Page 1

OPERATION MANUAL

DAKOTA ULTRASONICS

MMVVXX

Visual A / B Scan Thickness Gauge

P/N P-149-0002 Rev 1.10, January 2008

Page 2

Dakota Ultrasonics

2

Page 3

CHAPTER ONE INTRODUCTION.......................................................................1

CHAPTER TWO QUICK STARTUP GUIDE........................................................2

CHAPTER THREE KEYBOA RD, MENU, & CONNECTOR REFERENCE.......13

CHAPTER FOUR PRINCIPALS OF ULTRASONIC ME ASUREMENT .............23

CHAPTER FIVE SELECTING THE MEASUREMENT MODE..........................28

CHAPTER SIX MAKING MEASUREMENTS.....................................................31

CHAPTER SEVEN USING THE A-SCAN & B-SCAN DISPLAYS.....................45

CHAPTER EIGHT THRU PAINT MEASUREMENT TECHNIQUE....................70

CHAPTER NINE ADDITIONAL FEATURES OF THE MVX...............................73

CHAPTER TEN DATA STORAGE – SETUP, EDIT, & VIEW GRIDS...............82

CHAPTER ELEVEN SETUPS – CREATE, STORE, EDIT, & RECALL..........100

CHAPTER TWELVE USING THE FLAW MODE FEATURE...........................107

CHAPTER THIRTEEN USI NG THE UTILITY SOFTWARE.............................111

APPENDIX A - VELOCITY TABLE ...................................................................112

APPENDIX B - SETUP LIBRARY.....................................................................114

3

Page 4

Page 5

CHAPTER ONE

INTRODUCTION

The Dakota Ultrasonics model MVX is a visual A / B scan ultrasonic thickness gauge.

Based on the same operating principles as SONAR, the MVX is capable of

measuring the thickness of various materials with accuracy as high as ± 0.001

inches, or ± 0.01 millimeters. The principle advantage of ultrasonic measurement

over traditional methods is that ultrasonic measurements can be performed with

access to only one side of the material being measured.

Dakota Ultrasonics maintains a customer support resource in order to assist users

with questions or difficulties not covered in this manual. Customer support may be

reached at any of the following:

• Dakota Ultrasonics Corporation,

1500 Green Hills Road, #107 Scotts Valley, CA

95066 USA

• Telephone: (831) 431- 9722

• Facsimile: (831) 431-9723

• www.dakotaultrasonics.com

1.1 Disclaimer

Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the first echo from the back surface of the material being

measured. This may result in a thickness reading that is TWICE what it should be.

Responsibility for proper use of the instrument and recognition of this phenomenon

rest solely with the user of the instrument.

1

Page 6

CHAPTER TWO

QUICK STARTUP GUIDE

Turn the MVX on and off using the switch located on the bottom right corner of the

keypad. When MVX is initially turned on, a flash logo and blinking lights will be

displayed prior to entering into the main measurement screen. Note: This section is

primarily written as a basic startup guide only.

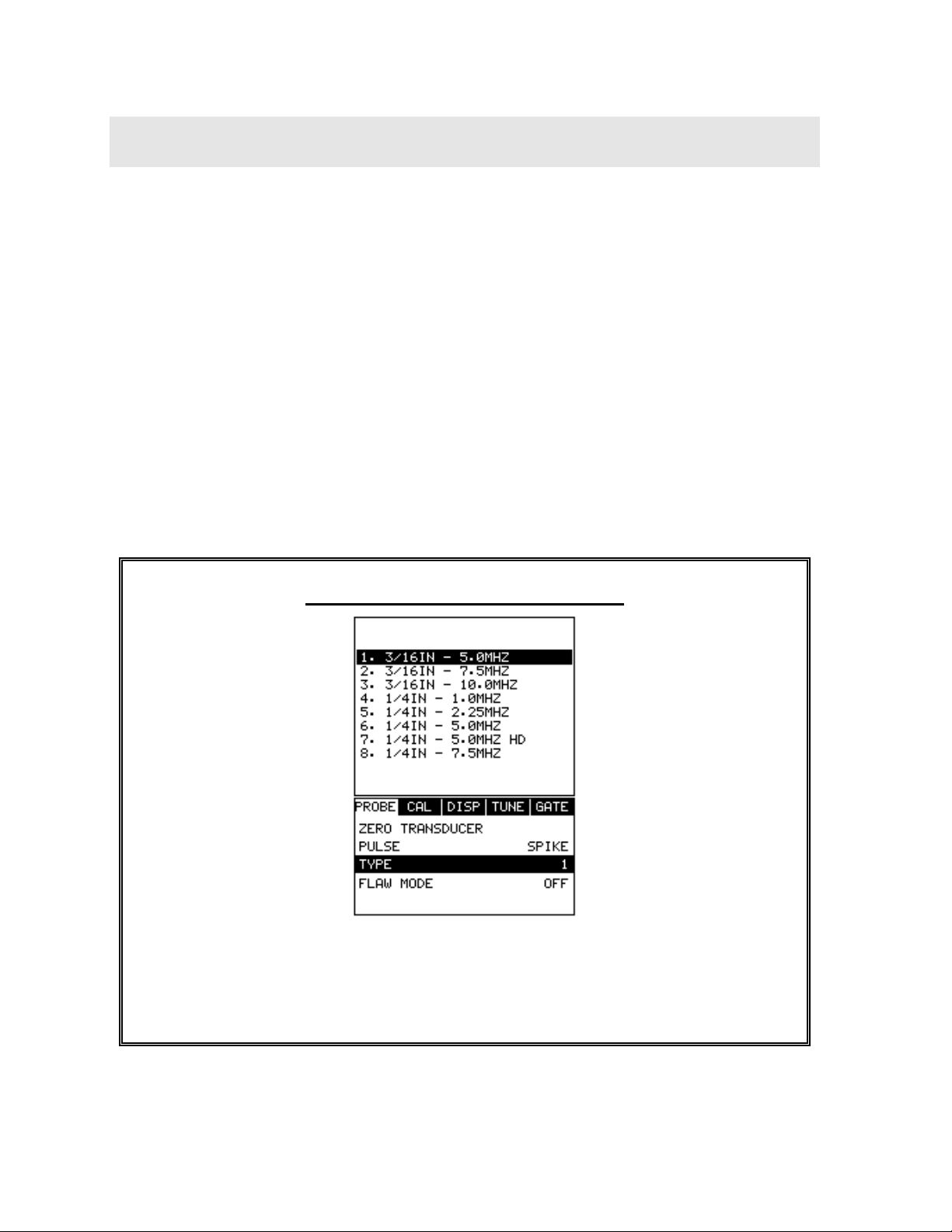

2.1 Selecting The Transducer Type

The first step in using the MVX is to select the transducer type according to

frequency and diameter. By selecting the transducer type from a predefined list, the

MVX can recall specif ic properties about the transducer. Note: Once the transducer

has been selected, the MVX will store and recall this transducer type every time the

MVX is powered on/off. The type will only change if the user physically selects

another transducer type from the list, or selects a previously saved setup. Therefore,

if you have previously gone through this section and selected the transducer you are

using, proceed to the next section. Use the following steps to select your transducer

type:

Selecting the Transducer Type

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the PROBE menu is highlighted and displaying the submenu items.

2

Page 7

MVX High Performance Thickness Gauge

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until TYPE is highlighted.

3) Press the ENTER key to display the list of transducer types.

4) Press the UP and DOWN arrow keys to scroll through the transducer list

until the appropriate type is highlighted.

5) Press th e ENTER key to display the confirmation screen.

6) Press the OK key to select the transducer and return to the menu screen, or

ESC to cancel the selecting the transducer.

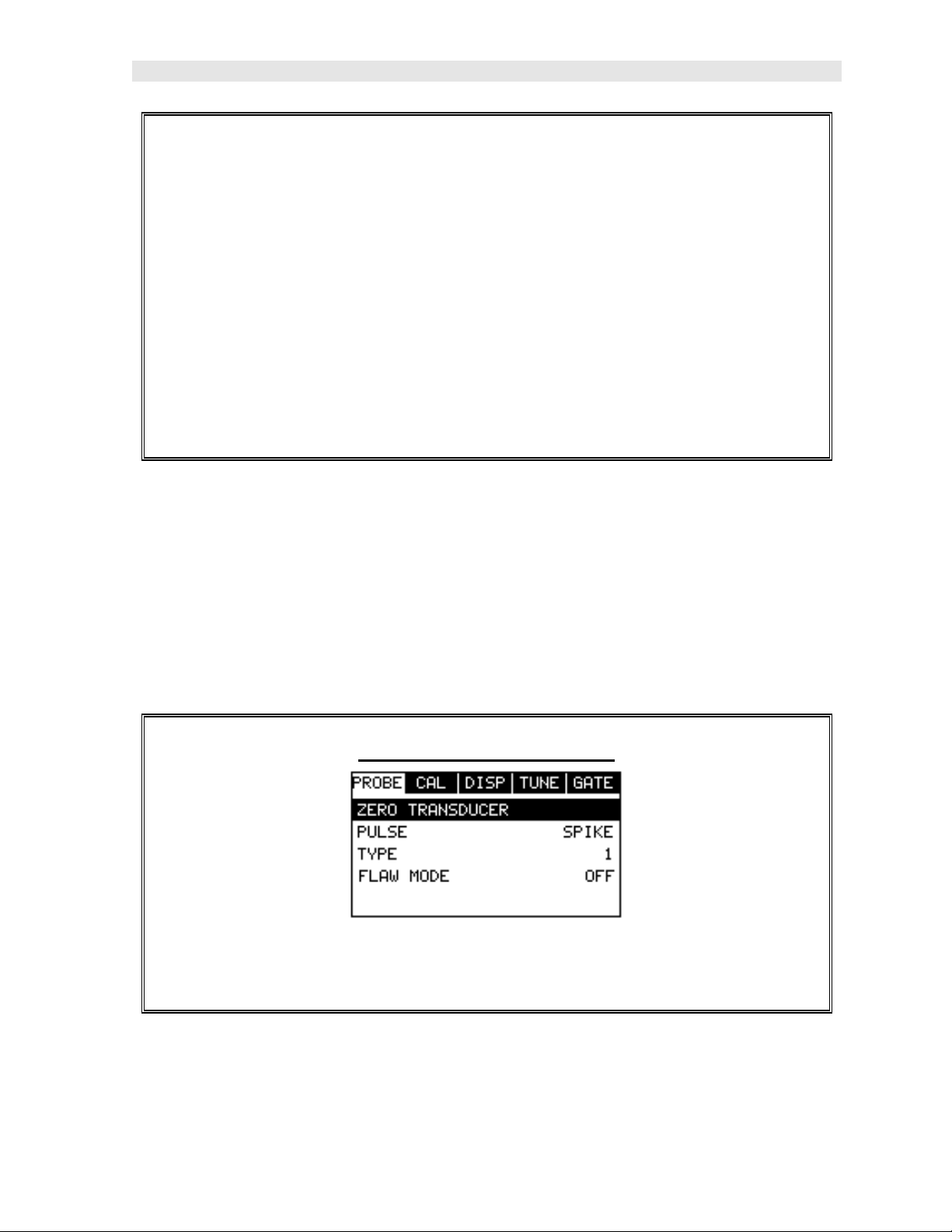

2.2 Probe Zero & Calibration

The next step is to calibrate the MVX to the material and transducer being used. If a

sound velocity is not known, the MVX can be calibrated to a known thickness sample.

This demo will briefly explain both of these techniques.

In either case, the transducer MUST be zeroed on the probe zero disk (battery cover

located on the top of the unit as follows:

Performing a Probe Zero

1) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the probe zero disk, and obtain a steady reading.

Page 8

Dakota Ultrasonics

2) Assuming the probe menu is still displayed from the previous type selection,

use the UP and DOWN arrow keys to scroll through the sub menu items

until ZERO TRANSDUCER is highlighted.

3) Press the ENTER key to display the confirmation screen.

4) Press the OK key to complete the probe zero function, or ESC key to cancel

the probe zero function.

5) Remove the transducer from the probe zero disk, and proceed to the

calibration section.

Note: The value that is displayed will change depending on the current velocity

setting in the MVX. Disregard the number that is displayed. It is not

important. What is important is accurately performing the steps outlined above

to insure reliability of the probe zero calculation.

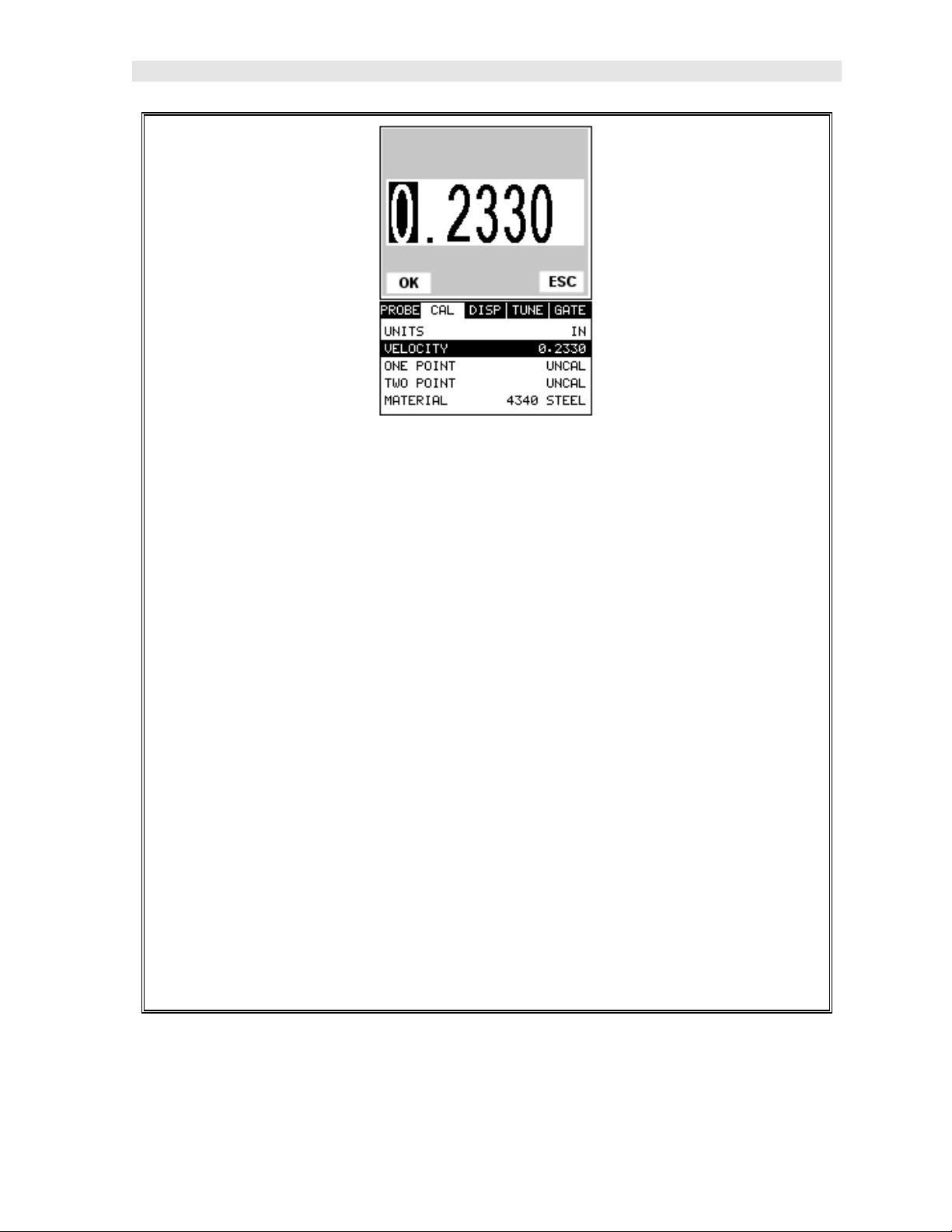

Known Velocity

If the material velocity is known, the user may wish to simply enter the velocity

number into the MVX, rather than have the MVX calculate the velocity value on using

a know thickness. The steps for entering the velocity are outlined below:

Using a Known Material Velocity

4

Page 9

MVX High Performance Thickness Gauge

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VELOCITY is highlighted.

