Daikin RWEYQ252PCYD, RWEYQ144PCYD, RWEYQ216PCYD, RWEYQ72PCTJ, RWEYQ84PCTJ Installation Manual

...

INSTALLATION MANUAL

System air conditioner

MODEL

RWEYQ72PCYD

RWEYQ84PCYD

RWEYQ144PCYD

RWEYQ168PCYD

RWEYQ216PCYD

RWEYQ252PCYD

Read these instructions carefully before installation.

Keep this manual in a handy place for future reference.

This manual should be left with the equipment owner.

Lire soigneusement ces instructions avant I’installation.

Concerver ce manuel à portée de main pour référence ultérieure.

Ce manuel doit être donné au propriétaire de l’équipement.

RWEYQ72PCTJ

RWEYQ84PCTJ

RWEYQ144PCTJ

RWEYQ168PCTJ

RWEYQ216PCTJ

RWEYQ252PCTJ

English

Français

Español

Lea cuidadosamente estas instrucciones antes de instalar.

Guarde este manual en un lugar a mano para leer en caso de tener alguna duda.

Este manual debe permanecer con el propietario del equipo.

1

2

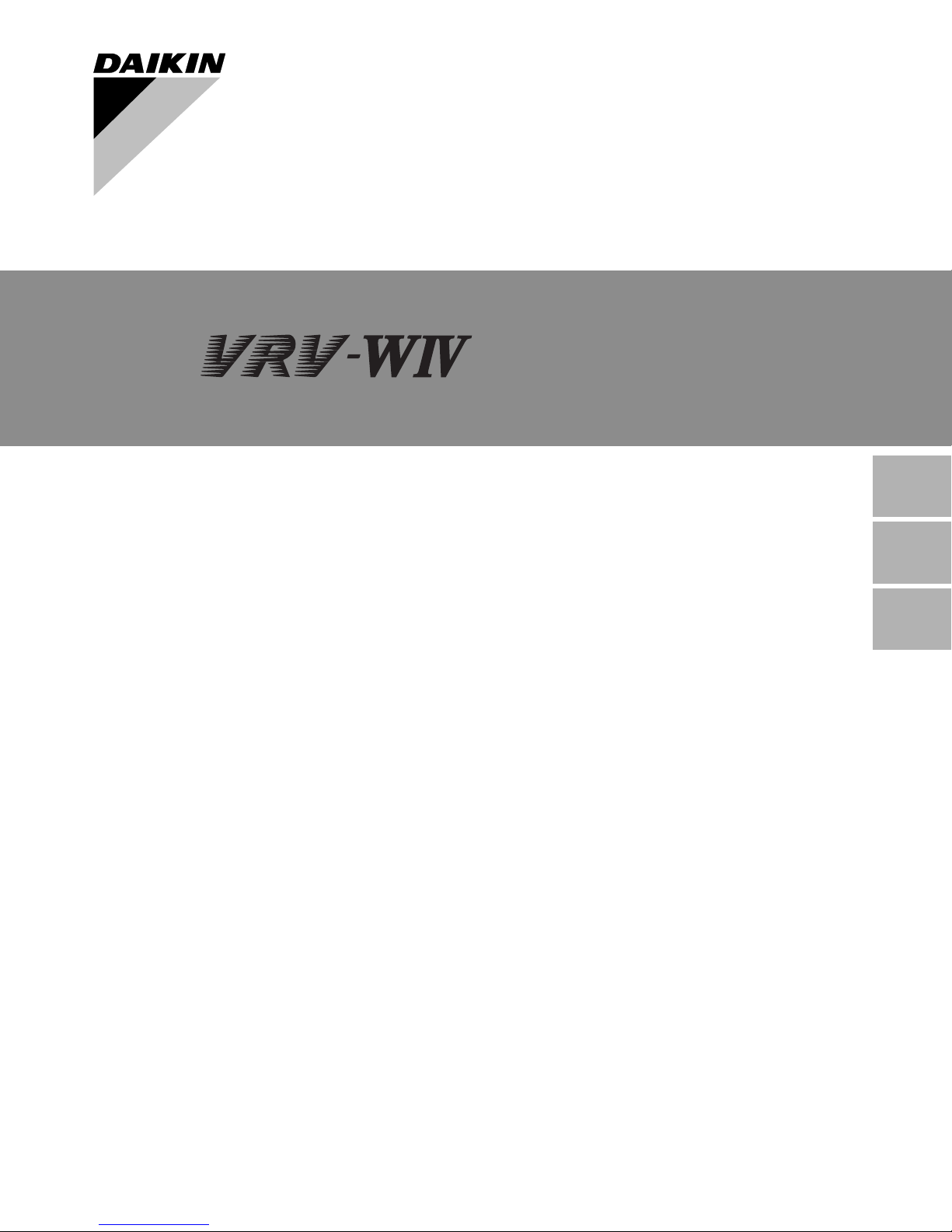

figure 1

2

figure 3

1

≥13/16 (20)

1

(350)

≤13-3/4

[3]

30-11/16 (780)

2 (PCYD)

2 (PCTJ)

≥13/16 (20)

1

2

A

B

5

3

BB

4

A

A

A

A: ≥60 in. (1500 mm)

B: ≥40 in. (1000 mm)

[4]

6

≥35-7/16

(900)

≥13-3/4

≤9-13/16

(250)

(350)

8

≥15-3/8

(390)

21-5/8

≥3-15/16 (100)

(550)

9

5

8

9

≥19-11/16

(500)

(300)

≥11-13/16

39-3/8 (1000)

75

≥13/16

(20)

7 7

5 5

9

8

6 6

≥13/16

(20)

∗10

8

Unit: in. (mm)

9

≥35-7/16 (900) ≥19-11/16 (500)

≥13/16

(20)

figure 2

3

1

4

2

(100)

3-15/16

2

15-3/4 (400)

29-5/16 (744)

3

(100)

3-15/16

12

13

7

14

6

8

2-3/8

(60)

5

11

9

10

[1]

≤15-3/4

(400)

15

Unit: in. (mm)

figure 6

2

4

Unit: in. (mm)

