Daikin FNA25A2VEB, FNA35A2VEB, FNA50A2VEB, FNA60A2VEB, FNA25A2VEB9 Installer reference guide

...

Installer reference guide

Split system air conditioners

FNA25A2VEB

FNA35A2VEB

FNA50A2VEB

FNA60A2VEB

FNA25A2VEB9

FNA35A2VEB9

FNA50A2VEB9

FNA60A2VEB9

Installer reference guide

Split system air conditioners

English

Table of Contents

Table of Contents

1 General safety precautions 2

1.1 About the documentation .......................................................... 2

1.1.1 Meaning of warnings and symbols.............................. 2

1.2 For the installer.......................................................................... 3

1.2.1 General ....................................................................... 3

1.2.2 Installation site ............................................................ 3

1.2.3 Refrigerant .................................................................. 5

1.2.4 Brine............................................................................ 5

1.2.5 Water .......................................................................... 5

1.2.6 Electrical ..................................................................... 6

2 About the documentation 6

2.1 About this document.................................................................. 6

2.2 Installer reference guide at a glance ......................................... 7

3 About the box 7

3.1 Overview: About the box ........................................................... 7

3.2 Indoor unit ................................................................................. 7

3.2.1 To unpack and handle the unit.................................... 7

3.2.2 To remove the accessories from the indoor unit......... 7

4 About the units and options 7

4.1 Overview: About the units and options...................................... 7

4.2 System layout............................................................................ 8

4.3 Combining units and options ..................................................... 8

4.3.1 Possible options for the indoor unit............................. 8

5 Preparation 8

5.1 Overview: Preparation............................................................... 8

5.2 Preparing the installation site .................................................... 8

5.2.1 Installation site requirements of the indoor unit .......... 8

5.3 Preparing refrigerant piping....................................................... 9

5.3.1 Refrigerant piping requirements.................................. 9

5.3.2 Refrigerant piping insulation ....................................... 9

5.4 Preparing electrical wiring ......................................................... 9

5.4.1 About preparing electrical wiring................................. 9

6 Installation 10

6.1 Overview: Installation ................................................................ 10

6.2 Mounting the indoor unit............................................................ 10

6.2.1 Precautions when mounting the indoor unit................ 10

6.2.2 Guidelines when installing the indoor unit................... 10

6.2.3 Guidelines when installing the ducting........................ 12

6.2.4 Guidelines when installing the drain piping................. 12

6.3 Connecting the refrigerant piping .............................................. 13

6.3.1 About connecting the refrigerant piping ...................... 13

6.3.2 Precautions when connecting the refrigerant piping... 13

6.3.3 Guidelines when connecting the refrigerant piping..... 14

6.3.4 Pipe bending guidelines.............................................. 14

6.3.5 To flare the pipe end................................................... 14

6.3.6 To connect the refrigerant piping to the indoor unit .... 15

6.3.7 To check for leaks....................................................... 15

6.4 Connecting the electrical wiring................................................. 15

6.4.1 About connecting the electrical wiring......................... 15

6.4.2 Precautions when connecting the electrical wiring ..... 15

6.4.3 Guidelines when connecting the electrical wiring ....... 15

6.4.4 Specifications of standard wiring components............ 16

6.4.5 To connect the electrical wiring on the indoor unit...... 16

7 Commissioning 17

7.1 Overview: Commissioning......................................................... 17

7.2 Checklist before commissioning................................................ 17

7.3 To perform a test run................................................................. 17

7.4 Error codes when performing a test run .................................... 18

9 Disposal 18

10 Technical data 19

10.1 Wiring diagram ........................................................................... 19

11 Glossary 20

1 General safety precautions

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and the installer reference guide MUST be

performed by an authorised installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious

injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol Explanation

Before installation, read the installation and

operation manual, and the wiring instruction sheet.

Before performing maintenance and service tasks,

read the service manual.

For more information, see the installer and user

reference guide.

8 Hand-over to the user 18

Installer reference guide

2

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

1 General safety precautions

1.2 For the installer

1.2.1 General

If you are NOT sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

1.2.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the unit's weight and

vibration.

