Daikin FCQ18TAVJU, FCQ24TAVJU, FCQ30TAVJU, FCQ36TAVJU, FCQ42TAVJU Service Manual

...

Service

Manual

SiUS281811E

RZR-TA, RZQ-TA Series

Cooling Only 60 Hz

Heat Pump 60 Hz

SiUS281811E

Introduction .......................................................................................1

1. Safety Cautions...........................................................................................2

1.1 Warnings and Cautions Regarding Safety of Workers................................. 2

1.2 Warnings and Cautions Regarding Safety of Users..................................... 4

2. Icons Used ..................................................................................................7

3. Revision History ..........................................................................................8

Part 1 General Information ...............................................................9

1. Model Names and Power Supply..............................................................10

1.1 Cooling Only............................................................................................... 10

1.2 Heat Pump ................................................................................................. 11

2. External Appearance.................................................................................12

2.1 Indoor Unit.................................................................................................. 12

2.2 Outdoor Unit ............................................................................................... 13

2.3 Remote Controller ...................................................................................... 14

3. Specifications ............................................................................................15

3.1 Cooling Only............................................................................................... 15

3.2 Heat Pump ................................................................................................. 28

Part 2 Refrigerant Circuit............................................................... 41

1. Refrigerant Circuit (Piping Diagrams) .......................................................42

1.1 RZR18/24TAVJU, RZQ18/24TAVJU.......................................................... 42

1.2 RZR30/36/42/48TAVJU, RZQ30/36/42/48TAVJU...................................... 44

1.3 Indoor Unit.................................................................................................. 46

2. Functional Parts Layout ............................................................................47

2.1 RZR18/24TAVJU, RZQ18/24TAVJU.......................................................... 47

2.2 RZR30/36/42/48TAVJU, RZQ30/36/42/48TAVJU...................................... 49

Part 3 Remote Controller ................................................................ 51

1. Applicable Models .....................................................................................52

2. Names and Functions ...............................................................................53

2.1 Wired Remote Controller............................................................................ 53

2.2 Simplified Remote Controller...................................................................... 56

2.3 Wireless Remote Controller ....................................................................... 57

3. Main/Sub Setting.......................................................................................59

3.1 Wired Remote Controller (BRC1E73) ........................................................ 59

3.2 When Wireless Remote Controller is Used Together................................. 60

4. Address Setting for Wireless Remote Controller.......................................61

5. Centralized Control Group No. Setting......................................................64

5.1 BRC1E73 ................................................................................................... 64

5.2 Wireless Remote Controller ....................................................................... 66

6. Service Settings Menu, Maintenance Menu..............................................67

6.1 BRC1E73 ................................................................................................... 67

6.2 Wireless Remote Controller ....................................................................... 71

i Table of Contents

SiUS281811E

Part 4 Functions and Control .......................................................... 72

1. Operation Mode ........................................................................................73

2. Basic Control.............................................................................................74

2.1 Normal Operation ....................................................................................... 74

2.2 Compressor PI Control............................................................................... 75

2.3 Electronic Expansion Valve PI Control....................................................... 77

2.4 Cooling Operation Fan Control................................................................... 78

3. Special Control..........................................................................................79

3.1 Startup Control ........................................................................................... 79

3.2 Oil Return Control....................................................................................... 81

3.3 Defrost Control ........................................................................................... 83

3.4 Pump Down Residual Control .................................................................... 84

3.5 Restart Standby.......................................................................................... 85

3.6 Stop Control ............................................................................................... 85

4. Protection Control .....................................................................................86

4.1 High Pressure Protection Control............................................................... 86

4.2 Low Pressure Protection Control................................................................ 87

4.3 Discharge Pipe Temperature Protection Control........................................ 89

4.4 Inverter Protection Control ......................................................................... 90

5. Other Control.............................................................................................92

5.1 Demand Operation ..................................................................................... 92

5.2 Heating Operation Prohibition .................................................................... 92

6. Outline of Control (Indoor Unit) .................................................................93

6.1 Remote Controller Thermistor .................................................................... 93

6.2 Thermostat Control..................................................................................... 95

6.3 Thermostat Control with Operation Mode Set to AUTO ............................. 97

6.4 List of Swing Flap Operations .................................................................... 98

6.5 Hot Start Control (In Heating Operation Only)............................................ 99

6.6 Louver Control for Preventing Ceiling Dirt (FCQ Models Only)................ 100

6.7 Drain Pump Control.................................................................................. 101

6.8 Freeze-Up Prevention .............................................................................. 103

6.9 Heater Control (Except FTQ-TA Models) ................................................. 105

6.10 Heater Control (FTQ-TA Models) ............................................................. 106

6.11 3-Step Thermostat Processing (FTQ-TA Models).................................... 110

6.12 Fan Control (Heater Residual) (FTQ-TA Models) .................................... 111

6.13 Interlocked with External Equipment (FTQ-TA Models) ........................... 111

Part 5 Field Settings and Test Operation ..................................... 113

1. Field Setting from Remote Controller......................................................114

1.1 Wired Remote Controller.......................................................................... 114

1.2 Simplified Remote Controller.................................................................... 116

1.3 Wireless Remote Controller ..................................................................... 117

1.4 List of Field Settings for Indoor Unit ......................................................... 118

1.5 Details of Field Settings for Indoor Unit.................................................... 122

1.6 Operation Control Mode........................................................................... 137

2. Field Settings from Outdoor Unit.............................................................138

2.1 Capacity Setting ....................................................................................... 138

Table of Contents ii

SiUS281811E

2.2 Setting Mode and Monitor Mode .............................................................. 139

2.3 Setting Mode 1 ......................................................................................... 140

2.4 Setting Mode 2 ......................................................................................... 142

2.5 Monitor Mode ........................................................................................... 146

2.6 Setting of Low Noise Operation and Demand Operation ......................... 148

2.7 Setting of Refrigerant Recovery Mode ..................................................... 151

2.8 Setting of Vacuuming Mode ..................................................................... 151

2.9 Check Operation ...................................................................................... 152

2.10 Setting of Auxiliary Heater Control ........................................................... 153

2.11 Setting of Heat Pump Lockout and Emergency Heat Mode..................... 154

3. Test Operation ........................................................................................156

3.1 Check Work Prior to Turning Power Supply ON ...................................... 156

3.2 Turn Power ON ........................................................................................ 156

3.3 Test Operation.......................................................................................... 157

3.4 Error Codes and Corresponding Measures.............................................. 160

3.5 When Turning ON Power First Time ........................................................ 162

3.6 When Turning ON Power the Second Time and Subsequent.................. 162

3.7 When an Indoor Unit or Outdoor Unit has been Added,

or Indoor or Outdoor Unit PCB has been Changed.................................. 162

Part 6 Service Diagnosis ............................................................... 163

1. Servicing Items to be Confirmed .............................................................166

1.1 Troubleshooting........................................................................................ 166

1.2 Precautions for Maintenance.................................................................... 166

1.3 Refrigerant Properties (R-410A)............................................................... 168

2. Symptom-based Troubleshooting ...........................................................169

2.1 Indoor Unit Overall ................................................................................... 169

2.2 With Optional Infrared Presence/Floor Sensor......................................... 172

3. Troubleshooting with Remote Controller.................................................174

3.1 Wired Remote Controller.......................................................................... 174

3.2 Wireless Remote Controller ..................................................................... 175

4. Troubleshooting by Error Codes .............................................................177

4.1 Error Codes and Description .................................................................... 177

4.2 Error Codes - Sub Codes ......................................................................... 179

4.3 Error Code Indication by Outdoor Unit PCB............................................. 181

4.4 External Protection Device Abnormality (Except FTQ-TA)....................... 185

4.5 External Protection Device Abnormality (FTQ-TA Only) .......................... 186

4.6 Indoor Unit PCB Abnormality ................................................................... 187

4.7 Drain Level Control System (S1L) Abnormality........................................ 188

4.8 Indoor Fan Motor (M1F) Lock, Overload .................................................. 190

4.9 Indoor Fan Motor Abnormality.................................................................. 192

4.10 Blower Motor Not Running ....................................................................... 196

4.11 Indoor Fan Motor Status Abnormality....................................................... 197

4.12 Low Indoor Airflow.................................................................................... 198

4.13 Swing Flap Motor Abnormality ................................................................. 199

4.14 Power Supply Voltage Abnormality .......................................................... 201

4.15 Blower Motor Stops for Over/Under Voltage ............................................ 202

4.16 Electronic Expansion Valve Coil Abnormality, Dust Clogging .................. 203

iii Table of Contents

SiUS281811E

4.17 Drain Level Above Limit ........................................................................... 205

4.18 Capacity Determination Device Abnormality ............................................ 206

4.19 Transmission Abnormality (between Indoor Unit PCB and Fan PCB) ..... 207

4.20 Blower Motor Communication Error ......................................................... 209

4.21 Thermistor Abnormality ............................................................................ 210

4.22 Combination Abnormality (between Indoor Unit PCB and Fan PCB)....... 211

4.23 Blower Motor HP Mismatch...................................................................... 212

4.24 Indoor Blower Does Not Have Required Parameters to Function............ 213

4.25 Remote Sensor Abnormality .................................................................... 214

4.26 Infrared Presence/Floor Sensor Error ...................................................... 215

4.27 Remote Controller Thermistor Abnormality .............................................. 220

4.28 Outdoor Main PCB Abnormality ............................................................... 221

4.29 Activation of High Pressure Switch .......................................................... 222

4.30 Activation of Low Pressure Sensor .......................................................... 224

4.31 Inverter Compressor Motor Lock.............................................................. 226

4.32 Outdoor Fan Motor Abnormality ............................................................... 228

4.33 Electronic Expansion Valve Coil Abnormality........................................... 230

4.34 Discharge Pipe Temperature Abnormality ............................................... 231

4.35 Refrigerant Overcharged.......................................................................... 232

4.36 Thermistor Abnormality ............................................................................ 233

4.37 High Pressure Sensor Abnormality .......................................................... 234

4.38 Low Pressure Sensor Abnormality ........................................................... 235

4.39 PCB (for Inverter Compressor) Abnormality............................................. 236

4.40 Radiation Fin Temperature Rise Abnormality .......................................... 237

4.41 Inverter Compressor Instantaneous Overcurrent ..................................... 238

4.42 Inverter Compressor Overcurrent............................................................. 239

4.43 Inverter Compressor Startup Abnormality ................................................ 240

4.44 Transmission Error

(Between Microcomputers on the Outdoor Main PCB) ............................ 241

4.45 Inverter Circuit Capacitor High Voltage .................................................... 242

4.46 Radiation Fin Thermistor Abnormality ...................................................... 243

4.47 Refrigerant Shortage ................................................................................ 244

4.48 Power Supply Insufficient or Instantaneous Abnormality ......................... 246

4.49 Check Operation Not Executed................................................................ 248

4.50 Transmission Error between Indoor Units and Outdoor Units.................. 249

4.51 Transmission Error between Remote Controller and Indoor Unit............. 251

4.52 Transmission Error between Main and Sub Remote Controllers ............. 252

4.53 Transmission Error between Indoor and Outdoor Units in the

Same System ........................................................................................... 253

4.54 Improper Combination of Indoor and Outdoor Units,

Indoor Units and Remote Controller......................................................... 254

4.55 Incorrect Electric Heater Capacity Setting................................................ 256

4.56 Address Duplication of Centralized Controller.......................................... 257

4.57 Transmission Error between Centralized Controller and Indoor Unit ....... 258

4.58 System Not Set ........................................................................................ 259

4.59 System Abnormality, Refrigerant System Address Undefined ................. 260

5. Check ......................................................................................................261

5.1 High Pressure Check ............................................................................... 261

5.2 Low Pressure Check ................................................................................ 262

Table of Contents iv

SiUS281811E

5.3 Superheat Operation Check..................................................................... 263

5.4 Power Transistor Check ........................................................................... 264

5.5 Refrigerant Overcharge Check................................................................. 265

5.6 Refrigerant Shortage Check..................................................................... 266

5.7 Vacuuming and Dehydration Procedure .................................................. 267

5.8 List of Inverter-Related Error Codes......................................................... 268

5.9 Concept of Inverter-Related Error Codes................................................. 269

5.10 Thermistor Check ..................................................................................... 270

5.11 Pressure Sensor Check ........................................................................... 273

5.12 Broken Wire Check of the Relay Wires .................................................... 274

5.13 Fan Motor Connector Check .................................................................... 275

5.14 Electronic Expansion Valve Coil Check ................................................... 277

5.15 Fan Motor Connector Check for FTQ-TA ................................................. 280

Part 7 Appendix ............................................................................. 284

1. Wiring Diagrams......................................................................................285

1.1 Outdoor Unit ............................................................................................. 285

1.2 Indoor Unit................................................................................................ 287

v Table of Contents

SiUS281811E

Introduction

1. Safety Cautions...........................................................................................2

1.1 Warnings and Cautions Regarding Safety of Workers................................. 2

1.2 Warnings and Cautions Regarding Safety of Users..................................... 4

2. Icons Used ..................................................................................................7

3. Revision History ..........................................................................................8

Introduction 1

Safety Cautions SiUS281811E

Warning

1. Safety Cautions

Be sure to read the following safety cautions before conducting repair work.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment

operates normally, and explain the cautions for operating the product to the customer.

