Page 1

DAKOTA PARLOR GUITAR KIT

MUSICMAKER’S KITS, INC

PO Box 2117

Stillwater, MN 55082

651-439-9120

harpkit.com

Page 2

WOOD PARTS:

A - Neck

B - Fretboard

C - Heel Block

D - Tail Block

E - 2 Heel Ribs

F - 2 Side Ribs

G - 2 Tail Ribs

H - 4 Corner Blocks

I - Back Panel

J - 3 Cross-Braces for Back

K - 2 Flat Braces for Back

L - Front

M - 10 Braces for Front (Soundboard)

N - 6 Inner Kerfing Strips

O - Bridge with Saddle

P - Bridge Clamp, w/4 machine screws,

2 washers, 2 wing nuts

Q - Bridge Plate

R - 4 Clamping Wedges

S - Spacer Block

T - 6 Binding Strips, walnut

U - Heel Cap

V - Truss Rod Cover

(Soundboard)

DAKOTA GUITAR KIT

I

L

O

E

C

HH

F

E

F

A

Z

R

P

B

N

X

V

U

T

Y

S

HARDWARE:

K

J

M

W - 48 Inches Fretwire

X - 1 White Side Marker Rod

5/64”” X 2”

H

H

Y - 6 Black Geared Tuners

w/6 sleeves, 6 washers & 6 tiny screws

Z - Double Truss Rod, with allen wrench

1 - Heavy Fretwire, 2” long, for #0 fret

1 - Set of 6 Guitar Strings, light

1 - Black Wood Nut

Fig 1

G

D

G

Q

W

1 - Hex Bolt, 1/4” X 2”, with washer

2 - Tiny Nails

1 - Drill Bit, 1/16” for tiny screws

1 - Drill Bit, 5/64” for Side Markers

1 - Drill Bit, 3/16” for bridge

If you have any questions about the assembly of your

kit - please visit our online Builder’s Forum

www.harpkit.com /forum

Assembly Instructions

A NOTE ABOUT GLUE

We recommend assembling this kit with standard woodworker’s glue (such as Elmer’s Carpenters Glue or Titebond Wood

Glue). Don’t use Hotmelt glue, Superglue, 5-minute Epoxy, or the plain white School Glue for assembling the major wood

parts -- they are not strong enough for a musical instrument. There is no need to look for any special violin-maker’s adhesive.

You may, however, see epoxy or superglue recommended occasionally for installing non-wood parts.

Every time you use wood glue on this project, it is wise to have a damp rag handy for cleaning up afterwards. It is always best

to scrub away any excess glue that squeezes out of the joints before it dries, especially on the outside of the instrument. Keep

your hands and workbench as clean as possible too. Glue smudges will show up vividly on the finished instrument.

ASSEMBLY INSTRUCTIONS

_____1. CAUTION: PLEASE DO NOT OPEN THE SEALED PLASTIC BAG CONTAINING THE FRONT

AND BACK PANELS UNTIL YOU REACH STEP #14. These two parts need to be kept very dry until you glue

the braces on them. Check over your kit parts to make sure you find everything listed (see fig. 1 above). Contact us

right away if you are missing anything so we can rectify the problem without causing too much delay for you. We

also recommend checking off each step in the directions as you finish it. You might be skipping forward to another

part of the assembly while waiting for something to dry, and it helps to keep track of where you left off.

2.

Page 3

GLUING THE BODY FRAME

It is smart to skim through the entire directions before beginning, just to get an overview of the project. You may need to gather

more tools or purchase a few optional decorations or accessories to enhance the finished instrument. Now is a good time to

make those plans so you can avoid delays later. Here are a few of the small items you’ll want to have on hand:

sharp chisel wire cutter 8 spring clamps 2 long-reach clamps for braces

masking tape (blue) clothes pins 8 small c-clamps 40 ft bungee cord (3/16” dia)

carpet tape razor knife triangle file router with flush-trim & inlay bits

straight-edge 6” rat tail file flat mill file wood filler (mahogany color)

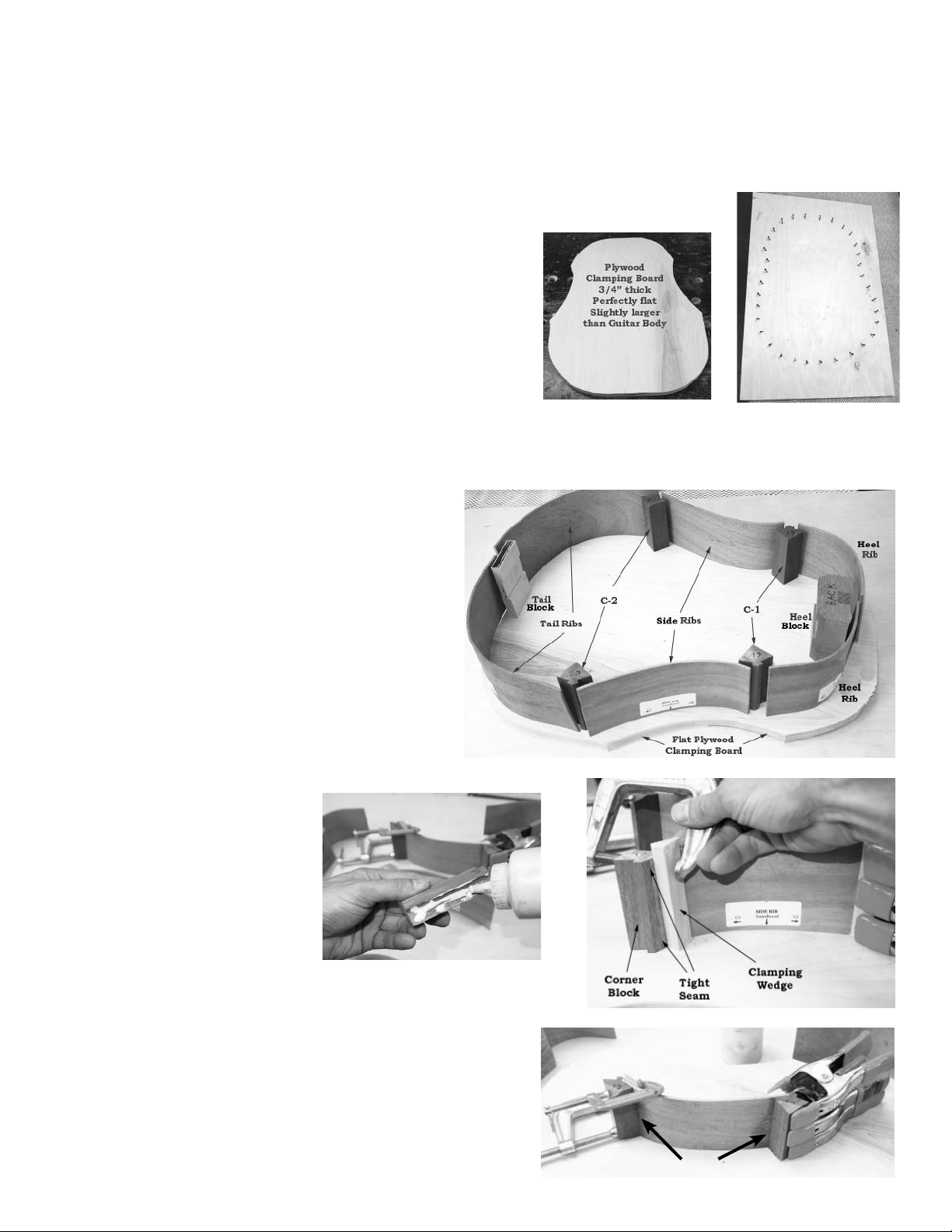

_____2. You will find it very helpful to make yourself a perfectly flat

work surface out of 3/4” thick plywood or particle board for use as a

flat clamping pad under the body of the instrument. If you cut it about

1” larger than the shape of the soundboard, you will be able to easily

fit clamps all the way around the perimeter of the instrument (fig 2a).

Plywood

Clamping Board

3/4” thick

perfectly f lat

about 22” X 28”

Another idea that works well is to use a rectangular piece about 22” X

28” (fig 2b) so you can clamp with bungee cords, as shown in steps 21

and 31. We use both types, as you will see in various photos. Just make

sure the clamping pads are good and flat.

Fig 2a

Fig 2b

CAUTION: IT IS POSSIBLE TO ASSEMBLE THE FRAME PARTS U PSIDE DOWN OR BACKWARDS!

_____3. Carefully arrange the side pieces, corner blocks,

heel block and tail block on your plywood clamping board

to see how they fit together (Fig 3).

CAUTION: Orient all parts so the front edges face downward on your flat clamping board. Notice that we have

marked each side piece, and heel & tail blocks, indicating

the proper orientation.

All front edges are marked “SB” for soundboard, and the

back edges are marked “B”.

The corner blocks do not have a front or back, but they are

numbered C-1 or C-2 to fit the corners with those numbers.

Please take the time to study this carefully so your parts will

fit properly.

ORIENT ALL PARTS WITH FRONT ED GES FACING DOWN

Fig 3

_____4. Begin by gluing and clamping the four corner blocks to the two

side ribs, taking care to orient them

at the correct ends, as printed on the

wood (each side rib gets a C1 at one

end and a C2 at the other end).

CAUTION: The larger part of the

corner blocks will face the inside of

the body, as shown in fig 3. Don’t

Fig 4a

glue them to the outside of the sides!

Clamping wedges are provided to help compensate for the angles of the

parts, as shown in fig 4b. HINT: If you cover the wedges with Scotch

tape, they won’t get stuck to the other parts when clamped.

Use either spring clamps or small c-clamps for this step (fig 4c), making sure the parts are fully seated together and flat on the edges. Use a

wet rag to clean off excess glue that squeezes out. This helps you see

the joints clearly, as well as prevent messy glue spots on the instrument.

3.

Fig 4b

Fig 4c

Clean off excess glue

Page 4

QUESTION

Have you checked to make sure you are still gluing the parts in the correct positions? If you nd a corner block

glued to the wrong end of a rib, you’ll need to correct it now, before proceeding further. You can so en the dried

glue by getting the seam wet to allow the parts to be separated without breaking anything. Be patient with this

process. It may take 10-20 minutes for water to penetrate far enough into the seam to so en the glue.

