Daikin VKM50GBMV1, VKM80GBMV1, VKM100GBMV1, VKM50GBV1, VKM80GBV1 Installation manuals

...

Total Heat Exchanger

INSTALLATION MANUAL

English

Heat Reclaim Ventilator -with DX Coil-

MODELS

(Ceiling mounted duct type)

With DX coil & HumidifierWith DX coil

VKM50GBMV1 VKM50GBV1

VKM80GBMV1 VKM80GBV1

VKM100GBMV1 VKM100GBV1

Heat Reclaim Ventilator

Heat Reclaim Ventilator

Please read this installation manual carefully and install the unit properly to keep it at full capacity for a long time.

Please provide some necessary parts, for example round hoods, air suction/discharge grilles etc., before the installation of the unit.

Wärmerückgewinnungslüftung

Lesen Sie dieses Installationshandbuch bitte sorgfältig durch, und installieren Sie die Einheit korrekt, so daß sie ihre Leistungsfähigkeit

noch lange Zeit behält.

Einige erforderliche Teile wie z. B. Rundkappen, Luftansaug-/Lufausblasgitter müssen bereits vor der Installation der Einheit vorhanden

sein.

Ventilateur Récupérateur de Chaleur

Veuillez lire attentivement ce Manuel d’installation et installer correctement l’appareil de manière à ce qu’il puisse être utilisé pendant

une longue période de temps sans aucun dérangement.

Veuillez vous procurer certains éléments nécessaires, tels que des capuchons de formes arrondies, des grilles d’aspiration/évacuation

d’air.,avant l’installation de cette unité.

Ventilación con recuperación de calor

Por favor lea cuidadosamente el manual de instalacion e instale correctamente la unided para que pueda conservar su plena capacidad

durante un largo periodo.

Por favor, antes de proceder a la instalacion de la unidad, proporcione las piezas necesarias, por ejemple tapas redondas, rejillas de

aspiracion y de impulsion de aire, etc.

Ventilatore a recupero di calore

Leggere attentamente questo mauale ed installare correttamente l’unit in modo da farla funzionare a lungo al massimo delle sue capacita.

Prima dell’installazione, è opportuno disporuno delle partinec-essarie, come ganci arrotondati, griglie di aspirazione/di mandata, ecc.

Εξαεριστήρας με Ανάκτηση Θερμότητας

Διαβάστε προσεκτικά το παρόν εγχειρίδιο εγκατάστασης και εγκαταστήστε σωστά τη μονάδα για να διατηρήσετε την πλήρη

απόδοσή της για πολύ καιρό.

Προμηθεμτείτε μερικά απαραίτητα εξαρτήματα π.χ. κυκλικά καλύμματα, εσχάρεξ αναρρόφησης/κατάθλιψης κ.τ.λ. πριν

εγκαταστήσετε τη μονάδα.

Hergebruik van Warmte

Lees eerst zorgvuldig deze installatiehandleiding en installeer de unit op de juiste manier, zodat deze gedurende lange tijd zijn volledige

vermogen kan leveren.

Zorg dat alle componenten aanwezig zijn, zoals ronde kappen, luchtaan-en afvoerroosters etc. voordat u de unit gaat installeren.

Ventilação de Recuperação Térmica

Leia atentamente este manual e instale correctamente esta unidade para que esta funcione inteiramente durante um longo período de

tempo.

Adquira algumas peças necessárias, por exemplo, tampas redondas, grelhas de aspiração/exaustão, etc., antes da instalação da unidade.

Вентилятор с рекуперацией тепла

Внимательно ознакомьтесь с данным руководством и установите блок надлежащим образом, чтобы он работал на полную мощность в течение

долгого времени.

Перед установкой блока подготовьте необходимые детали, например колпак округлой формы, решетки всасывания/выпуска воздуха и т.п.

Deutsch

Français

Español

Italiano

Ελληνικά

Nederlands

Portugues

Рссий

With DX coil & Humidifier VKM50GBMV1

WARNING

CAUTION

VKM80GBMV1

VKM100GBMV1

With DX coil VKM50GBV1

VKM80GBV1

VKM100GBV1

CONTENTS

1 SAFETY PRECAUTIONS ...............................................1

2 BEFORE INSTALLATION ...............................................2

3 SELECTING INSTALLATION SITE.................................3

4 PREPARATIONS BEFORE INSTALLATION ...................4

5 THE METHOD OF INSTALLATION ................................ 4

6 DRAIN PIPING AND WATER SUPPLY WORK...............5

7 REFRIGERANT PIPING WORK.....................................6

8 DUCT CONNECTION.....................................................8

9 ELECTRIC WIRING WORK............................................ 8

10 WIRING EXAMPLE AND HOW TO SET THE REMOTE

CONTROLLER ............................................................... 9

11 FIELD SETTING AND TEST RUN................................13

The original instructions are written in English. All other languages are translations of the original instructions.

1 SAFETY PRECAUTIONS

Be sure to follow this “SAFETY PRECAUTIONS”. This product comes

under the term “appliances not accessible to the general public”.

This manual classifies the precautions into WARNINGS and CAUTIONS. Be sure to follow all the precautions below: They are all

important for ensuring safety.

