Daikin RFS-040c, RFS-135c, RCS-040c, RPS-045c, RDT-045c Installation And Maintenance Manual

...

Installation and Maintenance Manual IM 738-2

Roof

Pak® Singlezone Roof Mounted

Heating and Cooling Units

RPS/RDT/RFS/RCS 015–135C

Group:

Part Number: IM 738

Date: October 2018

Applied Air Systems

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unit Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Compressor Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Gas Burner Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hazard Identification Information . . . . . . . . . . . . . . . . . . . . . . . 1

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Condenser Fan Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . 4

Refrigeration Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls, Settings, and Functions . . . . . . . . . . . . . . . . . . . . . 18

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ventilation Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Overhead Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Roof Curb Assembly and Installation . . . . . . . . . . . . . . . . . . 23

Post and Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rigging and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reassembly of Split Units . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unit Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Steam Coil Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Damper Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cabinet Weather Protection . . . . . . . . . . . . . . . . . . . . . . . . . 49

Installing Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Installing Duct Static Pressure Sensor Taps . . . . . . . . . . . . . 50

. . . . . 51

Installing Building Static Pressure Sensor Taps

. . . . .

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Field Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Field Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Preparing Unit for Operation . . . . . . . . . . . . . . . . . . . . . 56

Spring Isolated Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Relief Damper Tie-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Adjusting Scroll Dampers . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Adjusting Supply Fan Thrust Restraints . . . . . . . . . . . . . . . . 57

Sequences of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Economizer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Mechanical Cooling Operation . . . . . . . . . . . . . . . . . . . . . . . 59

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Enthalpy Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Hot Gas Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

SpeedTrol™ (N/A Unit Sizes 015C to 030C) . . . . . . . . . . . . 90

External Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Smoke and Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Entering Fan Temperature Sensor . . . . . . . . . . . . . . . . . . . . 91

Duct High Pressure Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

MicroTech II™ Remote User Interface (UI) . . . . . . . . . . . . . . 92

Variable Frequency Drive Operation . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . .93

Convenience Receptacle/Section Lights

DesignFlow™ Outdoor Air Damper Option . . . . . . . . . . . . . .93

Propeller Exhaust Fan Option . . . . . . . . . . . . . . . . . . . . . . . .96

Exhaust Fan On/Off Control . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Ultraviolet Lights Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Ultraviolet Light Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . .

Check, Test, and Start Procedures . . . . . . . . . . . . . . 100

Servicing Control Panel Components . . . . . . . . . . . . . . . . . 100

Before Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Fan Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Economizer Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Compressor Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Scroll Compressor Rotational Directio

Oil Pressure (sizes 115 to 135C only) . . . . . . . . . . . . . . . . . 103

Heating System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Sheave Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Drive Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Mounting and Adjusting Motor Sheaves . . . . . . . . . . . . . . . 106

n (sizes 15 to 105)

. .102

Final Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Keypad accessible menu structure . . . . . . . . . . . . . . . . . . . 110

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Servicing Control Panel Components . . . . . . . . . . . . . . . . . 113

Planned Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Setscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Supply Fan Wheel-to-Funnel Alignment . . . . . . . . . . . . . . . 116

Refrigerant Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Servicing Refrigerant Sensors or Switches

Winterizing Water Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Control Panel Components . . . . . . . . . . . . . . . . . . . . . . . . .118

. .

. . . . . . . . . . .117

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . .121

Service and Warranty Procedure . . . . . . . . . . . . . . . . 122

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Scroll Compressor (sizes 15 to 105C) . . . . . . . . . . . . . . . . . 122

Reciprocating Compressors (sizes 115 to 135C) . . . . . . . . 122

All Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

In-Warranty Return Material Procedure . . . . . . . . . . . . . . . . 123

Limited Product Warranty (North America) . . . . . . 124

Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Sole Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Rooftop Equipment Warranty

Registration Form . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Quality Assurance Survey Report . . . . . . . . . . . . . . . 128

Daikin and MicroTech II are registered trademarks of Daikin Applied

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

Copyright © 2018 Daikin Applied. All rights reserved throughout the world.

Introduction

Introduction: Unit Nameplate

This manual provides general information about the “C”

vintage Daikin RoofPak applied rooftop unit, models RPS,

RDT, RFS and RCS. In addition to an overall description of

the unit, it includes mechanical and electrical installation

procedures, commissioning procedures, sequence of operation

information, and maintenance instructions. For further

information on the optional forced draft gas-fired furnace,

refer to Bulletin No. IM 684 or IM 685.

The MicroTech II applied rooftop unit controller is available

on “C” vintage applied rooftop units. For a detailed description

of the MicroTech II components, input/output configurations,

field wiring options and requirements, and service procedures,

see IM 696. For operation and information on using and

programming the MicroTech II unit controller, refer to the

appropriate operation manual (see

Table 1).

For a description of operation and information on using the

keypad to view data and set parameters, refer to the

appropriate program-specific operation manual (see Table 1)

.

Table 1: Program specific rooftop u nit op eration literature

Rooftop unit control configuration

VFDs Vendor IM manuals

Discharge Air Control (VAV or CAV) OM 137-2

Space Comfort Con trol

(CAV-Zone temperature control)

Operation manual bulletin

number

OM 138-2

Unit Nameplate

The unit nameplate is located on the outside lower right corner

on the main control box door. It includes the unit model

number, serial number, unit part number, electrical

characteristics, and refrigerant charge.

Compressor Nameplate

On units with a single compressor on each circuit, the

compressor includes one compressor nameplate.

On units that utilize the tandem

compressor design, each

compressor includes an individual nameplate along with a

nameplate identifying the tandem compressors.

Gas Burner Nameplate

On units that include gas heat, the nameplate is located on the

lower right corner on the main control box door. It includes the

burner model number, minimum/maximum input, maximum

temperature rise, and minimum CFM.

On units that utilize the tandem scroll

compressor design, each

compressor includes an individual nameplate along with a

nameplate identifying the tandem compressors.

On units that utilize the tande

m reciprocating design, each

compressor includes an individual nameplate.

Hazard Identification Information

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

Figure 1. Nomenclature

R P S – 030 C S E

RoofPak

Unit configuration

P = Heating, mechanical cooling

F = Heating, future mechanical cooling

C = Condensing section only

D = Draw through cooling

Blow through cooling = S

Draw through cooling = T

Nominal capacity (tons)

RPS, RFS, RCS, RDT: 015, 018, 020, 025, 030, 036,

040, 045, 050, 060, 070, 075, 080, 090, 105, 115, 125, 135

IM 738-2 1

Heat medium

A = Natural gas

E = Electric

S = Steam

W = Hot water

Y = None (cooling only)

Cooling coil size

S=Standard (low airflow)

L =Large (high airflow)

Design vintage

Introduction: Unit Description

Unit Description

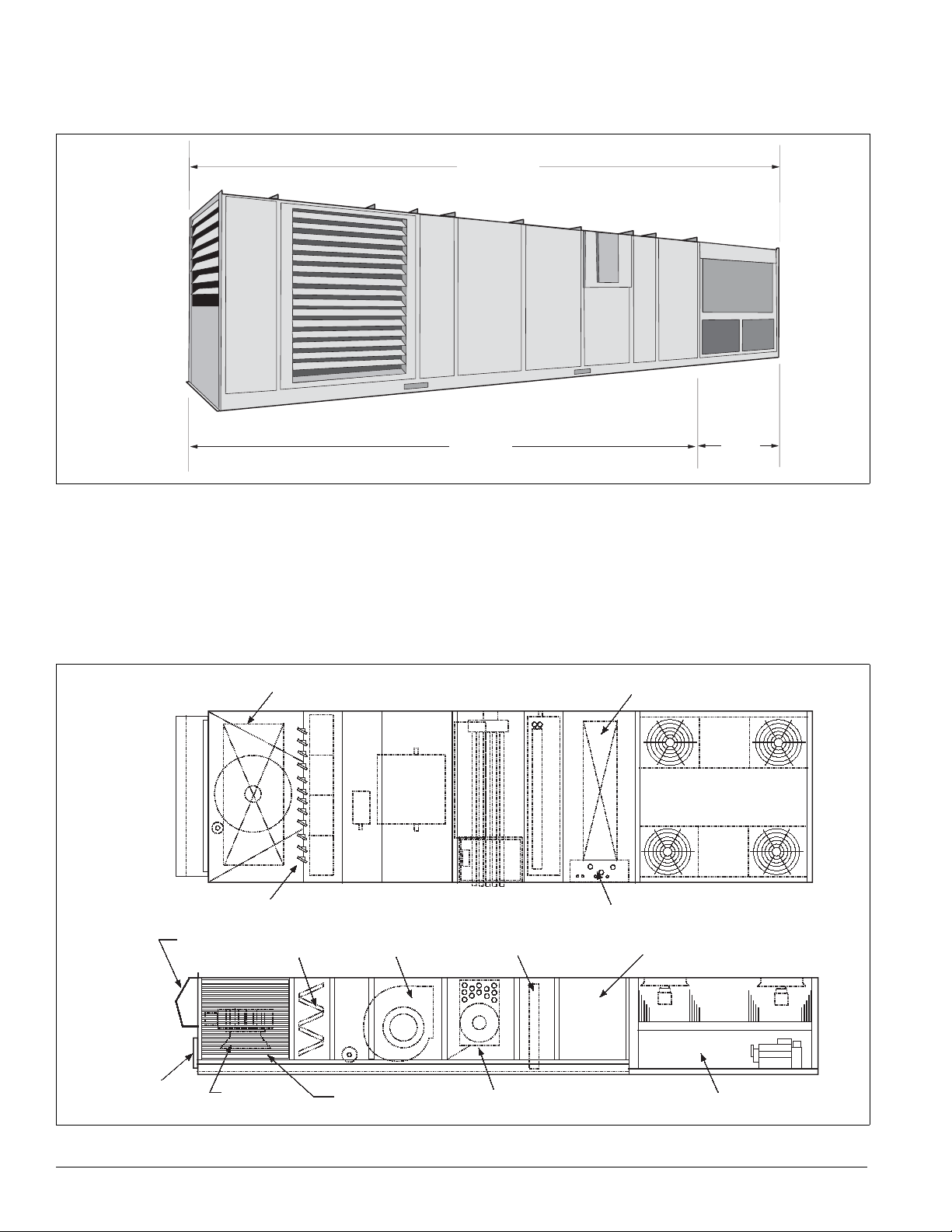

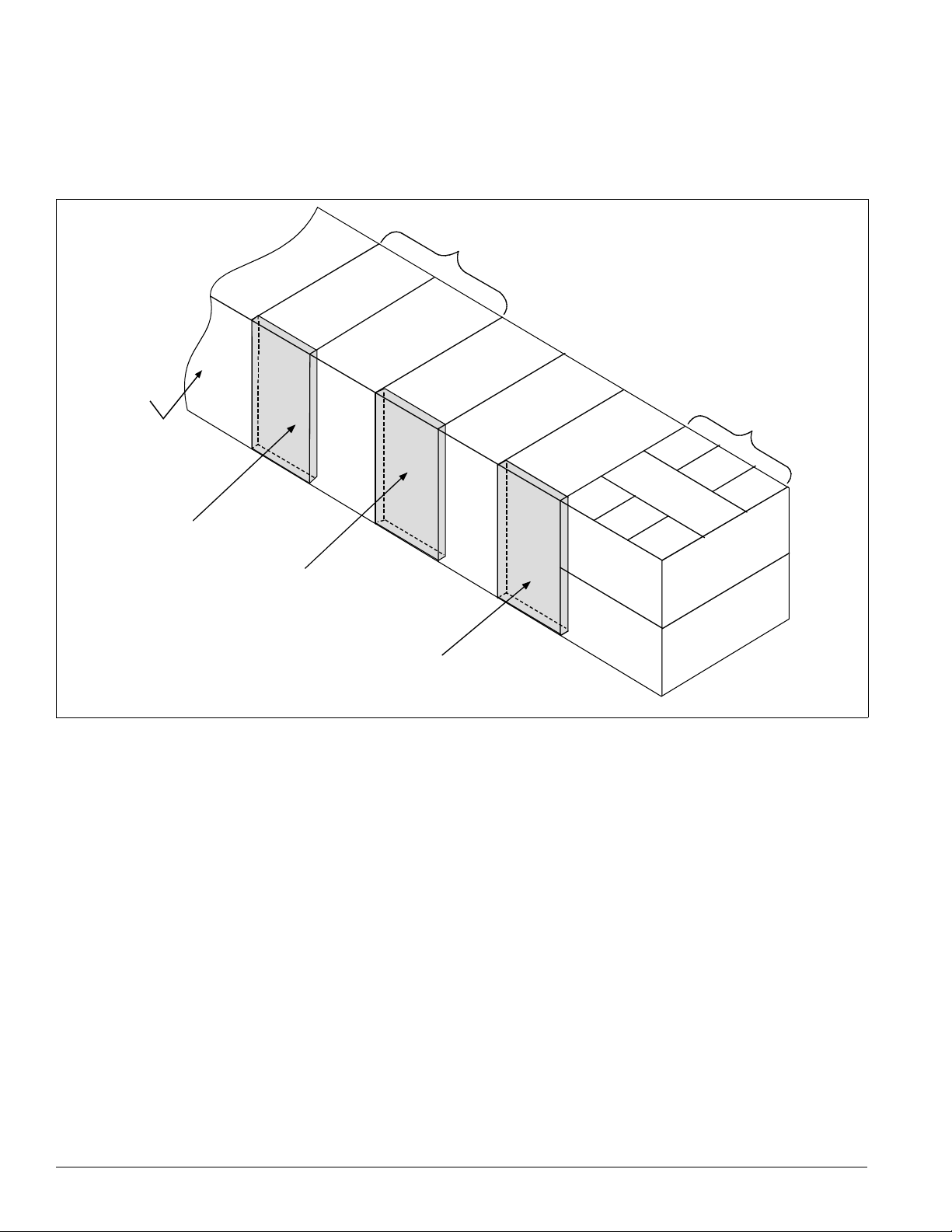

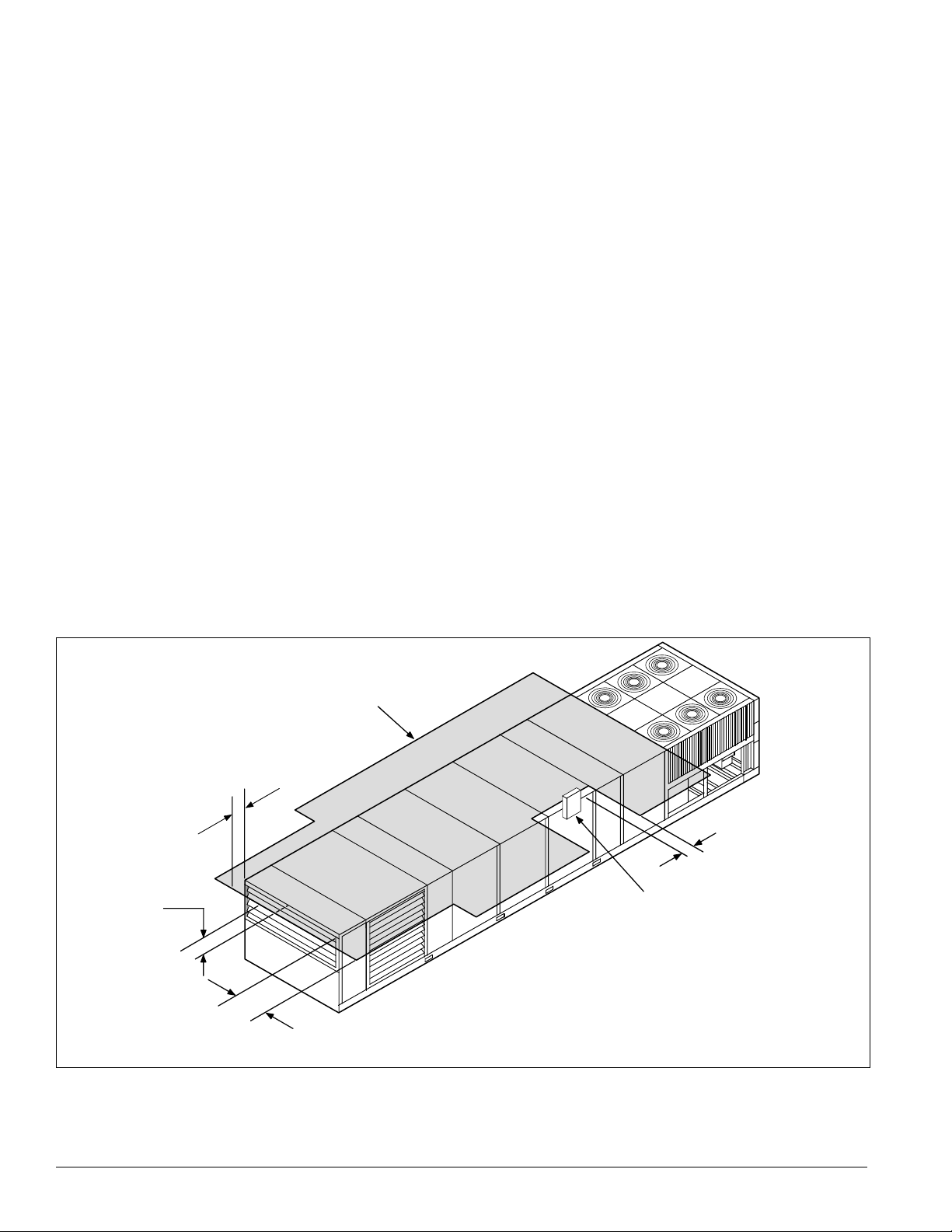

Figure 2. RPS/RDT/RFS/RCS unit

R P S / R D T

Typical Component Locations

Figure 2 shows an RPS/RDT/RFS/RCS unit. Figure 3 shows a

typical RPS unit with the locations of the major components.