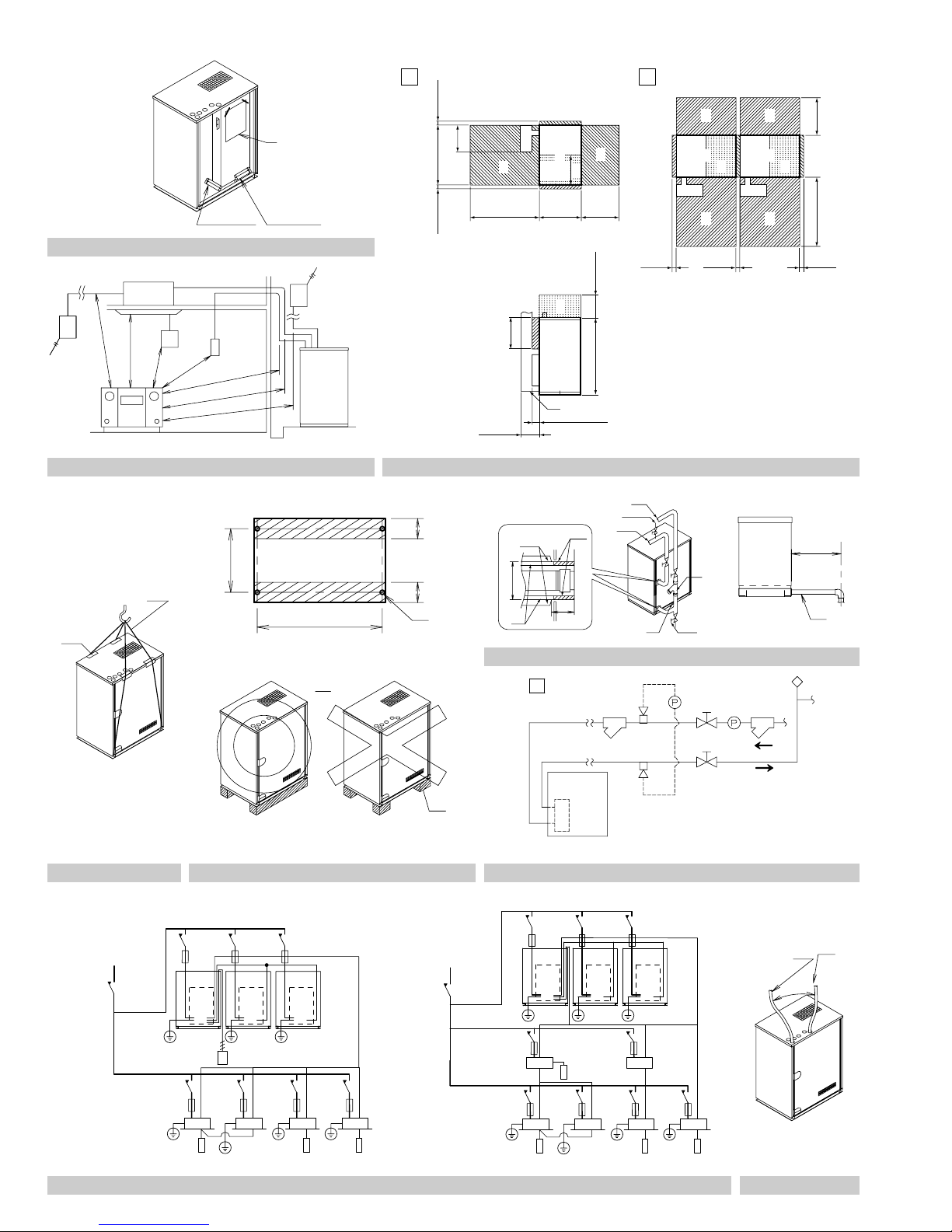

figure 4 figure 5 figure 7

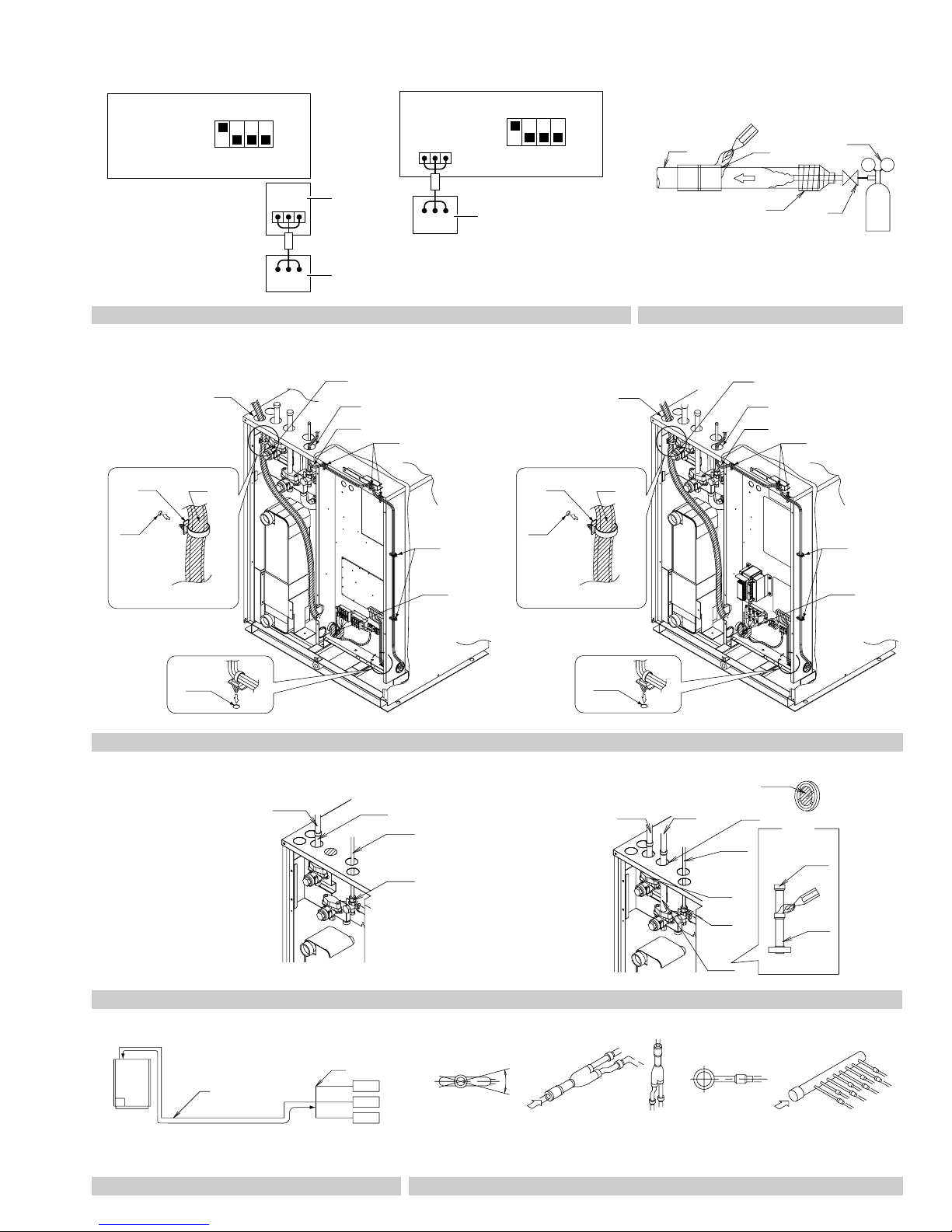

[Heat recovery system][Heat pump system]

3

3

1

2

4

6

1

2

9

3

4

8

3

4

5

1

2

4

3

5

7

6

8

9

10

11

4

6

7

9

2

1

3

8

5

figure 8

figure 9

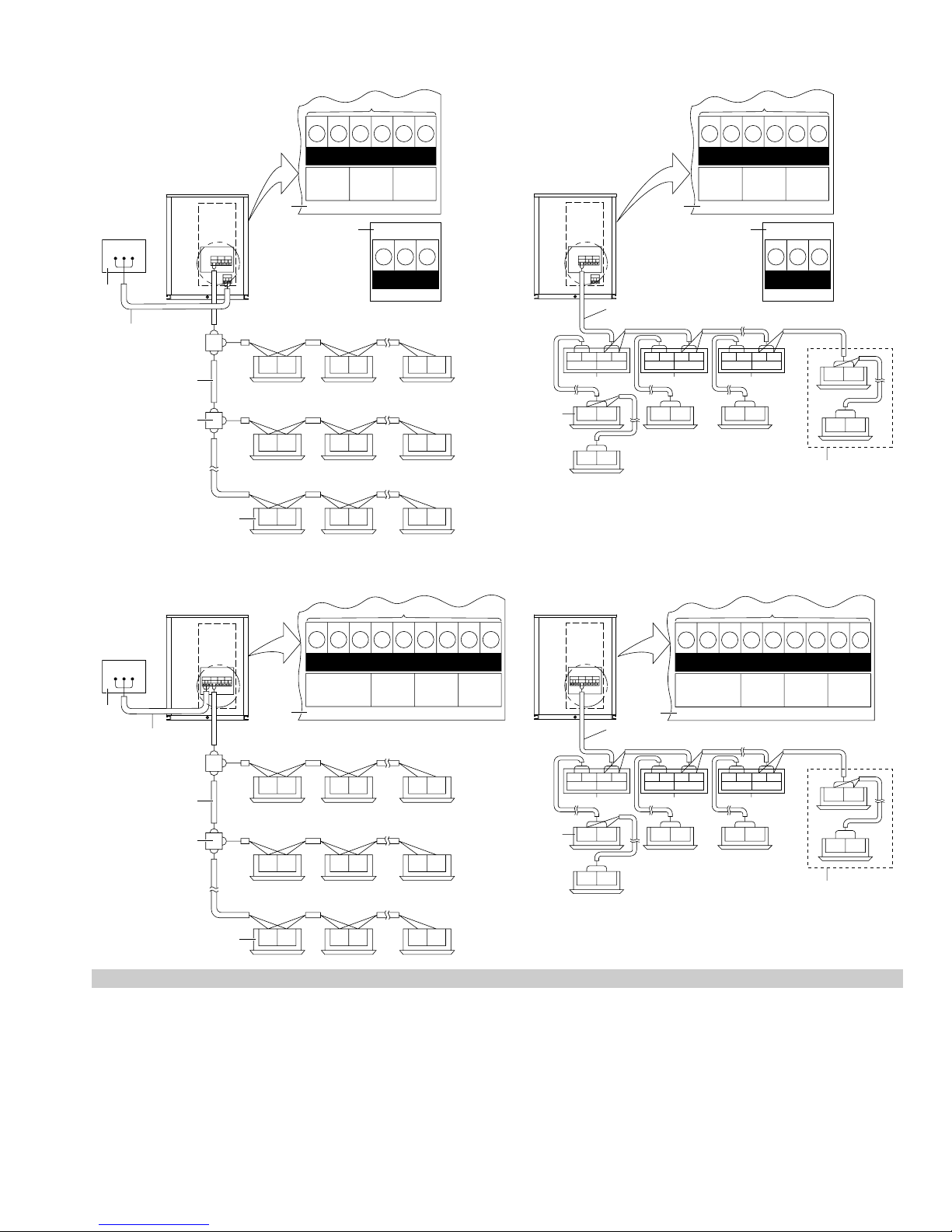

<RWEYQ-PCYD>

7

[Heat recovery system][Heat pump system]

7

A B C

1

3

<RWEYQ-PCTJ>

F1 F1F2 F2 Q1 Q2

TO IN/D UNIT

TO OUT/D UNIT TO MULTI UNIT

2

12

A1P

F1F2 F1F2 Q1Q2

ABC ABC

F1 F2 F1 F2 F1 F2

A5P

ABC

C/H SELECTOR

4

5

F1 F2 F1 F2 F1 F2

F1 F2 F1 F2 F1 F2

6

7

[Heat recovery system][Heat pump system]

