Page 1

OPERATION MANUAL

P/N P

-

129

-

0002

Rev

1.60

January

200

8

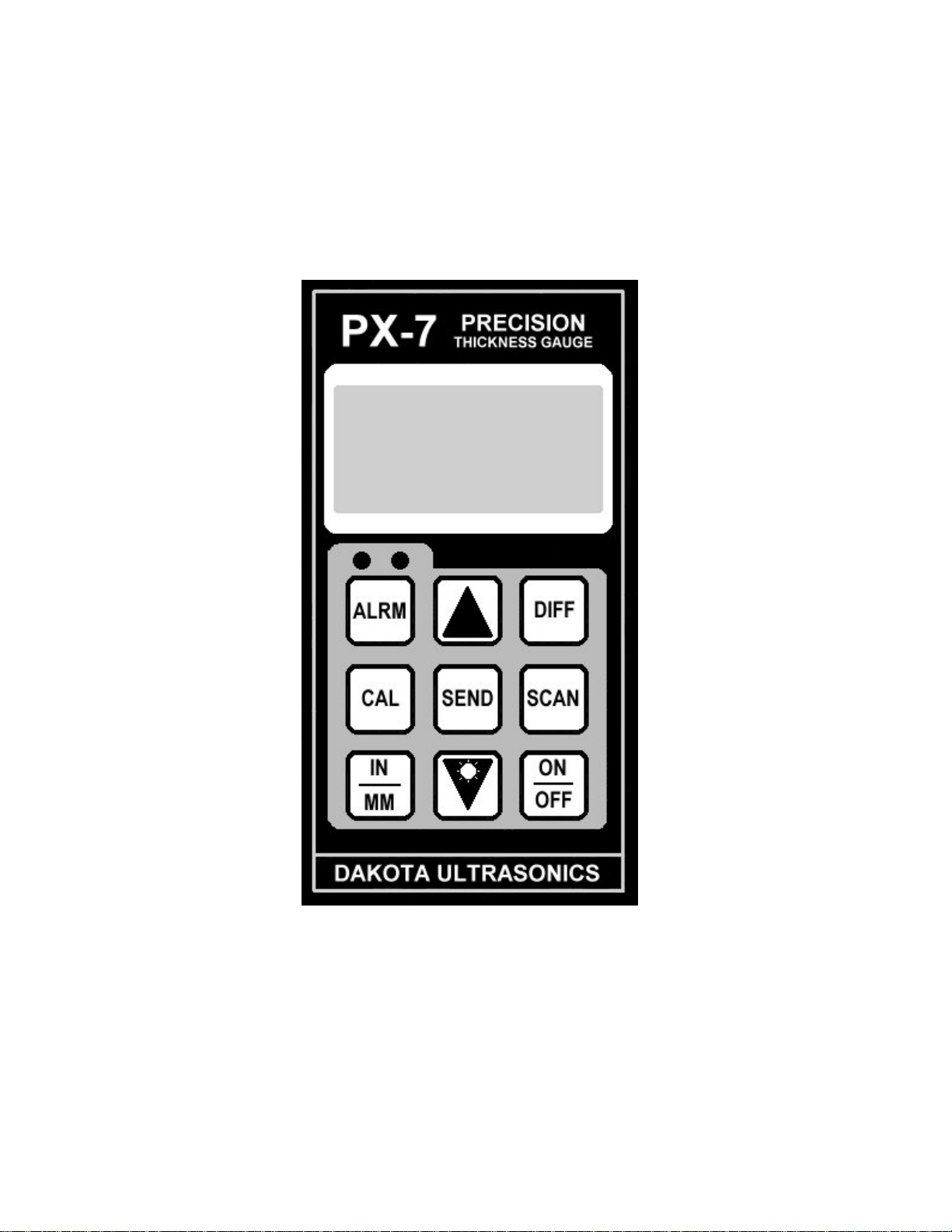

DAKOTA ULTRASONICS MODEL PX-7 PRECISION THICKNESS GAUGE

Page 2

Copyright 2008 Dakota Ultrasonics. All rights reserved.

No part of this publication may be reproduced, translated into another

language, stored in a retrieval system, or transmitted in any form or by any

means; electronic, mechanical, photocopying, recording, or otherwise,

without the prior written consent of Dakota Ultrasonics.

Every precaution has been taken in the preparation of this publication.

Dakota Ultrasonics assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of

information contained herein.

Any brand or product names mentioned herein are used for identification

purposes only, and are trademarks or registered trademarks of their

respective holders.