Figure 4 on page 3 shows a typical RDT unit with the locations

of the major components. These figures are for general

information on

ly. See the project’s certified submittals for

actual specific dimensions and locations.

Figure 3. Typical component locations—RPS units

Top View

Bottom return air opening

R F S

R S

Bottom discharge air opening

Outside and return air dampersa

Power and control entrances

Side View

Exhaust

hood

Optional back

return opening

Filter section

Return air

Return airReturn air

fan

Supply air fan

Outside air

louvers

Evaporator coil

Heat section (natural gas, oil,

steam, hot water, electric

Discharge plenum

(main control panel)

Air cooled condenser

2 IM 738-2

Figure 4. Component locations—RDT units

Top View

Introduction: Unit Description

Bottom supply air opening

1.50 MPT drain

Bottom return opening

Side View

Return air plenum

Exhaust dampers

Optional back return

air opening

Return air fan

Optional outside &

return air dampers

Filter section

Outside air louvers

(both sides)

Control entrances 7/8" dia K.O.

DX coil section

Evaporator coils

Power entrances 3" dia K.O.

Supply fan section

IM 738-2 3

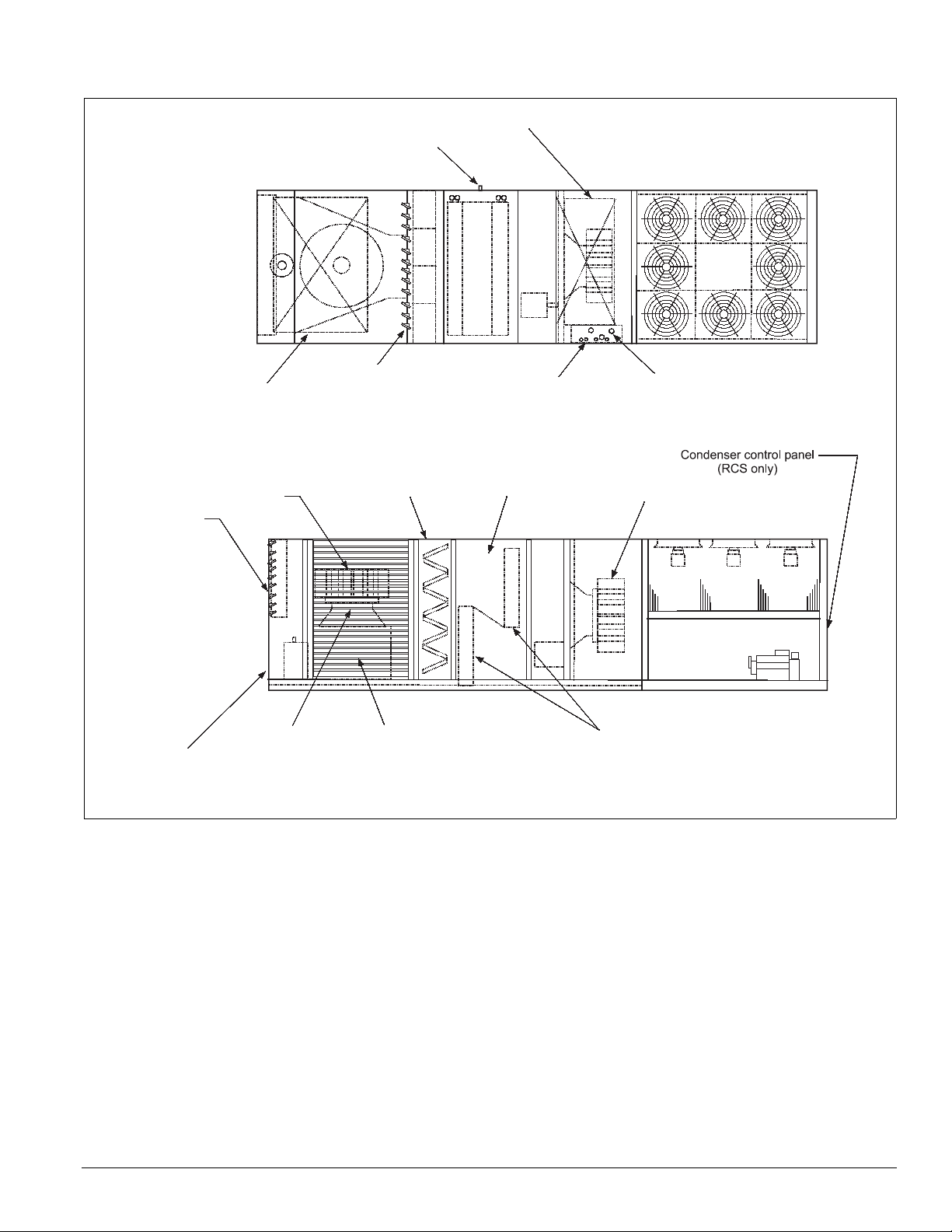

Introduction: Condenser Fan Arrangement

Condenser Fan Arrangement

Table 2 below shows the condenser fan numbering

conventions and locations for each unit size.

Table 2: Condenser fan arrangement

Unit size Refrigerant circuit Arrangement Unit size Refrigerant circuit Arrangement

COND

015C

018C

020C

1 or 2

12

11

AHU

075C

080C

090C

1

2

11

24

21

12

22

13

14

23

025C

030C 1 or 2

1

036C

040C

045C

05

0C

060C

0C

07

2

1

2

1

2

13

12

11

11

21

11

21

11

23

21

12

12

13

22

22

12

22

105C

115

125C

5C

13

1

2

1

C

2

1

2

4 IM 738-2

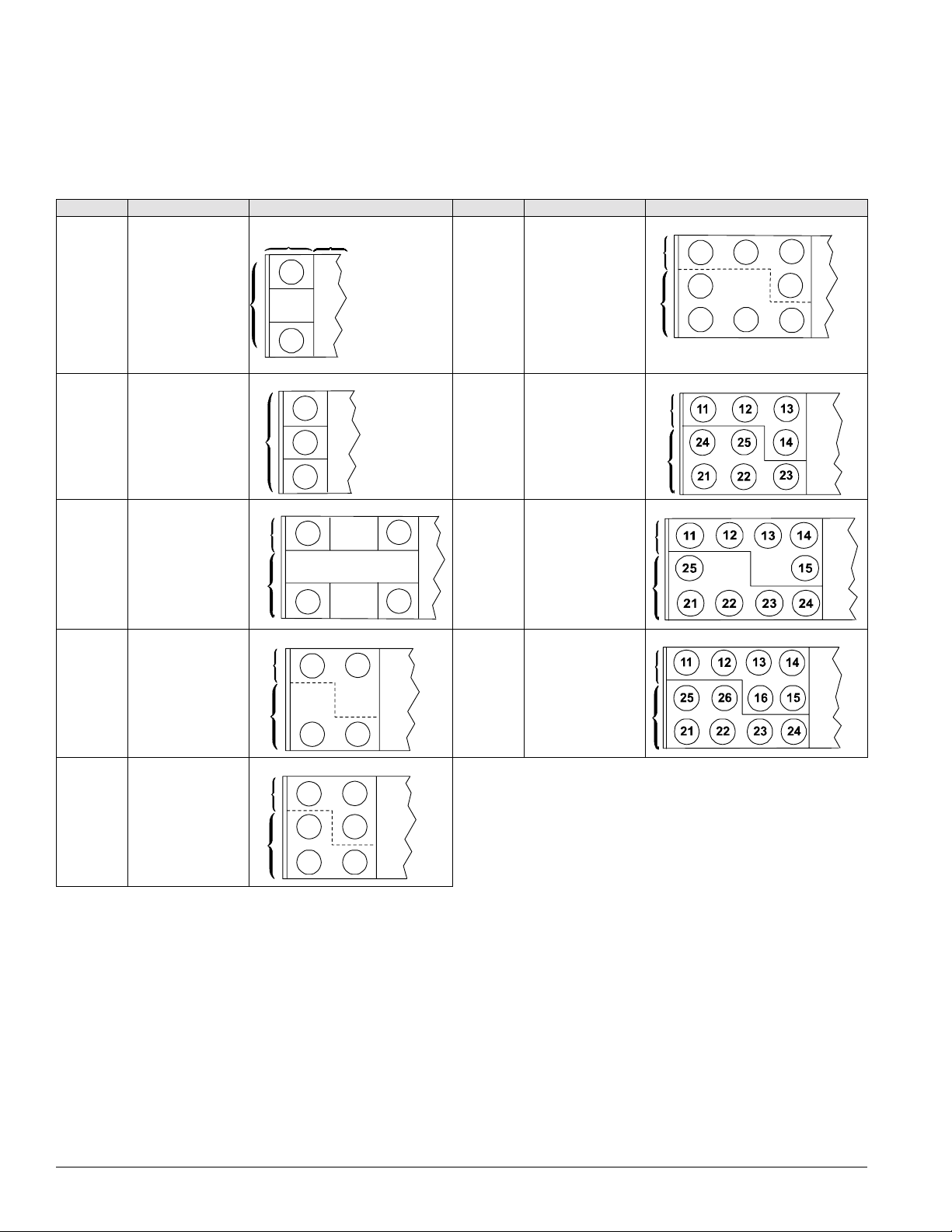

Introduction: Refrigeration Piping

Refrigeration Piping

This section presents the unit refrigeration piping diagrams for

the various available configurations.

Figure 5. Circuit schematic

A Compressor (1, 2, or 3 per circuit)†

B Discharge line †

B

A

M

C

J

N

L

K

G

H

I

F

E

D

Figure 6. Condenser piping, scroll compressors, one to three compressors p er circuit are provided (015 to 105C)

Legend

1 - Discharge shut-off valve—Circuit #1

2 - Liquid shut-off valve—Circuit #1

3 - Liquid shut-off valve—Circuit #2

4 - Discharge shut-off valve—Circuit #2

C Condenser coil †

D Evapo rator coil*

E Manual shutoff valve†

F Filter-drier*

G Liquid line solenoid valve*

H Sightglass*

I Liquid line*†

J Suction line

K Thermal expansion valve*

L Distributor*

M Hot gas bypass and solenoid valve (optional)*†

N Hot gas bypass lines (optional)* †

*Supplied on RFS unit

pplied on RCS units

†Su

s

Compressor #1

Discharge lines

Circuit #1

Circuit #2

1

Compressor #3

2

Liquid lines

Circuit #1

Circuit #2

3

Compressor #4

Compressor #2

Optional

hot gas

bypass

lines

Circuit #1

Circuit #2

Suction

lines

Circuit #1

Circuit #2

4

IM 738-2 5

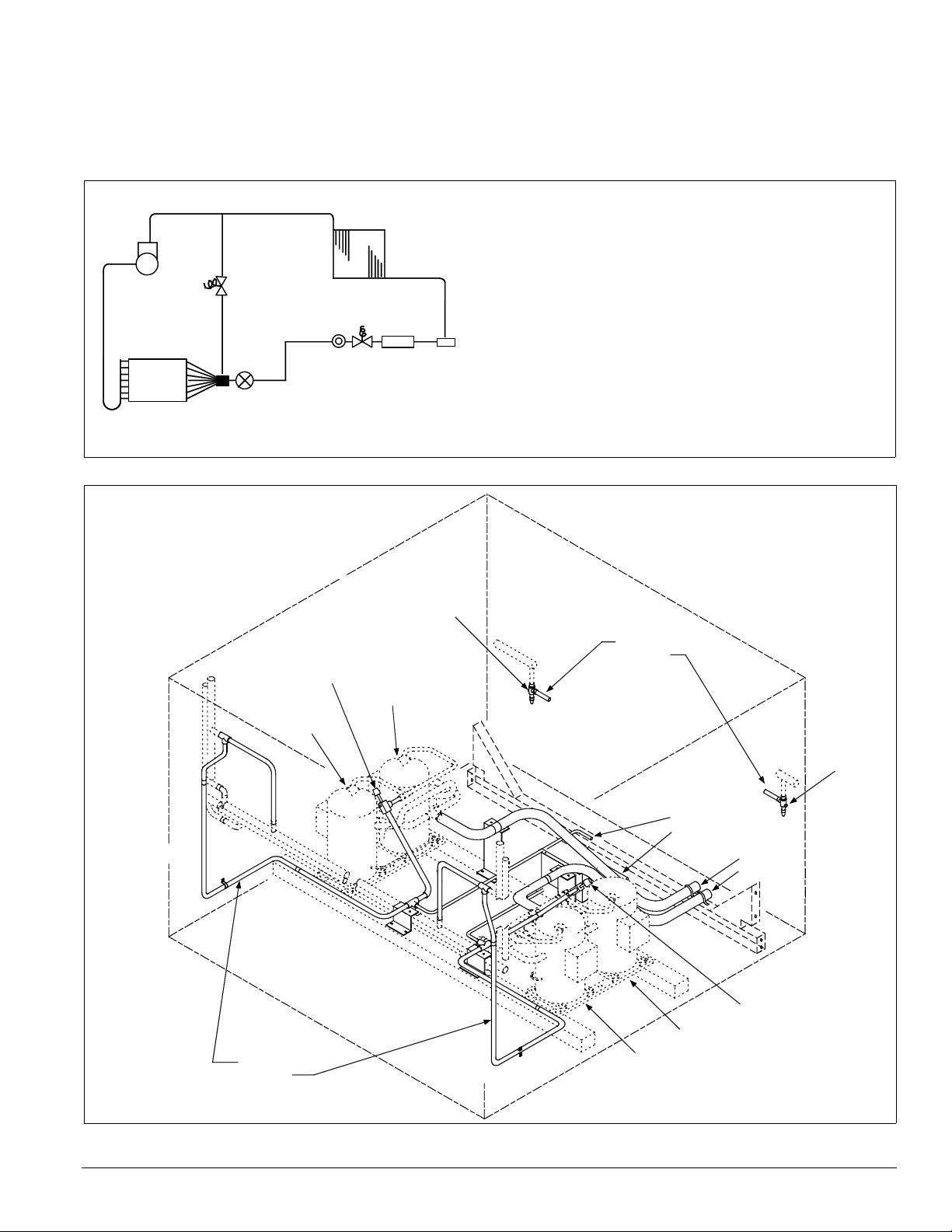

Introduction: Refrigeration Piping

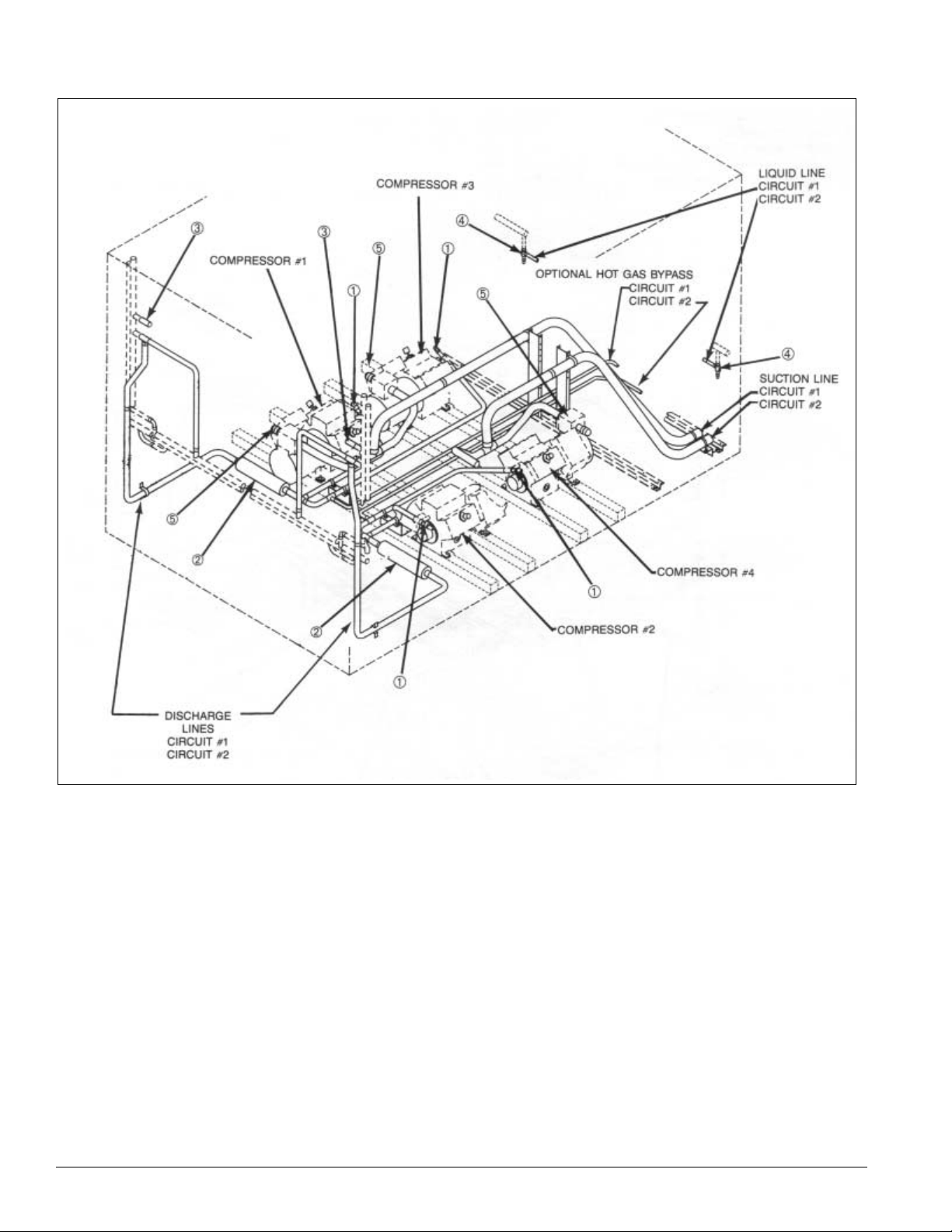

Figure 7. Condenser piping, four reciprocating compressors (115 to 135C)