F1 F1F2 F2

IN/D OUT/D.BS

6

A1P

F1F2 F1F2 Q1Q2

F1 F2

F1 F2

F1 F1F2 F2 Q1 Q2

TO IN/D UNIT

TO OUT/D UNIT TO MULTI UNIT

2

12

A5P

ABC

4

C/H SELECTOR

F1 F1F2 F2

IN/D OUT/D.BS

8

9

F1 F2

F1 F1F2 F2

IN/D OUT/D.BS

10

F1 F2

F1 F2

F1 F2

11

7

A B C

1

figure 10

A1P

ABCF1F2F1F2Q1Q2

A B C F1 F1F2 F2 Q1 Q2

C/H SELECTOR

TO IN/D UNIT

TO OUT/D UNIT TO MULTI UNIT

A1P

ABCF1F2F1F2Q1Q2

2

3

4

F1 F2 F1 F2 F1 F2

5

6

4

F1 F1F2 F2

IN/D OUT/D.BS

8

F1 F2

ABCF1 F1F2 F2 Q1 Q2

C/H SELECTOR

TO IN/D UNIT

2

F1 F1F2 F2

IN/D OUT/D.BS

9

F1 F2

F1 F1F2 F2

IN/D OUT/D.BS

10

F1 F2

TO OUT/D UNIT TO MULTI UNIT

F1 F2

F1 F2

F1 F2 F1 F2 F1 F2

F1 F2 F1 F2 F1 F2

6

F1 F2

11

<RWEYQ-PCYD>

1

A1P

4

F1 F2 F1 F2 Q1 Q2 Q1 Q2 Q1 Q2

8

23

56 6 6

A5P

A BC

9

7

<RWEYQ-PCYD>

1 4

X2M

12

A1P

2

X1M

F1 F2 F1 F2 Q1 Q2

5

A5P

X3M

ABC

43

3

3

<RWEYQ-PCTJ>

1

23

A1P

4

A B C F1 F2 F1 F2 Q1 Q2 Q1 Q2 Q1 Q2

7

56 6 6

9

8

1 23

4

LOW NOISE

TO OUT/D UNIT TO OUT/D UNIT TO OUT/D UNIT

F1 F2

F1

F2

F1 F2 F1 F2

6

5

7

<RWEYQ-PCTJ>

A1P

A B C F1 F2 F1 F2 Q1 Q2

1

12

X1M

X2M

2

X3M

43

3

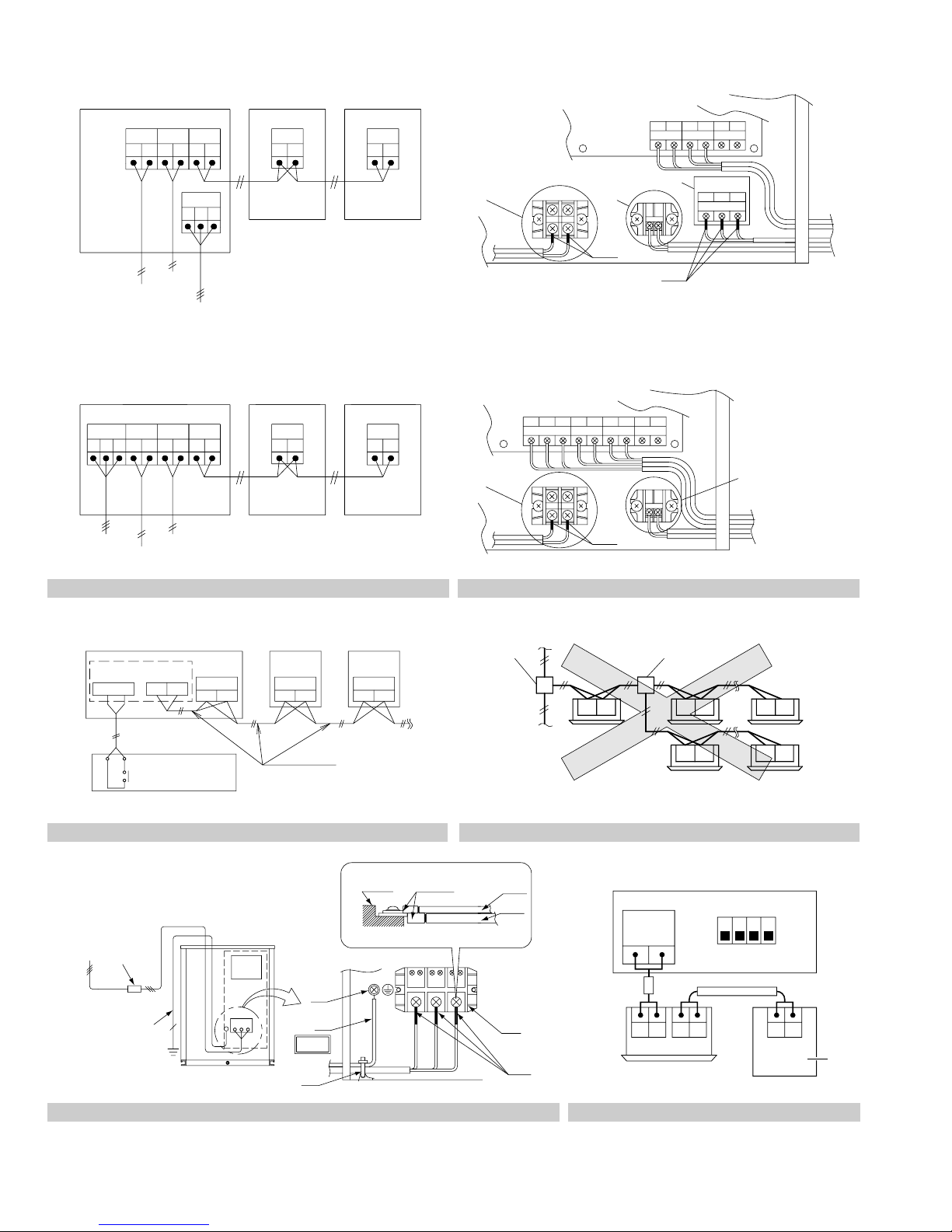

figure 12figure 11

12

F1 F2 F1 F2

F1 F2

4

F1 F2

F1 F2

figure 13

1

2

6

3

8

9

7

figure 15

10

11

12

figure 14

13

14

5

ON

OFF

O

U

T

1

I

N

DS1

234

P1 P2

1

A1P

TO IN/D

UNIT

F1 F2

F1 F2 P1 P2

4

figure 16

<RWEYQ-PCYD>

A1P

ON

OFF

O

U

T

1234

I

N

DS1

A5P

A B C

<RWEYQ-PCTJ>

O

ON

OFF

1

U

T

1234

I

N

DS1

12

3

4

5

6

3

A1P

A B C

2

A B C

figure 17

<RWEYQ-PCTJ>

5

3

A B C

1

figure 18

<RWEYQ-PCYD>

<RWEYQ-PCTJ>

2

2

1

4

6

7

8

9

5

5

3

10

11

3

1

1

4

4

6

6

2

7

7

8

8

9

9

10

10

11

11

figure 19

figure 20

1

figure 21

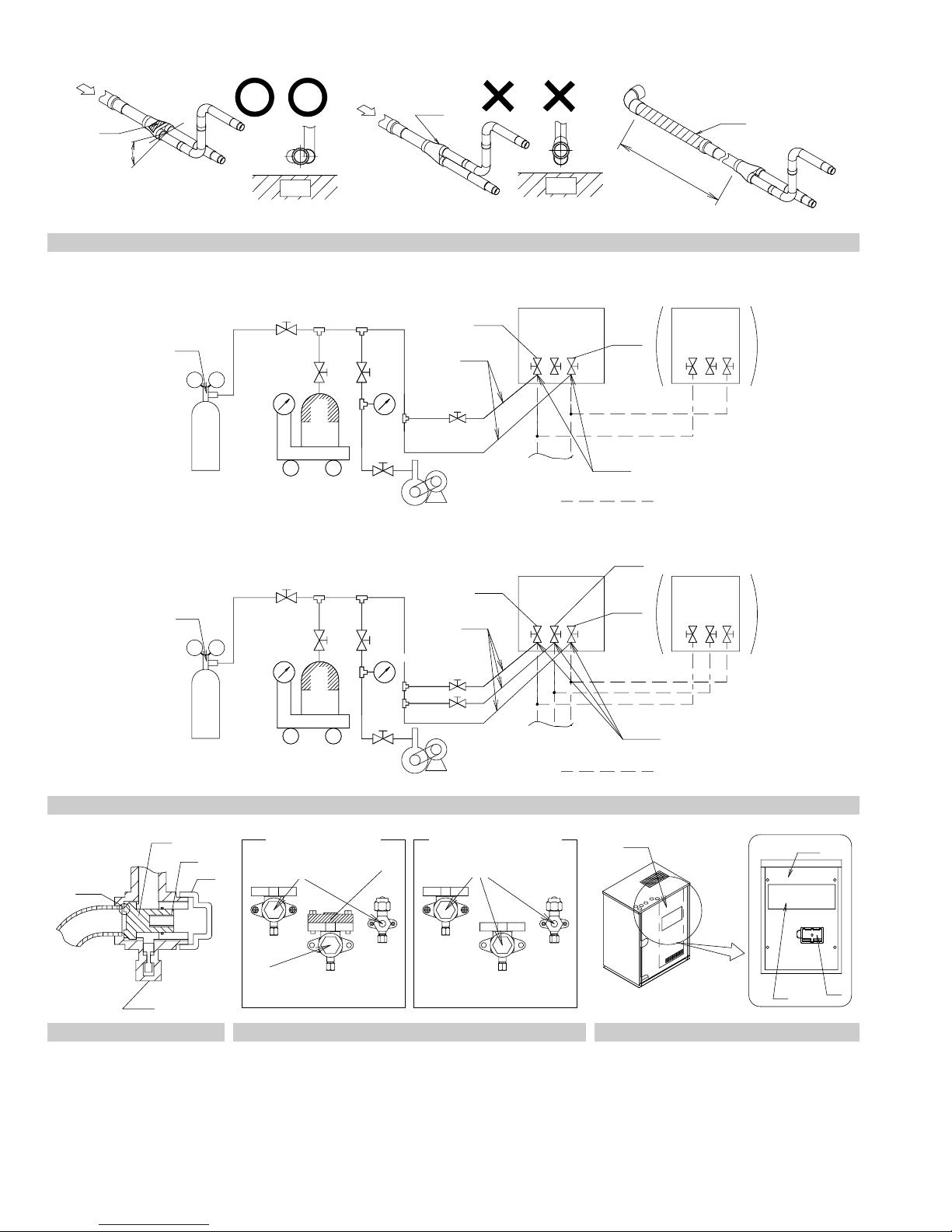

[Heat pump system]

2

3

[Heat recovery system]

1

2

3

4

78 9

10

[13]

4

14

5

11

5

15

16

∗6

12

∗17

4

1

2

A

3

B

5

[A-arrow view] [B-arrow view]

