Daikin RCS 06F, RCS 20F Installation Manual

© 2013 Daikin Applied

Installation Manual IM 962-2

Group: Applied Air Systems

Air-Cooled Split System Condensing Units

Models RCS 06F – 20F

6.5 to 20 Tons

R-410A Refrigerant

Part Number: IM 962-2

Date: August 2013

15.0 – 20.0 Tons

6.5 – 7.5 Tons

10.0 – 12.0 Tons

Table of Contents

Introduction .................................3

Hazard Identication Information ................3

Checking Product Received ....................3

Standard Unit Features .......................4

Dimensional and Weight Data ..................6

Physical Data ................................8

Unit Capacity and Physical Data . . . . . . . . . . . . . . . . 8

Electrical Data ...............................9

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation .................................10

Order Parts ...............................10

Standard Items .............................10

Crankcase Heaters .........................10

Corrosive Environment ......................10

Installation General .........................10

Rooftop Installation ..........................11

Slab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation of Piping .........................12

Typical Piping Recommendations ..............12

Electrical Wiring ............................14

Refrigerant Charge ..........................16

Evaporator Coil ............................17

Evacuation and Charging .....................17

Final Leak Testing ..........................18

Accessory Installation .......................19

Maintenance and Operation ...................20

Charging Charts ............................21

Wiring Diagrams ............................27

Service and Warranty Procedure ...............29

Replacement Parts .........................29

In-Warranty Return Material Procedure ..........29

Warranty Registration Form ...................30

Quality Assurance Survey Form................32

2 IM 962-2

Hazard Identication Information

DANGER

The use of unauthorized components, accessories or devices

may adversely affect the operation of the condensing unit and

may also endanger life and property.

The manufacturer disclaims any responsibility for such loss

or injury and the manufacturer’s warranty does not cover

any damage or defect to the air conditioner caused by the

attachment or use of any components, accessories or devices

(other than those authorized by the manufacturer) into, onto

or in conjunction with the condensing unit.

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which

canresult in property damage, severe personal injury, or death

ifnot avoided.

Introduction

Introduction

This manual contains the installation and operating

instructions for your split condensing unit. There are a

few precautions that should be taken to derive maximum

satisfaction from it. Improper installation can result in

unsatisfactory operation or dangerous conditions.

Read this manual and any instructions packaged with separate

equipment required to make up the system prior to installation.

Give this manual to the owner and explain its provisions. The

owner should retain this manual for future reference.

Checking Product Received

Upon receiving the unit, inspect it for any damage from

shipment. Claims for damage, either shipping or concealed,

should be led immediately with the shipping company.

Check the unit model number, electrical characteristics, and

accessories to determine if they are correct.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

Nomenclature

R C S – 06 – F – 078 – C

Rooftop Condensing System

Nominal capacity (tons)

06 = 6.5

07 = 7.5

10 = 10 (single compressor)

11 = 10 (tandem compressors)

12 = 12

15 = 15

20 = 20

Refrigerant

F = R-410A

Voltage

C = 208/230 - 3 - 60

D = 460 - 3 - 60

Y = 575 - 3 - 60

Compressor

078 = 6.5 ton, single

090 = 7.5 ton, single

120 = 10 ton, single

125 = 10 ton, tandem

150 = 12.5 ton, tandem

180 = 15 ton, tandem

240 = 20 ton, tandem

NOTE: For larger size units (greater than 20 ton), refer to Catalog 222.

