Page 1

Reproduction Reference

ED-13750 – P1279

DataMaster Gasoline Price Displays

1. This page is for reproduction reference only and will not be included in the manual.

2. This manual is to be copied on FRONT AND BACK PAGES –8 ½ x 11 paper.

3. Note: The first and second pages, Cover Page and Copyright Page, use the front of the page

(blank on back). Section heading pages always start on a new page; they never start on the back

of another page.

4. Drawings for this manual are listed in the following table. Group and insert the drawings in

alphanumeric order in Appendix A: Reference Drawings. Reduce all size B drawings to A-size,

and print all A drawings back-to-back and all B drawings back-to-back.

A-166142

A-166216

A-167237

A-168376

A-175342

A-177935

A-179599

A-38532

A-164988

A-164998

A-165028

A-165742

A-165743

A-166139

5. Insert the following documents in these Appendices as follows:

Appendix B:

Data

Master Frequently Asked

Questions ...................................................................................ED-13481

Appendix C:

Gasoline Price Displays

Direct-Wire Installation

Quick Install Reference...............................................................ED-13965

Riser Diagram, Indoor Wire Control................Drawing A-175342

Light Sensor Installation, G3...........................Drawing A-183775

Appendix D:

DataMaster Gasoline Price Displays

Quick Start Reference.................................................................ED-13960

A-181220

A-181222

A-181224

A-181233

A-181234

A-181235

A-181672

(Continued on next page)

A-181673

A-183775

A-184475

A-184918

A-185176

A-185177

A-185203

A-185204

A-185205

A-185206

A-189768

Page 2

(Continued from preceding page)

6. All sections and all Appendices are to be tabbed with the following labels:

Section 1: Introduction

Section 2: Display Specifications

Section 3: Installation

Section 4: Display Service Information

Section 5: DataMaster 100 Controller

Section 6: Display Operation

Section 7: POS Interface Installation and Operation

App A: Reference Drawings

App B: DataMaster FAQ

ED13481

App C: Gas Price Quick Install

ED13965

App D: Gas Price Quick Start

ED13960

7. Use a blue window cover and a blue back.

8. Punch all pages, window cover and back cover along the left edge and bind with a binder.

9. Please direct questions and suggestions to Engineering Support.

Page 3

DataMaster™ Outdoor LED

Gasoline Price Displays

Installation and Operation Manual

ED-13750 Rev 3 – 26 Jan 2005

332 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4036 or 877-605-1115 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 4

Page 5

ED-13750

Product 1279

Rev 3 – 26 Jan 2005

Please fill in the information below for your DataMaster display and controller;

use it for reference when calling Daktronics for assistance.

Display Serial No. _____________________________________________

Display Model No. _____________________________________________

Date Installed ________________________________________________

DataMaster Serial No. __________________________________________

DAKTRONICS, INC.

Copyright © 2004

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered by

the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

DataMaster™, All Sport ® and DataTime® are trademarks of Daktronics, Inc. Other trademarks used in this

manual are the property of their respective owners.

Page 6

Page 7

i

Table of Contents

Section 1: Introduction....................................................................................1-1

1.1 How To Use This Manual .........................................................................1-1

1.2 Daktronics Nomenclature.......................................................................... 1-2

1.3 Manual Overview......................................................................................1-3

1.4 Product Overview......................................................................................1-4

1.5 Model Names.............................................................................................1-5

1.6 Product Safety Approval ........................................................................... 1-5

Section 2: Gasoline Price Display Specifications........................................2-1

2.1 Mechanical Specifications Drawings ........................................................2-1

2.2 Electrical Specification Drawings ............................................................. 2-1

2.3 Specifications ............................................................................................ 2-3

Section 3: Mechanical and Electrical Installation ........................................3-1

3.1 Mechanical Installation..............................................................................3-1

Lifting the Display..............................................................................3-1

3.2 Electrical installation.................................................................................3-2

Power.................................................................................................. 3-3

3.3 Power and Signal Connection ................................................................... 3-5

Host/Client and Master/Slave Definitions and Address Settings....... 3-6

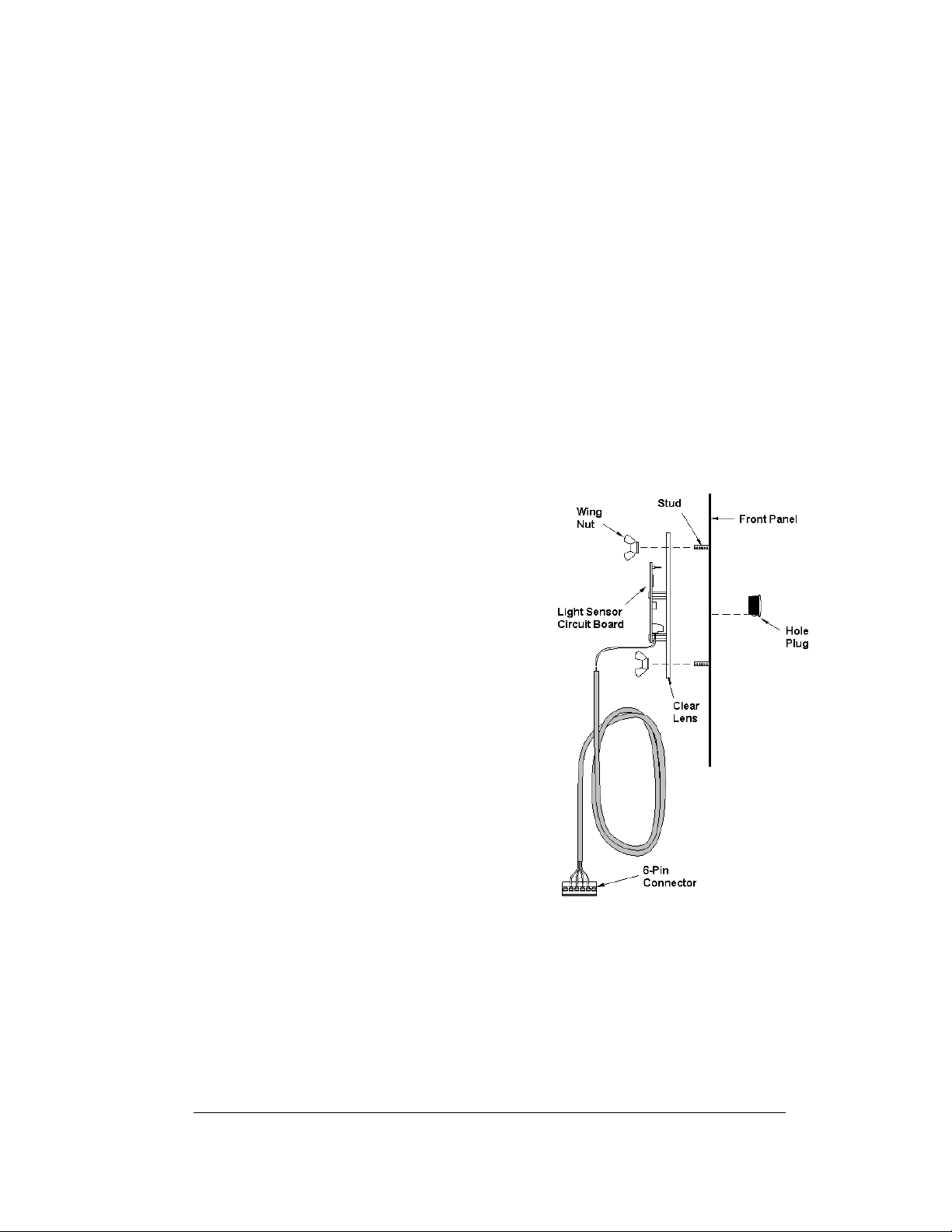

3.4 Photo Sensor Installation........................................................................... 3-7

Section 4: Display Maintenance and Troubleshooting................................4-1

4.1 Cabinet Specifications............................................................................... 4-1

4.2 Component Location and Access.............................................................. 4-1

Replacing a Digit................................................................................ 4-2

Replacing a Digit Segment.................................................................4-3

Replacing a Driver..............................................................................4-3

4.3 Schematics.................................................................................................4-4

4.4 LED Drivers .............................................................................................. 4-4

4.5 Segmentation and Digit Designation......................................................... 4-5

4.6 Troubleshooting......................................................................................... 4-6

Power On Self-Test:........................................................................... 4-7

4.7 Lightning Protection.................................................................................. 4-8

4.8 Replacement Parts ..................................................................................... 4-8

4.9 Daktronics Exchange and Repair and Return Programs..........................4-11

Section 5: DataMaster 100 Controller............................................................5-1

5.1 DataMaster 100 Overview......................................................................... 5-1

Replacement Parts List....................................................................... 5-1

5.2 Control System Overview .........................................................................5-2

Wire Control....................................................................................... 5-3

Table of Contents

Page 8

5.3 Controller Signal Connection....................................................................5-4

Section 6: Gas Price Display Operation........................................................ 6-1

6.1 DataMaster™ Insert and Code....................................................................6-1

6.2 Gas Price Display Operation .....................................................................6-1

Gas Price Display Startup................................................................... 6-2

Gas Price Controller Operation .......................................................... 6-2

Modifying Price Line Settings............................................................6-3

Dimming.............................................................................................6-3

Display Sequence ............................................................................... 6-5

Menu Items.........................................................................................6-6

Edit Price Line 1-5..............................................................................6-6

Section 7: POS Interface Installation and Operation................................... 7-1

7.1 Hardware installation:................................................................................7-1

7.2 Configuring the DM-100 for Gilbarco G-Site Interface............................7-2

Changing Prices:.................................................................................7-3

Appendix A: Reference Drawings .....................................................................A-1

Appendix B: DataMaster Frequently Asked Questions (FAQ) .......................B-1

Appendix C: DataMaster Gasoline Price Quick Installation Reference.........C-1

Appendix D: DataMaster Gasoline Price Quick Start Reference....................D-1

ii Table of Contents

Page 9

i

List of Figures

Figure 1: Daktronics Drawing Label ..................................................................................1-1

Figure 2: Display Identification Label................................................................................1-2

Figure 3: Gasoline Price Display........................................................................................1-4

Figure 4: Lifting the Display...............................................................................................3-2

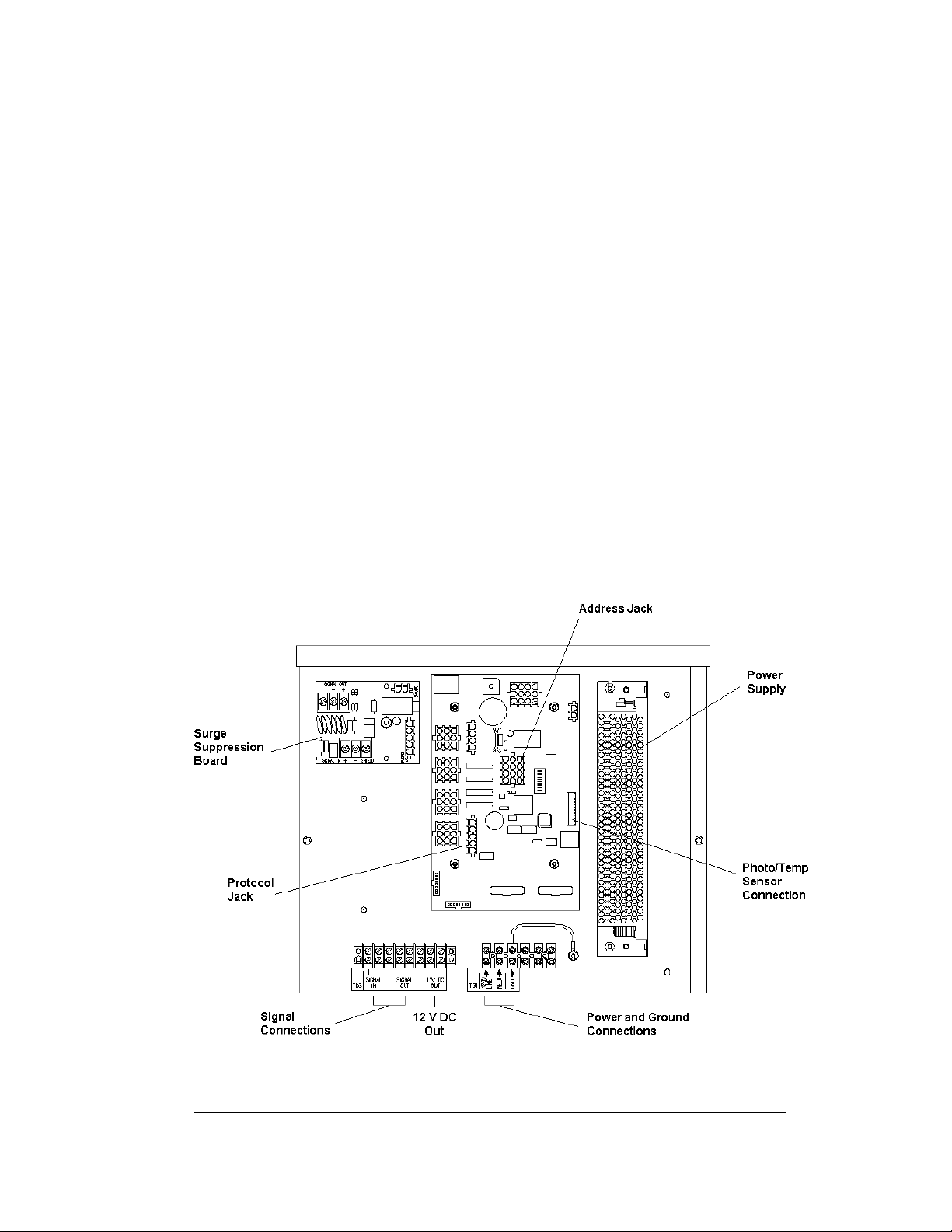

Figure 5: DataMaster Driver Enclosure with 4-Column Driver .........................................3-5

