Daikin VAM350FA5, VAM500FA5, VAM650FA5, VAM800FA5, VAM1000FA5 Installation manuals

...

INSTALLATION MANUAL

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

(Ceiling mounted duct type)

Installation Manual

Heat Reclaim Ventilation

Manuel D'installation

Echangeur de chaleur totale Unité

Руководство По Монтажу

Вентиляция с регенерацией тепла

Montaj Kılavuzu

Isı Geri Kazanım Havalandırma

لﯾﻐﺷﺗﻟا تﺎﻣﯾﻠﻌﺗ بﯾﺗﻛ

ةرارﺣﻟا ةدﺎﻌﺗﺳا ﺔﯾوﮭﺗ

English

Français

Русский

Türkçe

ﺔﯾﺑرﻌﻟا

VAM350FA5

VAM500FA5

VAM650FA5

VAM800FA5

VAM1000FA5

VAM1500FA5

VAM2000FA5

1

4

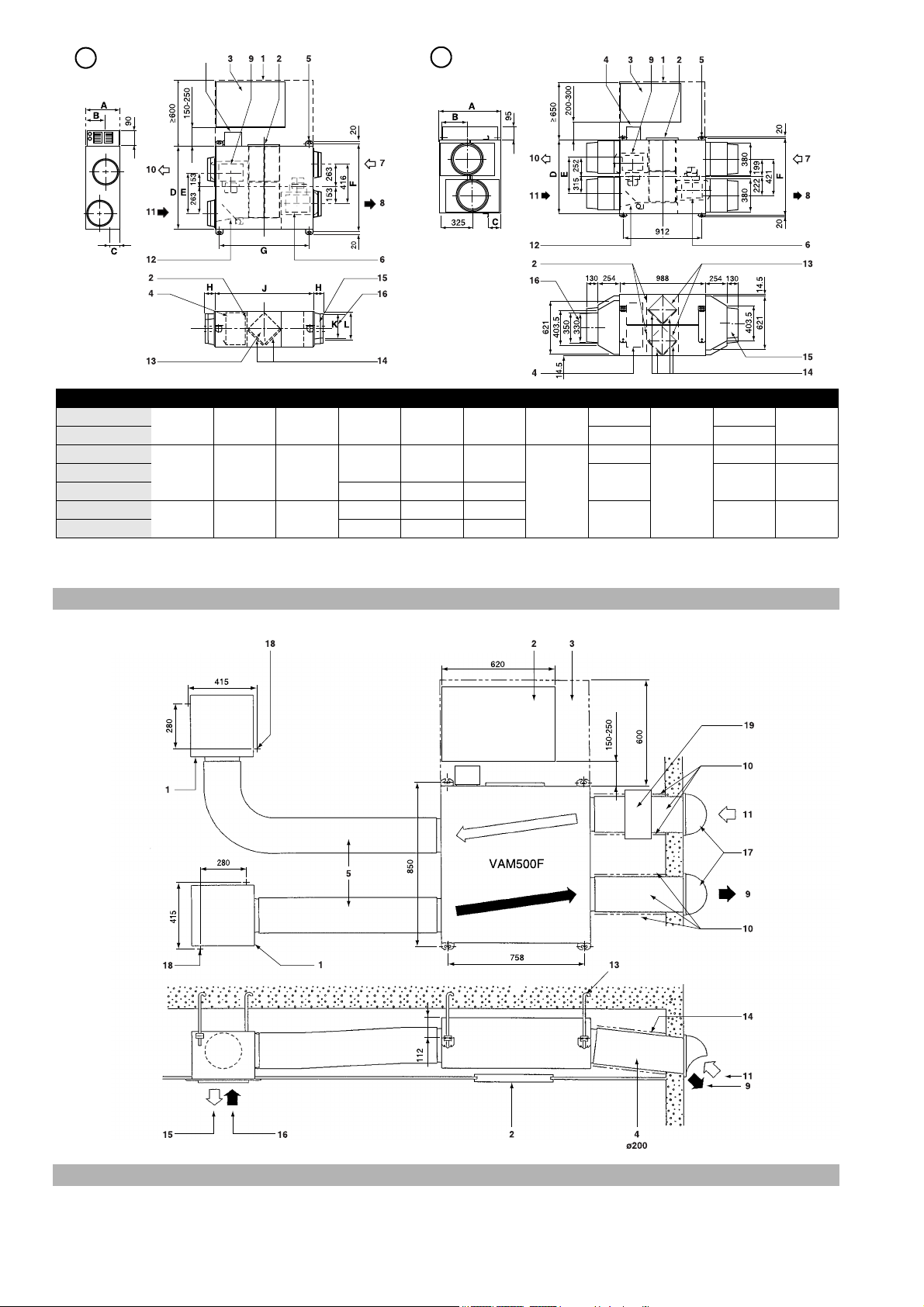

A B C D E F G H J K L

VAM350F

285 164 112 800 416 850 758

132

812

146

200

VAM500F 84 197

VAM650F

348 204 145

852 421 902

912

137

988

196 250

VAM800F

98 246 263

VAM1000F 1140 568 1190

VAM1500F

710 383 140

852 421 898

130 330 350

VAM2000F 1140 568 1186

A

B

1

2

2

3

3

4

4

VAM350F VAM800F VAM1500F

VAM500F VAM1000F VAM2000F

VAM 650 F

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

Installation manual

Contents Page

Safety considerations ........................................................................ 1

Dimensions........................................................................................ 2

Installation ......................................................................................... 2

System configuration......................................................................... 5

Electric wiring .................................................................................... 7

Test run............................................................................................ 21

Wiring diagram ................................................................................ 22

Thank you for purchasing this Daikin HRV.

The original instructions are written in English. All other languages

are translations of the original instructions.

HRV – Heat Reclaim Ventilation

Please read this installation manual carefully and install the

unit properly to keep it at full capacity for a long time.

Please prepare some necessary parts, for example round

hoods, air suction/discharge grilles etc., before the

installation of the unit.

Safety considerations

Please read these "Safety considerations" carefully before installing

air conditioning equipment and be sure to install it correctly. After

completing the installation, make sure that the unit operates properly

during the start-up operation. Please instruct the customer on how to

operate the unit and keep it maintained.

Also, inform customers that they should store this installation manual

along with the operation manual for future reference.

This air conditioner comes under the term “appliances not accessible

to the general public”.