IM 962-2 3

Introduction

Introduction

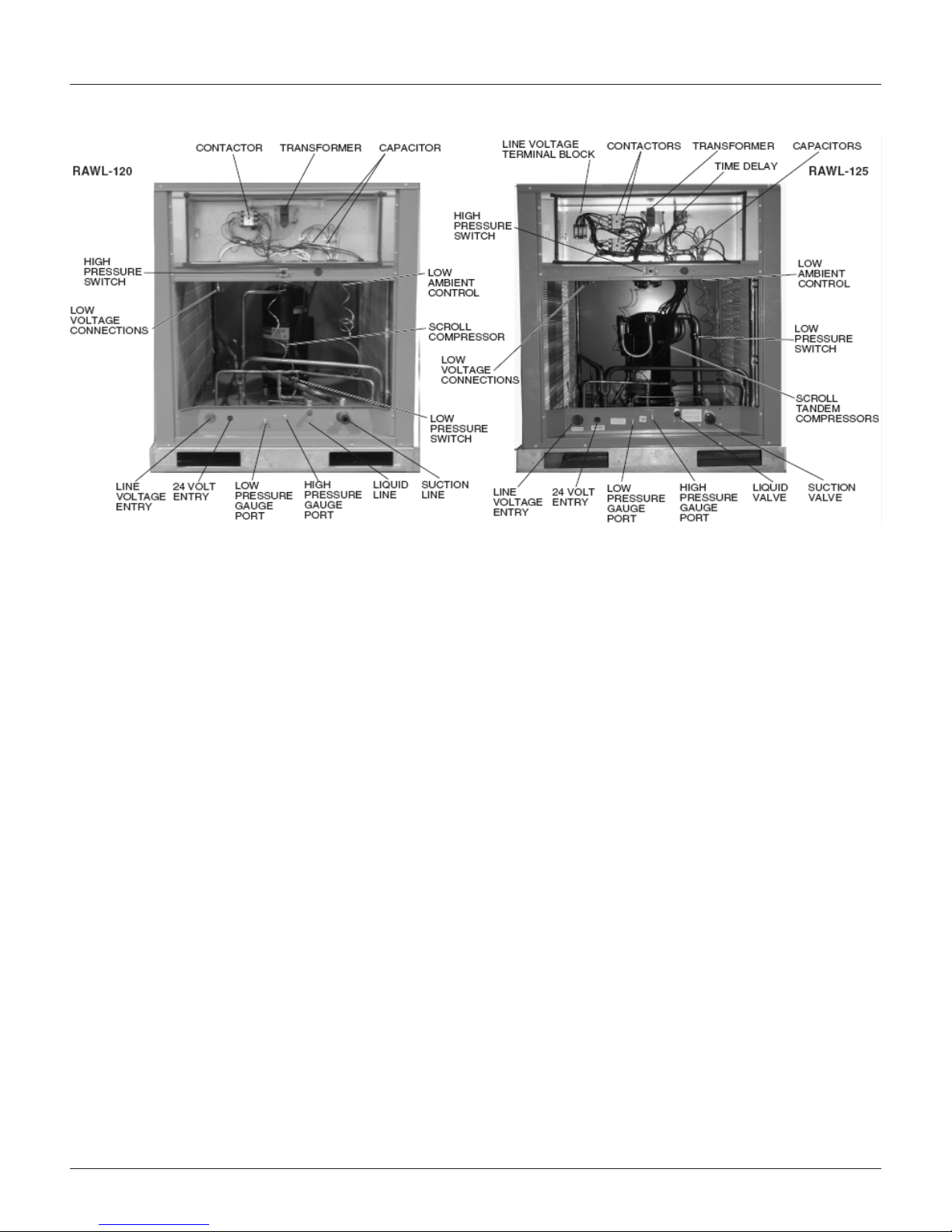

Standard Unit Features

Cabinet — Galvanized steel with a durable powder paint

nish. Stamped louvered panels offer 100% protection for the

condenser coil.

Compressor — Hermetically sealed scroll compressors.

Compressors are mounted on rubber-in-shear pads to reduce

vibration and noise.

Condenser Coil — Constructed with copper tubes and

aluminum ns mechanically bonded to the tubes for

maximum heat transfer capabilities. All coil assemblies are

leak tested at 450 psig internal pressure.

Refrigerant Connections — Field piping connections are made

through a xed panel. This allows complete access or removal of

access panels after piping connections have been made.

Crankcase Heater — Standard, all models.

Low Ambient Control — A pressure sensitive fan cycling

control to allow unit operation to 0°F is standard.

Service Valves — Standard on liquid lines and vapor lines.

Service Access — The control box, as well as the

compressor and other refrigerant controls, is accessible

through access panels. It may be opened without affecting

the normal operation of the unit. Condenser fan motors are

accessible by removing wire grilles.

Filter Drier — Field supplied.

Sight Glass — Optional, eld supplied.

Transformer — Step down type, line to 24 volts.

Contactor — The contactor is an electrical switch which

operates the compressor and condenser fans.

High Pressure Control — Opens the contactor circuit on

high refrigerant pressure; manual reset.

Low Pressure Control — Stops compressor operation in the

event of loss of refrigerant.

Condenser Fan Motor (Direct Drive) — Ball bearing 1075

RPM motors are mounted to minimize vibration and noise

problems.These are permanent split capacitor types and

require the same capacitance for both run and start.

Testing — All units are run tested at the factory prior to

shipment. Units are shipped with a holding pressure of nitrogen.