This manual is for the

person in charge of

maintenance and

inspection.

Caution Items The caution items are classified into Warning and Caution. The Warning items are

especially important since death or serious injury can result if they are not followed closely. The

Caution items can also lead to serious accidents under some conditions if they are not

followed. Therefore, be sure to observe all the safety caution items described below.

Pictograms This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown in the illustration or near the symbol.

1.1 Warnings and Cautions Regarding Safety of Workers

Do not store equipment in a room with fire sources (e.g., naked

flames, gas appliances, electric heaters).

Be sure to disconnect the power cable from the socket before

disassembling equipment for repair.

Working on equipment that is connected to the power supply may cause

an electrical shock.

If it is necessary to supply power to the equipment to conduct the repair or

inspect the circuits, do not touch any electrically charged sections of the

equipment.

If refrigerant gas is discharged during repair work, do not touch the

discharged refrigerant gas.

Refrigerant gas may cause frostbite.

When disconnecting the suction or discharge pipe of the

compressor at the welded section, evacuate the refrigerant gas

completely at a well-ventilated place first.

If there is gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it

may cause injury.

If refrigerant gas leaks during repair work, ventilate the area.

Refrigerant gas may generate toxic gases when it contacts flames.

2 Introduction

SiUS281811E Safety Cautions

Caution

Warning

Be sure to discharge the capacitor completely before conducting

repair work.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

A charged capacitor may cause an electrical shock.

Do not turn the air conditioner on or off by plugging in or

unplugging the power cable.

Plugging in or unplugging the power cable to operate the equipment may

cause an electrical shock or fire.

Be sure to wear a safety helmet, gloves, and a safety belt when

working in a high place (more than 2 m (6.5 ft)).

Insufficient safety measures may cause a fall.

In case of R-410A refrigerant models, be sure to use pipes, flare nuts

and tools intended for the exclusive use with the R-410A refrigerant.

The use of materials for other refrigerant models may cause a serious

accident, such as a damage of refrigerant cycle or equipment failure.

Do not mix air or gas other than the specified refrigerant (R-410A) in

the refrigerant system.

If air enters the refrigerant system, an excessively high pressure results,

causing equipment damage and injury.

Do not repair electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner with water.

Washing the unit with water may cause an electrical shock.

Be sure to provide an earth / grounding when repairing the

equipment in a humid or wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable

when cleaning the equipment.

The internal fan rotates at a high speed, and may cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

Introduction 3

Safety Cautions SiUS281811E

Caution

Warning

Be sure to check that the refrigerating cycle section has cooled

down enough before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

Conduct welding work in a well-ventilated place.

Using the welder in an enclosed room may cause oxygen deficiency.

1.2 Warnings and Cautions Regarding Safety of Users

Do not store the equipment in a room with fire sources (e.g., naked

flames, gas appliances, electric heaters).

Be sure to use parts listed in the service parts list of the applicable

model and appropriate tools to conduct repair work. Never attempt

to modify the equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires are scratched or have deteriorated,

be sure to replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the

same power outlet with other electrical appliances, since it may

cause an electrical shock, excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and

follow the local technical standards related to the electrical

equipment, the internal wiring regulations, and the instruction

manual for installation when conducting electrical work.

Insufficient power circuit capacity and improper electrical work may cause

an electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and

outdoor units.

Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

When wiring between the indoor and outdoor units, make sure that

the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may

cause an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cables may cause an electrical shock or fire.

Placing heavy items on the power cable, or heating or pulling the power

cable may damage it.

4 Introduction

SiUS281811E Safety Cautions

Caution

Warning

Do not mix air or gas other than the specified refrigerant (R-410A) in

the refrigerant system.

If air enters the refrigerant system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leaking point and

repair it before charging the refrigerant. After charging the

refrigerant, make sure that there is no leak.

If the leaking point cannot be located and the repair work must be

stopped, be sure to pump-down, and close the service valve, to prevent

refrigerant gas from leaking into the room. Refrigerant gas itself is

harmless, but it may generate toxic gases when it contacts flames, such

as those from fan type and other heaters, stoves and ranges.

When relocating the equipment, make sure that the new installation

site has sufficient strength to withstand the weight of the

equipment.

If the installation site does not have sufficient strength or the installation

work is not conducted securely, the equipment may fall and cause injury.

Check to make sure that the power cable plug is not dirty or loose,

then insert the plug into a power outlet securely.

If the plug is dusty or has a loose connection, it may cause an electrical

shock or fire.

When replacing the coin battery in the remote controller, be sure to

dispose of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Installation of a leakage breaker is necessary in some cases

depending on the conditions of the installation site, to prevent

electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if parts and wires are mounted and connected

properly, and if connections at the soldered or crimped terminals

are secure.

Improper installation and connections may cause excessive heat

generation, fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

A corroded installation platform or frame may cause the unit to fall,

resulting in injury.

Check the earth / grounding, and repair it if the equipment is not

properly earthed / grounded.

Improper earth / grounding may cause an electrical shock.

Introduction 5

Safety Cautions SiUS281811E

Caution

Be sure to measure insulation resistance after the repair, and make

sure that the resistance is 1 M or greater.

Faulty insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage may cause water to enter the room and wet the furniture

and floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

6 Introduction

SiUS281811E Icons Used

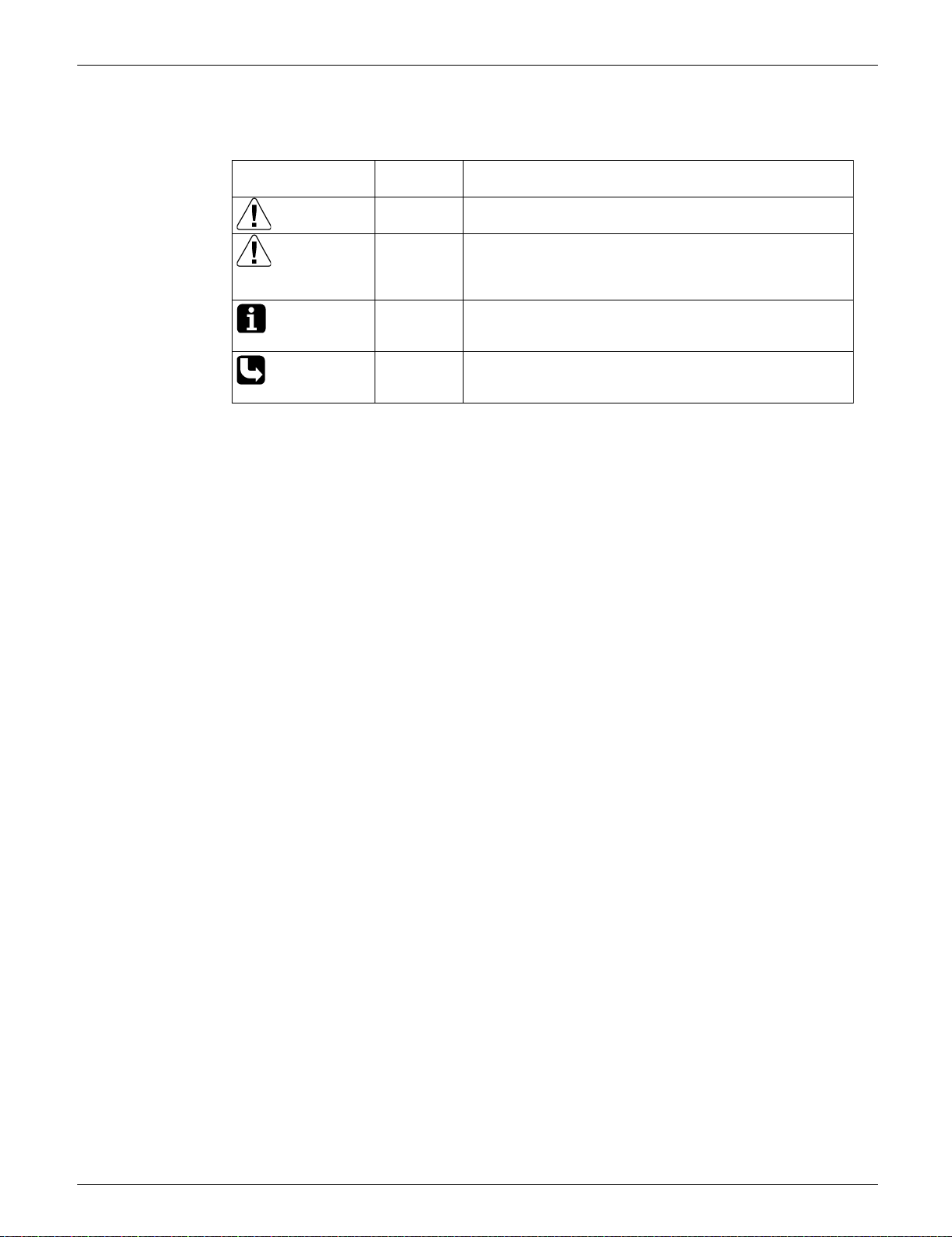

2. Icons Used

The following icons are used to attract the attention of the reader to specific information.

Icon Type of

Information

Warning Warning is used when there is danger of personal injury.

Warning

Caution Caution is used when there is danger that the reader,

Caution

Note Note provides information that is not indispensable, but

Note

Reference Reference guides the reader to other places in this binder

Reference

Description

through incorrect manipulation, may damage equipment,

lose data, get an unexpected result or have to restart (part

of) a procedure.

may nevertheless be valuable to the reader, such as tips

and tricks.

or in this manual, where he/she will find additional

information on a specific topic.

Introduction 7

Revision History SiUS281811E

3. Revision History

Month / Year Version Revised contents

04 / 2019 SiUS281811E First edition

8 Introduction

SiUS281811E

Part 1

General Information

1. Model Names and Power Supply..............................................................10

1.1 Cooling Only............................................................................................... 10

1.2 Heat Pump ................................................................................................. 11

2. External Appearance.................................................................................12

2.1 Indoor Unit.................................................................................................. 12

2.2 Outdoor Unit ............................................................................................... 13

2.3 Remote Controller ...................................................................................... 14

3. Specifications ............................................................................................15

3.1 Cooling Only............................................................................................... 15

3.2 Heat Pump ................................................................................................. 28

Part 1 General Information 9

Model Names and Power Supply SiUS281811E

Note(s)