Meaning of warning and caution symbols

WARNING Failure to follow these instructions properly may

result in personal injury or loss of life.

CAUTION Failure to observe these instructions properly

may result in property damage or personal

injury, which may be serious depending on the

circumstances.

WARNING

Never inspect or service the unit by

yourself.

Ask a qualified service person to

perform this work.

Electric shock may result. Before

servicing the unit, always shut off

power.

Persons servicing the unit are

required to wear gloves.

All wiring must be performed by an

authorized electrician and must

comply with the applicable

legislation.

Always use the air filter.

If the air filter is not used, heat

exchange elements will be clogged,

possibly causing poor performance

and subsequent failure.

Do not change operations suddenly.

It can result not only in malfunction

but also failure of switches or relays

in the body.

This appliance is not intended for

use by persons (including children)

with reduced physical, sensory or

mental capabilities, or lack of

experience and knowledge, unless

they have been given supervision or

instruction concerning use of the

appliance by a person responsible

for their safety.

Children should be supervised to

ensure that they do not play with the

appliance.

Do not use an HRV or an air

suction/discharge grille in the

following places:

- Places such as machinery plants

and chemical plants where gas,

which contains noxius gas or

corrosive components of

materials such as acid, alkali,

organic solvent and paint, is

generated.

- Places such as bathrooms

subjected to moisture.

Electric leak or electric shock and

other failure can be caused.

VAM350~2000FA

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

4PW90548-1 (2014.03)

Installation manual

1

- Places subjected to high

temperature or direct flame.

Avoid a place where the

temperature near the HRV unit

and the air suction/discharge air

grille exceeds 50°C. If the unit is

used at high temperature,

deformed air filter and heat

exchange element or burned

motor result. Unit ambient

temperature conditions should be

between -15°C and 50°C

(80% relative humidity or less)

- Places subjected to much carbon

black.

- Carbon black attaches to air filter

and heat exchange element,

disabling them.

- The equipment is not intended for

use in a potentially explosive

atmosphere.

Improper installation or attachment

of equipment or accessories could

result in electric shock, short-circuit,

leaks, fire or other damage to the

equipment. Be sure only to use

accessories, optional equipment

and spare parts made by Daikin

which are specially designed for

use with the products as of subject

in this manual and have them

installed by an installer.

