Daikin VAM150GJVE, VAM250GJVE, VAM350GJVE, VAM500GJVE, VAM650GJVE Installation manuals

...

INSTALLATION MANUAL

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

MODELS

(Ceiling mounted duct type)

VAM150GJVE

VAM250GJVE

VAM350GJVE

VAM500GJVE

VAM650GJVE

VAM800GJVE

VAM1000GJVE

VAM1500GJVE

VAM2000GJVE

HRV

HRV;Heat Reclaim Ventilation

Please read this installation manual carefully and install the unit properly to keep it at full capacity for a long time.

Please provide some necessary parts, for example round hoods, air suction/discharge grilles etc., before the installation of the unit.

HRV;Ventilación con recuperación de calor

Por favor lea cuidadosamente el manual de instalacion e instale correctamente la unided para que pueda conservar su plena capacidad durante un largo

periodo.

Por favor, antes de proceder a la instalacion de la unidad, proporcione las piezas necesarias, por ejemple tapas redondas, rejillas de aspiracion y de

impulsion de aire, etc.

HRV;Ventilação de Recuperação Térmica

Leia atentamente este manual e instale correctamente esta unidade para que esta funcione inteiramente durante um longo período de tempo.

Adquira algumas peças necessárias, por exemplo, tampas redondas, grelhas de aspiração/exaustão, etc., antes da instalação da unidade.

HRV;

Вентиляция с реãенерацией тепла

Внимательно ознаêомьтесь с данным рóêоводством и óстановите блоê надлежащим образом, чтобы он работал на

полнóю мощность в течение долãоãо времени.

Перед óстановêой блоêа подãотовьте необходимые детали, например êолпаê оêрóãлой формы, решетêи

всасывания/выпóсêа воздóха и т.п

HRV; Isý Geri Kazaným Vantilasyonu

Uzun süreyle tam kapasitede muhafaza etmek için lütfen bu montaj kýlavuzunu dikkatle okuyun ve üniteyi doðru bir

þekilde monte edin.

Ünitenin montajýndan önce yuvarlak külahlar, hava emiþ/boþaltma ýzgaralarý vs. gibi bazý gerekli parçalarý lütfen temin

edin.

.

English

Español

Portugues

Русский

• VAM150GJVE, VAM250GJVE, VAM350GJVE, VAM500GJVE,

VAM650GJVE, VAM800GJVE, VAM1000GJVE

4

GJVE

GJVE

GJVE

GJVE

GJVE

GJVE

GJVE

GJVE

GJVE

13

1

3

2

5

7

8

6

15

2

16

14

4

150-250

600 or more

9

10

11

12

Model name

1

• VAM1500GJVE, VAM2000GJVE

4

200-300

650 or more

10

11

9

1

12 6

2

4

3

14

2

5

7

8

13

[mm]

2

[1]

3

1

18

1

15 15 15 15

18

3

1

12

4 (φ350)

10

11

9

11

17

9

13

14

18

6

1

18

1

7

4 (φ250)

18

5 (φ250)

2500 or higher from the floor

For installation in high places

8

1

16

2

VAM2000GJVE

18

18

16

2

Floor

4

[2]

VAM150GJVE VAM500GJVE VAM1000GJVE

VAM250GJVE VAM650GJVE VAM1500GJVE

VAM350GJVE VAM800GJVE VAM2000GJVE

Total Heat Exchanger

HRV (Heat Reclaim Ventilation)

Installation

manual

CONTENTS

1. SAFETY PRECAUTIONS ............................................ 1

2. BEFORE INSTALLATION ............................................ 2

3. SELECTING INSTALLATION SITE ............................. 3

4. PREPARATIONS BEFORE INSTALLATION ............... 3

5. THE METHOD OF INSTALLATION ............................. 3

6. DUCT CONNECTION .................................................. 4

7. SYSTEM ...................................................................... 6

8. ELECTRIC WIRING WORK ......................................... 7

9. FIELD SETTING AND TEST RUN ............................. 12

10. DESCRIPTION OF SYSTEM

AND APPLICABLE PATTERNS ................................ 14

11. WIRING DIAGRAM .................................................... 19

1. SAFETY PRECAUTIONS

Please read these “SAFETY PRECAUTIONS” carefully before

installing HRV and be sure to install it correctly.

After completing installation, conduct a trial operation to check

for faults and explain to the customer how to operate the air

conditioner and take care of it with the aid of the operation

manual. Ask the customer to store the installation manual

along with the operation manual for future reference.

This HRV comes under the term “appliances not accessible to the general public”.

Meaning of WARNING and CAUTION notices.

WARNING..............Failure to follow these instructions

properly may result in personal injury

or loss of life.

CAUTION...............Failure to observe these instructions

properly may result in property damage or personal injury, which may be

serious depending on the circumstances.

WARNING

• Ask your dealer or qualified personnel to carry out installation work.

Do not attempt to install the air conditioner yourself.

Improper installation may result in water leakage, electric

shocks or fire.

• Installation should be done following the installation manual

and no changes should be made to the unit.

Improper installation may result in water leakage, electric

shocks or fire. Injuries may result if the HRV falls.

• Install the unit on a foundation strong enough to withstand

the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injuries.

• Do not allow exhaust air to enter the outside air intake vent.

This may cause the air of the room to become contaminated, harming the health.

• Locate the outside air intake vent so that it does not take in

exhaust air which contains combustion air, etc.

Incorrect installation may cause a loss of oxygen in the

room, leading to serious accidents.

• Make sure that a separate power supply circuit is provided

for this unit and that all electrical work is carried out by qualified personnel according to local laws and regulations and

this installation manual.

An insufficient power supply capacity or improper electrical

construction may lead to electric shocks or fire.

Insufficient power supply capacity or incorrect wiring may

cause electrical shocks or fire.

• Be sure to use only the specified accessories and parts for

installation work.

Failure to use the specified parts may result in the unit falling, water leakage, electric shocks or fire.

• Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Failure to do so during installation work may result in the unit

falling and causing accidents.

• Make sure that all wiring is secured, the specified wires are

used, and that there is no strain on the terminal connections

or wires.

Improper connections or securing of wires may result in

abnormal heat build-up or fire.

• When wiring the power supply and connecting the remote

controller wiring and transmission wiring, position the wires

so that the control box lid can be securely fastened.

Improper positioning of the control box lid may result in electric shocks, fire or the terminals overheating.

• Be sure to switch off the unit before touching any electrical

parts.

• Be sure to earth the HRV.

