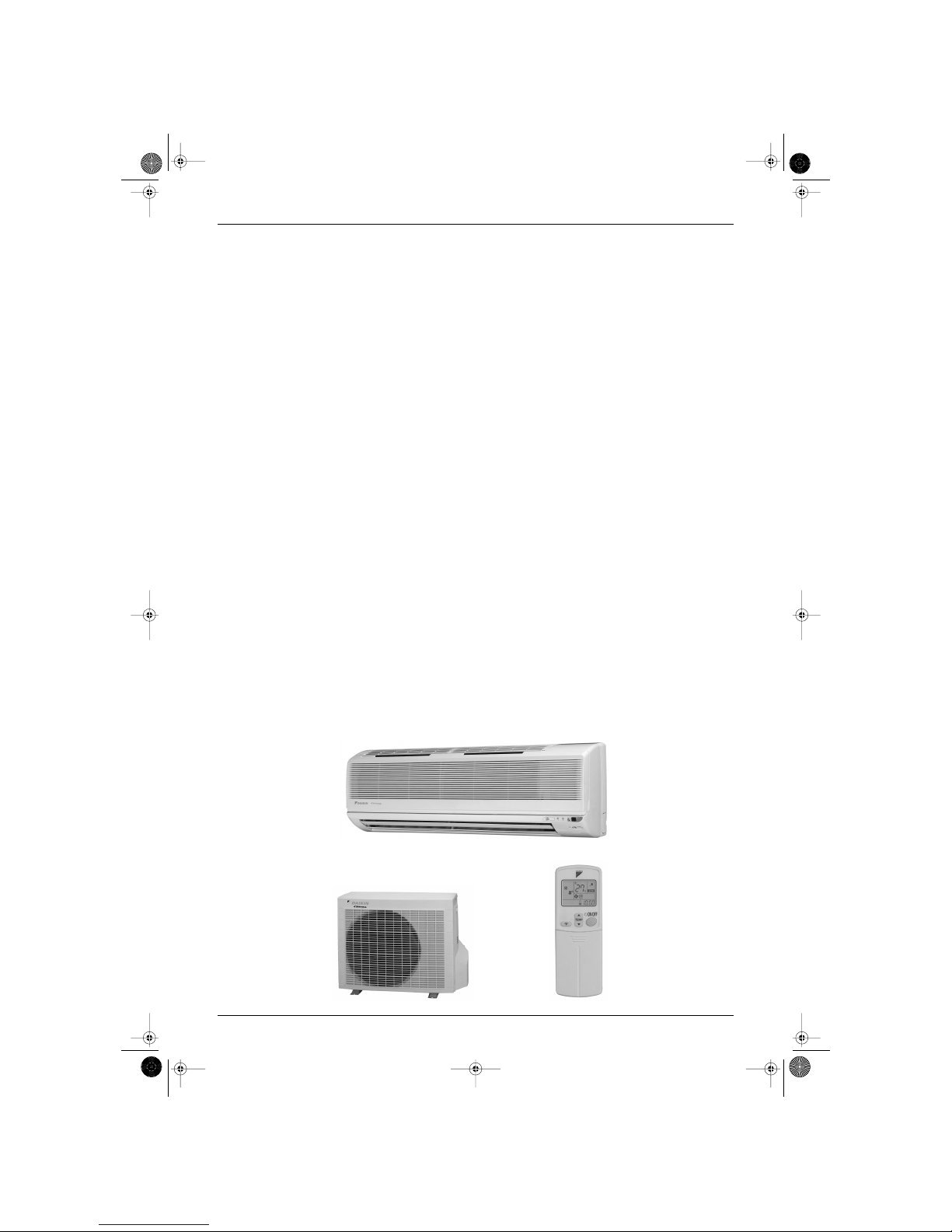

Daikin FTK25JV1NB, FTK35JV1NB, RK35JV1NB, FTX25JV1NB, FTX35JV1NB User Manual

...

SIE-86

Table of Contents i

Inverter Pair

FTK(X)-J / RK(X)-J Series

Cooling Only

Indoor Unit

FTK25JV1NB

FTK35JV1NB

Outdoor Unit

RK25JV1NB

RK35JV1NB

Heat Pump

Indoor Unit

FTX25JV1NB

FTX35JV1NB

Outdoor Unit

RX25JV1NB

RX35JV1NB

Si-86.book Page i Friday, June 23, 2000 10:26 AM

SIE-86

ii Table of Contents

1. Introduction .............................................................................................v

1.1 Safety Cautions ....................................................................................... v

Part 1 List of Function .................................................................1

1. Functions.................................................................................................2

1.1 Indoor Unit and Outdoor Unit................................................................... 2

Part 2 Printed Circuit Board Connector Wiring Diagram .............3

1. Printed Circuit Board Connector Wiring Diagram and Name..................4

1.1 FTK25/35J Series, FTX25/35J Series..................................................... 4

1.2 RK25/35J Series, RX25/35J Series......................................................... 6

Part 3 Main Function.....................................................................9

1. General Functionality ............................................................................10

1.1 Functions of Thermistors....................................................................... 10

1.2 Operating Modes................................................................................... 12

1.3 Frequency Principle............................................................................... 13

1.4 Defrost Control ...................................................................................... 15

1.5 Forced Operation Mode......................................................................... 16

1.6 Wide-angle Flaps, Diffuser, Louvres and Autoswing............................. 17

1.7 Fan Speed Control for Indoor Units....................................................... 19

1.8 Fan Speed Control for Outdoor Units.................................................... 20

1.9 General Functions ................................................................................. 21

1.10 Intelligent Eye (J type)........................................................................... 23

1.11 Good Sleep Cooling Control (J Type).................................................... 25

1.12 Automatic Operation.............................................................................. 26

1.13 Input Current Control (H / J Type) ......................................................... 27

1.14 Freeze Protection Function in Cooling. (H / J Type).............................. 28

1.15 Peak-Cut Control Function (H / J Type) ................................................ 29

1.16 Four-Way Valve Function Compensation (H / J Type).......................... 30

1.17 Compressor Protection Function (H / J Type) ....................................... 31

1.18 Wet Operation Protection (H / J Type) .................................................. 32

1.19 Dew Condensation Sweating Prevention Function (H / J type)............. 33

Part 4 System Configuration.......................................................35

1. Instruction..............................................................................................36

1.1 FTK25 / 35J, FTX25 / 35J ..................................................................... 36

Part 5 Service Diagnosis.............................................................51

1. Caution for Diagnosis............................................................................52

1.1 Troubleshooting with The Operation Lamp ........................................... 52

2. Problem Symptoms and Measures.......................................................54

3. Service Check Function ........................................................................55

3.1 ARC423 Series...................................................................................... 55

4. Code Indication on The Remote Controller...........................................56

4.1 Error Codes and Description of Fault .................................................... 56

5. Troubleshooting ....................................................................................57

5.1 Indoor Units ........................................................................................... 57

Si-86.book Page ii Friday, June 23, 2000 10:26 AM

SIE-86

Table of Contents iii

5.2 Outdoor Units ........................................................................................ 58

5.3 Faulty PCB ............................................................................................ 59

5.4 Operation Shutdown Due to High-Pressure Control

or Freeze-Up Protection (Thermistor Activation).................................. 60

5.5 Operation Halt Due to Fan Motor (AC Motor) or Related Abnormality. . 61

5.6 Operation Halt Due to Detection of Thermistor or Related Abnormality 62

5.7 Faulty Indoor Unit PCB.......................................................................... 63

5.8 Faulty Indoor Unit PCB.......................................................................... 64

5.9 Power Supply Abnormalities or Faulty Indoor Printed Circuit Boards ... 65

5.10 Signal Transmission Error (Between Indoor and Outdoor Units) .......... 66

5.11 Operation Halt Due to Detection of CT Error......................................... 67

5.12 Operation Halt Due to Thermistor Error or Disconnection Detection..... 68

5.13 Operation Halt Due to Compressor Startup Error.................................. 69

5.14 Output Overcurrent................................................................................ 70

5.15 Faulty Outdoor Unit PCB....................................................................... 72

5.16 Faulty Outdoor Unit PCB and Transmitting/Receiving Circuit ............... 73

5.17 Operation Halt Due to Detection of Input Over Current......................... 74

6. Check....................................................................................................76

6.1 How to Check ........................................................................................ 76

Part 6 Removal Procedure ..........................................................85

1. For FTK25J, FTK35J, FTX25J, FTX35J ...............................................86

1.1 Removal of Air Filter.............................................................................. 86

1.2 Removal of Front Grille.......................................................................... 88

1.3 Removal of Horizontal Blade and Vertical Blade................................... 90

1.4 Removal of Switch Box, PC Board and Swing Motor............................ 92

1.5 Removal of Heat Exchanger.................................................................. 97

1.6 Install of Drain Plug ............................................................................... 99

1.7 Removal of Fan Rotor and Motor ........................................................ 100

2. For RK25J, RK35J, RX25J, RX35J.....................................................103

2.1 Removal of External Casing................................................................ 103

2.2 Removal of Bellmouth and Left Side Plate.......................................... 105

2.3 Removal of PC Board and Switch Box................................................ 106

2.4 Removal of Propeller Fan and Fan Motor ........................................... 111

2.5 Removal of Compressor Noise Absorption Pad.................................. 112

2.6 Removal of Partition Plate and Reactor. ............................................. 114

2.7 Removal of Four-way Valve. ............................................................... 116

2.8 Removal of Compressor...................................................................... 118

Part 7 Others .............................................................................119

1. Others .................................................................................................120

1.1 Explanation.......................................................................................... 120

Part 8 Appendix.........................................................................123

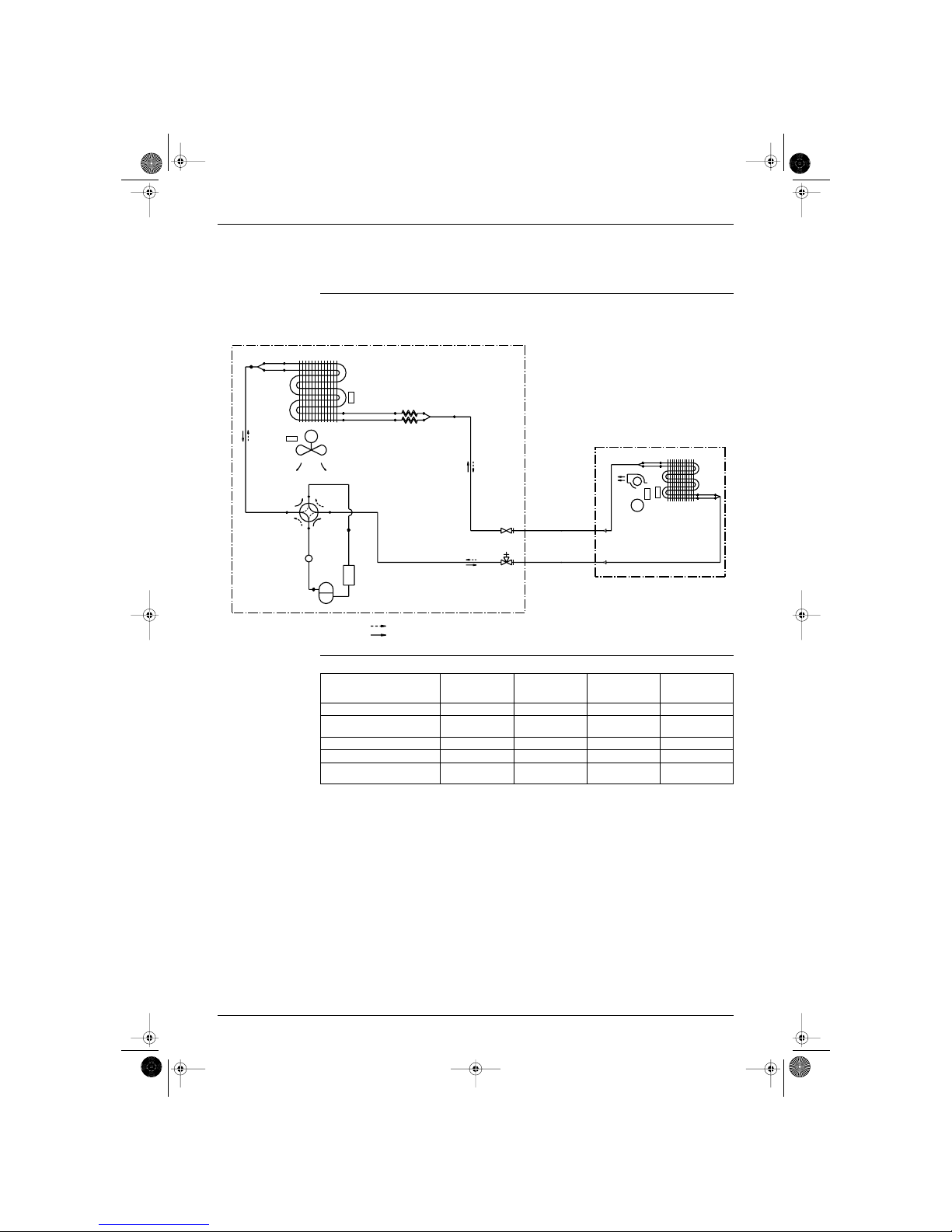

1. Piping Diagram....................................................................................124

1.1 Indoor Unit........................................................................................... 124

1.2 Outdoor Unit ........................................................................................ 125

2. Wiring Diagram ...................................................................................127

2.1 Indoor Unit........................................................................................... 127

2.2 Outdoor Unit ........................................................................................ 129

Si-86.book Page iii Friday, June 23, 2000 10:26 AM

SIE-86

iv Table of Contents

Index .............................................................................................i

Drawings & Flow Charts ...............................................................iii