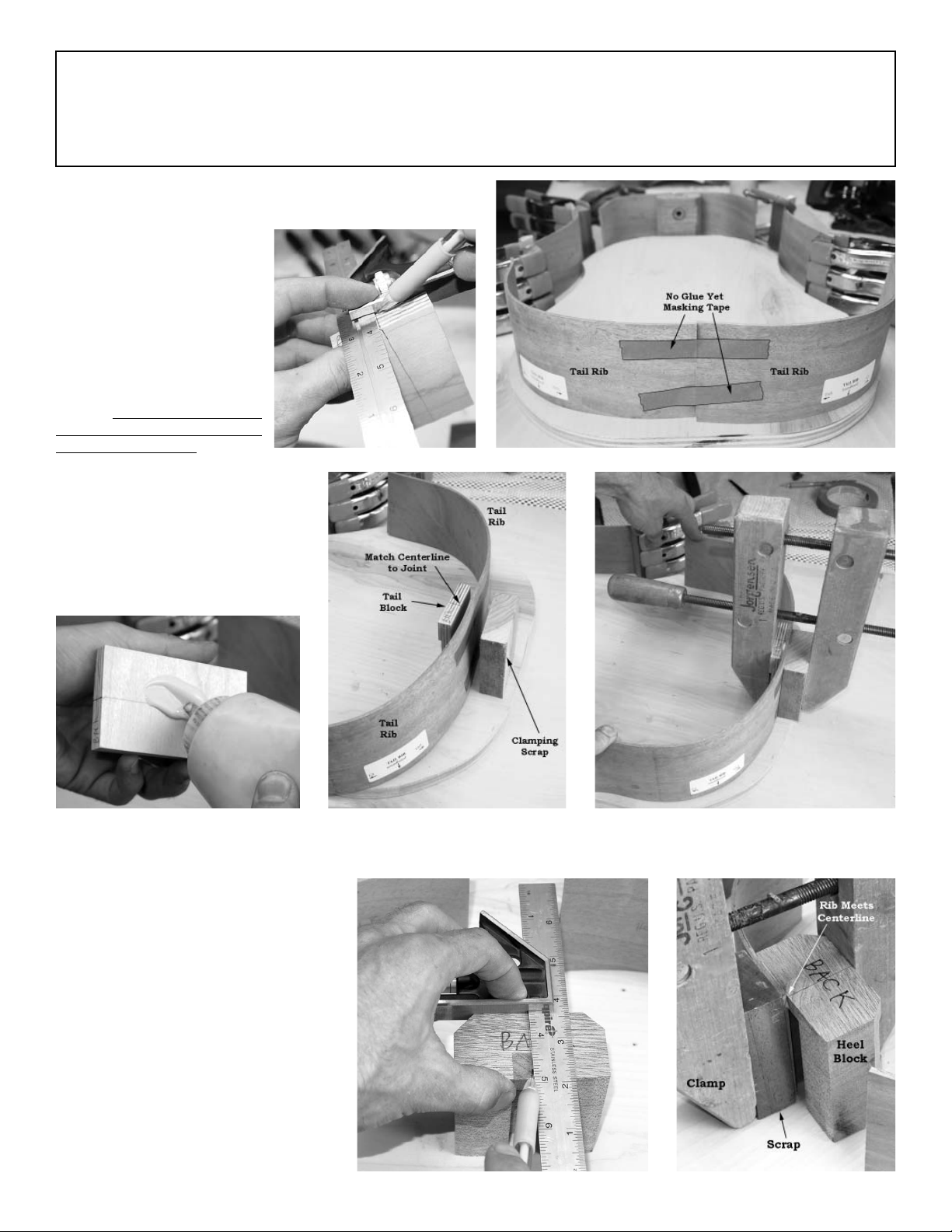

_____5. While the corner blocks are drying, you can work on

the tail end of the body. Use tape to hold the tail ribs together

as shown in fig 5a.

Find the center of the tail block

and mark it clearly (fig 5b).

Smear glue on the flat face of

the tail block (fig 5c) and place

it inside the seam, as shown in

fig 5d. Find a scrap of wood

to use as a clamping pad for

the outside of the joint, and add

clamps, making sure the block

is oriented correctly and nicely

centered on the seam (fig 5e).

IMPORTANT: Make sure the free

ends of the tail ribs can be pushed down

to the work surface (fig 5e). If not, then

you may have to release the clamps and

slide the parts into better alignment.

Fig 5b

Tail

Block

Fig 5a

Inside surface

of tail block

Fig 5c

_____6. Now you can move to the heel

end of the instrument. Mark the center of

the heel block, on the end marked “Back”

(fig 6a).

Glue this heel block to one heel rib for

now, aligning it to the centerline, as shown

in fig 6b.

Clean up excess glue with a wet rag, as

usual.

Fig 5d Fig 5e

IMPORTANT: Leave the other heel rib

for later. That will be the last step in closing the frame.

Fig 6a Fig 6b

4.

Page 5

_____7. When the corner

blocks are dry, you can remove the clamps and glue

the C2 blocks to the tail ribs,

as shown in fig 7a.

Make sure you can press

the C1 corner blocks down

Check for straightness

by pressing sides down

against clamping board.

Check for straightness

by pressing sides down

against clamping board.

against the work surface

when the side ribs are

clamped to the tail ribs. This

C2 Corner Blocks

ensures a flat frame for gluing the front (soundboard)

in place later.

Fig 7a

Leave the clamps on these C2 joints while you glue the remaining heel rib to

Tail end

Fig 7b

C1 Corner

Block

the open C1 corner, as shown in fig 7b. Leave clamps in place for several

hours to make sure the glue has cured to full strength.

PAUSE AND DOUBLE-CHECK

Before going further, double-check to make sure your parts are still in the correct positions. Do you see “Back”

written on the same edge of all the parts around the frame? If you find something oriented upside-down or backwards, you’ll need to correct it now, before proceeding further. You can soften the dried glue by getting the seam

wet to allow the parts to be separated without breaking anything. If the glue is fully cured, it may take 10-20 minutes for water to penetrate far enough into the seam to soften the adhesive.

_____8. When the four

corner joints have dried

fully, use tape to pull the last

heel rib into place at the heel

block as shown in fig 8a.

Remove the tape so you can

apply glue, and then tape the

parts together again as you

clamp this last joint together

permanently (fig 8b).

Fig 8a

_____9. Once the frame is closed and the glue is dry, you can install

the long spacer block between the heel and tail blocks as shown in fig 9.

This piece will be removed later, but you need it now to hold the frame to

the correct size. Note that the ends of the spacer will fit into the pre-cut

grooves of the heel and tail blocks. Use a clamp at each end to make sure

the heel and tail blocks are held firmly in alignment.

Fig 8b

Spacer block

5.

Fig 9

Page 6

_____10. Flip the instrument over (soundboard edge up) so you can fit kerfing inside the frame. Cut a length of kerfing to fit

between the corners and blocks inside each rib (fig 10a & 10b). We like to cut these strips a little oversize and then sand them

to fit nicely into the corners, as shown in fig 10c and 10d. CAUTION: Be sure to orient the kerfing with the flat side up. level

with the top edge of the ribs.

Fig 10a

Fig 10c

CHECK-POINT: You should be installing the kerfing on

the soundboard edge of the frame. You should see “S.B.”

written on the ribs at this edge of the frame all around.

We use spring-type clothes pins to clamp the kerfing in place

(fig 10e), but you may find some other small clamps to pinch

the parts together while you glue these kerfing strips in place.

If necessary, you can increase the clamping pressure by wrapping rubber bands around the clamps as we have.

Work your way around the soundboard edge of the frame

with the kerfing, but don’t do the back edge yet -- that will

be easier to do later.

Fig 10b

Fig 10d

Fig 10e

_____11. OPTIONAL: You can reduce the weight of your guitar a little by trimming off the large inside corners of the corner

blocks, as shown in fig 11a. This step is optional, but it is recommended.

The illustration shows a chisel, but we use a power drum sander to do this job more quickly. You’ll want the corners to be

trimmed so they blend in with the thickness of the kerfing, as shown in fig 11b.

NOTE: If you decide to leave the corner blocks full size, you should at least bevel the tops of the inside corners by sand-

ing them at an angle so they

won’t touch the soundboard

(fig 11c). This helps prevent

cracks in the soundboard

later, and allows for a little

more vibration in the top.

bevel

Fig 11a

Fig 11b Fig 11c

6.

Page 7

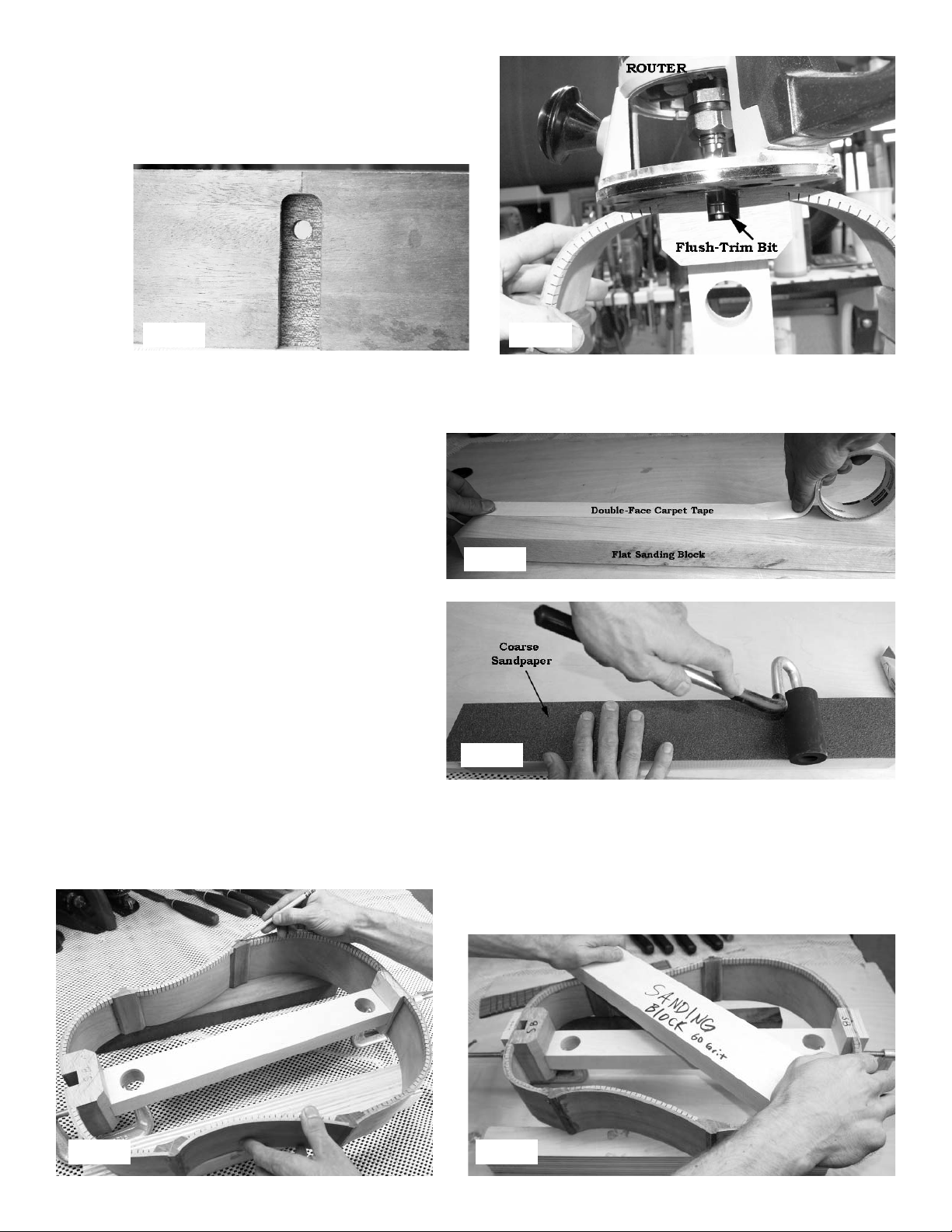

_____12. This is a good time to open up the slot for the tenon

in the heel block so it looks like fig 12a below. You could do

this by hand with a sharp chisel and/or razor knife, but we use a

router with a flush trim bit (fig 12b). The goal is to trim away

all rib material that covers the pre-cut slot in the heel block.

