Daikin RXYMQ4PVE, RXYMQ5PVE, RXYMQ6PVE, RXMQ4PVE, RXMQ5PVE Service Manual

...

Si34 - 603

Service Manual / R-410A RX(Y)MQ4·5·6PVE

Si34-603

RX(Y)MQ4·5·6PVE

R-410A

Heat Pump 50/60Hz

Cooling Only 50/60Hz

Si34-603

Table of Contents i

R-410A

Heat Pump / Cooling Only

50/60Hz

1. Introduction .............................................................................................v

1.1 Safety Cautions ........................................................................................ v

1.2 PREFACE ............................................................................................... ix

Part 1 General Information ...........................................................1

1. Model Names of Indoor/Outdoor Units....................................................2

2. External Appearance...............................................................................3

2.1 Indoor Units ..............................................................................................3

3. Capacity Range.......................................................................................4

Part 2 Specifications .................................................................... 5

1. Specifications..........................................................................................6

1.1 Outdoor Units ...........................................................................................6

1.2 Indoor Units ............................................................................................10

Part 3 List of Electrical and Functional Parts............................ 35

1. List of Electrical and Functional Parts ...................................................36

1.1 Outdoor Unit ...........................................................................................36

1.2 Indoor Unit..............................................................................................37

Part 4 Refrigerant Circuit ...........................................................43

1. Refrigerant Circuit .................................................................................44

1.1 RX(Y)MQ4 / 5 / 6P .................................................................................44

2. Functional Parts Layout ........................................................................46

2.1 RX(Y)MQ4 / 5 / 6P .................................................................................46

Part 5 Function............................................................................ 47

1. Operation Mode ....................................................................................48

2. Basic Control.........................................................................................49

2.1 Normal Operation ...................................................................................49

2.2 Compressor PI Control...........................................................................50

2.3 Electronic Expansion Valve PI Control...................................................51

2.4 Cooling Operation Fan Control...............................................................52

3. Special Control......................................................................................53

3.1 Startup Control .......................................................................................53

3.2 Oil Return Operation ..............................................................................54

3.3 Defrosting Operation ..............................................................................56

3.4 Pump-down Residual Operation ............................................................57

3.5 Restart Standby......................................................................................58

3.6 Stopping Operation ................................................................................59

Si34-603

ii Table of Contents

4. Protection Control .................................................................................60

4.1 High Pressure Protection Control ...........................................................60

4.2 Low Pressure Protection Control............................................................61

4.3 Discharge Pipe Protection Control .........................................................62

4.4 Inverter Protection Control .....................................................................63

5. Other Control.........................................................................................64

5.1 Demand Operation .................................................................................64

5.2 Heating Operation Prohibition ................................................................64

6. Outline of Control (Indoor Unit) .............................................................65

6.1 Drain Pump Control ................................................................................65

6.2 Louver Control for Preventing Ceiling Dirt..............................................67

6.3 Thermostat Sensor in Remote Controller ...............................................68

6.4 Freeze Prevention ..................................................................................70

6.5 View of Operations of Swing Flaps ........................................................71

6.6 Electronic Expansion Valve Control .......................................................72

6.7 Hot Start Control (In Heating Operation Only)........................................72

Part 6 Test Operation .................................................................73

1. Test Operation ......................................................................................74

1.1 Procedure and Outline ...........................................................................74

1.2 Operation when Power is Turned On .....................................................77

2. Outdoor Unit PC Board Layout .............................................................78

3. Field Setting ..........................................................................................79

3.1 Field Setting from Remote Controller .....................................................79

3.2 Field Setting from Outdoor Unit..............................................................92

Part 7 Troubleshooting .............................................................111

1. Symptom-based Troubleshooting .......................................................113

2. Troubleshooting by Remote Controller ...............................................116

2.1 The INSPECTION / TEST Button.........................................................116

2.2 Self-diagnosis by Wired Remote Controller .........................................117

2.3 Self-diagnosis by Wireless Remote Controller .....................................118

2.4 Operation of the Remote Controller’s Inspection /

Test Operation Button ..........................................................................120

2.5 Remote Controller Service Mode .........................................................121

2.6 Remote Controller Self-Diagnosis Function .........................................123

3. Troubleshooting by Indication on the Remote Controller....................130

3.1 “A0” Indoor Unit: Error of External Protection Device ...........................130

3.2 “A1” Indoor Unit: PC Board Defect.........................................................131

3.3 “A3” Indoor Unit: Malfunction of Drain Level Control System (33H)......132

3.4 “A6” Indoor Unit: Fan Motor (M1F) Lock, Overload...............................134

3.5 “A7” Indoor Unit: Malfunction of Swing Flap Motor (MA) .......................135

3.6 “A9” Indoor Unit: Malfunction of Moving Part of

Electronic Expansion Valve (20E) ........................................................137

3.7 “AF” Indoor Unit: Drain Level above Limit..............................................139

3.8 “AJ” Indoor Unit: Malfunction of Capacity Determination Device ..........140

3.9 “C4” Indoor Unit: Malfunction of Thermistor (R2T)

for Heat Exchanger ..............................................................................141

3.10 “C5” Indoor Unit: Malfunction of Thermistor (R3T) for Gas Pipes..........142

3.11 “C9” Indoor Unit: Malfunction of Thermistor (R1T) for Suction Air.........143

Si34-603

Table of Contents iii

3.12 “CA” Indoor Unit: Malfunction of Thermistor for Discharge Air...............144

3.13 “CJ” Indoor Unit: Malfunction of Thermostat Sensor

in Remote Controller ............................................................................145

3.14 “E1” Outdoor Unit: PC Board Defect ......................................................146

3.15 “E3” Outdoor Unit: Actuation of High Pressure Switch ..........................147

3.16 “E4” Outdoor Unit: Actuation of Low Pressure Sensor ..........................149

3.17 “E5” Compressor Motor Lock ................................................................151

3.18 “E7” Malfunction of Outdoor Unit Fan Motor..........................................152

3.19 “E9” Outdoor Unit: Malfunction of Moving Part of

Electronic Expansion Valve (Y1E, Y3E) ...............................................153

3.20 “F3” Outdoor Unit: Abnormal Discharge Pipe Temperature ..................155

3.21 “F6” Outdoor Unit: Refrigerant Overcharged.........................................156

3.22 “H9” Outdoor Unit: Malfunction of Thermistor (R1T) for Outdoor Air.....157

3.23 “J3” Outdoor Unit: Malfunction of Discharge Pipe Thermistor (R2T) ....158

3.24 “J5” Outdoor Unit: Malfunction of Thermistor (R3T, R5T) for

Suction Pipe 1, 2 ..................................................................................159

3.25 “J6” Outdoor Unit: Malfunction of Thermistor (R4T) for

Outdoor Unit Heat Exchanger ..............................................................160

3.26 “J7” Outdoor Unit: Malfunction of Thermistor (R7T) for

Outdoor Unit Liquid Pipe ......................................................................161

3.27 “J9” Outdoor Unit: Malfunction of Subcooling Heat Exchanger

Gas Pipe Thermistor (R6T) ..................................................................162

3.28 “JA” Outdoor Unit: Malfunction of High Pressure Sensor......................163

3.29 “JC” Outdoor Unit: Malfunction of Low Pressure Sensor.......................164

3.30 “L1” Outdoor Unit: Malfunction of PC Board ..........................................165

3.31 “L4” Outdoor Unit: Malfunction of Inverter Radiating Fin

Temperature Rise.................................................................................166

3.32 “L5” Outdoor Unit: Inverter Compressor Abnormal ...............................167

3.33 “L8” Outdoor Unit: Inverter Current Abnormal .......................................168

3.34 “L9” Outdoor Unit: Inverter Start up Error..............................................169

3.35 “LC” Outdoor Unit: Malfunction of Transmission between Inverter

and Control PC Board ..........................................................................170

3.36 “P1” Outdoor Unit: High Voltage of Capacitor in Main Inverter Circuit ...171

3.37 “P4” Outdoor Unit: Malfunction of Inverter Radiating Fin

Temperature Rise Sensor ....................................................................172

3.38 “UO” Outdoor Unit: Low Pressure Drop Due to Refrigerant Shortage

or Electronic Expansion Valve Failure..................................................173

3.39 “U2” Power Supply Insufficient or Instantaneous Failure ......................175

3.40 “U3” Check Operation not Executed......................................................177

3.41 “U4” Malfunction of Transmission between Indoor Units and

Outdoor Units .......................................................................................178

3.42 “U5” Malfunction of Transmission between Remote Controller

and Indoor Unit.....................................................................................180

3.43 “U8” Malfunction of Transmission between Main and

Sub Remote Controllers .......................................................................181

3.44 “U9” Malfunction of Transmission between Indoor and

Outdoor Units in the Same System......................................................182

3.45 “UA” Excessive Number of Indoor Units ................................................184

3.46 “UC” Address Duplication of Central Remote Controller........................185

3.47 “UE” Malfunction of Transmission between Central Remote Controller

and Indoor Unit.....................................................................................186

3.48 “UF” System is not Set yet .....................................................................188

3.49 “UH” Malfunction of System, Refrigerant System Address Undefined...189

Si34-603

iv Table of Contents

4. Troubleshooting by Indication on the Centralized

Remote Controller ...............................................................................190

4.1 “UE” Malfunction of Transmission between Centralized Remote

Controller and Indoor Unit ....................................................................190

4.2 “M1” PC Board Defect ............................................................................191

4.3 “M8” Malfunction of Transmission between Optional Controllers for

Centralized Control...............................................................................192

4.4 “MA” Improper Combination of Optional Controllers for

Centralized Control...............................................................................193

4.5 “MC” Address Duplication, Improper Setting ..........................................195

5. Troubleshooting by Indication on the Unified ON/OFF Controller.......196

5.1 Operation Lamp Blinks .........................................................................196

5.2 Display “Under Host Computer Integrate Control” Blinks

(Repeats Single Blink) ..........................................................................198

5.3 Display “Under Host Computer Integrate Control” Blinks

(Repeats Double Blink) ........................................................................201

Part 8 Appendix......................................................................... 205

1. Piping Diagrams..................................................................................206

1.1 Outdoor Unit .........................................................................................206

1.2 Indoor Unit............................................................................................207

2. Wiring Diagrams..................................................................................210

2.1 Outdoor Unit .........................................................................................210

2.2 Field Wiring ..........................................................................................212

2.3 Indoor Unit............................................................................................213

3. Option List...........................................................................................226

3.1 Option List of Controllers ......................................................................226

3.2 Option List of Outdoor Unit...................................................................228

4. Example of Connection.......................................................................229

5. Thermistor Resistance / Temperature Characteristics........................231

6. Pressure Sensor .................................................................................233

7. Method of Replacing the Inverter’s Power Transistors Modules.........234

Part 9 Precautions for New Refrigerant (R-410A).................... 237

1. Precautions for New Refrigerant (R-410A) .........................................238

1.1 Outline ..................................................................................................238

1.2 Refrigerant Cylinders............................................................................240

1.3 Service Tools........................................................................................241

Index .............................................................................................i

Drawings & Flow Charts ...............................................................iii

Si34-603 Introduction

v

1. Introduction

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “ Warning” and “ Caution”. The “ Warning”

items are especially important since they can lead to death or serious injury if they are not

followed closely. The “ Caution” items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

About the pictograms

This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer

1.1.1 Caution in Repair

Warning

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for a repair.

Working on the equipment that is connected to a power supply can cause an

electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas discharges during the repair work, do not touch the

discharging refrigerant gas.

The refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the

welded section, release the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it can

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas can generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor can cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging the

power cable plug.

Plugging or unplugging the power cable plug to operate the equipment can

cause an electrical shock or fire.

Introduction Si34-603

vi

1.1.2 Cautions Regarding Products after Repair

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands can cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water can cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when cleaning

the equipment.

The internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it.

The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down

sufficiently before conducting repair work.

Working on the unit when the refrigerating cycle section is hot can cause burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room can cause oxygen deficiency.

Warning

Be sure to use parts listed in the service parts list of the applicable model and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools can cause an electrical shock,

excessive heat generation or fire.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the provided standard

installation frame.

Incorrect use of the installation frame and improper installation can cause the

equipment to fall, resulting in injury.

For integral units

only

Be sure to install the product securely in the installation frame mounted on a

window frame.

If the unit is not securely mounted, it can fall and cause injury.

For integral units

only

Be sure to use an exclusive power circuit for the equipment, and follow the

technical standards related to the electrical equipment, the internal wiring

regulations and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work can cause an

electrical shock or fire.

Si34-603 Introduction

vii

1.1.3 Inspection after Repair

Be sure to use the specified cable to connect between the indoor and outdoor

units. Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections can cause excessive heat generation or fire.

When connecting the cable between the indoor and outdoor units, make sure

that the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section can cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable

can damage the cable.

Do not mix air or gas other than the specified refrigerant (R-410A) in the

refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before

charging the refrigerant. After charging refrigerant, make sure that there is no

refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to

perform pump-down and close the service valve, to prevent the refrigerant gas

from leaking into the room. The refrigerant gas itself is harmless, but it can

generate toxic gases when it contacts flames, such as fan and other heaters,

stoves and ranges.

When replacing the coin battery in the remote controller, be sure to disposed

of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Warning

Caution

Installation of a leakage breaker is necessary in some cases depending on the

conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water can enter the room and

wet the furniture and floor.

For integral units

only

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert

the plug into a power outlet all the way.

If the plug has dust or loose connection, it can cause an electrical shock or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires can cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances, since it can cause an electrical shock,

excessive heat generation or fire.

Introduction Si34-603

viii

1.1.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

icon is described in the table below:

1.1.5 Using Icons List

Caution

Check to see if the parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections can cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame can cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding can cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 Mohm or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture

and floor.

Icon Type of

Information

Description

Note:

Note A “note” provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution A “caution” is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get

an unexpected result or has to restart (part of) a procedure.