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

Instructions for equipment using R32 refrigerant

If applicable.

WARNING

▪ Do NOT pierce or burn.

▪ Do NOT use means to accelerate the defrosting

process or to clean the equipment, other than those

recommended by the manufacturer.

▪ Be aware that R32 refrigerant does NOT contain an

odour.

WARNING

The appliance shall be stored so as to prevent mechanical

damage and in a well-ventilated room without continuously

operating ignition sources (example: open flames, an

operating gas appliance or an operating electric heater)

and have a room size as specified below.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

NOTICE

▪ Do NOT re-use joints which have been used already.

▪ Joints made in installation between parts of refrigerant

system shall be accessible for maintenance purposes.

WARNING

Make sure installation, servicing, maintenance and repair

comply with instructions from Daikin and with applicable

legislation (for example national gas regulation) and are

executed only by authorised persons.

Installation space requirements

NOTICE

▪ Pipework shall be protected from physical damage.

▪ Installation of pipework shall be kept to a minimum.

Installer reference guide

3

1 General safety precautions

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO2eq

1000

GWP × kg

=

=

+

kg

=

kg

=

GWP: xxx

R32

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

500

510

520

530

540

550

1.822.2

2.4

2.6

2.833.2

3.4

3.6

3.844.2

4.4

4.6

4.855.2

5.4

5.6

5.866.2

6.4

6.6

6.877.2

7.4

7.6

7.8

1.843 7.956

8.0

A

min

(m2)

Floor-standing unit

(c)

Wall-mounted unit

(b)

Ceiling-mounted unit

(a)

m (kg)

Ceiling-mounted

unit

(a)

4.6 13.4

4.6 180

4.8 14.6

4.8 196

5.0 15.8

5.0 213

≤1.842 —

5.2 17.1

≤1.842 —

5.2 230

1.843 3.64

5.4 18.5

1.843 28.9

5.4 248

2.0 3.95

5.6 19.9

2.0 34.0

5.6 267

2.2 4.34

5.8 21.3

2.2 41.2

5.8 286

2.4 4.74

6.0 22.8

2.4 49.0

6.0 306

2.6 5.13

6.2 24.3

2.6 57.5

6.2 327

2.8 5.53

6.4 25.9

2.8 66.7

6.4 349

3.0 5.92

6.6 27.6

3.0 76.6

6.6 371

3.2 6.48

6.8 29.3

3.2 87.2

6.8 394

3.4 7.32

7.0 31.0

3.4 98.4

7.0 417

3.6 8.20

7.2 32.8

3.6 110

7.2 441

3.8 9.14

7.4 34.7

3.8 123

7.4 466

4.0 10.1

7.6 36.6

4.0 136

7.6 492

4.2 11.2

7.8 38.5

4.2 150

7.8 518

4.4 12.3

7.956 40.1

4.4 165

7.956 539

m (kg)

A

min

(m2)

4.6 20.0

4.8 21.8

5.0 23.6

≤1.842 —

5.2 25.6

1.843 4.45

5.4 27.6

2.0 4.83

5.6 29.7

2.2 5.31

5.8 31.8

2.4 5.79

6.0 34.0

2.6 6.39

6.2 36.4

2.8 7.41

6.4 38.7

3.0 8.51

6.6 41.2

3.2 9.68

6.8 43.7

3.4 10.9

7.0 46.3

3.6 12.3

7.2 49.0

3.8 13.7

7.4 51.8

4.0 15.1

7.6 54.6

4.2 16.7

7.8 57.5

4.4 18.3

7.956 59.9

Wall-mounted

unit

(b)

m (kg)

A

min

(m2)

Floor-standing

unit

(c)

m (kg)

A

min

(m2)