Legend

1 - Discharge Line Service Valve

2 - Discharge Muffler

3 - High Pressure Relief Valve

4 - Liquid Line Manual Shut-off Valve

5 - Suction Line Service Valve

6 IM 738-2

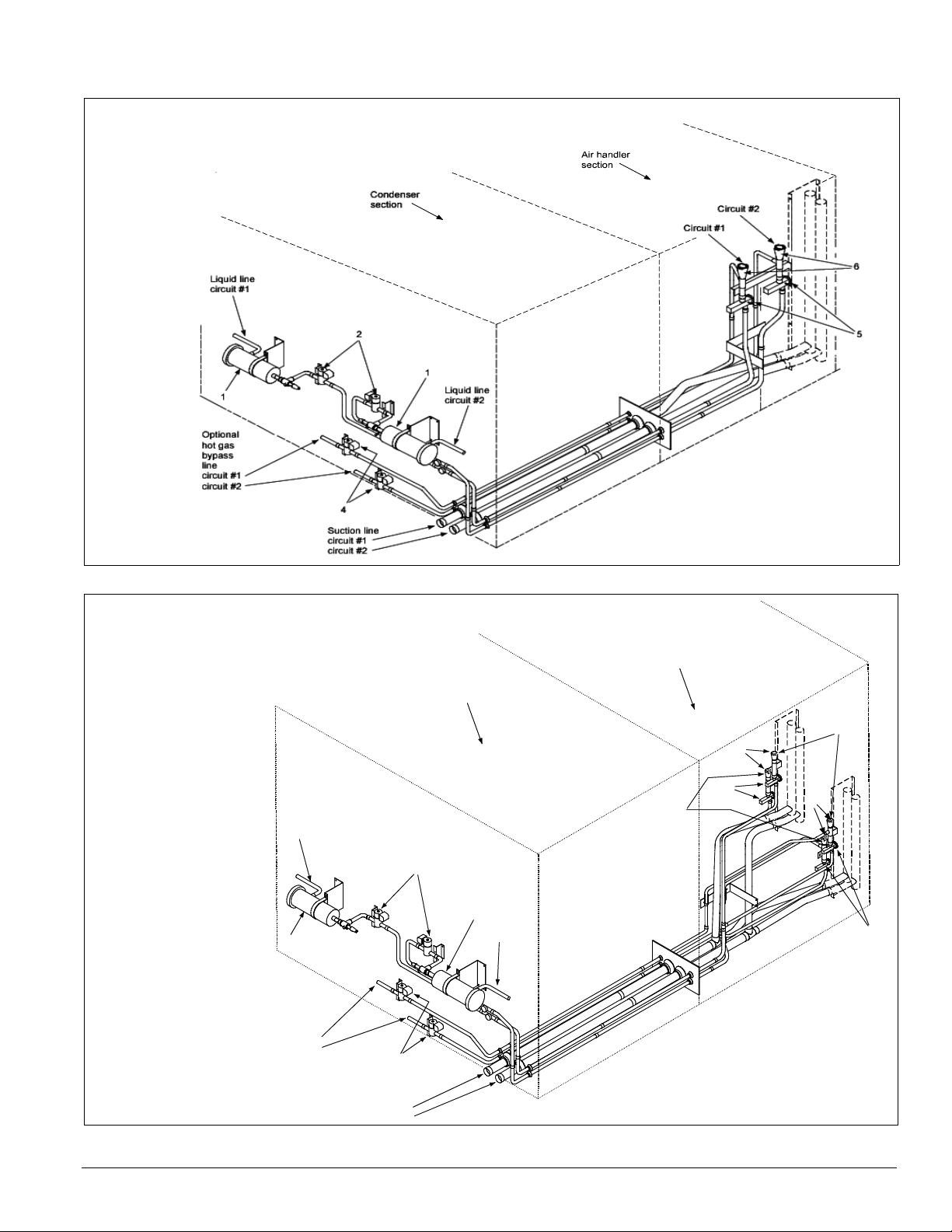

Figure 8. Air handler piping (flat DX)

circu

Legend

1 - Filter-drier

2 - Liquid line solenoid valve

3 - Sightglass

4 - Hot gas bypass

and solenoid valve (optiona l )

5 - Thermostatic

expansion valve

6 - Distributor

Introduction: Refrigeration Piping

Figure 9. Air handler piping (staggered DX)

Legend

1 - Filter-drier

2 - Liquid line solenoid valve

3 - Sightglass

4 - Hot gas bypass and solenoid valve (optional)

5 - Thermostatic expansion valve

6 - Distributor

Liquid line

circuit #1

1

Optional

hot gas

bypass

line

circuit #1

circuit #2

Air handler

section

Condenser

section

Circuit #1

6

5

Circuit #2

2

1

Liquid line

circuit #2

4

6

5

Suction line

circuit #1

it #2

IM 738-2 7

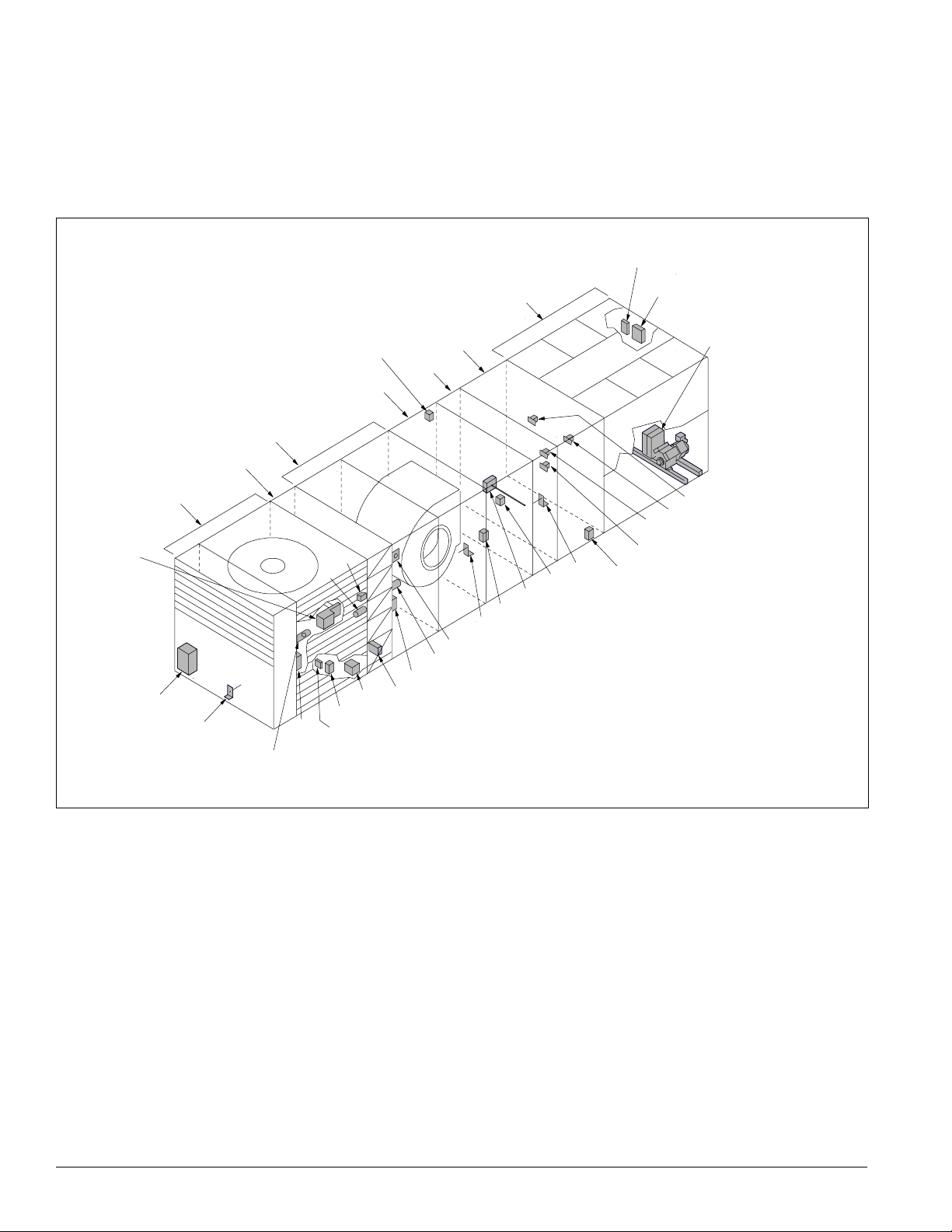

Introduction: Control Locations

Control Locations

Figure 10 (RPS Units) and Figure 11 on page 9 (RDT Units)

show the locations of the various control components mounted

hout the units. See “Control Panel” on page 10 for the

throug

locations of control components mounted in control panels.

Figure 10. Control locations—RPS units

FS1

SD2

(optional)

Return air

economizer

C19

RAT

Filter

section

Supply

fan

section

LT11

(optional)

OAT

S11,

REC11

(optional)

Heat

section

OAE

ACT3

ACT6 (optional)

RAE (optional)

section

S10, REC10

PC5

DX

LT10

ditional information is included in Table 3 on page 18 and

Ad

the wiring diagram legend, which is included in “Wiring

Diagrams” on page 62.

SC11, 12

(optional)

C11, 12

(optional)

SV1

SV5 (optional)

SV6 (optional)

ACT5 (optional)

HP1-2, HP3-4 (optional)

LP1-2

HTR1-2, HTR3-4 (optional)

SV2

Discharge

plenum

section

(optional)

HL22

(optional)

(optional)

Condensor

PC7

EFT

section

SD1

DAT

(optional)

VM1

(optional)

8 IM 738-2

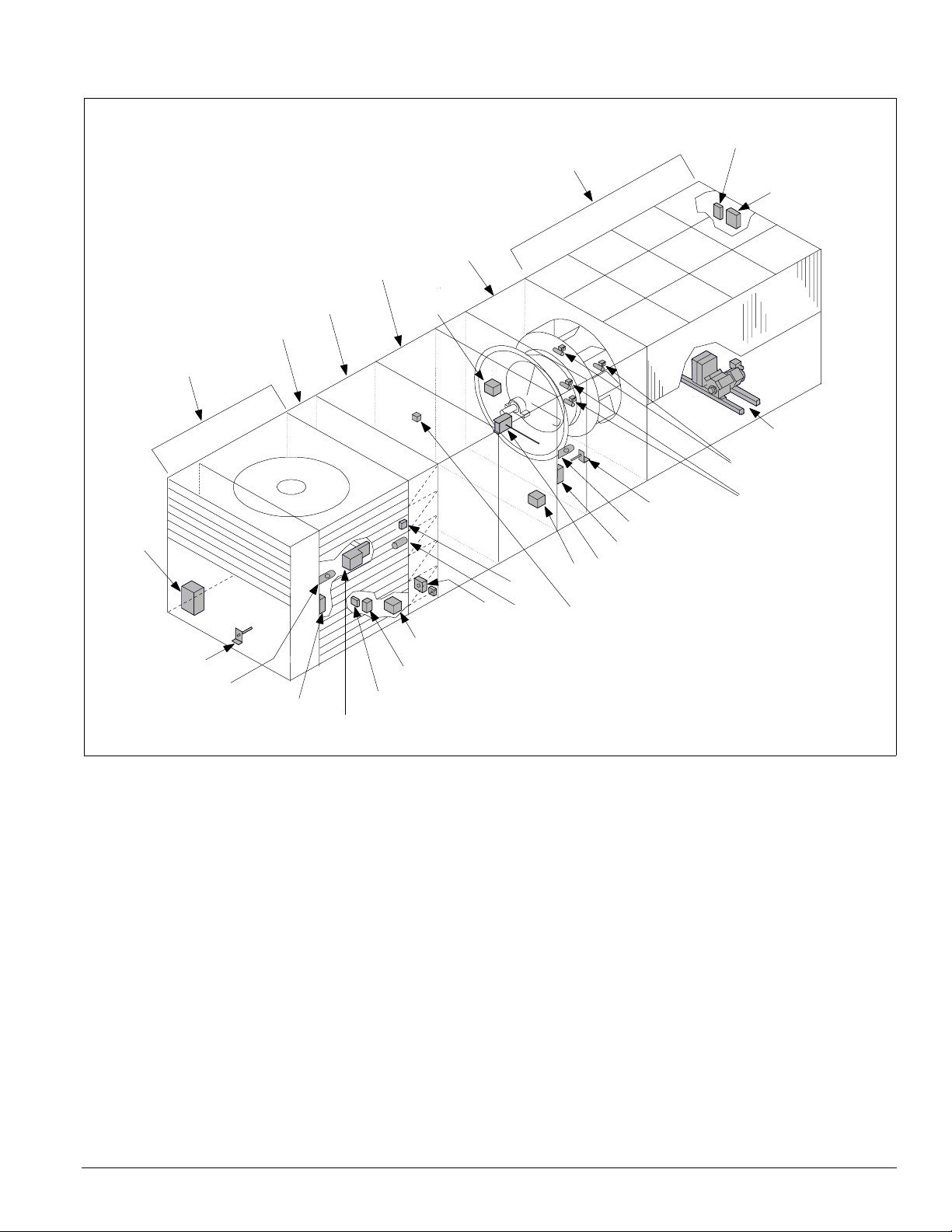

Figure 11. Control locations—RDT units

DX

section

Filter

section

Economizer

return air

Heat

section

Supply fan

discharge

plenum

section

C9

Condenser

section

Introduction: Control Locations

SC11, 21

(optional)

C11, 21

(optional)

HP1-2, LP1-2

HTR1-2, U1/U2

HP3-4 (optional)

HTR3-4 (optional)

SV1, 2

C19, 20

(optional)

RAT

LT11 (optional)

S11, REC11

SD2

(optional)

(optional)

RAE

(optional)

ACT3

ACT6

PC5

OAE

OAT

VM1

(optional)

FS1

(optional)

DAT

LT10 (optional)

S10, REC10 (optional)

SD1 (optional)

SV5, 6 (optional)