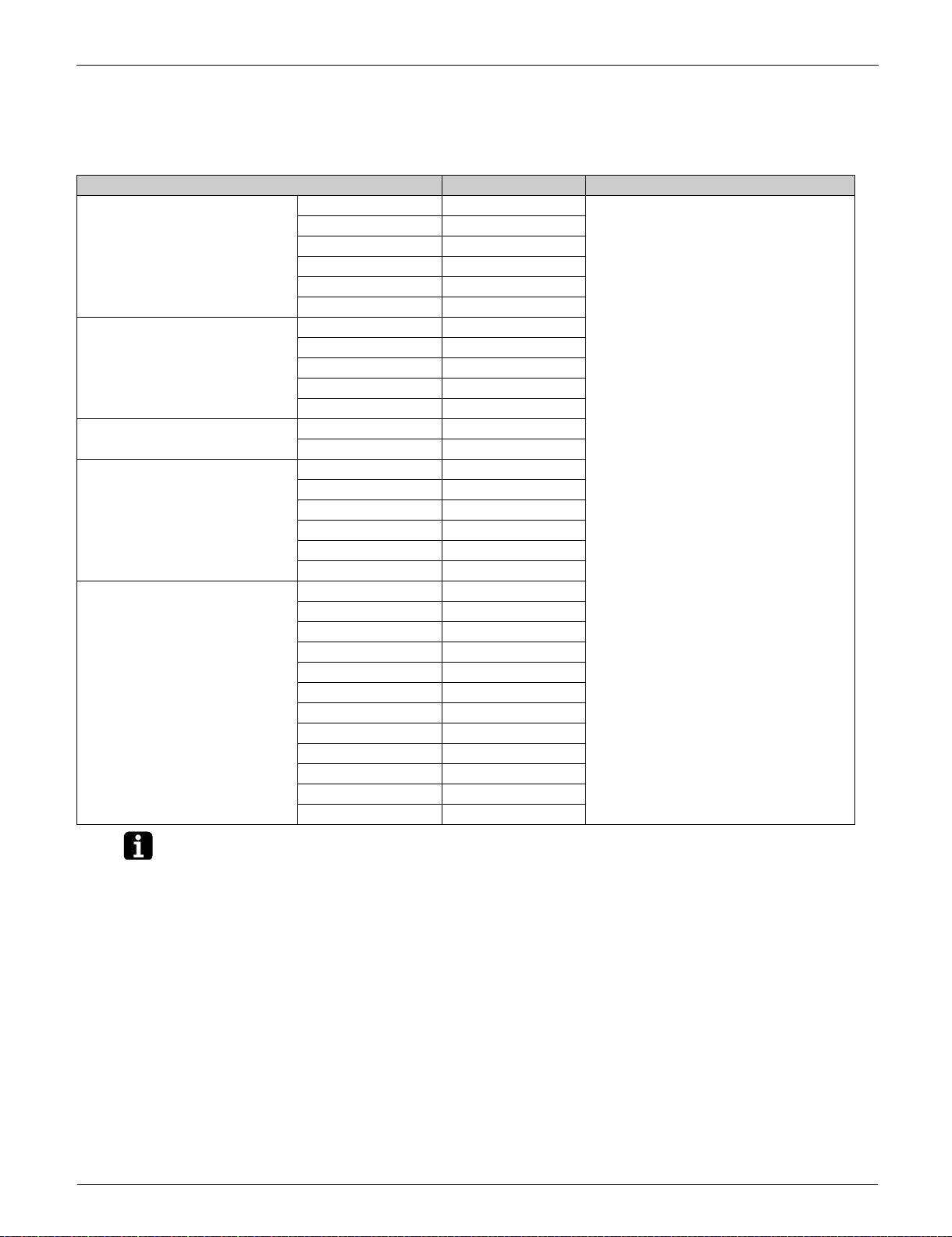

1. Model Names and Power Supply

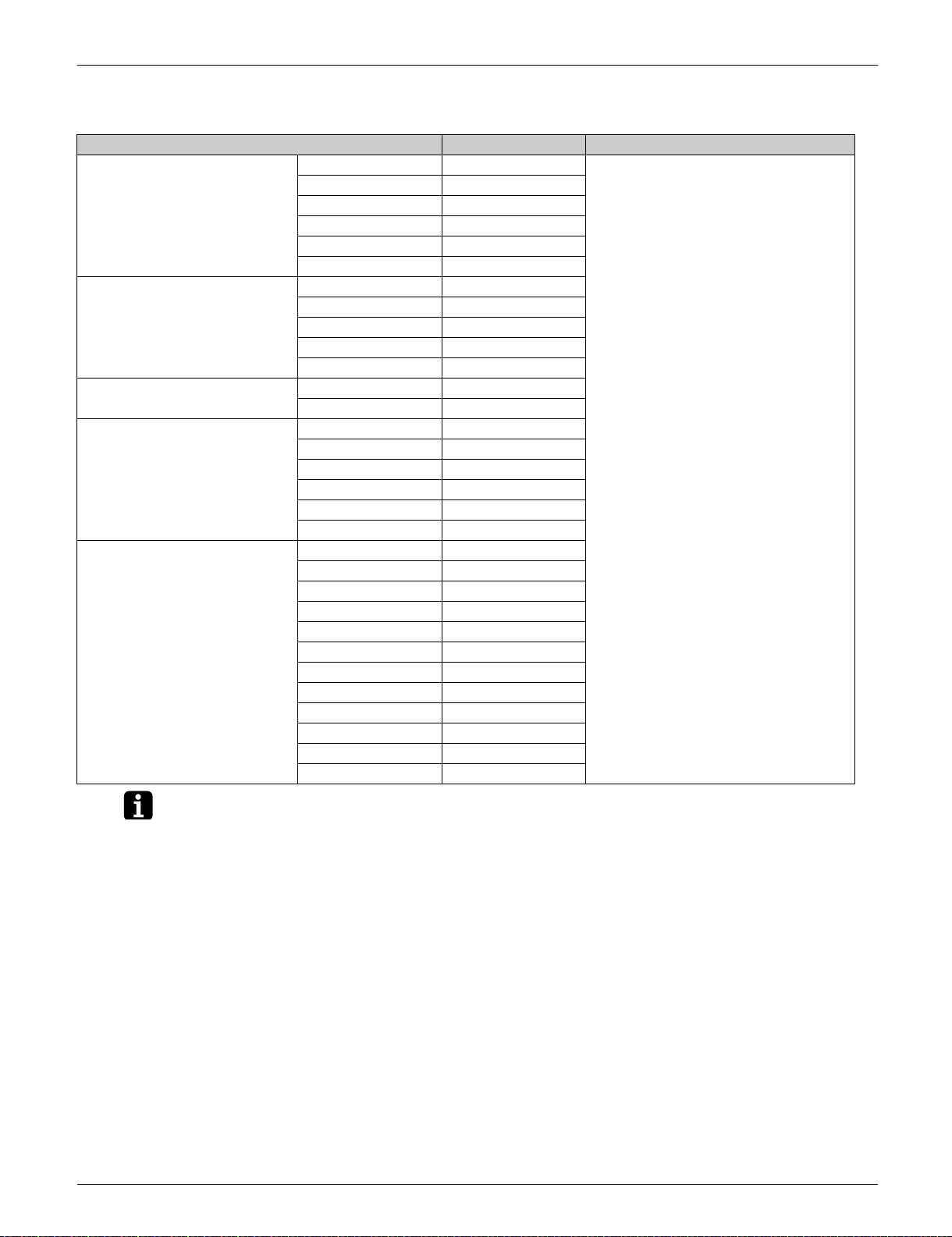

1.1 Cooling Only

Indoor unit Outdoor unit Power supply intake

Ceiling mounted cassette type

(Round flow with sensing)

Ceiling suspended type FHQ18PVJU RZR18TAVJU

Wall mounted type FAQ18TAVJU RZR18TAVJU

Ceiling mounted duct type

(High static pressure)

Multi position air handling unit FTQ18TAVJUD RZR18TAVJU

FCQ18TAVJU RZR18TAVJU

FCQ24TAVJU RZR24TAVJU

FCQ30TAVJU RZR30TAVJU

FCQ36TAVJU RZR36TAVJU

FCQ42TAVJU RZR42TAVJU

FCQ48TAVJU RZR48TAVJU

FHQ24PVJU RZR24TAVJU

FHQ30PVJU RZR30TAVJU

FHQ36MVJU RZR36TAVJU

FHQ42MVJU RZR42TAVJU

FAQ24TAVJU RZR24TAVJU

FBQ18PVJU RZR18TAVJU

FBQ24PVJU RZR24TAVJU

FBQ30PVJU RZR30TAVJU

FBQ36PVJU RZR36TAVJU

FBQ42PVJU RZR42TAVJU

FBQ48PVJU RZR48TAVJU

FTQ24TAVJUD RZR24TAVJU

FTQ30TAVJUD RZR30TAVJU

FTQ36TAVJUD RZR36TAVJU

FTQ42TAVJUD RZR42TAVJU

FTQ48TAVJUD RZR48TAVJU

FTQ18TAVJUA RZR18TAVJU

FTQ24TAVJUA RZR24TAVJU

FTQ30TAVJUA RZR30TAVJU

FTQ36TAVJUA RZR36TAVJU

FTQ42TAVJUA RZR42TAVJU

FTQ48TAVJUA RZR48TAVJU

Indoor unit: 1 phase, 208/230 V, 60 Hz

Outdoor unit: 1 phase, 208/230 V, 60 Hz

1. Power supply intake: outdoor unit

2. VJ: 1 phase, 208/230 V, 60 Hz

U (VJU): Standard Symbol

10 Part 1 General Information

SiUS281811E Model Names and Power Supply

Note(s)

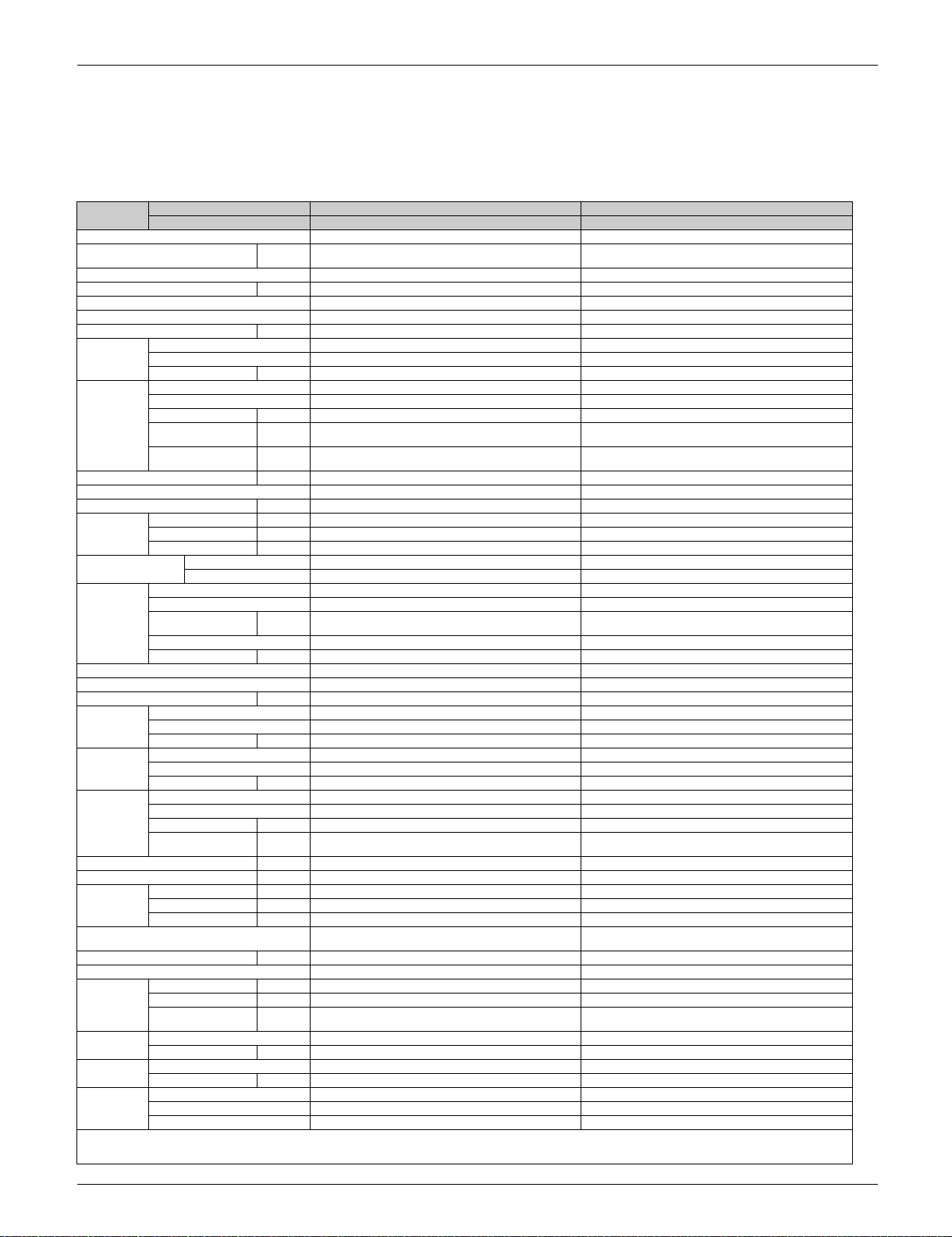

1.2 Heat Pump

Indoor unit Outdoor unit Power supply intake

Ceiling mounted cassette type

(Round flow with sensing)

Ceiling suspended type FHQ18PVJU RZQ18TAVJU

Wall mounted type FAQ18TAVJU RZQ18TAVJU

Ceiling mounted duct type

(High static pressure)

Multi position air handling unit FTQ18TAVJUD RZQ18TAVJU

FCQ18TAVJU RZQ18TAVJU

FCQ24TAVJU RZQ24TAVJU

FCQ30TAVJU RZQ30TAVJU

FCQ36TAVJU RZQ36TAVJU

FCQ42TAVJU RZQ42TAVJU

FCQ48TAVJU RZQ48TAVJU

FHQ24PVJU RZQ24TAVJU

FHQ30PVJU RZQ30TAVJU

FHQ36MVJU RZQ36TAVJU

FHQ42MVJU RZQ42TAVJU

FAQ24TAVJU RZQ24TAVJU

FBQ18PVJU RZQ18TAVJU

FBQ24PVJU RZQ24TAVJU

FBQ30PVJU RZQ30TAVJU

FBQ36PVJU RZQ36TAVJU

FBQ42PVJU RZQ42TAVJU

FBQ48PVJU RZQ48TAVJU

FTQ24TAVJUD RZQ24TAVJU

FTQ30TAVJUD RZQ30TAVJU

FTQ36TAVJUD RZQ36TAVJU

FTQ42TAVJUD RZQ42TAVJU

FTQ48TAVJUD RZQ48TAVJU

FTQ18TAVJUA RZQ18TAVJU

FTQ24TAVJUA RZQ24TAVJU

FTQ30TAVJUA RZQ30TAVJU

FTQ36TAVJUA RZQ36TAVJU

FTQ42TAVJUA RZQ42TAVJU

FTQ48TAVJUA RZQ48TAVJU

Indoor unit: 1 phase, 208/230 V, 60 Hz

Outdoor unit: 1 phase, 208/230 V, 60 Hz

1. Power supply intake: outdoor unit

2. VJ: 1 phase, 208/230 V, 60 Hz

U (VJU): Standard Symbol

Part 1 General Information 11

External Appearance SiUS281811E

2. External Appearance

2.1 Indoor Unit

Ceiling Mounted Cassette Type (Round Flow with Sensing)