Figure 1: RCS 06F & 07F Ton Features

4 IM 962-2

Figure 2: RCS 10F – 20F Ton Features

Introduction

IM 962-2 5

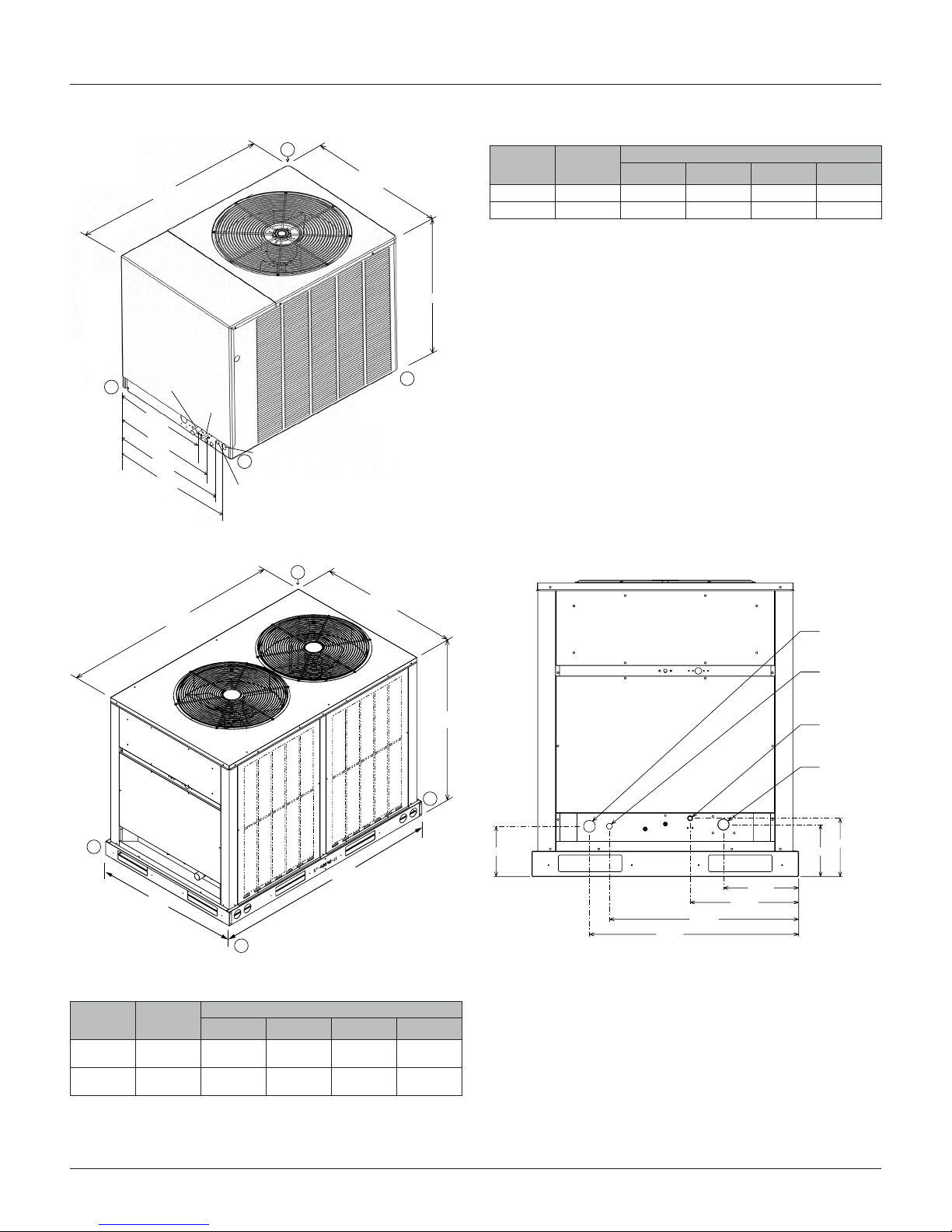

Dimensional and Weight Data

Dimensional and Weight Data

Figure 3: RCS 06F and 07F Dimensions and Weights Table 1: RCS 06F and 07F Operating Weights

43.00

CONTROL

PANEL ACCESS

C

31.06

RCS

model

06F 291 [132] 50 [22.7] 73 [33.1] 69 [31.3] 99 [44.9]

07F 318 [144] 53 [24.0] 84 [38.1] 71 [32.2] 110 [49.9]

32.81

Total

weight

lbs. [kg]

Corner weight lbs. [kg]

A B C D

D

SUCTION

LINE 1

21.69

24.19

26.63

28.44

1/8"

LIQUID

LINE

1/2"

HIGH VOLTAGE

B

3/4"

DIA. HOLE1

LOW VOLTAGE

7/8"

DIA. HOLE

A

Figure 4: RCS 10F and 11F Dimensions and Weights

B

38.375

60.625

CONTROL

PANEL ACCESS

High Voltage

1-3/4" Dia. Hole

Low Voltage

7/8" Dia. Hole

44.75

D

Liquid Line

5/8" Dia. Hole

Suction Line

1-3/8" Dia. Hole

A

39.94

C

Table 2: RCS 10F and 11F Operating Weights

RCS

model

10F

(Single)

11F

(Tandem)

Total

weight

lbs. [kg]

501 [228] 123 [53.9] 132 [60.0] 119 [54.1] 127 [58.0]

586 [266] 144 [65.3] 154 [69.9] 139 [63.2] 149 [67.6]

Corner weight lbs. [kg]

