Page 1

INSTALLATION

MANUAL

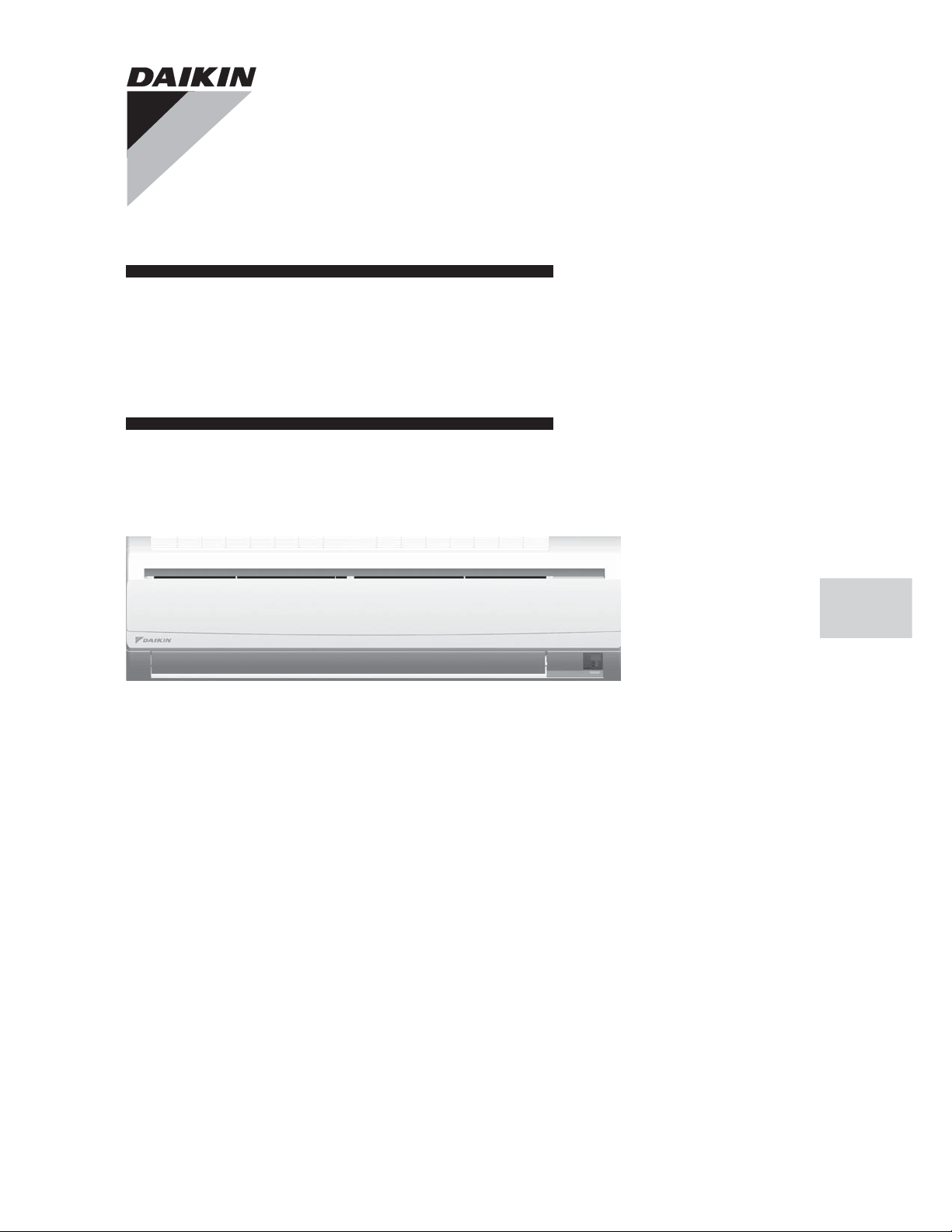

R22 SPLIT SERIES

MODELS

FTD20JEVLK RD20JEVLK

FTD25JEVLK RD25JEVLK

FTYD20JEVLK RYD20JEVLK

FTYD25JEVLK RYD25JEVLK

Installation Manual

R22 Split Series

English

IM-WMJ-0211(0)-DAIKIN (SASO)

Part No.: R08019036068

Page 2

Page 3

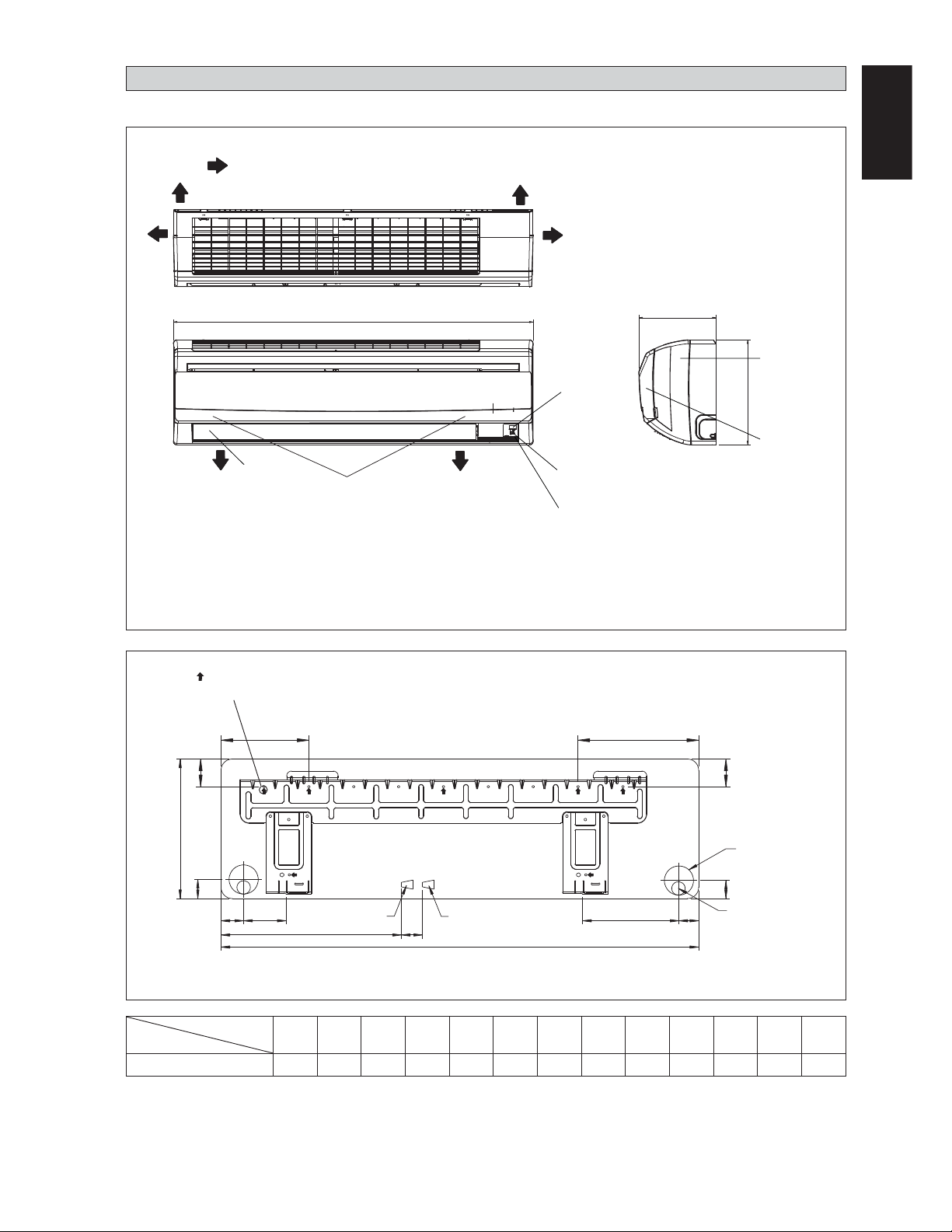

OUTLINE AND DIMENSIONS

Indoor Unit

THE MARK SHOWS PIPING DIRECTION

REAR REAR

TOP VIEW

A

BOTTOM BOTTOM

LOUVER

FRONT GRILLE FIXED SCREWS

(INSIDE)

