Daikin RHSX04P30D, RHSX04P50D, RHSXB04P30D, RHSXB04P50D, RHSX08P30D Installation manuals

...

Installation and

maintenance in-

structions

HPSU compact Ultra

RHSX(B)04P30D

RHSX(B)04P50D

06/2018

RHSX(B)08P30D

RHSX(B)08P50D

Installation and maintenance instructions

HPSU compact Ultra

English

List of contents

List of contents

1 General safety precautions 3

1.1 Particular safety instructions ..................................................... 3

1.1.1 Observing the instructions .......................................... 3

1.1.2 Meaning of warnings and symbols.............................. 4

1.2 Safety instructions for installation and operation....................... 4

1.2.1 General ....................................................................... 4

1.2.2 Intended use ............................................................... 5

1.2.3 Device installation room.............................................. 5

1.2.4 Electrical installation ................................................... 5

1.2.5 Requirements for the heating water............................ 5

1.2.6 Heating system and sanitary connection .................... 6

1.2.7 Operation .................................................................... 6

2 Handover to operator and warranty 7

2.1 Instruct the owner...................................................................... 7

2.2 Warranty conditions................................................................... 7

3 Product description 8

3.1 Design and components............................................................ 8

3.2 Function of the 3-way switch valves.......................................... 11

4 Set-up and installation 12

4.1 Dimensions and connection dimensions ................................... 12

4.2 Transport and delivery............................................................... 14

4.3 Installing the heat pump ............................................................ 14

4.3.1 Selecting the installation site....................................... 14

4.3.2 Installing the device .................................................... 15

4.4 Preparing the device for installation .......................................... 16

4.4.1 Remove the front screen............................................. 16

4.4.2 Remove the protective cover ...................................... 16

4.4.3 Moving the controller housing to the service position . 16

4.4.4 Open the controller housing........................................ 17

4.4.5 Removing the bottom thermal insulation..................... 17

4.4.6 Opening the vent valve ............................................... 18

4.4.7 Aligning the connections of the heating inflow and

return flow ................................................................... 18

4.4.8 Making the hood opening............................................ 19

4.4.9 Installing the rotary switch of the controller................. 20

4.5 Installing optional accessories................................................... 20

4.5.1 Installation of the electric backup heater..................... 20

4.5.2 Installation of the external heat generator connection

set ............................................................................... 20

4.5.3 Installation of the DB connection kit............................ 20

4.5.4 Installation of the P connection kit .............................. 21

4.6 Water connection ...................................................................... 21

4.6.1 Connecting hydraulic lines .......................................... 21

4.6.2 Connecting the drain................................................... 22

4.7 Electrical connection ................................................................. 23

4.7.1 Overall connection diagram ........................................ 24

4.7.2 Position of the printed circuit boards and terminal

strips ........................................................................... 25

4.7.3 Mains connection ........................................................ 25

4.7.4 General information on the electrical connection........ 25

4.7.5 Connecting the heat pump outdoor unit...................... 25

4.7.6 Connecting the outside temperature sensor

(optional) ..................................................................... 26

4.7.7 External switching contact .......................................... 26

4.7.8 EBA (external requirement request) ........................... 26

4.7.9 Connecting an external heat generator....................... 26

4.7.10 Connecting the room thermostat................................. 27

4.7.11 Connection of optional RoCon system components ... 28

4.7.12 Connecting the HP convector ..................................... 28

4.7.13 Connecting switching contacts (AUX outputs) ............ 29

4.7.14 Off-peak mains connection (HT/NT) ........................... 29

4.7.15 Connecting an intelligent controller (Smart Grid - SG) 30

4.8 Connection for refrigerant........................................................... 30

4.8.1 Laying refrigerant lines................................................. 30

4.8.2 Pressure test and filling the refrigerant circuit.............. 31

4.9 Filling the system........................................................................ 31

4.9.1 Checking the water quality and adjusting the

pressure gauge ............................................................ 31

4.9.2 Filling hot water heat exchangers ................................ 31

4.9.3 Filling the storage tank................................................. 31

4.9.4 Filling the heating system ............................................ 31

5 Start-up 32

5.1 Initial commissioning .................................................................. 32

5.1.1 Requirements............................................................... 32

5.1.2 Starting the unit and start-up........................................ 32

5.1.3 Bleeding the hydraulic system ..................................... 32

5.1.4 Checking the minimum flow ......................................... 33

5.1.5 Setting the screed program parameter (only as

required)....................................................................... 33

5.2 Re-commissioning...................................................................... 33

5.2.1 Requirements............................................................... 33

5.2.2 Start-up ........................................................................ 34

6 Hydraulic connection 35

6.1 Hydraulic system connection...................................................... 35

7 Inspection and maintenance 37

7.1 General overview of inspection and maintenance...................... 37

7.2 Inspection and maintenance tasks ............................................. 38

7.2.1 Filling, topping up the storage tank.............................. 38

7.2.2 Filling, topping up the heating system.......................... 39

8 Faults and malfunctions 41

8.1 Troubleshooting.......................................................................... 41

8.2 Overview of possible malfunctions ............................................. 41

8.3 Fault codes................................................................................. 44

8.4 Emergency operation ................................................................. 54

9 Taking out of operation 55

9.1 Temporary shutdown.................................................................. 55

9.1.1 Draining the storage tank............................................. 55

9.1.2 Draining the heating circuit and hot water circuit ......... 56

9.2 Final shutdown and disposal ...................................................... 56

10 Technical data 58

10.1 Basic data................................................................................... 58

10.2 Characteristic lines ..................................................................... 59

10.2.1 Sensor characteristic lines ........................................... 59

10.2.2 Characteristic curves for pumps .................................. 60

10.3 Tightening torque ....................................................................... 60

10.4 Minimum floor area and ventilation openings ............................. 60

10.5 Electrical connection diagram .................................................... 62

11 Notes 64

List of keywords 67

Installation and maintenance instructions

2

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

1 General safety precautions

1.1 Particular safety instructions

1 General safety precautions

WARNING

Devices that have not been set up and

installed correctly can impair the function of the device and/or cause serious

or fatal injury to the user.

▪ Work on the HPSU compact (such

as set-up, inspection, connection

and initial commissioning) must only

be carried out by persons who are

authorised and who have successfully completed qualifying technical

or vocational training and who

have taken part in advanced training

sessions recognised by the relevant

authorities responsible for the specific activity. These include, in particular, certified heating engineers,

qualified electricians and HVAC

specialists who, because of their

professional training and expert

knowledge, have experience in the

professional installation and maintenance of heating, cooling and air

conditioning systems as well as hot

water storage tanks.

WARNING

Disregarding the following safety instructions may result in serious physical injury or death.

▪ This device must only be used by

children aged 8 and above and by

persons with restricted physical,

sensory or mental capabilities or with

a lack of experience and knowledge,

if they are under supervision or if

they have been instructed in the safe

use of the equipment and understand the dangers arising therefrom.

Children must not play with the

device. Cleaning and user mainten-

ance must not be carried out by

children without supervision.

▪ Make up the power supply in accord-

ance with IEC 60335-1, via a separator device which exhibits contact

separation in all poles with a contact

opening distance that provide full

disconnection in accordance with

overvoltage category III.

▪ All the electrical work must only be

carried out by electrically qualified

experts and with consideration of the

local and national regulations, and

the instructions in this manual.

Check that a suitable electrical circuit is being used.

Inadequate capacity of the power circuit or improperly executed connections can cause electrocution or fire.

▪ The customer must install a pressure

relief device with rated over-pressure

less than 0.6MPa (6bar). The connected drain line must have a continuous gradient and a free outlet in

a frost-free environment (seeChap.

4.3).

▪ Water may drip out of the drain line

of the pressure relief device. The

drain opening must be left free to atmosphere.

▪ The pressure relief device must be

operated regularly in order to remove scale deposits and to make

sure it is not blocked.

▪ The storage tank and hot water cir-

cuit can be drained. The instructions

in chap. must be observed.

1.1.1 Observing the instructions

▪ The original documentation is written in German. All other lan-

guages are translations.

▪ Please read this manual carefully and thoroughly before proceed-

ing with the installation or modification of the heating system.

▪ The precautionary measures described in this document cover

very important topics. Follow them meticulously.

▪ The installation of the system, and all activities described in this

manual and the applicable documents for the installer must be

carried out by an approved installer.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

3

1 General safety precautions

This manual provides all the necessary information for installation,

start-up and maintenance, as well as basic information on operation

and settings. Please see the attached documents for a detailed description of operation and control.

All heating parameters needed for smooth operation are already

factory-set. Please refer to other relevant documents for information

on setting the control.

Relevant documents

▪ HPSU compact:

▪ Installation instructions

▪ Start-up checklist

▪ Heat pump operating manual

▪ RoCon+ HP:

▪ Installation instructions

▪ Operating instructions

▪ Outdoor unit: Installation instructions

▪ Room station RoCon U1 and mixer module RoCon M1: Operating

instructions

▪ Other optional accessories and optional system components: As-

sociated installation and operating instructions

The guides are included in the scope of supply for the individual

devices.

1.1.2 Meaning of warnings and symbols

Warnings in this manual are classified according into their severity

and probability of occurrence.

DANGER

Indicates an immediate danger.

Disregarding this warning can lead to serious injury or

death

WARNING

Indicates a potentially dangerous situation

Disregarding this warning may result in serious physical injury or death.

CAUTION

Indicates a situation which may cause possible damage

Disregarding this warning can cause damage to property

and the environment, and result in minor injuries.

This symbol identifies user tips and particularly useful information, but not warnings or hazards

Special warning signs

Some types of danger are represented by special symbols:

Electric current

Danger of explosion

Risk of burning or scalding

Risk of poisoning

Validity

Some information in this manual has limited validity. The validity is

highlighted by a symbol.

Exterior heat pump unitRRGA

Heat pump indoor unitHPSU compact

HP convector

Comply with the stipulated tightening torque (see

chap.Chap. 10.3)

Only applies to devices with unpressurised solar system

connection (DrainBack).

Only applies to devices with a bivalent solar system connection (Biv).

Only valid for HPSU compact with cooling function

Handling instructions

1 Handling instructions are shown as a list. Actions for which the

sequential order must be maintained are numbered.

è

Results of actions are identified with an arrow.

1.2 Safety instructions for installation and operation

1.2.1 General

WARNING

Devices that have not been set up and installed correctly

can impair the function of the device and/or cause serious

or fatal injury to the user.

▪ Work on the HPSU compact (such as set-up, inspection,

connection and initial commissioning) must only be carried out by persons who are authorised and who have

successfully completed qualifying technical or voca-

tional training and who have taken part in advanced

training sessions recognised by the relevant authorities

responsible for the specific activity. These include, in

particular, certified heating engineers, qualified elec-

tricians and HVAC specialists who, because of their

professional training and expert knowledge, have ex-

perience in the professional installation and maintenance of heating, cooling and air conditioning systems as

well as hot water storage tanks.

▪ Switch off the external main switch before starting any

work on the HPSU compact and secure it against unintentional switch-on.

▪ Do not leave any tools or other objects below the hood

of the unit after finishing installation or maintenance

work.

Avoiding danger

HPSU compact conforms to the state-of-the-art and meets all recognised technical requirements. However, improper use may result in

serious physical injuries or death, as well as property damage. To

prevent such risks, only install and operate the devices:

▪ as stipulated and in perfect condition,

▪ with an awareness of safety and the hazards involved.

This assumes knowledge and use of the contents of this manual, of

the relevant accident prevention regulations as well as the recognised safety-related and occupational health rules.

Before working on the hydraulic system

▪ Work on the system (such as installation, connection and initial

commissioning, for example) must only be carried out by persons

who are authorised, who have successfully completed qualifying

technical or vocational training for the respective activity and who

have taken part in advanced training sessions recognised by the

relevant responsible authority.

Installation and maintenance instructions

4

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

1 General safety precautions

▪ When carrying out any work on the system, switch off the main

switch and secure against being switched on inadvertently.

▪ Seals must not be damaged or removed.

▪ Make sure that the safety valves comply with the requirements of

EN12828 when connecting on the heating side, and with the requirements of EN12897 when connecting on the domestic water

side.

1.2.2 Intended use

The HPSU compact may only be used for the preparation of hot water, as a room heating system and, depending on its design, as a

room cooling system.