1500 Green Hills Road, #107 Scotts Valley, CA 95066 USA

Tel (831) 431-9722 Fax (831) 431-9723

www.dakotaultrasonics.com

Page 3

CONTENTS

PX-7 Ultrasonic Thickness Gauge

INTRODU CTION

OPERATION

THE KEYPAD

THE DISPLAY

THE TRANSDUCER

MAKING MEASUREMENTS

CONDITION AND PREPARATION OF SURFACES

SELECTING MEASUREMENT MODE & THE LOCK MODE

CALIBRATION

SCAN MODE, ALARM MODE, DIFF MODE, RS232 PORT

TRANSDUCER SELECTION

APPENDIX A: PRODUCT SPECIFICATIONS

APPENDIX B: APPLICATION NOTES

1

3

3

7

9

10

12

13

14

17

22

25

27

APPENDIX C: SOUND VELOCITIES OF COMMON MATERIALS

WARRANTY INFORMATION

29

31

DISCLAIMER

Inherent in ultrasonic thickness measurement is the possibility that the

instrument will use the second rather than the first echo from the back

surface of the material being measured. This may result in a thickness

reading that is TWICE what it should be. Responsibility for proper use of

the instrument and recognition of this phenomenon rests solely with the

user of the instrument.

Page 4

Dakota Ultrasonics

blank page

Page 5

PX-7 Ultrasonic Thickness Gauge

1

INTRODUCTION

The Dakota Ultrasonics model PX-7 is a precision Ultrasonic

Micrometer. Based on the same operating principles as SONAR, the PX-7

is capable of measuring the thickness of various materials with accuracy as

high as ± 0.0001 inches, or ± 0.001 millimeters. The principle advantage of

ultrasonic measurement over traditional methods is that ultrasonic

measurements can be performed with access to only one side of the

material being measured.

This manual is presented in three sections. The first section covers

operation of the PX- 7, and explains the keypad controls and display. The

second section provides guidelines in selecting a transducer for a specific

application. The last section provides application notes and a table of

sound velocity values for various materials.

Dakota Ultrasonics maintains a customer support resource in order to

assist users with questions or difficulties not covered in this manual.

Customer support may be reached at any of the following:

• Dakota Ultrasonics, 1500 Green Hills Road, #107

Scotts Valley, CA 95066 USA

• Telephone: (831) 431- 9722

• Facsimile: (831) 431-9723

• www.dakotaultrasonics.com

Page 6

Dakota Ultrasonics

2

blank page

Page 7

PX-7 Ultrasonic Thickness Gauge

3

OPERATION

The PX-7 interacts with the operator through the membrane keypad and

the LCD display. The functions of the various keys on the keypad are

detailed below, followed by an explanation of the display and its various

symbols.

The Keypad

This key is used to turn the PX-7 on and off. When the tool is turned

ON, it will first perform a brief display test by illuminating all of the

segments in the display. After one second, the tool will display the internal

software version number. After displaying the version number, the display

will show "0.0000" (or "0.000" if using metric units), indicating the tool is

ready for use.

The PX-7 is turned OFF by pressing the ON/OFF key. The tool has a

special memory that retains all of its settings even when the power is off.

The tool also features an auto-powerdown mode designed to conserve

battery life. If the tool is idle for 5 minutes, it will turn itself off.

Page 8

Dakota Ultrasonics

4

The CAL key is used to enter and exit the PX-7's calibration mode.

This mode is used to adjust the sound-velocity value that the PX-7 will use

when calculating thickness. The tool will either calculate the sound-velocity

from a sample of the material being measured, or allow a known velocity

value to be entered directly. Refer to page 14 for an explanation of the two

CAL functions available.

The IN/MM key is used to switch back and forth between English and

metric units. This key may be used at any time, whether the tool is

displaying a thickness (IN or MM) or a velocity value (IN/µs or M/s).

The UP arrow key has two functions. When the PX-7 is in calibration

mode, this key is used to increase numeric values on the display. An autorepeat function is built in, so that when the key is held down, numeric

values will increment at an increasing rate. When the PX-7 is in

measurement mode, this key is used to select between three different

modes of measurement ( echo-echo, interface-echo, or auto ). Refer to

page 14 for an explanation of the calibration procedure and page 13 to

review the various measurement modes.

Page 9

PX-7 Ultrasonic Thickness Gauge

5

The SCAN key switches the SCAN measurement mode on and off.

Refer to page 17 for an explanation of the SCAN measurement mode.

The DOWN arrow key has three functions. When the PX-7 is in the

CAL mode, this key is used to decrease numeric values on the display. An

auto-repeat function is built in, so that when the key is held down, numeric

values will decrement at an increasing rate. When the PX- 7 is not in

calibration mode, the DOWN arrow key switches the display backlight

between three available settings. OFF will be displayed when the backlight

is switched off. AUTO will be displayed when the backlight is set to

automatic mode, and ON will be displayed when the ba cklight is set to stay

on. In the AUTO setting, the backlight will illuminate while the PX-7 is

making a measurement and turn off after several seconds to conserve

battery life. Finally, if the DOWN arrow key is pressed and held down while

powering the PX-7 on, a LOC mode will be toggled on/off.

Page 10

Dakota Ultrasonics

6

The ALRM key has two functions. By holding down the ALRM key

when powering up the PX- 7, the audible beeper will be turned on or off

accordingly. After the unit has been turned on, pressing the ALRM key will

toggle the alarm mode to the on/off positions and allow the user to enter a

nominal thickness value. Refer to page 18 for details on how to use the

alarm feature.

The DIFF key is used to enable or disable the Differential mode and

allow the user to enter a nominal value as a comparison against actual

thickness measurements. Refer to page 19 for a complete explanation of

this feature.