3) Press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the velocity number is correctly displayed.

7) Press the OK key to set the velocity and return to the menu screen, or ESC

to cancel entering the velocity.

8) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Page 10

Dakota Ultrasonics

Known Thickness

Sometimes the sound velocity of a material is not known. In this case a sample with

a known thickness can be used to determine the sound velocity. It would be very

handy to carry a set of mechanical calipers to use in conjunction with the MVX for

calibration in the field:

Using a Known Thickness

Note: Be sure that the probe zero procedure has been performed prior to

performing this calibration procedure.

1) Physically measure an exact sample of the material or a location directly on

the material to be measured using a set of calipers or a digital micrometer.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

reading is stable and the repeatability indicator, in the top left corner of the

display, is fully lit and stable. Press the MENU key once to activate the

menu items tab. Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the CAL menu is highlighted and

displaying the submenu items.

6

Page 11

MVX High Performance Thickness Gauge

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel entering the velocity.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration point. The thickness reading should now match the known

thickness. If the thickness is not correct, repeat the steps above.

Page 12

Dakota Ultrasonics

Basic Material Type

If the material velocity is unknown, and a sample thickness cannot be taken from the

material, the user may opt to choose a basic material type from a list with

approximate velocity numbers. It’s important to note that these velocities will not

always be an exact representation of the material being tested. Use these values

only if a close approximation is acceptable. Follow the steps below to select a basic

material type:

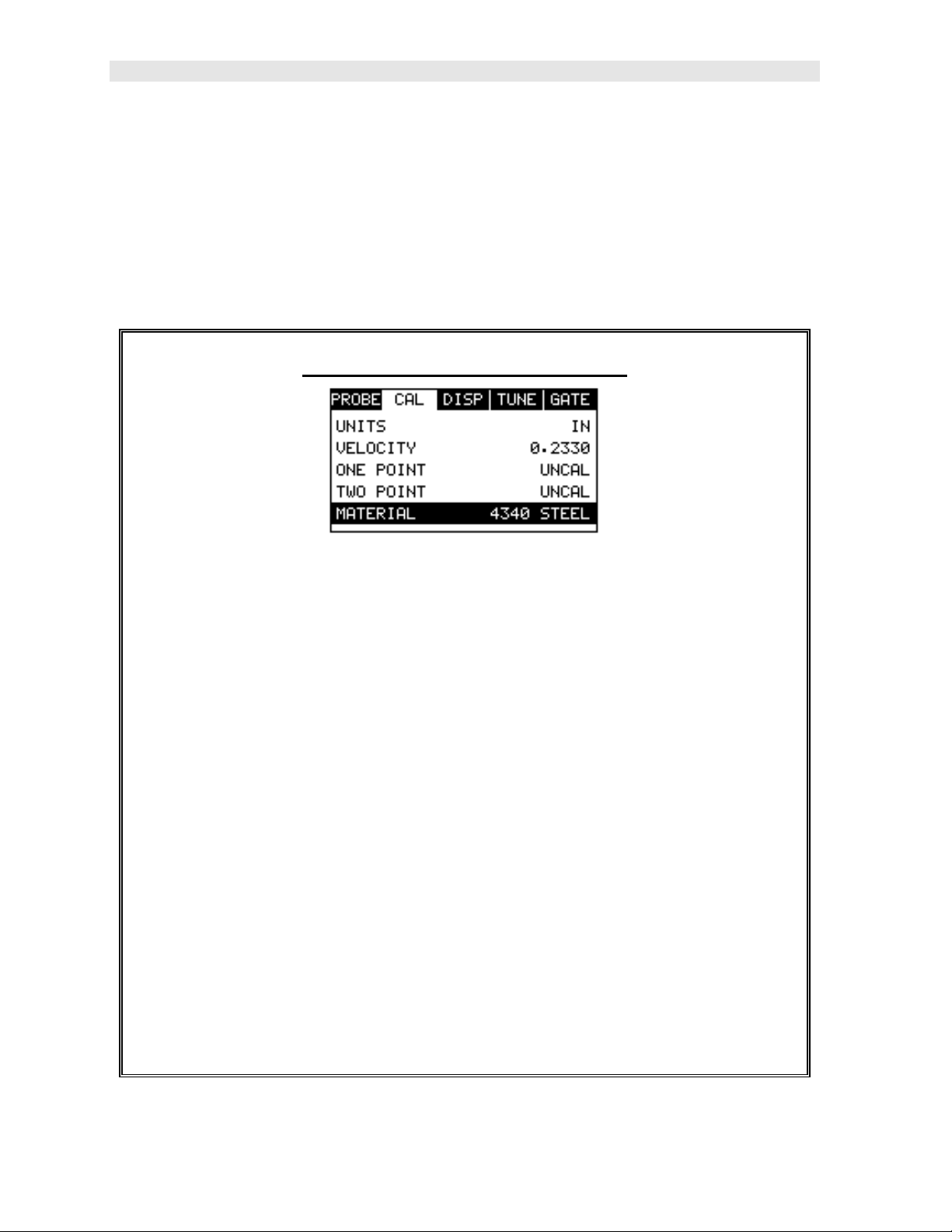

Selecting a Basic Material Type

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATERIAL is highlighted.

3) Press the ENTER key to display the list of material types.

4) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to sel ect the material and return to the menu screen, or

ESC to cancel the material selection.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

8

Page 13

MVX High Performance Thickness Gauge

2.3 Measure

The MVX is now ready to measure. There are four different measurement view

options, each with a specific purpose. The steps below outline how to toggle

between the different view mode options:

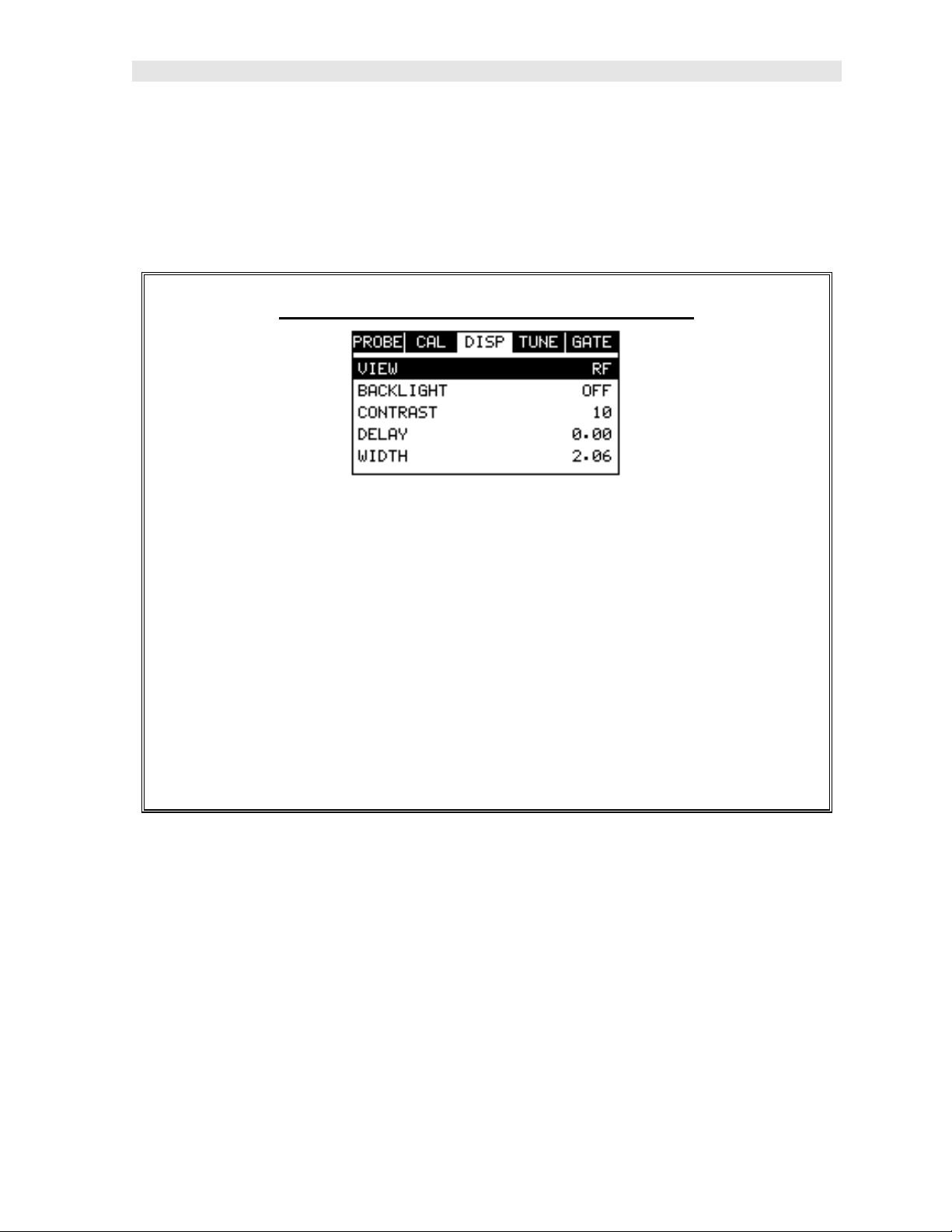

Selecting the Measurement View Option

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VIEW is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the view options.

4) Once the view is displayed, press the MEAS key to return to measurement

mode.

RF: Is useful to see exactly what the signal looks like directly around the detect

point. Use this view only when viewing smaller ranges (zoomed in) around the

detection point. This can be done manually by adjusting the delay and width

settings.

RECTIFIED (RECT): Displays the entire range being scanned. This screen is useful

to “get the big picture” when viewing wide ranges (zoomed out). The point which is

triggering the digital thickness reading (called the detect) is displayed as a vertical

dashed line.

BSCAN: The Time Based B-Scan provides the user with a cross sectional view of

the material being tested. This mode is useful when there is concern regarding the

profile of the blind surface. This can also be a useful view when scanning for pits and

flaws.

Page 14

Dakota Ultrasonics

DIGITS: Displays the digital thickness value using a larger font size. This view is

useful when the MVX is being used as a basic thickness gauge.

Once the view has been selected according to the application requirements, the

delay and width of the screen will potentially need to be adjusted, if the view has

been set to RF, RECT, or BSCAN. Use the following steps to adjust these settings

directly from the measurement screen as follows:

Adjusting the Delay & Width

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the either the DELAY or WIDTH cell is highlighted.

2) Use the UP, DOWN, LEFT, or RIGHT arrow keys to scroll the DELAY and

WIDTH values.

3) Repeat steps 1 & 2 until the range is correctly being displayed.

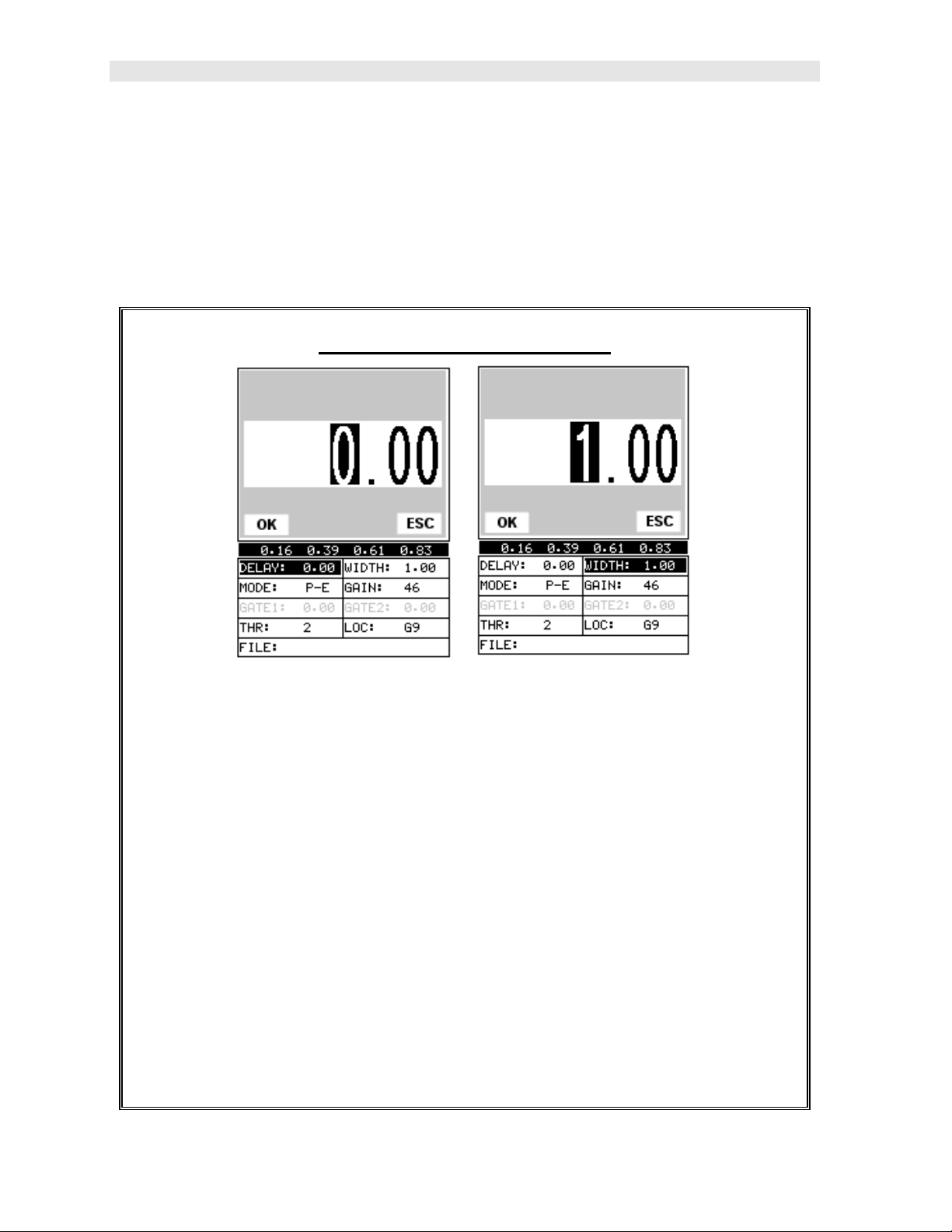

Alternatively, the DELAY and WIDTH values can be changed using the Digit

Edit Box as follows:

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the either the DELAY or WIDTH cell is highlighted.