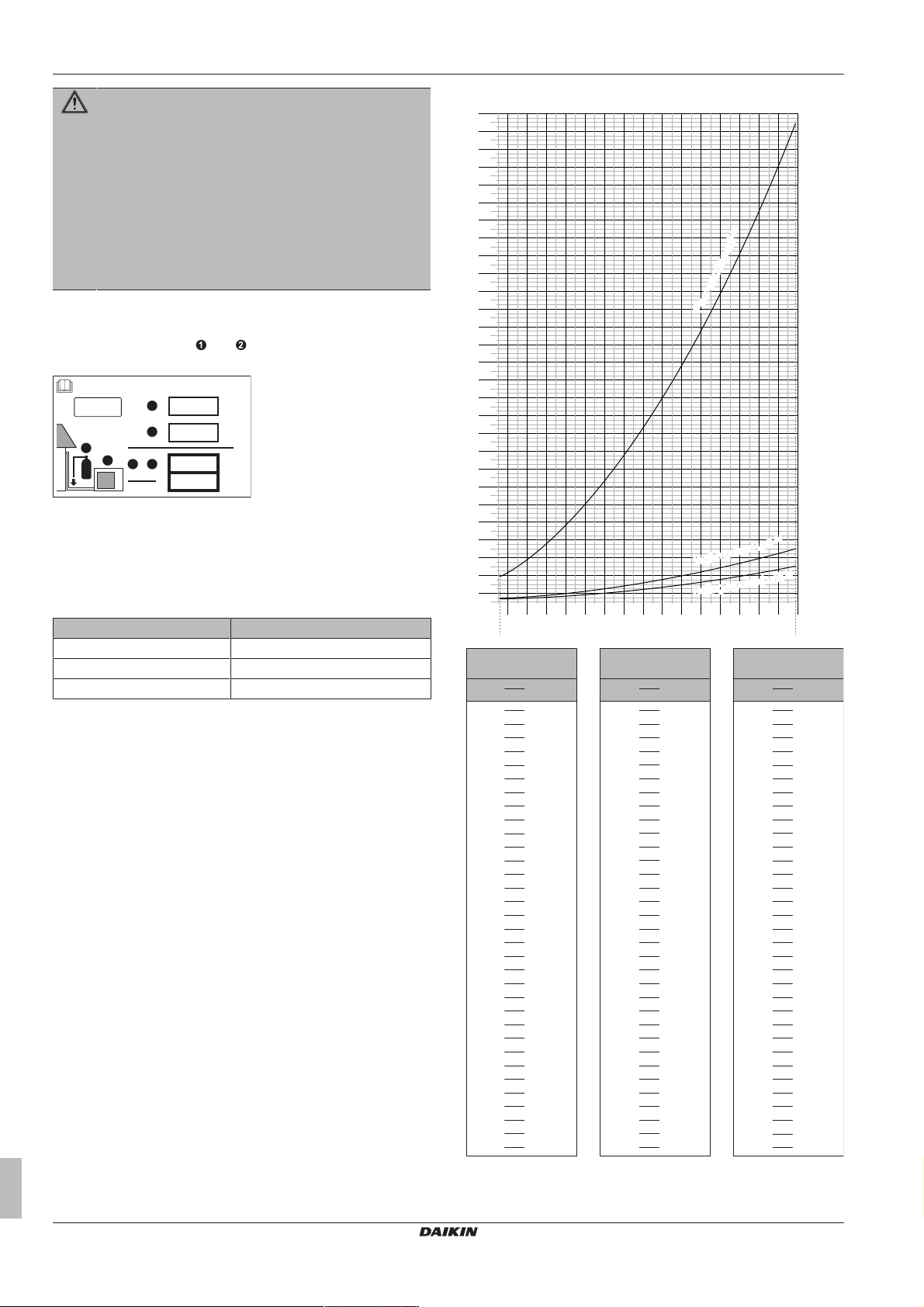

WARNING

If appliances contain R32 refrigerant, the floor area of the

room in which the appliances are installed, operated and

stored MUST be larger than the minimum floor area

defined in table below A (m2). This applies to:

▪ Indoor units without a refrigerant leakage sensor; in

case of indoor units with refrigerant leakage sensor,

consult the installation manual

▪ Outdoor units installed or stored indoors (e.g. winter

garden, garage, machinery room)

▪ Pipework in unventilated spaces

To determine the minimum floor area

1 Determine the total refrigerant charge in the system (= factory

refrigerant charge + additional refrigerant amount

charged).

