Page 1

Operation manual

Wall-mounted condensing boiler

R2CND024A4AA

R2TND012A4AA

R2TND018A4AA

R2TND024A4AA

Operation manual

Wall-mounted condensing boiler

English

Page 2

Table of Contents

Table of Contents

1 Introduction 2

1.1 About the unit ............................................................................ 2

1.2 About the documentation .......................................................... 2

1.2.1 Meaning of warnings and symbols.............................. 2

2 Safety instructions 2

2.1 Installation ................................................................................. 2

2.2 Smell of gas............................................................................... 3

2.3 Modifications on the unit............................................................ 3

2.4 Gas conversion ......................................................................... 3

2.5 For the user ............................................................................... 3

3 Operation 3

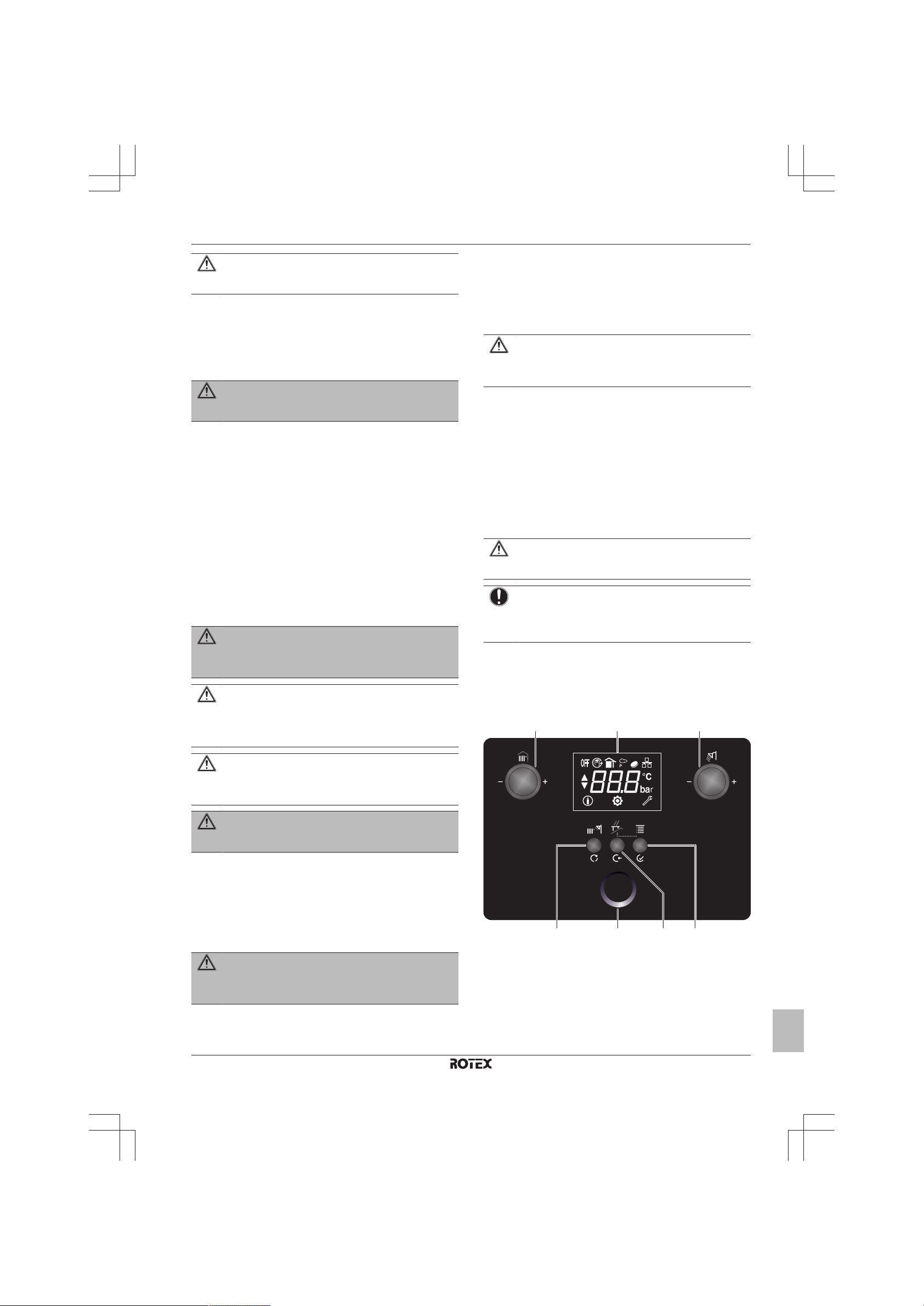

3.1 User interface ............................................................................ 3

3.1.1 Buttons and dials ........................................................ 4

3.1.2 LCD screen ................................................................. 4

3.1.3 Status indicator ........................................................... 4

3.2 Operating the unit...................................................................... 4

3.2.1 To switch ON the unit.................................................. 4

3.2.2 About the low water temperature function .................. 4

3.2.3 About the electronic gas adaptive system calibration. 4

3.3 Basic usage............................................................................... 4

3.3.1 About the home screen............................................... 4

3.3.2 To select the operation mode ..................................... 5

3.3.3 Possible operation modes........................................... 5

3.3.4 Changing temperature setpoints................................. 5

3.3.5 Possible central heating operation modes.................. 6

3.3.6 About the central heating ECO mode ......................... 6

3.3.7 About the domestic hot water operation ..................... 6

3.3.8 About the domestic hot water comfort mode .............. 7

3.3.9 About the boiler frost protection.................................. 7

3.4 Error handling............................................................................ 7

3.5 Menu functions .......................................................................... 7

3.5.1 To use menu level 1.................................................... 7

3.5.2 Info menu .................................................................... 7

3.5.3 User settings menu ..................................................... 8

3.5.4 Installer settings menu ................................................ 9

4 Maintenance and cleaning 9

4.1 To clean the outer surface of the unit........................................ 9

5 Energy saving tips 9

6 Contact 9

7 Error codes 9

Model Type Domestic hot water

supply

R2TND018A4AA R2TND018 Storage tank External

R2TND024A4AA R2TND024 Storage tank External

A control unit, which contains a user interface, controls the ignition,

safety systems, and other actuators. User interaction is provided via

that user interface, which is composed of an LCD screen, push

buttons, and two dials, and which is located on the front cover of the

unit.

Filling loop

1.2 About the documentation

The instructions contained in this document are intended to guide

you through the operation of the unit. Damage caused by nonobservance of these instructions are not under the responsibility of

ROTEX.

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document are written for users

and cover very important topics, follow them carefully.

▪ Please read the instructions in the manual carefully, for your

safety and health.

▪ Please keep this manual for future reference throughout the unit's

period of use.

▪ Request the installer to inform you about the settings that he