10

Page 15

MVX High Performance Thickness Gauge

2) Press the ENTER key to display the digits edit box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the DELAY or WIDTH value is correctly displayed.

6) Press the OK key to set the DELAY and WIDTH value and return to the

measure screen, or ESC to cancel entering the DELAY or WIDTH value.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: The DELAY & WIDTH can also be adjusted from the menu tab items.

However, using the hot menu keys is the easiest method.

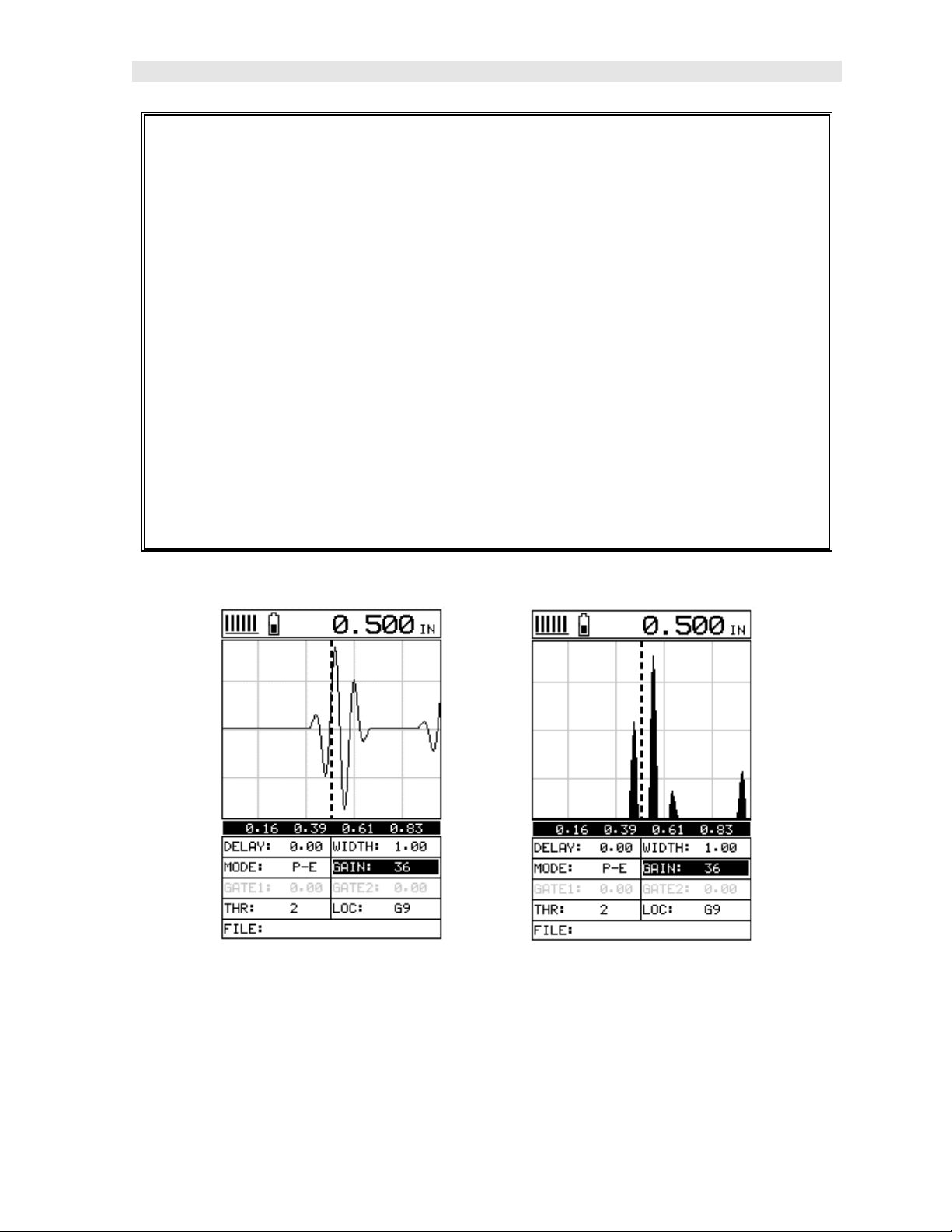

RF RECTIFIED

Page 16

Dakota Ultrasonics

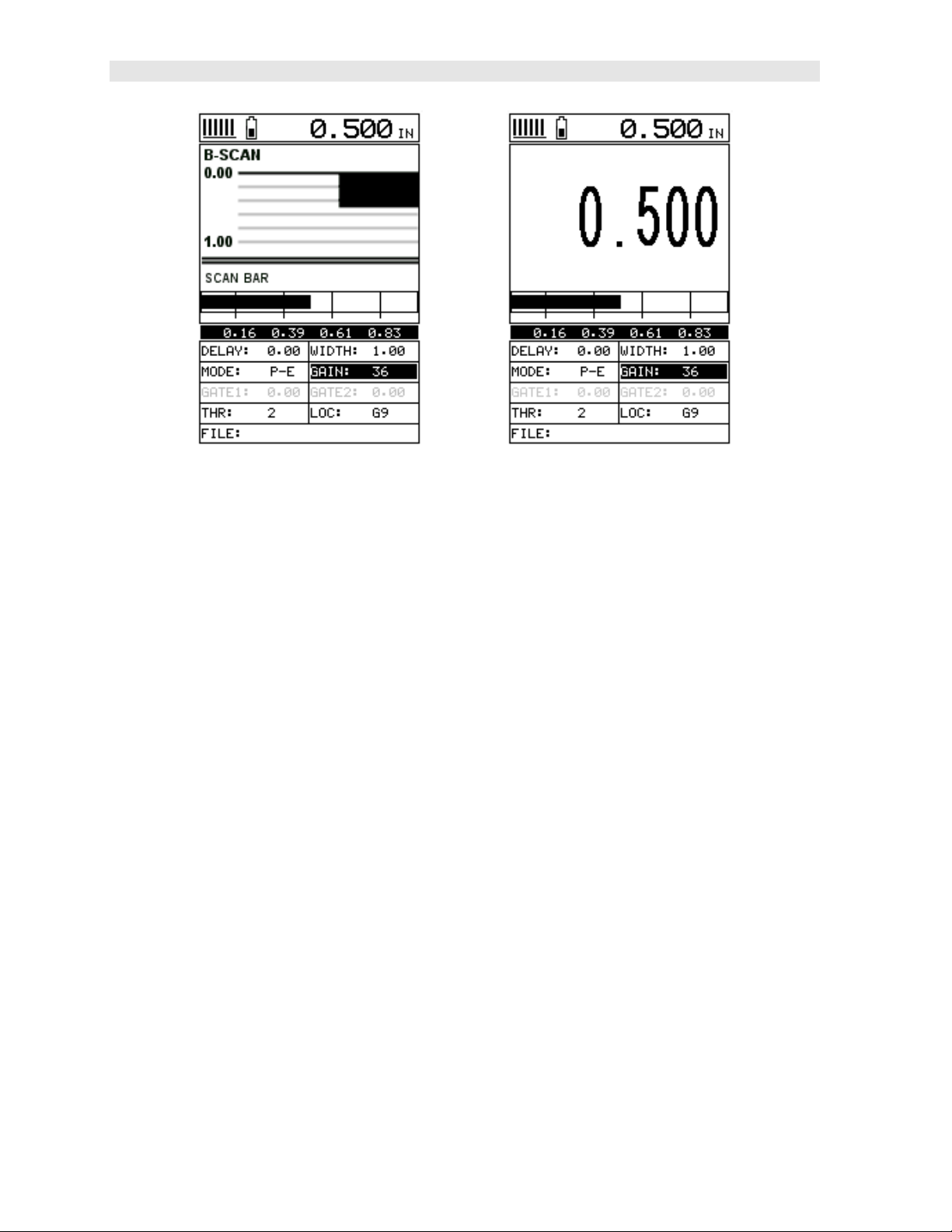

B-SCAN DIGITS

In the upper left corner of each of the mode photos above, is the repeatability

indicator. The repeatability indicator is represented by six vertical bars and

represents how repeatable the measurements are. In regular measurement mode,

the MVX makes 4 measurements a second. In scan mode, the MVX makes 32

measurements a second. When the MVX is idle, only the left vertical bar and the

underline will be displayed. However, when the MVX is making a measurement, five

or six of the bars should be displayed on the repeatability indicator. If fewer than five

bars are showing, the MVX is having difficulty achieving a stable measurement and

the thickness value displayed is potentially be unstable. Another thing to note is the

vertical broken line in the RF and RECTIFIED photos above. This line represents the

actual point of detection. The MVX uses a zero crossing or flank detection method,

and presents the actual point of measurement on the display.

12

Page 17

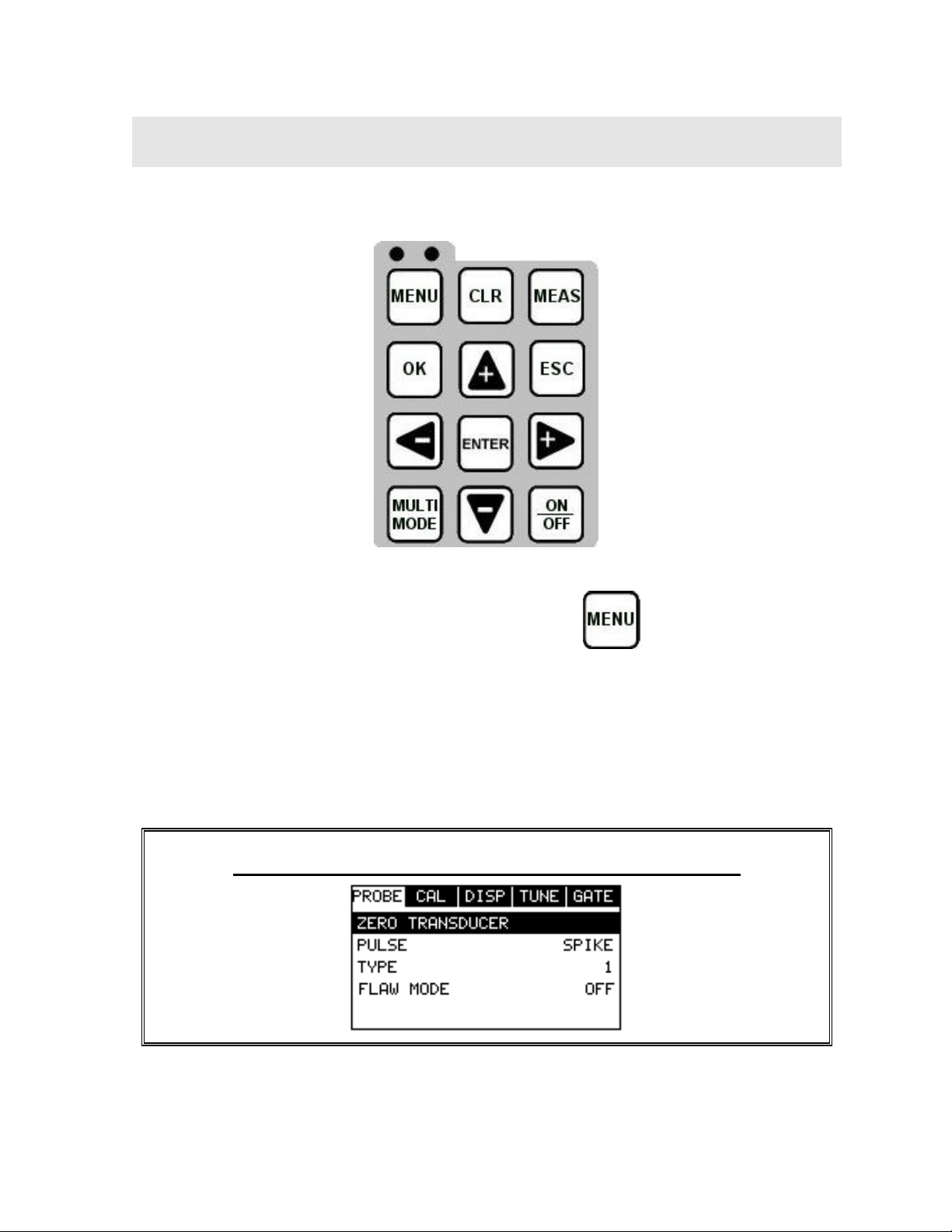

CHAPTER THREE

KEYBOARD, MENU, & CONNECTOR REFERENCE

3.1 Menu Key (Operation & Sub Menus )

The Menu key activates the primary menu structure containing 9 menu tab groups.

These tab groups then contain sub menu items, or functions. The sub menu items

have been organized in tab groups according to how closely they are related to the

individual tab group names. Let’s first get familiar with how to move around in these

tabs before continuing on to the sub menu functions. This procedure is outlined

below:

Activating and Getting Around in the Menu Items

13

Page 18

Dakota Ultrasonics

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left

until the desired tab group is highlighted and displaying the submenu items.

Now that your familiar with activating and moving amongst the tab groups, let’s have

a look at how to move around in the sub menu items as follows:

Getting Around in the Sub Menu Items

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until the desired function is highlighted.

2) Depending on which function is highlighted, use the LEFT, RIGHT, and

Enter keys to scroll the options or activate the Digit Edit and List Box

options.