FRONT VIEW

RIGHTLEFT

SIGNAL

RECEIVER

INDOOR UNIT

ON/OFF SWITCH

ROOM TEMPERATURE

THERMISTOR (INSIDE)

C

SIDE VIEW

English

Original Instruction

NAME PLATE

B

TERMINAL

BLOCK

WITH EARTH

TERMINAL

All dimensions are in mm

Recommended mounting plate retention spots

(7 spots in all)

D

F

B

G

HJ

Liquid pipe end Gas pipe end

L

M

A

E

F

Through the wall

hole Ø 65mm

G

K

I

Drain hose position

INSTALLATION PLATE FT(Y)D20/25JEVLK

All dimensions are in mm

Dimension

Model

ABCDE FGHI J KLM

FT(Y)D20/25JEVLK 1065 310 228 190 173 61 40 45 48 91 219 580 45

1-1

Page 4

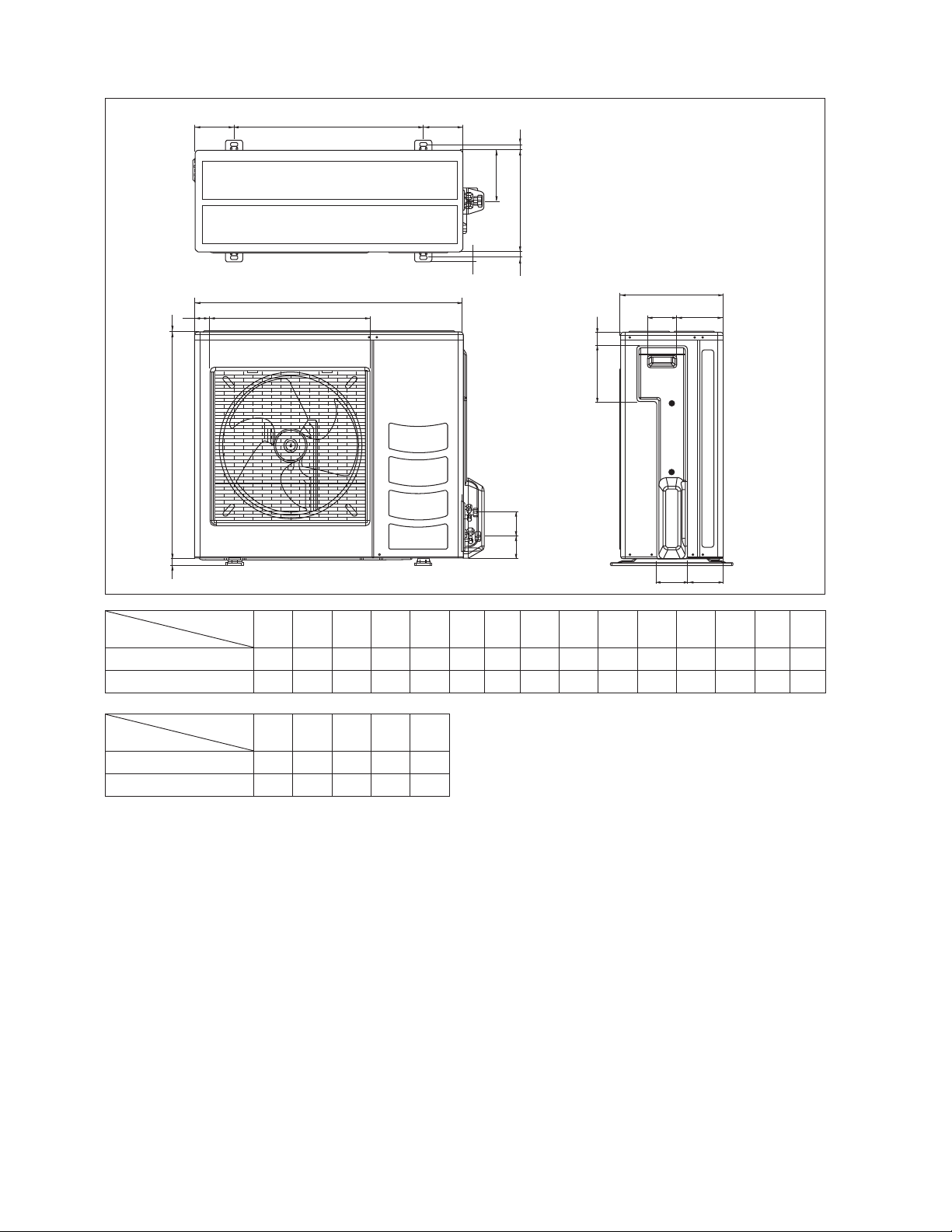

Outdoor Unit

KLL

A

O

QR

B

D

N

M

C

P

N

FE

ST

All dimensions are in mm

C

H

G

IJ

Dimension

Model

ABCDEFGH I JKLMNO

R(Y)D20JEVLK 855 628 328 508 181 44 93 149 101 113 603 126 164 17 49

R(Y)D25JEVLK 855 730 328 520 182 44 93 149 101 113 603 126 164 17 34

Dimension

Model

PQRS T

R(Y)D20JEVLK 32 3 237375

R(Y)D25JEVLK 32 3 237375

1-2

Page 5

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air

conditioner unit.

Special adjustment may be necessary to suit local requirement.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

SAFETY PRECAUTIONS

! WARNING ! CAUTION

Installation and maintenance should be performed by

•

qualiÀ ed persons who are familiar with local code and

regulation, and experienced with this type of appliance.

All À eld wiring must be installed in accordance with the

•

national wiring regulation.

Ensure that the rated voltage of the unit corresponds to

•

that of the name plate before commencing wiring work

according to the wiring diagram.

The unit must be GROUNDED to prevent possible hazard

•

due to insulation failure.

All electrical wiring must not touch the water piping or any

•

moving parts of the fan motors.

Confirm that the unit has been switched OFF before

•

installing or servicing the unit.

Risk of electric shock, can cause injury or death. Disconnect

•

all remain electric power supplies before servicing.

•

DO NOT pull out the power cord when the power is ON.

