Page 1

Rear-Ventilated GalaxyPro® GP3 Series

Installation and Operation Manual

DD1931807 Rev 7 – 14 February 2013

201 Daktronics Dr. PO Box 5128 Brookings SD 57006

Tel 866-343-3122 Fax 605-697-4700

www.daktronics.com

Page 2

DD1931807

Product 1630

Rev 7 – 14 February 2013

DAKTRONICS, INC.

Copyright 2011 – 2013

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher assumes

no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be reproduced

or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying, taping, or

information storage and retrieval systems – without written permission of the publisher.

GalaxyPro®, and Venus® are trademarks of Daktronics, Inc. Windows®, Explorer®, and Silverlight™ are trademarks of Microsoft® Corporation.

Java™ is a trademark of Oracle Corporation. All other trademarks are the property of their respective companies

Page 3

Table of Contents

Section 1: Introduction .......................................................................................................................1

1.1 Limitation of Liability .....................................................................................................................1

1.2 Contact Information ........................................................................................................................1

1.3 Model Number Guide ...................................................................................................................1

Section 2: Installation Preparation ....................................................................................................3

2.1 Pre-Installation Checklist ...............................................................................................................3

2.2 Structure Requirements ..................................................................................................................3

2.3 Electrical Requirements ..................................................................................................................3

Main Disconnect .......................................................................................................................4

2.4 Required Tools .................................................................................................................................4

Section 3: Display Installation ..........................................................................................................5

3.1 Display Installation .........................................................................................................................5

Section 4: Section Splicing ................................................................................................................7

4.1 Display Section Numbering...........................................................................................................7

4.2 Section Splicing Instructions..........................................................................................................7

Section 5: Electrical Installation ........................................................................................................9

5.1 Power Connection ...........................................................................................................................9

5.2 Earth Ground Installation ............................................................................................................10

Section 6: System Start-Up Procedure ...........................................................................................11

6.1 Boot Sequence ................................................................................................................................11

6.2 Start-Up Checklist .........................................................................................................................11

Section 7: Signal Cable Installation ................................................................................................13

7.1 Primary-Mirror Signal Connection .............................................................................................13

7.2 Sectional Display Signal Connections ........................................................................................13

Section 8: Network and Communication Installation ....................................................................15

8.1 Network and Communication Installation Dos .......................................................................15

8.2 Requirements For Communication Through A Network ......................................................15

8.3 Connecting To A Network And Using A DHCP Name ..........................................................15

Network Requirements .........................................................................................................15

Installation/Start-up Steps ...................................................................................................15

Table of Contents

i

Page 4

8.4 Connecting To A DHCP Network And Using A Static IP Address ......................................16

Network Requirements .........................................................................................................16

Conguration Steps ...............................................................................................................16

8.5 Connecting To A Network And Using A Static IP Address ...................................................16

Network Requirements .........................................................................................................17

Conguration Steps ...............................................................................................................17

8.6 Connecting To A Computer Using A Static IP Address..........................................................17

Requirements ..........................................................................................................................17

Conguration Steps ...............................................................................................................18

8.7 Standard Communication Options .............................................................................................18

Section 9: Venus

®

1500 Software Conguration ............................................................................19

9.1 Software Installation .....................................................................................................................19

9.2 System Requirements ...................................................................................................................19

9.3 Software Conguration ................................................................................................................19

Section 10: Display Maintenance ......................................................................................................21

10.1 Internal Display Access ................................................................................................................21

10.2 Ventilation System ........................................................................................................................22

Filter Inspection, Cleaning, and Replacement ...................................................................22

Fans ..........................................................................................................................................22

10.3 Display Face Cleaning ..................................................................................................................22

Wet Cleaning Process ............................................................................................................22

Dry Cleaning Process ............................................................................................................23

Section 11: Display Troubleshooting ................................................................................................25

11.1 Power and Signal Routing ...........................................................................................................25

Power Routing ........................................................................................................................25

Signal Routing ........................................................................................................................26

11.2 Player Diagnostics .........................................................................................................................27

11.3 PLR Diagnostics ............................................................................................................................27

PLR Self-Test ...........................................................................................................................27

11.4 Module and Power Supply Diagnostics ....................................................................................28

Module Self-Test ....................................................................................................................28

Section 12: Replacement Parts List .................................................................................................29

Section 13: Replacing Parts ..............................................................................................................31

13.1 Module and Power Supply Replacement ..................................................................................31

13.2 Player Replacement.......................................................................................................................31

13.3 PLR Replacement ..........................................................................................................................32

ii

Table of Contents

Page 5

Section 14: Daktronics Exchange and Repair & Return Programs ...............................................33

14.1 Exchange Program ........................................................................................................................33

Before Contacting Daktronics ..............................................................................................33

14.2 Repair & Return Program ............................................................................................................34

Shipping Address...................................................................................................................34

14.3 Daktronics Warranty and Limitation of Liability .....................................................................34

Appendix A: Reference Drawings .......................................................................................................35

Appendix B: Daktronics Warranty and Limitation of Liability ..........................................................37

Table of Contents

iii

Page 6

Section 1: Introduction

This manual provides the necessary information to install and service a GalaxyPro® GP3 series display.

Please read and understand all steps in this manual before beginning the installation process.

For a smooth installation, complete the steps in this manual in order. Contact Daktronics Technical

Support with any questions before or during the installation process.

1.1 Limitation of Liability

The factory warranty will be nullied if:

• The display is not installed according to the steps in this manual

• Proper electrical service is not provided or the display is not grounded properly

• Unauthorized modications are made to the display, display cabinet, or the control

system

Refer to AppendixB at the end of this manual for the full Daktronics Warranty and Limitation of

Liability.

1.2 Contact Information

For assistance before, during, or after display installation, please contact Daktronics Technical

Support: 800-DAKTRONICS (800-325-8766).

