Daikin DPS, MPS, RAH, RDT, RFS Installation And Maintenance Manual

...

Installation and Maintenance Manual IM 919-3

Group: Applied Air Systems

Part Number: IM 919

Date: October 2014

MicroTech® III Controller for Commercial Rooftop

Systems, Applied Rooftop Systems and Self-Contained

Air Conditioners

Models: DPS, MPS, RAH, RCS, RDS, RDT, RFS, RPE, SWP and SWT

Table of ConTenTs

Introduction .................................3

General Description ..........................3

Component Data ............................3

Main Control Board (MCB) ...................4

Keypad/Display ..............................5

Passwords .................................6

Navigation Mode ............................6

Edit Mode ..................................6

Remote Keypad Display Option .................6

About this AHU ..............................6

Controller Application Software

Upgrade Procedures ..........................7

Description of Operation ......................8

Temperature Sensors .........................8

Pressure Sensors ...........................9

Troubleshooting Pressure Transducers .........9

Duct Pressure Sensor ......................10

Building Pressure Sensor ...................11

Mamac Panel-Mounted Pressure Transducer ....12

Actuators ................................13

Variable Frequency Drives (VFD’s) ............13

Smoke Detectors .........................13

ECM (Electronically Commutated Motor)

fan/motor ................................13

Controller Inputs/Outputs .....................14

Table of ConTenTs

Field Wiring ................................24

Field Output Signals .......................24

Field Analog Input Signals ..................25

Field Digital Input Signals ...................28

Emergency Shutdown ......................29

OA Damper Flow Station with CO2 Reset Setup ..29

CO2 Sensor wiring .........................29

EBTRON or Field OA Flow Station Wiring.......30

Cooling: Multistage ..........................31

Compressor Staging ........................31

Communication Module ......................40

Network Communications ....................40

Unit Conguration Setup Menu ................41

Typical Electrical Drawings - RoofPak ..........44

Typical Electrical Drawings - Maverick...........59

Typical Electrical Drawings - Rebel .............64

Typical Electrical Drawings - Self-Contained .....75

Parts List ...................................81

IM 919-3 • MICROTECH III CONTROLLER 2 www.DaikinApplied.com

InTroduCTIon

This manual contains information regarding the MicroTech® III

control system used in the Daikin Rooftop and Self Contained

product lines. It describes the MicroTech III components, input/

output congurations, eld wiring options and requirements,

and service procedures. For a description of operation and

information on using the keypad to view data and set control

parameters, refer to the appropriate operation manual. For

installation and commissioning instructions and general

information on a particular unit model, refer to its model-

specic installation manual.

Table 1: Operation, Installation and Maintenance Resources

Unit Manual

MicroTech III Rooftop Unit Controller -

BACnet IP Communications

MicroTech III Rooftop Unit Controller

-BACnet MSTP Communications

MicroTech III Rooftop Unit Controller

-BACnet LON Communications

Rooftop/Self-Contained Operation OM 920

MicroTech III Remote Unit Interface IM 1005

RPS/RDT/RFS/RCS 015C-105C IM 926

RPS/RDT/RFS/RCS 015D-140D IM 893

SWP Self-Contained (012H-130H) IM 1032

RoofPak RAH/RDS IM 987

Maverick II Rooftop 62-75 ton IM 991

Maverick II Rooftop 15-50 ton IM 1058

IM 916

IM 917

IM 918

InTroduCTIon

WARNING

Excessive moisture in the control panel can cause hazardous

working conditions and improper equipment operation.

When servicing this equipment during rainy weather, the

electrical components in the main control panel must be

protected from the rain..

CAUTION

Extreme temperature hazard. Can cause damage to system

components.

The MicroTech III controller is designed to operate in ambient

temperatures from -20°F to 125°F. It can be stored in ambient

temperatures from -40°F to 140°F. It is designed to be stored

and operated in relative humidity up to 95% (non-condensing).

WARNING

Static sensitive components. A static discharge while

handling electronic circuit boards can cause damage to the

components.

Discharge any static electrical charge by touching the bare

metal inside the main control panel before performing any

service work. Never unplug any cables, circuit board terminal

blocks, relay modules, or power plugs while power is applied

to the panel.

NOTICE

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user is required to correct

the interference at his own expense. Daikin International

disclaims any liability resulting from any interference or for the

correction thereof.

WARNING

Electric shock hazard. Can cause personal injury or equipment

damage.

This equipment must be properly grounded. Connections and

service to the MicroTech III control panel must be performed

only by personnel that are knowledgeable in the operation of

the equipment being controlled.

General Description

The MicroTech III Unit Controller is a microprocessor-based

controller designed to provide sophisticated control of Daikin

Air Handling unit. In addition to providing normal temperature,

static pressure, and ventilation control, the controller can

provide alarm monitoring and alarm-specic component

shutdown if critical system conditions occur.

The operator can access temperatures, pressures, operating

states, alarm messages, control parameters, and schedules

with the keypad/display. The controller includes password

protection against unauthorized or accidental control parameter

changes.

This MicroTech III controller is capable of complete, standalone rooftop unit control, or it can be incorporated into a

building-wide network using an optional plug-in communication

module. Available communication modules include BACnet/IP,

BACnet® MS/TP, and LonMark®.

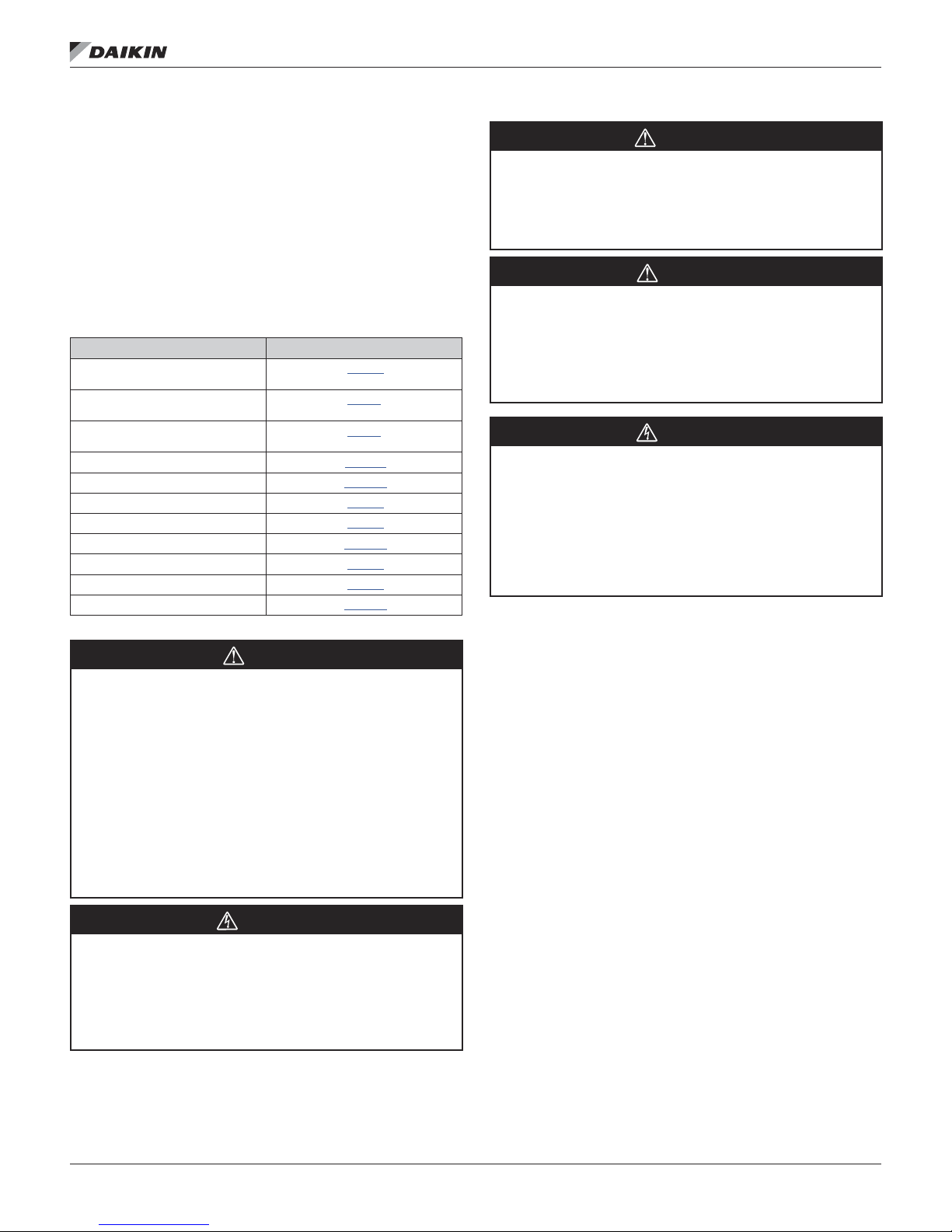

Component Data

The main components of the MicroTech III control system

include the main control board (MCB) with a built in keypad/

display and I/O’s, Expansion Modules A, B, C, D, E.

Transformers T2, T3 and T9 supply power to the system. The

following pages contain descriptions of these components and

their input and output devices.

www.DaikinApplied.com 3 IM 919-3 • MICROTECH III CONTROLLER

InTroduCTIon

Main Control Board (MCB)

Figure 1: Main Control Board

Analog Inputs

Power

Supply

Universal I/O

Figure 2: Expansion Boards A, B, C, D, E

Digital Output

Figure 3: Expansion Board Side Views

Digital Inputs

Digital Outputs

Universal I/O

Digital Inputs

Digital Input

Internal Modbus

Dip Switches

Remote

Keypad/

Display

Figure 4: Dip Switch Settings

Expansion

Board A

Expansion

Board B

Expansion

Board C

Expansion

Board D

Expansion

Board E

Switch #5 in the up

position (all others down)

Switch #4 in the up

position (all others down)

Switch #4 and #5 in the

up position (all others

down)

Switch #3 in the up

position (all others down)

Switch #3 and #5 in the

up position (all others

down)

Switch #6 must be in the

up position on the last

Dipswitch #6

expansion board in the

string regardless whether

it is A, B, C, D, or E.

Table 2: MCB I/O Connection Labeling

MCB I/O Connection Label

T1 24 VOLT POWER SUPPLY

T2 DIGITAL OUTPUT 1,

T3 DIGITAL OUTPUT 2, 3, 4

T4 DIGITAL OUTPUT 5, 6, 7, 8

T5 DIGITAL OUTPUT 9, 10

T6 DIGITAL INPUT 5, 6

T7 ANALOG INPUT 1, 2, 3

T8 UNIVERSAL I/O 1, 2, 3, 4

T9 UNIVERSAL I/O 5, 6, 7, 8

T10 DIGITAL INPUT 1, 2

T11 DIGITAL INPUT 3, 4

T12 MODBUS/VFD

T13 PROCESS BUS/FUTURE

IM 919-3 • MICROTECH III CONTROLLER 4 www.DaikinApplied.com

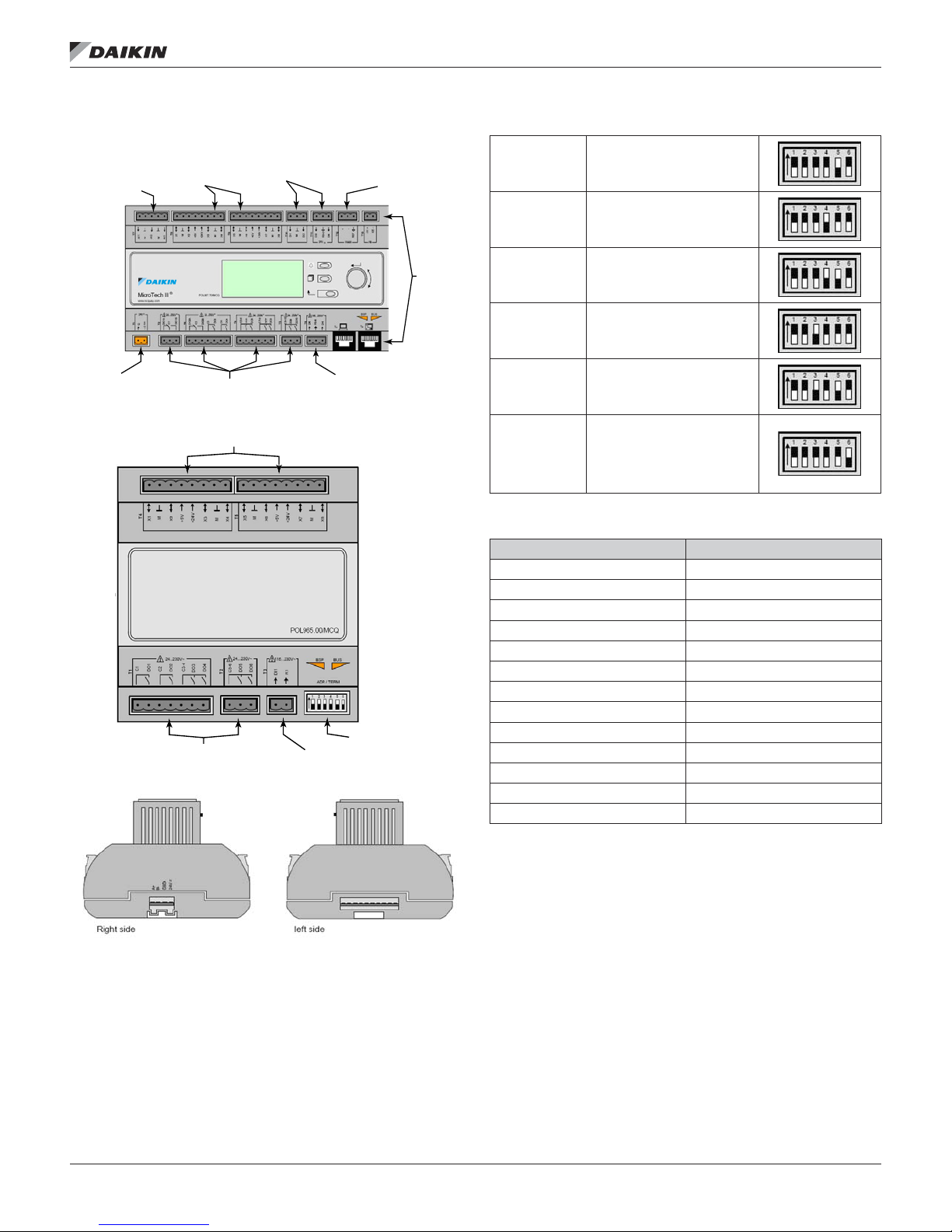

Keypad/dIsplay

The keypad/display consists of a 5-line by 22 character display,

three keys and a “push and roll” navigation wheel. There is an

Alarm Button, Menu (Home) Button, and a Back Button. The

wheel is used to navigate between lines on a screen (page)

and to increase and decrease changeable values when editing.

Pushing the wheel acts as an Enter Button.

Figure 5: Keypad/Display

The rst line on each page includes the page title and the line

number to which the cursor is currently “pointing”. The line

numbers are X/Y to indicate line number X of a total of Y lines

for that page. The left most position of the title line includes an

“up” arrow to indicate there are pages “above” the currently

displayed items, a “down” arrow to indicate there are pages

“below” the currently displayed items or an “up/down” arrow

to indicate there are pages “above and below” the currently

displayed page.

Each line on a page can contain status only information or

include changeable data elds. When a line contains status

only information and the cursor is on that line all but the value

eld of that line is highlighted meaning the text is white with

a black box around it. When the line contains a changeable

value and the cursor is at that line, the entire line is highlighted.

Each line on a page may also be dened as a “jump” line,

meaning pushing the navigation wheel will cause a “jump” to

a new page. An arrow is displayed to the far right of the line to

indicate it is a “jump” line and the entire line is highlighted when

the cursor is on that line.

The keypad/display Information is organized into Menu groups;

Main Menu, Quick Menu, View/Set Unit Menu, Commission

Unit Menu, Manual Control Menu, Service Menu, Unit

Conguration Menu and Alarm list Menus.