Fig 12a Fig 12b

_____13. Make yourself a long sanding block now, using a flat board about 2-3” wide and at least 16” long.

Apply double-stick carpet tape to the flat face of the

sanding block, covering the face the full 16” length (fig

13a).

Cut coarse sandpaper (60 grit) to match the width of

the board and press the clean side down against the tape

(fig 13b). You can add to the length of the sandpaper by

pressing a second piece in place at the end of the first.

Pencil hash-marks on the kerfing around body, as shown

in fig 13c.

Fig 13a

Fig 13b

Then use your flat sander to level the entire front edge of the

frame. Keep the sanding block flat by always having both ends

resting across the instrument, as shown in fig 13d.

The pencil marks should all be cleaned off by this sanding work.

Keep sanding until they are all removed.

Fig 13c Fig 13d

7.

Page 8

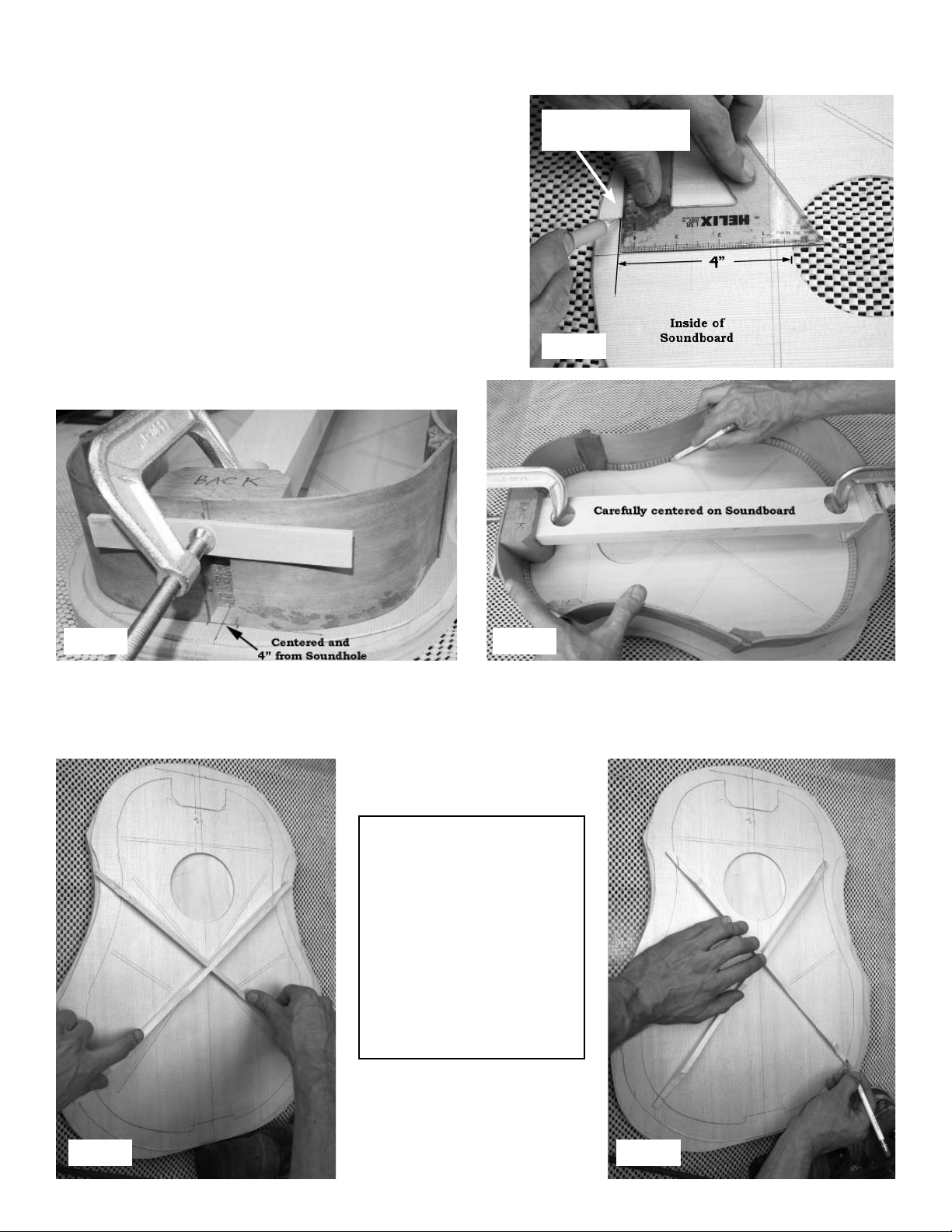

PREPARING THE SOUNDBOARD

_____14. Now you can open the sealed bag and begin working on

the soundboard. First thing is to outline the inside of the frame on the

inside face of the soundboard so you know how to trim the braces.

We have marked the location of most of the braces in pencil, but

there are a few things you need to draw. Begin with making a line 4”

from the sound hole and perpendicular to the center line, as shown

in fig 14a.

Center the frame of the guitar on the centerline of the soundboard,

lining up the heel end with your pencil mark (fig 14b).

Then draw a pencil line around the inside of the frame to show where

the kerfing touches the soundboard (fig 14c).

draw line to mark

heel end of frame

Fig 14a

Fig 14b Fig 14c

_____15. Find the two X braces and connect them together in the middle. Note that there is a wrong orientation for these

braces (fig 15a). When properly oriented, the X will match the outline on the soundboard, as shown in fig 15b. Center the X

on the soundboard and mark where the ends of the braces cross your outline of the frame.

WRONG RIGHT

POINT OF INTEREST

Some purists will leave these

braces long enough to fit into

“pockets” that they cut into the

kerfing. This is difficult to do

well, but helps prevent a brace

from breaking free at one end

due to future abuse. We provide bracing long enough to allow you to choose this method

if you wish, but it will increase

your working time a bit.

Fig 15a Fig 15b

8.

Page 9

Mark and trim these

braces to the pencil

line, as shown in

fig 15c and 15d.

(or cut them a little

longer if you plan to

cut pockets for them

in the kerfing)

Fig 15c Fig 15d

_____16. Before gluing the X braces in place, test your clamping system without glue to make sure you have sufficient pressure

everywhere. You want even pressure across the full length of the

braces. Make sure that the ends will be pressed fully against the

soundboard. You don’t want these braces to come loose!

When all is ready, glue and clamp them in place to the soundboard, pressing them against your flat clamping board. NOTE:

be sure to put glue in the notch where the two braces intersect.

Use the spacer block (or other long scrap) across the soundboard

to press the intersection firmly (fig 16).

Wipe off excess glue and leave the clamps in place for 3-4 hours

until dry.

_____17. When the braces are dry, use a chisel to clip a 1/4” end of the

thin flat back bracing material to use for a patch across the intersection of

the X braces, as shown below (fig 17a).

Glue and clamp this patch across the intersection forming a “bridge” to tie

the bracing together firmly (fig 17b).

Fig 16

Fig 17a Fig 17b

9.