WARNING..............Indicates a potentially hazardous situ-

CAUTION

•

After the installation is completed, test the Heat Reclaim Ventila-

...............Indicates a potentially hazardous situa-

tor unit and check if the Heat Reclaim Ventilator unit operates

properly. Give the user adequate instructions concerning the use

and cleaning of the Heat Reclaim Ventilator unit according to the

Operation Manual. Ask the user to keep this manual and the

Operation Manual together in a handy place for future reference.

•

Ask your local dealer or qualified personnel to carry out

installation work. Improper installation may result in water

leakage, electric shocks or a fire.

•

Installation should be done following the installation manual and

no changes should be made to the unit.

Improper installation may result in water leakage, electric shocks

or a fire. Injuries may result if the Heat Reclaim Ventilator unit falls.

•

Install the Heat Reclaim Ventilator unit on a foundation that can

withstand its mass.

Insufficient strength may result in the Heat Reclaim Ventilator

unit falling down and causing injury. In addition, it may lead to

vibration of indoor units and cause unpleasant chattering noise.

•

Do not allow exhaust air to enter the outside air intake vent.

This may cause the air of the room to become contaminated,

harming the health.

•

Locate the outside air intake vent so that it does not take in

exhaust air which contains combustion air, etc.

Incorrect installation may cause a loss of oxygen in the room,

leading to serious accidents.

•

Make certain that all electrical work is carried out by qualified

personnel according to the applicable legislation (note 1) and

this installation manual, using a separate circuit.

In addition, even if the wiring is short, make sure to use a wiring that has sufficient length and never connect additional

wiring to make the length sufficient. Insufficient capacity of

ation which, if not avoided, could result

in death or serious injury.

tion which, if not avoided, may result in

minor or moderate injury. It may also be

used to alert against unsafe practices.

Total Heat Exchanger

Heat Reclaim Ventilator -with DX Coil-

Installation

manual

the power supply circuit or improper electrical construction

may lead to electric shocks or a fire.

(note 1) applicable legislation means “All international,

national and local directives, laws, regulations and/

or codes which are relevant and applicable for a

certain product or domain”.

•

Be sure to use only the specified parts and accessories for

installation work. Failure to use the specified parts may result

in the Heat Reclaim Ventilator unit falling down, water leakage, electric shocks, a fire, etc.

•

Carry out the specified installation work in consideration of strong

winds, typhoons, or earthquakes. Improper installation may result

in an accident such as Heat Reclaim Ventilator unit falling.

•

Make sure that all wiring is secure, using the specified wiring and ensuring that external forces do not act on the terminal connections or wiring.

Incomplete connection or fixing may cause an overheat or a fire.

•

When wiring remote controller wiring and transmission wiring, and wiring the power supply, form the wiring orderly so

that the control box lid can be securely fastened. If the control

box lid is not in place, overheat of the terminals, electric

shocks or a fire may be caused.

•

Consult your local dealer regarding what to do in case of

refrigerant leakage.

When the Heat Reclaim Ventilator unit is installed in a small

room, it is necessary to take proper measures so that the

amount of any leaked refrigerant does not exceed the concentration limit in the event of a leakage. Otherwise, this may

lead to an accident due to oxygen deficiency.

•

If refrigerant gas leaks during installation work, ventilate the

area immediately. Toxic gas may be produced if refrigerant

gas comes into contact with a fire.

•

After completing the installation work, check to make sure that

there is no leakage of refrigerant gas. Toxic gas may be produced if refrigerant gas leaks into the room and comes into contact with a source of a fire, such as a fan heater, stove or cooker.

•

Disconnect the power supply before touching the electric components. If you touch the live part, you may get an electric shocks.

•

Never directly touch any accidental leaking refrigerant. This

could result in severe wounds caused by frostbite.

•

Earth the Heat Reclaim Ventilator unit.

Do not connect the earth wiring to gas or water piping, lightning

conductor or telephone earth wiring. Incomplete earthing may

cause electric shocks or a fire. A high surge current from lightning or other sources may cause damage to the air conditioner.

• Be sure to install an earth leakage circuit breaker.

Failure to do so may cause electric shocks and a fire.

•

Install drain piping according to this installation manual to

ensure good drainage, and insulate the piping to prevent

condensation. Improper drain piping may cause water leakage, make the furniture get wet.

•

Install the Heat Reclaim Ventilator unit, power supply wiring,

remote controller wiring and transmission wiring at least 1

meter away from televisions or radios to prevent image interference or noise. (Depending on the radio waves, a distance

of 1 meter may not be sufficient to eliminate the noise.)

•

Install the two outdoor ducts with down slope to prevent rainwater from entering the unit. If this is not done completely,

water may enter the building, may damage furniture, and

cause electric shocks and fire.

•

Insulate the two outdoor ducts and the supply air duct to prevent condensation. If this is not done completely, water may

enter the building, may damage furniture, etc.

•

Insulate the duct and the wall electrically when a metal duct

is to be penetrated through the metal lattice and wire lattice

or metal lining of a wooden structure wall. Improper duct

work may cause electric shocks or fire.

1 3P130768-6L English

• Do not install the Heat Reclaim Ventilator unit in places such

I.D.: φ35 I.D.: φ26

I.D.: φ15

as the following:

1. Place subjected to high temperature or direct flame.

May result in a fire or overheating.

2. Where corrosive gas, such as sulfurous acid gas, is produced.

This may cause a fire.