made to configure your system.

1.2.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

WARNING

Indicates a situation that could result in death or serious

injury.

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

1 Introduction

1.1 About the unit

This ROTEX unit is a wall-mounted gas-fired condensing boiler that

can supply heat to central heating systems, as well as supply

domestic hot water. Depending on settings, it is possible to use the

unit solely for hot water or solely for central heating. Hot water

supply type can be instantaneous or by means of a hot water

storage tank. The type of the boiler can be recognised from the

model name written on the identification label, which is located at the

right cover of the unit. See table below:

Model Type Domestic hot water

supply

R2CND024A4AA R2CND024 Instantaneous External

R2TND012A4AA R2TND012 Storage tank External

Operation manual

2

Filling loop

2 Safety instructions

Always observe the following safety instructions and regulations.

2.1 Installation

WARNING

Installation, service, maintenance and repair of the boiler

can only be carried out by suitably qualified competent

persons, in accordance with the applicable legislation,

regulations, rules and guidelines.

WARNING

The unit may only be operated with its casing properly

mounted. Otherwise, in unfavourable conditions, material

damage or even injury or death can result.

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Page 3

3 Operation

a

e f g

cb

d

CAUTION

A discharge pipe must be connected to the condensate

trap in order to prevent contact with the condensate.

In case your skin comes into contact with condensate, the contact

location should be washed with plenty of water. Condensate liquid

must never be used for purposes of cleaning, watering plants, or

drinking.

2.2 Smell of gas

DANGER

This is a gas unit. Gas leaks might lead to poisoning and

explosions.

If you smell gas:

▪ Do not use any electrical switches, including light switches.

▪ Do not use telephones in the affected area.

▪ Do not use naked flames, such as matches or lighters.

▪ Do not smoke.

▪ Turn off the main gas supply.

▪ Open windows and doors.

▪ Warn other people in the building.

▪ Get out of the building.

▪ Inform your gas supplier, service agent or other competent

person.

2.3 Modifications on the unit

DANGER

Malfunctions can lead to poisoning and explosions. Never

put the safety devices out of operation, nor tamper with

them so as to impair their function.

CAUTION

An inappropriate modification may cause damage. Never

tamper with the boiler or other parts of the system. Never

attempt to perform maintenance or repair yourself. Call a

qualified service agent.

This unit is able to be operated with both natural gas and LPG. The

preset gas type is indicated on the identification label of your unit. If

you desire to use your unit with the other fuel type, contact your

service agent.

2.5 For the user

CAUTION

Any misuse is forbidden. The manufacturer is not

responsible for any malfunctions and/or damage that may

occur due to misuse.

▪ Your unit is intended as a heater for central heating systems and

for domestic hot water generation. Any other use is considered as

"misuse".

▪ If you are not sure how to operate the unit, contact your service

agent.

▪ This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

CAUTION

Do not rinse the unit. This may cause electric shocks or

fire.

NOTICE

▪ Do not place any objects or equipment on top of the

unit.

▪ Do not sit, climb or stand on the unit.

3 Operation

3.1 User interface

CAUTION

Do not use sprays, solvents, chlorinated cleaning agents,

paint, and adhesives in the vicinity of the unit. These

substances can cause corrosion, even in the flue system.

DANGER

Do not damage or remove any seals on components. Only

qualified persons are allowed to alter sealed components.

Do not make any modifications on:

▪ Boiler

▪ Gas, water or power supply

▪ Flue system

2.4 Gas conversion

WARNING

Never attempt to do gas conversion yourself. Only qualified

persons can do gas conversion. Contact your service

agent.

