Daikin FTKM24PVMK, FTKM18PVMK, FTXM18PVMK, FTXM24PVMK, FTXM28PVMK Service Manual

...

Service

SiMT041509E

Manual

Inverter Pair

Wall Mounted Type

FTK(X)M-P Series

[Applied Models]

Inverter Pair : Heat Pump

z

zCooling Only

Indoor Unit

FTKM18PVMK

FTKM24PVMK

FTKM28PVMK

Outdoor Unit

SiMT041509E

Inverter Pair

Wall Mounted Type

FTK(X)M-P Series

RKM18PVMK

RKM24PVMK

RKM28PVMK

zHeat Pump

Indoor Unit

FTXM18PVMK

FTXM24PVMK

FTXM28PVMK

Outdoor Unit

RXM18PVMK

RXM24PVMK

RXM28PVMK

i Table of Contents

SiMT041509E

1. Safety Cautions.......................................................................................v

1.1 Warnings and Cautions Regarding Safety of Workers............................. v

1.2 Warnings and Cautions Regarding Safety of Users................................ xi

2. Used Icons ........................................................................................... xiv

Part 1 List of Functions ................................................................ 1

1. Functions.................................................................................................2

Part 2 Specifications .................................................................... 3

1. Specifications..........................................................................................4

Part 3 Printed Circuit Board Connector Wiring Diagram ............. 8

1. Indoor Unit...............................................................................................9

2. Outdoor Unit..........................................................................................11

Part 4 Function and Control........................................................12

1. Main Functions......................................................................................13

1.1 Temperature Control ..............................................................................13

1.2 Frequency Principle................................................................................13

1.3 Airflow Direction Control.........................................................................15

1.4 Fan Speed Control for Indoor Unit .........................................................16

1.5 Program Dry Operation ..........................................................................17

1.6 Automatic Operation...............................................................................18

1.7 Thermostat Control.................................................................................19

1.8 NIGHT SET Mode ..................................................................................20

1.9 ECONO Operation .................................................................................20

1.10 INTELLIGENT EYE Operation ...............................................................21

1.11 Inverter POWERFUL Operation .............................................................22

1.12 Clock Setting ..........................................................................................23

1.13 WEEKLY TIMER Operation ...................................................................24

1.14 Other Functions......................................................................................30

2. Function of Thermistor ..........................................................................31

3. Control Specification .............................................................................32

3.1 Mode Hierarchy ......................................................................................32

3.2 Frequency Control ..................................................................................33

3.3 Controls at Mode Changing / Start-up....................................................35

3.4 Discharge Pipe Temperature Control.....................................................36

3.5 Input Current Control ..............................................................................37

3.6 Freeze-up Protection Control .................................................................38

3.7 Heating Peak-cut Control .......................................................................38

3.8 Outdoor Fan Control...............................................................................39

3.9 Liquid Compression Protection Function................................................39

3.10 Defrost Control .......................................................................................40

3.11 Electronic Expansion Valve Control .......................................................41

3.12 Discharge Pipe Thermistor Disconnection Control.................................43

3.13 Malfunctions ...........................................................................................43

Table of Contents ii

SiMT041509E

Part 5 Remote Controller ............................................................44

1. Remote Controller .................................................................................45

Part 6 Service Diagnosis.............................................................47

1. General Problem Symptoms and Check Items .....................................48

2. Troubleshooting with LED.....................................................................49

2.1 Indoor Unit..............................................................................................49

2.2 Outdoor Unit ...........................................................................................49

3. Service Diagnosis .................................................................................50

4. Troubleshooting ....................................................................................53

4.1 Error Codes and Description ..................................................................53

4.2 Indoor Unit PCB Abnormality .................................................................54

4.3 Freeze-up Protection Control / Heating Peak-cut Control ......................55

4.4 Fan Motor (DC Motor) or Related Abnormality.......................................56

4.5 Thermistor or Related Abnormality (Indoor Unit)....................................58

4.6 Low-voltage Detection or Over-voltage Detection..................................59

4.7 Signal Transmission Error (Between Indoor Unit and Outdoor Unit)......61

4.8 Unspecified Voltage (Between Indoor Unit and Outdoor Unit) ...............63

4.9 Outdoor Unit PCB Abnormality...............................................................64

4.10 Actuation of High Pressure Switch .........................................................65

4.11 OL Activation (Compressor Overload) ...................................................66

4.12 Compressor Lock ...................................................................................68

4.13 DC Fan Lock ..........................................................................................69

4.14 Input Overcurrent Detection ...................................................................70

4.15 Four Way Valve Abnormality..................................................................71

4.16 Discharge Pipe Temperature Control.....................................................73

4.17 Compressor System Sensor Abnormality ..............................................74

4.18 Position Sensor Abnormality ..................................................................75

4.19 Thermistor or Related Abnormality (Outdoor Unit) .................................77

4.20 Electrical Box Temperature Rise ............................................................79

4.21 Radiation Fin Temperature Rise ............................................................80

4.22 Output Overcurrent Detection ................................................................81

5. Check ....................................................................................................83

5.1 Thermistor Resistance Check ................................................................83

5.2 Indoor Fan Motor Connector Output Check ...........................................84

5.3 Power Supply Waveforms Check...........................................................84

5.4 Electronic Expansion Valve Check.........................................................84

5.5 Four Way Valve Performance Check .....................................................85

5.6 Inverter Unit Refrigerant System Check.................................................85

5.7 Inverter Analyzer Check .........................................................................86

5.8 Rotation Pulse Check on the Outdoor Unit PCB ....................................87

5.9 Installation Condition Check ...................................................................88

5.10 Discharge Pressure Check.....................................................................88

5.11 Outdoor Fan System Check ...................................................................89

5.12 Main Circuit Short Check........................................................................89

5.13 Power Module Check .............................................................................90

Part 7 Trial Operation and Field Settings...................................91

1. Tips for Servicing ..................................................................................92

1.1 Pump Down Operation ...........................................................................92

iii Table of Contents

SiMT041509E

1.2 Forced Cooling Operation ......................................................................92

2. Trial Operation ......................................................................................93

3. Field Settings ........................................................................................94

3.1 When 2 Units are Installed in 1 Room....................................................94

3.2 Jumper Settings .....................................................................................94

4. Silicon Grease on Power Transistor / Diode Bridge..............................95

Part 8 Appendix...........................................................................96

1. Piping Diagrams....................................................................................97

1.1 Indoor Unit..............................................................................................97

1.2 Outdoor Unit ...........................................................................................98

2. Wiring Diagrams..................................................................................101

2.1 Indoor Unit............................................................................................101

2.2 Outdoor Unit .........................................................................................102

Table of Contents iv

Safety Cautions SiMT041509E

1. Safety Cautions

Be sure to read the following safety cautions before conducting repair work.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer.

Caution Items The caution items are classified into Warning and Caution. The Warning items are

especially important since they can lead to death or serious injury if they are not followed

closely. The Caution items can also lead to serious accidents under some conditions if they

are not followed. Therefore, be sure to observe all the safety caution items described below.

Pictograms This symbol indicates the item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates the prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates the action that must be taken, or the instruction.

The instruction is shown in the illustration or near the symbol.

1.1 Warnings and Cautions Regarding Safety of Workers

Warning

Do not store the equipment in a room with successive fire sources (e.g.,

naked flame, gas appliance, electric heater).

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for repair.

Working on the equipment that is connected to the power supply may cause an

electrical shock.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas is discharged during the repair work, do not touch

the discharged refrigerant gas.

The refrigerant gas may cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at

the welded section, evacuate the refrigerant gas completely at a wellventilated place first.

If there is gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it may

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area.

The refrigerant gas may generate toxic gases when it contacts flames.

Be sure to discharge the capacitor completely before conducting repair

work.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

A charged capacitor may cause an electrical shock.

v

SiMT041509E Safety Cautions

Warning

Do not start or stop the air conditioner operation by plugging or

unplugging the power cable plug.

Plugging or unplugging the power cable plug to operate the equipment may

cause an electrical shock or fire.

Be sure to wear a safety helmet, gloves, and a safety belt when working

at a high place (more than 2 m).

Insufficient safety measures may cause a fall accident.

In case of R-32 / R-410A refrigerant models, be sure to use pipes, flare

nuts and tools for the exclusive use of the R-32 / R-410A refrigerant.

The use of materials for R-22 refrigerant models may cause a serious accident

such as a damage of refrigerant cycle as well as an equipment failure.

Do not mix air or gas other than the specified refrigerant (R-32 / R-410A /

R-22) in the refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water may cause an electrical shock.

Be sure to provide the earth / grounding when repairing the equipment in

a humid or wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when

cleaning the equipment.

The internal fan rotates at a high speed, and may cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

Be sure to check that the refrigerating cycle section has cooled down

enough before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

vi

Safety Cautions SiMT041509E

Caution

Use the welder in a well-ventilated place.

Using the welder in an enclosed room may cause oxygen deficiency.

Checking the area

Before beginning work, conduct safety checks to minimise the risk of ignition. When repairing

the refrigerating system, take the following precautions before work.

Work procedure

Work shall be conducted under a controlled procedure so as to minimise the risk of working in

the presence of R-32 or vapour.

General working area

All maintenance staff and others working in the local area shall be instructed on the nature of

work being carried out.

Work in confined spaces shall be avoided.

The area around the workspace shall be sectioned off. Ensure that the conditions within the

area have been made safe by control of flammable materials.

Checking for presence of refrigerant

The working area shall be checked with an appropriate refrigerant detector before and during

work, to ensure the technician is aware of potentially flammable atmospheres.

Ensure that the leak detection equipment being used is suitable for use with R-32, i.e. nonsparking, adequately sealed or intrinsically safe.

Fire extinguishing equipment

If any hot work is to be conducted on the refrigeration equipment or any associated parts,

appropriate fire extinguishing equipment shall be made available at hand. Prepare a dry powder

fire extinguisher adjacent to the working area.

2

or CO

No ignition sources

During work on a refrigeration system which involves exposing any piping work that contains or

has contained R-32, any sources of ignition shall not be used in a manner that may lead to the

risk of fire or explosion. All possible ignition sources, including cigarette smoking, should be

kept at a safe distance from the site of installation, repairing, or removing space. Before starting

work, the area around the equipment shall be examined to make sure that there are no

flammable hazard or ignition risks. No Smoking signs shall be displayed.

Ventilated area

Ensure that the working area is open or that it is adequately ventilated before work.

Adequate ventilation shall be maintained during the entire period of work.

The ventilation should disperse any released refrigerant and preferably discharge it into the

external atmosphere.

vii

SiMT041509E Safety Cautions

Checking the refrigeration equipment

Where electrical components are to be changed, the new components shall be fit for the

purpose and have the correct specifications.

The manufacturer's maintenance and service guidelines shall be followed at all times.

If there are any unclear points, consult the manufacturer's technical department for assistance.

The following checks shall be applied to any installation work involving R-32:

• The amount of charge is in accordance with the size of the room where the refrigerant

containing parts are installed;

• The ventilation machinery and outlets are operating adequately and are not obstructed;

• If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for

the presence of refrigerant;

• Marking on the equipment is visible and legible. Markings and signs that are illegible shall

be corrected;

• Refrigeration pipes or components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing components, or the

refrigerant containing components are constructed of materials which are inherently

resistant to corrosion or are suitably protected against corrosion.

Checking electrical devices

Repair and maintenance to electrical components shall include initial safety checks and

component inspection procedures. In case there is any fault that could endanger safety, no

electrical supply shall be connected to the circuit until the fault is satisfactorily dealt with.

Initial safety checks shall include:

• that capacitors are discharged: this shall be done in a safe manner to avoid possibility of

sparking;

• that no live electrical components and wiring are exposed while charging, recovering or

purging the system;

• that the equipment is earthed at all times.