Warning

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or

in this manual, where he/she will find additional information on a

specific topic.

Si34-603 Introduction

ix

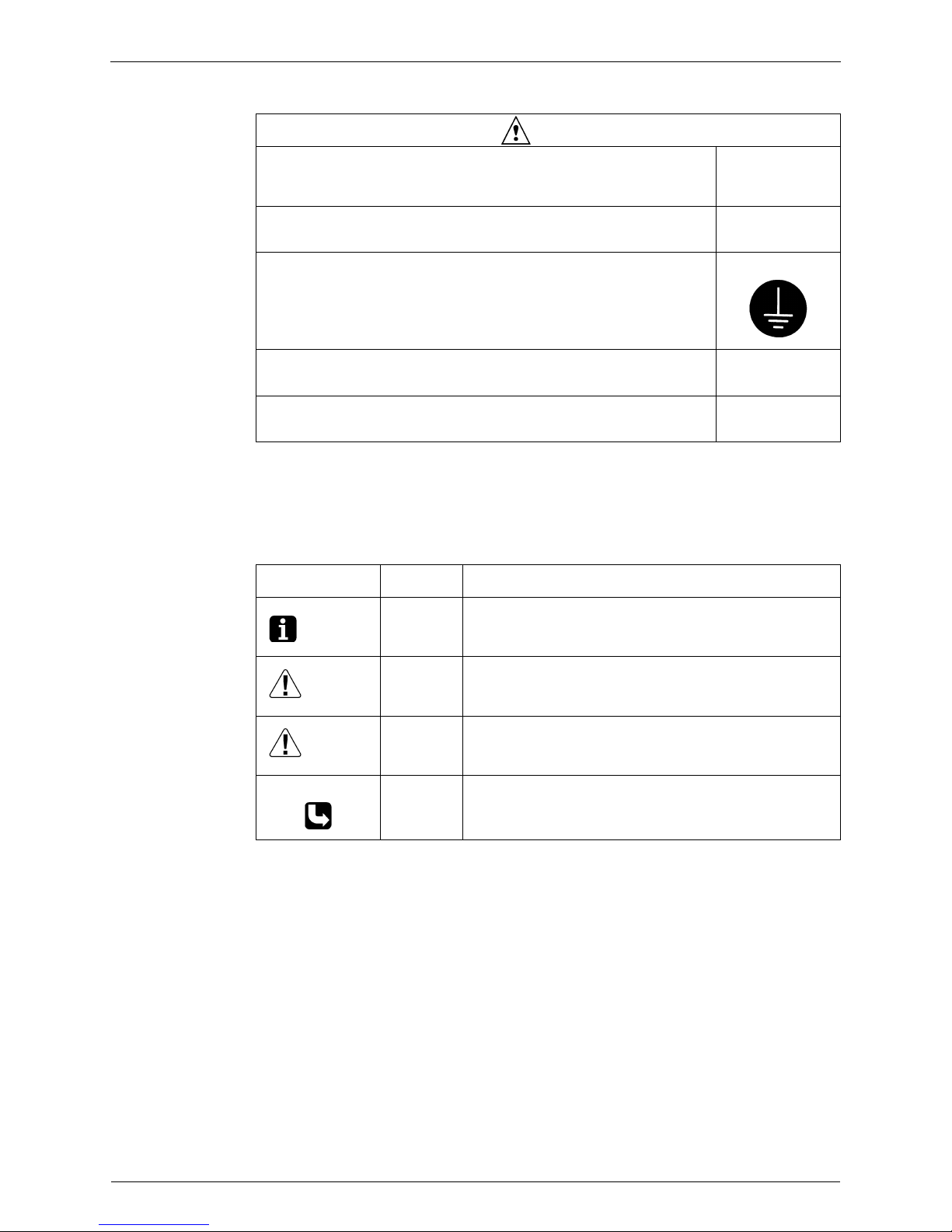

1.2 PREFACE

Thank you for your continued patronage of Daikin products.

This is the new service manual for Daikin's Year 2006 VRVIII-S series Heat Pump / Cooling

Only System.

Daikin offers a wide range of models to respond to building and office air conditioning needs.

We are confident that customers will be able to find the models that best suit their needs.

This service manual contains information regarding the servicing of VRVIII-S series R-410A

Heat Pump / Cooling Only System.

July, 2006

After Sales Service Division

Introduction Si34-603

x

Si34-603

General Information 1

Part 1

General Information

1. Model Names of Indoor/Outdoor Units....................................................2

2. External Appearance...............................................................................3

2.1 Indoor Units ..............................................................................................3

3. Capacity Range.......................................................................................4

Model Names of Indoor/Outdoor Units Si34-603

2 General Information

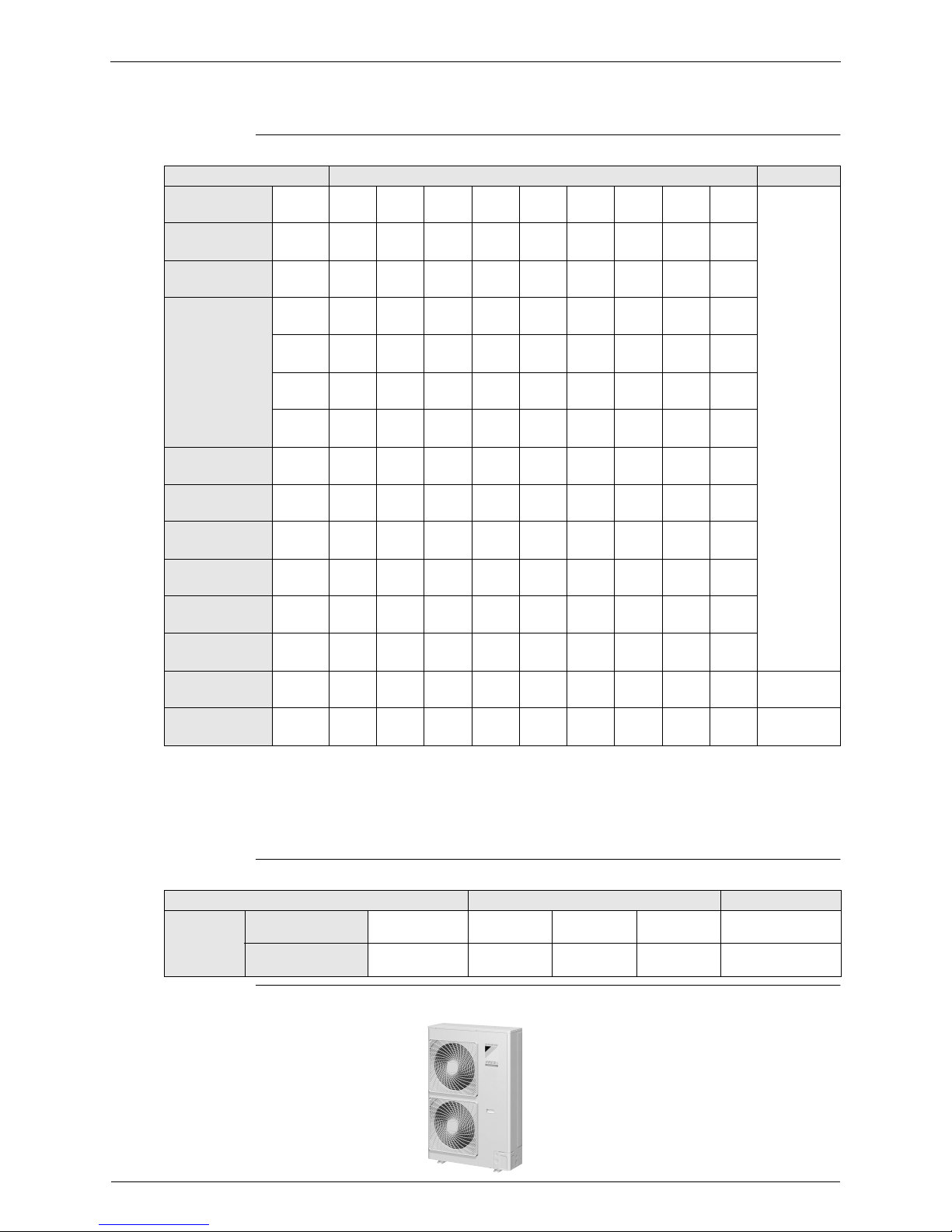

1. Model Names of Indoor/Outdoor Units

*Indoor Units

Note:FXDQ has following 2 Series, as shown below.

FXDQ-P, N(A)VET: without Drain Pump (For General, Asia: except for EU, China and Australia)

FXDQ-P, N(A)VE: with Drain Pump

BEV unit is required for each indoor unit.

*1 VE:1φ, 220~240V, 50Hz, 1φ, 220V, 60Hz

V1:1φ, 220~240V, 50Hz

Outdoor Units

Type Model Name

Power Supply

Ceiling Mounted

Cassette Type

(Double Flow)

FXCQ 20M 25M 32M 40M 50M 63M 80M — 125M

VE *1

Ceiling Mounted

Cassette Type

(Multi Flow)

FXFQ — 25M 32M 40M 50M 63M 80M 100M 125M

Ceiling Mounted

Cassette Corner

Type

FXKQ —

25MA 32MA 40MA

—

63MA

———

Slim Ceiling

Mounted Duct

Type

FXDQPVE

20P 25P 32P — — — — — —

FXDQPVET

20P 25P 32P — — — — — —

FXDQNAVE

20NA 25NA 32NA 40NA 50NA 63NA — — —

FXDQNVET

20N 25N 32N 40N 50N 63N — — —

Ceiling Mounted

Built-In Type

FXSQ 20M 25M 32M 40M 50M 63M 80M 100M 125M

Ceiling Mounted

Duct Type

FXMQ — — —

40MA 50MA 63MA 80MA

100MA 125MA

Ceiling Suspended

Type

FXHQ — —

32MA

——

63MA

—

100MA

—

Wall Mounted

Type

FXAQ

20MA 25MA 32MA 40MA 50MA 63MA

———

Floor Standing

Type

FXLQ

20MA 25MA 32MA 40MA 50MA 63MA

———

Concealed Floor

Standing Type

FXNQ

20MA 25MA 32MA 40MA 50MA 63MA

———

Ceiling Suspended

Cassette Type

FXUQ——————

71MA

100MA 125MA

V1

Connection Unit

BEVQM(A)

——————

71MA

100MA 125MA

VE *1

Series Model Name

Power Supply

Inverter

Heat Pump RXYMQ 4P 5P 6P VE *2

Cooling Only RXMQ 4P 5P 6P VE *2

*2 VE:1φ, 220~230V, 50Hz, 1φ, 220V, 60Hz

Si34-603 External Appearance

General Information 3

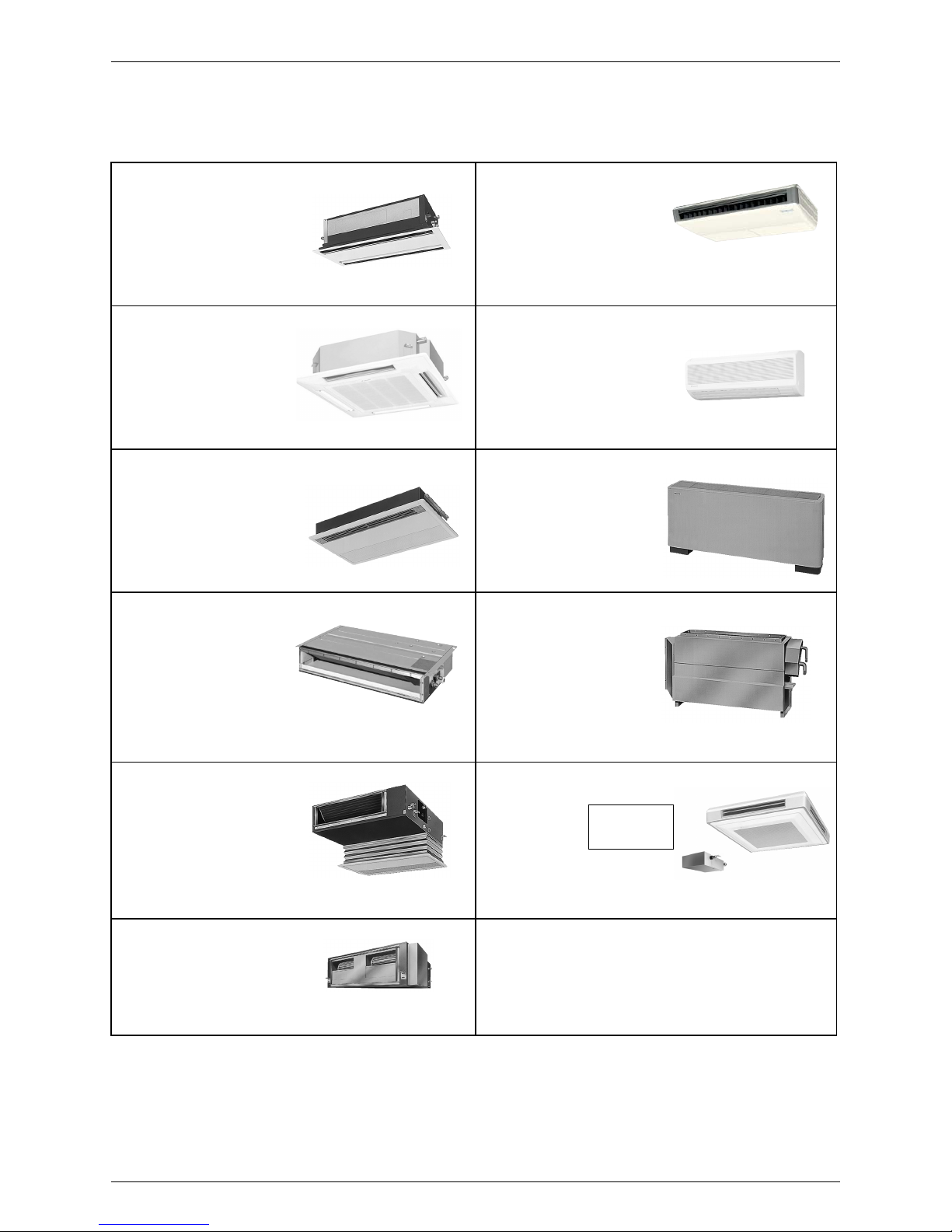

2. External Appearance

2.1 Indoor Units

Ceiling Mounted Cassette Type (Double Flow)