A B C D

6 IM 962-2

62.125

8.75

7.5

11.25

16.25

28.25

31.25

7.875

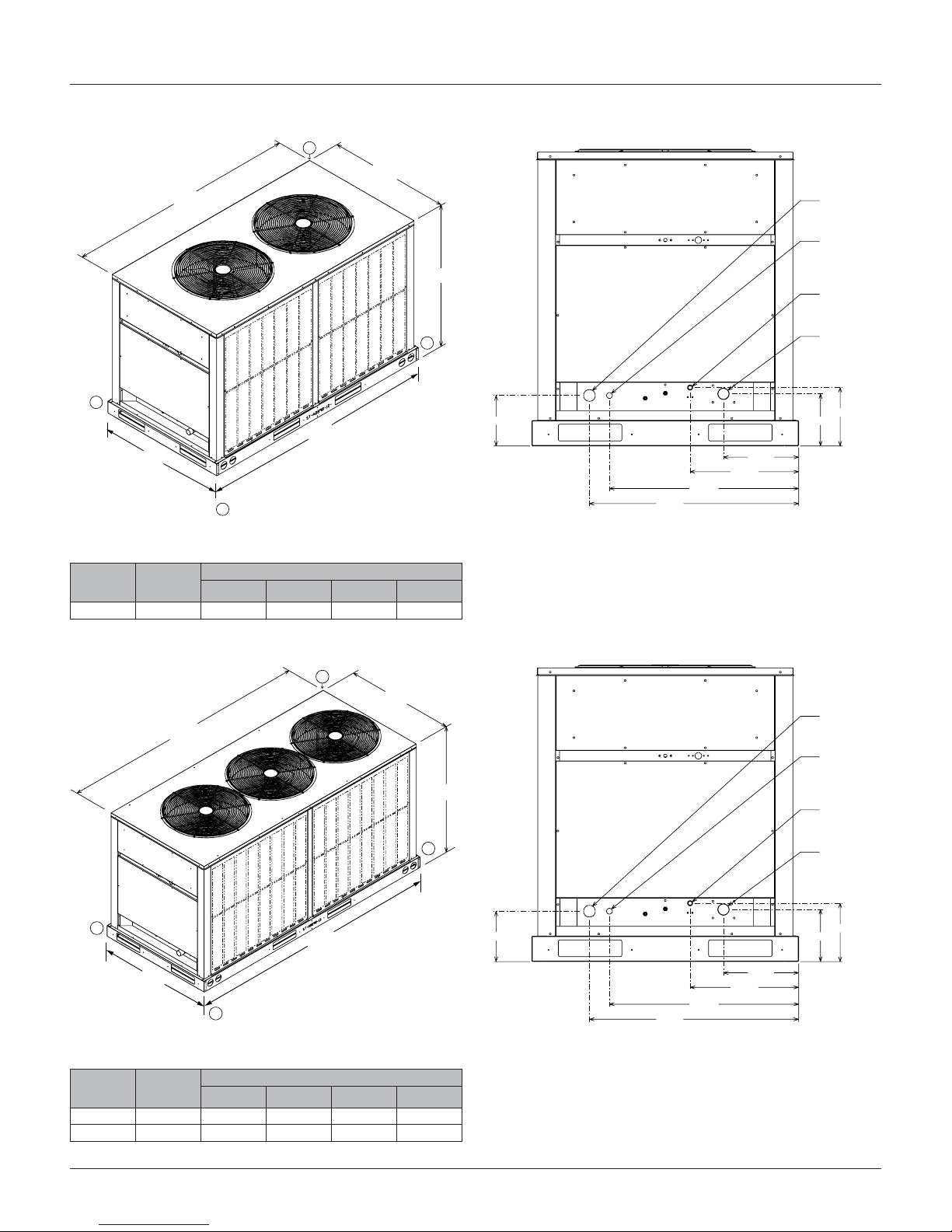

Figure 5: RCS 12F Dimensions and Weights

Dia. I.D. 15 Ton

Dia. I.D. 20 Ton

B

Dimensional and Weight Data

Dimensional and Weight Data

38.375

72.375

CONTROL

PANEL ACCESS

A

73.88

39.94

C

Table 3: RCS 12F Operating Weights

RCS

model

Total

weight

lbs. [kg]

12F 650 [293] 160 [72.0] 171 [78.0] 154 [70.0] 165 [75.0]

Corner weight lbs. [kg

A B C D

Figure 6: RCS 15F – 20F Dimensions and Weights

High Voltage

1-3/4" Dia. Hole

Low Voltage

7/8" Dia. Hole

44.75

D

7.5

11.25

16.25

28.25

31.25

Liquid Line

5/8" Dia. Hole

Suction Line

1-3/8" Dia. Hole

8.75

7.875

B

38.375

87.375

CONTROL

PANEL ACCESS

A

39.94

C

88.88

Table 4: RCS 15F and 20F Operating Weights

RCS

model

Total

weight

lbs. [kg]

15F 746 [338.0] 183 [83.0] 196 [89.0] 177 [80.0] 189 [86.0]

20F 952 [432.0] 234 [106.0] 251 [114.0] 226 [103.0] 241 [110.0]

Corner weight lbs. [kg]

A B C D

High Voltage

1-3/4" Dia. Hole

Low Voltage

7/8" Dia. Hole

44.75

D

7.5

11.25

16.25

28.25

31.25

Liquid Line

Liquid Line

5/8" Dia. Hole

5/8"

7/8"