The sections to follow will provide the user with an explanation of the sub menu

functions:

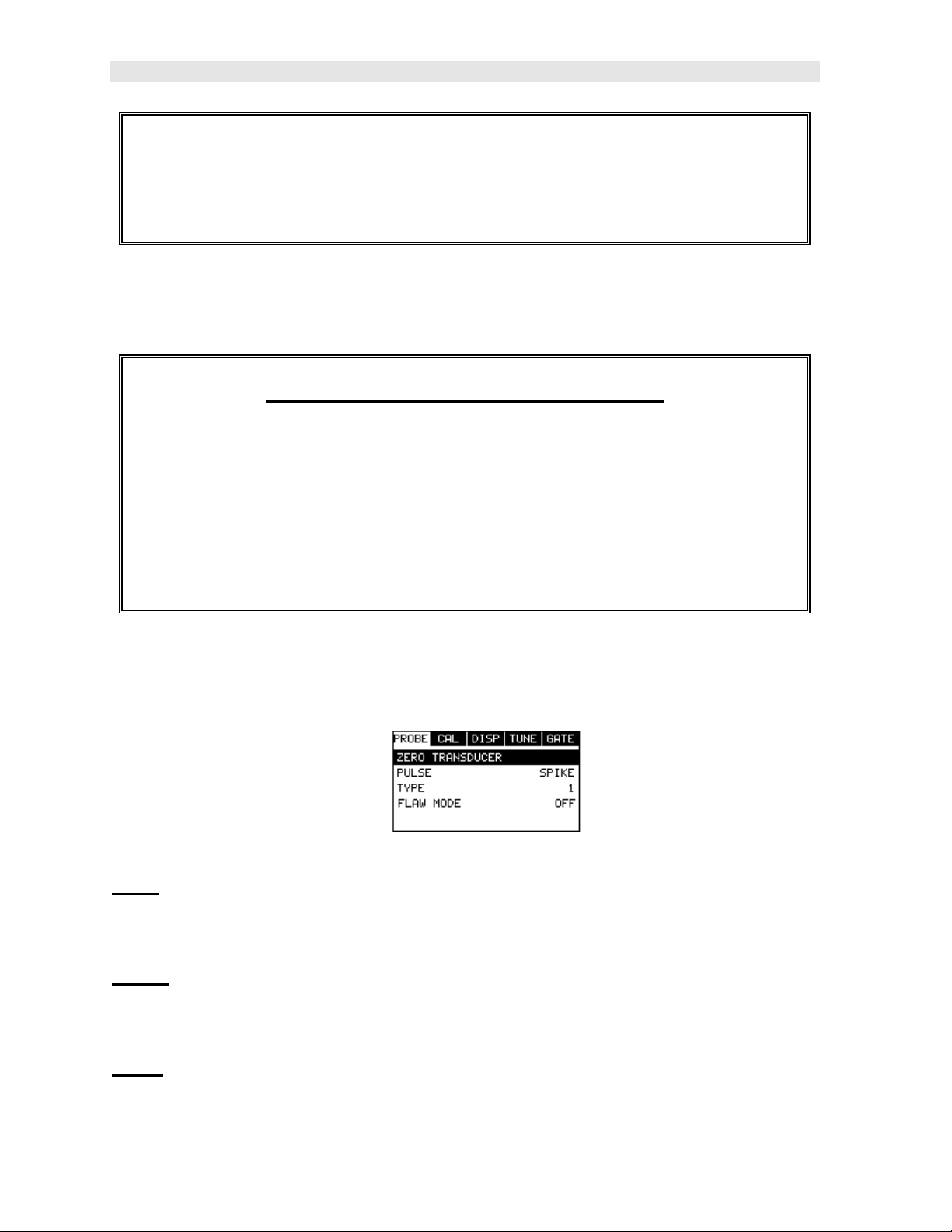

3.2 Probe – Menu

Zero: The MVX is zeroed in much the same way that a mechanical micrometer is

zeroed. If the MVX is not zeroed correctly, all of the measurements made using the

MVX may be in error by some fixed value. Refer to the section on page 35, for an

explanation of this important procedure.

Pulse: The MVX has an adjustable pulse width for both high penetration and

resolution applications. The pulse width refers to the duration of time the pulser is

on. The options are Spike, Thin, and Wide. Refer to page 73 for a further

explanation.

Type: Enables the user to select the type of transducer being used from a chart of

transducer types. This provides increased linearity between transducers. Refer to

page 31 for a further explanation.

14

Page 19

MVX High Performance Thickness Gauge

Flaw Mode: Activates the flaw detection mode and view. This feature is for use with

single element angle beam transducers and used as a general prove-up flaw

inspection mode. Refer to page 107 for a further explanation.

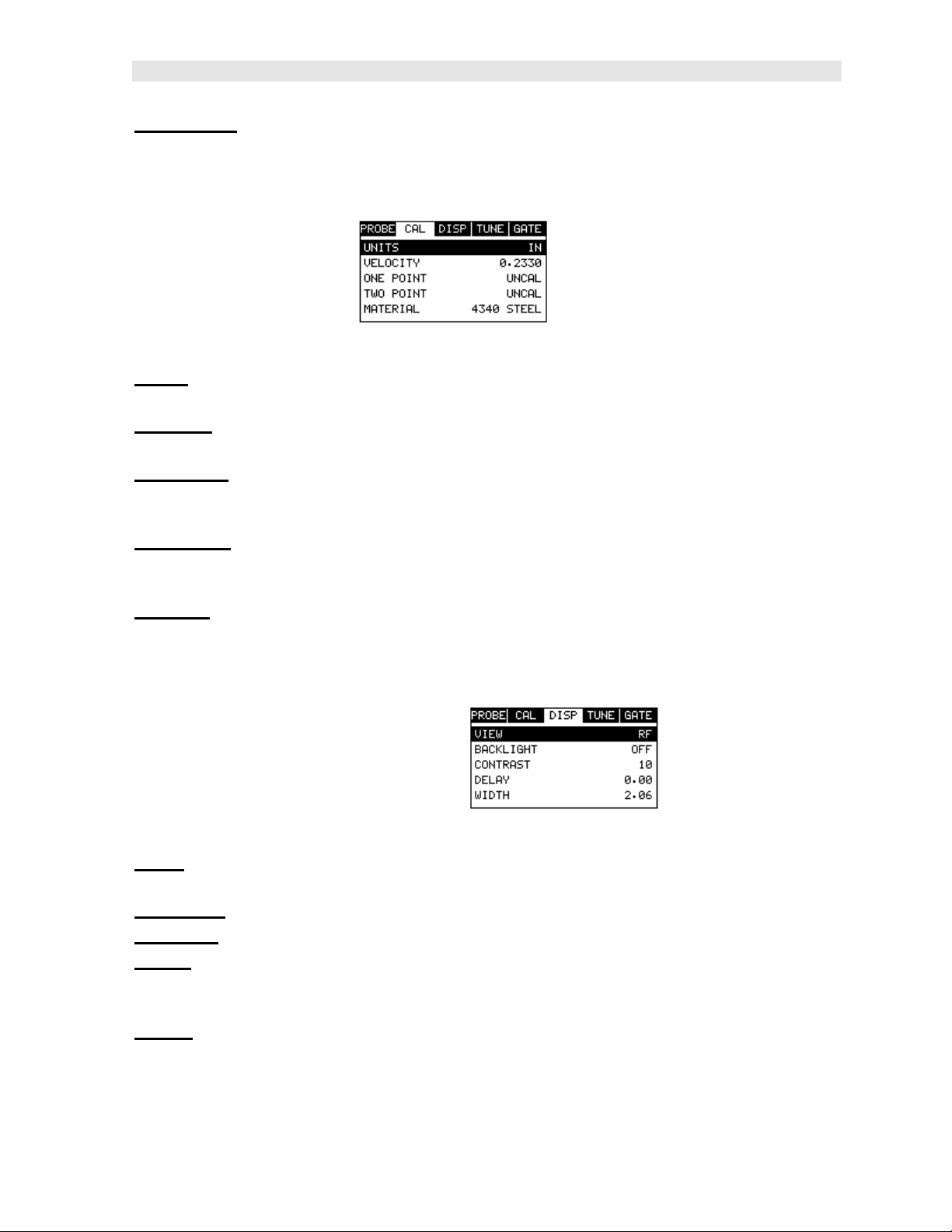

3.3 CAL – Menu

Units: Toggle between English or Metric units. The readout will change from inches

to millimeters.

Velocity: Function to calibrate the MVX by setting the velocity to a known material

velocity. Refer to page 37 for further info.

One Point: Performs a single point calibration. This option allows the user to

automatically calculate the velocity by entering a known sample thickness. Refer to

page 39 for further info.

Two Point: Performs a two-point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness.

Refer to page 40 for further info.

Material: Select the material velocity from a chart of basic material types, when a

known sample thickness, or material velocity cannot be obtained. Refer to page 44

for further info.

3.4 DISP (display) – Menu

View: Selectable RF wave, RECT (rectified) wave, BSCAN (cross section), and

DIGITS (large digits) views. Refer to page 46 for further info.

Backlight: Selectable OFF, ON, AUTO, or INVERT backlight option.

Contrast: Adjustable display contrast for variable light conditions.

Delay: Provides the user the ability to change where the left side of the display

window starts according to thickness, in inches or millimeters. Refer to page 55 for

further info.

Width: Provides the user the ability to change the overall size of the viewable

measurement area. It functions a lot like a zoom on a camera. Refer to page 52 for

further info.

Page 20

Dakota Ultrasonics

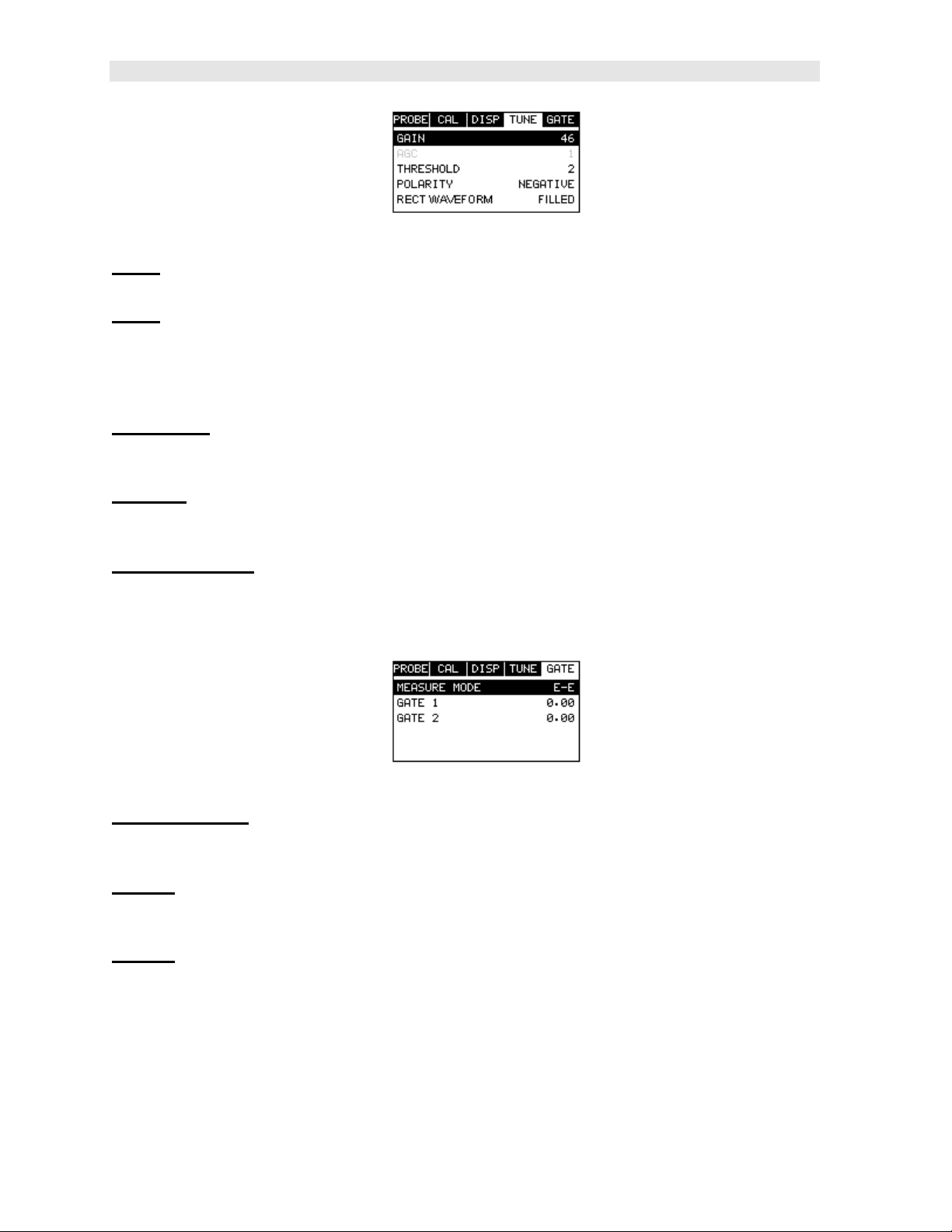

3.5 TUNE – Menu

Gain: Increases or decreases the overall amplitude of the signal. Much like turning

the volume up or down on a stereo receiver. Refer to page 57 for further info.

AGC: The MVX is equipped with an automatic gain control when operating in echo-

echo mode only. This is much like turning the volume up or down on a stereo

receiver. However, the MVX will automatically control how much the volume is

turned up or down. Alternatively, the AGC can be manually controlled using the

same procedures as GAIN described above. Refer to page 57 for further info.

Threshold: Enables the user to set the sensitivity level of the MVX. The amplitude

of the signal must reach and exceed the threshold level before a measurement is

detected. Refer to page 60 for further info.

Polarity: The MVX operates on a zer o crossing detection principle. This feature

toggles which stroke of the cycle the crossing detection uses, either positive or

negative. Refer to page 78 for further info.

Rect Waveform: This option provides the user an outlined or filled view option when

the display setting is in RECT (rectified) wave mode only. Refer to page 80 for

further info.

3.6 GATE – Menu

Measure Mode: Used to select the measurement mode for different application

requirements. The modes are P-E (pulse-echo), P-E GT(pulse-echo w/gate), and EE(echo-echo). Refer to page 24 for further info.

Gate 1: Gates allow the user to view areas or sections of the waveform and ignore

others. Gate 1 can be used in both pulse-echo and echo-echo measurement modes.

Refer to page 63 for further info.

Gate 2: Gates allow the user to view areas or sections of the waveform and ignore

others. Gate 2 is only used in echo-echo measurement mode. Refer to page 67 for

further info.