Repairs to sealed components

During repairs to sealed components, all electrical supplies shall be disconnected from the

equipment being worked upon before the removal of any sealed covers, etc. If it is absolutely

necessary to have power supplied to equipment during servicing, continuously operating leak

detection shall be installed at the most dangerous point of the system in order to warn of a

potentially hazardous situation.

Particular attention shall be paid to the following: ensure that working on electrical components

does not alter the casing in such a way that affects the level of protection including damage to

cables, excessive number of connections, terminals different from the original specification,

damage to seals, incorrect fitting of glands, etc.

Ensure that the equipment is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the

purpose of preventing the ingression of flammable atmospheres. Replacement parts shall be in

accordance with the manufacturer's specifications.

The use of silicon sealant may inhibit the effectiveness of some types of leak detection

equipment. Intrinsically safe components do not have to be isolated before working on them.

Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance load to the circuit without ensuring that

this will not exceed the permissible voltage and current for the equipment in use.

Only intrinsically safe components can be worked on in the presence of a flammable

atmosphere.

The test apparatus shall be of correct rating.

Replace components only with parts specified by the manufacturer. Using other parts may

result in ignition of the refrigerant leaked into the atmosphere.

Wiring

Check that wiring is not subject to wear, corrosion, excessive pressure, vibration, sharp edges

or any other adverse environmental effects. The check shall also take into account the effects of

ageing or continuous vibration from sources such as compressors or fans.

viii

Safety Cautions SiMT041509E

Detecting of R-32

Under no circumstances shall potential sources of ignition be used in the search for or detection

of refrigerant leaks. A halide torch (or any other detector using a naked flame) shall not be used.

Leak detection methods

The following leak detection methods can be applied for systems containing R-32.

Electronic leak detectors shall be used to detect R-32, but the sensitivity may not be adequate

or may need re-calibration (detection equipment shall be calibrated in a refrigerant-free area).

Ensure that the detector is not a potential source of ignition and that it is suitable for the

refrigerant used. Leak detection equipment shall be set to the percentage of the lower

flammability limit (LFL) of the refrigerant and calibrated to fit the refrigerant employed. The

appropriate percentage of gas (maximum 25%) shall be confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of detergents

containing chlorine shall be avoided as the chlorine may react with the refrigerant and corrode

the copper piping work.

If a leak is suspected, all naked flames shall be removed or extinguished.

If a refrigerant leakage which requires brazing is found, all of the refrigerant shall be recovered

from the system, or isolated (by means of shut off valves) in a part of the system remote from

the point of the leakage. Oxygen free nitrogen (OFN) shall then be purged through the system

both before and during the brazing process.

Removal and evacuation

When breaking the refrigerant circuit to make repairs or any other purpose, conventional

procedures may be used. However, flammability must be taken into consideration. The

following procedure shall be adhered to:

• Remove refrigerant;

• Purge the circuit with inert gas;

• Evacuate the inert gas;

• Purge again with inert gas;

• Carry out cutting or brazing of the circuit.

The refrigerant shall be recovered into the correct recovery cylinders. The system shall be

cleaned with OFN to render the unit safe. (= Flushing) This process may need to be repeated

several times. Compressed air or oxygen shall not be used for this task.

Flushing shall be achieved through breaking the vacuum by filling the system with OFN until the

working pressure is achieved, then venting the OFN into the atmosphere, and finally pulling the

system down to vacuum again. This process shall be repeated until no refrigerant remains

within the system. After the last OFN charge is finished, the system shall be vented down to

atmospheric pressure to enable work. This operation is especially important if brazing

operations on the piping work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and that there is

ventilation available.

Charging procedures

In addition to conventional charging procedures, the following requirements shall be met.

Ensure that the charging equipment to be used is not contaminated by different refrigerants.

Hoses or lines shall be as short as possible to minimise the amount of refrigerant contained in

them.

• Cylinders shall be kept upright.

• Ensure that the refrigeration system is earthed before charging the system with refrigerant.

• Label the system when charging is complete (if not already).

• Extreme care shall be taken not to overfill the refrigeration system.

Before recharging, the system shall be tested for leakage with OFN. On completion of charging,

the system shall be tested before commissioning. Follow up leakage test shall be carried out

before leaving the site.

ix

SiMT041509E Safety Cautions

Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with

the equipment and all its details. It is recommended to train technicians so that all of the

refrigerant is recovered safely. In case analysis is required before re-using the reclaimed

refrigerant, an oil and refrigerant sample shall be taken before proceeding with

decommissioning. It is essential that electrical power is available before work.

a) Comprehend the equipment and its operation.

b) Isolate the system electrically.

c) Before starting work, ensure that:

• mechanical handling equipment is available if required, for handling refrigerant cylinders;

• protective equipment can be used in compliance with specifications;

• the recovery process is supervised by a competent person at all times;

• recovery equipment and cylinders conform to the appropriate standards.

d) Pump down the refrigerant system, if possible.

e) If vacuum can not be ensured, apply a manifold so that refrigerant can be removed from

various parts of the system.

f) Make sure that the cylinder is situated on the scale before recovery takes place.

g) Start the refrigerant recovery device and operate it in accordance with the manufacturer's

instructions.

h) Do not overfill cylinders. (Do not exceed 80% liquid charge volume).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been filled correctly and the process is completed, make sure

that the cylinders and the equipment are removed from site promptly and all valves on the

equipment are closed.

k) Recovered refrigerant shall not be charged into another refrigeration system before it has

been cleaned and checked.

Labelling

Equipment shall be labelled stating that it has been decommissioned and emptied of refrigerant.

The label shall be dated and signed. Ensure that there are labels on the equipment stating the

equipment contains R-32.

Refrigerant recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is

recommended to conduct training so that all refrigerants can be removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery

cylinders are used.

Ensure that the correct number of cylinders for holding the total system charge are available. All

cylinders to be used must be designated for the recovered refrigerant and labelled for that

refrigerant (i.e. special cylinders for the recovery of refrigerant). Cylinders shall be equipped

with a pressure relief valve and associated shut-off valves in good working order. If possible,

empty recovery cylinders shall be cooled in a separate place before recovery is conducted.

The recovery equipment shall be in good working order with instructions concerning the

equipment at hand, and shall be suitable for the recovery of R-32. In addition, a set of calibrated

weighing scales shall be available and in good working order. Hoses shall be equipped with

leak-free disconnect couplings and in good condition. Before using the recovery device, check

that it has undergone proper maintenance, that it is in satisfactory working order, and that any

associated electrical components are sealed to prevent ignition in the event of a refrigerant

leakage. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery

cylinder, with the relevant Waste Transfer Note attached. Do not mix refrigerants in recovery

units and especially not in cylinders.

If compressors or compressor oil are to be removed, ensure that the refrigerant melted into the

oil has been evacuated to an acceptable level to make certain that R-32 does not remain within

the oil. The evacuation process shall be carried out before returning the compressor to the

supplier. Only electric heating to the compressor body shall be employed to accelerate this

process. Oil drained from the system shall be treated safely.

x

Safety Cautions SiMT041509E

1.2 Warnings and Cautions Regarding Safety of Users

Warning

Do not store the equipment in a room with successive fire sources (e.g.,

naked flame, gas appliance, electric heater).

Be sure to use parts listed in the service parts list of the applicable model

and appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires have scratches or deteriorated, be sure

to replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same

power outlet with other electrical appliances, since it may cause an

electrical shock, excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and follow

the local technical standards related to the electrical equipment, the

internal wiring regulations, and the instruction manual for installation

when conducting electrical work.

Insufficient power circuit capacity and improper electrical work may cause an

electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and

outdoor units.

Make the connections securely and route the cable properly so that there is no

force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

When wiring between the indoor and outdoor units, make sure that the

terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable may cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable

may damage the cable.

Do not mix air or gas other than the specified refrigerant (R-32 / R-410A /

R-22) in the refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leaking point and repair

it before charging the refrigerant. After charging refrigerant, make sure

that there is no refrigerant leak.

If the leaking point cannot be located and the repair work must be stopped, be

sure to perform pump-down and close the service valve, to prevent the

refrigerant gas from leaking into the room. The refrigerant gas itself is

harmless, but it may generate toxic gases when it contacts flames, such as fan

and other heaters, stoves and ranges.

xi

SiMT041509E Safety Cautions

Warning

When relocating the equipment, make sure that the new installation site

has sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment may fall and cause injury.

Check to make sure that the power cable plug is not dirty or loose, then

insert the plug into a power outlet securely.

If the plug has dust or loose connection, it may cause an electrical shock or fire.

Be sure to install the product correctly by using the provided standard

installation frame.

Incorrect use of the installation frame and improper installation may cause the

equipment to fall, resulting in injury.

Be sure to install the product securely in the installation frame mounted

on the window frame.

If the unit is not securely mounted, it may fall and cause injury.

When replacing the coin battery in the remote controller, be sure to

dispose of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Caution

Installation of a leakage breaker is necessary in some cases depending

on the conditions of the installation site, to prevent electrical shocks.

For unitary type

only

For unitary type

only

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If the combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if the parts and wires are mounted and connected properly,

and if the connections at the soldered or crimped terminals are secure.

Improper installation and connections may cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame may cause the unit to fall, resulting in

injury.

xii

Safety Cautions SiMT041509E

Caution

Check the earth / grounding, and repair it if the equipment is not properly

earthed / grounded.

Improper earth / grounding may cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make

sure that the resistance is 1 MΩ or higher.

Faulty insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage may cause the water to enter the room and wet the furniture

and floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water may enter the room and

wet the furniture and floor.

For unitary type

only

xiii

SiMT041509E Used Icons

2. Used Icons

The following icons are used to attract the attention of the reader to specific information.

Icon Type of

Information

Warning A Warning is used when there is danger of personal injury.

Warning

Caution A Caution is used when there is danger that the reader, through

Caution

Note A Note provides information that is not indispensable, but may

Note:

Reference A Reference guides the reader to other places in this binder or

Description

incorrect manipulation, may damage equipment, lose data, get

an unexpected result or has to restart (part of) a procedure.

nevertheless be valuable to the reader, such as tips and tricks.

in this manual, where he/she will find additional information on a

specific topic.