Figure 6: Internal Light Sensor...........................................................................................3-7

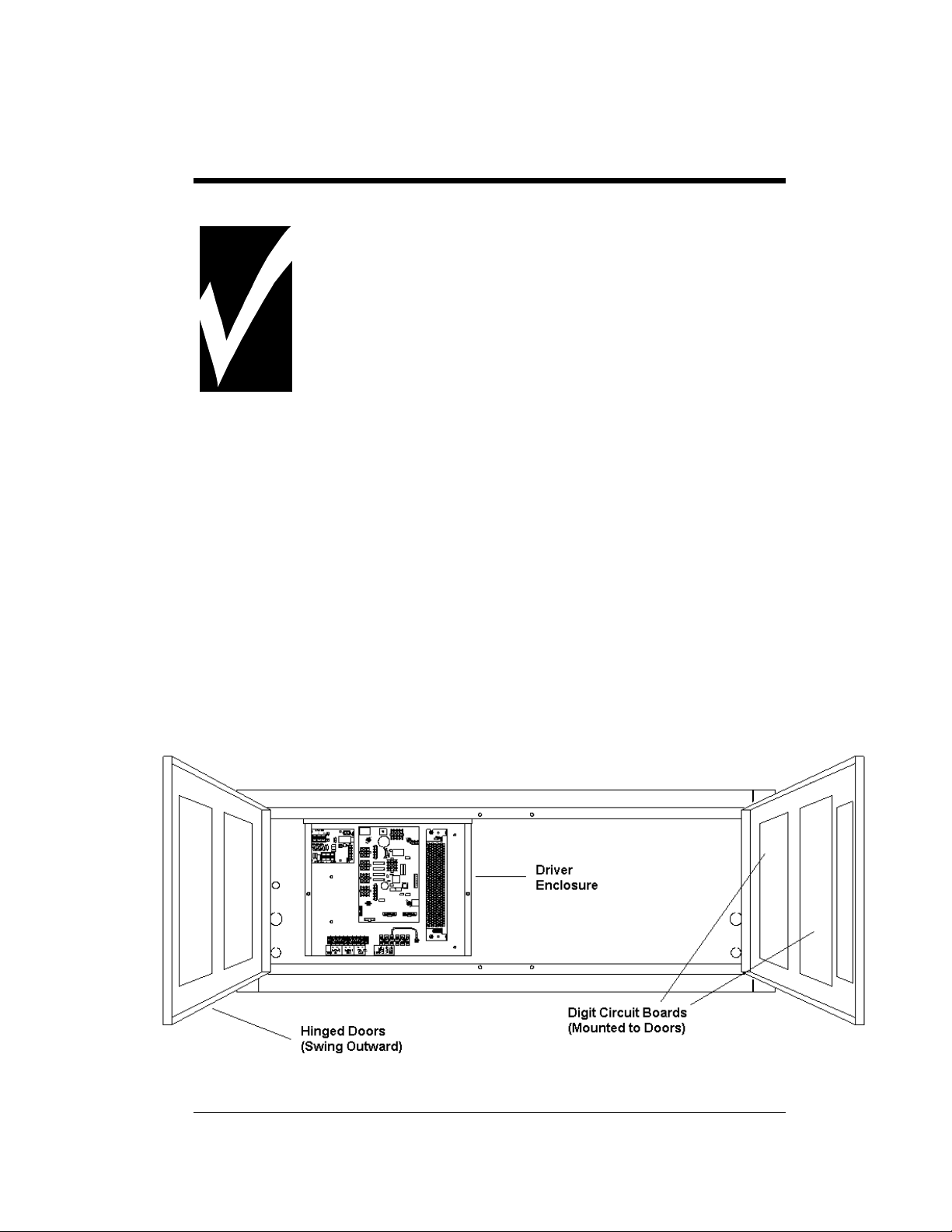

Figure 7: DataTime Time and Temp Display with Door Panels Open...............................4-1

Figure 8: Digit Assembly....................................................................................................4-2

Figure 9: Segmented Digit Panel........................................................................................4-3

Figure 10: Digit Designation...............................................................................................4-5

Figure 11: DataMaster 100 .................................................................................................5-1

Figure 12: DataMaster 100 Controller with Signal Cable...................................................5-3

Figure 13: Wire Control from Base of Sign........................................................................5-4

Figure 14: Wire Control from Building Location...............................................................5-5

Figure 15: DataMaster 100 Insert LL-2551........................................................................6-1

List of Figures

Page 10

Page 11

Section 1: Introduction

This manual explains the installation and operation of Daktronics DataMaster™ Outdoor

LED Gasoline Price Displays and provides details for display maintenance. If you have

questions regarding the safety, installation, operation, or service of these systems, contact

Daktronics. Customer Service Help Desk telephone numbers are listed on the cover page of

this manual.

1.1 How To Use This Manual

Important Safeguards:

1. Read and understand these instructions before installing your display.

2. Do not drop the controller or allow it to get wet.

3. Properly ground the display with a ground rod at the sign location.

4. Disconnect power when the display is not in use.

5. Disconnect power when servicing the display.

6. Do not modify the display structure or attach any panels or coverings

without the express written consent of Daktronics, Inc.

Figure 1, below, illustrates the Daktronics drawing numbering system. Daktronics

identifies individual drawings with a number (1279-RO4A-181218 in the example),

which is located in the bottom right corner of each drawing. This manual refers to

drawings by the last set of numbers in their ID as well as the letter preceding them.

The example would be Drawing A-181218.

Figure 1: Daktronics Drawing Label

Reference drawings in this manual are grouped and inserted in alphanumeric order

in the Appendix.

Listed below are a number of drawing types commonly used by Daktronics, along

with the information each is likely to provide.

System Riser Diagrams: overall system layout from control room to

display, power, and phase requirements.

Shop Drawings: fan locations, transformer locations, mounting

information, power and signal entrance points, and access method (front or

rear).

Introduction 1-1

Page 12

Schematics: power wiring, signal wiring, panelboard or power termination

panel assignments, signal termination panel assignments, and transformer

assignments.

Final Assembly: component locations, part numbers, display dimensions,

and assembly/disassembly instructions.

All references to drawing numbers, appendices, figures, or other manuals are

presented in bold typeface, as in this example: “Refer to Drawing A-181220 for the

location of the driver enclosure ”. Additionally, any drawings referenced within a

particular subsection are listed at the beginning of that subsection in the following

manner:

Reference Drawing:

Mechanical Specs, DF-1020-13, G3.....................Drawing A-181220

Daktronics identifies manuals by their engineering document (ED) number, which is

located on the cover page of the manual. For example, this manual would be referred

to as ED-13750.

The serial and model numbers of a Daktronics display can be found on the ID label

on the display. The label will be similar to the one shown in Figure 2. When calling

Daktronics Customer Service, please have this information available to ensure that

your request is serviced as quickly as possible. For future reference, note your

display model number, serial number, and installation date on the front page of this

manual.

Figure 2: Display Identification Label

Daktronics displays are built for long life and require little maintenance. However,

from time to time, certain display components will have to be replaced. The

Replacement Parts List in Section 4 provides the names and part numbers of

components that may require replacement during the life of this display.

Following the Replacement Parts List is an explanation of Daktronics exchange and

replacement programs. Refer to these instructions if you must replace or repair any

display component.

1.2 Daktronics Nomenclature

To fully understand some Daktronics drawings, such as schematics, it is necessary to

know how various components are labeled in those drawings. You will find this

information useful when trying to communicate maintenance or troubleshooting

efforts.

1-2 Introduction

Page 13

The label “A” on a drawing item typically denotes an assembly. An assembly can be

a single circuit board or a collection of components that function together, usually

mounted on a single plate or in a single enclosure.

In addition, the following labeling formats might be found on various Daktronics

drawings:

“TB _ _” denotes a termination block for power or signal cable.

“E _ _” denotes a grounding point.

“J _ _” denotes a power or signal jack.

“P _ _” denotes a power or signal plug for the opposite jack.

Finally, Daktronics part numbers are commonly found on drawings. Those part

numbers can be used when requesting replacement parts from Daktronics Customer

Service. Take note of the following part number formats. (Not all possible formats

are listed here.)

“0P- _ _ _ _- _ _ _ _” denotes an individual circuit board, such as a driver

board.

“0A-_ _ _ _ - _ _ _ _” denotes an assembly, such as a circuit board and the

plate or bracket to which it is mounted. A collection of circuit boards

working as a single unit may also carry an assembly label.

“W- _ _ _ _ ” denotes a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances. This is especially true for

ribbon cables.

“T- _ _ _ _ ” denotes a transformer.

“PR- _ _ _ _ _ - _” denotes a specially ordered part.

“M- _ _ _ ” denotes a metal part, and “0M-_ _ _ _ _ _” typically denotes a

fabricated metal assembly.

1.3 Manual Overview

This manual details outdoor LED numeric displays. It is divided into the following

sections:

Section 1: Contains an overview of the DataMaster Series, product safety

information, and labeling and numbering descriptions.

Section 2: Lists Gas Price display drawings with mechanical and electrical

information and contains a table detailing the mechanical

specifications, circuit specifications and power requirements for

each model.

Section 3: Contains information needed to perform the mechanical and

electrical installation for each model.

Section 4: Contains service and troubleshooting information.

Section 5: Contains an overview of the DataMaster controller, with a

description of the types of control systems and instructions for

DM-100 setup.

Introduction 1-3

Page 14

Section 6: Provides operating instructions for Gas Price displays.

Section 7: POS Interface Installation and Operation

Appendix: Contains all drawings referenced in this manual, quick-start

guides, and a list of frequently asked questions.