This may cause serious electrical shocks which may result

in the À re hazards.

•

Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios, to

prevent distorted pictures and static. {Depending on the

type and source of the electrical waves, static may be heard

even when more than 1m away}.

Please take note of the following important points when

installing.

Do not install the unit where leakage of Á ammable

•

gas may occur.

If gas leaks and accumulates around the unit, it

•

If the drainage piping is not connected properly, it

•

This unit is factory pre-charged. Overcharge will

•

Unsecured panels will cause the unit to operate

•

•

•

•

•

•

•

•

•

•

•

may cause À re ignition.

Ensure that drainage piping is connected properly.

may cause water leakage which will dampen the

furniture.

Do not overcharge the unit.

cause over-current or damage to the compressor.

Ensure that the unit·s panel is closed after service or

installation.

noisily.

Sharp edges and coil surfaces are potential locations

which may cause injury hazards. Avoid from being in

contact with these places.

Before turning off the power supply set the remote

controller·s ON/OFF switch to the “OFF” position to

prevent the nuisance tripping of the unit. If this is not done,

the unit·s fans will start turning automatically when power

resumes, posing a hazard to service personnel or the user.

Do not install the units at or near doorway.

Do not operate any heating apparatus too close to the air

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or

deform as a result of excessive heat or chemical reaction.

When the unit is used in kitchen, keep Á our away from

going into suction of the unit.

This unit is not suitable for factory used where cutting oil

mist or iron powder exist or voltage Á uctuates greatly.

Do not install the units at area like hot spring or oil

reÀ nery plant where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors respectively.

IMPORTANT : DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

Don·t use joined and twisted wires for incoming power

supply.

The equipment is not intended for use in a potentially

explosive atmosphere.

English

Disposal requirement

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be

mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant,

of oil and of other parts must be done by a qualiÀ ed installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this

product is disposed of correctly, you will help to prevent potential negative consequences for the environment and human

health. Please contact the installer or local authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and

national legislation.

NOTICE

1-3

Page 6

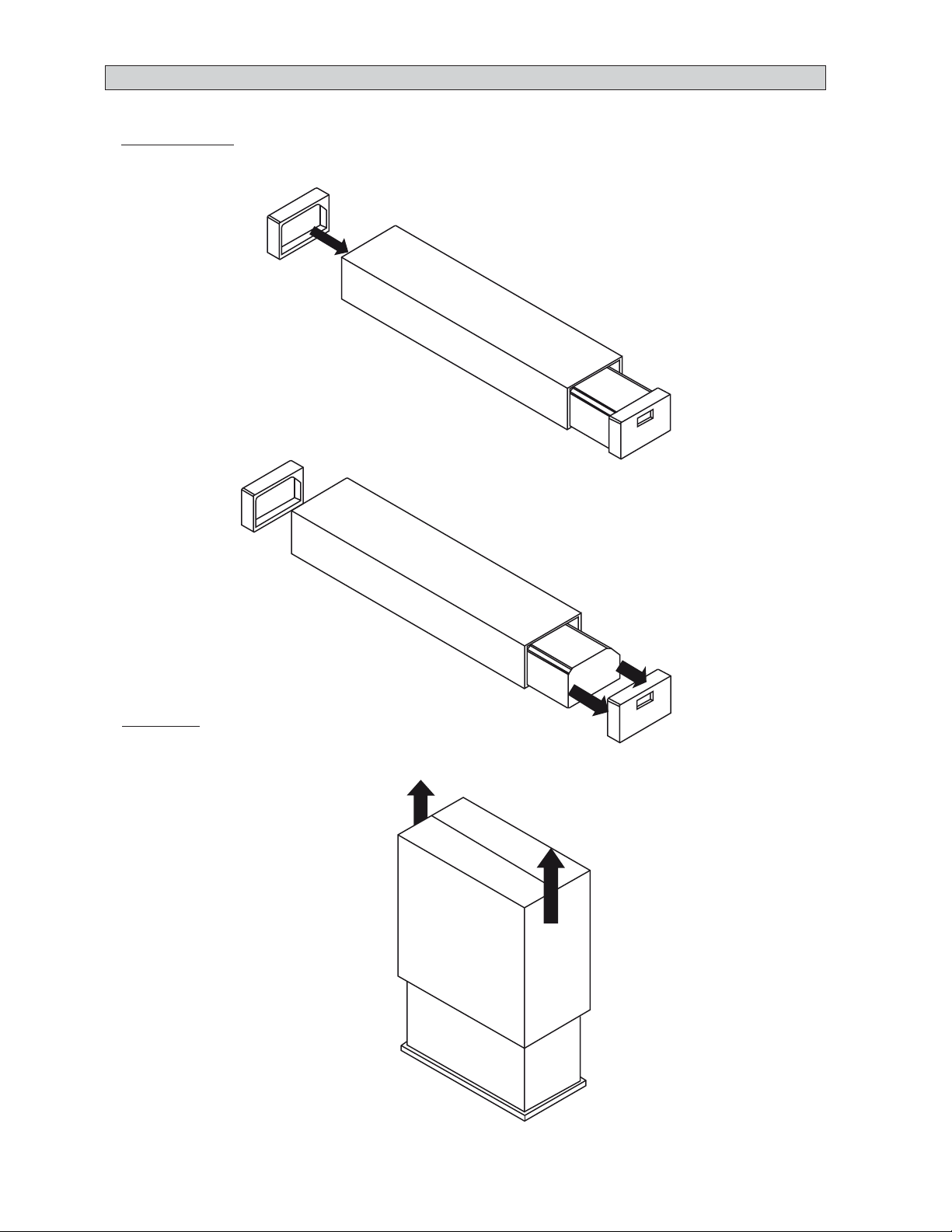

IMPORTANT

Unpacking Procedures

Wall Mounted Unit

•

1. After takeoff the bands and pull out one side cushion, push the unit to the opposite side.

2. Pull out the unit from the other side.

Outdoor Unit

•

1. After takeoff the bands, pull out the carton box from the top side of the unit.

* This product is not designed for re-packing. In case of re-packing, contact to Daikin Dealer.