xiv

SiMT041509E

Part 1

List of Functions

1. Functions.................................................................................................2

1 List of Functions

SiMT041509E Functions

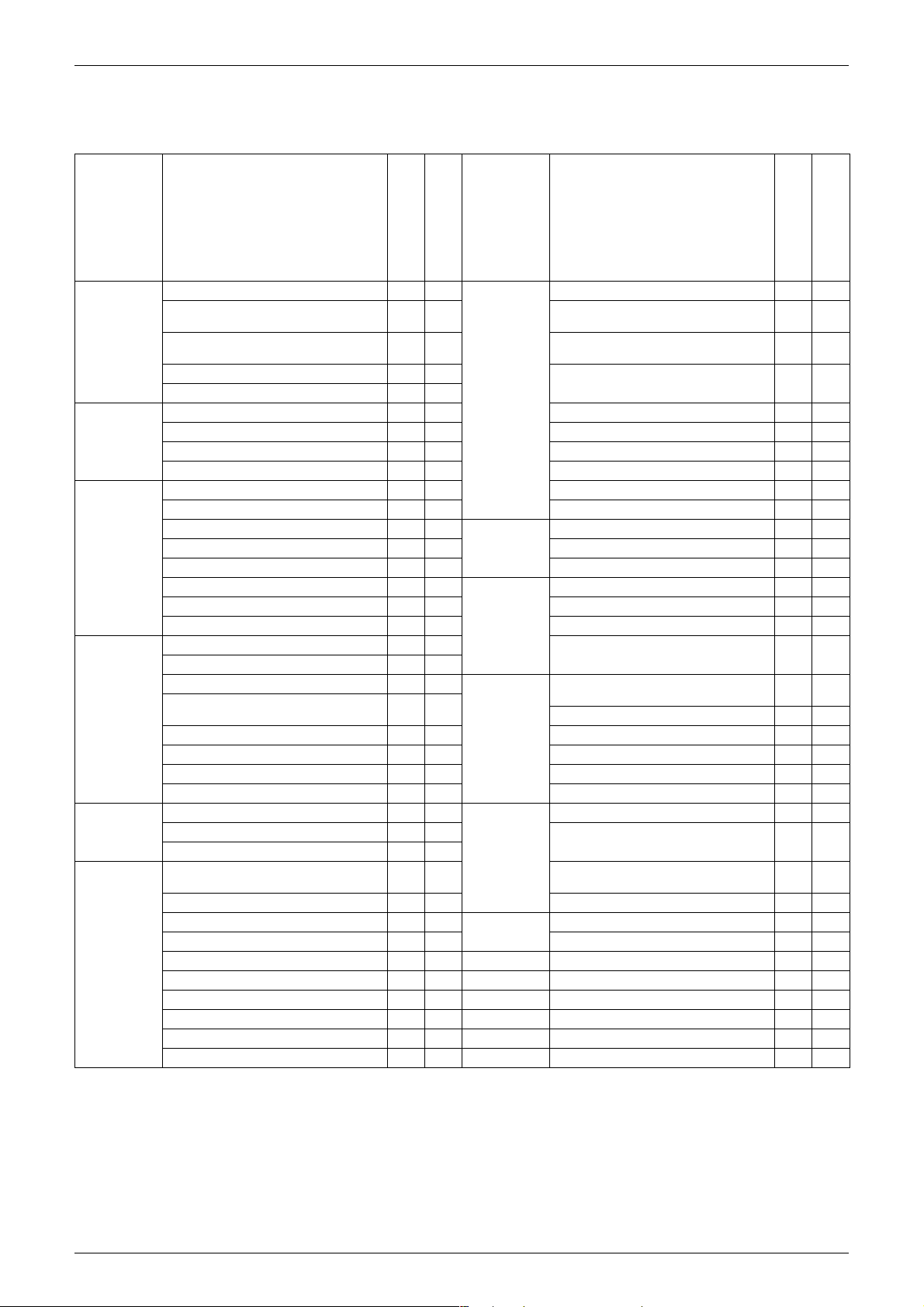

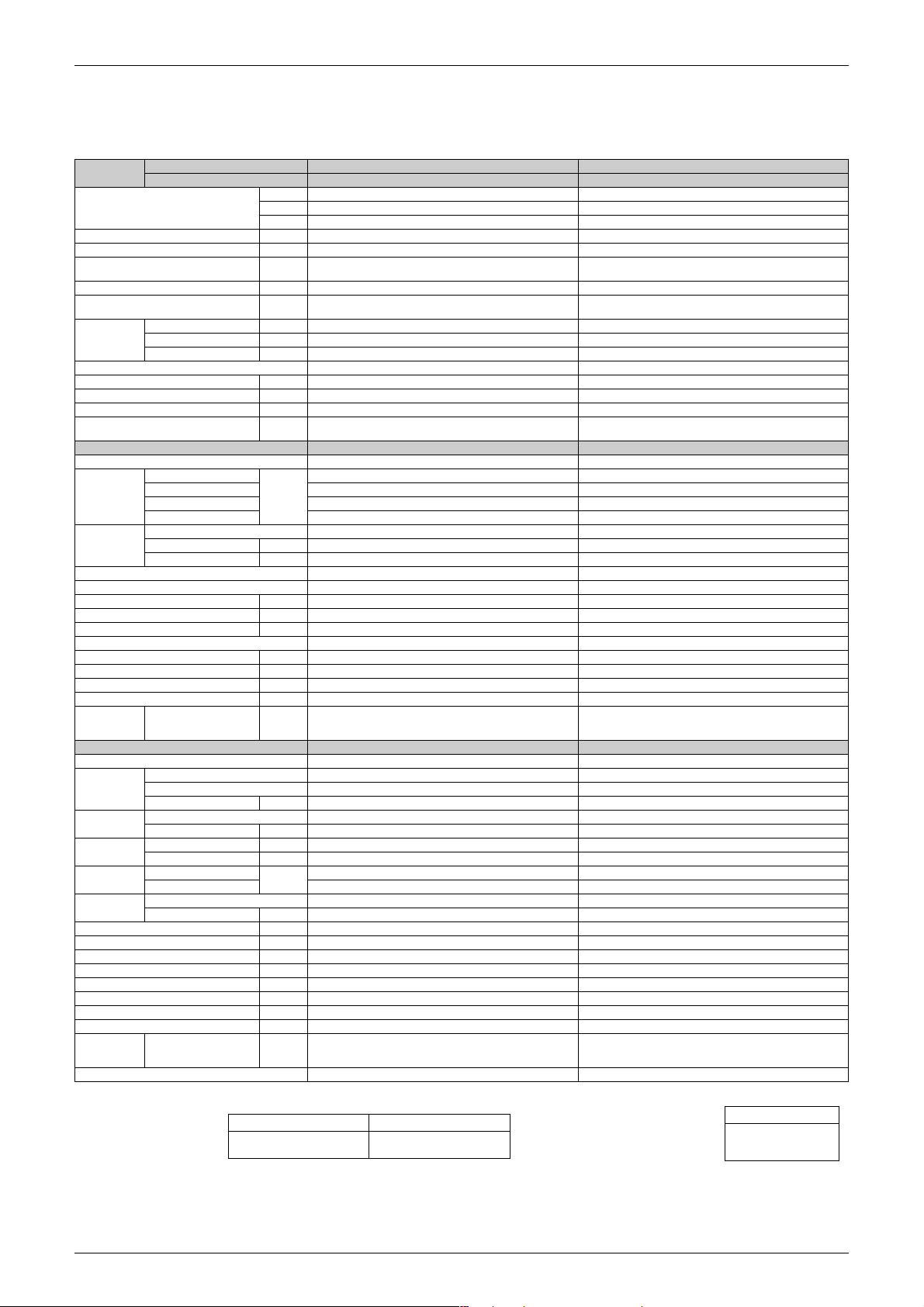

1. Functions

Category Functions

FTKM18/24/28PVMK

RKM18/24/28PVMK

Basic

Function

Compressor Oval scroll compressor — — Air filter (prefilter)

Comfortable

Airflow

Comfort

Control

Operation Automatic operation —

Lifestyle

Convenience

Inverter (with inverter power control)

Operation limit for cooling (°CDB)

Operation limit for heating (°CWB) —

PAM control

Standby electricity saving

Swing compressor

Rotary compressor — — Washable grille — —

Reluctance DC motor

Power-airflow flap — — Heating dry operation — —

Power-airflow dual flaps

Power-airflow diffuser — — Timer WEEKLY TIMER operation

Wide-angle louvers

Auto-swing (up and down)

Auto-swing (right and left)

3-D airflow

COMFORT AIRFLOW operation

Auto fan speed

Indoor unit quiet operation

NIGHT QUIET mode (automatic) — — Flexibility Multi-split / split type compatible indoor

OUTDOOR UNIT QUIET operation

(manual)

INTELLIGENT EYE operation

Quick warming function —

Hot-start function —

Automatic defrosting —

Program dry operation

Fan only

New POWERFUL operation

(non-inverter)

Inverter POWERFUL operation

Priority-room setting — — Remote

COOL / HEAT mode lock — — Wired — —

HOME LEAVE operation — —

ECONO operation

Indoor unit ON/OFF button

Signal receiving sign

R/C with back light

Temperature display — —

Note: z

: Available

zz

10 ~ 5210 ~

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

zz

——

zz

zz

zz

zz

zz

Category Functions

FTXM18/24/28PVMK

RXM18/24/28PVMK

52

~

0

18

z

z

z

z

Health &

Clean

Worry Free

(Reliability &

Durability)

Remote

Control

Controller

Air-purifying filter — —

Photocatalytic deodorizing filter — —

Air-purifying filter with photocatalytic

deodorizing function

Titanium apatite photocatalytic

air-purifying filter

Wipe-clean flat panel

MOLD PROOF operation — —

Good-sleep cooling operation — —

24-hour ON/OFF timer

NIGHT SET mode

Auto-restart (after power failure)

Self-diagnosis (R/C, LED)

Wiring error check function — —

Anti-corrosion treatment of outdoor

heat exchanger

unit

Flexible power supply correspondence

High ceiling application — —

Chargeless 10 m 10 m

Either side drain (right or left)

Power selection — —

5-room centralized controller (option)

Remote control adaptor

(normal open pulse contact) (option)

Remote control adaptor (normal open

contact) (option)

DIII-NET compatible (adaptor) (option)

Wireless

— : Not available

FTKM18/24/28PVMK

RKM18/24/28PVMK

FTXM18/24/28PVMK

RXM18/24/28PVMK

——

zz

zz

zz

zz

zz

zz

zz

zz

zz

——

zz

zz

zz

zz

zz

zz

zz

List of Functions 2

SiMT041509E

Part 2

Specifications

1. Specifications..........................................................................................4

3 Specifications

SiMT041509E Specifications

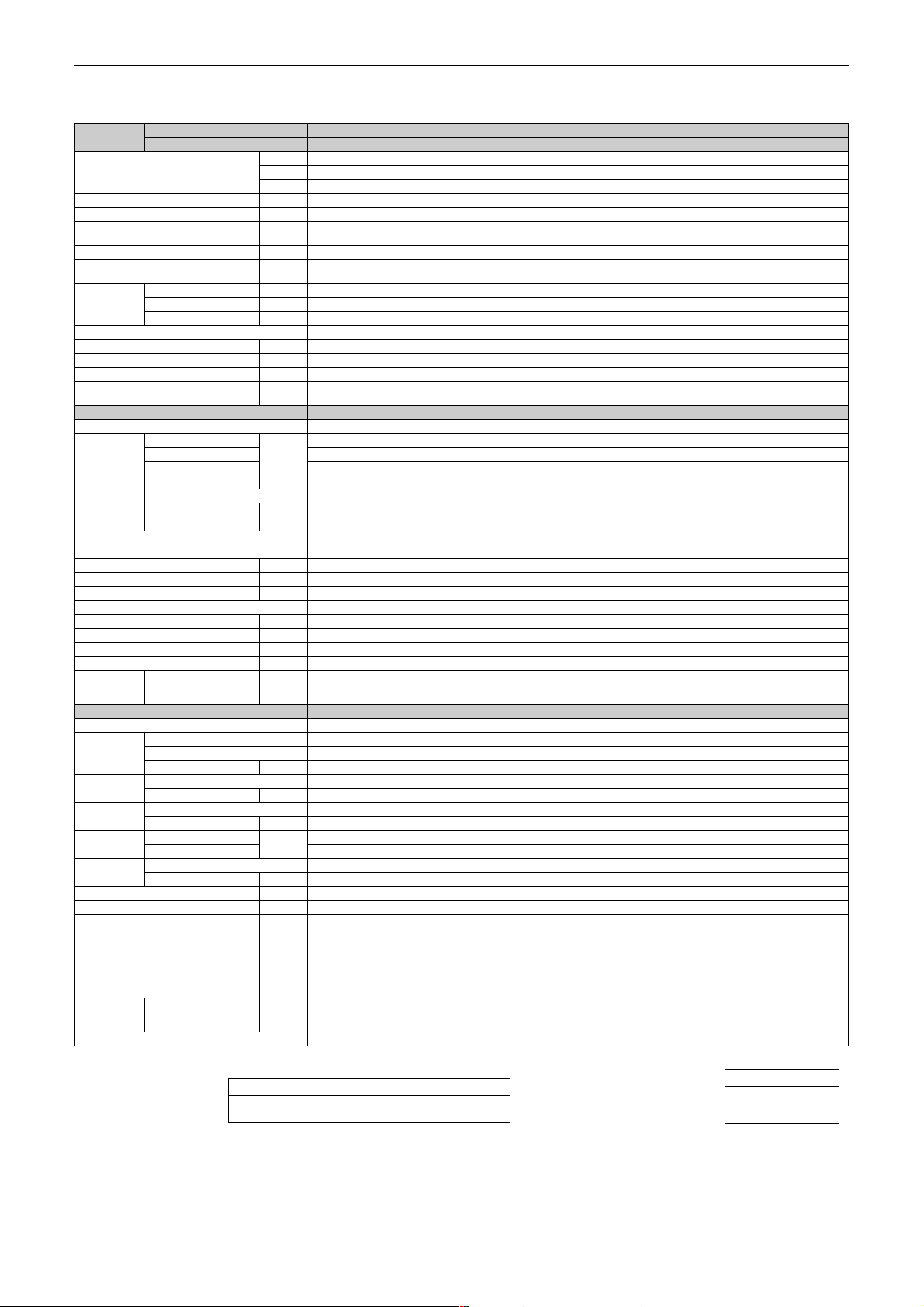

1. Specifications

50 Hz, 220 - 230 - 240 V / 60 Hz, 220 - 230 V

Model

Capacity

Rated (Min. ~ Max.)