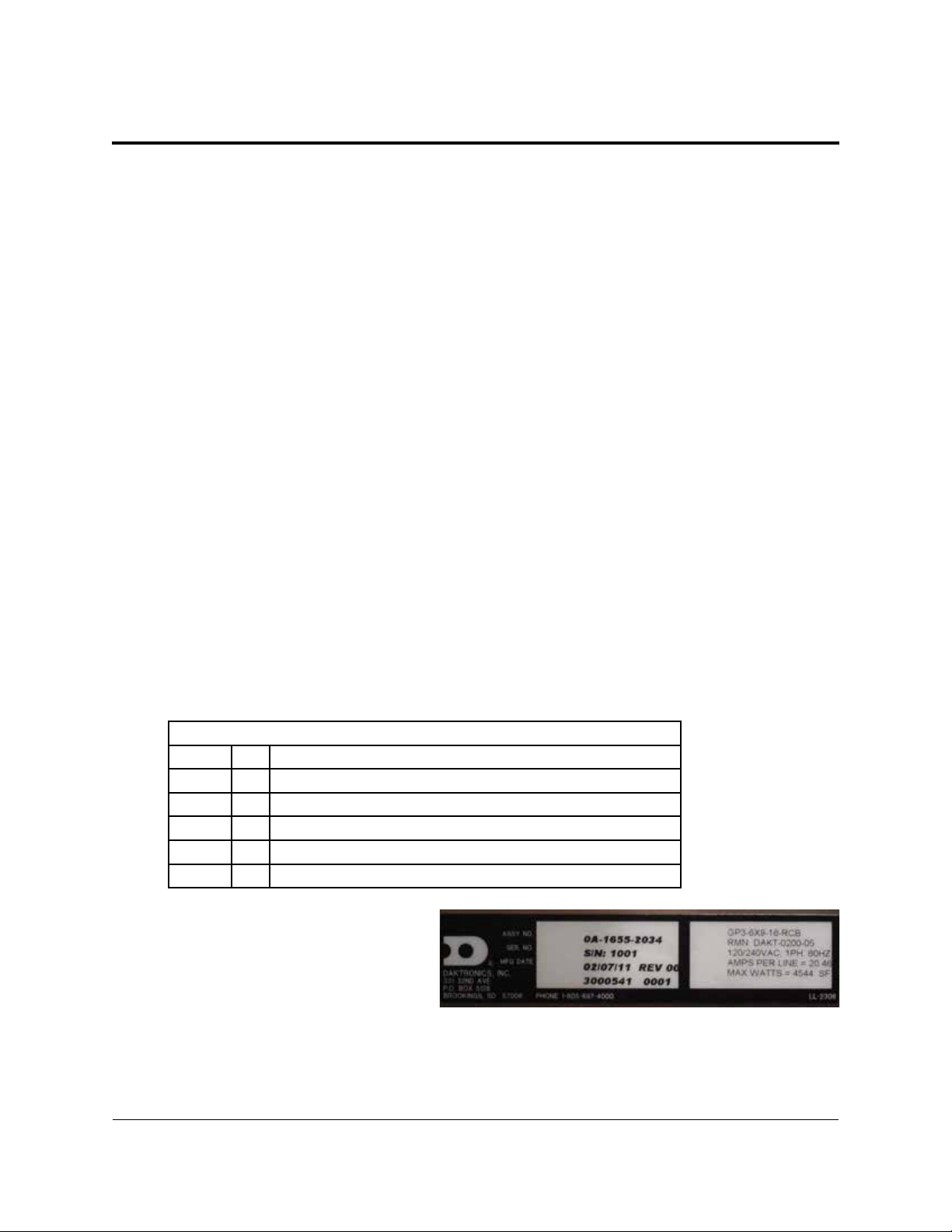

1.3 Model Number Guide

GalaxyPro® GP3 model numbers are dened as follows:

GP3-RxC-M-RGB-F

GP3

R

C

M

RGB

F

Figure1 shows a label on the display’s

back where the model number and

power requirements are located.

Displays are either single face (SF) or

two view (2V). In 2V units, the rst

display is referred to as the primary

and the second is called the mirror. If the second display is mounted more than 15 feet (4.5 m)

from the primary display, two primary displays are used.

= Outdoor GalaxyPro® display

= Number of pixel rows high

= Number of pixel columns long

= Pixel pitch in millimeters

= LED Color: R (Red), G (Green), B (blue)

= Face setup: SF – Single Face or 2V – Primary/Mirror

Figure 1: Display Label

Introduction

1

Page 7

A typical display system consists of a Windows

®

-based computer running Venus® 1500 software

and one or more displays. The Venus® 1500 software package runs on an IBM®-compatible

computer. Refer to the Venus®1500softwarehelple for operation instructions.

2

Introduction

Page 8

Section 2: Installation Preparation

This section explains what to consider before installing a Daktronics GalaxyPro® GP3 display.

Follow all guidelines and safety precautions in this manual when installing the display. Do not modify

the display or control system in any manner without the written permission of Daktronics’ engineering

staff.

Any unauthorized modications will nullify the display warranty.

2.1 Pre-Installation Checklist

• The display was not damaged during shipping

• The mounting structure will provide a straight and square mounting frame for the display

• The support structure can carry the weight of the display and meets local and national codes

• There is clearance at the back of the display to allow unobstructed airow – refer to shop

drawing for ventilation specications

• Ensure proper power is available at sign structure – refer to shop drawing for display power

requirements

• The display cabinet has no holes (accidental or intentional) that will allow water to enter the

display

• All display modules are fully latched into the display cabinet

2.2 Structure Requirements

Support structure design depends on mounting method, installation height, display size, and

weight. Because every installation site is unique, Daktronics approves no single procedure for

mounting displays.

Things to consider prior to installation:

• Display structure and mounting must not obstruct airow - refer to shop drawing for

ventilation space requirements

• All T-clips must be used for mounting to structure

• Light sensor must not be obstructed to maintain proper display dimming

For additional questions about display mounting requirements and specications, refer to the

display shop drawing or contact Daktronics Technical Support at 800-DAKTRONICS (800-325-

8766).

2.3 Electrical Requirements

ImportantNote: Size circuits according to local and national codes so the power distribution

system delivers full-load power to the display while maintaining a voltage within 5 percent of the

nominal voltage.

Installation Preparation

3

Page 9

Main Disconnect

Daktronics requires installation of a power disconnect switch with the display so all ungrounded

conductors can be disconnected near the point of power connection.

2.4 Required Tools

The following table lists the minimum tools Daktronics recommends having on site for each

installation. Daktronics only provides the specialized tools needed to complete the installation.

Daktronics Provided Customer Provided

Splice Wrench Hex Head Wrenches – 1/8” and 3/16”

Flathead and Phillips Head Screw Drivers

Crane or Lift Truck

Step Ladders

®

Computer with Venus

Ratchet and/or Impact Wrench –

Socket Set – Sizes up to 1

Tape Measure

Utility Knife

1500 Software and Internet Explorer® Installed

11

/16”

1

/16” Needed

4 Installation Preparation

Page 10

Section 3: Display Installation

This section explains the steps necessary for proper lifting and installation of the display to the sign

structure.

Follow all guidelines and safety precautions in this manual when installing the display.

Do not modify the display or control system in any manner without the written permission of Daktronics’

engineering staff. Any unauthorized modications will nullify the warranty.

Display Installation Dos

• Inspect the display for damage prior to installation

• Use all T-clips for mounting

• Provide an adequate support structure that is straight and level

• Provide adequate ventilation that meets or exceeds display specications.

Note: Shrouding may be used, but proper ventilation must be placed into the shrouding.

• Use all lift eyes when lifting the display

• Install all splice plates and splice T-clips when applicable

Display Installation Don’ts

• Drill holes into the display

• Block display ventilation system

• Use the lift eyes for display mounting

• Move clip angles outside the designated zones indicated by label

3.1 Display Installation

1. Use a utility knife to

carefully cut away all

of the white packaging

material from the display.

Be careful not to damage

the face of the display or

LEDs.

2. If the display is multi-

sectional, refer to Section

4 before continuing.