FCQ18TAVJU

FCQ24TAVJU

FCQ30TAVJU

FCQ36TAVJU

FCQ42TAVJU

FCQ48TAVJU

Shown with BYCQ125B-W1

Ceiling Suspended Type

FHQ18PVJU

FHQ24PVJU

FHQ30PVJU

FHQ36MVJU

FHQ42MVJU

Wall Mounted Type

FAQ18TAVJU

FAQ24TAVJU

Ceiling Mounted Duct Type (High Static Pressure)

FBQ18PVJU

FBQ24PVJU

FBQ30PVJU

FBQ36PVJU

FBQ42PVJU

FBQ48PVJU

12 Part 1 General Information

SiUS281811E External Appearance

Multi Position Air Handling Unit

FTQ18TAVJUD, FTQ18TAVJUA

FTQ24TAVJUD, FTQ24TAVJUA

FTQ30TAVJUD, FTQ30TAVJUA

FTQ36TAVJUD, FTQ36TAVJUA

FTQ42TAVJUD, FTQ42TAVJUA

FTQ48TAVJUD, FTQ48TAVJUA

2.2 Outdoor Unit

RZR18TAVJU

RZR24TAVJU

RZQ18TAVJU

RZQ24TAVJU

RZR30TAVJU

RZR36TAVJU

RZR42TAVJU

RZR48TAVJU

RZQ30TAVJU

RZQ36TAVJU

RZQ42TAVJU

RZQ48TAVJU

Part 1 General Information 13

External Appearance SiUS281811E

2.3 Remote Controller

Wired remote controller

BRC1E73

Wireless remote controller

BRC7E83 (FHQ)

BRC7E818 (FAQ)

BRC4C82 (FBQ (1), FTQ)

BRC082A43 (FBQ (1))

1. For FBQ series, the fan step control is different according to the wireless remote controller used.

BRC4C82 (Fan: 2 steps)

BRC082A43 (Fan: 3 steps)

14 Part 1 General Information

SiUS281811E Specifications

3. Specifications

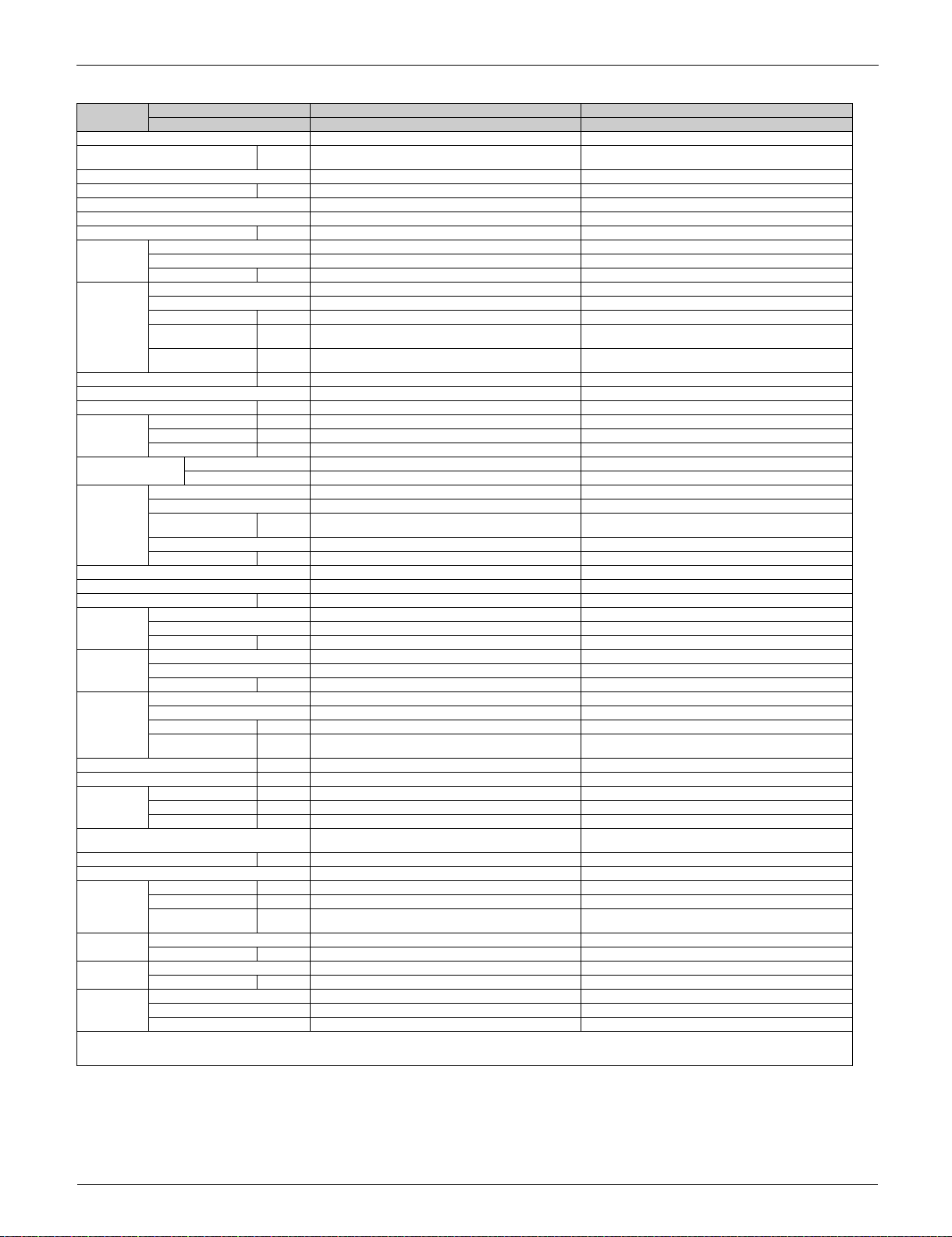

3.1 Cooling Only

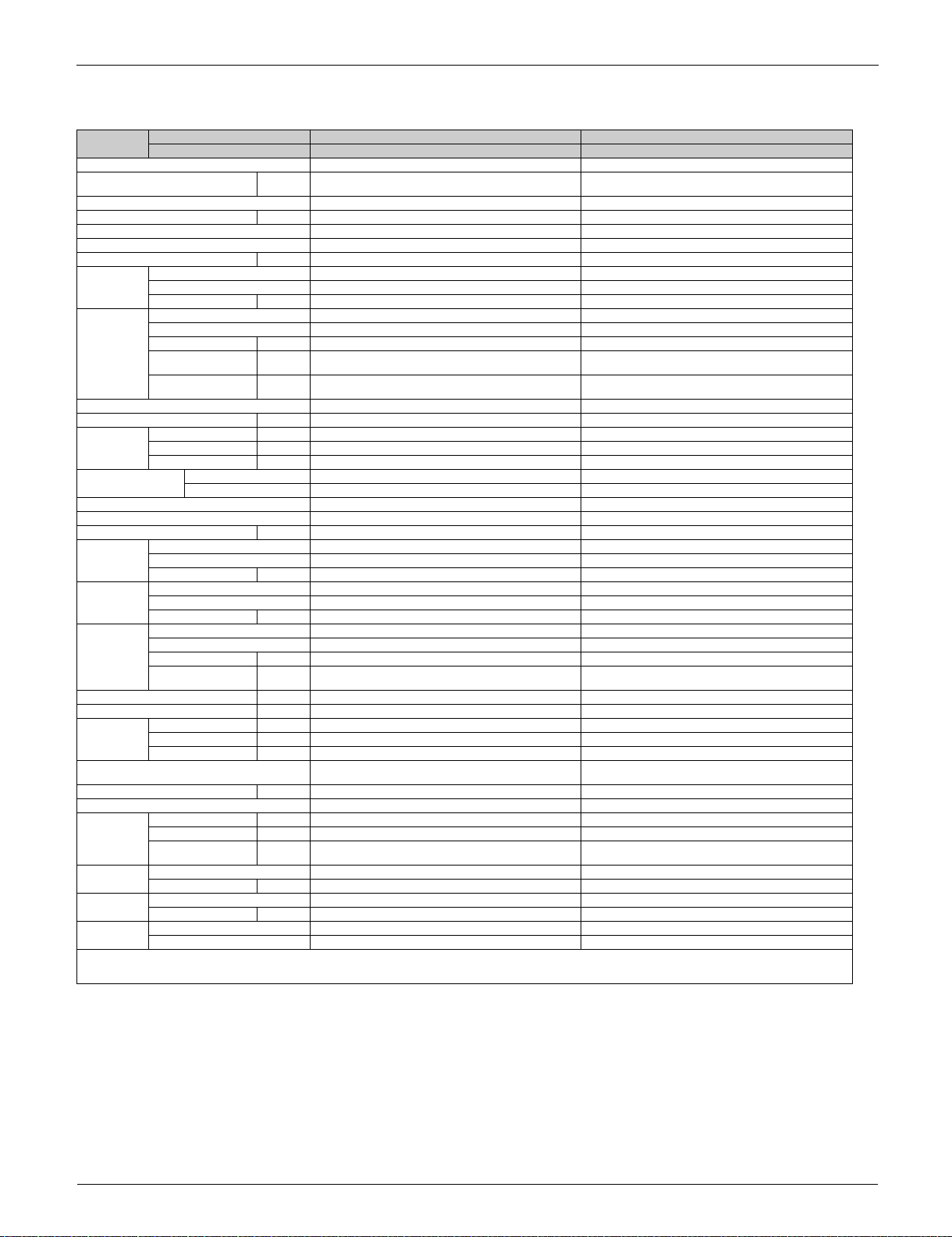

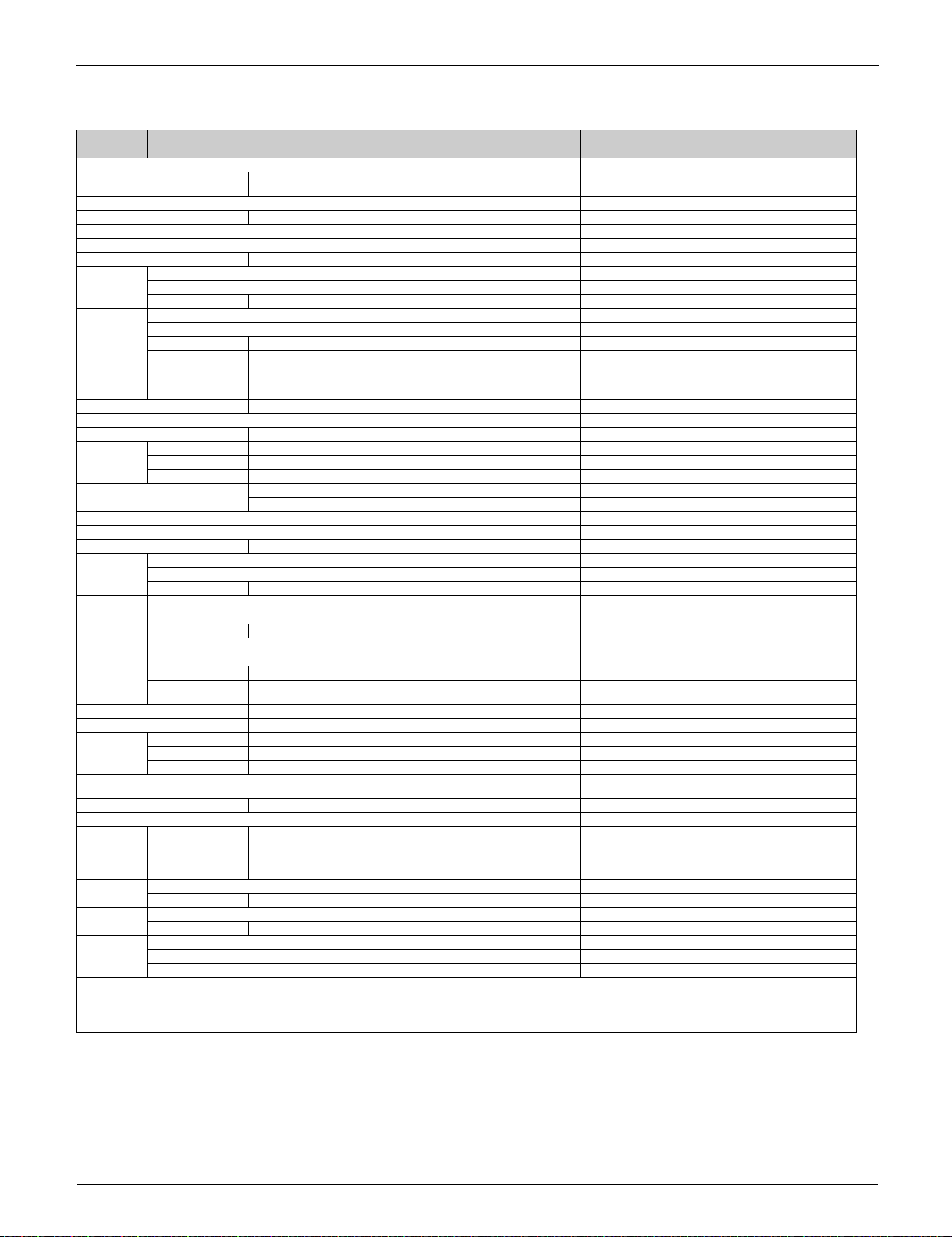

3.1.1 Ceiling Mounted Cassette Type (Round Flow with Sensing)

Model

name

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

SEER (Rated) 18.6 18.5

EER (Rated) Btu/h∙W 13.0 12.0

Indoor unit FCQ18TAVJU FCQ24TAVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 10–1/16 × 33–1/16 × 33–1/16 (256 × 840 × 840) 10–1/16 × 33–1/16 × 33–1/16 (256 × 840 × 840)