The SEND key is used to send the cu rrently displayed thickness

measurement to an external storage device via the PX-7's RS232 port.

Refer to page 20 for an explanation of how to use this feature.

Page 11

PX-7 Ultrasonic Thickness Gauge

7

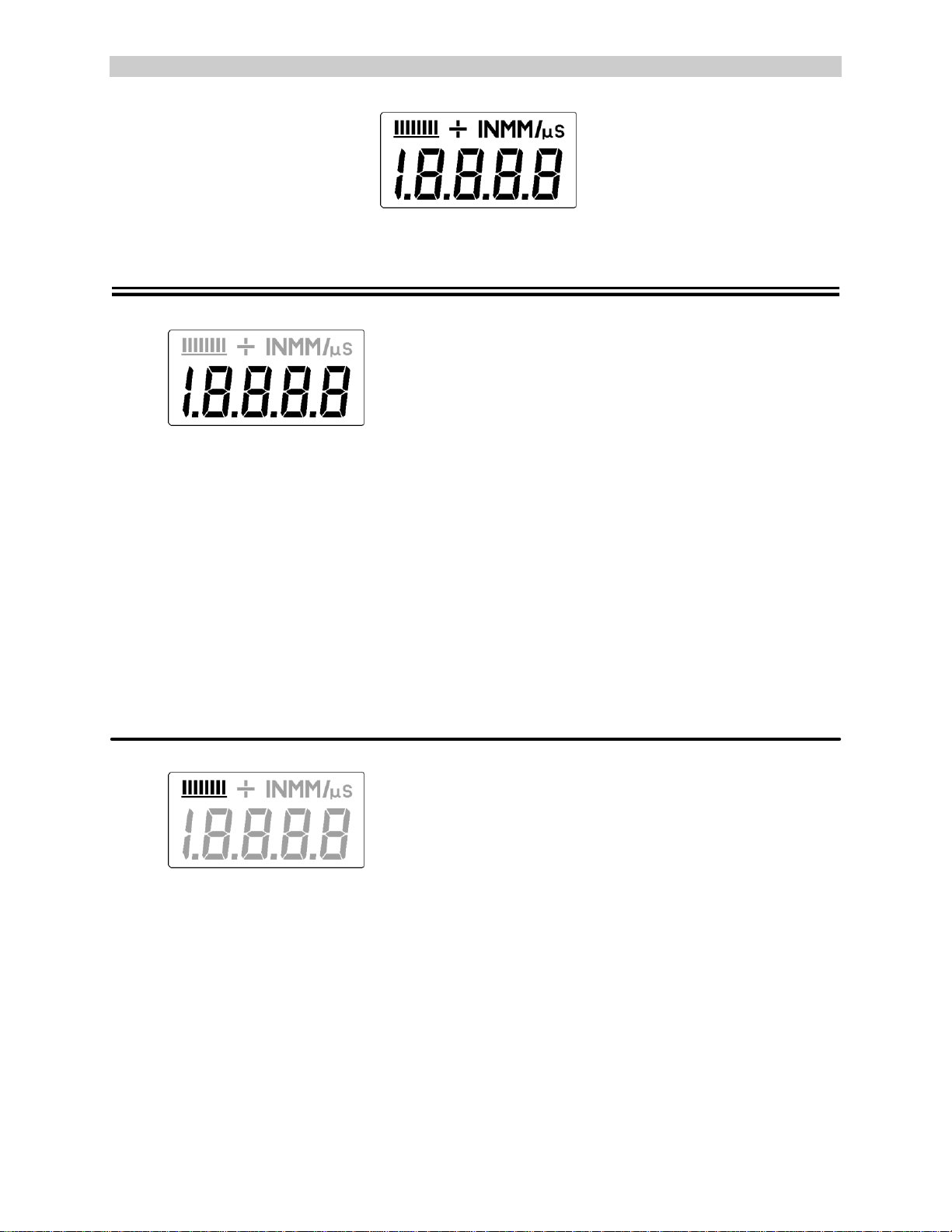

The Display

The numeric portion of the displ ay consists of 4 complete digits

preceded by a leading "1", and is used to display numeric values, as well

as occasional simple words, to indicate the status of various settings.

When the PX-7 is displaying thickness measurements, the display will hold

the last value measured, until a new measurement is made. Additionally,

when the battery voltage is low, the entire display will begin to flash. When

this occurs, the batteries should be replaced.

These eight vertical bars form the Stability Indicator. When the PX-7 is

idle, only the left -most bar and the underline will be on. While the gauge is

taking a measurement, six or seven of the bars should be on. If fewer than

five bars are on, the PX-7 is having difficulty achieving a stable

measurement, and the thickness value displayed will most likely be

erroneous.

Page 12

Dakota Ultrasonics

8

When the IN symbol is on, the PX-7 is displaying a thickness value in

inches. The maximum thickness that can be displayed is 1.0000 inches.

When the MM symbol is on, the PX- 7 is displaying a thickness value in

millimeters. If the displayed thickness exceeds 20.00 millimeters, the

decimal point will shift automatically to the right, allowing values up to 25.40

millimeters to be displayed.