Suction Line

Suction Line

1-5/8" Dia. Hole

1-3/8" Dia. Hole

8.75

7.875

IM 962-2 7

Physical Data

Physical Data

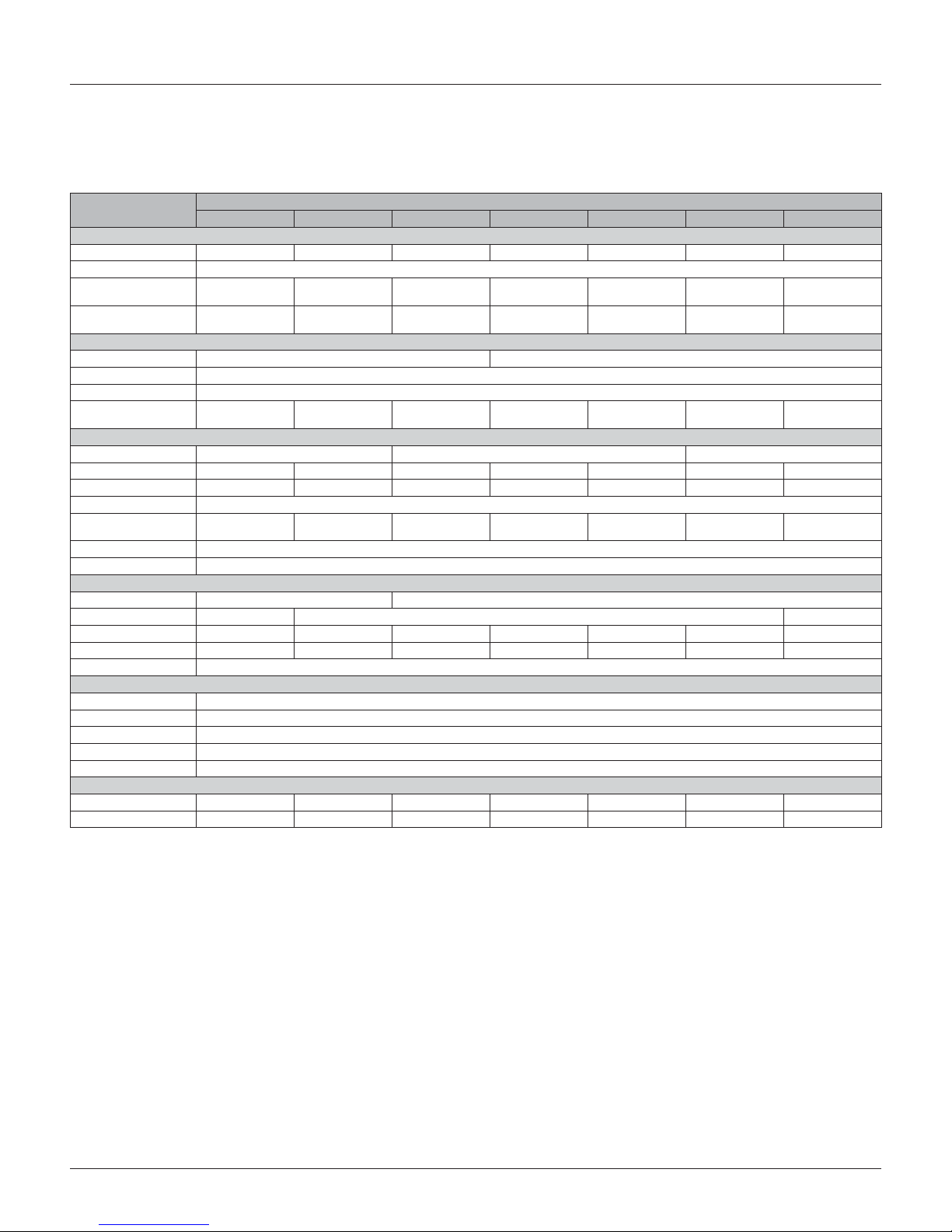

Unit Capacity and Physical Data

Table 5: RCS 06F – 20F Physical Data

Model

Capacity and Weight

Capacity (tons) [kW] 6.5 [22.9] 7.5 [26.4] 10 [35.2] 10 [35.2] 12 [42.2] 15 [52.8] 20 [70.3]

Number of circuits 1

Operating weight

(lbs) [Kg]

Shipping weight

(lbs) [Kg]

Compressor

Quantity 1 2

Type Scroll

RPM 3500

Refrigerant charge

R410A oz. [g]

Condenser Fans

Quantity 1 2 3

CFM [L/s] 4700 [2218] 4700 [2218] 8100 [3822] 8100 [3822] 8100 [3882] 12,000 [5663] 12,000 [5663]

Diameter (in.) [mm 24 [610] 24 [610] 24 [610] 24 [610] 24 [610] 24 [610] 24 [610]

Drive Direct

Motor horsepower

each [W]

Type PSC

RPM 1075

Condenser Coil

Quantity 1 2

Rows 1-1/2 2 3

Fins per inch 20 22 18 22 22 22 22

Cabinet

Sheet metal Galvanized

Gauge (nominal) top 20

Refrigerant Connection

Vapor sweat (in.) [mm] 1-1/8 [29] 1-1/8 [29] 1-3/8 [35] 1-3/8 [35] 1-3/8 [35] 1-5/8 [41.3] 1-5/8 [41.3]