1-4

Page 7

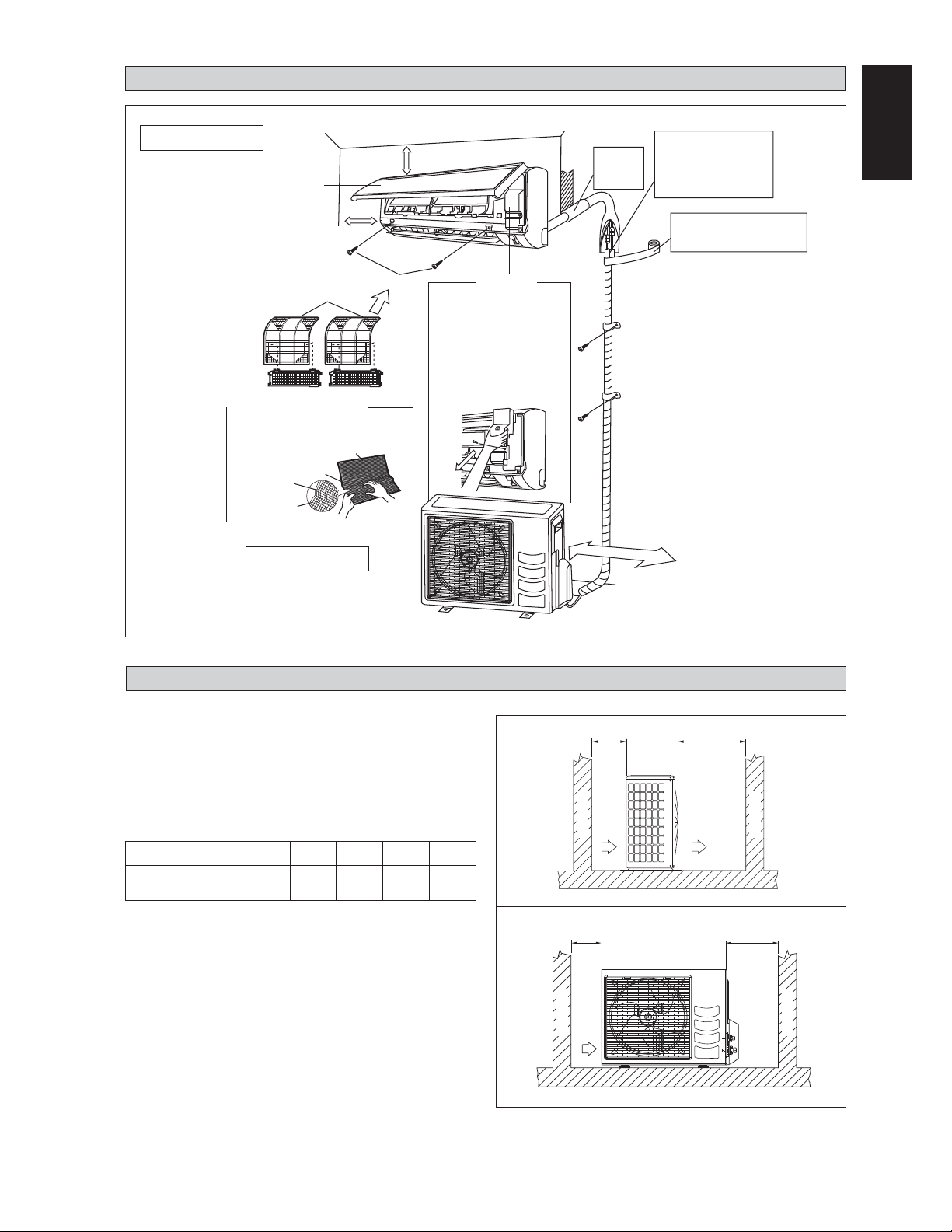

INSTALLATION DIAGRAM

Indoor unit

Front panel

50mm or more from walls

(on both sides)

Air À lter

Air-Purifying Filter with

bacteriostatic virustatic function (2)

Air-Purifying Filter

with bacteriostatic

virustatic function

Filter frame

Tab

M4 x 12L

Air À lter

Outdoor Unit

30mm or more from ceiling

Service lid

Q

Opening service lid

Service lid is opening/

closing type.

Q

Opening method

1) Remove the service lid

screws.

2) Pull out the service lid

diagonally down in the

direction of the arrow.

3) Pull down.

Caulk pipe

hole gap

with putty.

250mm from wall

Cut thermal insulation pipe

to an appropriate length and

wrap it with tape, making

sure that no gap is left in the

insulation pipe·s cut line.

Wrap the insulation pipe with

the À nishing tape from bottom

to top.

English

INSTALLATION OF THE OUTDOOR UNIT

The outdoor unit must be installed in such a way, so as to

prevent short circuit of the hot discharged air or obstruction to

the smooth air Á ow. Please follow the installation clearances

shown in the À gure. Select the coolest possible place where

intake air temperature is not greater than the outside air

temperature (please refer operating range).

Installation clearances

Dimension

Minimum Distance,

mm (in)

Note: If there is any obstacle higher than 2m, or if there is any

obstruction at the upper part of the unit, please allow more

space than the À gure indicated in the above table.

ABCD

300

(11.8)

1000

(39.4)

300

(11.8)

500

(19.7)

