift lines into the loft blocks,

start with the wire rope at the center of the

Vortek hoist and run it to the closest loft block.

Do the same with the next wire rope to the next

closest block until all of the wire rope has been

run through the loft blocks.

INSTALLATION

11

Page 14

Figure 30 illustrates the loft block as seen

from the Vortek hoist.

Using the example in Figure 29, the first loft

block closest to the center (#3) will feed onto

the load bearing sheave. The remaining wire

ropes 4 and 5 will pass through the block.

Be careful not to have the through cables

cross over each other when routing them.

The pass-through idler area on the block

is not load bearing. Make sure that the lift

line drops onto the load sheave for each

drop.

The last loft block will be a single line sheave

and will not contain a pass-through area.

Terminating the Wire Rope Cables

The cables have been fed through the loft

blocks assuring that there are no crossed lines

and the excess is on the ground.

In most situations the theater consultant or

architect will specify a trim height for the

battens to reside when at their lowest point. Be

sure to compensate for all attachment hardware

prior to cutting the cables to their fi nal length.

Do not cut the wire rope of double purchase

units. These must be terminated at the

I-beams on the dead-off connection.

Vortek hoists use 3/16" wire rope for all

standard installations. A 3/16" Nicopress

copper sleeve with thimble is used to terminate

the cable end to the turn buckle or trim chain.

Daktronics recommends that only copper

sleeves or zinc coated copper sleeves

be used for termination. Aluminum

sleeves are NOT acceptable for cable

terminations.

Be aware of minimum height requirements for

each batten. Double piped electrical battens

will need to have their cable terminations done

higher than normal single pipe battens.

Confirm the number of crimps required for

the copper sleeve by reviewing the Nicopress

crimp tool manual.

Figure 30: Load bearing sheave

12

Page 15

www.vortekrigging.com

7200 Rawson Road Victor, New York 14564 USA

tel 585-924-5000 fax 585-924-0545

www.daktronics.com/rigging email sales@daktronics.com

Copyright © 2010 Daktronics DD1697567

DD1697567 10 October 2009

Loading...

Loading...