Si-86.book Page iv Friday, June 23, 2000 10:26 AM

SIE-86 Introduction

v

1. Introduction

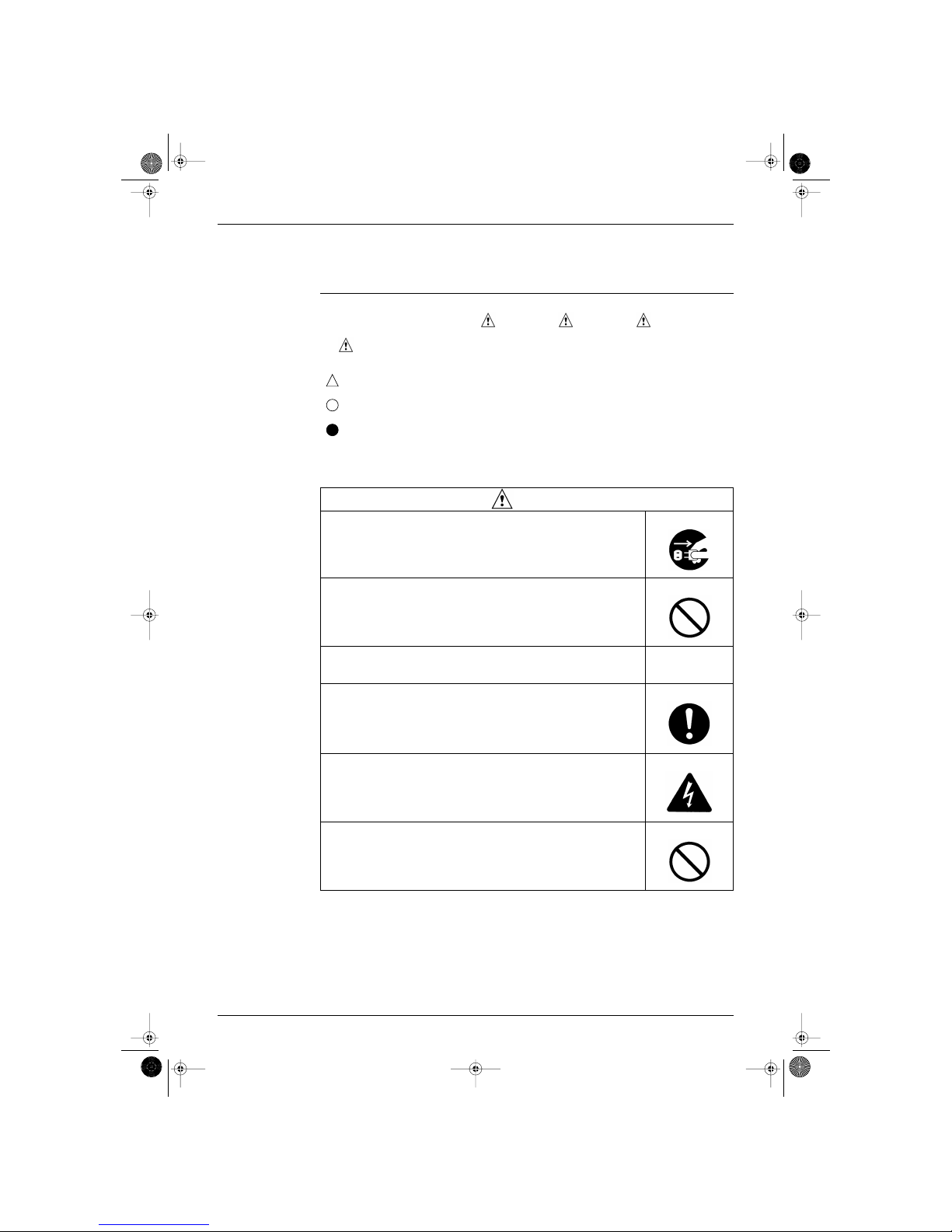

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “ Warning ” and “ Caution ”. The “ Warning ” items are

especially important since they can lead to death or serious injury if they are not followed closely. The

“

Caution ” items can also lead to serious accidents under some conditions if they are not followed.

Therefore, be sure to observe all the safety caution items described below.

About the pictograms

This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment

operates normally, and explain the cautions for operating the product to the customer

1.1.1 Caution in Repair.

Warning

Be sure to disconnect the power cable plug from the plug socket before disassembling

the equipment for a repair.

Working on the equipment that is connected to a power supply can cause an electrical

shook.

If it is necessary to supply power to the equipment to conduct the repair or inspecting the

circuits, do not touch any electrically charged sections of the equipment.

If the refrigerant gas discharges during the repair work, do not touch the discharging

refrigerant gas.

The refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the welded

section, release the refrigerant gas completely at a well-ventilated place first.

If there is a gas remaining inside the compressor, the refrigerant gas or refrigerating

machine oil discharges when the pipe is disconnected, and it can cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The refrigerant gas

can generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical components of the

outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor can cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging the power

cable plug.

Plugging or unplugging the power cable plug to operate the equipment can cause an

electrical shock or fire.

Si-86.book Page v Friday, June 23, 2000 10:26 AM

Introduction SIE-86

vi

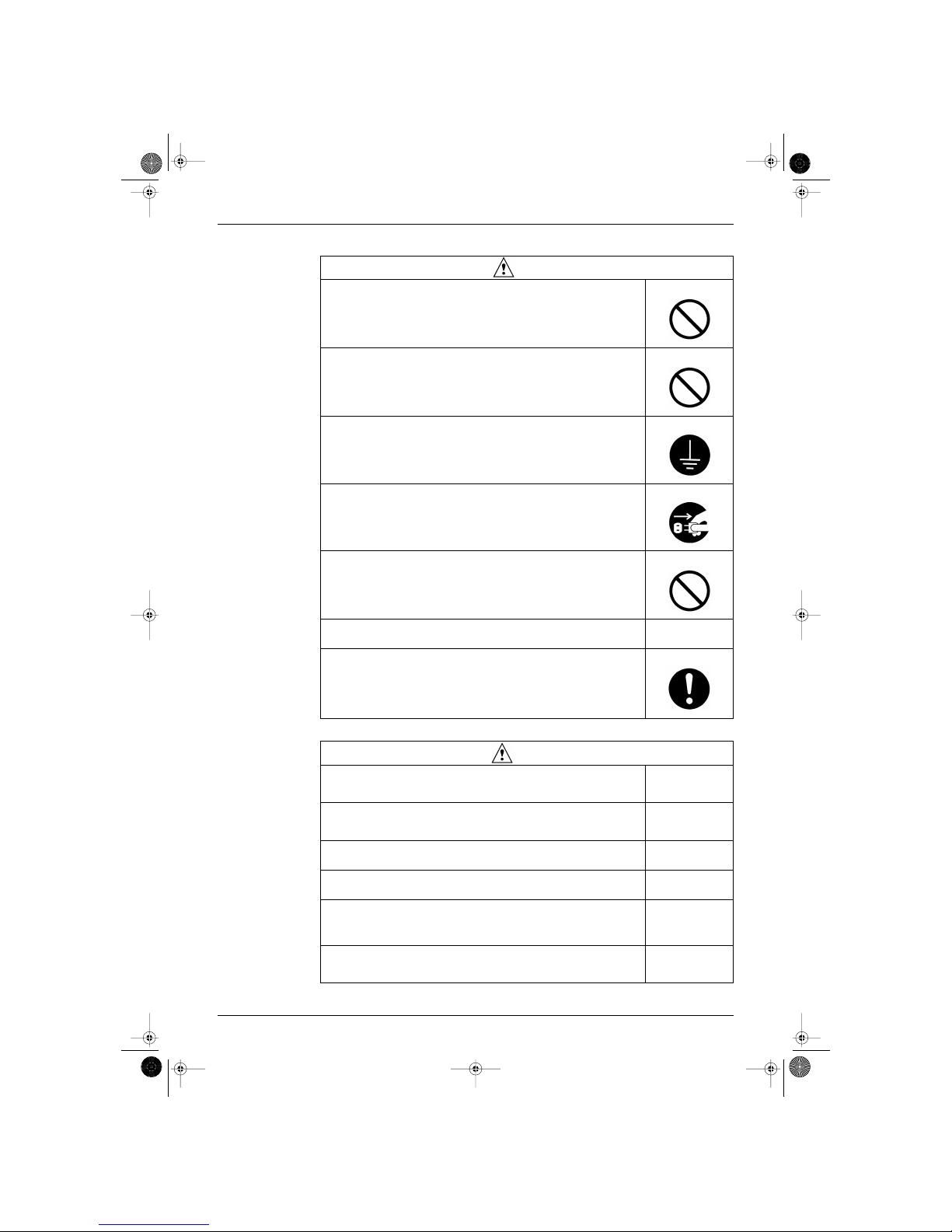

1.1.2 Cautions Regarding Products after Repair

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands can cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water can cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or wet place,

to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when cleaning the

equipment.

The internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it.

The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down sufficiently before

conducting repair work.

Working on the unit when the refrigerating cycle section is hot can cause burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room can cause oxygen deficiency.

Warning

Be sure to use parts listed in the service parts list of the applicable model and appropriate

tools to conduct repair work. Never attempt to modify the equipment.

The use of inappropriate parts or tools can cause an electrical shock, excessive heat

generation or fire.

When relocating the equipment, make sure that the new installation site has sufficient

strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation work is not

conducted securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the provided standard installation frame.

Incorrect use of the installation frame and improper installation can cause the equipment

to fall, resulting in injury.

For integral units only

Be sure to install the product securely in the installation frame mounted on a window

frame.

If the unit is not securely mounted, it can fall and cause injury.

For integral units only

Be sure to use an exclusive power circuit for the equipment, and follow the technical

standards related to the electrical equipment, the internal wiring regulations and the

instruction manual for installation when conducting electrical work.

Insufficient power circuit capacity and improper electrical work can cause an electrical

shock or fire.

Be sure to use the specified cable to connect between the indoor and outdoor units.

Make the connections securely and route the cable properly so that there is no force

pulling the cable at the connection terminals.

Improper connections can cause excessive heat generation or fire.

Si-86.book Page vi Friday, June 23, 2000 10:26 AM

SIE-86 Introduction

vii

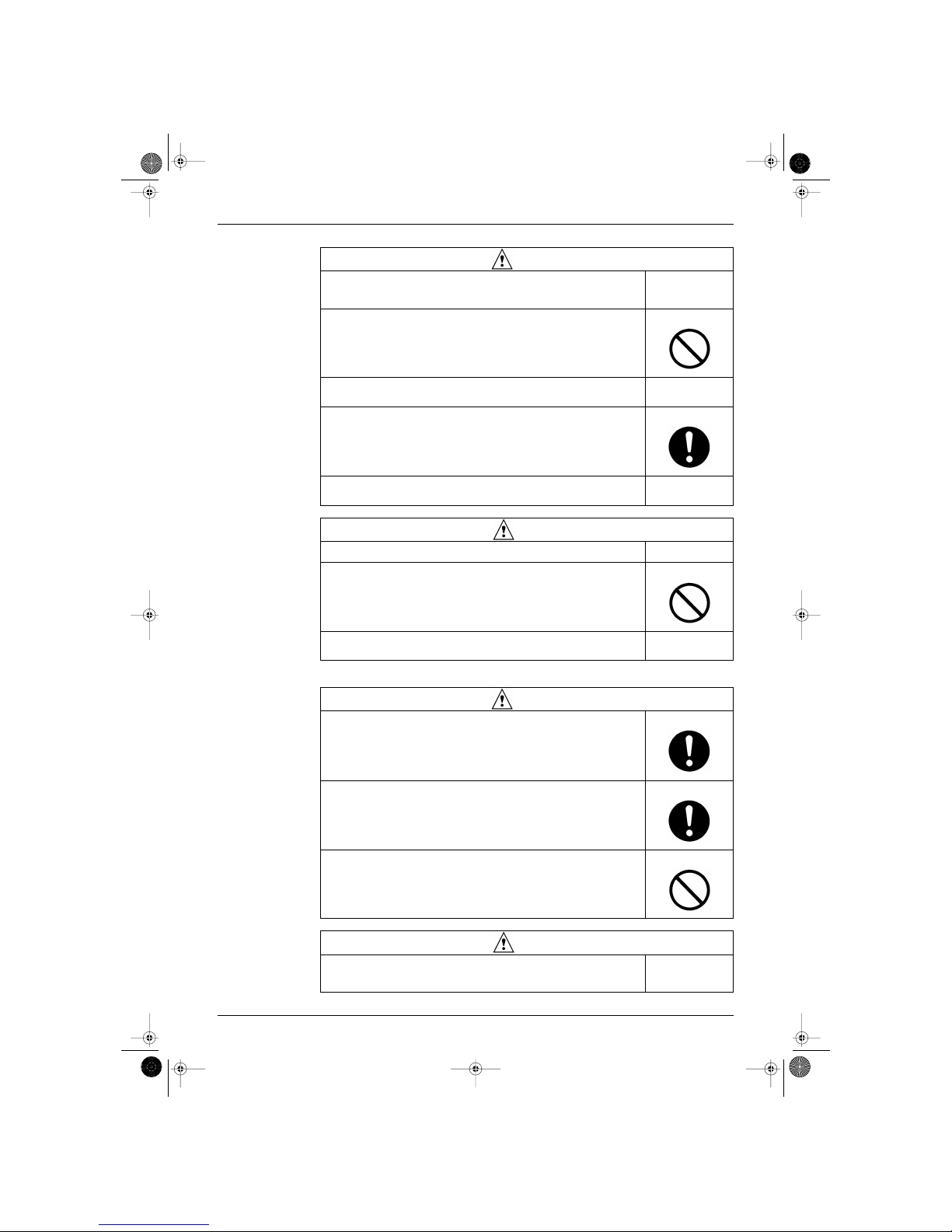

1.1.3 Inspection after Repair

When connecting the cable between the indoor and outdoor units, make sure that the

terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section can cause an

electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable can

damage the cable.

Do not mix air or gas other than the specified refrigerant (R22) in the refrigerant system.

If air enters the refrigerating system, an excessively high pressure results, causing

equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before charging the

refrigerant. After charging refrigerant, make sure that there is no refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to perform

pump-down and close the service valve, to prevent the refrigerant gas from leaking into

the room. The refrigerant gas itself is harmless, but it can generate toxic gases when it

contacts flames, such as fan and other heaters, stoves and ranges.

When replacing the coin battery in the remote controller, be sure to disposed of the old

battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Warning

Caution

Installation of a leakage breaker is necessary in some cases depending on the

conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of combustible gas

leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water can enter the room and wet the

furniture and floor.

For integral units only

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert the plug

into a power outlet all the way.

If the plug has dust or loose connection, it can cause an electrical shock or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to replace

them.

Damaged cable and wires can cause an electrical shock, excessive heat generation or

fire.

Do not use a joined power cable or extension cable, or share the same power outlet with

other electrical appliances, since it can cause an electrical shock, excessive heat

generation or fire.

Caution

Check to see if the parts and wires are mounted and connected properly, and if the

connections at the soldered or crimped terminals are secure.

Improper installation and connections can cause excessive heat generation, fire or an

electrical shock.

