Page 1

Dako Autostainer | English Handbook

Page 2

ii Autostainer Handbook

Page 3

Dako Autostainer Handbook

Document Number 0000620

Revision A

July 2006

Autostainer Handbook

iii

Page 4

iv Autostainer Handbook

Page 5

Copyright © 2006 Dako, Inc. All rights reserved.

This document may not be copied in whole or in part or reproduced in any other media

without the express written permission of Dako, Inc. Please note that under copyright

law, copying includes translation into another language.

User Resources

For the latest information on Dako products and services, please visit the Dako Web site

at:

http://www.dako.com

Installation Procedure

Dako employees will perform the initial installation and setup of all new System

instruments.

Relocation Procedure

Contact Dako’s Technical Service Group before relocating your system.

Scope

This handbook contains basic information on the use and operation of the Autostainer

and assumes you have received basic training on the instrument. Please contact our

Technical Service Group or refer to the Autostainer User Guide for information not

provided in this manual. This manual does not provide instructions for the installation or

upgrade of hardware.

Disclaimers

This manual is not a substitute for the detailed operator training provided by Dako, Inc.,

or for other advanced instruction. Dako Technical Service Group should be contacted

immediately for assistance in the event of any instrument malfunction. Installation of

hardware or software on your Autostainer should be performed only by a certified Dako

Field Service Representative.

Contact Information

U.S. Customers

Dako, Inc

6392 Via Real

Carpinteria, CA 93013 USA

Tel 805-566-6655

Fax 805-566-6688

Technical Support 800-424-0021

Customer Service 800-235-5763

Outside U.S.

Dako Denmark A/S

Produktionsvej 42

DK-2600 Glostrup Denmark

Tel +45 4485 9500

Fax +45 4485 9595

Autostainer Handbook

v

Page 6

vi Autostainer Handbook

Page 7

Table of Contents

Warnings, Precautions and Limitations............................................................................. 1

System Overview .............................................................................................................. 5

Software Overview ............................................................................................................7

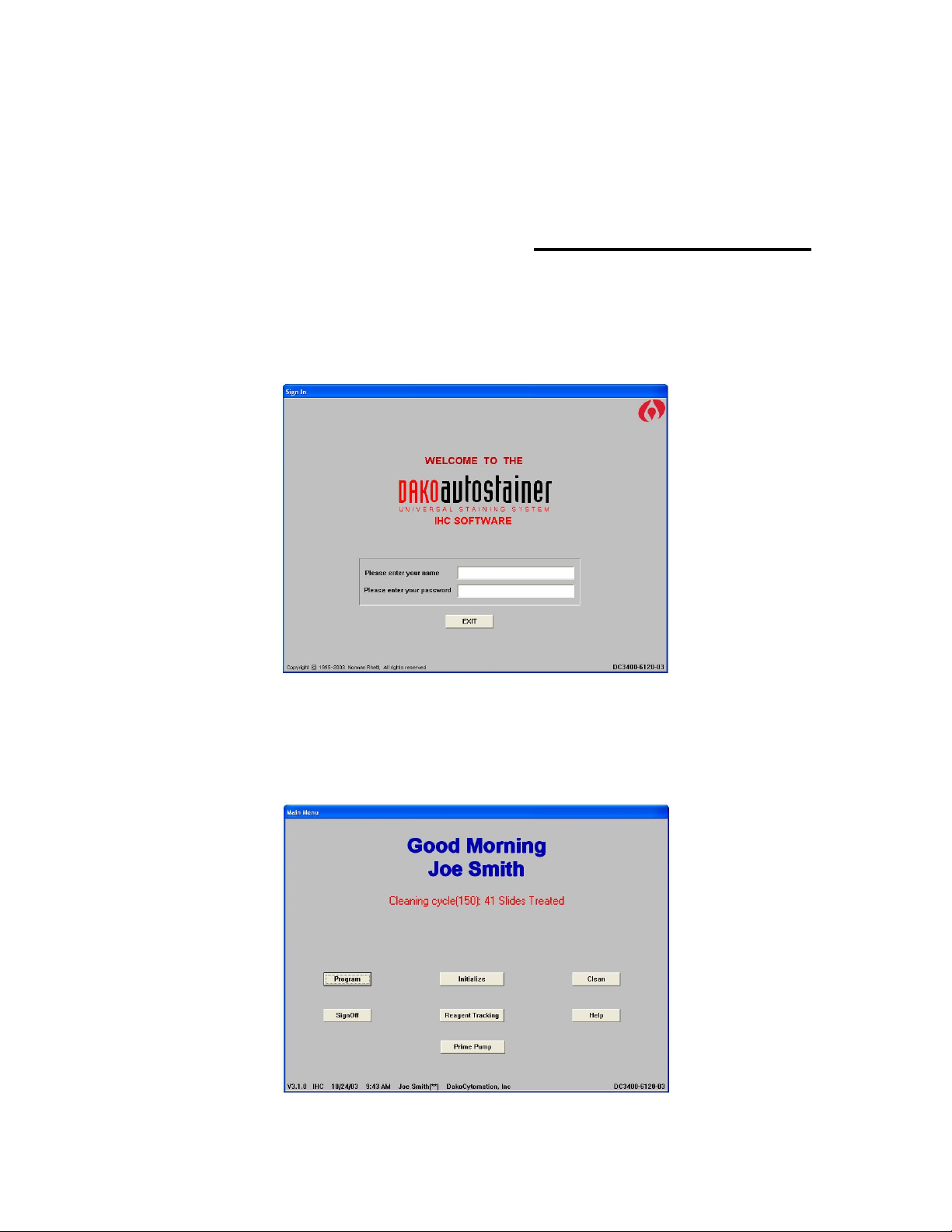

Sign In Screen............................................................................................................... 7

Main Menu ....................................................................................................................7

Initialize ......................................................................................................................... 8

Label Printing Initialization ........................................................................................8

Communication Port.................................................................................................. 9

Printer Selection...................................................................................................... 10

The Options Screen ................................................................................................ 10

Format Program Grid ..............................................................................................10

IHC Report ..............................................................................................................10

Custom Options ......................................................................................................10

Reagent Volume and Drop Zone Default ................................................................11

Clean........................................................................................................................... 11

Sign Off and Help........................................................................................................ 11

Reagent Tracking........................................................................................................ 11

Prime Pump ................................................................................................................12

Programming Grid Overview....................................................................................... 12

Entering Slide Information............................................................................................... 13

Adding Slides .............................................................................................................. 13

The Slide Info Button................................................................................................... 13

Deleting Slides ............................................................................................................ 14

Deleting Slides With the Slides Function.................................................................14

Deleting Slide ID Information Using the Slide Info Button....................................... 14

Rearranging slide positions on the Programming Grid ...............................................14

Designing a Protocol....................................................................................................... 15

Standard Protocol Elements .......................................................................................15

Additional Protocol Elements ...................................................................................... 16

Rinse Buffer ............................................................................................................16

Rinse Water ............................................................................................................16

Standard Rinse Replacement ................................................................................. 16

Substrate-Batch ......................................................................................................16

Switch...................................................................................................................... 16

Creating and Editing a Protocol Template ..................................................................16

Deleting a Protocol Template...................................................................................... 17

Using a New Protocol Template Without Saving ........................................................17

Using a Saved Protocol Template............................................................................... 17

Using a Saved Protocol Template for a Specific Auto Program.................................. 18

Selecting Reagent Dispense Volume for All Steps in a Protocol ................................ 18

Selecting Reagent Dispense Volume for a Specific Step in a Protocol ......................18