IM 738-2 9

Introduction: Control Panel

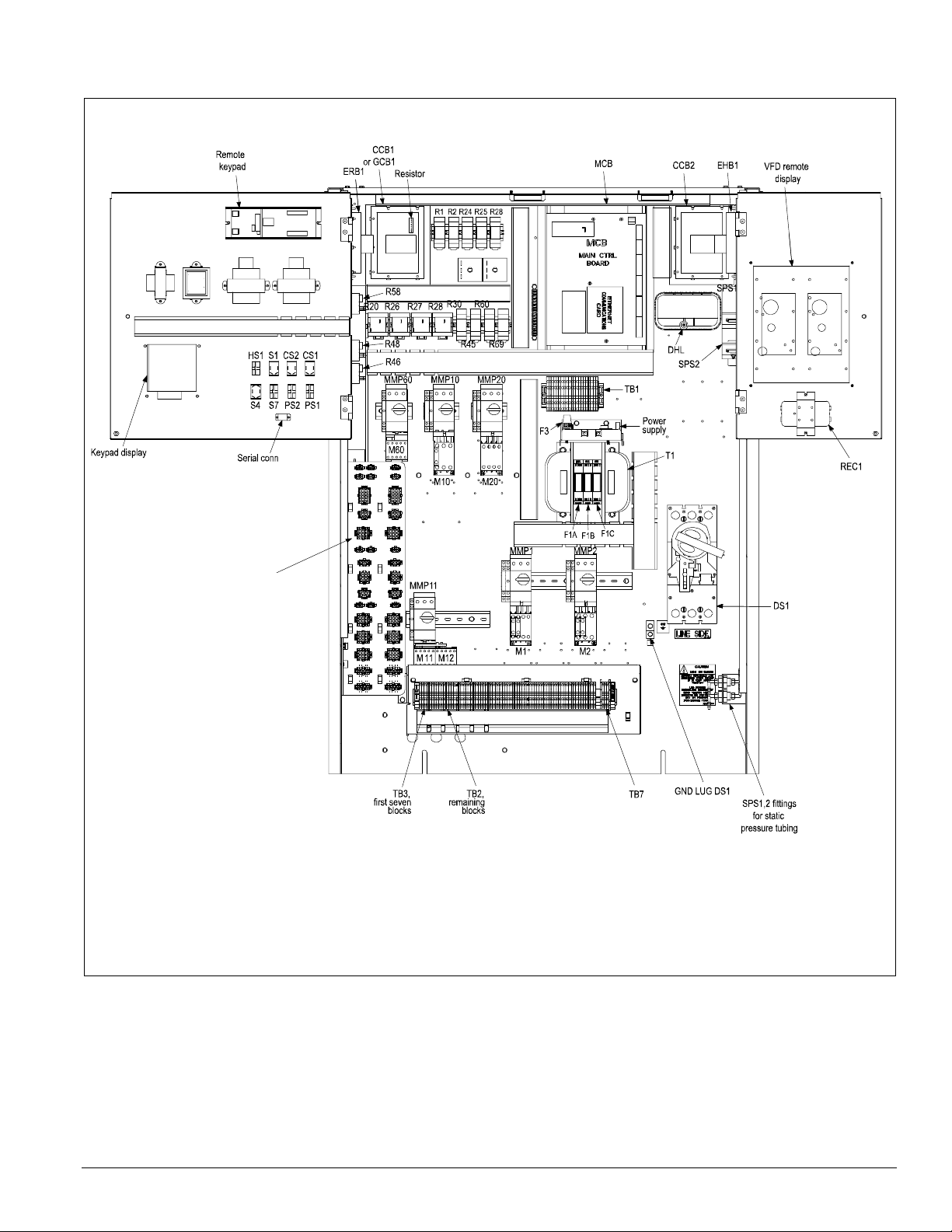

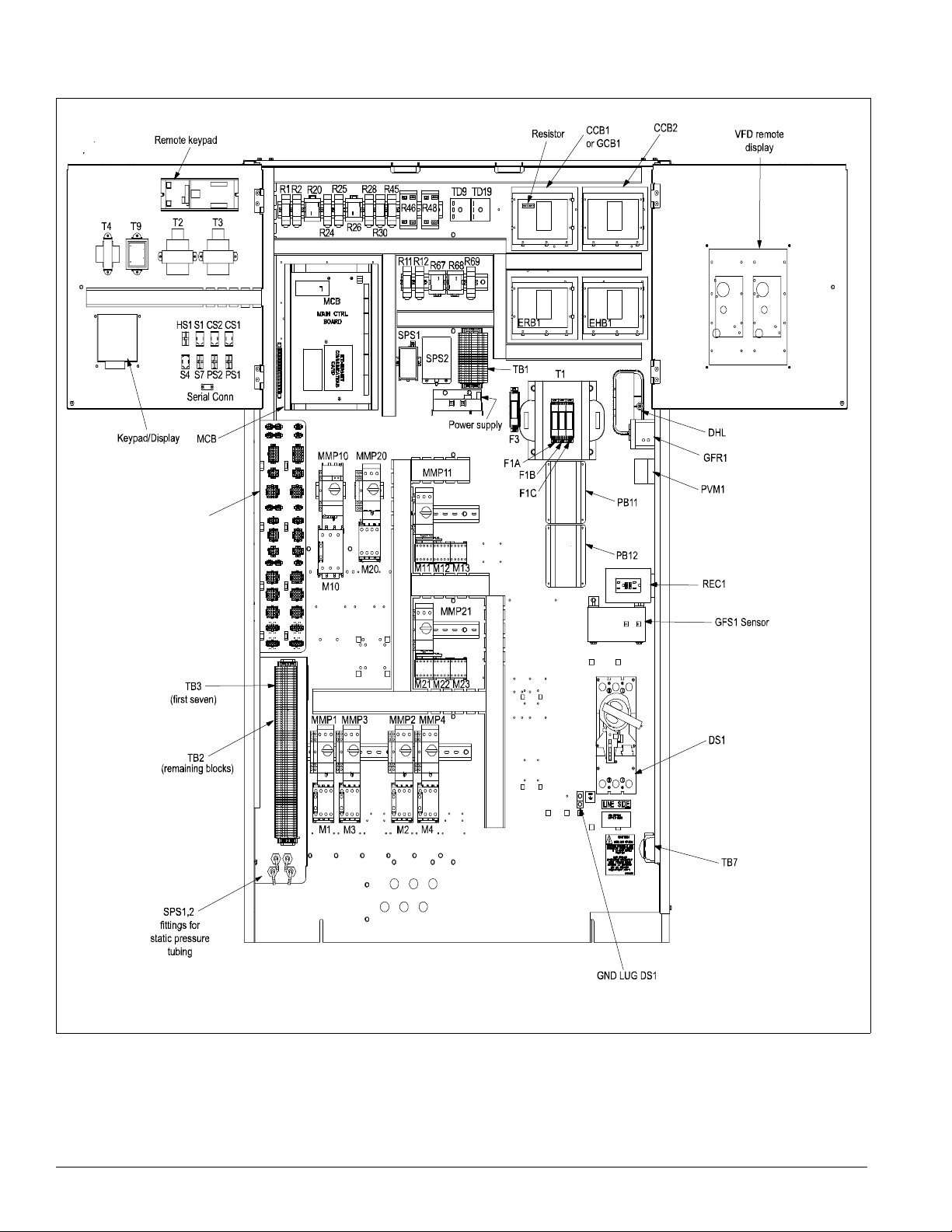

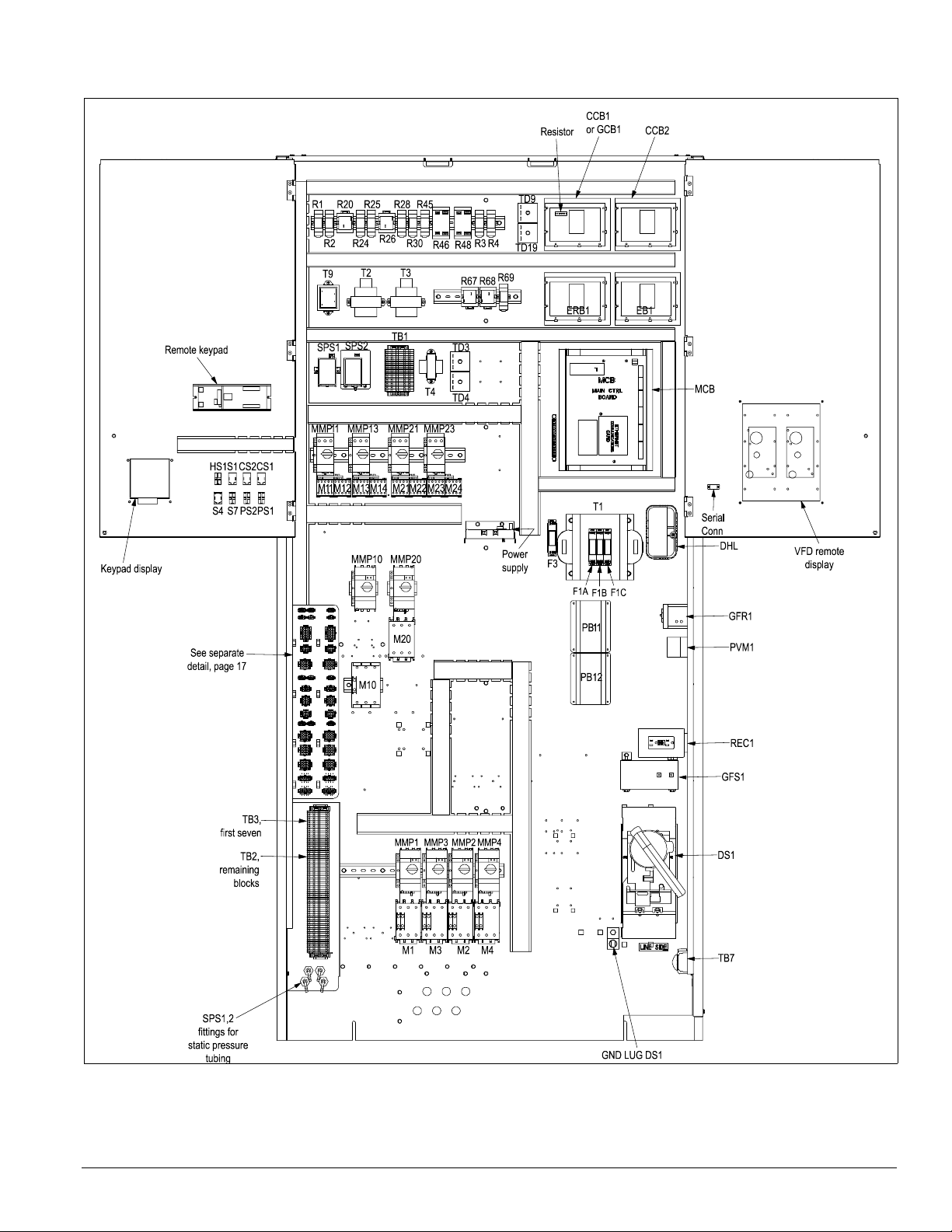

Control Panel

The unit control panels and their locations are shown in the

following figures. These figures show a typical unit

configuration. Specific unit configurations may differ slightly

Figure 12. Control panel locations

Prop exhaust

(optional)

not shown)

(

VFDs, line reactors, and

manual bypass

(optional)

Electric heat

control panel

(optional)

from these figures depending on the particular unit options.

See “Wiring Diagrams” on page 62 for the legend and

component description.

Supply fan

section

Condenser

section

Main control panel

10 IM 738-2

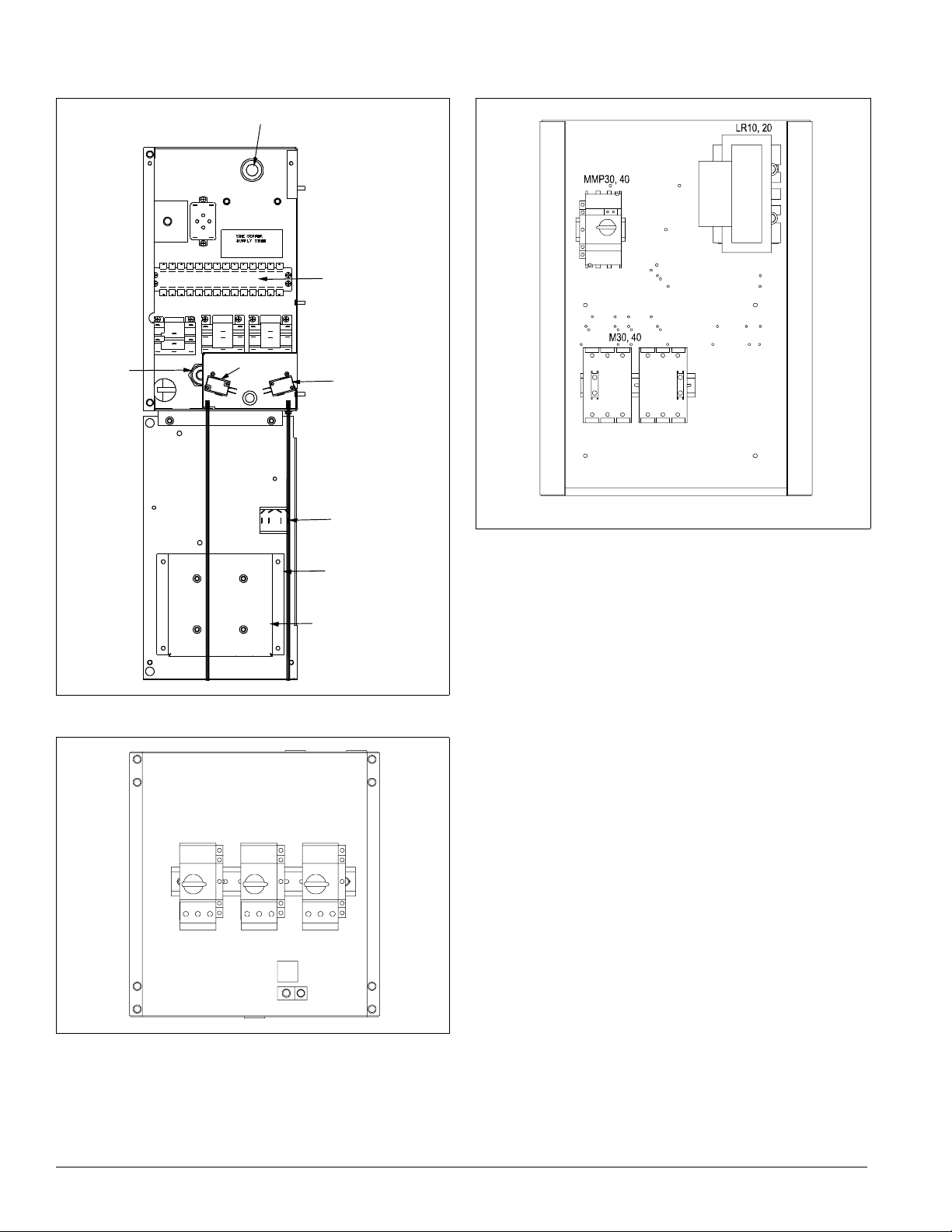

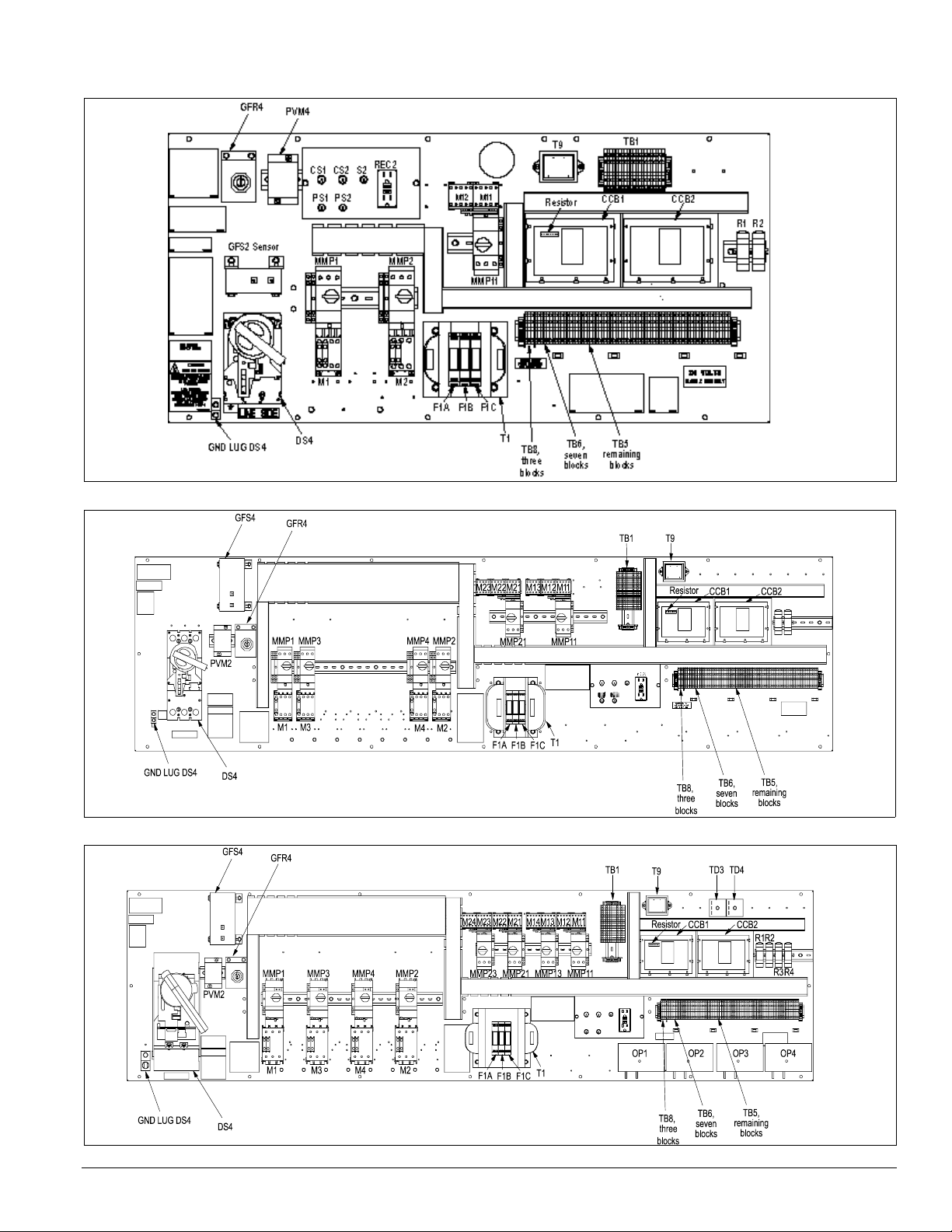

Figure 13. Typical main control panel, 015 to 040, 460 volt

Introduction: Control Panel

See separate

detail, page 17.

IM 738-2 11

Introduction: Control Panel

Figure 14. Typical main control panel, 045 to 075, 460 volt

See separate

detail, page 17.