Moisture Removal L/h 2.9 4.5

Running Current (Rated) A 6.4 - 6.1 - 5.8 / 6.4 - 6.1 8.8 - 8.4 - 8.1 / 8.8 - 8.4

Power Consumption

Rated (Min. ~ Max.)

Power Factor (Rated) % 95.9 - 96.2 - 97.0 / 95.9 - 96.2 97.6 - 97.8 - 97.2 / 97.6 - 97.8

COP

Rated (Min. ~ Max.)

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length m 30 30

Max. Interunit Height Difference m 20 20

Chargeless m 10 10

Amount of Additional Charge of

Refrigerant

Indoor Unit FTKM18PVMK FTKM24PVMK

Front Panel Color (Mancel No.) White (N95) White (N95)

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A 0.45 - 0. 43 - 0.41 / 0.45 - 0.43 0.70- 0.67 - 0.64 / 0.70 - 0.67

Power Consumption (Rated) W 59 85

Power Factor (Rated) % 59.6 - 59.7 - 60.0 / 59.6 - 59.7 55.2 - 55.2 - 55.3 / 55.2 - 55.2

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) mm 340 × 1,050 × 259 340 × 1,050 × 259

Packaged Dimensions (H × W × D) mm 342 × 1,160 × 429 342 × 1,160 × 429

Weight (Mass) kg 15 15

Gross Weight (Gross Mass) kg 21 21

Sound

Pressure

Level

Outdoor Unit RKM18PVMK RKM24PVMK

Casing Color Ivory White Ivory White

Compressor

Refrigerant

Oil

Refrigerant

Airflow Rate

Fan

Running Current (Rated) A 6.1 - 5.8 - 5.5 / 6.1 - 5.8 8.4 - 8.0 - 7.7 / 8.4 - 8.0

Power Consumption (Rated) W 1,291 1,805

Power Factor (Rated) % 96.2 - 96.8 - 97.8 / 96.2 - 96.8 97.7 - 98.1 - 97.7 / 97.7 - 98.1

Starting Current A 6.4 8.8

Dimensions (H × W × D) mm 695 × 930 × 350 695 × 930 × 350

Packaged Dimensions (H × W × D) mm 762 × 1,004 × 475 762 × 1,004 × 475

Weight (Mass) kg 46 49

Gross Weight (Gross Mass) kg 52 56

Sound

Pressure

Level

Drawing No. 3D093404 3D093405

Indoor Unit FTKM18PVMK FTKM24PVMK

Outdoor Unit RKM18PVMK RKM24PVMK

Liquid mm φ 6.4 φ 6.4

Gas mm φ 12.7 φ 12.7

Drain mm — —

H

M 16.5 (583) 17.7 (625)

L 12.6 (445) 13.7 (484)

SL 10.9 (385) 12.2 (431)

Type Cross Flow Fan Cross Flow Fan

Motor Output W 48 48

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 48 / 42 / 35 / 32 51 / 45 / 37 / 34

Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Model 2YC40BXD 2YC40BXD

Motor Output W 1,300 1,300

Type FW68DA FW68DA

Charge L 0.650 0.650

Type R-32 R-32

Charge kg 1.12 1.40

H

SL 62.0 (2,189) 61.4 (2,168)

Type Propeller Propeller

Motor Output W 128 128

HdB(A) 51 56

kW 5.28 (1.7 ~ 6.0) 7.03 (1.9 ~ 8.6)

Btu/h 18,000 (5,700 ~ 20,500) 24, 000 (6,500 ~ 29,500)

kcal/h 4,540 (1,440 ~ 5,170) 6,050 (1,640 ~ 7,430)

W 1,350 (300 ~ 1,700) 1,890 (350 ~ 2,600)

W/W 3.91 (5.57 ~ 3.54) 3.72 (5.46 ~ 3.32)

g/m 20 20

20.5 (724) 22.0 (777)

m³/min

(cfm)

m³/min

(cfm)

76.9 (2,715) 74.2 (2,620)

Note:

The data are based on the conditions shown in the table below.

Cooling Piping Length

Indoor ; 27°CDB / 19°CWB

Outdoor ; 35°CDB / 24°CWB

7.5 m

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Specifications 4

Specifications SiMT041509E

50 Hz, 220 - 230 - 240 V / 60 Hz, 220 - 230 V

Model

Capacity

Rated (Min. ~ Max.)

Moisture Removal L/h 5.6

Running Current (Rated) A 10.7 - 10.2 - 9.8 / 10.7 - 10.2

Power Consumption

Rated (Min. ~ Max.)

Power Factor (Rated) % 98.1 - 98.5 - 98.2 / 98.1 - 98.5

COP

Rated (Min. ~ Max.)

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes

Max. Interunit Piping Length m 30

Max. Interunit Height Difference m 20

Chargeless m 10

Amount of Additional Charge of

Refrigerant

Indoor Unit FTKM28PVMK

Front Panel Color (Mancel No.) White (N95)

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof

Running Current (Rated) A 0.74- 0.71 - 0.68 / 0.74 - 0.71

Power Consumption (Rated) W 91

Power Factor (Rated) % 55.9 - 55.7 - 55.8 / 55.9 - 55.7

Temperature Control Microcomputer Control

Dimensions (H × W × D) mm 340 × 1,200 × 259

Packaged Dimensions (H × W × D) mm 342 × 1,310 × 429

Weight (Mass) kg 18

Gross Weight (Gross Mass) kg 25

Sound

Pressure

Level

Outdoor Unit RKM28PVMK

Casing Color Ivory White

Compressor

Refrigerant

Oil

Refrigerant

Airflow Rate

Fan

Running Current (Rated) A 10.3 - 9.8 - 9.4 / 10.3 - 9.8

Power Consumption (Rated) W 2,219

Power Factor (Rated) % 97.9 - 98.4 - 98.4 / 97.9 - 98.4

Starting Current A 10.7

Dimensions (H × W × D) mm 695 × 930 × 350

Packaged Dimensions (H × W × D) mm 762 × 1,004 × 475

Weight (Mass) kg 49

Gross Weight (Gross Mass) kg 56

Sound

Pressure

Level

Drawing No. 3D093406

Indoor Unit FTKM28PVMK

Outdoor Unit RKM28PVMK

Liquid mm φ 6.4

Gas mm φ 15.9

Drain mm —

H

M 20.6 (727)

L 16.3 (576)

SL 14.5 (512)

Type Cross Flow Fan

Motor Output W 64

Speed Steps 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 54 / 49 / 42 / 39

Type Hermetically Sealed Swing Type

Model 2YC40BXD

Motor Output W 1,300

Type FW68DA

Charge L 0.650

Type R-32

Charge kg 1.60

H

SL 61.4 (2,168)

Type Propeller

Motor Output W 128

HdB(A) 57

kW 8.21 (1.9 ~ 9.4)

Btu/h 28,000 (6,500 ~ 32,000)

kcal/h 7,060 (1,640 ~ 8,070)

W 2,310 (310 ~ 3,030)

W/W 3.55 (6.16 ~ 3.10)

g/m 20

25.2 (890)

m³/min

(cfm)

m³/min

(cfm)

79.0 (2,789)

The data are based on the conditions shown in the table below.

Note:

Cooling Piping Length

Indoor ; 27°CDB / 19°CWB

Outdoor ; 35°CDB / 24°CWB

7.5 m

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

5 Specifications

SiMT041509E Specifications

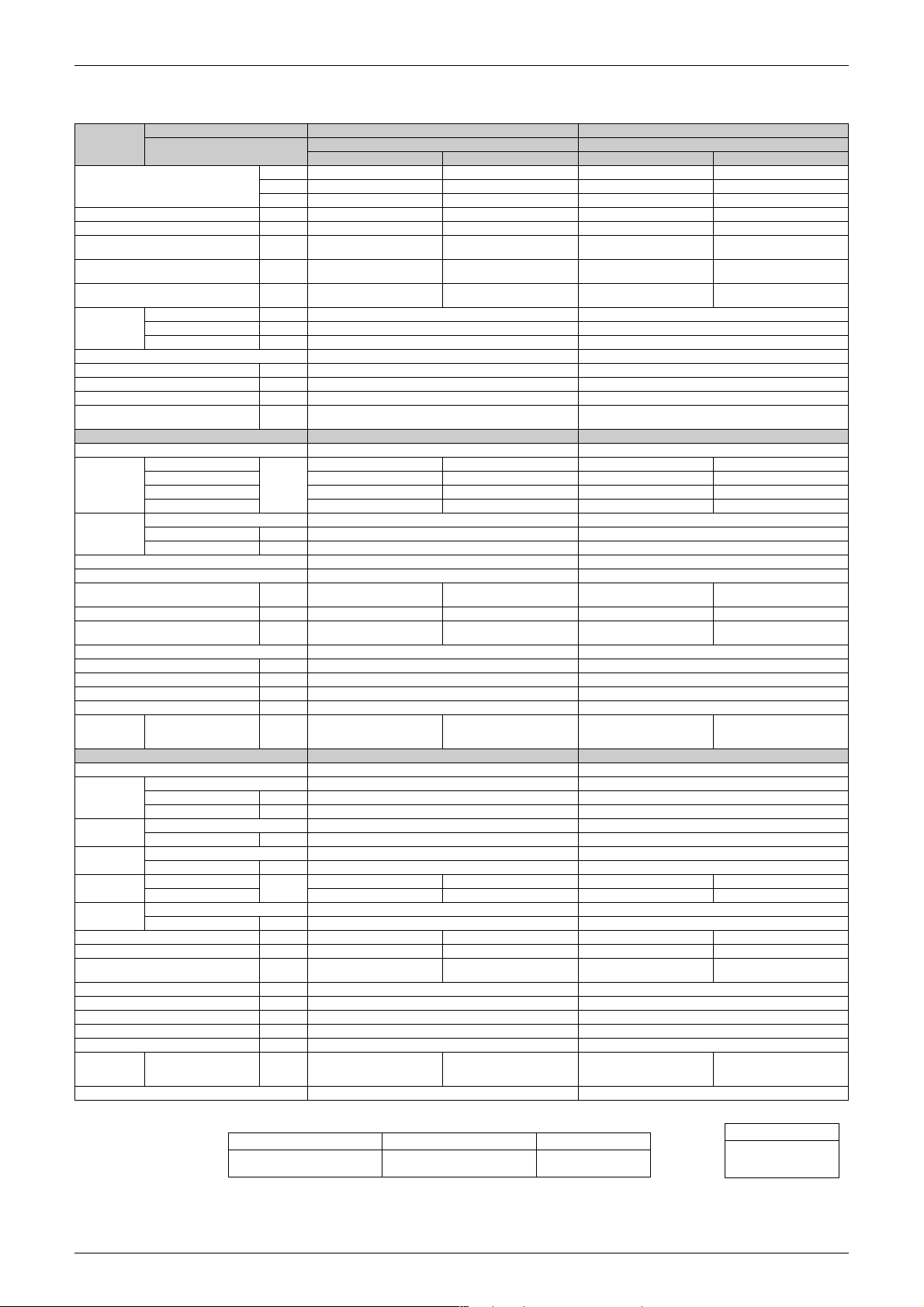

50 Hz, 220 - 230 - 240 V / 60 Hz, 220 - 230 V

Model

Capacity

Rated (Min. ~ Max.)