3. Place such as machinery plant and chemical plant where

gas, which contains noxious gas or corrosive components

of materials such as acid, alkali organic solvent and paint, is

generated. Place where combustible gas leakage is likely.

Copper piping and brazed joints may corrode, causing

refrigerant to leak or poisoning and a fire due to leaked gas.

4. Locations below freezing point. Using the unit at temperatures below 0°C may cause the drain pan the supply and discharge piping, the humidifying element, the solenoid valves,

and other parts to freeze, which can cause accidents.

5. Where there is machinery which emits electromagnetic waves.

Electromagnetic waves may disturb the control system, and

cause malfunction of the equipment.

6. Where flammable gases may leak, where carbon fibre or

ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

If the gas should leak and remained around the Heat

Reclaim Ventilator unit, it may cause ignition.

•

Make sure the temperature and humidity near the unit and

the air suction/discharge air grille is within limit dictated by

the usage conditions.

1. Refrigerated truck or other locations with low temperatures.

2. Place such as bathroom or heated pools subjected to moisture.

This may cause fires or electric leak or electric shocks.

•

Make sure that a snow protection measure is taken. If no protection snow may enter through the outdoor ducts, and cause

damaging furniture and electric shock and a fire.

•

In areas where insects are easily attracted to a light, such as

where there is a window or light near a ventilation opening,

extremely small insects can sometimes infiltrate the room by

passing through the ventilation opening. Since totally preventing

against infiltration by extremely small insects is difficult, it is

important to consider a serious solution like a filter box (field supply) during the design process to protect against insect infiltration.

• The Heat Reclaim Ventilator unit is not intended for use in a

potentially explosive atmosphere.

•

Where the air contains high levels of salt such as that near

the ocean and where voltage fluctuates greatly such as that

in factories. Also in vehicles or vessels.

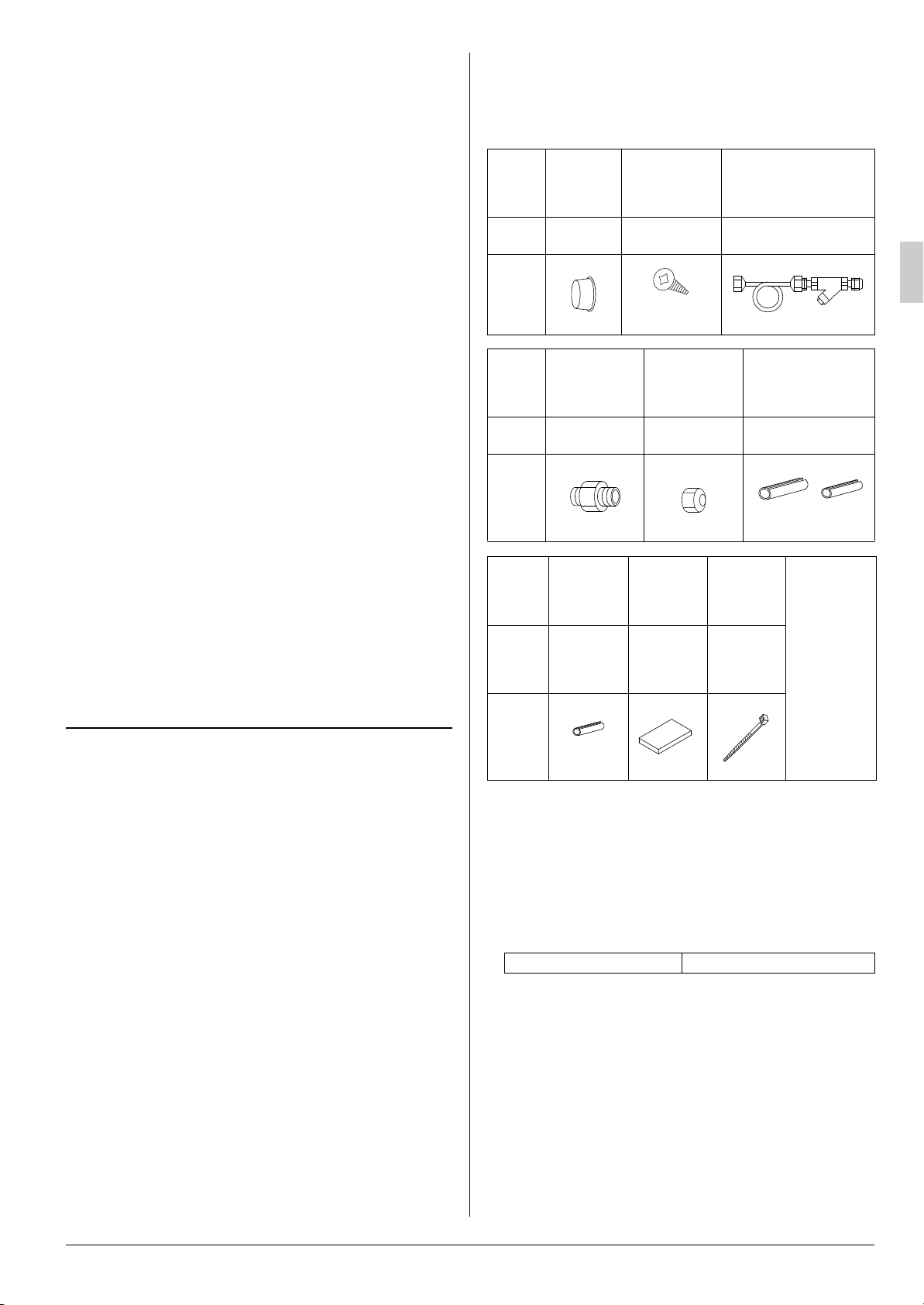

2. 2 ACCESSORIES

Check the following accessories are included with your unit.