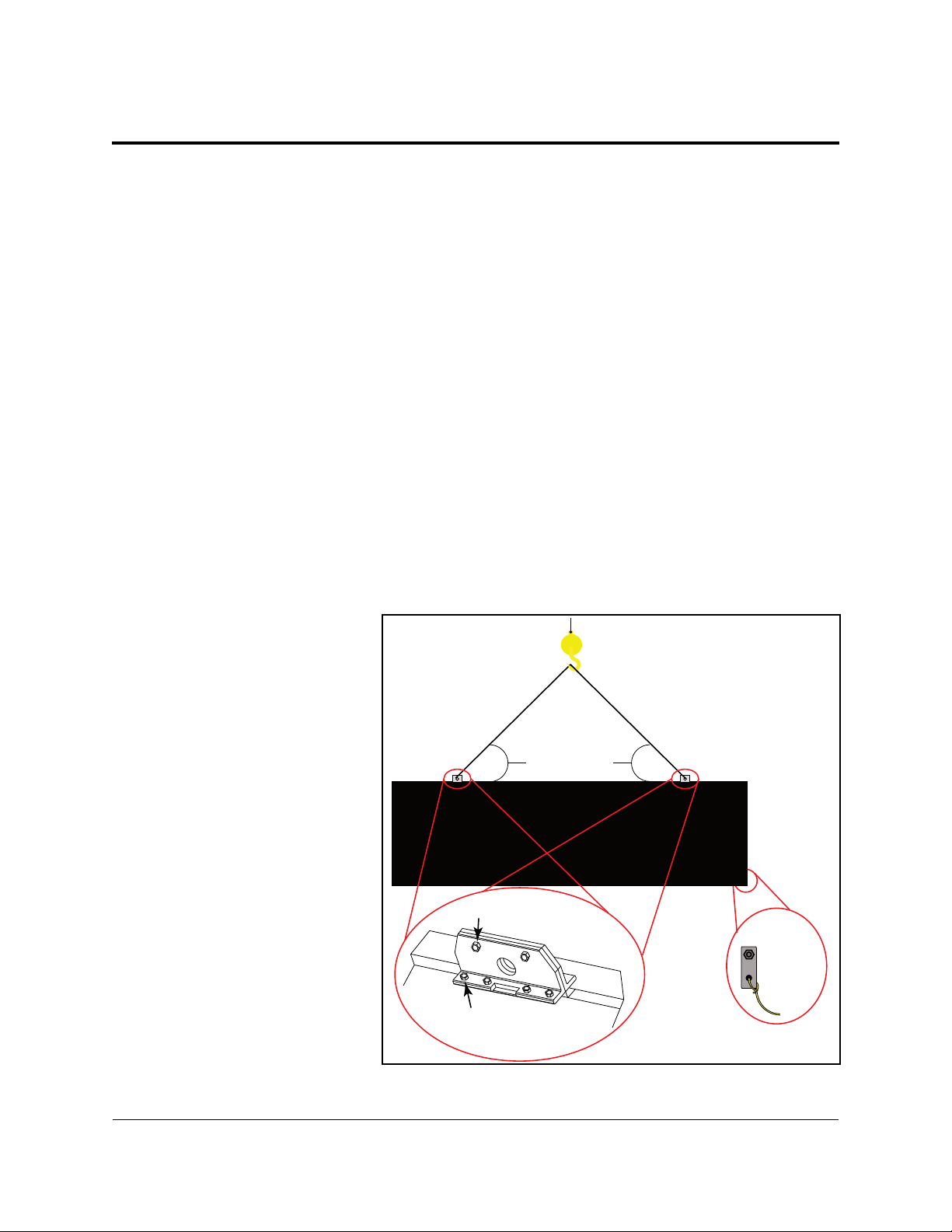

3. Attach a crane or lift

truck to the lift eyes on

the display’s top.

Note: Lift eye spacing

is set at Daktronics and

should not be moved.

Lift eyes should also

remain in place after

installation is complete.

Angle must be

greater than 55°

Lift-Eye Bolts

From Back

Tag Line

Tie Off

Set Bolts

Figure 2: Proper Display Lifting

Display Installation

5

Page 11

Note: Ensure the angle between the top of the display and the lifting strap is greater than 55

degrees, as shown in Figure2.

4. Apply tension to the lift lines.

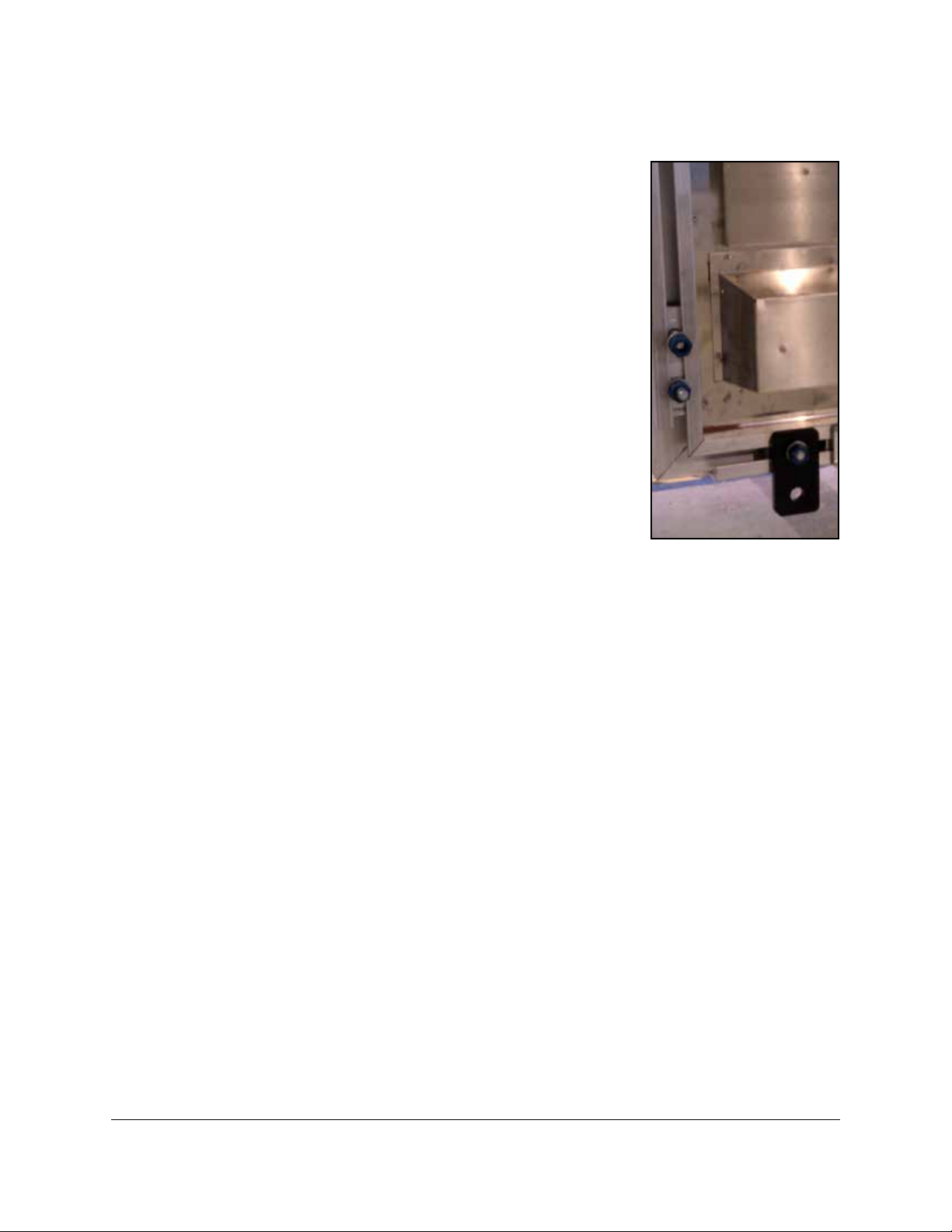

5. Attach tag lines to the bracket shown in

Figure3.

6. Unbolt the display from the shipping braces.

7. Lift the display off the truck to the display structure.

Note: Do not lift displays in wind speeds greater than 20 mph.

8. Mount the display to the structure by welding or bolting all

T-Clips to horizontal stringers.

Note: Use all T-Clips when mounting the display.

Note: The T-Clips are installed in the recommended locations

at Daktronics, but can be moved 12 inches either way to avoid

obstructions. Refer to the label on the display for limitations.

9. Remove crane support and tag lines from the display once

mounting is complete.

Figure 3: Tag Line Bracket

10. Locate the top border caps and install over lift eyes using

provided Tek screws.

6 Display Installation

Page 12

Section 4: Section Splicing

4.1 Display Section Numbering

For multiple-section displays, each section is numbered for

easy identication. In a two-section display, shown in Figure

4, the top section is 101 and the bottom section is 201.

In four-section displays, shown in Figure5, the upper-left

display section is 101 and the section to the right is 102; the

second row of sections is 201 on the left and 202 on the right.

Note: Left and Right sections are pre-assembled prior to

shipping for displays up to 48 feet wide.