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

a Left dial

b LCD screen

c Right dial

d Mode / Reset

e Status indicator

f Cancel / Back

g Menu / Enter

Operation manual

3

Page 4

3 Operation

3.1.1 Buttons and dials

The three buttons and two dials on the user interface have various

functions according to different situations, which are stated in the

table below:

Button/Dial Function Description

Mode /

Reset

Cancel /

Back

Menu / Enter Menu Enter the menu function.

Left dial User

Right dial User

Mode Change mode between summer,

winter, central heating only, standby

and full-off.

Reset Reset the lockout error.

Cancel Cancel changes.

Back Go back to the parent menu.

Enter Passing on to the next level in the

menu structure.

Confirm Confirmation of changes.

Central heating temperature setpoint.

interaction

level

Menu level Selection of info, user, service menu.

interaction

level

Menu level ▪ Selection parameter index.

This is either the central heating flow

temperature, the room temperature,

or the virtual room temperature,

depending on the system

configuration.

Domestic hot water temperature

setpoint.

▪ Change parameter values.

3.1.2 LCD screen

LCD screen is the monitor of the user interface. You can see the

boiler operation mode, setpoints, information about actuators and

menu parameters on this screen.

The LCD screen has a sleeping function. After one minute of noninteraction with the user interface, the screen darkens. Pressing any

button or rotating any dial awakens the display.

When you interact with the user interface, the LCD screen will show

the home screen of the active operation mode and the related

setpoint, depending on the system configuration (see "3.3.3Possible

operation modes"on page5).

Status icons

Meaning of icons that appear on the LCD screen:

Icon Description

Operation mode: Standby mode

Domestic hot water operation enabled

Domestic hot water comfort mode is enabled

Central heating operation enabled

Room temperature

Outdoor sensor connection

Central heating ECO mode enabled

Network connection

Info menu

User settings menu

Service settings menu

3.1.3 Status indicator

The status indicator gives first level feedback on the operation mode

and status of the boiler.

Status Description

Standby When there is no heat demand, the status

indicator shows this with a kind of breathing

pulsation of the blue and white LED.

Flame At the moment flame ignites for central heating or

domestic hot water, the ring flashes to its

maximum, then constantly keeps glowing during

burner operation.

Error The status indicator will go into error mode when a

warning, lockout or blocking error occurs (see

"3.4Error handling"on page7). During the error

condition the status indicator continuously shows

the red blinking LED.

NOTICE

In warning error, the status indicator colour turns to blue

while the boiler is operating.

3.2 Operating the unit

3.2.1 To switch ON the unit

1 Connect the unit to the main power supply.

2 Press the "Mode" button for 5seconds to switch ON the unit.

3 After that, you can select an operation mode by pressing the

"Mode" button shortly.

Use of the unit is explained in following parts of this manual.

3.2.2 About the low water temperature function

The low water temperature function is a safety function that takes

place at first central heating operation after each power supply

interruption and at first central heating operation after each 90 days.

When this function is active, boiler operates according to a defined

set value for around 15 minutes and the icon blinks. After this

function is ended, normal operation goes on.

INFORMATION

Low water temperature function is a safety function and it

cannot be disabled.

3.2.3 About the electronic gas adaptive system calibration

The electronic gas adaptive system calibrates itself in predetermined time intervals. First calibration takes place just after first

burner activation after each power ON. Calibration process duration

is around 60 seconds and the icon blinks. After calibration is

ended, boiler modulates to required capacity. Calibration process

has no effect on boiler operation.

3.3 Basic usage

3.3.1 About the home screen

It is the screen that is displayed after activating the LCD screen with

one of the dials or buttons. You can use the home screen to read out

settings that are meant for daily use. What you can see on the home

screen depends on your system configuration.

The following home screens may be possible:

▪ Room temperature (ROTEX room thermostat connected)

▪ Central heating set temperature

Operation manual

4

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Page 5

3 Operation

(5 s)

(5 s)

a

c

b

d

e

▪ Virtual room temperature (with outdoor sensor)

▪ Domestic hot water set temperature

▪ System pressure (at standby mode)

3.3.2 To select the operation mode

The operation mode can be changed by pressing the "Mode" button

( ).

a Central heating only mode

b Standby mode

c Summer mode

d Winter mode

e Full-off mode

3.3.3 Possible operation modes

Operation mode Description

Central heating only mode ▪ Only central heating operation mode

is enabled.

▪ The central heating temperature

setpoint (which setpoint is shown

depends on the system

configuration; see "3.3.5 Possible

central heating operation modes"on

page 6) and the icon is shown

on the home screen.

▪ The icon blinks if central heating

operation is active.

Standby mode ▪ Both central heating and domestic

hot water operation modes are

disabled.

▪ The protection functions such as

frost protection are still active at

standby mode.

▪ The home screen shows the system

pressure, as well as the icon.

Summer mode ▪ Only domestic hot water operation

mode is enabled. Central heating

operation mode is disabled. The

boiler will only produce heat for

domestic hot water.

▪ The domestic hot water setpoint,

and the icon is shown on the

home screen.

▪ The icon blinks if domestic hot

water operation is active.

Operation mode Description

Winter mode ▪ Both domestic hot water operation

mode and central heating operation

mode are enabled. The boiler can

produce domestic hot water, as well

as produce heat for central heating.

▪ The central heating temperature

setpoint (which setpoint is shown

depends on the system

configuration; see "3.3.5 Possible

central heating operation modes"on

page 6), and the icon, as well

as the icon are shown on the

home screen. When domestic hot

water operation is active, domestic

hot water setpoint is shown on the

home screen.

