Dakota PR-82 User Manual

OPERATION MA

NUAL

P/N P

-

102

-

0004

Rev 1.

9

0,

January

200

8

DAKOTA ULTRASONICS MODEL PR-82 SONIC TESTER

Copyright 2008 Dakota Ultrasonics. All rights reserved.

No part of this publication may be reproduced, translated into another

language, stored in a retrieval system, or transmitted in any form or by any

means; electronic, mechanical, photocopying, recording, or otherwise,

without the prior written consent of Dakota Ultrasonics.

Every precaution has been taken in the preparation of this publication.

Dakota Ultrasonics assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of

information contained herein.

Any brand or product names mentioned herein are used for identification

purposes only, and are trademarks or registered trademarks of their

respective holders.

1500 Green Hills Road. #107, Scotts Valley, CA 95066 USA

Tel (831) 431-9722 Fax (831) 431-9723

http://www.dakotaultrasonics.com

CONTENTS

PR-8 2 Ultrasonic Thickness Gauge

INTRODUCTION

OPERATION

THE KEYPAD

THE DISPLAY

THE TRANSDUCER

MAKING MEASUREMENTS

CONDITION AND PREPARATION OF SURFACES

PROBE ZERO

CALIBRATION

SCAN MODE

TRANSDUCER SELECTION

APPENDIX A: PRODUCT SPECIFICATIONS

APPENDIX B: APPLICATION NOTES

1

3

3

6

8

9

11

12

13

17

18

21

23

APPENDIX C: SOUND VELOCITIES OF COMMON MATERIALS

WARRANTY INFORMATION

27

29

DISCLAIMER

Inherent in ultrasonic thickness measurement is the possibility that the

instrument will use the second rather than the first echo from the back

surface of the material being measured. This may result in a thickness

reading that is TWICE what it should be. Responsibility for proper use of

the instrument and recognition of this phenomenon rests solely with the

user of the instrument.

Dakota Ultrasonics

blank page

PR-82 Sonic Tester

1

INTRODUCTION

The Dakota Ultrasonics model PR-82 is a precision Ultrasonic

Micrometer. Based on the same operating principles as SONAR, the PR-82

is capable of measuring the thickness of various materials with accuracy as

high as ± 0.001 inches, or ± 0.01 millimeters. The principle advantage of

ultrasonic measurement over traditional methods is that ultrasonic

measurements can be performed with access to only one side of the

material being measured.

This manual is presented in three sections. The first section covers

operation of the PR-82, and explains the keypad controls and display. The

second section provides guidelines in selecting a transducer for a specific

application. The last section provides application notes and a table of

sound velocity values for various materials.

Dakota Ultrasonics maintains a customer support resource in order to

assist users with questions or difficulties not covered in this manual.

Customer support may be reached at any of the following:

• Dakota Ultrasonics, Green Hills Road #10 7

Scotts Valley, California 95066 USA

• Telephone: (831) 431- 9722

• Facsimile: (831) 431-9723

• www.dakotaultrasonics.com

Dakota Ultrasonics

2

blank page

PR-82 Sonic Tester

3

OPERATION

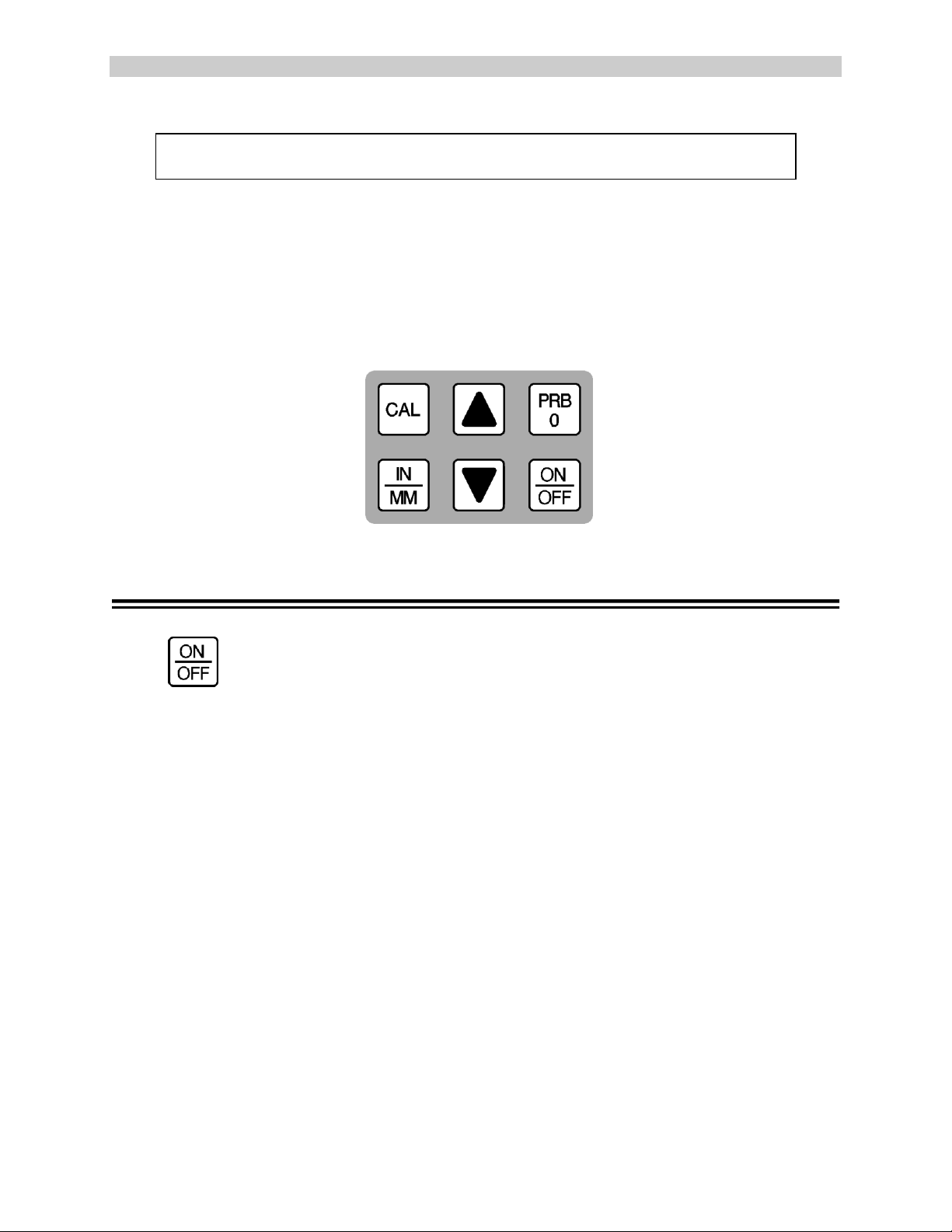

The PR-82 interacts with the operator through the membrane keypad

and the LCD display. The functions of the various keys on the keypad are

detailed below, followed by an explanation of the display and its various

symbols.

The Keypad

This key is used to turn the PR-82 on and off. When the tool is turned

ON, it will first perform a brief display test by illuminating all of the

segments in the display. After one second, the tool will display the internal

software version number. After displaying the version number, the display

will show "0.000" (or "0.00" if using metric units), indicating the tool is ready

for use.

The PR-82 is turned OFF by pressing the ON/OFF key. The tool has a

special memory that retains all of its settings even when the power is off.

The tool also features an auto-powerdown mode designed to conserve

battery life. If the tool is idle for 5 minutes, it will turn itself off.

Dakota Ultrasonics

4

The PRB- 0 key is used to "zero" the PR-82 in much the same way that

a mechanica l micrometer is zeroed. If the tool is not zeroed correctly, all of

the measurements that the tool makes may be in error by some fixed value.

Refer to page 12 for an explanation of this important procedure.

The CAL key is used to enter and exit the PR-82's calibration mode.

This mode is used to adjust the sound-velocity value that the PR-82 will use

when calculating thickness. The tool will either calculate the sound-velocity

from a sample of the material being mea sured, or allow a known velocity

value to be entered directly. Refer to page 13 for an explanation of the two

CAL functions available.

The IN/MM key is used to switch back and forth between English and

metric units. This key may be used at any time, whether the tool is

displaying a thickness (IN or MM) or a velocity value (IN/µs or M/s).

PR-82 Sonic Tester

5

The UP arrow key has two functions. When the PR-82 is in calibration

mode, this key is used to increase numeric values on the display. An autorepeat function is built in, so that when the key is held down, numeric

values will increment at an increasing rate. When the PR-82 is not in

calibration mode, the UP arrow key switches the SCAN measurement

mode on and off. Refer to page 17 for an explanation of the SCAN

measurement mode.

The DOWN arrow key has two functions. When the PR-82 is in the CAL

mode, this key is used to decrease numeric values on the display. An

auto-repeat function is bu ilt in, so that when the key is held down, numeric

values will decrement at an increasing rate. When the PR- 82 is not in

calibration mode, the DOWN arrow key switches the display backlight

between three available settings. OFF will be displayed when the backlight

is switched off. AUTO will be displayed when the backlight is set to

automatic mode, and ON will be displayed when the backlight is set to stay

on. In the AUTO setting, the backlight will illuminate when the PR-82 is

actually making a measurement.