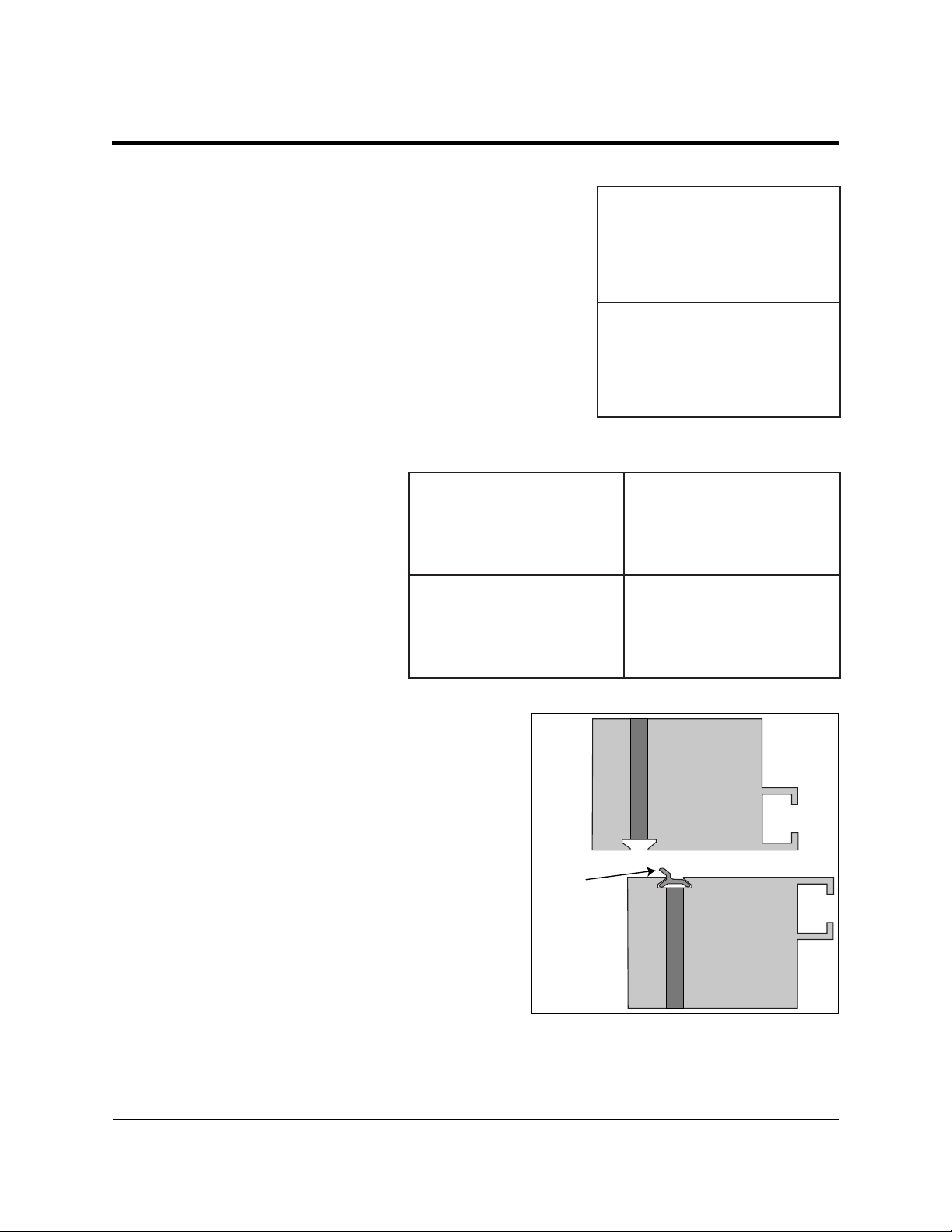

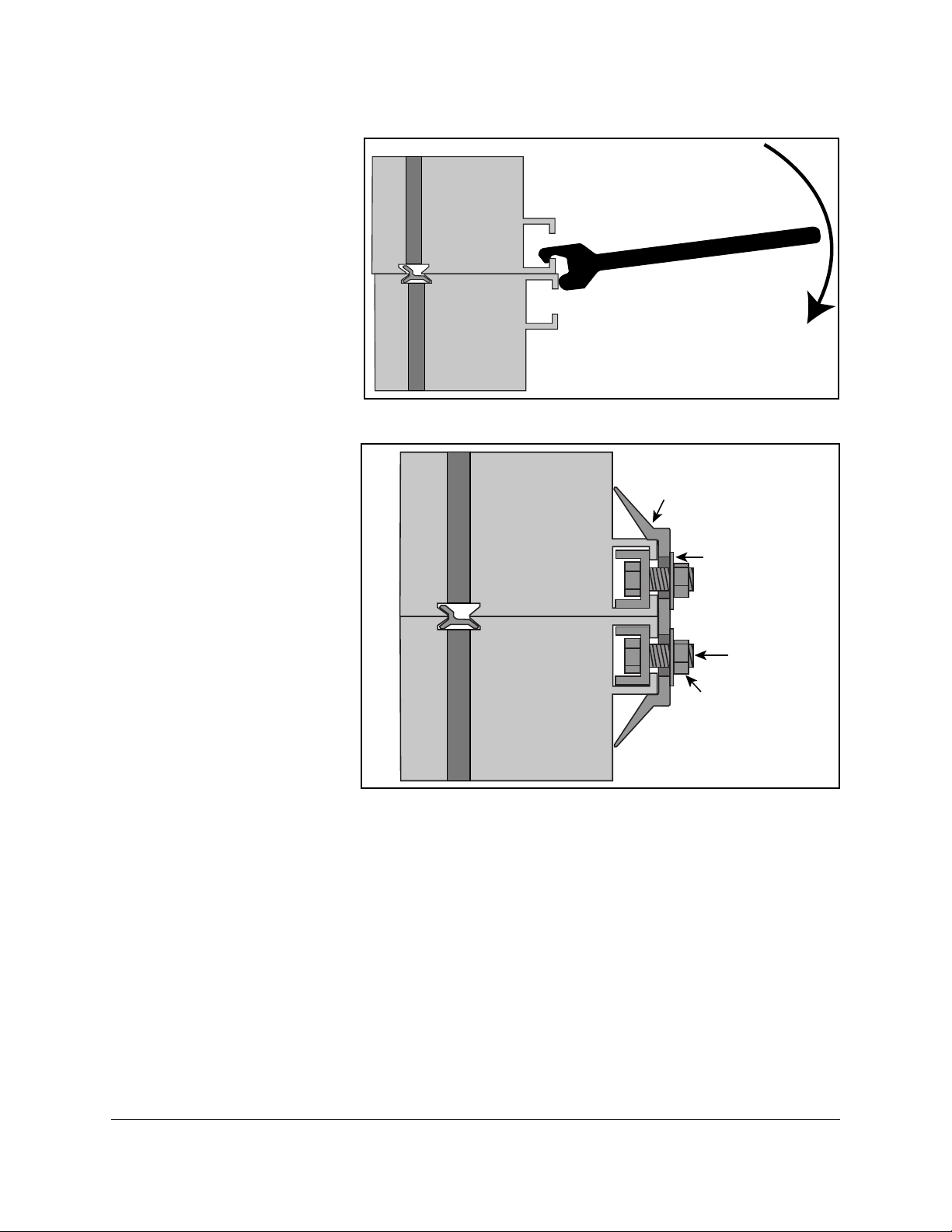

4.2 Section Splicing Instructions

1. Ensure the splice key is

inserted in the channel of the

bottom section, as shown in

Figure6.

2. Attach a crane or lift truck

to the lift eyes of the top

section and apply tension.

3. Unbolt the top section of the

display from the truck bed

and unbolt A-frame.