▪ The icon blinks if domestic hot

water operation is active.

▪ The icon blinks if central heating

operation is active.

Full-off mode ▪ Both central heating and domestic

hot water operation modes are

disabled.

▪ LCD display will be darkened and

will not be activated with any user

interaction.

▪ The protection functions such as

frost protection are still active at fulloff mode.

▪ Full-off mode is activated and

deactivated if "Mode" button is

pressed for 5seconds while boiler is

in any mode.

3.3.4 Changing temperature setpoints

Temperature setpoints can be changed with the Right/Left dials.

To change the central heating temperature setpoint

1 Turn the left dial while you are at the home screen. The setpoint

screen will appear as shown below and the setpoint can be

adjusted by turning the left dial. Note: The icon means you are

at the setpoint screen.

2 To apply changes done, wait for 3seconds or press the "Enter"

button. Pressing the "Cancel" button cancels the changes done.

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Operation manual

5

Page 6

3 Operation

To change the domestic hot water setpoint

1 Turn the right dial while you are at the home screen. The

setpoint screen will appear as shown below and the setpoint

can be adjusted by turning the right dial. Note: The icon

means you are at the setpoint screen.

2 To apply changes done, wait for 3seconds or press the "Enter"

button. Pressing the "Cancel" button cancels the changes done.

NOTICE

To be able to change the setpoint of central heating or

domestic hot water, the corresponding operation mode

must be enabled. If it is not, the related dial has no

function.

3.3.5 Possible central heating operation modes

Mode Description

Boiler only The case that the system only

contains the boiler. No room

thermostat or outdoor sensor are

connected. The central heating water

temperature setpoint is displayed. The

setpoint can be adjusted with the left

dial.

The icon is shown on the screen

when the central heating operation

mode is enabled.

Combination with ROTEX

Opentherm room

thermostat (DOTT )

The case that ROTEX Opentherm

room thermostat is connected to the

boiler. Room temperature setpoint is

displayed. The room temperature

setpoint can be adjusted from the user

interface by means of the left dial or

from the ROTEX room thermostat.

The icon is shown on the screen

instead of the icon when central

heating operation mode is enabled.

Mode Description

Boiler + outdoor sensor

(Weather compensation)

NOTICE

To enable weather compensation, the heating slope value

must be higher than "5" (see "User settings menu:

Parameters (short)"on page8).

INFORMATION

If an outdoor sensor is connected to the boiler together

with an Opentherm room thermostat (whether DOTT or

not), the rules of the case "Combination with Opentherm

room thermostat" are applicable. The outdoor sensor only

provides outdoor temperature data to the room thermostat

for water temperature calculation.

The case that outdoor sensor is

connected to the boiler. In this case,

the central heating water temperature

is regulated according to the outdoor

temperature. The virtual room

temperature setpoint is diplayed. The

virtual room temperature setpoint can

be adjusted by means of left dial.

Increasing or decreasing the setpoint

value reflects to the central heating

water temperature and the room

temperature, respectively.

The and icons are shown on the

screen when central heating operation

mode is enabled.

3.3.6 About the central heating ECO mode

The central heating ECO mode provides more economic central

heating. Main purpose of the ECO mode is to operate the boiler at

the condensing temperature range so to increase the efficiency.

ECO mode can be activated at any central heating operation mode

explained above.

ECO mode can be enabled from the user settings menu (see "User

settings menu: Parameters (short)"on page8).

INFORMATION

ECO mode is only for central heating, it has no effect to

domestic water heating.

When central heating ECO mode is enabled, icon is shown on the

screen while the central heating operation mode is enabled.

3.3.7 About the domestic hot water operation

This unit supplies domestic hot water by way of a plate heat

exchanger (instantaneous) or by way of a hot water storage tank

according to model of the boiler.

If the boiler is instantaneous type, domestic hot water operation is

activated when water is being tapped. Water flow rate must be at

least 2.5l/min.

If it is storage tank type, domestic hot water operation is activated

according to storage tank temperature value.

The icon blinks when domestic hot water operation is active.

Operation manual

6

INFORMATION

Domestic hot water operation mode must be enabled for

the boiler to be able to produce domestic hot water. (i.e.

summer mode or winter mode).

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Page 7

3 Operation

3.3.8 About the domestic hot water comfort mode

The domestic hot water comfort mode includes a domestic hot water

pre-heat function and a domestic hot water post-heat function. When

the comfort mode is enabled, both pre-heat and post-heat functions

are enabled.

The pre-heat function is a self-learning algorithm according to which

the boiler will heat up the domestic hot water, before the tapping

demand. The algorithm is based on your personal use pattern of the

last 24hours.

Note: Independent of personal use pattern, comfort mode

preheating function could be adjusted to operate continuously from

the user settings.

The post-heat function heats up the domestic hot water heat

exchanger after tapping, when the flow temperature of the boiler is

below the domestic hot water temperature setpoint.

Comfort mode can be enabled from the user settings menu (see

"User settings menu: Parameters (short)"on page8).

INFORMATION

Domestic hot water comfort mode is only valid for

instantaneous type hot water supply types.

When the domestic hot water comfort mode is enabled, the icon is

shown on the screen.

The icon blinks when the burner is on for comfort mode.

