Page 1

INSTALLATION MANUAL

ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺩ

English

SPLIT SYSTEM Air Conditioner

ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟﻢﺴﻘﻨﻤﻟﺍ ﻡﺎﻈﻨﻟﺍ

MODELS

(Ceiling mounted duct type)

FBQ20EAVAK

FBQ24EAVAK

FBQ36EAVAK

FBQ45EAVAK

FBQ48EAVAK

FBQ48EAVMK

ﺯﺮﻄﻟﺍ

(ﻲﺋﺍﻮﻫ ﻯﺮﺠﻤﺑ ﺩﻭﺰﻣ ﻒﻘﺳ ﻒﻴﻴﻜﺗ)

READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

.ﺐﻴﻛﺮﺘﻟﺍ ﻞﺒﻗ ﺔﻳﺎﻨﻌﺑ ﺕﺍﺩﺎﺷﺭﻹﺍ ﻩﺬﻫ ﺃﺮﻗﺍ

.ﺪﻌﺑ ﺎﻤﻴﻓ ﻪﻴﻟﺇ ﻉﻮﺟﺮﻠﻟ ﻪﻴﻟﺇ ﻝﻮﺻﻮﻟﺍ ﻞﻬﺴﻳ ﻥﺎﻜﻣ ﻲﻓ ﻞﻴﻟﺪﻟﺍ ﺍﺬﻬﺑ ﻆﻔﺘﺣﺍ

ﺔﻴﺑﺮﻌﻟﺍ

Page 2

FBQ20EAVAK

FBQ24EAVAK

FBQ36EAVAK

FBQ45EAVAK

FBQ48EAVAK

FBQ48EAVMK

SPLIT SYSTEM Air Conditioner Installation manual

CONTENTS

1. SAFETY PRECAUTIONS...............................................................................................1

2. BEFORE INSTALLATION ..............................................................................................4

3. SELECTING INSTALLATION SITE................................................................................6

4. PREPARATIONS BEFORE INSTALLATION .................................................................7

5. INDOOR UNIT INSTALLATION .....................................................................................9

6. REFRIGERANT PIPING WORK ..................................................................................10

7. DRAIN PIPING WORK.................................................................................................13

8. DUCT WORK ...............................................................................................................15

9. ELECTRIC WIRING WORK .........................................................................................16

10. WIRING EXAMPLE AND HOW TO SET THE REMOTE CONTROLLER....................16

11. FIELD SETTING...........................................................................................................22

12. TEST OPERATION ......................................................................................................25

1. SAFETY PRECAUTIONS

Please read the these " SAFETY CONSIDERATIONS" carefully before installing air conditioning unit and

be sure to install it correctly. After completing the installation, make sure that the unit operates properly

during the start-up operation.

Please instruct the customer on how to operate the unit and keep it maintained.

Also, inform customers that they should store this installation manual along with the operation manual for

future reference.

Meaning of WARNING and CAUTION notices.

Both are important notices for safety. Be sure to follow them.

WARNING .........Failure to follow these instructions properly may result in personal injury or loss

CAUTION ..........Failure to observe these instructions properly may result in property damage or

sonal injury, which may be serious depending on the circumstances.

per

After completing installation, conduct a trial operation to check for faults and explain to the customer how to

operate the air conditioner and take care of it with the aid of the operation manual. Ask the customer to store

the installation manual along with the operation manual for future reference.

This air conditioner comes under the term “appliances not accessible to the general public”.

WARNING

• Ask your dealer or qualified personnel to carry out installation work.

Do not attempt to install the air conditioner yourself. Improper installation may result in water leakage,

electric shocks or fire.

• Install the air conditioner in accordance with the instructions in this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• When installing the unit in a small room, take measures against to keep refrigerant concentration from

exceeding allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information. Excessive refrigeran

oxygen deficiency

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in the unit falling, water leakage, electric shocks or fire.

t in a closed ambient can lead to

of life.

1 English

Page 3

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injury.

• Carry out the specified installation work after taking into account strong winds, typhoons or earthquakes.

Failure to do so during installation work may result in the unit falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is carried

out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may

• Be sure to earth the air conditioner.

Do not earth the unit to a utility pipe, lightning conductor or telephone earth lead.

Imperfect earthing may result in electric shocks or fire.

A high surge current from lightning or other sources may cause damage to the air conditioner.

• Be sure to install the earth leakage breaker.

Failure to install the earth leakage breaker may result in electric shocks or fire.

• Be sure to switch off the unit before touching any electrical parts.

Touching a live part may result in electric shock.

• Make sure that all wiring is secured, the specified wires are used, and that there is no strain on the te

connections or wires.

Improper connections or securing of wires may result in abnormal heat build-up or fire.

• When wiring the power supply and connecting the wiring between the indoor and outdoor units, position the

wires so that the control box lid can be securely fastened.

Improper positioning of the control box lid may result in electric shocks, fire or overheating terminals.

• If refrigerant gas leaks during installation, ventilate the area immediately.

Toxic gas may be produced if the refrigerant comes into contact with fire.

• After completing installation, check for refrigerant gas leakage.

Toxic gas may be produced if the refrigerant gas leaks into the room an

of fire, such as a fan heater, stove or cooker.

• Do not touch any refrigerant that leaks out of refrigerant piping joints or connections.

Touching it may cause frostbite.

Consult your local dealer regarding what to do in case of refrigerant leakage, when the air coditioner is to

•

be installed in a small room, it is necessary to take proper measures so that the amount of any leaked

refrigerant does not exceed the concentration limit in the event of leakage. Otherwise, this may lead to

an accident due to oxygen depletion.

lead to electric shocks or fire.

rminal

d comes into contact with a source

CAUTION

• While following the instructions in this installation manual, install drain piping to ensure proper drainage and

insulate piping to prevent condensation.

Improper drain piping may result in indoor water leakage and property damage.

• Install the indoor and outdoor units, power cord and connecting wires at least 1 meter away from televisions

or radios to prevent picture interference and noise.

(Depending on the incoming signal strength, a distance of 1 meter may not be sufficient to eliminate noise.)

• Install the indoor unit as far away from fluorescent lamps as possible.

Remote controller (wireless kit) transmitting distance can be shorter than expected in rooms with electronic

fluorescent lamps (inverter or rapid start types).

•

In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

•

Do not allow children to climb on the outdoor unit and avoid placing objects on the unit.

Injury may result if the unit becomes loose and falls.

•

Make sure

shelter by small animals.

Small animals making contact with electrical parts can cause malfunctions, smoke or fire. Please instruct

the customer to keep the area around the unit clean.

Install in a machine room that is free of moisture. The unit is designed for indoor use.

•

•

Disposal requirements

Dismantling of the unit, treatment of the refrigerant, of oil and of other parts must be done in

accordance with relevant local and national legislation.

to provide for adequate measure in order to prevent that the outdoor unit be used as a

English 2

Page 4

• Do not install the air conditioner in the following locations:

1. Where there is a high concentration of mineral oil spray or vapour (e.g. a kitchen).

Plastic parts will deteriorate, parts may fall off and water leakage could result.

2. Where corrosive gas, such as sulphurous acid gas, is produced. Also areas that are rich in sodium

such as seashores.

Corroding of copper pipes or soldered parts may result in refrigerant leakage.

3. Near machinery emitting electromagnetic radiation.

Electromagnetic radiation may disturb the operation of the control system and result in a malfunction

of the unit.

4. Where flammable gas may leak, where there is carbon fibre or ignitable dust suspensions in the air,

or where v

Operating the unit in such conditions may result in fire.

olatile flammables such as paint thinner or gasoline are handled.

SPECIAL NOTICE OF PRODUCT

• Refrigerant

• The refrigerant R410A requires that strict Precautions be observed for keeping the system clean,

dry and tightly sealed.

A. Clean and Dry

Strict measure must be taken to keep impurities (including SUNISO oil and other mineral oils

as well as moisture) out of the system.

B. Tightly sealed

R410A contains no chlorine, does not destroy the ozone layer and so does not reduce the earth’s

protcetion against harmful ultraviolet radiation. R410A will contribute only slightly to the greenhouse

effect if released into the almosphere

• Since design pressure is 4.0 MPa or 40 bar (for R407C units: 3.3MPa or 33bar), the thickness of

pipes must be greater than previously. Since R410A is a mixed refrigerant, the required additional

refrigerant must be charged in its liquid state. (If the system is charged with refrigerant in its gaseous

state, due to composition change, the system will not function normally). The indoor units is designed

for R410A use.

See the catalogue for indoor unit models that can be connected. (Normal operation is not possible

when connecting units that are originally designed for other refrigerants)

English3

Page 5

2. BEFORE INSTALLATION

Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

Be sure to check the type of R410A refrigerant to be used before doing any work. (Using an incorrect

refrigerant will prevent normal operation of the unit.)

• When opening the unit or moving it after opening, be sure to lift it by holding on to the lifting lugs without

exerting any pressure on other parts, especially, drain piping, and flange.

• Decide upon a line of transport.

• Leave the unit inside its packaging while moving, until reaching the installation site. Use a sling of soft

rial, where unpacking is unavoidable or protective plates together with a rope when lifting, t

mate

damage

or scratches to the unit.

• Refer to the installation manual of the outdoor unit for items not described in this manual.

• Do not dispose of any parts necessary for installation until the installation is complete.

• In order to protect the indoor unit from damage, use packing materials to protect the unit after carrying until

the installation starts.

• Do not use the unit in locations with high salt content in the air such as beachfront property, locations where

the voltage fluctuates such as factories, or in automobiles or marine vessels.