Programming a Staining Run .......................................................................................... 19

Defining Detection Reagents ......................................................................................19

Defining Primary Antibodies........................................................................................ 20

Assigning Positive and Negative Control Reagents.................................................... 20

Adding Positive and Negative Control Reagents ....................................................21

Autostainer Handbook

vii

Page 8

Negative Controls.................................................................................................... 21

Defining Specific Rinses .............................................................................................22

Auto Programming ...................................................................................................... 22

Deleting an Auto Programming Item .......................................................................23

Using an Auto Programming Item ...........................................................................23

Copy/Paste.............................................................................................................. 23

Editing a Protocol Step................................................................................................ 24

Printing Options........................................................................................................... 24

Slide Labels............................................................................................................. 24

Reagent Labels .......................................................................................................25

Reports.................................................................................................................... 25

Viewing Programmed Slides .......................................................................................25

Assigning Reagent Dispense Locations.................................................................. 26

Printing a Slide Layout Map ....................................................................................26

Selecting a new reagent-dispense location for all slides:........................................ 26

Reagent Management..................................................................................................... 27

Adding Detection Reagents (Secondary, Tertiary, Substrate, etc.) ............................27

Adding Primary Antibodies.......................................................................................... 28

Editing and Deleting Reagent Lists .............................................................................28

Updating a Reagent Lot Number and Expiration Date................................................ 28

Compatibility Check ....................................................................................................29

Loading Reagents........................................................................................................... 31

Reagent Layout Map Screen ......................................................................................31

Missing Reagent Notice .............................................................................................. 32

Loading Slides.................................................................................................................33

Load Slides .................................................................................................................33

Starting a Staining Run ...................................................................................................35

Preparing the System for a Staining Run.................................................................... 35

Quick Start ..................................................................................................................35

Run Log Screen ...................................................................................................... 36

Shutting Down the Autostainer.................................................................................... 36

Maintenance and Troubleshooting.................................................................................. 37

Troubleshooting ..........................................................................................................37

System Specifications ..................................................................................................... 43

Hardware Specifications .............................................................................................43

Software Specifications............................................................................................... 43

Standard Configuration ...................................................................................................45

viii Autostainer Handbook

Page 9

Section 1

Warnings, Precautions and Limitations

Keep the cover closed during operation. The robotic arm will move unexpectedly

during the operation - stay clear. Do not impair the movement of the Autostainer robotic

arm in any way.

Do not pour liquid down the Autostainer sink. The system is not equipped to

drain large liquid volumes poured at high speed. Hazardous reagent wastes must be

disposed of according to local, state, and federal regulations. Wear appropriate personal

protective equipment to prevent exposure.

Do not use bleach in the Autostainer. Bleach may react with other chemicals and

create toxic fumes.

Do not attempt to service the Autostainer unless instructed to do so by an

authorized Dako representative. Doing so will void the warranty or service contract. Do

not relocate the Autostainer System within your facility before contacting your local Dako

representative for vital information that may affect your warranty.

Contact your local Dako representative prior to using non-Dako reagents or

solutions on your Autostainer. Some solvents, acids, and other solutions may cause

damage to internal components of the Autostainer and affect your instrument's

performance and warranty.

Remove caps from reagent vials before starting a run on the system. Place the reagent

racks firmly in their seated position before starting a run.

Place the slide racks in the down position before starting a run on the system.

Do not use the scroll bars to select reagents from the reagent lists when setting up

subsequent runs while the Autostainer is processing. Using the scroll bars during

operation will cause the Autostainer to pause temporarily.

Do not use symbols when programming reagents or protocols. Doing so may cause

errors during the run.

Do not run more than one software application during operation (this includes the CD

player and screen savers). Do not install third-party software or hardware products.

Installing third-party products may lock up the Autostainer and may void the warranty.

Autostainer Handbook

1

Page 10

Do not print slide labels while the Autostainer is running.

Immunohistochemistry is a multi-step diagnostic process that requires specialized

training in the selection of the appropriate reagents, tissue selection, fixation, and

processing, preparation of the IHC slide, and interpretation of the staining results.

Tissue staining is dependent on the proper handling and processing of tissues prior to

staining. Improper fixation, freezing, thawing, washing, drying, heating, sectioning or

contamination with other tissues or fluids may produce artifacts, antibody trapping, or

false-negative results. Inconsistent results may be due to variations in fixation and

embedding methods, or to inherent irregularities within the tissue. Excessive or

incomplete counterstaining may compromise proper results.

Use of old or unbuffered fixatives, or exposure of tissues to excessive heat (greater than

60°C) during processing may result in decreased staining sensitivity.

Normal/non-immune sera from the same animal source as the secondary antisera used

in blocking steps may cause false-negative or false-positive results due to autoantibodies or natural antibodies. False-positive results may be seen due to nonimmunologic binding of reagents to tissue sections. In some case the application of an

alternate blocking reagent prior to incubation with the primary antibody may be useful for

reducing background. A recommended blocking reagent is Dako Protein Block SerumFree (Code No. X0909).

Unexpected negative reactions in poorly differentiated neoplasms may be due to loss or

marked decrease of antigen expression or nonsense mutation in the gene(s) coding for

the antigen. Unexpected positive staining in tumors may be from expression of an

antigen not usually expressed in morphologically similar normal cells, or from

persistence or acquisition of an antigen in a neoplasm that develops morphologic and

immunohistochemical features associated with another cell lineage (divergent

differentiation). Histopathologic classification of tumors is not an exact science and some

literature reports of unexpected staining may be controversial.

The clinical interpretation of any positive staining or its absence should be

complemented by morphological and histological studies with proper controls.

Evaluations should be made within the context of the patient’s clinical history and other

diagnostic tests. It is the responsibility of a qualified pathologist who is familiar with the

antibodies, reagents and methods used to interpret the stained preparation. Staining

must be performed in a certified licensed laboratory under the supervision of a

pathologist who is responsible for reviewing the stained slides and assuring the

adequacy of positive and negative controls.

Reagents may demonstrate unexpected reactions in previously untested tissues. The

possibility of unexpected reactions in tested tissue groups cannot be completely

eliminated due to biological variability of antigen expression in neoplasms, or other

pathological tissues. Contact your local Dako representative with documented

unexpected reactions. Tissues from people infected with hepatitis B virus and containing

hepatitis B surface antigen (HBsAg) may exhibit nonspecific staining with horseradish

peroxidase.

2 Autostainer Handbook

Page 11

Correct Disposal of this Product

(according to Directive 2002/96/EC on Waste Electrical and

Electronic Equipment [WEEE] applicable in the European Union

and other European countries with separate collection systems).

Contact a Dako representative for disposal of the equipment at

the end of its working life. This product should not be mixed with

other commercial waste for disposal.

Autostainer Handbook

3

Page 12

4 Autostainer Handbook

Page 13

Section 2

System Overview

The Autostainer System is an automated slide processing system compatible with

currently available reagents for staining paraffin-embedded and frozen tissue sections,

cytospins, cell smears, and fine-needle aspirates. This system is designed to automate

manual staining methods routinely used in immunohistochemistry and cytochemistry,

enabling the transfer of established protocols from the bench to the Autostainer.

Flexible programming allows for an unlimited number of protocols containing up to 35

steps (including rinse and blow steps between reagent incubations) and 64 different

reagents. A staining run can process from 1 to 48 microscope slides. Individual slides

can be programmed to receive different reagents, of specified volume, during any step in

a staining protocol, and waste is segregated into hazardous and non-hazardous

collection containers, reducing disposal costs.