Error

type

Lockout Blocked and a

In case of a warning or a blocking error, the user interface will leave

error mode and return to the home screen when the cause of the

error disappears.

In case of a lockout error, the boiler needs to be reset. Press the

"Reset" button to remove the error, if the cause of the error is gone.

If the cause of the error is still there, the user interface will enter

error mode again. When the error is solved, the user interface

returns to the home screen.

If you turn any dial or press any button (except the "Reset" button)

during an error, the user interface will display the home screen. After

the timeout without any interaction, instead of darkening, the user

interface will enter error mode.

Boiler operation User interface and status

indicator

The status indicator enters error

reset is required

NOTICE

A table with all error codes, the reasons for their

appearance, and possible solutions, is located at the very

end of this manual.

mode. The LCD screen stays active

and displays the error code. Also,

the icon starts blinking, indicating

that a reset is required.

3.5 Menu functions

3.3.9 About the boiler frost protection

Frost protection safety system: This function protects the unit and

heating installation from frost damages. This protection activates the

boiler pump when the water temperature drops below 13°C and it

activates the burner when the water temperature drops below 8°C

(factory setting). The unit keeps running until the temperature

reaches 30°C. To enable this function, the unit must be connected to

the power supply and its main gas valve must be open. Any damage

caused by frost is not covered by the warranty. Frost Protection is

enabled in all modes, including standby mode and full-off mode.

WARNING

If the boiler is not connected to the power supply, frost

protection is not active. Consequently, the water may

freeze and cause cracks. The manufacturer is not

responsible for any damage that may occur this way.

NOTICE

When not using the boiler, we strongly recommend not to

cut off the electric supply to the boiler.

3.4 Error handling

When an error occurs, the normal behaviour of the user interface is

interrupted, and the status of the status indicator is affected.

However, be aware that not all errors have the same effect on the

user interface and the status indicator.

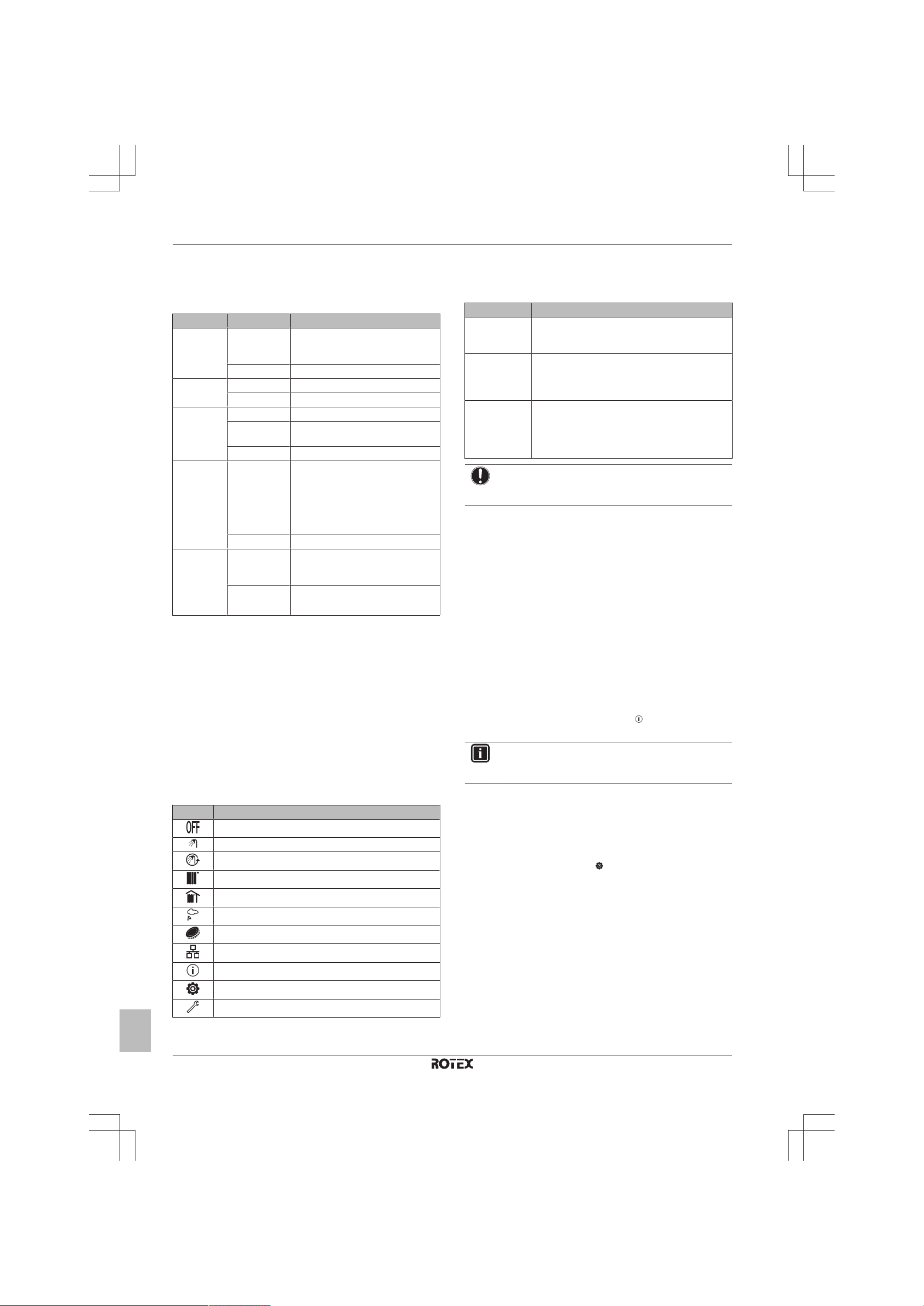

3.5.1 To use menu level 1

1 Press the "Menu" button while you are at home screen to go the

Menu screen. This is menu level 1 screen.