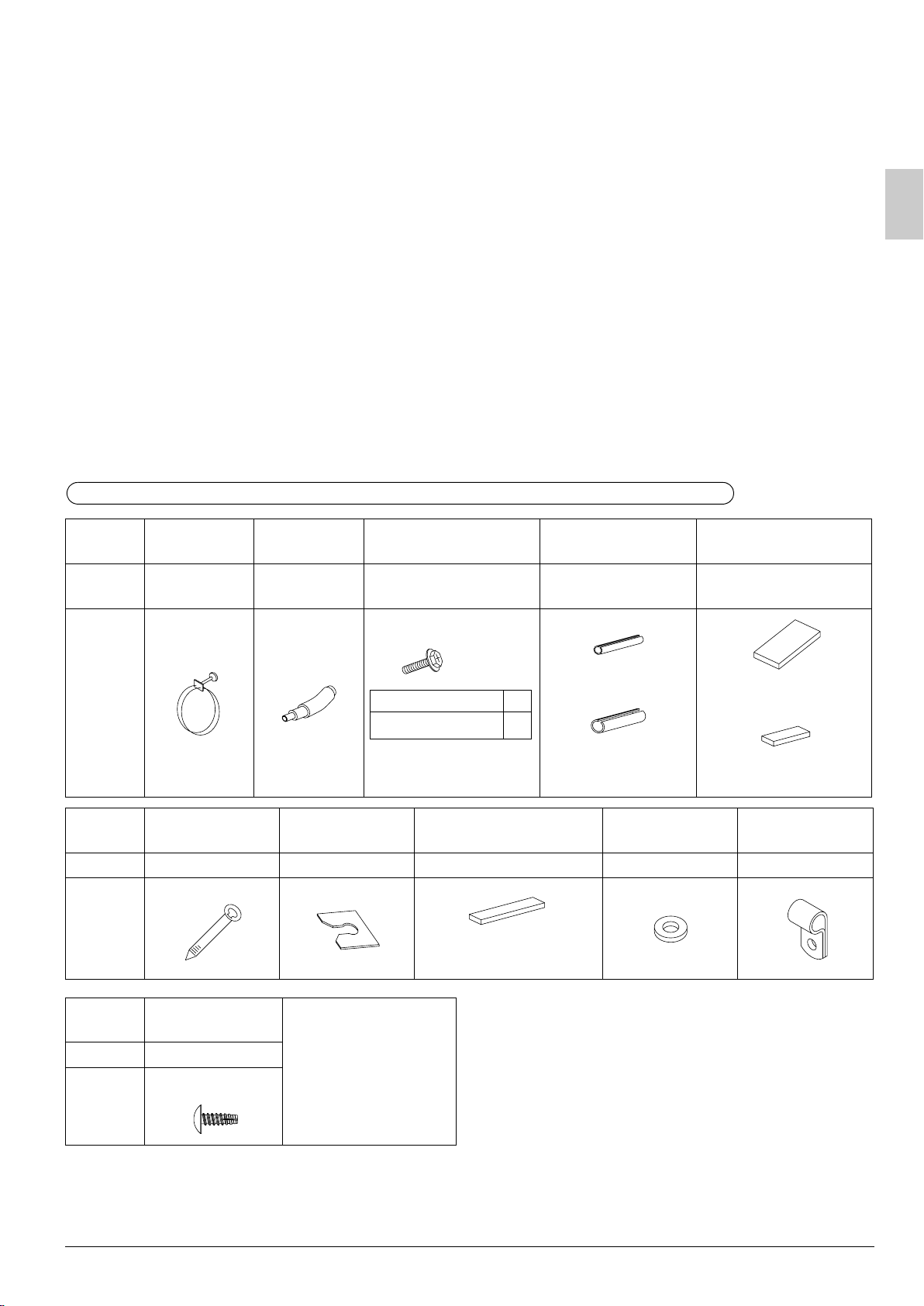

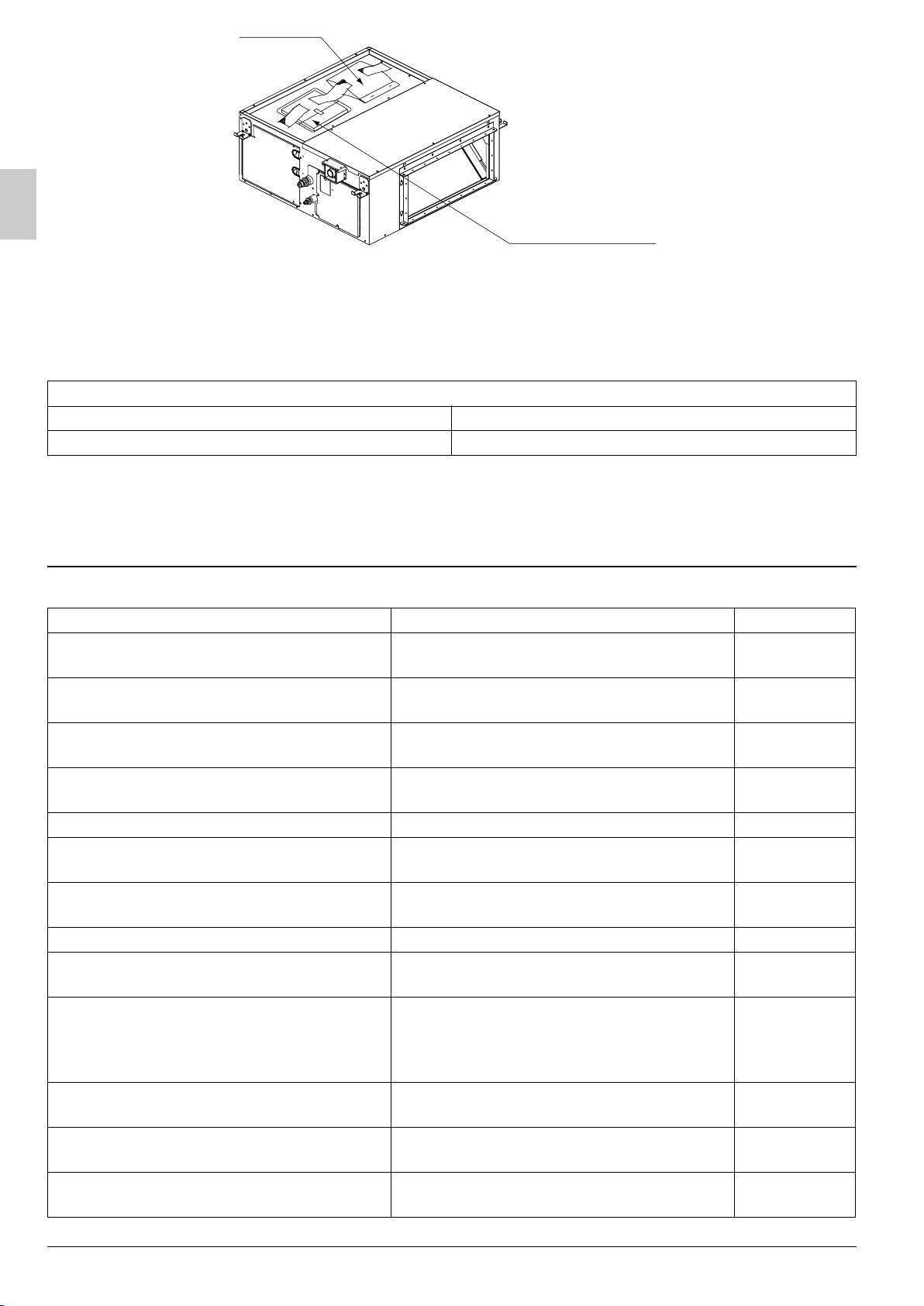

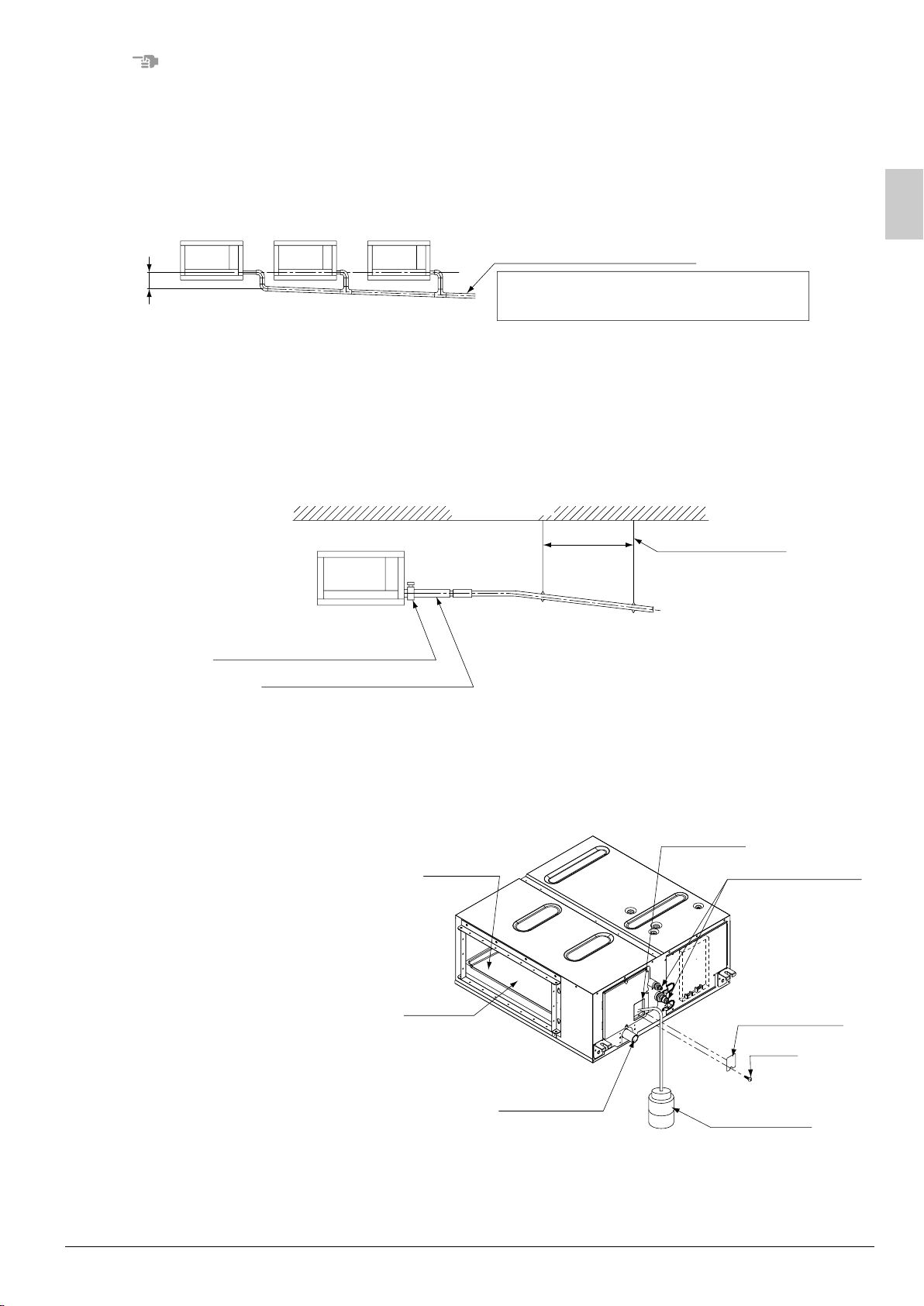

2-1 ACCESSORIES

Check the following accessories are included with your unit.

Refer to Fig. 1 for the location of the accessories.

Do not dispose of any parts necessary for installation until the installation is completed.

Name

Metal clamp

(1)

Quantity 1 pc. 1 pc.

Drain hose

(2)

Screws for duct

flanges (3)

As described in table

below

Insulation for

fitting

1 each –

Sealing pad

o avoid

Thin

1 pc.

Large (Dark gray) (6)

Shape

M5×16

20 • 24 type

36 • 45 • 48 type

18

26

for liquid pipe (4)

Thick

for gas pipe (5)

2 pcs.

Middle (Dark gray) (7)

Name Clamp (8)

Washer fixing

plate (9)

Wire sealing material

(10)

Washer (11)

Wire fixing

bracket (12)

Quantity 9 pcs. 4 pcs. 2 pcs. 8 pcs. 2 pcs.

Shape

Small (Gray)

Name

Quantity 2 pcs.

Wire fixing screw

(13)

(Other)

• Operation manual

M4×8

• Installation manual

Shape

English

4

Page 6

(1) - (13)

Operation manual

Installation manual

Fig. 1

2-2 OPTIONAL ACCESSORIES

• The optional remote controller are required for this indoor unit.

• These are two types of remote controllers: wired and wireless. Select a remote controller according to

customer request and install in an appropriate place.

(When installing, follow the instructions in the manual included with the remote controller.)

Remote controller

epyt deriW

BRC1C61

/ BRC1D61 / BRC1E62

26C4CRBepyt sseleriW

• BRC4C62 cannot be used for the indoor unit FBQ48EAVMK. If required, use wireless type BRC4C64

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE DURING CONSTRUCTION AND

CHECK AFTER INSTALLATION IS FINISHED.

a. Items to be checked after completion of work

k

cehCrucco ot ylekil si tahw ,enod ylreporp ton fIdekcehc eb ot smetI

Are the indoor unit and outdoor unit fixed

firmly?

Is the outdoor unit fully installed?

Is the gas leak test finished?

Is the unit fully insulated? (Refrigerant piping, drain piping, and duct)

Does drainage flow smoothly? Condensate water may drip.

Does the power supply voltage correspond

to that shown on the name plate?

Are wiring and pipi

Is the unit safely grounded? It may result in electric shock.

Is wiring size according to specifications?

Is something blocking the air outlet or inlet

of either the indoor or outdoor units?

(This can lead to malfunction or decreased

performance due to decreased air volume.)

Does the cold air (warm air) blow properly

during the cooling (heating) operation?

Are refrigerant piping length and additional

refrigerant charge noted down?

Has the field setting done (as necessary)?

ng correct?

The unit may drop, vibrate or make noise.

The unit may malfunction or components

burn out.

It may result in insufficient cooling or

heating.

Condensate water may drip.

The unit may malfunction or the

components burn out.

The unit may malfunction or the

components burn out.

The unit may malfunction or the

components burn out.

It may result in insufficient cooling or

heating.

It may result in insufficient cooling or

heating.

The refrige

clear.

It may result in insufficient cooling or

heating.

rant charge in the system is not

English5

Page 7

Did you set the external static pressure?

Did you check that no wiring connection

screws were loose?

b. Items to be checked at time of delivery

* Also review the “1. SAFETY PRECAUTIONS”

Items to be checked Check

Did you attach the control box lid, the air filter, air inlet grille and air outlet grille?

Did you explain about operations while showing the instruction manual to your customer?

Did you hand the instruction manual over to your customer?

Did you explain the customer the handling and cleaning methods of the field supplies

(e.g., the air filter, air inlet grilles, and air outlet grille)?

It may result in insufficient cooling or

heating.

Electric shock or fire.

Did you deliver instruction manual, if any, for the fiel

Points for explanation about operations

The items with WARNING and CAUTION marks in the instruction manual are the items

pertaining to possibilities for bodily injury and material damage in addition to the general usage

the product. Accordingly, it is necessary that you make a full explanation about the described

of

con

tents and also ask your customers to read the instruction manual.

d supplies to the customer?

2-3 NOTE TO THE INSTALLER

• Be sure to instruct customers how to properly operate the unit (especially cleaning filters, operating

ent functions, and adjusting the temperature) by having them carry out operations themselves while

differ

looking

at the manual.

3. SELECTING INSTALLATION SITE

When opening the unit or moving it after opening, be sure to lift it by holding on to the hanger bracket without

•

exerting any pressure on other parts, especially piping (refrigerant piping and dr

• Please attach additional thermal insulation material to the unit body when it is believed that the relative

humidity in the ceiling exceeds 80%.

•

Use glass wool, polyethylene foam, or similar with a thickness of 10 mm or more as thermal insulation material.

ain piping) and other resin parts.

(1) Select an installation site where the following conditions are fulfilled and that meets your

cus

tomer’s approval.

• Where optimum air distribution can be ensured.

• Where nothing blocks air passage.

• Where condensate can be properly drained.

• Where the ceiling is strong enough to bear the indoor unit weight.

• Where the false ceiling is not noticeably on an incline.

• Where sufficient clearance for mainte

• Where there is no risk of flammable gas leakage.

• Where piping between indoor and outdoor units is possible within the allowable limit.

(Refer to the installation manual for the outdoor unit.)

CAUTION

• The indoor and outdoor units and the power supply wiring and remote controller cord must be installed

at least 1m away from any televisions or radios. This is to prevent interference with picture and sound

reception. (Interference may occur even at 1m away depending on the reception quality.)

• If installing the wireless kit, the distance of the signal sent from the remote controller might be shorter if

there are fluorescent lights which are electrically started (such as with inverters, rapid starters, etc.) in

the room. The indoor unit should be installed as far away from fluorescent lights as possible.

English

nance and service can be ensured. (Refer to Fig. 2)