figure 22

(Fig. A) (Fig. B) (Fig. C)

C

figure 23

1

≤ ±15˚

2

[C-arrow view] [D-arrow view]

[Heat pump system]

1

2

[Heat recovery system]

R410A

1

5

D

3

3

4

11

10 10

12

9

7

3

4

15

5

6

16

18

14

figure 24

5

figure 25

13

1

9

10 10

12

R410A

7

3

2

4

8

15

17

5

4

3

2

[Heat pump system] [Heat recovery system]

1

2

5

3

6

4

1

figure 26 figure 27

6

18

1

2

1

2

4

3

4

3

RWEYQ72PCYD

RWEYQ84PCYD

RWEYQ144PCYD

RWEYQ168PCYD

RWEYQ216PCYD

RWEYQ252PCYD

RWEYQ72 PCTJ

RWEYQ84 PCTJ

RWEYQ14 4PCTJ

RWEYQ168PCTJ

RWEYQ216PCTJ

RWEYQ252PCTJ

VRV-WIV System

air conditioner

Installation

manual

CONTENTS

1. SAFETY CONSIDERATIONS ...................................................... 1

2. INTRODUCTION.......................................................................... 3

2-1 Combination......................................................................... 3

2-2 Standard operation limit ....................................................... 3

2-3 Standard supplied accessories ............................................ 3

2-4 Option accessories............................................................... 3

2-5 Technical specifications ....................................................... 4

2-6 Electrical specifications ........................................................ 4

3. SELECTION OF LOCATION........................................................ 5

4. INSPECTING AND HANDLING THE UNIT.................................. 6

5. UNPACKING AND PLACING THE UNIT ..................................... 6

6. WATER PIPING WORK............................................................... 6

7. HANDLING OF THE BRAZED PLATE-TYPE HEAT

EXCHANGER............................................................................... 7

7-1 When designing the equipment............................................ 7

7-2 Before starting a test run...................................................... 7