2 To switch between info, user settings and service settings, turn

the left dial.

3 To leave the menu and return to the home screen, press "Back"

for 2seconds.

When there is no user interaction for one minute, the user interface

will leave the menu and switch to the blank screen.

Error

type

Warning Continue The status indicator does not enter

Blocking Blocked, turns back

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Boiler operation User interface and status

indicator

error mode if the burner is on. It

turns to red when the burner is off.

The LCD screen stays active and

displays the error code.

The status indicator enters error

to operation if

cause disappears

mode. The LCD screen stays active

and displays the error code.

3.5.2 Info menu

Info menu: Parameters

The info menu ( ) covers all possible information that is made

available to the end user and to the installer. This parameters are

read only and cannot be changed.

# Description (short) Unit

A00 Actual flow temperature °C

A01 Actual return temperature °C

Operation manual

7

Page 8

3 Operation

a

# Description (short) Unit

A02 Actual domestic hot water temperature °C

A03 Actual flue temperature °C

(a)

A04

Actual outdoor temperature (if outdoor

°C

sensor is connected, otherwise "--")

(a)

A05

Actual solar temperature (if solar sensor is

°C

connected, otherwise "--")

A06 Actual water pressure bar

A07 Actual domestic hot water flow rate l/min

(b)

A08

A09

Current set point of burner capacity %

(b)

Actual capacity of boiler in relation to

%

nominal capacity

(c)

A10

A11 Status of On-Off room thermostat,

Actual phase of the burner —

—

indicate heat demand (HC1)

A12 Actual error code of boiler —

A13 Actual fan speed (rpm/100) rpm

A14 Current setpoint of boiler pump %

(a) Not applicable if the sensor is not connected.

(b) Maximum value for central heating = 91%

Maximum value for domestic hot water = 100%

(c) A10=0: Standby mode, burner is not active

A10=1: Start-up, preparation to ignition

A10=2: Ignition and flame stabilisation phase

A10=3: Release control (burner is on, operation phase)

A10=4: Post-purge phase

To use the info menu

1 Press the "Enter" button when the icon is displayed on the

menu level 1 screen.

2 Select an index between 00 and 14 with the right dial. Press the

"Back" button to return to menu level 1 screen.

a Index

3.5.3 User settings menu

User settings menu: Parameters (short)

The user settings menu ( ) comprises parameters that can be

changed and adjusted by users. You can read out and adjust the

parameters according to your preferences.

NOTICE

If you are not sure about the function of the parameter, do

not change it. Contact your service agent.

# Description Unit Default Range

U00 Summer-winter switch over

temperature

U01 Heating slope — 0 0~40

U02 Central heating ECO mode — 0 0~1

U03 Domestic hot water comfort

mode

U04 Domestic hot water set value °C 50 35~60

U05 Set value for the room

thermostat at day mode

U06 Set value for the room

thermostat at reduced mode

°C 20 10~30

— 0 0~1

°C 21 10~30

°C 18 10~30

# Description Unit Default Range

U07 Set value for the flow

°C 50 35~80

temperature at day mode

U08 Set value for the flow

°C 35 35~80

temperature at reduced mode

U09 Domestic hot water comfort

— 1 1, 2 or

mode user record dependency

U10 Room temperature setpoint

°C 18 10~30

used by ROTEX Opentherm

room thermostat during night

User settings menu: Parameters (detailed)

# Description

U00 When using outdoor sensor, above this parameter

value of outside temperature, the boiler senses the

season as summer and does not activate central

heating although there is demand. Summer-winter

switching has a hysteresis of ±1ºC.

i.e: When this parameter is adjusted to 20ºC, the boiler

switches to summer mode at 21ºC and switches back

to winter mode at 19ºC.

U01 This value is used when only outside sensor is

connected to the boiler (No Opentherm room

thermostat connection). The parameter heating slope is

important to adapt the weather compensation to the

individual heating system, the building and the thermal

insulation. The heating slope can be adjusted from 0

to 40. The heating slope needs to be increased to

increase the boiler central heating set temperature.

Colder regions require a higher heating slope value.

Note: To activate weather compensation, the heating

slope value must be higher than "5".

U02 Enabling / disabling central heating ECO mode.

1 = enabled, 0 = disabled

U03 Enabling / disabling domestic hot water comfort mode.

1 = enabled, 0 = disabled

U04 Domestic hot water set value (Same function that can

be done via the right dial when domestic hot water

mode is enabled).

U05 When On-Off room thermostat and outdoor sensor are

both connected, this parameter value is the virtual room

temperature setpoint when there is a heat demand.

U06 When On-Off room thermostat and outdoor sensor are

both connected, this parameter value is the virtual room

temperature setpoint when there is no heat demand.