FXCQ20M

FXCQ25M

FXCQ32M

FXCQ40M

FXCQ50M

FXCQ63M

FXCQ80M

FXCQ125M

Ceiling Suspended Type

FXHQ32MA

FXHQ63MA

FXHQ100MA

Ceiling Mounted Cassette Type (Multi Flow)

FXFQ25M

FXFQ32M

FXFQ40M

FXFQ50M

FXFQ63M

FXFQ80M

FXFQ100M

FXFQ125M

Wall Mounted Type

FXAQ20MA

FXAQ25MA

FXAQ32MA

FXAQ40MA

FXAQ50MA

FXAQ63MA

Ceiling Mounted Cassette Corner Type

FXKQ25MA

FXKQ32MA

FXKQ40MA

FXKQ63MA

Floor Standing Type

FXLQ20MA

FXLQ25MA

FXLQ32MA

FXLQ40MA

FXLQ50MA

FXLQ63MA

Slim Ceiling Mounted Duct Type

FXDQ20P FXDQ20N(A)

FXDQ25P FXDQ25N(A)

FXDQ32P FXDQ32N(A)

FXDQ40N(A)

FXDQ50N(A)

FXDQ63N(A)

with Drain Pump (VE)

without Drain Pump (VET)

Concealed Floor Standing Type

FXNQ20MA

FXNQ25MA

FXNQ32MA

FXNQ40MA

FXNQ50MA

FXNQ63MA

Ceiling Mounted Built-In Type

FXSQ20M

FXSQ25M

FXSQ32M

FXSQ40M

FXSQ50M

FXSQ63M

FXSQ80M

FXSQ100M

FXSQ125M

Ceiling Suspended Cassette Type

(Connection Unit Series)

FXUQ71MA +

FXUQ100MA +

FXUQ125MA +

Connection Unit

Ceiling Mounted Duct Type

FXMQ40MA

FXMQ50MA

FXMQ63MA

FXMQ80MA

FXMQ100MA

FXMQ125MA

BEVQ71MA

BEVQ100MA

BEVQ125MA

Capacity Range Si34-603

4 General Information

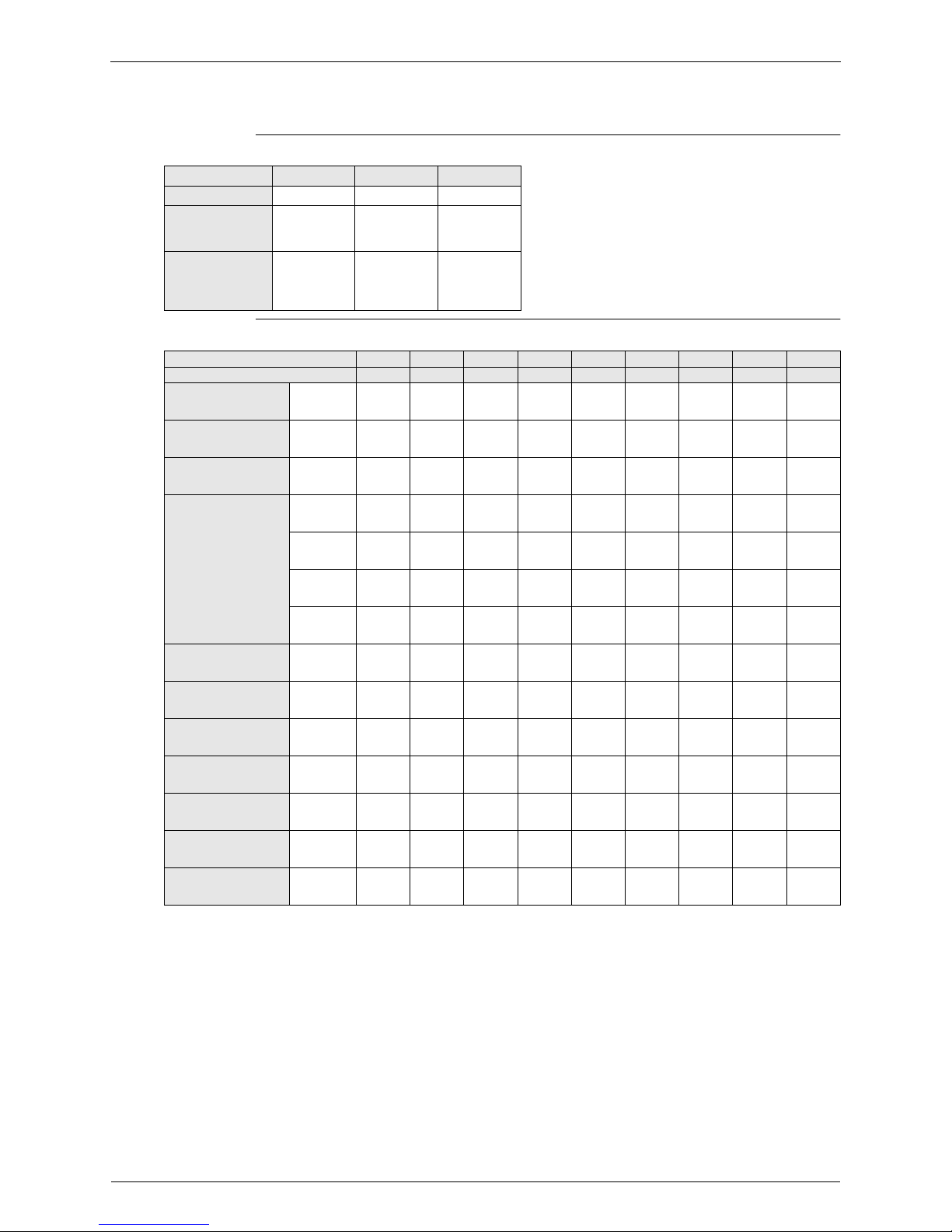

3. Capacity Range

Outdoor Units

Indoor Units

Note:FXDQ has following 2 Series, as shown below.

FXDQ-P, NVET: without Drain Pump (For General, Asia: except for EU, China and Australia)

FXDQ-P, NAVE: with Drain Pump

Capacity Range 4HP 5HP 6HP

RX(Y)MQ 4P 5P 6P

No of Indoor

Units to be

Connected

689

Total Capacity

Index of Indoor

Units to be

Connected

50~130 62.5~162.5 70~182

Capacity Range 0.8HP 1HP

1.25HP

1.6HP 2HP 2.5HP 3.2HP 4HP 5HP

Capacity Index 20 25 31.25 40 50 62.5 80 100 125

Ceiling Mounted

Cassette Type

(Double Flow)

FXCQ 20M 25M 32M 40M 50M 63M 80M — 125M

Ceiling Mounted

Cassette Type

(Multi Flow)