The HPSU compact must be installed, connected and operated only

according to the indications in this manual.

Only the use of a suitable outdoor unit approved by the manufacturer

is permitted.

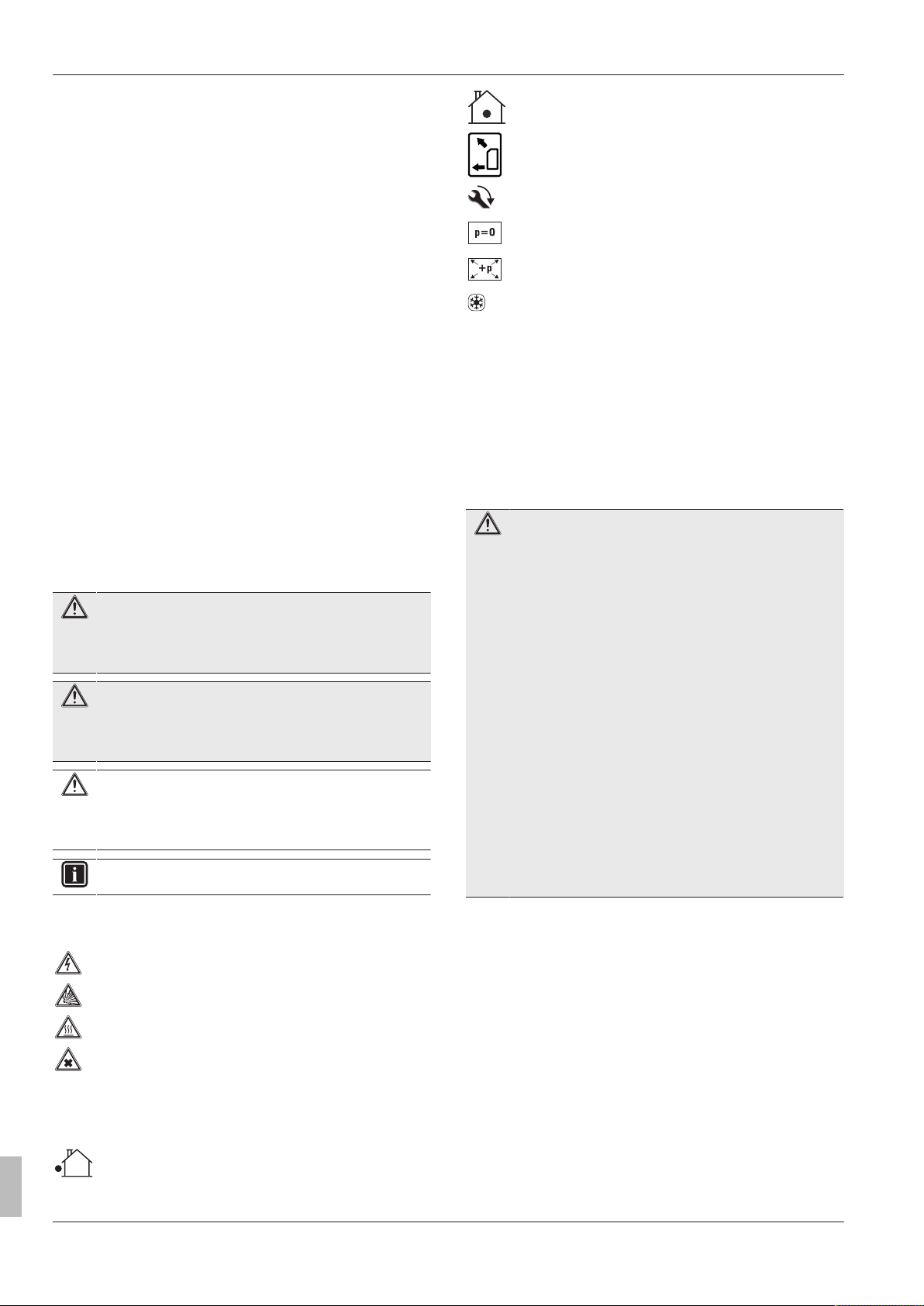

HPSU compact

RHSX04P30D

RHSX04P50D

RHSXB04P30D

RHSXB04P50D

RRGA04DAV3 P -

RRGA06DAV3 - P

RRGA08DAV3 - P

Tab.1-3 Permissible combinations

Any other use outside the intended use is considered as improper.

The operator alone shall bear responsibility for any resulting damage.

Intended use also includes compliance with the maintenance and inspection conditions. Replacement parts must at least satisfy the

technical requirements defined by the manufacturer. This is the

case, for example, with original spare parts.

RHSX08P30D

RHSX08P50D

RHSXB08P30D

RHSXB08P50D

1.2.3 Device installation room

WARNING

The plastic wall of the storage tank of the HPSU compact

can melt under the effects of external heat (>80°C) and, in

the extreme case, can catch fire.

▪ Only install the HPSU compact at a minimum distance of

1m to other heat sources (>80°C) (e.g. electrical

heater, gas heater, chimney) and combustible materials.

CAUTION

▪ Only install the HPSU compact if sufficient load-carrying

capacity of the ground of 1050kg/m2 plus safety margin

is ensured. The ground must be flat, horizontal and

level.

▪ Outdoor installation is not permissible.

▪ Installation in an explosion-risk environment is not per-

missible.

▪ The electronic control system must not be exposed to

whether effects like rain and snow under any circumstances.

▪ The storage tank may not be exposed to continuous dir-

ect sunlight, as the UV radiation and the effects of the

weather will damage the plastic.

▪ The HPSU compact must be installed protected from

frost.

▪ Make sure that the supply company does not provide

corrosive domestic water. Suitable water treatment may

be required.

▪ Always ensure the minimum distances to walls and other objects

( Chap. 4.1).

▪ Observe the special installation requirements of the R32 refriger-

ant (see Chap. 4.3.1).

CAUTION

▪ If a DrainBack solar heating system is connected:

Install the HPSU compact far enough under the solar

panels to allow complete emptying of the solar heating

system. (Follow instructions in the DrainBack solar heating system manual). An insufficient height difference

may lead to the destruction of the DrainBack solar heating system.

▪ The HPSU compact must not be operated in rooms with

ambient temperatures above 40°C.

1.2.4 Electrical installation

▪ Electrical installations may only be carried out by electrical techni-

cians and in compliance with valid electrical guidelines as well as

the specifications of the responsible energy supply company.

▪ Compare the mains voltage (230V, 50Hz) indicated on the name-

plate with the supply voltage before connecting to the mains.

▪ Before beginning work on live parts, disconnect them from the

power supply (switch off main switch, remove fuse) and secure

against unintentional restart.

▪ Device covers and service panels must be replaced as soon as

the work is completed.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

1.2.5 Requirements for the heating water

Avoid damage caused by deposits and corrosion: Comply with the

applicable engineering regulations on prevention of corrosion

products and deposits (VDI 2035, BDH/ZVSHK technical information

"Scale formation").

Minimum requirements regarding the quality of filling and supplementary water:

▪ Water hardness (calcium and magnesium, calculated as calcium

carbonate): ≤3mmol/l

▪ Conductivity: ≤1500 (ideal: ≤100) μS/cm

▪ Chloride: ≤250mg/l

▪ Sulphate: ≤250mg/l

▪ pH-values (heating water): 6.5 - 8.5

Installation and maintenance instructions

5

1 General safety precautions

Measures for desalination, softening or hardness stabilisation are

necessary if the filling and top-up water have a high total hardness

(>3mmol/l - total of the calcium and magnesium concentrations, calculated as calcium carbonate). We recommend the use of Fernox

KSK limescale and corrosion protector. For other properties deviating from the minimum requirements, suitable conditioning measures

are necessary to maintain the required water quality.

Using filling water and top-up water which does not meet the stated

quality requirements can cause a considerably reduced service life

of the device. The responsibility for this lies solely with the operator.

1.2.6 Heating system and sanitary connection

▪ Create a heating system according to the safety requirements of

EN12828.

▪ The plumbing connection must comply with the requirements of

EN12897. The requirements of the following must also be observed:

▪ EN1717 – Schutz des Trinkwassers vor Verunreinigungen in

Trinkwasser-Installationen und allgemeine Anforderungen an

Sicherheitseinrichtungen zur Verhütung von Trinkwasserverunreinigungen durch Rückfließen. Protection against pollution of

potable water installations and general requirements of devices

to prevent pollution by backflow. Protection contre la pollution

de l'eau potable dans les réseaux intérieurs et exigences

générales des dispositifs de protection contre la pollution par

retour

▪ EN61770 – Elektrische Geräte zum Anschluss an die

Wasserversorgungsanlage – Vermeidung von Rücksaugung

und des Versagens von Schlauchsätzen. Electric appliances

connected to the water mains – Avoidance of backsiphonage

and failure of hose-sets. Appareils électriques raccordés au

réseau d'alimentation en eau – Exigences pour éviter le retour

d'eau par siphonnage et la défaillance des ensembles de raccordement

▪ EN806 – Technische Regeln für Trinkwasserinstallationen

(TRWI). Specifications for installations inside buildings conveying water for human consumption. Spécifications techniques relatives aux installations pour l'eau destinée à la consummation

humaine à l'intérieur des bâtiments

▪ and, in addition, the country-specific legislation.

During operation of the HPSU compact with additional heat source,

the storage tank temperature may exceed 65°C, above all when

solar energy is used.

▪ For this reason, some form of scalding protection needs to be in-

cluded when you install the system (hot water mixing device, e.g.

VTA32).

If the HPSU compact is connected to a heating system with steel

pipes, radiators or non-diffusion-proof floor heating pipes, sludge

and chips can enter the hot water storage tank and cause blockages, local overheating or corrosion damage.

▪ To prevent possible damage, install a dirt filter or sludge separator

into the heating return flow of the system (SAS 1 or SAS 2).

▪ The dirt filter must be cleaned at regular intervals.

▪ only operate if the protective cover is installed.

The specified servicing intervals should be adhered to and inspection work must be carried out.

1.2.7 Operation

The HPSU compact:

▪ Do not operate until all installation and connection work is com-

pleted.

▪ Only operate with a completely full storage tank (Level indicator)

and heating circuit.

▪ Operate at a maximum pressure of 3bar.

▪ Only connect with a pressure reducer on the external water supply

(supply line).

▪ Only operate the with the specified quantity of coolant and the

type of coolant specified.

Installation and maintenance instructions

6

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

2 Handover to operator and

warranty

2.1 Instruct the owner

▪ Before you hand over the heating system, explain to the owner

how he/she can operate and check the heating system.

▪ Hand over the technical documentation (at least the operating in-

structions and operating manual) to the operator and advise him

that these documents must be made available at all times and be

stored in the immediate vicinity of the device.

▪ Document the handover by filling out the installation and instruc-

tion forms together with the owner and sign them.

2.2 Warranty conditions

Germany: www.rotex.de > "Warranty conditions" (via search

function)

Austria: www.daikin.at > General commercial terms and con-

ditions (WARRANTY AND LIABILITY)

Switzerland: www.domotec.ch > Documents > Download > Cata-

logue brochures > Price list… (general terms and

conditions/warranty conditions)

There is only an entitlement to warranty services when it can be certified that the annual maintenance work according to Chap. 7 has

been regularly completed.