Note: For this parameter value to be active, reducing

mode has to be enabled by your service agent,

otherwise central heating mode will not be activated

when there is no heat demand.

U07 When On-Off room thermostat is connected and

outdoor sensor is not connected, this parameter value

is the central heating water temperature setpoint when

there is a heat demand.

U08 When On-Off Room thermostat is connected and

outdoor sensor is not connected, this parameter value

is the central heating water temperature setpoint when

there is not a heat demand.

Note: For this parameter value to be active, reducing

mode has to be enabled by your service agent,

otherwise central heating mode will not be activated

when there is no het demand.

24

Operation manual

8

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Page 9

4 Maintenance and cleaning

a b c

# Description

U09 If parameter is 1, comfort mode preheating will depend

on the user record. It will preheat the water according to

the previous day user records.

If parameter is 2, comfort mode preheating will be

independent of the user record, and at the highest

comfort level (3-star comfort according to EN13302).

If parameter is 24, comfort mode preheating will be

independent of the user record.

Note: If you increase the comfort level, the energy

consumption increases.

U10 Room temperature setpoint used by ROTEX

Opentherm room thermostat during night mode. Only

visible in case ROTEX Opentherm room thermostat is

connected.

To use the user settings menu

1 Press the "Enter" button when the icon is displayed on the

menu level 1 screen.

Result: You can see the parameter values on menu level 2.

2 Select an index between "00" and "10" with the right dial.

3 Press the "Enter" button when the parameter that you want to

change is displayed.

Result: You can see the menu level 3 screen. Up and down

arrows will appear.

4 Change the parameter with the right dial.

5 Press the "Enter" button to confirm or the "Cancel" button to

cancel. You will return to menu level 2 after pressing "Enter" or

"Back"

a Menu level 1

b Menu level 2

c Menu level 3

3.5.4 Installer settings menu

Only qualified persons are allowed to enter the installer settings

menu.

4.1 To clean the outer surface of the unit

Clean the outer surface of your boiler with a damp cloth and a little

solvent-free soap.

CAUTION

Sprays, solvents or cleaning agents containing chlorine

can damage the exterior, the fittings or the control unit. Do

not use them for cleaning purposes.

5 Energy saving tips

▪ Operating the unit in central heating ECO mode provides the most

economical central heating operation conditions.

▪ Do not run the boiler in domestic hot water comfort mode.

Domestic hot water comfort mode involves pre- and post-heating,

which is luxury, not necessity.

▪ Close the thermostatic radiator valves when ventilating the rooms.

▪ The largest heat loss occurs through windows and outer doors.

Check windows and doors for air-tightness. Close any blinds at

night.

▪ Do not hide radiators behind large furniture (i.e. couch, desk, etc.).

Minimum 50cm of clearance must remain, otherwise the heated

air cannot be circulated and the room will not heat up efficiently.

▪ Do not let your room become too hot. Decreasing the room

temperature during the day saves energy.

▪ Have your combi boiler's maintenance performed at least

annually.

▪ Provide your building with sufficient heat insulation.

▪ Thermostatic valves should be used. Each room should be

adjusted according to comfort conditions. For reception rooms,

this is 20°C, living rooms 22°C, kitchens 18°C and bedrooms

18°C.

▪ Prevent radiators from getting covered by curtains.

6 Contact

Contact a local competent service agent if you have any questions

regarding the maintenance and repair of your system. You can find

the contact information of our competent services at www.rotexheating.com

4 Maintenance and cleaning

WARNING

The boiler should be maintained by authorised persons

every year.

Annual maintenance cycle is very important for safe operation of

your boiler and to ensure reliable, efficient and long lasting operation

of it.

Contact your service agent for details.

DANGER

Incorrect maintenance and repairs can lead to injury and

material damage.

▪ Never attempt to perform maintenance work or repairs

on the unit yourself.

▪ Contact your service agent.

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

7 Error codes

# Problem Solution

10-64 Gas valve circuit error Perform reset. If problem repeats,

contact your service agent.

10-65 Gas valve current

error

11-64 Ignition does not take

place

11-65 Flame stabilisation

fault

11-66 Flame signal loss in

safety time

11-67 Flame loss during

operation

Perform reset. If problem repeats,

contact your service agent.

Make sure valve on the gas line is

opened. Perform reset after third

unsuccessful ignition trial.

Wait for boiler's ignition trial.

Perform reset after third

unsuccessful ignition trial. If problem

repeats, contact your service agent.

Temporary error. Wait for boiler to

re-ignite.

Operation manual

9

Page 10

7 Error codes

# Problem Solution

12-64 Ion control deviation

is too big

12-65 Ignition SCOT

actuators fault does

not take place

12-66 Ion base value

exceeds lower factory

limit

12-67 Ion base value

exceeds upper

factory limit

12-68 Ion base value differs

excessively from

previous value

12-69 Offset adaption at

limit

12-70 Offset adaption not

executable

13-64 Fan speed error Perform reset if needed. If problem

13-65 Fan speed error Perform reset. If problem repeats,

16-64 Flue temperature

signalise overheating

1J-64 High limit thermostat

signalise overheating

80-01 Return temperature

sensor fault

81-01 Flow temperature

sensor fault

81-65 Domestic hot water

solar temperature

sensor fault

8A-46 Freeze protection Unit does not operate if flow

8H-64 Flow temperature

steep rise

8H-65 Flow-return

temperature

difference too much

E1-64 Flame detection

before burner

operation

E1-65 Internal SCOT

system error

E1-66 Calibration conditions

fault

E1-67 Missing calibration Perform reset. If problem repeats,

Perform reset if needed. If problem

repeats, contact your service agent.