Si-86.book Page vii Friday, June 23, 2000 10:26 AM

Introduction SIE-86

viii

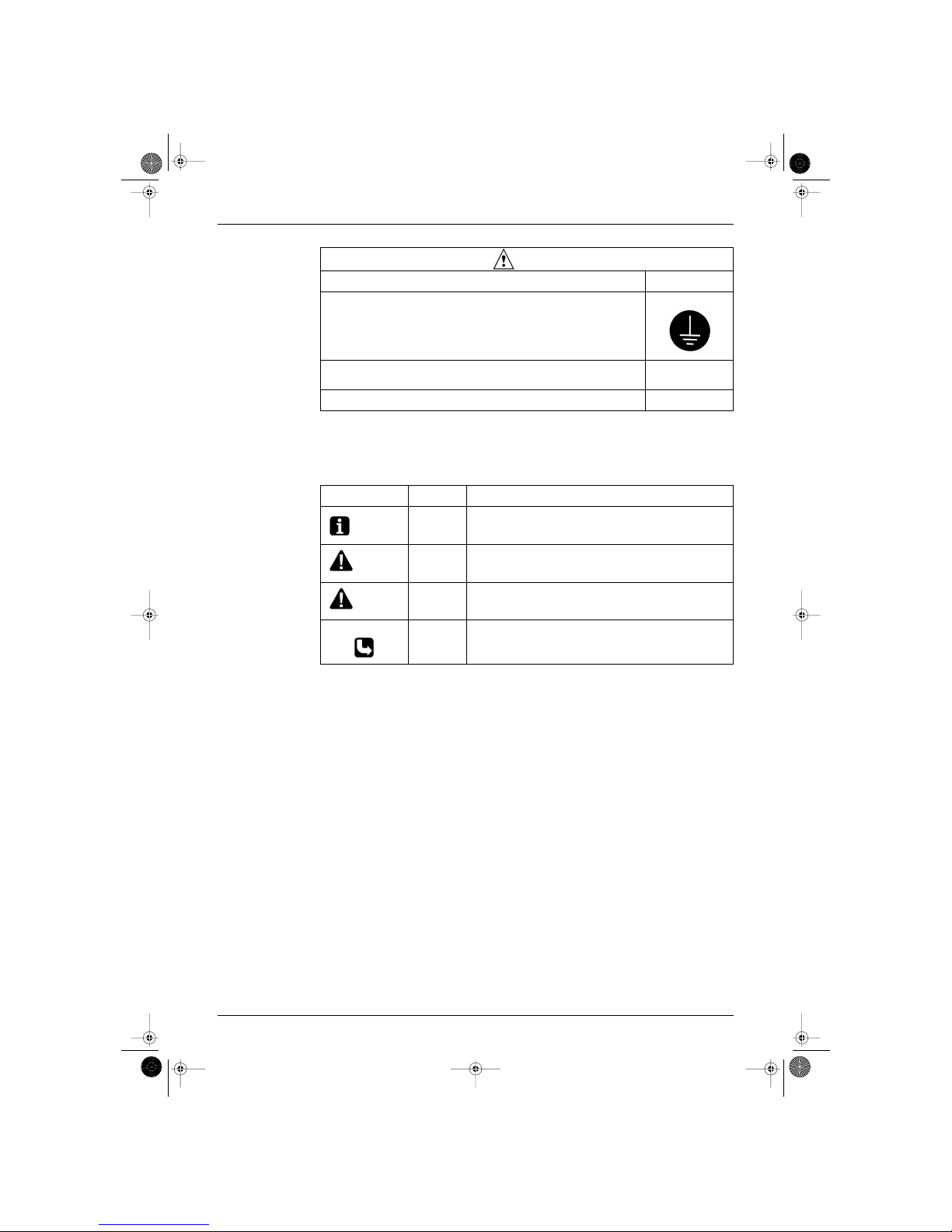

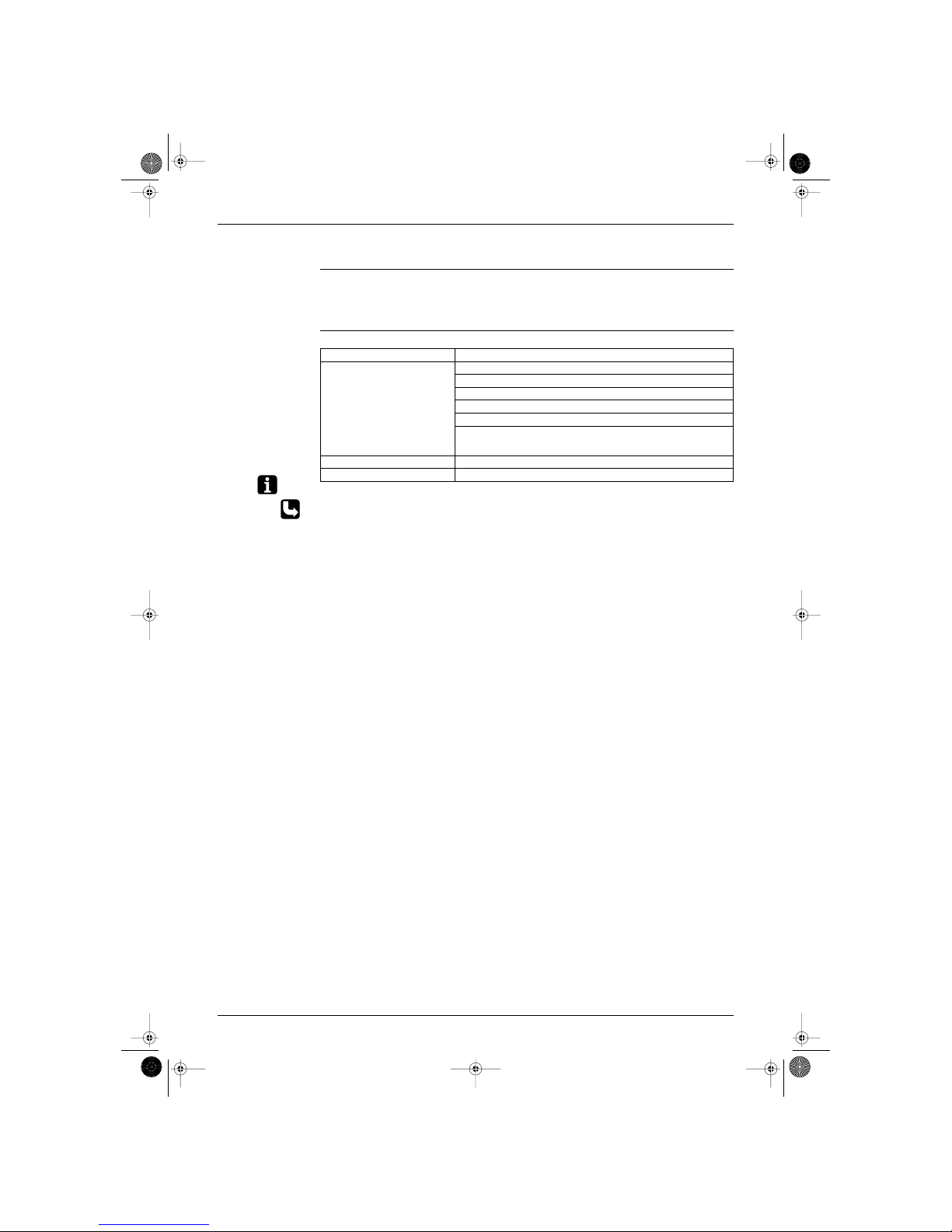

1.1.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each icon is

described in the table below:

1.1.5 Using Icons List

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame can cause the unit to fall, resulting in injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding can cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure that the

resistance is 1 Mohm or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture and floor.

Caution

Icon Type of

Information

Description

Note:

Note A “note” provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution A “caution” is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get an

unexpected result or has to restart (part of) a procedure.

Warning

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or in this

manual, where he/she will find additional information on a specific topic.

Si-86.book Page viii Friday, June 23, 2000 10:26 AM

SIE-86

List of Function 1

Part 1

List of Function

1. Functions.................................................................................................2

1.1 Indoor Unit and Outdoor Unit................................................................... 2

Si-86.book Page 1 Friday, June 23, 2000 10:26 AM

Functions SIE-86

2 List of Function

1. Functions

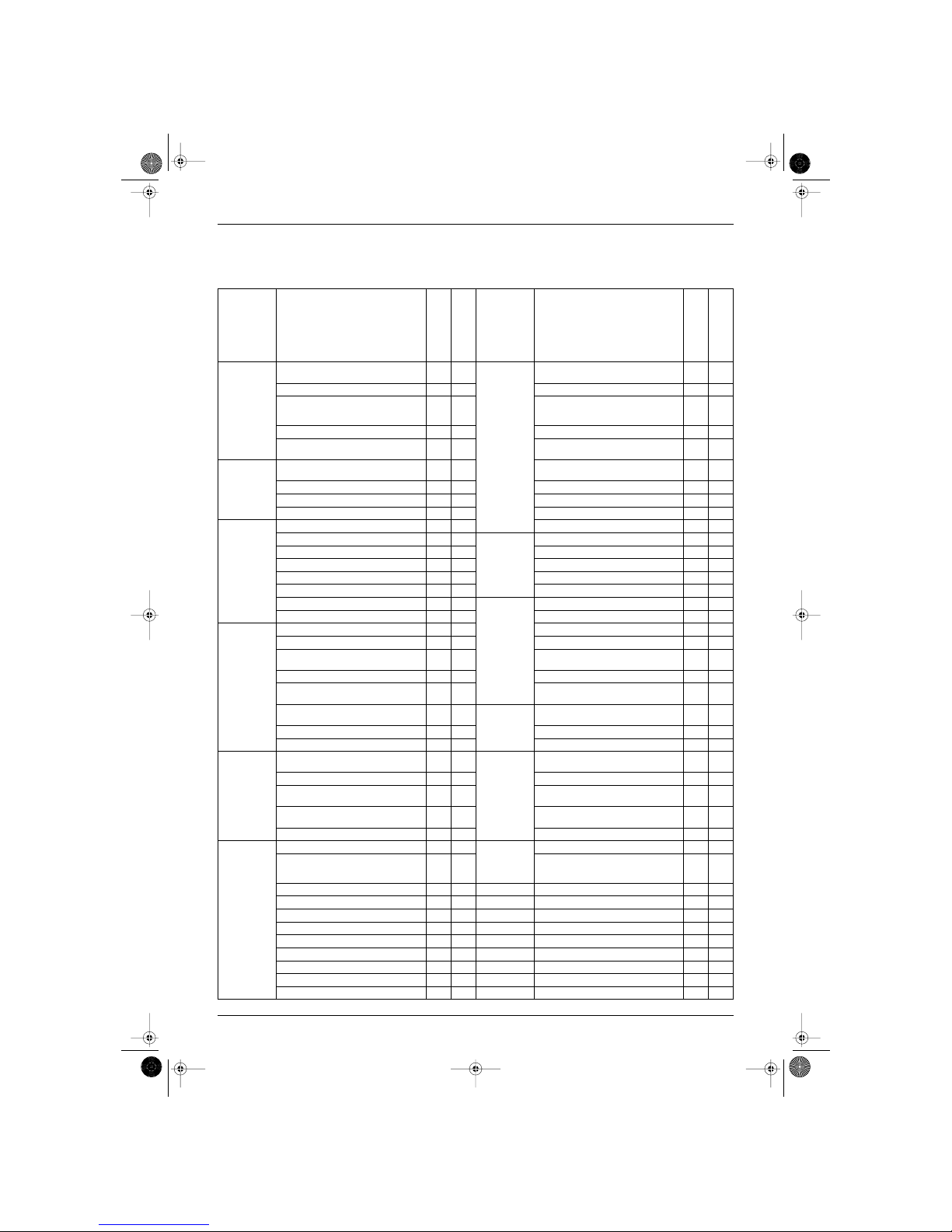

1.1 Indoor Unit and Outdoor Unit

Category Functions

FTK25·35J Series

RK25·35J Series

FTX25·35J Series

RX25·35J Series

Category Functions

FTK25·35J Series

RK25·35J Series

FTX25·35J Series

RX25·35J Series

Basic Funtion

Energy Saving

Health

Health &

Clean

Air Purifying Filter with Bacteriostatic,

Virustatic & Deodrizing Functions

Inverter (with Inverter Power Control)

Longlife Filter — —

Lower Limit of Outdoor Temperature for

Cooling Operation Limit : Outdoor

Temp. ˚C

10˚C 10˚C Ultra-Longlife Filter (Option) — —

Microprocessor Control

Photocatalytic Deodrizing Filter — —

PAM Control (Pulse Amplitude

Modulation Control)

— — Photocatalytic Filter with UV Lamp — —

Compressor

Horizontal Scroll, Oval Scroll

Compressor (DAIKIN SCROLL)

— — Mold Proof Air Filter

Swing Compressor (DAIKIN ROTARY) — — Washable Grille

Rotary Compressor

Filter Cleaning Indicator — —

Reluctance DC Motor — — Healthy Cooling Operation — —

Comfortable

Airflow

Dual Flaps

Good-Sleep Cooling Operation

Power-Airflow Dual Flaps

Timer

72-Hour On/Off Timer — —

Power-Airflow Flap 5 Step Control

24-Hour On/Off Timer

Power-Airflow Diffuser — — 12-Hour Timer — —

Wide-Angle Louvers

Night Set Mode

Vertical Auto-Swing (Up and Down)

Just Fit Thermostatic Timer — —

Horizontal Auto-Swing (Right and Left) — —

Worry Free

“Reliability &

Durability”

Auto-Restart (after Power Failure)

3-Step Airflow (H/P Only) — — Self-Diagnosis Digital Display

“Comfortable

Control”

Comfort

Control

Auto Fan Speed

Self-Diagnosis LED Display — —

Silent-Operation Control — — LCD Remote Controller (Option) — —

Double Thermostat Function — —

The Remote Controller Loss Prevention

with the Chain (Option)

Intelligent Eye

Wiring Error Check — —

Automatic Sensible Comfort Control

Anticorrosion Treatment of Outdoor

Hear Exchanger

Quick Warming Function —

Flexibility

Multi-Split / Split Type Compatible

Indoor Unit

Hot-Start Function —

Flexible Voltage Correspondence

Automatic Defrosting —

Chargeless —

Operation

Automatic Operation —

Remote

Control

5-Rooms Centralized Controller

(Option)

Programme Dry Function

Field-Supply Timer Operation

Height-Ceiling Application — —

Remote Control Adaptor (Option)

(Normal Open-Pluse Contact)

Circulation — —

Remote Control Adaptor (Normal Open

Contact)

Fan Only — DIII-NET Compatible (Adaptor)

Lifestyle

Convenience

New Powerful Operation (Non-Inverter) — —

Remote

Controller

Wireless

Inverter Powerful Operation (Increased

Air Volume / Increased Compressor

Rotation Speed)