When the IN symbol is on, in conjunction with the /µs symbol, the PX-7

is displaying a sound-velocity value in inches- per-microsecond.

When the M symbol is on, in conjunction with the /s symbol, the PX- 7

is displaying a sound-velocity value in meters-per-second.

Page 13

PX-7 Ultrasonic Thickness Gauge

9

The Transducer

The transducer is the "busi ness end" of the PX-7. It transmits and

receives ultrasonic sound waves that the PX-7 uses to calculate the

thickness of the material being measured. The transducer connects to the

PX-7 via the attached cable, and one coaxial connector.

The transducer must be used correctly in order for the PX-7 to produce

accurate, reliable measurements. Below is a short description of the

transducer, followed by instructions for its use.

The diagram above is a side view of a typical single element delay line

transducer. This delay line is fastened to the transducer with a retainer

ring. A drop of couplant is applied between the delay line and

transducer body. The transducer body contains one crystal element that

is responsible for conducting ultrasonic sound into and back from the

material being measured. When the transducer is placed against the

material being measured, it is the area directly beneath the delay line that

is being measured.

Page 14

Dakota Ultrasonics

10

When measuring, press against the top of the transducer with the

thumb or index finger to hold the transducer in place. Moderate pressure is

sufficient, as it is only necessary to keep the transducer stationary, and the

delay line seated flat against the surface of the material being measured.

Making Measurements

In order for the transducer to do its job, there must be no air gaps

between the wear-face and the surface of the material being measured.

This is accomplished with the use of a "coupling" fluid, commonly called

"couplant". This fluid serves to "couple", or transfer , the ultrasonic sound

waves from the transducer, into the material, and back again. Before

attempting to make a measurement, a small amount of couplant should be

applied to the surface of the material being measured. Typically, a single

droplet of coupl ant is sufficient.

After applying couplant, press the transducer (wearface down) firmly

against the area to be measured. The Stability Indicator should have six or

seven bars darkened, and a number should appear in the display. If the

PX-7 has been set to the correct sound velocity (see page 14), the number

in the display will indicate the actual thickness of the material directly

beneath the transducer.

Page 15

PX-7 Ultrasonic Thickness Gauge

11

If the Stability Indicator has fewer than five bars darkened, or the

numbers on the display seem erratic, first check to make sure that there is

an adequate film of couplant beneath the transducer, and that the

transducer is seated flat against the material. If the condition persists, it

may be necessary to select a different transducer (size or frequency) for

the material being measured. See page 22 for information on transducer

selection.

While the transducer is in contact with the material that is being

measured, the PX-7 will perform four measurements every second,

updating its display as it does so. When the transducer is removed from

the surface, the display will hold the last measurement made.

IMPORTANT

Occasionally, a small film of couplant will be drawn out between the

transducer and the surface as the transducer is removed. When this

happens, the PX-7 may perform a measurement through this couplant film,

resulting in a measurement that is larger or smaller than it should be. This

phenomenon is obvious when one thickness value is observed while the

transducer is in place, and another value is observed after the transducer is

removed.

Page 16

Dakota Ultrasonics

12

Condition and Preparation of Surfaces

In any ultrasonic measurement scenario, the shape and roughness of

the test surface are of paramount importance. Rough, uneven surfaces

may limit the penetration of ultrasound through the material, and result in

unstable, and therefore unreliable, measurements. The surface being

measured should be clean, and free of any small particu late matter, rust, or

scale. The presence of such obstructions will prevent the transducer from

seating properly against the surface. Often, a wire brush or scraper will be

helpful in cleaning surfaces. In more extreme cases, rotary sanders or

grinding wheels may be used, though care must be taken to prevent

surface gouging, which will inhibit proper transducer coupling.

Extremely rough surfaces, such as the pebble-like finish of some cast

iron, will prove most difficult to measure. These kinds of surfa ces act on

the sound beam like frosted glass on light:, the beam becomes diffused

and scattered in all directions.

In addition to posing obstacles to measurement, rough surfaces

contribute to excessive wear of the transducer, particularly in situations

where the transducer is "scrubbed" along the surface.

Page 17

PX-7 Ultrasonic Thickness Gauge

13

Selecting Measurement Mode

The PX-7 is equipped with four measurement mode options (echoecho, interface- echo, auto, or plas). In echo-echo mode, the gauge has the

ability to read thin metals dow n to .006 inches (.15 millimeters). The echoecho mode also allows the user to measure the thickness of metals that

have been previously coated or painted on the surface. This enables the

user to determine the thickness of the metal without having to remove the

paint. In interface-echo mode, the gauge has the ability to read plastics

and thicker materials. The PX-7's auto mode will automatically switch

between echo-echo and interface-echo according to the different materials

being measured. Finally, the plas mod can be used to measure thin plastics

using a special graphite tip. The following section outlines how to switch

between measurement modes:

Measurement Modes

1) Make sure the PX-7 is on.

2) Press the UP arrow key to toggle between measurement m odes.

The gauge will display GatE followed by I-E, E-E, Auto, or PLAS

depending on which mode the PX-7 was last used in.

3) Repeat step 2 until the desired mode has been displayed.