Page 10

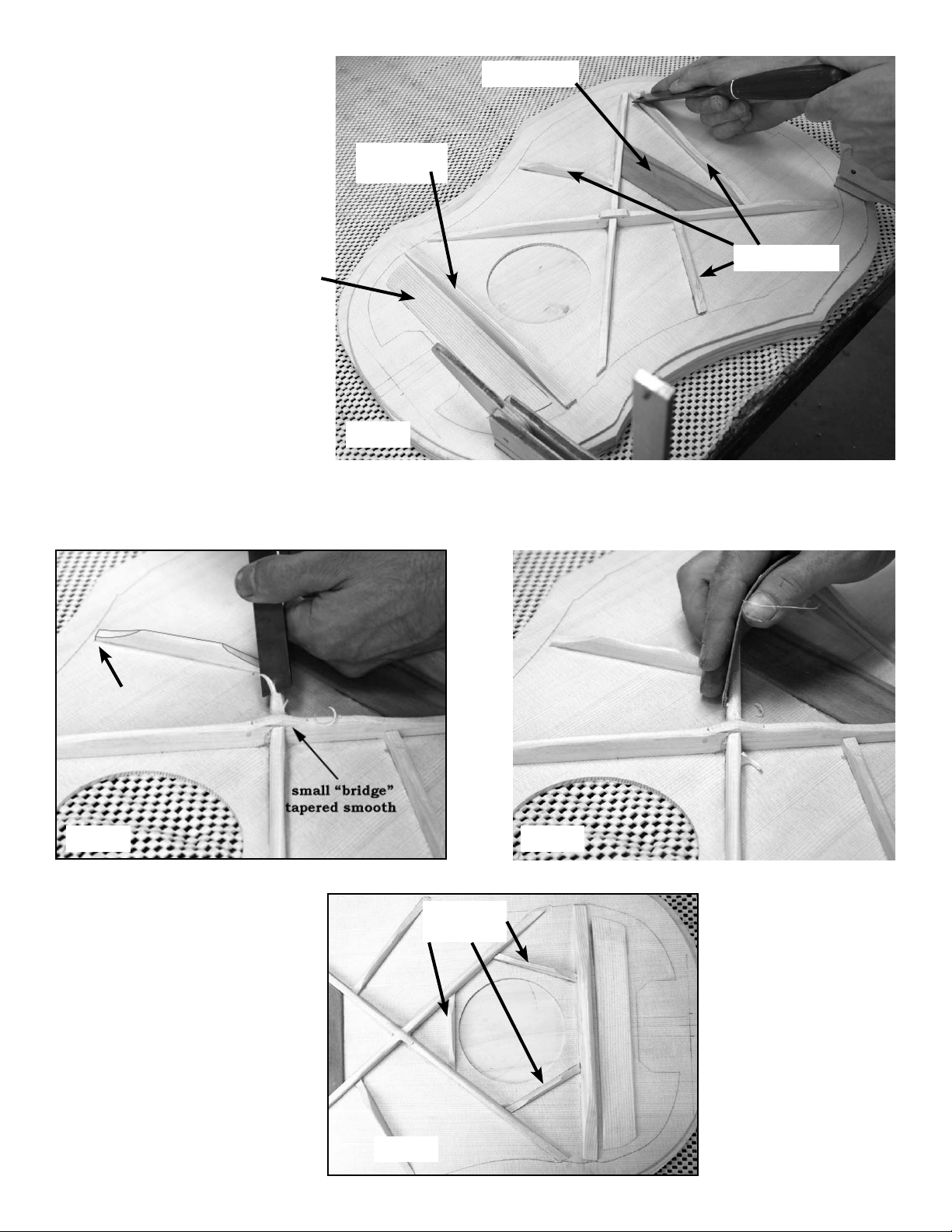

_____18. Mark and trim all but the

three shortest braces, and glue them

in place where they are marked on the

soundboard (fig 18).

bridge plate

NOTE: Hold off on the three short

soundhole braces for now. It is easier

to shape and sand the larger braces before installing the short ones.

additional

top brace

_____19. Use a sharp chisel to round over tops of braces

and to taper ends to about 1/8” high around the perimeter

of the soundboard (fig 19a).

transverse

brace

Fig 18

finger braces

Switch to medium sandpaper (150 grit) to smooth the

tops of all braces (fig 19b).

1/8” high

at end

Fig 19a Fig 19b

_____20. Fit and glue the three shortest braces around soundhole, as shown

in fig 20.

Fig 20

soundhole

braces

10.

Page 11

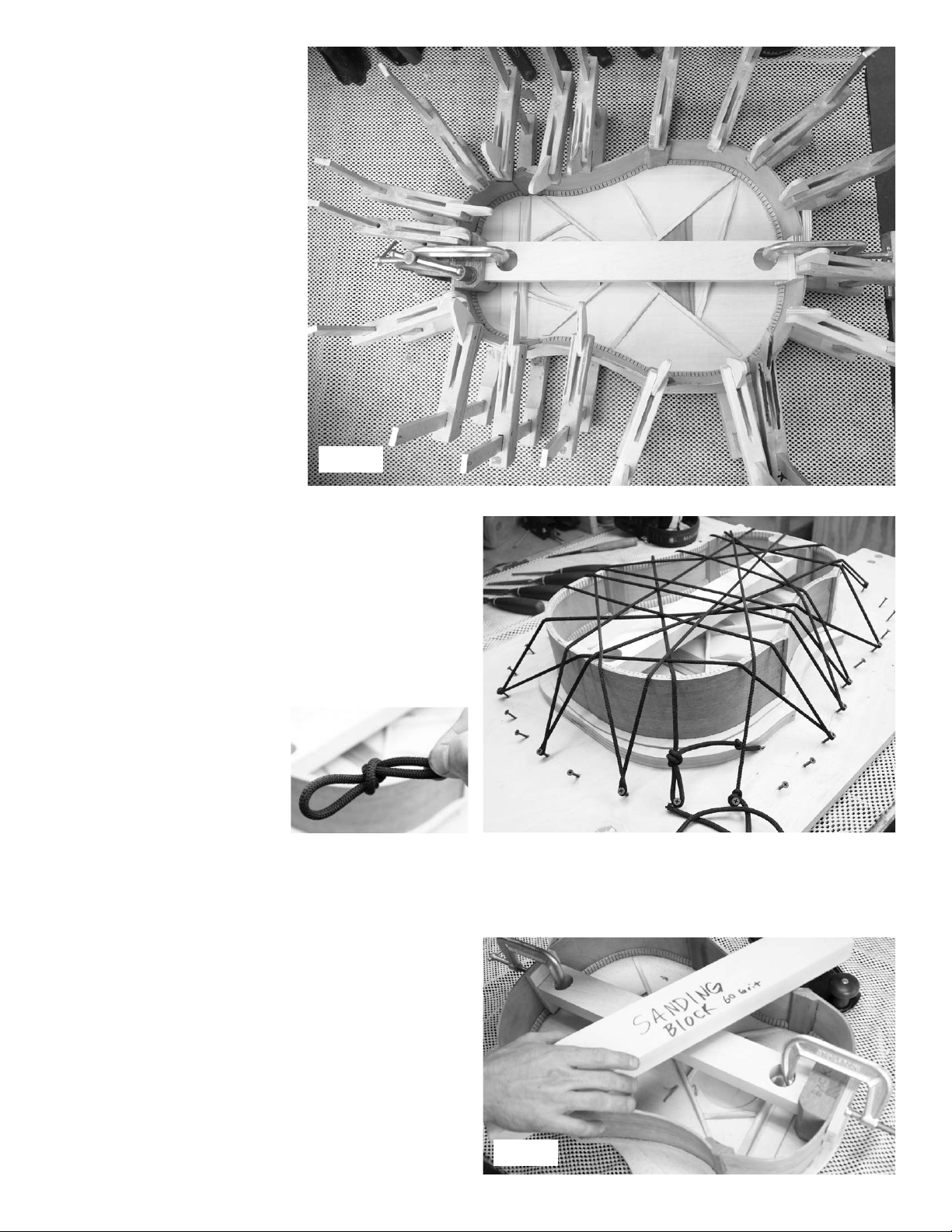

GLUING THE SOUNDBOARD

_____21. Be sure to keep the spacer block firmly clamped to the frame

for this operation! This will help

hold the shape of the body as you

apply clamps.

Test-fit the frame on top of the

soundboard without glue first, to see

how the braces fit inside the kerfing.

Trim the braces as necessary.

NOTE: If you plan to cut pockets

into the kerfing for the ends of the

main X braces, this will take some

time for trial and error fitting.

Plan out your clamping method and

assemble enough clamps (or Bungee cording) to do the job before

you begin.

spacer block

We show two ways to clamp the

body down against the soundboard:

20 clamps, as shown in fig 21a, or 20 feet of light bungee cording (available from Musicmakers), as shown in fig 21b.

If using the Bungee cord method, put screws around your flat

work surface at an angle, about 2-3” apart, for wrapping the

cord. If you didn’t make a 22” X 28” clamping board, you can

put the screws in the edge of your smaller plywood instead of

4” away from the guitar as shown.

When ready, spread glue all around the edge of the guitar frame

(including the kerfing), and put the frame back on the soundboard, making sure there are no obstructions preventing a nice

flat fit.

If using Bungee cord, tie a loop at

one end, hook it on a nail and work

your away cross the instrument in

spider web fashion to press the

entire frame down firmly against

the soundboard (fig 21b).

Fig 21a

Fig 21b

PREPARING THE BACK

_____22. When the soundboard is dry, remove the clamps and

turn the instrument over so you can start working on kerfing

for the back edge. Begin by leveling the edges of the ribs and

corner blocks, using your long flat sanding block (fig 22).

The goal is to eliminate glue blobs and other irregularities that

will interfere with a good fit of the back panel. You’ll be sanding more after the kerfing is installed, but you’ll use a curved

sanding block next time.

HINT: Leave the spacer block in to stablize the frame as you

sand, until you get to the heel and tail blocks. You’ll need to

remove the clamps in order to sand those areas.

Fig 22

11.

Page 12

Fig 23

_____24. Turn the body over onto the inside of the back

panel and center it carefully on the centerline. Draw around

the outside of the frame with a pencil, as shown in fig 24.

_____23. Now you need to install kerfing all around the back

edge of frame, just as you did on the front edge earlier (fig 23).

CAUTION: Don’t sand this kerfing with the flat sanding

block. You will make a curved block for this because the

back is arched (see step #30).

Fig 24

_____25. Set a compass to match thickness of the back

edge with kerfing, as

shown in fig 25a.

Then use that setting

to draw the inside

outline on the back

panel, as in fig 25b.

Fig 25a Fig 25b

_____26. Measure where the heel block and tail

block will fit on the back panel.

The heel block extends 1-3/4” (44.5mm) in from

the outer edge of the frame, as shown in fig 26a.

Fig 26a

The tail block extends just 3/4” (19mm) in from

the outer edge at the tail end of the frame, as in

fig 26b.

These two lines will help you place the the flat

back bracing that goes down the centerline to reinforce the glue seam in the back panel.

Fig 26b

12.

Page 13

_____27. Notice that only one brace is outlined on the back panel, but there are little circles drawn to show the ends of the other

two braces. Connect those circles with a straight edge to mark the location of the other two braces, as shown in fig 27a.

Find the three back braces and mark where to trim them so they don’t

interfere with the back kerfing (step 27b).

Trim braces

to length (or

fit the ends

into the back

kerfing), as

before.

_____28. Notice how the underside of

the back braces are curved. This curve

matches the 15’ (4.57m) radius curve

on one edge of the spacer block (fig

28a).

This means you can use the spacer

block to support the clamping pressure

when gluing each brace in place, thus

forming an arched back panel.

Make sure you have at least one clamp

that will reach to the middle of the

brace, as shown in fig 28b.

When ready, glue each brace in place

separately, being careful to center it on

the centerline over the outline you drew

for that brace in the previous step, and

supporting it with the curved side of

the spacer block underneath.

Fig 27a

Fig 28a

Fig 27b

_____29. When all three back braces

are dry, find the flat back braces and

mark and cut them to fit between the

other braces, to cover the center seam,

as shown in fig 29a.

It is best to sand these parts before

gluing them in place. They look best

when the top surface is sanded smooth

and the top edges are rounded over

gently (fig 29b).

Fig 28b

Fig 29a Fig 29b

13.

Page 14

Balance the back panel on a long flat board beneath the centerline to support this pressure. Use long clamps or weights to press

these braces in place with glue (fig 29c). Add scrap wood under the clamps to distribute the pressure evenly over this flexible

flat bracing. Notice the end braces are cut just short of the pencil line marking the heel and tail blocks (fig 29d).