6

Page 8

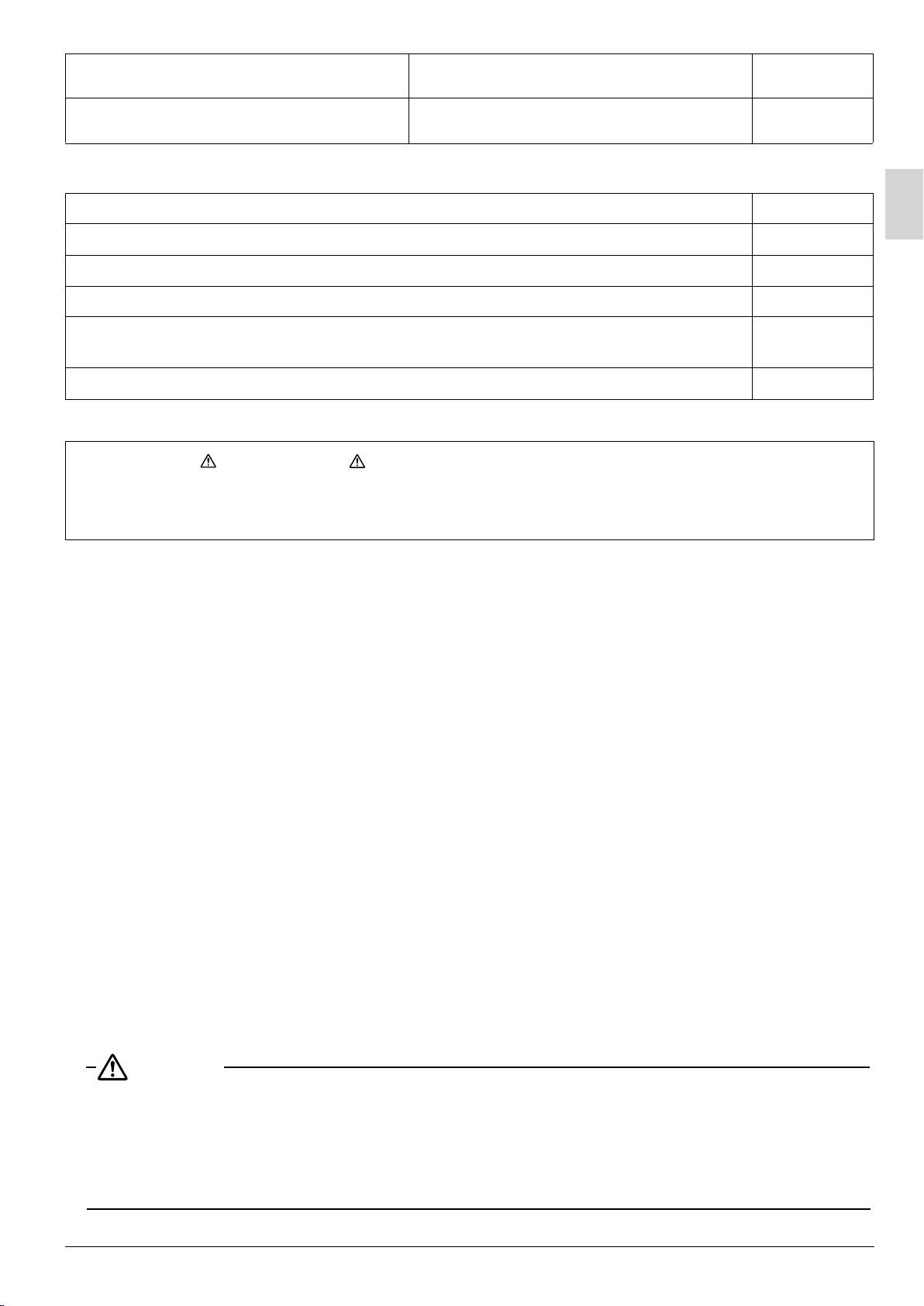

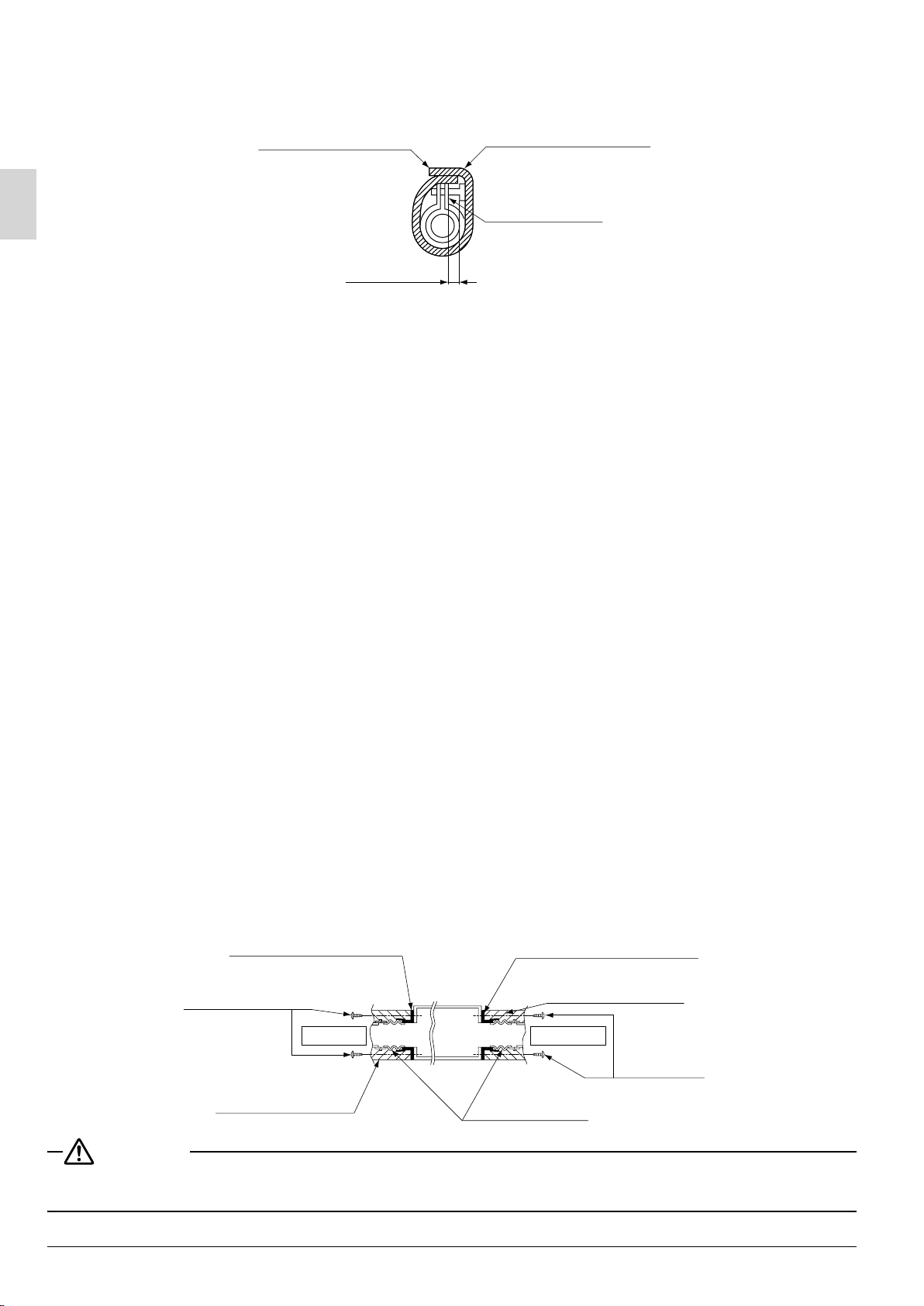

(2) Use suspension bolts for installation. Check if the location for the installation is strong enough to support

the weight of the unit, reinforce it if necessary, and install using suspension bolts.

(length: mm)

Min. 20Min. 300

*H1=300

*H2=Min. 620

Ceiling

Min. 2500

Floor surface

(If no ceiling board is provided.)

*The H1 dimension indicates the height of the

product.

*Determine the H2 dimension by maintaining

a downward slope of at least 1/100 as

specified in “7. DRAIN PIPING WORK”.

Min. 700 (service space)

[Required installation place]

The dimensions indicate the

minimum required space of

installation.

Fig. 2

Min. 450

4. PREPARATIONS BEFORE INSTALLATION

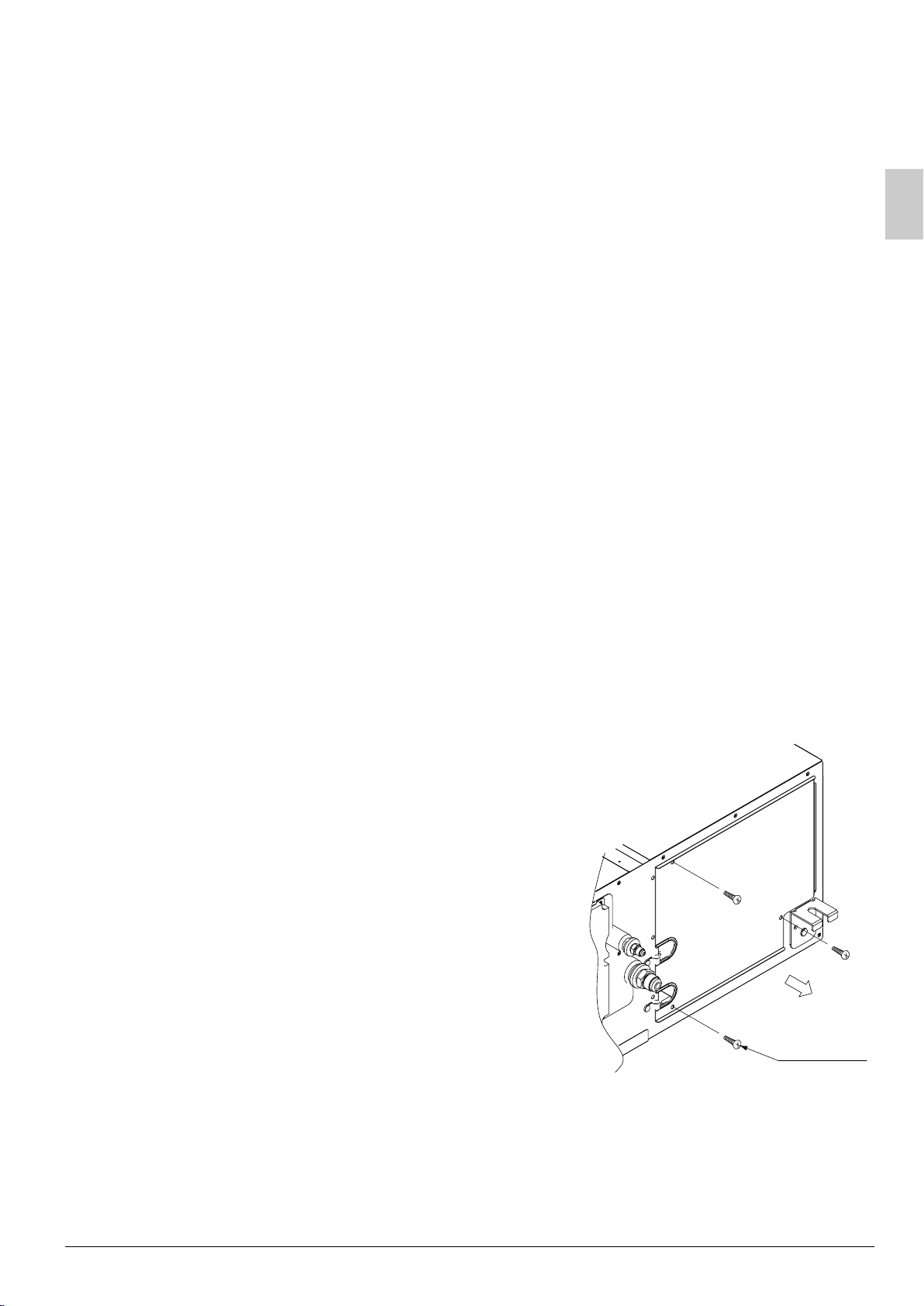

(1) Check the positional relationship between the ceiling opening hole and the hanging bolt of the unit.

• For the maintenance, inspection, and other servicing purposes of the control box, prepare one of the

lowing service spaces.

fol

1. Inspection hatch 1 (450 × 450) for the control box and a minimum space of 300 mm for the lower part

of the product. (Refer to Fig. 3)

2. Inspection hatch 1 (450 × 450) for the control box and inspection hatch 2 for the lower pa

prod

uct (see axial direction view A-1). (Refer to Fig. 4)

3. Inspection hatch 3 for the lower part of the product and the lower part of the control box (see axial

direction view A-2). (Refer to Fig. 4)

rt of the

Case 1

Inspection hatch

Control box

*H3=Min. 300

Ceiling

Air outlet

Fig. 3

700

631

(Hanging bolt pitch)

Bottom of unit

Hanging bolt (× 4)

Inspection hatch 1

(450×450)

Control box

B

C

Air inlet

(Hanging bolt pitch)

English7

Page 9

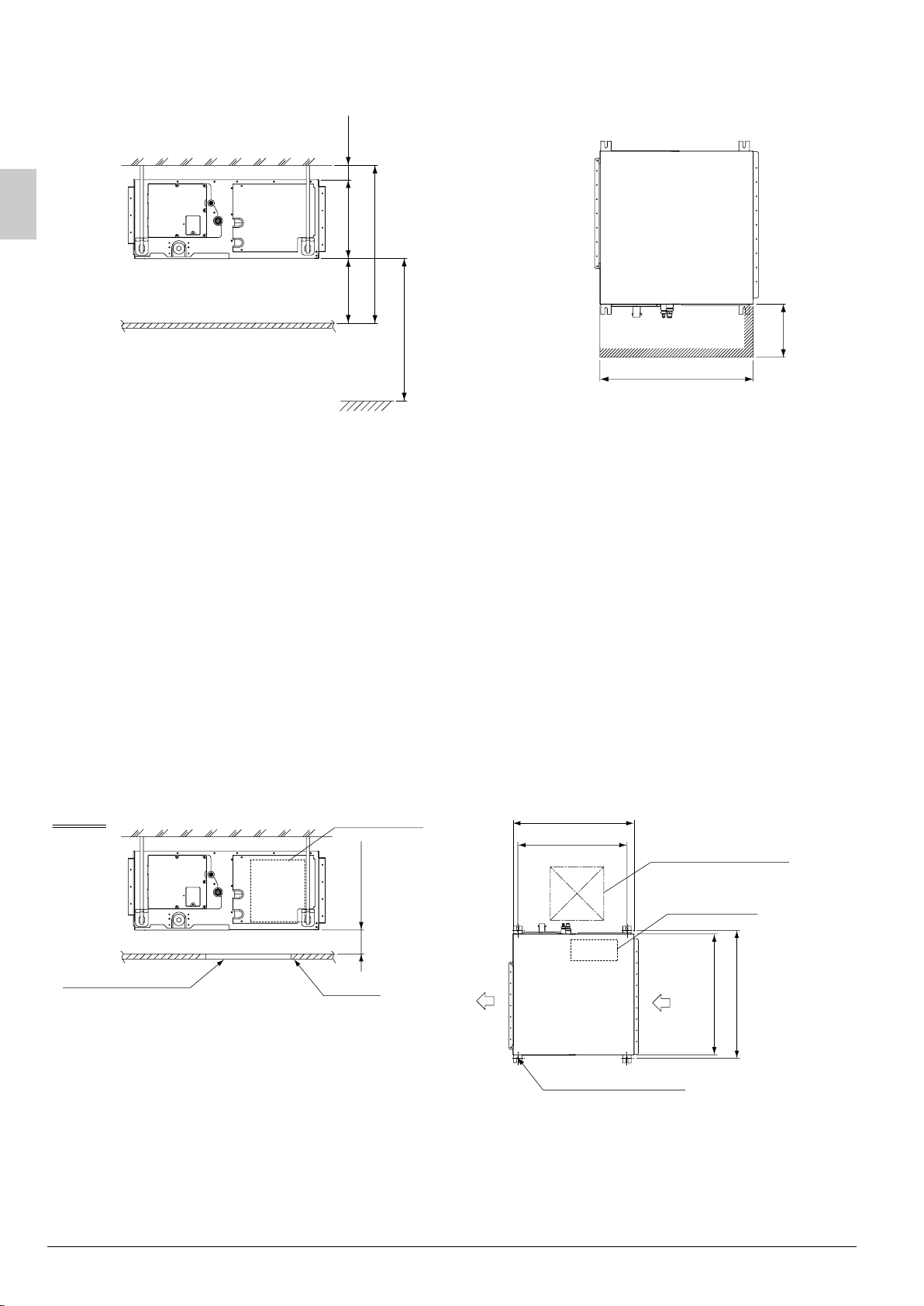

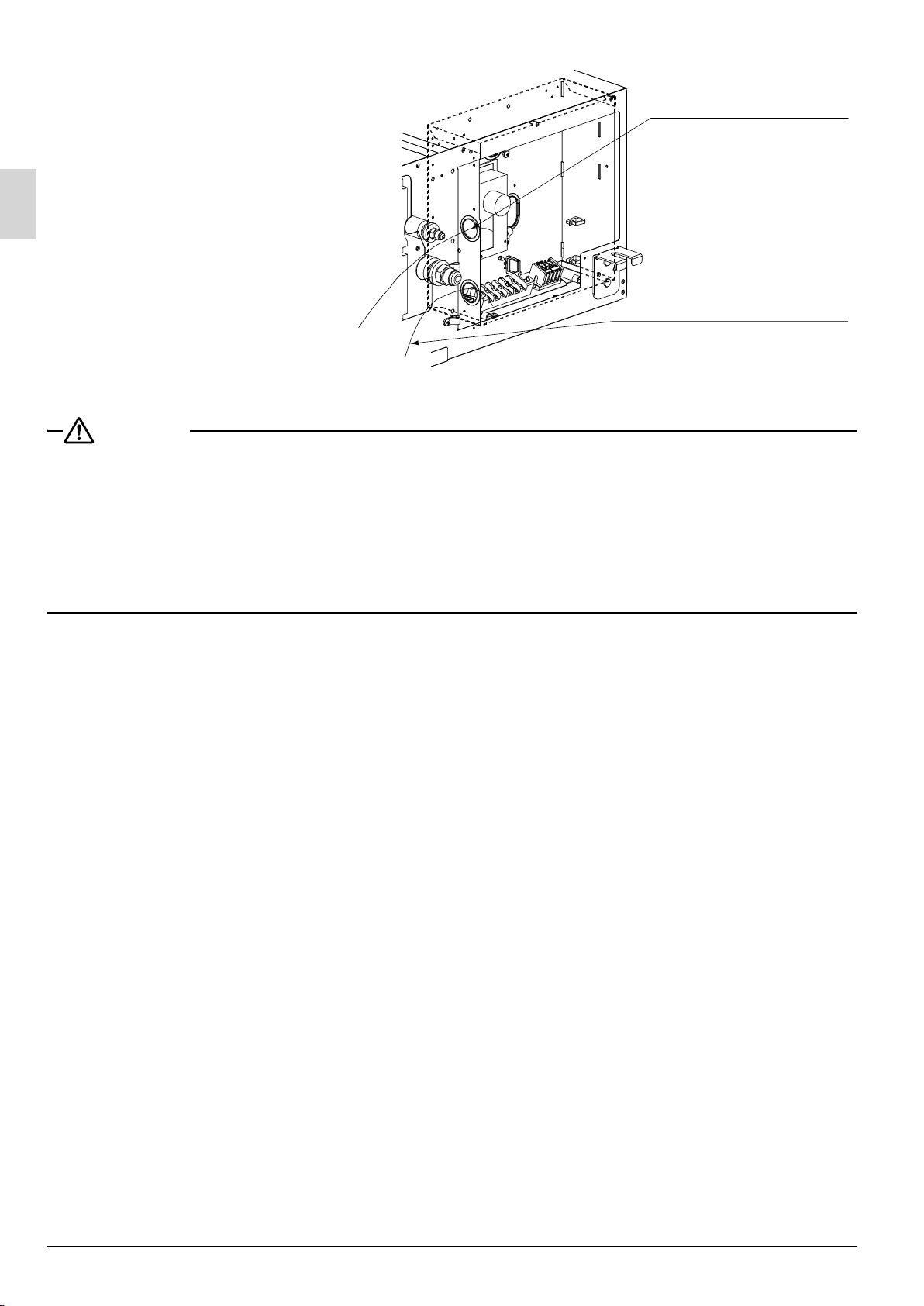

Case 2, 3

Inspection hatch

(Ceiling opening)

Control box

Inspection hatch 1

(450×450)

Min. 200B

Inspection hatch 3

(Same as the indoor

unit size +300 or more)

Control box

Inspection hatch

*H3=Min. 20

A

Ceiling

Control box

Min. D=B+300

007007

Inspection hatch 2

(Same as the indoor

unit size or more)

*Determine the H3 dimension by

maintaining a downward slope

of at least 1/100 as specified in

“7. DRAIN PIPING WORK”.