2 Handover to operator and warranty

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

7

3 Product description

RoCon+ B1 33 26

24

10

25

A

A

6

30

5

(34)

4

(34)

3UV DHW 3UVB1

15

17

1 32 3UV DHWDS31 35 38

t

V,BH

7

39 37

3UV DHW

2

FLS

8

t

V,BHtR

3

t

V

3 Product description

3.1 Design and components

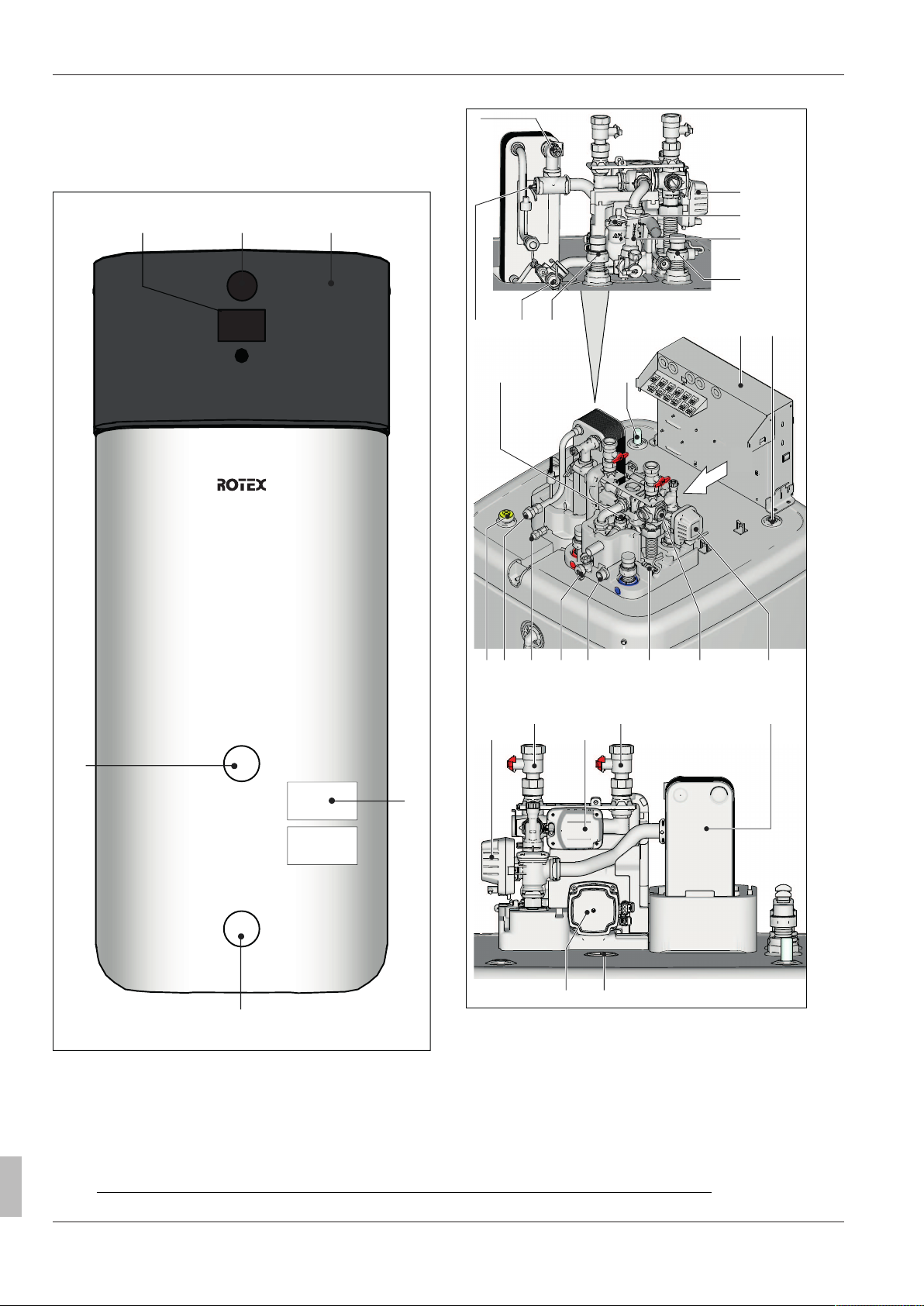

Outside of the device

Upper side of the device

Fig.3-1 Design and components - Outside of the device

Fig.3-2 Design and components - Top of the device

(1)

(1)

(1)

For legend, see Tab. 3-1

Installation and maintenance instructions

8

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

3 Product description

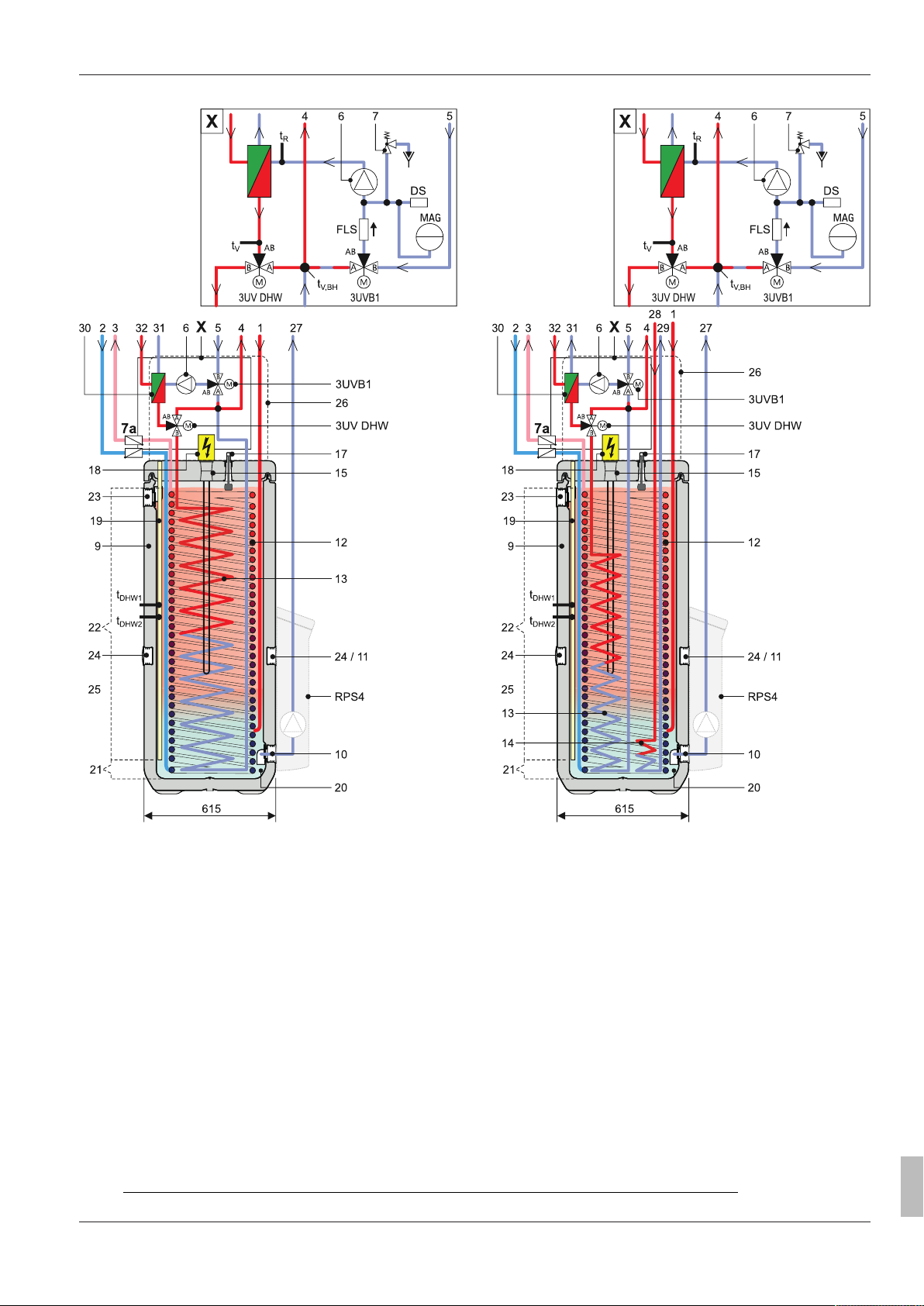

Internal structure…04P30D/…08P30D

Internal structure …B04P30D / …B08P30D (Biv)

Fig.3-3 Design and components – Internal struc-

ture ...04P30D/...08P30D

(1)

For legend, see Tab. 3-1

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

(1)

Fig.3-4 Design and components - Internal struc-

ture ...B04P30D / ...B08P30D (Biv)

Installation and maintenance instructions

(1)

9

3 Product description

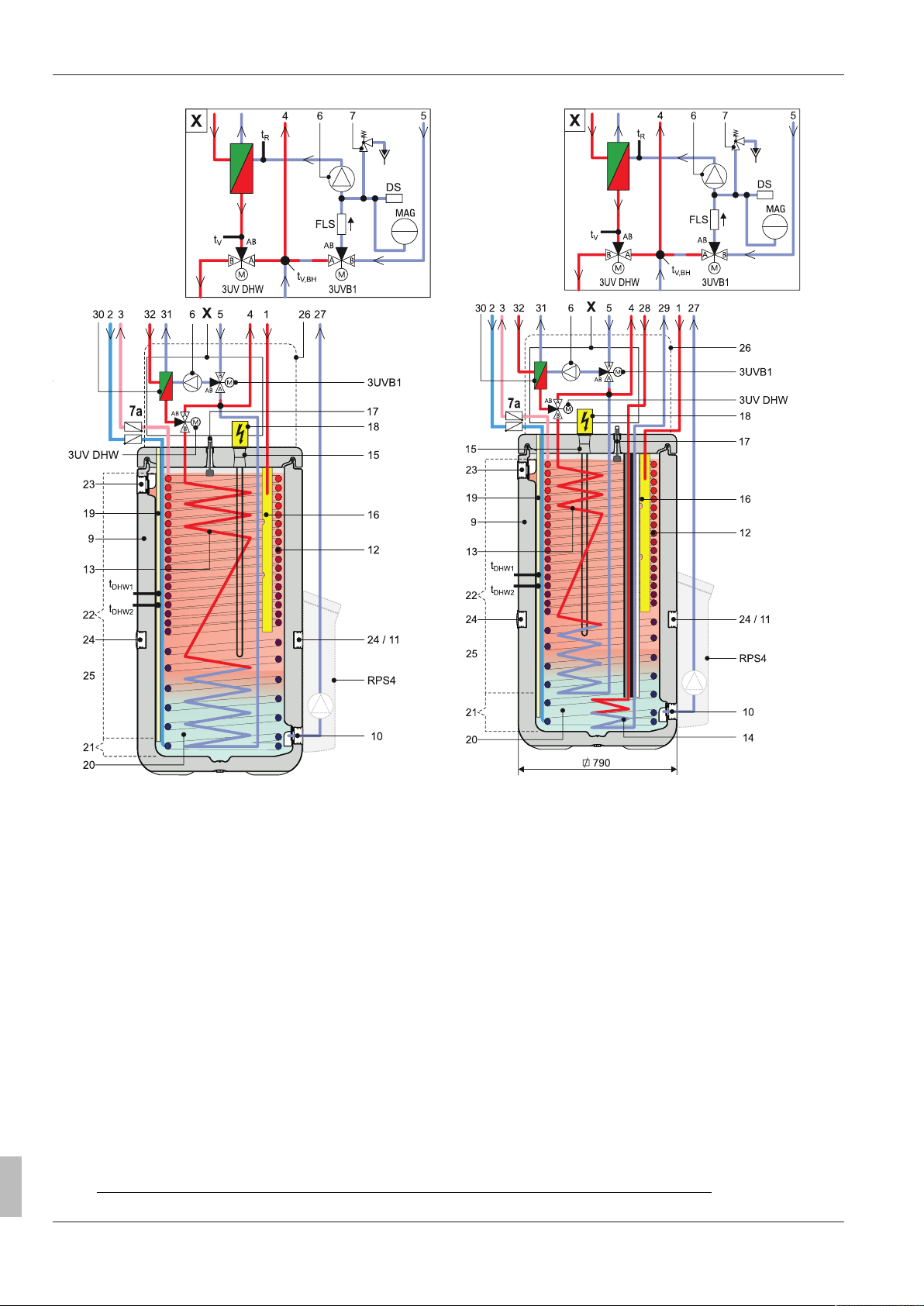

Internal structure …04P50D / …08P50D

Internal structure …B04P50D / …B08P50D (Biv)

Fig.3-5 Design and components - Internal struc-

ture ...04P50D / ...08P50D

(1)

For legend, see Tab. 3-1

Installation and maintenance instructions

(1)

10

Fig.3-6 Design and components - Internal structure …

B04P50D / …B08P50D (Biv)

(1)

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

3 Product description

Item Designation Item Designation

1 Solar inflow or connec-

25 Type plate

tion for another heat

source (BIV only)