NOTE: Only menus and items that are applicable to the

specic unit conguration are displayed.

Keypad/dIsplay

The Main Menu allows the user to enter a password, access

the Quick Menu pages, view the current unit state, access the

Alarm List Menu as well as access to information about the

unit. The Quick Menu provides access to status information

indicating the current operating condition of the unit. The

View/Set Unit Menus include basic menus and items required

to setup the unit for general operation. These include such

things as control mode, occupancy mode, and heating and

cooling setpoints. The Commission Unit Menus include more

advanced items for “tuning” unit operation such as PI loop

parameters and time delays. The Manual Control Menu allows

service personnel to test unit specic operation manually.

The Unit Conguration Menu allows the user to access to the

unit specic conguration information. These generally do not

needing changing or accessing unless there is a fundamental

change to, or a problem with, the unit operation. The Alarm

Lists Menu includes active alarm and alarm log information.

www.DaikinApplied.com 5 IM 919-3 • MICROTECH III CONTROLLER

About This AHU

Keypad/dIsplay

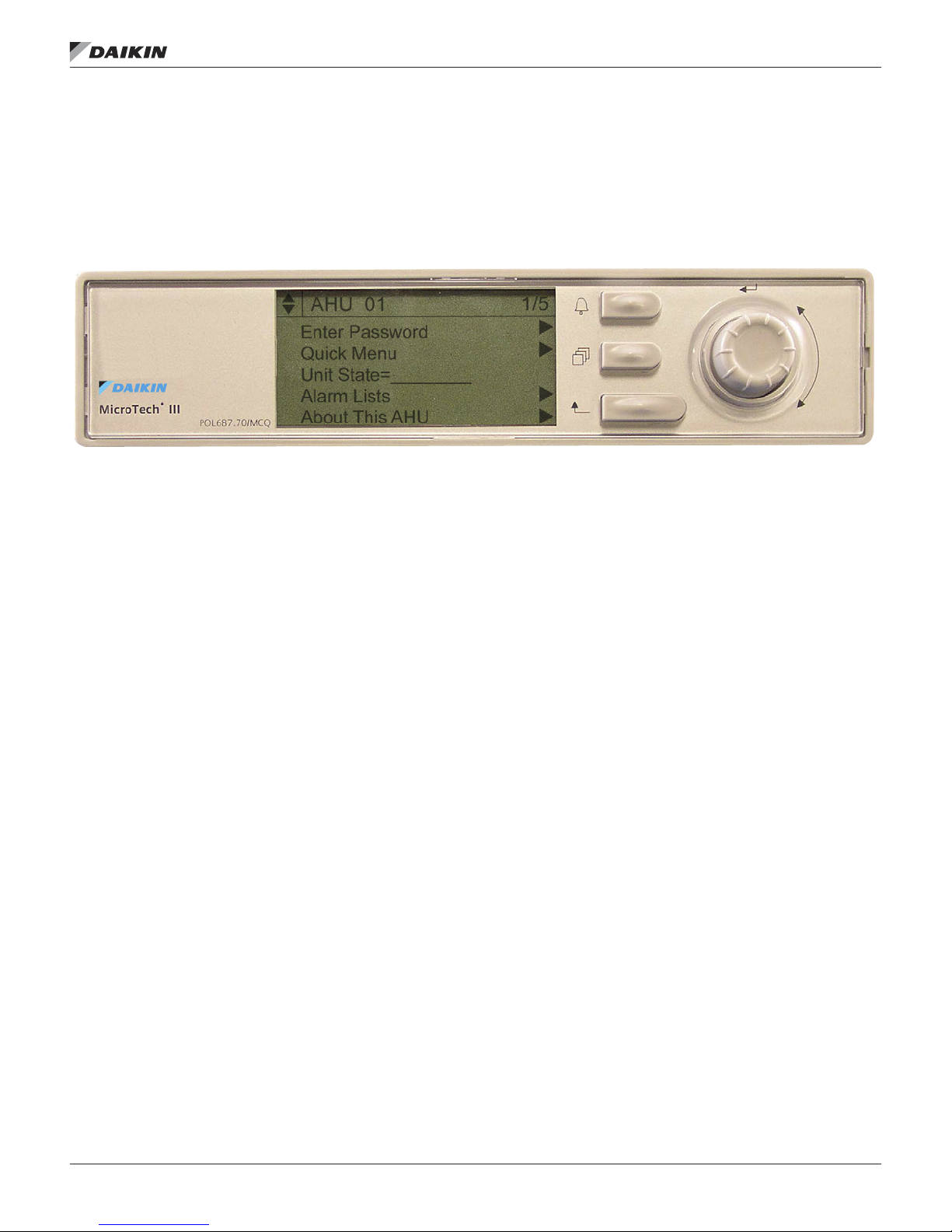

Passwords

Various menu functions are accessible or inaccessible,

depending on the access level of the user, and the password

they enter, if any. There are four access levels, including no

password, Level 2, Level 4, and Level 6, with Level 2 having

the highest level of access. Without entering a password, the

user has access only to basic status menu items. Entering

the Level 6 password (5321) allows access to the Alarm Lists

Menu, Quick Menu, and the View/Set Unit Menus group.

Entering the Level 4 password (2526) allows similar access

as Level 6 with the addition of the Commission Unit Menu,

Manual Control, and Service Menu groups. Entering the Level

2 password (6363) allows similar access as Level 4 with the

addition of the Unit Conguration Menu.

NOTE: Alarms can be acknowledged without entering a

password.

The main password page is displayed when the keypad/display

is rst accessed, the Home Key is pressed, the Back Key is

pressed multiple times, or if the keypad/display has been idle

longer than the Password Timeout (default 10 minutes). The

main password page provides access to enter a password,

access the Quick Menu, view the current Unit State, access the

alarm lists or view information about the unit.

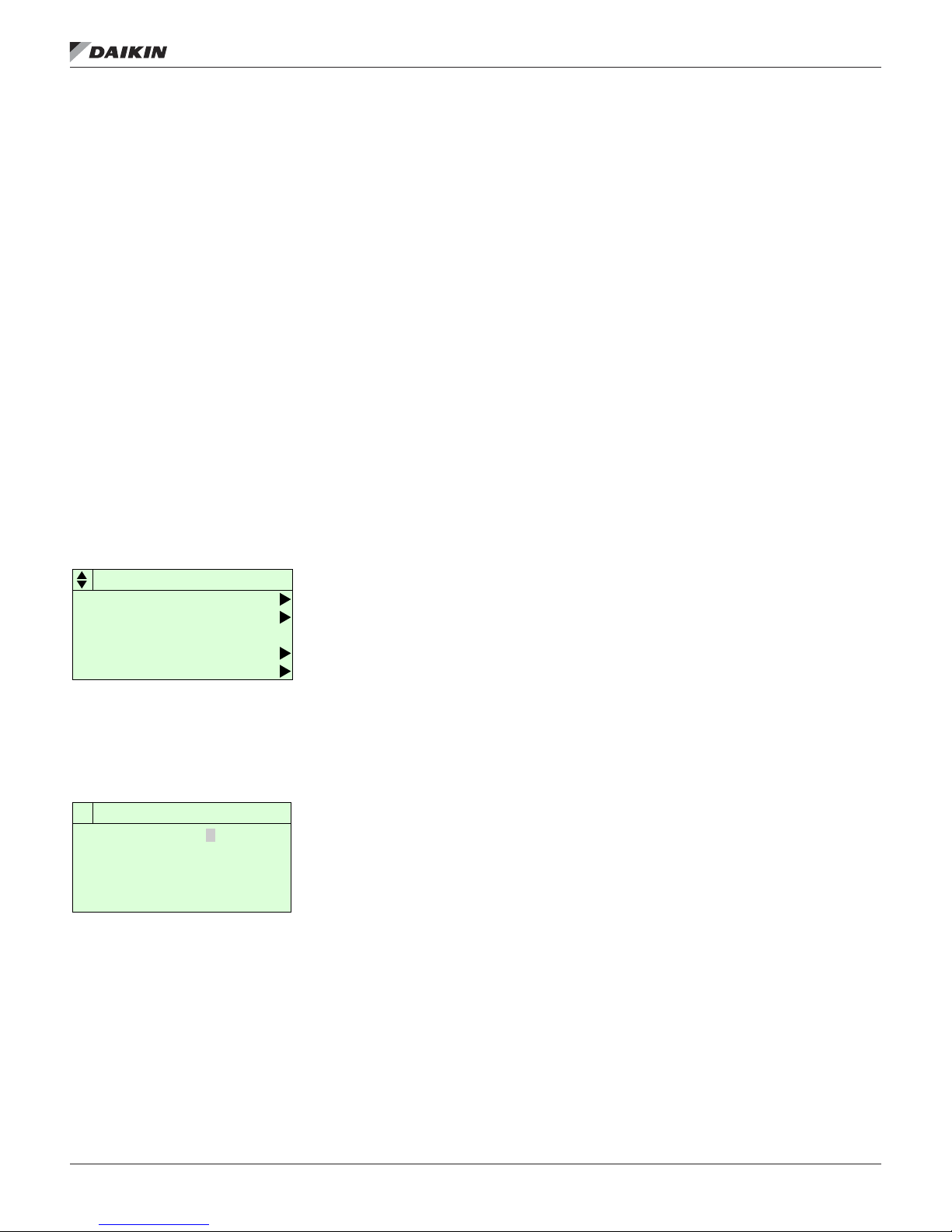

Figure 6: Password Main Page

AHU 01 1/5

Enter Password

Quick Menu

Unit State=________

Alarm Lists

The password eld initially has a value **** where each *

represents an adjustable eld. These values can be changed

by entering the Edit Mode described below.

Figure 7: Password Entry Page

Enter Password� 1/1

Enter Password

Entering an invalid password has the same effect as continuing

without entering a password. Once a valid password has been

entered, the controller allows further changes and access

without requiring the user to enter a password until either the

password timer expires or a different password is entered.

The default value for this password timer is 10 minutes. It is

changeable from 3 to 30 minutes via the Timer Settings menu.

** **

Navigation Mode

In the Navigation Mode, when a line on a page contains no

editable elds all but the value eld of that line is highlighted

meaning the text is white with a black box around it. When the

line contains an editable value eld the entire line is inverted

when the cursor is pointing to that line.

When the navigation wheel is turned clockwise, the cursor

moves to the next line (down) on the page. When the wheel is

turned counter-clockwise the cursor moves to the previous line

(up) on the page. The faster the wheel is turned the faster the

cursor moves.

When the Back Button is pressed the display reverts back to

the previously displayed page. If the Back button is repeatedly

pressed the display continues to revert one page back along

the current navigation path until the “main menu” is reached.

When the Menu (Home) Button is pressed the display reverts

to the “main page”.

When the Alarm Button is pressed, the Alarm Lists menu is

displayed.

Edit Mode

The Editing Mode is entered by pressing the navigation wheel

while the cursor is pointing to a line containing an editable eld.

Once in the edit mode pressing the wheel again causes the

editable eld to be highlighted. Turning the wheel clockwise

while the editable eld is highlighted causes the value to be

increased. Turning the wheel counter-clockwise while the

editable eld is highlighted causes the value to be decreased.

The faster the wheel is turned the faster the value is increased

or decreased. Pressing the wheel again cause the new value

to be saved and the keypad/display to leave the edit mode and

return to the navigation mode.

Remote Keypad Display Option

The remote user interface is designed for display, system

conguration, set-up and management of Daikin MicroTech III

applied air units.

In addition to the unit-mounted user interface provided with

MicroTech III controls, Daikin HVAC (applied rooftop systems,

indoor vertical self-contained systems, or commercial rooftop

systems) can be equipped with a remote user interface that

handles up to eight units per interface. The remote user

interface provides access to unit diagnostics and control

adjustments. The remote user interface provides the same

functionality as the unit-mounted controller.

About this AHU

The About this AHU menu item provides the user with

the current APP version (application code version), the

conguration code string for this unit, the BSP version

(rmware version) as well as the HMI/OBH GUID version

(software identiers). Each new release of application code

will have a unique set of software identiers. The information

shown in the HMI/OBH GUID version will list the information

needed to verify a match to the APP version.

IM 919-3 • MICROTECH III CONTROLLER 6 www.DaikinApplied.com

ConTroller applICaTIon sofTware upgrade proCedures

Use this procedure to upgrade the MicroTech III controller

application code software. To Load the les into the controller,

you will need an SD memory card no larger than 8GB with a

FAT32 le system format.

NOTE: If your existing BSP version is older than 8.40 or the

APP version is earlier than 2506017300 consult with

the Daikin Applied Technical Response Center (TRC)

for upgrade support.

NOTE: Attempting to install older rmware/software into the

controller than it currently has installed will prevent

the application code from operating. The controller

will have to be returned to TRC to restore operation.

1. The application and rmware les are compressed in

a ZIP archive le and MUST be extracted to the root

directory of the SD card. If your extraction program

automatically creates a le folder on the SD card the

contents of the le folder will need to be moved to the

root directory of the SD card.

2. Enter the 6363 password.

3. From the Main Menu, set the Control Mode to OFF.

4. Insert the SD memory card into the controller’s memory

card slot. The label on the SD card should be facing the

rear, toward the controller.

Figure 8: SD Memory Card Slot

Insert with

label to the

back

5. Save the existing conguration and parameters to the

memory card.

NOTE: If you do not want to Save & Restore, skip to Step

9 below.

6. From the Main Menu select Service Menus then Save/

Restore Settings.

7. Set the SaveToCard parameter to Yes, and press the

Enter button. When parameter reverts back to No Save

to Card is complete.

8. Power off the controller and wait 15 Seconds.

9. Make sure that all communication modules that need to

be updated are connected.

10. Insert a small tool such as a 3/64" (1mm) Hex key or

other similar tool in the service hole on the controller and

hold the service button depressed.

Figure 9: Service Button and BSP LED

ConTroller applICaTIon sofTware upgrade proCedures

Service Button

BSP LED

11. While holding the service button depressed apply power

to the controller.

12. Continue depressing the service button until the BSP LED

on the controller begins to ash between red and green.

13. Release the service button

14. When the BSP LED has stopped ashing between red

and green, remove power to the controller and wait 15

seconds.

15. Repeat steps 10-14. (Perform the uploading of code

procedure twice).

16. If you have a communication module to update you

will perform the procedure a third time. Make sure you

wait a full 30 seconds for the controller to recognize

the communication module (controller will perform an

automatic reset when it recognizes a communication

module is attached).

17. The procedure for updating rmware in the communication

module is the same except that you will wait for the BSP

LED on the communication module to begin ashing red

to green before you release the service button.

18. Load the previous conguration and parameters from

the memory card. If you did not save the existing

conguration, skip to Step 21 below.

19. Apply power to the controller if you have not already

done so.

20. Enter the 6363 password.

21. From the Main Menu select Service Menus then Save/

Restore Settings.

22. Set the LoadFromCard parameter to YES, and press

the enter button. The controller will reset.

23. Remove the SD memory card by momentarily pushing it

in. It will retract.

24. If you did not Save and Restore the existing

conguration as described above, perform the following.

25. Using table below, “Unit Conguration Menu,” as a guide,

set the unit conguration

26. From the Unit Conguration menu, set the Apply

Changes parameter to YES and press the enter button.

The controller will perform an automatic reset, at which

time the upgrade is complete.

www.DaikinApplied.com 7 IM 919-3 • MICROTECH III CONTROLLER

desCrIpTIon of operaTIon

desCrIpTIon of operaTIon

Temperature Sensors

The MicroTech III controller uses passive negative temperature

coefcient (NTC) 10K ohm sensors. These sensors vary their

input resistance to the MCB as the temperature changes. Table

3 details the resistance versus temperature values. For typical

sensor wiring examples refer to Figures 12, 13, and 14.