Wired — —

Priority-Room Setting — —

Quiet Operation — —

Laundry Programme Operation — —

Energy-Saving Operation — —

Power Selection — —

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display — —

Power-Control Function — —

: Holding Functions — : No Functions

Si-86.book Page 2 Friday, June 23, 2000 10:26 AM

SIE-86

Printed Circuit Board Connector Wiring Diagram 3

Part 2

Printed Circuit Board

Connector Wiring Diagram

1. Printed Circuit Board Connector Wiring Diagram and Name..................4

1.1 FTK25/35J Series, FTX25/35J Series..................................................... 4

1.2 RK25/35J Series, RX25/35J Series......................................................... 6

Si-86.book Page 3 Friday, June 23, 2000 10:26 AM

Printed Circuit Board Connector Wiring Diagram and Name SIE-86

4 Printed Circuit Board Connector Wiring Diagram

1. Printed Circuit Board Connector Wiring Diagram and

Name

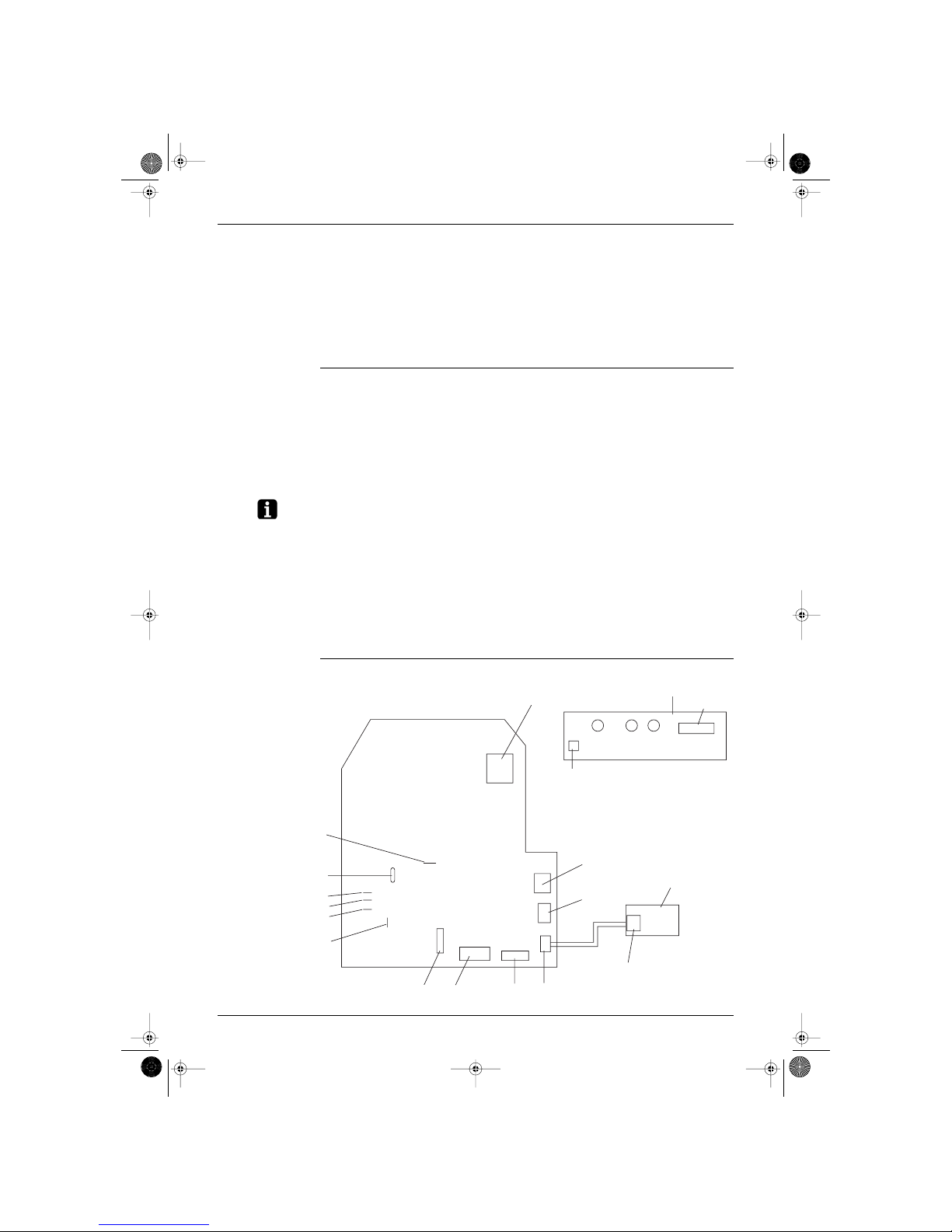

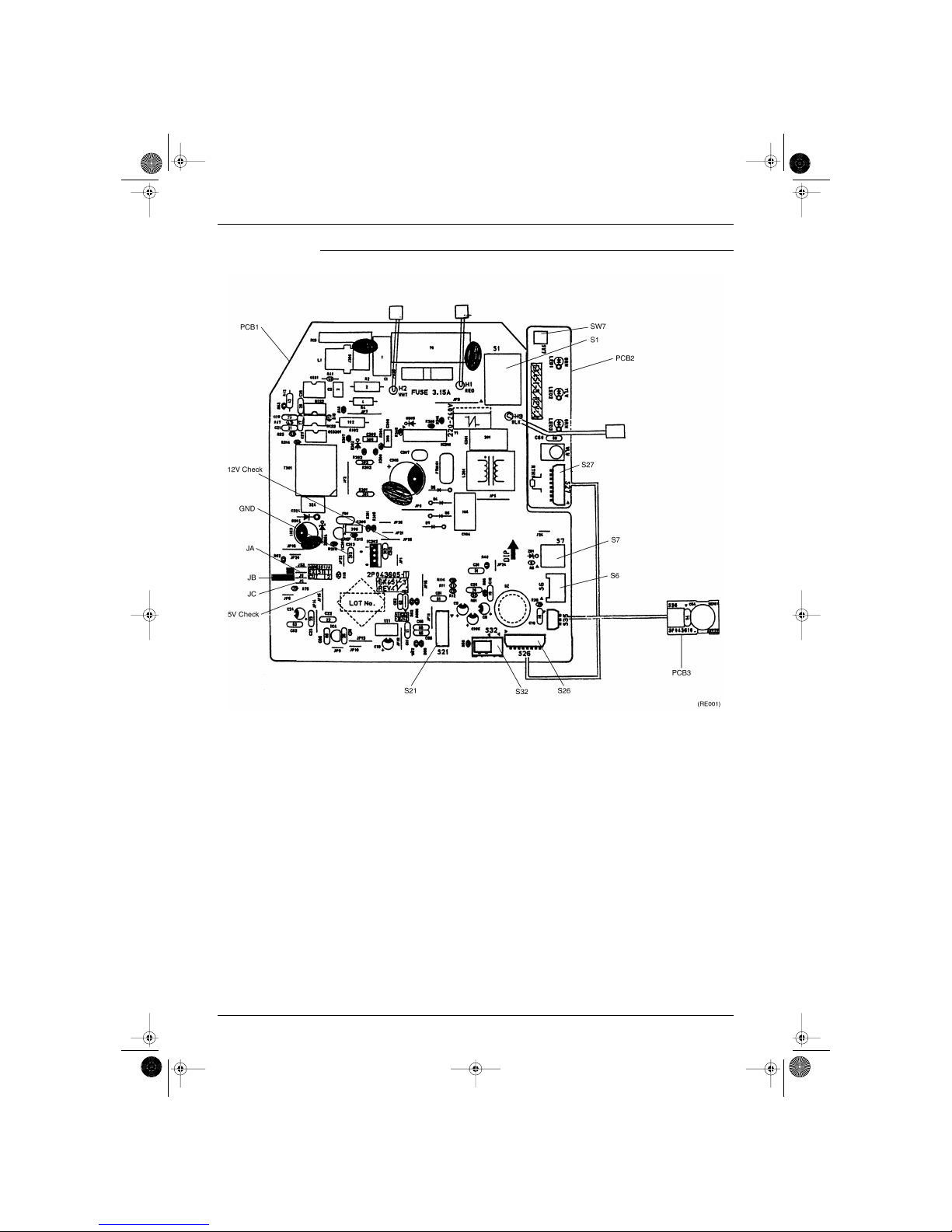

1.1 FTK25/35J Series, FTX25/35J Series

Printed circuit board (1) (Control PCB)

Printed circuit board (2) (Signal Receiver PCB)

Printed circuit board (3) (Intelligent Eye Sensor PCB)

Name of connector

Note: Other designations

Control PCB (1)

1) S1 Connector for fan motor

2) S6 Connector for swing motor (Horizontal Flap)

3) S7 Connector for fan motor

4) S21 Connector for centralized control to 5 rooms

5) S27, S36 Connector for control PCB

6) S26 Connector for signal receiver PCB

7) S32 Connector for room temp/Heat exchanger thermistor

8) S35 Connector for Intelligent Eye Sensor PCB

1) V1 Varistor

2) JA ADDRESS SETTING JAMPER

JB Fan speed setting when compressor is OFF on thermostat.

JC Power failure recovery function.

∗ Refer to page 121 for more detail.

3) SW7 OPERATION SWITCH

4) LED1 (GRN) LED for operation

5) LED2 (YLW) LED for timer

6) LED3 (GRN) LED for intelligent eye

(RL001)

Control P C B (1)

S1

Signal receive P C B (2)

S27

GRN

GRN

YLW

LED1 LED2 LED3

SW7

S7

S6

Intelligent eye

sensor P C B (3)