Name

Quantity 4 pcs. 24 pcs.

Shape

Name

Quantity

Shape

Name

Quantity

Shape

Duct connecting

flange

Half-union

joint

(Copper piping

joint)

VKM-GBMV1:1 pc.

VKM-GBV1: 0 pc.

Water supply piping

insulation

cover

VKM-GBMV1:

1 pc.

VKM-GBV1:

0 pc.

M4 tapping

screw (For

connecting

duct)

50 type M4

80, 100 type

×12

M4×16

Flare nut

(Copper piping

joint)

VKM-GBMV1:1 pc.

VKM-GBV1: 0 pc.

Sealing

material

1 pc.

Water supply piping

with strainer

VKM-GBMV1: 1 pc.

VKM-GBV1: 0 pc.

Refrigerant piping

insulation cover

1 set

Clamp

VKM-GBMV1:

10 pcs.

VKM-GBV1:

8 pcs.

• Installation

• Operation

(Other)

manual

manual

2 BEFORE INSTALLATION

The accessories needed for installation must be retained in

your custody until the installation work is completed. Do

not discard them!

After carrying in the unit, protect it with packing materials to prevent it from scratching until installation work is done.

[1] Decide upon a line of transport.

[2] Leave the unit inside its packaging while moving, until reach-

ing the installation site. Where unpacking is unavoidable,

use a sling of soft material or protective plates together with

a rope when lifting, to avoid damage or scratches to the unit.

Hold the unit by the hanger brackets (4) when opening the

crate and moving it, and do not lift it holding on to any other

part (especially the refrigerant piping, the drain piping, the

water supply piping, and the duct connecting flange).

•

Be sure to check the type of R410A refrigerant to be used

before installing the unit. (Using an incorrect refrigerant will

prevent normal operation of the unit.)

•

For the installation of an outdoor unit, refer to the installation manual attached to the outdoor unit.

2. 1 PRECAUTIONS

•

Be sure to instruct customers how to properly operate the

unit (especially maintenance of air filter, and operation procedure) by having them carry out operations themselves while

looking at the manual.

2. 3 OPTIONAL ACCESSORIES

•

This unit can be made a part of two different systems: as part

of the combined operation system used together with VRV

SYSTEM Air Conditioners, and as the independent system

using only the Heat Reclaim Ventilator. An operating remote

controller is required for this unit when using the unit as an

independent system.

Ta bl e

Remote controller type BRC1D527

NOTE) 1

If you use the remote controller except the above, please

consult your local dealer.

NOTE) 2

We recommend the remote controller “BRC1D527” especially when the unit is used as independent system. Because

it displays the ventilation mode and can be selected ventilation fan mode with the button.

•

When installing the unit, have ready the round shape hood, the

air discharge grille and the air suction grille, and other parts

needed for the installation.

Consult your local dealer when selecting optional accessories.

3P130768-6L English 2

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE

CAUTION

The items with WARNING or CAUTION mark in the

operation manual are the items pertaining to possibilities for

bodily injury and material damage in addition to the general

usage of the product. Accordingly, it is necessary that you

make a full explanation about the described contents and

also ask your customers to read the operation manual.