2 Cold water connection 26 Protective cover

3 Domestic hot water 27 Solar - return flow

4 Heating inflow 28 Solar - inflow

5 Heating return flow 29 Solar - return flow

6 Circulation pump 30 Plate heat exchanger

7 Pressure relief valve 31 Connection for refrigerant

fluid line

7a Non-return valve (ac-

cessory)

32 Connection for refrigerant

gas line

8 Automatic vent valve 33 Status display

9 Storage tank (polypropyl-

ene double walled jacket

34 Ball valve (heating cir-

cuit)

with PUR hard foam heat

insulation)

10 Filling and draining con-

nection or solar return

flow connection

11 Mount for solar controller

or handle

12 Heat exchanger (stain-

less steel) for domestic

35 Combined filling and

draining valve (heating

circuit)

37

Storage tank temperature

sensor

t

,

DHW1

t

DHW2

38 Connection for dia-

phragm expansion vessel

hot water heating

13 Heat exchanger (stain-

39 Control system housing

less steel) for storage

tank charging or heating

support

14 Heat exchanger (stain-

less steel) for pressurised solar system storage

3UVB13-way switch valve (in-

ternal heat generator circuit)

charging

15 Connection for optional

electrical backup heater

3UV

3-way switch valve (hot

DHW

water/heating)

BUxx

16 Solar - inflow layering

DS Pressure sensor

pipe

17 Fill level indicator (tank

FLS FlowSensor

water)

18 Optional: electric backup

heater (BUxx)

19 Submersible sensor

sleeve for storage tank

temperature sensor t

and t

DHW2

20 Pressure-free storage

tank water

21 Solar zone RoCon

DHW1

t

Return flow temperature

R

sensor

t

Inflow temperature

V

sensor

t

Backup heater inflow

V, BH

temperature sensor

Controller control panel

+ B1

22 Hot water zone RPS4 Optional: Solar control

and pump unit

23 Safety overflow connec-

tion

MAG Diaphragm expansion

vessel

24 Mount for handle

Tab.3-1 Legend for Fig. 3-1 to Fig. 3-6

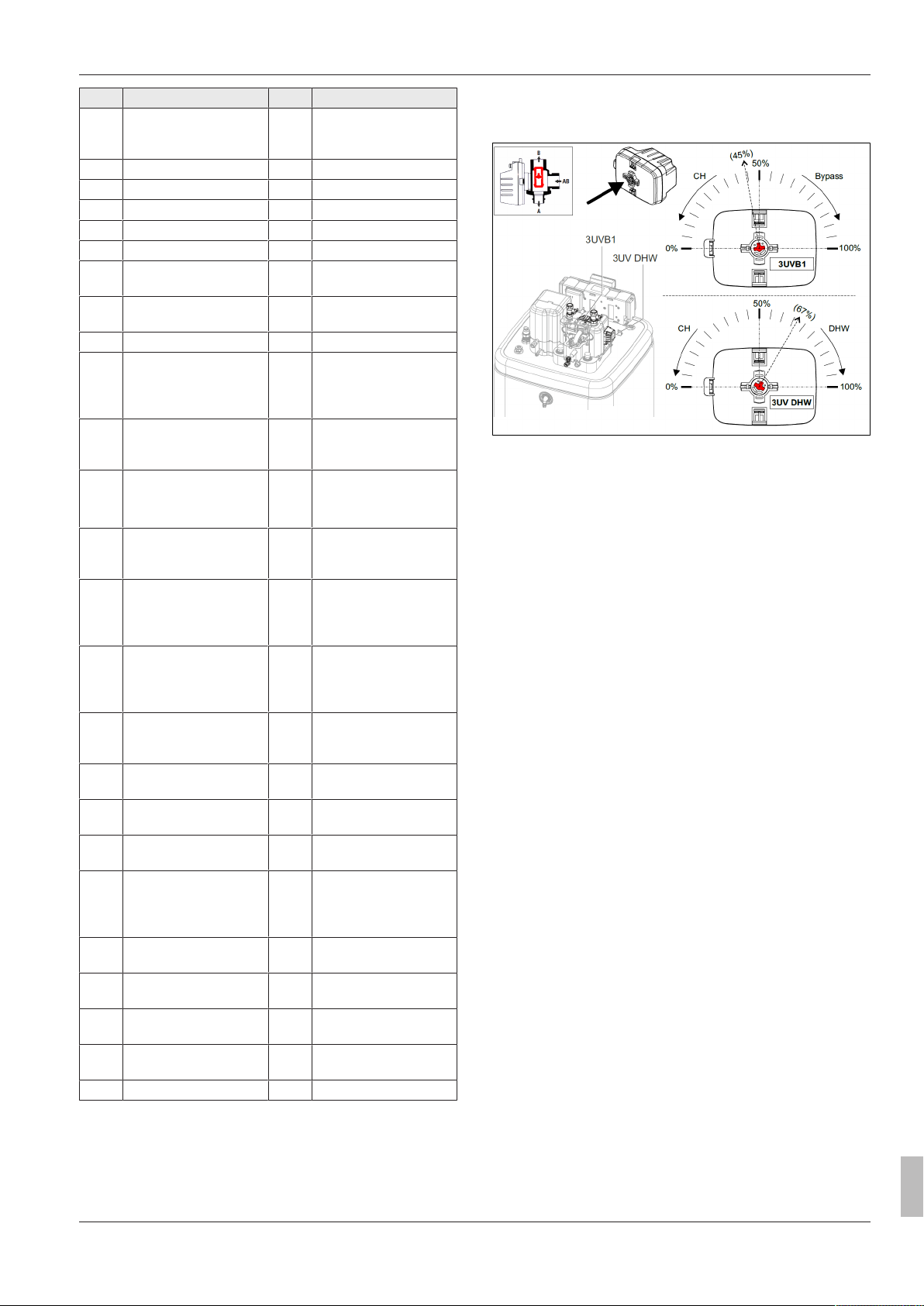

3.2 Function of the 3-way switch valves

Fig.3-7 3-way switch valve function

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

11

4 Set-up and installation

0

B

45

161

0

183

334

490

1770

1380

1659

1565

642

0 0

1599

1905

4 Set-up and installation

WARNING

Cooling systems (heating pumps), climate control systems

and heating devices that have been set up and installed incorrectly can both endanger human life and health and be

impaired in their function.

▪ Work on the HPSU compact (such as installation, repair,

connection and initial commissioning, for example) must

only be carried out by persons who are authorised, who

have successfully completed qualifying technical or vocational training for the respective activity and who have

taken part in advanced training sessions recognised by

the relevant responsible authority. These include, in particular, certified heating engineers, qualified electricians

and HVAC specialists who, because of their professional

training and expert knowledge, have experience in the

professional installation and maintenance of heating,

cooling and air conditioning systems and heat pumps.

Incorrect set-up and installation would render the manufacturer's

guarantee void. If you have questions, please contact our Technical

Customer Service.