Figure 5: Four-Section Display Section Numbers

Section 101

Section 201

Section 101

Section 201

Figure 4: Two-Section Display Section

Numbers

Section 102

Section 202

4. Lift the display top section off the truck high

enough to spin around 180 degrees.

Section Splicing

Top

Section

Splice

Key

Bottom

Section

Figure 6: Splice Key In Channel

7

Page 13

5. Slowly lower the top section until it rests on the bottom section with the splice key engaged.

Top

Section

Bottom

Section

Splice

6. Starting at one end of

the display, use the

splice tool to draw the

top section into the

bottom until the splice

key is fully engaged, as

shown in Figure7.

7. Ensure display

sections are aligned

and that LEDs are also

in alignment.

8. Attach the splice plates

and splice T-clips

along the section

splice, as shown in

Figure8. Use an

11

/16”impact wrench or

ratchet to tighten all

nuts on the splice

plates and splice

T-clips.

Figure 7: Pull Display Sections Flush

Top

Display Face

Section

Bottom

Section

Figure 8: Attach Splice Plates and T-clips.

Plate

Washer

Bolt

Nut

8

Section Splicing

Page 14

Section 5: Electrical Installation

This section explains the steps necessary to make nal electrical connections to the display from the

primary power source. For display-specic power requirements, refer to the shop drawing or label on the

display’s back.

Electrical Installation Dos

• Follow all installation guidelines

• Route power to the display through a disconnect switch

• Provide the required power per display requirements

• Provide a separate circuit for each display

• Connect each display face to a dedicated earth-ground electrode

• Follow all local and national electrical codes

Electrical Installation Don’ts

• Share circuits between displays and other electrical devices

• Connect the display to any voltage other than that listed on the product label

• Connect the neutral to the ground at the disconnect or the display

• Use the display support structure as an earth-ground electrode

5.1 Power Connection

1. Review the power requirements for the

display. Requirements are found on the

display shop drawing or label on the

display’s back, as shown in Figure9.

2. Route conduit from the main distribution

panel/disconnect to each display power

entrance. Each display section has a power

entrance and requires a dedicated circuit.

3. Remove the four screws that attach the

power entrance access door.

4. Connect conduit to the 2” Myers hub at

the left of the power entrance box.

5. Feed power cable from the conduit into

the power entrance box.

6. Connect the power ground wire to the

appropriate tap (green wire), as shown in

Figure10.

Note: Use a 3/16” hex head wrench to

tighten screws that hold wires in place.

Figure 9: Display Power Requirements Label

Figure 10: Power Entrance Box

Electrical Installation

9

Page 15

7. Connect power line 1 (L1) to the appropriate tap (black tape on cable).

Primary

Mirror

Display

Ground Lug

Thermal Weld

Connection

Preferred

Conduit

Copper Ground Conductor

(One Per Display Face)

Copper Ground Rods

8 ft.(2.5 m)

min.

8 ft.(2.5 m)

min.

8. Connect power line 2 (L2) to the appropriate tap (red tape on cable).

9. Connect the neutral to the appropriate tap (white tape on cable).

10. Reinstall the power enclosure cover using all four screws.

5.2 Earth Ground Installation

Daktronics GalaxyPro® GP3 displays require a resistance to ground of 10 ohms or less. Follow the

steps below to connect the display to an earth-ground electrode and measure the resistance to

ground.

1. Install an earth-ground

electrode (ground rod,

ground plate, etc.) near the

base of the display. Refer

to Figure11 for guidelines.

Note: Each display face

requires an earth-ground

electrode.

2. Connect a copper wire

from the grounding

electrode to the ground

lug on the back of the

display.

Figure 11: Proper Display Grounding

3. Using an Earth Ground Clamp Meter, shown in Figure12, measure the resistance to

ground near the grounding electrode. If the reading is greater than 10 ohms, install

additional grounding electrodes.

4. Bury any copper cable or grounding electrodes so they are

below grade.

Importantpointsaboutgrounding:

• Followlocalandnationalcodes:The material of an earth-

ground electrode differs from region to region and from

conditions present at site. Consult any electrical codes that

apply.

• Supportstructurecannotbeusedasanearth-ground

electrode: The support structure is generally embedded

in concrete, and if embedded in earth, the steel is either

primed or it corrodes, making it a poor ground.

• Onegroundingelectrodeforeachdisplayface

Figure 12: Measure

Resistance to Ground

10

Electrical Installation

Page 16

Section 6: System Start-Up Procedure

Displays show a boot sequence about two minutes after power is turned. This information is very useful

when conguring the display in Venus® 1500 software. Prior to turning the display on, make sure display

communications and any network connections have been made.

6.1 Boot Sequence

Description

Firmware Name and Version

Display Size (Pixels High by Pixels Wide)

DHCP Name Assigned

IP Address and State

MAC Address

Conguration Port

Status Port

Management Port (Used to Access Conguration)

Description

6.2 Start-Up Checklist

• Conrm power is correctly connected to the display

• Conrm there is sufcient power according to display requirements

• Conrm a main disconnect is installed

• Conrm the display is connected to an earth-ground electrode with a resistance of 10 ohms or

less

• Conrm that all communication equipment is installed according to provided documentation

• Conrm that any necessary network connections have been made

• Conrm the control computer has Venus® 1500 software installed

• Inspect peripheral equipment (temperature sensor, light sensor, etc.) for proper installation

System Start-Up Procedure

11

Page 17

Page 18

Section 7: Signal Cable Installation

This section describes signal cable installation for GalaxyPro® GP3 series displays. There are several types

of data signal connections that may need to be made depending on the size of the display and number of

sections.

7.1 Primary-Mirror Signal Connection

For data to get from the Primary display to the Mirror display, the ber interconnect cable must

be connected. This cable typically comes attached to the back of the display.

1. Locate cable and unpackage.

2. Connect one end of the cable to J34 on the

back of the Primary display, as shown in

Figure13.

3. Connect the other end of the cable to J32 on

the back of the Mirror display.

4. Coil up any excess cable and secure it to

prevent vandalism and weather-related

damage.

Note: Anchor points are found on each fan

hood for securing excess cable.

Figure 13: Signal Out Quick-Connect Jack

7.2 Sectional Display Signal Connections

For sectional displays, data is transmitted from one

section to the next through ber cables connected to the

outside of each section.

Each section has multiple jacks labeled either A or B.

Refer to drawing B-1033700 in the back of this manual for

correct cable routing between display sections. A label

on the display’s back also illustrates how to connect the

cables. An example of this label is shown in Figure14.

Figure 14: Example Cable Connection

Label on Back of Display

Signal Cable Installation

13

Page 19

Page 20

Section 8: Network and Communication Installation

This section explains how to setup communications with a GalaxyPro® GP3 series display through a

network or an individual computer. Obtain information about the available standard communication

options in the provided quick guides and reference manuals.

Daktronics is not responsible for setting up displays on a Wide Area Network (WAN), but can assist with

setting up communication on a Local Area Network (LAN) or directly to a personal computer.

8.1 Network and Communication Installation Dos

• Complete all network and communication installation prior to turning display on

• Have a laptop on site with Internet access (preferred)

• Work with the Customer’s IT professional for network integration

Daktronics GalaxyPro® GP3 series displays use DHCP by default, which allows automatic display

conguration by the customer’s network, and eliminates manual conguration of the player.

When the display is connected to a network that supports DHCP, a default DHCP name similar

to ‘DAKTxxxxxx’, where ‘xxxxxx’ represents the last 6 digits of the player’s MAC address, is

used. This information is shown in the display boot sequence.