Do not earth the unit to a utility pipe, lightning conductor or

telephone earth lead. Imperfect earthing may result in electric shocks or fire.

A high surge current from lightning or other sources may

cause damage to the air conditioner.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks or fire.

CAUTION

• Install the indoor and outdoor units, power cord and connecting wires at least 1 meter away from televisions or

radios to prevent picture interference and noise.

(Depending on the incoming signal strength, a distance of

1 meter may not be sufficient to eliminate noise.)

• Install the two outdoor ducts with down slope to prevent rainwater from entering the unit.

If this is not done completely, water may enter the building,

may damage furniture, and cause electric shocks and fire.

• Insulate the two outdoor ducts and the supply air duct to

prevent condensation.

If this is not done completely, water may enter the building,

may damage furniture, etc.

• Insulate the duct and the wall electrically when a metal duct

is to be penetrated through the metal lattice and wire lattice

or metal lining of a wooden structure wall.

Improper duct work may cause electric shocks or fire.

• Do not install the unit in the following locations:

1. Place subjected to high temperature or direct flame.

May result in fire or overheating.

2. Where there is a high concentration of mineral oil spray or

vapour (e.g. a kitchen).

This may cause fire.

3. Place such as machinery plant and chemical plant where

gas, which contains noxious gas or corrosive components

of materials such as acid, alkali organic solvent and paint, is

generated. Place where combustible gas leakage is likely.

Copper piping and brazed joints may corrode, causing

refrigerant to leak or poisoning and fire due to leaked gas.

4. Near machinery emitting electromagnetic radiation.

Electromagnetic radiation may disturb the operation of the

control system and result in a malfunction of the unit.

1 English

5. Where flammable gas may leak, where there is carbon

fibre or ignitable dust suspensions in the air, or where volatile flammables such as paint thinner or gasoline are

handled. Operating the unit in such conditions may result

in fire.

• The HRV is not intended for use in a potentially explosive

atmosphere.

• Make sure the temperature and humidity near the unit and

the air suction/discharge air grille is within limit dictated by

the usage conditions.

1. Refrigerated truck or other locations with low temperatures.

2. Place such as bathroom or heated pools subjected to

moisture.

This may cause fires or electric leak or electric shocks.

• Make sure that a snow protection measure is taken. If no

protection snow may enter through the outdoor ducts, and

cause damaging furniture and electric shock and fire.

• In areas where insects are easily attracted to a light, such as

where there is a window or light near a ventilation opening,

extremely small insects can sometimes infiltrate the room by

passing through the ventilation opening.

Since totally preventing against infiltration by extremely

small insects is difficult, it is important to consider a serious

solution like a filter box (field supply) during the design process to protect against insect infiltration.

BEFORE INSTALLATION

2.

The accessories needed for installation must be retained

in your custody until the installation work is completed. Do

not discard them!

1. Decide upon a line of transport.

2. Leave the unit inside its packaging while moving, until

reaching the installation site. Where unpacking is unavoidable, use a sling of soft material or protective plates

together with a rope when lifting, to avoid damage or

scratches to the unit.

Hold the unit by the hanger brackets (4) when opening the

crate and moving it, and do not lift it holding on to any

other part (especially the duct connecting flange).

2-1 PRECAUTIONS

• Be sure to instruct customers how to properly operate the

unit (especially maintenance of air filter, and operation procedure) by having them carry out operations themselves

while looking at the manual.

• Where the air contains high levels of salt such as that near

the ocean and where voltage fluctuates greatly such as that

in factories. Also in vehicles or vessels.