S36

S35

S26

S32

S21

5V check

Jamper

JA

JB

JC

ground

12V check

Jamper

Si-86.book Page 4 Friday, June 23, 2000 10:26 AM

SIE-86 Printed Circuit Board Connector Wiring Diagram and Name

Printed Circuit Board Connector Wiring Diagram 5

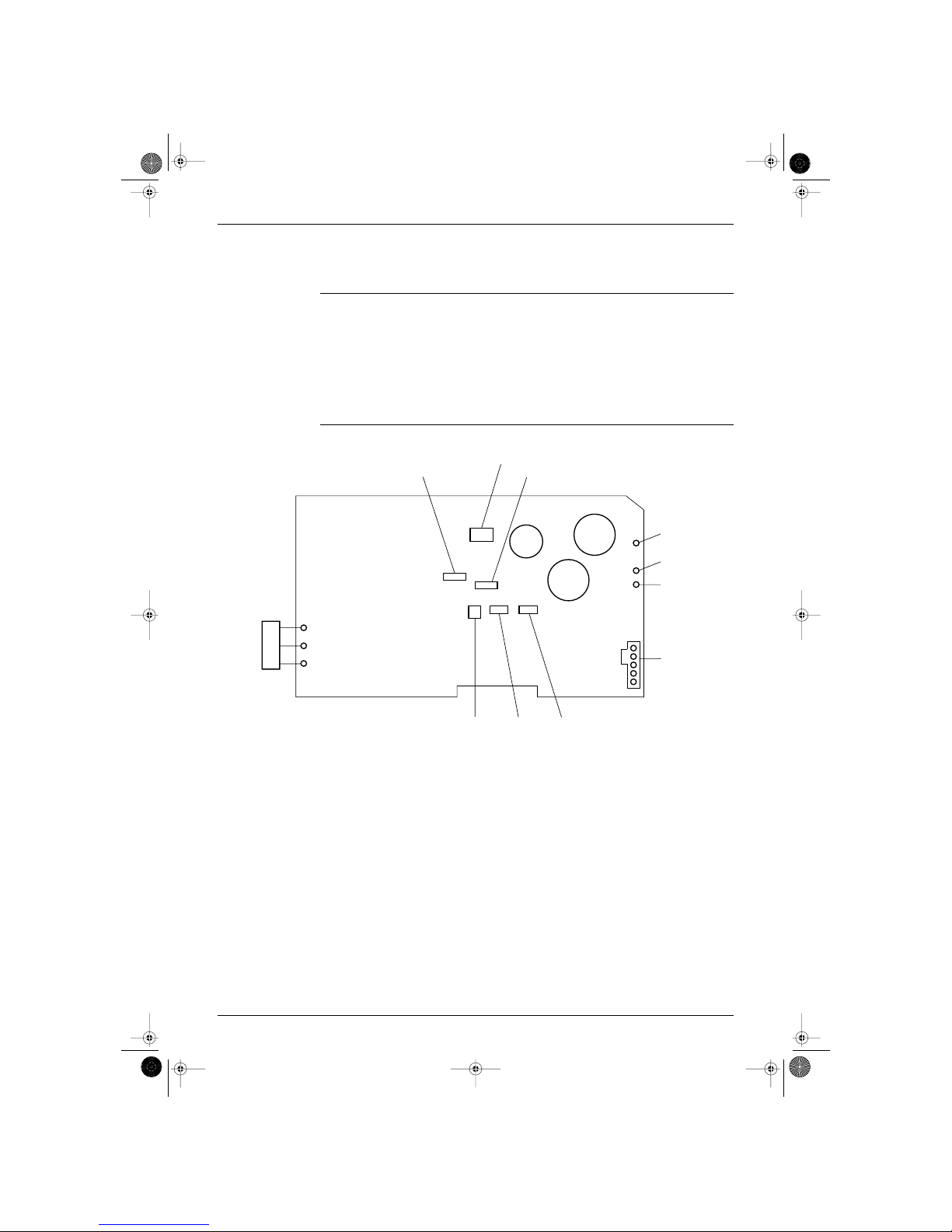

P.C.B (1) (Control P.C.B) Detail

Si-86.book Page 5 Friday, June 23, 2000 10:26 AM

Printed Circuit Board Connector Wiring Diagram and Name SIE-86

6 Printed Circuit Board Connector Wiring Diagram

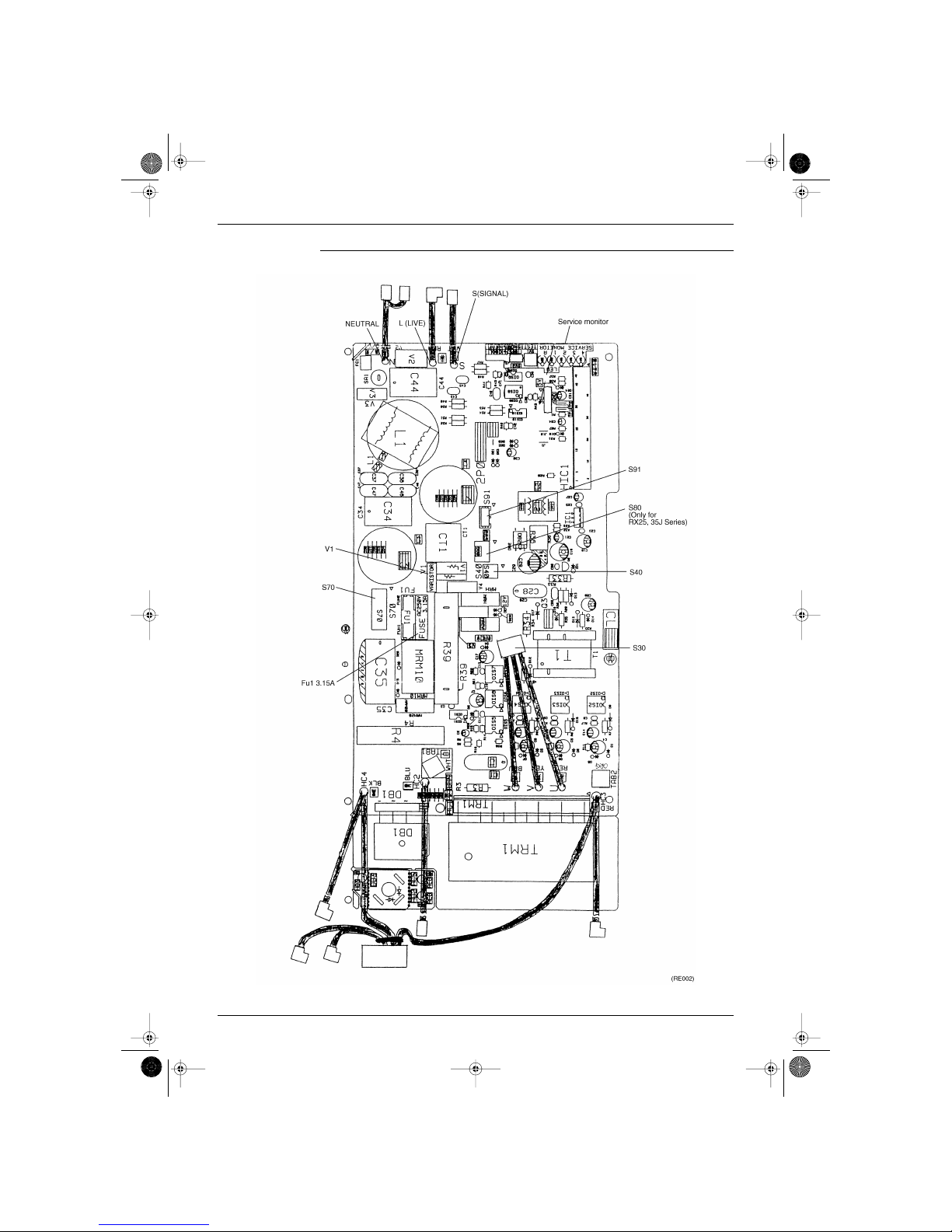

1.2 RK25/35J Series, RX25/35J Series

Printed circuit board (1) (Main-PCB)

Name of connector

PCB (1)

1) S30 Connector for compressor motor (with internal thermostat)

2) S70 Connector for fan motor

3) S80 Connector for 4 WAY VALVE COIL (RX25 · 35J Series only)

4) S91 Connector for THERMISTOR

5) S40 Connector for OL

6) SW1 NONE (Forced operation ON/OFF switch)

7) SW2 NONE (Forced operation Mode selector switch (H/P only))

S30

W

U

V

FU

S70

V1

Service

Monitor

S40 S80

S91

S(SIGNAL)

L(LIVE)

N(NEUTRAL)

(RL002)

Si-86.book Page 6 Friday, June 23, 2000 10:26 AM

SIE-86 Printed Circuit Board Connector Wiring Diagram and Name

Printed Circuit Board Connector Wiring Diagram 7

P.C.B (1) (Control P.C.B) Detail

Si-86.book Page 7 Friday, June 23, 2000 10:26 AM

Printed Circuit Board Connector Wiring Diagram and Name SIE-86

8 Printed Circuit Board Connector Wiring Diagram

Si-86.book Page 8 Friday, June 23, 2000 10:26 AM

SIE-86

Main Function 9

Part 3

Main Function

1. General Functionality ............................................................................10

1.1 Functions of Thermistors....................................................................... 10

1.2 Operating Modes................................................................................... 12

1.3 Frequency Principle............................................................................... 13

1.4 Defrost Control ...................................................................................... 15

1.5 Forced Operation Mode......................................................................... 16

1.6 Wide-angle Flaps, Diffuser, Louvres and Autoswing............................. 17

1.7 Fan Speed Control for Indoor Units....................................................... 19

1.8 Fan Speed Control for Outdoor Units.................................................... 20

1.9 General Functions ................................................................................. 21

1.10 Intelligent Eye (J type)........................................................................... 23

1.11 Good Sleep Cooling Control (J Type).................................................... 25

1.12 Automatic Operation.............................................................................. 26

1.13 Input Current Control (H / J Type) ......................................................... 27

1.14 Freeze Protection Function in Cooling. (H / J Type).............................. 28

1.15 Peak-Cut Control Function (H / J Type) ................................................ 29

1.16 Four-Way Valve Function Compensation (H / J Type).......................... 30

1.17 Compressor Protection Function (H / J Type) ....................................... 31

1.18 Wet Operation Protection (H / J Type) .................................................. 32

1.19 Dew Condensation Sweating Prevention Function (H / J type)............. 33

Si-86.book Page 9 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

10 Main Function

1. General Functionality

1.1 Functions of Thermistors

Location of

thermistors

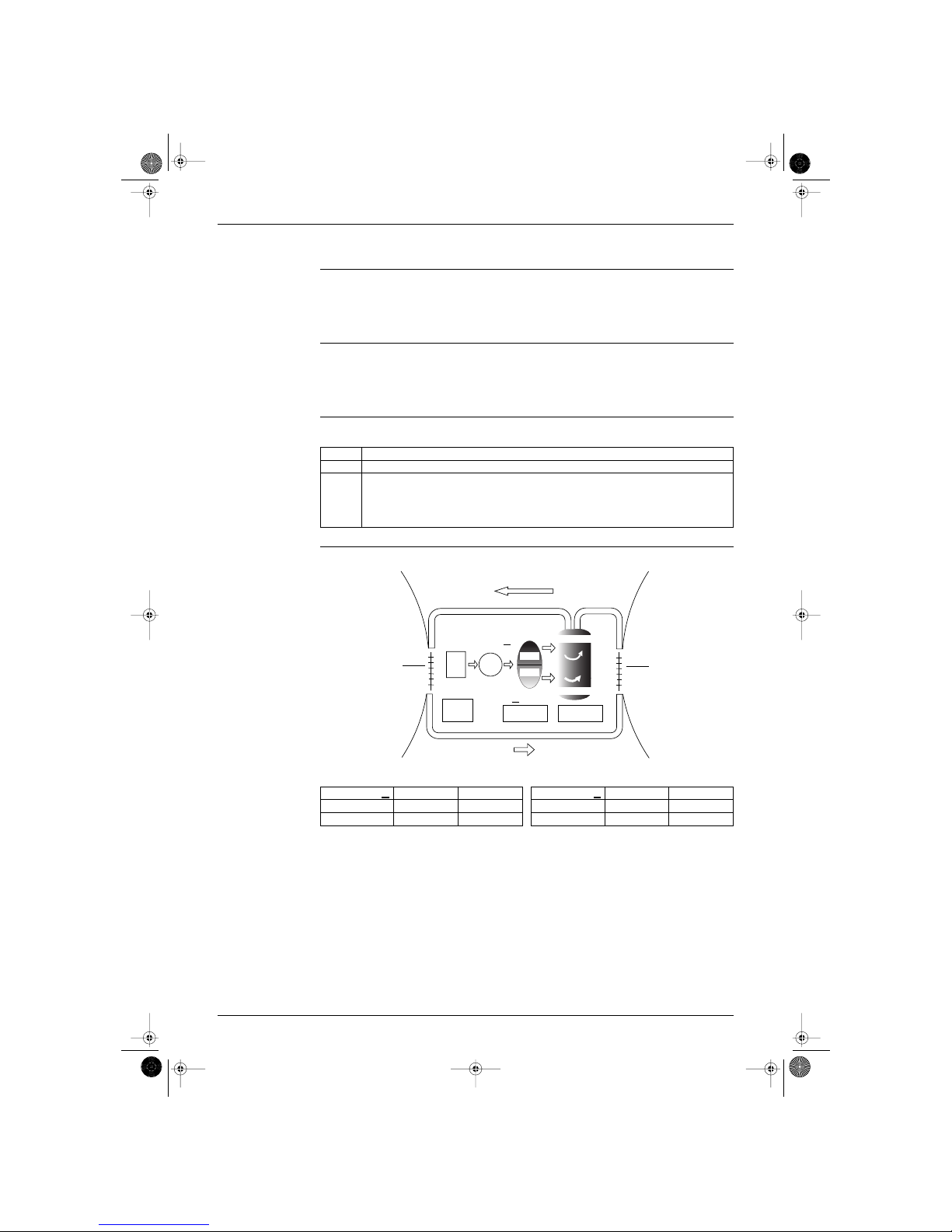

The thermistors on the drawing below are used to control the system. This control secures a proper cooling

and prevents problems of the unit:

Frequency control The following table shows the thermistors that control the frequency:

with : available functions and — : no available functions.

OUTDOOR UNIT

M

COOLING

HEATING

FIELD PIPING

FIELD PIPING

R1T

R2T

INDOOR UNIT

R1T

R2T

M

(RE003)

Controls

Outdoor heat

exchanger

thermistor

Outdoor ambient

temperature

thermistor

Indoor ambient

temperature

thermistor

Indoor heat

exchanger

thermistor

Symbol R2T R1T R1T R2T

Freeze-up prevention. Refer to

page 11.

———

Peak cut off. Refer to page 11. — — —

Defrost. Refer to page 15. —

High pressure limitation in

heating. Refer to page 11.

——

Si-86.book Page 10 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 11

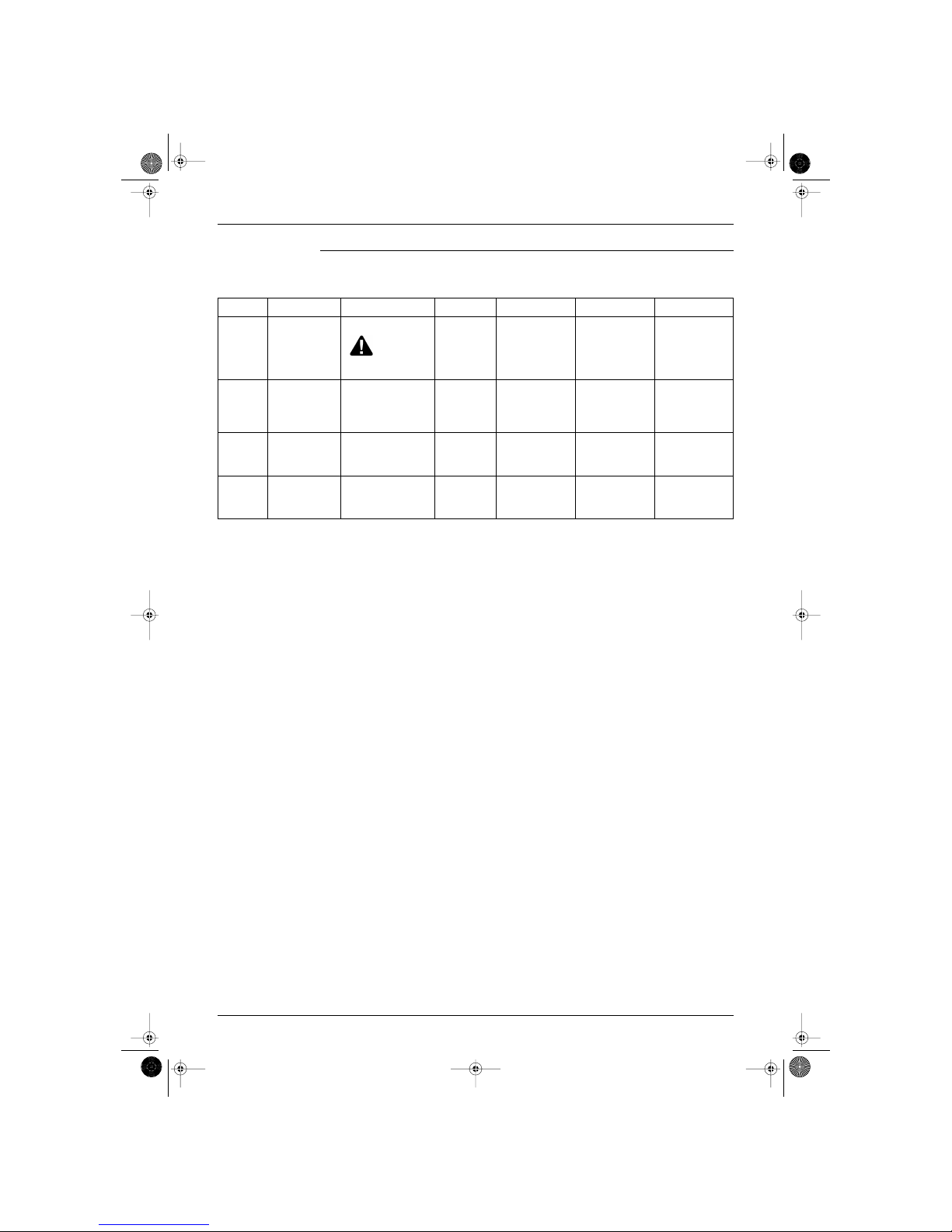

Frequency controlled functions

The following table shows the different functions, which are controlled by decreasing or increasing the

frequency:

Function

Sensor

Thermistor

Why? How? Set Reset Malfunction

Low outdoor

temperature

control

outdoor ambient

thermistor (R1T)

To avoid condensation in

cooling mode.

This control is

not executed when the unit

is in forced cooling mode or

in test mode.

By setting a high

frequency limit.

T

outdoor ambient

<

18˚C (J type)

25˚C (H type)

T

outdoor ambient

>

25˚C (J type)

33˚C (H type)

—

High

pressure

limitation in

heating

outdoor

temperature

thermistor (R1T)

indoor heat

exchanger

thermistor (R2T)

To control the pressure. By setting a high

frequency limit.

heating mode

T

outdoor

> 16 ˚C

T

indoor heat exchanger

> 22 ˚C

compressor on

compressor stop

timer delay (70 s)

has passed

—

Freeze-up

prevention

indoor heat

exchanger

thermistor (R2T)

To prevent the freezing up

of the indoor unit in cooling

mode.