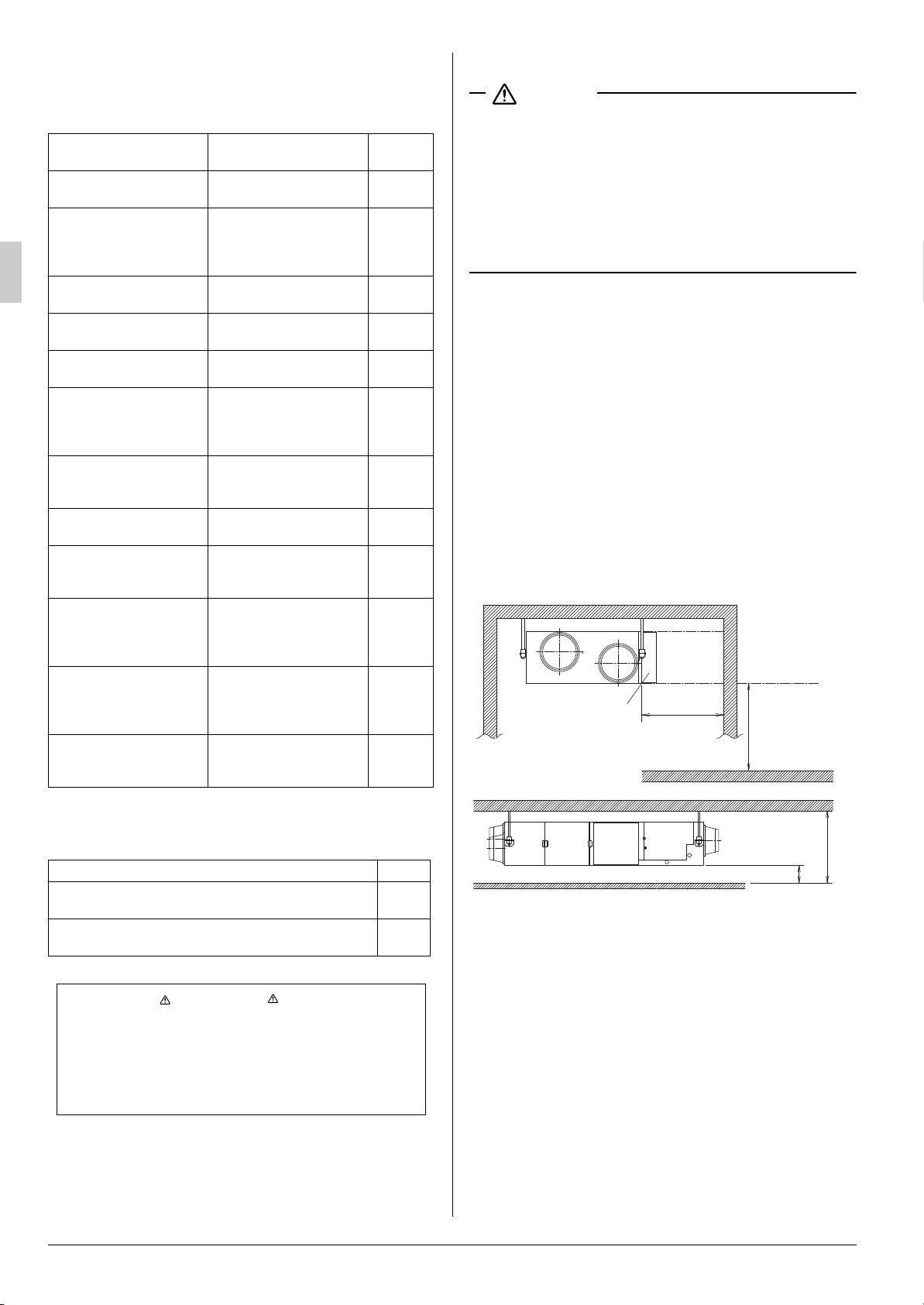

Control box

Maintenance

space

600

or more

2500

or more

20 or more

Fig. 1

minimum height

∗H

•

Select the ∗H dimension such that a downward slope

of at least 1/100 is ensured as indicated in “6 DRAIN

PIPING AND WATER SUPPLY WORK”.

Unit (mm)

DURING CONSTRUCTION AND CHECK AFTER

INSTALLATION IS FINISHED.

a.

Items to be checked after completion of work

Items to be checked

Are the indoor and outdoor units fixed firmly?

Is the outdoor duct

installed to outside

with down slope?

(Refer to page 8 Fig. 16)

Is the gas leak test finished?

Is the unit fully insulated?

Does drainage flow

smoothly?

Does the power supply

voltage correspond to

that shown on the

name plate?

Are wiring and piping

correct?

Is the unit safely

grounded?

Is wiring size according to specifications?

Is something blocking

the air outlet or inlet of

either the indoor or

outdoor units?

Are refrigerant piping

length and additional

refrigerant charge

noted down?

Is water supplied with

the water supply piping

connected?

If not properly done,

what is likely to occur

The units may drop,

vibrate or make noise.

Condensate water

may drip.

It may result in insufficient cooling.

Condensate water

may drip.

Condensate water

may drip.

The unit may malfunction or the components

may burn out.

The unit may malfunction or the components

may burn out.

Dangerous at electric

leakage.

The unit may malfunction or the components

may burn out.

It may result in insufficient cooling.

The refrigerant charge

in the system is not

clear.

Not humidified.

Check

3 SELECTING INSTALLATION SITE

•

When moving the unit during or after unpacking, make sure

to lift it by holding its hanger brackets. Do not exert any pressure on other parts, especially the refrigerant piping, drain

piping, water supply piping and duct connecting flange.

•

If you think the humidity inside the ceiling might exceed 30°C

and RH80%, reinforce the insulation on the inter-unit piping.

Use glass wool or polyethylene foam as insulation so that it is

no thicker than 10 mm and fits inside the ceiling opening.

• Use glass wool or polyethylene form of 10 mm or more thick

which fit into ceiling opening as insulation material.

(1) Select an installation site where the following conditions

are fulfilled and that meets with your customer’s approval.

•

Install in a place which has sufficient strength and stability. (Beams, ceiling, and other locations capable of fully

supporting the weight of the unit.)

Insufficient strength is dangerous. It may also cause

vibration and unusual operating noise.

•

Where piping between indoor and outdoor units is possible within the allowable limit. (Refer to the installation

manual for the outdoor unit.)

•

Where nothing blocks air passage.

•

Where condensate can be properly drained.

•

Install in a location where the air around the unit or taken

into the humidifier will not drop below 0°C.

•

Do not install the unit directly against a ceiling or wall.

(If the unit is in contact with the ceiling or wall, it can

cause vibration.)

•

Where sufficient clearance for maintenance and service

can be ensured. (Refer to Fig. 1)

Please check all items listed in the “SAFETY PRECAUTIONS”

above once again.

b.