A

Obstacle

Return air

CD

Obstacle

Return air

B

Obstacle

Discharge air

Obstacle

Service access

1-5

Page 8

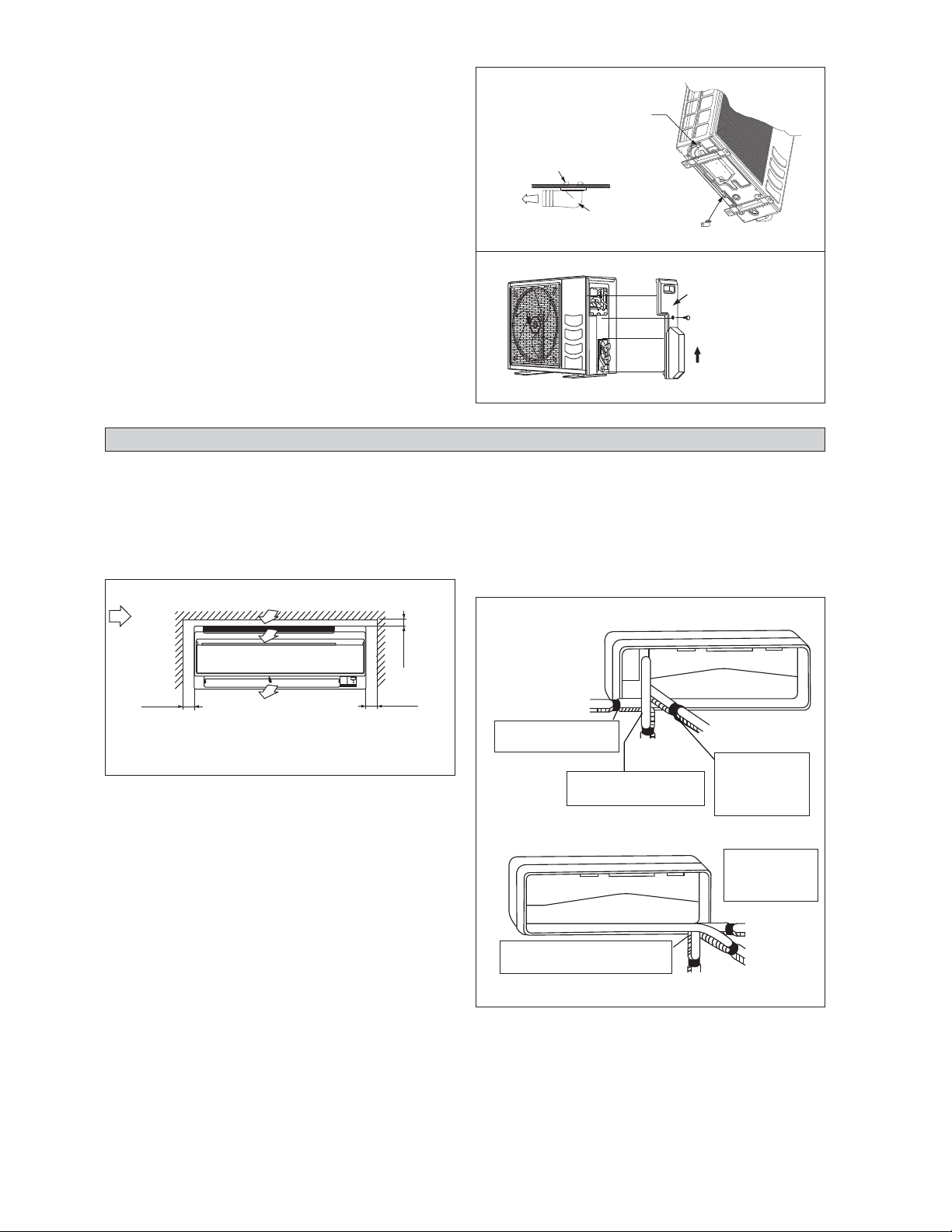

Condensed Water Disposal Of Outdoor Unit

(Heat Pump Unit Only)

There are 2 holes on the base of Outdoor Unit for

•

condensed water to Á ow out. Insert the drain elbow to

one of the holes.

To install the drain elbow, À rst insert one portion of the

•

hook to the base (portion A), then pull the drain elbow in

the direction shown by the arrow while inserting the other

portion to the base. After installation, check to ensure that

the drain elbow clings to base À rmly.

If the unit is installed in a snowy and chilly area, condensed

•

water may freeze in the base. In such case, please remove

plug at the bottom of unit to smooth the drainage.

INSTALLATION OF THE INDOOR UNIT

BASE

A

PLUG

DRAIN ELBOW

DRAIN ELBOW

Please remove

side plate when

connecting the piping

and connecting cord

PUSH & PULL UP

The indoor unit must be installed in such a way so as to prevent

short circuit of the cool discharged air with the hot return air.

Please follow the installation clearance shown in the À gure. Do

not place the indoor unit where there could be direct sunlight

shining on it. Also, this location must be suitable for piping

and drainage, and be away from doors or windows.

Air Á ow

(Indoor)

min. 30

(Space for

performance)

min. 50

(Space for

maintenance)

Required space

All dimensions are in mm

min. 50

(Space for

maintenance)

The refrigerant piping can be routed to the unit in a number of

ways (left or right from the back of the unit), by using the cutout holes on the casing of the unit (see À gure). Bend the pipes

carefully to the required position in order to align it with the

holes. For the side and bottom, hold the bottom of the piping

and then position it to the required direction (see À gure). The

condensation drain hose can be taped to the pipes.

Right-side, right-back or right-bottom piping

Right-side

piping

Remove pipe port cover

here for right-side piping

Remove pipe port cover

here for right-bottom piping

Right-bottom

piping

Right-back piping

Bind coolant pipe

and drain hose

together with

insulating tape.

Left-side, left-back or left-bottom piping

Remove pipe port

cover here for

left-side piping

Left-side

piping

Remove pipe port cover here for

left-bottom piping

Left-bottom piping

Left-back

piping

1-6

Page 9

Mounting Installation Plate

Ensure that the wall is strong enough to withstand the weight

of the unit. Otherwise, it is necessary to reinforce the wall

with plates, beams or pillars.

Use the level gauge for horizontal mounting, and À x it with

for FT(Y)D20/25JEVLK.

In case the rear piping draws out, drill a hole 65mm in

diameter with a cone drill, slightly lower on the outside wall

(see À gure).

Mounting plate

Mounting plate

À xing screw

Mount The Unit Onto The Installation Plate

Hook the indoor unit onto the upper portion of the installation

plate (Engage the two hooks at the rear top of the indoor unit

with the upper edge of the installation plate). Ensure that the

hooks are properly seated on theinstallation plate by moving

it to the left and right.

How To Attach The Indoor Unit

Hook the claws of the bottom frame to the mounting plate.

How To Remove The Indoor Unit

Push up the marked area (at the lower part of the front grille)

to release the claws.

Mounting plate

Clip

English

Recommended Mounting Plate Retention Spots

And Dimensions

Recommended mounting plate

retention spots (7 spots in all)

190

61

310

40

45

91

Liquid pipe end

580

Hole with cone drill

Wall embedded pipe

(Field supply)

Wall hole cover

(Field supply)

Gas pipe end

45

1065

Inside

173

61

Through the

wall hole

Ø 65mm

40

48

219

All dimensions are in mm

Outside

Caulking

Ø 65

Wall embedded pipe

(Field supply)

Drain hose

position

Bottom frame

Front grille

Hang indoor unit·s hook here.

When stripping the

ends of interconnecting

wires in advance, bind

right ends of wires with

insulating tape.

Wire guide

Mark (rear side)

Mounting plate

Interconnecting

wires

Water Drainage Piping

The indoor drain pipe must be in a downward gradient for

smooth drainage. Avoid situations that are likely to cause

water to leak.

Water Drainage

Water

Water

leaking

Water

leaking

Retention

Water

leaking

End

dipped

into

water

Correct

Wrong

Wrong

Wrong

! CAUTION

• Do not install the unit at altitude over 2000m for both

indoor and outdoor.

1-7

Drain

Page 10

REFRIGERANT PIPING

Allowable Piping Length

If the pipe is too long, both the capacity and reliability of the unit will drop. As the number of bends increases, resistance to

the Á ow of refrigerant system increases, thus lowering cooling capacity. As a result, the compressor may become defective.

Always choose the shortest path and follow the recommendations as tabulated below:

Indoor unit

Outdoor Unit

LE

Model FT(Y)D20JEVLK FT(Y)D25JEVLK

Min. Allowable Length (L), m 3

Max. Allowable Length (L), m 30

Max. Allowable Elevation (E), m 15

Gas Pipe Size, mm /(in) 15.88

(5/8")

Liquid Pipe Size, mm /(in) 6.35

(1/4")

*Be sure to add the proper amount of additional refrigerant. Failure to do so may result in reduced performance.

9.52

(3/8")

Remark: The refrigerant pre-charged in the outdoor unit is for piping length up to 7.5m.

1-8

Page 11

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If

•

any piping, evaporator or condenser had been exposed or

had been opened for 15 seconds or more, the system must

be vacuumed. Generally do not remove plastic, rubber

plugs and brass nuts from the valves, À ttings, tubing and

coils until it is ready to connect suction or liquid line into

valves or À ttings.

If any brazing work is required, ensure that nitrogen gas

•

is passed through coil and joints while the brazing work

is being done. This will eliminate soot formation on the

inside wall of copper tubings.

Cut the pipe stages by stages, advancing the blade of pipe

•

cutter slowly. Extra force and a deep cut will cause more

distortion of pipe and therefore extra burr. See Figure A.

Remove burrs from cut edges of the pipes with remover. See

•

Figure B. Hold the pipe on top position and burr remover

at lower position to prevent metal chips from entering the

pipe. This will avoid unevenness on the Á are faces which

will cause gas leak.