12 IM 738-2

Figure 15. Typical main control panel, 080 to 135, 460 volt

Introduction: Control Panel

IM 738-2 13

Introduction: Control Panel

A

Figure 16. Typical gas heat panel, 1000 MBH

IT

R22

TD10

TB11

R20

S

R23 R21

LS2

LS1

S3

Figure 18. VFD bypass panel, 40 HP , 460 volt)

FSG

FSG Time

Figure 17. Typical propeller exhaust panel, three fans, 460

vo

lt

M51 M52 M53

AFD20 GND

14 IM 738-2

Figure 19. RCS control panel with MicroTech II, 015 to 040C

Introduction: Control Panel

Figure 20. RCS control panel with MicroTech II, RPS 045 to 075C

Figure 21. RCS control panel with MicroTech II, RPS 080 to 135C

IM 738-2 15

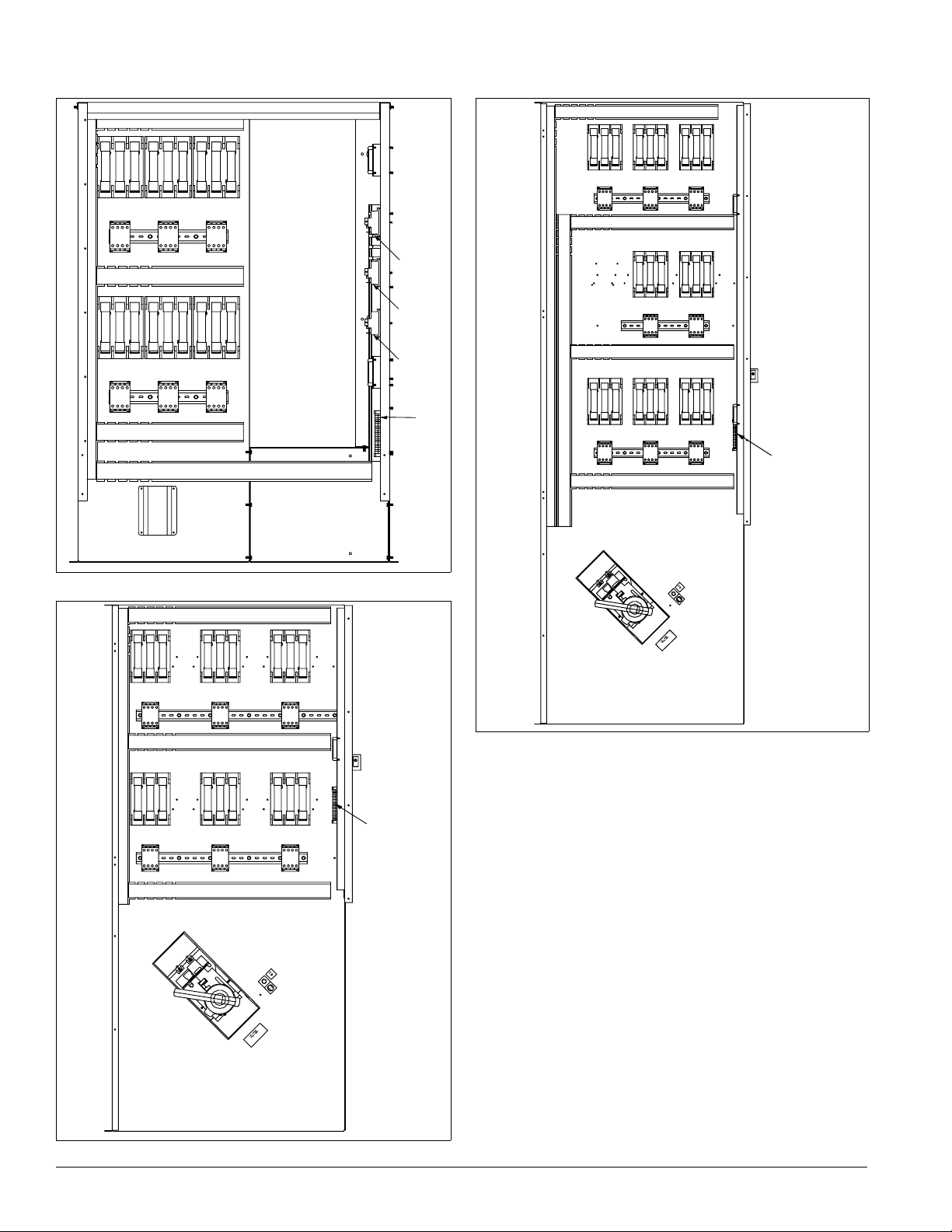

Introduction: Control Panel

Figure 22. Electric heat panel, sizes 15 to 40C

FB33 FB32 FB31

M33 M32 M31

FB43 FB42 FB41

M41 M42 M41

SR2

SR3

SR1

TB11

Figure 24. Electric heat panel, sizes 80 to 135

FB31FB32FB33

M31M32M33

FB34FB44

M34M44

FB41FB42FB43

M41M42M43

H53

TB11

PB3

Figure 23. Electric heat panel, sizes 45 to 75C

FB31FB32FB33

M31M32M33

FB41FB42FB43

M42

M41M43

GLG3

DS3

H53

TB11

GLG3

DS3

16 IM 738-2

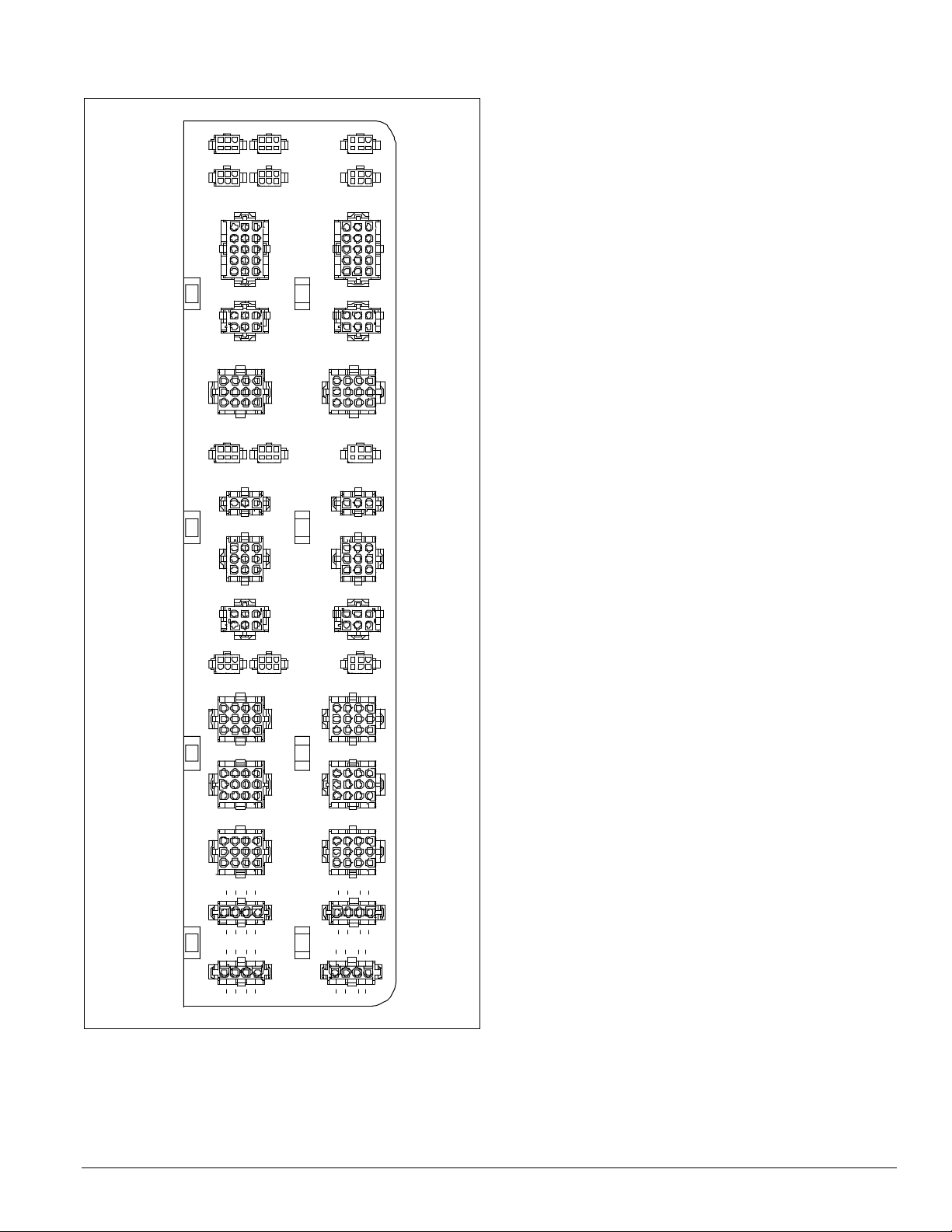

Figure 25. Harness plug connector detail

RATS OATSDATS

FP1 OPEN1EPTS

AFD10 AFD20

SV12 SV56

ACT3 OPEN2

OAE PC7PC5

Introduction: Control Panel

HL22 OPEN3

GSHT1 GSHT2

SD1 SD2

DFRH DFLH OPEN4

COMP1 COMP2

COMP3 COMP4

COMP6COMP5

LT11LT10

LT OP1 LT OP2

IM 738-2 17

Introduction: Controls, Settings, and Functio ns

Controls, Settings, and Functions

Table 3 below lists all of the unit control devices. Included in

the table are the device symbol, a descrip

tion of the device, its

setting, any setting ranges, differentials, and the device part

number.

function, and any reset information, its location, any device

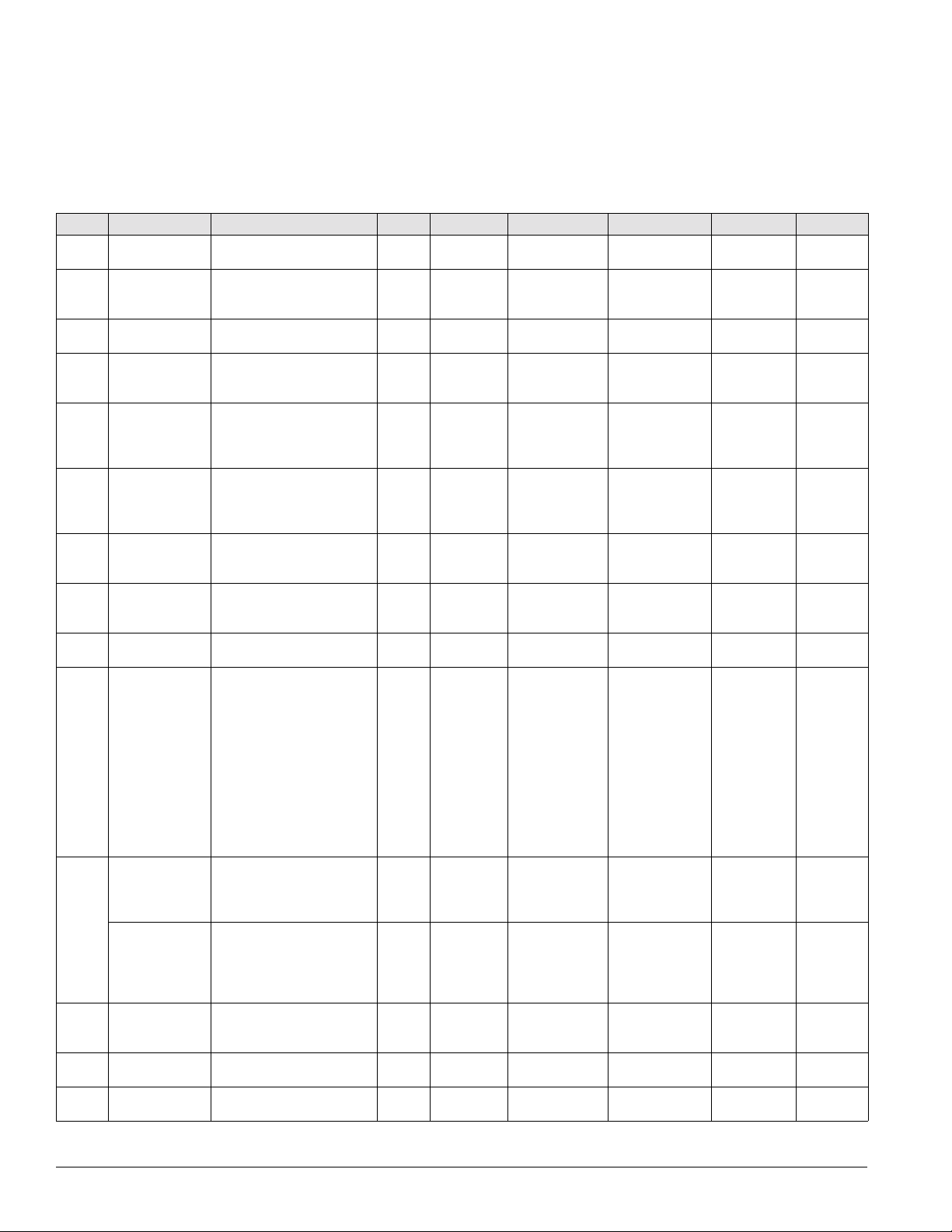

Table 3: Controls, settings, and functions

Symbol Description Function Reset Location Setting Range Differential Part no.

CS1 & 2 Switch (toggle),

HP1, 2,

MP1–6 Compressor

refrigerant circuit

DAT Discharge air

temperature

sensor

DHL Duct high limit

switch

EFT Entering fan air

temperature

sensor

FP1, 2 Evaporator frost

protection

FS1 Freezestat Shuts off fans, opens heating

High pressure

3 & 4

control

LP1, 2 Low pressure

control

MCB Main control board Processes input information N/A Main control

motor protector

OAE Enthalpy control

(electromechanical)

Enthalpy control

(electronic)

OAT Outside air

temperature

sensor

PC5 Dirty filter switch Senses filter pressure drop Auto First filter

PC6 Dirty filter switch Senses filter pressure drop Auto Final filter

Shut

s off compressor control

circuits manually

Senses discharge air

temperature

Prevents excessive VAV duct

pressures; shuts off fan

Senses entering fan air

temperature

Senses low refrigerant

temperature

valve, and closes outdoor

damper if low air temperature

at coil is detected

tops compressor when

S

refrigerant discharge pressure

is too high

Stops compressor when

suction pressure is too low

(used for pumpdown)

Senses motor winding

temperature, shuts off

compressor on high

temperature.

Notes:

1.Unit size 018C compressors

include internal moto

pr

otector.

2.Unit sizes 020C–036

circuit #1

internal motor protector (r ef er

to unit wiring diagram)

Returns outside air dampers to

minimum position when

enthalpy is too high

Returns outside air dampers to

minimum position when

outside air enthalpy is higher

than return air empalthy

(use RAE)

Senses outside air

temperature

compressors include

r

C,

.

N/A Main control

N/A Discharge air

Auto Main control

N/A Inlet of supply

N/A Return bends

Auto Heating

Manual

(relay

latched)

Auto Compressor See page 117. N/A 25 psi

Auto at

3400

ohms

Auto Economizer

Auto Economizer

N/A N/A N/A 060004705

panel

section

panel

fan

of

evaporative

coil

section

Compressor See page 117. N/A 100 psi

box

Compressor

junction box

section

section

section

section

N/A N/A N/A 01355000

N/A N/A 060004705

3.5" w.c

(871.8 Pa)

N/A N/A 060004705

Opens at 30°F

Closes at 45°F

38°F (3°C)

or as required

N/A N/A N/A 060006101

9 K–18 K ohms 700 ohms cold N/A 044691509

“B” or as required A–D Temperature:

Fully CW past “D”

(when used

with RAE)

As required .05-5" w.c.

As required .05-5" w.c.

0.05–5.0" w.c.

(12.5–1245.4 Pa)

N/A N/A 072501901

35°F–45°F

(2°C–7°C)

A–D N/A 049262201

(12.5–1245.4 Pa)

(12.5–1245.4 Pa)

.05" w.c.

(12.5 Pa), fixed

12°F (7°C),

fixed

(689 kPa)

(172 kPa)

3.5°F (2°C)

Humidity:

5% fixed

.05" w.c.

(12.5 Pa)

.05" w.c.

(12.5 Pa)

065493801

065830001

047356120

047356111

030706702

065493801

065493801

18 IM 738-2

Introduction: Controls, Settings, and Functio ns

Table 3: Controls, settings, and functions (continued)

Symbol Description Function Reset Location Setting Range Differential Part no.

PC7 A i r flow proving

switch

PS1, 2 Pumpdown switch Used to manually pump down

RAE Return air

enthalpy sensor

RAT Return air

temperature

sensor

SD1 Smoke detector,

supply air

SD2 Smoke detector,

return air

SPS1 Static pressure

sensor duct #1

SPS2 Static pressure

sensor duct #2

Static pr essure

sensor: building

(space) pressure

SV1, 2

Solenoid valve

(liquid line)

Solenoid valve

SV5, 6

(hot gas bypass)

System switch

S1

S7 ON-OFF-AUTO

switch

Senses supply fan pressure to

prove airflow

compressor

Used to compare return air

enthalpy to outside air

enthalpy (used with OAE)

Senses return air temperature N/A Return air

Initiates unit shutdown if

smoke is detected

Initiates unit shutdown if

smoke is detected

Converts static pressure

signals to voltage signals

Converts static pressure

signals to voltage signals and

sends them to MicroTech II

controller

Converts static pressure

signals to voltage signals.