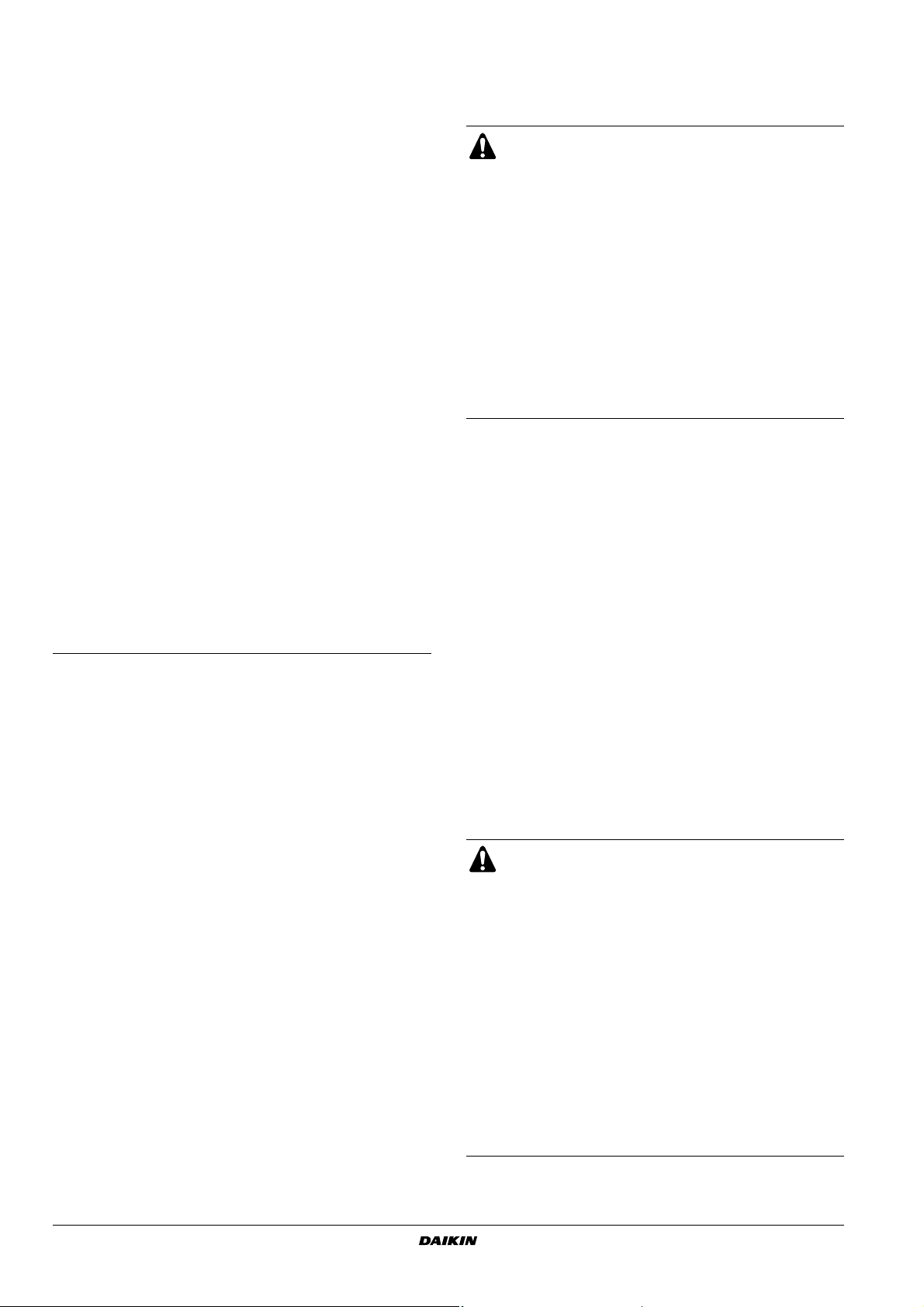

Dimensions

(See figure 1 (A = Models 350F~1000F, B = Models 1500F~2000F))

1 Maintenance space for the heat exchange elements, air filters and

fans

2 Maintenance cover

3

Inspection hole

4 Switch box

5 4x 14x40 mm Ceiling hook (Oval hole)

6 Exhaust air fan

7 OA (Outdoor air) Fresh air from outdoors

8 EA (Exhaust air) Exhaust air to outdoors

9 Supply air fan

10 SA (Supply air) Supply air to room

11 RA (Retun air) Return air from room

12 Damper plate

13 Heat exchange elements

14 Air filters

15 Applicable duct

16 Nominal diameter

Ø450 mm

Installation

Installation position

CAUTION

Install the unit in a place strong enough to

support its weight.

Poor installation is hazardous. It also causes

vibrations and unusual operating noise.

Provide the service space and the inspection

holes.

(Be sure to provide the inspection holes to inspect the

air filters, the heat exchange elements and fans.)

Do not install the unit directly against a ceiling or

wall.

(If the unit is in contact with the ceiling or wall, it can

cause vibration.)

This is a class A product. In a domestic

environment this product may cause radio

interference in which case the user may be

required to take adequate measures.