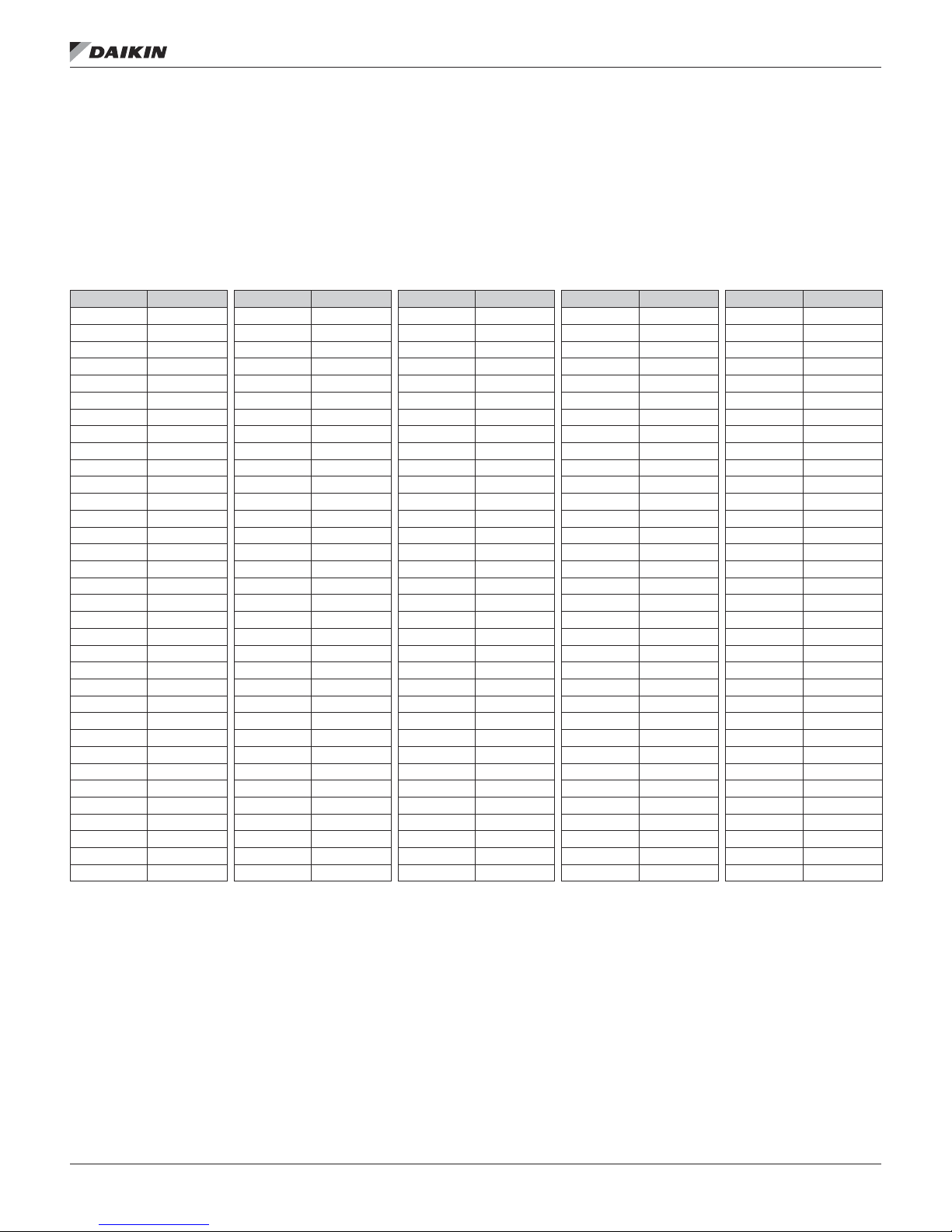

Table 3: Nominal Input Resistance versus Temperature

Temp (ºF) R nominal (Ω) Temp (ºF) R nominal (Ω) Temp (ºF) R nominal (Ω) Temp (ºF) R nominal (Ω) Temp (ºF) R nominal (Ω)

-40 336.050 -6 103.486 28 36.601 62 14.546 96 6.382

-39 323.889 -5 100.184 29 35.565 63 14.179 97 6.238

-38 312.212 -4 96.999 30 34.562 64 13.822 98 6.097

-37 300.999 -3 93.927 31 33.591 65 13.475 99 5.960

-36 290.229 -2 90.962 32 32.650 66 13.139 100 5.826

-35 279.884 -1 88.101 33 31.739 67 12.811 101 5.696

-34 269.945 0 85.340 34 30.856 68 12.493 10). 5.569

-33 260.396 1 82.676 35 30.000 69 12.184 103 5.446

-32 251.218 2 80.103 36 29.171 70 11.884 104 5.325

-31 242.397 3 77.620 37 28.368 71 11.591 105 5.208

-30 233.918 4 75.222 38 27.590 72 11.307 106 5.093

-29 225.766 5 72.906 39 26.835 73 11.031 107 4.981

-28 217.928 6 70.670 40 26.104 74 10.762 108 4.872

-27 210.390 7 68.510 41 25.394 75 10.501 109 4.766

-26 203.139 8 66.424 42 24.707 76 10.247 110 4.663

-25 196.165 9 64.408 43 24.040 77 10.000 111 4.562

-24 189.455 10 62.460 44 23.394 78 9.760 112 4.463

-23 182.998 11 60.578 45 22.767 79 9.526 113 4.367

-22 176.785 12 58.759 46 22.159 80 9.298 114 4.273

-21 170.804 13 57.001 47 21.569 81 9.077 115 4.182

-20 165.048 14 55.301 48 20.997 82 8.862 116 4.093

-19 159.506 15 53.658 49 20.442 83 8.652 117 4.006

-18 154.169 16 52.069 50 19.903 84 8.448 118 3.921

-17 149.030 17 50.533 51 19.380 85 8.249 119 3.838

-16 144.081 18 49.047 52 18.873 86 8.056 120 3.757

-15 139.313 19 47.610 53 18.380 87 7.868 121 3.678

-14 134.720 20 46.220 54 17.902 88 7.685 122 3.601

-13 130.295 21 44.875 55 17.438 89 7.506 123 3.526

-12 126.031 22 43.574 56 16.988 90 7.333 124 3.453

-11 121.921 23 42.315 57 16.551 91 7.164 125 3.381

-10 117.960 24 41.097 58 16.126 92 6.999 126 3.311

-9 114.141 25 39.917 59 15.714 93 6.839 127 3.243

-8 110.460 26 38.776 60 15.313 94 6.682 128 3.176

-7 106.910 27 37.671 61 14.924 95 6.530 129 3.111

IM 919-3 • MICROTECH III CONTROLLER 8 www.DaikinApplied.com

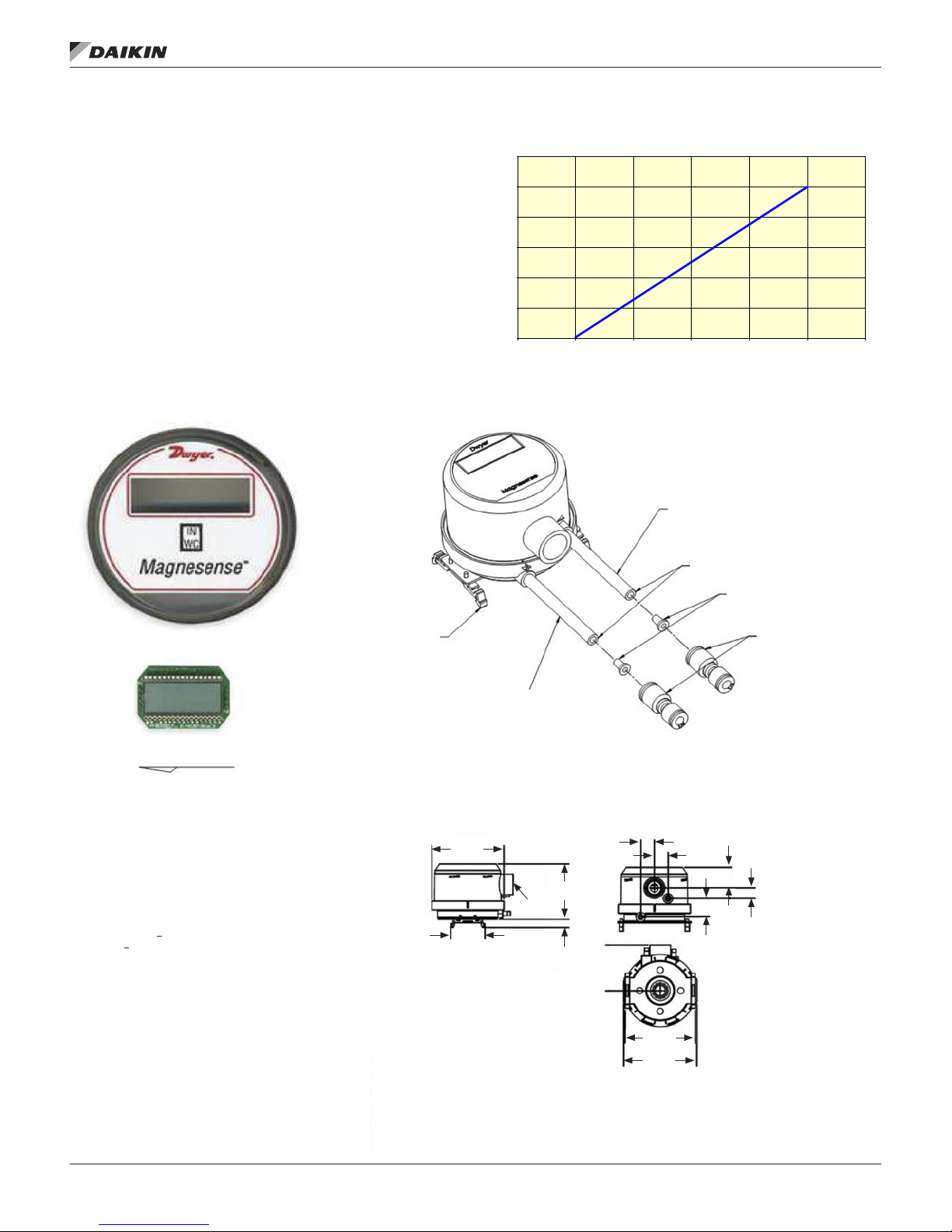

Pressure Sensors

The MicroTech III controller uses 0 to 5" W.C. static pressure

transducers for measuring duct static pressure. As the duct

static pressure varies from 0-5" W.C., the transducer output will

vary from 4-20mA.

If building static pressure control is provided, a -0.25" W.C. to

0.25" W.C. static pressure transducer is used. As the building

static pressure varies from -0.25" W.C. to 0.25" W.C., the

transducer output will vary from 4-20mA.

Troubleshooting Pressure Transducers

If the duct static pressure always reads 0" WC on the unit

keypad/display and the Supply fan speed is continuously

ramping to 100%, check the following:

If the unit has two duct static pressure sensors (SPS1 and

SPS2), verify that they both function properly per the following

procedure. Also check for faulty wiring connections at the

VFD analog inputs, ECM motor or at the unit controller.

The controller displays and controls to the lower of the two

readings. If a sensor is defective and inputs 0 volts to the VFD,

the static pressure reading on the keypad/display reads 0 and

the controller attempts to increase the 0 value to set point by

ramping the supply fan motor up. If a second sensor (SPS2) is

not installed or the pressure tubing to it is not connected, make

sure the 2nd DSP Sensor= parameter in the Unit Conguration

menu of the keypad/display is set to “No” so that the controller

ignores the second static pressure analog input. If a second

sensor (SPS2) is installed, make sure the 2nd DSP Sensor=

parameter in the Unit Conguration menu of the keypad/display

is set to “Yes”.

desCrIpTIon of operaTIon

Check the 24 VDC power supply to the sensor, verify that

there is 24 VDC between the suspect transducer “+” terminal

and case ground. Using an accurate manometer or gauge,

measure the same pressure that the suspect transducer

is sensing. To do this, tap into the transducer high and low

pressure tubing or locate the measurement device taps next to

the transducer taps. Measure the output from the transducer,

if the measured output and pressure do not match, there may

be a wiring issue, a connection problem, or the transducer may

be defective. Some VFD’s use a 500ohm resistor to change

the transducer signal from 4-20mA to 2-10VDC, the transducer

signal at the VFD will then be 2-10VDC. The factory installed

500 ohm resistor (if applicable) is installed across “VIA” and

“CC” terminals of the VFD.

NOTE: 3-wire transducers may have the resistor wired

across the S and – terminals of the transducer. If

the measured output and pressure match, the VFD

parameters and/or Modbus communication between

the controller and the VFD will need to be veried.

Remove power from the controller. If available,

swap a similar good transducer with the suspect

transducer. Restore power and verify whether the

suspect transducer is defective.

NOTE: If the suspect sensor is measuring duct static

pressure, verify that the high and low pressure

taps are properly installed. An improper pressure

tap installation can cause severe uctuations in

the sensed pressure. Refer to the model-specic

installation manual for pressure tap installation

guidelines.

www.DaikinApplied.com 9 IM 919-3 • MICROTECH III CONTROLLER

desCrIpTIon of operaTIon

Duct Pressure Sensor

Input Voltage - 24 VDC

Output - 4-20 mA

NOTE: The transducer output signal is 4-20mA however the

signal entering the VFD is converted to a DC voltage

signal via a 500 Ohm resistor on the Daikin MD

drives.

Figure 11: Duct Pressure Sensor

Figure 10: Duct Pressure Sensor Output

DC Volts

6

5

4

3

Inches W.C.

2

1

0

DC mA

Low Pressure (-) Port

Transducer provided with Dwyer #A-220 Vinyl

Tube (3'×5/16" O.D.) and Dwyer #A-3029-1

Quick Coupling Adapter (5/16"×1/4" O.D.),

Daikin McQuay #910122359. Coupler connects

to unit blue Vinyl Tubing (3/16" I.D.×1/4" O.D.),

Daikin McQuay #3499264-XX.

Tubes must be cut flush to insert fittings.

121086420

24201612840

Digital display is not included.

Order separately:

Daikin McQuay P/N #910117462

Dwyer P/N #A-441

Calibration: Factory set to 0.0" WC to +5.0" WC, where 4maDC is

output at 0.0" WC and 20maDC is output at +5" WC.

Jumper configuration: PJ3 = M position. PJ5 = N position. PJ7 = H20

position. Filter calibration change PJ3 position to = F, Factory Set = 1.

Return PJ3 to M position.

When required, use external loop resistor 499 OHMs, 1% Tol. Daikin

McQuay #044690105.

Accuracy: 0" to 5" WC

Range Accuracy: + 2%

Stability: +1% F.S./year

Temperature Limits: 0°F to 150° (-18°C to 66°C)

Pressure Limits: 1 psi maximum, operation; 10 psi, burst

Power Requirements: 10 to 35 VDC (2-wire)

Output Signals: 4 to 20 mA (2-wire)

Response Time: Field-adjustable 0.5 to 15 seconds time constant.

Provides a 95% response time of 1.5 to 45 seconds

Zero and Span Adjustments: Digital push button

Loop Resistance: Current output 0 to 1250 maximum

Current Consumption: 40 mA maximum

Display: 4 digit LCD (optional)

Electrical Connections: 4-20 mA, 2-wire; European-style terminal

block for 16 to 26 AWG

Electrical Entry: 1/2" NPS thread; accessory – cable gland for 5 to 10

mm diameter cable

Process Connection: 3/16" (5 mm) I.D. tubing; maximum O.D. 9 mm

Enclosure Rating: NEMA 4X (IP66)

Mounting Orientation: Diaphram in VERTICAL POSITION ONLY

Weight: 8.0 oz. (230 g)

Agency Approvals: CE and UL

DIN rail mounting

High Pressure (+) Port,

Transducer provided with Dwyer #A-220 Vinyl Tube

(3'×5/16" O.D.) and Dwyer #A-3029-1 Quick Coupling

Adapter (5/16"×1/4" O.D.), Daikin McQuay #910122359.