7-3 Daily service and maintenance ............................................ 7

7-4 Water quality ........................................................................ 7

7-5 Maintenance of plate-type heat exchanger .......................... 8

8. FIELD WIRING............................................................................. 8

8-1 Optional parts....................................................................... 8

8-2 Power supply circuit and wire requirements......................... 8

8-3 General ................................................................................ 9

8-4 Examples ............................................................................. 9

8-5 In case of a local setting..................................................... 11

9. REFRIGERANT PIPING ............................................................ 11

9-1 Selection of piping material ................................................ 11

9-2 Protection against contamination when installing pipes..... 12

9-3 Pipe connection.................................................................. 12

9-4 Connecting the refrigerant piping ....................................... 12

9-5 Example of connection....................................................... 14

9-6 Air tight test and vacuum drying......................................... 15

9-7 Pipe insulation.................................................................... 15

9-8 Checking of device and installation conditions................... 15

9-9 Additional refrigerant charge .............................................. 15

9-10 Stop valve operation procedure ......................................... 16

10. CHECKS AFTER INSTALLATION ............................................. 17

11. TEST RUN ................................................................................. 17

11-1 Air discharge ...................................................................... 17

11-2 Before turn on the power supply ........................................ 17

11-3 Check operation ................................................................. 17

11-4 Check of normal operation ................................................. 18

12. ONSITE SETTINGS ................................................................... 18

12-1 Energy saving and optimum operation............................... 18

13. CAUTION FOR REFRIGERANT LEAKS ................................... 21

1. SAFETY CONSIDERATIONS

Read these SAFETY CONSIDERATIONS for Installation carefully

before installing air conditioning equipment. After completing the installation, make sure that the unit operates properly during the startup operation.

Instruct the customer on how to operate and maintain the unit. Inform

customers that they should store this Installation Manual with the Operation Manual for future reference.

Always use a licensed installer or contractor to install this product.

Improper installation can result in water or refrigerant leakage, electrical

shock, fire, or explosion.

Meanings of DANGER, WARNING, CAUTION, and NOTE Symbols:

DANGER .....................Indicates an imminently hazardous situa-

tion which, if not avoided, will result in

death or serious injury.

WARNING................... Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION.................... Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury. It may also be used to

alert against unsafe practices.

NOTE.......................... Indicates situations that may result in

equipment or property-damage accidents

only.

DANGER

• Refrigerant gas is heavier than air and replaces oxygen. A

massive leak can lead to oxygen depletion, especially in basements, and an asphyxiation hazard could occur leading to serious injury or death.

• Do not ground units to water pipes, gas pipes, telephone

wires, or lightning rods as incomplete grounding can cause a

severe shock hazard resulting in severe injury or death. Additionally, grounding to gas pipes could cause a gas leak and

potential explosion causing severe injury or death.

• If refrigerant gas leaks during installation, ventilate the area

immediately. Refrigerant gas may produce toxic gas if it

comes in contact with fire. Exposure to this gas could cause

severe injury or death.

• After completing the installation work, check that the refrigerant gas does not leak throughout the system.

• Do not install unit in an area where flammable materials are

present due to risk of explosions that can cause serious injury

or death.

• Safely dispose all packing and transportation materials in accordance with federal/state/local laws or ordinances. Packing

materials such as nails and other metal or wood parts, including plastic packing materials used for transportation may

cause injuries or death by suffocation.

WARNING

• Only qualified personnel must carry out the installation work.

Installation must be done in accordance with this installation

manual. Improper installation may result in water leakage,

electric shock, or fire.

• When installing the unit in a small room, take measures to keep

the refrigerant concentration from exceeding allowable safety

limits. Excessive refrigerant leaks, in the event of an accident in

a closed ambient space, can lead to oxygen deficiency.

• Use only specified accessories and parts for installation work.

Failure to use specified parts may result in water leakage,

electric shocks, fire, or the unit falling.

• Install the air conditioner on a foundation strong enough that it

can withstand the weight of the unit. A foundation of insufficient strength may result in the unit falling and causing injuries.

• Take into account strong winds, typhoons, or earthquakes

when installing. Improper installation may result in the unit

falling and causing accidents.

• Make sure that a separate power supply circuit is provided for

this unit and that all electrical work is carried out by qualified

personnel according to local, state and national regulations.

An insufficient power supply capacity or improper electrical

construction may lead to electric shocks or fire.

• Make sure that all wiring is secured, that specified wires are

used, and that no external forces act on the terminal connections or wires. Improper connections or installation may result in fire.

English 1

• When wiring, position the wires so that the control box cover

can be securely fastened. Improper positioning of the control

box cover may result in electric shocks, fire, or the terminals

overheating.

• Before touching electrical parts, turn off the unit.

• This equipment can be installed with a Ground-Fault Circuit

Interrupter (GFCI). Although this is a recognized measure for

additional protection, with the grounding system in North

America, a dedicated GFCI may not be necessary.

• Securely fasten the outside unit terminal cover (panel). If the

terminal cover/panel is not installed properly, dust or water

may enter the outside unit causing fire or electric shock.

• When installing or relocating the system, keep the refrigerant

circuit free from substances other than the specified refrigerant (R410A) such as air. Any presence of air or other foreign

substance in the refrigerant circuit can cause an abnormal

pressure rise or rupture, resulting in injury.

• Do not change the setting of the protection devices. If the

pressure switch, thermal switch, or other protection device is

shorted and operated forcibly, or parts other than those specified by Daikin are used, fire or explosion may occur.

• Indoor and outside units are for indoor installation only.

• Do not install the air conditioner in the following locations:

(a) Where a mineral oil mist or oil spray or vapor is produced,

for example, in a kitchen.

Plastic parts may deteriorate and fall off or result in water

leakage.

(b) Where corrosive gas, such as sulfurous acid gas, is pro-

duced.

Corroding copper pipes or soldered parts may result in

refrigerant leakage.

(c) Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of the

control system and cause the unit to malfunction.

(d) Where flammable gas may leak, where there is carbon fiber,

or ignitable dust suspension in the air, or where volatile

flammables such as thinner or gasoline are handled. Operating the unit in such conditions can cause a fire.