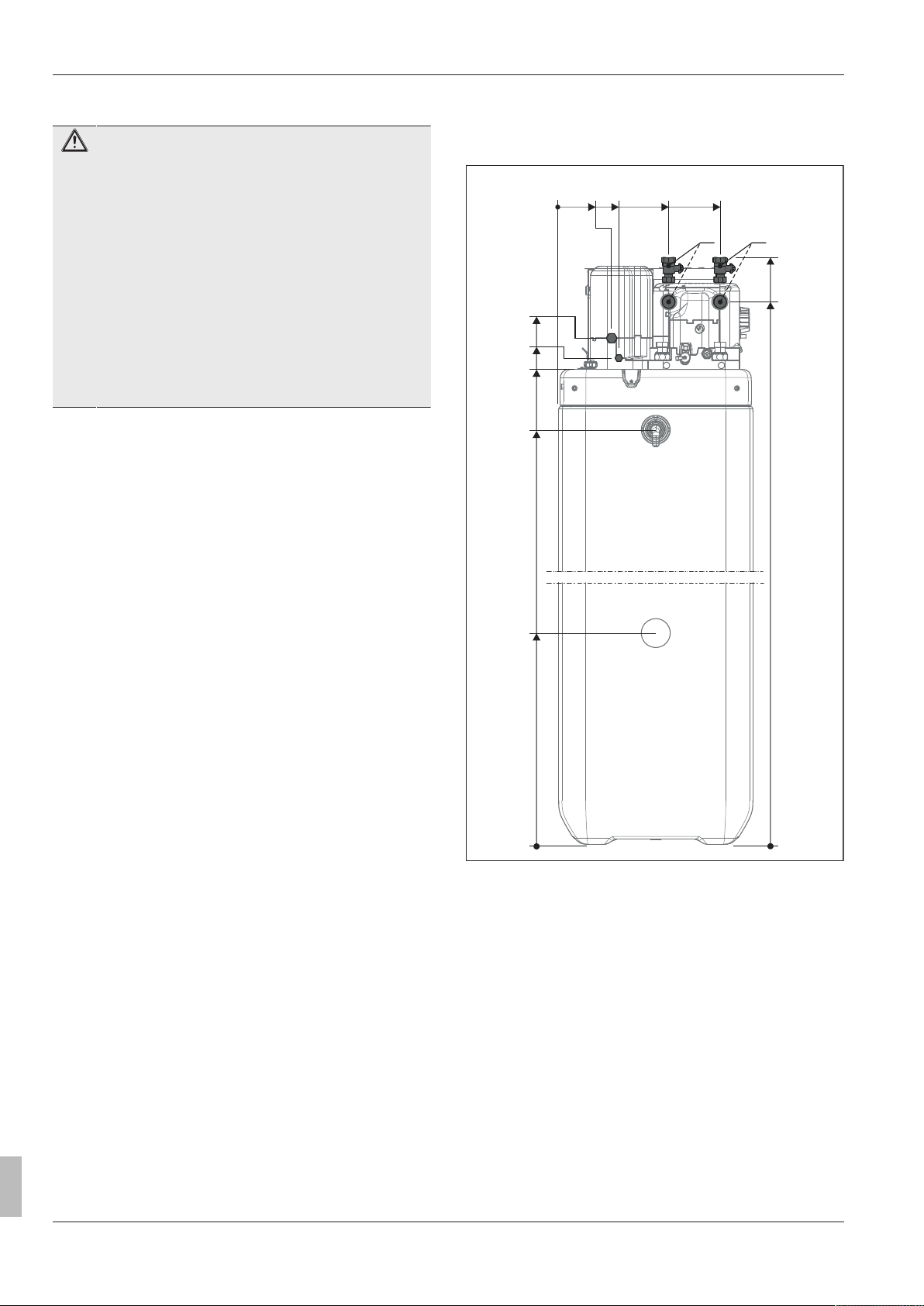

4.1 Dimensions and connection dimensions

Dimensions …04P30D/…08P30D

Fig.4-1 Dimensions, side view - …04P30D/…08P30D

Installation and maintenance instructions

12

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

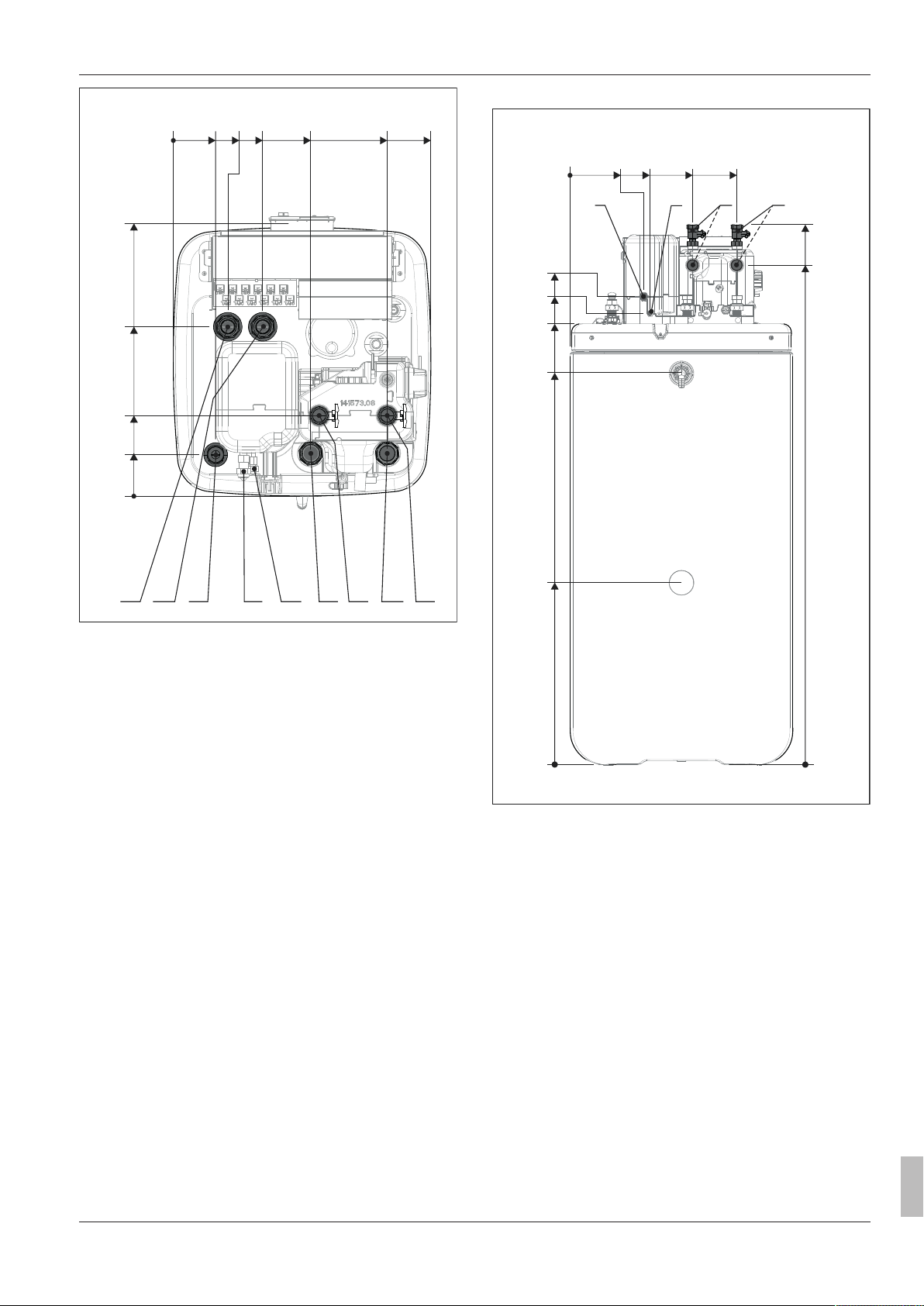

4 Set-up and installation

0

125

315

490

590

9

7

5

26

A

B

418

3

0

388

615

±5

95

97

184

205

259

0

280

432

588

1651

1591

1555

B

1380

642

0

0

1762

1905

45

7

6

Dimensions …04P50D/…08P50D

Fig.4-2 Dimensions, top of the device - Type …04P30D/…

08P30D

Fig.4-3 Dimensions, side view - Type …04P50D/…08P50D

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

13

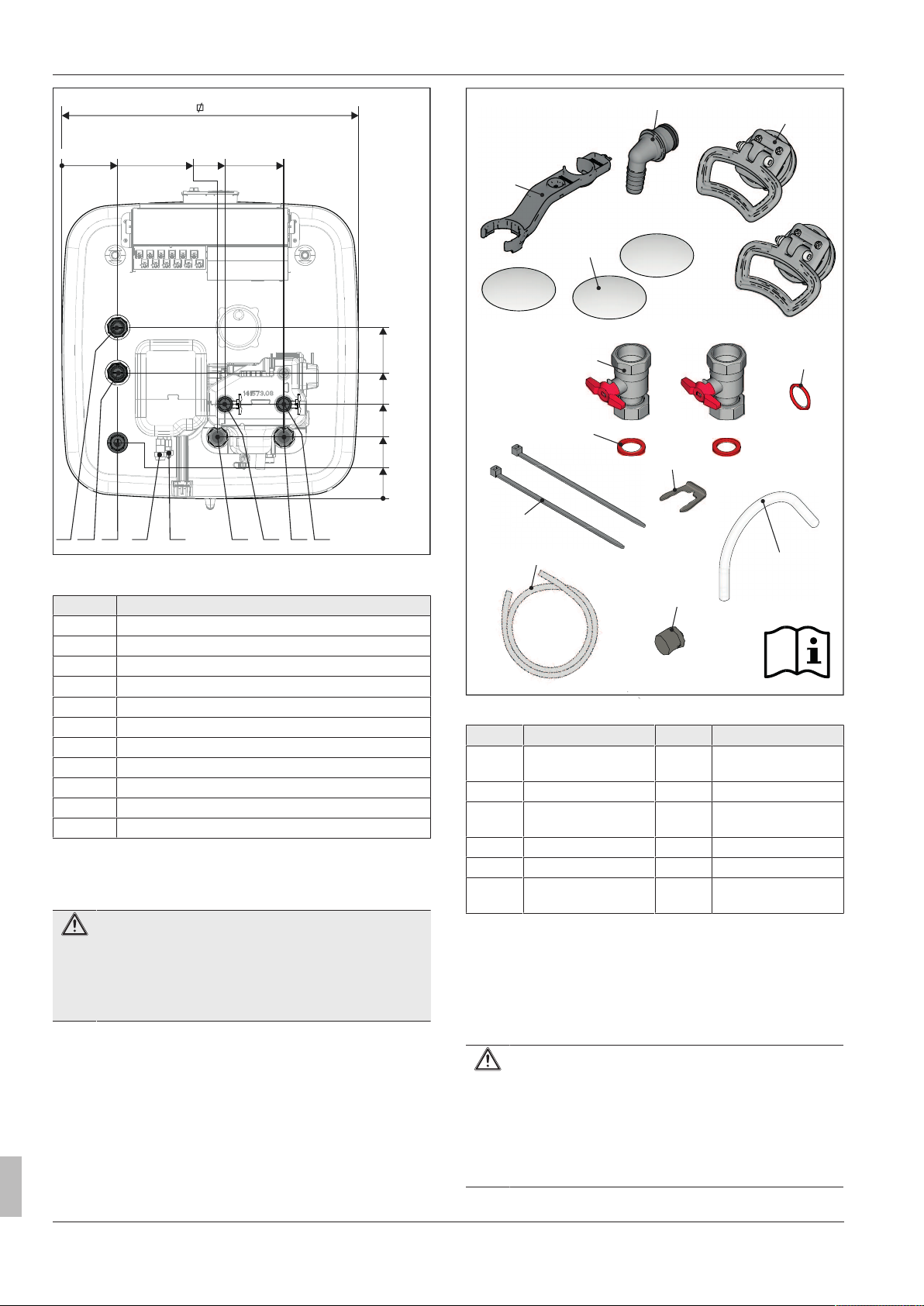

4 Set-up and installation

587,5

0

432

412,5

147,5

9 8

21

45

3

A

B

6 7

785

0

249

332,5

452,5

162,5

147,5

A (2x)

B (3x)

C (1x)

D (1x)

E (2x)

H (2x)

F (2x)

G (1x)

I (1x)

J (1x)

K (1x)

L (1x)

Fig.4-4 Dimensions, top of the device - Type …04P50D/…

Item Designation

1 Solar - inflow

2 Cold water

3 Domestic hot water

4 Heating inflow

5 Heating return flow

6 Connection for refrigerant gas line

7 Connection for refrigerant fluid line

8 Solar – inflow (…Biv type only)

9 Solar – return flow (…Biv type only)

A front

B rear

Tab.4-1

4.2 Transport and delivery

The HPSU compact is delivered on a pallet. All industrial trucks,

such as lifting trucks and forklift trucks, are suitable for transporting

it.

Scope of delivery

▪ HPSU compact (preassembled),

▪ Bag of accessories (see Fig. 4-5),

▪ Document pack.

08P50D

WARNING

The HPSU compact is top-heavy in the unfilled state and

could tip over during transport. That could put persons in

danger or damage the unit.

▪ Secure the HPSU compact well, transport carefully, use

the handles.

Installation and maintenance instructions

14

Fig.4-5 Contents of bag of accessories

Item Designation Item Designation

A Handles (only required

for transport)

B cover panel H Cable tie

C Hose connecting piece

for safety overflow

D Assembly wrench J Venting hose

E Ball valve K Drain hose cover

F Flat gasket L RoConPlus controller

Tab.4-2

For further accessories for the HPSU compact, see Price list.

G O-ring

I Plug bracket

rotary switch

4.3 Installing the heat pump

4.3.1 Selecting the installation site

CAUTION

If the total refrigerant charge in the system is ≥ 1.84kg, it is

essential to comply with additional requirements for minimum footprint and minimum ventilation openings. ObserveChap. 10.4.

Information on the total refrigerant charge can be found on

the type plate of the outdoor unit. Please follow the installation instructions.

HPSU compact

008.1444444_00 – 06/2018 – EN

HPSU compact Ultra

4 Set-up and installation

The installation site of the HPSU compact must meet the minimum

requirements below (see alsoChap. 1.2.3).

Installation area

▪ The base must be level and smooth and have a sufficient ground

load-bearing capacity of 1050kg/m² plus safety factor. Install a

pedestal if necessary.

▪ Observe the installation dimensions (see Chap. 4.1).

Minimum distance

DANGER: RISK OF BURNING

The plastic wall of the storage tank of the HPSU compact

can melt under the effects of external heat (>80°C) and, in

the extreme case, can catch fire.

▪ Only install the HPSU compact with a minimum distance

of 1m to other heat sources (>80°C) (e.g. electrical

heater, oil heater, chimney) and the material to be combusted.

CAUTION

If the HPSU compact is not installed a sufficient

distance below the flat solar panels (the top edge of the

storage tank is higher than the bottom edge of the solar

panels), the unpressurised solar system in the outdoor

area will not be able to drain completely.

▪ When a solar connection is used, install the HPSU com-

pact low enough at the flat solar panels (observe minimum gradient in the solar connection lines).

Recommended minimum distances:

To the wall: (back) ≥100mm, (sides) ≥500mm

To the ceiling: ≥1200mm, at least 480mm.

Installation

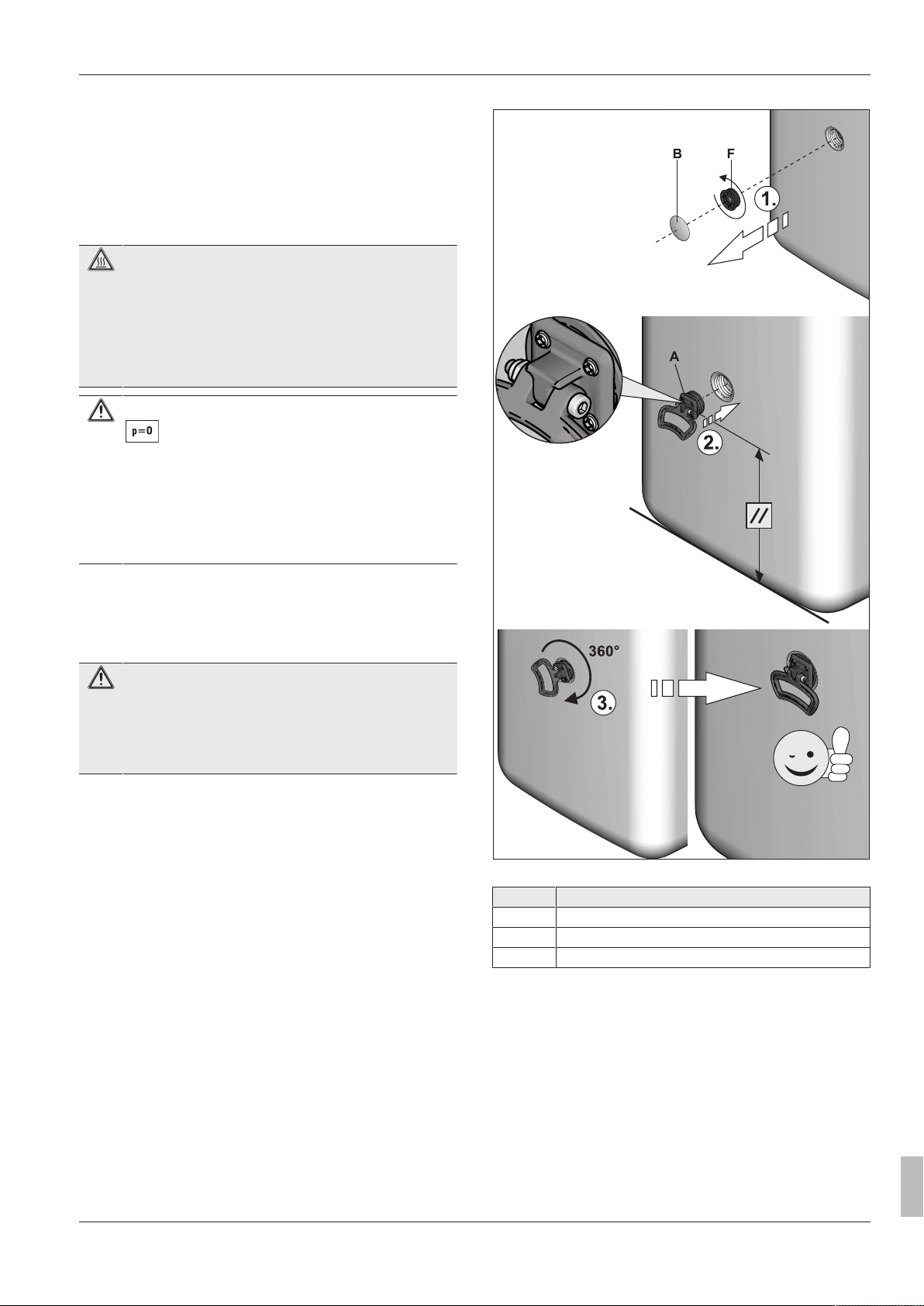

4.3.2 Installing the device

WARNING

The HPSU compact is top-heavy in the unfilled state and

could tip over during transport. That could put persons in

danger or damage the unit.