Coil Type Cross fin coil Cross fin coil

Fan Model QTS48C15M QTS48C15M

Sound pressure level (H/M/L) dB (A) 35.5/32.0/28.0 36.0/32.0/28.0

Air filter ——

Weight lbs (kg) 63 (28.5) 63 (28.5)

Connecting

Pipes

Remote controller

(option)

Decoration

panels

(option)

Outdoor unit RZR18TAVJU RZR24TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 39 × 37 × 12–5/8 (990 × 940 × 320) 39 × 37 × 12–5/8 (990 × 940 × 320)

Coil Type Cross fin coil Cross fin coil

Compressor Model 2YC63ABXDD 2YC63ABXDD

Fan Model P51J11F P51J11F

Weight lbs (kg) 172 (78) 172 (78)

Sound pressure level dB(A) 61 61

Connecting

Pipes

Safety devices High pressure switch, Outdoor fan driver overload

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Refrigerant Model R-410A R-410A

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Indoor unit FCQ18TAVJU FCQ24TAVJU

Outdoor unit RZR18TAVJU RZR24TAVJU

(kW)

Rows×Stages×FPI 3 × (12 + 15 × 2) × (20 + 21 × 2) 3 × (12 + 15 × 2) × (20 + 21 × 2)

Face area ft² (m

Type Turbo fan Turbo fan

Motor output W 48 48

Airflow rate (H/M/L) cfm

External static

pressure

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless — —

Model BYCQ125B–W1 / BYCQ125BGW1 BYCQ125B–W1 / BYCQ125BGW1

Color Fresh white Fresh white

Dimensions:

(H×W×D)

Air filter Resin net (with mold resistance) Resin net (With mold resistance)

Weight lbs (kg) 12.2 (5.5) / 22.1 (10.0) 12.2 (5.5) / 22.1 (10.0)

Rows×Stages×FPI 2 × 44 × 19 2 × 44 × 19

Face area ft² (m

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 1.9 1.9

Type Propeller fan Propeller fan

Motor output W 200 200

Airflow rate cfm

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 164 (50) 164 (50)

Max. height

difference

Charge lbs (kg) 6.4 (2.9) 6.4 (2.9)

Charge L 1.08 1.08

Specification C: 4D115509 C: 4D115509

Sound (indoor) C: 4D087483B C: 4D087474B

Sound (outdoor) C: 4D101948E C: 4D101948E

2

) 4.59 (0.427) 4.59 (0.427)

3

/min)

(m

O

inH

2

(Pa)

in (mm) 2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

2

) 9.5 (0.88) 9.5 (0.88)

3

/min)

(m

protector, Inverter overload protector, Fusible plugs, Fuse

ft (m)

(50 × 950 × 950 / 130 × 950 × 950)

18,000 (5.3) 24,000 (7.0)

742/618/477 (21.0/17.5/13.5) 777/618/477 (22.0/17.5/13.5)

——

2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

(50 × 950 × 950 / 130 × 950 × 950)

2,682 (76) 2,682 (76)

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

98 (30) 98 (30)