Insert the Á are nuts, mounted on the connection parts of

•

both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface

•

of the swaging block is determined by the Á aring tool. See

Figure C.

Fix the pipe À rmly on the swaging block. Match the centers

•

of both the swaging block and the Á aring punch, then

tighten the Á aring punch fully.

Piping Connection To The Units

Align the center of the piping and tighten the Á are nut

•

sufÀ ciently with À ngers. See Figure D.

Finally, tighten the Á are nut with torque wrench until the

•

wrench clicks.

When tightening the Á are nut with the torque wrench,

•

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe connection are insulated by closed

•

cell polyurethane.

Figure A

Figure B

Figure C

Swaging Block

Cutting Copper Tube

1/4t

Remove Burr

Copper Tube

Copper Tube

D

A

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

5/8" 15.88 2.2 1.7

Figure D

Flare Joint

Indoor Piping

Flared Tube

Flare Nut

English

Pipe Size mm/(in) Torque Nm/(ft-Ib)

6.35 (1/4") 18 (13.3)

9.52 (3/8") 42 (31.0)

15.88 (5/8") 65 (48.0)

1-9

Spanar

Torque Wrench

Page 12

ELECTRICAL WIRING CONNECTION

Cooling Unit

IMPORTANT : * The À gures shown in the table are for information purpose only. They should be checked and selected

** The appropriate voltage range should be checked with label data on the unit.

to comply with the local/national codes of regulations. This is also subject to the type of installation and

conductors used.

Cooling Unit (single phase)

Indoor Unit

Terminal Block

COMP

N1

N

L

Interconnection cable

Model

Voltage range**

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

Outdoor Unit

Terminal Block

COMP

L1

N1

L

N

Power Supply Cable

FTD20JEVLK

RD20JEVLK

2.5

3

1.0

4

There must be an all pole

!

disconnection in the supply

mains with a contact separation

of at least 3mm.

220V/1Ph/60Hz + !

FTD25JEVLK

RD25JEVLK

Recommended time delay fuse* A 20 25

Heat Pump Unit (single phase)

Indoor Unit

Terminal Block

Outdoor coil sensor connection wire

(8m long) attached in the indoor unit

Outdoor Unit

Terminal Block

2.5

3

1.0

4

Interconnection cable

4WV

OF

COMP

N1

N

L

Model

Voltage range**

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

FTYD20JEVLK

RYD20JEVLK

2

2

4WV

OF

COMP

L1

N1

L

N

Power Supply Cable

2.5

3

1.0

6

!

220V/1Ph/60Hz + !

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

FTYD25JEVLK

RYD25JEVLK

2.5

1.0

Recommended time delay fuse* A 20 25

1-10

3

6

Page 13

• All wires must be À rmly connected.

• All wires must not touch the refrigerant piping, compressor or any moving parts of the fan motor.

• The connecting wires between the indoor unit and the outdoor unit must be clamped on the wire clamps.

• The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

• Make sure no external pressure is applied to the terminal connectors and wires.

• Make sure all the covers are properly À xed to avoid any gap.

• Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching to

the indication on terminal block. (Refer to the wiring diagram attached on the unit).

Attach insulation sleeve

Electric wire

Round crimp-style terminal

• Used the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

• Over tightening can damage the terminal screws.

• Do not connect wire of different gauge to same terminal.

• Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

English

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Do not connect wires

of different gauges.

1-11

Page 14

VACUUMING AND CHARGING

Vacuuming is necessary to eliminate all moisture and air from the system.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with

refrigerant, the indoor unit and the refrigerant connection

pipes must be air-purged because the air containing moisture

that remains in the refrigerant cycle may cause malfunction

of the compressor.

• Remove the caps from the valve and the service port.

• Connect the center of the charging gauge to the vacuum

pump.

• Connect the charging gauge to the service port of the 3-way

valve.

• Start the vacuum pump. Evacuate for approximately 30

minutes. The evacuation time varies with different vacuum

pump capacity. ConÀ rm that the charging gauge needle has

moved towards -760mmHg.

Caution

• If the gauge needle does not move to -760mmHg, be sure to

check for gas leaks (using the refrigerant detector) at Á are

type connection of the indoor and outdoor unit and repair

the leak before proceeding to the next step.

• Close the valve of the changing gauge and stop the vacuum

pump.

• On the outdoor unit, open the suction valve (3 way) and

liquid valve (2 way) (in anti-clockwise direction) with 4mm

key for hexagon sacked screw.

Charge Operation

This operation must be done by using a gas cylinder and a

precise weighing machine. The additional charge is topped-up

into the outdoor unit using the suction valve via the service

port.

• Remove the service port cap.

• Connect the low pressure side of the charging gauge to the

suction service port center of the cylinder tank and close

the high pressure side of the gauge. Purge the air from the

service hose.

• Start the air conditioner unit.

• Open the gas cylinder and low pressure charging valve.

• When the required refrigerant quantity is pumped into

the unit, close the low pressure side and the gas cylinder

valve.

• Disconnect the service hose from service port. Put back the

service port cap.

Allen key

Service Port

LOW PRESSURE GAUGE

-760mmHg

HANDLE LO

CHARGE HOSE

LIQUID

VA LV E

GAS VALVE

(3-WAY)

LOW PRESSURE GAUGE

HANDLE LO

CHARGE HOSE

LIQUID

VA LV E

GAS VALVE

(3-WAY)

Flare nut

-760mmHg

Refrigerant Piping

Outdoor Unit 3 ways valve

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

VACUUM PUMP

ADAPTER FOR

COUNTER FLOW

PREVENTION

CHECK

VA LV E

CONFIGURATION OF AIR

PURGE BY CHARGING

CHECK

VA LV E

CONFIGURATION OF AIR

PURGE BY CHARGING

1-12

Page 15

Additional Charge

The refrigerant is pre-charged in the outdoor unit. If the piping length is less than 7.5m, then additional charge after vacuuming

is not necessary. If the piping length is more than 7.5m, then use the additional charge value as indicated in the table.

Additional refrigerant charge [g] per additional 1m length as tabulated (For R22 models)

Indoor FTD20JEVLK FTYD20JEVLK FTD25JEVLK FTYD25JEVLK

Outdoor RD20JEVLK RYD20JEVLK RD25JEVLK RYD25JEVLK

Additional charge [g/m] 22 22 55 55

Example:

FTD20JEVLK & RD20JEVLK with 12m piping length, additional piping length is 4.5m. Thus,

Additional charge = 4.5[m] x 22[g/m]

= 99.0[g]

INDICATOR LIGHTS

IR Signal Receiver

When an infrared remote control operating signal has been

transmitted, the signal receiver on the indoor unit will respond

as below to conÀ rm acceptance of the signal transmission.

ON to OFF 1 Long Beep

OFF to ON

Pump down/Cool force on

Others 1 Short Beep

Cooling Unit / Heat Pump Unit

The table shows the LED indicator lights for the air conditioner

unit under normal operation and fault conditions.

The LED indicator lights are located at the right bottom of

the air conditioner unit.

The heat pump units are equipped with an “auto” mode

sensor whereby it will provide reasonable room temperature

by switching automatically to either “cool” or “heat” mode

according to the temperature set by the user.