Moisture Removal L/h 2.9 — 4.5 —

Running Current (Rated) A 6.4 - 6.1 - 5.8 / 6.4 - 6.1 5.9 - 5.6 - 5.4 / 5.9 - 5.6 8.8 - 8.4 - 8.1 / 8.8 - 8.4 7.2 - 6.9 - 6.6 / 7.2 - 6.9

Power Consumption

Rated (Min. ~ Max.)

Power Factor (Rated) %

COP

Rated (Min. ~ Max.)

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Max. Interunit Piping Length m 30 30

Max. Interunit Height Difference m 20 20

Chargeless m 10 10

Amount of Additional Charge of

Refrigerant

Indoor Unit FTXM18PVMK FTXM24PVMK

Front Panel Color (Mancel No.) White (N95) White (N95)

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof Removable, Washable, Mildew Proof

Running Current (Rated) A

Power Consumption (Rated) W 59 65 85 85

Power Factor (Rated) %

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) mm 340 × 1,050 × 259 340 × 1,050 × 259

Packaged Dimensions (H × W × D) mm 342 × 1,160 × 429 342 × 1,160 × 429

Weight (Mass) kg 15 15

Gross Weight (Gross Mass) kg 21 21

Sound

Pressure

Level

Outdoor Unit RXM18PVMK RXM24PVMK

Casing Color Ivory White Ivory White

Compressor

Refrigerant

Oil

Refrigerant

Airflow Rate

Fan

Running Current (Rated) A 6.1 - 5.8 - 5.5 / 6.1 - 5.8 5.6 - 5.3 - 5.1 / 5.6 - 5.3 8.4 - 8.0 - 7.7 / 8.4 - 8.0 6.8 - 6.5 - 6.2 / 6.8 - 6.5

Power Consumption (Rated) W 1,291 1,185 1,805 1,455

Power Factor (Rated) %

Starting Current A 6.4 8.8

Dimensions (H × W × D) mm 695 × 930× 350 695 × 930× 350

Packaged Dimensions (H × W × D) mm 762 × 1,004 × 475 762 × 1,004 × 475

Weight (Mass) kg 46 49

Gross Weight (Gross Mass) kg 52 56

Sound

Pressure

Level

Drawing No. 3D093401 3D093402

Indoor Unit FTXM18PVMK FTXM24PVMK

Outdoor Unit

kW 5.28 (1.7 ~ 6.0) 5.42 (1.0 ~ 5.4) 7.03 (1.9 ~ 8.6) 6.33 (1.1 ~ 6.3)

Btu/h 18,000 (5,700 ~ 20,500) 18,500 (3,500 ~18,500) 24,000 (6,500 ~ 29,500) 21,600 (3,700 ~ 21,600)

kcal/h 4,540 (1,440 ~ 5,170) 4,660 (890 ~ 4,660) 6,050 (1,640 ~ 7,430) 5,440 (930 ~ 5,440)

W 1,350 (300 ~ 1,700) 1,250 (240 ~ 1,250) 1,890 (350 ~ 2,600) 1,540 (280 ~ 1,540)

W/W 3.91 (5.57 ~ 3.54) 4.34 (4.29 ~ 4.34) 3.72 (5.46 ~ 3.32) 4.11 (3.86 ~ 4.11)

Liquid mm φ 6.4 φ 6.4

Gas mm φ 12.7 φ 12.7

Drain mm φ 16.0 φ 16.0

g/m 20 20

H

M 16.5 (583) 17.5 (618) 17.7 (625) 17.7 (625)

L 12.6 (445) 13.4 (473) 13.7 (484) 13.8 (487)

SL 10.9 (385) 11.7 (413) 12.2 (431) 12.0 (424)

Type Cross Flow Fan Cross Flow Fan

Motor Output W 48 48

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 48 / 42 / 35 / 32 50 / 42 / 34 / 31 51 / 45 / 37 / 34 51 / 43 / 35 / 32

Type Hermetically Sealed Swing Type Hermetically Sealed Swing Type

Model 2YC40BXD 2YC40BXD

Motor Output W 1,300 1,300

Type FW68DA FW68DA

Charge L 0.650 0.650

Type R-32 R-32

Charge kg 1.12 1.40

H

SL 62.0 (2,189) 48.3 (1,705) 61.4 (2,168) 55.3 (1,953)

Type Propeller Propeller

Motor Output W 128 128

H dB(A) 51 51 56 55

m³/min

(cfm)

m³/min

(cfm)

Cooling Heating Cooling Heating

95.9 - 96.2 - 97.0 /

95.9 - 96.2

20.5 (724) 22.2 (784) 22.0 (777) 22.9 (809)

0.45 - 0.43 - 0.41 /

0.45 - 0.43

59.6 - 59.7 - 60.0 /

59.6 - 59.7

76.9 (2,715) 49.8 (1,758) 74.2 (2,620) 62.5 (2,207)

96.2 - 96.8 - 97.8 /

96.2 - 96.8

RXM18PVMK RXM24PVMK

96.3 - 97.0 - 96.5 /

96.3 - 97.0

0.49 - 0.47 - 0.45 /

0.49 - 0.47

60.3 - 60.1 - 60.2 /

60.3 - 60.1

96.2 - 97.2 - 96.8 /

96.2 - 97.2

97.6 - 97.8 - 97.2 /

97.6 - 97.8

0.70 - 0.67 - 0.64 /

0.70 - 0.67

55.2 - 55.2 - 55.3 /

55.2 - 55.2

97.7 - 98.1 - 97.7 /

97.7 - 98.1

97.2 - 97.0 - 97.2 /

97.2 - 97.0

0.70 - 0.67 - 0.64 /

0.70 - 0.67

55.2 - 55.2 - 55.3 /

55.2 - 55.2

97.3 - 97.3 - 97.8 /

97.3 - 97.3

Note:

The data are based on the conditions shown in the table below.

Outdoor ; 35°CDB / 24°CWB

Cooling Heating Piping Length

Indoor ; 27°CDB / 19°CWB

Indoor ; 20°CDB

Outdoor ; 7°CDB / 6°CWB

7.5 m

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Specifications 6

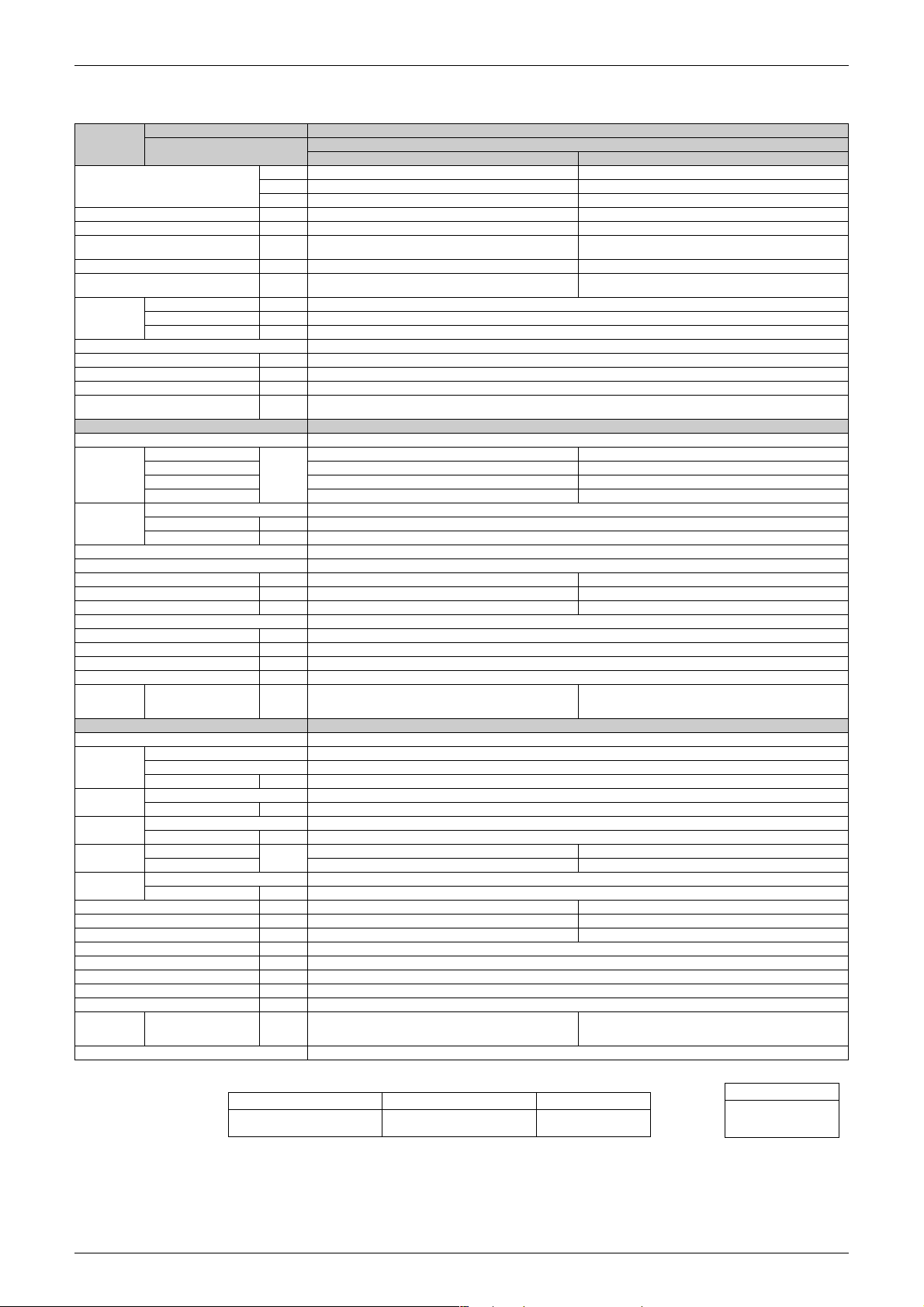

Specifications SiMT041509E

50 Hz, 220 - 230 - 240 V / 60 Hz, 220 - 230 V

Model

Capacity

Rated (Min. ~ Max.)

Moisture Removal L/h 5.6 —

Running Current (Rated) A 10.7 - 10.2 - 9.8 / 10.7 - 10.2 8.4 - 8.0 - 7.7 / 8.4 - 8.0

Power Consumption

Rated (Min. ~ Max.)

Power Factor (Rated) % 98.1 - 98.5 - 98.2 / 98.1 - 98.5 95.2 - 95.7 - 95.2 / 95.2 - 95.7

COP

Rated (Min. ~ Max.)