Part 1 General Information 15

Specifications SiUS281811E

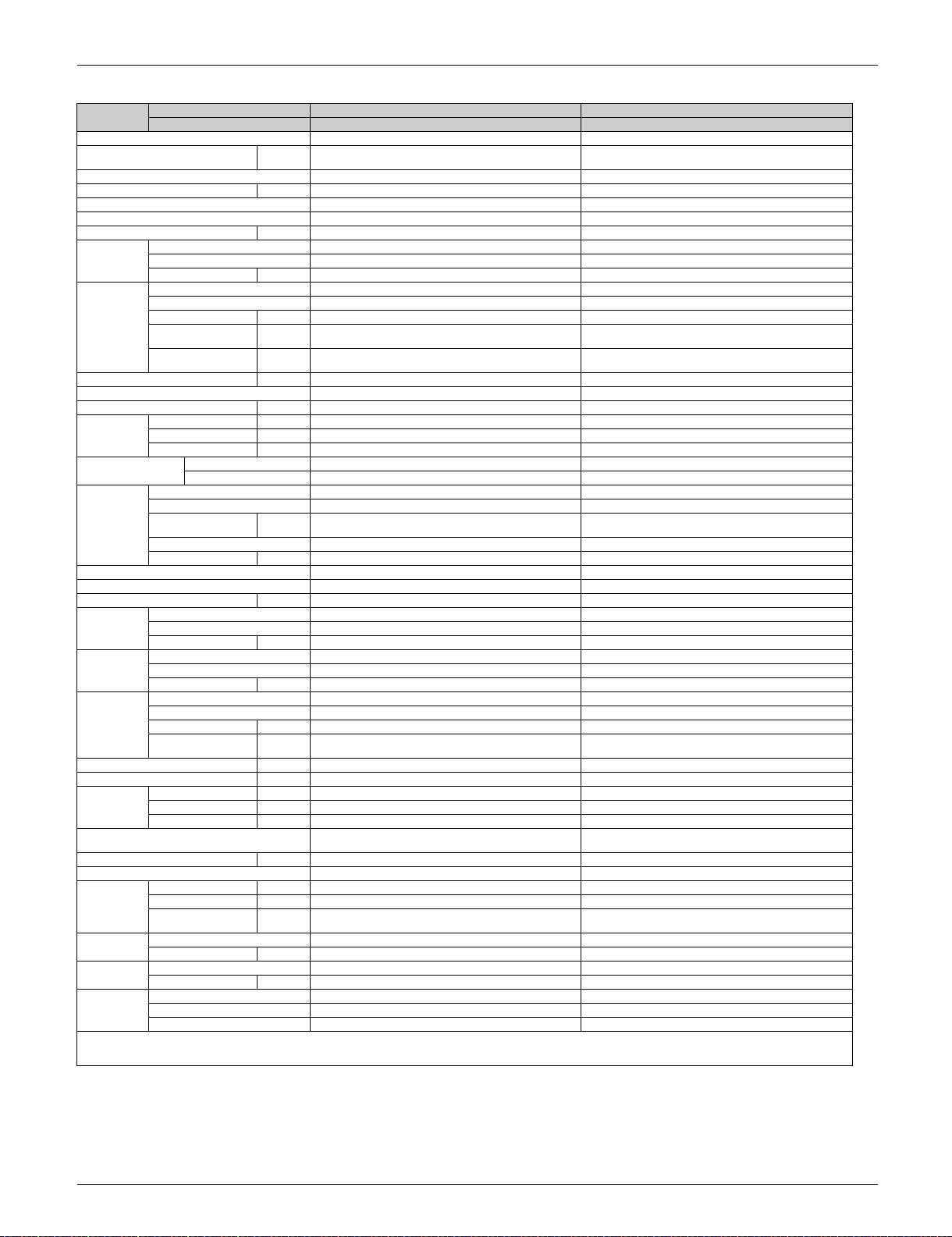

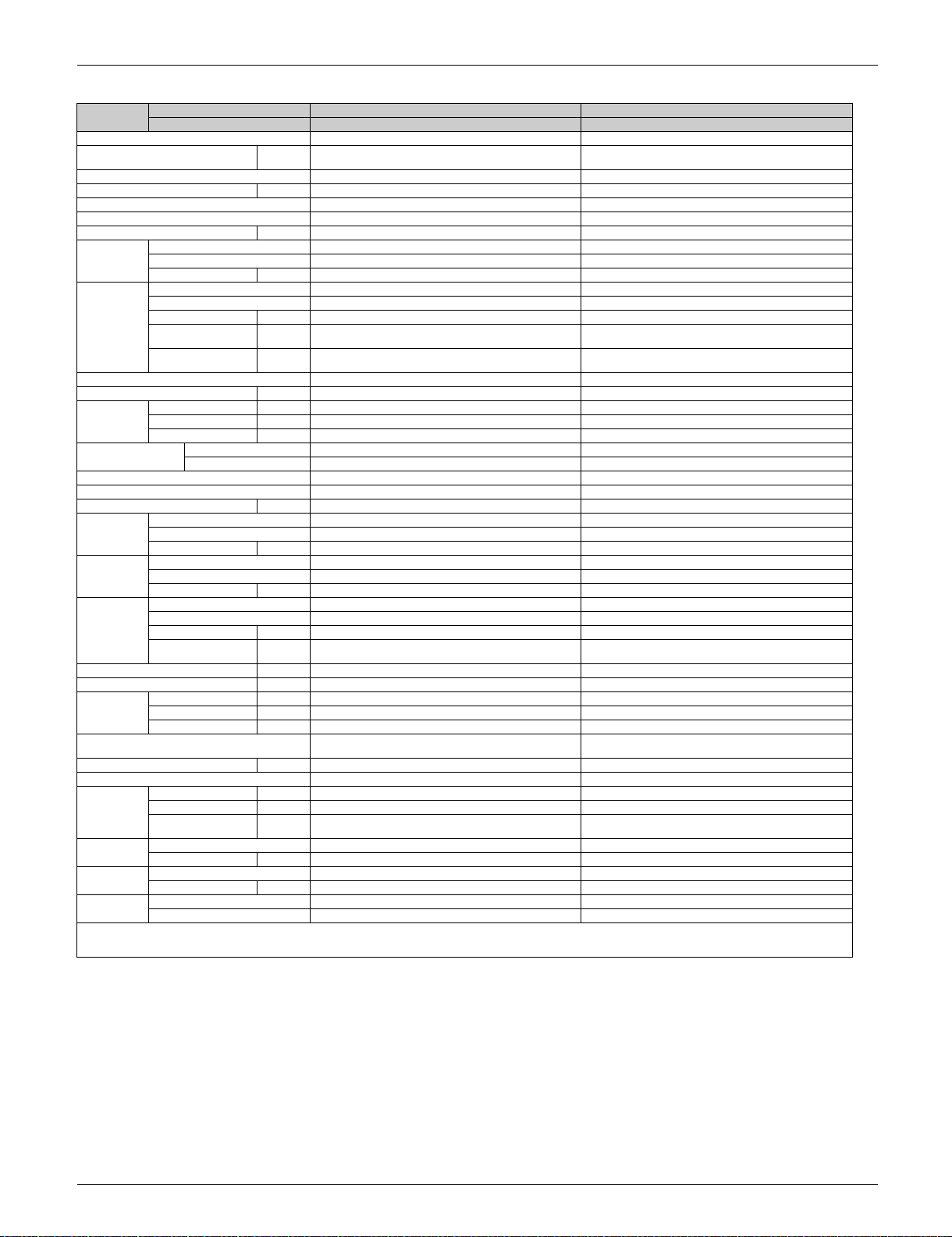

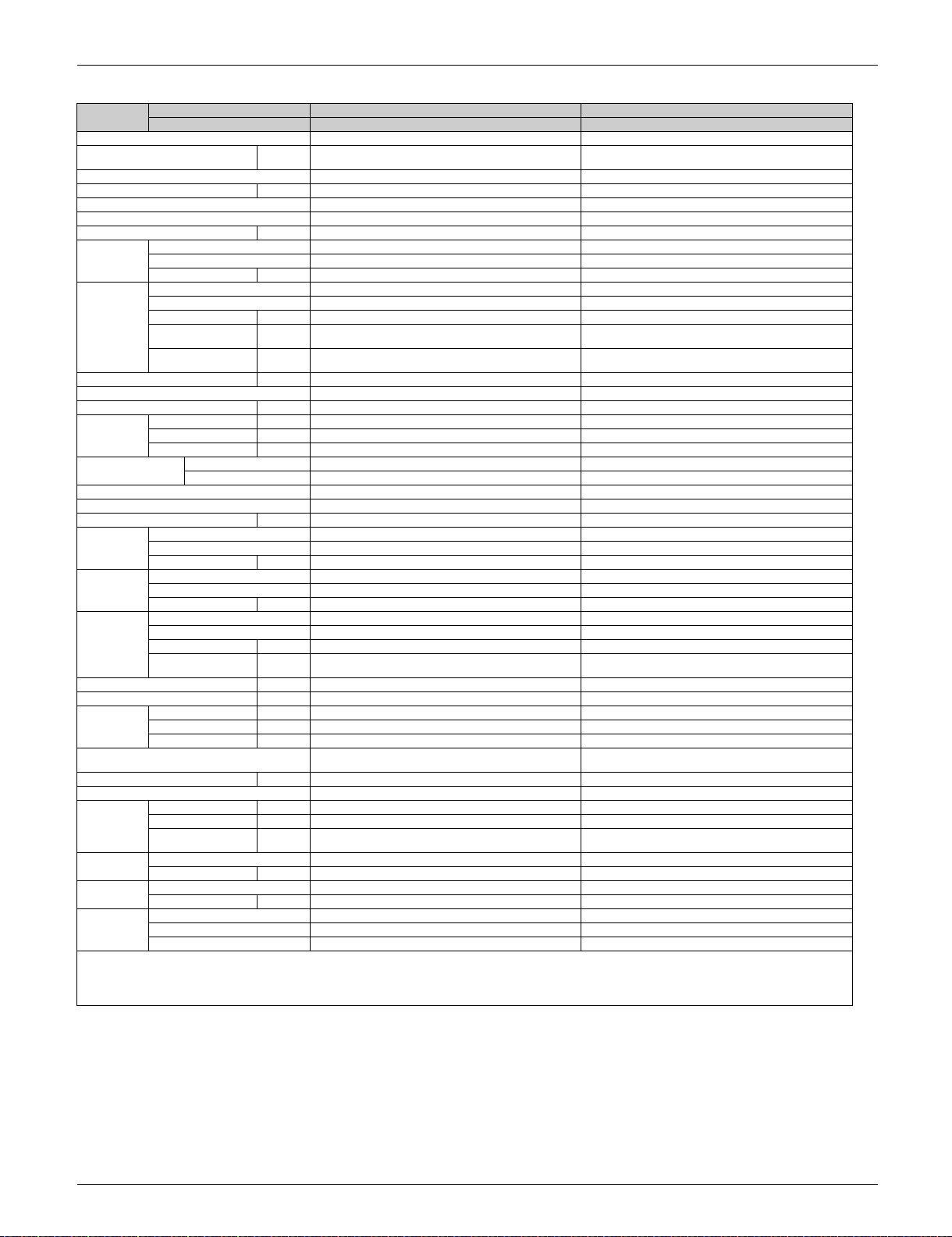

Model

name

Indoor unit FCQ30TAVJU FCQ36TAVJU

Outdoor unit RZR30TAVJU RZR36TAVJU

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

30,000 (8.8) 36,000 (10.6)

SEER (Rated) 17.2 17.6

EER (Rated) Btu/h∙W 9.3 11.4

Indoor unit FCQ30TAVJU FCQ36TAVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 11–23/32 × 33–1/16 × 33–1/16 (298 × 840 × 840) 11–23/32 × 33–1/16 × 33–1/16 (298 × 840 × 840)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 3 × 18 × (20 + 21 × 2) 3 × 18 × (20 + 21 × 2)

Face area ft² (m

2

) 5.92 (0.550) 5.92 (0.550)

Fan Model QTS48C15M QTS48C15M

Type Turbo fan Turbo fan

Motor output W 106 106

Airflow rate (H/M/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

1,112/918/671 (31.5/26.0/19.0) 1,165/918/671 (33.0/26.0/19.0)

——

Sound pressure level (H/M/L) dB(A) 43.5/38.0/32.0 44.0/38.0/32.0

Air filter ——

Weight lbs (kg) 70 (31.5) 70 (31.5)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Remote controller

(option)

Decoration

panels

(option)

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless — —

Model BYCQ125B–W1 / BYCQ125BGW1 BYCQ125B–W1 / BYCQ125BGW1

Color Fresh white Fresh white

Dimensions:

(H×W×D)

in (mm) 2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

(50 × 950 × 950 / 130 × 950 × 950)

2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

(50 × 950 × 950 / 130 × 950 × 950)

Air filter Resin net (with mold resistance) Resin net (with mold resistance)

Weight lbs (kg) 12.2 (5.5) / 22.1 (10.0) 12.2 (5.5) / 22.1 (10.0)

Outdoor unit RZR30TAVJU RZR36TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 60 × 19 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134) 12.2 (1.134)

Compressor Model 2YC90GXD#D 2YC90GXD#D

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 3.5 3.5

Fan Model P47N P47N

Type Propeller fan Propeller fan

Motor output W 70 × 2 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106) 3,741 (106)

Weight lbs (kg) 225 (102) 225 (102)

Sound pressure level dB(A) 59 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 230 (70) 230 (70)

Max. height

difference

ft (m)

98 (30) 98 (30)

Refrigerant Model R-410A R-410A

Charge lbs (kg) 7.9 (3.6) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Charge L 1.52 1.52

Drawing

No

Specification C: 4D115511 C: 4D115511

Sound (indoor) C: 4D087479B C: 4D087475B

Sound (outdoor) C: 4D101950E C: 4D101950E

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

16 Part 1 General Information

SiUS281811E Specifications

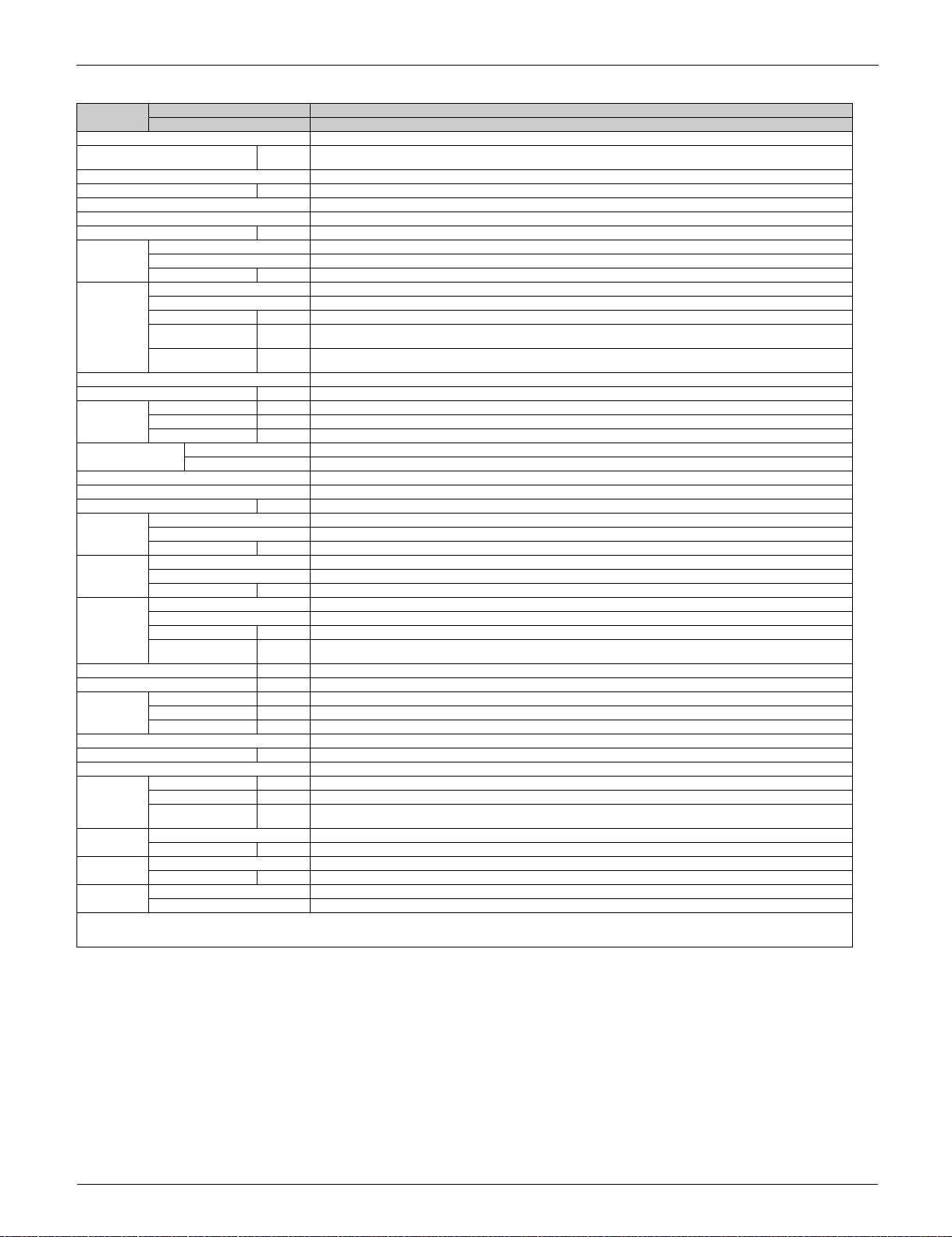

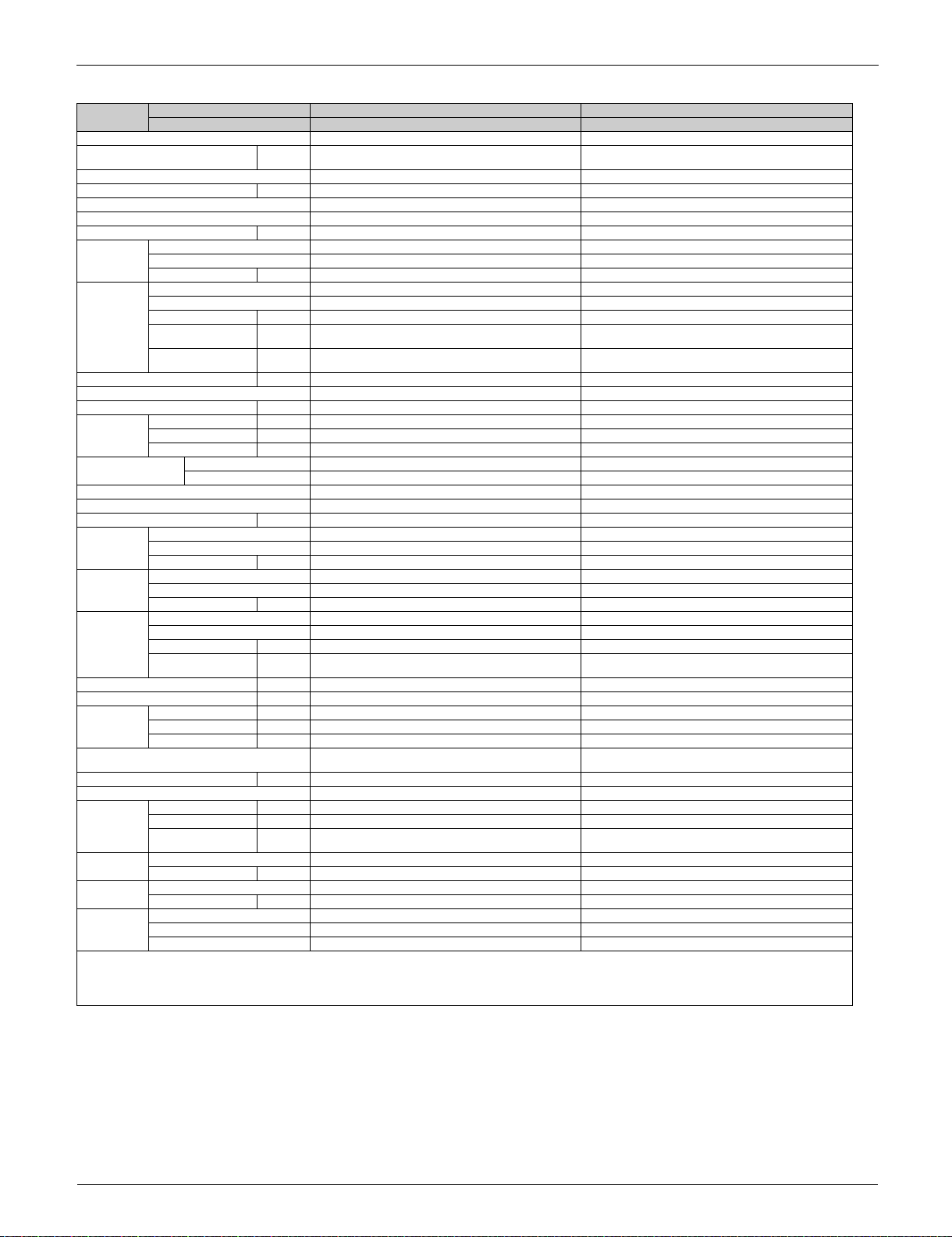

Model

name

Indoor unit FCQ42TAVJU FCQ48TAVJU

Outdoor unit RZR42TAVJU RZR48TAVJU

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

42,000 (12.3) 48,000 (14.1)

SEER (Rated) 17.0 17.0

EER (Rated) Btu/h∙W 10.3 9.0

Indoor unit FCQ42TAVJU FCQ48TAVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 11–23/32 × 33–1/16 × 33–1/16 (298 × 840 × 840) 11–23/32 × 33–1/16 × 33–1/16 (298 × 840 × 840)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 3 × 18 × (20 + 21 × 2) 3 × 18 × (20 + 21 × 2)

Face area ft² (m

2

) 5.92 (0.550) 5.92 (0.550)