FXFQ — 25M 32M 40M 50M 63M 80M 100M 125M

Ceiling Mounted

Cassette Corner Type

FXKQ — 25MA 32MA 40MA — 63MA — — —

Slim Ceiling Mounted

Duct Type

FXDQPVE

20P 25P 32P — — — — — —

FXDQPVET

20P 25P 32P — — — — — —

FXDQNAVE

20NA 25NA 32NA 40NA 50NA 63NA — — —

FXDQNVET

20N 25N 32N 40N 50N 63N — — —

Ceiling Mounted

Built-In Type

FXSQ 20M 25M 32M 40M 50M 63M 80M 100M 125M

Ceiling Mounted

Duct Type

FXMQ — — — 40MA 50MA 63MA 80MA 100MA 125MA

Ceiling Suspended

Type

FXHQ — — 32MA — — 63MA — 100MA —

Wall Mounted Type

FXAQ 20MA 25MA 32MA 40MA 50MA 63MA — — —

Floor Standing Type

FXLQ 20MA 25MA 32MA 40MA 50MA 63MA — — —

Concealed Floor

Standing Type

FXNQ 20MA 25MA 32MA 40MA 50MA 63MA — — —

Ceiling Suspended

Cassette Type

FXUQ — — — — — — 71MA 100MA 125MA

Si34-603

Specifications 5

Part 2

Specifications

1. Specifications..........................................................................................6

1.1 Outdoor Units ...........................................................................................6

1.2 Indoor Units ............................................................................................10

Specifications Si34-603

6 Specifications

1. Specifications

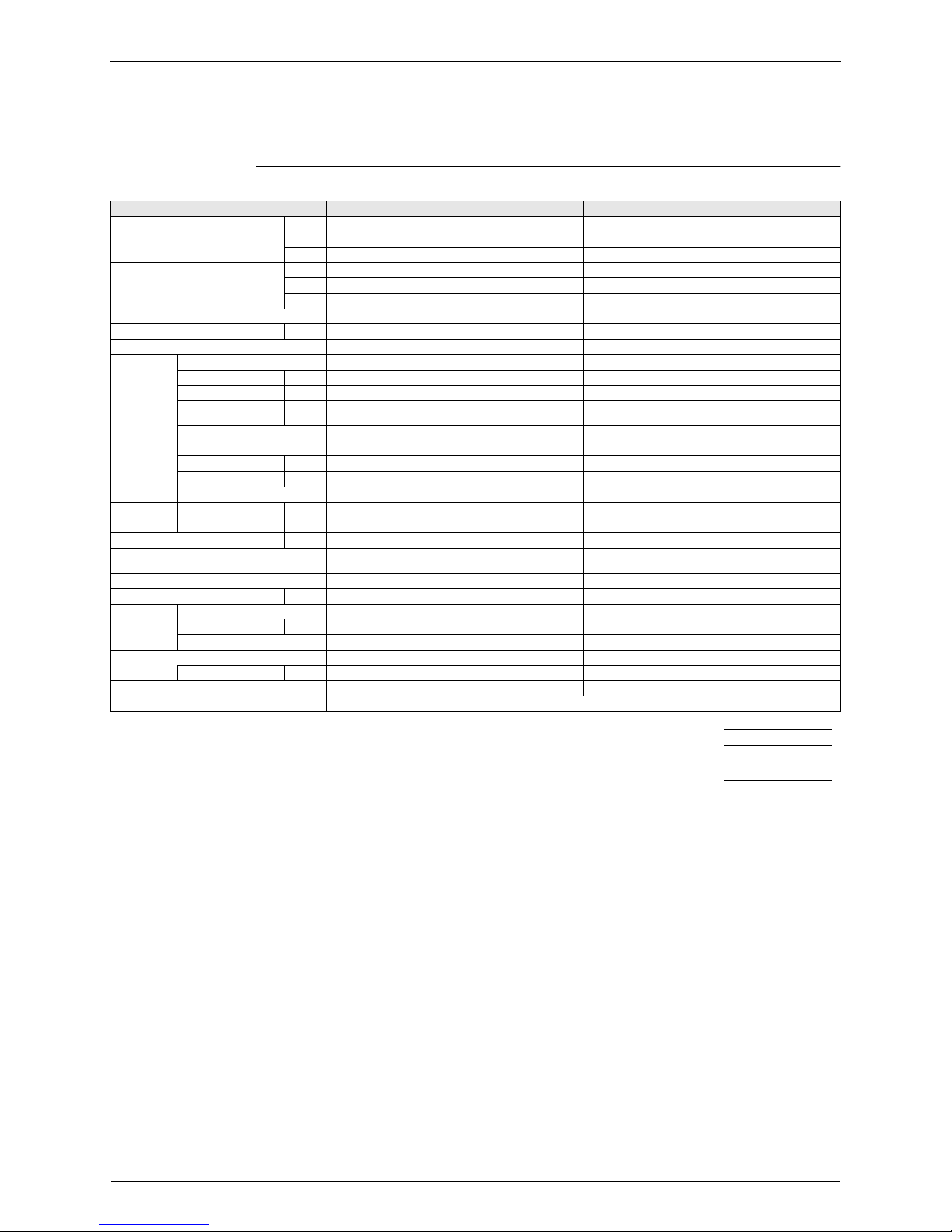

1.1 Outdoor Units

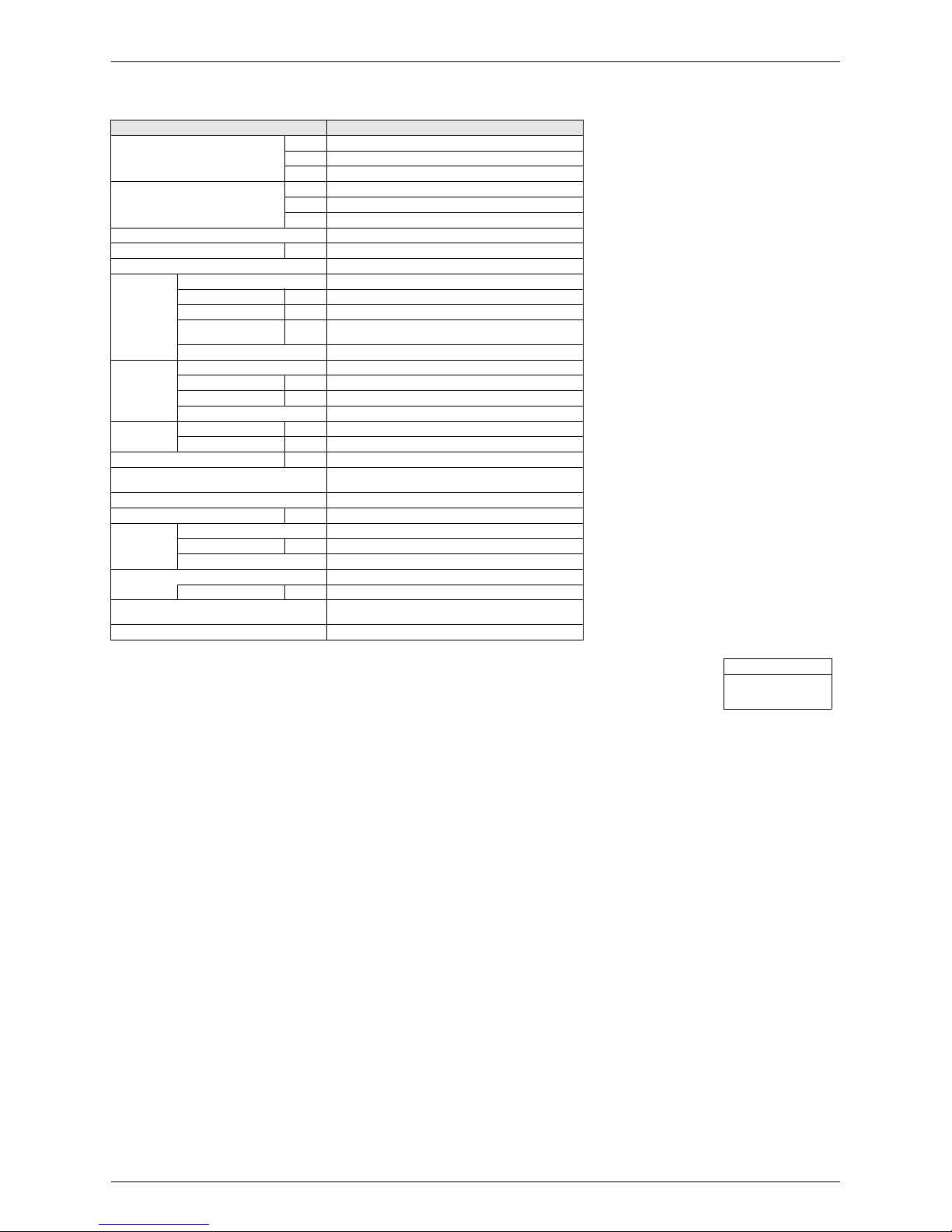

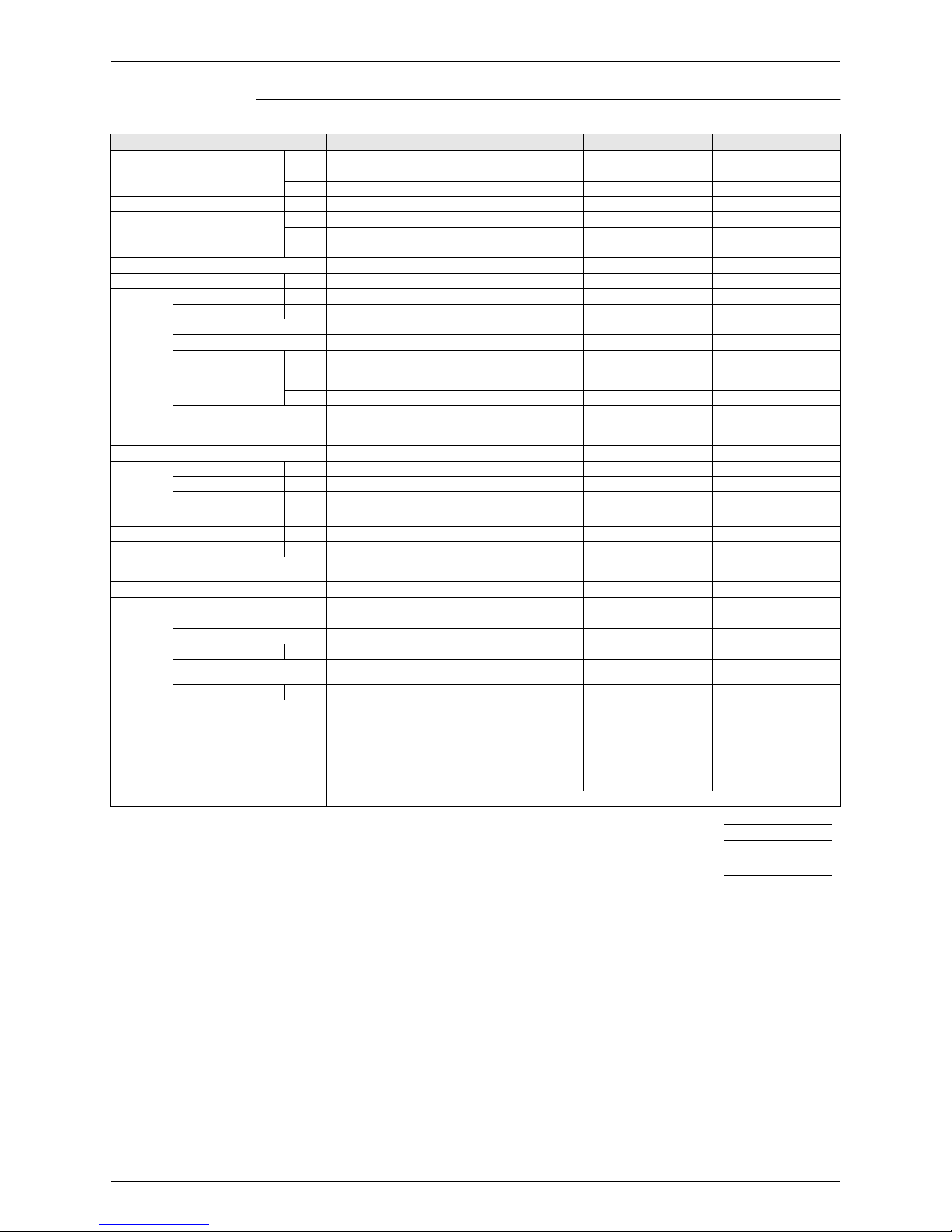

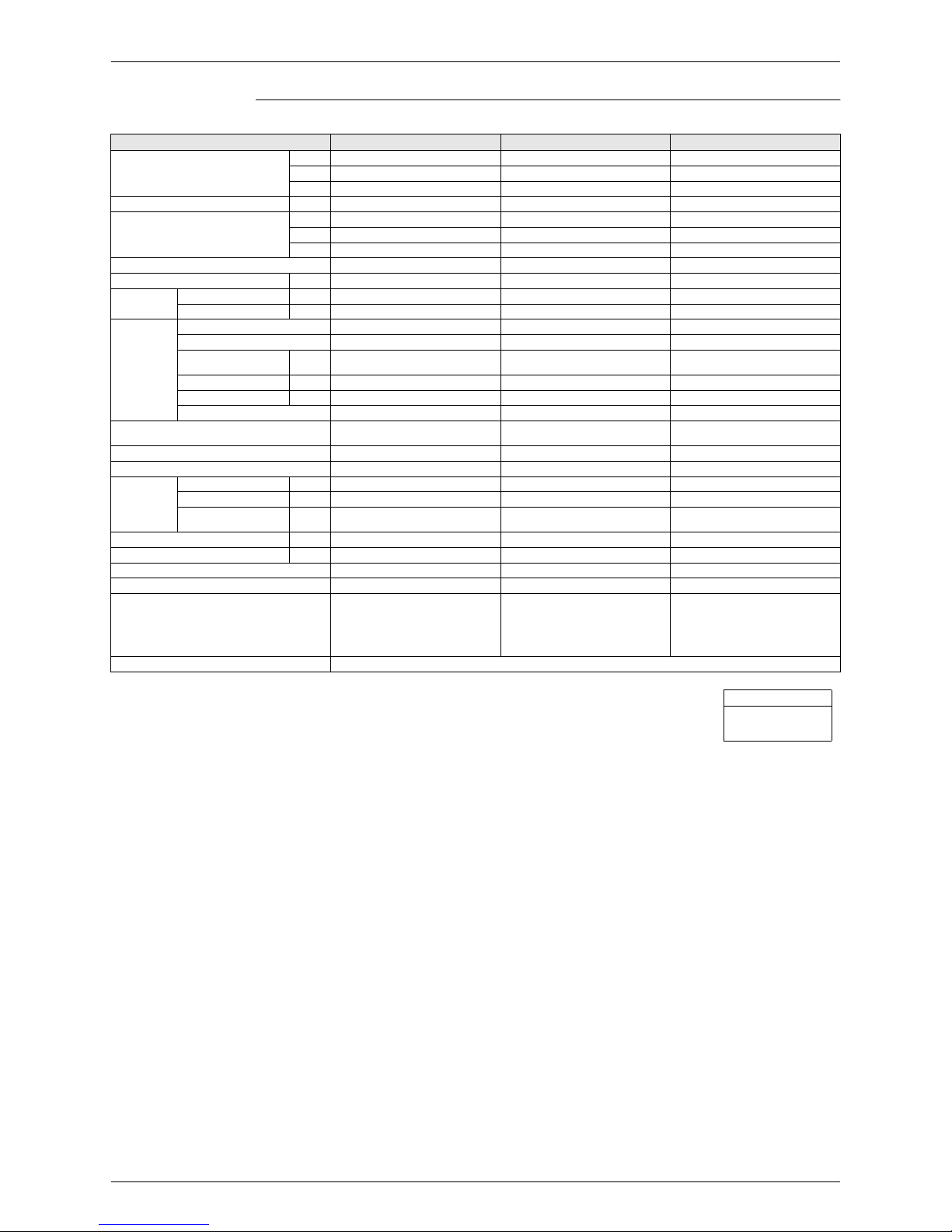

Heat Pump 50/60Hz <RXYMQ-PVE>

Notes:

1 Indoor temp. : 27°CDB, 19°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

2 Indoor temp. : 20°CDB / outdoor temp. : 7°CDB, 6°CWB / Equivalent piping length : 7.5m, level difference

: 0m.

Model Name RXYMQ4PVE RXYMQ5PVE

1 Cooling Capacity

kcal / h 9,600 12,000

Btu / h 38,200 47,800

kW 11.2 14.0

2 Heating Capacity

kcal / h 10,800 13,800

Btu / h 42,700 54,600

kW 12.5 16.0

Casing Color Ivory White Ivory White

Dimensions: (H×W×D) mm 1,345×900×320 1,345×900×320

Heat Exchanger Cross Fin Coil Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type

Piston Displacement m³/h 19.36 19.36

Number of Revolutions r.p.m 6,480 6,480

Motor Output×Number

of Units

kW 2.5×1 3.0×1

Starting Method Direct on line Direct on line

Fan

Type Propeller Fan Propeller Fan

Motor Output W 70×270×2

Air Flow Rate m³/min 106 106

Drive Direct Drive Direct Drive

Connecting

Pipes

Liquid Pipe mm φ9.5 (Flare Connection) φ9.5 (Flare Connection)

Gas Pip e mm φ15.9 (Flare Connection) φ15.9 (Flare Connection)

Machine Weight kg 125 125

Safety Devices

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

Defrost Method Reverse cycle defrosting Reverse cycle defrosting

Capacity Control % 24~100 24~100

Refrigerant

Refrigerant Name R-410A R-410A

Charge kg 4.0 4.0

Control Electronic Expansion Valve Electronic Expansion Valve

Refrigerator

Oil

DAPHNE FVC68D DAPHNE FVC68D

Charge Volume L 1.5 1.5

Standard Accessories Installation Manual, Operation Manual, Clamps Installation Manual, Operation Manual, Clamps