Perform reset if needed. If problem

repeats, contact your service agent.

Perform reset. If problem repeats,

contact your service agent.

Perform reset. If problem repeats,

contact your service agent.

Perform reset if needed. If problem

repeats, contact your service agent.

Boiler continues operation but

contact your service agent.

Boiler continues operation but

contact your service agent.

repeats, contact your service agent.

contact your service agent.

Check flue gas discharge path.

Perform reset if needed. If problem

repeats, contact your service agent.

▪ Check the valves of the radiators

in the heating circuit.

▪ Check the combi boiler water

pressure. If it is low, fill the heating

circuit with water.

▪ Perform reset. If problem repeats,

contact your service agent.

Perform reset. If problem repeats,

contact your service agent.

Perform reset. If problem repeats,

contact your service agent.

Boiler continues operation but solar

sensor is defective. Contact your

service agent.

temperature sensor reads value less

than 1°C. Wait until the error code is

removed from the screen.

Make sure radiator valves are open

enough to circulate water. Your

boiler will operate again after a while.

If problem repeats, contact your

service agent.

Make sure radiator valves are open

enough to circulate water. If problem

repeats, contact your service agent.

Perform reset. If problem repeats,

contact your service agent.

Perform reset if needed. If problem

repeats, contact your service agent.

No reset needed. Wait burner to

restart. If problem repeats, contact

your service agent.

contact your service agent.

# Problem Solution

E1-68 Ion base value is

outside the factory

limits or saved

incorrectly

E1-69 Parameter CRC error Perform reset. If problem repeats,

E1-70 Parameter CRC error Perform reset. If problem repeats,

E1-71 EK lockout failure Permanent error. Contact your

E1-72 SCOT flame amplifier Perform reset if needed. If problem

E1-73 Internal PCB error Perform reset if needed. If problem

H9-01 Outside sensor fault Boiler continues operation but

HC-01 Domestic hot water

temperature sensor

fault

HJ-08 High system pressure Discharge water down to 0.8bar.

HJ-09 Low system pressure Increase the system pressure to

HJ-10 Water pressure

sensor fault

J6-01 Flow temperature

sensor overheating

(Can be a blocking

error or a lockout

error)

J6-20 Return temperature

sensor overheating

(Can be a blocking

error or a lockout

error)

J6-21 Return temperature is

higher than flow

temperature

JJ-64 Flue temperature

sensor fault

U2-01 Supply voltage is

below low limit

U2-01 Supply voltage is

above high limit

U4-65 Opentherm room

thermostat

connection is

defective

U4-66 CAN-bus timeout If problem repeats, contact your

U4-67 Remote reset

supervision

UA-64 Blocking during BCC

update process

UA-65 PCB requires a BCC

update

Perform reset. If problem repeats,

contact your service agent.

contact your service agent.

contact your service agent.

service agent.

repeats, contact your service agent.

repeats, contact your service agent.

outside sensor is defective. Contact

your service agent.

Boiler continues operation but you

must contact your service agent.

(You can bleed the radiators.)

0.8bar

Contact your service agent.

▪ Check the valves of the radiators

in the heating circuit.

▪ Check the combi boiler water

pressure. If it is low, fill the heating

circuit with water.

▪ Perform reset if needed. If problem

repeats, contact your service

agent.

Perform reset if needed. If problem

repeats, contact your service agent.

No reset needed, burner operates

itself after a small amount of time. If

problem repeats, contact your

service agent.

Perform reset. If problem repeats,

contact your service agent.

Contact your service agent.

Your boiler will continue operation

but you must contact your service

agent.

Your boiler will continue operation

but Opentherm room thermostat is

out of operation. Contact your

service agent.

service agent.

Switch off - switch on power mains. If

problem repeats, contact your

service agent.

Contact your service agent.

Contact your service agent.

Operation manual

10

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Page 11

# Problem Solution

UA-66 BCC-ID of internal

EEPROM is

inconsistent

UA-67 BCC is missing Contact your service agent.

UA-68 BCC is not

compatible with PCB

(BCC-ID)

UA-69 BCC is not

compatible with PCB

(firmware)

UA-70 BCC update error Contact your service agent.

Contact your service agent.

Contact your service agent.

Contact your service agent.

7 Error codes

R2CND024A4AA + R2TND012~024A4AA

Wall-mounted condensing boiler

3P469438-4D – 2017.07

Operation manual

11

Page 12

ROTEX Heating Systems GmbH

Langwiesenstraße 10

D-74363 Güglingen

www.rotex-heating.com

Unsere Partner im Ausland

Our partners abroad • Unsere Partner im Ausland

Nos partenaires à l’étranger • Le nostre sedi all'estero

Neustros representantes en el extranjero

Nasi partnerzy za granicą • Naši partneři v zahraničí

http://de.rotex-heating.com > ueber-rotex > international

© ROTEX ∙ Subject to change and correction

3P469438-4D 2017.07

Loading...

Loading...