Note: Once the mode has been selected, the user can use the built-in

LOC feature to prevent additional users from accidentally changing

the mode. When the PX-7 is in LOC mode, all features (with the

exception of the calibration and units), are locked and cannot be

Page 18

Dakota Ultrasonics

14

altered by the user. Press and hold the DOWN arrow key while

powering up the PX-7 to toggle the LOC feature on/off. Repeat

procedure to toggle on/off status.

Calibration

In order for the PX- 7 to make accurate measurements, it must be set to

the correct sound-velocity for the material being measured. Different types

of material have different inherent sound-velocities. For example, the

velocity of sound through steel is about 0.233 inches-per-microsecond,

versus that of aluminum, which is about 0.248 inches-per-microsecond. If

the tool is not set to the correct sound-velocity, all of the measurements the

tool makes will be erroneous by some fixed percentage. The one point

calibration is the simplest and most commonly used calibration procedure -

optimizing linearity over large ranges. The PX-7 provides two simple

methods for setting the sound-velocity, described in the following pages.

Page 19

PX-7 Ultrasonic Thickness Gauge

15

Calibration to a known thickness

NOTE: This procedure requires a sample piece of the specific

material to be measured, the exact thickness of which is known,

e.g. from having been measured by some other means.

1) Make sure the PX-7 is on.

2) Apply couplant to the sample piece.

3) Press the transducer against the sample piece, making sure that

the transducer sits flat against the surface of the sample. The

display sh ould show some (probably incorrect) thickness value,

and the Stability Indicator should have nearly all its bars on.

4) Having achieved a stable reading, remove the transducer. If the

displayed thickness changes from the value shown while the

transducer was coupled, repeat step 3.

5) Press the CAL key. The IN (or MM ) symbol should begin flashing.

6) Use the UP and DOWN arrow keys to adjust the displayed

thickness up or down, until it matches the thickness of the sample

piece.

7) Press the CAL key again. The IN/µs (or M/s) symbols should

begin flashing. The PX-7 is now displaying the sound velocity

value it has calculated based on the thickness value that was

entered in step 6.

8) Press the CAL key once more to exit the calibration mode. The

PX-7 is now ready to perform measurements.

Page 20

Dakota Ultrasonics

16

Calibration to a known velocity

NOTE: This procedure requires that the operator know the sound-

velocity of the material to be measured. A table of common

materials and their sound-velocities can be found in Appendix C.

1) Make sure the PX-7 is on.

2) Press the CAL key to enter calibration mode. If the IN (or MM)

symbol is flashing, press the CAL key again, so that the IN/µs (or

M/s) symbols are flashing.

3) Use the UP and DOWN arrow keys to adjust the displayed velocity

up or down, until it matches the sound-velocity of the material to be

measured.

4) Press the CAL key once more to exit the calibration mode. The

PX-7 is now ready to perform measurements.

NOTE: At any time during the calibration procedure (IN, MM, IN/ µs, or

M/s flashing in the display), pressing the SCAN key will restore the tool to

the factory default sound- velocity for steel (0.233 IN/µs).

To achieve the most accurate measurements possible, it is generally

advisable to always calibrate the PX-7 to a sample piece of known

thickness. Material composition (and thus, its sound-velocity) sometimes

varies from lot to lot and from manufacturer to manufacturer. Calibration to

a sample of known thickness will ensure that the tool is set as closely as

possible to the sound velocity of the material to be measured.

Page 21

PX-7 Ultrasonic Thickness Gauge

17

PX-7 Modes

Scan Mode

While the PX-7 excels at making single point measurements, it is

sometimes desirable to examine a larger region, searching for the thinnest

point. The PX-7 includes a feature, called Scan Mode, which allows it to do

just that.

In normal operation, the PX-7 performs and displays four

measurements every second, which is quite adequate for single

measurements. In Scan Mode, however, the tool performs eight

measurements every second, but does not display them. While the

transducer is in contact with the material being measured, the PX-7 is

keeping track of the lowest measurement it finds. The transducer may be

"scrubbed" across a surface, and any brief interruptions in the signal will be

ignored. When the transducer loses contact with the surface for more than

a second, the PX-7 will display the smallest measurement it found.

When the PX-7 is not in calibration mode, press the SCAN key to turn

Scan Mode on and off. A brief message will appear in the display

confirming the operation. While scanning, the display will show a moving

series of dashes instead of a thickness value. When the transducer is

removed from the material being scanned, the PX-7 will (after a brief

pause) display the smallest measurement it found.

Page 22

Dakota Ultrasonics

18

Alarm Mode

The Alarm Mode feature of the PX-7 allows the user to set an audible

and visual Hi / Lo parameter when taking measurements. If the

measurement falls below or above the Hi / Lo limits, set by the user, a red

light will be illuminated on the front panel of the gauge and the beeper

sounded. This improves the speed and efficiency of the inspection process

by eliminating constant viewing of the actual reading displayed. The

following pages outline how to enable and set up this feature:

Using the Beeper

1) While the unit is off, press and hold down the ALRM key.

2) Press ON/OFF key to power up the unit.

3) Release the ALRM key - BEEP ON or BEEP OFF will be displayed

enabling or disabling the beeper.