Items to be checked at time of delivery

Items to be checked Check

Did you explain about operations while showing the

operation manual to your customer?

Did you hand the operation manual and warranty

over to your customer?

c.

Points for explanation about operations

3 3P130768-6L English

[PRECAUTION]

•

Install the indoor and outdoor units, power supply wiring and

connecting wires at least 1 meter away from televisions or

radios in order to prevent image interference or noise.

Depending on the radio waves, a distance of 1 meter may

not be sufficient enough to eliminate the electric noise.

•

The bellows may not be able to be used in some districts,

so exercise caution. (Contact your local government

office or fire department for details.)

•

When discharging exhaust air to a common duct, the

Building Standard Law requires the use of fire-proof

materials, so attach a 2 m copper plate standing duct or

smoke back flow prevention damper.

(2)

CAUTION

CAUTION

Note: All the above parts are locally procured.

Suspension bolt

Antivibration lifting

lug or turn buckle

Anchor bolt

Indoor unit

Ceiling slab

Fig. 3

Fig. 4

Hanger bracket

Duct layout precaution label

Washer

Nut

Transportation

anchors

Screw

Double nut

Use suspension bolts for installation. Check whether

the ceiling is strong enough to support the weight of

the unit or not. If there is a risk, reinforce the ceiling

before installing the unit.

(Installation pitch is mentioned as follow. Refer to it to check

for points requiring reinforcing.)

5 THE METHOD OF INSTALLATION

<<Hold underside of the unit or hanger bracket without

putting force on other parts when unpacking or moving

the unit.>>

4 PREPARATIONS BEFORE INSTALLATION

(1)

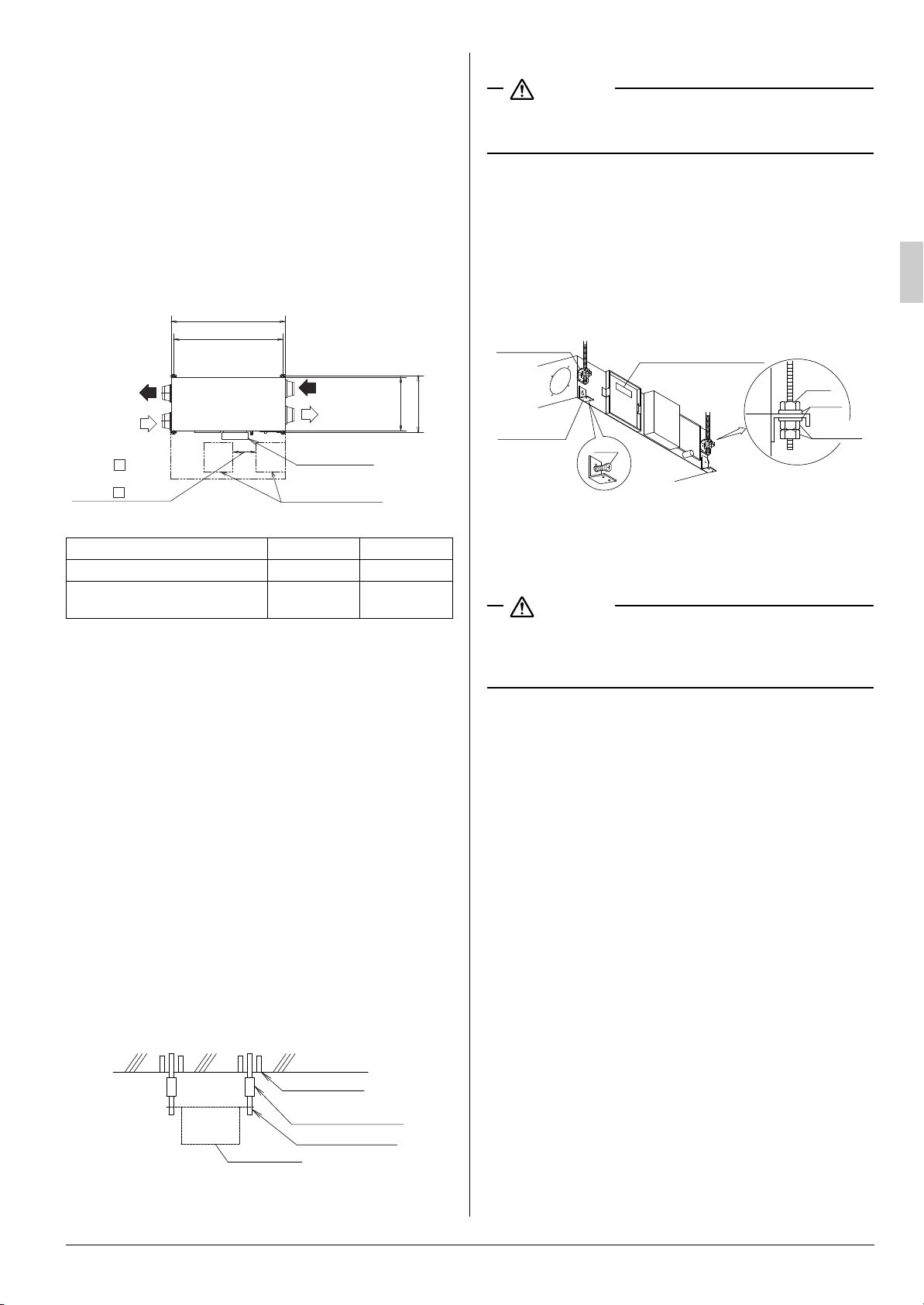

Confirm the positional relationship between the unit

and suspension bolts. (Refer to Fig. 2)

Leave space for servicing the unit and include inspection

hatches. (Always open a hole on the side of the control box

so that the air filters, heat exchange elements, fans, and

humidifier elements can easily be inspected and serviced.)