Drawing No. C: 4D052608

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 7

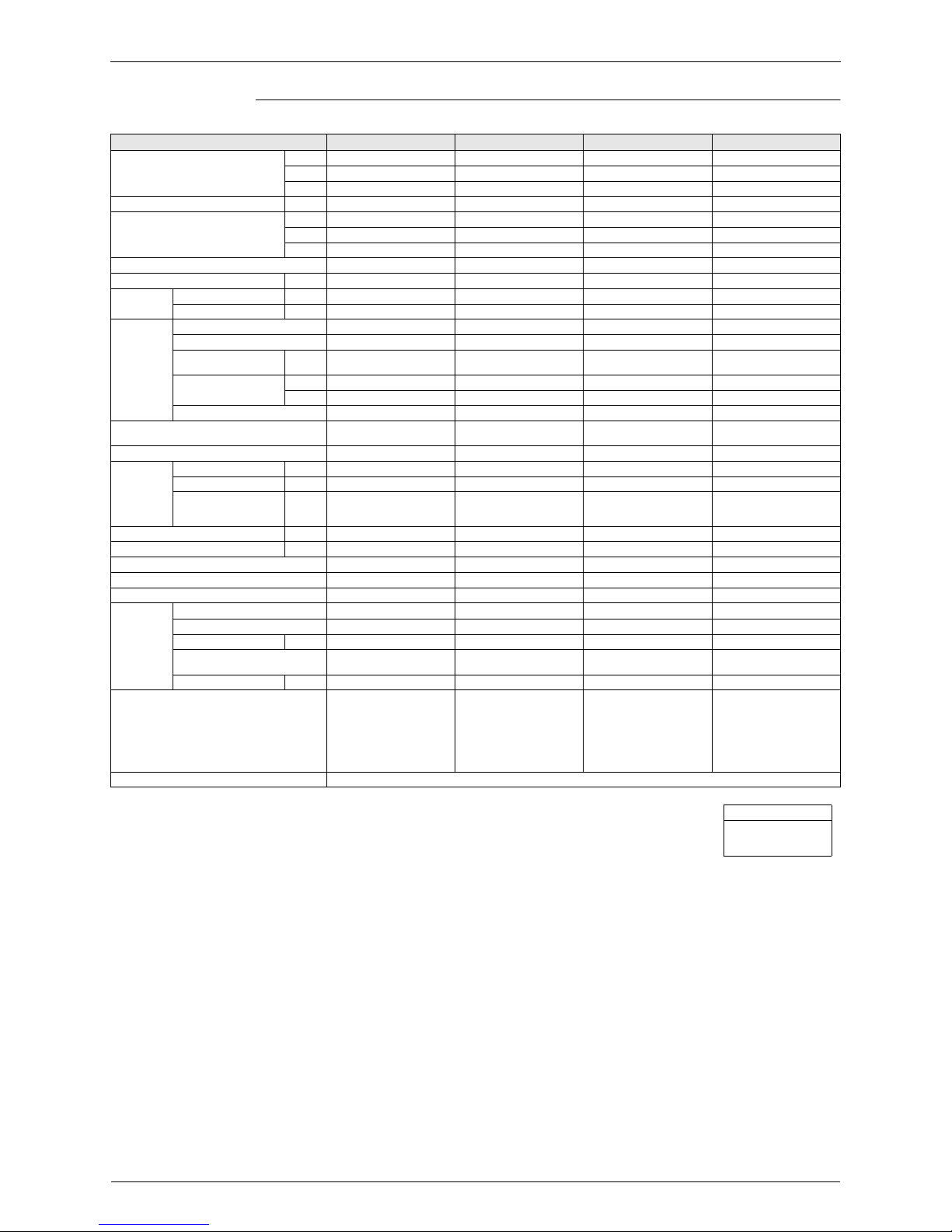

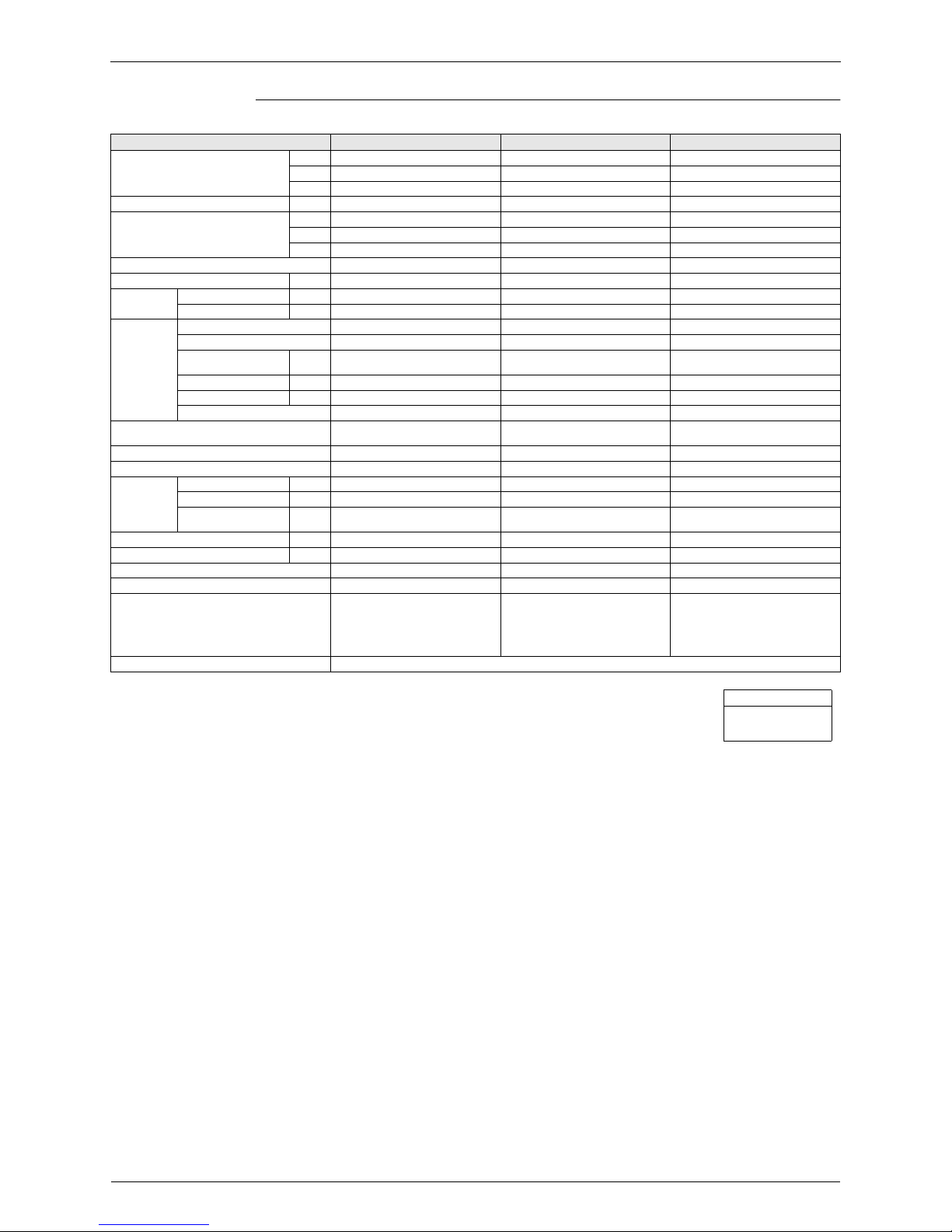

Notes:

1 Indoor temp. : 27°CDB, 19°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

2 Indoor temp. : 20°CDB / outdoor temp. : 7°CDB, 6°CWB / Equivalent piping length : 7.5m, level difference

: 0m.

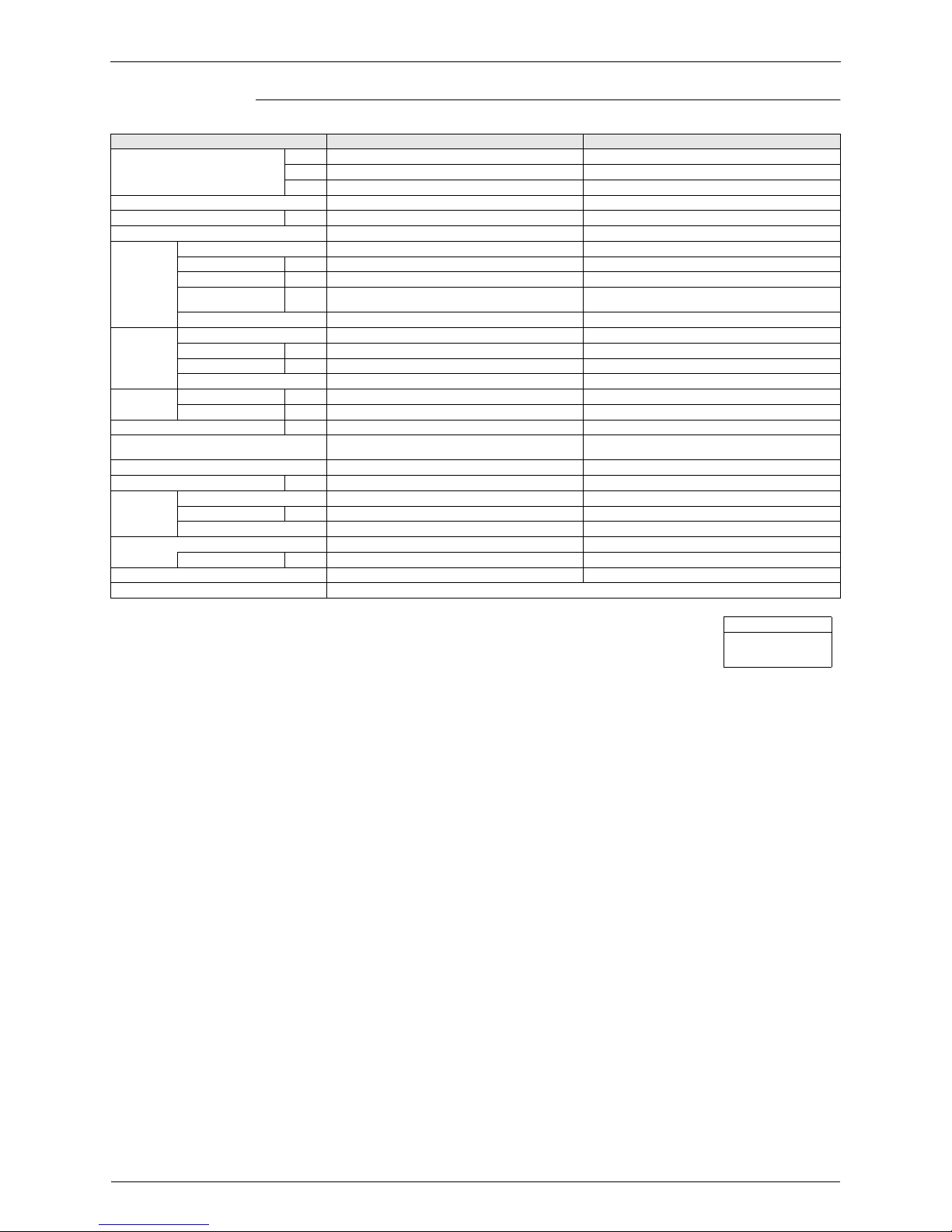

Model Name RXYMQ6PVE

1 Cooling Capacity

kcal / h 13,300

Btu / h 52,900

kW 15.5

2 Heating Capacity

kcal / h 15,500

Btu / h 61,400

kW 18.0

Casing Color Ivory Whi te

Dimensions: (H×W×D) mm 1,345×900×320

Heat Exchanger Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type

Piston Displacement m³/h 19.36

Number of Revolutions r.p.m 6,480

Motor Output×Number

of Units

kW 3.5×1

Starting Method Direct on line

Fan

Type Propeller Fan

Motor Output W 70×2

Air Flow Rate m³/min 106

Drive Direct Drive

Connecting

Pipes

Liquid Pipe mm φ9.5 (Flare Connection)

Gas Pip e mm φ19.1 (Brazing Connection)