8.2 Requirements For Communication Through A Network

• Ports 4500-4525 must be open for communication on the switch or router

8.3 Connecting To A Network And Using A DHCP Name

The following steps explain how to congure a display and connect to a network that supports

DHCP and using the display’s DHCP name is desired for communication.

Network Requirements

• DHCP Server

• Existing Network

• Available network port, congured properly

• PC with Venus 1500 software installed

Installation/Start-up Steps

1. Make sure computer with Venus 1500 software installed is turned on.

2. Ensure computer has an established link with the network.

3. Turn display on.

Network and Communication Installation

15

Page 21

8.4 Connecting To A DHCP Network And Using A Static IP Address

The following steps explain how to congure a display when it is connected to a network that

supports DHCP, but a static IP address is desired for the display.

Network Requirements

• Existing Network

• Available network port, congured properly

• PC with Venus 1500 software installed

• Static IP information (provided by customer)

Conguration Steps

1. Connect a computer to the display setup for ObtainIPaddressautomatically.

2. Turn display on.

3. Launch DisplayFind and discover the display.

4. Once the display is found, click the link to launch the conguration utility.

5. Click Logon to connect to the display (refer to the help le for additional information about

the conguration utility).

6. Congure the IP settings.

7. Click UploadConguration.

8. Log out of the conguration utility.

9. Turn display off.

10. Disconnect the computer from the display and connect display to the network.

11. Make sure computer with Venus 1500 software installed is turned on.

12. Ensure computer has an established link with the network.

13. Turn display on.

14. Congure the display in Venus 1500.

8.5 Connecting To A Network And Using A Static IP Address

The following steps explain how to congure a display when it is connected to a network that

does not support DHCP.

16

Network and Communication Installation

Page 22

Network Requirements

• Existing network

• PC with Venus 1500 software installed

• Static IP information (provided by customer)

• Available network port, congured properly

Conguration Steps

1. Write down the IP address on the computer with Venus 1500 software installed.

2. Change the IP address to ObtainAutomatically.

3. Allow computer to fail over to DHCP – process may take up to 3 minutes.

4. Turn display on.

5. Launch DisplayFind and discover the display.

6. Once the display is found, click the link to launch the conguration utility.

7. Click Logon to connect to the display (refer to the help le for additional information about

the conguration utility).

8. Congure the IP settings.

9. Click UploadConguration.

10. Logout of the conguration utility.

11. Turn display off.

12. Change the computer’s IP address back (written down in step 1).

13. Turn display on.

14. Congure display in Venus 1500 software.

8.6 Connecting To A Computer Using A Static IP Address

When connecting a display to a computer and not a network, it is recommended to use the USBto-Ethernet adapter. This allows the computer to maintain any Internet or network connections

while still being able to control the display.

Requirements

• PC with Venus 1500 software installed

• USB-to-Ethernet adapter

Network and Communication Installation

17

Page 23

Conguration Steps

1. Install USB-to-Ethernet adapter driver on computer.

2. Establish a link between the adapter and the display.

3. Turn display on.

4. Launch DisplayFind and discover the display.

5. Once the display is found, click the link to launch the conguration utility.

6. Click Logon to connect to the display (refer to the help le for additional information about

the conguration utility).

7. Congure the displays IP address to:

IP Address: 172.16.192.25

Subnet Mask: 255.255.0.0

8. Click UploadConguration.

9. Log out of the conguration utility.

10. Turn display off.

11. Congure IP address on USB-to-Ethernet adapter to:

IP Address: 172.16.192.20

Subnet Mask: 255.255.0.0

12. Turn display on.

13. Congure display in Venus 1500 software.

8.7 Standard Communication Options

Daktronics GalaxyPro® GP3 displays can receive various forms of Ethernet communication.

The standard communication options are listed below along with the communication-specic

document numbers. For additional information regarding communication installation, refer to

these documents, which are provided with the communication kits.

Communication Type Manual Document Number Quick Guide Document Number

Ethernet – Wire DD1417609 DD1417573

Ethernet – Fiber DD1417611 DD1417581

Ethernet Bridge Radio DD1685027 DD1417586

These are the standard communication types, but each site is unique and may include additional

equipment. For questions, contact Daktronics Technical Support.

18 Network and Communication Installation

Page 24

Section 9: Venus® 1500 Software Conguration

Other control software is available on a contract basis. Refer to that product’s help le for system

requirements, installation, and conguration information.

9.1 Software Installation

Venus® 1500 is the standard control software for GalaxyPro® GP3 displays. Install Venus® 1500

software either from a disc or from www.daktronics.com\venus1500. Click the Downloads tab

and Venus1500setup.exe. Venus® 1500 requires registration which must be completed within 90

days of installation. Refer to the Venus®1500HelpFile for registration instructions.

9.2 System Requirements

Minimum System Requirements

Windows XP®, Vista®, or 7® with current updates

applied (32-or 64-bit versions)

800 Mhz or higher Processor 1.6 GHz or higher Processor

512 MB RAM or higher 1.5 GB RAM or higher

1 GB of Free Hard Disk space (additional space

required for content storage)

Monitor and video adapter capable of 1024x768 or

higher resolution with DirectX

Microsoft Internet Explorer

.NET 3.5 Framework Service Pack 1 .NET 3.5 Framework Service Pack 1

CD-ROM or DVD drive CD-ROM or DVD drive

Keyboard and Mouse or other compatible pointing

device

®

9 support

®

7 or higher Microsoft Internet Explorer® 7 or higher

9.3 Software Conguration

Ensure all display communications and network connections are made before conguring a

display in Venus® 1500 software. Once everything is installed, turn the display on, allow it to

complete the boot sequence, then follow the steps below.

1. Click the Windows® Start

button. Hover over All

Programs>Daktronics

>Venus1500V4. Click

Venus1500.

Recommended System Requirements

Windows XP®, Vista®, or 7® with current updates

applied (32-or 64-bit versions)

1 GB of Free Hard Disk space (additional space

required for content storage)

Monitor and video adapter capable of 1280x1024 or

higher resolution with DirectX® 9 support

Keyboard and Mouse or other compatible pointing

device

2. Click the Application

button, highlight

Congure, click Displays,

as shown in Figure15.

Venus 1500 Software Conguration

Figure 15: Begin Display Conguration

19

Page 25

3. Click AddDisplay...

from the Display

Management window. Or

right-click in the Display

Management window and

select AddDisplay..., as

shown in Figure16.

4. The software searches for

displays on the local

network and returns a list

Figure 16: Congure a New Display

of displays it nds.

5. Select the display you wish to

congure and click Continue,

as shown in Figure17.

Note: If the display is password

protected, enter the password

on the AuthenticationPage.

Note: Save the password in a

secure location. Physical access

to the display is required to

reset the password if it is lost.

6. Give the display an easy-to-

identify name when the Display

Found prompt opens. This

Figure 17: Displays Found List

prompt also provides a brief

description of the display. Click Continue.

Note: If the display is not

found, refer to the Venus

1500HelpFilefor manual

conguration instructions.

7. Select the correct time zone

for the display’s location.

Greenwich Meantime,

along with country and

city or region are the

guides used to select the

correct time zone.

8. A Summary box, shown

in Figure18, provides

basic information about

the newly congured

Figure 18: Display Conguration Summary Window

display. Click BacktoStart

to return to the beginning of the process to congure another display. Click Finish to

complete display conguration.

20

Venus 1500 Software Conguration

Page 26

Section 10: Display Maintenance

This section explains the steps necessary

to maintain the GalaxyPro® GP3 display.

Daktronics GalaxyPro® GP3 displays

are front accessible. Remove modules

on the front of the display to gain access

to internal components. Figure19 and

Figure22 show internal component

locations.

ImportantNotes: Turn OFF power before

any repair or maintenance work is done

on the display.