16

Page 21

MVX High Performance Thickness Gauge

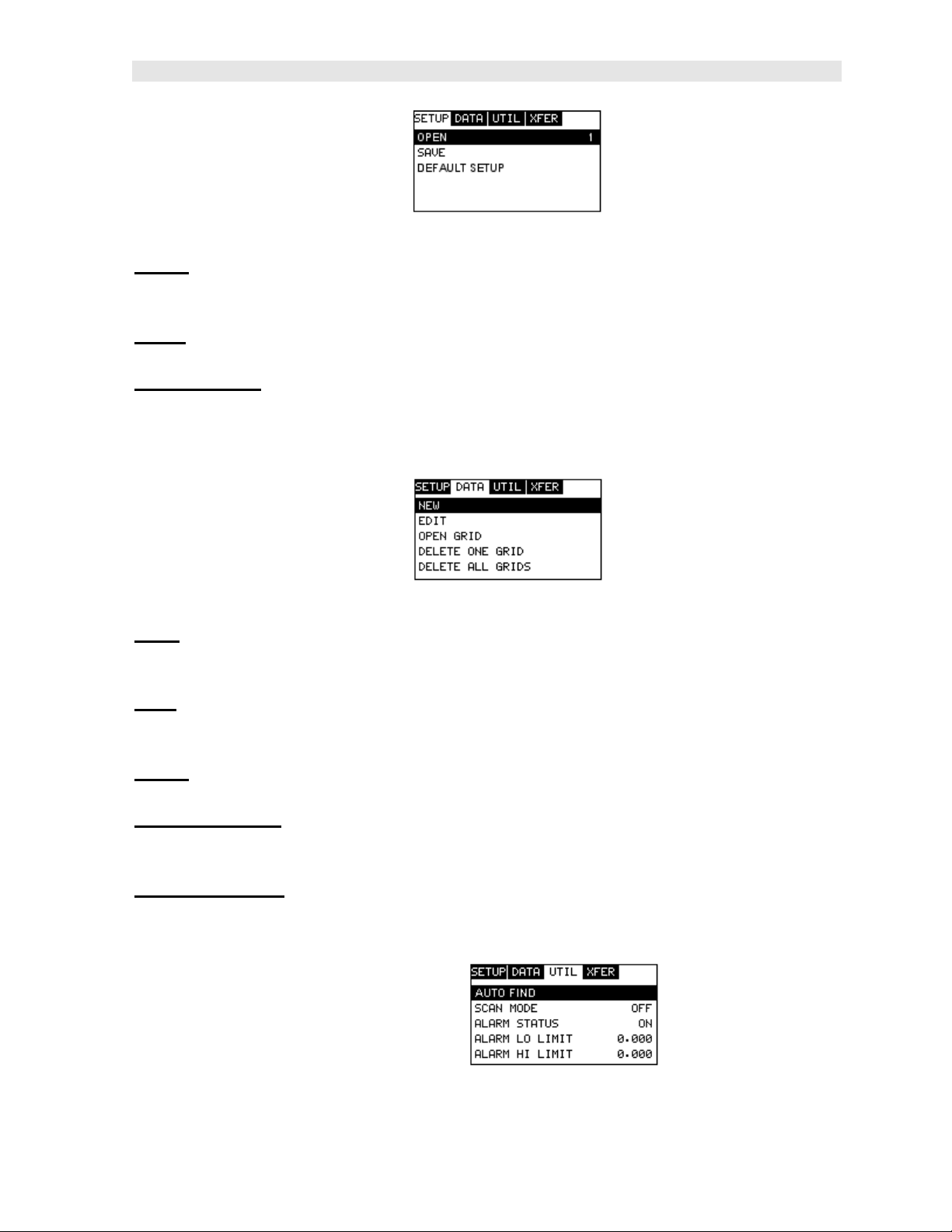

3.7 SETUP – Menu

Open: Displays a list of factory and user defined setups currently stored in memory.

These setups can be recalled and used at any time. Refer to page 100 for further

info.

Save: Provides the user with the ability to save a custom setup that has been

modified or created by the user. Refer to page 102 for further info.

Default Setup: Loads a basic default setup. Use only as a last r esort when the

setups in the MVX have been corrupted and a computer is not accessible. Refer to

page 105 for further info.

3.8 DATA – Menu

New: Allows the user the ability to create a new alpha numeric grid with custom

parameters, rows, and columns depending on their application reporting

requirements. Refer to page 82 for further info.

Edit: Gives the user the ability to change parameters of grid that have been

previously saved. Note: Pre-defined coordinates cannot be changed once they have

been created. Refer to page 95 for further info.

Open: This function provides the user with the ability to recall grids that currently

exist in memory from a list of grids. Refer to page 97 for further info.

Delete One Grid: This function provides the user with the ability to delete one

individual grid from a list of multiple grids previously saved in memory. Refer to page

93 for further info.

Delete All Grids: This function provides the user with the ability to delete all grids

currently stored in memory. Refer to page 93 for further info.

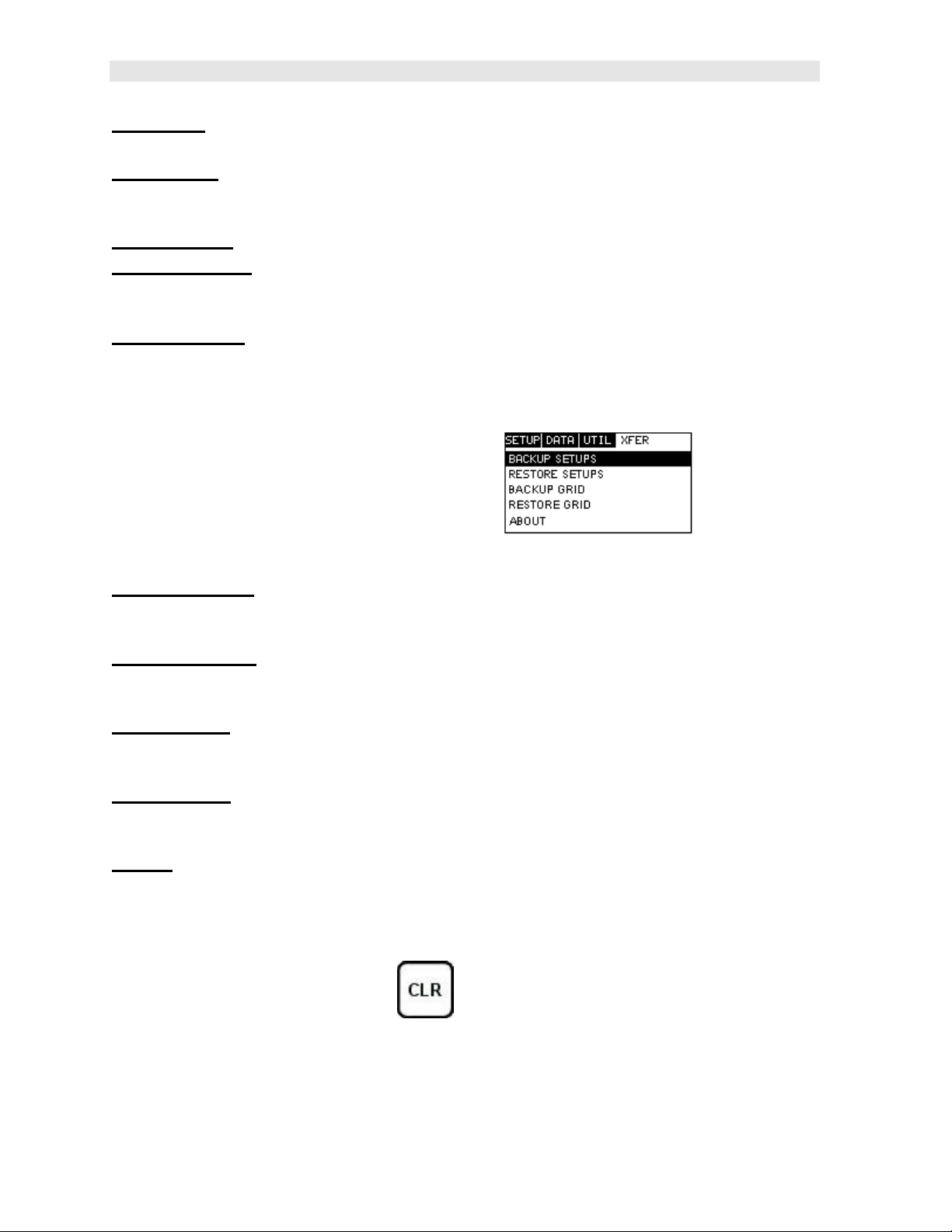

3.9 UTIL (utilities) – Menu

Page 22

Dakota Ultrasonics

Auto Find: Automatically locates the detection point if the measurement is out of the

viewable display area. Refer to page 74 for further info.

Scan Mode: This function enables a hi speed scan mode that increases the overall

sample rate from the standard 4 measurements a second to 32 measurements a

second. Refer to page 75 for further info.

Alarm Status: Toggles alarm mode on or off. Refer to page 76 for further info.

Alarm LO Limit: Gives th e user the ability to set the LO limit parameter. If the

measurement falls below this value, a red light will illuminate and sound the internal

beeper. Refer to page 77 for further info.

Alarm HI Limit: Gives the user the ability to set the HI limit parameter. If the

measurement exceeds this value, a red light will illuminate and sound the internal

beeper. Refer to page 78 for further info.

3.10 XFER (transfer) – Menu

Backup Setups: Enables the user the ability to backup the setups currently stored

in the MVX to a PC via RS232 port. Refer the help section of the DakView 3 or

MVXview software for a complete electronic manual.

Restore Setups: Enables the user the ability to restore the setups currently saved

on a PC to an MVX via RS232 port. Refer the help section of the DakView 3 or

MVXview software for a complete electronic manual.

Backup Grid: Enables the user the ability to backup grids currently stored in the

MVX to a PC via RS232 port. Refer the help section of the DakView 3 or MVXview

software for a complete electronic manual.

Restore Grid: Enables the user the ability to restore grids currently saved on a PC

to an MVX via RS232 port. Refer the help section of the DakView 3 or MVXview

software for a complete electronic manual.

About: Provides the user with Dakota Ultrasonics contact information and the MVX

software version. Refer the help section of the DakView 3 or MVXview software for

a complete electronic manual.

3.11 CLR (clear) Key

The primary functions of the CLR key, is to clear a measurement from a grid cell

location or set obstruct, and backspace in an Alpha Edit Box. If a user has already

saved a measurement and waveform to a cell location, use this key to clear the

measurement at any time.

18

Page 23

MVX High Performance Thickness Gauge

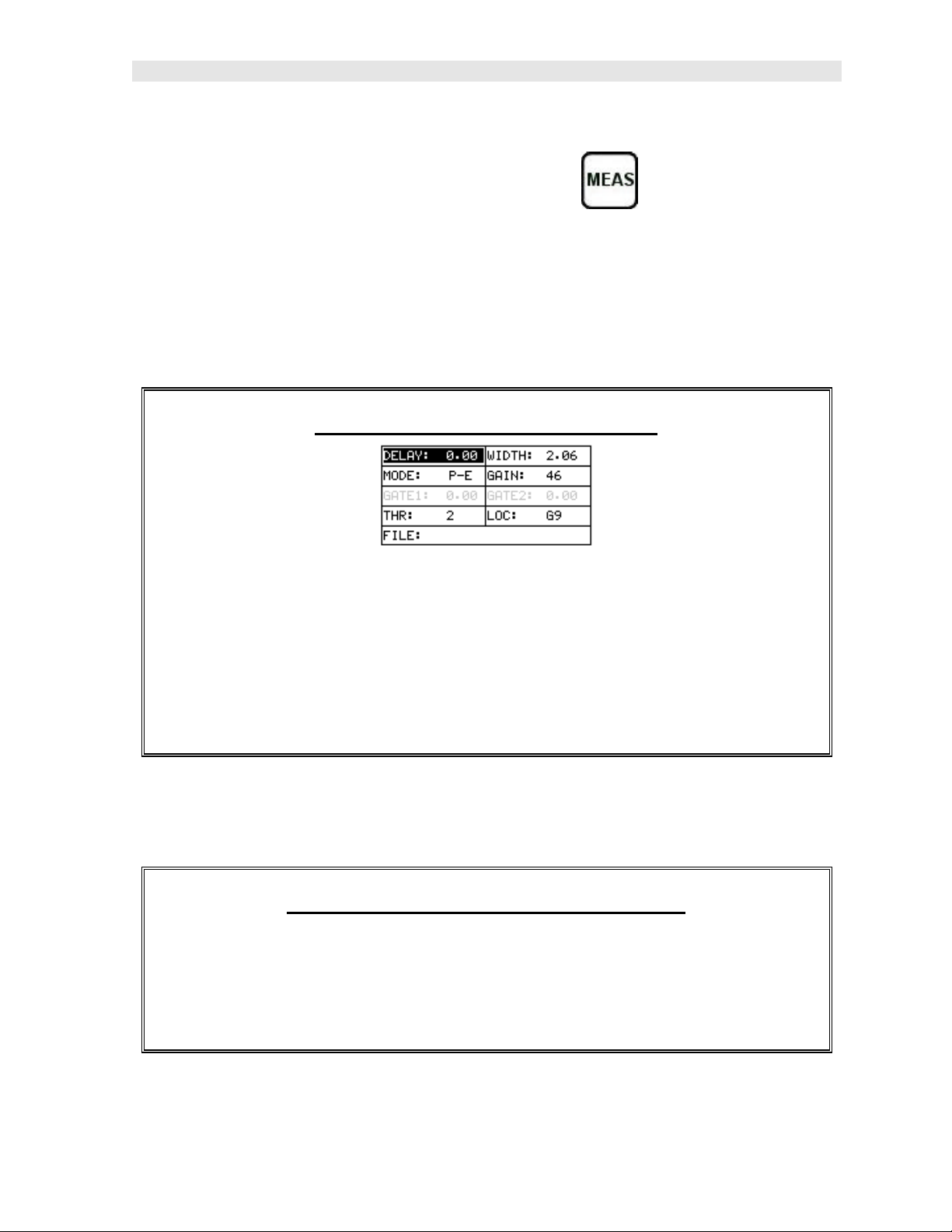

3.12 MEAS (measurement mode) Key

The MEAS key puts the MVX into it’s primary mode of operation. In this mode, the

user has a complete view of the LCD, as well as control of the Hot Menu Functions.

These hot functions provide the user with the ability to make crucial adjustments to

the display, waveform settings, and grid storage locations without having to search

through the menu and sub menu items. It’s important to first get familiar with moving

around in the hot functions as follows:

Getting Around in the Hot Menus

1) Press the MEAS key at any time to return to the primarily measurement

mode.

2) Press the MEAS key multiple times to tab right through the menu fields, and

the ESC key multiple times to tab left through the menu fields, until the

desired hot function is highlighted.

Now that you’re familiar with activating and moving amongst the hot function fields,

let’s have a look at how to adjust or change the values of these fields:

Adjusting the Values of the Hot Menus

1) Use the UP, DOWN, LEFT, and RIGHT arrow keys to increase and

decrease the values of the hot function fields.

2) Repeat step 1 until the desired value has been achieved.

Page 24

Dakota Ultrasonics

Alternatively, the delay, width, gain, and threshold hot function fields can be

changed using the Digit Edit Box as follows:

1) Press the ENTER key to display the Digits Edit Box.

2) Press the UP and DOWN arrow keys to scroll the highlighted value.

3) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

4) Repeat steps 2 & 3 until the delay, width, gain, or threshold number is

correctly displayed.

5) Press the OK key to set and return to the measure screen, or ESC to cancel

entering the delay, width, gain, or threshold value.

3.13 OK Key

The primary function of the OK key is confirmation of a change or selection. This key

also has a secondary function: pressing the OK key while in the main measurement

screen, toggles large digits to be displayed in place of the hot menu items. This will

provide the user with a larger digital readout of the measurement, while in RF or

RECT display modes.

3.14 ESC Key

The ESC key is used in the MENU, MEAS, and EDIT functions as a back or escape

function. This key also has a secondary function: pressing the ESC key, while in the

main measurement screen, toggles between all of the possible display view options –

RF, RECT, B-SCAN, and DIGITS.

3.15 Arrow Keys

The Arrow Keys are used to navigate through the menus, increase/decrease values,

and toggle specific function keys.

20

Page 25

MVX High Performance Thickness Gauge

3.16 ENTER key

The ENTER key is used in the overall menu selection process, to activate list and

edit boxes, and save measurements to grid locations.

3.17 MULTI MODE Key

The MULTI MODE key toggles the measurement mode of the MVX, from pulse-echo

(flaw mode), to echo-echo (thru paint) mode. This is a quick automatic preset mode

that enables the user to change modes without having to manually adjust the view

and gate parameters. Both modes have been configured for use with any transducer

type selected.

3.18 ON/OFF Key

The ON/OFF key simply powers the unit either ON or OFF. Note: Unit will

automatically power off when idle for 5 minutes. All current settings are saved prior

to powering off.

3.19 Top & Bottom End Caps

The top & bottom end panels are where all connections are made to the MVX. The

diagram above shows the layout and description of the connectors:

Page 26

Dakota Ultrasonics

Transducer Connectors

Refer to Diagram: The transducer connectors, and battery cover/probe zero disk are

located on the MVX’s top end cap. The transducer connectors are of type Lemo

“00”. Note: There is no polarity associated with connecting the transducer to the

MVX.

Probe Zero Disk & Battery Cover

Refer to Diagram: The Battery cover is the large round disk shown in the diagram.

Note: This same disk is also used as a probe zero disk. Simply remove the cover

when replacing the batteries (3 AA cells). When performing a probe zero function,

simply place the transducer on disk making firm contact. Important: Be sure to

follow the polarity labels located on the back label of the MVX. Note: Rechargeable

batteries can be used, however they must be recharged outside of the unit in a stand

alone battery charger.

RS-232 Connector

Refer to Diagram: The RS-232 connector, located on the bottom end cap, is a 2 pin

female Lemo connector. It is designed to connect directly from the MVX to a

standard AT serial port on a PC. The cable supplied with the MVX is a Lemo to 9 pin

serial cable. Note: This connector is also used to upgrade the MVX with the latest

version of firmware.

22

Page 27

CHAPTER FOUR

PRINCIPALS OF ULTRASONIC MEASUREMENT

4.1 Time versus thickness relationship

Ultrasonic thickness measurements depend on measuring the length of time it takes

for sound to travel through the material being tested. The ratio of the thickness

versus the time is known as the sound velocity. In order to make accurate

measurements, a sound velocity must be determined and entered into the

instrument.

The accuracy of a thickness measurement therefore depends on having a consistent

sound velocity. Some materials are not as consistent as others and accuracy will be

marginal. For example, some cast materials are very granular and porous and as a

result have inconsistent sound velocities.

While there are many different ultrasonic techniques to measure thickness, which will

be discussed bel ow, all of them rely on using the sound velocity to convert from time

to thickness.

4.2 Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the

material being measured. Not all materials are good at transmitting sou nd.

Ultrasonic thickness measurement is practical in a wide variety of materials including

metals, plastics, and glass. Materials that are difficult include some cast materials,

concrete, wood, fiberglass, and some rubber.

4.3 Range of measurement and accuracy

The overall measurement capabilities, based on the wide variety of materials, is

determined by the consistency of the material being measured

The range of thickness that can be measured ultrasonically depends on the material

as well as the technique being used and the type of transducer. Thickness

measurements can be made from a minimum of 0.010 inch to 9.999” in steel.

However, the maximum attainable thickness is much less for more attenuative

materials (materials that absorb sound).

Accuracy, is det ermined by how consistent the sound velocity is through the sound

path being measured and, is a function of the overall thickness of the material. For

example, the velocity in steel is typically within 0.5% while the velocity in cast iron

can vary by 4%.

4.4 Couplant

All ultrasonic applications require some medium to couple the sound from the

transducer to the test piece. Typically a high viscosity liquid is used as the medium.

The sound frequencies used in ultrasonic thickness measurement do not travel

23

Page 28

Dakota Ultrasonics

through air efficiently. By using a liquid couplant between the transducer and test

piece the amount of ultrasound entering the test piece is much greater.

4.5 Temperature

Temperature has an effect on sound velocity. The higher the temperature, the slower

sound travels in a material. High temperatures can also damage transducers and

present a problem for various liquid couplants.

Since the sound velocity varies with temperature it is important to calibrate at the

same temperature as the material being measured.

Normal temperature range

Most standard transducers will operate from 0°F to 180°F.

High temperature measurements

Special transducers and couplants are available for temperatures above 180°F up to

650°F with intermittent contact. It is necessary to cool the transducer, by submerging

the transducer in water between readings, when measuring high temperatures.

Modes and temperature errors

In addition to errors caused by velocity changing with temperature, some modes

(measurement techniques) are affected more than others. For example, dual

element mode has larger errors due to changes in temperature of the delay line.

However, multi-echo techniques help to minimize these errors.

4.6 Measurement Modes

In this section we will discuss the different measurements modes the MVX is capable

of operating in, the transducers required, and the reasons for using specific modes:

Pulse-Echo Mode (Flaw & Pit detection)

Pulse-echo mode measures from the initial pulse (sometimes referred to as an

artificial zero) to the first echo (reflection). In this mode, the transducer is placed on a

reference disk, located on top of the MVX, and a key is pressed to establish a zero

point for the particular transducer.

In this mode errors result from surface coatings and temperature variation s.

Since pulse-echo only requires one reflection, it is the most sensitive mode for

measuring weak reflections (flaws) typically found when measuring heavily corroded

metals.

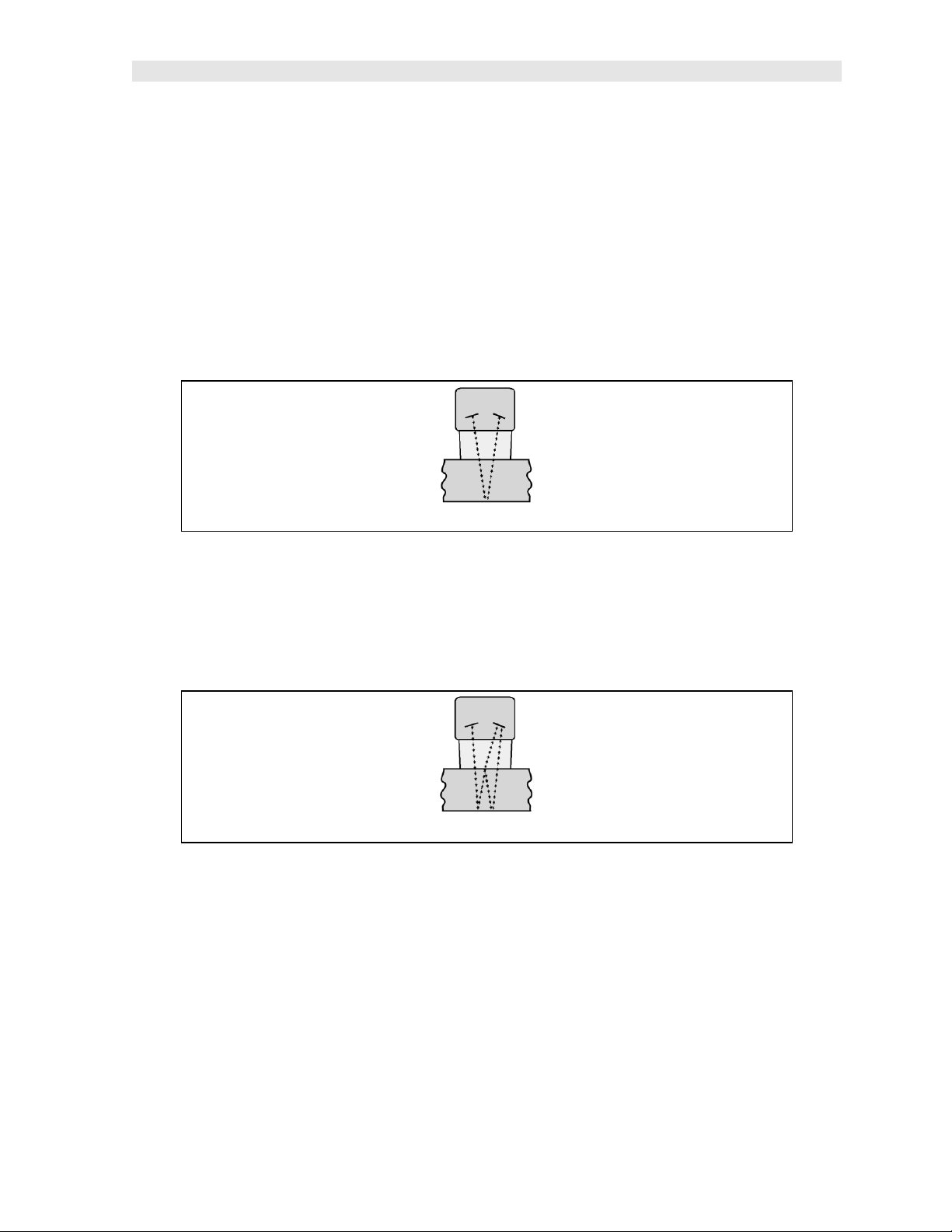

V-Path Correction

Dual element delay line transducers have two piezoelectric elements mounted at an

angle on one end of the delay line. One element is used for transmitting sound, while

the other element only receives sound. The two elements and their delay lines are

packaged in a single housing but acoustically isolated from each other with a sound

24

Page 29

MVX High Performance Thickness Gauge

barrier. This allows the transducer the ability to achieve very high sensitivity for

detecting small defects. Also, the surface of the test material does not have to be as

flat in order to obtain good measurements.

Dual element transducers are normally used in pulse-echo mode for finding defects,

and in echo-echo mode for through coating measurements.

Dual element delay line transducers are usable over a range of 0.025 inches to 20

inches depending on the material, frequency, and diameter.

A limitation of dual element delay-line transducers is the V shaped sound path.

Because the sound travels from one element to another, the time versus thickness

relationship is non-linear. Therefore, a correction table in the instruments software is

used to compensate for this error.

Dual Element Transducer showing V-path of signal

Echo-Echo Mode

The echo-echo mode measures between two reflections. This technique is

commonly used to eliminate errors from surface coatings and also to make

measurements in multiple layered materials. The disadvantage is that two echoes

are needed which requires a much stronger echo (reflection).

Dual Element Transducer in Echo to Echo mode

Searching for small defects

Dual element delay line transducers are especially useful in searching for small

defects. In the pulse-echo mode with high amplifier gain, very small defects can be

measured. The A-Scan display of the MVX can be used to see the defect and

optimize the transducer placement.

Sometimes a grain particle or air bubble will cause a reflection. Without the A-Scan

display it is impossible to know if this is a thin area or just a harmless defect. The AScan allows the user to see the backwall as well as the defect similar to a flaw

detector.

Page 30

Dakota Ultrasonics

Waveform showing echo from corroded backwall

26

Waveform showing flaw with solid backwall

Page 31

MVX High Performance Thickness Gauge

4.7 Glossary of terms

Repetition Rate & Display Update

The repetition rate is how often the MVX generates a burst of ultrasound.

The MVX has a fixed repetition rate of 1 kHz, or 1000 times per second. The MVX

updates the display 4 times per second in regular measurement mode and 32 times a

second in hi speed scan mode. Therefore, the scan mode is most suitable for fast

scans of a test piece at a lower resolution.

Variable Pulser Width

Transducers have a center frequency where they are most efficient at transmitting

sound (i.e. they are resonant). The MVX has a variable width pulser with three

setting options (spike, thin, wide). These settings determine the period of time the

pulser turned is on. High frequency applications, where resolution is a requirement,

may require the spike or thin settings to achieve optimal results. Low frequency

applications, where more penetration is a needed, may require the thin or wide

settings, offering increased penetration. The variety of transducer frequencies and

diameters used in conjunction with the pulser settings, enable users to fine tune the

MVX for their application needs.

Gates

Gates control the time measurement process. They enable the user to select

measurement regions and threshold levels (sensitivity). The MVX is equipped with

two gates. In pulse-echo mode a single gate can be used to eliminate noise. In

echo-echo mode both gates are used. In this mode the second gate starts

automatically after a signal is detected during the gates region, and after a user

adjustable delay, sometimes called a hold-off.

Page 32

CHAPTER FIVE

SELECTING THE MEASUREMENT MODE

5.1 The setup library

The MVX contains 64 user configurable preset locations to store custom setups for

easy recall. These setups can be optimized for the user’s specific application needs

and can also be stored on a PC and transferred bi-directionally using Dakota’s PC

interface software included with the instrument.

The setups supplied with the instrument cover some of the more typical applications

commonly used with this type of instrument. These setups can be recalled, modified,

and overwritten to one of 64 setup locations. Therefore, these factory setups can

also be considered a good starting point t o be modified for custom applications. The

PC software includes a default setup file that can be uploaded to the gauge at any

time to restore factory settings. However, it is recommended that the user consider

saving modified setups to an empty location rather than overwriting the factory setups

in the MVX. Once again, these factory settings are excellent starting points for

custom setups.

5.2 Which mode & transducer do I use for my application?

High penetration plastics and castings

The most common mode for these types of applications is pulse-echo. Select a low

frequency transducer. Depending on the thickness of the material, use a 2.25MHz or

lower frequency transducer. Larger diameters offer greater penetration power

because of the crystal size, for difficult to measure materials.

Corrosion & Pit Detection in steel

Use pulse-echo mode whenever attempting to locate pits and flaws. Typically a

5MHz transducer, or higher, will be used for these types of applications. Use low

frequencies for greater penetration and use higher frequencies for better resolution.

Thru Paint & Coatings

Often times users will be faced with applications where the material will be coated

with paint or some other type of epoxy material. Since the velocity of the coating is

approximately 2.5 times slower than that of steel, pulse-echo mode will induce error if

the coating or paint is not completely removed. By using echo-echo mode, the user

is able to successfully measure through both, the coating and steel, and completely

eliminate the thickness of the paint or coating. Therefore, the steel can be measured

without having to remove the coating prior to measuring. Users will often use pulseecho mode and echo-echo mode in conjunction when performing inspections on

coated materials.