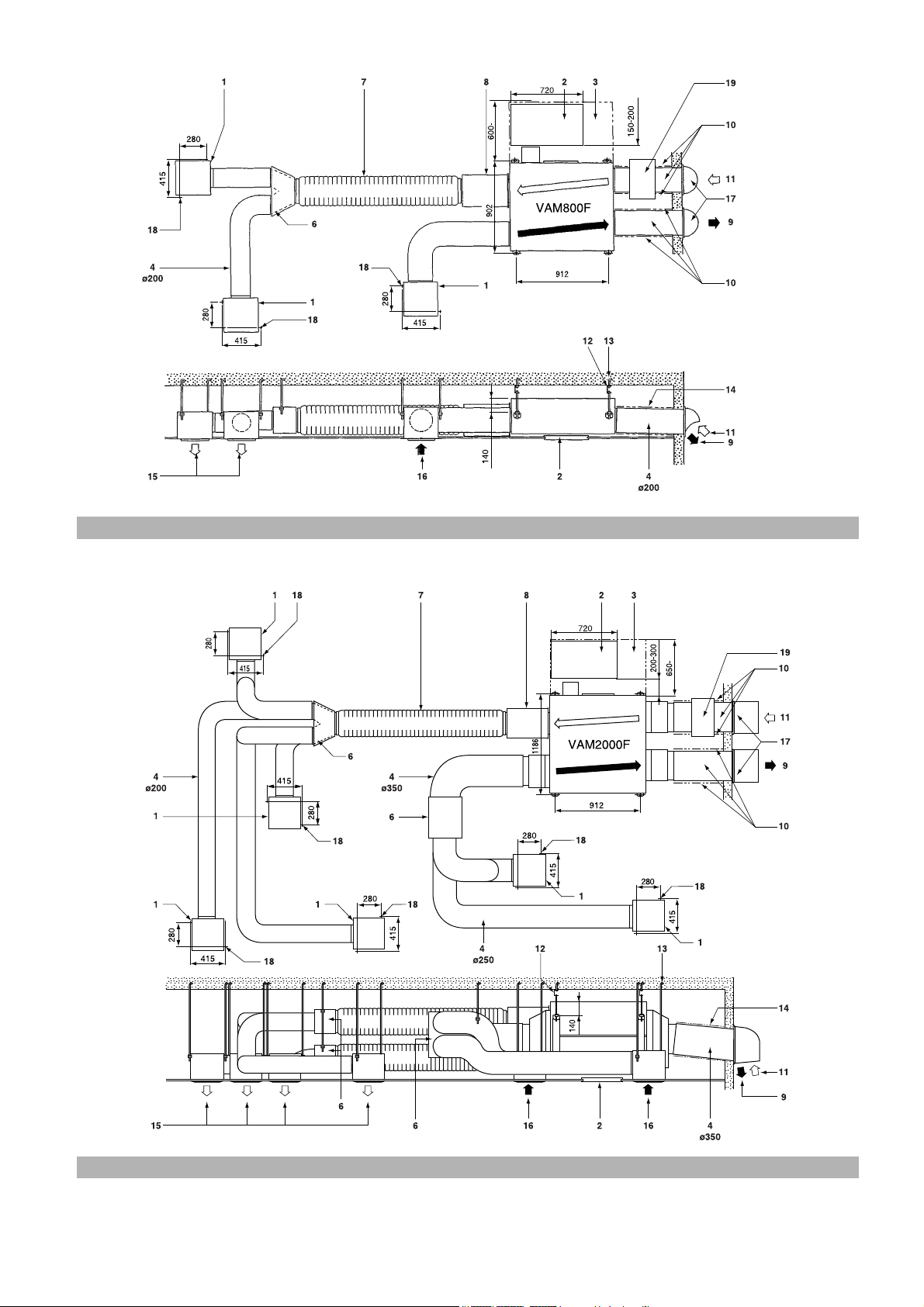

Example of Installation, VAM500F (See figure 2), VAM800F

(See figure 3), VAM2000F (See figure 4)

1 Air suction/discharge grille (option)

2

Inspection hole Ø 450 mm (field supply)

3 Maintenance space for the heat exchange elements, air filters and

fans

4 Duct (field supply)

5 Duct (Ø200) (field supply) or (*) Flexible duct (option)

6 Branch duct (field supply)

7 (*) Flexible duct (field supply)

8 (*) Silencer (option) (only for VAM500 till 2000)

9 EA (Exhaust air to outdoors)

10 Heat Insulator (field supply)

11 OA (Outdoor air) Fresh air from outdoors

12 Metal suspension bracket for absorbing vibration (field supply)

13 Suspension bolt (field supply)

14 Gradient of down to outdoor ≥1/50

15 SA (Supply air to room)

16 RA (Return air from room)

17 Round hood (field supply)

18 Suspension bolt postion

19 Additional external damper (field supply)

CAUTION

on installing the ducts

The parts marked with (*) are effective in reducing

blowing noise.