Axial direction view A-1 Axial direction view A-2

Fig. 4

Model B C D

20

• 24 type

36 • 45 • 48 type

1000 1038 1300

1400 1438 1700

(length: mm)

(2) Mount the canvas ducts to the air outlet and inlet so that the vibration of the air conditioner will not be

mitted to the duct or ceiling. Apply a sound-absorbing material (insulation material) to the inner wall

trans

of the

duct and vibration insulation rubber to the hanging bolts (refer to 8. DUCT WORK).

(3) Open installation holes (if the ceiling already exists).

• Open the installation holes on the ceiling. Lay the refrigerant piping, drain piping, power line,

transmis

sion wiring, and remote controller wiring for the piping and wiring connection port of the unit.

In the case of the installation of a wireless remote controller, refer to the installation manual provided

with the wireless remote controller.

Refer to 6. REFRIGERANT PIPING WORK, 7. DRAIN PIPING WORK, and 10. WIRING EXAMPLE

AND HOW T

• The ceili

O SET THE REMOTE CONTROLLER.

ng framework may need reinforcement in order to keep the ceiling horizontal and prevent the

vibration of the ceiling after the installation holes are opened. For details, consult your construction or

interior contractor.

(4) Install the hanging bolts. Make sure that the hanging bolts are M10 in size.

• Use hole-in anchors if the hanging bolts

already exist; otherwise use embedded

inserts and embedded foundation bolts so that

Installation example

Ceiling slab

they will withstand the weight of the unit.

Adjust the distance to the ceiling surface in

Anchor

advance.

Long nut or turn-buckle

English

Hanging bolt

Indoor unit

Note) All the above parts are field supplied.

8

Page 10

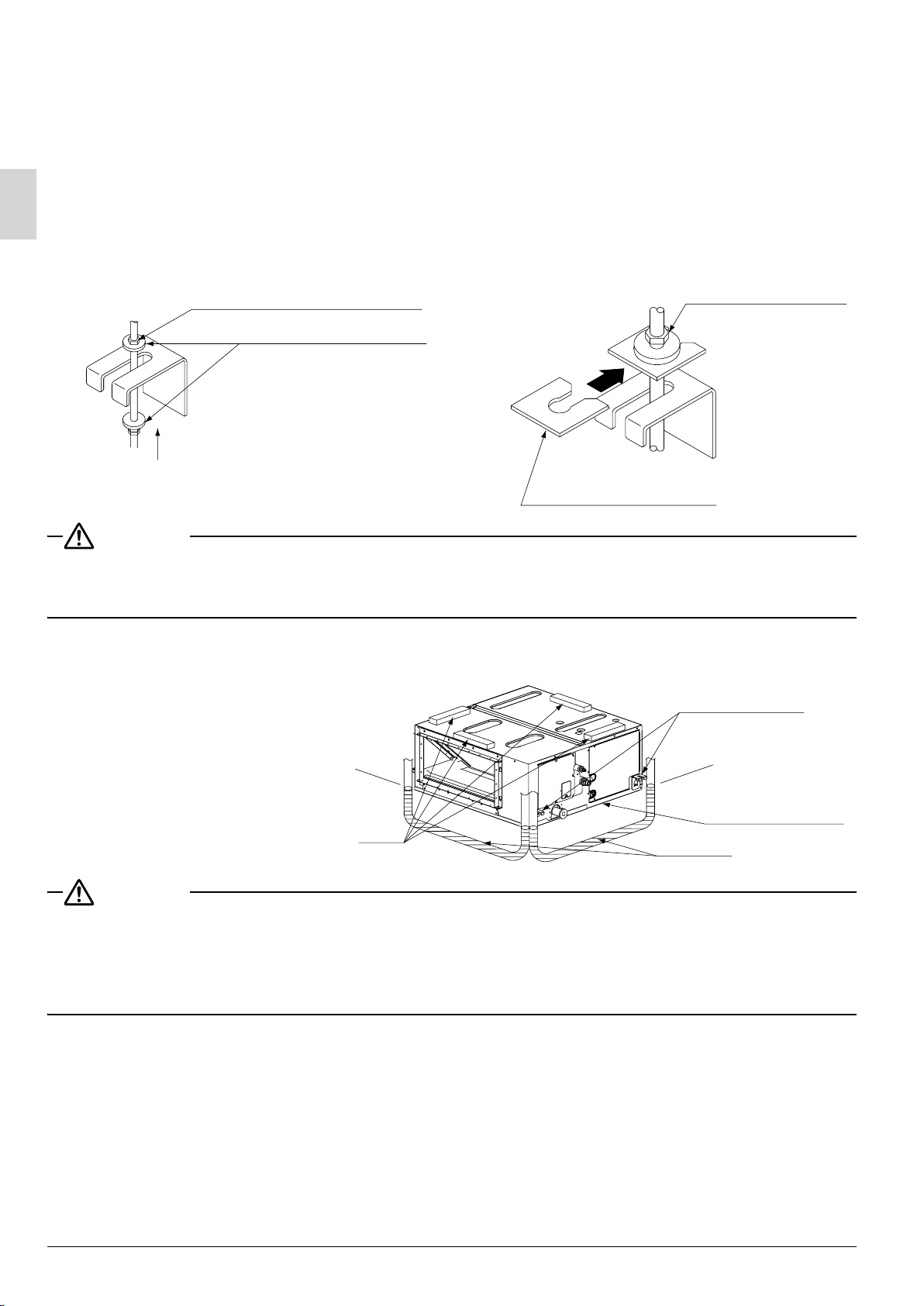

5. INDOOR UNIT INSTALLATION

It may be easier to install accessories (sold separately) before installing the indoor unit. Refer to the

〈

installation manuals provided to the accessories as well.〉

As for the parts to be used for installation work, be sure to use the provided accessories and specified parts

designated by our company.

(1) Temporally install the indoor unit.

• Connect the hanging brackets to the hanging bolts. Be sure to use and tighten the nut and washer (11) for

each hanging bracket from both upper and lower sides of the hanging bracket.

the fall of the washer (11) for the hanging bracket can be prevented if the washing fixing plate (9) is used.

Part to be procured in the field

Washer (11) (accessory)

Insert

Tighten from above and below

(Double nut)

Fig. 5

Washer fixing plate (9)

(accessory)

(Refer to Fig. 5)

Nut on the upper side

At that time,

]srehsaw fo dohtem gnixiF[]stekcarb gnignah gnixiF[

CAUTION

• During the installation work, perform the curing of the air outlet and protect the resin drain pan of

the indoor unit from the intrusion of foreign substances, such as welding spatters.

Otherwise, water leakage may occur as a result of damage, such as hole damage, to the resin drain pan.

(2) Make adjustments so that the unit will be in the right position.

(3) Check the level of the unit.

(4) Remove the washer fixing plates for

the falling prevention of the washers

for the hanging brackets, tighten the

nuts on the upper side, and securely

fix the unit.

Level

CAUTION

• Use the level and check that the unit is installed horizontally. (4-directions)

• In the case of using a vinyl tube in place of the level, put the both edges of the vinyl tube in close contact

with the bottom of the product to make levelness adjustment.

If the unit is installed at a slant with the drain pipe side set high, in particular, the float switch will not operate

normally and water leakage may result.

Hanging bracket

Bottom of product

Vinyl tube

9

English

Page 11

6. REFRIGERANT PIPING WORK

For refrigerant piping of outdoor units, see the installation manual attached to the outdoor unit.〉

〈

〈Execute heat insulation work completely on both sides of the gas piping and the liquid piping. Otherwise, a

water leakage can result sometimes.〉

(When using a heat pump, the temperature of the gas piping can reach up to approximately 120°C, so use

insulation which is sufficiently resistant.)

〈Also, in cases where the temperature and humidity of the refrigerant piping sections might exceed 30°C or

RH80%, reinforce the refrigerant insulation. (20mm or thicker) Condensate may form on the surface of the

insulating material.〉

〈Be sure to chec

erant will prevent normal operation of the unit.)〉

refrig

CAUTION

This product is designed to be used with new refrigerant (R410A). Always observe the precautions on the

following when installing.

• Use a pipe cutter and flare suitable for the type of refrigerant.

• Apply ester oil or ether oil around the flare section before connecting.

• Use the flare nut provided to the unit. Do not use a different flare nut (class 1), or otherwise refrigerant

leakage may result.

• To prevent dust, moisture or other foreign matter from infiltrating the tube, either pinch the end or cover

it with tape.

• Do not allow anything other than the designated refrigerant to get mixed into the refrigerant circuit, such

as air, etc. If any refrigerant gas leaks while working on the unit, ventilate the room thoroughly right away.

k the type of R410A refrigerant to be used before doing any work. (Using an incorrect

• The outdoor unit is charged with refrigerant.

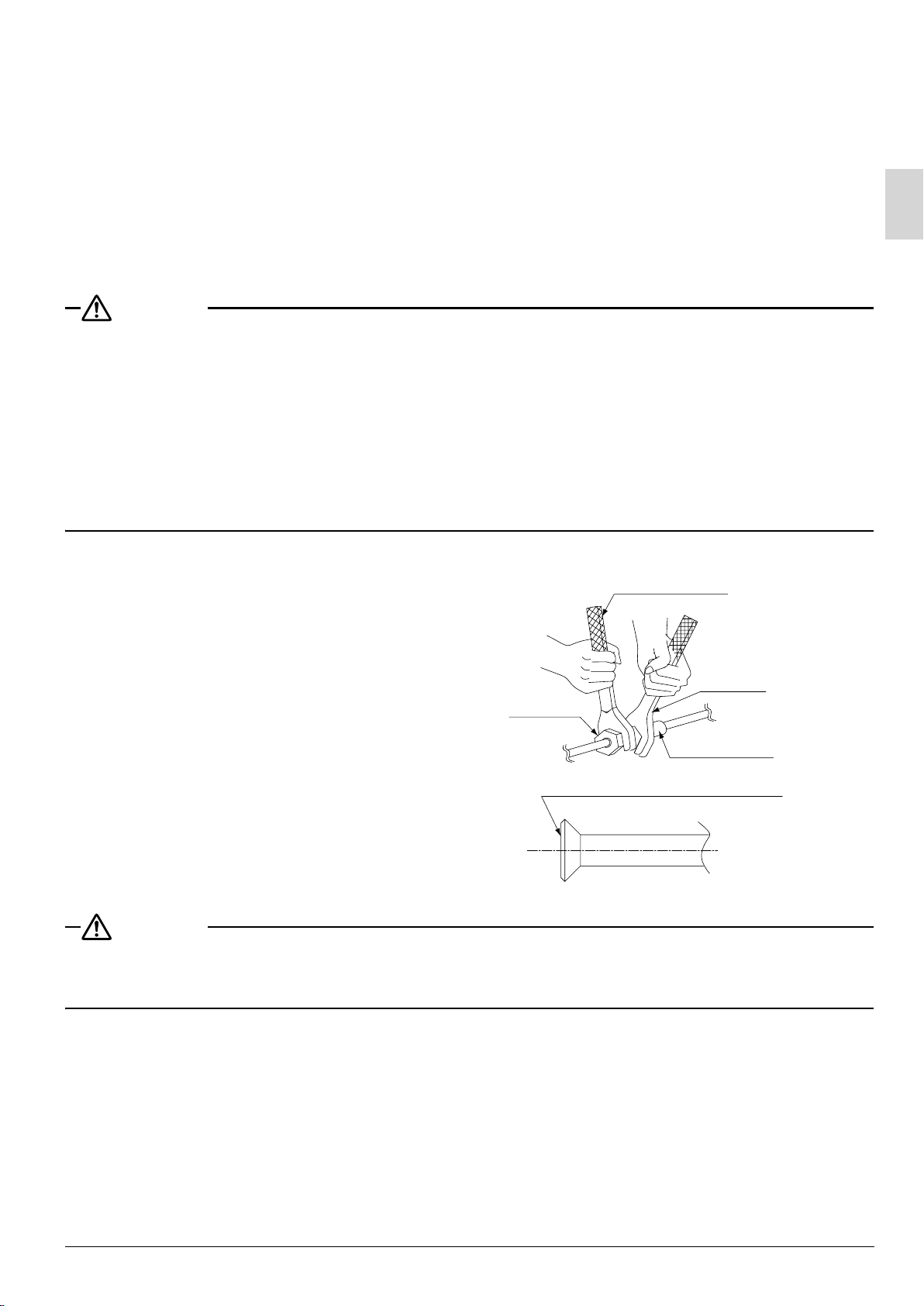

• Be sure to use both a spanner and torque wrench

together, as shown in the drawing, when connecting

or disconnecting pipes to/from the unit.

(Refer to Fig. 6)

• Refer to “Table 1” for the dimensions of flare nut

spaces.

• Use the flare nut included with the unit main body.

• When connecting the flare nut, apply ester oil or

ether oil to the flare section (inside only), and spin

3

-

4 times before screwing in.

(Refer to Fig. 7)

CAUTION

• Do not let oil get on the screw holders on the dressing board. Oil can weaken the screw holders.

• Refer to “Table 1” to determine the proper tightening torque.

• Be careful not to damage the flare section.

Flare nut

Coat here with ester or ether oil.