The Autostainer is designed to track a variety of data. It can generate patient, reagent,

and real-time operation data reports, as well as track reagent usage and log instrument

maintenance.

Autostainer Handbook

5

Page 14

6 Autostainer Handbook

Page 15

Section 3

Software Overview

Sign In Screen

The Sign In screen appears when you double-click the Autostainer icon on the desktop.

After your name and password have been validated, the Main Menu appears.

Main Menu

The buttons on the Main Menu allow you to access the other Autostainer screens.

Note: Change Password replaces the Initialize button for users with middle and low

security access.

Autostainer Handbook

7

Page 16

Initialize

The Initialize screen is used to establish and update default information for the system.

This includes the institution information, Autostainer serial number, user names, the

doctors requesting IHC tests, a library of tissues that may be used during staining, the

default volume and the drop zone for reagent dispensation, and the number of slides

allowed between routine cleaning runs. Slide and reagent label formatting, user-defined

printing formats for the Programming Grid, and IHC Reports can also be configured

from this screen.

Label Printing Initialization

The Slide Labels and Reagent Labels buttons are displayed on the Initialize screen

and are used to access the Design Label screens for configuring and adjusting slide

and reagent label printing.

Slide Labels

The Slide Labels button is displayed on the Initialize screen and it is used to access

the Design Slide Label screen for configuring and adjusting slide label printing. Slide

labels are printed from the Print button on the Programming Grid. Do not print labels

while the Autostainer is operating.

1. Select the Slide Labels button.

Note: If Slide ID, Doctor, or Tissue is selected to print on the label, then these items

must be selected from the Options button in the Initialize screen. If these

Programming Grid items are not selected by using the Options button in the

Initialize screen, then these fields will not be present in the Slide Information

screen.

8 Autostainer Handbook

Page 17

2. Select the desired option for each field.

Note: Static information, such as the institution name, can be entered into the field.

This information is printed on every label. To enter static information, highlight the

text in the desired field and type the text in the text box. Press ENTER.

3. Select the number of characters for each line (10, 12, 14, or 16) by selecting a

number from the Length list (Selecting 10 characters will display bold text).

Reagent Labels

Access the Reagent Labels button through the Initialize screen.

1. Select the Reagent Labels button. Reagent Name 1/2 and Reagent Name 2/2 are

used together on adjacent lines to split a long reagent name into 2 separate lines.

Reagent Name 1/2 will contain the first half of the reagent name, and Reagent Name

2/2 will contain the second half of the reagent name. The length of each line is set up

using the Length tool.

2. Select the desired option for each field.

Note: Static information, such as the institution name, can be entered into the field.

This information is printed on every label. To enter static information, highlight the

text in the desired field and type the text in the text box. Press ENTER.

3. Select the number of characters for each line (10, 12, 14, or 16) by selecting a

number from the Length list (Selecting 10 characters will display bold text).

Label Adjustment

1. To check the position of the text on the slide or reagent label and to generate a

test label, select the Adjust Label button from the Design Slide Label or

Design Reagent Label screen.

2. Select the Test Print button. A label is generated by the label printer.

Note: The horizontal adjustment is automatically positioned by the printer. If the

text does not begin along the left edge of the label, the printer may need to be

reset. Turn off the printer. Hold down the green label feed button on top of the

printer and turn the printer on again. When the LED begins to flash red, release

the label reed button and then quickly press the button twice. The labels advance

forward and printer will print. Release the feed button. Press and release the feed

button one more time to advance one label. Perform a test print.

Communication Port

The communication port for the printer is assigned using the Port box on the Design

Slide Label screen. The number displayed in the box must correspond to the

communication serial port where the label printer is connected (e.g., 1 for A and 2 for B).

Autostainer Handbook

9

Page 18

Printer Selection

To select the proper Seymour printer type on the Design Slide Label screen, scroll

though the printer list using the keyboard arrows or the scroll bar.

Note: If the incorrect printer is selected, error messages display on the screen when

slide or reagent labels are printed. To find the model number of your Seymour Glass

Label printer, check the cover of the printer for a number (e.g.,TPL2642). The last four

digits represent the model number (e.g., 2642).

The Options Screen

The Options button is displayed on the Initialize screen. The Options screen enables

you to select format options for the Programming Grid and IHC Report, in addition to

options for rinsing, and slide layout maps.

Format Program Grid

This function enables you to select format options for the Programming Grid.

Selected items are displayed on the Slide Info screen and the Programming Grid.

Note: Selecting the Comment item creates a column for data entry on the

Programming Grid printout. This column is not displayed on the Programming Grid

screen.

IHC Report

Printing options for the IHC Report include:

• One slide ID/page – prints each Slide ID on a separate page

• One case/page – prints one case per page

• No page break – prints continuously all slides for a run

Custom Options

This function enables you to select rinse and blow options and modify the Slide Layout

Map. To activate an option click the corresponding check box.

Delayed Start Water Rinse:

For a delayed start, idle rinses may be performed with water or buffer. If this option is not

selected, buffer will be used for the idle rinse. Note: This option cannot be selected

when the No Pre-Rinse option is selected.

10 Autostainer Handbook

Page 19

Add Rinse to Protocol Steps:

When creating a new protocol template, a buffer rinse can be added automatically,

following each step. Select the Add Rinse to Protocol Steps option to automatically

add buffer rinses. If this option is not checked, the rinse step must be manually selected.

No Pre-Rinse:

When creating a new protocol template, the default pre-rinse step may be removed. If

this option is not checked, the protocol template will include a buffer rinse step.

Flex-time Blow:

When a blow instead of a rinse is required, this option enables Autostainer to perform

the blow without interrupting other functions.

Show Only Programmed Slides:

This option displays only the programmed slides on the Slide Layout Map.

Reagent Volume and Drop Zone Default

From the Initialize screen you can set the default reagent volume by clicking a raised

diamond next to the appropriate volume. Select the default drop zone by clicking the

desired area of the slide image. Select multiple drop zones by holding the CTRL key

while clicking drop-zone areas.

Clean

The Clean screen allows you to initiate a cleaning run. It gives a status report on the

number of slides processed since the last cleaning cycle and the total number of runs. It

also generates a cleaning log.

A cleaning run is recommended after 150 slides have been processed or after one week,

whichever comes first. Once the instrument has processed 150 slides, a message

prompts the user to clean the instrument. The software allows up to 200 slides to be run

between cleaning cycles to allow for flexibility in workflow. If more than 200 slides have

been run, the Program button becomes unavailable and the system does not allow

additional processing until the instrument is cleaned.

Sign Off and Help

Sign Off exits the program and Help displays information regarding Main Menu

features.

Reagent Tracking

The Reagent Tracking screen allows you to monitor the total volume of each reagent

used by the instrument, and generate reports that include all or specific reagents.

Autostainer Handbook

11

Page 20

Prime Pump

u

The Prime Pump screen is used to flush the intake tubing with buffer or DI water without

initiating an actual run. Frequently running fluid through the instrument keeps the

Autostainer running properly. Dako recommends priming the pumps weekly.

Programming Grid Overview

The Programming Grid is the main screen used to define slide information, primary

antibodies, staining reagents, and staining protocols.

Programming Grid

rows represent

individual slides

including complete

identification and all

reagents applied.

The grid can

accommodate 48

slides per staining

n.

r

Software

Version

Menu Bar

Slides – enter the number of slides for a run

File – general information such as opening, saving, and printing slide runs

Edit lists – establish lists of reagents for programming a staining protocol

Copy and Auto – items used during programming

Date/Time

User Name

** high security

* medium security

low security

Institution

Name

Serial

Number

Grid Header

lists the steps and

dispense volumes of

the selected protocol

template for the

current staining run.