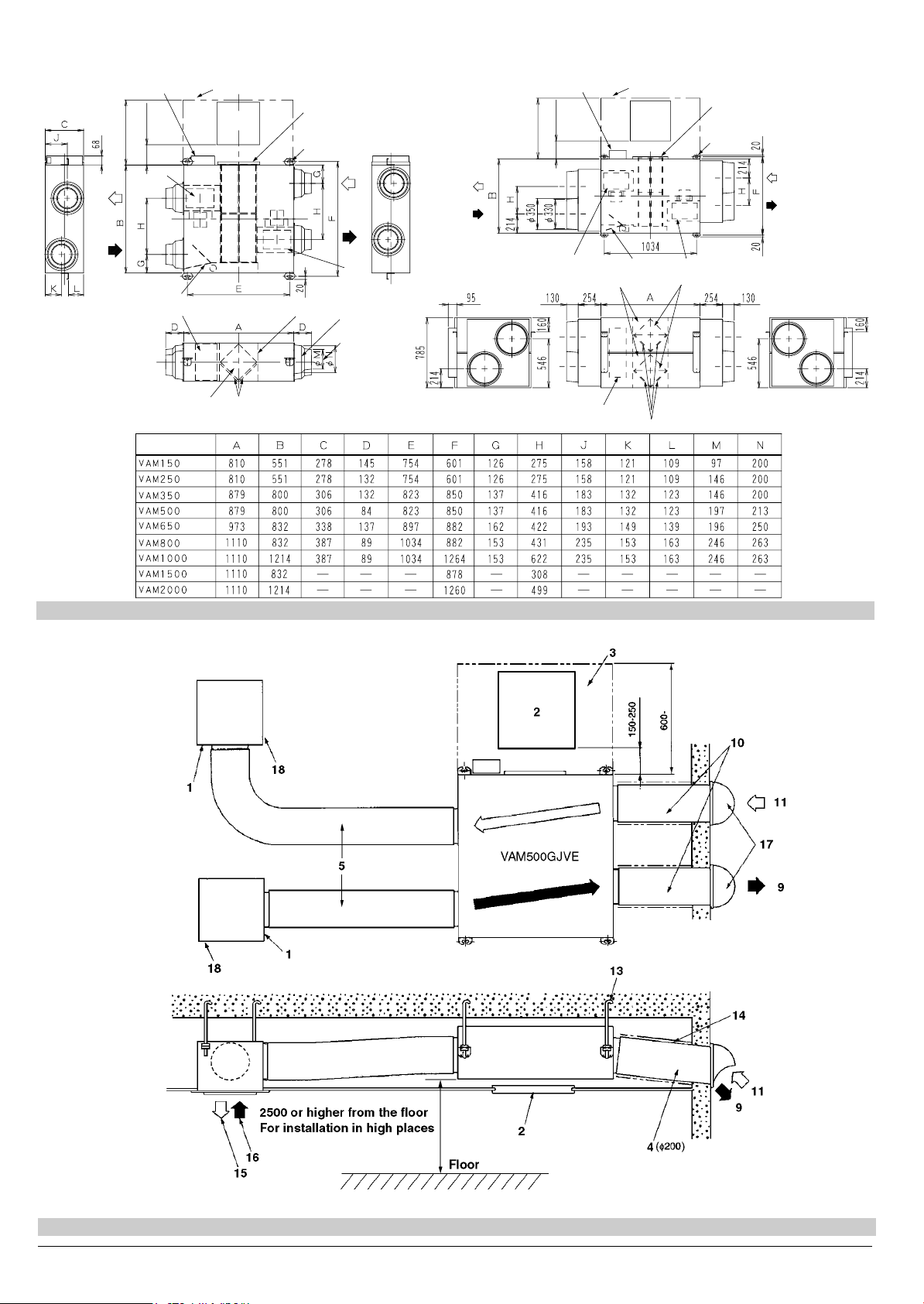

2-2 DIMENSIONS

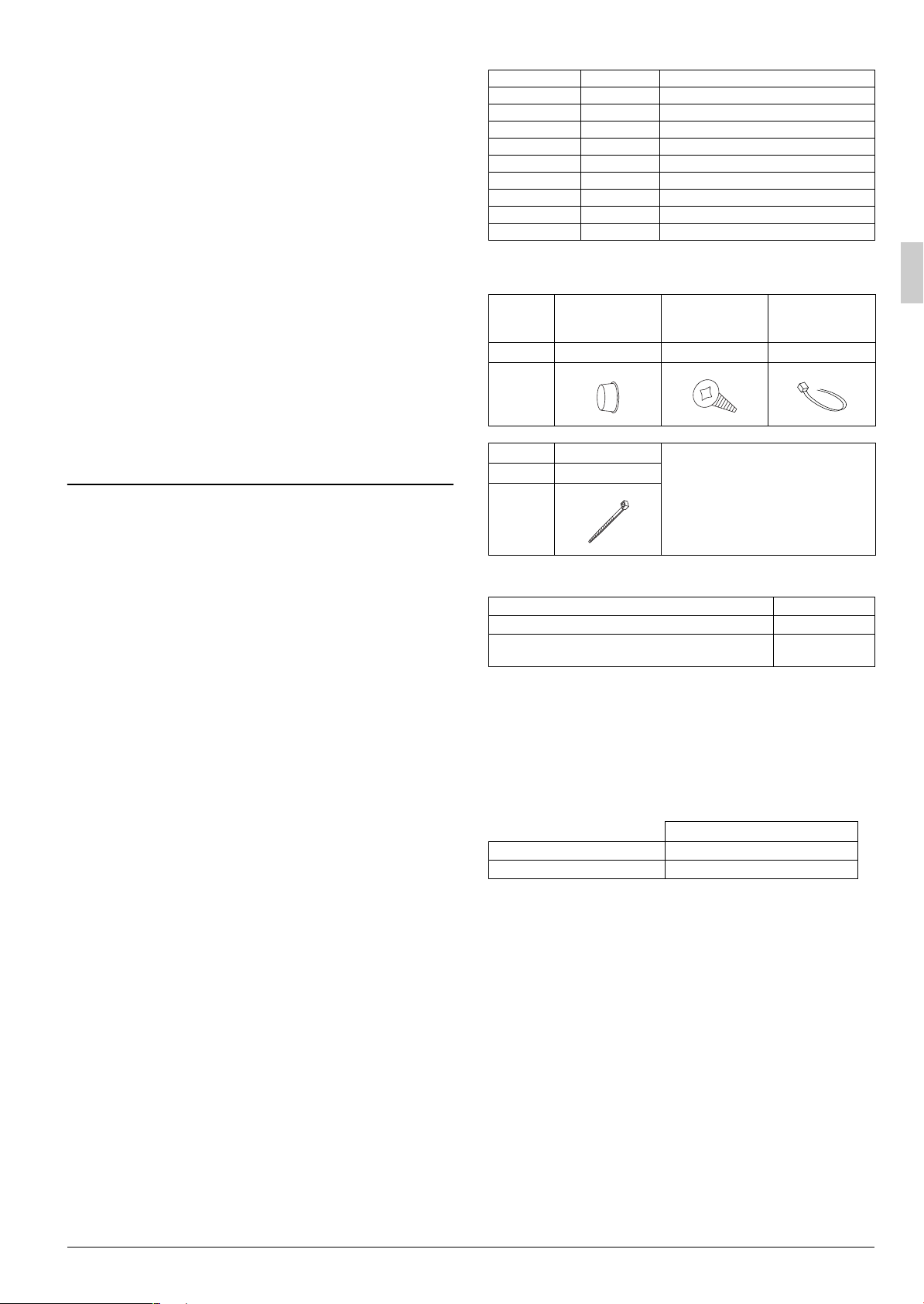

•See figure 1

1. Maintenance space for the heat exchange elements, the air

filters, control box, and fans

2. Maintenance cover

3. Inspection hatch (

4. Control box

5. Hanger bracket (14×40 mm oval hole)

6. Exhaust air fan

7. OA (Outdoor air) Fresh air from outdoors

8. EA (Exhaust air) Exhaust air to outdoors

9. Supply air fan

10. SA (Supply air) Supply air to room

11. RA (Return air) Return air from room

12. Damper

13. Heat exchange elements

14. Air filters

15. Applicable duct

16. Nominal diameter

à

450 mm)

[mm]

Model name Weight (kg) Applicable nominal diameters of ducts

VAM 15 0GJVE 24 φ100

VAM 25 0GJVE 24 φ150

VAM 35 0GJVE 32 φ150

VAM 50 0GJVE 32 φ200

VAM 65 0GJVE 45 φ200

VAM 80 0GJVE 55 φ250

VAM1000GJVE 67 φ250

VAM1500GJVE 129 φ350

VAM2000GJVE 157 φ350

2-3 ACCESSORIES

Check the following accessories are included with your unit.

Name

Quantity 4 pcs. Refer to Table 1 1 pc.

Shape

Name Clamp

Quantity 3 pcs.

Shape

Duct connecting

flange

M4 tapping screw

(For connecting

duct)

• Installation manual

• Operation manual

• Warranty

Harness for

external damper

operation

(Other)

Tabl e 1

Quantity of tapping screw

Model name Quantity

VAM150GJVE, 250GJVE, 350GJVE, 500GJVE 16 pcs.

VAM650GJVE, 800GJVE, 1000GJVE, 1500GJVE,

2000GJVE

24 pcs.