Fan Model QTS48C15M QTS48C15M

Type Turbo fan Turbo fan

Motor output W 106 106

Airflow rate (H/M/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

1,218/971/742 (34.5/27.5/21.0) 1,218/971/742 (34.5/27.5/21.0)

——

Sound pressure level (H/M/L) dB(A) 45.0/40.0/35.0 45.0/40.0/35.0

Air filter ——

Weight lbs (kg) 70 (31.5) 70 (31.5)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Remote controller

(option)

Decoration

panels

(option)

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless — —

Model BYCQ125B–W1 / BYCQ125BGW1 BYCQ125B–W1 / BYCQ125BGW1

Color Fresh white Fresh white

Dimensions:

(H×W×D)

in (mm) 2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

(50 × 950 × 950 / 130 × 950 × 950)

2 × 37–3/8 × 37–3/8 / 5–1/8 × 37–3/8 × 37–3/8

(50 × 950 × 950 / 130 × 950 × 950)

Air filter Resin net (with mold resistance) Resin net (with mold resistance)

Weight lbs (kg) 12.2 (5.5) / 22.1 (10.0) 12.2 (5.5) / 22.1 (10.0)

Outdoor unit RZR42TAVJU RZR48TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 60 × 19 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134) 12.2 (1.134)

Compressor Model 2YC90GXD#D 2YC90GXD#D

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 3.5 3.5

Fan Model P47N P47N

Type Propeller fan Propeller fan

Motor output W 70 × 2 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106) 3,741 (106)

Weight lbs (kg) 225 (102) 225 (102)

Sound pressure level dB(A) 59 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 230 (70) 230 (70)

Max. height

difference

ft (m)

98 (30) 98 (30)

Refrigerant Model R-410A R-410A

Charge lbs (kg) 7.9 (3.6) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Charge L 1.52 1.52

Drawing

No

Specification C: 4D115511 C: 4D115511

Sound (indoor) C: 4D087476B C: 4D087476B

Sound (outdoor) C: 4D101950E C: 4D101950E

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Part 1 General Information 17

Specifications SiUS281811E

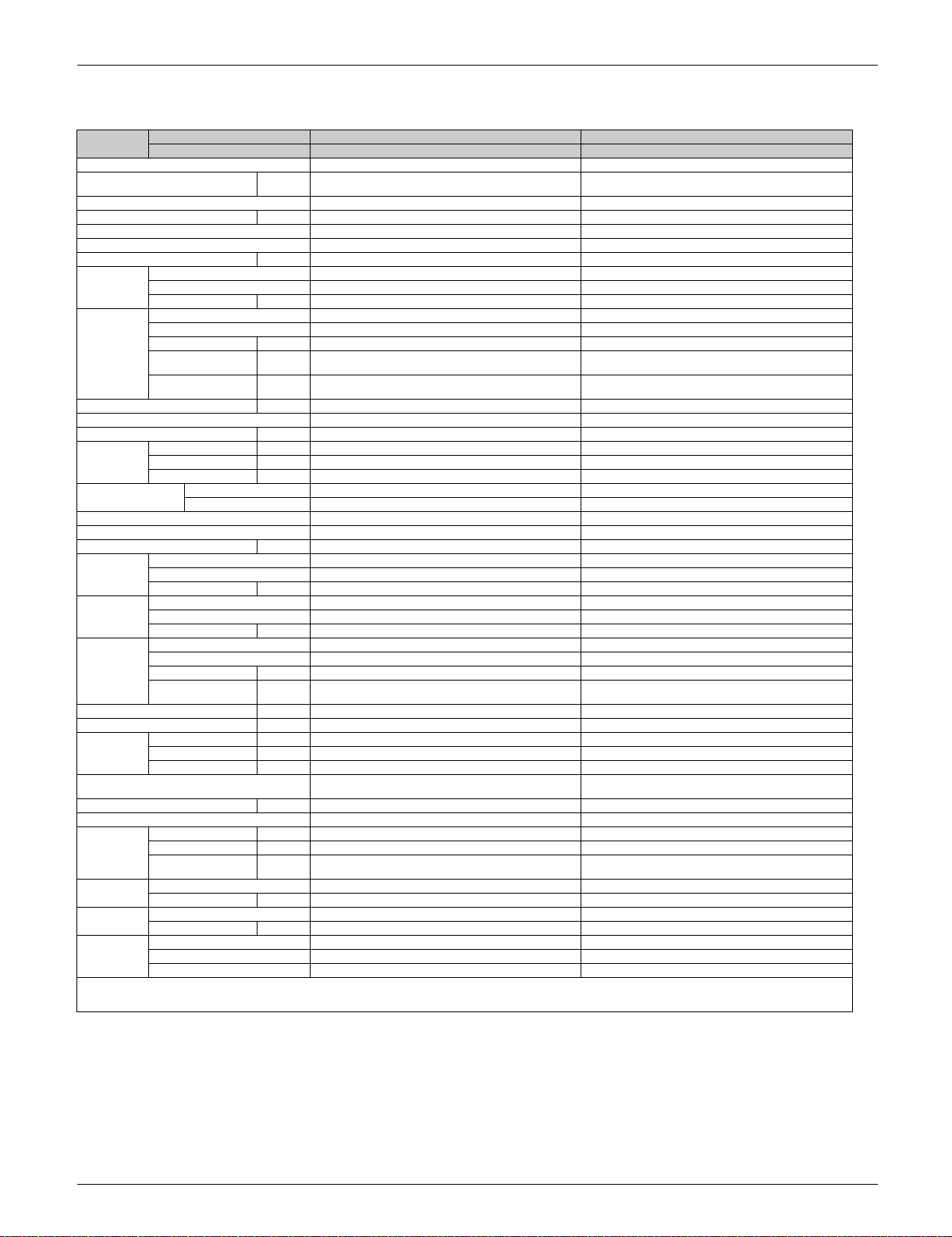

3.1.2 Ceiling Suspended Type

Model

name

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

SEER (Rated) 16.3 16.6

EER (Rated) Btu/h∙W 12.9 11.3

Indoor unit FHQ18PVJU FHQ24PVJU

Casing color White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) in (mm) 7–11/16 × 62–5/8 × 26–3/4 (195 × 1,590 × 680) 7–11/16 × 62–5/8 × 26–3/4 (195 × 1,590 × 680)

Coil Type Cross fin coil Cross fin coil

Fan Model — —

Air filter Resin net (with mold resistance) Resin net (with mold resistance)

Weight lbs (kg) 90 (19.8) 90 (19.8)

Connecting

Pipes

Remote controller

(option)

Outdoor unit RZR18TAVJU RZR24TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 39 × 37 × 12–5/8 (990 × 940 × 320) 39 × 37 × 12–5/8 (990 × 940 × 320)

Coil Type Cross fin coil Cross fin coil

Compressor Model 2YC63ABXDD 2YC63ABXDD

Fan Model P51J11F P51J11F

Weight lbs (kg) 172 (78) 172 (78)

Sound pressure level dB(A) 61 61

Connecting

Pipes

Safety devices High pressure switch, Outdoor fan driver overload

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Refrigerant Model R-410A R-410A

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Indoor unit FHQ18PVJU FHQ24PVJU

Outdoor unit RZR18TAVJU RZR24TAVJU

(kW)

Rows×Stages×FPI 2 × 12 × 15 + 2 × 10 × 15 2 × 12 × 15 + 2 × 10 × 15

Face area ft² (m

Type Sirocco fan Sirocco fan

Motor output W 130 130

Airflow rate (H/L) cfm

External static

pressure

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP20 (External dia. 1 (26), internal dia. 3/4 (19.1)) VP20 (External dia. 1 (26), internal dia. 3/4 (19.1))

Wired BRC1E73 BRC1E73

Wireless BRC7E83 BRC7E83

Rows×Stages×FPI 2 × 44 × 19 2 × 44 × 19

Face area ft² (m

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 1.9 1.9

Type Propeller fan Propeller fan

Motor output W 200 200

Airflow rate cfm

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 164 (50) 164 (50)

Max. height

difference

Charge lbs (kg) 6.4 (2.9) 6.4 (2.9)

Charge L 1.08 1.08

Specification C: 4D115558A C: 4D115558A

Sound (outdoor) C: 4D101948E C: 4D101948E

2

) 3.66 (0.34) + 2.95 (0.27) 3.66 (0.34) + 2.95 (0.27)

3

/min)

(m

inH

O

2

(Pa)

2

) 9.5 (0.88) 9.5 (0.88)

3

/min)

(m

protector, Inverter overload protector, Fusible plugs, Fuse

ft (m)

18,000 (5.3) 24,000 (7.0)

790/670 (22.4/19.0) 790/670 (22.4/19.0)

——

2,682 (76) 2,682 (76)

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

98 (30) 98 (30)

18 Part 1 General Information

SiUS281811E Specifications

Model

name

Indoor unit FHQ30PVJU FHQ36MVJU

Outdoor unit RZR30TAVJU RZR36TAVJU

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

30,000 (8.8) 36,000 (10.6)

SEER (Rated) 16.0 14.0

EER (Rated) Btu/h∙W 10.5 9.5

Indoor unit FHQ30PVJU FHQ36MVJU

Casing color White (10Y9/0.5) White (10Y9/0.5)

Dimensions: (H×W×D) in (mm) 7–11/16 × 62–5/8 × 26–3/4 (195 × 1,590 × 680) 7–11/16 × 62–5/8 × 26–3/4 (195 × 1,590 × 680)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 12 × 15 + 2 × 10 × 15 2 × 12 × 15 + 2 × 10 × 15

Face area ft² (m

2

) 3.66 (0.34) + 2.95 (0.27) 3.66 (0.34) + 2.95 (0.27)

Fan Model — —

Type Sirocco fan Sirocco fan

Motor output W 130 130

Airflow rate (H/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

790/670 (22.4/19.0) 830/670 (23.5/19.0)

——

Air filter Resin net (with mold resistance) Resin net (with mold resistance)

Weight lbs (kg) 90 (19.8) 90 (19.8)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP20 (External dia. 1 (26), internal dia. 3/4 (19.1)) VP20 (External dia. 1 (26), internal dia. 3/4 (19.1))

Remote controller

(option)

Wired BRC1E73 BRC1E73

Wireless BRC7E83 BRC7E83

Outdoor unit RZR30TAVJU RZR36TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 60 × 19 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134) 12.2 (1.134)

Compressor Model 2YC90GXD#D 2YC90GXD#D

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 3.5 3.5

Fan Model P47N P47N

Type Propeller fan Propeller fan

Motor output W 70 × 2 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106) 3,741 (106)

Weight lbs (kg) 225 (102) 225 (102)

Sound pressure level dB(A) 59 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 230 (70) 230 (70)

Max. height

difference

ft (m)

98 (30) 98 (30)

Refrigerant Model R-410A R-410A

Charge lbs (kg) 7.9 (3.6) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Charge L 1.52 1.52

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Specification C: 4D115560A C: 4D115560A

Sound (outdoor) C: 4D101950E C: 4D101950E

Part 1 General Information 19

Specifications SiUS281811E

Model

name

Indoor unit FHQ42MVJU

Outdoor unit RZR42TAVJU

Power supply 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

40,500 (11.9)

SEER (Rated) 14.0

EER (Rated) Btu/h∙W 8.8

Indoor unit FHQ42MVJU

Casing color White (10Y9/0.5)

Dimensions: (H×W×D) in (mm) 7–11/16 × 62–5/8 × 26–3/4 (195 × 1,590 × 680)

Coil Type Cross fin coil

Rows×Stages×FPI 2 × 12 × 15 + 2 × 10 × 15

Face area ft² (m

2

) 3.66 (0.34) + 2.95 (0.27)

Fan Model —

Type Sirocco fan

Motor output W 130

Airflow rate (H/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

850/700 (24.1/19.8)

—

Air filter Resin net (with mold resistance)

Weight lbs (kg) 90 (19.8)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP20 (External dia. 1 (26), internal dia. 3/4 (19.1))

Remote controller

(option)

Wired BRC1E73

Wireless BRC7E83

Outdoor unit RZR42TAVJU

Casing color Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil

Rows×Stages×FPI 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134)

Compressor Model 2YC90GXD#D

Type Hermetically sealed swing type

Motor output kW 3.5

Fan Model P47N

Type Propeller fan

Motor output W 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106)

Weight lbs (kg) 225 (102)

Sound pressure level dB(A) 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100

Refrigerant control Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6)

Max. length ft (m) 230 (70)

Max. height

difference

ft (m)

98 (30)

Refrigerant Model R-410A

Charge lbs (kg) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K

Charge L 1.52

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Specification C: 4D115560A

Sound (outdoor) C: 4D101950E

20 Part 1 General Information

SiUS281811E Specifications

3.1.3 Wall Mounted Type

Model

name

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

SEER (Rated) 17.0 17.6

EER (Rated) Btu/h∙W 11.9 10.2

Indoor unit FAQ18TAVJU FAQ24TAVJU

Casing color White (3.0Y8.5/0.5) White (3.0Y8.5/0.5)