1.4 Product Overview

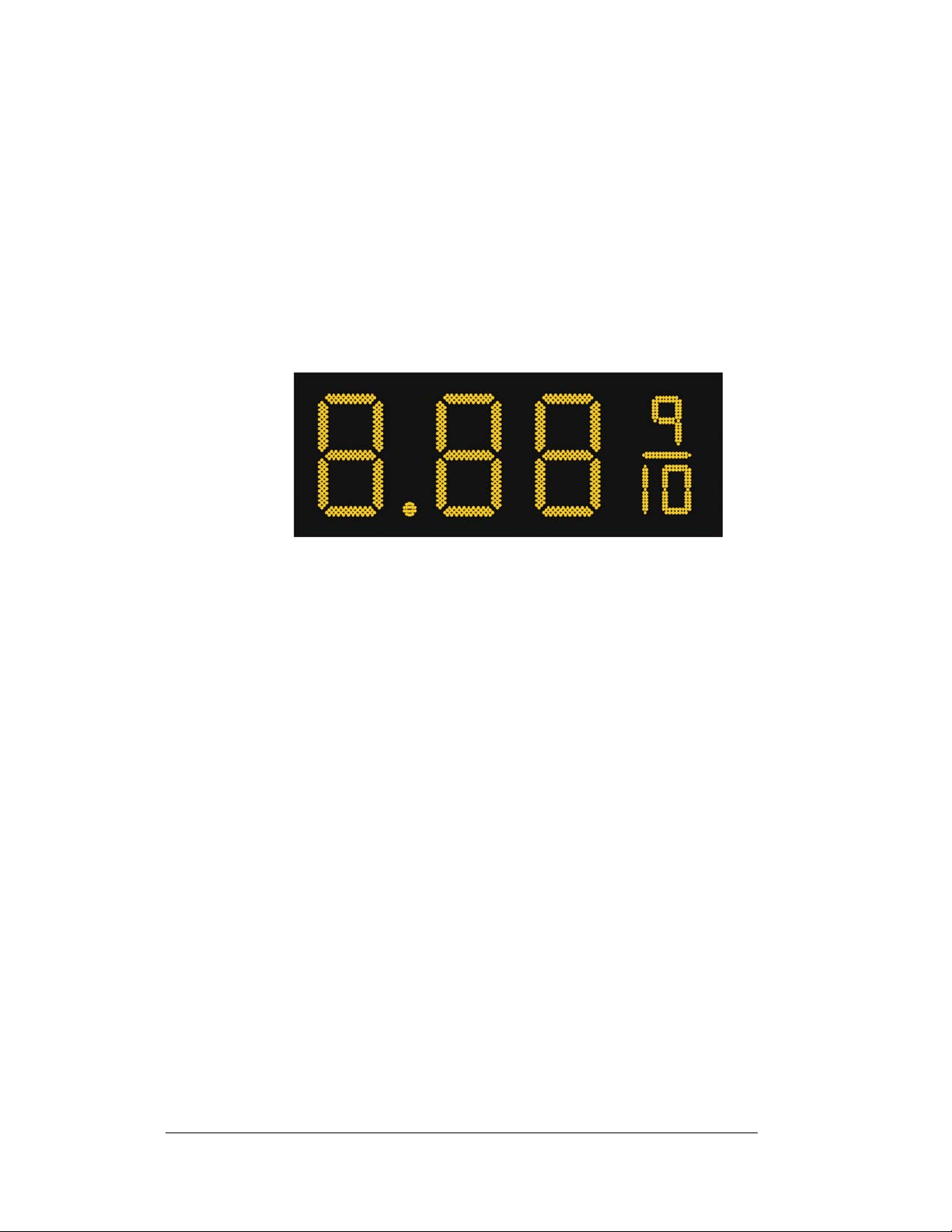

DataMaster Gasoline Price displays are part of a family of Daktronics products

designed for easy installation, readability, and reliability. Microprocessor control

assures consistent operation and accuracy. The Gas Price display is illustrated in

Figure 3 below.

The DataMaster Series includes:

The Gasoline Price displays are available in two styles, a full-cabinet model

designed for standalone use (DF-1020), and a front-insertion, or “drop-in”, model

designed for installation in an existing or custom sign (DF-1021).

DataMaster displays use light emitting diodes to illuminate their numeric digits.

(Light emitting diodes, or LEDs, are tiny, solid-state components that use a

semiconductor to transform electrical current into light; they are high-intensity, lowenergy lighting units.)

The displays feature highly visible PanaView

(The front-insertion Gas Price model is available with 13", 18" and 24" digits.) All

DataMaster displays are configured with red or amber LEDs.

Because of their LED technology, the displays consume little power, some barely

more than a household lamp. Power usage for individual displays in this series is a

maximum 300 W. All models have a 120 V power requirement.

Figure 3: Gasoline Price Display

Gasoline Price Displays: gas price signs with three standard digits,

decimal, and

9

Rate Displays: two- or four-digit signs, typically used to display

hotel/motel room rates or commodity prices.

Time & Temperature Displays: Automatic time & temp signs capable of

displaying temperatures in Fahrenheit or Celsius (three digits, degree

symbol, and F or C character) and 12- or 24-hour time.

/

fraction.

10

®

digits 13", 18", 24", 36" and 48" tall.

1-4 Introduction

Page 15

DataMaster cabinets, specially developed for outdoor use, are constructed of heavygauge aluminum. Digit faceplates are black, and they are set directly into the surface

of the display. Mounting weights and dimensions for each model are listed in

Section 2 of this manual.

The DataMaster outdoor LED displays have been designed for use with a

DataMaster

an insert) for display control, and the DataMaster displays themselves operate

without modification on All Sport

provides complete operating instructions.

™

100 hand-held controller. The device uses a keyboard overlay (called

1.5 Model Names

Daktronics displays, video screens, and scoreboards are differentiated by their model

numbers. The displays described in this manual all carry the two-letter prefix, DF-,

which indicates that they are DataMaster models. The letter D indicates that they are

numeric displays; the letter F indicates LED technology.

In the outdoor LED display series, typically the first set of numbers following the

prefix identifies the series or product line, while the second set of numbers refers to

digit height. A final letter denotes digit color. With Model DF-1020-13-A, for

example, 1020 identifies the Gas Price full-cabinet line, and 13 signifies that the

display’s primary digits are a nominal 13" tall. In the example, the letter A signifies

that the digits are amber, while R would indicate red LED digits.

Another designation often used with the Model DF-1021 Gas Price display is an M

or an S; those letters indicate that the display is either a master or a slave unit.

®

5000 signal protocol. Section 6 of this manual

1.6 Product Safety Approval

Daktronics outdoor displays are ETL listed and tested to CSA standards for outdoor

use. Contact Daktronics with any questions regarding the testing procedures.

Introduction 1-5

Page 16

Page 17

Section 2: Gasoline Price Display

Specifications

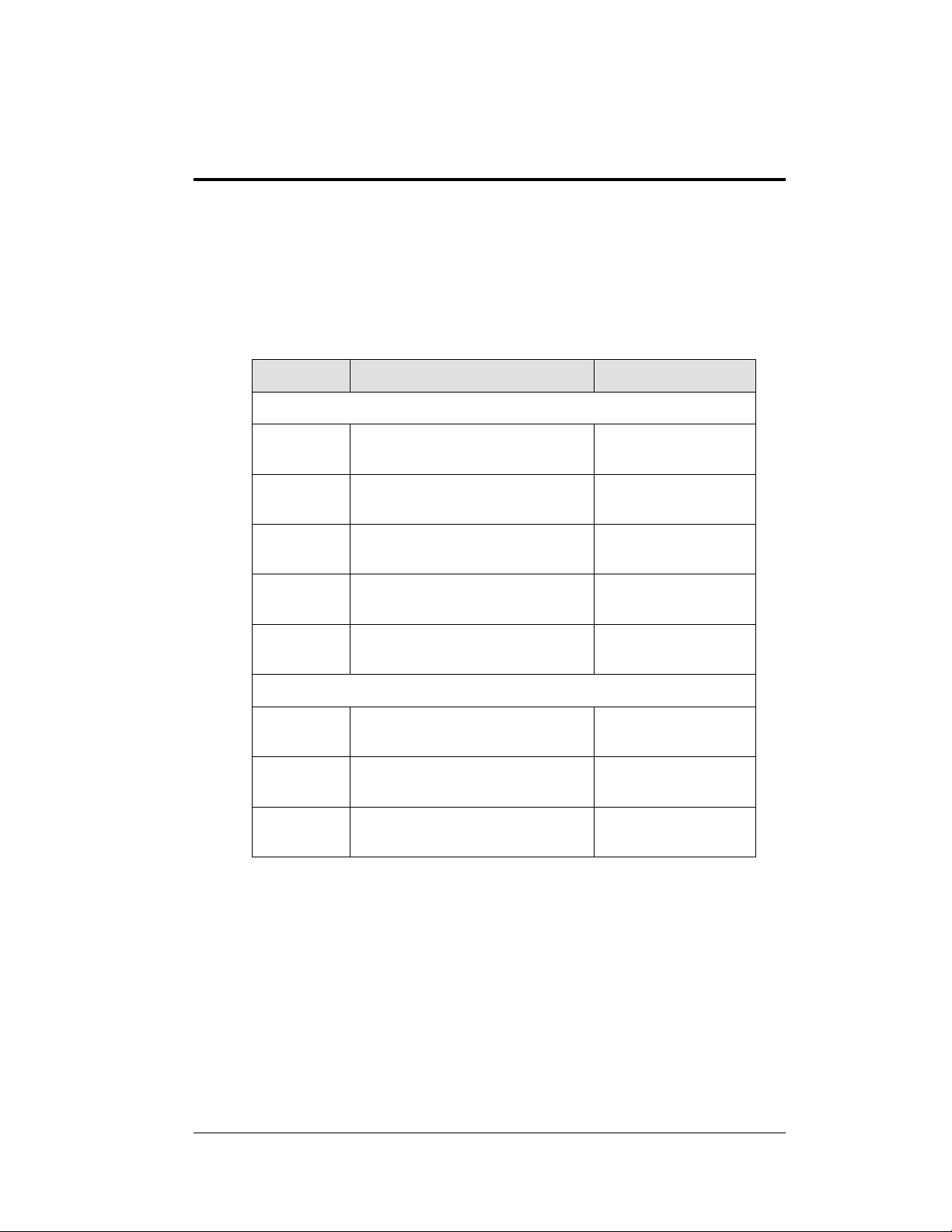

2.1 Mechanical Specifications Drawings

Use the following table to determine the mechanical specifications for your display.

The drawings are listed below by model number; they have been inserted in the

Appendix in alphanumeric order by drawing number.

Model Drawing Title Drawing Number

Full-Cabinet Displays (DF-1020 Series)

DF-1020-13 Mechanical Specs, DF-1020-13, G3 Drawing A-181220

DF-1020-18 Mechanical Specs, DF-1020-18, G3 Drawing A-181224

DF-1020-24 Mechanical Specs, DF-1020-24, G3 Drawing A-181234

DF-1020-36 Mechanical Specs, DF-1020-36, G3 Drawing A-165742

DF-1020-48 Mechanical Specifications,

DF-1020-48, G3

Front-Insertion/Drop-In Displays (DF-1021 Series)

DF-1021-13 Mechanical Specs, DF-1021-13, G3 Drawing A-185176

DF-1021-18 Mechanical Specs, DF-1021-18, G3 Drawing A-185203

DF-1021-24 Mechanical Specs, DF-1021-24, G3 Drawing A-185205

2.2 Electrical Specification Drawings

Use the following table to determine the electrical specifications for your display.

The drawings are listed below by model number; they have been inserted in the

Appendix in alphanumeric order by drawing number.