2 Short Beep

IR Receiver

LED Indicator Lights for Cooling Unit

IR Receiver

Cool/Heat

Timer

Sleep

ON/OFF

ON/OFF switch

English

1-13

Page 16

LED Indicator Lights: Normal Operation And Fault Conditions For Cooling/Heat Pump Unit

COOL/HEAT

(GREEN/RED)

Green

Red

Red

Green

1 time

3 times

2 times

Red

4 times

5 times

1 time

3 times

6 times

Normal Operation/Fault Indication Action Error Code

Cool mode - -

Heat mode - -

Auto mode in Heating operation - -

Auto mode in Cooling operation - -

Timer on - -

Sleep mode on - -

Fan mode on - -

Dry mode on - -

Room air sensor contact

Loose/Short

Call your dealer Blink E1

Outdoor coil sensor open Call your dealer Blink E3

Indoor coil sensor open Call your dealer Blink E2

Compressor overload/ Indoor coil sensor short/

outdoor coil sensor short

Call your dealer Blink E4

Defrost operation - -

Gas leak Call your dealer Blink E5

Hardware error (tact switch pin short) Call your dealer Blink E8

No feedback from indoor fan Call your dealer Blink E9

EEPROM error Call your dealer Blink EE

ON

ON or OFF

Note: The unit will not detect sensor missing when the compressor is ON.

Blink N times

ON

OFF

ON

OFF

12N 1 2N

500ms 500ms 3 seconds

Blink continuously

500ms 500ms

Blinking

1-14

Page 17

AIR CONDITIONER UNIT OPERATION

Dry Mode

When the air humidity is high, the unit can operate in dry

•

mode. Press <MODE> button and choose <DRY>.

If the room temperature is 2°C/3.6°F higher than the

•

set temperature, the air conditioner will operate under

cooling mode until it reaches within the 2°C/3.6°F range

of difference compared to the set temperature before it

converts to dry mode.

If the room temperature is within the 2°C/3.6°F range of

•

difference compared to the set temperature, it will directly

operate under dry mode.

The unit will operate at LOW speed under dry mode.

•

Heat Mode (for heat pump unit only)

When the unit is switched on from cold start or defrosting

•

cycle, the indoor fan will start to operate only after the coil

reaches the desired temperature.

When the set temperature is achieved, the indoor fan will

•

operate until the coil cannot provide anymore additional

heat.

Air Flow Control

For more effective air circulation, you can manually adjust

•

the air discharge grille to the left or right.

During cool mode operation and dry mode operation, do

•

not direct the air discharge louver downwards for too long.

If operating continues in this way, condensation may occur

on the louver, thus resulting in drippings.

Overheating Protection (for heat pump unit only)

In case the internal and/or the external temperature is

•

too high, or that the À lter is dirty and clogged up, the

refrigerant may be overheated. The compressor will cut out

when the condensing temperature reaches 62°C/143.6°F.

Frost Prevention

When the air À lter is dirty, the evaporating temperature

•

will decrease and eventually cause frosting.

If the evaporating temperature reaches -1°C/33.8°F, the

•

unit will trip.

Fan Speed And Rated Cooling Capacity

The rated cooling capacity is provided at the HIGH fan

•

speed.

•

The cooling capacity is lower when the unit is operating

at MEDIUM and LOW fan speed.

Notes On Flaps And Louvers Angles

When “SWING button” is selected, the Á aps swinging

•

range depends on the operation mode. (See the À gure.)

ATTENTION

Always use a remote controller to adjust the Á aps angle.

•

If you attempt to move it forcibly with hand when it is

swinging, the mechanism may be broken.

•

Be careful when adjusting the louvers. Inside the air outlet,

a fan is rotating at a high speed.

In COOL, DRY and FAN mode

When stop

operation

Upper limit 55Ý

Lower limit 75Ý

In HEAT mode

When stop

operation

Upper limit 70Ý

Lower limit 110Ý

English

Outdoor

DB (ÝC)

54

52

19

COOLING

14 19 23

Indoor WB (ÝC)

OPERATING RANGE

HEATING

Outdoor

WB (ÝC)

18

10

-9

15 20 27

Indoor DB (ÝC)

DB: Dry bulb WB: Wet bulb

1-15

Page 18

Open the front panel.

1.

Hold the panel at the recesses on the main unit (2 recesses

•

on right and left sides) and lift it until it stops.

AIR FILTER

Clean or replace each À lter.

4.

See À gure.

•

When shaking off remaining water, do not wring the À lter.

Recess on

main unit

Pull out the air À lters.

2.

Push a little upwards the tab at the center of each air À lter,

•

then pull it down.

Take off the Bio À lter with bacteriostatic, virustatic

3.

functions.

Hold the recessed parts of the frame and unhook the

•

four claws.

Titanium Apatite Filter (Bio Filter)

Attached Concept

Heat exchanger

Bio À lter attached part

* Bio Filter and Titanium Apatite Filter are optional accessories.

Air À lter

Titanium apatite À lter

Filter frame

Tab

Set the air À lter and Bio À lter with bacteriostatic,

5.

Air À lter

Bio À lter with

bacteriostatic,

virustatic functions

virustatic functions as they were and close the front

panel.

Insert claws of the À lters into slots of the front panel.

•

Close the front panel slowly and push the panel at the 3

points. (1 on each side and 1 in the middle.)

The air À lter and Bio À lter with bacteriostatic, virustatic

•

functions have a symmetrical form in the horizontal

direction.

FRONT

Installation Procedure for Bio Filter

Bio À lter packs in a

hermetically-sealed bag.

Take it out

at the time of installation.

Slip the À lter in between À lter frame and

Titanium apatite À lter.

Filter frame

Bio À lter

Titanium apatite À lter

! CAUTION

Please use this Bio À lter during dry season such as winter.

•

Storage, handling and disposal methods.

•

•

The lifetime of this Bio À lter is about a year after opening.

•

In case you do not use this Bio À lter right away, please don·t place the Bio À lter in any place where it will be

subjected to direct sunlight, high temperatures and/or high humidity.

•

There can be slight differences between Bio À lter color because of the manufacturing reasons, there is no effect

on the unit performance.

•

Please open this bag right before you use it. Bio À lter should remain unopened and sealed in its packaging until

right before usage. (It may cause performance deterioration or quality change.)

•

To avoid danger of suffocation and any unexpected accident, please dispose the plastic bag immediately after you

remove the Bio À lter. Keep out of reach of babies and children.

•

If you keep this Bio À lter for a long time, please keep it unopened and store in a cool place avoiding direct

sunlight.

•

Please dispose the old Bio À lter as nonÁ ammable garbage after use.

•

Operation with dirty À lters:

(1) cannot deodorize the air. (3) results in poor heating or cooling.

(2) cannot clean the air. (4) may cause odour.

•

To order Bio À lter, contact the service shop where you bought the air conditioner.

1-16

Page 19

SERVICE AND MAINTENANCE

Service Parts Maintenance Procedures

Indoor air À lter Remove any dust adhering to the À lter by using a vacuum cleaner or wash in lukewarm water

1.