Closes liquid line for

pumpdown

Closes hot gas bypass line for

pump-down

Shuts off entire control circuit

(except crankcase heaters)

Used to manually switch unit N/A Main control

Auto Supply fan

section

N/A Condenser

control box

N/A Economizer

section

section

Manual Discharge air

section

Manual Return air

section

N/A Main control

box

N/A Main control

box

N/A Main control

box

N/A Condenser

section

N/A Condenser

section

N/A Main control

box

box

.10" w.c. (25 Pa) .05-5" w.c.

N/A N/A N/A 01355000

N/A N/A N/A 049262202

N/A N/A 060004705

N/A N/A N/A 04925001

N/A N/A N/A 04925001

N/A 0–5" w.c.

N/A 0–5" w.c.

N/A -025–0.25" w.c.

N/A N/A N/A See parts

N/A N/A N/A 111011001

N/A N/A N/A 001355000

N/A N/A N/A

(12.5–1245.4 Pa)

(0–1245.4 Pa)

1–6 VDC out

(0–1245.4 Pa)

1–6 VDC out

(-62.3–62.3 Pa

VDC out

1–5

.05" w.c.

(12.5 Pa), fixed

N/A 049545007

N/A 049545007

N/A 049545006

)

060015801

catalog

IM 738-2 19

Introduction: Controls, Settings, and Functio ns

FanTrol

The FanTrol, provided on all units, is a method of head

pressure

control that automatically cycles the condenser fans

in response to ambient air temperature. This feature maintains

head pressure and allows the unit to run at low ambient air

temperatures.

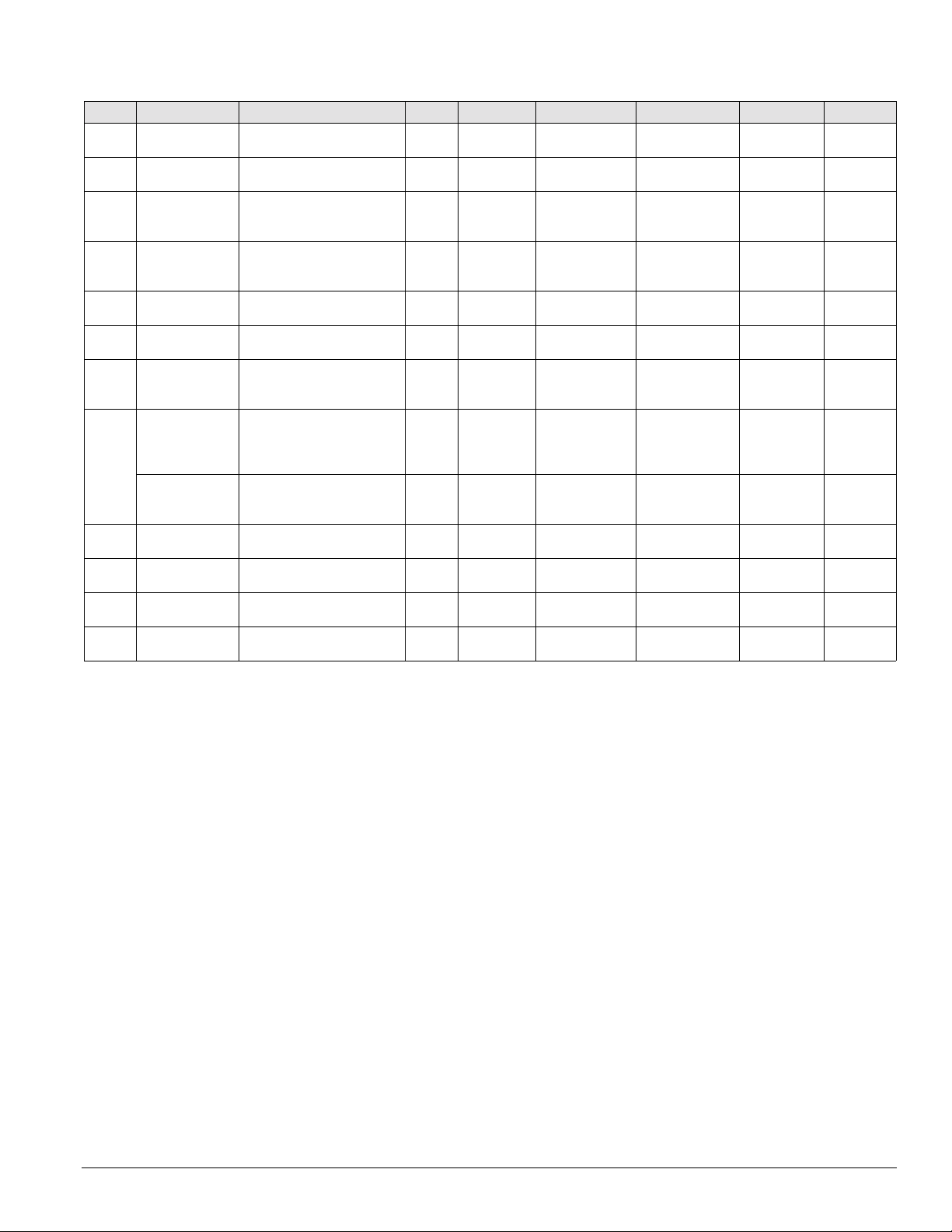

Table 4: R-22 FanTrol setpoints in °F with MicroTech II controls

RPS RCS

RDT RPR

Setpoint Differential Setpoint Differential Setpoint Differential Setpoint Differential

015 to 020C0 5605 ————

025 to 030C0 5655 ————

0360 5705 ————

045 to 045C0 5655 ————

0500 5605 ————

0600 5255705——

0700 5405705——

075 to 090C 0 5 65 5 75 5 0 5

1050505585705

1150505555755

1250 5655355805

1350 5555255655

B05 B06 B07 B08

RPS/RDT and RCS units have two independent refrigerant

s with one to four condenser fans being controlled

circuit

independently by the ambient air temperature of each circuit.

See the following sections for sequence of operation for

condenser fans with FanTrol.

Degrees Farenheit

Table 5: R-407C FanTrol setpoints in °F with MicroTech II controls

Degrees Farenheit

RPS, RCS, RDT

Setpoint Differential Setpoint Differential Setpoint Differential Setpoint Differential

015 0 5 60 5

018 to 020C0505————

025 to 036C0 5655 ————

040 0 5 60 6

0450 5555 ————

050 0 5 50 5 — —

0600 5155705——

0700 5305705——

0750 5655755 0 5

080 to 090C 0 5 65 5 75 5 0 5

1050505525705

1150505455755

1250 5555305805

1350 5455205655

B05 B06 B07 B08

20 IM 738-2

Mechanical Installation

Mechanical Installation: Receiving Inspection

The installation of this equipment shall be in accordance with

the regulations of authorities having jurisdiction and all

applicable codes. It is the responsibility of the installer to

determine and follow the applicable codes.

Note: Low head pressure may lead to poor, erratic refrigerant

feed control at the thermostatic expansion valve. The

units have automatic control of the condenser fans

which should provide adequate head pressure control

down to 50°F (10°C) provided the unit is not exposed to

windy conditions. The system designer is responsible

for assuring the condensing section is not exposed to

excessive wind or air recirculation.

CAUTION

Sharp edges on sheet metal and fasteners can c ause

personal injury.

This equipment must be installed, opera

only by an experienced installation company and fully

trained personnel.

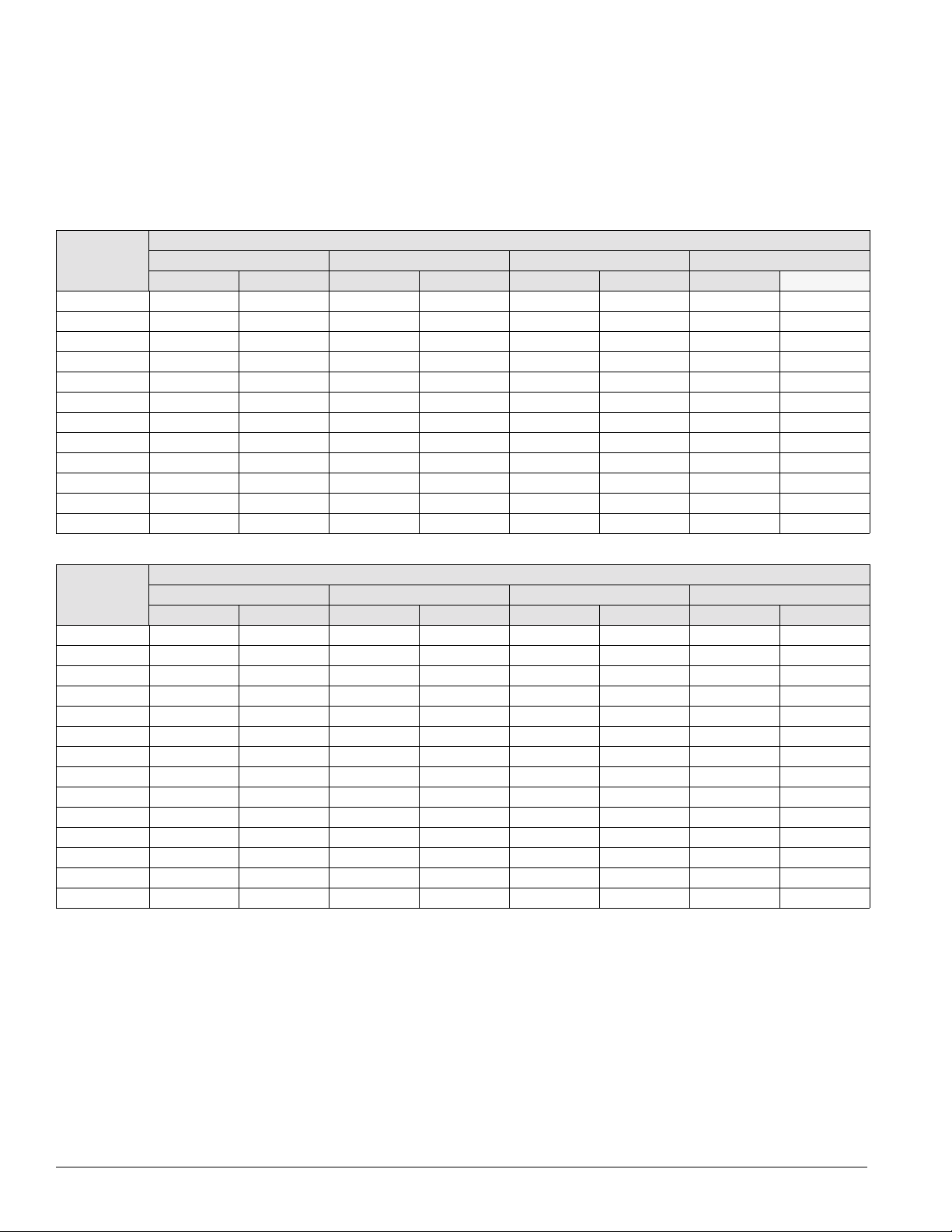

Figure 26. Service clearances

ted, and serviced

Receiving Inspection

When the equipment is received

, all items s

hould be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. If the unit has become dirty

during shipment (winter road chemicals are of particular

concern), clean it when received.

All units should be carefully

inspected for damage when

received. Report all shipping damage to the carrier and file a

claim. In most cases, equipment is shipped F.O.B. factory and

claims for freight damage should be filed by the consignee.

Before unloading the unit, check the unit nameplate to make

the voltage complies with the power supply available.

sure

Unit Clearances

Service Clearance

Allow service clearance approximately as indicated in Figure

26. Also, Daikin recommends providing a roof walkway to

the rooftop unit as well as along at least the two sides of the

unit that provide access to most controls and serviceable

components.

60"

(1524 mm)

Roof walkway

To roof

access

location

A

60"

(1524 mm)

BC

72"

(1829 mm)

DE

96"

(2438 mm)

Varies with unit arrangement

Refer to certified drawing & note.

C

F

60"

(1524 mm)

Legend:

A = Return air section

B = Filter section

C = Cooling section

D = Cooling/supply fan section

E = Heat section

F = Discharge plenum section

IM 738-2 21

Mechanical Installation: Ventilation Clearance

V entilation Clearance

Below are minimum ventilation clearance recommendations.

The system designer must consider each application and

provide adequate ventilation. If this is not done, the unit will

not perform properly.

Unit(s) surrounded by a screen or a fence:

The bottom of the screen or fence should be at least 1 ft.

1

(305 mm) above the roof surface.

2 The distance between the unit and a screen or fence should

be as described in “Service Clearance” on page 21. See also

Figure 26 on page 21.

3 The distance between any two units within a screen or

fence should be at least 120" (3048 mm).

Unit(s) surrounded by solid walls:

1 If there are walls on one or two adjacent sides of the unit,

the walls may be any height. If there are walls on more than

two adjacent sides of the unit, the walls should not be

higher than the unit.

2 The distance between the unit and the wall should be at

least 96" (2438 mm) on all sides of the unit.

3 The distance between any two units within the walls should

be at least 120" (3048 mm).

Do not locate outside air intakes near exhaust vents or other

sources

of contaminated air.

If the unit is installed where windy conditions are common,

in

stall wind screens around the unit, maintaining the

clearances specified (see Figure 27). This is particularly

important to prevent blowing snow from entering outside air

take and to maintain adequate head pressure control when

in

mechanical cooling is required at low outdoor air

temperatures.

Overhead Clearance

1 Unit(s) surrounded by screens or solid walls must have no

overhead obstructions over any part of the unit.

2 The area above the condenser must be unobstructed in all

installations to allow vertical air discharge.

3 The following restrictions must be observed for overhead

obstructions above the air handler section (see Figure 27):

a There must be no overhead obstructions above the

furnace flue, or within 9" (229 mm) of the flue box.

b Overhead obstructions must be no less than 96"

(2438 mm) above the top of the unit.

c There must be no overhead obstructions in the areas

above the outside air and exhaust dampers that are

farther than 24" (610 mm) from the side of the unit.

Figure 27. Overhead clearance

24" (610 mm)

maximum

96" (2438 mm)

minimum,

top of unit to

permanent

overhead

obstruction

Overhead

canopy

9" (229 mm)

minimum to flue box,

typical all sides

Flue box

24" (610 mm)

maximum

22 IM 738-2

Roof Curb Assembly and Installation

Mechanical Installation: Roof Curb Assembly and Installation

Locate the roof curb and unit on a portion of the roof that can

support the weight of the unit. The unit must be supported to

prevent bending or twisting of the machine.

If building construction allows sound and vibration into the

occupied s

pace, locate the unit over a non-critical area. It is

the responsibility of the system designer to make adequate

provisions for noise and vibration in the occupied space.

WARNING

Mold can cause personal injury. Some materials such as

gypsum wall board can promote mold growth when damp.

Such materials must be protected from moisture that can enter

units during maintenance or normal operation.

Install the curb and unit level to

allow the condensate drain to

flow properly and allow service access doors to open and close

without binding.

Integral supply and return air duct flanges are provided with

the RPS/

RFS roof curb, allowing connection of duct work to

the curb before the unit is set. The gasketed top surface of the

duct flanges seals against the unit when it is set on the curb.

These flanges must not support the total weight of the duct

work. See “Installing Ductwork” on page 49 for details on duct

connections. It is critical that the con

densate drain side of the

unit be no higher than the opposite side.