2-4 OPTIONAL ACCESSORIES

• This unit can be made a part of different systems: as part of

the combined operation system used together with VRV

SYSTEM Air Conditioners, and as the independent system

using only the HRV. An operating remote controller is

required for this unit when using the unit as an independent

system.

Select a suitable remote controller from below table according to customer request and technical materials.

Tabl e 2

Combined operation system BRC1A61, 62, BRC1C61

Independent system BRC301B61

NOTE) 1

If you use the remote controller which is not listed in above

table, please consult your dealer.

NOTE) 2

We recommend the remote controller “BRC1C61” or

“BRC301B61”. Because it displays the ventilation mode and

can be selected ventilation fan mode with the button.

NOTE) 3

The remote controller “BRC301B61” can be used by sub remote

controller when using the unit as combined operation system.

• When installing the unit, have ready the round shape hood,

the air discharge grille and the air suction grille, and other

parts needed for the installation.

Consult your Daikin dealer when selecting optional accessories.

Remote controller type

English 2

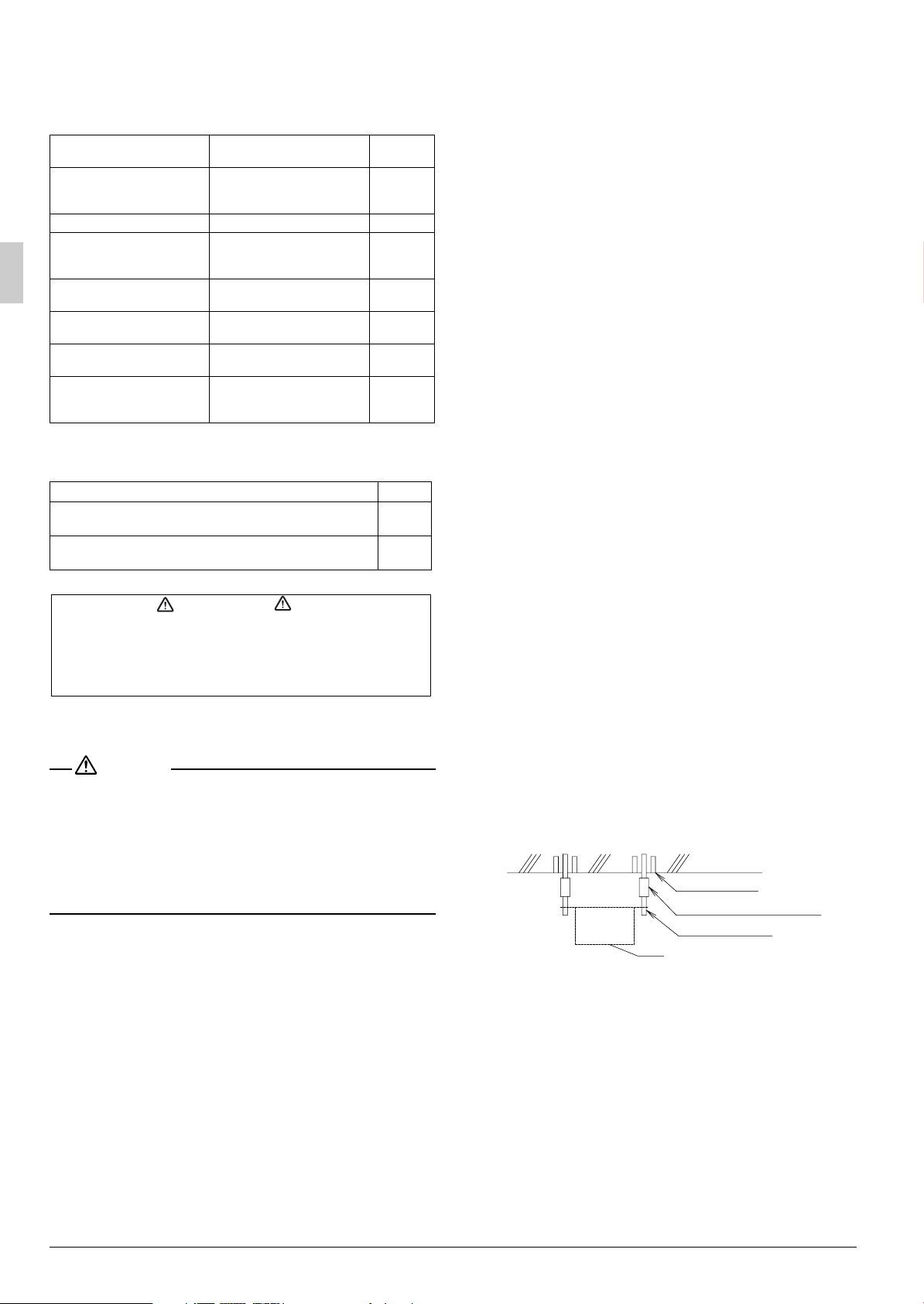

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE

DURING CONSTRUCTION AND CHECK AFTER

INSTALLATION IS FINISHED.

a. Items to be checked after completion of work

Items to be checked

Is the outdoor duct installed

to outside with down

slope?

Is the unit fully insulated? Condensate water may drip.

Dose the power supply

voltage correspond to that

shown on the name plate?

Are wiring correct?

Is the unit safely grounded?

Is wiring size according to

specifications?

Is something blocking the

air outlet or inlet of the unit?

If not properly done, what is

likely to occur

Penetration of rain water

may drip.

The unit may malfunction or

the components burn out.

The unit may malfunction or

the components burn out.

Dangerous at electric leakage.

The unit may malfunction or

the components burn out.

It may result in insufficient

ventilation or unusual operating noise.

Check

Please check all items listed in the “SAFETY PRECAUTIONS”

above once again.

b. Items to be checked at time of delivery

Items to be checked Check

Did you explain about operations while showing the operation manual to your customer?

Did you hand the operation manual and warranty over to

your customer?

c. Points for explanation about operations

The items with WARNING and CAUTION marks in

the operation manual are the items pertaining to possibillties

for bodily injury and material damage in addition to the general usage of the product. Accordingly, it is necessary that

you make a full explanation about the described contents

and also ask your customers to read the operation manual.

3. SELECTING INSTALLATION SITE

CAUTION

• When moving the unit during or after unpacking, make sure

to lift it by holding its hanger brackets. Do not exert any

pressure on other parts, especially duct connecting flange.

• Please attach additional thermal insulation material to the

unit body when it is believed that the temperature and the

relative humidity in the ceiling exceed 30°C and 80%.

Use glass wool, polyethylene foam, or similar with a thickness of 10 mm or more as thermal insulation material.