Torque wrench

Spanner

Piping union

Fig. 7

Fig. 6

10English

Page 12

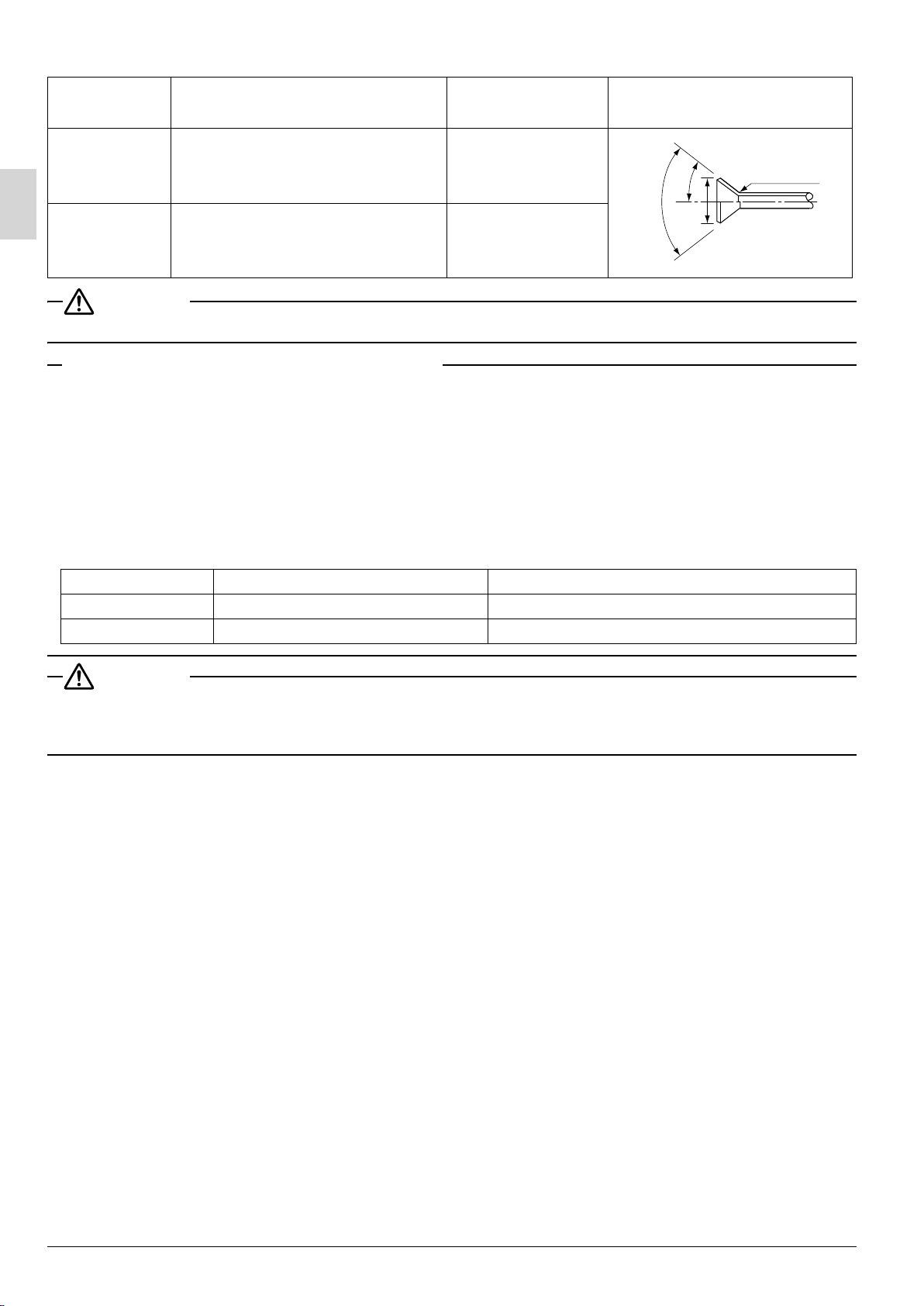

Table 1

Pipe size Tightening torque (N·m)

φ 9.5 (3/8”) 32.7 – 39.9 12.8 – 13.2

Flare dimensions

A (mm)

2˚

±

90˚

2˚

±

45˚

Flare

R0.4-0.8

A

φ 15.9 (5/8”) 61.8 – 75.4 19.3 – 19.7

CAUTION

• Over-tightening the flare nut may break it and/or cause the refrigerant to leak.

Not recommendable but in case of emergency

You must use a torque wrench but if you are obliged to install the unit without a torque wrench, you may

follow the installation method mentioned below.

After the work is finished, make sure to check that there is no gas leak.

When you keep on tightening the flare nut with a spanner, there is a point where the tightening torque

suddenly increases. From that position, further tighten the flare nut the angle shown below:

Unless followed the tightening instruction (it is loose tightening), it will lead to the refrigerant leakage (slow

leak) and the device malfunction (it does not sufficiently cool or heat).

Pipe siz

φ mm002 .

e Further tightening angle Recommended arm length of tool

xorppAseerged 09 ot 06)”8/3( 5.9

φ mm003 .xorppAseerged 06 ot 03)”8/5( 9.51

CAUTION

For local insulation, be sure to insulate local piping all the way into the pipe connections inside the

machine.

Exposed piping may cause condensation or burns on contact.

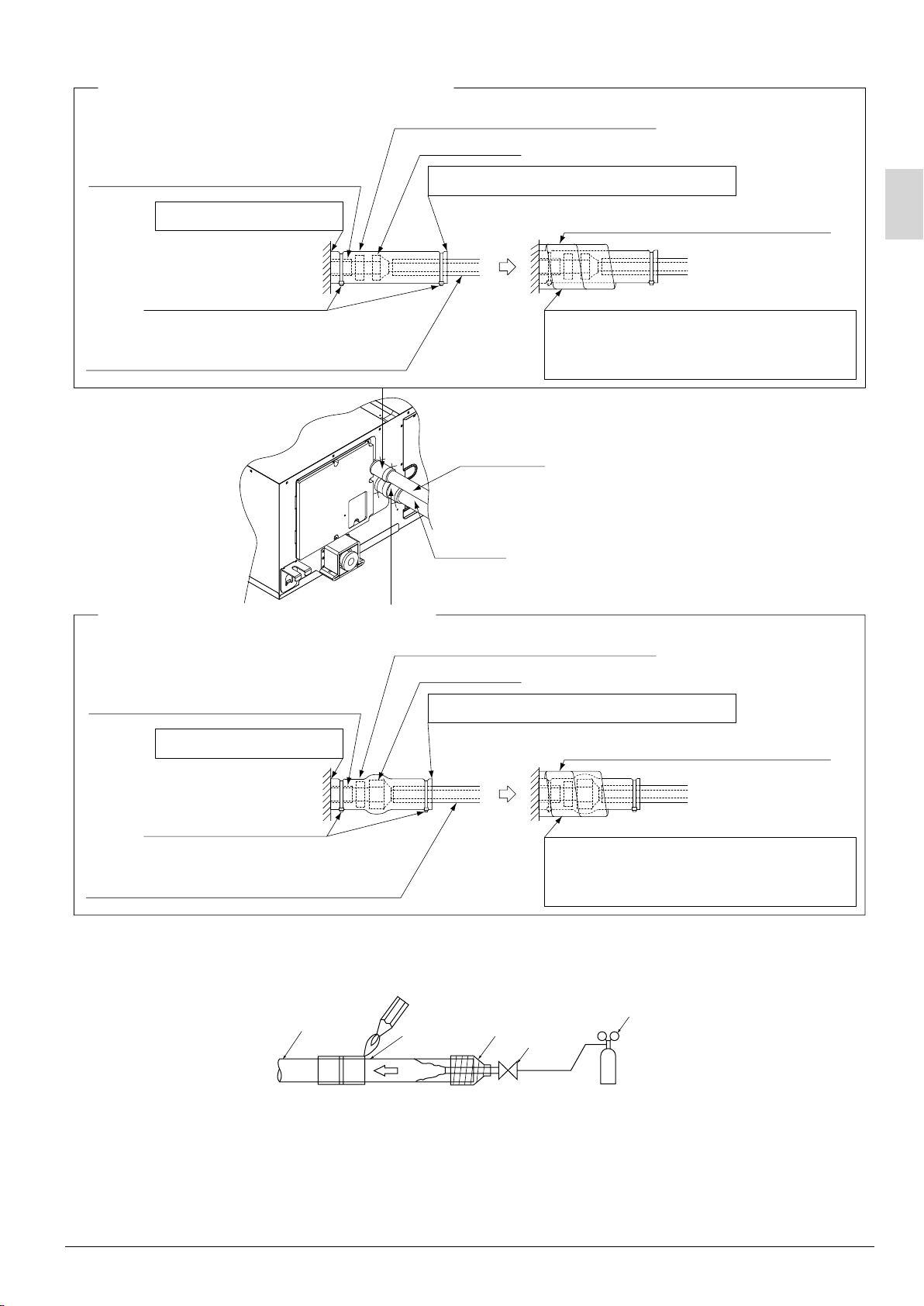

• Make absolutely sure to execute heat insulation works on the pipe-connecting section after checking gas

leakage by thoroughly studying the following figure and using the attached heat insulating materials for

ting (4) and (5). (Fasten both ends with the clamps (8).) (Refer to Fig. 8)

fit

• Wrap the middle sealing material (7) around the insulation for fitting (4) and (5) for the joint (flare nut part).

• Make sure that the joint of the insulation for fitting (4) and (5) for the joint on the liquid piping and gas piping

side faces upward.

English11

Page 13

Heat insulation procedure for liquid piping

Insulation for fitting (4) (accessory)

Insulation material for piping

(on unit side)

Attached to the surface.

Main unit

Clamp (8) (accessory)

Insulation material for piping (field supply)

Flare nut joint

Make sure that the seam faces upward.

Middle sealing pad (7) (accessory)

Wrap the insulation material around the

portion from the surface of the main unit

to the upper part of the flare nut joint.

Liquid pipe

Gas pipe

Fig. 8

Heat insulation procedure for gas piping

Insulation for fitting (5) (accessory)

Insulation material for piping

(on unit side)

Attached to the surface.

Flare nut joint

Make sure that the seam faces upward.

Middle sealing pad (7) (accessory)

Clamp (8) (accessory)

Wrap the insulation material around the

Insulation material for piping (field supply)

portion from the surface of the main unit

to the upper part of the flare nut joint.

• When brazing the refrigerant piping, only begin brazing after having carried out nitrogen

substitu

tion or while inserting nitrogen into the refrigerant piping.

Once this is done, connect the indoor unit with a flared or a flanged connection.

Pressure-reducing valve

Refrigerant piping

Part to be

brazed

Nitrogen

Taping

Hands valve

Nitrogen

English

Fig. 9

12

Page 14

• Nitrogen should be set to 0.02MPa with a pressure-reducing valve if brazing while inserting nitrogen into

the piping. (Refer to Fig. 9)

• Do not use flux when brazing refrigerant piping. Therefore, use the phosphor copper brazing filler metal

(BCuP-2: JIS Z 3264/B-Cu93P-710/795: ISO 3677) which does not require flux.

(Flux has extremely harmful influence on refrigerant piping systems. For instance, if the chlorine based flux is

used, it will cause pipe corrosion or, in particular, if the flux contains fluorine, it will damage the r

• When the airtight test is performed for the indoor unit and inter-unit piping after indoor unit installation, be

sure to refer to the installation manual for the indoor unit or technical guide for airtight pressurization and

refrigerant piping installation.

• Shortage of refrigerant due to air purge or losing the additional refrigerant charging may cause the failure

of the unit (does not sufficiently cool or heat).

Be sure to refer the installation manual or the engineering guide for the outdoor unit at the refrigerant piping

work.

CAUTION

• Do not use anything such as the oxidation inhibitor when brazing. (Residues may result in the clogging pipe

or parts damage.)

efrigerant oil.)

7. DRAIN PIPING WORK

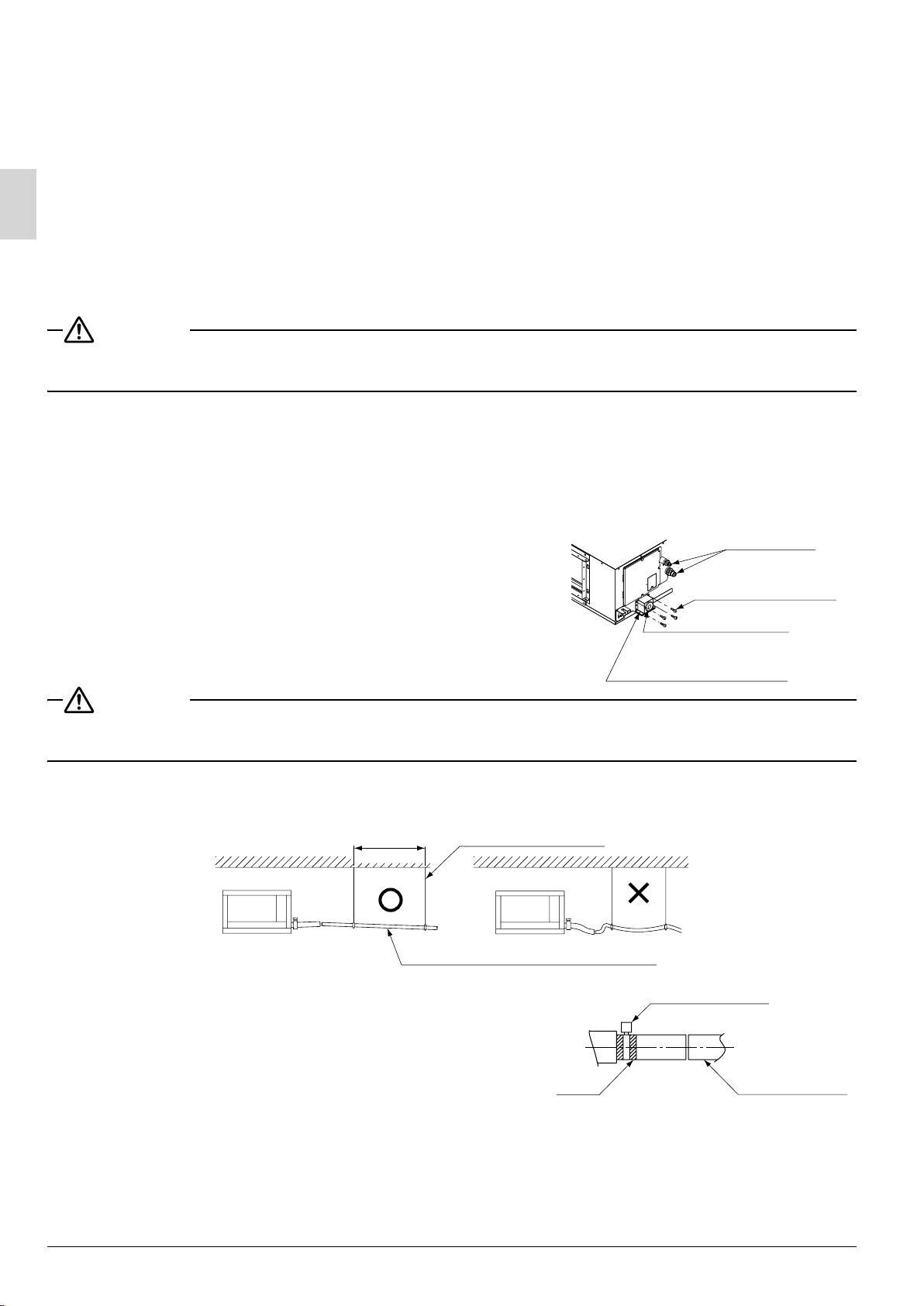

(1) Remove the drain socket cover. (for transportation)

(2) Conduct drain piping work.