Coupler connects to unit red Vinyl Tubing (3/16" I.D.×1/4"

O.D.), Daikin McQuay #3499264-XX.

Ø3-7/16

[Ø87.31]

1/2 NPT

1-41/64

[41.71]

2-41/64

[67.24]

25/64

[9.96]

21/32

[16.67]

3-11/32

[84.84]

3-1/2

[88.9]

Insert fitting into tubes after tube

has been cut flush. Then insert

both into coupling.

Clear tubes must be

inserted into couplings at

least 1/2".

29/32

[23.02]

21/32

[16.67]

57/64

[22.62]

1/2

[12.7]

IM 919-3 • MICROTECH III CONTROLLER 10 www.DaikinApplied.com

desCrIpTIon of operaTIon

Building Pressure Sensor

Input Voltage - 24 VDC

Output - 4-20 mA

NOTE: The transducer output signal is 4-20mA however the

signal entering the VFD is converted to a DC voltage

signal via a 500 Ohm resistor on the Daikin MD

drives.

Figure 13: Building Pressure Sensor

DIN rail mounting

Figure 12: Building Pressure Sensor Output

DC Volts

0.3

0.2

0.1

0

Inches W.C.

-0.1

-0.2

-0.3

DC mA

Low Pressure (-) Port

Transducer provided with Dwyer #A-220 Vinyl

Tube (3'×5/16" O.D.) and Dwyer #A-3029-1

Quick Coupling Adapter (5/16"×1/4" O.D.),

Daikin McQuay #910122359. Coupler connects

to unit blue Vinyl Tubing (3/16" I.D.×1/4" O.D.),

Daikin McQuay #3499264-XX.

Tubes must be cut flush to insert fittings.

Insert fitting into tubes after tube

has been cut flush. Then insert

both into coupling.

Clear tubes must be

inserted into couplings at

least 1/2".

121086420

24201612840

Digital display is not included.

Order separately:

Daikin McQuay P/N #910117463

Dwyer P/N #A-441

Calibration: Factory set to 0.0" WC to =5.0" WC, where 4maDC is

output at 0.0" WC and 20maDC is output at +5" WC.

Jumper configuration: PJ3 = M position. PJ5 = N position. PJ7 = H20

position. Filter calibration change PJ3 position to = F, Factory Set = 1.

Return PJ3 to M position.

When required, use external loop resistor 499 OHMs, 1% Tol. Daikin

McQuay #044690105.

Accuracy: 0" to 5" WC

Range Accuracy: + 2%

Stability: +1% F.S./year

Temperature Limits: 0°F to 150° (-18°C to 66°C)

Pressure Limits: 1 psi maximum, operation; 10 psi, burst

Power Requirements: 10 to 35 VDC (2-wire)

Output Signals: 4 to 20 mA (2-wire)

Response Time: Field-adjustable 0.5 to 15 seconds time constant.

Provides a 95% response time of 1.5 to 45 seconds

Zero and Span Adjustments: Digital push button

Loop Resistance: Current output 0 to 1250 maximum

Current Consumption: 40 mA maximum

Display: 4 digit LCD (optional)

Electrical Connections: 4-20 mA, 2-wire; European-style terminal

block for 16 to 26 AWG

Electrical Entry: 1/2" NPS thread; accessory – cable gland for 5 to 10

mm diameter cable

Process Connection: 3/16" (5 mm) I.D. tubing; maximum O.D. 9 mm

Enclosure Rating: NEMA 4X (IP66)

Mounting Orientation: Diaphram in VERTICAL POSITION ONLY

Weight: 8.0 oz. (230 g)

Agency Approvals: CE and UL

High Pressure (+) Port,

Transducer provided with Dwyer #A-220 Vinyl Tube

(3'×5/16" O.D.) and Dwyer #A-3029-1 Quick Coupling

Adapter (5/16"×1/4" O.D.), Daikin McQuay #910122359.

Coupler connects to unit red Vinyl Tubing (3/16" I.D.×1/4"

O.D.), Daikin McQuay #3499264-XX.

Ø3-7/16

[Ø87.31]

1-41/64

[41.71]

1/2 NPT

2-41/64

[67.24]

25/64

[9.96]

21/32

[16.67]

3-11/32

[84.84]

3-1/2

[88.9]

21/32

[16.67]

57/64

[22.62]

29/32

[23.02]

1/2

[12.7]

www.DaikinApplied.com 11 IM 919-3 • MICROTECH III CONTROLLER

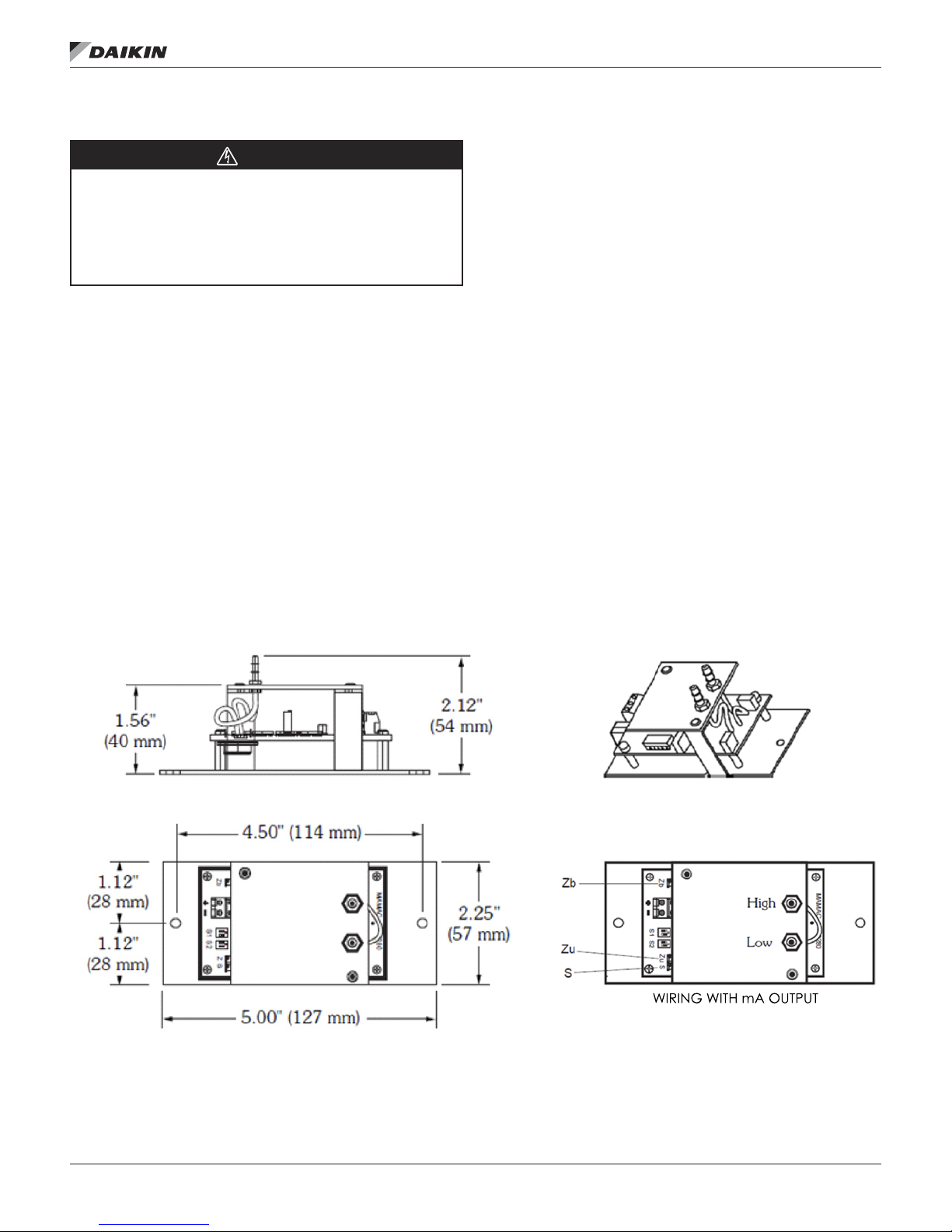

Mamac Panel-Mounted Pressure Transducer

desCrIpTIon of operaTIon

WARNING

Electric shock hazard. Can cause personal injury or equipment

damage.

This equipment must be properly grounded. Connections and

service to the MicroTech III control panel must be performed

only by personnel that are knowledgeable in the operation of

the equipment being controlled.

The following describes the proper wiring of these pressure

transducers with mA output.

1. Remove the terminal block by carefully pulling it off the

circuit board.

2. Locate the [+] and [-] terminal markings on the board.

3. Attach the supply voltage to the [+] lead.

4. Connect the 4-mA output ([-] terminal) to the controller’s

input terminal.

5. Ensure that the power supply common is attached to the

common bus of the controller.

6. Re-insert the terminal block to the circuit board and apply

power to the unit.

7. Check for the appropriate output signal using a DVM set

on DC milliamps connected in series with the [-] terminal.

Specications

Accuracy: ± 1% FS

Overpressure: 10 PSID

Supply Voltage: 12–40 VDC

12–35 VAC (VDC output units only)

Supply Current: VDC units — 10mA max.

mA units — 20 mA max.

Enclosure: 18 Ga. C R Steel NEMA 4 (P-65) or panel-mount

chassis

Finish: Baked-on enamel PMS2GR88B

Compensated Temp Control: 25°F – 175°F (-18°C – -80°C)

T.C. Error: ± 0.0125%/°F (± 0.02%/°C)

Operating Temp Range: 0°F – 175°F (-18°C – 80°C)

Media Compatibility: Clean dry air or any inert gas

Environmental: 10 – 90% RH Non-condensing

Wire Size: 12 Ga. max.

Load Impedance: 1.6K ohms max. at 40VDC (mA output units)

1K ohms min. VDC output units)

Weight: Enclosure — 1.0 lbs. (45 kg)

Panel-mount — 0.5 lbs. (25 kg)

Figure 14: Mamac Panel-Mounted Pressure Transducer Dimensions

IM 919-3 • MICROTECH III CONTROLLER 12 www.DaikinApplied.com

desCrIpTIon of operaTIon

Actuators

The actuators are controlled by an analog signal from the

unit controller. Damper actuators utilize a 0-10VDC analog

signal while modulating heating/cooling valve actuators utilize

a 210VDC signal. Spring-return actuators are used for the

0 - 30% outdoor air and economizer dampers. The mixing

dampers are normally closed to the outside air.

Figure 15: Actuator Wiring Diagram

Variable Frequency Drives (VFD’s)

When controlling discharge, return or exhaust fan, energy

recovery wheel or evaporating condenser fan variable

frequency drives, the MicroTech III controller uses an internal

ModBus communications channel for control and monitoring of

the Variable Frequency Drives.

Figure 16: VFD Wiring Diagram

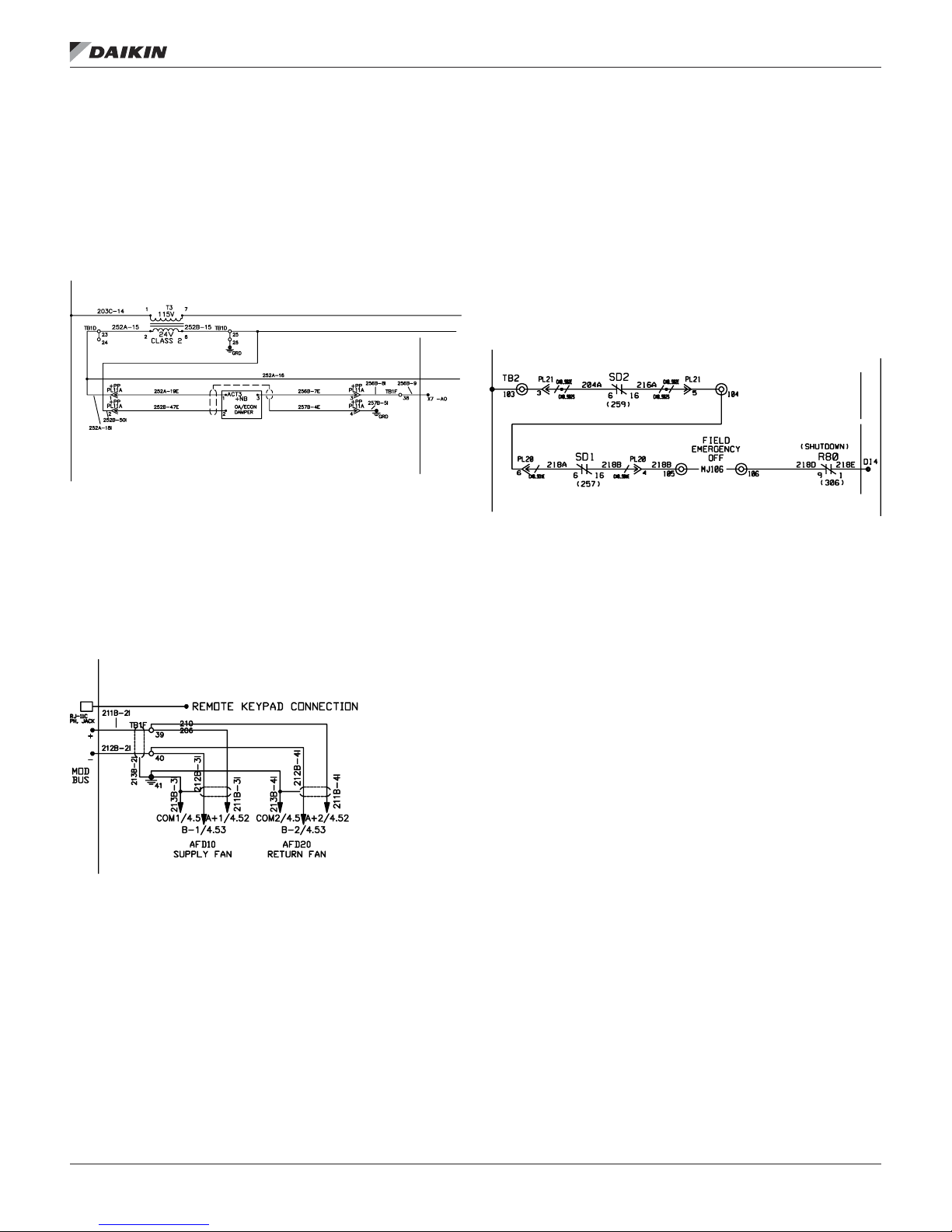

Smoke Detectors

Field installed smoke detectors in the return air ductwork or

the supply air ductwork can be coordinated with the units

operation through the main controller’s binary input, DI4. This

input is wired to TB2 and the supply air smoke detector can be

wired between terminals 103 and 104 and the return air smoke

detector can be wired between terminals 104 and 105. The T2

transformer supplies 24 V (ac) across each of these terminals

and a dry set of contacts can be wired to these terminals

respectively. This and additional wiring information can be seen

on the input wiring schematics at line number 220.

Figure 17: Smoke Detector Wiring Diagram

NOTE: Factory smoke detectors are wired the same as eld

mounted.