(1)Select an installation site where the following conditions

are fulfilled and that meets with your customer’s approval.

• Install in a place which has sufficient strength and stability. (Beams, ceiling, and other locations capable of

fully supporting the weight of the unit.)

Insufficient strength is dangerous. It may also cause

vibration and unusual operating noise.

• Where nothing blocks air passage.

• Do not install the unit directly against a ceiling or wall.

(If the unit is in contact with the ceiling or wall, it can

cause vibration.)

• Where sufficient clearance for maintenance and service

can be ensured.

[PRECAUTION]

• Install the units, power supply wiring and connecting

wires at least 1 meter away from televisions or radios in

order to prevent image interference or noise. (Depending on the radio waves, a distance of 1 meter may not

be sufficient enough to eliminate the electric noise.)

• The bellows may not be able to be used in some disctricts, so exercise caution. (Contact your local government office or fire department for details.)

• When discharging exhaust air to a common duct, the

Building Standard Law requires the use of fire-proof

materials, so attach a 2m copper plate standing duct.

(2)Use suspension bolts for installation. Check whether

the ceiling is strong enough to support the weight of

the unit or not. If there is a risk, reinforce the ceiling

before installing the unit.

(Installation pitch is mentioned as follow. Refer to it to check

for points requiring reinforcing.)

4. PREPARATIONS BEFORE INSTALLATION

(1)Confirm the positional relationship between the unit

and suspension bolts. (Refer to Fig. 1)

Leave space for servicing the unit and include inspection

hatches. (Always open a hole on the side of the electric

parts box so that the air filters, heat exchange elements and

fans can be easily inspected and serviced.)

(2)Make sure the range of the unit’s external static pres-

sure is not exceeded.

(See the fan-strength and static performance characteristic

drawings as well as the general catalog for the range of the

external static pressure setting.)

(3)Open the installation hole. (Pre-set ceilings)

• Once the installation hole is opened in the ceiling where

the unit is to be installed, pass transmission wiring, and

remote controller wiring to the unit’s wiring holes.

See “8. WIRING EXAMPLE AND HOW TO SET THE

REMOTE CONTROLLER”.

• After opening the ceiling hole, make sure ceiling is level

if needed. It might be necessary to reinforce the ceiling

frame to prevent shaking.

Consult an architect or carpenter for details.

(4)Install the suspension bolts.

(Use M10 to M12 suspension bolts.)

Use a hole-in-anchor, sunken insert, sunken anchor for

existing ceilings, or other part to be procured in the field to

reinforce the ceiling to bearing the weight of the unit.

Ceiling slab

Anchor bolt

Long nut or turn-buckle

Suspension bolt

Unit

Note: All the above parts are locally procured.