When using the unit at a quiet place, use the optional

silencer box and flexible duct at the part of the air

discharge outlet on the indoor side “SA” (supply air to

room) of the unit, to counter the noise.

When selecting installation materials, consider the

required volume of air flow and noise level in that

particular installation.

When the outdoor air infiltrates into the ceiling and the

temperature and humidity in the ceiling become high,

insulate the metal portions of the unit.

Access inside the unit is only allowed through the

service hole. Install grilles in case no ducts are

installed.

Unit sound pressure level is less than 70dB (A).

Installation manual

2

VAM350~2000FA

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

4PW90548-1 (2014.03)

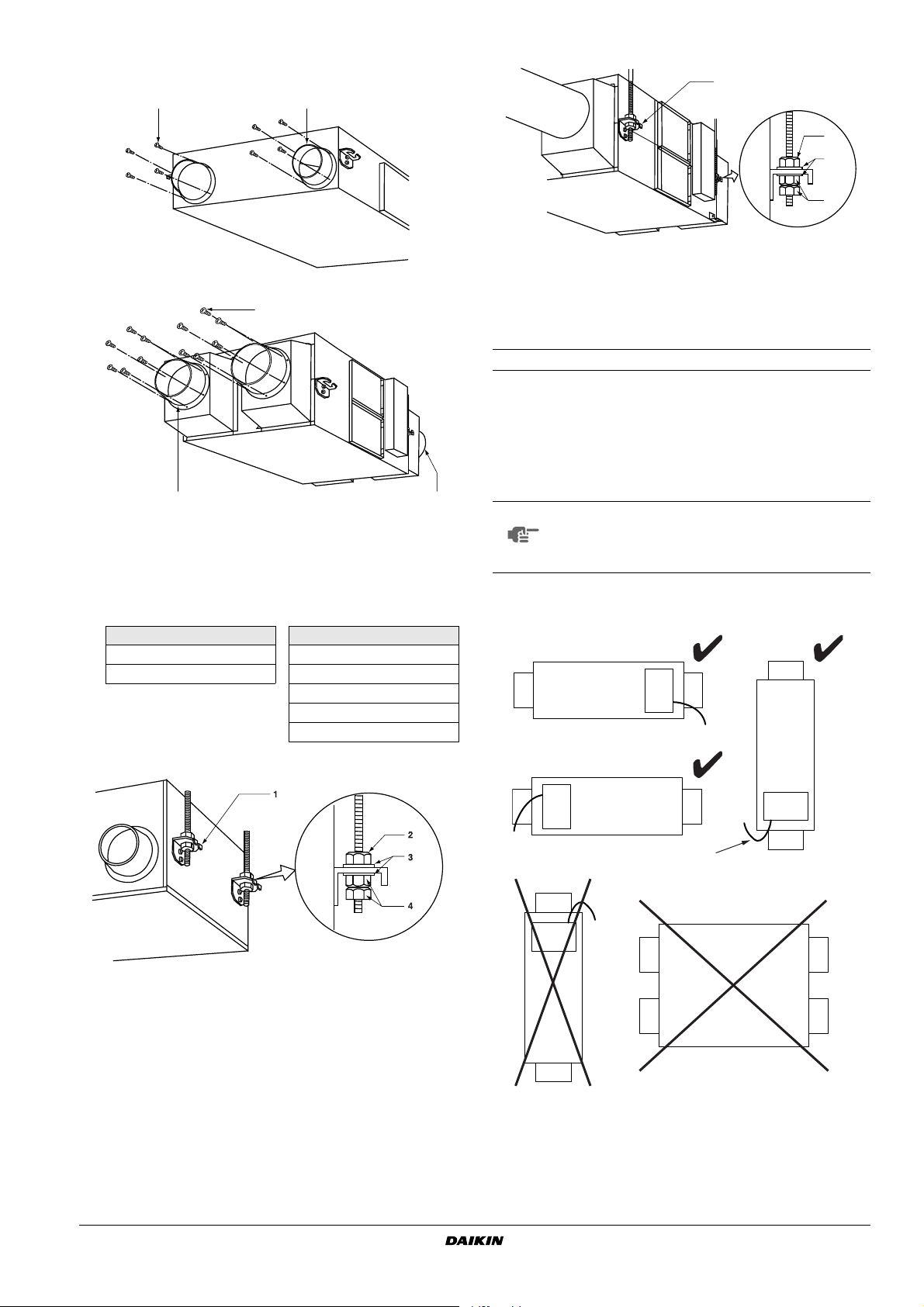

Preparations

12

1

22

1

2

3

4

normal installation

upside down

external wiring

VAM350F, VAM500F

VAM650F, VAM800F, VAM1000F, VAM1500F, VAM2000F

VAM1500F, VAM2000F

1 Ceiling hook

2 Nut

3 Washer

4 Double nuts

Installation of HRV

Install the anchor bolt (M10 to 12) in advance.