ECM (Electronically Commutated Motor)

fan/motor

The Rebel unit is equipped with a direct drive, ECM

(Electronically Commutated Motor) fan/motor combination

with a built in inverter. When equipped, the exhaust fan will

be the same. The Maverick II unit also has this as an exhaust

fan option. The MTIII controller uses an internal Modbus

communications channel for control and monitoring of the ECM

fan/motor.

www.DaikinApplied.com 13 IM 919-3 • MICROTECH III CONTROLLER

ConTroller InpuTs/ouTpuTs

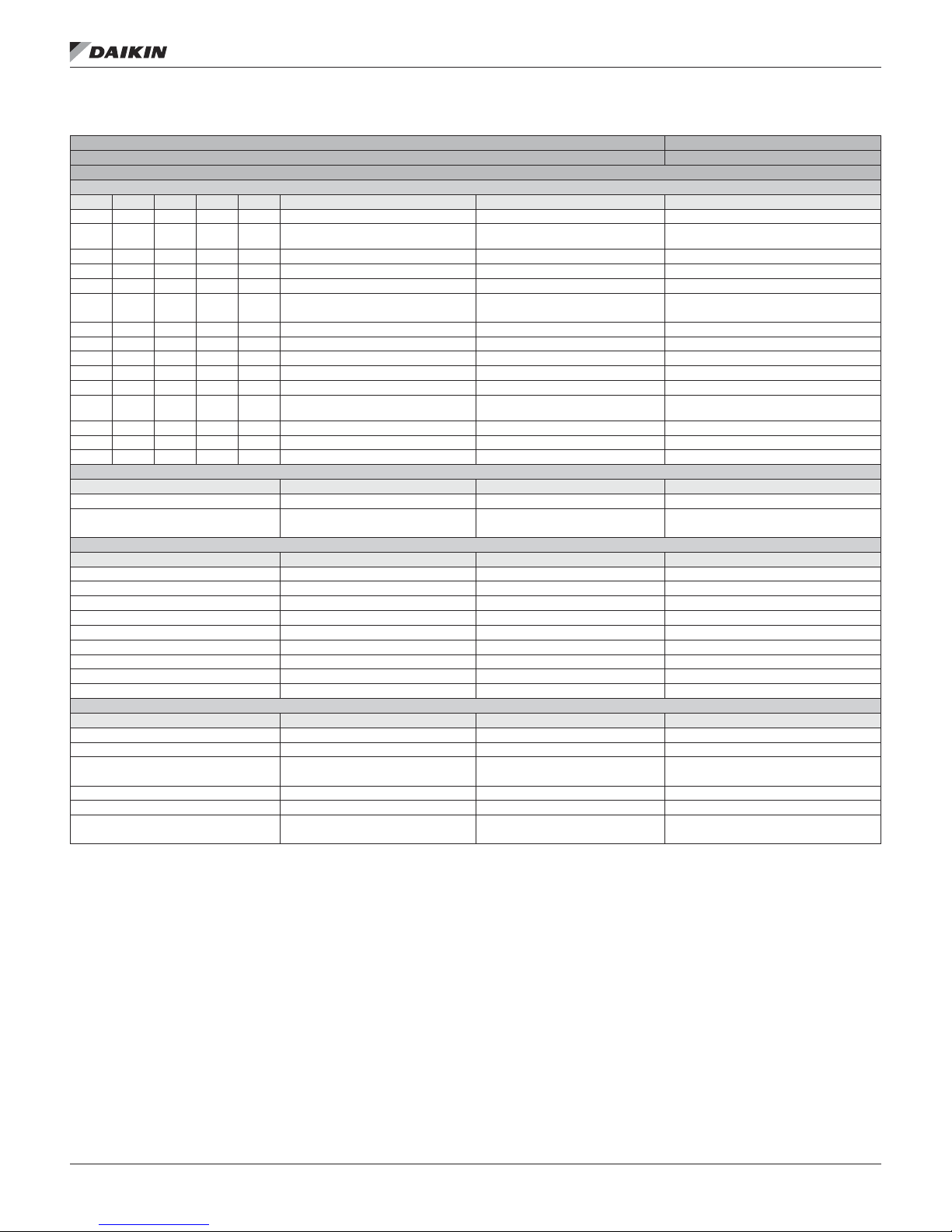

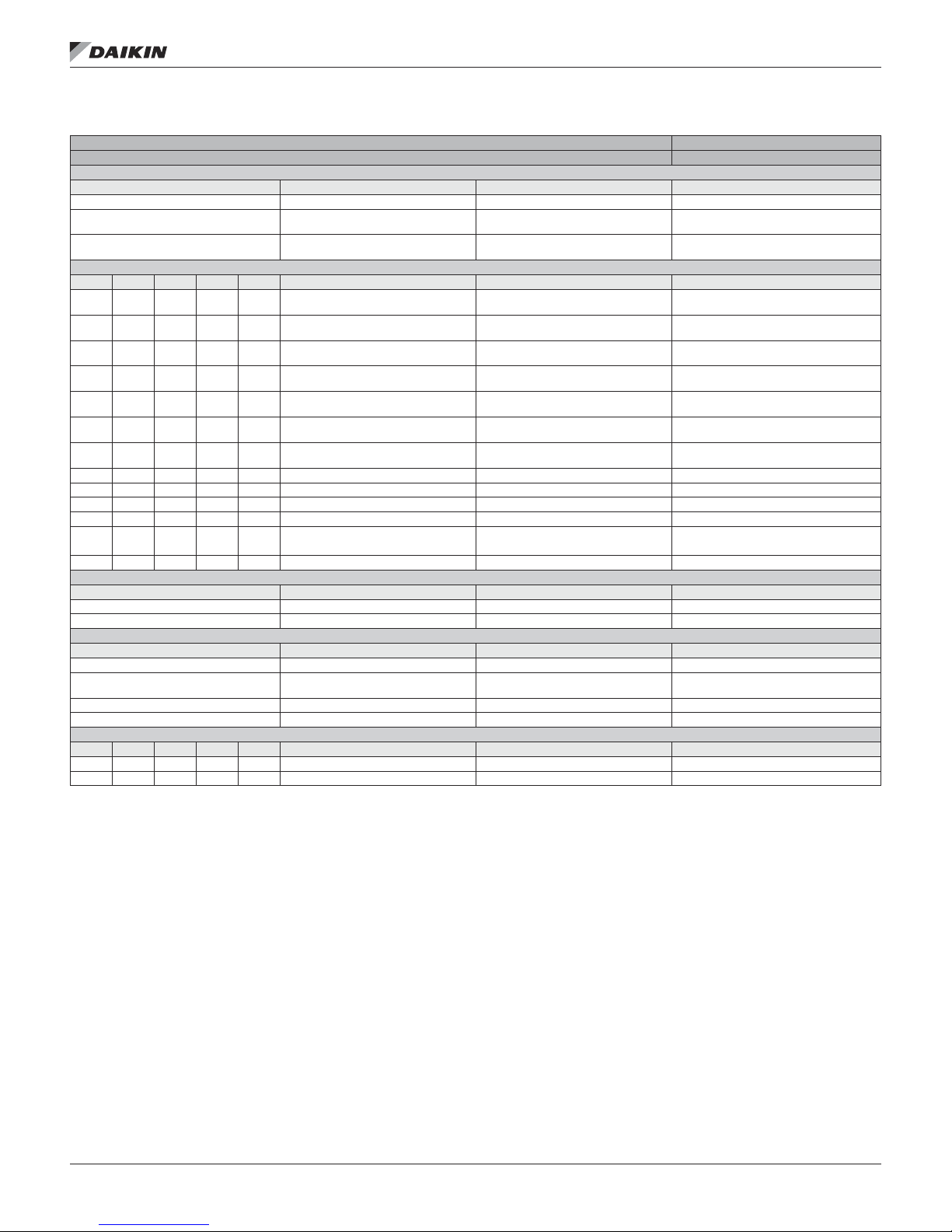

Table 4: RTU/MPS/DPS/DPH Main Control Board I/O

ConTroller InpuTs/ouTpuTs

PolyCool 600 Main Controller — RTU & MPS & DPS Pos. 1 = 0, 2, 3 or 4

# Point Comments Cong. Code Condition

AI 1 Discharge Temperature 10K Thermistor (STD) All

AI 2 Return Temperature 10K Thermistor (STD) 8 <> 2 or 8 = 2 and 20 > 0

AI 3 Outdoor Temperature 10K Thermistor (STD) All

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X CO2 /Min OA/OA CFM 0–10VDC or 4–20 mA 8 = 1, 2 3, 5, 6, 7, 8 or 9

X 2 X Low Pressure 1 and 2

X 2 X Chilled Wtr 2–10 VDC 3 = 2 or 3 = 3

X 2 X Ent Fan & Lvg Coil T 10K Thermistor 1 = 3 or 4 & 19 = 1

X 3 X Space Temperature 10K Thermistor (STD) All

X 4 X Zone Setpoint 5–15 kOhm All

X 4 X DAT Reset 0–10 VDC / 4–20 mA 2 = 1 or 2

X 5 X Enthalpy & Freeze Sw

X 5 X Relative Humidity 0–10 VDC or 4–20 mA 1 = 3 or 4

X 6 X Ent Fan & Lvg Coil T

X 6 X Duct Static Pressure 4–20 mA 1 = 2, 3 or 4 & 15 = 1–6

X 7 X OA Damper 0–10 VDC RPS 0-10 VDC MPS 8 = 1, 2, 3, 5, 6, 7, 8 or 9

X 8 X Building Static Pressure 4–20 mA 1 = 2, 3, 4 & 16 = 8, 9, A or F

X 8 X OAD End Switch Input Dry Contact 1 = 0 & 8 = 8 or 9

# Point Comments Cong. Code Condition

DI 1 Air Flow Switch / DHL (R63) Dry Contact All

DI 2 Filter Switch Dry Contact All

# Point Comments Cong. Code Condition

DI 3 Remote START / STOP External 24V All

DI 4 Emergency OFF / DHL (R63) External 24 V All

# Point Comments Cong. Code Condition

DI 5 High Pressure 1 115 VAC Input 3 = 1 & 4 > 1 & 4 < H

DI 5

Standard Comp High Pressure

DI 6 High Pressure 2 115 VAC Input 3 = 1 & 4 > 1 & 4 < H

DI 6 Enthalpy Switch 115 VAC Input 1 = 3 or 4 & 8 = 3, 6, 8 or 9

1. When used for LP1 and LP2, LP1 is considered CLOSED when resistance value is 0–799 or 1250–1800. Otherwise LP1 is considered OPEN. LP2 is considered

CLOSED when the resistance value is 0–1249, otherwise LP2 is considered OPEN.

2. Enthalpy switch is considered CLOSED when resistance value is 0–799 or 1250–1800. Otherwise it is considered OPEN. Freezestat is considered CLOSED when

the resistance value is 0–1249, otherwise it is considered OPEN.

I/O Cong. Code Condition

Analog Inputs — NTC

Universal Inputs/Outputs

1

2

1K & 2K Ohm Input 3 = 1 & 4 > 1 & 4 < H

1 = 0 or 2

1K & 1.5K Ohm Input

Enth: 8 = 3, 6, 8 or 9

Frz: 3 = 2, 3 = 3, 10 = 1 or 10 = 5

10K Thermistor (STD) — Gas or

Electric Heat & Dehum

1 = 0 & 19 = 1

Digital Inputs — Dry Contacts

Digital Inputs — 24V

Digital Inputs — 115V

(HP3 / HP5)

1 = 3 or 4

IM 919-3 • MICROTECH III CONTROLLER 14 www.DaikinApplied.com

Table 4 continued: RTU/MPS/DPS/DPH Main Control Board I/O

I/O Cong. Code Condition

PolyCool 600 Main Controller — RTU & MPS & DPS Pos. 1 = 0, 2, 3 or 4

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp

# Point Comments Cong. Code Condition

DO 1 Compressor 1 / GC Stg 1 3 = 1

DO 1 INV Comp ON / OFF Currently Not Used

DO 1 Comp 1 3 = 5 & 4 = 4, 7, A, D or J

DO 1 VFD Comp 1 Enable 3 = 4

DO 2 Compressor 3 / GC Stg 2

DO 2 STD3 Compressor 3 = 4 & 4 = M

DO 2 Unld 2 Comp 1 4 = 4 and 7 = 2, 3, 4 or 5

DO 2 Comp 3 3 = 5 & 4 = 7, A, D or J

DO 3 Compressor 2 / GC Stg 3

DO 3 Heat Stage 1 1 = 3 or 4 & 10 = 2

DO 3 Gas Heat (ON/OFF) 1 = 3 or 4 10 = 7 or 8

DO 3 SCR Enable 1 1 = 3 or 4 & 10 = 6

DO 3 Comp 2 3 = 4 & 4 = 4, D

DO 3 VFD Comp 2 Enable 3 = 5

DO 4 Compressor 4 / GC Stg 4

DO 4 Unld 2 Comp 2 4 = 4 and 7 = 2, 3, 4 or 5

DO 4 Heat Stage 2 1 = 3 or 4 & 10 = 2 & 11 > 1

DO 4 Comp 4

DO 5 Supply Fan All

DO 6 Cond Fan Output C

DO 6 HGBP Vavle 1 = 2 & 3 = 1 & 28 = 2

DO 6 Constant Speed Enthalpy Wheel Energy Recovery 20 = 1 or 6 & 30 = 3, 4, 5, 6

DO 7 Cond Fan Output A 2 Relays, CF3 & CF4 3 = 1 & 4 > 1 & 4 < F

DO 7 Generic Comp Stg 7 3 = 1 & 4 = 1 & 5 > 6

DO 7 Heat Stage 3 1 = 3 or 4 & 10 = 2 & 11 > 2

DO 8 Cond Fan Output B 2 Relays, CF5 & CF6

DO 8 Generic Comp Stg 8 3 = 1 & 4 =1 & 5 > 7

DO 8 Heat Stage 4 1 = 3 or 4 & 10 = 2 & 11 > 3

Digital Outputs – Solid State Relays, 24-230 VAC, 0.5 A

# Point Comments Cong. Code Condition

DO 9 Alarm All

DO 10 Fan Operation All

ConTroller InpuTs/ouTpuTs

1 = 3 or 4 &

3 = 4 &

4 = L or M &

24, 25, 26 = 003–015

3 = 1 & any of the following:

4 = 7, 9, A, D, E or

4 = 3 & 1 = 2 or

4 = 3 & 1 = 0 & 27 = 0 or 1 or

4 = 1 & 5 > 1

3 = 1 & any of the following:

4 > 1 & 4 < F or

4 = 1 and 5 > 2

3 = 1 & any of the following:

4 = 7, A, E or 4 = 1 & 5 > 3 or

1 = 0 & 4 = 3 & 27 = 2

[3 = 4 & 4 = D & 5 = 1] or

[3 = 5 & 4 = 7, J & 5 = 2] or

[3 = 5 & 4 = A & 5 = 3]

1 = 0 & 3 = 1 & 4 > 1 &

24, 25, 26 = (060–105) &

(27 = 0 or 27 = 1) & (7 ≠ 2, 3, 4 or 5)

1 = 0 & 3=1 & 4 > 1 & 4 < D &

24, 25, 26 = (075–105) &

(27 = 0 or 27 = 1) or 1 = 0 &

3 = 1 & 4 > & 4 < D &

24, 25, 26 = (075 or 090–140) &

27 = 2 or 1 = 2 & 3 = 1 &

24, 25, 26 = 030, 035, 040 or 050

Note: If 7 = 2, 3, 4 or 5

then this applies only if 24, 25, 26

is greater than 110.