Drawing A-181672

Gasoline Price

Display Specifications

2-1

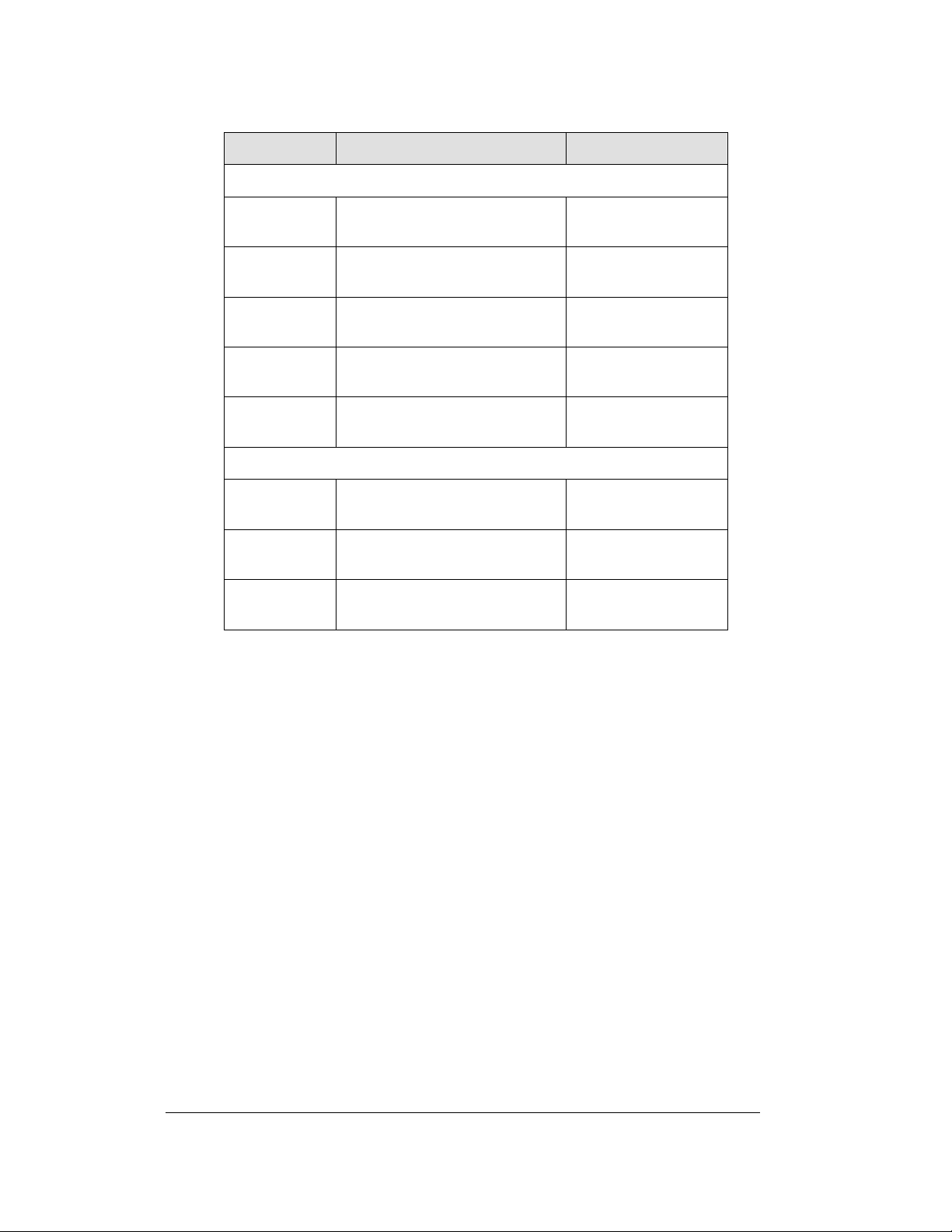

Page 18

Model Drawing Title Drawing Number

Full-Cabinet Displays (DF-1020 Series)

DF-1020-13 Electrical Specs, DF-1020-13, G3 Drawing A-181222

DF-1020-18

DF-1020-24

DF-1020-36

DF-1020-48

Electrical Specs, DF-1020-18, G3 Drawing A-181233

Electrical Specs, DF-1020-24, G3 Drawing A-181235

Electrical Specs, DF-1020-36, G3 Drawing A-165743

Electrical Specs, DF-1020-48, G3 Drawing A-181673

Front-Insertion/Drop-In Displays (DF-1021 Series)

DF-1021-13 Electrical Specs, DF-1021-13, G3 Drawing A-185177

DF-1021-18

DF-1021-24

Electrical Specs, DF-1021-18, G3 Drawing A-185204

Electrical Specs, DF-1021-24, G3 Drawing A-185206

2-2

Gasoline Price

Display Specifications

Page 19

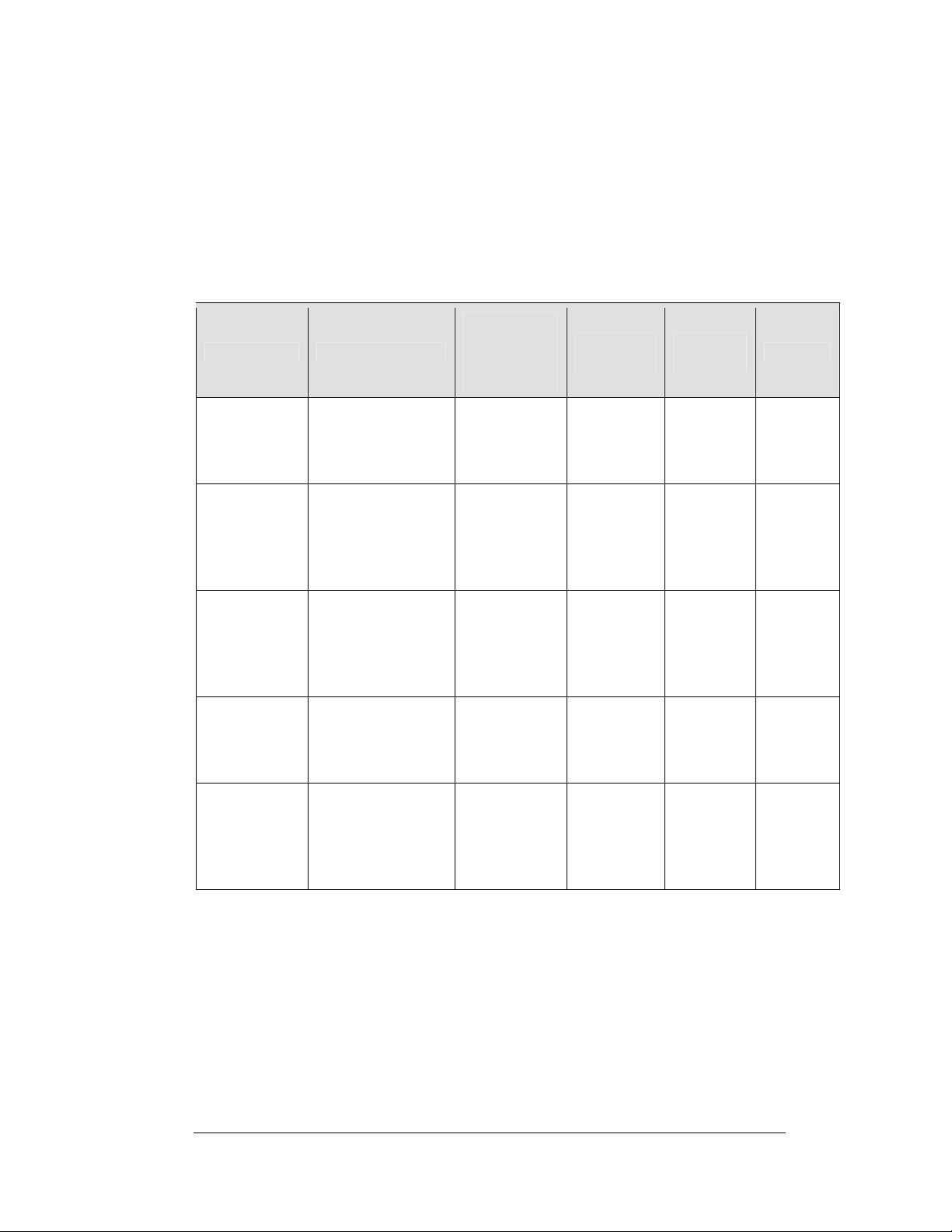

2.3 Specifications

The table below shows all of the mechanical specifications, circuit specifications, and

maximum power requirements for each model in this series. Models are listed in

alphanumeric order by digit size.

DataMaster Gasoline Price Displays

Weight

Model Dimensions

Uncrated

Crated

Digit

Size/Color

Maximum

Wattage

Circuit

DF-1020-13-A

DF-1020-13-R

DF-1020-18-A

DF-1020-18-R

DF-1020-24-A

DF-1020-24-R

DF-1020-36-A

DF-1020-36-R

DF-1020-48-A

DF-1020-48-R

H1’-6", W4’-0", D6"

(457 mm, 1219 mm,

152 mm)

H2’-0", W5’-0", D6"

(610 mm, 1524 mm,

152 mm)

H2’-6", W6’-6", D6"

(762 mm, 1981 mm,

152 mm)

H3’-6", W8’-6", D8"

(1067 mm, 2591

mm, 203 mm)

H4’-6", W11’-0", D8"

(1372 mm, 3353

mm, 203 mm)

36 lb (16 kg)

58 lb (26 kg)

60 lb (27 kg)

96 lb (44 kg)

90 lb (41 kg)

144 lb (65 kg)

160 lb (73 kg)

256 lb (116 kg)

280 lb

(127 kg)

448 lb (203 kg)

13"

(330 mm)

Amber, red

18"

(457 mm)

Amber, red

24"

(610 mm)

Amber, red

36"

(914 mm)

Amber, red

48"

(1219 mm)

Amber, red

150 W

150 W

150 W

300 W

300 W

120 V AC

1.3 A

120 V AC

1.3 A

120 V AC

1.3 A

120 V AC

2.5 A

120 V AC

2.5 A

Gasoline Price

Display Specifications

2-3

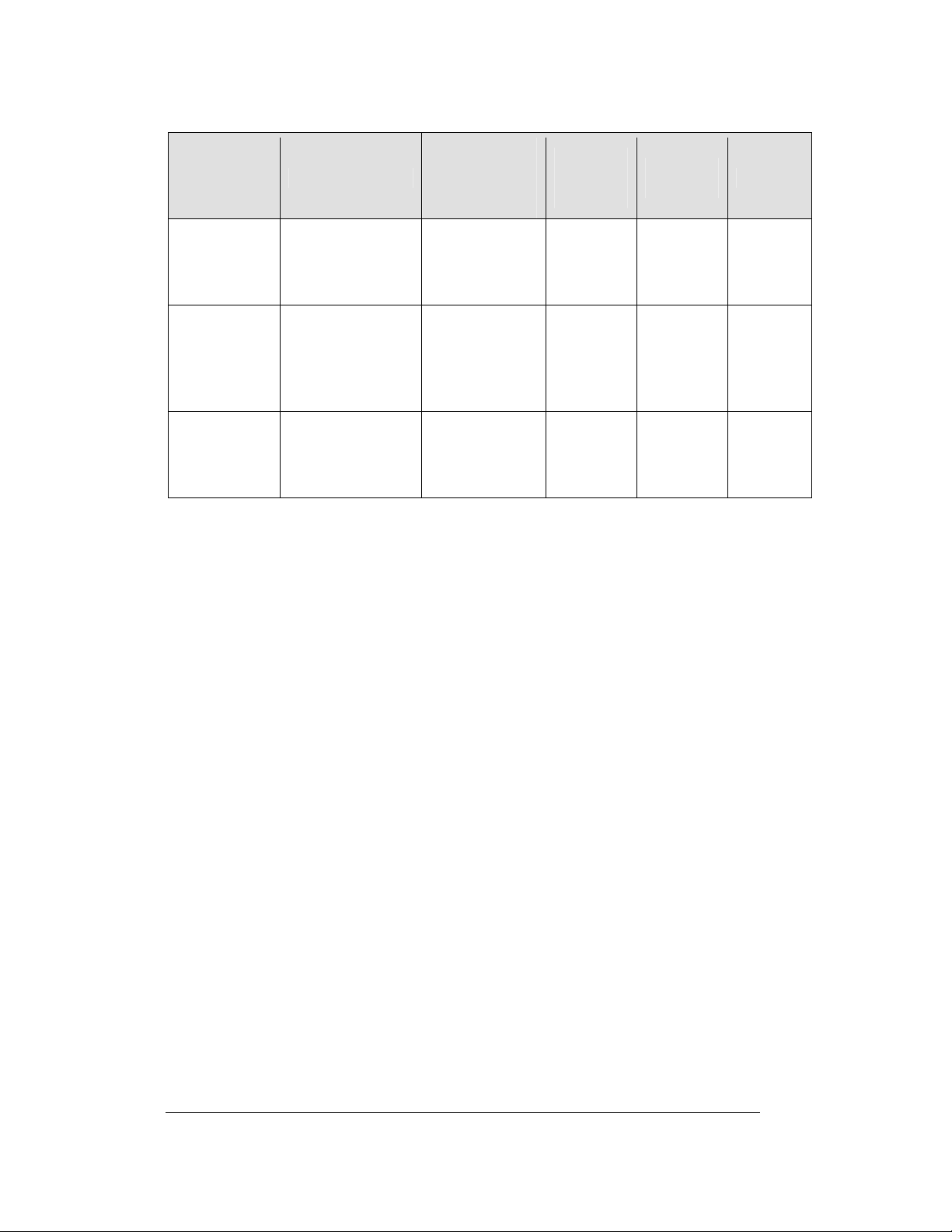

Page 20

Model Dimensions

DF-1021-13-A

DF-1021-13-R

DF-1021-18-A

DF-1021-18-R

DF-1021-24-A

DF-1021-24-R

H1’-6", W4’-0", D6"

(457 mm, 1219

mm, 152 mm)

H2’-0", W5’-0", D6"

(610 mm, 1524

mm, 152 mm)

H2’-6", W6’-0", D6"

(762 mm, 1829

mm, 152 mm)

Weight

Uncrated

Crated

36 lb (16 kg)

58 lb (26 kg)

60 lb (27 kg)

96 lb (44 kg)

90 lb (41 kg)

144 lb (65 kg)

Digit

Size/Colo

r

13"

(330 mm)

Amber, red

18"

(457 mm)

Amber, red

24"

(610 mm)

Amber, red

Maximum

Wattage

150 W

150 W

150 W

Circuit

120 V AC

1.3 A

120 V AC

1.3 A

120 V AC

1.3 A

2-4

Gasoline Price

Display Specifications

Page 21

Section 3: Mechanical and Electrical

Installation

Mechanical installation typically consists of installing concrete footings and steel beams and

mounting the display and any accompanying panels to the beams.