(below 40°C/104°F) with a neutral cleaning detergent.

Rinse the À lter well and dry before placing it back onto the unit.

2.

Do not use gasoline, volatile substances or chemicals to clean the À lter.

3.

English

Indoor unit Clean any dirt or dust on the grille or panel by wiping it with a soft cloth soaked in lukewarm

1.

water (below 40°C/104°F) and a neutral detergent solution.

Do not use gasoline, volatile substances or chemicals to clean the indoor unit.

2.

! CAUTION

Avoid direct contact of any coil treatment cleaners on plastic part. This may cause plastic part to deform as a result

•

of chemical reaction.

Open the front panel.

1.

Hold the panel at the recesses on the main unit (2 recesses

•

on right and left sides) and lift it until it stops.

Remove the front panel.

2.

While lifting the front panel further, slide it to the right

•

and pull it to the front side. The left rotating shaft is

detached. Slide the right rotating shaft to the left and

pull it to the front side to remove it.

Attach the front panel.

3.

Align the right and left rotating shafts of the front panel

•

with the grooves and push them all the way in.

Gently close the front panel. (Push both ends and the

•

center on the front panel.)

Rotating

shaft

Recess on

main unit

! CAUTION

Don·t touch the metal parts of the indoor unit. It may cause an injury.

•

When removing or attaching the front panel, support the panel securely with hand to prevent it from falling.

•

For cleansing, do not use hot water above 40°C, benzine, gasoline, thinner, nor other volatile oils, polishing

•

compound, scrubbing brushes, nor other hand stuff.

After cleaning, make sure that the front panel is securely À xed.

•

1-17

Page 20

When The Unit Is Not To Be Used For An Extended Long Period Of Time

Operate the unit for 2 hours

with the following setting.

Operating mode : cool

Temperature : 30°C/86°F

Remove the power plug.

If you are using an independent

electric circuit for your unit,

cut off the circuit.

Remove the batteries in the

remote control.

TROUBLESHOOTING

For any enquiries on spare part please contact your authorized dealer. When any malfunction of the air

conditioner unit is noted, immediately switch off the power supply to the unit. Check the following fault

conditions and causes for some simple troubleshooting tips.

Fault Causes / Action

The compressor does not operate 3 minutes after the

1. Protection against frequent starting. Wait for 3 to 4

air conditioner unit is started.

The air conditioner unit does not operate.2. Power failure, or the fuse needs to be replaced.

The air Á ow is too low.3. The air À lter is dirty.

minutes for the compressor to start operating.

The power plug is disconnected.

It is possible that your delay timer has been set

incorrectly.

If the fault persist after all these veriÀ cations, please

contact the air conditioner unit installer.

The doors or windows are open.

The air suction and discharge are clogged.

The regulated temperature is not high enough.

-

Discharge air Á ow has bad odour.4. Odours may be caused by cigarettes, smoke particles,

Condensation on the front air grille of the indoor unit.5. This is caused by air humidity after an extended long

Water Á owing out from the air conditioner unit.6. Switch off unit and call dealer.-

Hissing air Á ow sound from the air conditioner unit

7. Refrigerant Á uid Á owing into the evaporator coil.

during operation.

perfume etc. which might have adhered onto the coil.

period of operation.

The set temperature is too low, increase the

temperature setting and operate the unit at high fan

speed.

-

If the fault persists, please call your local dealer / serviceman.

1-18

Page 21

SPECIFICATIONS

MODEL INDOOR UNIT FTD20JEVLK FTD25JEVLK

OUTDOOR UNIT RD20JEVLK RD25JEVLK

RATED VOLTAGE V 220 220

RATED FREQUENCY Hz 60 60

COOLING (T1)

INDOOR

O

27DB

C/19WBOC

OUTDOOR

O

35DB

C/24WBOC

COOLING (T3)

INDOOR

O

C/19WBOC

29DB

OUTDOOR

O

46DB

C/24WBOC

NET WEIGHT INDOOR UNIT kg 14.0 14.0

REFRIGERANT R22 kg 1.60 1.80

COUNTRY OF ORIGIN INDOOR UNIT

MODEL INDOOR UNIT FTYD20JEVLK FTYD25JEVLK

RATED VOLTAGE V 220 220

RATED FREQUENCY Hz 60 60

COOLING (T1)

INDOOR

O

27DB

C/19WBOC

OUTDOOR

O

35DB

C/24WBOC

COOLING (T3)

INDOOR

O

C/19WBOC

29DB

OUTDOOR

O

46DB

C/24WBOC

HEATING

INDOOR

O

20DB

C/--WBOC

OUTDOOR

O

7DB

C/6WBOC

NET WEIGHT INDOOR UNIT kg 14.0 14.0

REFRIGERANT R22 kg 1.60 1.80

COUNTRY OF ORIGIN INDOOR UNIT

RATED CURRENT A 8.80 11.1

RATED POWER INPUT kW 1.92 2.44

CAPACITY Btu/h 19000 22700

kW 5.57 6.65

EER

(Btu/h)/W 9.89 9.30

RATED CURRENT A 10.7 12.8

RATED POWER INPUT kW 2.33 2.80

CAPACITY Btu/h 16100 20000

kW 4.72 5.86

EER

(Btu/h)/W 6.90 7.14

OUTDOOR UNIT kg 49 57

Malaysia

OUTDOOR UNIT

Malaysia

OUTDOOR UNIT RYD20JEVLK RYD25JEVLK

RATED CURRENT A 8.80 11.1

RATED POWER INPUT kW 1.92 2.44

CAPACITY Btu/h 19000 22700

kW 5.57 6.65

EER

(Btu/h)/W 9.89 9.30

RATED CURRENT A 10.7 12.8

RATED POWER INPUT kW 2.33 2.80

CAPACITY Btu/h 16100 20000

kW 4.72 5.86

EER (Btu/h)/W

6.90 7.14

RATED CURRENT A 8.70 10.6

RATED POWER INPUT kW 1.89 2.32

CAPACITY Btu/h 20000 24000

W 5860 7030

COP W/W

3.10 3.03

OUTDOOR UNIT kg 49 57

Malaysia

OUTDOOR UNIT

Malaysia

English

NOTE:

This product is not designed for repacking. In case of re-packing, contact to Daikin Dealer.

1-19

Page 22

MEMO

Page 23

Page 24

•

In the event that there is any conÁ ict in the interpretation of this manual and any translation of the same in any language,

the English version of this manual shall prevail.

The manufacturer reserves the right to revise any of the speciÀ cation and design contain herein at any time without prior

•

notiÀ cation.

Lot 60334, Persiaran Bukit Rahman Putra 3,

Taman Perindustrian Bukit Rahman Putra,

47000 Sungai Buloh,

Selangar Darul Ehsan,

Malaysia.

Head offi ce:

Umeda Center Bldg., 2-4-12, Nakazaki-Nishi, Kita-ku,

Osaka, 530-8323 Japan

Tokyo offi ce:

JR Shinagawa East Bldg., 2-18-1, Konan, Minato-ku,

Tokyo, 108-0075 Japan

http://www.daikin.com/global_ac/

Loading...

Loading...