www.DaikinApplied.com 15 IM 919-3 • MICROTECH III CONTROLLER

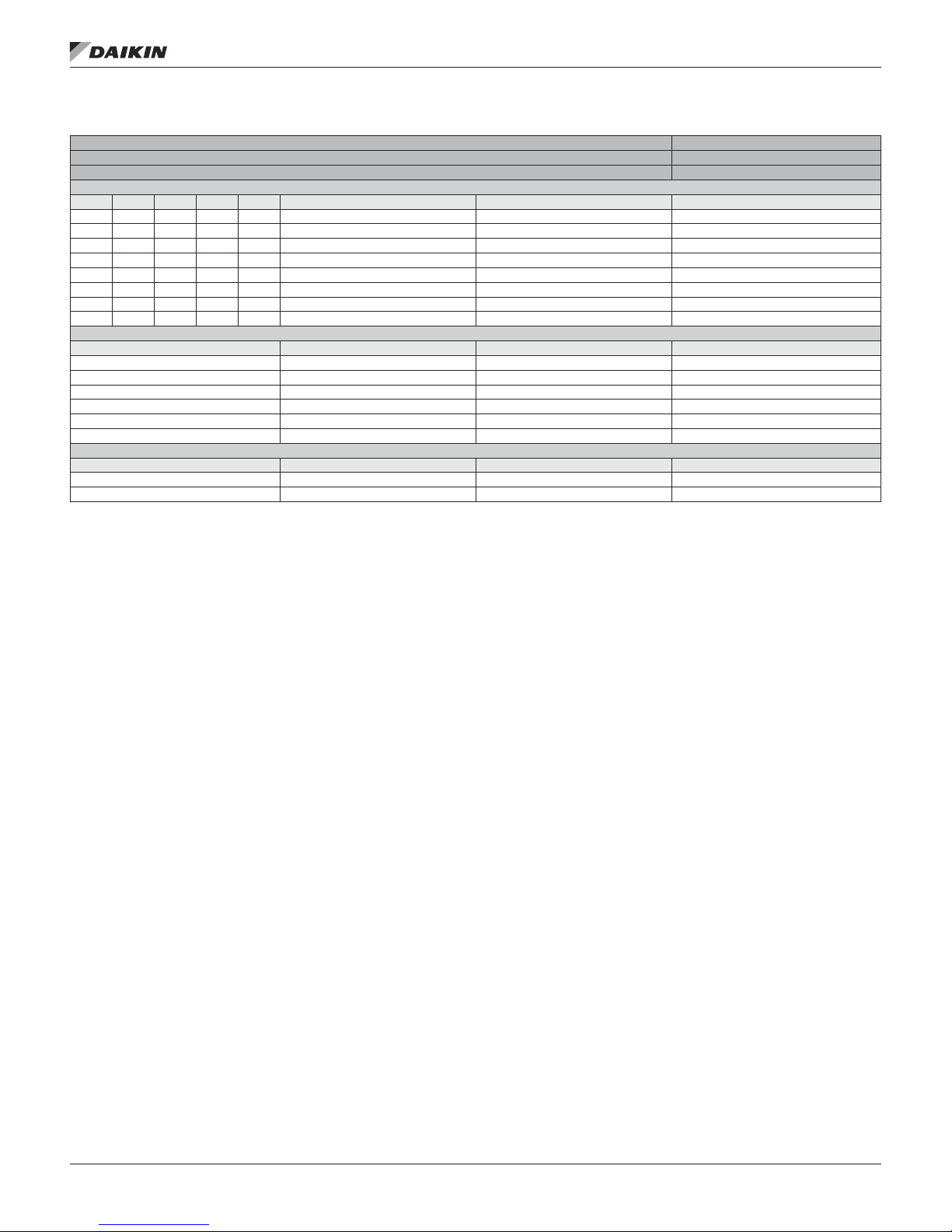

ConTroller InpuTs/ouTpuTs

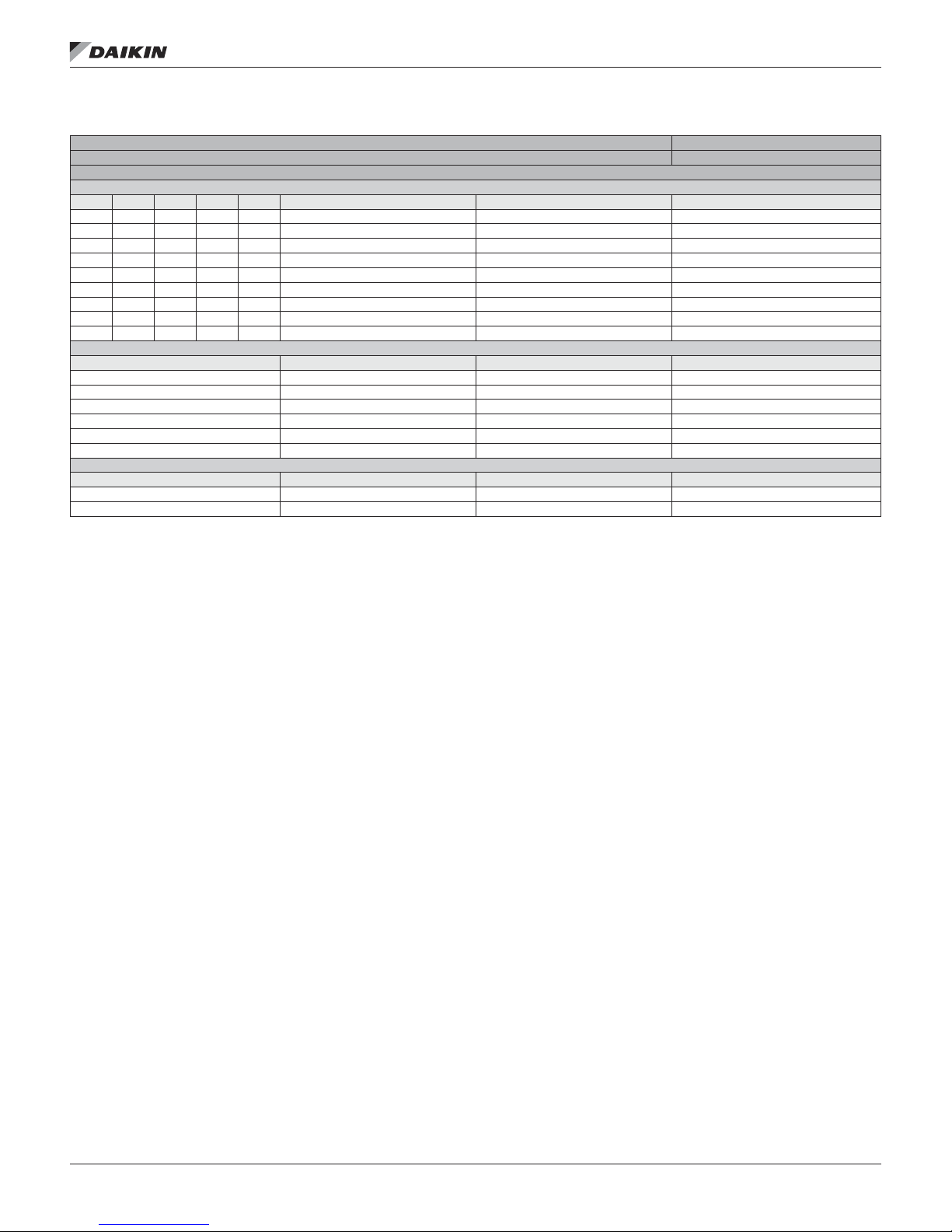

Table 5: SCU Main Control Board I/O

I/O Cong. Code Condition

PolyCool 600 Main Controller – SCU Pos. 1=1

Analog Inputs – 10K NTC

# Point Comments Cong. Code Condition

AI 1 Discharge Temperature 10K Thermistor (STD) All

AI 2 Return Temperature 10K Thermistor (STD) All

AI 3 Outdoor Temperature 10K Thermistor (STD) All

Universal Inputs/Outputs

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X Entering WaterTemperature 10K Thermistor (STD) 3 = 1 & 4 > 3

X 2 X Low Pressure 1 and 2

X 2 X Chilled Wtr 0–10 VDC 3 = 2 or 3 = 3

X 3 X Space Temperature 10K Thermistor (STD) All

X 4 X Zone Setpoint 5–15 kOhm 2 = 0

X 4 X DAT Reset 0–10 VDC / 4–20 mA 2 = 1

X 5 X Enthalpy & Freeze Sw

X 6 X Bypass Valve 2–10 VDC 3 = 1

X 6 X Water Regulating Valve 2–10 VDC 3 = 1 & 8 <> 4 & 22 =1

X 7 X Economizer

X 8 X Mixed Air Temp 10K Thermistor (STD) All

# Point Comments Cong. Code Condition

DI 1 Air Flow Switch Dry Contact All

DI 2 Filter Switch Dry Contact All

# Point Comments Cong. Code Condition

DI 3 Remote START / STOP External 24V All

DI 4 Emergency OFF External 24V All

# Point Comments Cong. Code Condition

DI 5 High Pressure 1 115 VAC Input 3 = 1 & 4 > 1 or 3 = 4

DI 6 High Pressure 2 115 VAC Input 3 = 1 & 4 > 1

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp

# Point Comments Cong. Code Condition

DO 1 Compressor 1 3 = 1

DO 2 Compressor 3 3 = 1 & 4 > 4

DO 3 Compressor 2 3 = 1

DO 4 Compressor 4 3 = 1 & 4 > 6

DO 5 Supply Fan All

DO 6 NA

DO 7 Outdoor Damper OPEN / CLOSE 8 <> 3

DO 8 Pump ON/OFF 3 = 1 & 4 > 1

Digital Outputs – Solid State Relays, 24-230 VAC, 0.5 A

# Point Comments Cong. Code Condition

DO 9 Alarm All

DO 10 Fan Operation All

1. When used for LP1 and LP2, LP1 is considered CLOSED when resistance value is 0–799 or 1250–1800. Otherwise LP1 is considered OPEN. LP2 is considered

CLOSED when the resistance value is 0–1249, otherwise LP2 is considered OPEN.

2. Enthalpy switch is considered CLOSED when resistance value is 0–799 or 1250–1800. Otherwise it is considered OPEN. Freezestat is considered CLOSED when

the resistance value is 0–1249, otherwise it is considered OPEN.

1

2

Digital Inputs — Dry Contacts

Digital Inputs — 24V

Digital Inputs — 115V

1K & 2K Ohm Input 3 = 1 & 4 > 3

1K & 1.5K Ohm Input

0–10 VDC (Air Econo) / 2–10 VDC

(Water Econo)

Frz: 3 = 2, 3 = 3, 8 = 4, 10 = 1, 10 = 5

Enth: 8 = 3

8 = 3 or 8 = 4

IM 919-3 • MICROTECH III CONTROLLER 16 www.DaikinApplied.com

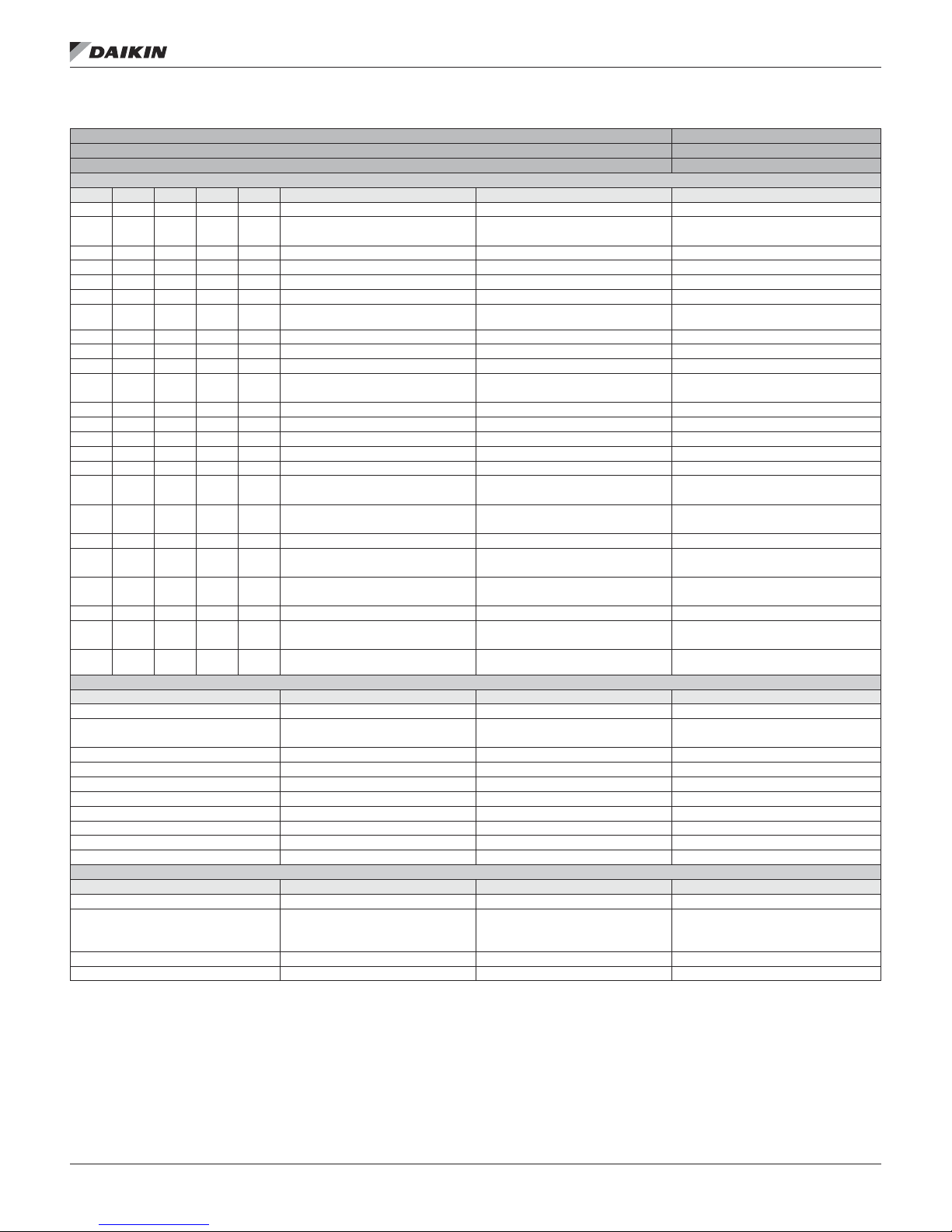

ConTroller InpuTs/ouTpuTs

Table 6: RTU Expansion Module A I/O

RTU — Expansion Module A Pos. 1 = 0

Design Flow, RPS Energy Recovery, RPS Dehumidication, 5 or 6 Compressors

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X LSCRH Valve 0-10 VDC 28 = 4 or 5

X 2 X Reheat #1 0-10 VDC 28 = 2

X 3 X Reheat #2 0-10 VDC NA

X 4 X Supply Temp Leaving Wheel 10K Thermistor (STD) 20 > 0

X 4 X DesignFlo 1 Ratiometric 9 > 0

X 5 X Exhaust Temp Leaving Wheel 10K Thermistor (STD) 20 > 1

X 5 X DesignFlo 2 Ratiometric 9 > 0

X 6 X Relative Humidity 0-10 VDC or 4-20 mA All

X 7 X High Refrigerant Pressure 1 (future) Ratiometric input required NA

X 8 X High Refrigerant Pressure 2 (future) Ratiometric input required NA

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1 Compressor 5 / GC Stg 5 3 = 1 & 4 = A or 3 = 1 & 4 = 1 & 5 > 4

DO 2 Compressor 6 / GC Stg 6 3 = 1 & 4 = A or 3 = 1 & 4 = 1 & 5 > 6

DO 3 Reheat Output 28 = 1, 2, or 5

DO 4 Constant Speed Enthalpy Wheel Energy Recovery 20 = 1 or 6

# Point Comments Cong. Code Condition

DO 5 Bypass Damper CLOSED Energy Recovery 20 > 0 & 8 <> 2

DO 6 Bypass Damper OPEN Energy Recovery 20 > 0 & 8 <> 2

I/O Cong. Code Condition

Universal Inputs/Outputs

Digital Outputs — Triac (24 VAC, 0.5 Amp)

Table 7: SCU Expansion Module A I/O

All Units: (CO2/Remote Min OA, Waterow Switch, Head Pressure Control, 5 or 6 Compressors)

SCU — Expansion Module A Pos. 1 = 1

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X CO2 / Min OA / OA CFM 0–10 VDC or 4–20 mA 8 = 3 & 9 = 5 for OA CFM

X 2 X Duct Static Pressure 1 4–20 mA 1 = 1 & 15 = 6

X 3 X OA CFM 0–10 VDC or 4–20 mA 8 = 3 or 6 & 9 = 6 for OA CFM

X 4 NA

X 5 X Waterow Switch Dry Contact 3 = 1 & 4 > 1 & 22 = 0

X 6 X Relative Humidity

X 7 X High Refrigerant Pressure 1 Ratiometric input required 22 = 1

X 8 X High Refrigerant Pressure 2 Ratiometric input required 22 = 1

# Point Comments Cong. Code Condition

DI OAD End Switch Input 115 VAC Input 1 = 1 & 8 = 8 or 9

Digital Outputs – Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1 Compressor 5 3 = 1 & 4 > A