Electrical installation consists of the following processes:

Providing power and ground to a disconnect near the display.

Routing power and ground from the main disconnect to the display driver/power

enclosure.

Connecting the display ground to a grounding electrode at the sign location.

Routing the control signal cable from the control location to the sign location.

3.1 Mechanical Installation

Reference Drawings:

Mounting Method, Flag Style, One Pole......................Drawing A-166139

Mounting Method, Single Line on One Pole................Drawing A-166142

While DataMaster outdoor digit displays are designed for wall or pole mounting, every

installation will be different. Actual site demands will dictate the appropriate mounting

method. Most DataMaster models have fully finished exteriors, for example, but other

models are designed to be inserted into an existing sign cabinet and require a custom

installation.

The engineering drawings referenced above detail a number of mounting methods,

from a single display on a single column support to multiple displays stacked above

one another in a two-pole installation. The drawings include welding and hardware

notes that will be applicable for most installations.

Note: The drawings suggest mounting methods and are not to be considered as

specifications for construction. The actual mounting hardware and structural

design must be specified by a qualified engineer.

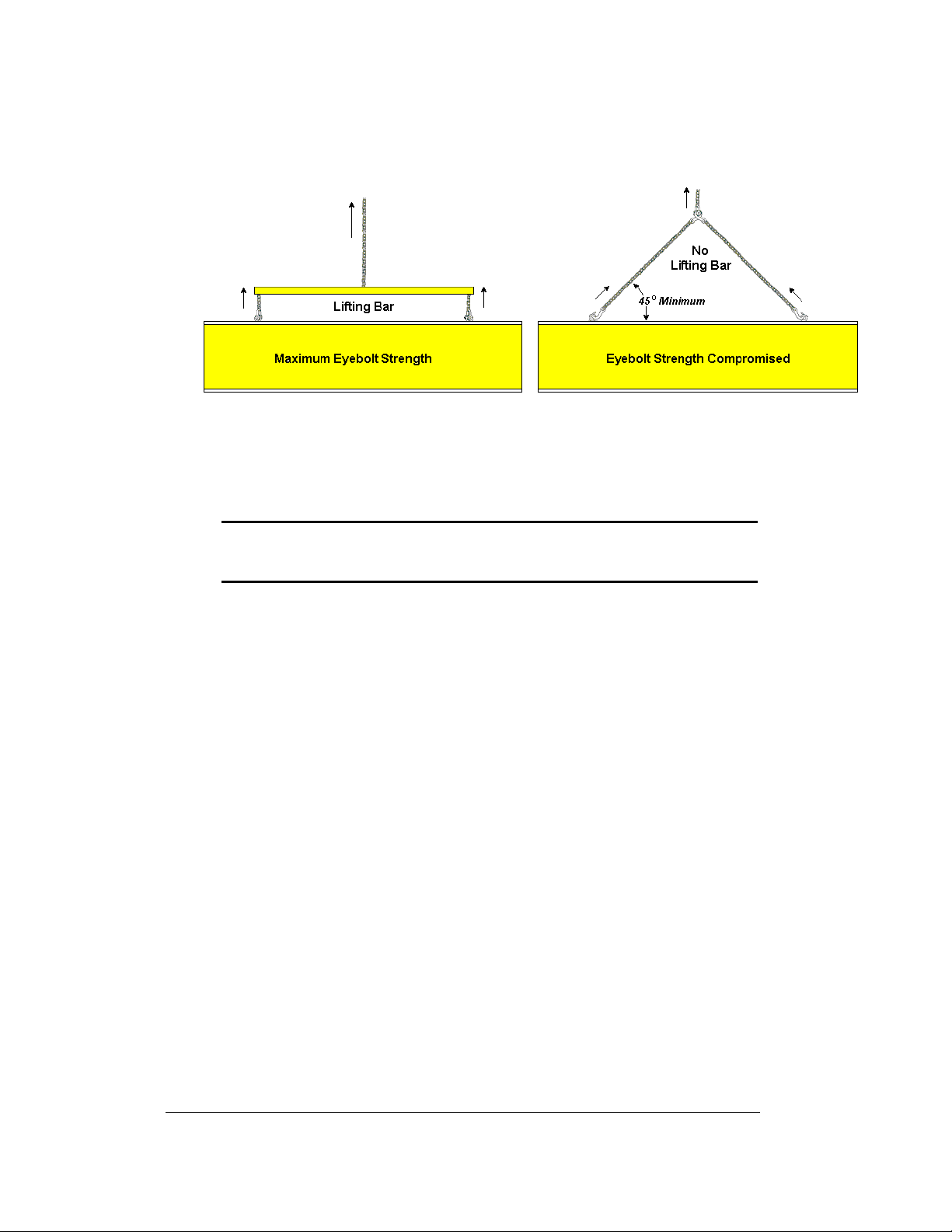

Lifting the Display

Model DF-1020 displays are shipped equipped with 3/8" eyebolts that are used for

lifting and positioning the modules. Eyebolts are located along the top outer edges of

the cabinet. Model DF-1021 drop-in displays are not so equipped.

Mechanical and 3-1

Electrical Installation

Page 22

Daktronics strongly recommends using a spreader bar, or lifting bar, to lift the

display. Using a spreader bar ensures that the force on the eyebolts is straight up,

minimizing lifting stress. Figure 4, below, illustrates two lifting methods.

Figure 4: Lifting the Display

The illustration shows both the preferred method (left example) and an alternative

method (right example) for lifting a display. Be sure to use every lifting point

provided.

Note: Daktronics assumes no liability for display damage or injury

resulting from incorrect setup or incorrect lifting methods.

Eyebolts are intended for lifting during installation o nly. Do not attempt to

permanently support the display by the eyebolts.

In installations in which an ad panel or some other display section may be added to

the base display, the lower section is installed first and secured to the support beams,

and then the upper section is placed atop or above the lower sign section and

attached to the beams. There may be cables extending from the top of the lower

section. Guide these cables into the hole in the bottom of the upper section for later

connection.

Installers may remove the lift eyebolts once the display is in place. On models with

13", 18" or 24" digits, thread

digits, install

1

/2"-13 bolts in the holes.

3

/8"-13 bolts into the holes. On models with 36" or 48"

3.2 Electrical installation

Reference Drawing:

Quick Install, DF-1020 Gas Price Displays................. Drawing A-189768

Drawing A-189768 provides detailed instructions for power and signal connections

for Gas Price displays, including hookup of the light sensor and connections

between host and client displays. Refer to this drawing before undertaking any part

of the electrical installation.

3-2

Mechanical and

Electrical Installation

Page 23

Note: Only qualified individuals should perform power routing and termination

to the display. It is the responsibility of the electrical contractor to ensure that

all electrical work meets or exceeds local and national codes.

Power

Reference Drawings:

Schematic; Multipurpose 4 Col. LED Drvr.............Drawing A-165028

Schematic; Gen III Outdoor LED,

8 Column Drvr.................................................Drawing A-177935

Schematic; 16 Col Multipurpose LED Drvr............Drawing A-179599

Daktronics DataMaster displays have been designed for easy access to components,

and the power and control signal hookup has been simplified. Front panels are

removable or hinged to allow access to the digits, cabling, and other electronic

components.

Correct power installation is imperative for proper display operation. The

subsections that follow give details of display power installation. Only qualified

individuals should attempt to complete the electrical installation; untrained personnel

should not attempt to install these displays or any of the electrical components.

Improper installation could result in serious damage to the equipment and could be

hazardous to personnel.

The DataMaster outdoor displays require a dedicated, 120 V circuit for incoming

power. The display itself has no breakers or fuses.

WARNING: It is critical that the display circuit be fused at 15 A, and that all

conductors used must be designed to pass a 15 A current in normal operation.

Failure to meet wiring and overcurrent protection device requirements is a

violation of the National Electrical Code

®

and will void the display warranty.

Refer to the DataMaster display schematics listed above and to the chart in Section 2

to determine circuit specifications and maximum power requirements for the models

described in this manual.

Grounding

Reference Drawings:

Schematic; Multipurpose 4 Col. LED Drvr.............Drawing A-165028

Schematic; 16 Col Multipurpose LED Drvr............Drawing A-179599

Enclosed Driver, 4 Column Reference..................Drawing A-184918

Schematic; Gen III Outdoor LED,

8 Column Drvr.................................................Drawing A-177935

Displays MUST be grounded according to the provisions outlined in Article 250

of the National Electrical Code and according to the specifications in this

manual. Daktronics recommends a resistance-to-ground of 10 ohms or less.

Mechanical and 3-3

Electrical Installation

Page 24

The contractor performing the electrical installation can verify ground

resistance. Technicians from Daktronics Sales and Service offices can also

provide this service.

The display system must be connected to an earth electrode installed at the display.

Proper grounding is necessary for reliable equipment operation. It also protects the

equipment from damaging electrical disturbances and lightning. The display must

be properly grounded, or the warranty will be void. Refer to the schematics,

Drawings A-165028, A-177935, and A-179599, or the driver reference, Drawing

A-184918, for information on where to connect the grounding wire. Connection at

the driver enclosure terminal block is illustrated at the bottom of Drawing 184918.

The material for an earth-ground electrode differs from region to region and may

vary according to conditions present at the site. Consult the National Electrical Code

and any local electrical codes that may apply. The support structure of the display

cannot be used as an earth-ground electrode. The support is generally embedded in

concrete, and if it is in earth, the steel is usually primed or it corrodes, making it a

poor ground in either case.

Power Installation

There are two considerations for power installation: installation with ground and

neutral conductors provided, and installation with only a neutral conductor provided.

These two power installations differ slightly, as described in the following

paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power circuit must contain an isolated earth-ground

conductor. Under this circumstance, do not connect neutral to ground at the

disconnect or at the display. This would violate electrical codes and void the

warranty. Use a disconnect so that all hot lines and neutral can be disconnected. The

National Electrical Code requires the use of a lockable power disconnect within

sight of or at the display.

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with Article

250-32 of the National Electrical Code. If the installation in question meets all of the

requirements of Article 250-32, the following guidelines must be observed:

+ Connect the grounding electrode cable at the local disconnect, never at the

display driver/power enclosure.

+ Use a disconnect that opens all of the ungrounded phase conductors.