Machine Weight kg 125

Safety Devices

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

Defrost Method Reverse cycle defrosting

Capacity Control % 24~100

Refrigerant

Refrigerant Name R-410A

Charge kg 4.0

Control Electronic Expansion Valve

Refrigerator

Oil

DAPHNE FVC68D

Charge Volume L 1.5

Standard Accessories

Installation Manual, Operation Manual, Clamps,

Auxiliary Piping

Drawing No. C: 4D052608

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Specifications Si34-603

8 Specifications

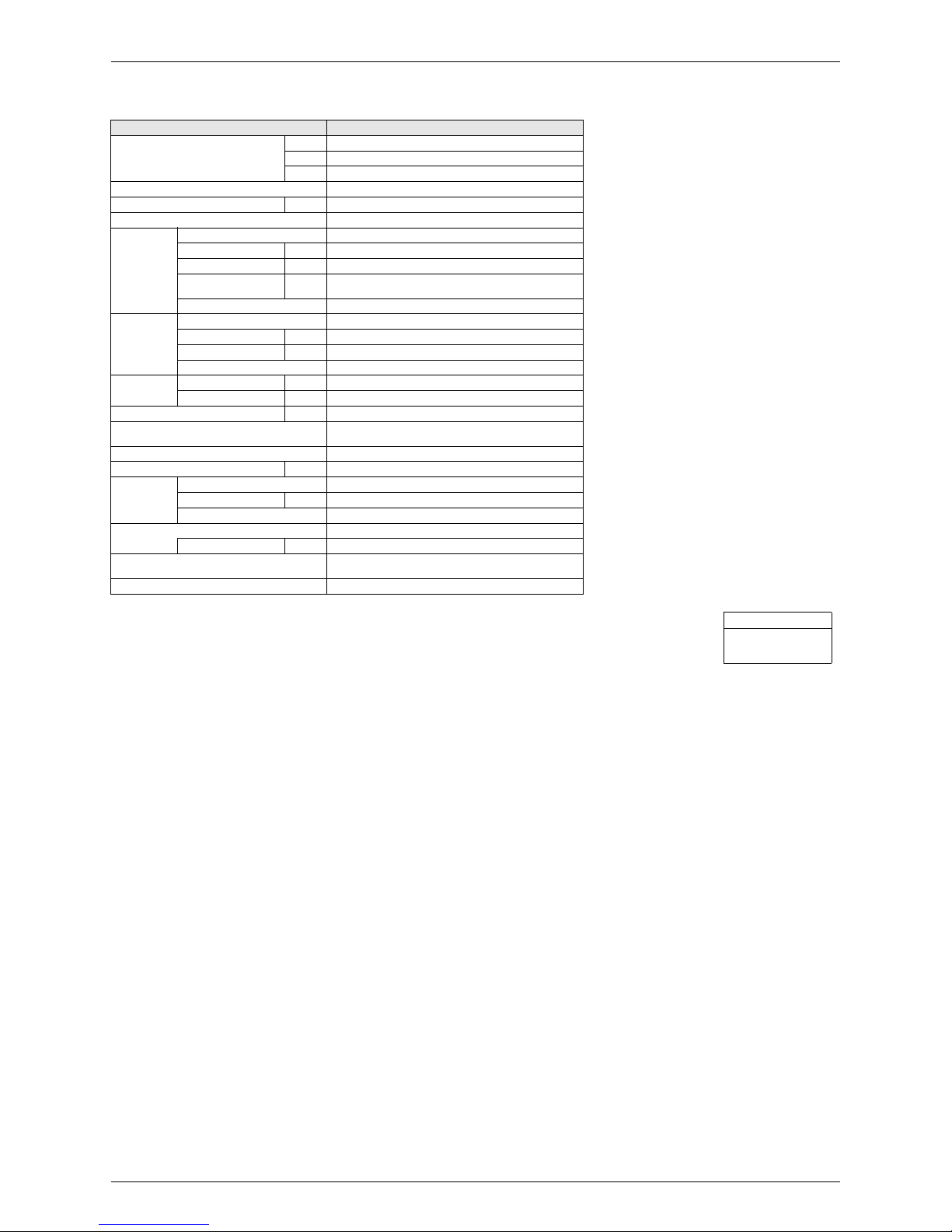

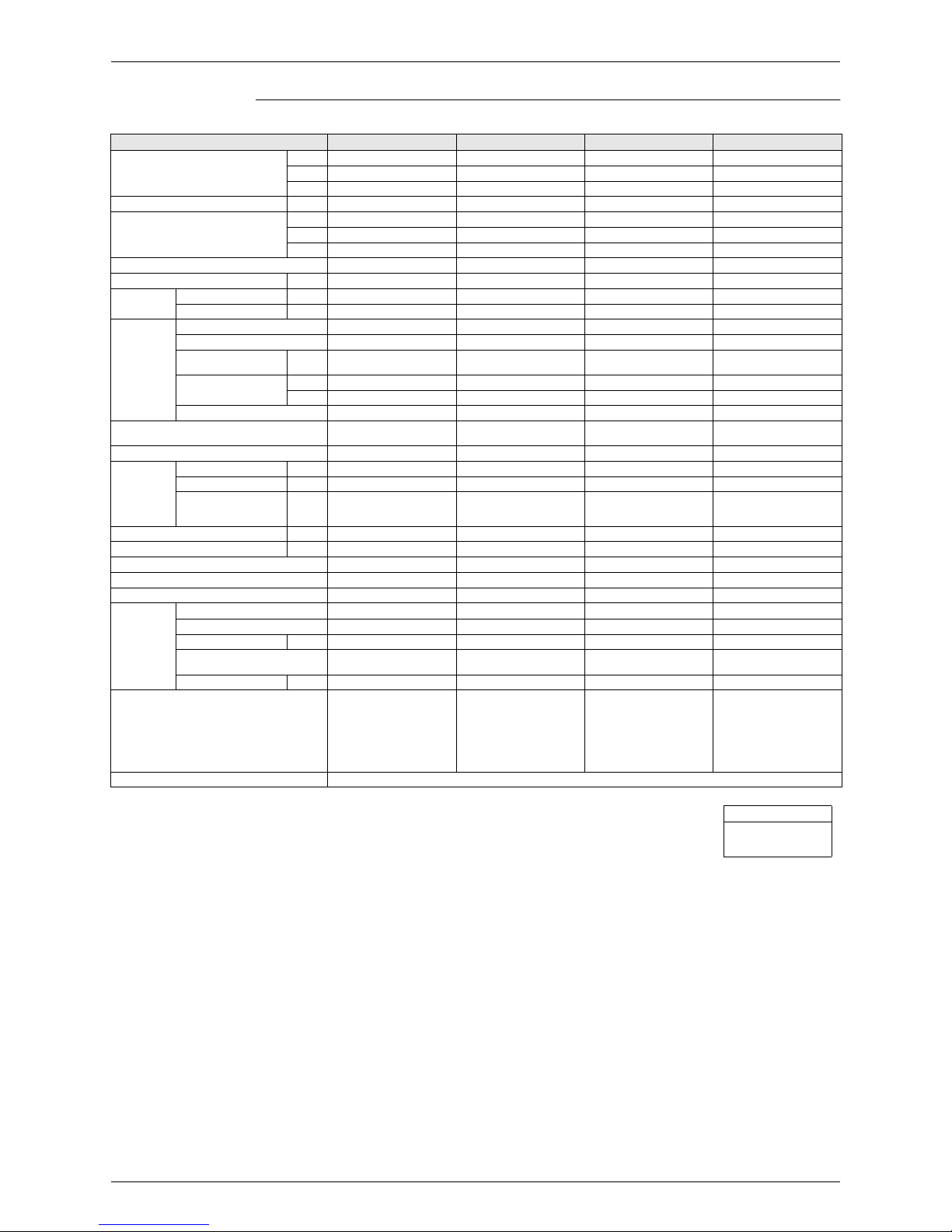

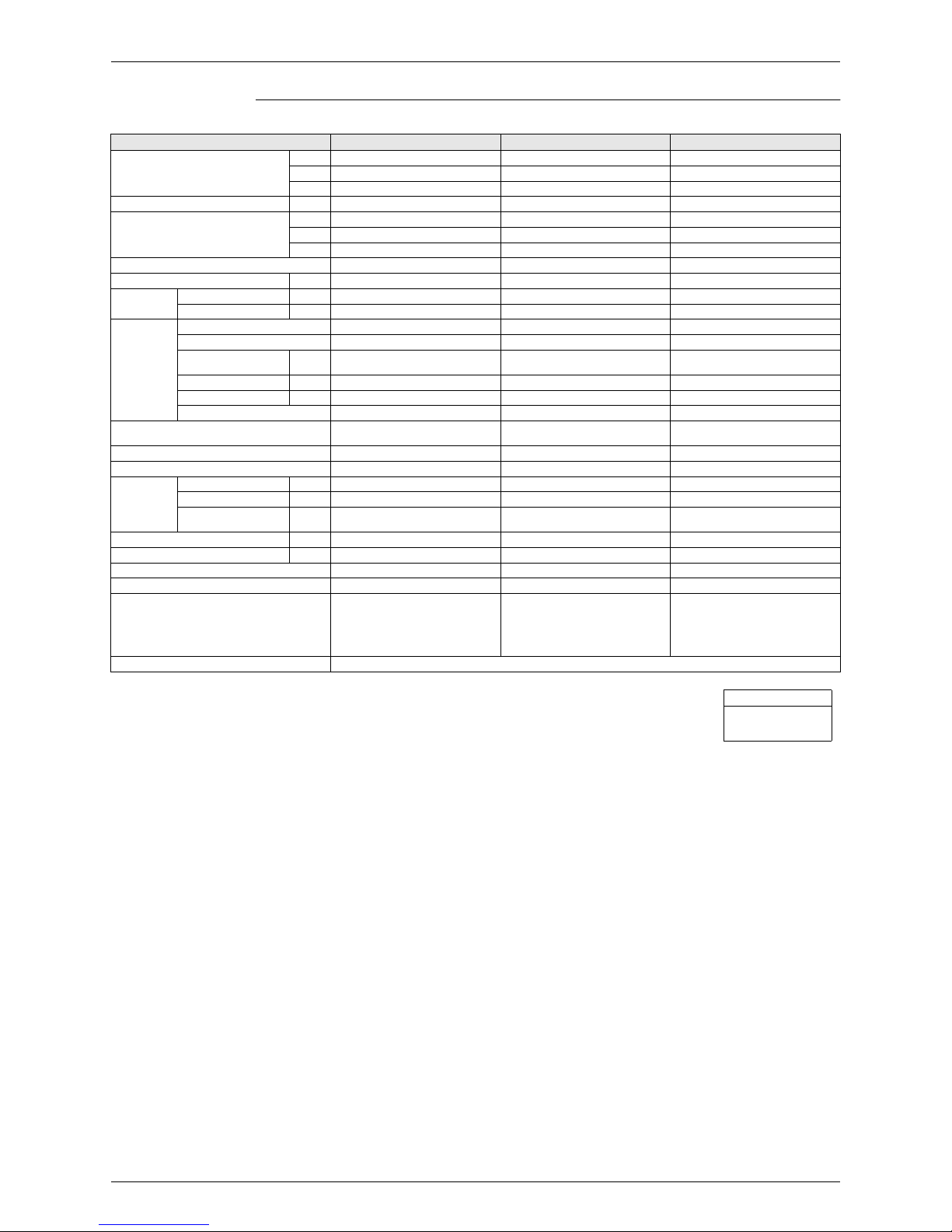

Cooling Only 50/60Hz <RXMQ-PVE>

Notes:

1 Indoor temp. : 27°CDB, 19°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

Model Name RXMQ4PVE RXMQ5PVE

1 Cooling Capacity

kcal / h 9,600 12,000

Btu / h 38,200 47,800

kW 11.2 14.0

Casing Color Ivory White Ivory White

Dimensions: (H×W×D) mm 1,345×900×320 1,345×900×320

Heat Exchanger Cross Fin Coil Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type Hermetically Sealed Scroll Type

Piston Displacement m³/h 19.36 19.36

Number of Revolutions r.p.m 6,480 6,480

Motor Output×Number

of Units

kW 2.5×1 3.0×1

Starting Method Direct on line Direct on line

Fan

Type Propeller Fan Propeller Fan

Motor Output W 70×270×2

Air Flow Rate m³/min 106 106

Drive Direct Drive Direct Drive

Connecting

Pipes

Liquid Pipe mm φ9.5 (Flare Connection) φ9.5 (Flare Connection)

Gas Pip e mm φ15.9 (Flare Connection) φ15.9 (Flare Connection)

Machine Weight kg 125 125

Safety Devices

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

Defrost Method Reverse cycle defrosting Reverse cycle defrosting

Capacity Control % 24~100 24~100

Refrigerant

Refrigerant Name R-410A R-410A

Charge kg 4.0 4.0

Control Electronic Expansion Valve Electronic Expansion Valve

Refrigerator

Oil

DAPHNE FVC68D DAPHNE FVC68D

Charge Volume L 1.5 1.5

Standard Accessories Installation Manual, Operation Manual, Clamps Installation Manual, Operation Manual, Clamps