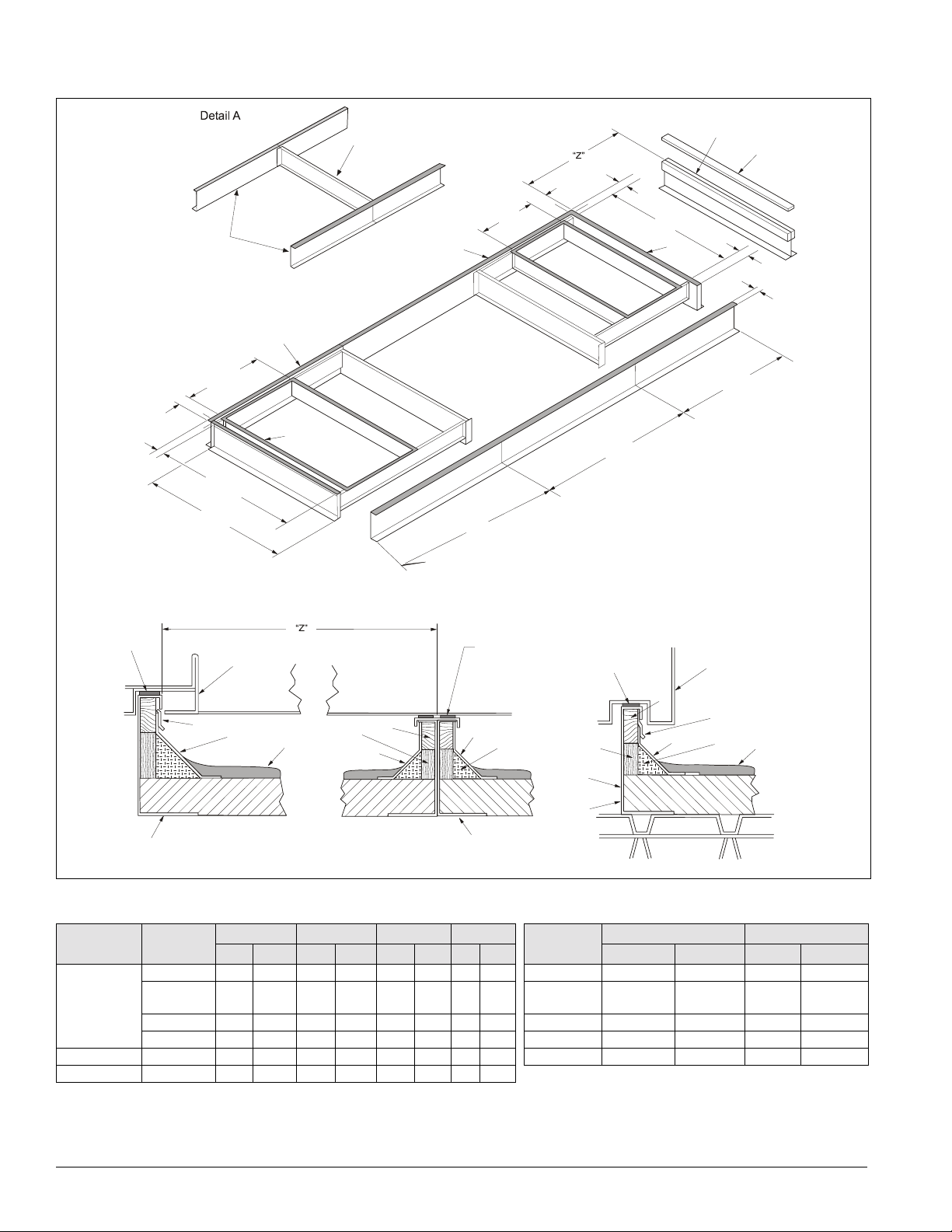

Assembly of a typical RPS/RDT roof curb is shown in

Figure 29 on page 24. Parts A through K are common to all

units having bottom return openings. Depending on the unit

th, Parts L and M may be included with the roof curb kit to

leng

create the correct overall curb length. Figure 28 shows the

assembly of the RCS roof curb.

RPS/RDT Assembly instructions (Figure 29 on

page 24)

1 Set curbing parts A through K per dimensions shown over

roof opening or on a level surface. Note location of return

and supply air openings.

2 If applicable, set other curbing parts (D, L, M, etc.) in place

making sure that the orientation complies with the

assembly instructions. Check alignment of all mating bolt

holes. See Detail A.

3 Bolt curbing parts together using fasteners provided.

Tighten all bolts finger tight.

4 Square entire curbing assembly and securely tighten all

bolts.

5 Position curb assembly over roof openings. Curb must be

level from side to side and over its length. Check that top

surface of the curb is flat with no bowing or sagging.

6 W eld curbing in place. Caulk all seams watertight. Remove

backing from 0.25" (6 mm) thick × 1.50" (38 mm) wide

gasketing and

7 Flash curbing into roof as shown in Detail B.

8 Parts E and F are not required on units with no return shaft

apply to surfaces shown by cross-hatching.

within the curb perimeter.

9 Parts G and H are not required on units with no supply shaft

within the curb perimeter.

10 Be sure that electrical connections are coordinated (see

Figure 30).

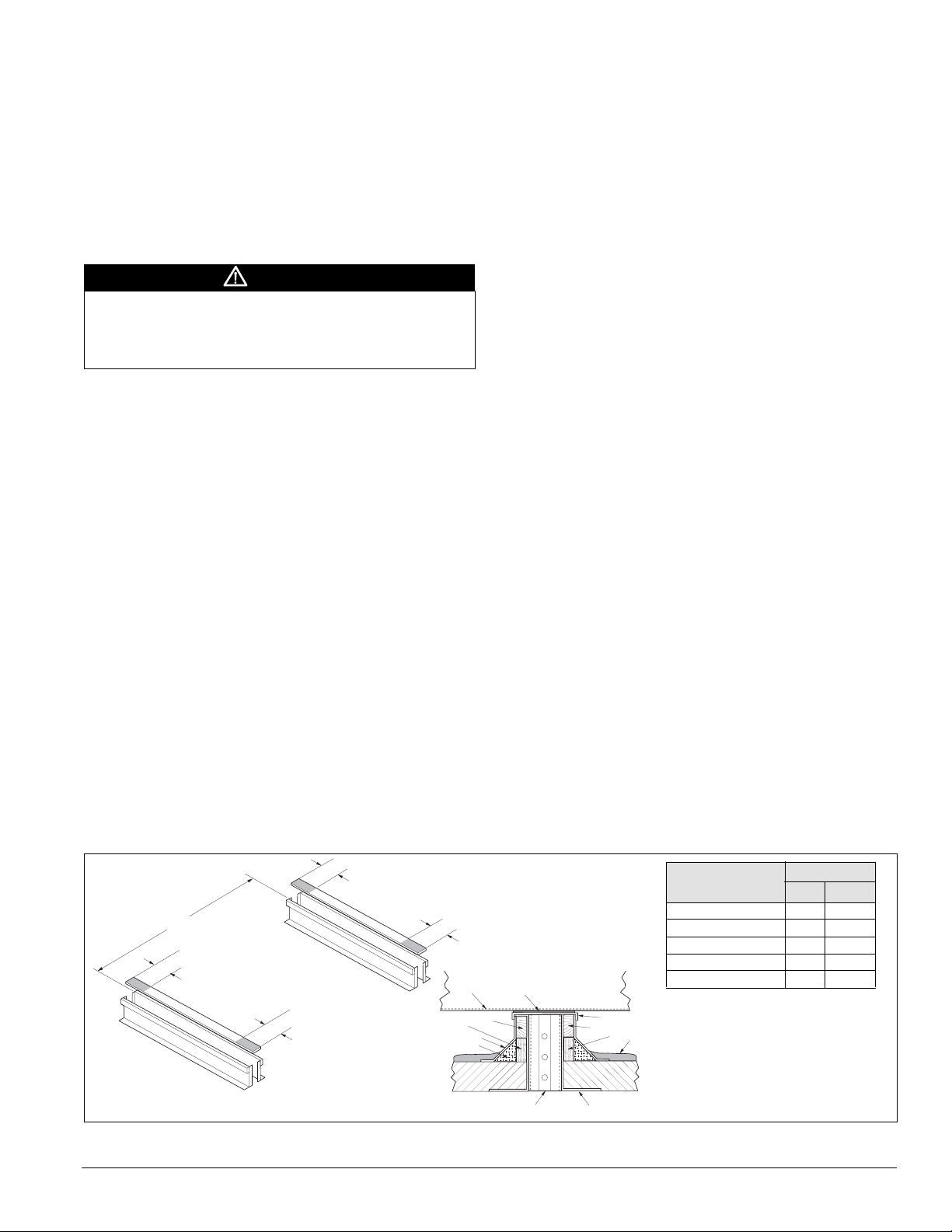

RCS Assembly instructions (Figure 28)

1 Set curbing parts (A) in place making sure that the

orientation complies with the assembly instructions. Check

alignment of all mating bolt holes.

2 Bolt curbing parts together using fasteners provided.

3 Curb must be level from side to side and over its length.

4 Weld curbing in place. Caulk all seams watertight and

insulate between channels.

5 Flash curbing into roof as shown in Detail C.

Figure 28. RCS roof curb assembly

6 "

" Z Z "

6 "

B

A

A

4 . x 4 N a i l e r S t r i p

6 "

6 . a n t S t r i p ( n o t f u r n i s h e d )

8 . u r b G a s k e t i n g

9 . I n s u l a t i o n b e t w e e n

G a l v a n i z e d u r b ( n o t f u r n i s h e d )

B

A

A

. U n i t B a s e

. G a l v a n i z e d u r b

. G a l v a n i z e d u i r b o v e r

. R i g i d I n s u l a t i o n ( n o t f u r n i s h e d )

. F l a s h i n g ( n o t f u r n i s h e d )

0 . R o o f i n g M a t e r i a l ( n o t f u r n i s h e d )

6 "

D e t a i

8

4

6

9

4

0

RCS unit size

015C–030C 31.0 787

036C & 040C 94.0 2057

045C–060C 62.0 1575

070C–105C 100.0 2540

115C–135C 120.0 3048

ZZ

in. mm

IM 738-2 23

Mechanical Installation: Roof Curb Assembly and Installation

Figure 29. RPS/RFS roof curb assembly

Using remaining side supports

in this area, align lengths on

opposite sides of assembly

M

and install a cross support

“D” at each side.

2

“Y”

Equal Length

Side Supports

“X”

8

Inside

“Y”

Inside

85"

L

“X”

E

A

1

9

B

F

Detail B

6

D

L

Return

Air

M

D

F

E

3

7

9

B

C

62.8"

Condenser

section

support

(RPS only)

9

“W”

inside

5

Condenser

Section Support

K

1.5"

6.8"

76"

G

Supply

H

Air

D

See Detail “A”

Inside

H

A

G

C

38.8"

1. Unit Base

2. Curb Gasketing

3. 2 x 4 Nailer Strip

4. Galvanized Curb

5. Cant Strip (not furnished)

6. Roofing Material (not furnished)

7. Rigid Insulation (not furnished)

8. Counterflashing (not furnished)

9. Flashing (not furnished)

7.5"

2"

Detail C

2

3

7

4

1

8

9

5

6

Main

unit curb

4

Height of perimeter curb and

Note:

condensing section support are not equal.

4

Table 6: Roof curb assembly dimensionsRPS/RFS dimensions

Unit size Fan

X Y XX YY

in mm in mm in mm in mm in mm in mm

Unit size

015–040C None 24.0 610 82.0 2083 6.8 173 1.5 38 015C–030C 45.9 1165 20.0 508

(2)15” FC 24.0 610 82.0 2083 6.8 173 1.5 38 036C and

040C

30" AF 30.0 762 76.0 1930 6.8 173 4.5 114 045C–075C 77.0 1956 28.0 712

40" AF 36.0 914 78.0 1981 14.8 376 3.5 89 80C–90C 113 2870 38.0 965

045C–075C All units 38.0 965 87.0 2210 8.8 222 3.5 89 105C—135C 113 2870 46.0 1168

80C–135C All units 62.0 1575 87.0 2210 8.8 222 3.5 89

Note: These dimensions do not apply to units with energy recovery wheels.

Z W

94.0 2388 20.0 508

24 IM 738-2

Mechanical Installation: Roof Curb Assembly and Installation

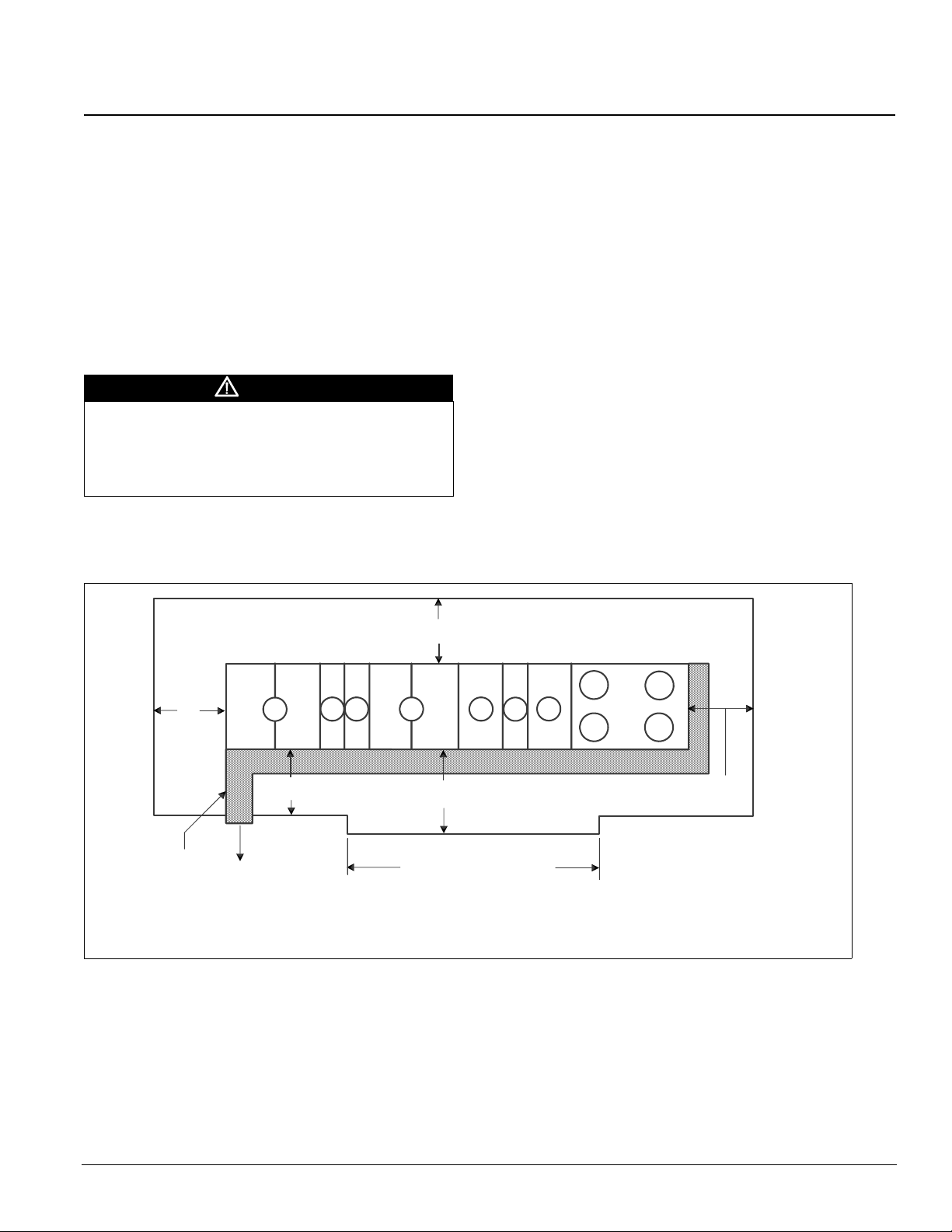

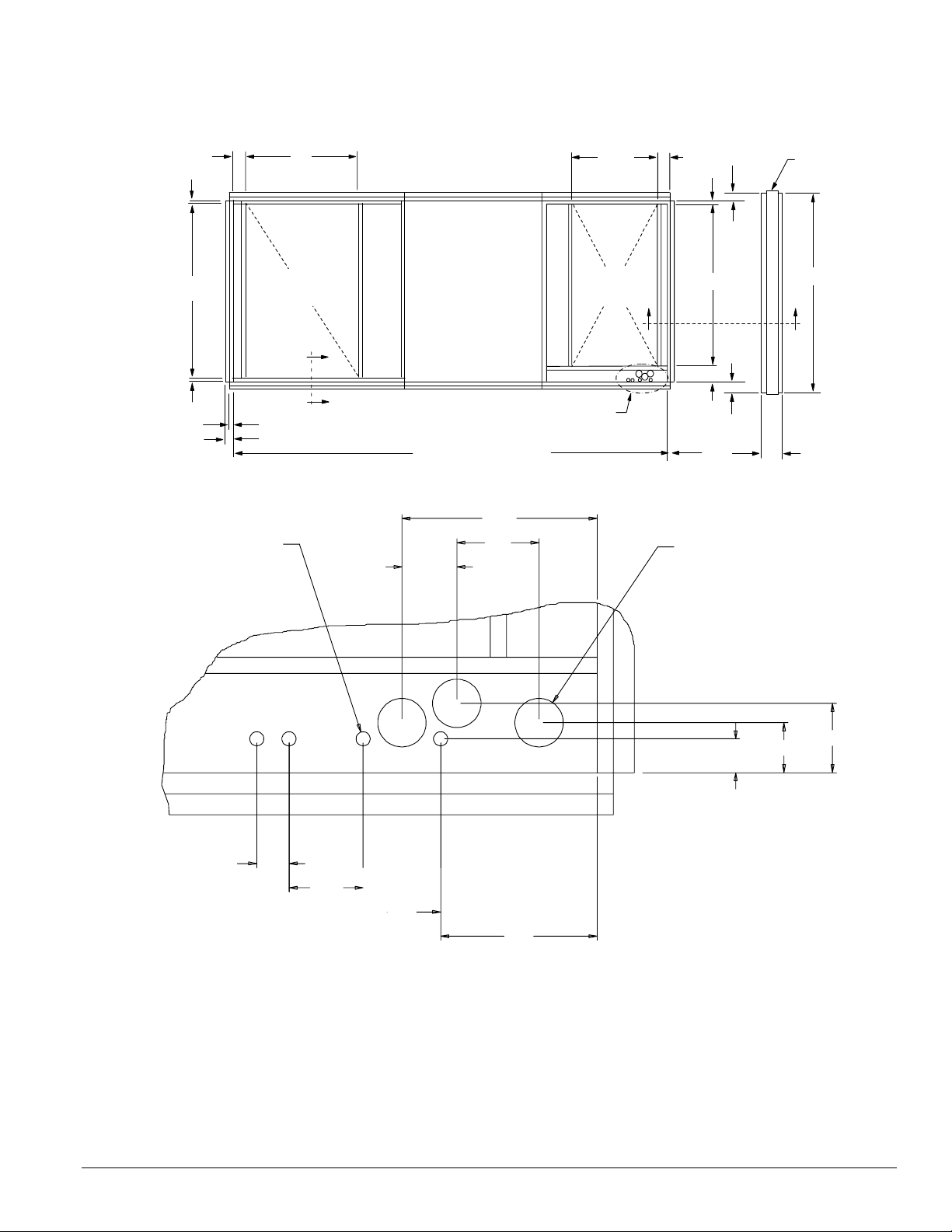

Figure 30. Typical power wire entrance, curb view (RPS/RFS 015C to 040C shown, see project certified drawings)

D

B

D

Detail A

C

2Typ

4Typ

0.9 Dia.

K.O.