Piping

Connections

Heat Insulation Both Liquid and Gas Pipes

Max. Interunit Piping Length m 30

Max. Interunit Height Difference m 20

Chargeless m 10

Amount of Additional Charge of

Refrigerant

Indoor Unit FTXM28PVMK

Front Panel Color (Mancel No.) White (N95)

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward

Air Filter Removable, Washable, Mildew Proof

Running Current (Rated) A 0.74 - 0. 71 - 0.68 / 0.74 - 0.71 0.69 - 0.66 - 0.63 / 0.69 - 0.66

Power Consumption (Rated) W 91 84

Power Factor (Rated) % 55.9 - 55.7 - 55.8 / 55.9 - 55.7 55.3 - 55.3 - 55.6 / 55.3 - 55.3

Temperature Control Microcomputer Control

Dimensions (H × W × D) mm 340 × 1,200 × 259

Packaged Dimensions (H × W × D) mm 342 × 1,310 × 429

Weight (Mass) kg 18

Gross Weight (Gross Mass) kg 25

Sound

Pressure

Level

Outdoor Unit RXM28PVMK

Casing Color Ivory White

Compressor

Refrigerant

Oil

Refrigerant

Airflow Rate

Fan

Running Current (Rated) A 10.3 - 9.8 - 9.4 / 10.3 - 9.8 8.0 - 7.6 - 7.3 / 8.0 - 7.6

Power Consumption (Rated) W 2,219 1,676

Power Factor (Rated) % 97.9 - 98.4 - 98.4 / 97.9 - 98.4 95.2 - 95.9 - 95.7 / 95.2 - 95.9

Starting Current A 10.7

Dimensions (H × W × D) mm 695 × 930× 350

Packaged Dimensions (H × W × D) mm 762 × 1,004 × 475

Weight (Mass) kg 49

Gross Weight (Gross Mass) kg 56

Sound

Pressure

Level

Drawing No. 3D093403

Indoor Unit FTXM28PVMK

Outdoor Unit

kW 8.21 (1.9 ~ 9.4) 6.57 (1.1 ~ 6.6)

Btu/h 28,000 (6,500 ~ 32,000) 22, 400 (3,700 ~ 22,400)

kcal/h 7,060 (1,640 ~ 8,070) 5,650 (930 ~ 5,650)

W 2,310 (310 ~ 3,030) 1,760 (270 ~ 1,760)

W/W 3.55 (6.16 ~ 3.10) 3.73 (4.00 ~ 3.73)

Liquid mm φ 6.4

Gas mm φ 15.9

Drain mm φ 16.0

g/m 20

H

M 20.6 (727) 21.2 (749)

L 16.3 (576) 16.2 (572)

SL 14.5 (512) 14.9 (526)

Type Cross Flow Fan

Motor Output W 64

Speed Steps 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 54 / 49 / 42 / 39 53 / 45 / 38 / 35

Type Hermetically Sealed Swing Type

Model 2YC40BXD

Motor Output W 1,300

Type FW68DA

Charge L 0.650

Type R-32

Charge kg 1.60

H

SL 61.4 (2,168) 55.3 (1,953)

Type Propeller

Motor Output W 128

HdB(A) 57 57

m³/min

(cfm)

m³/min

(cfm)

Cooling Heating

25.2 (890) 27.2 (960)

79.0 (2,789) 66.8 (2,359)

RXM28PVMK

The data are based on the conditions shown in the table below.

Note:

Cooling Heating Piping Length

Indoor ; 27°CDB / 19°CWB

Outdoor ; 35°CDB / 24°CWB

Indoor ; 20°CDB

Outdoor ; 7°CDB / 6°CWB

7.5 m

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

7 Specifications

SiMT041509E

Connector Wiring Diagram

Part 3

Printed Circuit Board

1. Indoor Unit...............................................................................................9

2. Outdoor Unit..........................................................................................11

Printed Circuit Board Connector Wiring Diagram 8

Indoor Unit SiMT041509E

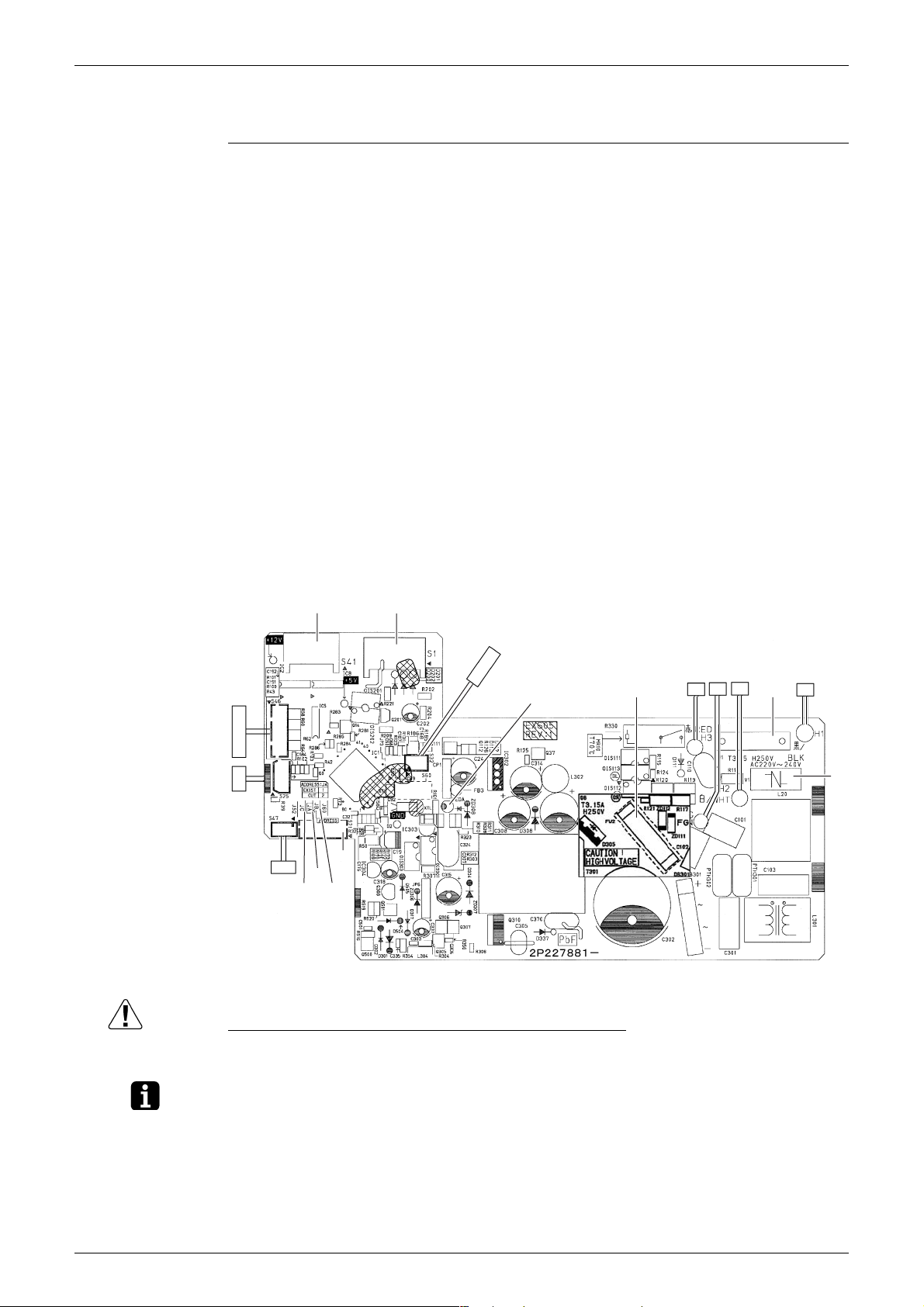

1. Indoor Unit

Control PCB

(PCB1)

1) S1 Connector for DC fan motor

2) S21 Connector for centralized control (HA)

3) S25 Connector for INTELLIGENT EYE sensor PCB

4) S32 Indoor heat exchanger thermistor

5) S41 Connector for swing motors

6) S46 Connector for display PCB

7) S47 Connector for signal receiver PCB

8) H1, H2, H3, FG Connector for terminal board

9) JA Address setting jumper

∗ Refer to page 94 for detail.

10)JB Fan speed setting when compressor stops for thermostat OFF

∗ Refer to page 94 for detail.

11)JC Power failure recovery function (auto-restart)

∗ Refer to page 94 for detail.

12)LED A LED for service monitor (green)

13)FU1 (F1U),

Fuse (3.15 A, 250 V)

FU2 (F2U)

14)V1 Varistor

S1S41

S32

LED A

S46

S25

S21

JA

S47

JC

JB

Caution Replace the PCB if you accidentally cut a wrong jumper.

Jumpers are necessary for electronic circuit. Improper operation may occur if you cut any of

them.

FU2

H2FGH3

FU1

2P227881-10

2P227881-11

H1

V1

Note: The symbols in the parenthesis are the names on the appropriate wiring diagram.

9 Printed Circuit Board Connector Wiring Diagram

SiMT041509E Indoor Unit

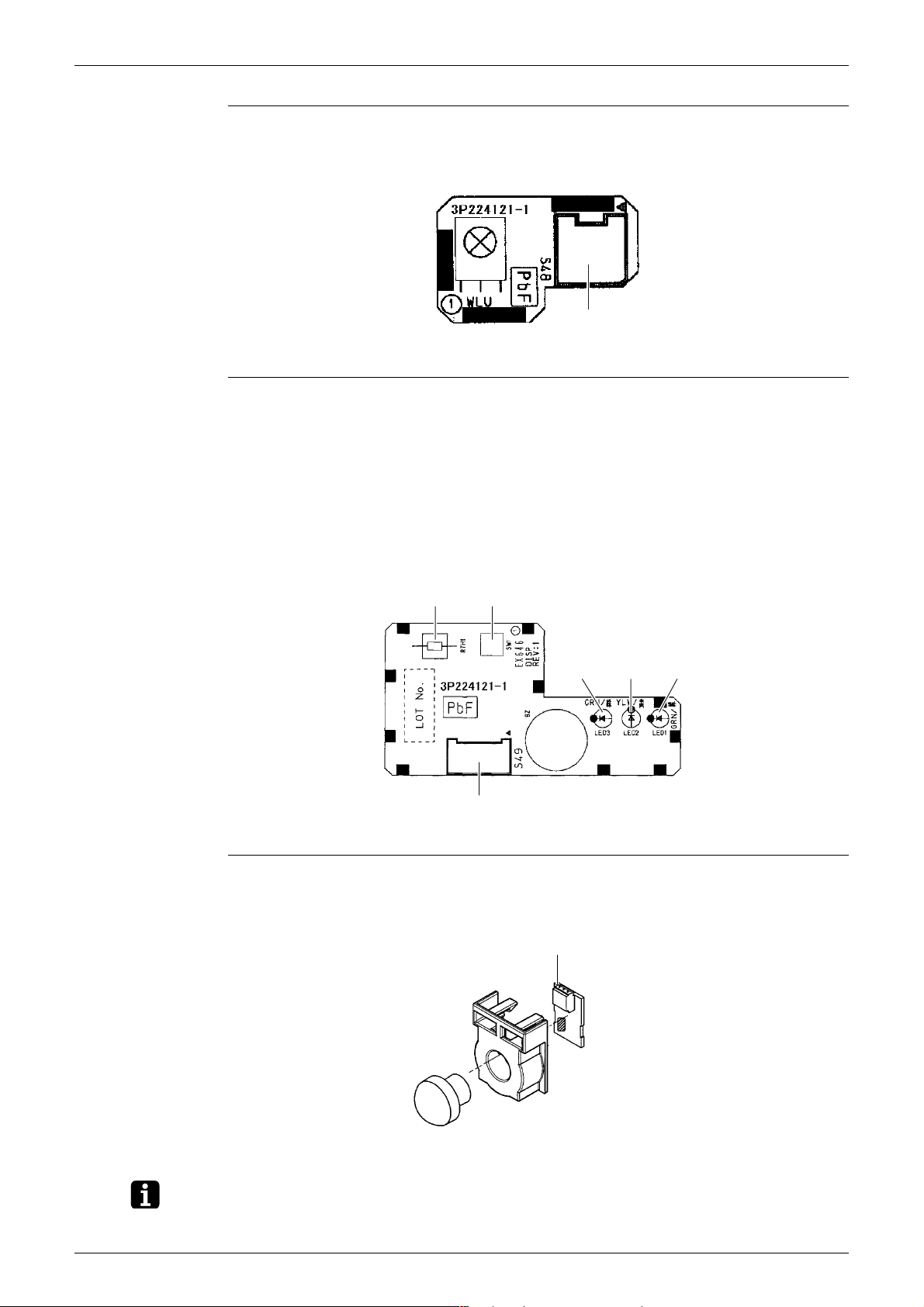

Signal Receiver

PCB (PCB2)

1) S48 Connector for control PCB

S48

3P224121-1

Display PCB

(PCB3)

1) S49 Connector for control PCB

2) SW1 Forced cooling operation ON/OFF button

∗ Refer to page 92 for detail.