3-4

Mechanical and

Electrical Installation

Page 25

3.3 Power and Signal Connection

Reference Drawings

Schematic; Multipurpose 4 Col. LED Drvr...................Drawing A-165028

Enclosed Driver, 4 Column Reference ........................Drawing A-184918

4 Column MASC LED Driver Specifications................Drawing A-166216

Quick Install, DF-1020 Gas Price Displays..................Drawing A-189768

Schematic; Gen III Outdoor LED, 8 Column Drvr........Drawing A-177935

Schematic; 16 Col Multipurpose LED Drvr..................Drawing A-179599

8 Column MASC LED Driver Specifications................Drawing A-167237

16 Col. MASC Driver Specification..............................Drawing A-184475

Route power and signal cables into the display from the side or rear. There are

knockouts for

and on the back panels. All power and signal wiring terminates at the driver

enclosure.

Refer to Drawing A-189768 for a complete review of power and signal connections

for Gasoline Price displays. Drawings A-184918, A-167237 and A-184475 illustrate

and provide connection specifications for drivers used in DataMaster Gas Price

displays. The schematics listed above detail both the wiring in the enclosure and

external connections to the display. Power and signal connections, illustrated in

Figure 5 below, are similar for all three drivers.

1

/2" and 3/4" conduit fittings on the sides of all DataMaster cabinets

Figure 5: DataMaster Driver Enclosure with 4-Column Driver

Mechanical and 3-5

Electrical Installation

Page 26

To gain access to the driver enclosure, open the access door and remove the cover

from the enclosure. Refer to the electrical specifications drawings for the access

location for your sign.

Connect the power and signal cables at the appropriate locations on the driver

enclosure panel, as shown in Drawing A-184918.

The power feeder circuit connects directly to a terminal block in the driver

enclosure. The block is located in the bottom center of both types of driver

enclosure. Refer to the driver illustrations and the schematics, Drawings A-165028,

A-177935 and A-179599, for wiring details.

Route signal cabling to the terminal block on the lower left edge of the enclosure

(see Figure 5). The connections are labeled to permit easy installation. (In the 16column enclosure, the signal block is at bottom center.) For signal cable, Daktronics

recommends 2-pair shielded cable, 22 AWG (Daktronics part number W-1234).

Host/Client and Master/Slave Definitions and Address

Settings

Reference Drawings:

Host/Client and Master/Slave Definitions ............. Drawing A-168376

4 Column MASC LED Driver Specifications......... Drawing A-166216

8 Column MASC LED Driver Specifications......... Drawing A-167237

16 Col. MASC Driver Specifications.....................Drawing A-184475

One driver at each sign installation is designated as the “host driver”. This driver

receives its signal directly from the controller on the Signal In terminals, and it is the

only driver that is connected to the light/temp sensor. The Sign al Out terminals are

used to connect to “client drivers”.

Select the host driver by inserting the Protocol 4 plug into the 5-pin protocol jack

(J20.) For protocol jack location, refer to the driver specifications drawings listed

above.

The 12 V DC terminals connected to the host driver (see “Signal Connections” in

Figure 5) run to the controller junction box. This output is used to power the

DataMaster 100 controller.

All other drivers in the display system are client drivers. These drivers receive signal

from the host driver on the Signal In terminals and can re-drive this signal to other

“client drivers” on the Signal Out terminals.

Some multiple-module signs use “slave displays”. These displays do not contain a

driver and may use either the client or host digit outputs. Refer to Drawing A-

168376 for an illustration of the client/host driver and master/slave display setups.

The address of each driver is set using the address jack (J19), and the address setting

is based on that driver's position in the sign or display system. If a single-line sign is

3-6

Mechanical and

Electrical Installation

Page 27

used, the address will typically be address “1”. This is the default addr ess plug that is

shipped with each display. In a multiple-module display, the address plug determines

which line of information is shown on the drivers' digits. The address plug for each

line is included in the address plug kit, if applicable.

3.4 Light Sensor Installation

Reference Drawing:

Light Sensor Installation, G3........................................Drawing A-183775

Displays in the DataMaster series use a light sensor to regulate sign dimming

functions. (Dimming involves decreasing overall display intensity, both for better

display viewing and to prolong LED life. The brightness level should be highest

during the day to compete with daylight, and lower at night.) Use Drawing A-

183775 and the following instructions to install the light sens or in your DataMaster

Gasoline Price display. If the sign or sign system has more than one display, install

the light sensor in the host display only.

1. Remove the screws on the front

of the display and open the

hinged access door.

2. Locate and remove the

plastic plug from front panel of

the display, as shown in Figure

6. The location of the plug varies

by model. Refer to the

mechanical specifications

drawings for model-specific

information.

3. There are two 6-32 studs above

and below the plughole. Position

the internal light sensor assembly

on the studs, with the clear lens

toward the front of the cabinet

and the cable at the bottom.

Secure the sensor with the plastic

wing nuts provided with the

assembly kit.

4. Route the signal cable to the driver and insert the 6-postion plug into the

mating jack on the driver, TB1.

5. Close the hinged access doors and replace the screws.

5

/8"

Figure 6: Internal Light Sensor

Mechanical and 3-7

Electrical Installation

Page 28

Page 29

Section 4: Display Maintenance

and Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair or maintenance

work on the display!

2. Allow only qualified service personnel access to internal

display electronics.

3. Disconnect power when not using the display.

4.1 Cabinet Specifications

Cabinets for the Daktronics outdoor LED digit displays are constructed of heavygauge aluminum. Exact dimensions and weights for each model are listed in the

chart in Section 2. Hinged panels for servicing digits and indicators and for

component access are detailed in each model's mechanical specifications drawing.

4.2 Component Location and Access

For the front-access modules in this series, all internal electronic components and

digits can be reached by opening one of the hinged access doors on the front of the

display. Each door swings outward when the two screws on the display face panel

are removed, as shown in Figure 7. For front and opened views of the displays, refer

to your model's electrical and mechanical specifications drawings, listed in Sections

2.1 and 2.2.

Figure 7: DataTime Time and Temp Display with Door Panels Open

Maintenance and 4-1

Troubleshooting

Page 30

Component placement varies slightly with each DataMaster model; consult the

model-specific mechanical drawing to determine the layout for your display.

Note: Disconnect power before servicing the display! Disconnect power, too,

when the display is not in use. Prolonged power-on may shorten the life of some

electronic components.

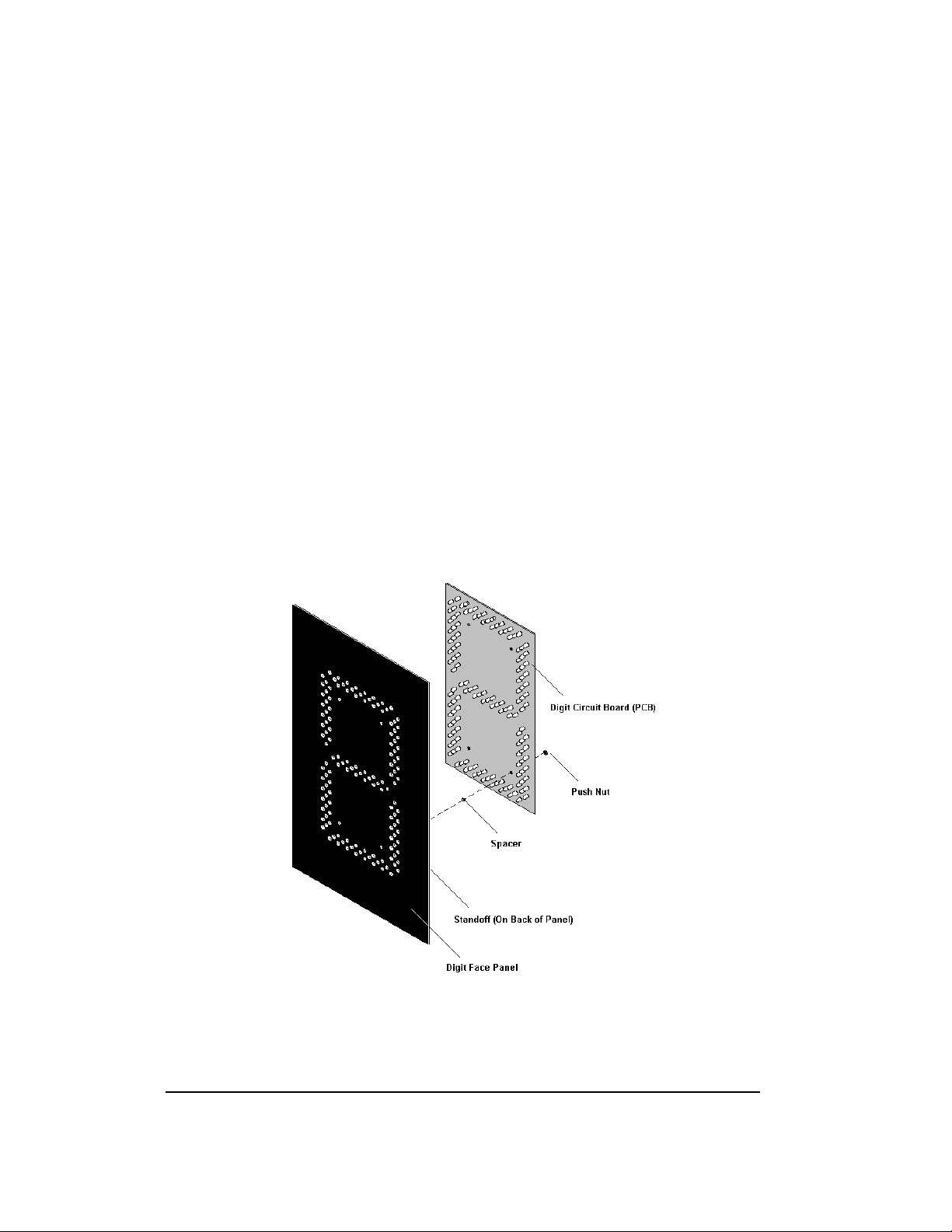

Replacing a Digit

The digit circuit board, the platform for the LEDs, is mounted to the back of the digit

panel. Do not attempt to remove individual LEDs. In the case of a malfunctioning

board, replace the entire digit panel. Refer to Figure 8 below.

To remove a display digit, follow these steps:

1. Open the digit panel as described in the preceding section.

2. Disconnect the power/signal connector from the back of the digit. Release

the connector by squeezing together the locking tabs as you pull the

connector free.

3. The digits are secured to the inside of the panel with fixed machine screws,

spacers, and push nuts. Remove the nuts and lift the digit off the standoff

screws. (The push nuts can be removed in several ways, but Daktronics

recommends using a

9

/32" nut driver.)

Figure 8: Digit Assembly

4-2

Maintenance and

Troubleshooting

Page 31

4. Position a new digit over the screws and tighten the nuts.

5. Reconnect the power/signal connector. Note: This is a keyed connector, it

6. Close and secure the digit panel and test the display.

Replacing a Digit Segment

When a digit malfunctions, in most cases it is

necessary to replace the entire digit circuit board.

Some larger digits (24", 36", 48"), however, may

be constructed in segments, as shown in Figure

9 and it may be possible to make repairs by

removing only the defective segment. As with

smaller digits, the digit segment circuit boards

are mounted to the back of the digit panel. Do

not attempt to remove individual LEDs.

To remove a digit segment, follow these steps:

1. Open the digit panel as described

2. Disconnect the 2-pin power/signal

3. The individual segments are secured to the inside of the panel with fixed

4. Position a new segment over the screws and tighten the nuts.

5. Reconnect the power/signal connector. Note: This is a keyed connector it

6. Close and secure the digit panel and test the display.

Replace a malfunctioning colon, decimal, or indicator assembly in the same manner.

will attach in one way only. Do not attempt to force the connection!

above.

connector from the back of the

individual segment. Release the

connector by squeezing together the

locking tabs as you pull the connector

free.

machine screws, spacers, and push nuts. Remove the nuts and lift the

segment off the standoff screws.

will attach in one way only. Do not attempt to force the connection!

Figure 9: Segmented Digit Panel

(Rear View)

Replacing a Driver

Drivers are typically mounted inside the display and immediately behind a digit, but

location and mounting varies by model. Refer to the component locations drawings

in Section 2 for the location of your driver. All displays in this manual are frontaccessible.