DO 2 Compressor 6 3 = 1 & 4 > A

DO 3 Compressor 7 3 = 1 & 4 = F or G

DO 4

# Point Comments Cong. Code Condition

DO 5 Compressor 8 3 = 1 & 4 = F or G

DO 6

I/O Cong. Code Condition

Universal Inputs/Outputs

0–10 VDC or 4–20 mA —

Dehumidication

Digital Input – 115V-230V

Digital Outputs – Triac (24 VAC, .5 Amp)

All

www.DaikinApplied.com 17 IM 919-3 • MICROTECH III CONTROLLER

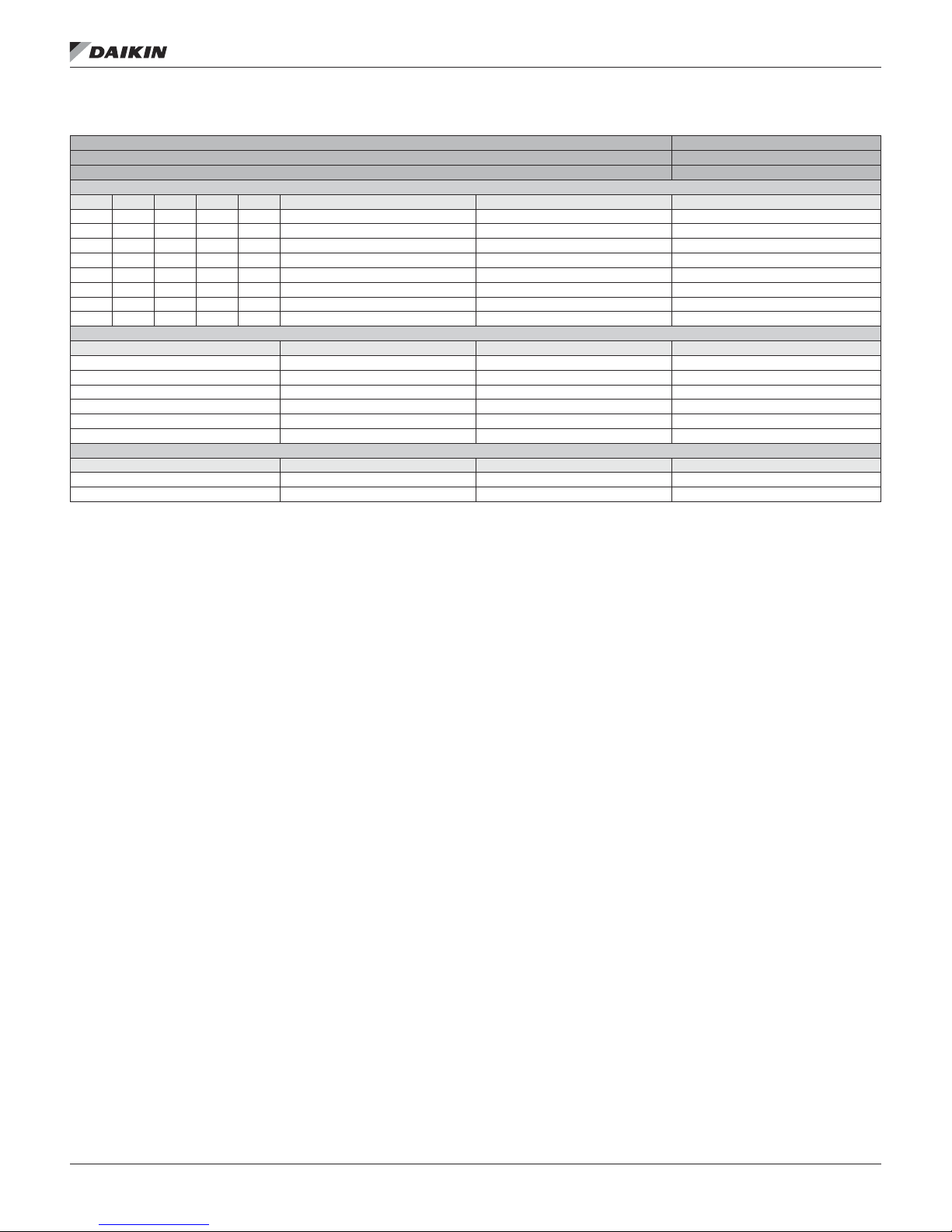

ConTroller InpuTs/ouTpuTs

Table 8: RTU/MPS/DPS/DPH Expansion Module B I/O

Heating, F&BP Dampers, MPS Dehumidication, MPS/DPS Energy Recovery, MPS Staged Exhaust Fan

RTU, MPS & DPS – Expansion Module B Pos. 1=0,2,3o4

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X FSG Ign_Pilot Input (FSG-8) Dry Contact 1 = 0 & 10 = 4

X 1 X Ent Fan & Lvg Coil T

X 2 X Gas Heat LS1 Switch Dry Contact 1 = 0 & 10 = 4

X 2 X Reheat #1 0–10 VDC 1 = 2 & 28 = 2

X 3 X Gas Heat LS2 Switch Dry Contact 1 = 0 & 10 = 4

X 3 X OA Flow 0–10 VDC or 4–20 mA

X 4 X FSG Alarm Input (FSG-3) 1=0 & (10=3 or 10=4)

X 4 X Supply Temp Leaving Wheel 10K Thermistor (STD) 1 = 2, 3 or 4 & 20 > 0 & 30 ≠ 3, 4, 5 or 6

X 5 X Exhaust Temp Leaving Wheel 10K Thermistor (STD) 1 = 2, 3 or 4 & 20 > 0 & 30 ≠ 3, 4, 5 or 6

X5 X Duct Static Pressure 1 4–20 mA 1 = 0 & 15 = 6

X 6 X Relative Humidity 0–10 VDC or 4–20 mA 1 = 2

X 7 X Heating Valve 2–10 VDC

X 7 X SCR 0–10 VDC 1 = 0, 1 or 2 & 10 = 6

X 8 X F & BP Damper 0–10 VDC 1 = 0 or 1 & 3 = 3 or 10 = 1

X8 X Constant Speed Enthalpy Wheel Energy Recovery 1 = 2 & 20 =1 or 6

# Point Comments Cong. Code Condition

DI OAD End Switch Input 115 VAC Input 1 = 2 & 8 = 8 or 9

DI Freezestat Switch 115 VAC Input

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1 Gas Heat (ON/OFF) 1 = 0 or 2 10 =3 , 4, 7 or 8

DO 1 Heat Stage 1 1 = 0, 1 or 2 & 10 = 2

DO 1 SCR Enable 1 1 = 0, 1 or 2 & 10 = 6

DO 1 Constant Speed Enthalpy Wheel Energy Recovery 1 = 3 or 4 & 20 = 1 or 6 & 30 = 1 or 2

DO 2 Pilot Gas (ON/OFF) 10 = 4

DO 2 Heat Stage 2 1 = 0, 1 or 2 & 10 = 2 & 11 > 1

DO 2 SCR Enable 2 1 = 0, 1 or 2 & 10 = 6

DO 3 Heat Stage 3 1 = 0, 1 or 2 & [10 = 8 or 10 = 2 & 11 > 2]

DO 4 Heat Stage 4 1 = 0, 1 or 2 & [10 = 8 or 10 = 2 & 11 > 3]

# Point Comments Cong. Code Condition

DO 5 Heat Stage 5 1 = 0, 1 or 2 & 1 = 0 & 10 = 2 & 11 > 4

DO 5 Exh Fan Stage 1 1 = 2 & 16 = C, D or E

DO 5 Bypass Damper CLOSED Energy Recovery

DO 6 Heat Stage 6 1 = 0 & 10 = 2 & 11 > 5

DO 6 Exh Fan Stage 2 1 = 2 & 16 = D or E

DO 6 Bypass Damper OPEN Energy Recovery

I/O Cong. Code Condition

Universal Inputs/Outputs

10K Thermistor (STD) — Gas or

Electric Heat & Dehum

Digital Input — 115V-230V

Digital Outputs — Triac (24 VAC, .5 Amp)

1 = 2, 3 or 4 & 8 = 1, 2, 3, 5, 6 or 7 & 9 = 6

1 = 0, 1 or 2 & 10 = 1, 10 = 3, 10 = 4, 10 =

(1 = 2) & (19 = 1)

& 30 ≠ 3, 4, 5 or 6

5, 10 = 7 or 10 = 8

1 = 3 or 4 & 10 = 5 & 8 = 8 or 9 &

30 ≠ 3, 4, 5 or 6

1 = 2, 3 or 4 & 20 > 0 & 8 = 3 or 6 &

30 ≠ 3, 4, 5 or 6

1 = 2, 3 or 4 & 20 > 0 & 8 = 3 or 6 &

30 ≠ 3, 4, 5 or 6

IM 919-3 • MICROTECH III CONTROLLER 18 www.DaikinApplied.com

ConTroller InpuTs/ouTpuTs

Table 9: SCU Expansion Module B I/O

SCU — Expansion Module B Pos. 1 = 1

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X Low Pressure 7 3 = 1 & 4 = G & 21 = 0

X 2 X Low Pressure 8 3 = 1 & 4 = G & 21 = 0

X 3 X High Pressure 7 3 = 1 & 4 = G & 21 = 0

X 4 X High Pressure 8 3 = 1 & 4 = G & 21 = 0

X 5

X 6

X 7 X Heating Valve 2–10 VDC 10 = 1 or 10 = 5

X 7 X SCR 0–10 VDC 10 = 6

X 8 X F & BP Damper 0–10 VDC 3 = 3 or 10 = 1

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1 Heat Stage 1 10 = 2

DO 1 SCR Enable 1 10 = 6

DO 2 Heat Stage 2 10 = 2 & 11 > 1

DO 2 SCR Enable 2 10 = 6

DO 3 Heat Stage 3 10 = 2 & 11 > 2

DO 4 Heat Stage 4 10 = 2 & 11 > 3

# Point Comments Cong. Code Condition

DO 5 Heat Stage 5 10 = 2 & 11 > 4

DO 6 Heat Stage 6 10 = 2 & 11 > 5

I/O Cong. Code Condition

Heating, F & BP Dampers

Universal Inputs/Outputs

Digital Outputs — Triac (24 VAC, 0.5 Amp)

www.DaikinApplied.com 19 IM 919-3 • MICROTECH III CONTROLLER

ConTroller InpuTs/ouTpuTs

Table 10: RTU - Expansion Module C I/O

RTU Evaporative Condensing, VFD Compressors

RTU — Expansion Module C

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X PS1 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

X 1 X Comp 1 0–5 VDC

X 1 X VFD (Comp 1) 0–10 VDC 3 = 4

X 1 X VFD (Comp 2) 0–10 VDC 3 = 5

X 2 X PS2 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

X 3 X Comp 2 0–5 VDC 3 = 9 or 10 & Unit Size ≠ 120

X 3 X Sump Temperature

X 3 X Comp 1 Oil Status 3 = 4

X 3 X Comp 2 Oil Status 3 = 5

X 4 X Conductivity 4–20 mA — Evaporative Condensing Pos. 1 = 0 & 7 = 2, 3, 4 or 5

X 4 X Com 1 Alm Dry Contact

X 4 X Comp 1 Status 3 =4

X 4 X Comp 2 Status 3 = 5

X 5 X LP1 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

X 5 X Comp 2 Alm Dry Contact 3 = 9 or 10 & Unit Size ≠ 120

X 6 X LP2 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

X 6 X Disch. Refrig. Pressure Ckt1

X 6 X Disch. Refrig. Pressure Ckt1

X 7 X Separator Flush Valve 0-10VDC Pos. 1 = 0 & 7 = 2, 3, 4 or 5

X 7 X Disch. Refrig. Pressure Ckt2

X 7 X Disch. Refrig. Pressure Ckt2

X 8 X Sump Water Level Switch Dry Contact

X 8 X Comp 1 DLT

X 8 X Comp 2 DLT

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1 SV1 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

DO 1 Cond Coil Solenoid Ckt1

DO 1 Cond Coil Splitter Solenoid Circuit 1 3 = 4 or 5

DO 2 Unld 1 Comp 1 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

DO 2 Cond Coil Solenoid Ckt2 3 = 9 or 10 & Unit Size ≠ 120

DO 2 Cond Coil Splitter Solenoid Circuit 2 3 = 4 or 5

DO 3 SV2 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

DO 4 Unld 1 Comp 2 Pos. 1 = 0 & 7 = 2, 3, 4 or 5 & 4 = 4 or E

DO 4 VFD Comp 1 Emergency Stop 3 = 4

DO 4 VFD Comp 2 Emergency Stop 3 = 5

# Point Comments Cong. Code Condition

DO 5 Drain Valve Evaporative Condensing

DO 5 Comp 5

DO 6 Sump Pump Evaporative Condensing

DO 6 Comp 6 3 = 5 & 4 = A & 5 =3

I/O Cong. Code Condition

Universal Inputs/Outputs

[3 = 10 & Unit Size ≠ 120] or

[3 = 9 & Unit Size = 120]

10K Thermistor (STD) — Evaporative

Digital Outputs — Triac (24 VAC, 0.5 Amp)

Condensing

Ratiometric input required

(0.5–4.5 VCD: 0–700 psi)

Ratiometric input required

(0.5–4.5 VCD: 0–700 psi)

Ratiometric input required

(0.5–4.5 VCD: 0–700 psi)

Ratiometric input required

(0.5–4.5 VCD: 0–700 psi)

Resistance Input

(T = 0.4637 R–431.72)

Resistance Input (T = 0.4637

R–431.72)

Pos. 1 = 0 & 7 = 2, 3, 4 or 5

[3 = 10 & Unit Size ≠ 120] or

[3 = 9 & Unit Size = 120]

[3 = 10 & Unit Size ≠ 120] or

[3 = 9 & Unit Size =1 20]

3 = 4 or 5

3 = 9 or 10 & Unit Size ≠ 120

3 = 4 or 5

3 = 4

3 = 5

[3 = 10 & Unit Size ≠ 120] or

[3 = 9 & Unit Size = 120]

[3 = 5 & 4 = 7 & 5 = 1] or

[3 = 5 & 4 = J & 5 = 2] or

[3 = 5 & 4 = A & 5 = 3]

IM 919-3 • MICROTECH III CONTROLLER 20 www.DaikinApplied.com

ConTroller InpuTs/ouTpuTs

Table 11: SCU Expansion Module C I/O

SCU — Expansion Module C Pos. 1 = 1

One Compressor Per Circuit

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X Low Pressure 3 Dry Contact 3 = 1 & 4 = 5, 6, 8, 9, B or C & 21 = 0

X 2 X Low Pressure 4 Dry Contact 3 = 1 & 4 = 8, 9, B or C & 21 = 0

X 3 X High Pressure 3 Dry Contact 3 = 1 & 4 = 5, 6, 8, 9, B or C & 21 = 0

X 4 X High Pressure 4 Dry Contact 3 = 1 & 4 = 8, 9, B or C & 21 = 0

X 5 X Low Pressure 5 Dry Contact 3 = 1 & 4 = B or C & 21 = 0

X 6 X Low Pressure 6 Dry Contact 3 = 1 & 4 = B or C & 21 = 0

X 7 X High Pressure 5 Dry Contact 3 = 1 & 4 = B or C & 21 = 0

X 8 X High Pressure 6 Dry Contact 3 = 1 & 4 = B or C & 21 = 0

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1

DO 1

DO 2

DO 2

DO 3

DO 4

# Point Comments Cong. Code Condition

DO 5

DO 6

I/O Cong. Code Condition

Universal Inputs/Outputs

Digital Outputs — Triac (24 VAC, 0.5 Amp)

www.DaikinApplied.com 21 IM 919-3 • MICROTECH III CONTROLLER

ConTroller InpuTs/ouTpuTs

Table 12: DPS/DPH Expansion Module D I/O

I/O Cong. Code Condition

Expansion Module D Pos. 1=3or4

# Point Comments Cong. Code Condition

AI 1 Indoor Refrigerant Temperature (IRT) 10K Thermistor (STD) 1 = 4 & 30 = 3, 4, 5 or 6