2 Determine which graph or table to use.

▪ For indoor units: Is the unit ceiling-mounted, wall-mounted or

floor-standing?

▪ For outdoor units installed or stored indoors, and field piping

in unventilated spaces, this depends on the installation

height:

If the installation height is… Then use the graph or table for…

<1.8m Floor-standing units

1.8≤x<2.2m Wall-mounted units

≥2.2m Ceiling-mounted units

3 Use the graph or table to determine the minimum floor area.

Installer reference guide

4

m Total refrigerant charge in the system

A

Minimum floor area

min

(a) Ceiling-mounted unit (= Ceiling-mounted unit)

(b) Wall-mounted unit (= Wall-mounted unit)

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

1 General safety precautions

(c) Floor-standing unit (= Floor-standing unit)

1.2.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are NOT

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit. Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant MUST be treated according to the applicable

legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case re-charge is required, refer to the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

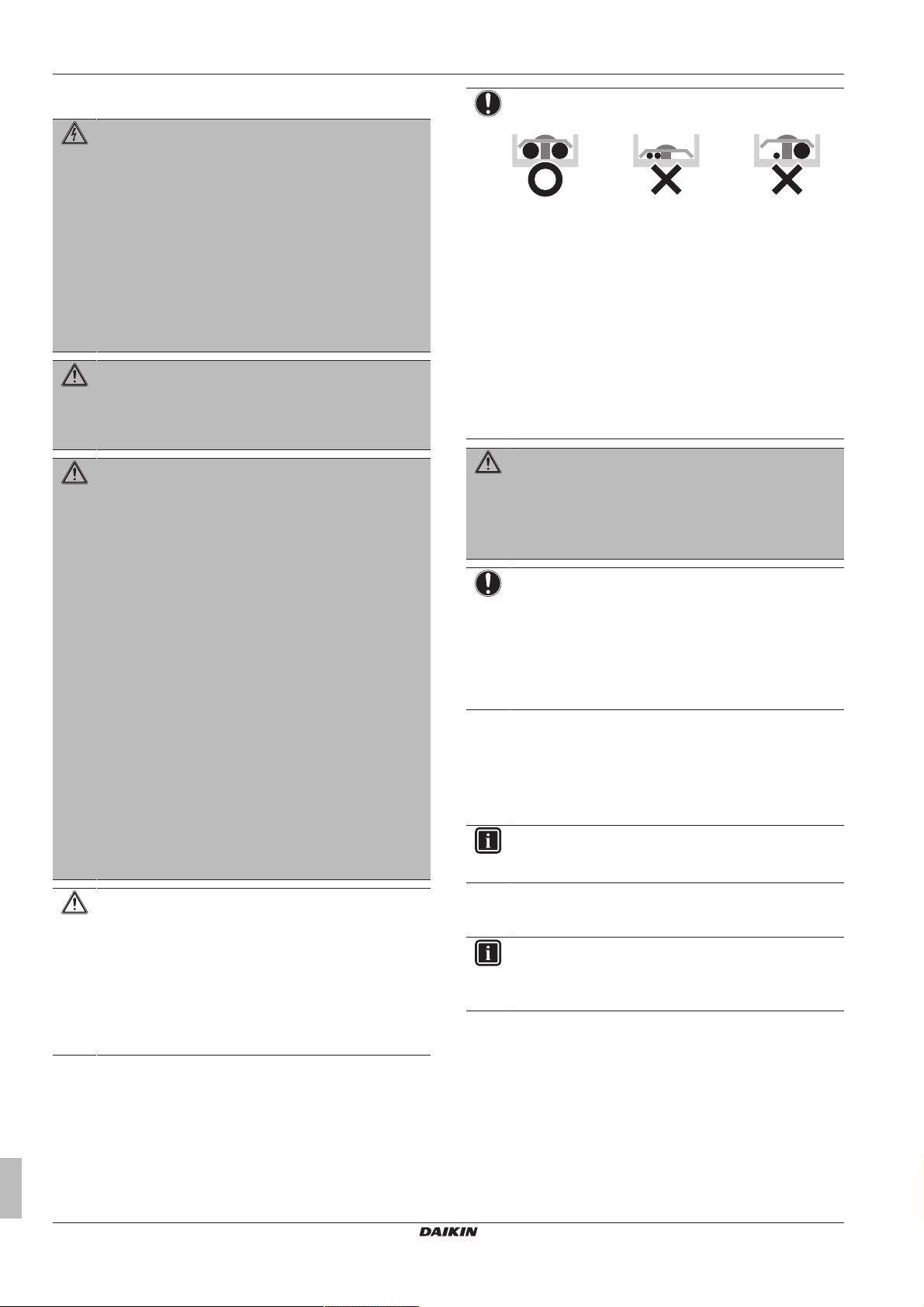

▪ Charge the liquid refrigerant as follows:

If Then

A siphon tube is present

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is NOT closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

Charge with the cylinder upright.

down.

1.2.4 Brine

If applicable. See the installation manual or installer reference guide

of your application for more information.

WARNING

The selection of the brine MUST be in accordance with the

applicable legislation.

WARNING

Take sufficient precautions in case of brine leakage. If

brine leaks, ventilate the area immediately and contact

your local dealer.

WARNING

The ambient temperature inside the unit can get much

higher than that of the room, e.g. 70°C. In case of a brine

leak, hot parts inside the unit can create a hazardous

situation.

WARNING

The use and installation of the application MUST comply

with the safety and environmental precautions specified in

the applicable legislation.

1.2.5 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

Installer reference guide

5

2 About the documentation

1.2.6 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, MUST be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring MUST be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do NOT come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

When connecting the power supply, the earth connection

must be made before the current-carrying connections are

established. When disconnecting the power supply, the

current-carrying connections must be separated before the

earth connection is. The length of the conductors between

the power supply stress relief and the terminal block itself

must be as such that the current-carrying wires are

tautened before the earth wire is in case the power supply

is pulled loose from the stress relief.

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure above.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

2 About the documentation

2.1 About this document

INFORMATION

Make sure that the user has the printed documentation and

ask him/her to keep it for future reference.

Target audience

Authorised installers

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry, and on farms, or for

commercial and household use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you MUST read before installing

▪ Format: Paper (in the box of the indoor unit)

▪ Indoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the indoor unit)