By setting a high

frequency limit.

during cooling

0 ˚C <

T

indoor heat exchanger

< 8 ˚C

T

indoor heat exchanger

>

8 ˚C for 2 seconds

T

indoor heat exchanger

<

0 ˚C

(result: compressor

stop)

Peak cut off indoor heat

exchanger

thermistor (R2T)

To prevent an abnormal

high temperature on the

indoor heat exchanger in

heating mode.

By setting a high

frequency limit.

during heating

50 ˚C <

T

indoor heat exchanger

< 67 ˚C

T

indoor heat exchanger

<

50 ˚C for 2 seconds

T

indoor heat exchanger

>

67 ˚C

(result: compressor

stop)

Si-86.book Page 11 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

12 Main Function

1.2 Operating Modes

Modes There are two operating modes:

normal operating mode

forced operating mode.

Overview The following table shows the different control modes of the Split inverter room air conditioners:

Note: The outdoor unit retains the operating mode, when the thermostat is switched off.

Refer to “Pre-heat operation” on page 21

Mode Item

Normal operating mode Auto (Heat pump only)

Cooling

Dry keep

Heating (Including Automatic defrost)

Fan (for Cooling only)

Stop mode:

Pre-heat operation. Refer to “Pre-heat operation”.

Stop

Test Operation Forced cooling / heating

Forced operating mode Forced cooling

Si-86.book Page 12 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 13

1.3 Frequency Principle

Main control

parameters

The compressor is frequency-controlled during normal operation. The target frequency is set by the

following 2 parameters coming from the operating indoor unit:

the load condition of the operating indoor unit

the difference between the room temperature and the set temperature.

Additional control

parameters

The target frequency is adapted by additional parameters in the following cases:

frequency limits

initial settings

forced cooling/heating operation.

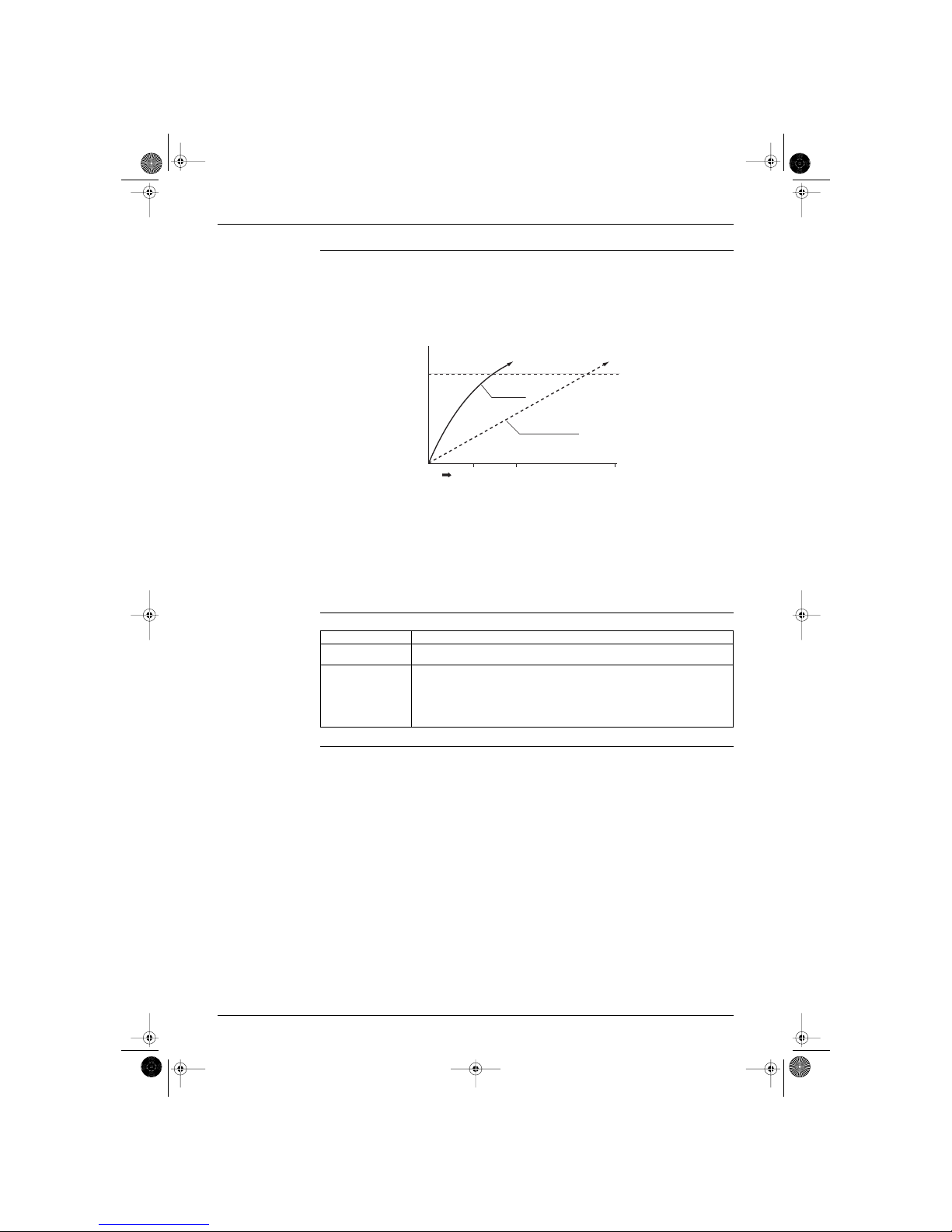

Inverter principle To regulate the capacity, a frequency control is needed. The inverter makes it possible to vary the rotation

speed of the compressor. The following table explains the conversion principle:

Drawing of inverter The following drawing shows a schematic view of the inverter principle:

Phase Description

1 The single phase power supply in AC is converted into DC.

2 The single phase power supply DC is converted into a three phase shopped DC voltage with a

variable frequency.

When the frequency increases, the rotation speed of the compressor increases resulting in an

increased refrigerant circulation. This leads to a higher amount of the heat exchange per unit.

When the frequency decreases, the rotation speed of the compressor decreases resulting in a

decreased refrigerant circulation. This leads to a lower amount of the heat exchange per unit.

Min. frequency A H type J type Max. frequency B H type J type

Cooling 36 34 Cooling 94 98

Heating 36 34 Heating 94 98

50 Hz

60 Hz

Refrigerant circulation rate (high)

Amount of heat

exchanged (large)

Amount of heat

exchanged (small)

AC

power

freq=cte

max. freq.=

A Hz

DC

power

Amount of heat

exchanged (large)

Amount of heat

exchanged (small)

high f

low f

min. freq.=

B Hz

freq=variable

capacity=

variable

Refrigerant circulation rate (low)

high speed

low speed

(RL003)

Si-86.book Page 13 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

14 Main Function

Inverter features The inverter provides the following features:

The regulating capacity can be changed according to the changes in the outside temperature and

cooling/heating load.

Quick heating and quick cooling

The compressor rotational speed is increased when starting the heating (or cooling). This enables a

quick set temperature.

Even during extreme cold weather, the high capacity is achieved. It is maintained even when the

outside temperature is 0˚C.

Comfortable air conditioning

A detailed adjustment is integrated to ensure a fixed room temperature. It is possible to air condition

with a small room temperature variation.

Energy saving heating and cooling

Once the set temperature is reached, the energy saving operation enables to maintain the room

temperature at low power.

Frequency limits The following table shows the functions that define the minimum and maximum frequency:

Forced cooling/

heating operation

For more information, refer to “Forced mode” on page 16.

60 120 300

45˚C

Air discharge

temperature

inverter

normal heat pump

Start seconds

(RG001)

Frequency limits Limited during the activation of following functions

Low four way valve operation compensation. Refer to page 30.

Wet Operation Protection Function. Refer to page 32.

High Input current control. Refer to page 27.

Compressor protection function. Refer to page 31.

low outdoor temperature control. Refer to page 11.

high pressure limitation. Refer to page 11.

peak cut off. Refer to page 11.

freeze-up prevention. Refer to page 11.

defrost control. Refer to page 15.

Si-86.book Page 14 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 15

1.4 Defrost Control

Principle Defrost control is carried out by reversing the cycle from heating to cooling.

Start conditions Defrost control is set by the following conditions:

during heating

More than 6 minutes after the compressor has started up

when condition 1 or 2 in the table below are applicable:

Conditions The following table shows the different conditions on which defrost control is based:

Stop conditions Defrost control is reset by the following conditions:

T

[heat exchanger]

> 4˚C if T

[ambient outdoor]

< 19˚C

T

[heat exchanger]

> 18˚C if T

[ambient outdoor]

< -3˚C

T

[heat exchanger]

> (-1˚C ∞ T

[ambient outdoor]

) + C if -3˚C < T

[ambient outdoor]

< 19˚C.

Condition Description

1

A minutes of accumulated runtime

not yet 90 minutes of accumulated runtime

condition 1 or 2 or 3 in the table below

2

90 minutes of accumulated runtime

condition 1 or 4 or 5 in the table below

Conditions Description

1 T

[outdoor heat exchanger]

< B˚C for 1 min.

2

T

[ambient outdoor]

< 5˚C

T

[outdoor heat exchanger]

< (-5 + T

[ambient outdoor]

∞ 0,4)

check if T

[indoor heat exchanger]

decreases 5 times every 10 seconds

3

T

[ambient outdoor]

≥ 5˚C

T

[outdoor heat exchanger]

< -3˚C

check if T

[indoor heat exchanger]

decreases 5 times every 10 seconds

4

T

[ambient outdoor]

< 5˚C for 60 seconds

T

[outdoor heat exchanger]

< (-5 + T

[ambient outdoor]

∞ 0,4) for 60 seconds

5

T

[ambient outdoor]

≥ 5˚C for 60 seconds

T

[outdoor heat exchanger]

< -3˚C for 60 seconds

Class

A B C

H type 25 32 -15 23

35 40 -15 17

J type 25 32 -15 17

35 32 -14 17

Si-86.book Page 15 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

16 Main Function

1.5 Forced Operation Mode

1.5.1 H type

Forced mode The following table explains the different forced operation modes, forced cooling and forced heating:

The protective functions overrule the forced mode. (H type only)

1.5.2 J type

Forced mode

A way to enter the test operation mode by a remote controller.

1. Set on the desirous mode and push ON/OFF button. (operation ON)

2. Two buttons; Center of temperature set buttons “ ”, and “ Mode” button, should be pushed

simultaneously. (then a left figure of the liquid crystal temperature’s display number starts to blink.)

3. Moreover, push “MODE” button twice. (If the liquid crystal display becomes “ ”, the test operation

mode will startup under the mode displayed in a liquid crystal. )

Item Forced cooling Forced heating

Conditions

not in the 3-minute stand-by mode

normal operation mode

outdoor unit off

no malfunction in the outdoor unit

forced mode: cooling mode.

not in the 3-minute stand-by mode

normal operation mode

outdoor unit off

no malfunction in the outdoor unit

forced mode: heating mode.

Start

Adjustment

(H type)

Press the forced operation switch SW1 to

start the following items:

command frequency: 66 Hz

timer: 60-minute

fan speed: H

swing flap: preservation of last setting

indoor adjustment: send forced mode to

unit.

Press the forced operation switch SW1

while short circuiting SW2 to start the

following items:

command frequency: 66 Hz

timer: 60-minute

fan speed: H

swing flap: preservation of last setting

indoor adjustment: send forced mode to

unit.

Reset

(H type)

Press the forced operation switch again or after

60 minutes.

Press the forced operation switch again or after

60 minutes.

Item Forced cooling Forced heating

Conditions

not in the 3-minute stand-by mode

normal operation mode

outdoor unit off

no malfunction in the outdoor unit

forced mode: cooling mode.

not in the 3-minute stand-by mode

normal operation mode

outdoor unit off

no malfunction in the outdoor unit

forced mode: heating mode.

Start

Adjustment

1. Keep pushing the operation switch of the

indoor unit for 5 to 10 seconds.

2. Change the remote controller setting to a

cooling test operation.

( Regarding a way to enter the test

operation, refer to the note in a margin

below)

Possible to enter the forced cooling mode by

either way of 1. or 2..

Fix operation frequency to 66 Hz.

Operation-on timer :15 min.

Indoor unit’s fan : H tap.

Swing flap: the latest set position.

With a change of the remote controller setting

to a heating test operation, the unit enters the

forced heating mode.

(Regarding a way to enter the test operation

mode, refer to the note in a margin below)

Fix operation frequency to 66 Hz.

Operation-on timer :15 min.

Indoor unit’s fan : H tap.

Swing flap: the latest set position.

Reset

1. Push the operation switch of the indoor unit

in an usual way.

2. Push the stop button on a remote controller.

3. Operation-on timer : 15 min. overtime.

1. Push the operation switch of the indoor unit

in an usual way.

2. Push the stop button on a remote controller.

3. Operation-on timer : 15 min. overtime.

TEMP

Si-86.book Page 16 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 17

1.6 Wide-angle Flaps, Diffuser, Louvres and Autoswing

1.6.1 H type

Wide-angle flap The large flaps send a large volume of air downwards to the floor. The flap provides an optimum control in

cooling, heating and dry mode.

Diffuser The diffuser enables the air coming out of the indoor unit to reach all surfaces in cooling mode.

Heating mode During heating mode, the large flap enables direct warm air straight downwards. The diffuser presses the

warm air above the floor to reach the entire room.

Cooling mode During cooling mode, the diffuser retracts into the indoor unit. This enables a distribution of cooled air

throughout the entire room.

Louvres The louvres, made of elastic synthetic resin, provide a wide range of airflow that guarantees a comfortable

air distribution.