• Take adequate measures to prevent the outside unit from be-

ing used as a shelter by small animals. Small animals making

contact with electrical parts can cause malfunctions, smoke,

or fire. Instruct the customer to keep the area around the unit

clean.

CAUTION

• Do not touch the switch with wet fingers. Touching a switch

with wet fingers can cause electric shock.

• Do not allow children to play on or around the unit to prevent

injury.

• Do not touch the refrigerant pipes during and immediately after operation as the refrigerant pipes may be hot or cold, depending on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other refrigerant cycle

parts. Your hands may suffer burns or frostbite if you touch

the refrigerant pipes. To avoid injury, give the pipes time to return to normal temperature or, if you must touch them, be sure

to wear proper gloves.

• Heat exchanger fins are sharp enough to cut.

To avoid injury wear glove or cover the fins when working

around them.

• Install drain piping to proper drainage. Improper drain piping

may result in water leakage and property damage.

• Insulate piping to prevent condensation.

• Be careful when transporting the product.

• Do not turn off the power supply immediately after stopping

operation. Always wait for at least 5 minutes before turning off

the power supply. Otherwise, water leakage may occur.

• Do not use a charging cylinder. Using a charging cylinder may

cause the refrigerant to deteriorate.

• Refrigerant R410A in the system must be kept clean, dry, and

tight.

(a) Clean and Dry -- Foreign materials (including mineral oils

such as SUNISO oil or moisture) should be prevented from

getting into the system.

(b) Tight -- R410A does not contain any chlorine, does not

destroy the ozone layer, and does not reduce the earth’s protection again harmful ultraviolet radiation. R410A can contribute to the greenhouse effect if it is released. Therefore

take proper measures to check for the tightness of the refrigerant piping installation. Read the chapter Refrigerant Piping and follow the procedures.

• Since R410A is a blend, the required additional refrigerant

must be charged in its liquid state. If the refrigerant is charged

in a state of gas, its composition can change and the system

will not work properly.

• The indoor unit is for R410A. See the catalog for indoor models that can be connected. Normal operation is not possible

when connected to other units.

• Remote controller (wireless kit) transmitting distance can be

shorter than expected in rooms with electronic fluorescent

lamps (inverter or rapid start types). Install the indoor unit far

away from fluorescent lamps as much as possible.

NOTE

• Install the power supply and transmission wires for the indoor

and outside units at least 3.5 feet (1 m) away from televisions

or radios to prevent image interference or noise. Depending

on the radio waves, a distance of 3.5 feet (1 m) may not be sufficient to eliminate the noise.

• Dismantling the unit, treatment of the refrigerant, oil and additional parts must be done in accordance with the relevant local, state, and national regulations.

• Do not use the following tools that are used with conventional

refrigerants: gauge manifold, charge hose, gas leak detector,

reverse flow check valve, refrigerant charge base, vacuum

gauge, or refrigerant recovery equipment.

• If the conventional refrigerant and refrigerator oil are mixed in

R410A, the refrigerant may deteriorate.

• This air conditioner is an appliance that should not be accessible to the general public.

• The wall thickness of field-installed pipes should be selected

in accordance with the relevant local, state, and national regulations.

Codes and Regulations

This product is designed and manufactured to comply with national

codes. Installation in accordance with such codes and/or prevailing

local codes/regulations is the responsibility of the installer. The manufacturer assumes no responsibility for equipment installed in violation of

any codes or regulations. Rated performance is achieved after charge

adjustment (sub-cooling of 14±1°F (8±0.5°C) and superheat of 3±1°F

(1.7±0.5°C)) and 72 hours of operation.

2 English

2. INTRODUCTION

This installation manual concerns VRV inverters of the Daikin

RWEYQ-PC series. These units are designed for indoor installation and

used for cooling and heat pump applications.

The RWEYQ-PC units can be combined with Daikin VRV series indoor

units for air conditioning purposes.

The present installation manual describes the procedures for unpacking, installing and connecting the RWEYQ-PC units. Installation of the

indoor units is not described in this manual. Always refer to the installation manual supplied with these units for their installation.

2-1 Combination

The indoor units can be installed in the following range.

• Always use appropriate indoor units compatible with R410A.

To learn which models of indoor units are compatible with

R410A, refer to the product catalogs.

• The Branch Selector units that combined with RWEYQ-PC units for

changing the refrigerant flow to indoor units are T type (BSQ-TVJ,

BS-Q54TVJ) only, or P type (BSVQ-PVJU, BSV-Q36PVJU) only. Do

not combine the T type and P type in the system. Combination of T

type and P type cause malfunction.

• Total capacity/quantity of indoor units

〈Outside unit〉〈Total capacity index of indoor units〉〈Total quantity of indoor units〉

RWEYQ72PCYD/CTJ

RWEYQ84PCYD/CTJ

RWEYQ144PCYD/CTJ

RWEYQ168PCYD/CTJ

RWEYQ216PCYD/CTJ

RWEYQ252PCYD/CTJ

2-2 Standard operation limit

The figures below assume following operating conditions for indoor and

outside units:

Equivalent pipe length ........................................25 ft. (7.6 m)

Level difference..................................................................... 0

Cooling Heating

120

110

100

90

80

70

60

50

6050 70 80 90 6050 70 80 90

〈In case of antifreeze usage〉

Cooling Heating

120

110

100

90

80

70

60

50

40

30

20

6050 70 80 90 6050 70 80 90

A Entering water temperature (°F)

B Indoor temperature (°FWB)

C Indoor temperature (°FDB)

Range for continuous operation

Range for operation

Range for pull down operation

Range for warming up operation

......... 36-93.5 12 units

......... 42-109 14 units

....... 72-187 24 units

....... 84-218 29 units

..... 108-280 36 units

..... 126-327.5 36 units

AA

120

110

100

90

80

70

60

50

CB

AA

110

100

90

80

70

60

50

40

30

20

10

CB

• Operation range of water flow rate is 13.2-39.6 gpm (50-150 L/min).

(21.2-39.6 gpm (80-150 L/min) in case of antifreeze usage.)

• The unit is designed for the following operation range;

Entering water temperature: 67-95°F (20-35°C)

Water flow rate: 15.9gpm (60L/min) or more

• During cooling operation when the outside temperature is very low, it

is possible that the thermostat switches off automatically in order to

protect the unit from freezing.