Fig 29c Fig 29d

_____30. Put double-stick carpet tape on the curved edge of

the large spacer block that was holding the frame (fig 30a).

Fig 30a

Use this curved sanding block to shape and smooth the back

edge of the instrument frame, as shown in fig 30c.

PLEASE NOTE: Keep the sanding block oriented across

the frame as shown, perpendicular to the centerline of the

body. This is the direction of the curve in the back panel,

and it will give you nice firm glue joints around the perimeter of the frame when clamping the back in place.

Then cut strips of coarse (60 grit) sandpaper to fit along the

edge and press the paper against the adhesive tape (fig 30b).

You may need to butt two strips end-to-end.

Fig 30b

Fig 30d

Fig 30c

Turn the frame over on top of the back panel and check carefully

to see that the braces do not interfere with the kerfing (fig 30d).

Take your time with this. Trim any braces that are too long to

fit inside the frame. If you end up applying clamping pressure

to an area where the braces are in the way of the kerfing, you

might break something!

14.

Page 15

_____31. Turn the frame back-side-up and arrange it on

your work surface. Apply glue to the back edge, all the way

around the circumference, including the kerfing, heel, tail,

and corner blocks.

Carefully position the back panel on top, nicely centered at

each end, and apply clamping pressure. If using individual

clamps, we recommend placing clamps at the heel and tail

ends first to hold the back on the centerline, then work your

way around the circumference with more clamps. Check the

seams by looking under the overhang of the back to make

sure it is fully pressed down all the way around.

If using the Bungee cord clamping system, put screws all

around the frame, about 4” away from the body, and spaced

about 2-3 inches apart, as shown in fig 31a.

Place the back panel carefully centered on the frame and

begin pulling Bungee cording across, making sure the back

does not slide out of position as you work. We show two

20-ft lengths of Bungee cords, 40 feet (10 m) total, in the

photo at right (fig 31b).

Fig 31a

Be sure to check around the entire glue seam, looking under

the overhang and pressing down to see if there is any section that is not held firmly. Watch for glue squeezing out of

the joint -- that’s a good sign of sufficient pressure.

_____32. When dry, trim off the excess overhang

of the soundboard and back flush with the outside

of the body.

We like using a flush-cutting router bit (fig 32a)

for this step. Move the router clockwise around

the instrument (this is called “climb cutting”) to

minimize the chance of chipping the thin spruce

top and mahogany back panels (fig 32b).

You can achieve the same results more slowly using a coping saw to cut close to the sides, and then

a sanding block to sand it flush.

The corner blocks protrude a little beyond the sides, so you’ll want to sand those flush too.

A spindle sander or attachment to a drill press works well for this (fig 32c), but you can also

make a curved sanding block using a tin can or other round object to wrap your sandpaper

around (fig. 32d). Always watch closely to make

sure you don’t distort the shape of the corners.

Fig 32a

flush-cutting

Fig 31b

router bit

Fig 32b

This is an important step for achieving a nice-looking guitar. The corner blocks and sides should meet

seamlessly and smoothly.

If you find gaps in the joints, fill them with mahogany colored wood filler, available from most hardware

Fig 32c Fig 32d

stores. Or make your own paste of mahogany sanding dust and Superglue.

14.

Page 16

_____33. OPTIONAL DECORATING: If you have a router, you can install

binding around edges of the guitar. This is not a necessary step, but it adds

a lot to the appearance of the finished instrument. Use our Inlay Router Bit

with the smaller bearing for this operation. Set the depth of cut to match the

width of the binding strip, as shown in fig 33a.

Make a test cut in a

scrap of wood, and

check the fit of the

Fig 33b

binding strip (fig 33b).

Be careful not to

“fall” into the

slot for the tenon

Use the router to cut a ledge all the way around the top and bottom of

the instrument for inlay strips, working clockwise around the perimeter, as before (fig 33c). The roller bearing will prevent the router bit

from cutting too deeply. You may need to go around the instrument

twice, just to make sure the ledges are cut to full depth.

Wet the wood binding in a tub of warm water for just

1-2 minutes before bending it around the guitar.

cutter height matches

width of inlay strip

Fig 33a

Fig 33c

Fig 33e

SANDING

BLOCK

Fig 33g

Bend one long strip

around the tail end

of the instrument,

holding it in place

with a few pieces

of tape.

Fig 33d

Mark the length and

trim it close with a

chisel or razor knife

(figs 33e & 33f).

CHISEL

Fig 33f

BINDING STRIP

Then test-fit again using a sanding block to make small adjustments to the ends until they

are just the way you want them (fig 33g). We like to make mitered joints in the binding

at each corner block (fig 33h), but that can take some extra time. An easier option is to

make “lap” joints instead (fig 33i).

For lap joints you would install the first piece a little longer than necessary and trim it

off after the glue dries, sanding the end to match the next ledge. Then your next piece

MITERED

JOINT

LAP

JOINT

can also be longer than

needed, so you just

trim it off and sand it

flush with the outside

edge of the first binding piece.

Fig 33h

Fig 33i

16.

Page 17

Once you have planned your joint, you can apply glue to the

groove and use lots of masking tape to hold the binding in place

until dry (fig 33j). Be sure to pull the binding fully into the slot as

you tape it.

HINT: Think of the tape as being somewhat elastic (even though

it isn’t). That helps you use a pulling action as you install it.

Cut binding to fit the next section of the guitar (fig 33k). Glue and

tape it as before.

Fig 33k

Fig 33j

When you get to the heel end of the top (soundboard), you can

leave the trim a little short because it will be covered (hidden) by

the neck and fingerboard (fig 33-l).

Fig 33-l

The back binding is easier to install in a different sequence. It

is best to install one long piece of binding for the heel end just

as you do for the tail end (fig 33m). Notice that the binding at

heel end of the back will not be covered when you install the

neck, so you don’t want any gaps in the back binding.

Fig 33m

Once the binding is installed and dry, remove all the tape, being careful to

avoid lifting the grain of the spruce soundboard. HINT: Pull slowly, and

if you see any damage starting, pull in the other direction from the

opposite end of the tape.

Then you can fit the two side bindings in place last around

the back side.

When the tape is all off, do some sanding to eliminate all glue residue

around the instrument. The tape has a nasty tendency to smear excess

glue over wide areas, but it is relatively easy to sand off with medium

(100-150 grit) sandpaper.

We even use a hand orbital sander for some of this work (fig 33n), though

you need to be careful not to sand too deeply when you use power equipment.

17.

Fig 33n

Page 18

PREPARING THE FRETBOARD

_____34. ANOTHER OPTIONAL STEP: You can trim the width of your fretboard to

suit the grip of your left hand. Most production guitars measure about 1-3/4” (44-45mm)

wide at the narrow end (by the “nut”), and 2-1/4” (57mm) wide at the 12th fret. You’ll

notice that we supply slightly wider parts in this kit to allow someone to make the neck fit

a larger hand.

If you want to trim the width a little

bit, be sure to draw a straight line

along one or both edges to mark the

final desired width (fig 34a). Then

you can use a block plane or coarse

sanding block to remove the excess

material (fig 34b).

Fig 34a

_____35. YET ANOTHER OPTIONAL STEP: You may sand a small

radius into the top surface of the fretboard if you wish. Most production

steel-string guitars have about a 15” (38cm) radius on top of the fretboard.

This is quite easy to do with either a block plane or a coarse sanding block.

Begin by putting double-stick carpet tape at each end of the underside of

the fretboard, as shown in fig 35a.

Stick the fretboard to your work surface and use your block plane or sanding block at a tilted angle to remove some material from each side along the

entire length of the fretboard (fig 35b).

Use a pencil on the end of a 15” string to draw the desired arc onto a stiff

notecard. Cut on the curved line and check your progress by holding the

card against the wood (fig 35c).

Fig 35b

Fig 34b

Fig 35a

Fig 35c

POINT OF INTEREST

The fretboard radius can vary from 7.5” to 20”, depending on your playing preferences. The tighter radius is more comfortable

for the curvature of your hand, but a flatter radius is better for fingerpicking and for bending notes. In fact, classical guitars

(nylon strung) have flat fretboards, no radius at all. It is also possible to achieve a compound radius in which the fretboard

resembles a slice off a cone. This gives you a tighter radius at the nut and a flatter radius near the body of the instrument. Such

a shape actually fits the natural plane of the strings. So you can work your fretboard to suit your playing style.

Hold a straight-edge against the fretboard to make sure the wood is still straight across the top from one end to the other (fig 35d).

You don’t want any depressions or high spots in the playing surface. Use a coarse sanding block to do the major leveling (fig 35e).

Fig 35d

_____36. OK, HERE’S ANOTHER OPTIONAL STEP: Many people like the appearance of having pearl inlay dots in cer-

tain spaces on the top of the fretboard to guide their playing. We have included white side markers for the fretboard, but you may

also purchase 1/4” diameter pearl dots from Musicmaker’s if you want to inlay them on the top surface as well. It is common to

see from 5 to 7 marking dots located in the spaces shown in fig 36a (numbering the spaces from the narrow end of the board).

Fig 35e

18.

Page 19

Fig 36a

Draw a centerline down the fretboard and use an awl to punchmark the locations of the marking dots, as shown above.

Then use a 1/4” drill bit to bore shallow holes (1/16”, or 2mm deep) at each punch (fig 36b).

Glue each dot with a drop of 5-minute epoxy or Superglue (CA adhesive) (fig 36c), and press

or tap it down into the hole (fig 36d). A scrap of wood works well to pad the dot (and the

surrounding wood) from your hammer. Ideally, you can push it close to level with the top

surface, but it is fine to have the dots stand a little higher than the wood. You’ll sand them

down flush after they dry.

Fig 36d

Fig 36c

_____37. Use your coarse sanding block to level the dots with the wood. Then you can smooth the entire top surface of the

fretboard with progressively finer sandpaper in this approximate sequence: 100 grit, 180 grit, 240 grit, 320 grit, 400 grit, and

finally 600 grit.

Fig 36b

2mm

deep

1/4” drill

POINT OF INTEREST

This final sanding should leave the fretboard silky smooth, almost as if it were finished and polished. Your fretboard is made

from Bolivian Rosewood which has natural oils that seal the pores, so there will be no need to apply a surface finish over the

top. Your sanding at this point will give you the final playing surface.