Pass the metal suspension bracket through the anchor bolt and

secure the anchor bolt with washer and nut.

(Before installation, check for foreign objects such as vinyl and

paper remaining inside the fan housing.)

Attach the indoor (SA, RA) and outdoor (EA, OA) ducts by

refering to the duct diagram on the swithbox.

1 Screw (accessories)

2 Duct connecting flange (accessories)

Installation of duct connecting flanges

Attach the provided duct connecting flanges using screws

(accessories).

screws provided screws provided

VAM350 16 VAM650 24

VAM500 16 VAM800 24

VAM1000 24

VAM1500 24

VAM2000 24

VAM350F, VAM500F, VAM650F, VAM800F, VAM1000F

NOTE

Remove the two fixing metals for transportation if it

prevents installation work. (Be sure to screw in the

removed mounting screw on the body side to prevent

air leakage.)

Unit orientation

VAM350~2000FA

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

4PW90548-1 (2014.03)

Installation manual

3

Installation in positions other than horizontal are allowed under the

HRV

1

2

3

1

4

4

2

1

5

HRV

3

6

8

7

7

8

9

6

3

following conditions:

There shall be no danger of water entering the control box

(condensation, nearby piping, etc.).

The unit shall be sufficiently fixated.

External switchbox wiring shall point downwards.

Fan shaft has to remain horizontally.