Installer reference guide

6

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

3 About the box

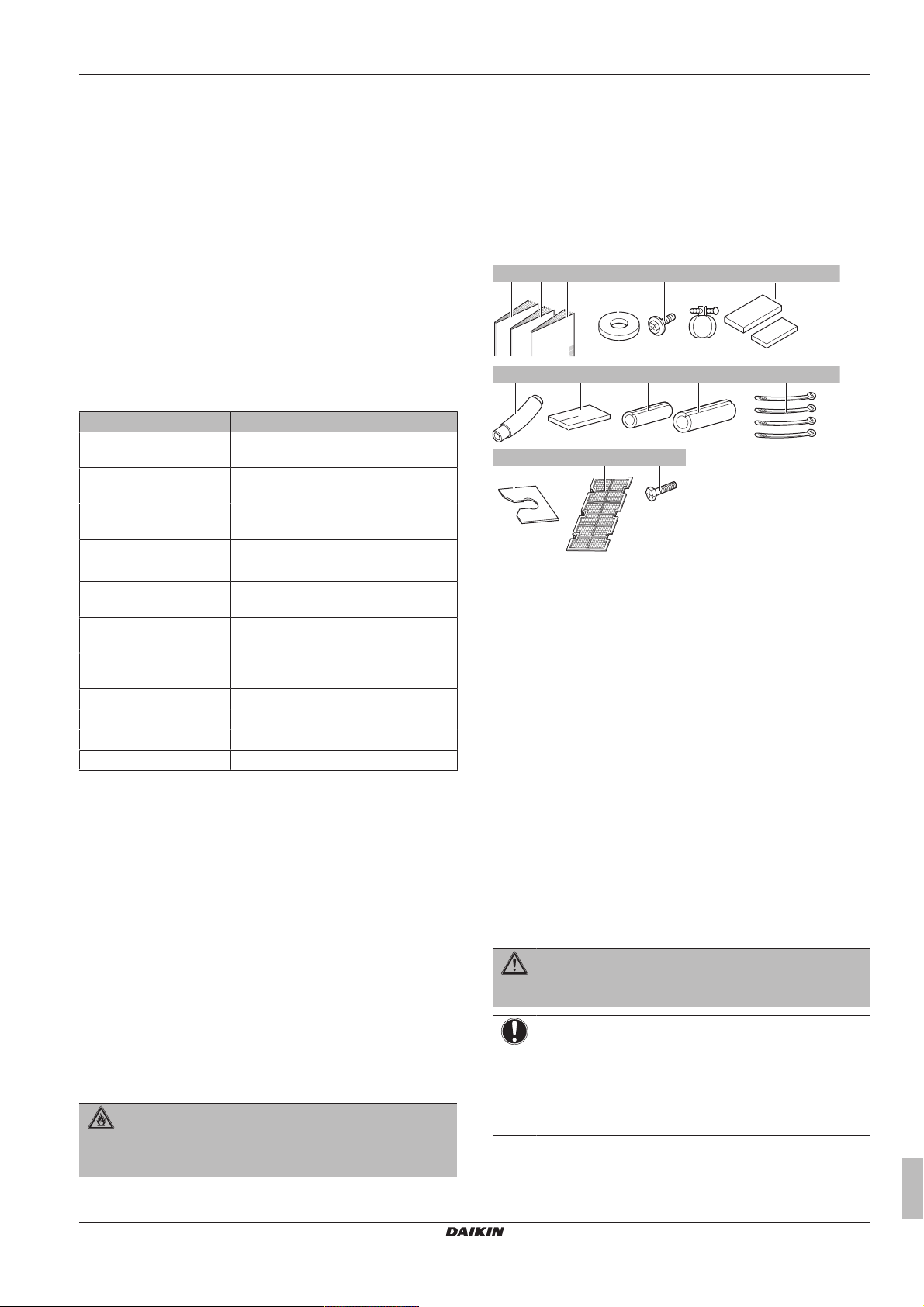

6×

24×8×1× 1×

2×

1×

1×

1×

2×

1×

e

dba

1×

c f g

h i j k

l

6×

m

4×

n o

1×

▪ Installer reference guide:

▪ Preparation of the installation, good practices, reference data,…

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

extranet (authentication required).

2.2 Installer reference guide at a glance

Chapter Description

General safety

precautions

About the documentation What documentation exists for the

About the box How to unpack the units and remove

About the units and

options

Preparation What to do and know before going

Installation What to do and know to install the

Commissioning What to do and know to commission the

Hand‑over to the user What to give and explain to the user

Disposal How to dispose of the system

Technical data Specifications of the system

Glossary Definition of terms

Safety instructions that you MUST read

before installing

installer

their accessories

▪ System layout

▪ Combining units and options

on‑site

system

system after it is configured

3.2.1 To unpack and handle the unit

Use a sling of soft material or protective plates together with a rope

when lifting the unit. This to avoid damage or scratches to the unit.

Lift the unit by holding on to the hanger brackets without exerting

any pressure on other parts, especially on refrigerant piping, drain

piping and other resin parts.

3.2.2 To remove the accessories from the indoor unit

a Installation manual

b Operation manual

c General safety precautions

d Washers for hanger bracket

e Screws for duct flanges

f Metal clamp

g Sealing pads: small and large

h Drain hose

i Sealing material

j Insulation piece: Small (liquid pipe)

k Insulation piece: Large (gas pipe)

l Tie wraps

m Washer fixing plate

n Air filter

o Levelling screws

3 About the box

3.1 Overview: About the box

This chapter describes what you have to do after the box with the

indoor unit is delivered on-site.