Dakota Ultrasonics

6

The Display

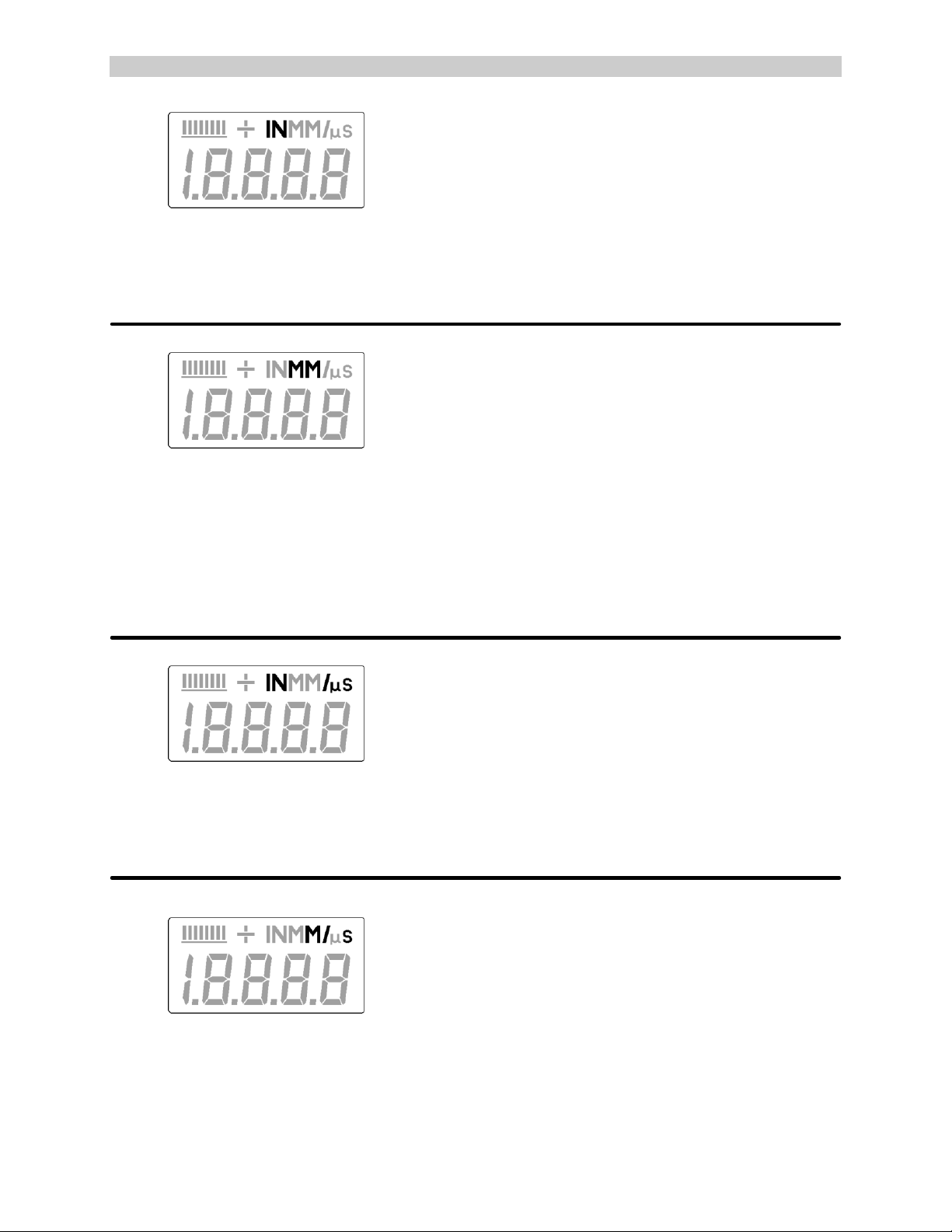

The numeric portion of the display consists of 4 complete digits

preceded by a leading "1", and is used to display numeric values, as well

as occasional simple words, to indicate the status of various settings.

When the PR-82 is displaying thickness measurements, the display will hold

the last value measured, until a new measurement is made. Additionally,

when the battery voltage is low, the entire display will begin to flash.

When this occurs, the batteries should be replaced.

These eight vertical bars form the Stability Indicator. When the PR-82 is

idle, only the left -most bar and the underline will be on. When the tool is

making a measurement, six or seven of the bars should be on. If fewer

than five bars are on, the PR-82 is having difficulty achieving a stable

measurement, and the thickness value displayed will most likely be

erroneous.

PR-82 Sonic Tester

7

When the IN symbol is on, the PR-82 is displaying a thickness value in

inches. The maximum thickness that can be displayed is 19.999 inches.

When the MM symbol is on, the PR- 82 is displaying a thickness value in

millimeters. If the displayed thickness exceeds 199.99 millimeters, the

decimal point will shift automatically to the right, allowing values up to

1999.9 millimeters to be displayed.

When the IN symbol is on, in conjunction with the /µs symbol, the PR-82

is displaying a sound-velocity value in inches- per-microsecond.

When the M symbol is on, in conjunction with the /s symbol, the PR- 82

is displaying a sound-velocity value in meters-per-second.

Loading...

Loading...