1764 Unit (mm)

1688

(Suspension

Exhaust air to

outdoors (EA)

Fresh air from

outdoors (OA)

360(If the inspection

hatch is 450)

140(If the inspection

hatch is 600)

Model A B

VKM50GBMV1, VKM50GBV1

VKM80GBMV1, VKM80GBV1

VKM100GBMV1, VKM100GBV1

(2)

Make sure the range of the unit’s external static pressure is not exceeded.

(See the fan-strength and static performance characteristic

drawings as well as the general catalog for the range of the

external static pressure setting.)

(3)

Open the installation hole. (Pre-set ceilings)

•

Once the installation hole is opened in the ceiling where

the unit is to be installed, pass refrigerant, drain piping,

transmission wiring, and remote controller wiring to the

unit’s piping and wiring holes.

See “6 DRAIN PIPING AND SUPPLY WATER WORK”,

“7 REFRIGERANT PIPING WORK”, and

“10 WIRING EXAMPLE AND HOW TO SET THE

REMOTE CONTROLLER”.

•

After opening the ceiling hole, make sure ceiling is level if

needed. It might be necessary to reinforce the ceiling

frame to prevent shaking.

Consult an architect or carpenter for details.

(4)

Install the suspension bolts.

(Use M10 to M12 suspension bolts.)

Use a hole-in-anchor, sunken insert, sunken anchor for

existing ceilings, or other part to be procured in the field to

reinforce the ceiling to bearing the weight of the unit.

(Refer to Fig. 3)

bolt pitch)

Return air from

room (RA)

Supply air to

room (SA)

Control box

Inspection hatches

832 878

1214 1262

A

B

(Suspension bolt pitch)

Fig. 2

(mm)

<<As for the parts to be used for installation work, be sure

to use the provided accessories and specified parts designated by our company.>>

(1)

Install the unit temporarily.

•

Attach the hanger bracket to the suspension bolt. Be sure

to fix it securely by using nuts (M10, M12) and washers

(M10 with external dia. 30 to 34 mm, M12 with external

dia. 36 to 38 mm) (locally procured) from the upper and

lower sides of the hanger bracket.

(2)

If unnecessary, remove the four transportation

anchors.

•

Loosen the screws.

•

Slide upward and remove the transportation anchors.

•

Securely tighten the screws as before.

•

The screws shouldn’t be removed from the unit and should

be tightened in order to prevent air from escaping.

•

Check that foreign objects such as plastic or paper are not

contained in the unit when installing.

•

Install the unit after checking the indoor (SA/RA) and outdoor (EA/OA) in accordance with the figure duct layout

precaution label.

•

Do not turn the unit upside down.

(3)

Adjust the height of the unit.

(Tighten the double nuts securely.)

(Refer to Fig. 4)

3P130768-6L English 4

(4)

CAUTION

CAUTION

CAUTION

Level

Level

Drain hole

Horizontal line

Drain hole

Duct connecting

flange

1

0 or

less

10 or less

Fig. 5

Fig. 6

Duct connecting flange marking

Screws (Accessory)

(6pcs.×4, total 24pcs.)

(RA is a φ3 indentation)

Duct connecting flange

Duct connecting

flange

Unit alignment

Attached drain hose

Bottom of unit

50 mm

or more

50 mm

or more

Fig. 7-1

100 mm

or more

Fig. 7-2

Central drain piping

(Install with a downward slope of at least 1/100)

Check the unit is horizontally level.

Use a level to make sure that the unit is level and that

the tilt (downward slope) to the drain piping connection

is within 1°. (Refer to Fig. 5)

(One thing to watch out for in particular is if it is installed so

that the slope is not in the direction of the drain piping, as

this might cause leaking.)

Do not connect the drain piping directly to sewage pipes

that smell of ammonia. The ammonia in the sewage might

enter the indoor unit through the drain pipes and corrode

the heat exchanger (Direct expansion coil).

•

Keep the drain pipe short and sloping downwards at a

gradient of at least 1/100 to prevent air pockets from

forming. (Refer to Fig. 7-2)

•

If converging multiple drain pipes, install according to the

procedure shown below. (Install a drain trap for each

indoor unit.)

(5)

Tighten the upper nut.

(6)

Attach the accessory duct connecting flanges using

the included screws to the outlet and intake holes

(a total of four).