A

RA

OPNG

A

A

See Detail A

Unit length minus 6.4

12.1

5.1

3.4

20.0

SA

OPNG

6.0

6.8

1.5

76.0

B

7.5

6.0

E

3.0 Dia.

K.O.

RPS only

97.0

B

8.0

4.3

2.0

4.6

4.8

9.7

2.1

3.1

IM 738-2 25

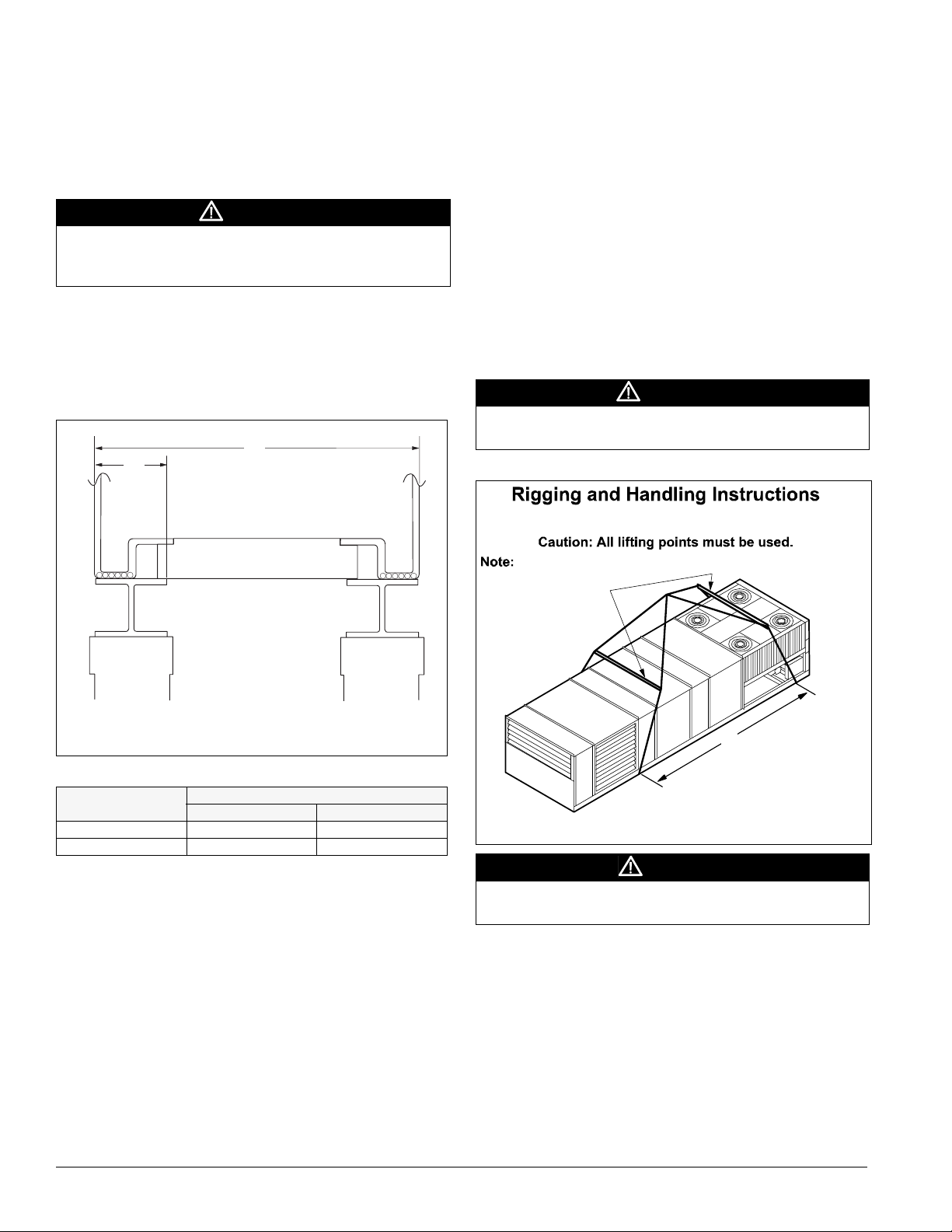

Mechanical Installation: Post and Rail Mounting

Post and Rail Mounting

When mounting by post and rail, run the structural support the

full length of the unit. Locate the structural member at the base

of the unit as shown in Figure 31, assuring the I-beam is well

supported by the structural member.

CAUTION

The unit must be level side to side

and over the entire length.

Equipment damage can result if the unit is not level.

If resilient material is placed between the unit and the

rail,

insert a heavy steel plate between the unit and the resilient

material to distribute the load. Seal cabinet penetrations

(electrical, piping, etc.) properly to protect against moisture

and weather.

Figure 31. Post and rail mounting

W

" *

3 Provide proper drainage around the unit to prevent flooding

of the equipment.

4 Provide adequate protection from vandalism, mechanical

contact, etc.

5 Securely close the doors.

6 If there are isolation dampers, make sure they are properly

installed and fully closed to prevent the entry of animals

and debris through the supply and return air openings.

7 Cover the supply and return air openings on units without

isolation dampers.

Figure 32 shows an example of the rigging instruction label

shipped with each unit.

WARNING

Use all lifting points. Improper lifting can cause severe personal

injury and property damage.

Figure 32. Rigging and handling instruction lab el

Unit has either four or six lifting points (four-point shown below).

Rigging cables must be at least as long as distance “A.”

Spreader bars

required

Maximum recommended width for structural member is 5" (127 mm) to

allow for adequate space for duct connections and electrical entry.

Table 7: W dimension (Figure 31)

Unit

015C-040C 94 2388

045C-135C 99 2538

inches mm

Dimension W

Rigging and Handling

Lifting brackets with 2" (51 mm) diameter holes are provided

on the sides of the unit.

Use spreader bars, 96" to 100" (2438 to 2540 mm) wide to

prev

ent damage to the unit cabinet. Avoid twisting or uneven

lifting of the unit. The cable length from the bracket to the

hook should always be longer than the distance between the

outer lifting points.

If the unit is stored at the constru

period, take these additional precautions:

1 Support the unit well along the length of the base rail.

2 Level the unit (no twists or uneven ground surface).

ction site for an intermediate

A

Caution: Lifting points may not

be symmetrical to center of

gravity of unit. Balast or unequal

Lift only as indicated

cable lengths may be required.

CAUTION

Lifting points may not be symmetrical to the center of gravity of

the unit. Ballast or unequal cable lengths may be required.

26 IM 738-2

Mechanical Installation: Rigging and Handling

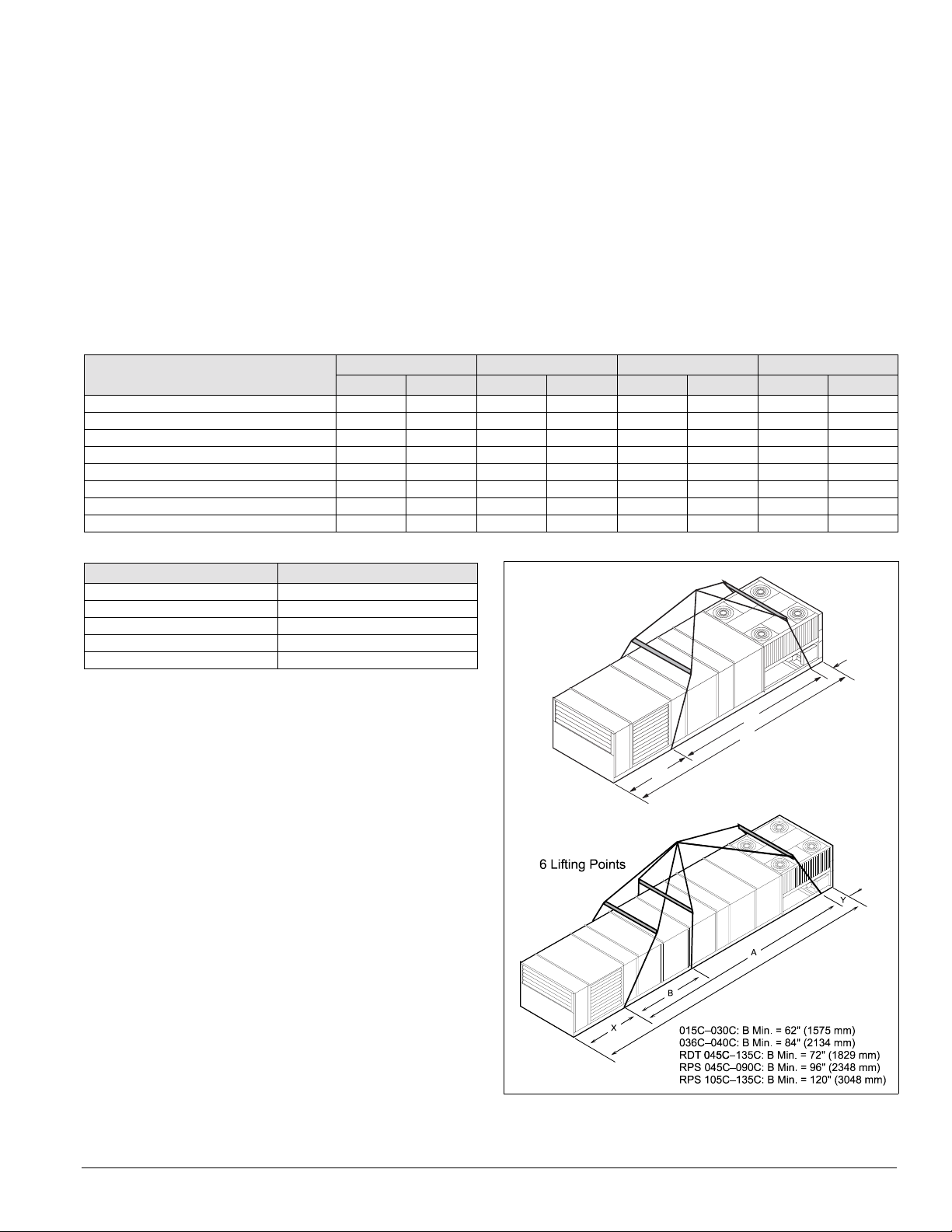

Lifting Points

To determine the required lifting cable lengths and whether

fo

ur-or six-point lifting is required, use Tables 8 and 9 and

Figures 33 and 34.

Referring to Figure 33 and Figure 34, note that dimension A is

the distance between the outer lift

ing points. The four outer

rigging cables must be equal to or longer than dimension A.

Dimension B shows the minimum distance between the outer

and the inner lifting points for six-point lifting. Use this to

roughly determine the required length of the middle cables for

six-point lifting. Determine dimension A by subtracting

Where:

Z = Total unit length in inches

(refer to certified drawings for this di

mension).

X = Outdoor/return air section length (refer to Table 8for this

dimension).

Y = Refer to Table 9 for this dimension (see Figure 33 and

Figure 34).If A ≤

288" (7315 mm), 4-point lifting is sufficient.

If A > 288" (7315 mm), 6-point lifting is required.

dimensions X and Y from dimension Z (e.g., A = Z – X – Y).

Table 8: X dimension (Figure 33 and Figure 34)

Outdoor/return air section

100 O.A. 000 00000

Plenum 40 1016 52 1321 48 1259 72 1829

0–30% O.A. 40 1016 52 1321 48 1259 72 1829

0–100% economizer 40 1016 52 1321 72 1829 96 2438

0–100% economizer with 15” return fan 62 1575 — — — — — —

0–100% economizer with 30” return fan 52 1321 52 1321 — — — —

0–100% economizer with 40” return fan — — 80 2032 — — — —

0–100% economizer with return fan — — — — 72 1829 96 2438

015C–030C 036C–040C 045C–075C 080C–135C

in mm in mm in mm in mm

Table 9: Y dimension (Figure 33 and Figure 34)

RPS unit size Dimension Y

015C–030C 49.5" (1257 mm)

036C & 040C 38.2" (970 mm)

045C–090C 39.5" (1003 mm)

105C 30.5" (775 mm)

115C–135C 39.5‘” (1003 mm)

Figure 33. Unit type RPS/RDT lifting points

4 L i f t i n g P o i n t s

Y

A

Z

X

IM 738-2 27

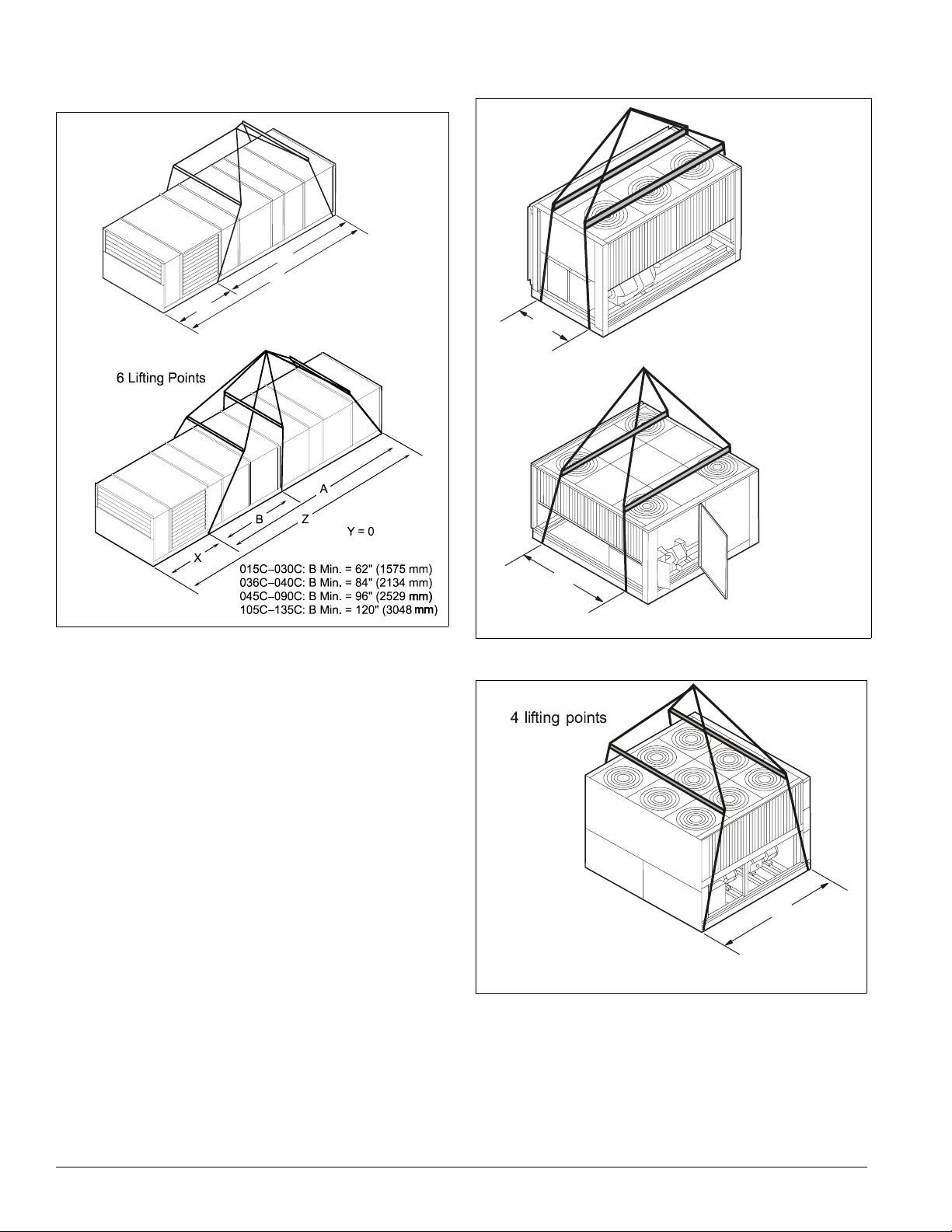

Mechanical Installation: Rigging and Handling

(

)

Figure 34. Unit type RFS or RPS/RDT factory split at

condenser

4 L i f t i n g P o i n t s

A

Z

Y = 0

X

Figure 35. Unit type RCS

4 L i f t i n g P o i n t s

A

0 - 0 0 : A M i n . = . 9 " ( 8 6 m m )

4 L i f t i n g P o i n t s

A

0 6 & 0 4 0 : A M i n . = 8 . 6 " ( 4 m m )

Figure 36. Unit type RCS or condenser section from RPS/

RDT

factory split at condenser

B

0 4 5 C – 0 6 0 C : B ( mi n .) = 5 7 " ( 1 4 4 8 m m )

0 7 0 C : B ( mi n .) = 9 3 " ( 2 3 6 2 m m )

C – 105

115C – 135C: B

min.) = 113" (2870 cm

28 IM 738-2

Loading...

Loading...