Thru coating measurements require special high damped transducers. The most

common transducers are the 3.5, 5, and 7.5MHz hi damped transducers. These

28

Page 33

MVX High Performance Thickness Gauge

transducers are suitable for use in both pulse-echo and echo-echo modes. This

conveniently enables the user to accurately measure overall material thickness using

the thru Coating mode, and then conveniently switch to pit detection mode without

changing transducers.

Thin materials

Use pulse echo mode and a high frequency transducer for these types of

applications. The most common transducers are the 7.5MHz and 10MHz models

with extra resolution. The higher frequencies provide greater resolution and a lower

minimum thickness rating overall.

High temperature

Use and select a special 2.25MHz and 5 MHz High temperature transducer for these

types of applications. Both pulse-echo and echo-echo modes will also work for these

applications. However, echo-echo mode will eliminate error caused by temperature

variations in the delay line of the transducer.

Noisy Material

Materials such as titanium, stainless steel, and aluminum may have inherent surface

noise issues. This is a signal that appears at the surface of the material when using

a dual element delay line probe. Select a higher frequency transducer to reduce this

noise – 7.5MHz and higher for better resolution. Alternatively, enable a single gate to

block this noise. See the section Gate 1 on page 63 for more information.

Restricted access

In order to measure materials with lots of curvature or restricted access, use and

select higher frequencies with smaller diameters. The smallest diameter uses 3/16”

crystals with a contact area of .250”.

Page 34

Dakota Ultrasonics

STEEL THRU PNT EXT

ALUMINUM W/GATE

PLASTIC W/GATE THK

½ 1MHZ CPZT

5.3 Factory Setup Chart

Num Name Comment 1 Gn/AGC Velocity

1 STEEL BASIC 45 0.2330 in/uSec

2 STEEL THRU PNT STD ¼ 5MHZ HD 15 0.2330 in/uSec

3

4

5

6 PLASTIC BASIC ¼ 2.25MHZ 45 0.0940 in/uSec

½ 3MHZ HD 14 0.2330 in/uSec

¼” 7.5MHZ 45 0.2510 in/uSec

45 0.0940 in/uSec

30

Page 35

CHAPTER SIX

MAKING MEASUREMENTS

The steps involved in making measurements are detailed in this section. The

following sections outline how to setup and prepare your MVX for field use.

In pulse-echo modes, the probe zero must be measured on the reference disk

(battery disk) attached to the top of the instrument. This compensates for variation in

the transducer. In all modes the sound velocity must be determined. The sound

velocity is used to convert the transit time to a physical length. The sound velocity

can be selected from a material chart in the manual, selected from a material list in

the MVX, or for greater precision, determined from a sample of the test material that

has been mechanically measured. To enter the velocity from a table, look up the

material on the chart in the appendix of this manual and refer to the section below on

Calibration to a Known Velocity. To determine the velocity of a single sample, refer

to the Material Calibration section on page 39.

When measuring curved materials, it is more accurate to calibrate from two test

points, one at the minimum limit of the target thickness and one at the maximum limit.

In this case the reference disk mounted to the MVX is not used. This is called twopoint calibration and is described on page 40.

6.1 Selecting The Transducer Type

The first step in using the MVX is to select the transducer type from the transducer

list located in the tabbed menu items by frequency and diameter. By selecting the

transducer type from a predefined list, the MVX can recall specific properties about

the transducer. Note: Once the transducer has been selected, the MVX will store

and recall this transducer type every time the MVX is powered on/off. The type will

only change if the user physically selects another type from the list, or selects a

previously saved setup. Therefore, if you have previously gone through this section

and selected the transducer you are using, proceed to the next section. Use the

following steps to select your transducer type. Note: Be sure the transducer type

selected is the same as the transducer plugged into the MVX. Failure to do this will

result in erroneous measurements:

31

Page 36

Dakota Ultrasonics

Selecting the Transducer Type

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the PROBE menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until TYPE is highlighted.

3) Press the ENTER key to display the list of transducer types.

4) Press the UP and DOWN arrow keys to scroll through the tran sducer list

until the appropriate type is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the transducer and return to the menu screen, or

ESC to cancel the material selection.

Now that the proper transducer has been selected and connected to the MVX, the

measurement mode must be chosen according to the type of application. Following

the recommendations in the prior chapter, there are three different ways to select the

measurement mode as follows:

32

Page 37

MVX High Performance Thickness Gauge

Selected from a Setup

Important Note: Stored setups will save all the parameters of the MVX.

Therefore, if a transducer was selected in the previous section and a setup is

now being recalled, the transducer saved in the setup will overwrite the

transducer previously selected. Be sure the transducer saved with the setup is

the same as the transducer currently being used. Alternatively, you can select

a transducer again after recalling a setup. This will override the transducer

saved with the setup.

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the SETUP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until OPEN is highlighted.

3) Press the ENTER key to display the list of stored setups.

4) Press the UP and DOWN arrow keys to scroll through the list of setups until

the appropriate setup is highlighted.

5) Press the ENTER key to display the confirmation screen.

Page 38

Dakota Ultrasonics

6) Press the OK key to select the setup and return to the menu screen, or ESC

to cancel the selection process.

7) Press the MEAS key to return to the measurement screen.

Alternatively, the measurement mode can be simply selected from the Hot Menu

Items or selected from a sub menu feature as follows:

Hot Menu Selection

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the MODE cell is highlighted.

2) Use the UP, DOWN, LEFT, or RIGHT arrow keys to scroll the modes P-E

(pulse-echo flaws and pits), P-E GT (pulse-echo flaws and pits w/gate), and

E-E (echo-echo thru paint w/2 gates) until the target mode is selected.

Finally, the measurement mode can be selected from the menu items as follows:

34

Page 39

MVX High Performance Thickness Gauge

Selected Using The Tabbed Submenu Items

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the GATE menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MEASURE MODE is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the mode options. Once the

mode is displayed, press the MEAS key to return to the measurement mode

screen.

6.2 Probe zero

As noted in chapter 3, the probe zero function is a very important and necessary

function that must done prior to calibration. It should also be done on a regular basis.

If the MVX is not zeroed correctly, all of the measurements taken, may be in error by

some fixed value. In order to perform a probe zero, the MVX must be in pulse-echo

mode. If echo-echo mode was previously selected in the last section, skip this

section and continue on to the next. Note: If you intend to switch between

measurement modes simultaneously, temporarily select the pulse-echo mode using

the hot menu option, perform the probe zero function, and switch back to echo-echo

measurement mode after zeroing. The following steps outline the procedure for

performing a probe zero:

Page 40

Dakota Ultrasonics

Performing a Probe Zero

1) Clean the surface of the Probe Zero Disk, located on top of the MVX

(battery cover).

2) Apply a drop of couplant to the end of the transducer, or probe disk, and

hold the transducer in steady contact with the reference disk.

3) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the PROBE menu is highlighted and displaying the submenu items.

4) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ZERO TRANSDUCER is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to zero the transducer and return to the menu screen, or

ESC to cancel the zeroing process.

7) Remove the transducer from the probe zero disk.

8) Press the MEAS key to return to the measurement screen.

6.3 Material Calibration

In order for the MVX to make accurate measurements, it must be set to the correct

sound velocity of the material being measured. Different types of materials have

different inherent sound velocities. For example, the velocity of sound through steel

is about 0.233 inches per microsecond, versus that of aluminum, which is about

0.248 inches per microsecond. If the gauge is not set to the correct sound velocity,

36

Page 41

MVX High Performance Thickness Gauge

all of the measurements the gauge makes will be erroneous by some fixed

percentage.

The One Point calibration is the simplest and most commonly used calibration

method - optimizing linearity over large ranges. The Two Point calibration allows for

greater accuracy over small ranges by calculating the probe zero and velocity. The

MVX provides four simple methods for setting the sound-velocity outlined below:

Calibration to a known velocity

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VELOCITY is highlighted.

3) Press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the velocity number is correctly displayed.

7) Press the OK key to set the velocity and return to the menu screen, or ESC

to cancel entering the velocity.

Page 42

Dakota Ultrasonics

8) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

38

Page 43

MVX High Performance Thickness Gauge

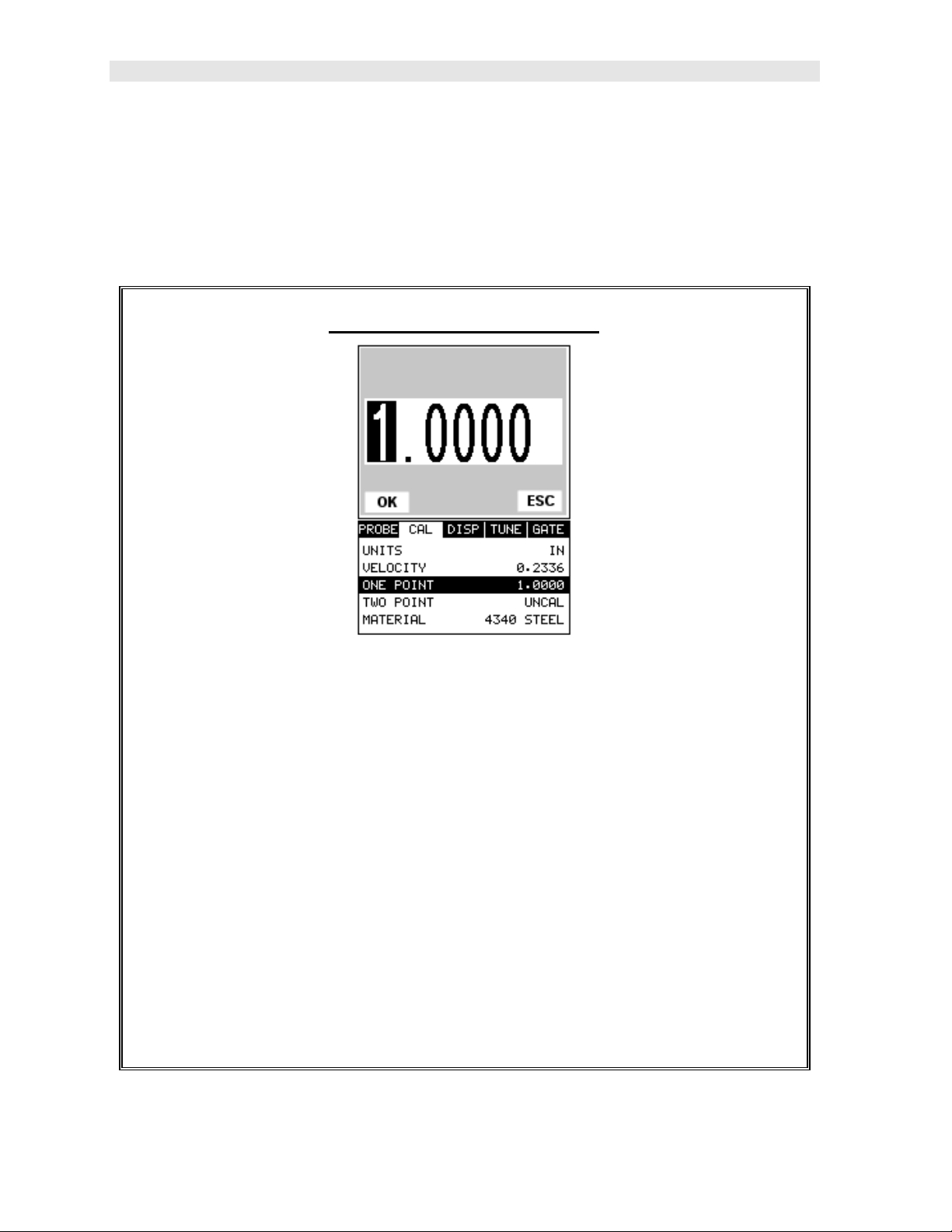

One Point Calibration

Note: Be sure that a probe zero has been done prior to performing this

calibration procedure.

1) Physically measure a location on the sample to be measured using a set of

calipers or a digital micrometer. Note: It’s always best to calibrate on

thickest location on the sample, rather than on the thinnest location, as the

percentage error is much less with respect to the MVX’s resolution of +/ -

.001” (0.01mm).

2) Apply a drop of couplant on the transducer. Place the transducer in st eady

contact on the known thickness location. Be sure that the reading is stable

and the repeatability indicator, located in the top left corner of the display, is

fully lit and stable. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the ESC key multiple

times to tab left until the CAL menu is highlighted and displaying the

submenu items.

Page 44

Dakota Ultrasonics

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel entering the velocity.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration point. The thickness reading should now match the known

thickness. If the thickness is not correct, repeat the steps above.

Two Point Calibration

40

Page 45

MVX High Performance Thickness Gauge

Note: Be sure that a probe zero has been done prior to performing this

calibration procedure.

1) Using a set of calipers, physically measure two known thickness locations

on the sample of material. Note: The two locations should represent the

desired thickness range being measured. If the range is from .250” - 1.000”,

then the two known locations should represent this range, or be slightly

outside or inside of this range. A typical example would be to find two

locations at .236” and the other at 1.047”. These thickness points will satisfy

the required thickness range noted above.

2) Apply a drop of couplant on the transducer. Place the transducer in steady

contact on thickest known location first. Be sure that the reading is stable

and the repeatability indicator, located in the top left corner of the display, is

fully lit and stable. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right, and the ESC key multiple

times to tab left, until the CAL menu is highlighted and displaying the

submenu items.

Page 46

Dakota Ultrasonics

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8) Press the OK key to calculate the velocity for the ONE POINT calibration

and return to the CAL menu screen, or press ESC to cancel entering the

velocity.

9) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material on the thinnest, or

second known thickness location. Be sure that the reading is stable and the

repeatability indicator, located in the top left corner of the display, is fully lit

and stable.

10) Use the UP and DOWN arrow keys to highlight the TWO POINT calibration

submenu item.

11) Press the ENTER key to display the Digits Edit Box.

12) Press the UP and DOWN arrow keys to scroll the highlighted value.

13) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

14) Repeat steps 12 & 13 until the known thickness value is correctly displayed.

15) Press the OK key to calculate the velocity for the TWO POINT calibration

42

and return to the CAL menu screen, or press ESC to cancel entering the

velocity.

Page 47

MVX High Performance Thickness Gauge

16) Finally, press the MEAS key to return to the measurement screen and

begin taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on both

calibration points. The thickness readings should now match the known

thickness locations. If they are not correct, repeat the steps above.

Page 48

Dakota Ultrasonics

Built in Material Selection

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATERIAL is highlighted.

3) Press the ENTER key to display the list of Material Types.

4) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the material and return to the menu screen, or

press ESC to cancel the material selection.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

44

Page 49

CHAPTER SEVEN

USING THE A-SCAN & B-SCAN DISPLAYS

A key feature of the MVX is the waveform display. The waveform is a graphical

representation of the sound reflections returning to the transducer. Consider

standing at the base of a canyon and screaming “Hello There”. After a brief delay,

you will here multiple echoes, “Hello There’s” repeated back to you. The waveform

display shows the amplitude of the signal received on the vertical (Y) axis and time

(shown in units of thickness) on the horizontal (X) axis.

The waveform display is very useful for viewing and adjusting the location of the

gates. The gates are typically used to eliminate potential surface noise by adjusting

the starting point in single echo modes, for multi echo measurement modes, as well

as to adjust the threshold (sensitivity) in either mode. The waveform display is also

very useful for locating pits and internal flaws in materials.

The B-Scan display is also very useful when scanning surfaces and viewing the cross

section of the test material. It provides a convenient way of profiling the blind

surfaces during a scan. The B-Scan display is also equipped with a scan bar

representing the overall thickness. The scan bar gives the user a visual indication

when a flaw or defect passed over during the scan process. The scan bar will deflect

off of the defect and return back to the overall thickness. Visually, this is much easier

to notice than watching for changes in the digital value displayed. The scan bar has

also been included in the large digits display mode for the same purpose.

Note: The following chapter outlines some of the fine adjustment features of the

MVX. The MVX has four different display options (RF A-Scan, Rectified A-Scan, B-

Scan, and Large Digits). We’ll take a better look at these options in this chapter.

Note: In order to recall and use the new adjustments made to the MVX at a later

time, the user must save the modified settings in one of the setup locations prior to

powering off the unit. Refer page 100 for more information on setups.

7.1 Selecting a Display Option

The following procedure outlines how to select or toggle display options:

Changing Display Options

45

Page 50

Dakota Ultrasonics

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VIEW is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the view options. Once the

appropriate view is displayed, press the MEAS key to return to the

measurement screen.

7.2 Display Views

RF

RF View

The RF mode shows the waveform in a similar fashion to an oscilloscope. It shows

both the positive and the negative peaks. The peak (either positive or negative)

selected for measurement is shown in upper portion of the display.

It’s important to note tha t a measurement must fall inside the displays viewable range

in order to see the waveform. However, even if the waveform is outside of the

viewable range of the display, a measurement can be taken and viewed on the digital

46

Page 51

MVX High Performance Thickness Gauge

readout. If the wave is outside of the display range, you can manually change the

range by adjusting the Delay and Width values, or you can use the Auto Find

feature located in the UTIL menu of the tabbed menu items. Refer to page 74 for

additional information on the Auto Find feature.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the return echo on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the MVX is displaying a reading from memory, the repeatability indicator

will be replaced by the text “MEM”.

B) Battery life Indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness Reading – Digital readout of thickness (inches or millimeters).

D) Detect Indicator – The broken vertical line displays the zero crossing (flank)

detection point on the waveform where the measurement has been obtained.

Notice that the digit al thickness readout is the same as the location of the detect

indicator according to the measurements labels F, also in the diagram.

E) Echo Signal – Graphical full waveform representation of the echo signal

displayed as an amplitude (vertical or “Y” axis) plotted against time (horizontal or

“X” axis), this time is then converted to a physical measurement and displayed

according.

F) Measurement Labels – The measurement labels are calculated and displayed

based on where the left side of the display has been set (Delay), and the overall

viewable area (Width) of the display. Note: The gray hash marks break the

display up into 5 segments, or quadrants. The measurement labels correspond to

the measurement at each hash mark.

G) Units Label - Displays the current units of measurement (inches or millimeters).

H) Hot Menus - Each of the fields located under the waveform display are called the

Hot Menu Fields. These fields allow quick control of some of the fine

adjustments needed to control the display settings, measurement modes, and grid

memory control. All of these fields can be adjusted without having to activate the

tabbed menu items and searching through a variety of menus to make

adjustments.

Page 52

Dakota Ultrasonics

Rectified

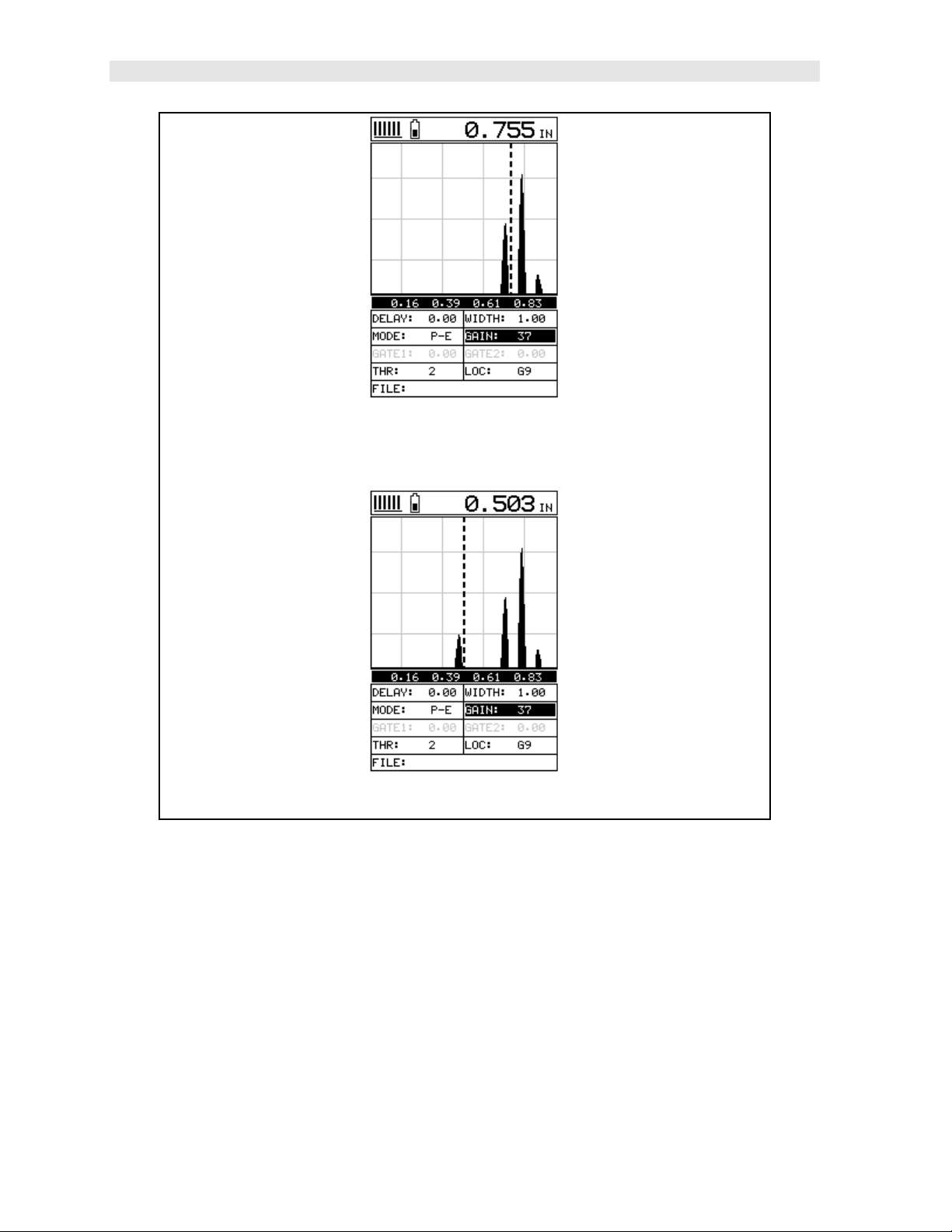

Rectified View

The rectified A-Scan mode shows half of the waveform. Either the positive or

negative peaks are displayed, depending on the polarity selected. This is the

preferred display view for flaw and pit detection applications.

It’s important to note that a measurement must fall inside the viewable display range

in order to see the waveform. However, even if the waveform is outside of the

viewable area, a measurement can be taken and viewed on the digital readout. If the

waveform is outside of the display range, you can manually change the range by

adjusting the Delay and Width values, or you can use the Auto Find feature located

in the UTIL menu in the tabbed menu items. Refer to page 74 for additional

information on the Auto Find feature.

The following is a list of the viewabl e features on the display:

A) Stability of Reading Indicator – Indicates the stability of the return echo on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the MVX is displaying a reading from memory, the repeatability indicator

will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inches or millimeters).

D) Detect Indicator – The broken vertical line displays the zero crossing (flank)

detection point on the waveform where the measurement has been obtained.

Notice that the digital thickness readout is the same as the location of the detect

indicator according to the measurements labels F, also in the diagram.

48

Page 53

MVX High Performance Thickness Gauge

E) Echo Signal – Graphical full waveform representation of the return echo

displayed as an amplitude (vertical or “Y” axis) plotted against time (horizontal or

“X” axis), this time is then con verted to a physical measurement.

F) Measurement Labels – The measurement labels are calculated and displayed

according to where the left side of the display has been set (Delay), and the

overall viewable area (Width) of the display. Note: The gray hash marks break

the display up into 5 segments, or quadrants. The measurement labels

correspond to the measurement at each hash mark.

G) Units Label - Displays the current units of measurement (inches or millimeters).

H) Hot Menus - Each of the fields located under the waveform display are called the

Hot Menu Fields. These fields allow quick control of some of the fine

adjustments needed to control the display settings, measurement modes, and grid

memory control. All of these fields can be adjusted without having to activate the

tabbed menu items and searching through a variety of menus to make

adjustments.

B-Scan View

B-Scan

The B-Scan displays a time based cross section view of test material. This view is

commonly used to display the contour of the blind, or underside, surface of a pipe or

tank application. It is very similar to a fish finder. If a flaw or pit is located during a

scan, the B-Scan will draw the pit on the screen. The solid black rectangle in the

diagram at location E represents the cross section, or side view of the material. You

will notice that the overall thickness of the material is .500”, and the display range is

0.00” to 1.00” respectively. The B-Scan view draws at a rate of 15 seconds per

Page 54

Dakota Ultrasonics

screen from right to left. Also notice at location J, the pits and corroded bottom

surface of the material.

It’s important to note that the measurement range on the display be set wide enough,

so that the maximum thickness of the material can be viewed on the display. Using

the diagram above, if th e material thickness was actually 1.75”, the underside of the

material would not be viewable according to the current range at 0.00” – 1.00”. All

the user would see is a black screen from 0.00” – 1.00” with no view of the bottom

contour at 1.75”.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the echo signal on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the MVX is displayin g a reading from memory, the repeatability indicator

will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inches or millimeters).

D) B-Scan Display Area – This is the area representing where the B-Scan will be

drawn. Notice the range of the area in the diagram at 0.00” – 1.0” respectively.

E) Displayed B-Scan – Graphical presentation of the cross section, or side view of

the test material. The top, or accessible side of the material represented as 0.00”,

and the bottom, or blind surface at .500”. You will notice the contour in the B-

Scan, indicating a very corroded bottom surface. The B-Scan is displayed from

right to left at a rate of 15 screens per second.

F) Measurement Labels – The measurement labels are calculated and displayed

based on where the left side of the display has been set (Delay), and the overall

viewable area (Width) of the display. Note: The gray hash marks break the

display up into 5 segments, or quadrants. The measurement labels correspond to

the measurement at each hash mark.

G) Units Label - Display’s the current unit of measurement (inches or millimeters).

H) Hot Menus - Each of the fields located under the B-Scan display are called the

Hot Menu Fields. These fields allow quick control of some of the fine

adjustments needed to control the display settings, measurement modes, and grid

memory control. All of these fields can be adjusted without having to activate the

tabbed menu items and searching through a variety of menus to make

adjustments.

I) Scan Bar – The scan bar corresponds directly with thickness represented by the

horizontal labels on the on the display. As you can see from the diagram above,

the filled horizontal bar is displayed at .500”. This display can be very useful

when scanning materials in either B-Scan or Digits display views. It is much

easier to watch and notice deflections for flaws and pits using th e scan bar, rather

than trying to notice changes in digital values. If the user is scanning a pipe, for

50

Page 55

MVX High Performance Thickness Gauge

instance, and passes over a pit in the process, the scan bar will quickly deflect

and alarm the user to go back and search for the defect.

J) Contour (blind surface) – A view of the B-Scan displaying the blind side surface

contour of the material.

DIGITS VIEW

DIGITS

The Digits view is a basic digital thickness gauge look and feel. The larger digits

make it much easier for the operator to monitor the thickness readings. The Scan

Bar has also been added to the Digits view to provide the user with yet another visual

tool for easily monitoring changes in thickness readings due to internal flaws or

defects.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the return echo on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the MVX is displaying a reading from memory, the repeatability indicator

will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inches or millimeters).

D) Large Digits – Large readout of thickness (inches or millimeters).

E) Units Label – Display’s the current unit of measurement (inches or millimeters).

F) Measurement Labels – The measurement labels are calculated and displayed

based on where the left side of the display has been set (Delay), and the overall

viewable area (Width) of the display. Note: The gray hash marks break the

Page 56

Dakota Ultrasonics

display up into 5 segments, or quadrants. The measurement labels correspond to

the measurement at each hash mark.

G) Scan Bar – The scan bar corresponds directly with thickness represented by the

horizontal labels on the on the display. As you can see from the diagram above,

the filled horizontal bar is displayed at .500”. This display can be very useful

when scanning materials in either B-Scan or Digits display views. It is much

easier to watch and notice deflections for flaws and pits using the scan bar, rather

than trying to notice changes in the digital value. If the user is scanning a pipe,

for instance, and passes over a pit during the process, the scan bar will quickly

deflect and alarm the user to go back and search for the defect.

H) Hot Menus - Each of the fields located under the display are called the Hot Menu

Fields. These fields allow quick control of some of the fine adjustments needed

to control the display settings, measurement modes, and grid memory control.

All of these fields can be adjusted without having to activate the tabbed menu

items and searching through a variety of menus to make adjustments.

7.3 Adjusting the screen

The width refers to the overall viewable range, with respect to depth, being displayed

on the screen. The starting depth is displayed at the lower left side of the screen,

and the ending depth is shown at the lower right hand side of the screen. The

difference between these values is called the Width. The procedures to adjust the

Width are outlined below:

Adjusting the Width using the Hot Menus

52

Page 57

MVX High Performance Thickness Gauge

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the WIDTH cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the WIDTH value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the WIDTH.

The user can also access and adjust the width from the tabbed menus. However,

this method is a more tedious than making the adjustments using the Hot Menus.

The procedure using the tabbed menus is outlined below:

Page 58

Dakota Ultrasonics

Adjusting the Width using the Tabbed Menus

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until WIDTH is highlighted.

3) Press the LEFT and RIGHT arrow keys to scroll the value. When the

correct width is being displayed, proceed to step 8.