Liquid sweat (in.) [mm] 1/2 [13] 1/2 [13] 5/8 [16] 5/8 [16] 5/8 [16] 5/8 [16] 7/8 [22]

2

Sq. ft. [m

Fins/tubes Aluminum/Copper

Base rails 14

] 23.0 [2.14] 23.0 [2.14] 27.0 [2.51] 27.0 [2.51] 33.9 [3.05] 40.38 [3.75] 40.38 [3.75]

Finish Powder Coat

Sides 20

06F Single 07F Single 10F Single 11F Tandem 12F Tandem 15F Tandem 20F Tandem

291 [132] 318 [144] 501 [227.3] 586 [265.8] 650 [294.8] 746 [338.4] 952 [431.8]

314 [142.5] 341 [154.7] 541 [245.4] 626 [284.0] 690 [313.0] 786 [356.5] 992 [450.0]

178 [5046] 242 [6861] 339 [9661] 300 [8505] 378 [10,716] 506 [14,345] 655 [18,569]

1/3 [249] 1/3 [249] 1/3 [249] 1/3 [249] 1/3 [249] 1/3 [249] 1/3 [249]

RCS

8 IM 962-2

Electrical Data

Power Wiring

Table 6: RCS 06F – 20F Electrical Data

Model

Compressor Motor

Voltage 208/230 460- 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575

Phase and hertz 3 – 60

Number of compressors Single Tandem

Operating Current

Rated load amps (each)

Locked rotor amps (each)

Condenser Fan Motors

Voltage 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575 208/230 460 575

Phase Single

Full load amps (each) 2.2 1.3 1.0 2.2 1.3 1.0 2.4 1.4 1.0 2.4 1.4 1.0 2.4 1.4 1.0 2.4 1.4 1.0 2.4 1.1 0.8

System characteristics

Unit full load amps

Minimum circuit ampacity 31.0 15.0 11.0 34.0 17.0 13.0 43.0 24.0 18.0 45.0 25.0 16.0 56.0 27.0 20.0 64.0 32.0 24.0 83.0 44.0 32.0

Maximum fuse size (amps)

or HACR circuit breaker

ampacity

Disconnect size 60 30 30 60 30 30 60 40 25 60 30 30 60 30 30 100 60 60 200 60 60

Note:

1 Each compressor

2 Conditions at 45° suction and 95° ambient

3 Local codes take precedent over recommended fuse size

1

1

2

3

06F 07F 10F 11F 12F 15F 20F

22.4 10.6 7.7 25.0 12.2 9.0 30.1 16.7 12.2 17.6 9.6 6.1 22.4 10.6 7.7 25.0 12.2 9.0 33.3 17.9 12.8

149 75 54 164 100 78 225 114 80 123 64 40 14 75 54 164 100 78 239 125 80

24.6 11.9 8.7 27.2 13.5 10.0 34.9 19.5 14.2 40.0 22.0 14.2 49.6 24.0 17.4 57.2 28.6 21.0 73.8 39.1 28.0

50 25 15 50 25 20 60 40 25 60 30 20 70 35 25 80 40 30 11 0 60 40

RCS

Electrical Data

Figure 7: Control Box Example – RCS 10F Through 20F

IM 962-2 9

Installation

Installation

Order Parts

When reporting shortages or damaged parts, or when

ordering repair parts, give the complete unit model and serial

numbers which are stamped on the unit rating plate.

Standard Items

The condensing unit consists of a completely assembled

package which includes a compressor pack, condenser coils,

fans, fan motors, outdoor control box, factory wiring, factory

tubing and ttings.

Crankcase Heaters

These units are equipped with a crankcase heater that is

factory wired to operate whenever the main power supply

to the unit is “ON” and compressors are “OFF.” Before

starting the equipment after prolonged shutdown or at the

time of initial spring startup, be sure that the circuits to the

condensing units are closed for at least 24 hours.

DANGER

Disconnect all power to unit before starting maintenance.

Failure to do so can cause electrical shock resulting in severe

personal injury or death.

Regular maintenance will reduce the buildup of contaminants

and help to protect the unit’s nish.

• Frequent washing of the cabinet, fan blade and coil

with fresh water will remove most of the salt or other

contaminants that build up on the unit.

• Regular cleaning and waxing of the cabinet with a good

automobile polish will provide some protection.

• A good liquid cleaner may be used several times a year

to remove matter that will not wash off with water.

Several different types of protective coatings are offered in

some areas. These coatings may provide some benet, but the

effectiveness of such coating materials cannot be veried by

the equipment manufacturer.

Corrosive Environment

The metal parts of this unit may be subject to rust or

deterioration if exposed to a corrosive environment. This

oxidation could shorten the equipment’s useful life. Corrosive

elements include salt spray, fog or mist in seacoast areas,

sulphur or chlorine from lawn watering systems, and various

chemical contaminants from industries such as paper mills

and petroleum reneries.

If the unit is to be installed in an area where contaminants are

likely to be a problem, special attention should be given to the

equipment location and exposure.