4) Repeat step s 1 through 3 to toggle between BEEP ON or BEEP

OFF.

Page 23

PX-7 Ultrasonic Thickness Gauge

19

Alarm Mode

1) Press ON/OFF key to power up the PX-7.

2) Press the ALRM key. ALAr OFF, or ALAr followed by a thickness

value and flashing IN (or MM ) symbol will be displayed - indicating

the alarm mode is enabled.

3) Repeat step 2 to toggle between ALAr OFF or ALAr value and

flashing IN / MM symbol (On).

4) Assuming ALAr value flashing IN is displayed, use the UP and

DOWN arrow keys to scroll to the desired Lo alarm value.

5) Press the SEND key to select the Lo value entered. The Hi value

will now be displayed. Repeat step 4 select the Hi alarm value.

6) The PX-7 is now ready to perform measurements using the Alarm

feature.

Differential Mode

In the Quality Control environment, it is sometimes necessary to know

the difference between a nominal (target) thickness value and an actual

thickness value. This feature is also included in the PX-7. With the

Differential Mode enabled, the PX-7 will display the positive or negative

difference from an entered nominal value. The following steps outline the

procedure for setting up this feature:

Page 24

Dakota Ultrasonics

20

Differential Mode

1) Press ON/OFF key to power up the PX-7.

2) Press the DIFF key. DIFF OFF or DIFF followed by a thickness

value and flashing IN (or MM ) will be displayed.

3) Repeat step 2 to toggle between DIFF OFF or DIFF value and

flashing IN.

4) Assuming DIFF value flashing IN is displayed, use the UP and

DOWN arrow keys to scroll to the desired nominal thickness value.

5) Press the SEND key once again to select the nominal value

entered.

6) The PX-7 is now ready to perform measurements using the

Differential feature.

RS232 Serial Port

The PX-7 is equipped with an RS232 serial port. Using the accessory

cable (part# N-306- 0010), the PX-7 has the ability to connect to a

computer, or ex ternal storage device. The following section outlines the

procedure for connecting the PX- 7 to a computer, and how to collect data

using any standard communications program:

Page 25

PX-7 Ultrasonic Thickness Gauge

21

Connecting To a Computer

1) Connect the accessory cable (part# N-306- 0010) to the 2 pin jack

located on the bottom of the PX-7, and the 9 pin connector to a

serial port on the computer.

2) Start the communications software that will be used to collect the

measurements (i.e. Windows 95/98 - HyperTerminal).

3) Setup the communications software using the following

parameters: Data Bits - 8, Parity - None, Stop Bits - 1, Baud

Rate 1200.

4) Set the communications software COMM port to the port number

that the PX-7 is connected.

5) After taking a measurement, press the SEND key to send the

measurement to the computer. The measurement will be displayed

on the computer screen.

NOTE: Communications software packages generally have the ability

to capture the screen data to a common text file. This text file,

containing the measurements, can then be imported into any

common spreadsheet program (i.e. Excel, Quattro Pro, Lotus123)

for further reporting requirements.

Page 26

Dakota Ultrasonics

22

TRANSDUCER SELECTION

The PX-7 is inherently capable of performing measurements on a wide

range of materials, from various metals to glass and plastics. Different

types of material, however, will require the use of different transducers.

Choosing the correct transducer for a job is critical to being able to easily

perform accurate and reliable measurements. The following paragraphs

highlight the important properties of transducers, which should be

considered when selecting a transducer for a specific job.

Generally speaking, the best transducer for a job is one that sends

sufficient ultrasonic energy into the material being measured such that a

strong, stable echo is received by the PX-7. Several factors affect the

strength of ultrasound as it travels. These are outlined below:

• Initial Signal Strength

The stronger a signal is to begin with, the stronger its return echo

will be. Initial signal strength is largely a factor of the size of the

ultrasound emitter in the transducer. A large emitting area will send

more energy into the material being measured than a small emitting

area. Thus, a so-called "1/4-inch" transducer will emit a stronger signal

than a "1/8-inch" transducer.

• Absorption and Scattering

As ultrasound travels through any material, it is partly absorbed. If

the material through which the sound travels has any grain structure,

the sound waves will experience scattering. Both of these effects

reduce the strength of the waves, and thus, the PX-7's ability to detect

the returning echo.

Page 27

PX-7 Ultrasonic Thickness Gauge

23

Higher frequency ultrasound is absorbed and scattered more than

ultrasound of a lower frequency. While it may seem that using a lower

frequency transducer might be better in every instance, low frequencies

are less directional than high frequencies.

• Geometry of the Transducer

The physical constraints of the measuring environment sometimes

determine a transducer's suitability for a given job. Some transducers

may simply be too large to be used in tightly confined areas. Also, the

surface area available for contacting with the transducer may be limited,

requiring the use of a transducer with a small cone tipped delay line.

Measuring on a curved surface, may require the use of a transducer

with a matching curved wearface.

• Temperature of the Material

When it is necessary to measure on surfaces that are exceedingly

hot, special delay lines may be neccessary. Additionally, care must be

taken when performing a "Calibration to Known Thickness" with a high

temperature application. See Appendix B for more information on

measuring materials with a high temperatures.