Each driver is enclosed with a power supply and signal terminal block. Before a

failed driver can be reached, the enclosure must be accessed. Follow these steps:

1. Open the digit panel or display face panel as described in Section 4.2.

2. Remove the cover from the driver enclosure.

Maintenance and 4-3

Troubleshooting

Page 32

3. Disconnect all connectors from the driver. Release each connector by

squeezing together the locking tabs as you pull the connector free. Note:

When reconnecting, remember that these are keyed connectors and

will attach in one way only. Do not attempt to force the connections.

4. Remove the screws, nuts, or wing nuts securing the driver to the inside of

the enclosure.

5. Carefully lift the driver from the display and place it on a clean, flat surface.

6. Follow steps 1 through 5 in reverse order to attach a new driver.

4.3 Schematics

Reference Drawings:

Schematic; Multipurpose 4 Col. LED Drvr................... Drawing A-165028

Schematic; Gen III Outdoor LED, 8 Column Drvr ....... Drawing A-177935

Schematic; 16 Col Multipurpose LED Drvr.................. Drawing A-179599

Drawings A-165028, A-177935, and A-179599 are the schematic diagrams for the

4-, 8- and 16-column drivers used in the DataMaster Gas Price displays. The

schematics include power and signal inputs and all wiring for the models described

in this manual.

4.4 LED Drivers

Reference Drawings:

4 Column MASC LED Driver Specifications......... Drawing A-166216

8 Column MASC Driver Specifications................. Drawing A-167237

16 Col. MASC Driver Specification.......................Drawing A-184475

In the display, the LED drivers perform the task of switching digits on and off. Refer

to Drawings A-166216 or A-184475 for a complete listing of driver connector

functions and wiring pin numbers.

DataMaster Gas Price displays may use 4-, 8-, or 16-column drivers, depending on

the model and size of digits. Each 16-column driver has 20 or more connectors

providing power and signal inputs to the circuit, and outputs to the digits and

indicators. The following table describes connector functions for a 16-column driver.

(Major functions are the same on 4- and 8-column drivers.)

Connector No. Function

J1 – 16 Outputs to digits

J17 Power and signal input

16-Column LED Driver

J18 Relay

J19 Address

4-4

Maintenance and

Troubleshooting

Page 33

Connector No. Function

16-Column LED Driver

J20 Protocol

J21-22 ISP

J23 12 V DC out

J24 Modem

J28 Switch inputs

TB1 CAN (photo/temp sensor)

Output connectors 1 through 16 each have nine pins. Pin 7 provides power (hot) to

the digit or indicators wired to that connector. The other eight pins provide switching

connections.

The display line controlled by the driver is set with jumper wires in the 12-p in

address plug inserted in jack J19. All DataMaster displays ship with a “Line 1” plug

installed.

4.5 Segmentation and Digit Designation

Reference Drawing:

Segmentation, 7 Segment Bar Digit ..............................Drawing A-38532

In each digit, certain LEDs

always go on and off together.

These groupings of LEDs are

referred to as “segments”.

Drawing A-38532 illustrates

digit segmentation. It also

details which connector pin is

wired to each digit segment

and the wiring color code used

throughout the display.

The component locations

drawings in Section 2 specify

the driver connectors

controlling the digits. Numbers

displayed in hexagons in the

upper half of each digit, as shown in Figure 10, indicate which connector or

connectors are wired to that digit. (Larger digits, like the 36" digits shown in Figure

10, are each wired to two connectors.)

Figure 10: Digit Designation

Maintenance and 4-5

Troubleshooting

Page 34

4.6 Troubleshooting

This section lists potential problems with the display, indicates possible causes, and

suggests corrective action. This list does not include every possible problem, but it

does represent some of the more common situations that may occur. (Refer to the

appropriate manual for a list of potential problems with add-on or separately

mounted message centers.

Symptom/Condition Possible Cause

Garbled display

Digit will not light

Segment will not light

Segment stays lit

Data appears in the wrong place

on the display, wrong data on a

particular line of the display

Internal driver logic malfunction

Control console malfunction

Black wire to digit broken

Poor contact at driver connection

Driver malfunction

Broken LED or connection

Driver shift register failure

Broken wire between driver and digit

Poor contact at driver connector

Driver shift register failure

Short circuit on digit

Incorrect address settings on drivers

(Refer to “Power On Self-Test” in the

following section, and consult tables to set

correct addresses.)

Some DataMaster displays have their own built-in troubleshooting mechanism.

Failures that may occur in the display driver are described using codes. In the event

a sign malfunctions, a failure code registers by displaying an “Ex” value on the first

two digits of the display. “E” simply indicates an error, and the letter “x” represents

the actual code number. Refer to the following table for a description of each failure

code and for possible solutions.

Note: The LCD screen on the DataMaster 100 controller will not show the

failure codes described in the table below. Failure codes will only be displayed

on the DataMaster sign.

4-6

Maintenance and

Troubleshooting

Page 35

Failure Code Description Possible Solution

E1 Protocol Setting Error: There is an

unsupported driver protocol

setting.

E2 Time Error: There is no valid time

stored in the driver; it may be a

failure of the real-time clock on

board or other timekeeping

device.

E3 Temp Error: There is no response

from the temp sensor or light

sensor, or general temp sensor

failure.

E4 No Message Error: This code is

shown when there are no

messages downloaded to the

display

E5 No Line Number Selected Error:

The driver for this line has a

Protocol 4 plug installed in J20,

but there is no address plug

installed in J19.

Check the value set in the protocol

plug of the driver (J20).

Set the time in the display using the

Set Time menu option on the

DataMaster 100 controller.

(DataTime Time & Temp displays

only)

Check the temp sensor location and

verify all connections. Refer to the

instruction sheet for the CAN

Temperature/Light Sensor

mounting, ED13364.

Note: The temp sensor takes

approximately 10 seconds to

initialize on power-up. The sign

will display this error until

initialization is complete.

Download a new message to the

display using the <

SEQUENCE

100 controller.

Set the line number by installing the

correct plug in J19. The Protocol 4

plug designates this driver as the

“host “. If this is not the host,

remove the Protocol 4 plug from

J20.

DISPLAY

> key on the DataMaster

Power On Self-Test:

A useful troubleshooting tool is the power on self-test the host driver performs every

time it powers up:

+ If the signal wiring between each controller is correct, the first two digits of

each driver will display “Ad” momentarily, and the first digit will then flash

three numbers indicating the decimal address that is set with the address

plug in J19. (If a client driver displays “A <number>,” followed by “P

Maintenance and 4-7

Troubleshooting

Page 36

<number>,” it is not receiving “signal in,” and is performing its own selftest.)

+ Next, the first two digits of each line will display “Lx”, where “x” is the line

number that the driver is set to control (set with address plug).

+ Finally, each line will display “1234…” according to the column number of

each of its digits. Every line should show “1” on the left-most digit, and all

digits should be numbered consecutively from left to right. If this is not the

case, either the wrong address plug is installed, or the driver or digit harness

is connected incorrectly.

If there is no address plug in the host driver, the host driver will display “E5,” and

all client drivers will continually cycle through the power on self-test.

4.7 Lightning Protection

The use of a disconnect near the display to completely cut all current-carrying lines

significantly protects the circuits against lightning damage. The National Electrical

Code also requires it. In order for this device to provide protection, the power must

be disconnected when the display is not in use. The control console should also be

disconnected from power and from the signal j-box when the system is not being

used. The same surges that may damage the display's driver can also damage the

console's circuit.

4.8 Replacement Parts

4-8

Maintenance and

Troubleshooting

Page 37

Refer to the following table for Daktronics replacement parts.

Description

Daktronics

Part No.

Light sensor, G3 0A-1279-0203

Protocol plug (Protocol 4) 0A-1279-0089

Transformer, wall pack (for DataMaster 100) T-1118

DataMaster 100 hand-held controller 0A-1196-0088

Junction box, outdoor, 9-pin D-male 0A-1196-0093

Junction box, indoor, 9-pin D, male 0A-1196-0099

Power supply, 24 V DC, 150 W A-1720

Signal surge suppression board 0P-1110-0011

Driver, 4-column MASC, LED 0P-1192-0068

Driver, 8-column MASC, LED 0P-1192-0082

Driver, 16-column, MASC, LED 0P-1192-0086

DataMaster 100 outdoor wired installation kit 0A-1279-0087

DataMaster 100 indoor wired installation kit 0A-1279-0103

Maintenance and 4-9

Troubleshooting

Page 38

Description Daktronics

Part No.

Cable, 6-conductor, 22 AWG (for radio installation) W-1210

Cable, serial, DB9 male to DB9 female W-1267

Digit, 13" red, pc board 0P-1192-0200

Digit, 13" amber, pc board 0P-1192-0214

Digit, 13" 9/10, red, pc board 0P-1192-0234

Digit, 13" 9/10, amber, pc board 0P-1192-0234

Digit, 18" 7-segment, red, pc board 0P-1192-0235

Digit, 18" 7-segment, amber, pc board 0P-1192-0216

Digit, 13" 7-segment, red, w/ faceplate 0A-1192-2223

Digit, 13" 7-segment, amber, w/ faceplate 0A-1192-2224

Digit, 18" 7-segment, red, w/ faceplate 0A-1192-2227

Digit, 18" 7-segment, amber, w/ faceplate 0A-1192-2228

Digit, 24" 9/10 red, pc board 0P-1192-0232

Digit, 24" 9/10 amber, pc board 0P-1192-0233

Digit, 24" 7-segment, red, w/ faceplate 0A-1192-2231

Digit, 24" 7-segment, amber, w/ faceplate 0A-1192-2232

Digit segment, 24" red, vert 0P-1192-0204

Digit segment, 24" red horiz 0P-1192-0205

Digit segment, 24" amber, vert 0P-1192-0218

Digit segment, 24" amber horiz 0P-1192-0219

Digit, 24" 9/10 red, w/faceplate 0P-1192-2359

Digit, 24" 9/10 amber, w/faceplate 0P-1192-2360

Digit, 36" 7-segment, red, hinged 0A-1279-0195

Digit, 36" 7-segment, amber, hinged 0A-1279-0196

Digit segment, 36" red, vert 0P-1192-0208

Digit segment, 36" red horiz 0P-1192-0209

Digit segment, 36" amber, vert 0P-1192-0222

Digit segment, 36" amber horiz 0P-1192-0223

4-10

Maintenance and

Troubleshooting

Page 39

Description Daktronics

Digit, 48" 7-segment, red, hinged 0A-1279-0181

Digit, 48" 7-segment, amber, hinged 0A-1279-0182

Digit segment, 48" red, vert 0P-1192-0212

Digit segment, 48" red horiz 0P-1192-0213

Digit segment, 48" amber, vert 0P-1192-0226

Digit segment, 48" amber horiz 0P-1192-0227

Decimal, 13" red, pc board (used in DF-1020-13) 0P-1192-0238

Decimal, 13" amber, pc board (used in DF-1020-13) 0P-1192-0239

Part No.

Indicator, 2" red, pc board (used in 18" and 24" displays) 0P-1192-0228

Indicator, 2" amber, pc board (used in 18" and 24" displays) 0P-1192-0229

Indicator, 4" red, pc board (used in 36" and 48" displays) 0P-1192-0244

Indicator, 4" amber, pc board (used in 36" and 48" displays) 0P-1192-0245

Indicator, 4" red w/ face plate (used in 36" and 48" displays) 0A-1192-2434

Indicator, 4" amber w/ face plate (used in 36" and 48" displays) 0A-1192-2435

4.9 Daktronics Exchange and Repair and Return

Programs

To serve customers' repair and maintenance needs, Daktronics offers both an

Exchange Program and a Repair and Return Program. Daktronics' unique Exchange

Program is a quick, economical service for replacing key components in need of

repair. If a component fails, Daktronics sends the customer a replacement, and the

customer, in turn, sends the failed component to Daktronics. This not only saves

money but also decreases display downtime.

Daktronics provides these plans to ensure users get the most from their Daktronics

products, and it offers the service to qualified customers who follow the program

Maintenance and 4-11

Troubleshooting

Page 40

guidelines explained below. Please call the Help Desk – 877-605-1115 – if you have

questions regarding the Exchange Program or any other Daktronics service.

When you call the Daktronics Help Desk, a trained service technician will work with

you to solve the equipment problem. You will work together to diagnose the

problem and determine which exchange replacement part to ship. If, after you make

the exchange, the equipment still causes problems, please contact our Help Desk

immediately.