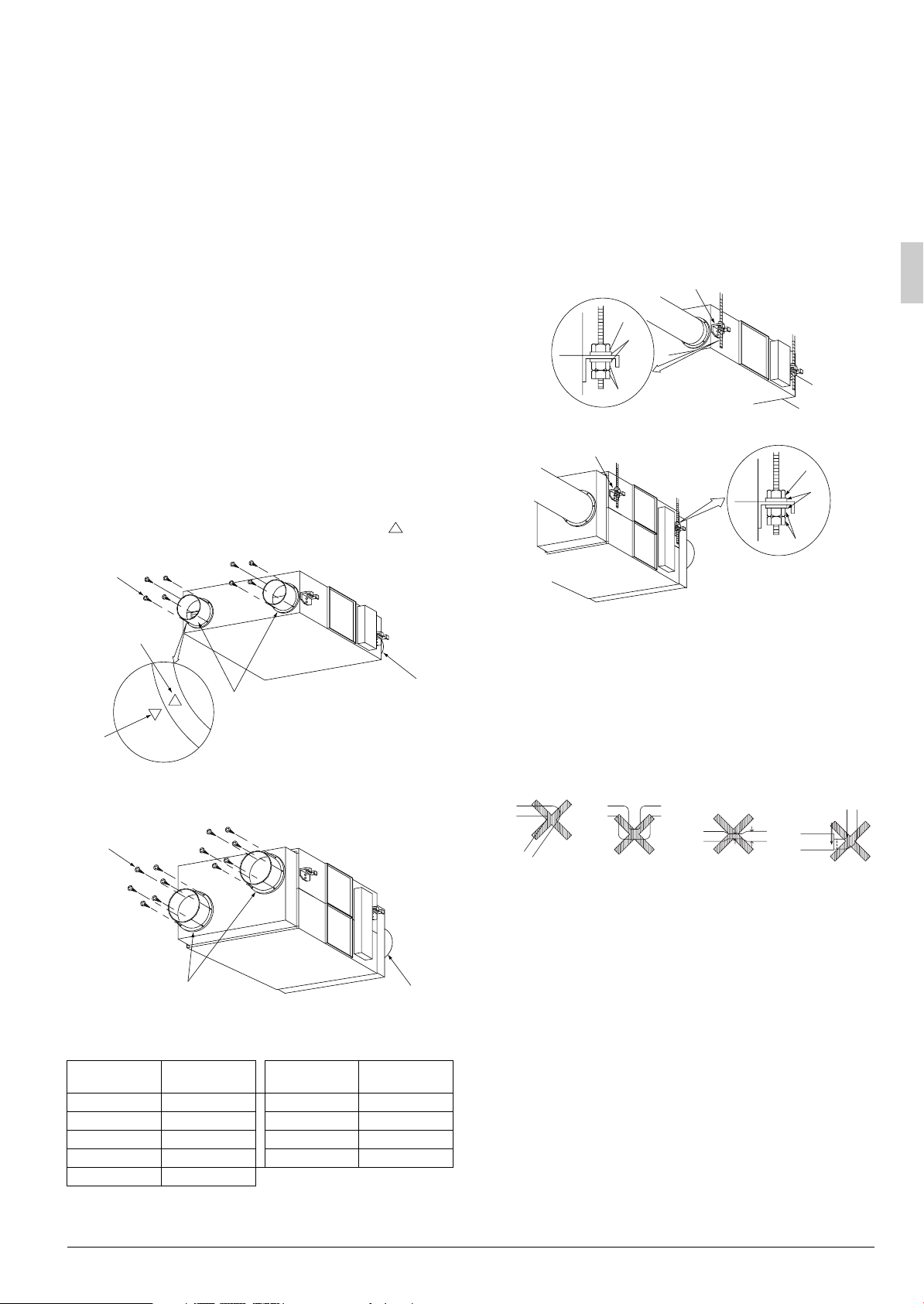

5. THE METHOD OF INSTALLATION

〈〈As for the parts to be used for installation work, be sure

to use the provided accessories and specified parts designated by our company.〉〉

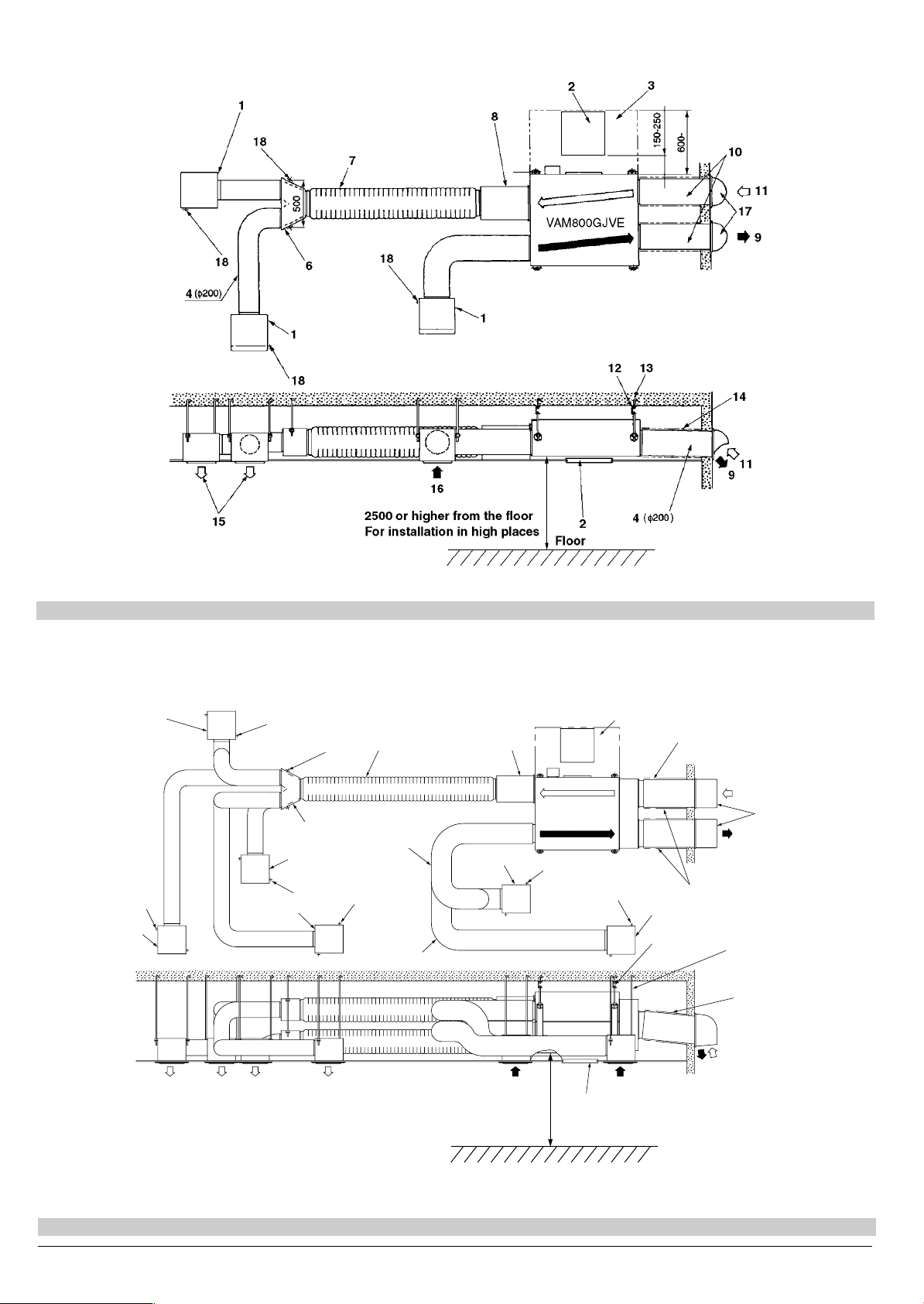

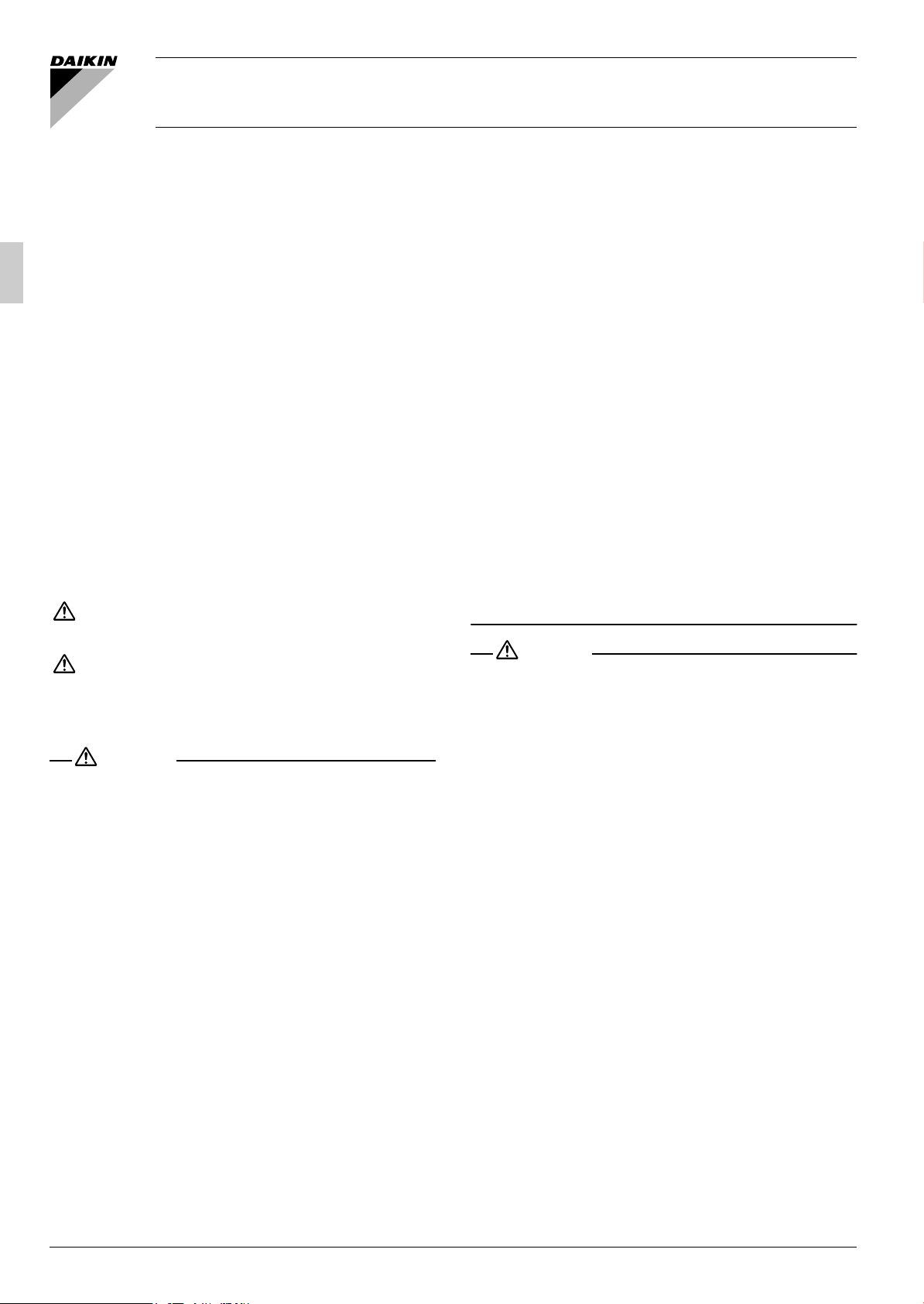

• Example of Installation, VAM500GJVE (See figure 2),

VAM800GJVE (VAM1000GJVE) (See figure 3),

VAM1500GJVE, VAM2000GJVE (See figure 4)

1. Air suction/discharge grille (field supply)

2. Inspection hatch (

3. Maintenance space for the heat exchange elements, air filters, control box and fans

4. Duct (field supply)

5. Duct (field supply) or flexible duct (option)

à

450 mm) (field supply)

3 English

6. Branch duct (field supply) or (only for

VAM800GJVE~2000GJVE)

7. Flexible duct (option)

8. Silencer (option)

9. EA (Exhaust air to outdoors)

10. Heat insulator (field supply)

11. OA (Outdoor air) fresh air from outdoors

12.

Metal suspension bracket for absorbing vibration (field supply)

13. Suspension bolt (field supply)

14. Gradient of down to outdoor ≥ 1/30

15. SA (Supply air to room)

16. RA (Return air from room)

17. Round hood (field supply)

18. Suspension bolt position

<Cautions on installing the ducts>

• The parts marked with* are effective in reducing blowing noise.

• When using the unit at a quiet place, use the optional

silencer box and flexible duct at the part of the air discharge