Selection of the proper transducer is often a matter of tradeoffs

between various characteristics. It may be necessary to experiment

with a variety of transducers in order to find one that works well for a

given job. Dakota Ultrasonics can provide assistance in choosing a

transducer, and offers a broad selection of transducers for evaluation in

specialized applications.

Page 28

Dakota Ultrasonics

24

blank page

Page 29

25

Physical

Weight: 10 ounces(with batteries).

Size: 2.5W x 4.5 H x 1.24 D inches

(63.5W x 114.3 H x 31.5 D mm).

Operating Temperature: -20 to 120 °F ( -30 to 50 °C)

Case: Extruded aluminum body / nickel plated aluminum end

caps.

PX-7 Ultrasonic Thickness Gauge

APPENDIX A

Product Specifications

Keypad

Sealed membrane, resistant to water and petroleum products.

Power Source

Two “AA” size, 1.5 volt alkaline or 1.2 volt NiCad cells. 150 hours

typical op erating time on alkaline, 100 hours on NiCad.

Display

Liquid-Crystal-Display, 4.5 digits, 0.500 inch high numerals. LED

backlight.

Measuring

Range: 0.0060 to 1.0000 inches (0.15 to 25.40 millimeters) -Steel

Resolution: 0.0001 inch (0.001 millimeter)

Accuracy: ±0.0001 inch (0.001 millimeter), depends on material

and conditions

Sound Velocity Range: 0.0492 to 0.3937 in/µs (1250 to 10000m/s)

Page 30

Dakota Ultrasonics

26

blank page

Page 31

PX-7 Ultrasonic Thickness Gauge

27

APPENDIX B

Application Notes

• Measuring tubing

When measuring a piece of tubing for wall thickness, it may pr ove

beneficial to have multiple delay lines with different radiuses for different

tubing diameters. The delay lines can be easily radiused by placing a

piece of emery cloth around the tubing and moving the transducer back

and forth until a radius has formed on the tip of the delay line.

• Measuring hot surfaces

The velocity of sound through a substance is dependant upon its

temperature. As materials heat up, the velocity of sound through them

decreases. In most applications with surface temperatures less than about

200°F (100 °C), no special procedures must be observed. At temperatures

above this point, the change in sound velocity of the material being

measured starts to have a noticeable effect upon ultrasonic measurement.

At such elevated temperatures, it is recommended that the user perform

a calibration procedure (refer to page 14) on a sample piece of known

thickness, which is at or near the temperature of the material to be

measured. This will allow the PX-7 to correctly calculate the velocity of

sound through the hot material.

When performing measurements on hot surfaces, it may also be

necessary to use a specially constructed high -temperature delay line. It is

recommended that the probe be left in contact with the surface for as short

Page 32

Dakota Ultrasonics

28

a time as needed to acquire a stable measurement. While the transducer

is in contact with a hot surface, it will begin to heat up, and through thermal

expansion and other effects, may begin to adversely affect the accuracy of

measurements.

• Measuring laminated materials

Laminated materials are unique in that their density (and therefore

sound-velocity) may vary considerably from one piece to another. Some

laminated materials may even exhibit noticeable changes in sound-velocity

across a single surface. The only way to reliably measure such materials is

by performing a calibration procedure on a sample piece of known

thickness. Ideally, this sample material should be a part of the same piece

being measured, or at least from the same lamination batch. By calibrating

to each test piece individually, the effects of variation of sound-velocity will

be minimized.

An additional important consideration when measuring laminates, is that

any included air gaps or pockets will cause an early reflection of the

ultrasound beam. This effect will be noticed as a sudden decrease in

thickness in an otherwise regular surface. While this may impede accurate

measurement of total material thickness, it does provide the user with

positive indication of air gaps in the laminate.

Page 33

PX-7 Ultrasonic Thickness Gauge

29

in/us

m/s

Aluminum

0.250

6350

Brass

0.173

4394

Cast Iron

0.180

(apprx)

4572

Copper

0.184

4674

Epoxy resin

0.100

(apprx)

2540

Glass, crown

0.223

5664

Gold

0.128

3251

Iron

0.232

5893

Magnesium

0.228

5791

Nylon

0.102

(apprx)

2591

Platinum

0.156

3962

Polystyrene

0.092

2337

PVC

0.094

2388

Rubber, vulcanized

0.091

2311

Silver

0.142

3607

Steel, stainless

0.223

5664

Teflon

0.056

1422

Titanium

0.240

6096

Zinc

0.166

4216

APPENDIX C

Sound Velocities of some Common Materials

Material sound velocity

Bismuth 0.086 2184

Cadmium 0.109 2769

Constantan 0.206 5232

German silver 0.187 4750

Glass,flint 0.168 4267

Ice 0.157 3988

Lead 0.085 2159

Mercury 0.057 1448

Nickel 0.222 5639

Paraffin 0.087 2210

Plexiglass 0.106 2692

Porcelain 0.230 (apprx) 5842

Quartz glass 0.222 5639

Steel, common 0.233 5918

Stellite 0.275 (apprx) 6985

Tin 0.131 3327

Tungsten 0.210 5334

Water 0.058 1473

Page 34

Dakota Ultrasonics

30

blank page

Page 35

PX-7 Ultrasonic Thickness Gauge

31

WARRANTY INFORMATION

• Warranty Statement •

Dakota Ultrasonics warrants the PX-7 against defects in materials and workmanship

for a period of five years from receipt by the end user. Additionally, Dakota Ultrasonics

warrants transducers and accessories against such defects for a period of 90 days from

receipt by the end user. If Dakota Ultrasonics receives notice of such defects during the

warranty period, Dakota Ultrasonics will either, at its option, repair or replace products

that prove to be defective.