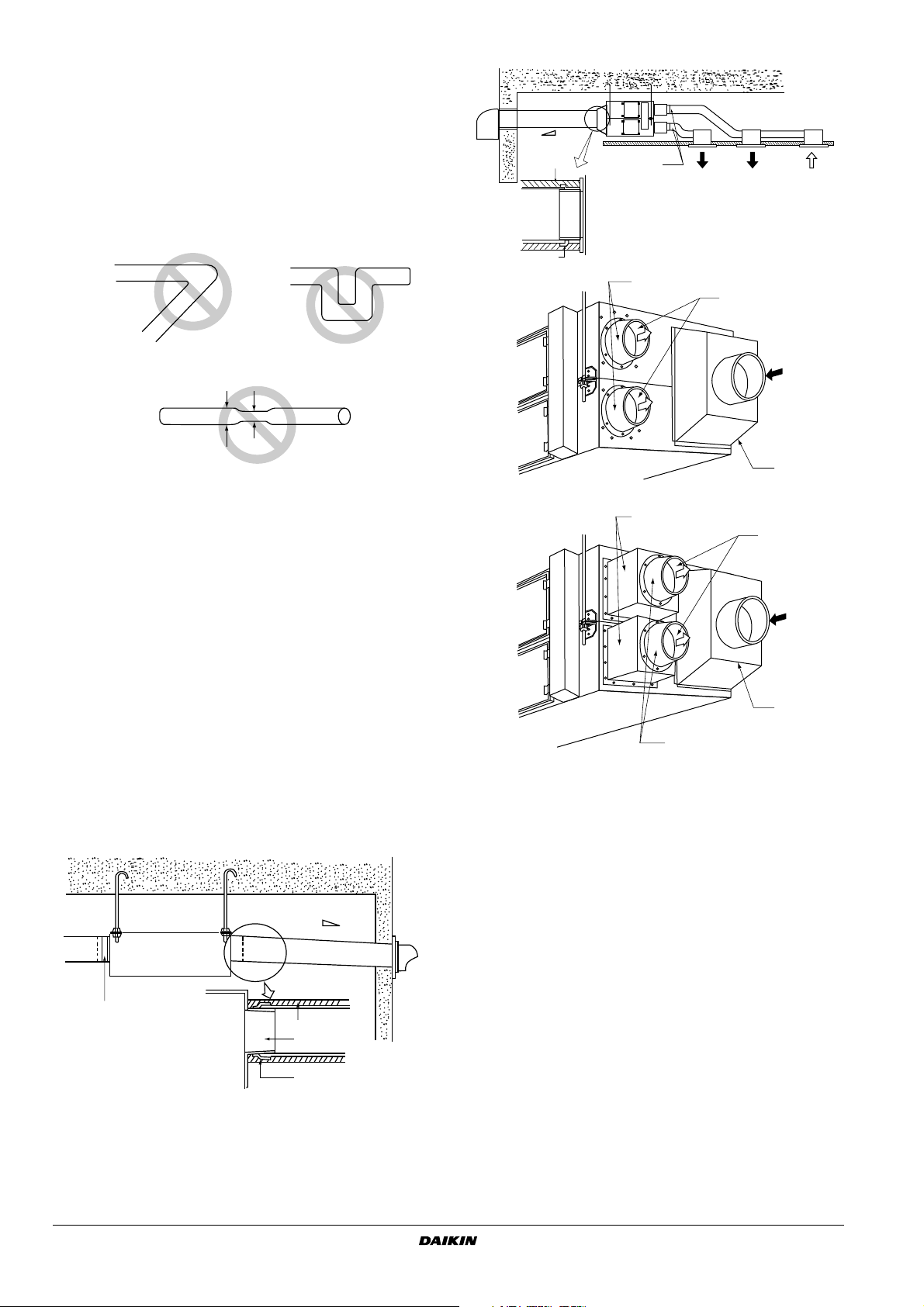

Duct connection

Do not connect the ducts as follows

VAM1500F, VAM2000F

Extreme bend

Do not bend the duct over 90°

Reduce the diameter of the duct to be connected.

Do not reduce the duct diameter halfway.

Multi bend

1 The minimal radius of bends for flexible ducts are as follows:

300 mm duct: 200 mm diameter

375 mm duct: 250 mm diameter

2 To prevent air leakage, wind aluminum tape round the section

after the duct connecting flange and the duct are connected.

3 Install the opening of the indoor air intake (SA) as far as possible

from the opening of the exhaust suction (RA).

4 Use the duct applicable to the model of unit used (Refer to the

outline drawing).

5 Install the two outdoor ducts with down slope (slope of 1/50 or

more) to prevent entry of rain water. Also, provide insulation for

both ducts to prevent dew formation. (Material: Glass wool of

25 mm thick)

6 If the level of temperature and humidity inside the ceiling is

always high, install a ventilation equipment inside the ceiling.

7 Insulate the duct and the wall electrically when a metal duct is to

be penetrated through the metal lattice and wire lattice or metal

lining of a wooden structure wall.

VAM350F, VAM500F, VAM650F, VAM800F, VAM1000F

1 Aluminium tape (field supply)

2 Insulation material (field supply)

3 Duct connecting flange (option)

4 Slope over 1/50

5 Duct connecting flange (option)

6 SA (Supply air)

7 RA (Return air)

8 Connecting chamber

9 Silencer (option)

Installation manual

4

Use Ø250 mm round ducts for the SA (supply air) and RA

(return air) sides

1. Loosen the 12 screws off the SA (supply air) side and remove

the connection chamber. Be sure to tighten up these screws

back in position in order not to allow any air leak from the unit.

2. Fix the duct connecting flanges (option) with their accompanying

12 screws.

Introducing the silencers and other options.

This model handles a high air flow rate.

To reduce the blow-out noise, some optional attachments are

available: silencer, flexible duct, thin air intake/exhaust grille, etc.

1. Remove the connection chamber off the SA (supply air) side and

attach the upper and lower silencers.

2. Now fix the duct connecting flanges (option) and connect the

Ø250 mm flexible ducts.

VAM350~2000FA

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

4PW90548-1 (2014.03)