_____38. Now you are ready to install the frets. IMPORTANT: Begin by finding the special #0 fret in your parts pack-

age. This short piece of fretwire has a little fatter bead than the rest, and it must be placed in the very first slot at the

narrow end of the fretboard to hold the strings at the proper height.

Clip that #0 fret slightly longer than necessary to reach across the narrow end of the board (fig 38a). Notice that the fretwire is

shaped with a rounded cap that stays on top of the wood, and a thin tang that will fit tightly down into the pre-cut slot.

Use a small hammer to tap one

end of the tang into the slot, and

work your way across to the

other end of the fret, checking

to see that it is fully seated along

the way. It should go easily, requiring only 4-8 taps for each

fret (fig 38b).

Continue the same process

with the rest of the fretwire until all of the frets are installed.

Double-check carefully, under

good lighting, to make sure the

frets are fully seated against the

wood. Tap them down further

as necessary.

The ends of the frets need to be sanded flush and smooth with the sides of the

fretboard. This goes quickly if you hold the fretboard up against a belt sander, but

you can also use a fine flat file or a sanding block with time and some effort. Once

the ends are flush with the wood, tip the file (or sandpaper) to bevel the ends of

the frets about 45 degrees, as shown here (fig 38c). Check how smooth it feels by

running your hand along the edges of the fretboard. Be sure to eliminate all sharp

points and roughness.

Fig 38b

Fig 38a

bevel

Fig 38c

#0 fret

frets

19.

Page 20

PREPARING THE NECK

_____39. Temporarily clamp the fretboard to the neck, carefully centering it and

leaving enough flat space at the narrow end to allow for the ebony nut. Use a

pencil to outline the fretboard as shown in fig 39a. These lines will be helpful

reference points as you do more shaping on the neck to fit your grip.

Remove the temporary clamps and set the fretboard aside while you work on the

neck. We like to clamp the neck upside-down and hanging over the edge of our

work table, as shown in fig 39b. This allows you free use of both hands for doing

some shaping at the heel with a rasp and/or coarse sandpaper.

When the shape looks rounded enough for you, switch to medium (100-grit) sandpaper to smooth out the surface (fig 39c). This area will be difficult to sand when

the guitar is assembled, so take the time to do it now.

Fig 39a

Fig 39b

Fig 39c

CAUTION: Be careful not to damage or remove the thin edges at the heel of the

neck. You can reduce their width to match your fingerboard, but leave them full

height to make it easier to fit the neck to the body.

In these directions, we will refer to the four corners of the heel as A, B, C, & D, as

shown in fig 39d, to help you plan your adjustments.

Chamfer the edges of the slot in the heel of the body for the tenon to make sure

the sharp corners don’t interfere with the tenon fitting all the way into the slot. A

chisel or file works well for this task (fig 39e).

Test-fit the neck to the body. If the tenon is too tight for an easy fit, you can file it on

one or both sides, as necessary, but try to avoid making it too loose and sloppy in the

slot (fig 39f). Check for glue residue in the slot that might interfere with a good fit.

TENON

SLOT

C

Fig 39d

HEEL

BD

A

Fig 39e

TENON

Fig 39f

20.

Page 21

_____40. Before doing more fitting of the neck to the body, it is best to

use your flat sanding block to make sure the heel end of the body is flat and

level (fig 40). Try to keep the sanding block from rocking too much as

you work on the end of the guitar. You should not have to remove much

material, but you want to get rid of irregularities in the surface, like glue

blobs, bumps, and depressions in the wood.

_____41. Test fit the

neck to the body again.

Find the bolt and washer for holding the neck

to the body, and use a

7/16” socket wrench

to draw the parts together from inside the

body, as shown at right

(figs 41a and 41b).

Fig 41a

HINT: When you assemble the neck

to the body, you should be able to slide

the neck up or down about 1/16” to

get the top of the neck level with the

top of the soundboard.

Fig 40

Fig 41b

If that isn’t quite enough adjustment for

your parts, you can remove the neck

and use a round file to elongate the hole

in the heel block a little bit to allow the

bolt to move up or down further (fig

41c). This would be easier than doing a

lot of sanding on the top surfaces!

Your goal is to have the neck aligned with the

centerline of the body (fig 41d), and level with

the soundboard. Use a straight-edge to check

these details.

Notice (fig 41e) that our neck tilts downward

from the plane of the soundboard, leaving a gap

under the straight-edge, so we need to adjust the

heel to level those parts together.

Your parts will likely be different, so you can

adapt these instructions to achieve your goal.

The neck at right (fig 41e)

slopes down ward toward

the peghead, so it needs

a little adjustment at the

heel to raise the peghead

end and remove the slope.

We want the surface of the

neck and soundboard to be

level and flat.

Fig 41e

Fig 41c

Elongated

hole

Center Line

Fig 41d

No gap here!

In the next step we show

how to accomplish this type

of adjustment.

21.

Page 22

POINT OF INTEREST

Many guitar builders angle the neck down a few degrees from the plane of the

soundboard on purpose to help lower the string action, but on this kit, we have

sloped the fretboard to accomplish the same result. This makes your kit easier

to assemble, with less guess-work. So all you need to worry about is to achieve

a level playing field along the top of the guitar from the tail end to the peghead.

_____42. For our situation shown earlier, we need to carefully shave the thin

edges of the heel to slope them slightly lower toward the corners marked A and

C, as shown in fig 42a.

We like using a flat sanding block for this careful work, checking the fit frenquently to make sure the parts are fitting better and better as we go.

Once the neck is flat with the soundboard, you

need to make sure it lines up with the centerline

on the body (fig 42b).

Use the bolt to hold the neck in place as you lay a

straight-edge down the center of the neck to see

how it aligns with the body.

If it is off, sand one side of the heel a little further

to straighten the neck. Be sure to keep track of

which side needs work! Use your A, B, C, & D

marks (fig 42c).

A

Fig 42a

Fig 42c

Assemble the parts again and double-check for

any unevenness along the top surfaces where

the neck meets the body. You will want the

fretboard to fit nicely across this seam, so use a

sanding block if necessary to remove any irregularities in those surfaces (fig 42d). This should

only require light sanding.

Fig 42b

ADDING THE FRETBOARD

_____43. Now you are ready to glue the fretboard to the

neck. Begin by centering the fretboard on the neck, leaving sufficient flat space at the narrow end (near peghead)

for the “nut”. Pencil the outline of the fretboard so you can

easily re-position it in the same spot (fig 43a).

Fig 42d

space for

“nut”

22.

Fig 43a

Page 23

We recommend installing two tiny nails partway into the neck: one near each end, as shown in fig 43b. Clip the nails close to the

wood (fig 43c). These studs will help prevent the fretboard from slipping out of position as you glue and clamp it to the neck.

Fig 43b

_____44. Push the truss

rod into the slot in the neck,

with the barrel nut facing the peghead (fig 44).

HINT: We like to orient

the truss rod so the adjustment barrel nut rests at the

bottom of the slot instead of

the top. That is the normal

orientation on production

guitars.

_____45. Carefully place the fretboard back over the neck, aligning it with your

outline, and leaving enough flat space for the “nut” near the peghead, and press

the fretboard firmly down against the neck, especially where the tiny nails are

located (fig 45a). This will create pin-pricks under the fretboard to keep the

parts from sliding out of position during gluing.

Get some clamps and scrapwood ready for clamping the fretboard onto the

neck. Look at the following photos to see how we press these parts together.

Barrel nut for

adjustment

Fig 44

Truss Rod

Fig 43c

space for

“nut”

Fig 45a

When ready for gluing and clamping, squirt

glue on the neck, as shown in fig. 45b

space for

“nut”

Replace the fretboard on the neck so the tiny

nails “fall” into the pin-prick dents made earlier.

Remember to leave enough flat space at the peghead end for the “nut”.

Notice the scrap

wood pads

under the metal

c-clamps. These

are important for

protecting the

instrument wood

from dents

Fig 45c Fig 45d

(figs 45c & 45d).

23.

Fig 45b

Page 24

_____46. The peghead can be shaped a little further at the end if you want to customize

the instrument that way. Just make sure you don’t interfere with the fit of the geared tuners

by removing too much material. We use a band saw and spindle sander or drum sander for

this kind of modification (fig 46a).

You can also trim the end of the fretboard to fit the sound hole. Bolt the neck back onto the

body and use a short pencil stub to outline the edge of the sound hole on the underside of

the fretboard, as shown in fig 46b. Use a band saw or coping saw to cut close to the curve

(fig 46c), and then a drum sander or curved sanding block to smooth it out to the line, or a

little beyond. It is OK to have the fretboard fall 1/8” short of the sound hole. We also like

to bevel the curved end, or round over the top edge a little. Just check how it looks on the

guitar, and work on it until you like the results.

Fig 46a

Fig 46b

Fig 46c

_____47. Now it is time to do final shaping and sanding of the neck and fingerboard assembly. We like to clamp it upside-down

at the heel so we have both hands free for filing, sanding, scraping, etc. (fig 47a). The goal is to reduce the thickness until it feels

good in your hands for playing. If you don’t play guitar, you might ask a musical friend to help evaluate the neck for comfort.

Use a rasp for removing material quickly. Then switch to sandpaper to smooth things out and remove the coarse file marks.

Work carefully near the peghead to round things over and

smooth out the curves (fig 47b.

Fig 47a

We like to shape the thinnest part of the neck (near the peghead) to about

1 - 3/4” (44 mm)

Fig 47b

7/8” (22mm) thick, including the fretboard, and 1-3/4” (44mm) wide.

We also like the back of the neck to be shaped somewhere between a V and

a U, so it does not seem “boxy”. Here is a drawing of the cross-section we

Cross-section

of neck

7/8” (22 mm)

like at about the first space next to the peghead (fig 47c).

24.

Fig 47c

rounded

“V” shape

Page 25

Fig 48

_____48. When you have the neck shaped to your liking, smooth everything off with medium

sandpaper (about 100-150 grit). Check carefully for scratches from your coarser tools, and

sand with the grain direction wherever possible (fig 48).

_____49. OPTIONAL: Some players like having side-marking dots on the fretboard for easier

reference from the player’s perspective. The most common positions are shown in fig 49a.

Fig 49a

Use a sharp awl to punch-mark the placement for

the marking dots so your drilling will be accurate.

Then use the 5/64” drill bit included with this kit

for drilling holes about 1/8” deep along the edge, as

shown in fig 49b.

You don’t really need to glue the white stick into

the hole if it is a tight fit, but Superglue will work

fine if needed. Clip off the excess as you move

from hole to hole.