Should Dakota Ultrasonics be unable to repair or replace the product within a

reasonable amount of time, the customer's alternative exclu sive remedy shall be refund

of the purchase price upon return of the product.

• Exclusions •

The above warranty shall not apply to defects resulting from: improper or

inadequate maintenance by the customer; unauthorized modification or misuse; or

operation outside the environmental specifications for the product.

Dakota Ultrasonics makes no other warranty, either express or implied, with respect

to this product. Dakota Ultrasonics specifically disclaims any implied warranties of

merchantability or fitn ess for a particular purpose. Some states or provinces do not

allow limitations on the duration of an implied warranty, so the above limitation or

exclusion may not apply to you. However, any implied warranty of merchantability or

fitness is limited to the five-year duration of this written warranty.

This warranty gives you specific legal rights, and you may also have other rights

which may vary from state to state or province to province.

• Obtaining Service During Warranty Period •

If your hardware should fail during the warranty period, contact Dakota Ultrasonics

and arrange for servicing of the product. Retain proof of purchase in order to obtain

warranty service.

For products that require servicing, Dakota Ultrasonics may use one of the following

methods:

- Repair the product

- Replace the product with a re-manufactured unit

- Replace the product with a product of equal or greater performance

- Refund the purchase price.

• After the Warranty Period •

If your hardware should fail after the warranty period, contact Dakota Ultrasonics for

details of the services available, and to arrange for non-warranty service.

Page 36

MATERIAL SAFETY DATA SHEET

N/A = not applicable or not available (To comply with 29 CFR 1910.1200)

SECTION 1 – PRODUCT IDENTIFICATION

Product Name: SOUNDSAFE

Generic Name: Ultrasonic Couplant

Manufacturer: Sonotech, Inc.

774 Marine Dr., Bellingham, WA 98225

(360) 671-9121

SECTION 2 – HAZARDOUS INGREDIENTS

This material does not contain any ingredients having

known health hazards in concentrations greater than 1%.

This material does not contain any known or suspected

carcinogens.

SECTION 4 – FIRE AND EXPLOSION

HAZARD DATA

Flash Point : none

Upper Exposure Limit: none

Lower Exposure Limit: none

Special Fire Fighting Procedures : N/A

Extinguishing media: N/A

Unusual Fire and Explosion Hazards : none

NFPA Hazardous Materials

Identification System (est)

Health……………………0

Flammability…………….0

Reactivity………………..0

SECTION 3 – PHYSICAL DATA

(nominal)

Boiling Point: >220 °F pH: 7.35 – 7.9

Freezing Point: <20°F Acoustic Imp.: 1.726x10

Vapor Pressure: N/A Vapor Density: N/A

Evaporation Rate: N/A Specific Gravity: >1.02

Solubility in Water: complete

Appearance and Odor: water white, opaque gel;

bland odor

6

SECTION 5 – REACTIVITY DATA

Stability: Stable

Conditions to Avoid: none

Incompatibility (Materials to Avoid): none known

Hazardous Polymerization: will not occur

Hazardous Decomposition or Byproducts: none known

SECTION 6 – HEALTH HAZARD AND FIRST AID DATA

Routes of Entry :

Skin: not likely Ingestion: not normally

Eyes: not normally Inhalation: no

Effects of Overexposure: Acute: May cause temporary

1

eye irritation

Chronic: none expected

SECTION 7 – STORAGE AND HANDLING

INFORMATION

Precautions to be taken in handling and storage: Store

between 20°F and 120 °F. Spills are slippery and should

be cleaned up immediately.

Steps to be taken in case material is released or spilled:

Pick up excess for disposal. Clean with water.

Waste disposal method: Dispose of in accordance with

federal, state, and local regulations.

1

SOUNDSAFE contains only food grade and cosmetic grade ingredients.

SONOTECH, INC.

Toll Free: 1-800-458-4254

774 Marine Dr., Bellingham, WA 98225

Telephone: (360) 671-9121

First Aid Procedures :

Skin: Remove with water if desired.

Eyes: Flush with water for 15 minutes.

Ingestion: For large quantities, induce vomiting and

call a physician.

Inhalation: N/A

SECTION 8 – CONTROL MEASURES

Respiratory Protection: not required

Ventilation: not required

Protective Gloves : on individuals demonstrating

sensitivity to SOUNDSAFE

Eye Protection: as required by working conditions

Other Protective Equipment : not required

Fax: (360) 671-9024

Loading...

Loading...