3) LED1 (H1P) LED for operation (green)

4) LED2 (H2P) LED for timer (yellow)

5) LED3 (H3P) LED for INTELLIGENT EYE (green)

6) RTH1 (R1T) Room temperature thermistor

INTELLIGENT

EYE Sensor PCB

(PCB4)

RTH1 SW1

S49

1) S36 Connector for control PCB

S36

LED3

LED2

3P224121-1

LED1

3P227885-1

Note: The symbols in the parenthesis are the names on the appropriate wiring diagram.

Printed Circuit Board Connector Wiring Diagram 10

Outdoor Unit SiMT041509E

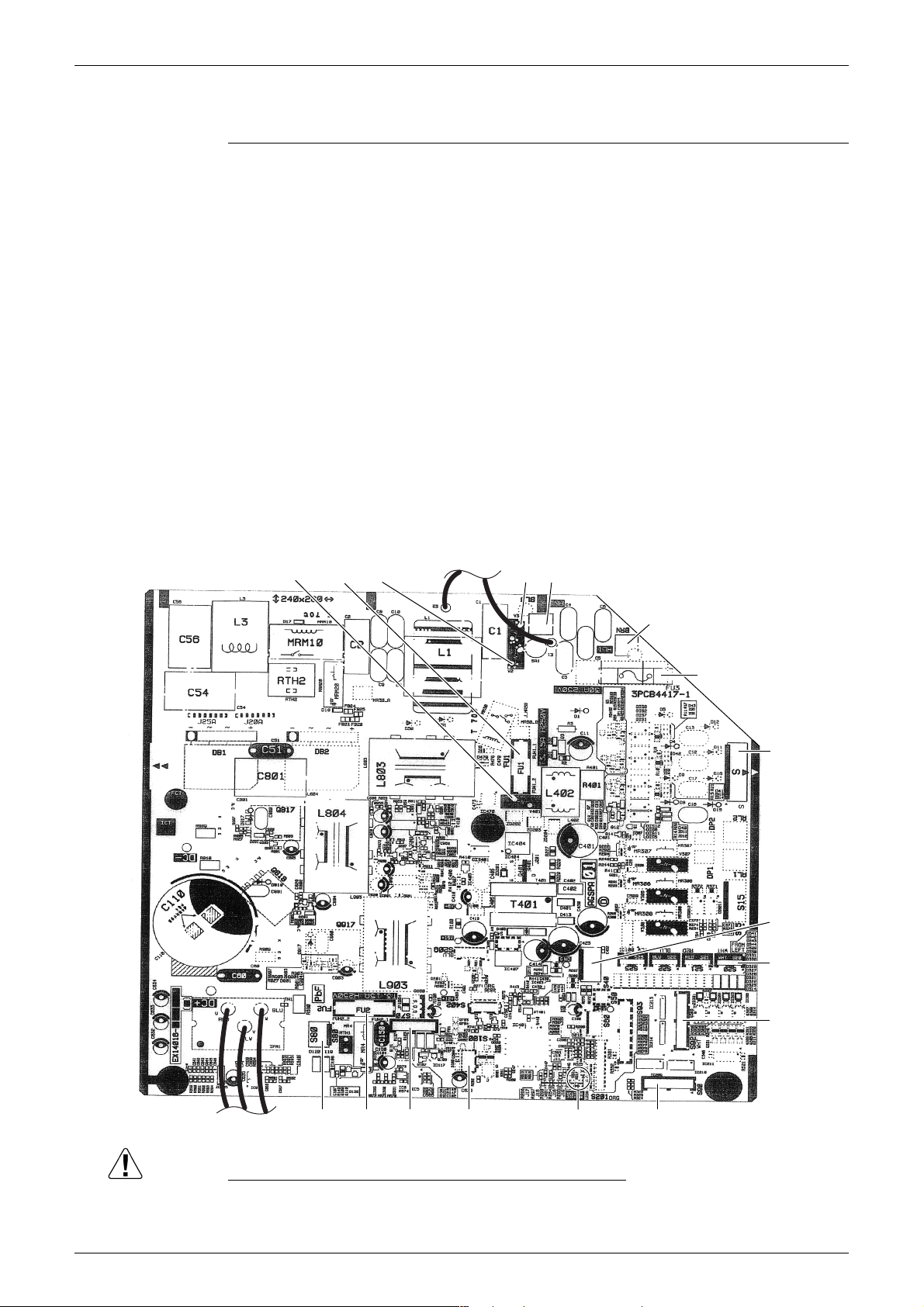

2. Outdoor Unit

Main PCB

1) S20 Connector for electronic expansion valve coil

2) S40 Connector for overload protector and high pressure switch

3) S70 Connector for DC fan motor

4) S80 Connector for four way valve coil

5) S90 Connector for thermistors

(outdoor temperature, outdoor heat exchanger, discharge pipe)

6) S92 Jumpers for local setting

∗ Neither disconnect the connector nor cut any of the jumpers.

7) S100 Connector for fan motor (for cooling electrical box)

8) HL1, HN1, S Connector for terminal board

9) E1, E2 Terminal for earth wire

10) U, V, W Connector for compressor

11) FU1, FU2 Fuse (3.15 A, 250 V)

12) FU3 Fuse (30 A, 250 V)

13) LED A LED for service monitor (green)

14) V2, V3, V401 Varistor

V401

FU1

V2

E2 E1

V3

HN1

HL1

FU3

S

S40

S20

S92

UV W

FU2S80

S70

S100

LED A

S90

2P387226-1

Caution Replace the PCB if you accidentally cut a wrong jumper.

Jumpers are necessary for electronic circuit. Improper operation may occur if you cut any of

them.

11 Printed Circuit Board Connector Wiring Diagram

SiMT041509E

Part 4

Function and Control

1. Main Functions......................................................................................13

1.1 Temperature Control ..............................................................................13

1.2 Frequency Principle................................................................................13

1.3 Airflow Direction Control.........................................................................15

1.4 Fan Speed Control for Indoor Unit .........................................................16

1.5 Program Dry Operation ..........................................................................17

1.6 Automatic Operation...............................................................................18

1.7 Thermostat Control.................................................................................19

1.8 NIGHT SET Mode ..................................................................................20

1.9 ECONO Operation .................................................................................20

1.10 INTELLIGENT EYE Operation ...............................................................21

1.11 Inverter POWERFUL Operation .............................................................22

1.12 Clock Setting ..........................................................................................23

1.13 WEEKLY TIMER Operation ...................................................................24

1.14 Other Functions......................................................................................30

2. Function of Thermistor ..........................................................................31

3. Control Specification .............................................................................32

3.1 Mode Hierarchy ......................................................................................32

3.2 Frequency Control ..................................................................................33

3.3 Controls at Mode Changing / Start-up....................................................35

3.4 Discharge Pipe Temperature Control.....................................................36

3.5 Input Current Control ..............................................................................37

3.6 Freeze-up Protection Control .................................................................38

3.7 Heating Peak-cut Control .......................................................................38

3.8 Outdoor Fan Control...............................................................................39

3.9 Liquid Compression Protection Function................................................39

3.10 Defrost Control .......................................................................................40

3.11 Electronic Expansion Valve Control .......................................................41

3.12 Discharge Pipe Thermistor Disconnection Control.................................43

3.13 Malfunctions ...........................................................................................43

Function and Control 12

Main Functions SiMT041509E

1. Main Functions

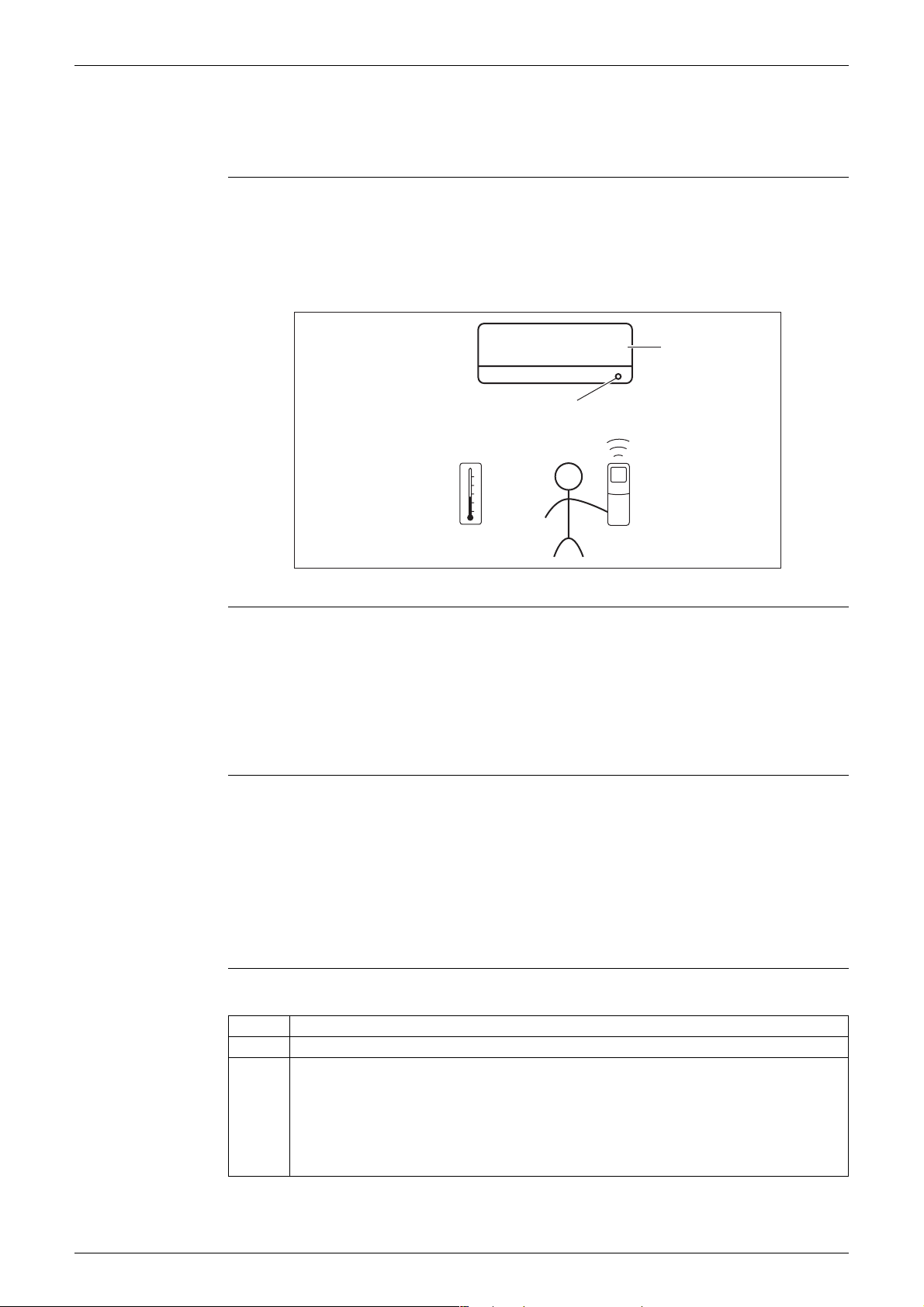

1.1 Temperature Control

Definitions of

Temperatures

Temperature

Control

The definitions of temperatures are classified as following.

Room temperature: temperature of lower part of the room

Set temperature: temperature set by remote controller

Room thermistor temperature: temperature detected by room temperature thermistor

Target temperature: temperature determined by microcomputer

Target temperature

Room thermistor temperature

Set temperature

Room temperature

(R12321)

The temperature of the room is detected by the room temperature thermistor. However, there is

a difference between the temperature detected by room temperature thermistor and the

temperature of lower part of the room, depending on the type of the indoor unit or installation

condition. Practically, the temperature control is done by the target temperature appropriately

adjusted for the indoor unit and the temperature detected by room temperature thermistor.