AI 2

AI 3

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X

X 2 X

X 3 X

X 4 X

X 5 X Heating Valve

X 6 X

X 7 X

X 7 X INV Compressor Body Temperature 100K Thermistor (HT) 24, 25, 26 = 0, 1, 5

X 8 X Reheat Output 0–10 VDC 28 = 2

X 9 X Supply Temp Leaving Wheel 10K Thermistor (STD) 20 > 0 & 30 = 3, 4, 5 or 6

X 10 X Exhaust Temp Leaving Wheel 10K Thermistor (STD) 20 > 0 & 30 = 3, 4, 5 or 6

X 11 X OA Flow 0–10 VDC or 4–20 mA

X 12 X Freezestat Switch 0-5 VDC 10 =5 & 8 = 8 or 9 & 30 = 3, 4, 5 or 6

# Point Comments Cong. Code Condition

DI Freezestat Switch 115 VAC Input 10 = 5 & 8 = 3 or 6

DI OAD End Switch Input 115 VAC Input 8 = 8 or 9

# Point Comments Cong. Code Condition

DO 1 INV Board Power Up

DO 2

DO 3 Bypass Solenoid Valve (SVB)

DO 4 4 Way Reversing Valve (4WV) 1 = 4

# Point Comments Cong. Code Condition

DO 5 Bypass Damper CLOSED Energy Recovery 20 > 0 & 8 = 3 or 6 & 30 = 3, 4, 5 or 6

DO 6 Bypass Damper OPEN Energy Recovery 20 > 0 & 8 = 3 or 6 & 30 = 3, 4, 5 or 6

Outdoor Refrigerant Temperature

Outdoor Coil Defrost Temperature

Compressor Suction Pressure Sensor

Compressor Discharge Pressure

INV Compressor Discharge Line

Refrigerant Temperature (DRT1)

STD3 Compressor Discharge Line

Refrigerant Temperature (DRT3)

Compressor Suction Line Refrigerant

Outdoor Coil Defrost Temperature

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

Refrigerant Receiver Gas Line

(ORT)

(DFT)

(PTS)

Sensor (PTD)

Temperature (SRT)

(DFT)

Solenoid Valve (SVR)

Digital Outputs — Triac (24 VAC, 0.5 Amp)

Analog Inputs — NTC

10K Thermistor (STD) 1 = 4 & 30 = 3, 4, 5 or 6

10K Thermistor (STD) 1 = 4 & 30 = 3, 4, 5 or 6

Universal Inputs/Outputs

0.5–4.5 VDC 0–350 psi

0.5–4.5 VDC 0–700 psi

100K Thermistor (HT)

100K Thermistor (HT) 4 = M

Gas 2–10 VDC HW/STM 2–10 VDC

10K Thermistor (STD)

10K Thermistor (STD) 1 = 4 & 30 = 1 or 2

Digital Input — 115V-230V

SCR 0–10 VDC

10 = 5, 6 or 7

8 = 1, 2, 3, 5,6 or 7 & 9 = 6 &

30 = 3, 4, 5 or 6

1 = 4

IM 919-3 • MICROTECH III CONTROLLER 22 www.DaikinApplied.com

ConTroller InpuTs/ouTpuTs

Table 13: RTU/SCU/MPS/DPS/DPH Expansion Module E I/O

I/O Cong. Code Condition

Simultaneous OA Flow and CO2 OA Reset

Expansion Module E

Universal Inputs/Outputs

# DI AI DO AO Point Comments Cong. Code Condition

X 1 X OA Flow 0–10 VDC or 4–20 mA 1 = 0 & 8 = 1, 2, 3, 5, 6 or 7 & 9 = 6

X 2

X 3

X 4

X 5

X 6

X 7

X 8

Digital Outputs — Relay (SPST, Normally Open, 230 VAC 3 Amp)

# Point Comments Cong. Code Condition

DO 1

DO 1

DO 2

DO 2

DO 3

DO 4

Digital Outputs — Triac (24 VAC, 0.5 Amp)

# Point Comments Cong. Code Condition

DO 5

DO 6

Pos. 1 = 0, 1, 2, 3 or 4

www.DaikinApplied.com 23 IM 919-3 • MICROTECH III CONTROLLER

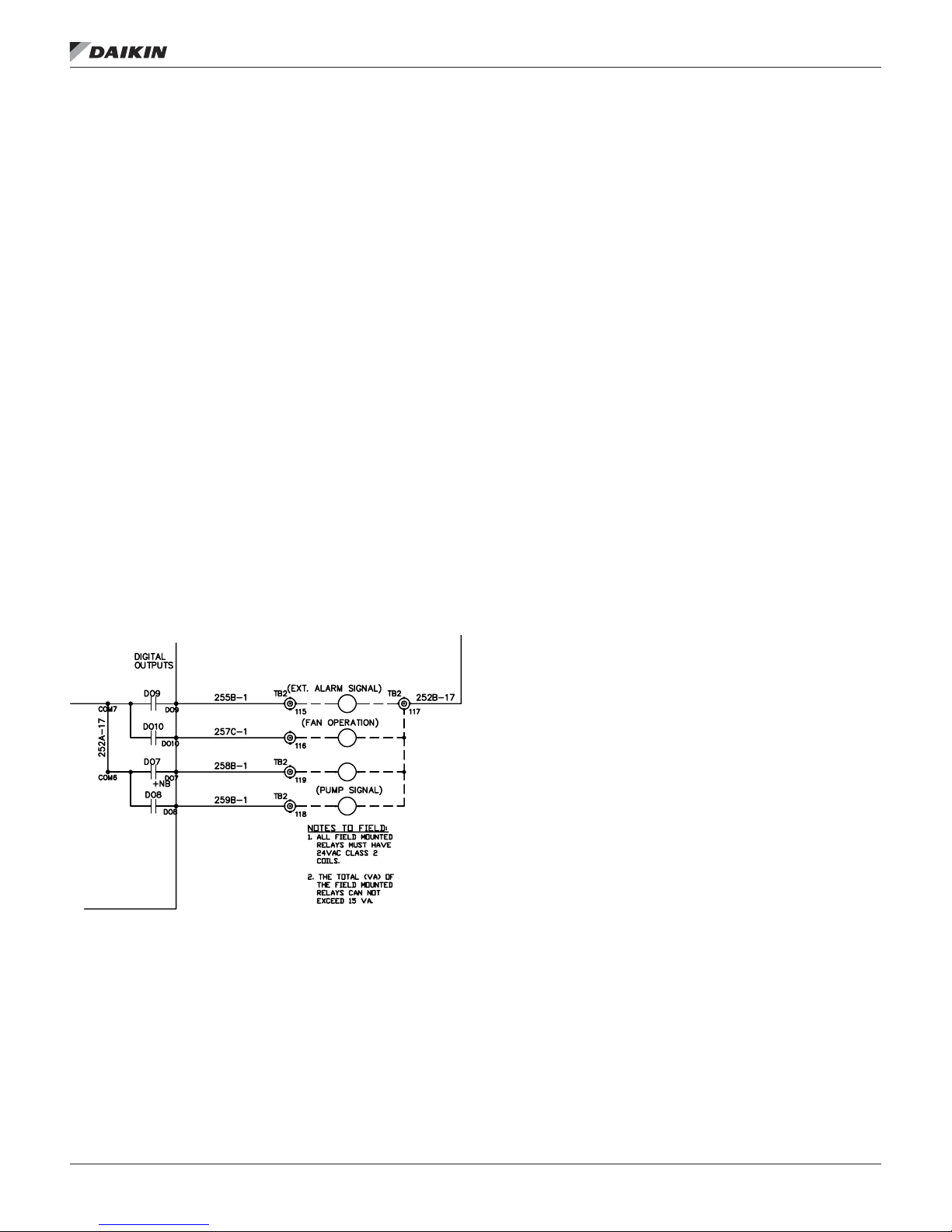

fIeld wIrIng

Below are descriptions of the various options and features

that may require eld wiring to the MicroTech III controller.

Refer to the job plans and specications and the as-built wiring

schematics for information regarding the specic unit.

Field Output Signals

The following outputs may be available for eld connections to

a suitable device.

Remote Alarm Output

The Remote Alarm Output (MCB-DO9) supplies 24 VAC to

terminal 115 on the eld terminal block (TB2) when the output

is on. To use this signal, wire the coil of a eld supplied and

installed 24 VAC pilot relay across terminals 115 and 117 on

TB2. When this output is on, 24 VAC is supplied from the

control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

The digital alarm output indicates the alarm group that contains

the highest priority active alarm. This output (MCB-DO9) is On

when no alarms are active. The options for the action of this

output when an alarm in a group occurs are On, Fast Blink,

Slow Blink, or Off. These can be edited via the Alarm Out

Cong menu in the Extended menus on keypad/display. The

default values for the three groups of alarms are:

Warnings - Off

Problems - Slow Blink

Faults - Fast Blink

A user could eliminate any signal of a particular group of

alarms through this output by selecting On for that alarm group

in the keypad/display.

VAV Box Signal/Fan Operation Signal

The VAV Box Signal/Fan Operation signal affects how Digital

Output #10 operates. The output is either a supply fan

operation indication or a VAV box signal depending on how

this parameter is set. Digital output #10 is wired to a set of

terminals for eld use.

Fan Operation

The Fan Operation Output (MCB-DO10) supplies 24 VAC to

terminal 116 on the eld terminal block (TB2) when the output

is on. To use this signal, wire the coil of a eld supplied and

installed 24 VAC pilot relay across terminals 116 and 117 on

TB2. When this output is on, 24 VAC is supplied from the

control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

The Fan Operation output is on when the unit is not Off and

when both the unit is Off and airow is detected. It is off when

the unit is off and airow is not detected.

fIeld wIrIng

VAV Output

In the Heating state, the VAV Output is turned off to indicate

that hot air instead of the normal cool air is being supplied to

the VAV boxes. The VAV boxes are driven to their Heating

Position when hot air is provided based on either the normally

open or normally closed contacts of the VAV output. The VFD

will continue to be controlled to maintain the desired duct static

pressure. This output is also off when the unit is in the Startup

or Recirculation states. If this output is in the Heat (off) position

when the unit enters the Fan Only state or Minimum DAT

Control state, the output remains off for an adjustable Post

Heat Time. When the Unit State is Off, the VAV Box Output

is in the Cool (on) position unless airow is detected. When

airow is detected, it switches to the Heat (off) position.

Cooling Only Units

For cooling only VAV systems, the VAV Box Output can

override zone thermostat control and drive the VAV boxes fully

open to facilitate air circulation during the Recirc operating

state. During this time, the VAV Box Output is in the OFF

(or heat) position (eld-installed pilot relay de-energized).

VAV units have a “post heat” control feature that forces the

VFD speed to a minimum before turning on the VAV Box

Output when the Recirc operating state is complete. Post

heat operation prevents excessive duct static pressure that

could otherwise occur when the zone thermostats regain VAV

box control. The setting of a “post heat” timer determines the

duration of post heat operation. This timer is set to zero at the

factory and must be set to a non-zero value to enable the “post

heat” function.

Units with Modulating Heat

The VAV Box Output should be used to switch the VAV boxes

between heating and cooling control. While the unit is in

Startup, Recirc, or Heating operating state (UnocHtg, MWU, or

Heating), the VAV Box Output is in the OFF (or heat) position

(eld-installed pilot relay de-energized) switching the VAV

boxes into heating operation.

VAV units have a “post heat” control feature that forces the

VFD speed to a minimum before closing the VAV Box Output

when the unit leaves the Recirc or Heating operating state.

“Post heat” operation prevents excessive duct static pressure

that could otherwise occur when the zone thermostats regain

VAV box control. When the unit is not in Startup, Recirc, or

Heating operating state, the VAV Box Output is in the ON (or

cool) position (eld-supplied pilot relay energized) switching the

boxes to cooling control.

IM 919-3 • MICROTECH III CONTROLLER 24 www.DaikinApplied.com

fIeld wIrIng

Staged Cooling Outputs

Rooftop air handlers can be ordered with factory-installed

evaporator coils and the capability to control up to eight stages

of eld-supplied cooling equipment. The MicroTech III outputs

designated for these applications are DO 1-4 and DO 7,8 on

the MCB and DO 1,2 on Expansion board A. These outputs

are wired to terminal block TB4 in the main control panel for

connection to the eld supplied condensing unit. Refer to the

as-built wiring schematics for the unit

Outdoor Damper

When applicable the Outdoor Damper Output supplies 24

VAC to terminal 119 on the eld terminal block (TB2) when the

output is on. To use this signal, wire the coil of a eld supplied

and installed 24 VAC pilot relay across terminals 119 and 117

on TB2. When this output is on, 24 VAC is supplied from the

T3 control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

Pump Signal

When applicable the Pump Signal Output supplies 24 VAC to

terminal 113 on the eld terminal block (TB2) when the output

is on. To use this signal, wire the coil of a eld supplied and

installed 24 VAC pilot relay across terminals 113 and 117 on

TB2. When this output is on, 24 VAC is supplied from the T3

control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

Figure 18: Fan Operation Output Wiring Diagram

Field Analog Input Signals

The following inputs may be available for eld connections to a

suitable device.

NOTE: The eld needs to be careful not to ground their

transformer for a eld signal to chassis ground. They

need to use the same ground as the controller to

prevent a voltage potential above 3V. This voltage

potential can damage the Microtech III Controller.

Zone Temperature Sensor Packages

A zone temperature sensor (ZNT1) is optional for all units

except for the 100% outdoor air

Zone Control unit in which case one is required. In all unit

congurations, however, a zone temperature sensor is required

to take advantage of any of the following standard controller

features:

• Unoccupied heating or cooling

• Pre-occupancy purge

• Discharge air reset based on space temperature (DAC

units only)

• Remote timed tenant override

• Remote set point adjustment (CAV-ZTC units only)

A Zone Setpoint Source (Apply Tstat change =No/Yes)

parameter is provided on the keypad/display to allow for

setting the setpoint via the zone thermostat input. The menu is

located in the Heating/Cooling Changeover Setup menu of the

Commission Unit section. When Apply Tstat change is set to

No, the Occupied Cooling Setpoint and the Occupied Heating

Setpoint may be set through the keypad or via a network signal

(all units). In this case these setpoints are changed whenever

the network or keypad value changes.

When Apply Tstat change is set to Yes these setpoints can

only be adjusted through the zone thermostat. This option is

available for all control types (Zone, DAT, and Single zone

VAV). Heating and cooling setpoints must not overlap. The

Occupied Heating Setpoint must be equal to or less than the

Occupied Cooling Setpoint. If a conict occurs from values

entered via the keypad or network, Occupied Heating Setpoint

is automatically adjusted down to eliminate the conict.

When Apply Tstat change =No, the Occupied Heating and

Cooling setpoints may be changed manually by changing the

setpoint displayed on the keypad.

When Apply Tstat change =Yes, the Occupied Cooling Setpoint

is set through a setpoint adjustment included with a wall

mounted space sensor. When the Occupied Cooling Setpoint is

changed by more than 0.5 degrees through the wall mounted

sensor, the Occupied Heating Setpoint is raised or lowered the

same amount so that the difference between the Cooling and

Heating setpoints does not change.

The dead band between the Occupied Cooling Setpoint and

the Occupied Heating Setpoints can be set by setting the Apply

Tstat change to No, setting the differential via the keypad and

resetting the Apply Tstat change back to Yes. The setpoint

adjustment is a resistance value that varies from 5000 ohm to

15000 ohms.

www.DaikinApplied.com 25 IM 919-3 • MICROTECH III CONTROLLER

Loading...

Loading...