Each column

represents one step

of the protocol

template.

Command Buttons:

Slide Info – enter or

edit individual slide

information.

Protocol Template –

select or create a

template to apply to the

current staining run.

Next – displays the

Slide Layout Map:

Program Slides screen.

Print – prints slide and

reagent labels, main

grid, IHC report,

reagent list, or Run

logs.

Exit – returns to Main

Menu without saving.

Help – information on

grid features.

12 Autostainer Handbook

Page 21

Section 4

Entering Slide Information

Slides can be programmed from the Programming Grid either through

menu bar for quick programming of total slide count, or through the Slide Info button for

entering specific slide identification information.

Adding Slides

The Slides option expedites programming by reducing the amount of information

required to program a staining run.

1. Select Slides on the menu bar. This function is used to bypass the Slide Information

screen when programming a staining run.

2. Enter the desired number of slides in the text box or use the scroll bar to select the

desired number of slides and click OK.

Note: Once a run has been set up using this function, slide, tissue, or doctor

information cannot be added to the run. Slide Identification, Case #, Block ID, Tissue,

or Doctor Name will not be associated/displayed in the Programming Grid when the

Slides function is used. If the Slide Info button is selected the Slide Count text box

appears rather than the Slide Information screen.

Slides on the

The Slide Info Button

The Slide Info button allows you to enter specific information for individual slides. The

fields displayed are determined during initialization.

1. Select the Program button on the Main Menu screen.

2. Select the Slide Info button on the Programming Grid and enter slide information.

Note: An entry is required to proceed from one field to the next. Each field requires

at least one key stroke. Type the specified information or press the SPACE BAR

before moving to the next field. The Slide/case field requires entry of the actual

number of slides.

3. Select the Finish Entry button or press ENTER until the Finish Entry button is

highlighted to complete the slide identification entry process. The Programming

Grid appears.

Autostainer Handbook

13

Page 22

Deleting Slides

Deleting Slides With the Slides Function

When using the

deleted if there is at least one entirely blank (unprogrammed) row. Select the

menu item, adjust the number of slides, and click OK.

Note: If all rows are programmed, the slide must be deleted from the Programming

Grid (see Deleting a Specific Slide, later in this section).

Deleting Slide ID Information Using the Slide Info Button

Deleting Slide Identification – deletes all slides associated with the selected slide

identification.

Deleting a Case Number – deletes all slides associated with the selected slide

identification’s case.

Deleting a Block ID – deletes all Block IDs associated with the selected case number.

1. Select the Slide Info button from the Programming Grid.

2. Press the DOWN ARROW key until the desired slide identification is highlighted in

the Slide ID field and press ENTER. The cursor moves to the Case # field. Select

additional criteria if needed.

3. Select the Delete button. A dialog box asks if you want to delete the selected slide

identification.

4. Select the Yes button. Select the Finish Entry button to save changes.

Deleting a Specific Slide

This method deletes one slide at a time.

1. On the Programming Grid left-click the slide number on the row representing the

slide. A dialog box asks if you want to delete the selected slide.

2. Select the Yes button and the selected slide is deleted from the current program.

Note: If slide labels have been printed, the reagent names are replaced with blank

tiles in the deleted slide row.

Slides option on the menu bar to program a staining run, a slide can be

Slides

Rearranging slide positions on the Programming Grid

1. On the Programming Grid right-click the slide number on the row representing the

slide.

2. Move the mouse pointer to the position where the slide is to be inserted and left-

click. The slide information is inserted in the new position.

14 Autostainer Handbook

Page 23

Section 5

Designing a Protocol

Protocol templates allow you to enter the series of steps required to stain a slide and

save the protocol for future use. Low level security does not allow creating or editing

protocol templates.

Standard Protocol Elements

Protocol elements are categories of reagents used to build the protocol outline in the

Protocol Template Design screen. Reagents can be added, deleted and edited by

choosing protocol element categories from the Edit Lists menu item on the

Programming Grid.

Endogenous Enzyme Block

Protein Block

Primary Antibody

Pretreatment

Secondary Reagent (e.g., biotinylated secondary antibodies or link)

Tertiary Reagent (e.g., enzyme-labeled streptavidin or label)

Labeled Polymer (e.g., used in the EnVision visualization systems)

Substrate-Batch

Substrate

Auxiliary (e.g., counterstain)

Autostainer Handbook

15

Page 24

Additional Protocol Elements

Rinse Buffer

A buffer rinse step consists of a buffer wash and air blow cycle and should be

programmed between each protocol template step. Each buffer rinse is displayed as

a blue droplet in the programming grid with a droplet icon in each programmed row.

The buffer icon appears on the Programming Grid printout as a filled-in droplet.

Rinse Water

A water rinse step consists of a water wash and air blow cycle. Each water rinse is

displayed as a white droplet in the programming grid with a droplet icon in each

programmed row. The water icon appears on the Programming Grid printout as a

white droplet.

Standard Rinse Replacement

The standard rinse cycle can be replaced by a blow only step (reagent is blown off

the slide but no buffer is applied) by right-clicking on the droplet icon in the

programming grid. The droplet icon is replaced by a wind symbol.

Substrate-Batch

This step splits the staining run into two distinct operations. The first includes all

steps prior to the application of the substrate, and the second groups all steps

starting with the substrate application. This feature allows you to use unstable

substrates that need to be prepared immediately prior to application. The Autostainer

stops after the steps in the first operation (non-substrate) are completed. An audible

signal indicates when the substrate should be loaded and the screen displays where

it should be placed (typically in position D8 of reagent rack a).

Note: The Substrate-batch step can only be used once in a Protocol Template.

Switch (*Switch)

This step programs the switching of waste disposal from one container to another for

the separation of hazardous from non-hazardous waste. The Switch step is

displayed in the Programming Grid as a skull-and-crossbones icon in each

programmed row. The Switch step can be used multiple times in any Protocol

Template. When programming successive switch steps, the skull-and-crossbones

icon alternates with a flower icon to indicate switching from hazardous to nonhazardous waste.

Note: The switch step must be preceded by a rinse step in the protocol template.

The first switch step in any protocol template is a switch to hazardous waste.

Creating and Editing a Protocol Template

Note: Template names must contain eight or fewer alpha-numeric characters, and no

symbols or spaces should be used.

1. Select the Protocol Template button on the Programming Grid. The Protocol

Template Design screen appears with the default protocol template displayed in the

Protocol Outline column.

2. Select the New Template button. The default protocol template is replaced by the

default first step (rinse buffer) of the new template.

16 Autostainer Handbook

Page 25

Note: If No Pre-rinse is selected at the Options screen, the first rinse buffer is not

displayed (See Initializing, Section 3).

3. Build the new protocol template from the Protocol Elements list. Click on a reagent

in the list, the item is copied to the Protocol Outline list and sequentially numbered.

Note: If Add Rinse to Protocol Steps is selected at the Options screen, rinses are

automatically added after each step, except following a substrate step.

4. To delete a step, select it in the Protocol Outline list. The name is outlined. Select

the Delete Step button.

5. Additional steps can be inserted in the Protocol Outline by highlighting a step and

clicking on the desired step from Protocol Elements. The selected step will be

inserted above the highlighted area in the Protocol Outline.

Note: The Autostainer can accommodate protocol templates containing as many as

35 steps (including rinse steps between reagent incubations).