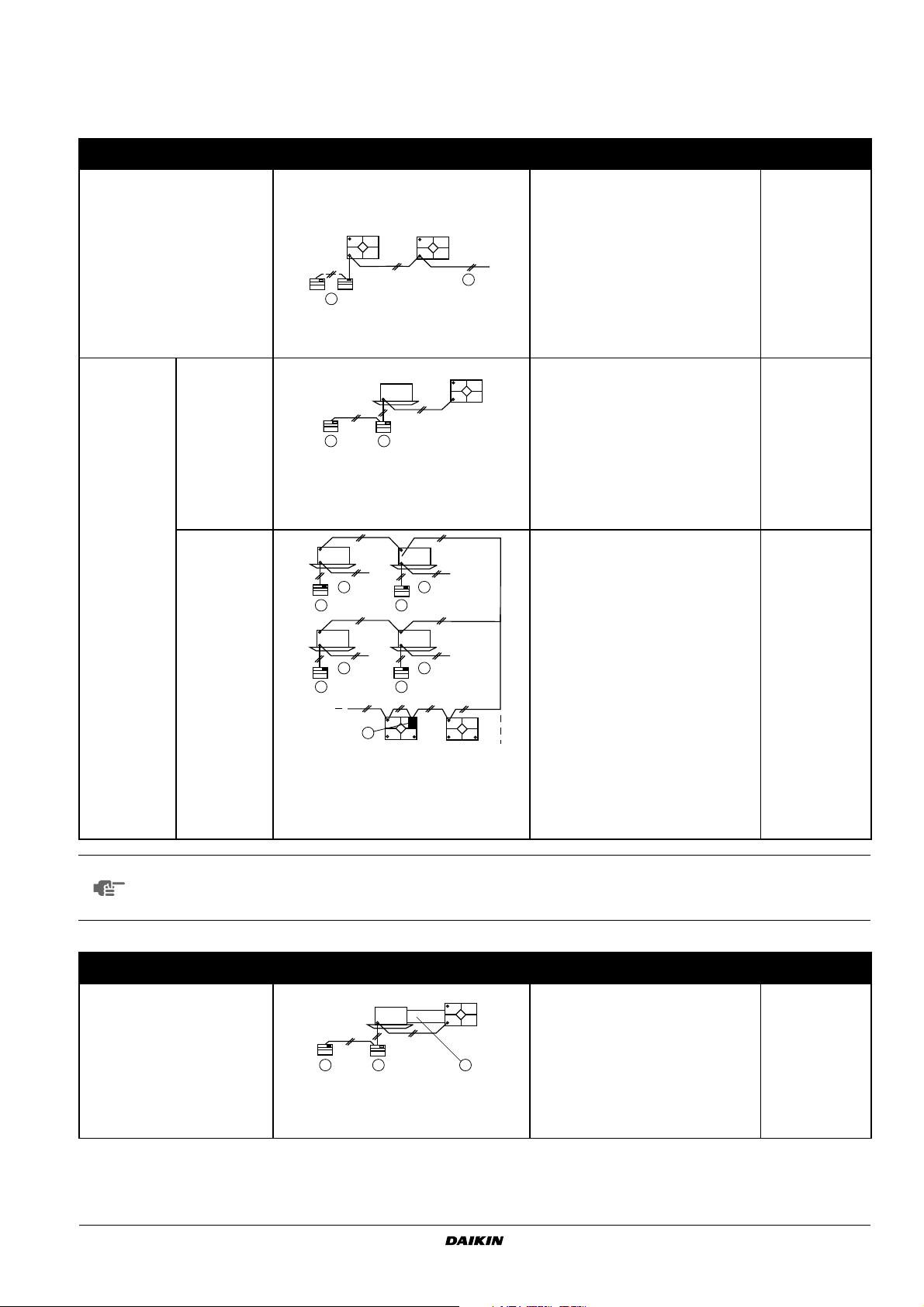

System configuration

HRV

HRV

1

2

1

Remote controller

for HRV

2

2-wire cord

(produced locally)

VRV

HRV

1 2

1

Remote controller

for air conditioner

(Remote controller

for HRV)

2

Remote controller

for air conditioner

VRV

VRV

VRV

VRV

HRV HRV

1 2

5 5

5 5

3 4

6

1

Group 1

4

Group 4

2

Group 2

5

Remote controller

for VRV

3

Group 3

6

Distant control

adapter

VRV

HRV

1 2 3

1

Remote controller

for air conditioner

(Remote controller

for HRV)

2

Remote controller

for air conditioner

3

Duct

Independent system

Air conditioner linked operation system

Independent system

1-group linked

operation system

Combined

operation system

with VRV systems

and Sky-air series

System Standard method

• Up to 16 units can be controlled with the

remote controller for HRV. (A system with

two remote controls can be created in the

master/slave switching.)

• All HRV operations can be used and

indicated.

• Operation monitor output and humidifier

operation are possible using Adapter

PCB.

• Remote control cord should be procured

locally.

(Maximum cord length: 500 m)

• A combined total of up to 16 air

conditioners and the HRV can be

controlled.

• The HRV ventilation mode can be

operated independently when air

conditioners are not being used.

• Using the local setting of the remote

controller for air conditioners, various

settings such as precool/pre-heat

reservation on/off, ventilation flow rate,

ventilation mode, etc.

• Since all VRV units are connected to a

single line in view of installation, all VRV

units are subjects for operation.

• If there are problems operating all VRV

units, do not use this system.

Related items in

Electric wiring

"When connecting to

Remote controller for

HRV" on page 16

"Standard 1-group

linked-control

system" on page 16

Multi-group

(2 or more) linked

operation system

NOTE

Adapter PCB for external input/output: BRP4A50A; Distant control adapter: KRP2A61 (installation box: KRP1B101).

Operation of two or more groups is not possible with direct duct connection.

With VAM types, the direct duct connection shown can also be selected for 1-group operation systems.

Direct duct connection system

System Standard method

• The HRV will operate only when the air

conditioner fan is on.

• Other specifications are the same as

those of the standard system.

"Linked control with

more than two

groups" on page 18

Related items in

Electric wiring

"Direct duct

connection system

for 1-group operation

system" on page 17

VAM350~2000FA

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

4PW90548-1 (2014.03)

Installation manual

5

Loading...

Loading...