Check that the piping ensures proper draining.

• Make sure that the diameter of the piping excluding the rising

part is the same as or larger than the diameter of the

connect

of 32 mm

• Make sure that the piping is short enough with a downward

slope of at least 1/100 and that there is no air bank formed.

No drain trap is required.

ing pipe (vinyl chloride pipe with an outer diameter

and a nominal inner diameter of 25 mm).

Drain socket cover

(for transportation)

Refrigerant

piping

Screw (4 portions)

Drain socket

CAUTION

• The drain piping will be clogged with water and water leakage may result if the water is accumulated in the

drain piping.

• Conduct drain-up piping work if the gradient is insufficient.

• Attach some support brackets at 1 to 1.5 m intervals for the prevention of piping deflection.

1 - 1.5 m

Downward slope of at least 1/100

• Be sure to use the drain hose (2) and metal clamp (1).

Insert the drain hose (2) deep into the base of the drain

socket, and securely fasten the metal clamp (1) within the

taped part on the insertion front end of the hose.

Be sure to fasten the screw of the metal clamp (1) until the

margin of the screw thread decreases to 4 mm or less.

Supporting hanger

Tape

Metal clamp (1)

(accessory)

Drain hose (2)

(accessory)

13

English

Page 15

NOTE

Be sure to follow the instructions as below.

• Do not connect the drain piping directly to a sewer that smells of ammonia.

The ammonia in the sewer may reach through the drain piping and corrode the heat exchanger of the

indoor unit.

• Do not bend or twist the provided drain hose (2) in order not to impose excessive force on the hose.

(Doing so may result in water leakage.)

• Take the procedure shown in the following illustration to perform concentrated drain piping.

Concentrated drain piping

Maintain a downward slope of at least

1/100 so that no air bank will be formed.

Min. 100 mm

The drain piping will be clogged with

water and water leakage may result if the

water is accumulated in the drain piping.

• Select the diameter of the concentrated drain piping to suit the capacity of equipment connecting to the

concentrated drain piping (see the equipment design sheet).

Ceiling slab

1 - 1.5 m

Support bracket

Metal clamp (1) (accessory)

Drain hose (2) (accessory)

(3)

Check the smooth draining of the piping on completion of the installation of the piping.

• Provide approximately one liter of water gradually into the drain pan through the water inlet on the

bottom of the drain socket or the outlet.

(4) Be sure to conduct heat insulation work on the following portions, or otherwise water leakage may

occur as a result of dew condensation.

• Drain piping indoors

• Drain socket

Drain pan

Water inlet

Refrigerant piping

English

Air outlet

Drain socket

Water inlet lid

Screw

Plastic water

container

14

Page 16

• On completion of the drainage check, refer to the following illustration, and use the provided large

seal

ing pad (6) and heat insulate the metal clamp (1) and drain hose (2).

Make sure that the

seam faces upward.

4 mm max.

Large sealing pad (6)

(accessory)

Metal clamp (1)

(accessory)

8. DUCT WORK

Pay the utmost attention to the following items and conduct the ductwork.

• Check that the duct will not be in excess of the setting range of external static pressure for the unit. (Refer

to the technical datasheet for the setting range.)

• Attach a canvas duct each to the air outlet and air inlet so that the vibration of the equipment will not be

transmitted to the duct or ceiling.

Use a sound-absorbing material (insulation material) for the lining of the duct

rubber to the hanging bolts.

• At the time of

the drain pan for the filter.

• If the metal duct pass through a metal lath, wire lath, or metal plate of a wooden structure, separate the duct

and wall electrically.

• Be sure to heat insulate the duct for the prevention of dew condensation. (Material: Glass wool or styrene

foam; Thickness: 25 mm)

• Be sure to attach the field supply air filter to the air inlet of the unit or field supply inlet in the air passage on

the air suction side. (Be s

• Explain the operation and washing methods of the locally procured components (i.e., the air filter, air inlet

grille, and air outlet grille) to the customer.

• Locate the air outlet grille on the indoor side for the prevention of drafts in a position where indirect contact

with people.

The air conditioner incorporates a function to adjust the fan to rated speed automatically.

•

Therefore, do not use booster fans midway in the duct.

duct welding, perform the curing of the duct so that the sputter will not come in contact with

ure to select an air filter with a duct collection efficiency of 50 weight percent.)

and apply vibration insulation

(11. FIELD SETTING)

Connection method of ducts on air inlet and outlet sides.

• Connect the field supply duct in alignment with the in

• Connect the flange and unit with the flange connection screw (3).

• Wrap aluminum tape around the flange and duct joint in order to prevent air leakage.

Flange on air inlet side

(provided with the unit)

Screws for duct

flanges (3)

(accessory)

Insulation material

(field supply)

CAUTION

Connect the flange and unit with the flange connection screw (3) regardless of whether the duct is connected to the air inlet side.

Air inlet

ner side of the flange.

Flange on air outlet side

(provided with the unit)

Insulation material

(field supply)

Unit

Canvas duct

(field supply)

Air outlet

Screws

for duct

flanges (3)

(accessory)

English15

Page 17

9. ELECTRIC WIRING WORK

WIRING INSTRUCTIONS

• Electric wiring work must be conducted by electrician authorized by power companies. (Only licensed

trician can conduct electric work and earth connections.)

elec

• All wiring must be performed by an authorized electrician.

• Be sure to install an earth leakage breaker to the outdoor unit.

(This installation of an earth leakage breaker is mandatory for the prevention of electric shocks and fire

disasters.)

• Install the earth leakage breaker which can handle harmonics.

(This unit has an inverter, so an interrupter capable of handling high frequencies is needed to prevent

mal

function of the interrupter itself.)

e sure to use earth leakage breaker dedicated for earth leakage protection in combination with the load

• B

break switch with fuse or breaker f

• Make sure that 230V is specified wiring between the indoor and outdoor units and between indoor units.

• Do not turn on the power supply (of the indoor unit) until all the installation work is completed.

• Be sure to earth the air conditioner.

• Do not connect the earth wire to gas pipes, plumbing pipes, lightning rods, or telephone earth wires.

• Gas pipes: might cause explosions or fire if gas leaks.

• Plumbing: no earth effect if hard vinyl piping is used.

• Telephone earth wires or lightning rods: might cause abnormally high electric potential in the earth

dur

ing lighting storms.

• The earth is ne

appliances and to release the charge built up in the product box by leaked current.

• For electric wiri

• Never connect the power supply wire to the terminal block for remote controller wire, or otherwise the entire

system may be damaged.

• For remote controller wiring details, refer to the installation manual attached to the remote controller.

• Do not touch the printed circuit board ASSY during the wiring work. Otherwise, it may cause damage.

eded in order to reduce the noise generated by the unit’s inverter and influence on other

ng work, refer to also “WIRING DIAGRAM” attached to the unit body.

or wiring.

10. WIRING EXAMPLE AND HOW TO SET THE REMOTE CONTROLLER

10-1 Connection of wiring between units, earth wire and for the remote controller cord

(Remove the control box lid as shown below and connect each wire.)

(1) Remove the control box lid.

Screw

(3 portions)

English

16

Page 18

(2) Lay the wires in the control box

through the wire inlet on the side of

the control box.

Low-voltage wiring inlet

• Remote controller wiring

(Low voltage)

High-voltage wiring inlet

Wiring the units (High voltage)

•

•

Power supply wiring (High voltage)

• Ground wiring (High voltage)

CAUTION

• Do not lay the remote controller wiring along with the wiring the units, power supply wiring or other electric

wiring in the same route. Separate the remote controller wiring at least 50 mm from the wiring the units,

power supply wiring or other electric wiring, or otherwise malfunctions or failures may be caused by

nal electric noise that may interfere with the remote controller wiring.

exter

• For the installation and wiring of the remote controller, refer to the remote controller installation manual

pro

vided with the remote controller.

• For wiring the units, power supply wiring, refer to the wiring diagram as well.

• Be sure to connect the remote controller wiring correctly to the right terminal block (X2M).

English17

Page 19

(3) Follow the instructions below, and lay the wires in the control box.

Fix the wires with clamp (8)

to the wire fixing bracket

provided to the control box.

Power supply terminals (X1M)

Earth L1 2 3 N

Wiring

the units

Power supply

wiring

Connection method of

power supply terminals

Outdoor unit

Indoor unit

Remote controller

wiring (Low voltage)

Twist and fix the upper part so

that the wires will not drop out.

Fix the cord with the

clamp (8) to the wire

fixing bracket provided

to the control box.

Insert the cord into the wire clips

provided with the control box.

PROHIBITED

Never connect wiring the units

and the power supply wiring.

P1 P2 F1 F2

Remote controller

wiring (No polarity)

Connection method of remote

controller terminals (X2M)

• If stranded wires are used,

do not solder the front end

of the wires.

(Terminal block)

(Terminal block)

Match both numbers.

Connecting wiring between units

WARNING

Trim and lay the wiring neatly and attach the control box lid securely.

An electric shock or fire may result if the control box lid catches any wiring or the wires push up the lid.

(4) Put the control box lid, and wrap the wire sealing

material (Small) (10) around the wires so as to

Wire through holes

block the wire through holes.

18English

Page 20

CAUTION

• After all the wiring connections are done, fill in any gaps in the through holes with putty or insulation

(procured locally) to prevent small animals and insects from entering the unit from outside. (If any do get in,

they

could cause short circuits in the control box.)

(5) Mount the provided wire fixing bracket (12) with

the wire fixing screw (13). Fix each wire with the

provided clamp (8).

Precautions to be taken for power supply wiring

Use a round crimp-style terminal for connection to the

power supply terminal block.

Remote controller

wiring

Wiring the units

Power supply wiring

Ground wiring

Fixing use

Clamp (8) (accessory)

Wire fixing bracket (12) (accessory)

Wire fixing screw (13) (accessory)

Attach insulation sleeve

Electric wireRound crimp-style terminal

In case it cannot be used due to unavoidable reasons, be sure to observe the following instructions.

Connect wires of the

same gauge to both

side. (GOOD)

Do not connect wires

of the same gauge to

one side. (WRONG)

Do not connect wires

of different gauges.

(WRONG)

Good Wrong Wrong

(Loose wiring and similar problems may result in abnormal heat build-up.)

• In wiring, make certain that prescribed wires are used, carry out complete connections, and fix the wires so

that external forces are not applied to the terminals.

• If the strand wire is used, do not solder it.

Tightening torque for the terminal screws.

• Use the correct screwdriver for

head of the screw might be damaged, and the screw will not be properly tightened.

• If the terminal screws are tightened too hard, screws might be damaged.

Refer to the table below for the tightening torque of the terminal screws.

tightening the terminal screws. If

the blade of screwdriver is too small, the

19

Tightening torque (N·m)

69.0 ot 08.0rellortnoc etomer rof kcolb lanimreT

44.1 ot 81.1stinu eht gniriw rof kcolb lanimreT

44.1 ot 81.1lanimret htraE

English

Page 21

Specifications for field wire.

• Remote controller transmission and power supply wiring are field supply. Refer to Table 2.

• Follow 60245 IEC 57 for wiring type (insulating sheath specification, etc.)

Table 2

2

)

2.5 –

Wiring the units

Remote

controller cord

Type Field fuses Wire spec.

20

45 • 48 –

36

• 24 • – 4 cores (incl. earth wire)

4 cores (incl. earth wire)

Shield wire

– –

Size(mm

0.75-1.25 Max.500m*

2 cores

Power supply

wiring (for Fan)

*Total length of system wiring if using group control.

• Wiring specifications assume a voltage drop of 2%.

WIRING EXAMPLE

CAUTION

Be sure to install an earth leakage breaker to the outdoor unit.

Installation of an earth leakage breaker is mandated to avoid electric shocks or fire.

Length

––A51–

For the wiring of outdoor units, refer to the installation manual attached to the outdoor units.

Confirm the system type.

• Pair type: 1 remote controller controls 1 indoor unit. (standard system)

• Group control: 1 remote controller controls up to 16 indoor units. (All indoor units operate according to

te controller) (Refer to Fig. 10)

remo

the

• 2 remote controllers control: 2 remote controllers control 1 indoor unit. (Refer to Fig. 14)

Pair type

Main power supply

Earth leakage breaker

Outdoor unit

1 2 3

P1

P2

P1

P2

Remote controller

(Optional accessory)

Earth leakage breaker

Power supply

single phase

L

N

50Hz/60Hz

1

2

3

L

N

Indoor unit

220-240V/230V

Group control: 1 remote controller controls up to 16 indoor units. (All indoor units operate according to the

remote controller) (Refer to Fig. 10)

n this case, all the indoor units in the group will operate in accordance with the group control remote contro

•

I

FBQ48EAVMK is only 50Hz model.

•

ller.

English

20

Page 22

• For group control remote controller, choose the remote controller that suits the indoor unit which has the

most functions (as attached swing flap)

Group control

Outdoor unit 1

Outdoor unit 2

Indoor unit 1

Indoor unit 2

Indoor unit 16

Group control remote controller

Wiring Method

(1) Remove the control box lid. (See ‘‘9. ELECTRIC WIRING WORK’’.)

(2) Cross-wire the terminal block for remote controller (P

) inside the control box. (There is no

1 P2

polarity.) (Refer to Fig. 10 and Table 2)

Indoor unit 1 Indoor unit 2

2P1P2P1P

Terminal for remote

controller wiring

To next unit

Group control remote controller

Two remote controllers control (Controlling 1 indoor unit by 2 remote controllers)

• When using 2 remote controllers, one must be set to “MAIN” and the other to “SUB”.

Outdoor unit 16

Fig. 10

Fig. 11

MAIN/SUB CHANGEOVER

(1) Insert a screwdriver into the recess between the upper and lower part of remote controller and, working

from the 2 positions, pry off the upper part. (The remote controller PC board is attached to the upper part

of remote controller.) (Refer to Fig. 12)

Fig. 12

Upper part of

remote controller

Lower part of

Insert the screwdriver

remote controller

here and gently work

off the upper part of

remote controller.

21

English

Page 23

(2) Turn the main/sub changeover switch on one of the two remote controller PC boards to “S”. (Leave the

switch of the other remote controller set to “M”.) (Refer to Fig. 13)

Fig. 13

S

(Factory setting)

S

M

Remote

controller

(Only one remote

controller needs

S

M

PC board

to be changed if

factory settings

have remained

untouched.)

Wiring Method (See “9. ELECTRIC WIRING WORK’’.)

(3) Remove the control box lid

(4) Add remote controller 2 (slave) to the terminal block for remote controller (P

, P2) in the control

1

box. (There is no polarity.)

Outdoor unit

P1 P2

Terminal for remote

controller wiring

Remote

controller 1

Remote

controller 2

Remote

controller 1

(Master)

Remote

controller 2

(Slave)

Fig. 14

11. FIELD SETTING

NOTE

• Before 12. TEST OPERATION, be sure to make the following field settings as explained in 11. FIELD

SETTING.

• Be sure to check that the outdoor unit has been wired.

• Make sure the control box lids are closed on the indoor and outdoor units.

• Field setting must be made from the remote controller in accordance with the installation condition.

• Setting can be made by changing the “MODE NO.”, “FIRST CODE NO.”, and “SECOND CODE NO.”.