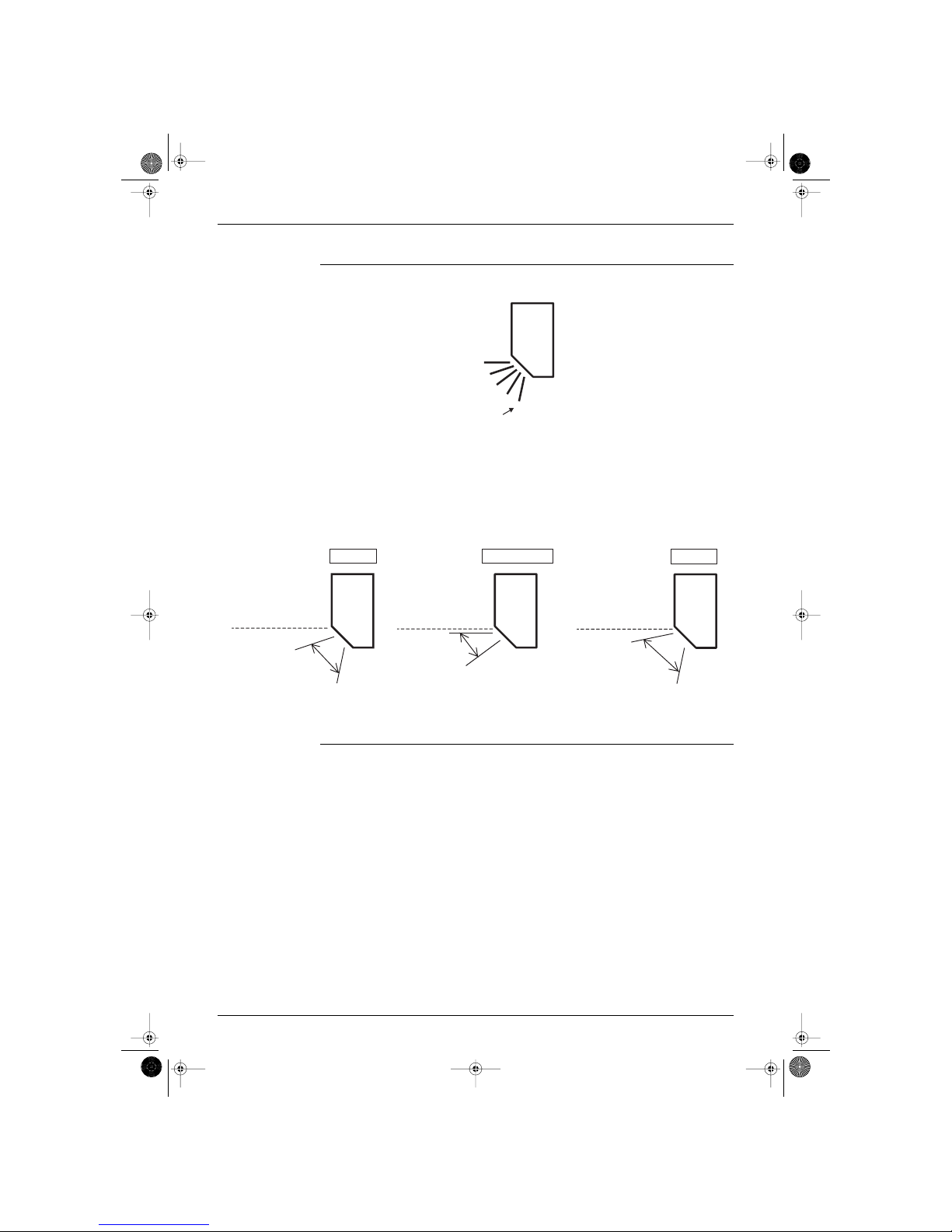

Autoswing The following table explains the autoswing process for heating and cooling:

Item Description Drawing

heating

The flap swings up and down as shown in

the drawing alongside.

cooling

The flap swings up and down as shown in

the drawing alongside.

(RL004)

(RL005)

Si-86.book Page 17 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

18 Main Function

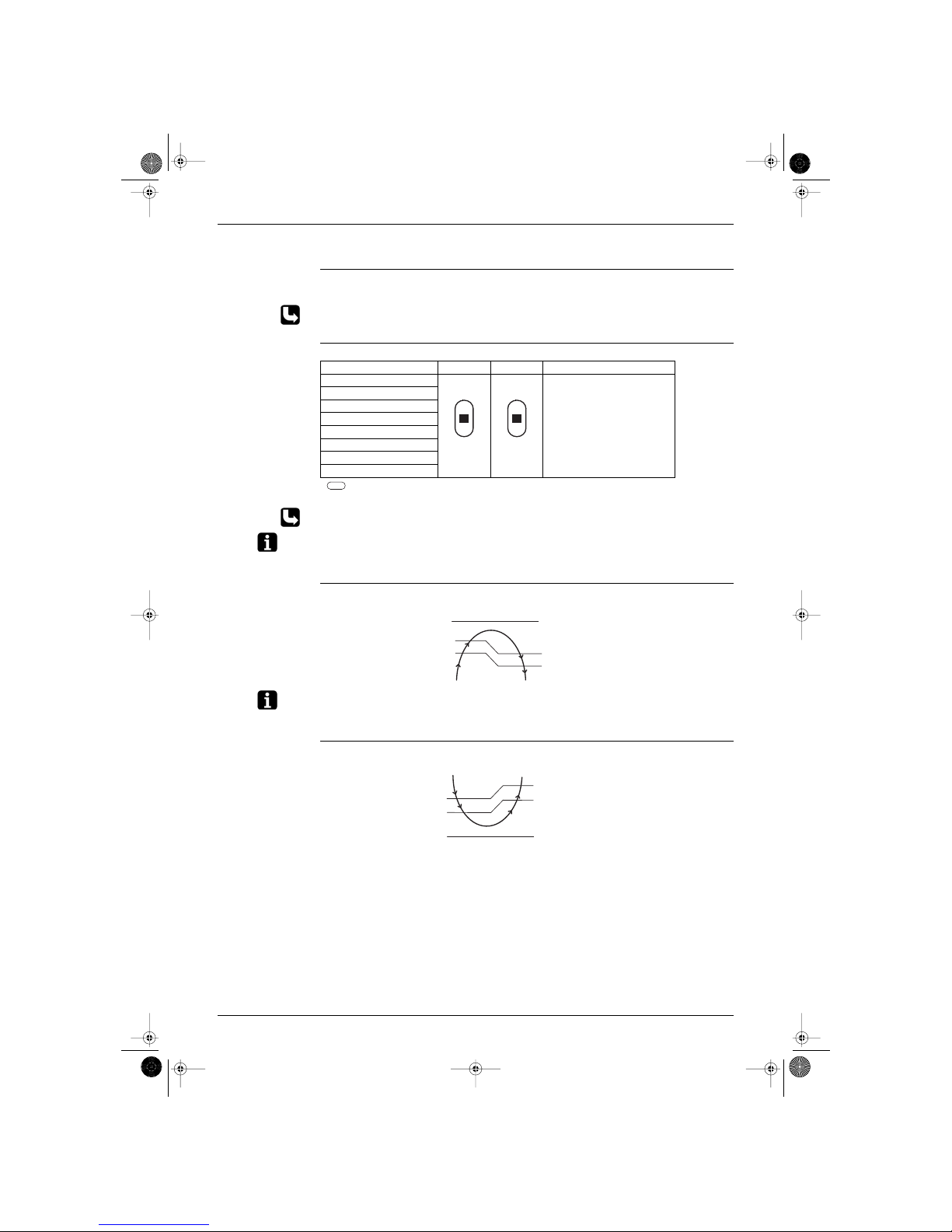

1.6.2 J type

Outline of the

action

It can be commanded for J type by means of a user setting to select either any one desired position among

the five-step directions of air flow adjusted on a remote controller, or Auto-swing.

Although the liquid crystal display of the five-step directions of the air flow is common for the modes of

Cooling·Dry/Heating as illustrated above, in fact the range of the swing angle is slightly different in every

operation mode.

The position a user set will be selected among the five positions calculated through the preliminary and

evenly divided into four partitions which were taken from the upper and lower flap angle’s range limits of

each mode.

When Auto-swing is chosen, the flap swings in the swing range which meets the operation mode selected.

Others The vertical louver can be adjusted manually. The movable range is 60 degrees for left or right, and

total 120 degrees.

A diffuser is not available for J type.

1

2

3

4

5

Initial

(RL006)

∗ Fan mode is available for the models of cooling-only.

20˚

45˚

Heating mode

0 degree based on

the horizontal line.

(RL007)

0˚

25˚

Cooling /Dry mode

0 degree based on

the horizontal line.

(RL008)

10˚

45˚

0 degree based on

the horizontal line.

Fan mode

(RL009)

Si-86.book Page 18 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 19

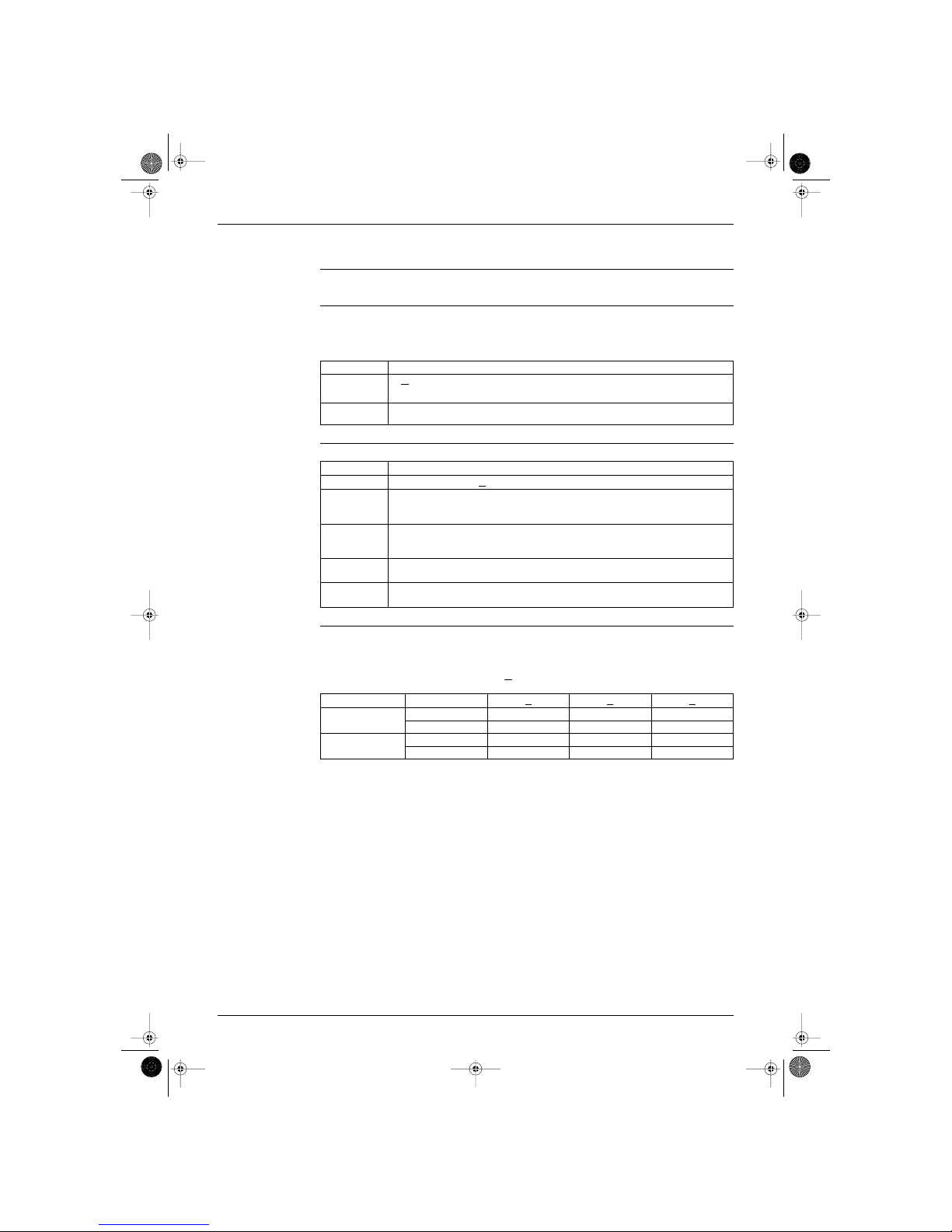

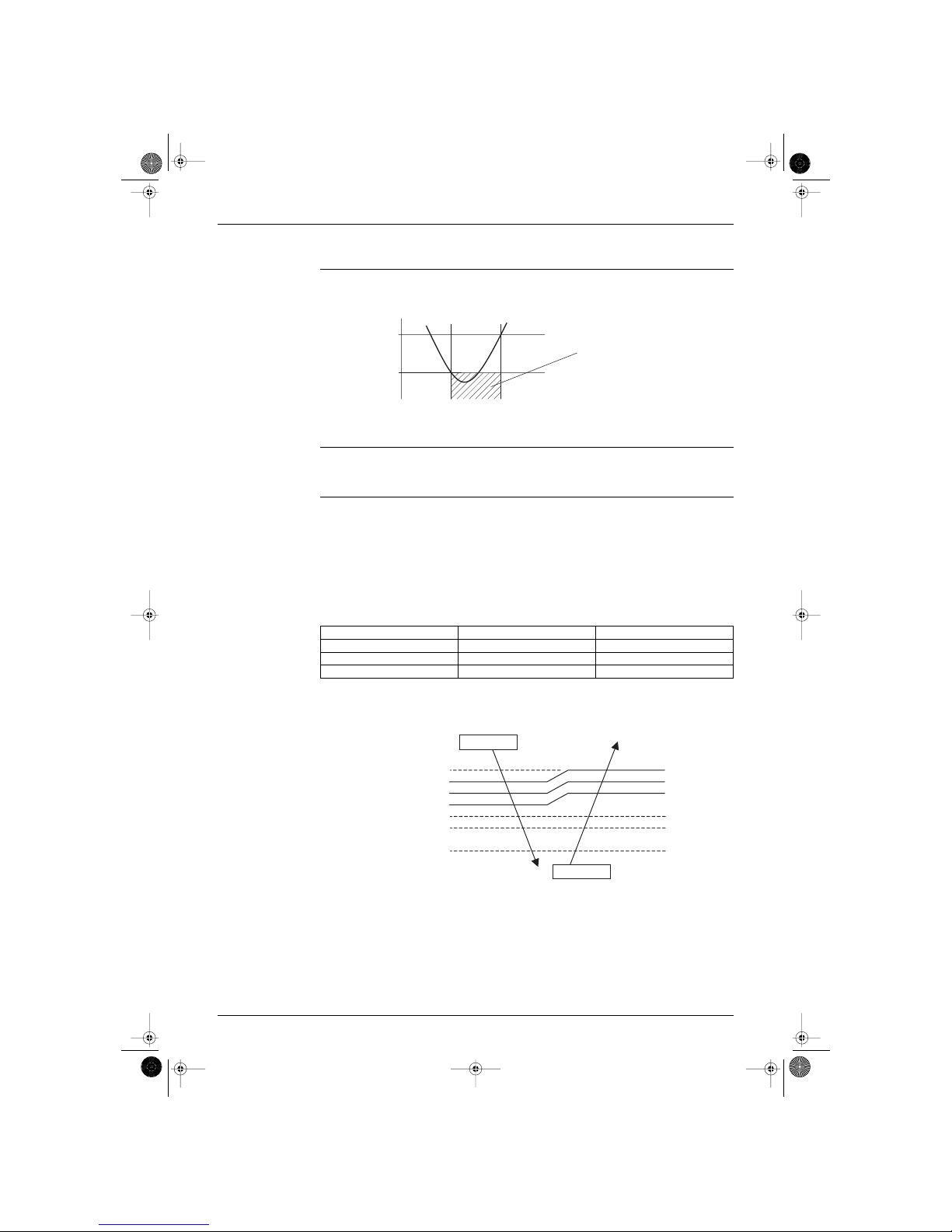

1.7 Fan Speed Control for Indoor Units

Control mode The airflow rate can be automatically controlled depending on the difference between the set temperature

and the room temperature. This is done through phase control and Hall IC control.