Keep the following in mind:

▪ At delivery, the unit MUST be checked for damage. Any damage

MUST be reported immediately to the carrier's claims agent.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

▪ Prepare the path along which you want to bring the unit inside in

advance.

3.2 Indoor unit

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

WARNING: FLAMMABLE MATERIAL

The R32 refrigerant (if applicable) in this unit is mildly

flammable. Refer to the outdoor unit specifications for the

type of refrigerant to be used.

4 About the units and options

4.1 Overview: About the units and options

This chapter contains information about:

▪ Combining outdoor and indoor units

▪ Combining the indoor unit with options

WARNING

NEVER use a flammable spray such as hair spray, lacquer

or paint near the unit. It may cause a fire.

NOTICE

Do NOT wipe the controller operation panel with benzine,

thinner, chemical dust cloth, etc. The panel may get

discoloured or the coating peeled off. If it is heavily dirty,

soak a cloth in water-diluted neutral detergent, squeeze it

well and wipe the panel clean. Wipe it with another dry

cloth.

Installer reference guide

7

5 Preparation

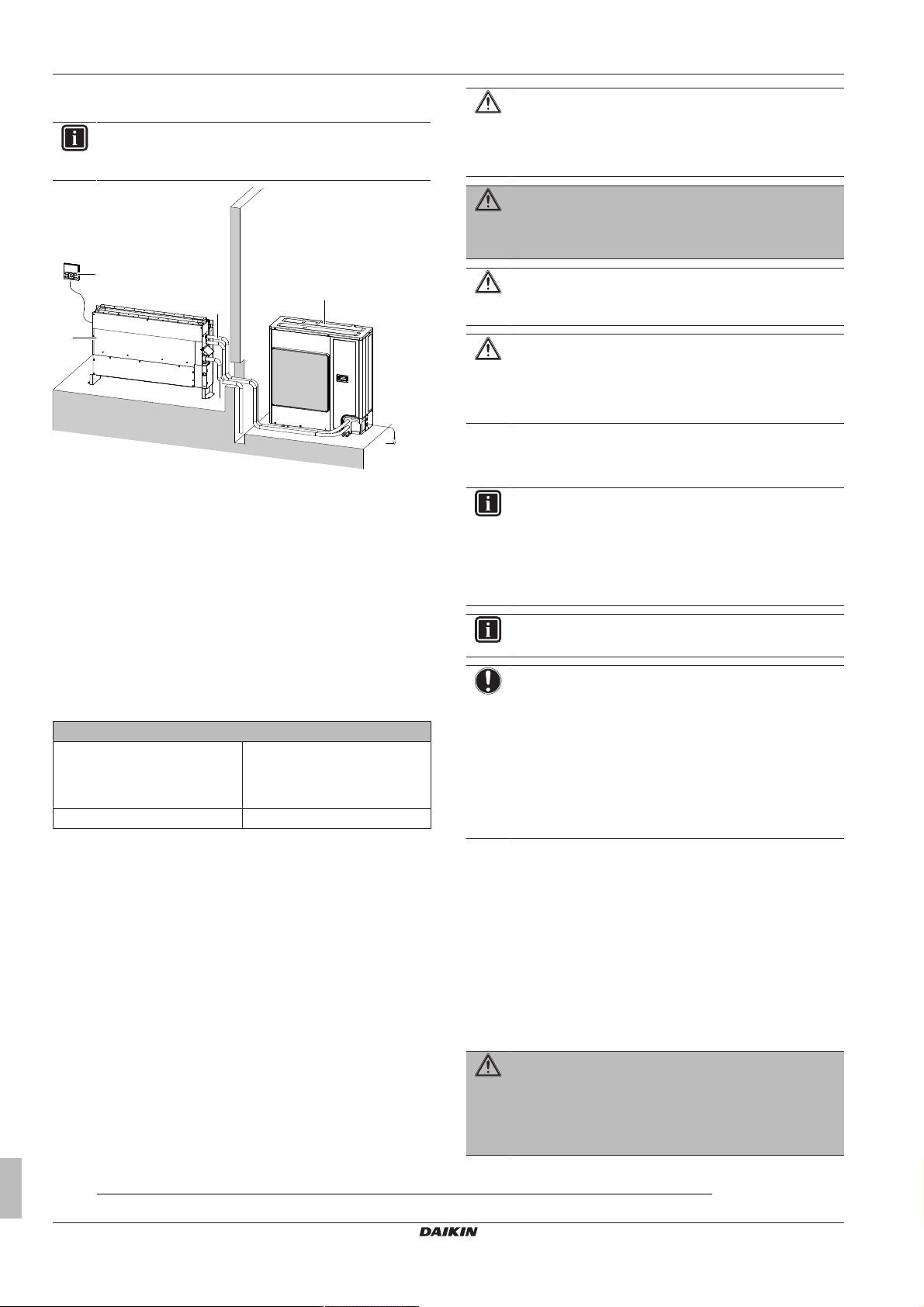

a

b

c

f

d

e

4.2 System layout

INFORMATION

The following illustration is an example and might NOT

match your system layout.

a Indoor unit

b Outdoor unit

c User interface

d Refrigerant piping + interconnection cable

e Drain pipe

f Earth wiring

4.3 Combining units and options

4.3.1 Possible options for the indoor unit

Make sure you have the following mandatory options:

▪ User interface: Wired or wireless

Select a user interface in accordance with the customer's request.

Refer to the table below to select a suitable user interface.

User interface

Wired user interface BRC1D52/BRC1D61/

BRC1E51A/BRC1E53A7/

BRC1E53B7/BRC1E53C7/

BRC1H519

Wireless user interface BRC4C65

5 Preparation

5.1 Overview: Preparation

This chapter describes what you have to do and know before going

on-site.

It contains information about:

▪ Preparing the installation site

▪ Preparing the refrigerant piping

▪ Preparing the electrical wiring

5.2 Preparing the installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Choose the installation location with sufficient space for carrying