• For setting and operation, refer to the “FIELD SETTING” in the installation manual of the remote controller.

• Do not set numbers unless mentioned in the table.

22English

Page 24

With Wireless Remote Controller Used

Set the wireless remote controller address before using the wireless remote controller.

For the setting method of the address, refer to the operation manual provided with the wireless remote

con

troller.

NOTE

• A “MODE NO.” is set on a group basis. To make a mode setting on a room unit basis or check the setting

made, however, set the corresponding mode number in the parentheses.

1. Settings for Optional Accessories

• In the case of connecting optional accessories, refer to the operation manuals provided with the optional

accessories and make necessary settings.

2. External Static Pressure Settings

Make settings in either method (a) or method (b) as explained below.

(a) Use the airflow auto adjustment function to make settings.

Airflow auto adjustment: The volume of blow-off air is automatically adjusted to the rated quantity.

NOTE

Be sure to check that the external static pressure is within the rated range before making the settings.

the external static pressure is beyond the rated range, no automatic adjustments will be made and an

If

air

flow rate insufficiency or water leakage may result. (Refer to the relevant technical datasheet for the

rated

range of the external static pressure.)

Table 3

(1)Check that power supply wiring and wiring the units to the air conditioner is completed along with

duct installation. If a closing damper is installed in the air-conditioning system, make sure that the

closing damper is opened. Furthermore, check that the

air passage on the suction side.

(2)If there are a number of air outlets and inlets, adjust the throttles so that the airflow rate of each air

outlet and inlet will coincide with the designed airflow rate. At that time, operate the air conditioner

in “fan operation mode”. To change the airflow rate, press and set the airflow adjustment button of

the remote controller to H, or L.

(3)Make settings for airflow automatic adjustment. After setting the air conditioner to “fan operation

mode”, stop the air conditioner, go to “FIELD SET MODE”, select “MODE NO. 21” (11 in the case

of group settings), set the setting “FIRST CODE NO.” to 7, and set the setting “SECOND CODE

NO.” to 03.

Return t

operation lamp will be lit and the air conditioner will go into fan operation for airflow automatic

adjustment. Do not adjust the throttles of the air outlets or inlets during automatic adjustment of the

air conditioner. After the air conditioner runs approximately one to eight minutes, the air conditioner

will finish airflow adjustment automatically, the operation lamp will be turned OFF, and the air

con

MODE NO. FIRST CODE NO. Setting contents

o normal mode after these settings, and press the ON/OFF OPERATION button. Then the

ditioner will come to a stop.

11 (21 tnemtsujda wolfriA7)

SECOND CODE NO.

OFF Completion of airflow adjustment Start of airflow adjustment

air filter as a field supply is attached to the

302010

(4)After the air conditioner stops operating, check with “MODE NO. 21” on an indoor unit basis that 02

is set for the “SECOND CODE NO.” in Table 3. If the air conditioner does not stop operating

auto

matically or the “SECOND CODE NO.” is not

check

the defective point.

02, repeat steps from (3). If error is displayed,

English23

Page 25

CAUTION

• If there is any change after airflow adjustment in the ventilation paths (e.g., the duct and air outlet), be sure

to make airflow auto adjustment again.

• Consult your Daikin representative if there is any change in the ventilation paths (e.g., the duct and air

out

let) after the test operation is finished or the air conditioner is moved to another place.

(b) Select External Static Pressure with Remote Controller

Check that 01 (OFF) is set for the “SECOND CODE NO.” in “MODE NO. 21” for airflow adjustment on an

indoor unit basis in Table 3. The “SECOND CODE NO.” is set to 01 (OFF) at factory set. Change the

OND CODE NO.” as shown in Table 4 according to the external static pressure of the duct to be

“SEC

connected.

(1)The “SECOND CODE NO.” is set to 01 (an external static pressure of 50 Pa) at

factory set.

Table 4

External Static Pressure

(Pa)

50

MODE NO.

Note

FIRST CODE NO. SECOND CODE NO.

01

60 02

70 03

80 04

90 05

100 06

110 07

120 08

13 (23) 06

130 09

140 10

150 11

160 12

180 13

200 14

NOTE

“Mode No.” setting is done in a batch for the group. To make or confirm settings for an individual unit, set

the Mode No. shown in parentheses.

CAUTION

Keep in mind that a shortage of airflow quantity or water leakage will result because the air conditioner will

be operated outside the rated range of airflow quantity if the external static pressure is wrongly set.

3. Filter Sign Settings

• The remote controller is provided with an LCD that tells the time of air filter cleaning.

• If the air conditioner is used in places with excessive dust, change the “SECOND CODE NO.” as shown

in Table 5. The “SECOND CODE NO.” is set to 01 (standard) at factory set.

Table 5

Dirt Time for display

Standard

Excessive dust

Approximately

2500 hours

Approximately

1250 hours

MODE NO.

Note

10 (20)

FIRST CODE NO.

0

SECOND CODE

NO.

01

02

3)*( yalpsid oN

Select “No display” under conditions in which the cleaning display is not required, such as the time of regular maintenance.

*

NOTE

“Mode No.” setting is done in a batch for the group. To make or confirm settings for an individual unit, set

the Mode No. shown in parentheses.

English

24

Page 26

12. TEST OPERATION

Refer to the section of “FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE DURING

CONSTRUCTION AND CHECK AFTER INSTALLATION IS FINISHED” .

• Make sure that wiring work for the outdoor units is completed.

• Make sure the control box lids are closed on the indoor and outdoor units.

• After finishing installation work for refrigerant piping, drain piping, and electrical wiring, clean the insides of

the indoor units.

• Conduct test operation in accordance with the instructions in the installation manual included with the

outdoor units.

• If interior work is still unfinished when test operation finishes, explain to th

must not be operated until interior work is completed in order to protect the indoor units.

(Substances generated from paints and adhesives used for the interior work may contaminate indoor units

if the air conditioner is operated.)

• Refer to the diagnoses below if the unit does not operate properly.

• After completing the test run, press the INSPECTION/TEST OPERATION button once to put the unit in

inspection mode, and make sure the malfunction code is “00”. (=normal)

If the code reads anything other than “00”, refer to the malfunction diagnoses below.

• Press the INSPECTION/TEST OPERATION button four times to return to normal operation mode.

• When using wireless remote controllers, conduct test operation after installing the decoration panel.

[Mode switching]

e customer that the air conditioner

Normal operating mode

Once

(Press

4 seconds

or more)

Field setting

* After leaving 10 seconds or

more, the mode returns to

the normal operating mode.

Once

Once

*

“Error code”

display

Once

“Indoor unit type

Once Once

code” display

Measures

Test run

Once

**

“Outdoor unit type

code” display

12-1 Troubleshooting

• When the wired remote controller display is in any of the states described in Table 6, inspect for the

corre

sponding issues.

Table 6

noitcnuflaMyalpsid rellortnoc etomeR

• Power supply trouble or Open phase connection

• Wrong wiring between indoor and outdoor unit

No display

88*

88 flashing • Wrong wiring between indoor and outdoor unit

• Indoor PC board faulty

• Wrong remote controller conection wiring

• Remote controller faulty

• Fuse faulty

• Indoor PC board faulty

• Wrong wiring

between indoor and outdoor unit

*After turning on the power, the maximum is 90 seconds, although it will only display “88”. This is not a

problem, and it will be set for 90 seconds.

English25

Page 27

With the power on. Troubles can be monitored on the remote controller.

Trouble shooting with the display on the liquid crystal display remote controller.

1. With the wired remote controller. (NOTE 1)

When the operation stops due to trouble, operation lamp flashed, and “ ” and the Malfunction code are

indicated on the liquid crystal display. In such a case, diagnose the fault contents by referring to the table

on the Malfunction code list it case of group control, the unit No. is displayed so that the indoor unit no with

the trouble can be recognized. (NOTE 2)

2. With the wireless remote controller.

(Refer also to the operation manual at

When the operation stops due to trouble. the display on the indoor unit flashes. In such a case, diagnose

the fault contents with the table on the Malfunction code list looking for the Malfunction code which can be

found by following procedures. (NOTE 2)

(1) Press the INSPECTION /TEST OPERATION button, “ ” is displayed and “ 0 ” flashes.

(2) Press the PROGRAMMING TIME button and find the unit No. which stopped due to trouble.

Number of beeps 3 short beeps Perform all the following operations

1 short beep Perform (3) and (6)

1 long beep No trouble

(3) Press the OPERATION MODE SELECTOR button and upper figure of the Malfunction code flashes.

Continue pressing the PROGRAMMING TIME button unit it makes 2 short beeps and find the upper code.

(4)

(5) Press the OPERATION MODE SELECTOR button and lower figure of the Malfunction code flashes.

(6) Continue pressing the PROGRAMMING TIME button unit it makes a long beep and find the lower code.

• A long beep indicate the Malfunction code.

NOTE

1. In case wired remote controller. Press the INSPECTION /TEST OPERATION button on remote controller,

“ ” starts flashing and changes the inspection mode.

2. Keep down the ON/OFF button for 5 seconds or longer in the inspection mode and the above trouble

tory disappears, after the trouble code goes on and off twice, followed by the code “00”(normal).

his

The display changes from the inspection mode to the normal mode.

tached to the wireless remote controller)

12-2 Malfunction code list

• For places where the Malfunction code is left blank, the “ ” indication is not displayed. Though the system

continues operating, be sure to inspect the system and make repairs as necessary.

• Depending on the type of indoor or ou

A1 Indoor unit’s PC board faulty

A3 Drain water level abnormal

A6 Indoor fan motor overloaded, overcurrent or locked

A8 Indoor unit power supply voltage abnormal

AF

AH

AJ

C1

C4 Sensor for heat exchanger lamp is fault

C6 Indoor unit fan driver PCB combination failure, control PCB type-wise setting failure

C9 Sensor for suction air lamp is fault

CC

CJ

E0 Action of safety device (outdoor unit)

E1 Outdoor unit’s PC board faulty (outdoor unit)

Humidifier faulty

Air cleaner faulty

Only the air cleaner does not function.

Type set improper

Capacity data is wrongly preset. Or there is nothing programmed in the data hold IC.

Indoor unit fan driver PCB ↔ Indoor control PCB transmission abnormal

Power source malfunction (indoor unit)

Temperature sensor system faulty

Sensor for remote controller is fault

The remote controller thermistor does not function, but the system thermo run is possible.

tdoor unit, the Malfunction code may or may not be displayed.

skrameR/noitcnuflaMedoC

26English

Page 28

E3 High pressure abnormal (outdoor unit)

E4 Low pressure abnormal (outdoor unit)

E5 Compressor motor lock malfunction (outdoor unit)

E7

E9 Electronic expansion valve faulty (outdoor unit)

F3 Discharge pipe temperature abnormal (outdoor unit)

H3 High pressure switch faulty (outdoor unit)

H7 Outdoor motor position signal malfunction (outdoor unit)

H9

J1 Pressure sensor system error (batch) (outdoor unit)

J2

J3

J5 Suction pipe thermistor faulty (outdoor unit)

J6

J7

J8

J9 Suction temperature sensor faulty (outdoor unit)

JA Pressure sensor for discharge pipe faulty (outdoor unit)

JC Pressure sensor for suction pipe faulty (outdoor unit)

L1 Inverter system error (outdoor unit)

L4

L5

L8

L9

LC Transmission malfunction between the ou

P1

P3 PC board temperature sensor malfunction (outdoor unit)

P4 Heat-radiating fin temperature sensor malfunction (outdoor unit)

PJ

U0

U1

U2

Outdoor fan motor lock malfunction

Outdoor fan instantaneous overcurrent malfunction (outdoor unit)

Outdoor air thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Current sensor faulty

Discharge pipe thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Heat exchanger thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Heat exchanger thermistor faulty (outdoor unit)

Equipment operation in response to errors will vary according to model.

Liquid piping temperature sensor system error (outdoor unit)

Overheated heat-radiating fin (outdoor unit)

Inverter cooling defect.

Instantaneous overcurrent (outdoor unit)

Possible earth fault or short circuit in the compressor motor.

Electric thermal (outdoor unit)

Possible electrical overload in the compressor or cut line in the compressor motor.

Stall prevention (outdoor unit)

Compressor possibly locked.

tdoor control units’ inverters (outdoor unit)

Open-phase (outdoor unit)

Type set improper (outdoor unit)

Capacity data is wrongly preset. Or there is nothing programmed in the data hold IC.

Suction pipe temperature abnormal

The quantity of refrigerant may be insufficient.

Reverse phase

Reverse two of the L1,L2 and L3 leads.

Power source voltage malfunction (outdoor unit)

Inverter phase loss or a failure in the main circuit capacitor may be resulting.

27

English

Page 29

Transmission error (indoor unit – outdoor unit)

Wrong wiring between indoor and outdoor units or malfunction of the PC board mounted

U4

UF

U5

U8

UA

UC

UJ Transmission failure in accessory equipment

CAUTION

• Refer to “b. Items to be checked at time of delivery” on page 5 upon completion of the test run and make

sure that all the items are checked.

• If the customer’s interior work has not been finished on completion of the test run, explain the customer

not to operate the air conditioner. This is essential until the interior work is finished so as to protect the

product.

Substances generated from paints and adhesives used for the interior work may contaminate the product

if the unit is operated.

on the indoor and the outdoor units.

If UF is shown, the wiring between the indoor and outdoor units is not properly wired.

Therefore, immediately disconnect the power supply and correct the wiring. (The

compressor and the fan mounted on the outdoor unit may start operation independent of

the remote controller operation.)

Transmission error (indoor unit – remote controller)

Transmission is improper between the indoor unit and the remote controller.

Malfunction in transmission between main and sub remote controllers.

(Malfunction in sub remote controller.)

Miss setting for multi system

Error in multi-system settings for simultaneous ON/OFF operation.

Central control address overlapping

To test run Contractors

When delivering the product to the customer after the test run is completed, check that the control box lid,

the air filter and the suction grille are mounted. In addition, explain to the customer regarding the state

(ON/OFF) of the power supply breaker.