Fig 49b

____50. Before you proceed to installing the neck permanently, it is smart to sand the

soundboard now when the fretboard is not in the way. Use a sanding block with fine

(180-220 grit) sandpaper to smooth especially the area where the fretboard will cover

(fig 50).

This is also a good time to use sandpaper to round over the inside edges of the sound

hole, just to remove splinters and make it smooth to the touch.

____51. Prepare for the gluing operation by having the bolt, wrench, small c-clamp, and

a scrap of wood to use as a clamping pad, as shown in fig 51b on the next page. Then

you can carefully put glue on just a few places at the heel of the neck and under the

fretboard, as shown here in fig 51a. If you overdose here, you’ll end up with a lot of

messy cleanup, and the extra glue will not make the guitar any stronger.

Use a sharp blade or razor knife to trim flush, and

follow up with a sanding block to smooth the area

(fig 49c).

narrow edges that you fitted earlier

both sides of tenon

Fig 49c

Fig 50

near edges of fretboard

POINT OF INTEREST

Some luthiers say that gluing just the edges of the the fretboard to the soundboard

may help prevent shrinkage and/or stress cracks in the spruce later on. It also facilitates removing the fretboard from the soundboard if repairs are needed.

25.

Fig 51a

Page 26

Quickly slide the neck into place and install the bolt to pull the parts together. Make sure the fretboard is resting flat on the soundboard. Remember

that you have a little “wiggle room” to slide the neck up or down to get a

tight fit.

Add a clamp or two on the fretboard to hold that area. We like to put a scrap

wood under the clamp to avoid making dents in the fretboard (fig 51b).

Before the glue dries, use a wet rag

to clean up the excess that squeezes

out of the joints. Go over the area

2-3 times with a clean wet rag to

Fig 51b

We like to wrap the rag around a putty knife or thin screwdriver to help clean into the

corners (fig 51c). This will save you some frustration later.

____52. Find the thin walnut heel cap for covering heel of the neck and trim it a little oversize before gluing it in place (fig 52a).

You’ll want to fit the edge that meets the body

nicely (fig 52b). Use sandpaper to smooth it

off and fit it against the end of the instrument.

make sure you don’t just smear the

glue around.

Fig 51c

The other edges can hang over the heel for

trimming off after the glue dries.

Fig 52a

When ready, add glue to the heel cap and hold

it securely in place with tape while you get a

clamp ready to press it firmly (52c & 52d).

Fig 52c Fig 52d

Be sure to pad the clamp area so you don’t dent the

instrument (fig 52e).

Fig 52b

Fig 52e

26.

Page 27

INSTALLING THE BRIDGE

____53. Now that the neck is in place permanently, you can find the

proper location for the bridge and install that on the soundboard. Begin

by measuring 24-1/2” from the #0 fret at the narrow end of the fretboard and placing a piece of masking tape lightly on the soundboard at

that location (fig 53a).

Then hold a straight-edge along each side of the fretboard and mark the

masking tape where the straight-edge crosses it, as shown .

Find the center between those two

Center line

Fig 53b

____54. OPTIONAL: The bridge we provide is a bit

larger than necessary, but you can use it as is if you like it.

Some people enjoy customizing the guitar by shaping the

bridge, and that is another option for you. The photos at

right give you some ideas. Note: We recommend leaving

the straight side as is. That will make it easier to align the

bridge properly on the soundboard.

marks so you can

center the bridge to

align with the fretboard (fig 53b).

(165m m) 1-1/2”

Straight edge

Fig 53a

6-1/2” (165mm)

Original size

Custom shape

Don’t reduce the size of the bridge any smaller than the bottom sample at right.

The best way to proceed is to draw the outline you want

right on the wood, then cut and sand to the lines. Be sure

to sand the cuts to smooth the edges nicely.

____55. When you are ready to install the bridge, carefully measure 24-5/8” (625.5mm) from the center of the #0 fret to the

center of the bass end of the saddle slot on the bridge. Notice that the saddle is angled on the bridge. The bridge itself should be

aligned with the front edge perpendicular to the center line of the instrument, so the bass end of the saddle will be a little further

toward the tail end than the treble end of the saddle. It should lookjust like the drawing below (fig 55a).

(32m m) 1-1/4”

(625.5m m)

Bare minimum size

6” (152m m)

Fig 55a

27.

Page 28

When you determine the correct place for the bridge, use

masking tape to hold it in place while you drill just the outer

two peg holes with a 3/16” bit, as shown in fig 55b. Don’t

risk trying to drill all six holes now - the bridge may slip out

of position.

Bridge

Drill two outer-

most peg holes

with 3/16” bit.

Bridge

Clamp

Fig 55b

Fig 55c

Assemble the bridge clamp to the bridge as in fig 55c, with the machine screws lightly installed. Test-fit the assembly into the

two holes you just drilled in the soundboard, to make sure everything fits well. IMPORTANT: the bridge can be installed

backwards! Be careful to make sure the flat edge closest to the saddle slot is facing the soundhole.

When ready, spread glue on the underside of the bridge and push it down into place with the two screws going through the

soundboard. Reach into the soundhole with one hand to install the washers and wing-nuts on each screw. Then use a Phillips

screwdriver to tighten the two inner screws on the bridge clamp (fig 55d). You should see some glue squeezing out around the

bridge from this pressure.

Make sure to slide a scrap of wood under each of the end screws to

protect the “wings” of the bridge as you screw pressure onto them (fig

55e). We actually use a thin wood scrap with a piece of thick leather

or fabric underneath, to prevent scratching or denting the bridge.

Fig 55d

____56. We like to use a flat mill file to level

the tops of the frets, as shown in fig 56a. You

can use a regular mill file from the hardware

store for this job. We use epoxy glue to adhere

the file to a thick block of wood, creating a nice

handle.

File until all the frets are slightly touched by the

action. That’s when you know they are all the

same height.

Carefully clean up excess glue with a damp rag, making several passes to scrub away all glue residue.

Fig 55e

Fig 56a

28.

Page 29

If you ended up flattening the tops of some frets significantly with the big

file, you’ll want to round them over again by knocking off the sharp corners with a small triangle file or needle file (fig 56b). Be sure to protect

the surface of the fretboard with some tape when doing this work so you

don’t scratch the wood you so carefully sanded earlier.

Sometimes a guitar string will buzz at a certain fret because the neighboring fret is a little higher, and sometimes because of a flat spot on the top

of the fret. Your leveling work should prevent the first problem, and this

light filing should correct the second one.

Follow up with sanding the tops of the frets as shown in fig 56c. Just

wrap your hand with medium sandpaper (180 grit) and drag the edge of

your hand across the frets in both directions to smooth all the filing marks

from the earlier steps.

Switch to fine sandpaper (220 grit or higher) if you want to polish the

frets nicely.

The fretwire is relatively soft metal, so your handwork here will make a

nice difference in smooth playability.

Small file

held at angle

Fig 56b

Fig 56c

____57. Before applying finish to your guitar, you’ll want to seal off the playing surface of the fretboard with masking tape,

as shown in figs 57a and 57b below. You don’t want to put varnish on this surface because it can become gummy over time

from your fingers. You can oil it lightly (linseed oil) after the rest of the guitar is finished, but we just leave the playing surface

unfinished. Rosewood has enough natural oils to resist moisture on its own.

Start with tape

across end of

fretboard.

Spread tape along the

length of the fretboard,

pressing it down on both

Fig 57a Fig 57b

____58. Find the little truss rod cover plate and sand one side to prepare it for finish.

We like to customize the shape a little bit too, though that is not necessary. You can

narrow it down a little and add more curvature around the edges. Then smoothe it

all nicely and round the top edges (fig 58).

Don’t install the cover plate until the end. Just set it out for finishing.

sides of each fret.

Finish with tape

across last fret.

Whew! You are just about ready for finishing. But before you get to that, we highly

recommend that you relax and check over the entire instrument closely to see if you

can find any more glue smudges or dings that might need a little attention. It is much

easier to correct that sort of thing before the finish is applied.

Also check for gaps in the glue joints. You can use mahogany colored wood filler

from the hardware to fill those gaps, pressing the paste in with a putty knife or flat

screwdriver blade. Sand the filled area after it dries to remove any excess paste.

29.

Fig 58

stock

piece

custom

shape

Page 30

APPLYING THE FINISH

Use a clean cloth to wipe off any sanding dust from the wood. Some people buy tack cloth for this purpose, but we just use a

clean rag.

Another option is to wet the rag with denatured alcohol (from the hardware store) for cleaning the wood more fully. Alcohol

does not raise the grain like water does, and it evaporates quickly, leaving no spots. But this trick is not a necessary step -- just

kind of fun to do. The alcohol will give you a preview of the beautiful depth and color of the wood.

Now you are ready to apply the finish. Here are some recommendations:

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the wood. We generally discourage people from trying to stain this project because the natural wood grain is so beautiful with a simple clear finish. It is

difficult to mask off the soundboard, for instance, and just stain the sides and back of the body because the stain tends to “bleed”

under the masking tape. If you are a novice at finishing, or facing a deadline for completion, we especially recommend avoiding

stain.

OIL -- An oil finish (such as Watco Danish Oil) will give your wood a low luster appearance, bringing out the natural color of

the grain, but it tends soak into the wood and appear dry and “thirsty” after awhile. The principal advantage of an oil finish is

that it can be applied and wiped dry immediately, allowing you to proceed to installing hardware (and strings) right away. The

disadvantage of oil is that it usually does not give much surface protection or sheen, unless you know how to polish out many

coats of gun stock oil.

POLYURETHANE -- Any polyurethane will work fine on this project, but we like the solvent-based ones better than waterborne versions. One of our favorites is a wipe-on satin Gel Topcoat polyurethane that comes with our Instrument Finishing Kit.

The advantages of this finish are its simple application (no drips or runs), durability, and deep, soft luster.

LACQUER -- Many professional instrument makers still use nitro-cellulose lacquer for their finish. The most readily available

lacquer is called Deft Clear Wood Finish (semi-gloss). If you choose this product, it is best to purchase a can of liquid Deft to

brush on as a sealer coat first, and then use an aerosol can of the same product to spray the final coats. The advantage of this

finish is its quick drying time, but the disadvantage is the strong odor and toxic lacquer fumes. CAUTION: Lacquer finish may

smear some painted decorations or blister some types of decorative decals. If you plan to add paints or decals to your instrument, it would be better to finish with polyurethane instead of lacquer.

So choose your weapon and proceed with finishing all the wood parts except the top of the fretboard. Plan on applying at least

three coats of finish. If you don’t use our Gel Topcoat, be sure to follow the directions on the can.