Drawing No. C: 4D052613

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 9

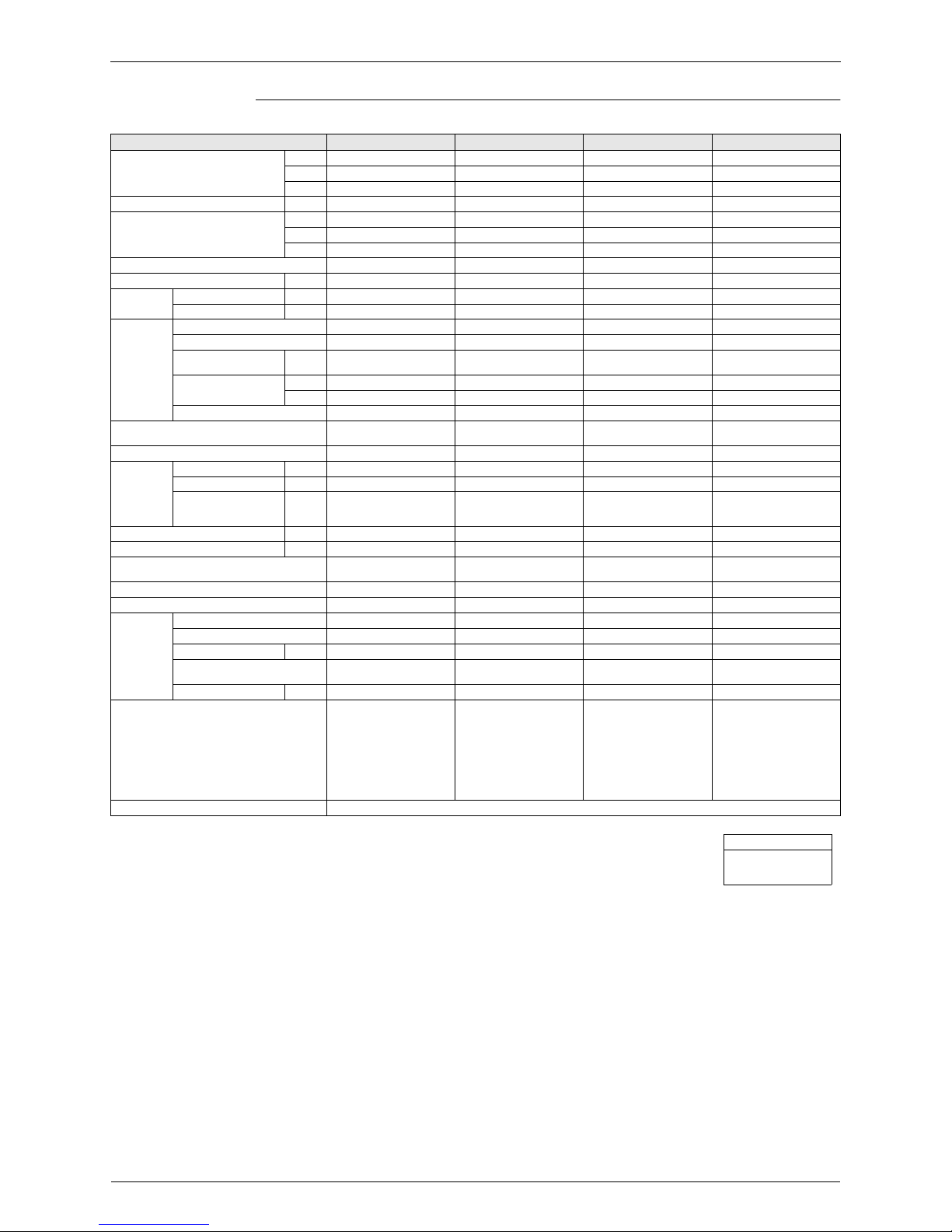

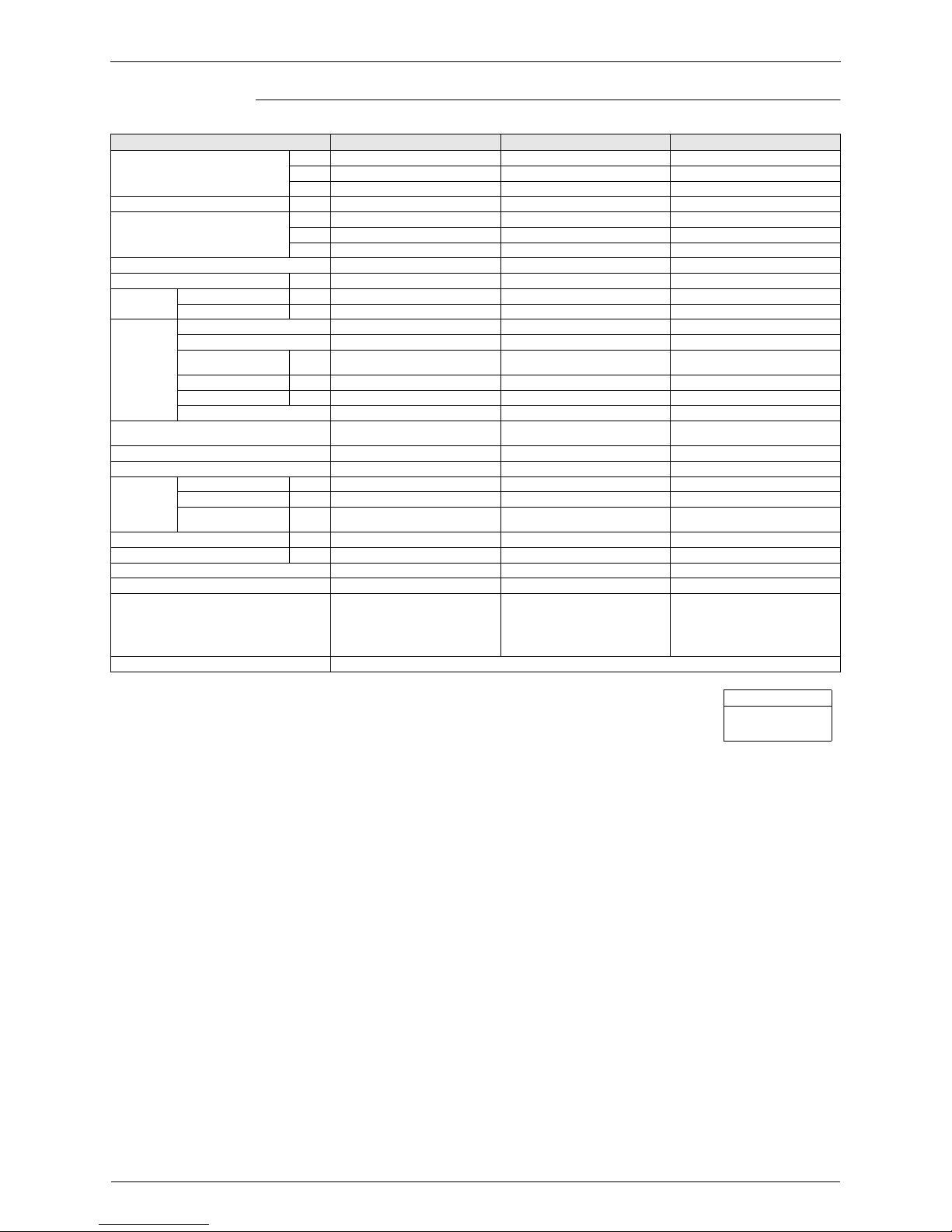

Notes:

1 Indoor temp. : 27°CDB, 19°CWB / outdoor temp. : 35°CDB / Equivalent piping length : 7.5m, level

difference : 0m.

Model Name RXMQ6PVE

1 Cooling Capacity

kcal / h 13,300

Btu / h 52,900

kW 15.5

Casing Color Ivory Whi te

Dimensions: (H×W×D) mm 1,345×900×320

Heat Exchanger Cross Fin Coil

Comp.

Type Hermetically Sealed Scroll Type

Piston Displacement m³/h 19.36

Number of Revolutions r.p.m 6,480

Motor Output×Number

of Units

kW 3.5×1

Starting Method Direct on line

Fan

Type Propeller Fan

Motor Output W 70×2

Air Flow Rate m³/min 106

Drive Direct Drive

Connecting

Pipes

Liquid Pipe mm φ9.5 (Flare Connection)

Gas Pip e mm φ19.1 (Brazing Connection)

Machine Weight kg 125

Safety Devices

High Pressure Switch, Fan Driver Overload Protector,

Inverter Overload Protector, Fusible Plugs, Fuse

Defrost Method Reverse cycle defrosting

Capacity Control % 24~100

Refrigerant

Refrigerant Name R-410A

Charge kg 4.0

Control Electronic Expansion Valve

Refrigerator

Oil

DAPHNE FVC68D

Charge Volume L 1.5

Standard Accessories

Installation Manual, Operation Manual, Clamps,

Auxiliary Piping

Drawing No. C: 4D052613

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Specifications Si34-603

10 Specifications

1.2 Indoor Units

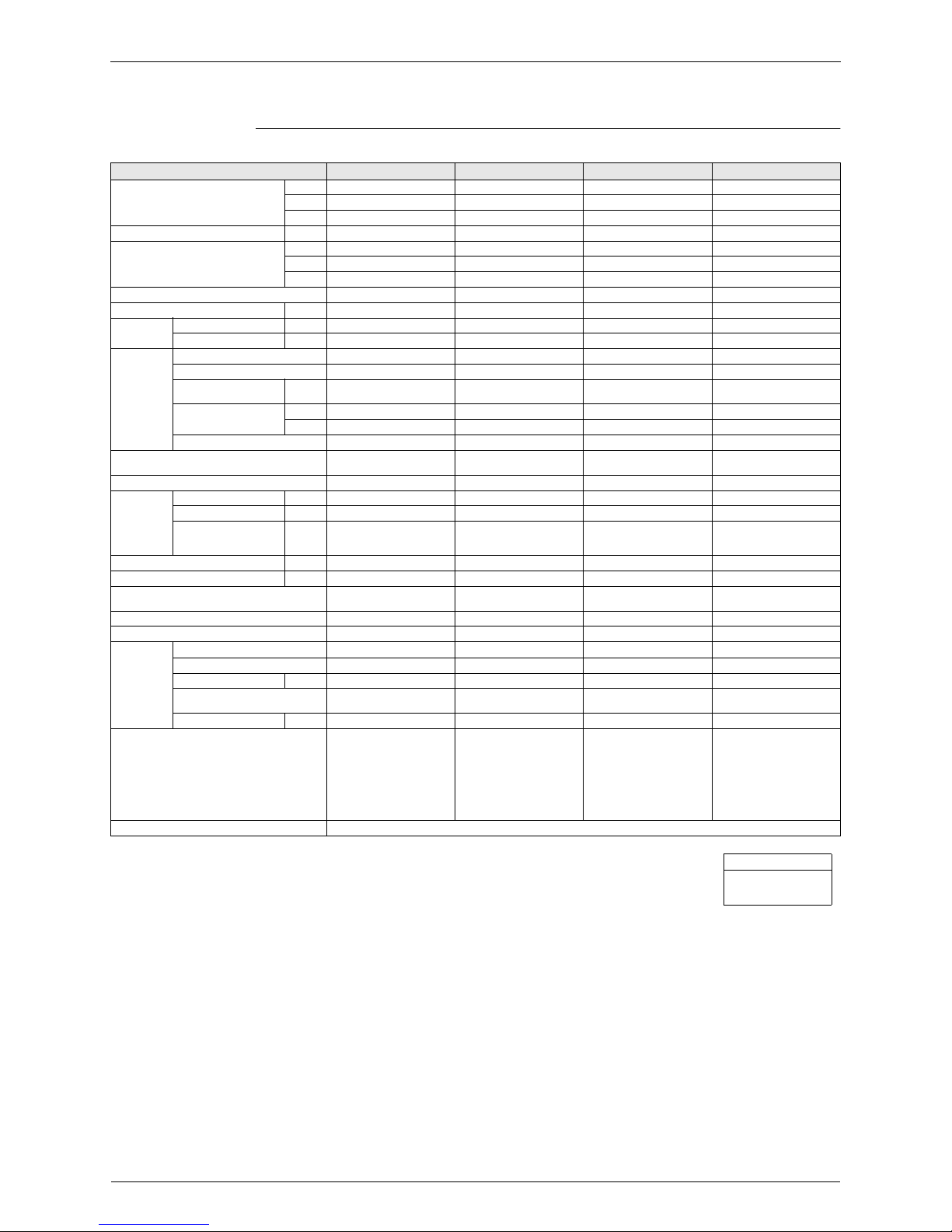

Ceiling Mounted Cassette Type (Double Flow)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 Anechoi c chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model FXCQ20MVE FXCQ25MVE FXCQ32MVE FXCQ40MVE

1 Cooling Capacity (19.5°CWB)

kcal/h 2,000 2,500 3,200 4,000

Btu/h 7,800 9,900 12,600 16,000

kW 2.3 2.9 3.7 4.7

2 Cooling Capacity (19.0°CWB) kW 2.2 2.8 3.6 4.5

3 Heating Capacity

kcal/h 2,200 2,800 3,400 4,300

Btu/h 8,500 10,900 13,600 17,100

kW 2.5 3.2 4.0 5.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 305×775×600 305×775×600 305×775×600 305×990×600

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×10×1.5 2×10×1.5 2×10×1.5 2×10×1.5

Face Area m² 2×0.100 2×0.100 2×0.100 2×0.145

Fan

Model D17K2AA1 D17K2AB1 D17K2AB1 2D17K1AA1

Type Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 10×1 15×1 15×1 20×1

Air Flow Rate (H/L)

m³/min 7/5 9/6.5 9/6.5 12/9

cfm 247/177 318/230 318/230 424/318

Drive Direct Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Sound Absorbing Thermal Insulation Material Glass Wool/Urethane Foam Glass Wool/Urethane Foam Glass Wool/Urethane Foam Glass Wool/Urethane Foam

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ12.7 (Flare Connection)

Drain Pipe mm

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

Machine Weight (Mass) kg 26 26 26 31

5 Sound Level (H/L) (220V) dBA 32/27 34/28 34/28 34/29

Safety Devices

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Connectable outdoor unit R-410A P Series R-410A P Series R-410A P Series R-410A P Series

Decoration

Panels

(Option)

Model BYBC32G-W1 BYBC32G-W1 BYBC32G-W1 BYBC50G-W1

Panel Color White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) mm 53×1,030×680 53×1,030×680 53×1,030×680 53×1,245×680

Air Filter

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Weight kg 8 8 8 8.5

Standard Accessories

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installation Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Drawing No. 3D039413

()()()()

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 11

Ceiling Mounted Cassette Type (Double Flow)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 Anechoi c chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model FXCQ50MVE FXCQ63MVE FXCQ80MVE FXCQ125MVE

1 Cooling Capacity (19.5°CWB)

kcal/h 5,000 6,300 8,000 12,500

Btu/h 19,800 24,900 31,700 49,500

kW 5.8 7.3 9.3 14.5

2 Cooling Capacity (19.0°CWB) kW 5.6 7.1 9.0 14.0

3 Heating Capacity

kcal/h 5,400 6,900 8,600 13,800

Btu/h 21,500 27,300 34,100 54,600

kW 6.3 8.0 10.0 16.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 305×990×600 305×1,175×600 305×1,665×600 305×1,665×600

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×10×1.5 2×10×1.5 2×10×1.5 2×10×1.5

Face Area m² 2×0.145 2×0.184 2×0.287 2×0.287

Fan

Model 2D17K1AA1 2D17K2AA1VE 3D17K2AA1 3D17K2AB1

Type Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 20×1 30×1 50×1 85×1

Air Flow Rate (H/L)

m³/min 12/9 16.5/13 26/ 21 33/25

cfm 424/318 582/459 918/741 1,165/883

Drive Direct Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Sound Absorbing Thermal Insulation Material Glass Wool/Urethane Foam Glass Wool/Urethane Foam Glass Wool/Urethane Foam Glass Wool/Urethane Foam

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ9.5 (Flare Connection) φ9.5 (Flare Connection) φ9.5 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connection) φ15.9 (Flare Connection) φ15.9 (Flare Connection) φ15.9 (Flare Connecti on)

Drain Pipe mm

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

Machine Weight (Mass) kg 32 35 47 48

5 Sound Level (H/L) dBA 34/29 37/32 39/34 44/38

Safety Devices

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Fuse, Thermal Protector for

Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Connectable outdoor unit R-410A P Series R-410A P Series R-410A P Series R-410A P Series

Decoration

Panels

(Option)

Model

BYBC50G-W1 BYBC63G-W1 BYBC125G-W1 BYBC125G-W1

Panel Color White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) mm 53×1,245×680 53×1,430×680 53×1,920×680 53×1,920×680

Air Filter

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Weight kg 8.5 9.5 12 12

Standard Accessories

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installation Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation,

Washer for Hanging

Brackets, Clamp Metal,

Drain Hose, Insulation for

Fitting, Washer Fixing

Plates, Sealing Pads,

Clamps, Screws, Washers.

Drawing No. 3D039413

()()()()

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Specifications Si34-603

12 Specifications

Ceiling Mounted Cassette Type (Multi-flow)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 Anechoi c chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model FXFQ25MVE FXFQ32MVE FXFQ40MVE FXFQ50MVE

1 Cooling Capacity (19.5°CWB)

kcal/h 2,500 3,200 4,000 5,000

Btu/h 9,900 12,600 16,000 19,800

kW 2.9 3.7 4.7 5.8

2 Cooling Capacity (19.0°CWB) kW 2.8 3.6 4.5 5.6

3 Heating Capacity

kcal/h 2,800 3,400 4,300 5,400

Btu/h 10,900 13,600 17,100 21,500

kW 3.2 4.0 5.0 6.3

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 246×840×840 246×840×840 246×840×840 246×840×840

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×8×1.2 2×8×1.2 2×8×1.2 2×8×1.2

Face Area m² 0.363 0.363 0.363 0.363

Fan

Model QTS46D14M QTS46D14M QTS46D14M QTS46D14M

Type Turbo Fan Turbo Fan Turbo Fan Turbo Fan

Motor Output × Number

of Units

W 30×1 30×1 30×1 30×1

Air Flow Rate (H/L)

m³/min 13/10 13/10 15/11 16/11

cfm 459/353 459/353 530/388 565/388

Drive Direct Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Sound Absorbing Thermal Insulation Material Polyurethane Form Polyurethane Form Polyurethane Form Polyurethane Form

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ12.7 (Flare Connecti on)

Drain Pipe mm

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

Machine Weight (Mass) kg 24 24 24 24

5 Sound Level (H/L) (220V) dBA 30/27 30/27 31/27 32/27

Safety Devices FuseFuseFuseFuse

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Connectable outdoor unit R-410A P Series R-410A P Series R-410A P Series R-410A P Series

Decoration

Panels

(Option)

Model BYCP125D- W1 BYCP12 5D-W1 B YCP125D-W 1 BY CP125D-W1

Panel Color White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) mm 45×950×950 45×950×950 45×950×950 45×950×950

Air Filter

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Weight kg 5.5 5.5 5.5 5.5

Standard Accessories

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installation manual, Paper

pattern f or installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Drawing No. 3D038812

()()()()

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 13

Ceiling Mounted Cassette Type (Multi-flow)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 Anechoi c chamber conversion value, measured under JISB8616 conditions. During actual operation,

these values are normally somewhat higher as a result of ambient conditions.