▪ Secure the HPSU compact well, transport carefully, use

handles.

Precondition

▪ The installation site complies with applicable country-specific reg-

ulations and meets the minimum requirements described in Chap.

4.3.1.

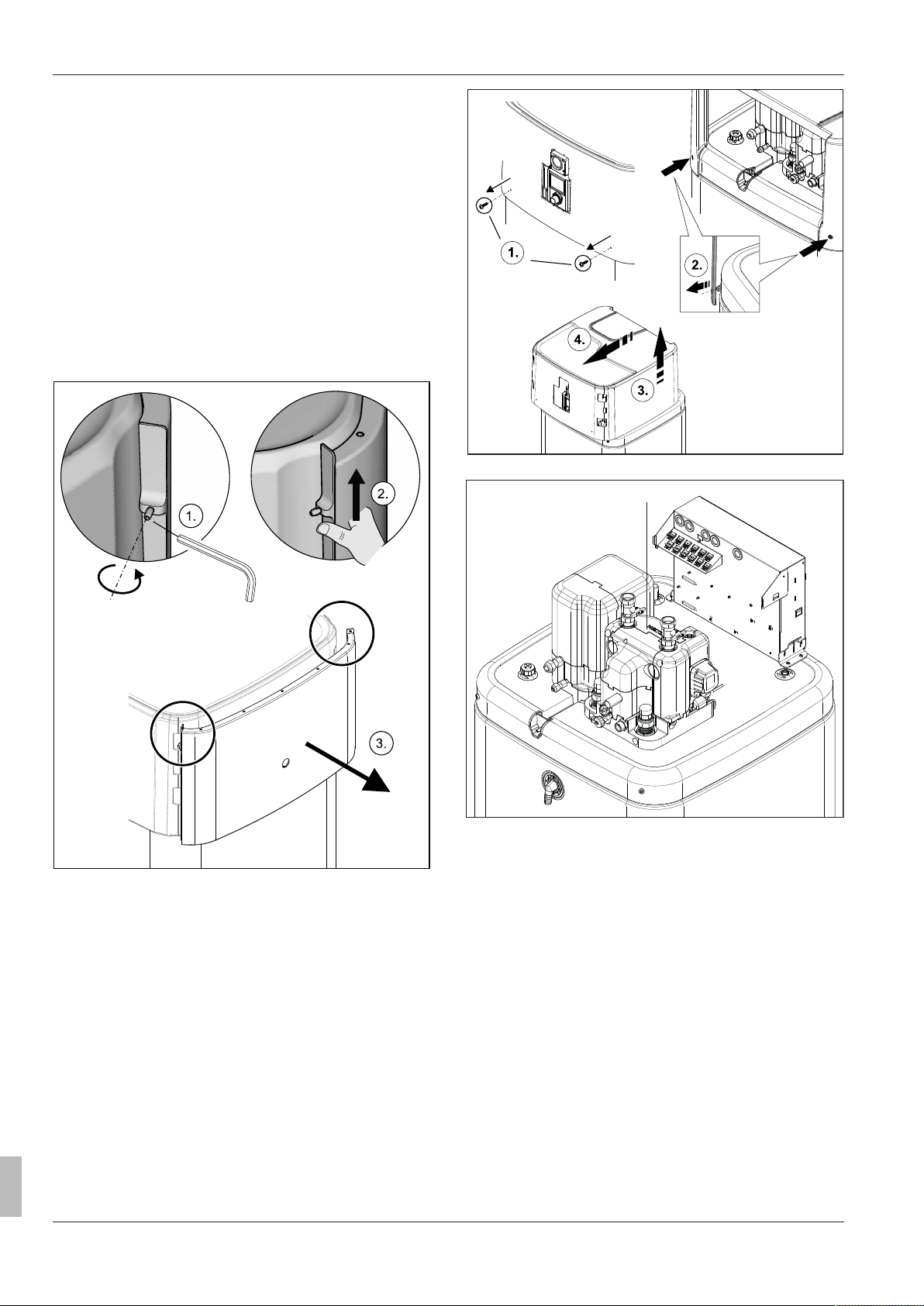

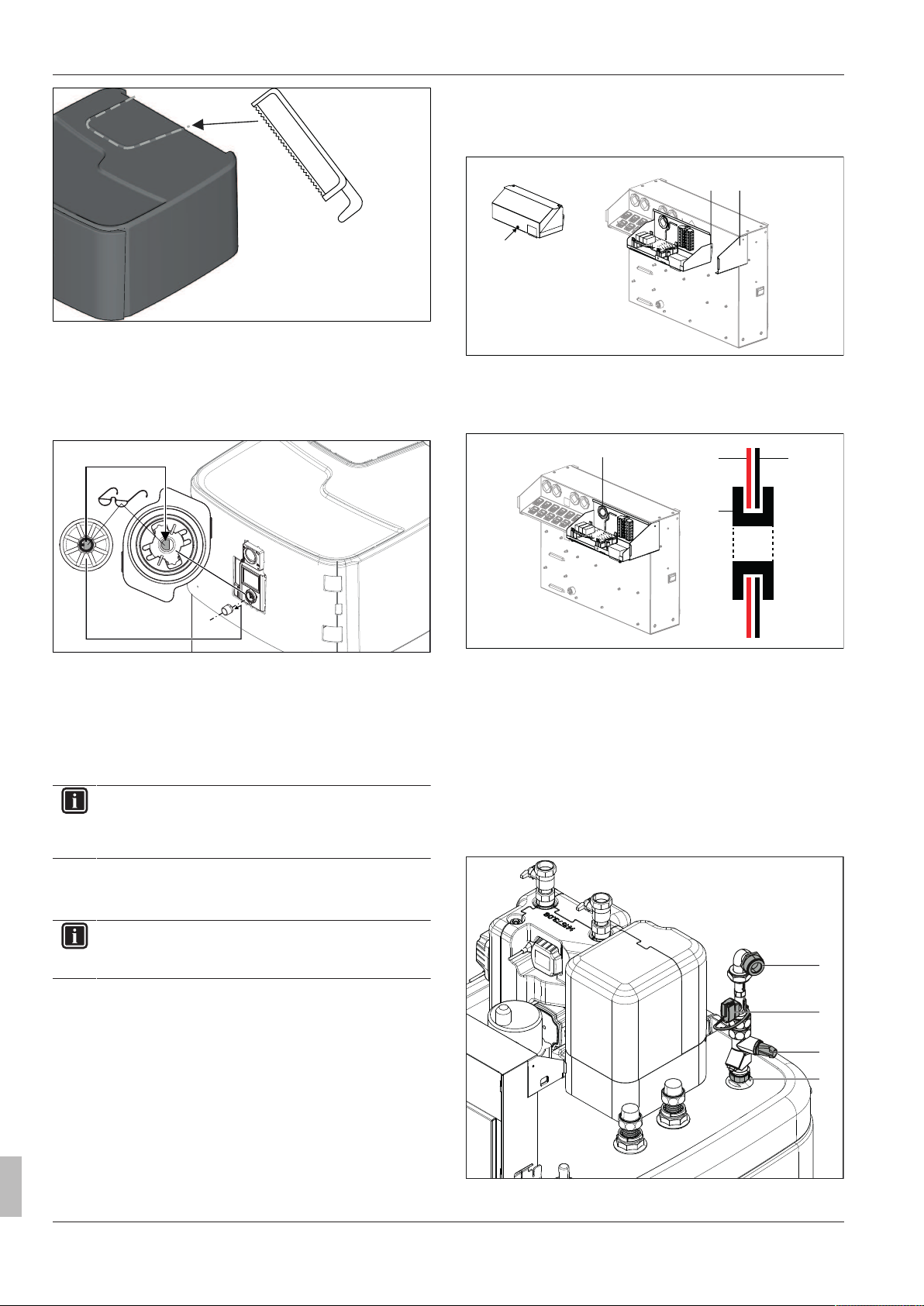

Fig.4-6 Installing the handles

Item Designation

A Handle

B cover panel

F Threaded piece

Tab.4-3

1 Remove packing and dispose of it in an environment-friendly

manner.

2 Pull off the cover screens from the storage tank (Fig. 4-6, itemB)

and unscrew the threaded fittings (Fig. 4-6, itemF) from the

openings at which the handles are to be fitted.

3 Screw the handles (Fig. 4-6, itemA) into the now uncovered

threaded holes.

4 Carefully transport the HPSU compact to the installation site,

use the handles.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

15

4 Set-up and installation

A

5 Installing the HPSU compact at the installation site.

▪ When setting up the unit in a cabinet, behind panels or in other

restricted conditions, ensure sufficient ventilation (e.g. using

ventilation gratings). If the total refrigerant charge in the system

is ≥ 1.84kg, further requirements of the ventilation openings

must be met (see Chap. 10.4).

4.4 Preparing the device for installation

4.4.1 Remove the front screen

1 Undo the screws (1.).

2 Press the lateral holding burls upwards with your fingers (2.),

stem from above with the thumbs.

3 Remove the front screen to the front (3.).

Fig.4-8 Remove the protective cover

Fig.4-7 Remove the front screen

4 After completing the installation: Place the front screen

straight directly above the rotary switch of the RoCon+ HP.

Press on the top and bottom until the front screen is securely engaged again.

4.4.2 Remove the protective cover

1 Undo the screws (1.).

2 Unhook the protective cover from the rearward facing holding

burls (2.), lift at the back (3.) and remove to the front (4.).