10.1 Internal Display

Access

1. Disconnect power to the

display.

2. Locate the two access holes to

gain access to the quarter-turn fasteners

on the module.

Fans

Thermostat

Player

Power

Supply

PLR

Light

Sensor

Figure 19: Component Locations In Lower Left of Display

Player

Enclosure

Filter

Power

Termination

Panel

3. Using a 1/8” hex head wrench, turn each latch a

quarter turn

counterclockwise.

4. Gently pull

the module

far enough

forward

to reach

behind and

disconnect

the power

and signal

cables.

Note: Do not

allow module

to hang by its

cables. Doing

so causes

Figure 20: Lanyard Attachment Top

View

Figure 21: Module Attached To Lanyard

irreversible

damage to the module. Use the provided lanyards to hang a module, as shown in Figure20

and Figure21.

Display Maintenance

21

Page 27

5. When ready to reinstall the module, reconnect the cables, push the cables into the display so

they do not get pinched and latch the module using a

Note: A fully seated module should be ush with the modules around it.

10.2 Ventilation System

GalaxyPro® GP3 displays are equipped with a ventilation system that helps keep internal

components at operable temperatures. GalaxyPro® GP3 displays are rear ventilated, so the

display support structure must allow adequate space or air movement for proper ventilation.

Refer to the display shop drawing for ventilation requirements.

Filter Inspection, Cleaning, and Replacement

The ventilation system includes lters that prevent dirt and debris from entering the display

cabinet. Check and replace lters regularly to ensure adequate air ow in the display. At

a minimum, check lters every six months, but more frequent inspection may be required

depending on conditions around the display.

Clean lters with water or compressed air (no greater than 60psi and at least 6” away) blown

through the lter in the opposite direction from which air normally ows. Allow lters to dry

before returning them to their trays. Again, Daktronics encourages users and service technicians

to use their own discretion when deciding whether to clean or replace the lters.

1

/8” hex head wrench.

Fans

Fans help bring fresh air into the display while exhausting hot air through the upper vents. Fans

are controlled via a thermostat in the display cabinet. The thermostat is equipped with a bypass

button for testing fan operation. Replace fans that are not working properly.

10.3 Display Face Cleaning

Wet Cleaning Process

1. Turn off power to the display.

2. Mix a mild, non-abrasive, non-petroleum-based detergent and cold water, one ounce of

detergent to one gallon of cold water.

3. Saturate a light/medium duty cleaning brush with the soapy water.

4. Use horizontal brush strokes to loosen and remove dirt and grime, washing the display from

top to bottom. Use light pressure so as not to damage the LEDs. Clean only an area that is

safely within reach from a lift or stage, and then move on to the next section of modules.

5. Rinse the display face with generous amounts of cold water under low pressure. A spot-free

rinse agent can be used to reduce water spots.

22

Display Maintenance

Page 28

6. Use soft, dry terrycloth to dry and remove any excess water. Take care not to damage LEDs

by catching the cloth on them.

7. Allow the display to completely air-dry for 12 hours before applying power to the display.

Dry Cleaning Process

1. Turn off power to the display.

2. Rub a dry, soft terrycloth towel horizontally across each row of LEDs. Make four passes per

row of LEDs before moving to the next row of LEDs. Work from top to bottom safely within

reach from a lift or a stage. Take care not to damage LEDs or the plastic louvers by catching

the cloth on them.

Display Maintenance

23

Page 29

Page 30

Section 11: Display Troubleshooting

This section provides basic display information such as power and signal routing as well as basic

troubleshooting tips for common problems. For issues not addressed in this manual, please contact

Daktronics Technical Support.

11.1 Power and Signal Routing

Understanding power

and signal ow through

the display can help a

technician troubleshoot

an issue.

Power Routing

Figure22 shows how

power is routed through

the display.

1. AC Power enters

the display

through the

power entrance

box on the back

of the display

and travels

to the Power

Termination

Panel.

Player

Module

Power

Supply

Light

Sensor

Module

Power

Supply

(one on

every

module)

Power

Supply

3

PLR

4

Figure 22: Power Routing

Player

Enclosure

2a

2b

Fans

Thermostat

2d

2c

Power

Termination

Panel

Filter

1

2. Power is

distributed to Module Power Supplies (2a), Player Power Supply (2b), Thermostat (2c),

and Fans (2d).

Note: Each module has its own Module Power Supply attached to the back of the

module.

3. DC Power is supplied to the Player (3) from the Player Power Supply.

4. DC Power is also supplied to the PLR (4) from the PLR power jack on the back of the

module.

Display Troubleshooting

25

Page 31

Signal Routing

Figure23 shows how signal is routed through the display.

1. Signal enters

2b

2c

4b

2d

the display

from the

external

signal

enclosure

4a

through

the signal

input quickconnect jacks

(1).

5

2. Signal travels

from the J32

signal input

jack through

an Ethernet

Figure 23: Signal Routing

Cat5e cable

to the J32

Ethernet jack on the player (2a)

4c

3

2a

1

4b

5

6

• The J33 auxiliary input jack is connected to the J33 jack on the player (2b).

• The temperature sensor is connected to the J31 input quick-connect jack. From

the J31 quick-connect jack it is connected to the J31 jack on the player (2c).

• The light sensor is connected to the J35 input quick-connect jack. From the J35

quick-connect jack it is connected the J35 jack on the player (2d).

3. Signal travels from the player from Fiber A to the PLR Port A (3).

4. From SATA A on the PLR, signal goes to the rst module (4a) and travels from module

to module via SATA cables (4b), nally returning to the PLR to SATA B (4c).

5. Signal leaves the PLR from Fiber B and travels to the Output Fiber Quick Connect (5).

6. Signal from the primary display face Output Fiber Quick Connect travels to the mirror

face (6) to jack J32.

26 Display Troubleshooting

Page 32

11.2 Player Diagnostics

1

2

3

4

5

6

7

8

C

D

E

F

9

A

B

0

DMP-4060 is the player in a

GalaxyPro® GP3 display. The

player is located in the lowerleft portion of the display in an

environmental enclosure. The

player receives incoming signal

from the control computer and

routes that signal to the ProLink

Router (PLR). The player has

several LEDs on it that can be

useful when troubleshooting a

communication issue. Figure24

explains those LEDs.

11.3 PLR Diagnostics

The ProLink Router (PLR),

receives signal from the display

player, which transfers it on

to the modules through SATA

cables. GalaxyPro® GP3 displays

are equipped with a redundant

signal path, meaning two SATA

cables are connected to each

module. If one of the two SATA

cables fail, the module continues

to receive data from the other SATA cable and the display continues functioning normally.

INDICATORS

RUN-Flashes

during

operation

ETH0 1000MB

ETH0 100MB

ETH0 10MB

ETH0-ON

Full Duplex

ETH1 1000MB

ETH1 100MB

ETH1 10MB

ETH1-ON

Full Duplex

ETHERNET

Hardware link

flashes during

TX comm.

Flashes during

RX comm.

Figure 24: Controller Diagnostic LEDs

PLR Self-Test

When put into self-test mode, the PLR tests

for correct operation and displays pass/fail

status on the 7-segment display.

To put the PLR into self-test mode, loop a

SATA cable between ports A and B. Then

take a ber cable and connect the ber

ports together, as shown in Figure25. Once

the cables are connected, cycle power to

the PLR and it will boot-up in self-test

mode. Following is a table of a few possible

messages. Contact Daktronics Technical

Support for additional information or

questions.