Don’t forget to finish the truss rod cover too!

INSTALLING HARDWARE AND STRINGS

____59. When the finish is dry, and you are happy with the results, you

can begin installing the last few pieces. The first item is the African

Blackwood nut that gets glued at the end of the fretboard, as shown at

right (fig 59a).

It is easiest to trim and shape it before gluing it in place. It should stand

just a little higher than the #0 fret. We like to slope the top down toward

the peghead as shown in fig 59b.

African

Blackwood

Nut

Fig 59a

When you have the nut trimmed and shaped, use Superglue or 5-minute

epoxy to glue it in place.

30.

Fig 59b

Page 31

____60. The nut needs to be notched for spacing the strings evenly across

the width. We like to leave about 1/8” (3mm) space at each side before

the first and last notches. Then we try to space the other 4 notches evenly

between them.

The exact spacing for your guitar will depend on the overall width of the

fretboard at the nut. If you have 45 mm total width, then you can put the first

and last notch 3mm from each side, and space the rest of them 8mm apart,

as shown in fig 60a.

Notice that we use tape to hold or ruler to the fretboard, and another piece of

tape on the nut for drawing our notch positions.

If you don’t have the same width on your guitar, then we recommend using

on of the patterns printed below. If necessary, you could have one of these

illustrations slightly enlarged or reduced to suit your instrument.

Fig 60a

1-3/4” NUT 1-13/16” NUT

Once you have your notches marked evenly across the nut, you

need to cut slots for the strings at each position. Since the strings

vary in thickness, you should make sure your slots will accommodate them all. An experienced luthier will keep a set of nut

files in different sizes so he can cut each slot for each particular

string, but that is not necessary on this kit.

You can cut these notches using a very small “V” shaped needle

file or triangle file. You just need to file them deep enough to

make sure the strings will rest firmly on the #0 fret. You’ll need

to angle the file downward toward the peghead, and avoid cutting into the #0 fret, as shown in fig 60b. We like to cover the

peghead with thin cardboard to protect it from being scraped

accidentally by the file.

Fig 60b

cardboard

cover

1-7/8” NUT

POINT OF INTEREST

Normally, the notches in the nut would have to be filed to a specific depth to support the strings at the right height above the frets.

For this kit, however, the #0 fret holds the strings at the correct height, and the notches only serve to separate the strings evenly

across the width. This saves you some headache and guesswork at the end of the project.

____61. Press the geared tuners into

the peghead from the back side (fig

61a). If they are a bit tight, you can

clean the inside of the holes a little

with a rat-tail file to make them easier

to press in. Orient the handles so they

look evenly spaced and straight.

Fig 61a

Then flip the peghead over and insert the

threaded sleeves and washers. Use a 716”

nut driver or small adjustable wrench to

tighten the sleeves firmly (fig 61b).

Fig 61b

31.

Pre-drill for the tiny screws with the

1/16” drill bit provided (fig 61c). Then

install the screws using a #1 size Phillips screwdriver.

Fig 61c

Page 32

____62. Before covering the truss rod slot, find the Allen wrench provided and tighten the nut finger-tight for now, just to keep it

from rattling (fig 62a). You may need to adjust it one way or the other later to correct a bow in the neck. Then center the truss rod

cover over the opening and hold it in place with masking tape while you drill 1/16” pilot holes into the peghead for the tiny screws

(fig 62b). Then you can install the three tiny screws that hold the cover in place.

Fig 62a Fig 62b

____63. Drill through the remaining holes in the bridge with the 3/16” bit provided (fig 63a). These holes need to be slightly tapered to accept the bridge pegs. A cheap and simple way to do that is to use a small (6”) rat-tail file (fig 63b). You can chuck it

into your hand drill and spin it in reverse as you push it gently into the hole. Be careful not to file too far -- it is best to fit the pegs

fairly snugly (fig 63c).

Fig 63a

____64. Test-fit the first string on the guitar, pushing the

“ball end” into the first hole in the bridge, followed by the

bridge peg (fig 64a). Note that the pegs have a hollow side

of the shaft large enough to accommodate the thick string.

Fig 64a

Fig 63b

Fig 63c

HINT: The ball on the end of the string is meant to be

deflected to one side of the peg, as shown in fig 64b. This

prevents the string from pulling out along with the peg

when you tune the string up to full tension.

Fig 64b

32.

Page 33

____65. Stretch the string across the instrument to the peghead and attach it to the first tuning post. Turn the gear so the string

wraps to the inside of the post, as shown in fig 65a. Be careful not to over-tighten -- it is best to pluck the string and let it ring as

you tighten the tuning gear. This first string is the lowest note on the instrument: Low E almost two octaves below Middle C.

Fig 65a

When the first string is up to pitch, check how it lies over the frets of the playing surface. You should not need to worry about the

height at the first fret near the peghead, unless you didn’t file the notches in the nut deep enough to allow the string to rest on top of

the #0 fret. Correct that detail now if needed (fig 65b).

Fig 65b

Check the space under the string at the 12th fret, near the joint with the body. That should not be more than about 1/8” for the

instrument to be easy to play. Here are some things to check for correcting the string height if necessary:

a) Sight down the length of the fretboard to see if it is still flat. If you see a significant bend in the middle, then you’ll need to

adjust the truss rod. CAUTION: Remember that you have a double-action truss rod. Turning it one way will correct the bend

in the neck, but turning it the other way will increase the bend. So be careful to watch which way your adjustment is affecting

the guitar. DO NOT FORCE THE TRUSS ROD NUT! Some people have broken the nut right off the rod by torquing it too

much. Contact us if you need assistance.

b) If the neck is pretty straight, and the string is still too high above the

12th fret, then you need to shave the saddle a little lower at the bridge.

Loosen the string so you can remove the saddle. We like to draw a pencil

line near the bottom of the saddle to guide our sanding process (fig 65c).

You can sand the bottom of the saddle with a coarse sanding block, checking to make sure the bottom edge stays parallel with your pencil line. You

don’t need to sand all the way to the line -- just use it as a reference point.

Then replace the saddle in the bridge again and tighten the string to test

the gap at the 12th fret.

c) If, on the other hand, the string is too low over the 12th fret, you may

need to shim the saddle a little higher. You can clip a section of excess

guitar string to lay in the slot under the saddle.

Once you have the first string hanging the right height above the strings, you can install the rest of the strings as shown in fig 65a

above. Notice that the strings wrap around to the inside of all the tuning gear posts on the peghead. This is a helpful

detail to keep the strings from pulling sideways and jumping out of the notches in the nut.

Fig 65c

33.

Page 34

FINE ADJUSTMENTS AND TROUBLESHOOTING

_____66. There may still be some fine adjustments needed to make your guitar work its best. Test each string by plucking it

with one hand while you press it down at each playing position (fret) along the neck. Here is what to check for:

a). If the string is difficult to push all the way to the fretboard, it is too high. If the neck has bent forward because of the

string tension, you will use the truss rod to counteract that. Loosen the strings before adjusting the truss rod, and be careful not

to break the nut of the truss rod! This is a double-action rod, so turning one way will bend the neck forward and the other way

will bend it backward.

b). If the neck is straight but the strings are still too high, remove the saddle from the bridge and sand the bottom so it

does not stand so tall. Sanding 1/8” off the saddle will lower the strings by 1/16” at the 12th fret, near the middle of the guitar.

c). If a string buzzes when plucked in the OPEN POSITION ONLY (when not held down to a fret), then the notch in

the NUT is probably not deep enough to allow the string to rest firmly on the #0 fret. File that notch a little deeper.

d). If your strings buzz and rattle in general as you play, sight down the fretboard first. Some seasonal changes may

cause it to bend backward. Adjust the truss rod to allow the strings to pull the neck forward. You may also shim up the saddle

in the bridge to raise the strings a little higher, or change to heavier gauge strings to exert greater tension on the neck.

e). If a string rattles or buzzes at just one or two positions (frets), or if you discover that two or three frets all give the

same pitch, then look for a fret that stands up higher than its neighbors. You will need to either tap that fret down fully into

its slot in the fretboard or use flat mill file to level the tops of the frets some more. Just loosen the strings, lift them out of the

grooves in the nut, and hold them along either side of the fingerboard as you work the file lengthwise along the tops of the frets.

You can easily see which frets are the highest, as they are the ones that receive the most filing.

f). If you find that the strings rattle a little as you strum aggressively, you may want to simply change to a heavier set

of strings. This kit comes with light strings, which are easier to play, but your style of playing may be too aggressive for them,

so heavier strings might suit your playing style better.

ACCESSORIES AVAILABLE FOR GUITAR

1/4” diameter Pearl marking dots for front of fretboard

Musicmaker’s finishing kit

Plastic pick-guard

Spare set of 6 steel strings (light gauge)

Guitar strap with 2 mounting buttons

Hard-shell, plush-lined case for parlor size guitar

Electronic Tuner (chromatic) to aid in accurate tuning

Piezo Pickup for amplification

Call us toll-free (1-800-432-5487) or check our web sit (www.harpkit.com) for pricing and availability.

34.

Page 35

INSTALLING OPTIONAL ACCESSORIES

____66. If you want to install a strap on your guitar, place

one mounting button centered at the tail end of the body, and

the other button at the heel, as shown in fig 66.

NOTE: The screw should be located about 1-1/2” from the

bottom of the heel so as to avoid interfering with the bolt inside the heel.

Be sure to drill a pilot hole for the mounting screws -- otherwise you might crack the wood in the heel! If the screw is

difficult to turn into the wood, then your pilot hole is too small

for the screw.

____67. You can add a pick guard around the soundhole

to protect the finish from damage from strumming with a

flatpick (fig 67). This standard shaped guard fits around the

inlaid ring very nicely, and it is simple to install -- just peel

and stick.

Fig 66

1-1/2”

Mounting

Button

Fig 67

____68. If you’d like to amplify your guitar, one nice option is to install a piezo pickup inside, with a jack at the tail end that

serves the double purpose of a strap button and output jack. We offer either single-sensor or double-sensor piezo pickups at

Musicmaker’s, and they are excellent quality for a reasonable price.

Installing a piezo pickup involves drilling a 1/2” diameter hole through the tail end of the guitar for the jack. You will also need

to remove the strings so you can reach one hand into the soundhole to place the sensors against the inside of the soundboard.

The adhesive for the sensors is included with the pickup. The most effective locations for the sensors is shown in the drawings

below (fig 68a and 68b).

Position for single sensor

Fig 68a

Position for double sensor

Fig 68b

35.

Page 36

Loading...

Loading...