outlet on the indoor side “SA” (supply air to room) of the unit,

to counter the noise.

• When selecting installation materials, consider the required

volume of air flow and noise level in that particular installation.

• When the outdoor air infiltrates into the ceiling and the temperature and humidity in the ceiling become high, insulate

the metal portions of the unit.

(1)Attach duct connecting flange

<VAM150GJVE, VAM250GJVE, VAM350GJVE, VAM500GJVE>

Attach the 4 included duct connecting flanges using the

included screws.

Match the symbol on the duct joints (the triangle on the

flange) to the position marking on the unit when attaching.

(2)Installing the main unit

Pass hanger bracket over the bolts and secure with commercially available washers and nuts.

(When installing the main unit, make sure there are no foreign

objects (plastic, paper, etc.) inside the fan housing by looking

inside through the duct hole before connecting the duct.)

• When reversing the hanger brackets in order to install the

unit upside down, be sure to secure them with the removed

screws.

• Attach the indoor (SA, RA) and outdoor (EA, OA) ducts by

referring to the duct diagram on the name plate.

<VAM150GJVE, VAM250GJVE, VAM350GJVE, VAM500GJVE,

VAM650GJVE, VAM800GJVE, VAM1000GJVE>

1

2

3

4

<VAM1500GJVE, VAM2000GJVE>

1

2

3

4

1

2

3

4

<VAM650GJVE, VAM800GJVE, VAM1000GJVE,

VAM1500GJVE, VAM2000GJVE>

Attach the 4 included duct joints using the included screws.