6. Protocol templates can be used with or without saving. To save a newly created

template select the Save button on the Protocol Template Design screen. The

Save Template window appears with the cursor in the File Name box.

Deleting a Protocol Template

1. Select the Protocol Template button on the Programming Grid.

2. Select the Get Template button and click on the file name of the desired template.

3. Click the Delete Template button. A message asks if you want to delete the selected

protocol template. Click the Yes button.

Note: If the default template is deleted, a new template must be selected from the

Get Template window and saved as the default template.

Using a New Protocol Template Without Saving

1. After a Protocol Template has been created or modified, click the Use Template

button in the Protocol Template Design screen. A dialog box asking “Save on disk

now?” is displayed.

2. Select No and the Programming Grid appears with the new protocol template in the

header row.

Note: If a staining run had already been programmed and the new protocol template

omits previously programmed steps, a warning message is displayed stating that

programmed steps will be discarded if the new protocol template is applied.

Using a Saved Protocol Template

1. Select the Protocol Template button in the Programming Grid.

2. Select the Get Template button, select the template from the choices in the list, and

click OK.

Autostainer Handbook

17

Page 26

3. Click the Use Template button. The Programming Grid appears with the selected

protocol template displayed in the grid header.

Using a Saved Protocol Template for a Specific Auto Program

Auto Programming is a feature for making slide programming more efficient (see

Programming a Staining Run, Section 6).

1. Select the Protocol Template button in the Programming Grid.

2. Select the Get Template button.

3. Select the Auto File check box.

4. Select the desired Auto Program by clicking on it and click OK.

5. Click the Use Template button in the Protocol Template Design screen. The

Programming Grid appears with the selected protocol template displayed in the grid

header.

Selecting Reagent Dispense Volume for All Steps in a Protocol

1. Select the Reagent Volume button in the upper-right corner of the Protocol

Template Design screen. A dialog box with the dispense volume choices for the

selected reagent step appears.

2. Select the raised diamond next to the appropriate volume and click OK. The selected

volume is applied to all steps in the protocol template.

3. Click the Use Template button. A message asks “Save on Disk now”. Select the Yes

button, enter a template name and click OK. Select the No button to use the

template without saving the change. The newly selected dispense volume is

displayed in the grid header of the Programming Grid.

Selecting Reagent Dispense Volume for a Specific Step in a

Protocol

1. Select a protocol template step in the Protocol Outline list to assign a new reagent

dispense volume.

2. Select the Reagent Volume button in the upper-right corner of the Protocol

Template Design screen. A dialog box with the dispense volume choices for the

selected reagent step appears.

3. Select the desired reagent dispense volume by clicking on the raised diamond next

to the appropriate volume and click OK. The selected volume is applied to the

specific step in the Protocol Template.

4. Click the Use Template button. A message asks “Save on Disk now”. Select the Yes

button, enter a template name and click OK. Select the No button to use the

template without saving the change. The newly selected dispense volume is

displayed in the grid header of the Programming Grid.

18 Autostainer Handbook

Page 27

Section 6

Programming a Staining Run

The Autostainer can process a maximum of 48 microscope slides in a single staining

run. Each slide can be stained using an independently designed protocol. After the slide

information is entered and protocol template is selected, specific reagents are assigned

to each slide. This is accomplished from the Programming Grid. The following section

describes how to program specific reagents for a staining run.

Each row

represents one

slide and its

information.

Reagents that

are available for

the highlighted

step.

Defining Detection Reagents

Before you can program specific reagents for slides, you must enter slide information

and select a protocol template as described in Section 4 and Section 5. The

Programming Grid is displayed listing the slides identified during Slide Count or Slide

Information entry. The first programmable field is highlighted and a list of available

reagents for the step is displayed.

1. Select a reagent using the UP and DOWN arrow keys and insert the reagent by

pressing ENTER. A message asks, “Assign to the following unprogrammed slides?”

2. Select Yes to assign the selected reagent to the remaining slides in the grid and the

next programmable step is highlighted. Select No and the reagent is assigned to only

the highlighted step.

3. After all reagents are programmed, click the Next button. The system checks the grid

for missing rinses. If a rinse is missing between two reagents, a message asks if you

want to continue.

Autostainer Handbook

19

Page 28

4. Select Yes and, if the program is new, a dialog box prompts “Save program on

disk?” Otherwise, the Slide Layout Map screen appears. Select Back to Grid to

return to the Programming Grid and the missing rinse appears in the grid.

Defining Primary Antibodies

Each primary antibody reagent is programmed individually and will appear in the

Programming Grid with its programmed pretreatment (see Reagent Management,

Section 7). Primary antibodies and/or pretreatments can be manual steps and are noted

on the Programming Grid and printouts. If a reagent is a manual step (i.e., overnight

incubation, target retrieval, etc.), then it is performed before the slides are loaded.

Note: A primary antibody’s pretreatment automatically appears with the primary antibody

only if the protocol template contains a pretreatment protocol element (see Designing a

Protocol, Section 5).

1. Enter slide information, select a protocol template, and add necessary detection

reagents. When the first programmable Primary Antibody is highlighted, a list of

available Primary Antibodies for the step is displayed.

2. Select the desired antibody from the list using the UP and DOWN arrow keys on the

keyboard and press ENTER.

Note: To make a pretreatment a manual step, right-click on a pretreatment. The list

of available pretreatments is displayed. Select the desired pretreatment from the list.

3. Universal negative controls and previously assigned and saved matched negative

controls are listed at the end of the primary antibody list and are accessed on the

keyboard by pressing the SHIFT key and typing “_”. Once the correct negative

control is selected, press ENTER and the selected negative reagent and

pretreatment will appear in the Programming Grid.

4. Select the Next button, the system checks the grid for missing rinses. If a rinse is

missing between two reagents, a message asks if you want to continue.

5. Select Yes and, if the program is new, a dialog box prompts “Save program on

disk?” Otherwise, the Slide Layout Map screen appears. Select No to return to the

Programming Grid and the missing rinse appears on the screen.

Assigning Positive and Negative Control Reagents

Positive and negative control reagents can be automatically added for each primary

antibody that is added to the Programming Grid. The controls are added as new slides

and contain the matching detection reagents of the test specimen.

20 Autostainer Handbook

Page 29

Adding Positive and Negative Control Reagents

1. Enter Slide Information and select a protocol template. A minimum of one slide must

be programmed through Slide Count or the Slide Information screen. Click OK or

the Finish Entry button.

2. Fill in Programming Grid columns with specific reagents for one slide. After the

primary antibody is applied, Neg.Ctl and Pos.Ctl buttons display in the menu bar.

Continue entering the detection reagents.

3. To insert a matching positive control, click the Pos.Ctl button. One slide will be

added to the Programming Grid with reagents that match the last programmed

slide. In the slide number column, PC appears signifying a positive control reagent.

Negative Controls

Two options are available for Negative Controls:

Unique negative controls for each primary antibody.

Universal Negative Controls that use a generic negative control for all antibodies of a

certain species. The Autostainer uses two different types of negative control, N series

(mouse and rabbit) and NP series (mouse and rabbit). The Neg.Ctl button automatically

assigns the appropriate universal negative control such as, UNC for N series antibodies

or UNC+ for NP series antibodies. The NP series is used with higher sensitivity kits like

EnVision+, LSAB+.

Dako Universal Negative Controls (UNC) are available for ready-to-use antibodies. If the

Universal Negative Control option is chosen, all matching negative controls designated

as “_NC” (i.e., NCVimentin) on the primary antibody list must be deleted from the

reagent list.