Installation and maintenance instructions

16

Fig.4-9 Without protective cover

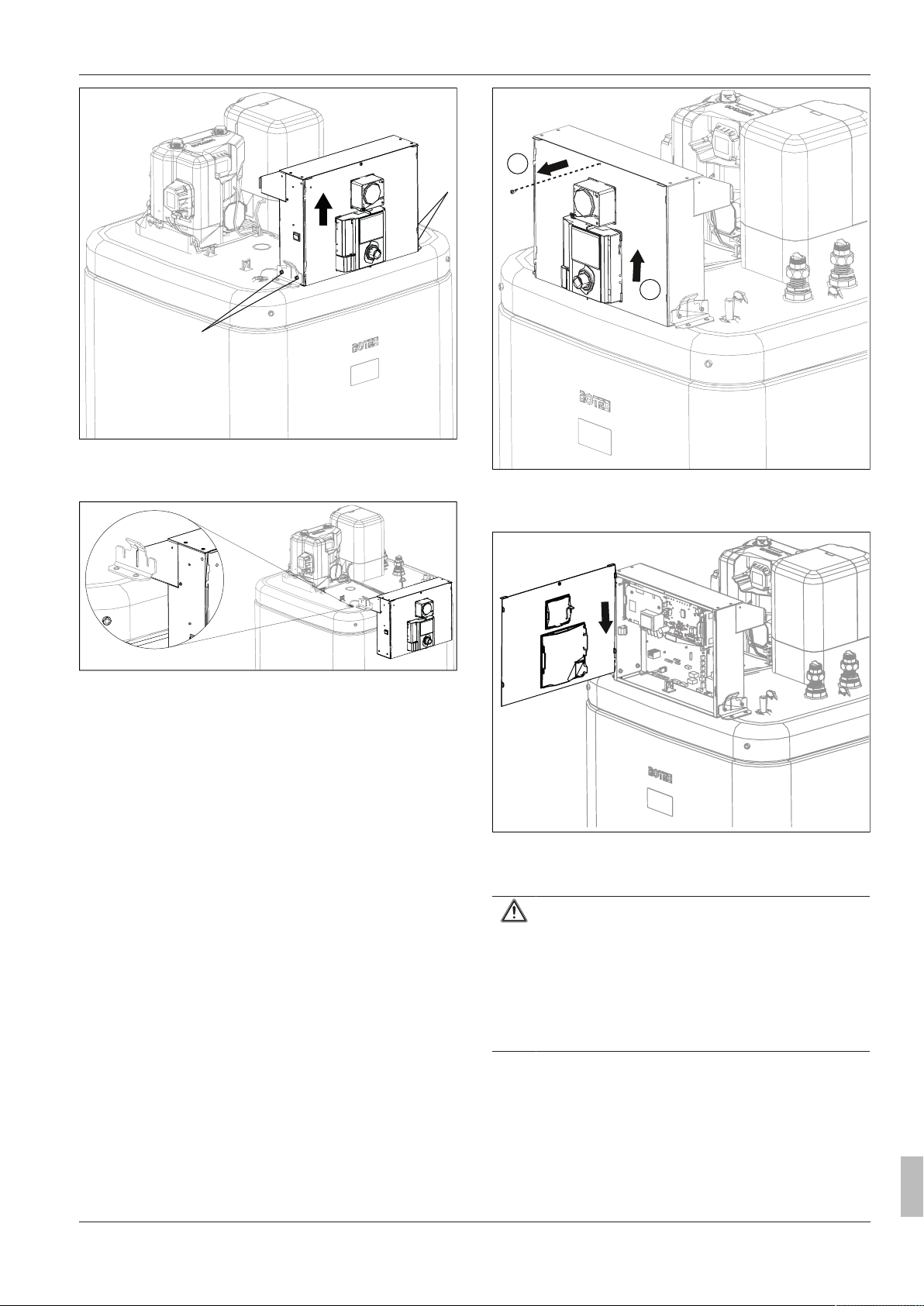

4.4.3 Moving the controller housing to the service position

To facilitate work on the hydraulics of the HPSU compact, the control

box can be moved to the service position.

1 Loosen the screws (1) of the holder of the controller housing.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

1

1

Fig.4-10 Moving the controller housing to the service position

1

2

2 Remove the controller housing from the front and insert it into

the bracket with the hooks on the rear brackets.

4 Set-up and installation

Fig.4-12 Open the controller housing

3 Hook in the cover on the controller housing with the lateral

hooks.

Fig.4-11 Controller housing in the service position

4.4.4 Open the controller housing

To make the electrical connections, the controller housing itself must

be opened. This can be done in both the normal and the service position.

1 Loosen the front screw.

2 Push the cover upwards and pull it away to the front.

Fig.4-13 Hooking in the cover

4.4.5 Removing the bottom thermal insulation

CAUTION

The thermal insulation (Fig. 4-9, itemA) consists of pressure-sensitive EPP moulded parts that can be easily damaged if not handled correctly.

▪ Only remove the thermal insulation in the order stated

1 Remove the thermal insulation in the following order:

below and in the stated directions.

▪ Do not use force.

▪ Do not use tools.

▪ Pull the side insulating element off horizontally (itemA).

▪ Pull the rear insulating element off horizontally (itemB).

▪ Pull the front insulating element off horizontally (itemC).

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

17

4 Set-up and installation

A

B

C

A

B

Fig.4-14 Removing the top thermal insulation

2 As required: Remove the bottom thermal insulation in the fol-

lowing order:

▪ Pull the side insulating element off vertically (itemA).

▪ Pull the rear insulating element off vertically (itemB).

Fig.4-16 Opening the vent valve

4.4.7 Aligning the connections of the heating inflow and return flow

CAUTION

When working on the hydraulics, pay attention to the installation position of the O-rings to avoid damaging them

and causing leaks.

▪ Always place O-rings on the part to be inserted after dis-

assembly or before assembly (see Fig. 4-18).

▪ The heating lines must be connected free of tension via

the plug connectors. Establish a suitable strain relief especially when connecting with flexible lines (not open to

diffusion!) (see ).

Fig.4-15 Removing the bottom thermal insulation

INFORMATION

The thermal insulation is installed in reverse order.

4.4.6 Opening the vent valve

1 Removing the thermal insulation (see Chap. 4.4.5).

2 Open the vent valve on the pump by one turn.

CAUTION

If the plug brackets cannot be put on properly, the couplings can be detached from their mountings to ensure a

very strong or continuous escape of liquid can occur.

▪ Before putting on a plug bracket, make sure that the stir-

rup engages in the coupling groove. To do so, insert the

coupling far enough into the mounting that the groove is

visible through the plug bracket mounting.

▪ Insert the plug bracket up to the end stop.

The connections of the heating inflow and return flow can be directed upwards or backwards in order to adapt it optimally to the structural conditions of the installation site.

The device is supplied with upwards aligned connections as standard. The following conversion steps are required in order to direct

the connections to the rear out of the device:

1 Remove the protective cover and top thermal insulation

(seeChap. 4.4.2).

Installation and maintenance instructions

18

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

4 Set-up and installation

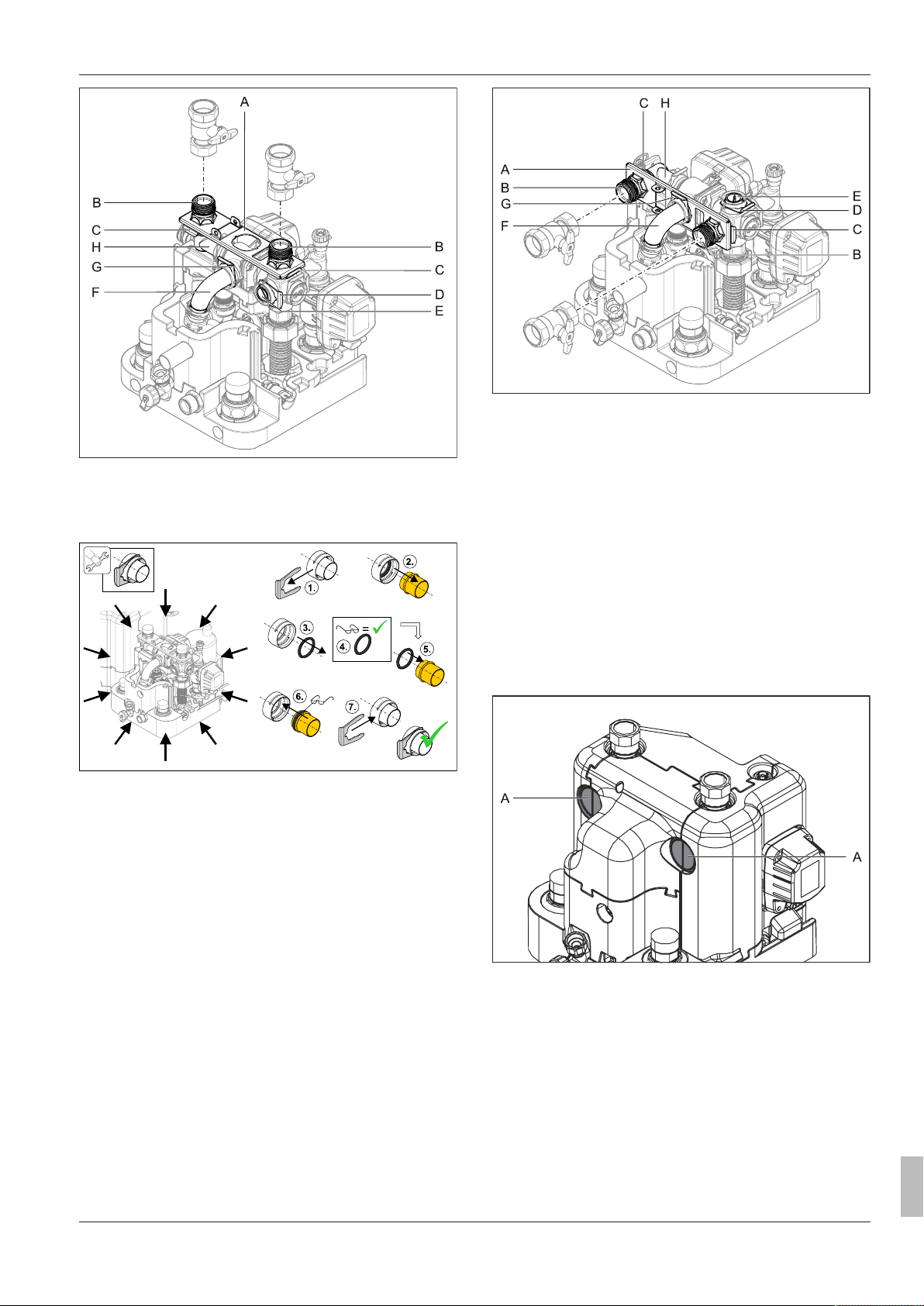

Fig.4-17 Aligning the heating inflow and return flow upwards

2 Pull the two plug brackets off the connection couplings (Fig.

4-17, itemC).

3 Pull off the two connection couplings (Fig. 4-17, itemB).

Fig.4-18 Hydraulic system plug connectors

4 Remove the retaining plate (Fig. 4-17, itemA).

5 Pull off the sealing plug bracket (Fig. 4-17, itemD).

6 Pull out the sealing plug (Fig. 4-17, itemE).

7 Turn the elbow (Fig. 4-17, itemH) 90° to the rear.

8 Pull the plug bracket off the manifold (Fig. 4-17, itemG).

9 Carefully pull the manifold (Fig. 4-17, itemF) so far backwards

out of its horizontal mounting that the retaining plate (Fig. 4-19,

itemA) can be pushed vertically in between.

Fig.4-19 Heating inflow and return flow connections aligned to the

rear

10 Slide the retaining plate between the manifold and its horizontal

mounting and insert the manifold (Fig. 4-19, itemF) back into its

mounting through the middle hole of the retaining plate.

11 Secure the manifold with plug bracket (Fig. 4-19, itemG) in its

mounting again.

12 Insert the two connection couplings (Fig. 4-19, itemB) into the

lateral mountings through the retaining plate.

13 Secure the two connection couplings with plug bracket (Fig.

4-19, itemC) in their mountings.

14 Insert the sealing plug (Fig. 4-19, itemE) into the upper mount-

ing.

15 Secure the sealing plug with plug bracket (Fig. 4-19, itemD).

16 Cut out side openings in the thermal insulation (Fig. 4-20,

itemA) using a suitable tool.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Fig.4-20 Cut-out in thermal insulation

4.4.8 Making the hood opening

1 With the heating inflow and return flow directed upwards: Cut the

hood along the perforation with a suitable tool.

Installation and maintenance instructions

19

4 Set-up and installation

1 2

3

A B

3

A

D

B

C

Fig.4-21 Making the hood opening

3 Attach the connection set to the controller housing of the HPSU

compact. To do this, insert the hooks (1) of the connection set

into the slots of the controller housing (2); then press the connection set downwards.

4.4.9 Installing the rotary switch of the controller

1 Place the rotary switch on the rotary switch holder of the RoCon

+ HP and press it on.