1

3

1. Screw

2. Duct joint symbol

3. Duct connecting flange

4. Unit position marking (RA has a φ3 indentation)

Model

VAM150GJVE 16 VAM800GJVE 24

VAM250GJVE 16 VAM1000GJVE 24

VAM350GJVE 16 VAM1500GJVE 24

VAM500GJVE 16 VAM2000GJVE 24

VAM650GJVE 24

Number of

screw

Model

Number of

screw

1. Hanger bracket

2. Nut

3. Washer

4. Double nuts

3

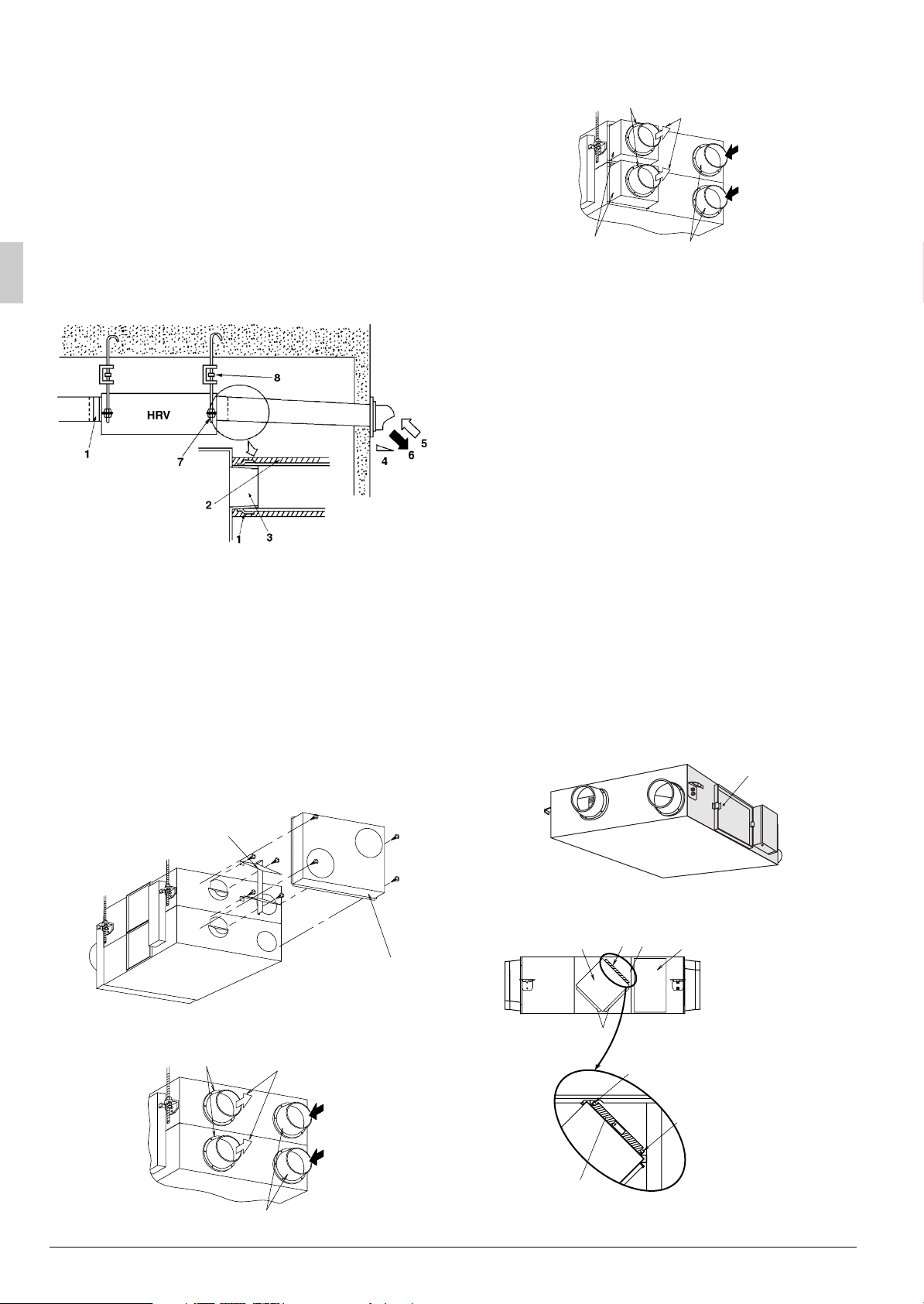

6. DUCT CONNECTION

<Perform duct work keeping the following things in mind>

1. Do not connect the ducts as shown below.

(1) Exterme bend (2) Multi bend (4) a bend right

(Do not bend the

duct over 90˚)

(3) Reduce the

diameter of the

duct to be

next to the

outlet

connected.

(Do not reduce the duct

diameter halfway.)

2. The minimal radius of bends for flexible ducts are as follows.

100 mm diameter duct : 100 mm

150 mm diameter duct : 150 mm

200 mm diameter duct : 300 mm

250 mm diameter duct : 375 mm

3

3. To prevent air leakage, wind aluminum tape round the sec-

tion after the duct connecting flange and the duct are connected. (Refer to Fig. below)

4. To prevent air leakage install the opening of the indoor air

intake as far as from the opening of the exhaust suction.

5. Use the duct applicable to the model of unit used (Refer to

the outline drawing.)

6. Install the two outdoor ducts with down slope (slope of

1/30 or more) to prevent entry of rain water. Also, provide

insulation for both ducts to prevent dew formation.

(Material : Glass wool of 25mm thick)

If the unit is going to be used in cold places where the outside temperature reaches –10°C or below, insulate the

indoor ducts as well.

English 4

7. If the level of temperature and humidity inside the ceiling is

always high, install a ventilation equipment inside the ceiling.

8. Insulate the duct and the wall electrically when a metal

duct is to be penetrated through the metal lattice and wire

lattice or metal lining of a wooden structure wall.

9. Using flexible or silent ducts can be effective in reducing the

air discharge sound of the supply air to room (SA). Select

materials keeping in mind the fan strength and operating

sound of the unit. Consult your Daikin dealer for selection.

10. Set the pitch between the exhaust air outlet (EA) and the

outside air intake (OA) to at least 3 times the duct diameter.

11. Do not use a bent cap or a round hood as the outdoor

hood if they might get rained on directly. (We recommend

using a deep hood (optional accessory).)

12. When using a deep hood, make sure the duct from the

deep hood (outer wall) to the unit is at least 1m long.

Select the proper materials taking fan strength and noise levels

into consideration before installation.

1. Aluminium tape (field supply)

2. Insulation material (field supply)

3. Duct connecting flange (option)

4. Slope over 1/30

5. OA (Outdoor air) Fresh air from outdoors

6. EA (Exhaust air to outdoors)

7. Suspension bolt (field supply)

8. Metal suspension bracket for absorbing vibration

(field supply)

WHEN USING ROUND φ250 DUCTS FOR SA (SUPPLY

AIR) AND RA (RETURN AIR) (φ350

→ φ250 × 2)

(1) Remove the 4 installation screws and then the indoor

connection chamber.Remove the 4 installation screws

and then the wind direction slats.

(3) When attaching muffling boxes (Option), attach them to

the upper and lower SA (Supply air).

3

4

1. Connection chamber

2. Wind direction slats

3. Duct adapter (Option)

4. Silencer (Option)

5. SA (Supply air)

6. RA (Return air)

5

6

6

3

• Attachment of the ducts should be done after the unit

has been transported (i.e. using a lifter, etc.).

(Do not transport the machine by holding the duct joints

or duct adapters.)

• This product has a very strong fan strength, so we recommend using a muffling box (Option), flexible duct

(Option), thin intake/outlet grille (Option), or other items

in order to reduce the noise of the air being blown.

• See our general catalog (for designers and engineers)

for items which are options.

INTRODUCING THE SILENCERS AND OTHER OPTIONS.

This model handles a high air flow rate.

To reduce the blow-out noise, some optional attachments

are available silencer, flexible duct, thin air intake/exhaust

grille, etc.

Remove the connection chamber off the SA (Supply air)

side and attach the upper and lower silencers.

Fix the duct connecting flanges (Option) and connect the

250 mm dia. flexible ducts.

USING A HIGH-EFFICIENCY FILTER (OPTION)

• Replace the high-efficiency filter around once a year.

• Replace more often when used in heavily polluted locations. (The high-efficiency filter is option.)

(1)Remove the maintenance cover.

1

2

(2)Attach the high-efficiency filter.

Make sure it is attached in the correct location.

2

1

3

5

6

1. Maintenance cover

6

2. High-efficiency filter

3. Control box

4. Heat exchanger element

5. Air filter

6. Rails

(2) Attach the duct adapter (Option) depending on the

included screws.

3

5

6

6

3

4

1

Attach along the

inside of the rails.

2

(3)Attach the maintenance cover.

5 English

Loading...

Loading...