Note: If you require assistance deleting the matched negative controls, please contact

your Dako representative.

Assigning Negative Control Type to Antibodies

1. From the Programming Grid select Edit Lists from the menu bar.

2. Select the Primary Antibody category from the reagents list.

3. Select a previously defined antibody or add a new antibody to the list.

4. Enter the correct compatibility code for the antibody (see Compatibility Check in

Section 7).

5. Select UNC or UNC plus from the Neg.Ctl Type field to assign a Universal Negative

Control.

Using the Negative Control Tool

To insert a Universal Negative control, click the Neg.Ctl button in the Programming

Grid.

Note: The Neg.Ctl tool selects one of the four Universal Negative Controls based on the

compatibility and negative control type defined for the primary antibody. If the primary

Autostainer Handbook

21

Page 30

antibody does not have either a compatibility or negative control type defined, an error

appears stating that there is no matching negative control reagent.

Note: If you do not wish to use this feature noted above, then continue programming as

usual. This feature is not active when using Auto Program.

Defining Specific Rinses

A rinse is automatically added following every programmed reagent (except for Protein

Block, where a blow step is added) when assigned as described above. The type of

rinse is selected in the Protocol Template screen (see Designing a Protocol, Section 5).

The type of rinse can also be changed from the Programming Grid.

Click an activated tile in a rinse column. Click again to change the rinse to a different

selection: rinse buffer, rinse (DI) water, blow, or none.

Note: Rinses that precede a switch cannot be changed from the Programming Grid.

The rinse at the end of a run cannot be changed into a blow step.

Auto Programming

Auto Programming is a feature to make slide programming more efficient. This function

is used to save all or any portion, of a protocol to be used in future programming. An

Auto Program can consist of one or more rows of programming. Low level security does

not allow access to creating and saving Auto Programs.

1. Enter Slide Information and select a protocol template. A minimum of one slide must

be programmed through Slide Count or the Slide Information screen. Click OK or

the Finish Entry button.

2. Fill in the Programming Grid columns with specific reagents, except primary

antibody, for one of the programmed slides.

Note: This creates an Auto Program for the detection reagents only. To create an

Auto Program for a protocol that includes the primary antibody, enter specific primary

antibody and detection reagents in the programming grid columns.

3. Select Auto from the menu bar on the Programming Grid.

4. Select Setup from the Auto menu. Auto changes to Setup on the menu bar.

5. Select one or more rows of programmed tiles by clicking on the first row. Click and

drag to select additional rows. Each selected row is highlighted. Release the mouse

button and the Save Auto Program window appears.

6. Enter a file name for the saved protocol. The Auto Program file name must contain

eight or fewer alpha-numeric characters, and no symbols or spaces can be used.

Select the OK button.

7. Select Setup from the menu bar. Setup changes to Auto and exits the Auto

Program function.

Note: To use a saved Auto Program, the template you are programming must

contain the same protocol elements, listed in the same order, as the saved Auto

Program. To find the correct protocol template, use the Auto file function. The

dispense volumes do not have to be the same.

22 Autostainer Handbook

Page 31

Deleting an Auto Programming Item

1. Select Auto from the menu bar on the Programming Grid.

2. Select Setup from the Auto menu. The word Auto changes to Setup.

3. Select any activated tile in the Programming Grid to display the Save Auto

Program window.

4. Click the Auto Program to be deleted.

5. Click the Delete Program button.

6. Click the Yes button to delete the program.

Using an Auto Programming Item

1. Select Auto from the menu bar in the Programming Grid.

2. Select Program from the Auto menu.

3. Select a tile in the row where the Auto Program is to be inserted. A list displays the

saved Auto Program files that can be assigned for this slide.

4. Select the desired Auto Program file name to insert the program.

5. If the Auto Program does not contain a primary antibody, a message prompts

“Assign to all following slides.”

6. Click Yes to assign the Auto Program to all unprogrammed slides. Click No to assign

the Auto Program to only this slide.

Note: Skip is the first item in the Auto Program list. Select this option when you

want to leave a slide unprogrammed.

7. Select Program.

8. Click the Next button. The system checks the grid for missing rinses. If a rinse is

missing between two reagents, a message asks if you want to continue.

9. Select Yes and, if the program is new, a dialog box prompts “Save program on

disk?” Otherwise, the Slide Layout Map screen appears. Select No to return to the

Programming Grid and the missing rinse appears in the grid.

Copy/Paste

1. The Copy/Paste feature copies reagents from one slide to another during slide

programming.

2. Select Copy from the menu bar on the Programming Grid. The word Copy

changes to Select.

3. Use the mouse pointer to select the steps to be copied by clicking and dragging

across the desired tiles. Once the tiles or rows have been highlighted, the word

Select will change to Paste.

4. Click in the area where you wish to insert the copied selection.

Note: Copied rows can only be pasted under the same heading and cannot be

pasted over areas that are currently highlighted.

5. Select Paste on the menu bar to deactivate the Copy function.

Autostainer Handbook

23

Page 32

Editing a Protocol Step

The Autostainer software provides multiple methods for editing the reagents in a defined

staining run from the Programming Grid.

Changing a reagent for a step:

1. Click the reagent step you wish to change.

2. Select the desired reagent from the list. The new reagent is displayed for the step.

Replacing a reagent with skip step (no reagent added to slide):

1. Click the reagent step you wish to change.

2. Select the word None.

Editing a reagent in a staining step for one run only:

1. To edit a reagent in a staining step, or to use a reagent not listed in the reagent list,

click the appropriate step.

2. Select Edit Slide from the reagent list. The Edit Individual Slide Reagent window

displays the information associated with the reagent.

Note: Lot and date cannot be edited here and are grayed out. The reagent long

name, short name, compatibility, and incubation time can be edited.

3. Add a new reagent by entering the appropriate information.

4. Select the OK button. The new reagent is added for the current staining run only and

will not be added to the available list of reagents for this step.

Note: Do not use symbols when entering reagent information. Doing so may cause

errors during the run.

Printing Options

Autostainer allows you to print slide and reagent labels as well as reports that include

information regarding programs, runs, and stored reagents.

Slide Labels

1. Select the Print button at the bottom of the Programming Grid screen. The Which

Report screen displays seven options.

2. Select the Slide Labels button.

3. To print all slide labels for the program, select the All Labels button. The slide label

format is determined by the Design Slide Label screen that is accessed from the

Initialize screen (see Initializing, Section 3).

4. To print a range of labels, type the range of labels with a hyphen between the

starting and ending numbers in the range (i.e., 5-12). To print individual labels, type

the label number with commas between each number (i.e., 1,14,22). Both formats

can be used to print a combination of a range of labels with individual labels (i.e., 512,14,22). Do not use a space between numbers.

24 Autostainer Handbook

Page 33

Reagent Labels

Printing reagent labels from a programmed run:

1. Program or retrieve a previously saved run on the Programming Grid, and select

the Print button.

2. The Which Report screen appears, click the Reagent Labels button.

3. To print all reagent labels, select the Print All button.

4. To print specific reagents, click the desired reagents and select the OK button.

Printing reagent labels not associated with a specific program:

1. From the Programming Grid select the Print button.

2. The Which Report screen appears, click the Reagent Labels button.

3. The Print Reagent Labels screen appears.

4. Select the Other Reagents button.

5. To print all reagent labels, select the Print All button.

6. To print specific reagents, click the desired reagents and select the OK button.

Reports

Program

Grid Report

IHC Report Groups all slides by case number and includes slide numbers, primary

Run Log

Report

1. From the Programming Grid, select the Print button.

2. Select the Program Grid, IHC, or Run Log button.

Prints the Programming Grid including all slide information, protocol

headings, specific reagents, institution information, user, date printed,

number of slide ID’s, number of case numbers, and the Autostainer serial

number.

antibody information, and name and incubation time for all reagents used.