Dimensions: (H×W×D) in (mm) 11–3/8 × 41–3/8 × 9-1/4 (290 × 1,050 × 238) 11–3/8 × 41–3/8 × 9-1/4 (290 × 1,050 × 238)

Coil Type Cross fin coil Cross fin coil

Fan Model QCL9686M QCL9686M

Sound pressure level (H/L) dB(A) 43.0/37.0 47.0/41.0

Air filter Resin net (washable) Resin net (washable)

Weight lbs (kg) 31 (14) 31 (14)

Connecting

Pipes

Remote controller

(option)

Outdoor unit RZR18TAVJU RZR24TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 39 × 37 × 12–5/8 (990 × 940 × 320) 39 × 37 × 12–5/8 (990 × 940 × 320)

Coil Type Cross fin coil Cross fin coil

Compressor Model 2YC63ABXDD 2YC63ABXDD

Fan Model P51J11F P51J11F

Weight lbs (kg) 172 (78) 172 (78)

Sound pressure level dB(A) 61 61

Connecting

Pipes

Safety devices High pressure switch, Outdoor fan driver overload

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Refrigerant Model R-410A R-410A

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

Indoor unit FAQ18TAVJU FAQ24TAVJU

Outdoor unit RZR18TAVJU RZR24TAVJU

(kW)

Rows×Stages×FPI 2 × 14 × 7 2 × 14 × 7

Face area ft² (m

Type Cross flow fan Cross flow fan

Motor output W 43 43

Airflow rate (H/L) cfm

External static

pressure

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP13 (External dia. 11/16 (18), internal dia. 1/2 (13)) VP13 (External dia. 11/16 (18), internal dia. 1/2 (13))

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless BRC7E818 BRC7E818

Rows×Stages×FPI 2 × 44 × 19 2 × 44 × 19

Face area ft² (m

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 1.9 1.9

Type Propeller fan Propeller fan

Motor output W 200 200

Airflow rate cfm

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 164 (50) 164 (50)

Max. height

difference

Charge lbs (kg) 6.4 (2.9) 6.4 (2.9)

Charge L 1.08 1.08

Specification C: 4D115552A C: 4D115552A

Sound (indoor) C: 4D075583A C: 4D075584A

Sound (outdoor) C: 4D101948E C: 4D101948E

2

) 1.73 (0.16) 1.73 (0.16)

3

/min)

(m

inH

O

2

(Pa)

2

) 9.5 (0.88) 9.5 (0.88)

3

/min)

(m

protector, Inverter overload protector, Fusible plugs, Fuse

ft (m)

18,000 (5.3) 24,000 (7.0)

500/400 (14/11) 635/470 (18/13)

——

2,682 (76) 2,682 (76)

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

98 (30) 98 (30)

Part 1 General Information 21

Specifications SiUS281811E

3.1.4 Ceiling Mounted Duct Type (High Static Pressure)

Model

name

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

SEER (Rated) 16.7 16.5

EER (Rated) Btu/h∙W 13.0 12.0

Indoor unit FBQ18PVJU FBQ24PVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 11–13/16 × 39–3/8 × 27–9/16 (300 × 1,000 × 700) 11–13/16 × 39–3/8 × 27–9/16 (300 × 1,000 × 700)

Coil Type Cross fin coil Cross fin coil

Fan Model — —

Sound pressure level (HH/H/L) dB(A) 41.0/39.0/37.0 42.0/40.0/38.0

Air filter — 4— 4

Weight lbs (kg) 80 (36) 80 (36)

Connecting

Pipes

Remote controller (option) Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Outdoor unit RZR18TAVJU RZR24TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 39 × 37 × 12–5/8 (990 × 940 × 320) 39 × 37 × 12–5/8 (990 × 940 × 320)

Coil Type Cross fin coil Cross fin coil

Compressor Model 2YC63ABXDD 2YC63ABXDD

Fan Model P51J11F P51J11F

Weight lbs (kg) 172 (78) 172 (78)

Sound pressure level dB(A) 61 61

Connecting

Pipes

Safety devices High pressure switch, Outdoor fan driver overload protector,

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Refrigerant Model R-410A R-410A

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Drawing

No

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

3 External static pressure is changeable in 14 stages within the < > range by remote controller.

4 Air filter is not standard accessory, but please mount it in the duct system of the suction side. Select its dust collection efficiency (gravity method) 50% or more.

Indoor unit FBQ18PVJU FBQ24PVJU

Outdoor unit RZR18TAVJU RZR24TAVJU

(kW)

Rows×Stages×FPI 3 × 16 × 15 3 × 16 × 15

Face area ft² (m

Type Sirocco fan Sirocco fan

Motor output W 350 350

Airflow rate (H/M/L) cfm

External static

pressure

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Rows×Stages×FPI 2 × 44 × 19 2 × 44 × 19

Face area ft² (m

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 1.9 1.9

Type Propeller fan Propeller fan

Motor output W 200 200

Airflow rate cfm

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 164 (50) 164 (50)

Max. height

difference

Charge lbs (kg) 6.4 (2.9) 6.4 (2.9)

Charge L 1.08 1.08

Specification C: 4D115554 C: 4D115554

Sound (indoor) C: 4D075278 C: 4D075279

Sound (outdoor) C: 4D101948E C: 4D101948E

2

) 2.68 (0.249) 2.68 (0.249)

3

/min)

(m

inH

O

2

(Pa)

Wireless BRC4C82, BRC082A43 BRC4C82, BRC082A43

2

) 9.5 (0.88) 9.5 (0.88)

3

/min)

(m

ft (m)

Standard 0.40 <0.80-0.20> (100 <200-50>) 3 Standard 0.40 <0.80-0.20> (100 <200-50>) 3

Inverter overload protector, Fusible plugs, Fuse

18,000 (5.3) 24,000 (7.0)

635/582/529 (18.0/16.5/15.0) 688/618/565 (19.5/17.5/16.0)

2,682 (76) 2,682 (76)

High pressure switch, Outdoor fan driver overload protector,

Inverter overload protector, Fusible plugs, Fuse

98 (30) 98 (30)

22 Part 1 General Information

SiUS281811E Specifications

Model

name

Indoor unit FBQ30PVJU FBQ36PVJU

Outdoor unit RZR30TAVJU RZR36TAVJU

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

30,000 (8.8) 36,000 (10.6)

SEER (Rated) 16.0 17.5

EER (Rated) Btu/h∙W 10.5 11.1

Indoor unit FBQ30PVJU FBQ36PVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 11–13/16 × 39–3/8 × 27–9/16 (300 × 1,000 × 700) 11–13/16 × 55–1/8 × 27–9/16 (300 × 1,400 × 700)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 3 × 16 × 15 3 × 16 × 15

Face area ft² (m

2

) 2.68 (0.249) 4.12 (0.383)

Fan Model — —

Type Sirocco fan Sirocco fan

Motor output W 350 350

Airflow rate (H/M/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

882/794/706 (25.0/22.0/20.0) 1,130/953/812 (32.0/27.0/23.0)

Standard 0.40 <0.80-0.20> (100 <200-50>) 3 Standard 0.40 <0.80-0.20> (100 <200-50>) 3

Sound pressure level (HH/H/L) dB(A) 43.0/41.0/39.0 43.0/41.0/39.0

Air filter — 4— 4

Weight lbs (kg) 80 (36) 102 (46)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Remote controller

(option)

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless BRC4C82, BRC082A43 BRC4C82, BRC082A43

Outdoor unit RZR30TAVJU RZR36TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 60 × 19 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134) 12.2 (1.134)

Compressor Model 2YC90GXD#D 2YC90GXD#D

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 3.5 3.5

Fan Model P47N P47N

Type Propeller fan Propeller fan

Motor output W 70 × 2 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106) 3,741 (106)

Weight lbs (kg) 225 (102) 225 (102)

Sound pressure level dB(A) 59 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 230 (70) 230 (70)

Max. height

difference

ft (m)

98 (30) 98 (30)

Refrigerant Model R-410A R-410A

Charge lbs (kg) 7.9 (3.6) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Charge L 1.52 1.52

Drawing

No

Specification C: 4D115556A C: 4D115556A

Sound (indoor) C: 4D075280 C: 4D075281

Sound (outdoor) C: 4D101950E C: 4D101950E

Notes:

1 Indoor temp. : 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / outdoor temp. : 95°FDB (35.0°CDB) / Equivalent piping length : 25 ft (7.6m), level difference : 0 ft (0m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

3 External static pressure is changeable in 14 stages within the < > range by remote controller.

4 Air filter is not standard accessory, but please mount it in the duct system of the suction side. Select its dust collection efficiency (gravity method) 50% or more.

Part 1 General Information 23

Specifications SiUS281811E

Model

name

Indoor unit FBQ42PVJU FBQ48PVJU

Outdoor unit RZR42TAVJU RZR48TAVJU

Power supply 1 phase, 208/230 V, 60 Hz 1 phase, 208/230 V, 60 Hz

1 2 Cooling capacity Btu/h

(kW)

40,500 (11.9) 48,000 (14.1)

SEER (Rated) 16.0 14.0

EER (Rated) Btu/h∙W 10.1 8.6

Indoor unit FBQ42PVJU FBQ48PVJU

Casing color Galvanized steel plate Galvanized steel plate

Dimensions: (H×W×D) in (mm) 11–13/16 × 55–1/8 × 27–9/16 (300 × 1,400 × 700) 11–13/16 × 55–1/8 × 27–9/16 (300 × 1,400 × 700)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 3 × 16 × 15 3 × 16 × 15

Face area ft² (m

2

) 4.12 (0.383) 4.12 (0.383)

Fan Model — —

Type Sirocco fan Sirocco fan

Motor output W 350 350

Airflow rate (H/M/L) cfm

External static

pressure

(m

inH

(Pa)

3

/min)

2

O

1,400/1,165/988 (39.6/33.0/28.0) 1,400/1,165/988 (39.6/33.0/28.0)

Standard 0.40 <0.80-0.20> (100 <200-50>) 3 Standard 0.40 <0.80-0.20> (100 <200-50>) 3

Sound pressure level (HH/H/L) dB(A) 44.0/42.0/40.0 44.0/42.0/40.0

Air filter — 4— 4

Weight lbs (kg) 102 (46) 102 (46)

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26)) VP25 (External dia. 1–1/4 (32), internal dia. 1 (26))

Remote controller

(option)

Wired BRC1E73, BRC2A71 BRC1E73, BRC2A71

Wireless BRC4C82, BRC082A43 BRC4C82, BRC082A43

Outdoor unit RZR42TAVJU RZR48TAVJU

Casing color Ivory white Ivory white

Dimensions: (H×W×D) in (mm) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320) 52–15/16 × 35–7/16 × 12–5/8 (1,345 × 900 × 320)

Coil Type Cross fin coil Cross fin coil

Rows×Stages×FPI 2 × 60 × 19 2 × 60 × 19

Face area ft² (m

2

) 12.2 (1.134) 12.2 (1.134)

Compressor Model 2YC90GXD#D 2YC90GXD#D

Type Hermetically sealed swing type Hermetically sealed swing type

Motor output kW 3.5 3.5

Fan Model P47N P47N

Type Propeller fan Propeller fan

Motor output W 70 × 2 70 × 2

Airflow rate cfm

(m

3

/min)

3,741 (106) 3,741 (106)

Weight lbs (kg) 225 (102) 225 (102)

Sound pressure level dB(A) 59 59

Connecting

Pipes

Liquid Pipe in (mm) 3/8 (9.5) (Flare connection) 3/8 (9.5) (Flare connection)

Gas Pipe in (mm) 5/8 (15.9) (Flare connection) 5/8 (15.9) (Flare connection)

Drain Pipe in (mm) 1 (26) (Hole) 1 (26) (Hole)

Safety devices High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

High pressure switch, Outdoor fan driver overload

protector, Inverter overload protector, Fusible plugs, Fuse

Capacity Control % 14-100 14-100

Refrigerant control Electronic expansion valve Electronic expansion valve

Ref.

piping

Standard length ft (m) 25 (7.6) 25 (7.6)

Max. length ft (m) 230 (70) 230 (70)

Max. height

difference

ft (m)

98 (30) 98 (30)

Refrigerant Model R-410A R-410A

Charge lbs (kg) 7.9 (3.6) 7.9 (3.6)

Ref. oil Model DAPHNE FVC50K DAPHNE FVC50K

Charge L 1.52 1.52

Drawing

No

Specification C: 4D115556A C: 4D115556A

Sound (indoor) C: 4D075282A C: 4D075282A

Sound (outdoor) C: 4D101950E C: 4D101950E

Notes:

1 Indoor temp.: 80°FDB (26.7°CDB), 67°FWB (19.4°CWB) / Outdoor temp.: 95°FDB (35.0°CDB) / Equivalent piping length: 25 ft (7.6 m), level difference: 0 ft (0 m).

2 Capacities are net, including a deduction for cooling for indoor fan motor heat.

3 External static pressure is changeable in 14 stages within the < > range by remote controller.

4 Air filter is not standard accessory, but please mount it in the duct system of the suction side. Select its dust collection efficiency (gravity method) 50% or more.

24 Part 1 General Information

Loading...