• Hold ambient temperature at 35-104°FDB (2-40°CDB).

Heat release from the unit (approx.): RWEYQ72: 2200 Btu/h

(0.64kW), RWEYQ84: 2450 Btu/h (0.71kW)

It is therefore recommended to always ventilate the room.

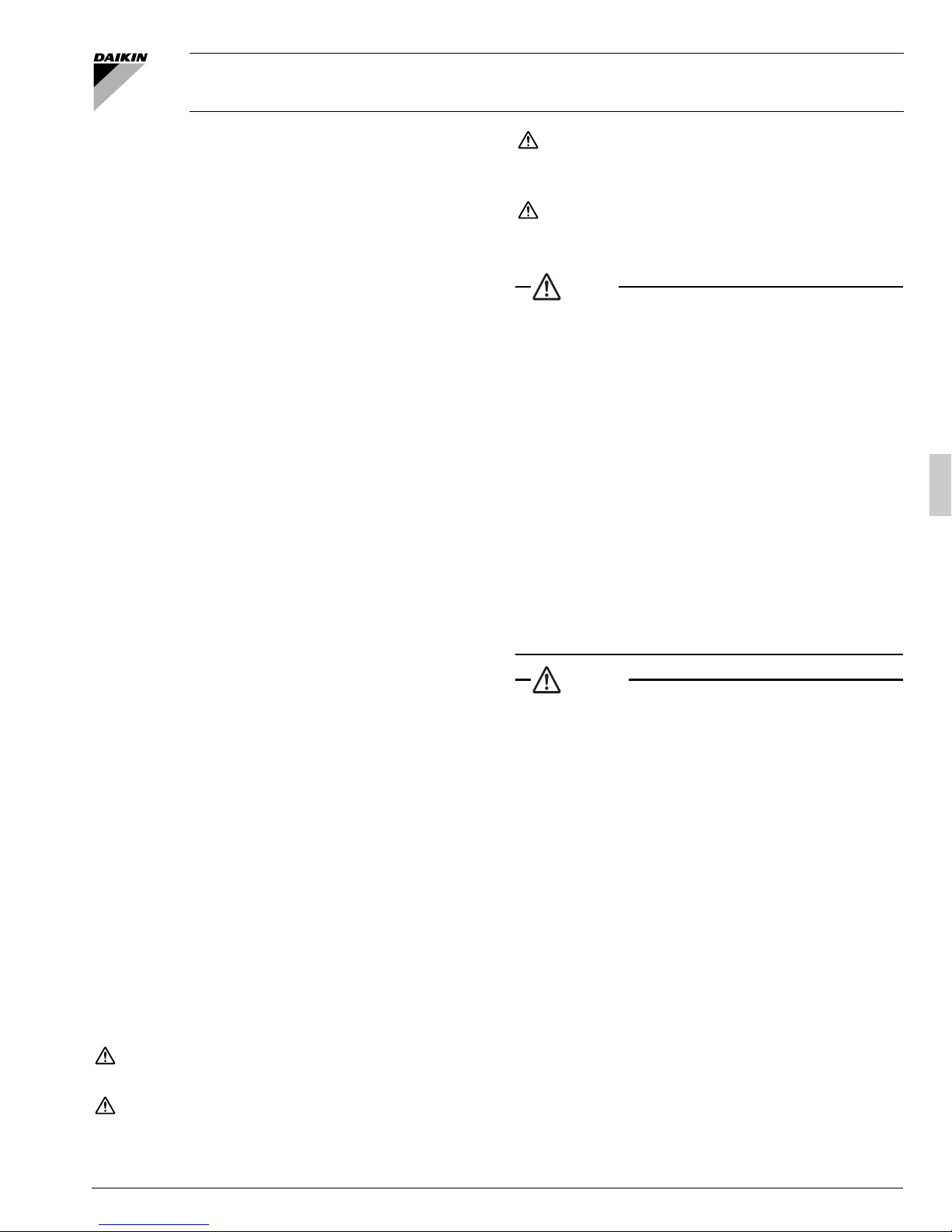

2-3 Standard supplied accessories

• Make sure that the following accessories are included.

(Check by removing the front panel.)

Name

For discharge

gas

For suction

Quantity 1 pc. 1 pc. 1 pc. 7 pcs. 2 pcs.

(Note)

Shape

Name Conduit mounting plate

Quantity 2 pcs. 2 pcs.

Shape

gas (1)

Accessory pipes

For suction

gas (2)

[Others]

•

Installation manual

•

Operation manual

Clamp (A) Clamp (B)

White

Black

(Refer to figure 1)

1. • Operation manual

• Installation manual

•Clamp (A)

•Clamp (B)

• Conduit mounting plate

2. Accessory pipes

• For discharge gas

• For suction gas (1)

• For suction gas (2)

NOTE

The accessory pipe for discharge gas is used for the heat recovery system. (Not used for the heat pump system.)

2-4 Option accessories

To install the above outside units, the following optional parts are also

required.

• Refrigerant branch kit

(For R410A only: Always use an appropriate kit dedicated for your

system.)

〈Heat pump system〉

REFNET header

REFNET joint

〈Heat recovery system ..... For 3-tube piping〉

REFNET header

REFNET joint

〈Heat recovery system ..... For 2-tube piping〉

REFNET header

REFNET joint

• Outside unit multi connection piping kit

(For R410A only: Always use an appropriate kit dedicated for

your system.)

Number of outside units

connected

Heat pump system BHFP22MA56U BHFP22MA84U

Heat recovery system BHFP26MA56U BHFP26MA84U

∗ To select an optimum kit, refer to 9. REFRIGERANT PIPING

KHRP26M22H9 KHRP26M33H9 KHRP26M72H9

KHRP26A22T9 KHRP26A33T9

KHRP26M72TU9 KHRP26M73TU9

KHRP25M33H9 KHRP25M72H9

KHRP25A22T9 KHRP25A33T9

KHRP26M22H9 KHRP26M33H9

KHRP26A22T9 KHRP26A33T9

KHRP25M72TU9 KHRP25M73TU9

KHRP26M72H9 KHRP26M73HU9

KHRP26M72TU9 KHRP26M73TU9

2 units 3 units

KHRP26M73HU9

KHRP25M73HU9

English 3

Loading...

Loading...