Prints each step performed during a run.

Viewing Programmed Slides

When reagent programming is complete, the first Slide Layout Map appears. The Slide

Layout Map screen is a representation of all 48 slides as they would be viewed facing

the front of the Autostainer. The dispense volume and drop zone(s) for each slide can be

changed on this screen. The location for reagent dispense is displayed by a yellow

highlight.

Autostainer Handbook

25

Page 34

Assigning Reagent Dispense Locations

The non-frosted area of each slide is equally divided into three horizontal sections – or

dispense locations. Each slide can have one to three dispense locations, and the

maximum dispense volume of a slide cannot exceed 800 µL. The default dispense

location is programmed during initialization. Modifications to the dispense volume or

dispense location of a slide in the Slide Layout Map: Program Slides will change the

text color of that slide from black to red in the Slide Layout Map.

Printing a Slide Layout Map

The Slide Layout Map provides a record of reagent dispense volume and dispense

location. It is useful for ensuring that slides are loaded correctly.

1. Select the Next button on the Reagent Layout Map (see Section 8).

2. Select the Print button.

Selecting a new reagent-dispense location for all slides:

1. Select the All Slides tool in the upper left corner of the Slide Layout Map: Program

Slides.

2. Click the desired location on the slide to select a new reagent dispense location.

3. To assign multiple dispense locations on the All Slides tool, press and hold the

CTRL key while clicking on the desired dispense locations.

4. Click the dispense volume. A message displays the dispense volume choices.

5. Select the diamond next to the desired dispense volume.

6. Select the OK button or press ENTER.

7. The Slide Dispense Tool enables the user to make these changes for a specific

slide. The Slide Dispense Tool button tool functions identically to the All Slides tool

except the user is able to manipulate drop zone and reagent application amounts to

only the selected slide.

26 Autostainer Handbook

Page 35

Section 7

Reagent Management

Reagent lists are created and modified using the commands on the Edit Lists menu on

the Programming Grid.

Adding Detection Reagents (Secondary, Tertiary, Substrate, etc.)

1. From the Programming Grid select Edit Lists from the menu bar.

2. Select the reagent category from the list.

3. Enter the full name of the reagent you want to add to the current list and press

ENTER. The software allows the entry of 33 alpha-numeric characters for detection

reagents. No symbols can be used in the reagent Long Name field.

4. Enter an abbreviated name for the reagent in the Short Name field and press

ENTER. The abbreviated name cannot exceed 10 alpha-numeric characters and

should be unique to distinguish it from other reagents. No symbols can be used in

the reagent short name. The cursor moves to the Compatibility field.

5. Enter the correct compatibility code and press ENTER. Assigning compatibility

information to reagents is optional (See Compatibility Check at the end of this

section).

6. Enter the reagent lot number and press ENTER. The lot number cannot exceed 8

alpha-numeric characters. Lot number information is optional.

7. Enter the reagent expiration date and press ENTER. The reagent expiration date is

optional. Use MM/YY format.

Note: All expiration dates are limited to a maximum of 10 years from the date of

entry.

8. Enter the reagent incubation time and press ENTER. Follow steps 3-8 until all

reagents have been added.

Note: A minimum of two minutes incubation time is required for proper operating

conditions.

9. Select the OK button to add the new reagent(s) to the Reagent List.

Autostainer Handbook

27

Page 36

Adding Primary Antibodies

A primary antibody can be added to the reagent list with a related pretreatment reagent.

This facilitates automatic selection of the pretreatment whenever a primary antibody is

selected from the Programming Grid.

1. Follow the same steps as in the Adding Detection Reagents section.

Note: To add a matching negative control use exactly the same name as the positive

control and add the prefix “_NC” to the beginning of the reagent name.

2. If the primary antibody is a step that is preformed off the Autostainer (i.e., overnight

incubation) or requires heating, check the Manual Step check box by pressing the

SPACE BAR.

3. Enter the correct compatibility code and press ENTER. Assigning compatibility

information to reagents is optional (see Compatibility Check at the end of this

section).

4. Select the pretreatment from the box by using the UP and DOWN arrows, or type a

new pretreatment name, and press ENTER

Note: If Manual Step is selected, the incubation time will be “0”. Do not change this

time.

Editing and Deleting Reagent Lists

1. From the Programming Grid select Edit Lists on the menu bar.

2. Select the reagent category from the list.

3. Edit fields by highlighting the information and typing over it. When changing the

reagent name, the software saves the change as a new reagent.

4. To delete, click the Delete button.

5. Select the OK button.

Updating a Reagent Lot Number and Expiration Date

1. From the Programming Grid select Edit Lists on the menu bar.

2. Select the reagent category from the list, and choose a specific reagent.

3. Highlight the current lot number displayed in the lot box. Type the new lot number

and the Change button appears.

4. Highlight the date displayed in the box and enter the new expiration date.

5. Click the Change button – all fields clear.

6. Select the OK button until a dialog box prompts “Save changes on disk?”

7. Select Yes to save the new lot number and expiration date. Select the No button and

the reagent is not edited.

28 Autostainer Handbook

Page 37

Compatibility Check

A compatibility check is included to minimize programming errors resulting from

assigning incompatible reagents (such as alkaline phosphatase-labeled streptavidin and

DAB substrate) to a slide protocol. This feature has two check levels. The first check is

for the species reactivity compatibility of the primary antibody and the secondary

reagent. The second addresses the compatibility rules dictated by the enzyme used in

the detection system. The following tables summarize the compatibility rules and codes

assigned to each reagent type.

Every reagent in the reagent categories list (or Protocol Element) can be programmed

with an appropriate compatibility code or combination of codes. For example, a linking

reagent that reacts with mouse and rabbit antibodies can be marked with compatibility

code AB. The software verifies that these compatibility rules are not violated during the

programming of a staining run. If an incompatible reagent is assigned to a tile in the

programming grid, a message displays the two reagents that are incompatible.

Species Reactivity

Reagent Type

(Protocol Element)

Primary Antibody Monoclonal primary antibodies raised in

mouse (e.g., mouse anti-human)

Primary Antibody Polyclonal primary antibodies raised in

rabbit (e.g., rabbit anti-human)

Secondary Reagent Secondary reagents (antibodies)

compatible with monoclonal antibodies

raised in mouse (e.g., biotinylated antimouse IgG)

Secondary Reagent Secondary reagents (antibodies) reacting

with polyclonal antibodies raised in rabbit

(e.g., biotinylated anti-rabbit IgG)

Secondary Reagent Secondary reagents (antibodies) reacting

with both monoclonal and polyclonal

antibodies raised in mouse or rabbit,

respectively

Enzyme System Compatibility

Reagent Type

(Protocol Element)

Endogenous Enzyme Block, HRP-compatible X

Endogenous Enzyme Block, AP-compatible Y

Tertiary Reagent HRP-labeled streptavidin X

Tertiary Reagent AP-labeled streptavidin Y

Substrate HRP-compatible substrates (e.g., DAB, AEC) X

Substrate AP-compatible substrates (e.g., Fast Red,

New Fuchsin)

Description Compatibility

Code

A

B

A

B

AB

Description Compatibility

Code

Y

Autostainer Handbook

29

Page 38

30 Autostainer Handbook

Page 39

Section 8

Loading Reagents

After programming is complete, the Autostainer calculates the time required for the

staining run, the amount of wash buffer or deionized water required, and the most

efficient placement for the reagent vials.