the unit in and out of the site.

(1)

Only for units using R32 refrigerant. Refer to the outdoor unit specifications for the type of refrigerant to be used.

CAUTION

Do NOT install or use in places filled with smoke, gas,

chemicals etc. Sensors inside the indoor unit may detect

these substances, and display a refrigerant leak

abnormality.

WARNING

Do NOT install the air conditioner at any place where

flammable gas may leak out. If the gas leaks out and stays

around the air conditioner, a fire may break out.

CAUTION

Do NOT install or use in highly airtight spaces, e.g.

soundproof chambers or rooms with sealed doors.

CAUTION

This unit is equipped with electrically powered safety

measures, such as a refrigerant leak detector. In order to

be effective, the unit must be electrically powered at all

times after installation, except for short service periods.

1

1

1

5.2.1 Installation site requirements of the indoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

INFORMATION

The sound pressure level is less than 70dBA.

NOTICE

The equipment described in this manual may cause

electronic noise generated from radio-frequency energy.

The equipment complies to specifications that are

designed to provide reasonable protection against such

interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment and

electric wires keeping proper distances away from stereo

equipment, personal computers, etc.

▪ Fluorescent lights. When installing a wireless user interface in a

room with fluorescent lights, mind the following to avoid

interference:

▪ Install the wireless user interface as close as possible to the

indoor unit.

▪ Install the indoor unit as far as possible from the fluorescent

lights.

▪ Take care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

▪ Choose a location where the hot/cold air discharged from the unit

or the operation noise, will NOT disturb anyone.

WARNING

Do NOT place objects below the indoor and/or outdoor unit

that may get wet. Otherwise condensation on the main unit

or refrigerant pipes, air filter dirt or drain blockage may

cause dripping, and objects under the unit may get dirty or

damaged.

▪ Air flow. Make sure nothing blocks the air flow.

Installer reference guide

8

FNA25~60A2VEB(9)

Split system air conditioners

4P550955-3 – 2018.08

Loading...

Loading...