Fig.4-22 Putting on the rotary switch

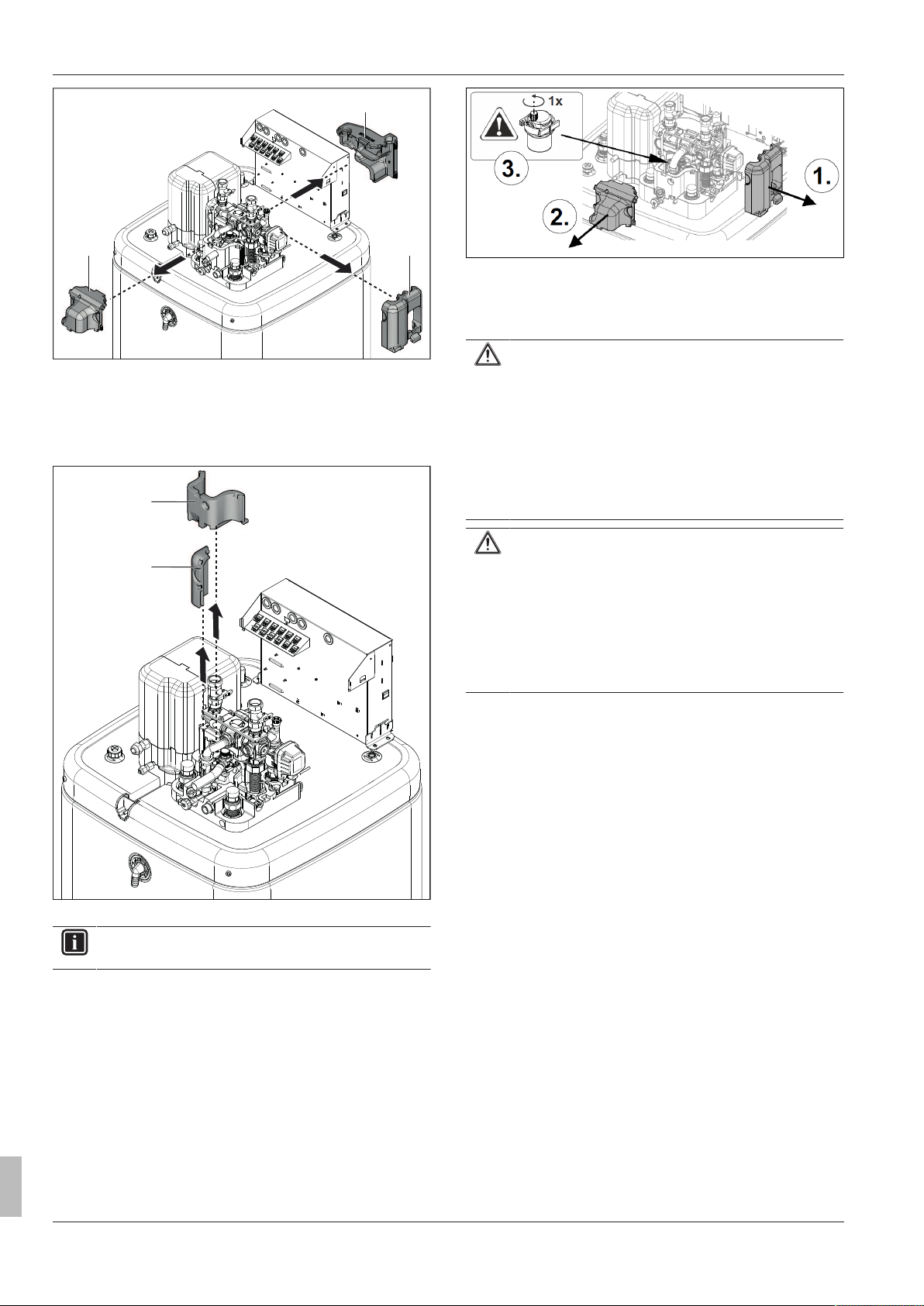

4.5 Installing optional accessories

4.5.1 Installation of the electric backup heater

(BUxx)

INFORMATION

If the ceiling height is low, the storage tank must be tilted to

install the backup heater when empty. This must be done

before any further installation steps.

The HPSU compact provides the option of installing an electrical

auxiliary heater (backup heater BUxx). For example, renewable energy can be used as an additional heat source.

Fig.4-23 Fitting the connection set

4 Attach the grommet (3) to the bushing between the connection

set (A) and the controller housing (B). Make sure that the grommet surrounds both plates.

Fig.4-24 Cable gland

5 Guide the cable of the Ultra EHS printed circuit board through

the cable grommet and connect it to the RoCon BM2C (see Fig.

4-38).

6 After the installation and the electrical connections (see Chap.

4.6or Chap. 4.7) have been completed, replace the cover and

close it with the screw.

4.5.3 Installation of the DB connection kit

The optional DB connection kit allows better access for connecting

the DrainBack pipe (solar inflow).

INFORMATION

A separate manual containing instructions about installation and operation is included with this component.

4.5.2 Installation of the external heat generator connection set

The connection set for external heat generators must be installed to

control an electrical backup heater or another external heat generator.

1 Open the housing by removing the screw.

2 Remove additional components from the housing (strain relief

clip, cable tie, grommet).

Installation and maintenance instructions

20

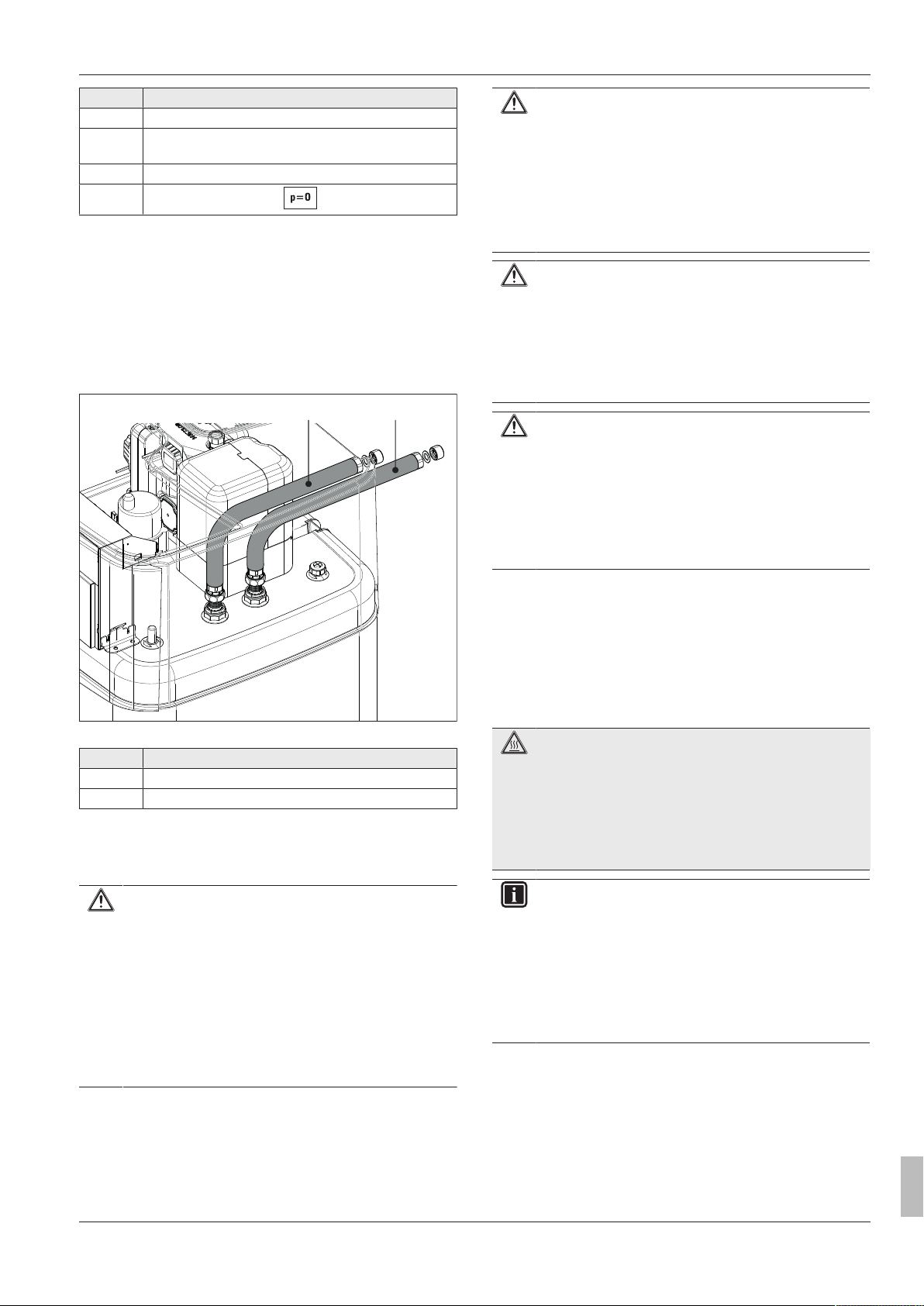

Fig.4-25 DB connection kit

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

4 Set-up and installation

AB

Item Designation

A DB pipe connection (solar inflow)

B FlowSensor (not part of the DB connection kit, but in-

cluded with RPS4)

C Flow rate limiter (FlowGuard)

D

Tab.4-4

Solar - inflow connection on the storage tank

4.5.4 Installation of the P connection kit

The optional P connection kit for Biv device types allows better access for connecting the inflow and return flow lines of a pressurised

solar system or another external heat generator on the storage tank.

The kit contains two thermally insulated corrugated pipes that are

connected to the connections of the storage tank via a union nut. At

the other end of the corrugated pipes there is an adapter for different

connection sizes of the inflow and return flow lines.

CAUTION

If the HPSU compact is connected to a cold water line

where steel pipes are used, chips can get into the stainless

steel corrugated pipe heat exchanger and remain there.

This can lead to contact corrosion damage and subsequently to leakage.

▪ Flush the feed pipes before filling the heat exchanger.

▪ Install the dirt filter in the cold water supply (e.g. SAS 1

or SAS 2).

CAUTION:BIV ONLY

If the heat exchanger for pressurised solar system charging (see Chap. 4.1, items8+ 9) is connected to an ex-

ternal heater (e.g. wood-burning boiler), the HPSU compact can be damaged or destroyed due to an excessively

high inflow temperature at these connections.

▪ The inflow temperature of the external heating unit

should be limited to max. 95°C.

CAUTION

Corrosion may be caused by air entering the heating water

network and by a quality of the heating water that does not

comply with the requirements in accordance with Requirements for the heating water. Corrosion products (particles)

thus created may clog pumps and valves and cause malfunctions.

▪ Device may not be connected by permeable, flexible

lines.

▪ For potable water lines, observe the provisions of EN806,

DIN1988 and the additional applicable national regulations for

potable water installation.

▪ Install the HPSU compact close to the withdrawal point to dis-

pense with the need for a circulation line. If a circulation line is

mandatory, it must be installed according to the schematic diagrams in Chap. 6.1.

Fig.4-26 P connection kit for Biv device types

Item Designation

A Connection for inflow (red)

B Connection for return flow (blue)

4.6 Water connection

Important information

CAUTION

If the HPSU compact is connected to a heating system

with steel pipes, radiators or non-diffusion-proof floor

heating pipes, slurry and swarf could enter the hot water

storage tank and cause blockages, local overheating or

corrosion damage.

▪ Rinse supply lines before filling the device.

▪ Rinse out the heat distribution network (in the existing

heating system).

▪ Install a dirt filter or sludge separator in the heating re-

turn flow (see chap.).

4.6.1 Connecting hydraulic lines

DANGER: RISK OF BURNING

There is a danger of scalding at hot water temperatures

over 65°C. This is possible when using solar energy if an

external heater is connected, the Legionella protection is

activated, or the target hot water temperature is set to be

greater than 65°C.

▪ Install a scalding protection (hot water mixer device (e.g.

VTA32)).

INFORMATION

The HPSU compact is equipped with a pressure sensor.

The system pressure in monitored electronically and can

be displayed with the device switched on.

Nevertheless, we recommend installing a mechanical pressure gauge between the HPSU compact and the diaphragm expansion vessel, for example.

▪ Install the pressure gauge so that it is easy to see when

filling.

1 Check the cold water connection pressure (maximum 6bar).

▪ If a higher pressure is present in the domestic water pipe, a

pressure reducer will need to be installed.

2 Fix the hydraulic block in place with a screwdriver.

HPSU compact

HPSU compact Ultra

008.1444444_00 – 06/2018 – EN

Installation and maintenance instructions

21

Loading...

Loading...