If the replacement part fixes the problem, package the defective part in the same box

and wrapping in which the replacement part arrived, fill out and attach the enclosed

UPS shipping document, and RETURN THE PART TO DAKTRONICS. In most

circumstances, you will be invoiced for the replacement part at the time it is shipped.

This bill is due when you receive it.

Daktronics expects immediate return of an exchange part if it does not solve the

problem. The company also reserves the right to refuse equipment that has been

damaged due to acts of nature or causes other than normal wear and tear.

If the defective equipment is not shipped to Daktronics within 30 working days from

the invoice date, it is assumed you are purchasing the replacement part, and you will

be invoiced for it. This second invoice represents the difference between the

exchange price and the full purchase price of the equipment. The balance is due

when you receive the second invoice. If you return the exchange equipment after 30

working days from the invoice date, you will be credited for the amount on the

second invoice, minus a restocking fee.

To avoid a restocking charge, please return the defective equipment within 30

days from the invoice date.

Daktronics also offers a Repair and Return program for items not subject to

exchange.

Return Materials Authorization: To return parts for service, contact your local

representative prior to shipment to acquire a Return Material Authorization (RMA)

number. If you have no local representative, call the Daktronics Help Desk for the

RMA. This expedites repair of your component when it arrives at Daktronics.

Packaging for Return: Package and pad the item well so that it will not be

damaged in shipment. Electronic components such as printed circuit boards should

be installed in an enclosure or placed in an antistatic bag before boxing. Please

enclose your name, address, phone number and a clear description of symptoms.

4-12

Maintenance and

Troubleshooting

Page 41

This is how to reach us:

Mail: Customer Service

Daktronics, Inc.

PO Box 5128

331 32nd Ave

Brookings SD 57006

Phone: Daktronics Help Desk: 877-605-1113 (toll free)

or 605-697-4034

Fax: 605-697-4444

E-mail: helpdesk@daktronics.com

Maintenance and 4-13

Troubleshooting

Page 42

Page 43

Section 5: DataMaster 100 Controller

This section describes the DataMaster 100 and includes the following subsections:

+ DM-100 Controller Overview identifies the control equipment, lists replacement

parts, and describes how the DM-100 operates the displays.

+ Control System Overview reviews the three main options for display control.

+ Controller Signal Connection further details the actual setup of the DM-100 when

used in an indoor location and in a base-of-sign application.

5.1 DataMaster 100 Overview

Reference Drawing:

System Riser Diagram, Control Combinations............Drawing A-164988

The DataMaster

designed to operate Daktronics LED

DataMaster

controller, 6

encased in ABS plastic, making it a

durable and convenient control option.

The console’s liquid crystal display

(LCD) guides the user through the

operation of the system.

The DataMaster 100, identified by the

series number DM-100, can be configured

to display gasoline price, motel rates, and

time and temperature data. Refer to

Drawing A-164988 for information on

possible control options and connection

procedures.

For details on configuring the DataMaster

to operate a display, refer to Section 6:

Gas Price Display Operation.

Note: When your carrier delivers your Daktronics order, open the packages

and inspect for shipping damage such as rattles and dents. See that all

equipment is included as shown on the packing slip. Immediately report any

deficiencies to Daktronics. Save all packing materials for shipping if warranty

repair or exchange is needed.

100 Series controller, shown in Figure 11, is a hand-held controller

displays. This lightweight

1

/4" high by 4 1/4" wide, is

Figure 11: DataMaster 100

Replacement Parts List

The following is a list of possible replacement parts for the DataMaster 100

controller. When re-ordering a part, be sure to use its corresponding part number.

DM-100 5-1

Controller

Page 44

Wall pack transformer T-1118

DataMaster 100 controller 0A-1196-0088

Control Insert 0G-164998

Cable, DB-9 male to DB-9 female, 10' W - 1267

Description Daktronics Part No.

Refer to Section 4.9 for details concerning the Daktronics exchange and repair

programs.

5.2 Control System Overview

All of the displays in the LED DataMaster Series have three main control options:

direct wire, radio, and data download from a junction box at the sign. Refer to the

appropriate system riser diagram, listed above, for detailed instructions on control

system setup.

This manual covers direct-wire installations only! For

systems using modem or radio communication, also

refer to the following manuals:

ED13953: DataMaster Modem Installation Manual

ED13894: DataMaster Radio Installation Manual

5-2

DM-100

Controller

Page 45

Wire Control

Reference Drawings:

Riser Diagram, Outdoor Wire Control...................Drawing A-164988

Riser Diagram, Indoor Wire Control......................Drawing A-175342

For display systems using a base-of-sign

connection, the DataMaster 100

controller, shown with a connecting cable

in Figure 12, plugs directly into an

outdoor junction box, where the operator

keys in instructions for the sign.

Typically, the j-box is mounted to the

display pedestal or column support, and

the controller connects with the box via

TIA/EIA-232 signal cable (formerly RS-

232). The controller draws its power from

the display itself. Refer to Drawings A-

175342 and A-164988 for complete

details on both indoor and outdoor directwire installations.

Signal from the junction box enters the

sign and travels to the first display driver

over 2-pair, shielded signal cable. The 22

Figure 12: DataMaster 100 Controller

with Signal Cable

AWG cable must be enclosed in conduit.

Re-driven signal travels from the driver of

the first display to the driver of the next over another line, also 22 AWG shielded

cable in conduit. The process repeats for as many displays as there are in the system.

Once instructions have been input into the display, the driver's memory retains the

data, and the controller can be unplugged. The sign will continue to operate on the

stored information.

Signal cabling is similar for systems where the DataMaster displays will be operated

remotely from a building location, except that the controller requires a wall pack

transformer. The transformer plugs into both the hand-held controller and into a 120

V AC outlet. The DataMaster controller also connects to a junction box to send

signal to the display, but the j-box will be located within the store or office. The

control location can be up to 2000 feet from the actual sign.

The operator changes the display by entering current prices, rates, and operating

instructions on the keypad of the DataMaster controller. For complete details on sig n

operation, refer to Section 6.

DM-100 5-3

Controller

Page 46

5.3 Controller Signal Connection

This section provides information on the setting up the signal connection between

the DM-100 and DataMaster Gasoline Price displays.

Reference Drawing:

System Riser Diagram; Control Combinations.....Drawing A-164988

The DataMaster displays may be controlled from a location inside a building, or

from the base of the display, depending on customer preference. Drawing A-164988

and the subsections that follow provide greater detail on both installations using

signal wire.

Wire Control from the Base of the Sign

This control option, illustrated in

Figure 13, permits operation of the

sign from the base of the display. The

controller is connected to an outdoor

junction box mounted on the display

pole, which routes the signal to the

sign through one 2-pair cable, 22

AWG. Cable is in conduit where

required.

This control option does not require

the controller to be connected to a

power outlet. In this configuration,

the DataMaster 100 uses the sign as a

power source.

To operate the DataMaster display

using this setup, connect the 9-pin to

9-pin cable from the DataMaster

controller to the 9-pin j-box mounted

on the display pole.

Figure 13: Wire Control from Base of Sign

Wire Control from a Building Location

This control option, illustrated in Figure 14, permits operation of the sign from an

indoor control location. The hand-held controller is connected to an indoor junction

box (j-box), which routes the signal to the sign through one 2-pair cable, 22 AWG.

Cable is in conduit where required.

5-4

DM-100

Controller

Page 47

To operate the DataMaster

display using this setup, connect

the 9-pin to 9-pin cable from the

DataMaster controller to the 9pin j-box, and plug the

controller's wall pack transformer

into a 120 V AC outlet.

Figure 14: Wire Control from Building Location

DM-100 5-5

Controller

Page 48

Page 49

Section 6: Gas Price Display Operation

This section covers the basic operation of the DataMaster Gasoline Price display using the

DataMaster 100 controller.

6.1 DataMaster™ Insert and Code

Reference Drawing:

Insert, LL-2551 Price/T&T Display..................................Drawing A-164998

The DataMaster 100 uses a keypad insert to program gas price information into

Daktronics LED DataMaster Gas Price displays.

Figure 15 illustrates the DM-100

insert used to control the

displays. For more details on the

insert, refer to the DataMaster

100 insert drawing, Drawing A-

164998, located in the

Appendix.

If an insert is lost or damaged, a

copy of the insert drawing

located at the end of this section

can be used until a replacement is

ordered.

To start the controller and use the

insert, refer to the display

operation information located in

this section. Read the section

carefully to fully understand the

operation instructions.

Figure 15: DataMaster 100 Insert LL-2551

6.2 Gas Price Display Operation

The DataMaster 100 controller can be configured to program gas price variances

displayed on the LED DataMaster Gas Price sign. The instructions provided in this

section discuss the functions the operator uses to control the Gas Price display.

In the unlikely event that the Gas Price display malfunctions, refer to Appendix B

for some troubleshooting actions that can be taken.

Gas Price 6-1

Display Operation

Page 50

Gas Price Display Startup

To operate the DataMaster Gas Price displays, the DataMaster 100 must first be

programmed to the gas price function. Use the <

the following table as a guide to startup procedures.

LCD Screen Action

SET FUNCTION> key on startup. Use

CURRENT FUNCTION

GAS PRICE

CHANGE FUNCTION?

PRESS SET FUNCT

SELECT FUNCTION

GAS PRICE ↓↑

The DataMaster 100 handheld controller should now be ready for use. The controller

will “remember” the last function setting, so this step should only need to be done

with a new controller, or one that is configured for different displays. To operate the

DataMaster 100, press any of the keys listed in the following gas price sections.

Plug the wall pack transformer into a 120 V AC

power outlet, and connect it to the DataMaster

100.

This display appears briefly.

This message appears next on the screen.

If “GAS PRICE” was shown on the bottom line

of the LCD during startup, do nothing. The

controller will automatically default to previous

Gas Price settings.

If a function other than “GAS PRICE” was

shown on the bottom line of the LCD during

startup, press the <

the second LCD prompt is displayed.

Press the arrow up or down keys<↑↓> until the

gas price option is shown. Press the <

key to accept.

SET FUNCTION> key while

ENTER>

Gas Price Controller Operation

The Gas Price Controller LCD display will default to showing the current display

settings on power up. The following text will be shown on the LCD.

6-2

Gas Price

Display Operation

Page 51

LCD Screen Action

LINE PRICE

1 ↓ $1.23 9/10

<EDIT> TO MODIFY

1 ↓ $1.23 9/10

The display will toggle between these two

screens.

Press the up or down arrow keys <

through the current setting for any of the lines

on the display.

Press the <

the line settings.

ENTER/EDIT> key to modify any of

↑↓> to scroll

Modifying Price Line Settings

The gas price can be modified either by pressing the <EDIT> key during operation

(see Gas Price Controller Operation) or using the <

Refer to the following key to identify the item to be edited.

L = Current line number to be edited

D.CC = Current dollars and cents value to edit

T = Current tenths of cent value to edit

LCD Screen Action

MENU> key (see Menu Items).

EDIT LINE L

$D.CC T/10 ↓

Press any of the number keys to edit the price

value for this line. Press the down arrow key <

to modify the value of the 1/10-cent data for this

line (see note below).

Press <

<

Note: The flashing asterisk on the LCD shows

the current data being edited.

Many displays do not have a changeable 1/10cent digit. Changing the tenths-cent value from 9

on these digits will make the digit appear

incorrect.

ENTER> to accept the new value or press

CLEAR> to abort the changes.

↓>

Dimming

The dimming level of the Gas Price display can be adjusted in two ways. A

temperature/light sensor, mounted near the display, can detect the level of ambient

light at the display location and dim the sign's LEDs accordingly. This function is

known as automatic dimming. When the manual dimming function is selected, the

Gas Price 6-3

Display Operation

Page 52

LEDs remain at the same level of brightness regardless of the level of light detected

at the display.

To select either of these dimming functions, or to enter the Blank Sign function,

press <

DIMMING>. The current setting is shown on the bottom line of the LCD.

LCD Screen Action

DIMMING

1) AUTOMATIC ↓

If AUTOMATIC dimming is selected, the following LCD prompt will be shown:

LCD Screen Action