1.2 Frequency Principle

Control

Parameters

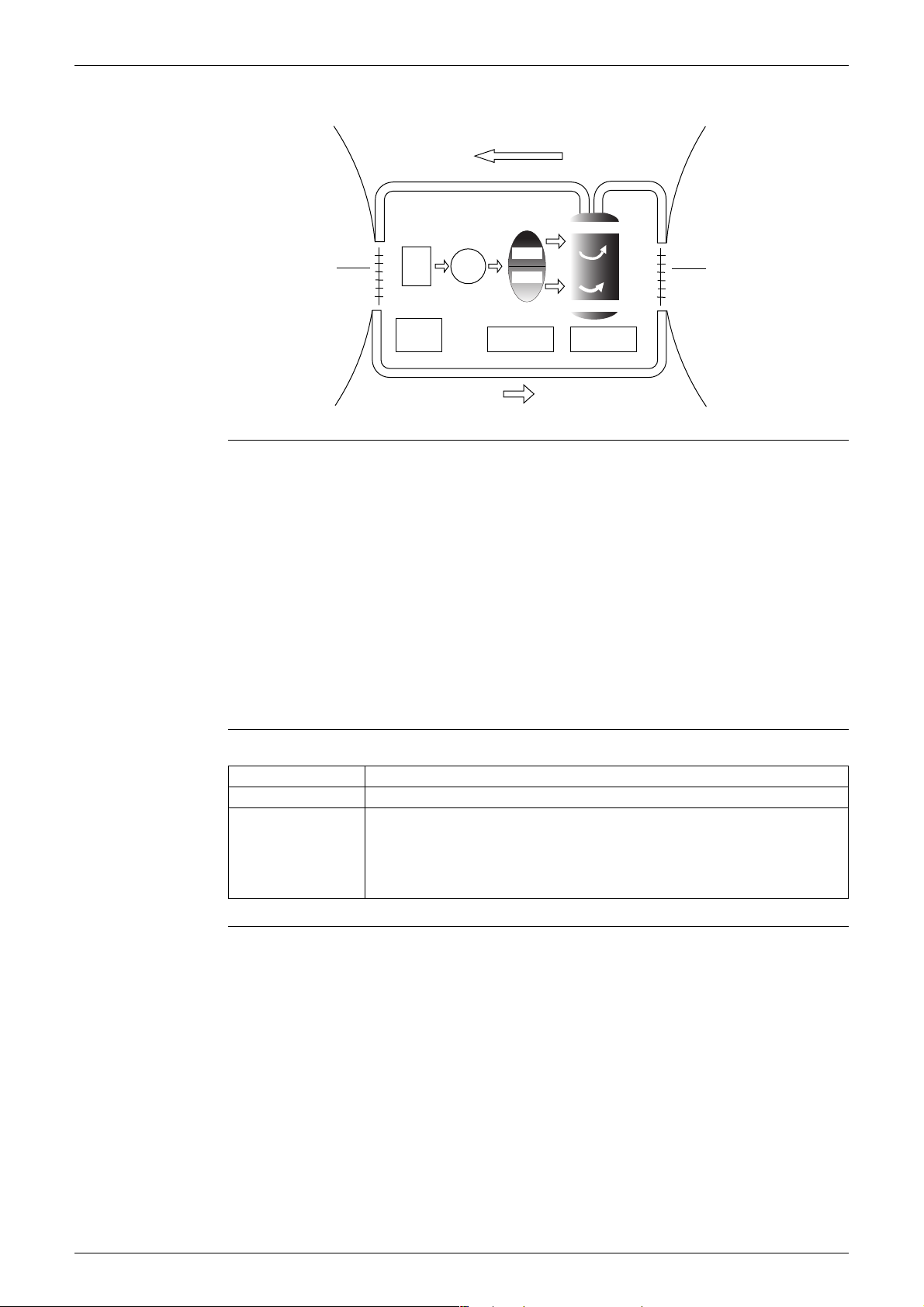

Inverter Principle To regulate the capacity, a frequency control is needed. The inverter makes it possible to

The frequency of the compressor is controlled by the following 2 parameters:

The load condition of the operating indoor unit

The difference between the room thermistor temperature and the target temperature

The target frequency is adapted by additional parameters in the following cases:

Frequency restrictions

Initial settings

Forced cooling operation

control the rotation speed of the compressor. The following table explains the inverter principle:

Phase Description

1 The supplied AC power source is converted into the DC power source for the present.

2 The DC power source is reconverted into the three phase AC power source with variable

frequency.

When the frequency increases, the rotation speed of the compressor increases resulting

in an increase of refrigerant circulation. This leads to a larger amount of heat exchange

per unit.

When the frequency decreases, the rotation speed of the compressor decreases

resulting in a decrease of refrigerant circulation. This leads to a smaller amount of heat

exchange per unit.

13 Function and Control

SiMT041509E Main Functions

The following drawing shows a schematic view of the inverter principle:

Refrigerant circulation rate (high)

Amount of heat

exchanged air (large)

Amount of heat

exchanged air (small)

AC

freq=

constant

DC

power

power

50 Hz

freq=variable

60 Hz

Refrigerant circulation rate (low)

Inverter Features The inverter provides the following features:

The regulating capacity can be changed according to the changes in the outdoor

temperature and cooling / heating load.

Quick heating and quick cooling

The rotation speed of the compressor is increased when starting the heating (or cooling).

This enables to reach the set temperature quickly.

Even during extreme cold weather, high capacity is achieved. It is maintained even when the

outdoor temperature is 2°C.

Comfortable air conditioning

A fine adjustment is integrated to keep the room temperature constant.

Energy saving heating and cooling

Once the set temperature is reached, the energy saving operation enables to maintain the

room temperature at low power.

high f

low f

high speed

low speed

capacity=

variable

Amount of heat

exchanged air (large)

Amount of heat

exchanged air (small)

(R2812)

Frequency Limits The following functions regulate the minimum and maximum frequency:

Frequency Functions

Low Four way valve operation compensation. Refer to page 35.

High Compressor protection function. Refer to page 36.

Discharge pipe temperature control. Refer to page 36.

Input current control. Refer to page 37.

Freeze-up protection control. Refer to page 38.

Heating peak-cut control. Refer to page 38.

Defrost control. Refer to page 40.

Forced Cooling

Refer to page 92 for detail.

Operation

Function and Control 14

Main Functions SiMT041509E

1.3 Airflow Direction Control

Power-Airflow

Dual Flaps

The large flap sends a large volume of air downward to the floor and provides an optimum

control in cooling, dry, and heating operation.

<Cooling / Dry>

During cooling or dry operation, the flap retracts into the indoor unit. Then, cool air can be blown

far and distributed all over the room.

<Heating>

During heating operation, the large flap directs airflow downward to spread the warm air to the

entire room.

Wide-Angle

Louvers

The louvers, made of elastic synthetic resin, provide a wide range of airflow that guarantees

comfortable air distribution.

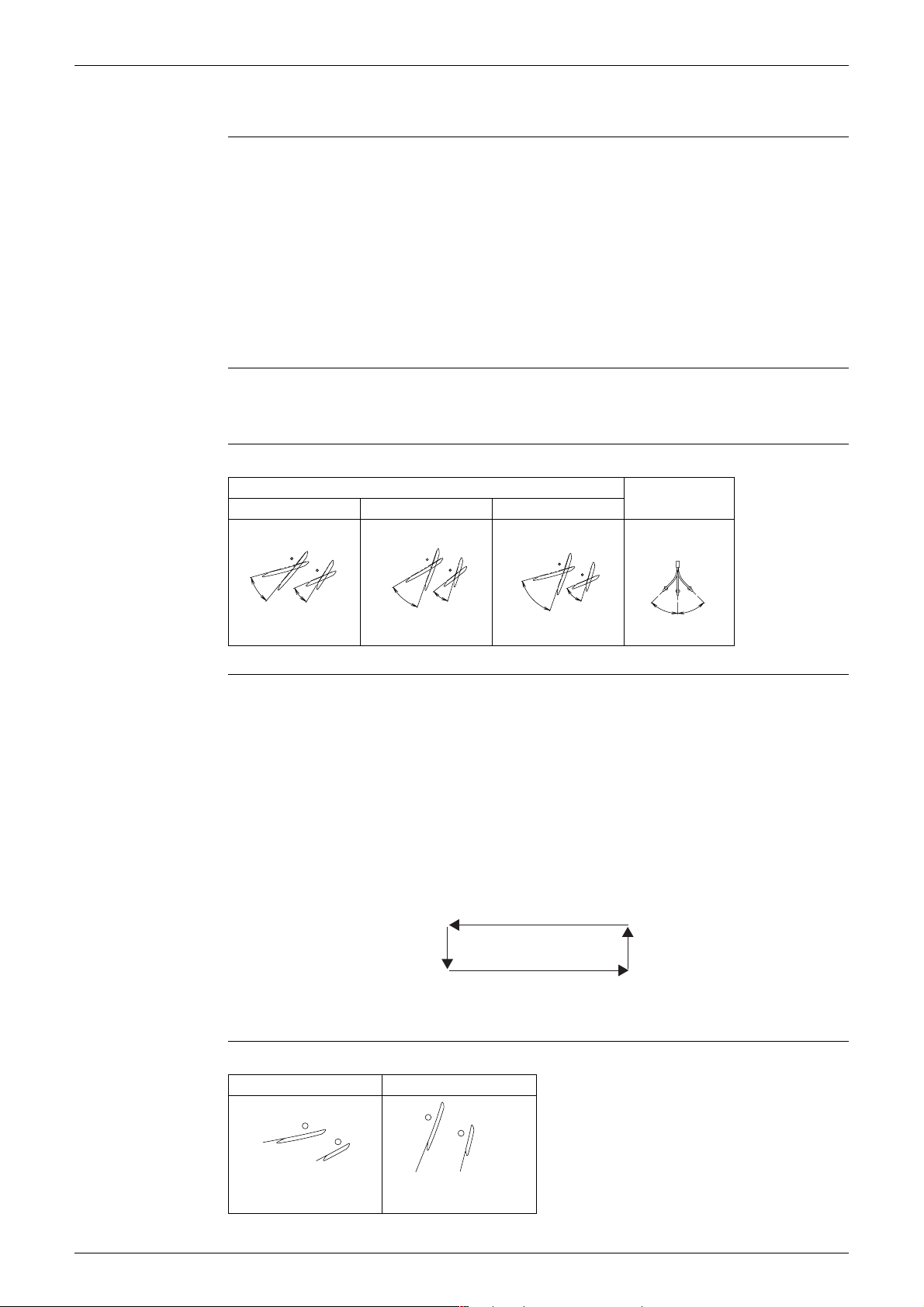

Auto-Swing The following table explains the auto-swing process for cooling, dry, heating, and fan:

Flap (up and down)

Cooling / Dry Heating Fan

°

15

50

°

°

25

°

°

60

(R9303)

30

70

40

°

°

75

°

(R9304)

15

°

°

25

°

75

°

70

(R9305)

Louver

(right and left)

°

45

°

45

(R9306)

3-D Airflow Alternative repetition of vertical and horizontal swing motions enables uniform air-conditioning of

the entire room.

When the horizontal swing and vertical swing are both set to automatic operation, the airflow

becomes 3-D airflow. The horizontal and vertical swing motions are alternated and the airflow

direction changes in the order shown in the following diagram.

(1) The louvers move from the right to the left.

(2) The flaps move downward.

(3) The louvers move from the left to the right.

(4) The flaps move upward.

(1)

COMFORT

AIRFLOW

(2)

(3)

The flaps are controlled not to blow the air directly at the people in the room.

Cooling Heating

(4)

(R13554)

Operation

°

10

20

°

(R22374)

75

°

°

80

(R9654)

15 Function and Control

Loading...

Loading...