When attaching, make sure the alignment markings on the

unit match up with the triangle on the each duct connecting

flange. (Refer to Fig. 6)

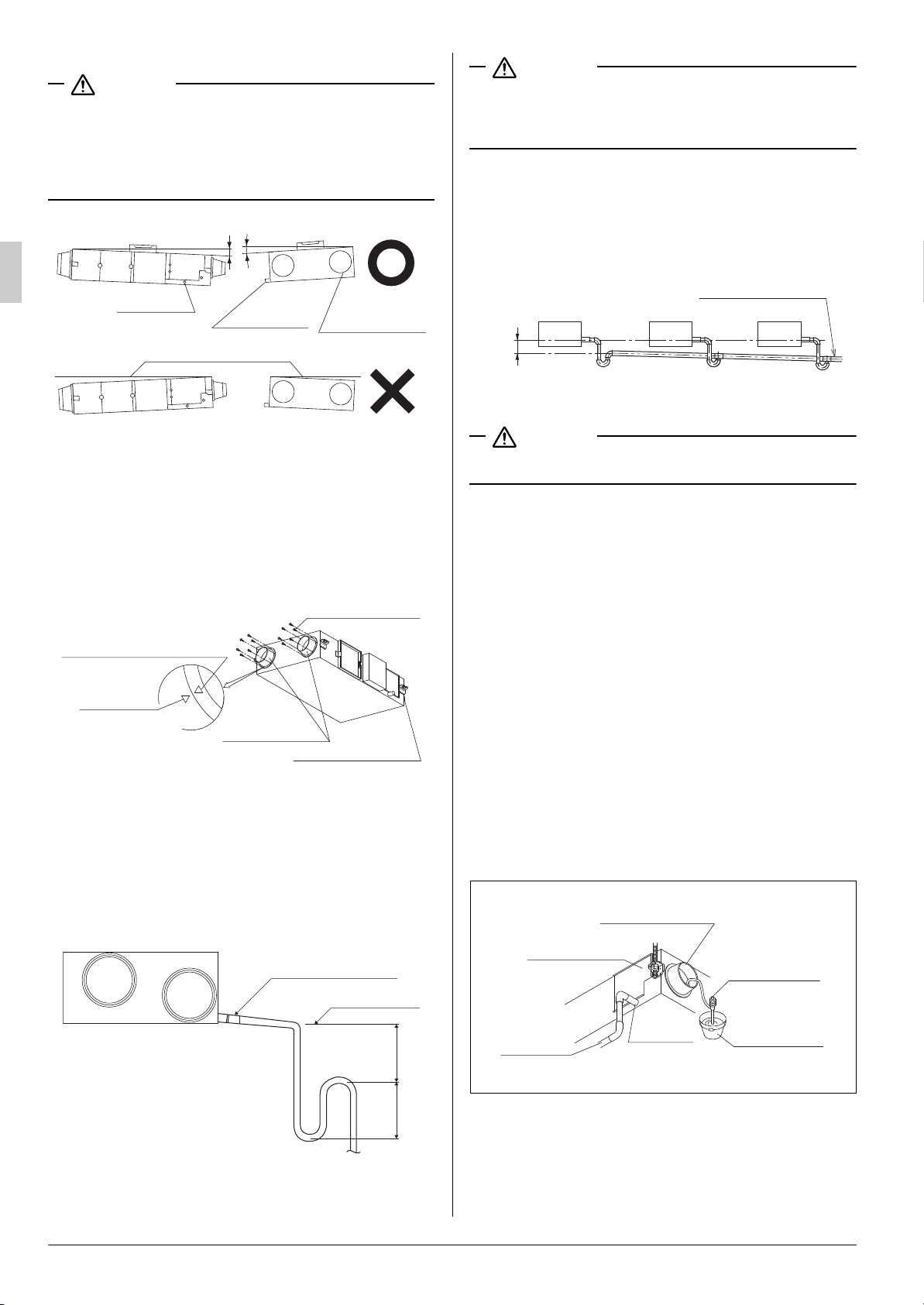

6 DRAIN PIPING AND WATER SUPPLY

WORK

(1)

Install the drain piping.

•

Make sure the drain works properly.

•

In case of the direct duct connection system, there is negative pressure inside the unit relative to atmospheric

pressure when the unit is running, so be sure to provide

drain trap on the drain outlet. (Refer to Fig. 7-1)

Water accumulating in the drain piping can cause the

drain to clog.

•

The diameter of the drain pipe should be greater than or

equal to the diameter of the connecting pipe.

(pipe size: PT3/4B)

•

When piping passes indoors, always insulate it all the

way to the base of the drain socket.

•

In areas where freezing may occur, always take steps to

prevent the pipes from freezing.

•

Make sure water doesn’t leak from the drain pipes.

•

Avoid bends and curves in the pipes to prevent them getting clogged.

•

If you are using central drain piping, follow the procedure

outlined in the figure 7-2.

•

Select central drain pipes of proper size according to the

capacity of the connected unit.

•

Make sure the tip of the drain pipes opens out into a location where the drainage can be safely processed.

(2)

After piping work is finished, check drainage flows

smoothly.

•

Test the drainage by pouring around 1000cc of water into

the drain pan through the inspection hole by removing the

maintenance cover (10 screws) or through the outlet duct

joint of supply air to room (SA). (Refer to Fig. 8)

Supply air to room (SA)

Duct connecting flange

(Accessory)

Maintenance cover

Portable pump

(Locally procured)

5 3P130768-6L English

Drain piping

Drain outlet

(Locally procured)

Fig. 8

(3)

Make sure that heat insulation work is executed on the

(Figure shows VKM-GBMV1)

Bucket

(Locally procured)

following 2 spots to prevent any possibility water leakage due to dew condensation.

• Indoor drain piping

• Drain outlet

Loading...

Loading...