Reagent Layout Map Screen

The Reagent Layout Map documents the rack positions of the reagents including the fill

volume needed for completing the staining run. It displays a maximum of 32 reagent

vials per rack. The abbreviations for the reagents are displayed in their appropriate

alpha-numeric rack positions.

Each reagent position is color coded to correspond to Dako reagent colors and the

colors from the Programming Grid. If more than 32 reagent vials are required, a

Second Rack button becomes available.

1. Select the Next button in the Slide Layout Map: Program Slides, a message asks,

“Save program on disk?”

2. Select No and the Reagent Layout Map appears.

3. Load the reagent vials according to the reagent map. The reagent volume displayed

includes a dead volume of at least 200 µL.

4. Make sure that enough reagent is in the vials to complete the programmed run and

that the reagent rack is properly seated in its correct location.

Autostainer Handbook

31

Page 40

5. Check that the reagent vials have no bubbles on top of the solution. Remove any

bubbles.

Missing Reagent Notice

The Autostainer displays a prompt when an insufficient volume of reagent is detected.

You can pause the system to add more reagent to the specified vial. If sufficient volume

of a reagent is not available, and you do not respond to the alarm, the Autostainer

continues the run and provides a list of skipped or partially applied slides on the Run

Log.

To program the system to check for sufficient volumes at the start of the run, select the

Check Volumes option on the Set Start Time screen (see Starting a Run, Section 9).

32 Autostainer Handbook

Page 41

Section 9

Loading Slides

After programming is complete and the reagents are loaded, you are ready to load the

slides on the slide racks. Print the Slide Layout Map: Load Slides screen by selecting

the Print button at the bottom of the screen. This map provides a guide for loading slides

and can be saved as part of your staining record.

Note: Soak slides in a buffer solution containing 0.05% Tween-20 for a minimum of five

minutes prior to loading the Autostainer.

Load Slides

Autostainer has four slide racks that hold up to twelve slides each. Slide racks 1-4 have

slide positions 1-12, 13-24, 25-36, and 37-48, respectively. The first rack is located

toward the front of the instrument. Racks two, three, and four are located behind the first.

1. Load slides into the racks by inserting the label end of the slide (with the specimen

facing up) into a slide clip. The rack may be positioned in the angular setting to

facilitate slide loading.

2. Load each slide, in numerical order from left to right, into the slide rack according to

the Slide Layout Map: Load Slides printout.

3. Once all of the slides have been loaded into their correct slide positions and the slide

racks are properly positioned on their locating pins, gently pour buffer over the slides

to keep them from drying out. For best results, pour buffer over the slide label

instead of directly over the specimen. The buffer will then flow over the specimen

without washing it off.

Note: When the slides have been loaded, put the rack back to its horizontal position.

Autostainer Handbook

33

Page 42

34 Autostainer Handbook

Page 43

Section 10

Starting a Staining Run

Preparing the System for a Staining Run

After the specimen-containing slides and reagent vials are loaded, perform the following

checklist:

Slides

• Deparaffinized and rehydrated, soaking in buffer containing 0.05% Tween 20

using a squirt bottle to prevent slides from drying while loading additional slides.

• Seated securely in slide rack.

Racks

• Properly seated in the Autostainer.

Reagents

• At room temperature.

• Placed at proper locations in the reagent racks.

• Contain no air bubbles.

• Contain at least the reagent volume in each vial as specified in the Reagent

Layout Map.

Buffer

• Contains at least the volume of buffer indicated in the Reagent Layout Map plus

any additional volume listed for the completion of a delayed run.

Water

• Contains at least the volume of water indicated in the Reagent Layout Map.

Waste Containers

• Have enough room to accommodate the volume of buffer and water used during

the staining run.

Quick Start

1. Turn on the computer system. Double-click the Autostainer icon.

2. Enter User Name and password and press ENTER.

3. Select the Program button on the main menu.

4. Select Slides from the menu bar. (To enter information for a specific slide see

Section 4.)

5. Enter the slide count for the staining run and click OK.

Note: Skip steps six and seven if you are using the default template.

Autostainer Handbook

35

Page 44

6. Select the Protocol Template button and select a protocol template for the run.

7. Select the Use Template button. The Programming Grid appears with the selected

protocol.

8. Select the desired volume and drop zones for either all slides, or on an individual

side basis.

9. Assign specific antibodies and reagents to all slides and select the Next button. The

Slide Layout Map: Program Slides screen appears.

10. Select the Next button and the Reagent Layout Map appears.

11. Load reagents using the Reagent Layout Map. Check water and buffer volume, and

make sure you have enough space for waste.

12. Select the Next button. The Slide Layout Map: Load Slides screen appears.

13. Load slides using the Slide Layout Map: Load Slides screen.

14. Click the Next button.

15. The Set Start Time screen appears. The system calculates the run time and amount

of buffer and DI water needed to complete the run.

16. Select the Prime Pump (Water) button, and click OK.

17. Select the Prime Pump (Buffer) button.

18. Set reagent levels to Check Volumes or Do Not Check Volumes.

19. Select the Start Run button.

Run Log Screen

During a staining run the Run Log screen is updated with each step performed.

• The New Program button is used to program a new run while the current run is

in process.

• The Review Program button is used to return to the Programming Grid to view

the run in progress.

• The Emergency Stop button can be used to stop a run at any time.

Shutting Down the Autostainer

1. Select the Sign Off button on the Main Menu.

2. A message prompts, “Quit using Autostainer?” Select the Yes button.

3. Shut down the computer.

36 Autostainer Handbook

Page 45

Section 11

Maintenance and Troubleshooting

The Autostainer should be cleaned after 150 slides have been processed or after one

week, whichever comes first. The instrument keeps track of the number of staining runs

performed and displays a maintenance message listing the number of slides since the

last cleaning cycle.

Note: Please contact your Dako representative regarding maintenance details.

Troubleshooting

Problem Possible Cause Course of Action

Autostainer will not turn on (top

green LED not on). Message

displays “Instrument Not On” when

a run is started.

The Autostainer does not respond

when you initiate a prime pump or

a run (bottom LED not on).

Message displays “Instrument Not

On” when a run is started.

Autostainer suddenly stops during

a run.

Buffer or DI Water does not flow

out during a run or a prime.

Not enough buffer or DI

Bent or pinched tubing.

The Autostainer is

unplugged at the power

source.

The cable between the

Autostainer and the

computer is not connected

properly.

The Autostainer will stop

frequently during the run.

This is due to set

incubation times. Check

the run log to verify.

Autostainer was not primed

properly.

water in the appropriate

reservoir.

Check the power cord

connections and verify the

surge protector is plugged in

and turned on.

Shut down the system and

turn the power off. Disconnect

and reconnect the cable

between the Autostainer and

the computer.

Please use caution. Pins

can be bent and cause

damage to the instrument

during operation.

No action is needed. The

Autostainer will resume

movement. Check Run Log

screen.

Prime pump. Pump may need

to be activated several times.

Fill the reservoir with the

proper level of fluid. Then

prime the pump.

Straighten out the tubing and

prime the pump.

Autostainer Handbook

37

Page 46

Problem Possible Cause Course of Action

Buffer or DI Water does not flow

out during a run or a prime. (Cont.)

Inlet filters are clogged and

Tubing not completely

Faulty buffer / DI water

All waste collects into one waste

container.

Waste tubing not placed in

Faulty waste pump.