Model FXFQ63MVE FXFQ80MVE FXFQ100MVE FXFQ125MVE

1 Cooling Capacity (19.5°CWB)

kcal/h 6,300 8,000 10,000 12,500

Btu/h 24,900 31,700 39,600 49,500

kW 7.3 9.3 11.6 14.5

2 Cooling Capacity (19.0°CWB) kW 7.1 9.0 11.2 14.0

3 Heating Capacity

kcal/h 6,900 8,600 10,800 13,800

Btu/h 27,300 34,100 42,700 54,600

kW 8.0 10.0 12.5 16.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 246×840×840 246×840×840 288×840×840 288×840×840

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×10×1.2 2×10×1.2 2×12×1.2 2×12×1.2

Face Area m² 0.454 0.454 0.544 0.544

Fan

Model QTS46D14M QTS46D14M QTS46C17M QTS46C17M

Type Turbo Fan Turbo Fan Turbo Fan Turbo Fan

Motor Output × Number

of Units

W 30×1 30×1 120×1 120×1

Air Flow Rate (H/L)

m³/min 18.5/14 20/15 26/21 30/24

cfm 653/494 706/530 918/741 1,059/847

Drive Direct Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Sound Absorbing Thermal Insulation Material Polyurethane Form Polyurethane Form Polyurethane Form Polyurethane Form

Piping

Connections

Liquid Pipes mm φ9.5 (Flare Connection) φ9.5 (Flare Connection) φ9.5 (Flare Connection) φ9.5 (Flare Connection)

Gas Pipes mm φ15.9 (Flare Connection) φ15.9 (Flare Connection) φ15.9 (Flare Connection) φ15.9 (Flare Connection)

Drain Pipe mm

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

Machine Weight (Mass) kg 25 25 29 29

5 Sound Level (H/L) dBA 33/28 36/31 39/33 42/36

Safety Devices FuseFuseFuseFuse

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Connectable outdoor unit R-410A P Series R-410A P Series R-410A P Seri es R-410A P Series

Decoration

Panels

(Option)

Model BYCP125 D-W 1 B YCP125D -W1 BYCP1 25D-W1 BYC P125D-W1

Panel Color White (10Y9/ 0.5) White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) mm 45×950×950 45×950×950 45×950×950 45×950×950

Air Filter

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Weight kg 5.5 5.5 5. 5 5.5

Standard Accessories

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installation manual, Paper

pattern f or installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Operation manual,

Installati on manual, Paper

pattern for installation, Drain

hose, Clamp metal, Washer

fixing plate, Sealing pads,

Clamps, Screws, Washer for

hanging bracket, Insulation

for fitting.

Drawing No. 3D038812

()()()()

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Specifications Si34-603

14 Specifications

Ceiling Mounted Cassette Corner Type

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp.: 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 Anechoic chamber conversion value, measured at a poi nt 1m in front of the unit and 1m downward.

During actual operation, these values are normally somewhat higher as a result of ambient conditions.

Model FXKQ25MAVE FXKQ32MAVE FXKQ40MAVE FXKQ63MAVE

1 Cooling Capacity (19.5°CWB)

kcal/h 2,500 3,200 4,000 6,300

Btu/h 9,900 12,600 16,000 24,900

kW 2.9 3.7 4.7 7.3

2 Cooling Capacity (19.0°CWB) kW 2.8 3.6 4.5 7.1

3 Heating Capacity

kcal/h 2,800 3,400 4,300 6,900

Btu/h 10,900 13,600 17,100 27,300

kW 3.2 4.0 5.0 8.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 215×1,110×710 215×1,110×710 215×1,110×710 215×1,310×710

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×11×1.75 2×11×1.75 2×11×1.75 3×11×1.75

Face Area m² 0.180 0.180 0.180 0.226

Fan

Model 3D12H1AN1V1 3D12H1AN1V1 3D12H1AP1V1 4D12H1AJ1V1

Type Sirocco Fan Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 15×1 15×1 20×1 45×1

Air Flow Rate (H/L)

m³/min 11/9 11/9 13/10 18/15

cfm 388/318 388/318 459/353 635/530

Drive Direct Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Sound Absorbing Thermal Insulation Material Polyethylene Foam Polyethylene Foam Polyethylene Foam Polyethylene Foam

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ9.5 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ12.7 (Flare Connection) φ15.9 (Flare Connecti on)

Drain Pipe mm

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

VP25

External Dia. 32

Internal Dia. 25

Machine Weight (Mass) kg 31 31 31 34

5 Sound Level (H/L) (220V) dBA 38/33 38/33 40/34 42/37

Safety Devices

Fuse,

Thermal Fuse for Fan Motor

Fuse,

Thermal Fuse for Fan Motor

Fuse,

Thermal Fuse for Fan Motor

Fuse,

Thermal Fuse for Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Connectable Outdoor Units R-410A P Series R-410A P Series R-410A P Seri es R-410A P Series

Decoration

Panels

(Option)

Model

BYK45FJW1 BYK45FJW1 BYK45FJW1 BYK71FJW1

Panel Color White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) mm 70×1,240×800 70×1,240×800 70×1,240×800 70×1,440×800

Air Filter

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Resin Net

(with Mold Resistant)

Weight kg 8.5 8.5 8.5 9.5

Standard Accessories

Operation Manual,

Installati on Manual, Paper

Pattern for Installation, Drain

Hose, Clamp Metal,

Insulation f or Fitting, Seali ng

Pads, Clamps, Screws,

Washers, Positioning Jig for

Installation, Insulation for

Hanger Bracket, Air Outlet

Blocking Pad.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation, Drain

Hose, Clamp Metal,

Insulation f or Fitting, Sealing

Pads, Clamps, Screws,

Washers, Positioning Jig for

Installation, Insulation for

Hanger Bracket, Air Outl et

Blocking Pad.

Operation Manual,

Installation Manual, Paper

Pattern for Inst allation, Drain

Hose, Clamp Metal,

Insulation f or Fitting, Sealing

Pads, Clamps, Screws,

Washers, Positioning Jig for

Installation, Insulation for

Hanger Bracket, Air Outlet

Blocking Pad.

Operation Manual,

Installati on Manual, Paper

Pattern for Installation, Drain

Hose, Clamp Metal,

Insulation for Fitting, Sealing

Pads, Clamps, Screws,

Washers, Positioning Jig for

Installation, Insulation for

Hanger Bracket, Air Outlet

Blocking Pad.

Drawing No. 3D038813A

()()()()

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 15

Slim Ceiling Mounted Duct Type (with Drain Pump)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable to set by the remote controller this pressure means “High static

pressure - Standard static pressure”.

6 The operation sound levels are the conversion values in anechoi c chamber. In practice, the sound tend to

be larger than the specified values due to ambient noise or reflections.

When the place of suction is changed to the bottom suction, the sound level will increase by approx.

5dBA.

Model FXDQ20NAVE FXDQ25NAVE FXDQ32NAVE

1 Cooling Capacity (19.5°CWB)

kcal/h 2,000 2,500 3,200

Btu/h 7,800 9,900 12,600

kW 2.3 2.9 3.7

2 Cooling Capacity (19.0°CWB) kW 2.2 2.8 3.6

3 Heating Capacity

kcal/h 2,200 2,800 3,400

Btu/h 8,500 10, 900 13,600

kW 2.5 3.2 4.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 200×900×620 200×900×620 200×900×620

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×12×1.5 2×12×1.5 2×12×1.5

Face Area m² 0.176 0.176 0.176

Fan

Model — — —

Type Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 62×1 62×1 62×1

Air Flow Rate (H/L) m³/min 9.5/7.5 9.5/7.5 10. 5/8.5

External Stati c Pressure Pa 44-15

5 44-15

5 44-15

5

Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Sound Absorbing Thermal Insulation Material Foamed Polyethylene Foamed Polyet hylene Foamed Polyet hylene

Air Filter Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connecti on) φ12.7 (Flare Connection) φ12.7 (Flare Connection)

Drain Pipe mm

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

Machine Weight (Mass) kg 26 26 26

6 Sound Level (H/L) dBA 33/29 33/29 33/29

Safety Devices Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Operation Manual,

Installation Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation for Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Operation Manual,

Installati on Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation f or Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Operation Manual,

Installation Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation for Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Drawing No. 3D051253

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Specifications Si34-603

16 Specifications

Slim Ceiling Mounted Duct Type (with Drain Pump)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength: 7.5m, level di fference:

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable to set by the remote controller this pressure means “High static

pressure - Standard static pressure”.

6 The operation sound levels are the conversion values in anechoi c chamber. In practice, the sound tend to

be larger than the specified values due to ambient noise or reflections.

When the place of suction is changed to the bottom suction, the sound level will increase by approx.

5dBA.

Model FXDQ40NAVE FXDQ50NAVE FXDQ63NAVE

1 Cooling Capacity (19.5°CWB)

kcal/h 4,000 5,000 6,300

Btu/h 16,000 19,800 24,900

kW 4.7 5.8 7.3

2 Cooling Capacity (19.0°CWB) kW 4.5 5.6 7.1

3 Heating Capacity

kcal/h 4,300 5,400 6,900

Btu/h 17,100 21,500 27,300

kW 5.0 6.3 8.0

Casing Color Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 200×900×620 200×900×620 200×1100×620

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 3×12×1.5 3×12×1.5 3×12×1.5

Face Area m² 0.176 0.176 0.227

Fan

Model — — —

Type Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 62×1 130×1 130×1

Air Flow Rate (H/L) m³/min 10.5/8.5 12.5/10.0 16.5/13.0

External Stati c Pressure Pa 44-15

5 44-15

5 44-15

5

Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Sound Absorbing Thermal Insulation Material Foamed Polyethylene Foamed Polyet hylene Foamed Polyet hylene

Air Filter Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ9.5 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connecti on) φ12.7 (Flare Connection) φ15.9 (Flare Connection)

Drain Pipe mm

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

Machine Weight (Mass) kg 27 28 31

6 Sound Level (H/L) dBA 34/30 35/31 36/32

Safety Devices Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Operation Manual,

Installation Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation for Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Operation Manual,

Installati on Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation f or Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Operation Manual,

Installation Manual, Warranty,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation for Fitting,

Clamp Metal, Washer Fixing Plate,

Screws for Duct Flanges, Air Filter

Drawing No. 3D051253

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3412

cfm=m³/min×35.3

Si34-603 Specifications

Specifications 17

Slim Ceiling Mounted Duct Type (without Drain Pump)

Notes:

1 Indoor temp. : 27°CDB, 19.5°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

2 Indoor temp. : 27°CDB, 19.0°CWB / outdoor temp; 35°CDB / Equivalent piping length: 7.5m, level

difference: 0m.

3 Indoor temp. : 20°CDB / outdoor temp.: 7°CDB, 6°CWB / Equivalent piping l ength; 7.5m, level di fference;

0m. (Heat pump only)

4 Capacities are net, including a deduction for cooling (an addition for heating) for indoor fan motor heat.

5 External static pressure is changeable to set by the remote controller this pressure means “High static

pressure - Standard static pressure”.

6 The operation sound levels are the conversion values in anechoi c chamber. In practice, the sound tend to

be larger than the specified values due to ambient noise or reflections.

When the place of suction is changed to the bottom suction, the sound level will increase by approx.

5dBA.

Model FXDQ20NVET FXDQ25NVET FXDQ32NVET

1 Cooling Capacity (19.5°CWB)

kcal/h 2,000 2,500 3,200

Btu/h 7,800 9,900 12,600

kW 2.3 2.9 3.7

2 Cooling Capacity (19.0°CWB) kW 2.2 2.8 3.6

3 Heating Capacity

kcal/h 2,200 2,800 3,400

Btu/h 8,500 10, 900 13,600

kW 2.5 3.2 4.0

Casing Galvanized Steel Plate Galvanized Steel Plate Galvanized Steel Plate

Dimensions: (H×W×D) mm 200×900×620 200×900×620 200×900×620

Coil (Cross

Fin Coil)

Rows×Stages×Fin Pitch mm 2×12×1.5 2×12×1.5 2×12×1.5

Face Area m² 0.176 0.176 0.176

Fan

Model — — —

Type Sirocco Fan Sirocco Fan Sirocco Fan

Motor Output × Number

of Units

W 62×1 62×1 62×1

Air Flow Rate (H/L) m³/min 9.5/7.5 9.5/7.5 10. 5/8.5

External Stati c Pressure Pa 44-15

5 44-15

5 44-15

5

Drive Direct Drive Direct Drive Direct Drive

Temperature Control

Microprocessor Thermostat

for Cooling and Heating

Microprocessor Thermostat

for Cooling and Heati ng

Microprocessor Thermostat

for Cooling and Heating

Sound Absorbing Thermal Insulation Material Foamed Polyethylene Foamed Polyet hylene Foamed Polyet hylene

Air Filter Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof Removal / Washable / Mildew Proof

Piping

Connections

Liquid Pipes mm φ6.4 (Flare Connection) φ6.4 (Flare Connection) φ6.4 (Flare Connection)

Gas Pipes mm φ12.7 (Flare Connecti on) φ12.7 (Flare Connection) φ12.7 (Flare Connection)

Drain Pipe mm

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

VP20

(External Dia. 26 Internal Dia. 20)

Machine Weight (Mass) kg 26 26 26

6 Sound Level (H/L) dBA 33/29 33/29 33/29

Safety Devices Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor Fuse, Thermal Protector for Fan Motor

Refrigerant Control Electronic Expansion Valve Electronic Expansion Valve Electronic Expansion Valve

Standard Accessories

Operation Manual,

Installation Manual,

Drain Hose, Sealing Pads, Clamps,

Washers, Insulation for Fitting,