For more information about Hall IC, refer to ‘Hall IC check (A6)’ on page 61.

Phase steps Phase control and fan speed control contains 8 steps: LLL, LL, L, ML, M, HM, H and HH.

= Within this range the airflow rate is automatically controlled when the AIRFLOW ADJUSTING

button is set to AUTOMATIC

Refer to automatic airflow rate control on page 19.

Note: 1. During powerful operation, fan operate H tap + 50 - 70 rpm.

2. Fan stops during defrost operation.

Automatic air flow

control for heating

The following drawing explains the principle for fan speed control for heating:

Note: When there is no operation and the night set mode turns on, the step is low. Refer to “Night set mode” on

page 22.

Automatic air flow

control for cooling

The following drawing explains the principle of fan speed control for cooling:

Step Cooling Heating Dry mode

LLL (Heating thermostat OFF) H type : 500 - 860 rpm

(During powerful operation :

850 - 910 rpm)

J type : 800 - 980 rpm

(During powerful operation :

1050 rpm)

LL (Cooling thermostat OFF)

L

ML

M

MH

H

HH (Powerful)

(RL010)

(RL010)

-1.5˚C

-0.5˚C

-1˚C

-2˚C

L

ML

M

Thermostat

setting

temperature

Phase control

Temperature difference between

ambient and set temperature

fan speed

(RL012)

+1.5˚C

+0.5˚C

+2˚C

+1˚C

M

ML

L

fan speed

Temperature difference between

ambient and set temperature

Phase control

Thermostat

setting

temperature

(RL013)

Si-86.book Page 19 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

20 Main Function

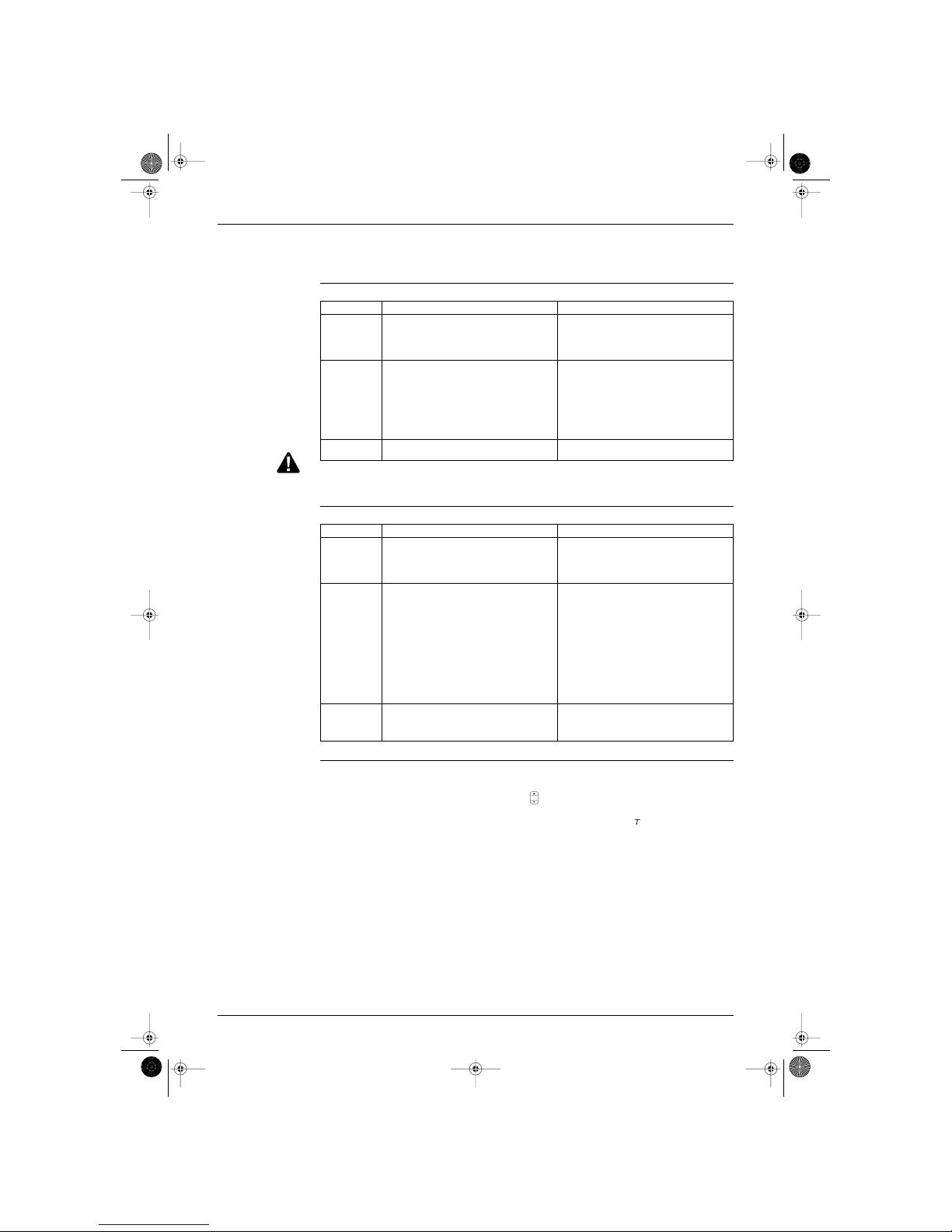

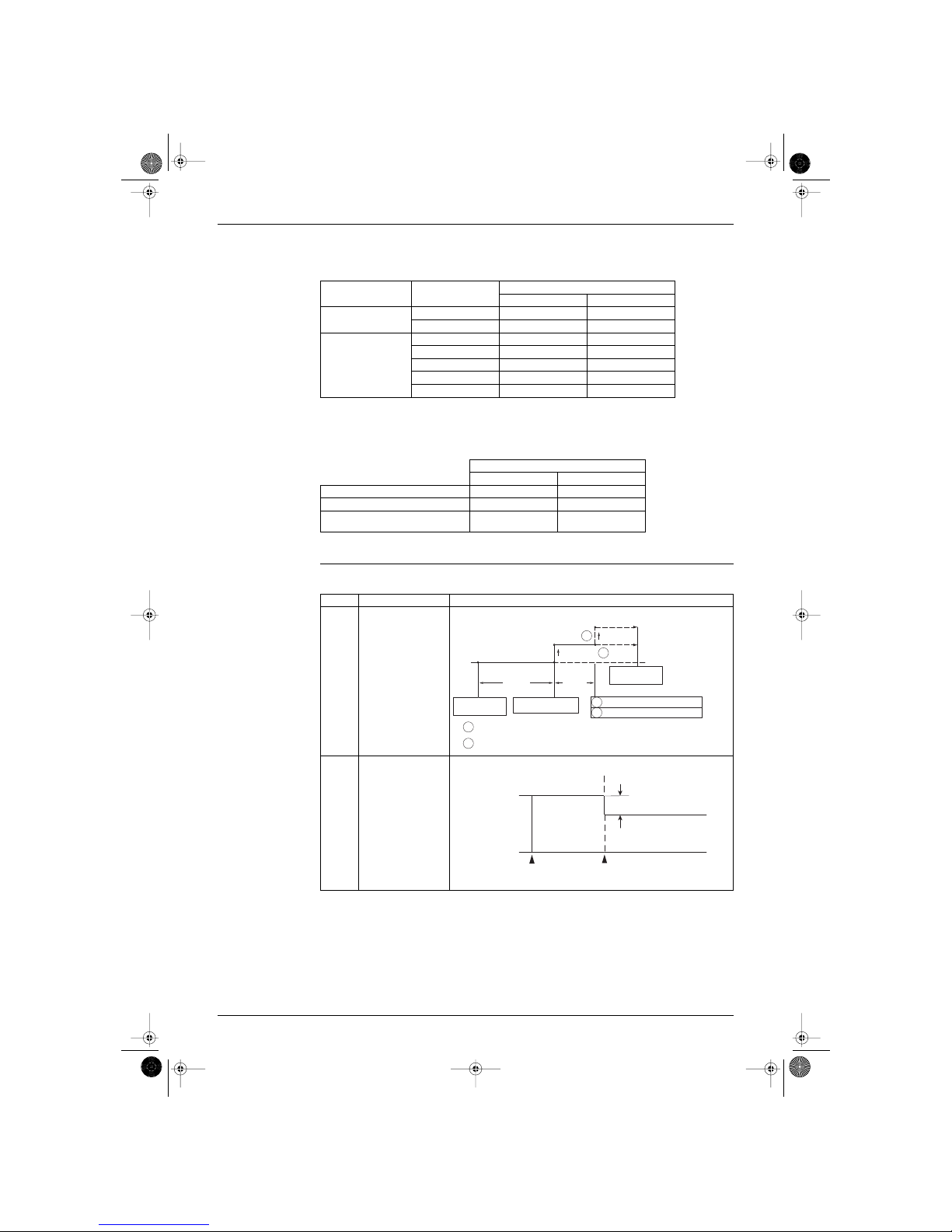

1.8 Fan Speed Control for Outdoor Units

Control The following drawing explains the fan speed control:

Fan off delay When the compressor turns off and T

[outdoor ambient]

> D˚C, the outdoor fan stays running at the same

speed for

E seconds.

ON

OFF

A˚C

B˚C

For ambient temperature

between C˚C.

outdoor heat exchanger temperature

(RL014)

A (˚C) B (˚C) C (˚C) D (˚C) E (sec)

H type 28 34 0 - 18 10 30

J type 33 39 0 - 9 10 60

Caution

∗ J type operates the outdoor unit fans in the cooling mode even at the condition that a compressor is

not operated. (In case of existing model H series, the outdoor unit fans stops at the condition that a

compressor is not operated.)

Si-86.book Page 20 Friday, June 23, 2000 10:26 AM

SIE-86 General Functionality

Main Function 21

1.9 General Functions

Pre-heat operation When the equipment has stopped and t

[outside]

< 11.5˚C, the compressor is warmed-up by passing a

single-phase (U, V phase) current through the compressor motor to speed up the start. The power

consumption is 30-40W.

∗ For both H / J type

Hot start function During defrosting or when the thermostat is on in heating mode, the indoor heat exchanger temperature

≥ 29˚C to fan starts to avoid cold draft.

Dry mode The dry mode removes humidity while maintaining the room temperature. The temperature and fan cannot

be regulated during dry mode.

<Management>

1. Decision of the dry setting temperature

When entering the following dry mode,

1 Stop → an operation will start with Dry.

2 Mode except Dry → changing to dry mode

Thermostat ON/OFF point is decided in accordance with the following conditions.

2. Frequency command

The frequency command is decided based on a room temperature zone.

The room temperature zone is decided as follows.

11.5˚C

13.5˚C

Outside

temperature

OFF ON OFF

warm-up

control for

compressor

(RL015)

Room temp. cond. at entering Dry. Set temp. (thermostat ON) Thermostat OFF temp.

24˚C ≤ Room temp. Room temp. at the entering. Room temp. -2˚C at the entering.

18˚C ≤ Room temp. < 24˚C Room temp. at the entering. Room temp. -1.5˚C at the entering.

Room temp. < 18˚C18˚C17˚C

Room temp. - setting temp.

Room temp.

zone

1.0

Room temp.

zone

F

0.5 F

E

0E

D

-0.5 D B

-1

-1.5

Thermostat OFF point

dTmpOff

B

AA

at falling temp.

at rising temp.

(RL016)

Si-86.book Page 21 Friday, June 23, 2000 10:26 AM

General Functionality SIE-86

22 Main Function

The frequency command for every zone is stated below.

(Please note that an operation will not carry out in the commanded frequency sometimes in case a

protection control like a freeze-protection etc. will be actuated.)

3. Required fan speed

Fan speed changes the rotation speed every time when a thermostat switches over ON and OFF.

When the thermostat becomes Off, fan continues to operate 10 minutes more with low speed so as to

prevent recovery of humidity caused by reevaporation of the drain water, and then stops.

∗ For both H / J type

Night set mode The night set mode is activated when the off timer is set. It restricts the operation frequency, to minimize

the noise.

∗ For both H / J type

Room temperature Room temp. zone

Command frequency

H type (25 / 35) J type (25 / 35)

Room temp. < 18˚C

A 0 / 0Hz 0 / 0Hz

except A 36 / 36Hz 34 / 34Hz

Room temp. ≥ 18˚C

A 0 / 0Hz 0 / 0Hz

B 36 / 36Hz 34 / 34Hz

D 36 / 36Hz 40 / 40Hz

E 40 / 40Hz 42 / 42Hz

F 40 / 44Hz 42 / 42Hz

Fan rpm (thermostat ON)

H type (25 / 35) J type (25 / 35)

Thermostat ON 800 / 800rpm 970 / 980rpm

Thermostat OFF 700 / 700rpm 800 / 800rpm

Thermostat ON and dry on powerful

operation

850 / 910rpm 1050 / 1050rpm

Item Description Drawing

cooling The set temperature

stays on for one hour,

then decreases slightly

for economical

operation.

heating The set temperature

stays on for one hour,

then increases slightly

for economical

operation.

0,5˚C

0,5˚C

0,5˚C

temperature shift

A

A

B

B

A

B

temperature setting +1˚C

temperature setting +0.5˚C

temperature setting

operation stops

at the set hours

1 hour

30 min.

Timer operation

Night set circuit on

+0.5˚C temperature shift

Temperature setting remains

When the outside temperature is lower than 27˚C and the room

temperature is at the set temperature.

When the outside temperature is 27˚C or higher.

(RL017)

2˚C

Thermostat

setting

Timer operation

Night set circuit on

1 hour later

(RL018)

Si-86.book Page 22 Friday, June 23, 2000 10:26 AM

Loading...

Loading...