Display Troubleshooting

Figure 25: PLR Self-Test Setup

27

Page 33

Code Description

8 8 8 Testing 7 segments (held for 2 seconds)

t s t Initial test in progress (60-second duration)

P A S All tests passed

E r r Test failures reported

F 0 1 Fiber Port A Error

F 0 2 Fiber Port B Error

F 0 3 RJ45 IN (Port A) Error

F 0 4 RJ45 OUT (Port B) Error

F 0 5 ProLink5 (SATA) Port A Error

F 0 6 ProLink5 (SATA) Port B Error

If any Err message is displayed, send the PLR back to Daktronics for repair or replacement.

11.4 Module and Power Supply Diagnostics

Each module in a GalaxyPro® GP3 display has a power supply attached to it. Each power supply

provides power only to the module it is connected to. Display modules are equipped with a

status indicator LED that can help troubleshoot possible issues. Under normal operation, the

status indicator LED should ash once every 4 seconds.

Module Self-Test

If a module is blank, but has power supplied to it, perform a module self-test to diagnose a

module or SATA cable failure. To perform a self-test, follow the steps below.

1. Attach a SATA cable to Port A

and Port B on the module, as

shown in Figure26.

2. Disconnect the power to the

power supply for 10 seconds.

3. Reconnect the power to start

the self-test.

4. Verify the module is running a

self-test.

Remove the SATA cable and cycle

power to the module to stop the selftest.

Figure 26: Module Self-Test

28 Display Troubleshooting

Page 34

Section 12: Replacement Parts List

The following table contains some of the items that may need to be replaced over a period of time. All

GalaxyPro® GP3 displays ship with at least two spare modules

with power supplies and two spare SATA cables depending on

the size of the display.

0P-1127-0024

If a component is not listed in the replacement parts list, use the

label to order a replacement. Most components within displays

carry a label that lists the part number of the unit. A typical label

is shown in Figure27, with the part number in bold.

Part Number Description

0A-1576-7001 26 mm Module With Power Supply Attached

0A-1586-7001 20 mm Module With Power Supply Attached

0A-1621-7001 16 mm Module With Power Supply Attached

0A-1327-0300 DMP-4060 Controller Enclosure Assembly

0A-1487-6009 PLR Assembly

W-2094 SATA Cable, 2 Foot

W-1659 Fiber Cable

B-1045 Fan Assembly

0A-1327-1094 Quick Connect, Primary Input

0A-1327-1095 Quick Connect, Primary Output

0A-1327-1096 Quick Connect, Mirror Input

W-1658 Fiber-Optic Cable, 10 Foot

W-1685 Fiber-Optic Cable, 33 Foot

W-2030 Fiber-Optic Cable, 25 Foot

0A-1327-3105 Thermostat Assembly

0A-1327-3016 Light Sensor Assembly

SN: 2465

02/19/12 Rev. 1

Figure 27: Typical Parts Label

Replacement Parts List

29

Page 35

Page 36

Section 13: Replacing Parts

13.1 Module and Power Supply Replacement

Each module in a GalaxyPro® GP3 display has an attached power supply and is replaced as an

entire assembly.

Note: When removing modules from the display, do not allow them to hang by the cables.

Lanyards, shown in Figure20, are provided with the spare parts kit for hanging modules.

1. Turn off power to the display.

2. Remove module using a 1/8” hex head wrench.

3. Pull the module slightly out of the display.

4. Disconnect the power cable to the power supply.

5. Carefully disconnect the two SATA cables from the module.

6. Connect the two SATA cables to the new module.

7. Connect power to the power supply.

8. Reinsert the module making sure not to pinch any cables.

9. Latch the new module into place making sure it is fully seated.

13.2 Player Replacement

The player is located in the lower-left area of the display, as shown in Figure19. From the

bottom-left corner of the Primary face, go up to the second row of modules and over to the right

two modules to locate the player. The player is in an enclosure which is not to be opened. Replace

the entire enclosure.

1. Remove the modules in front of the player.

Note: Do not allow the modules to hang by their cables

2. Disconnect the cables at the bottom of the enclosure.

3. Loosen the four screws connecting the enclosure to the back of the display.

4. Carefully lift the enclosure up and out of the display.

5. Insert the new enclosure and tighten all four screws.

Replacing Parts

31

Page 37

6. Reattach the cables to the bottom of the enclosure using the label as a guide.

13.3 PLR Replacement

The PLR is located behind the second module up from the bottom in the rst column of modules,

as shown in Figure19. PLRs can be found in both Primary and Mirror display faces as well as all

sections of a sectional display.

1. Remove the module in front of the PLR.

Note: Do not allow module to hang by its cables.

Note: This module will likely have four cables attached as it provides power to the PLR.

2. Disconnect the two SATA cables and ber cables to the PLR.

3. Loosen the screw at the top of the PLR mounting plate.

4. Lift the mounting plate up and out of the display.

5. Insert the new PLR with mounting plate and tighten the screw.

6. Insert the two SATA cables and ber cables in the appropriate locations.

32

Replacing Parts

Page 38

Section 14: Daktronics Exchange and Repair &

Return Programs

14.1 Exchange Program

The Daktronics Exchange Program is a quick, economical service for replacing key components

in need of repair. If a component fails, Daktronics sends a replacement part to the customer who,

in turn, returns the failed component to Daktronics. This not only saves money but also decreases

equipment downtime. Customers who follow the program guidelines explained below will

receive this service.

Before Contacting Daktronics

Fill in these numbers before calling Customer Service:

Display Model Number: ________________________________________

Date Installed: ________________________________________________

Location of Display: ___________________________________________

Daktronics Customer ID Number: _______________________________

To participate in the Exchange Program, follow these steps:

7. Call Daktronics Customer Service: 866-343-3122.

8. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part xes the problem, send in the problem part which is being

replaced.

a. Packagetheoldpartinthesameshippingmaterialsinwhichthereplacementpart

arrived.

b. FilloutandattachtheenclosedUPSshippingdocument.

c. ShiptheparttoDaktronics.

9. A charge will be made for the replacement part immediately, unless a qualifying service

agreement is in place. In most circumstances, the replacement part will be invoiced at the

time it is shipped.

If the failed part or replacement part is not returned to Daktronics within 3 weeks of the ship

date, Daktronics will assume that the customer is purchasing the replacement part and will send

an invoice for the value of the new sale part. If the part or parts are returned within 2 weeks of

the second invoice date, Daktronics will credit the customer for the second invoice.

If after 2 weeks Daktronics has still not received the parts back, the customer must pay the second

invoice and will not be credited for the return of the failed part. Daktronics reserves the right to

refuse parts that have been damaged due to acts of nature or causes other than normal wear and

tear.

Daktronics Exchange and Repair & Return Programs

33

Page 39

14.2 Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a part

for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Phone:866-343-3122 Fax:605-697-4444

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an antistatic

bag before boxing.

4. Enclose:

• Your name

• Address

• Phone number

• The RMA number

• A clear description of symptoms

Shipping Address

Daktronics Customer Service

PO Box 5128

201 Daktronics Dr.

Brookings SD 57006

14.3 Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix B. The Warranty is

independent of Extended Service agreements and is the authority in matters of service, repair,

and display operation.

34

Daktronics Exchange and Repair & Return Programs

Page 40

Appendix A: Reference Drawings

Shop drawings show display dimensions, signal and power connection locations, as well as information

on service access and power requirements. To obtain copies of shop drawings or other reference

drawings specic to your display, contact Daktronics Customer Service:

Phone: 866-343-3122 Fax: 605-697-4444

GP3 SATA Cable Routing ...............................................................................................B-1033990

GP3 External Signal Cable Routing ................................................................................B-1033700

GP3 Block Diagram .........................................................................................................B-1036837

Reference Drawings

35

Page 41

Page 42

Appendix B: Daktronics Warranty and Limitation

of Liability

Daktronics Warranty and Limitation of Liability

37

Loading...

Loading...