• Avoid having lawn sprinkler heads spray directly on the

unit cabinet

• In coastal areas, locate the unit on the side of the

building away from the waterfront.

• Shielding provided by a protection, based on clearances

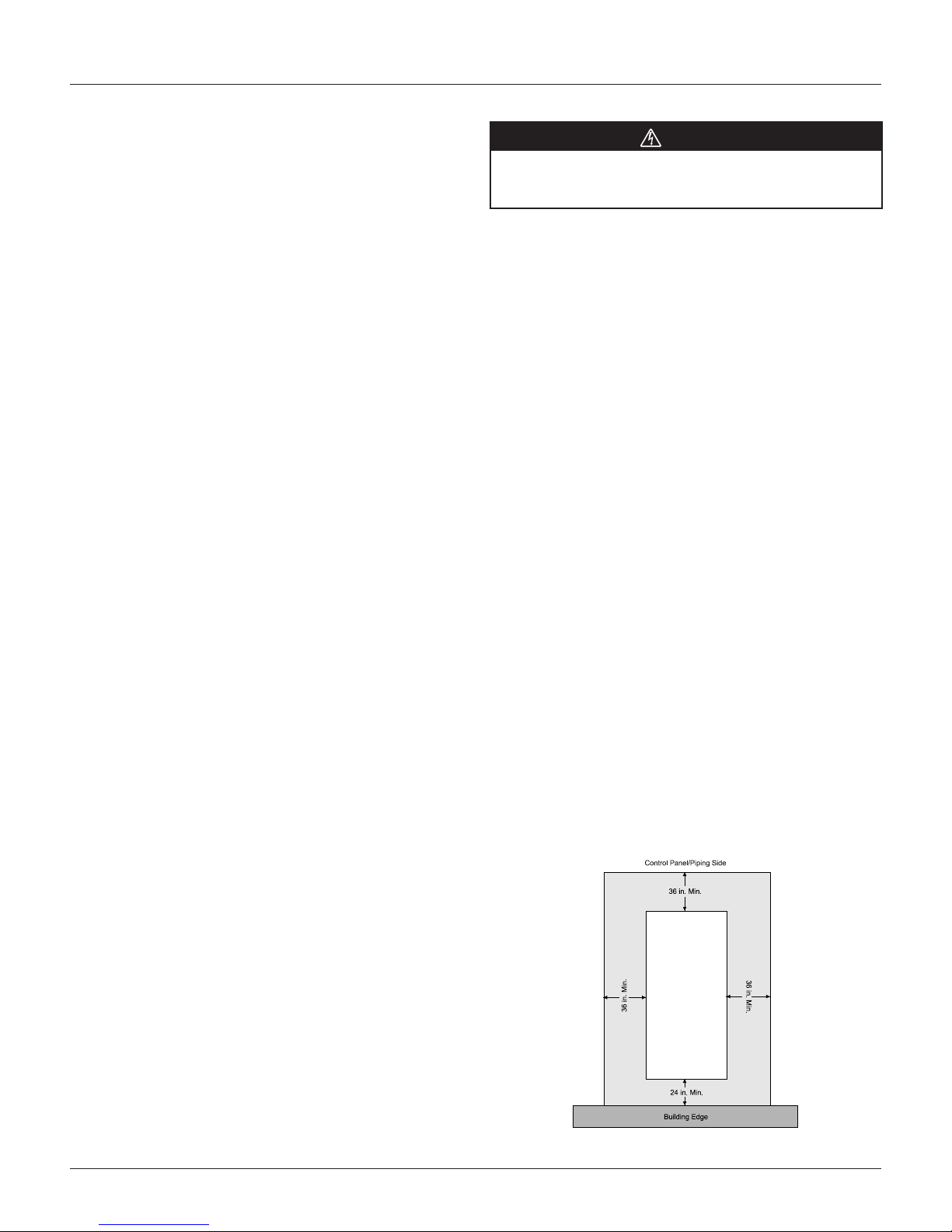

Installation General

The condensing unit should be installed outdoors. It should be

located as near as possible to the evaporator section to keep

connecting refrigerant tubing lengths to a minimum. The unit

must be installed to allow a free air ow to the condenser coils

If several units are installed adjacent to each other, take care

to avoid recirculation of air from one condenser to another.

In all installations, adequate space must be provided for

installation and servicing.

The unit must not be connected to any duct work. Do not

locate unit under a roof drip; if necessary, install gutters,

etc., to prevent water runoff onto the unit. To prevent air

recirculation, it is recommended that the unit not be installed

under an overhang. However, if this is necessary, allow a

minimum of 60" above the unit for air discharge

Figure 8: Clearances RCS 06F – 20F Service Clearances

10 IM 962-2

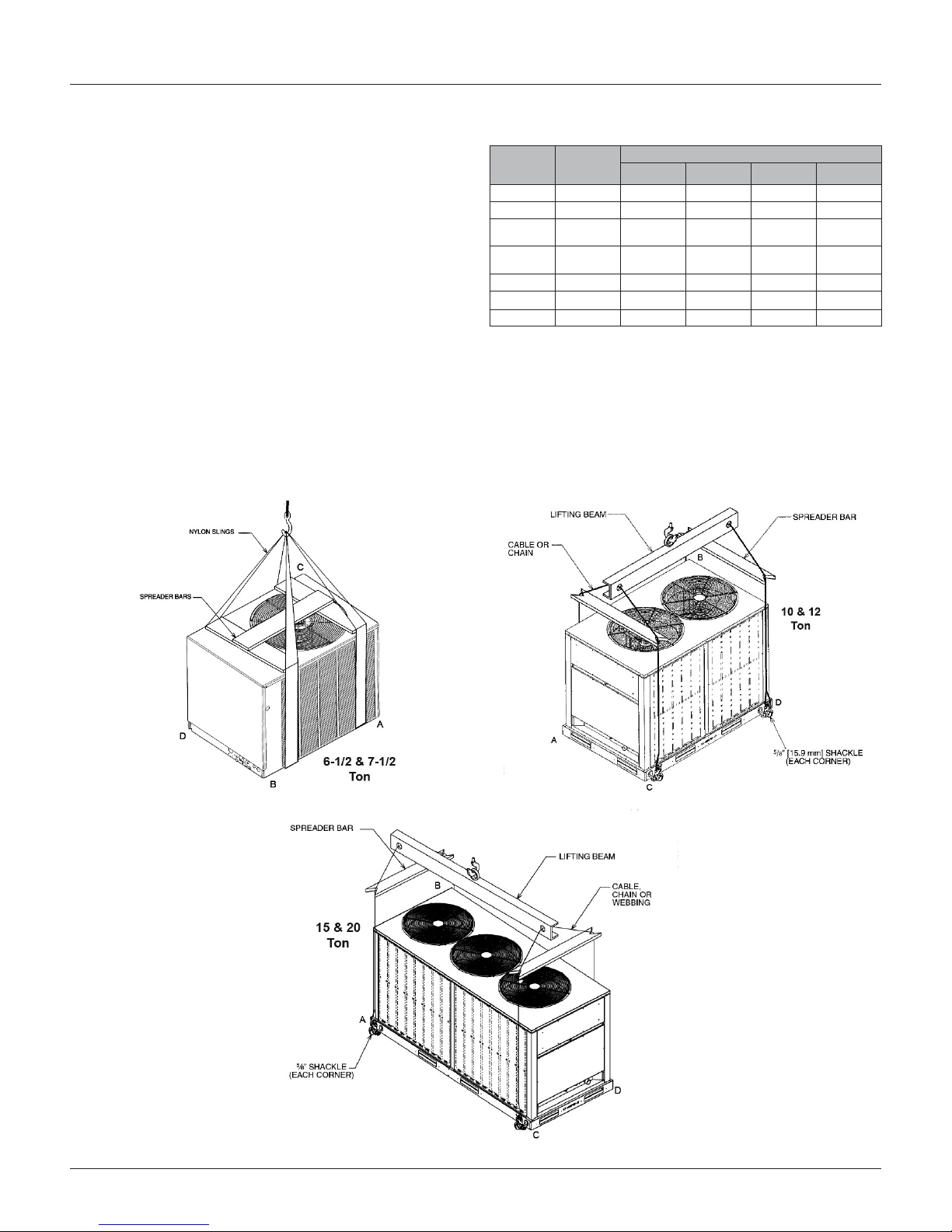

Rooftop Installation

If rooftop installation is required, make certain that the

building construction is adequate for the weight of the

unit. (Table 5 ) Before placing the unit on the roof, make

certain that the nylon rigging slings are of sufcient length

to maintain equilibrium of the unit when lifting. Under no

circumstances should the unit be lifted by only one corner for

rooftop installation.

Slab Installation

Condensing units should be set on a solid level foundation.

When installed at ground level, the unit should be placed on

a 6" cement slab. If the pad is formed at the installation site,

do not pour the pad tight against the structure, otherwise

vibration will be transmitted from the unit through the pad.

Figure 9: Rigging

Installation

Table 7: RCS 06F and 07F Operating Weights

RCS

model

06F 291 [132] 50 [22.7] 73 [33.1] 69 [31.3] 99 [44.9]

07F 318 [144] 53 [24.0] 84 [38.1] 71 [32.2] 110 [49.9]

10F

(Single)

11F

(Tandem)

12F 650 [293] 160 [72.0] 171 [78.0] 154 [70.0] 165 [75.0]

15F 746 [338.0] 183 [83.0] 196 [89.0] 177 [80.0] 189 [86.0]

20F 952 [432.0] 234 [106.0] 251 [114.0] 226 [103.0] 241 [110.0]

Total

weight

lbs. [kg]

501 [228] 123 [53.9] 132 [60.0] 119 [54.1] 127 [58.0]

586 [266] 144 [65.3] 154 [69.9] 139 [63.2] 149 [67.6]

Corner weight lbs. [kg]

A B C D

Installation

IM 962-2 11

Loading...

Loading...