28English

Page 30

MEMO

Page 31

FBQ20EAVAK

FBQ24EAVAK

FBQ36EAVAK

ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺩ ﻢﺴﻘﻨﻤﻟﺍ ﻡﺎﻈﻨﻟﺍ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ

FBQ45EAVAK

FBQ48EAVAK

FBQ48EAVMK

ﺕﺎﻳﻮﺘﺤﻤﻟﺍ

١ .................................................................................................................. ﺔﻣﻼﺴﻟﺍ ﺕﺎﻃﺎﻴﺘﺣﺍ .١

٤ ........................................................................................................................ ﺐﻴﻛﺮﺘﻟﺍ ﻞﺒﻗ .٢

٦ ................................................................................................................ﺐﻴﻛﺮﺘﻟﺍ ﻊﻗﻮﻣ ﺪﻳﺪﺤﺗ .٣

٧ .......................................................................................................... ﺐﻴﻛﺮﺘﻟﺍ ﻞﺒﻗ ﺕﺍﺮﻴﻀﺤﺘﻟﺍ .٤

٩ ............................................................................................................. ﺔﻴﻠﺧﺍﺪﻟﺍ ﺓﺪﺣﻮﻟﺍ ﺐﻴﻛﺮﺗ .٥

١٠ .......................................................................................................ﺪﻳﺮﺒﺘﻟﺍ ﺐﻴﺑﺎﻧﺃ ﻞﻴﺻﻮﺗ ﻝﺎﻤﻋﺃ .٦

١٣ ...................................................................................................ﻒﻳﺮﺼﺘﻟﺍ ﺐﻴﺑﺎﻧﺃ ﻞﻴﺻﻮﺗ ﻝﺎﻤﻋﺃ .٧

١٥ ................................................................................................................ءﺍﻮﻬﻟﺍ ﻯﺮﺠﻣ ﻝﺎﻤﻋﺃ .٨

١٦ ................................................................................................ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﻙﻼﺳﻷﺍ ﻞﻴﺻﻮﺗ ﻝﺎﻤﻋﺃ .٩

١٦ .................................................................... ﺪﻌُﺑ ﻦﻋ ﻢﻜﺤﺘﻟﺍ ﺓﺪﺣﻭ ﻦﻴﻴﻌﺗ ﺔﻴﻔﻴﻛﻭ ﻙﻼﺳﻷﺍ ﻞﻴﺻﻮﺘﻟ ﺝﺫﻮﻤﻧ .١٠

٢٢ ......................................................................................................................... ﻞﻘﺤﻟﺍ ﺩﺍﺪﻋﺇ .١١

٢٥ ..................................................................................................................... ﺭﺎﺒﺘﺧﻻﺍ ﺔﻴﻠﻤﻋ .١٢

١ .ﺔﻣﻼﺴﻟﺍ ﺕﺎﻃﺎﻴﺘﺣﺍ

ﻥﺃ ﻦﻣ ﺪﻛﺄﺗ ،ﺐﻴﻛﺮﺘﻟﺍ ﻦﻣ ءﺎﻬﺘﻧﻻﺍ ﺪﻌﺑ .ﺢﻴﺤﺻ ﻞﻜﺸﺑ ﺎﻬﺒﻴﻛﺮﺗ ﻦﻣ ﺪﻛﺄﺗﻭ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺓﺪﺣﻭ ﺐﻴﻛﺮﺗ ﻞﺒﻗ ﺔﻳﺎﻨﻌﺑ ﻩﺬﻫ "ﺔﻣﻼﺴﻟﺍ ﺕﺎﻃﺎﻴﺘﺣﺍ" ﺓءﺍﺮﻗ ﻰﺟﺮُﻳ

.ﻞﻴﻐﺸﺘﻟﺍ ءﺪﺑ ﺔﻴﻠﻤﻋ ءﺎﻨﺛﺃ ﺢﻴﺤﺻ ﻞﻜﺸﺑ ﻞﻤﻌﺗ ﺓﺪﺣﻮﻟﺍ

.ﺎﻬﺘﻧﺎﻴﺻ ﻰﻠﻋ ﻅﺎﻔﺤﻟﺍﻭ ﺓﺪﺣﻮﻟﺍ ﻞﻴﻐﺸﺗ ﺔﻴﻔﻴﻛ ﻦﻋ ﻞﻴﻤﻌﻟﺍ ﺩﺎﺷﺭﺇ ﻰﺟﺮُﻳ

.ﺪﻌﺑ ﺎﻤﻴﻓ ﻪﻴﻟﺇ ﻉﻮﺟﺮﻠﻟ ﻞﻴﻐﺸﺘﻟﺍ ﻞﻴﻟﺩ ﻊﻣ ﺍﺬﻫ ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺪﺑ ﻅﺎﻔﺘﺣﻻﺍ ﻲﻐﺒﻨﻳ ﻪﻧﺃ ﻞﻴﻤﻌﻟﺍ ﻍﻼﺑﺇ ﺐﺠﻳ ﺎﻤﻛ

.ﻪﻴﺒﻨﺘﻟﺍﻭ ﺮﻳﺬﺤﺘﻟﺍ ﺕﺍﺭﺎﻌﺷﺇ ﻰﻨﻌﻣ

.ﺎﻤﻬﻋﺎﺒﺗﺍ ﻦﻣ ﺪﻛﺄﺗ .ﺔﻣﻼﺴﻠﻟ ﺔﻣﺎﻫ ﺕﺍﺭﺎﻌﺷﺇ ﺎﻤﻫﻼﻛ

.ﺡﺍﻭﺭﻷﺍ ﻲﻓ ﺮﺋﺎﺴﺧ ﻭﺃ ﺔﻴﺼﺨﺷ ﺔﺑﺎﺻﻹ ﺽﺮﻌﺘﻟﺍ ﺢﻴﺤﺻ ﻞﻜﺸﺑ ﺕﺍﺩﺎﺷﺭﻹﺍ ﻩﺬﻫ ﻉﺎﺒﺗﺍ ﻡﺪﻋ ﻦﻋ ﻢﺠﻨﻳ ﺪﻗ..........

،ﺹﺎﺨﺷﻸﻟ ﺕﺎﺑﺎﺻﺇ ﻭﺃ ﺕﺎﻜﻠﺘﻤﻤﻟﺍ ﻲﻓ ﺕﺎﻴﻔﻠﺗ ﻲﻓ ﺐﺒﺴﺘﻟﺍ ﻰﻟﺇ ﺢﻴﺤﺻ ﻞﻜﺸﺑ ﺕﺍﺩﺎﺷﺭﻹﺍ ﺓﺎﻋﺍﺮﻣ ﻲﻓ ﺲﻋﺎﻘﺘﻟﺍ ﻱﺩﺆﻳ ﺪﻗﻭ ...........

.ﺔﻄﻴﺤﻤﻟﺍ ﻑﻭﺮﻈﻟﺍ ﻰﻠﻋ ًءﺎﻨﺑ ﺓﺮﻴﻄﺧ ﻥﻮﻜﺗ ﺪﻗ ﻲﺘﻟﺍﻭ

ﺔﻧﺎﻌﺘﺳﻻﺍ ﻊﻣ ﻪﺑ ﻡﺎﻤﺘﻫﻻﺍﻭ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﻞﻴﻐﺸﺗ ﺔﻴﻔﻴﻛ ﻞﻴﻤﻌﻠﻟ ﺡﺮﺷﺍﻭ ،ﺏﻮﻴﻋ ﺔﻳﺃ ﺩﻮﺟﻭ ﻦﻣ ﻖﻘﺤﺘﻠﻟ ﻲﺒﻳﺮﺠﺗ ﻞﻴﻐﺸﺗ ءﺍﺮﺟﺈﺑ ﻢﻗ ،ﺐﻴﻛﺮﺘﻟﺍ ﻝﺎﻤﺘﻛﺍ ﺪﻌﺑ

.ﺪﻌﺑ ﺎﻤﻴﻓ ﻪﻴﻟﺇ ﻉﻮﺟﺮﻠﻟ ﻞﻴﻐﺸﺘﻟﺍ ﻞﻴﻟﺩ ﻊﻣ ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺪﺑ ﻅﺎﻔﺘﺣﻻﺍ ﻞﻴﻤﻌﻟﺍ ﻦﻣ ﺐﻠﻃﺍ .ﻞﻴﻐﺸﺘﻟﺍ ﻞﻴﻟﺪﺑ

."ﻡﺎﻌﻟﺍ ﺭﻮﻬﻤﺠﻟﺍ ﺩﺍﺮﻓﻷ ﺔﺣﺎﺘﻤﻟﺍ ﺮﻴﻏ ﺓﺰﻬﺟﻷﺍ" ﻒﻴﻨﺼﺗ ﺖﺤﺗ ﺍﺬﻫ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺝﺭﺪﻨﻳ

.ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺕﺎﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻭﺃ ءﺎﻤﻟﺍ ﺏﺮﺴﺗ ﻰﻟﺇ ﺢﻴﺤﺼﻟﺍ ﺮﻴﻏ ﺐﻴﻛﺮﺘﻟﺍ ﻱﺩﺆﻳ ﺪﻘﻓ .ﻚﺴﻔﻨﺑ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺐﻴﻛﺮﺗ ﻝﻭﺎﺤﺗ ﻻ

.ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺕﺎﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻭﺃ ءﺎﻤﻟﺍ ﺏﺮﺴﺗ ﻰﻟﺇ ﺢﻴﺤﺼﻟﺍ ﺮﻴﻏ ﺐﻴﻛﺮﺘﻟﺍ ﻱﺩﺆﻳ ﺪﻘﻓ

ﻦﻴﺠﺴﻛﻷﺍ ﺺﻘﻧ ﻰﻟﺇ ﻖﻠﻐﻣ ﻂﻴﺤﻣ ﻲﻓ ﺪﻳﺍﺰﺘﻤﻟﺍ ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﻱﺩﺆﻳ ﺪﻘﻓ .ﺕﺎﻣﻮﻠﻌﻤﻟﺍ ﻦﻣ ﺪﻳﺰﻣ ﻰﻠﻋ ﻝﻮﺼﺤﻠﻟ ءﺍﺮﺸﻟﺍ ﻥﺎﻜﻤﺑ ﻞﺼﺗﺍ

.ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺕﺎﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻭﺃ ءﺎﻤﻟﺍ ﺏﺮﺴﺗ ﻭﺃ ﺓﺪﺣﻮﻟﺍ ﻁﻮﻘﺳ ﻰﻟﺇ ﺓﺩﺪﺤﻤﻟﺍ ءﺍﺰﺟﻷﺍ ﻡﺍﺪﺨﺘﺳﺍ ﻡﺪﻋ ﻱﺩﺆﻳ ﺪﻘﻓ

ﺮﻳﺬﺤﺗ

ﻪﻴﺒﻨﺗ

ﺮﻳﺬﺤﺗ

•.ﺐﻴﻛﺮﺘﻟﺍ ﻝﺎﻤﻋﺄﺑ ﻡﺎﻴﻘﻟﺍ ﻦﻴﻠﻫﺆﻤﻟﺍ ﻦﻴﻔﻇﻮﻤﻟﺍ ﻭﺃ ﻚﺑ ﺹﺎﺨﻟﺍ ﻉﺯﻮﻤﻟﺍ ﻦﻣ ﺐﻠﻃﺍ

•.ﺍﺬﻫ ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺩ ﻲﻓ ﺓﺩﺭﺍﻮﻟﺍ ﺕﺍﺩﺎﺷﺭﻺﻟ ﺎًﻘﻓﻭ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺐﻴﻛﺮﺘﺑ ﻢﻗ

•.ﺪﻳﺮﺒﺘﻟﺍ ﺓﺩﺎﻣ ﺏﺮﺴﺗ ﺔﻻﺣ ﻲﻓ ﺎﻬﺑ ﺡﻮﻤﺴﻤﻟﺍ ﺔﻣﻼﺴﻟﺍ ﺩﻭﺪﺤﻟ ﺪﻳﺮﺒﺘﻟﺍ ﺓﺩﺎﻣ ﺰﻴﻛﺮﺗ ﺯﻭﺎﺠﺗ ﻊﻨﻤﻟ ﺔﻣﺯﻼﻟﺍ ﺮﻴﺑﺍﺪﺘﻟﺍ ﺬﺨﺗﺍ ،ﺓﺮﻴﻐﺻ ﺔﻓﺮﻏ ﻲﻓ ﺓﺪﺣﻮﻟﺍ ﺐﻴﻛﺮﺗ ﺪﻨﻋ

•.ﺐﻴﻛﺮﺘﻟﺍ ﻝﺎﻤﻋﻷ ﻂﻘﻓ ﺓﺩﺪﺤﻤﻟﺍ ءﺍﺰﺟﻷﺍﻭ ﺕﺎﻘﺤﻠﻤﻟﺍ ﻡﺍﺪﺨﺘﺳﺍ ﻦﻣ ﺪﻛﺄﺗ

ﺔﻴﺑﺮﻌﻟﺍ ١

Page 32

.ﺔﺑﺎﺻﺇ ﻲﻓ ﺐﺒﺴﺘﻟﺍﻭ ﺯﺎﻬﺠﻟﺍ ﻁﻮﻘﺳ ﻰﻟﺇ ﻲﻔﻜﻳ ﺎﻤﺑ ﺔﻳﻮﻘﻟﺍ ﺮﻴﻏ ﺓﺪﻋﺎﻘﻟﺍ ﻱﺩﺆﺗ ﺪﻗ

.ﺙﺩﺍﻮﺣ ﻉﻮﻗﻭﻭ ﺓﺪﺣﻮﻟﺍ ﻁﻮﻘﺳ ﻰﻟﺇ ﺐﻴﻛﺮﺘﻟﺍ ﻝﺎﻤﻋﺃ ءﺎﻨﺛﺃ ﻚﻟﺬﺑ ﻡﺎﻴﻘﻟﺍ ﻡﺪﻋ ﻱﺩﺆﻳ ﺪﻘﻓ

.ﺍﺬﻫ ﺐﻴﻛﺮﺘﻟﺍ

.ﻖﻳﺮﺣ ﻉﻻﺪﻧﺍ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺕﺎﻣﺪﺻ ﺙﻭﺪﺣ ﻰﻟﺇ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺔﻴﻨﺒﻟﺍ ﺔﻣﻼﺳ ﻡﺪﻋ ﻭﺃ ﺔﻗﺎﻄﻟﺍ ﺕﺍﺩﺍﺪﻣﺇ ﺔﻳﺎﻔﻛ ﻡﺪﻋ ﻱﺩﺆﺗ ﺪﻗ

.ﻲﺿﺭﺃ ﻥﻮﻔﻴﻠﺗ ﻚﻠﺳ ﻭﺃ ﻖﻋﺍﻮﺻ ﺔﻌﻧﺎﻣ ﻭﺃ ﻡﺪﺨﺘﺴﻣ ﺏﻮﺒﻧﺃ ﻝﻼﺧ ﻦﻣ ﻲﺿﺭﺃ ﻑﺮﻄﺑ ﺓﺪﺣﻮﻟﺍ ﻞﺻﻮﺗ ﻻ

.ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻰﻟﺇ ﺔﻤﻴﻠﺳ ﺮﻴﻏ ﺔﻘﻳﺮﻄﺑ ﻲﺿﺭﺃ ﻑﺮﻄﺑ ﻞﻴﺻﻮﺘﻟﺍ ﻱﺩﺆﻳ ﺪﻗ

.ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﻒﻠﺗ ﻰﻟﺇ ،ﻯﺮﺧﺃ ﺭﺩﺎﺼﻣ ﻭﺃ ،ﻖﻋﺍﻮﺻ ﺙﻭﺪﺣ ﺐﺒﺴﺑ ﺓﺪﺸﺑ ﺭﺎﻴﺘﻟﺍ ﻉﺎﻓﺪﻧﺍ ﻱﺩﺆﻳ ﺪﻗ

.ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻰﻟﺇ ﺭﺎﻴﺘﻠﻟ ﻲﺿﺭﻷﺍ ﺏﺮﺴﺘﻟﺍ ﻦﻣ ﺔﻳﺎﻤﺤﻠﻟ ﺔﻴﺳﺎﺴﺣ ﻱﺫ ﻊﻃﺎﻗ ﺐﻴﻛﺮﺗ ﻡﺪﻋ ﻱﺩﺆﻳ ﺪﻗ

.ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻰﻟﺇ ﺔﻠﻣﺎﻋ ءﺍﺰﺟﺃ ﺔﻳﺃ ﺲﻤﻟ ﻱﺩﺆﻳ ﺪﻘﻓ

.ﻖﻳﺮﺣ ﻉﻻﺪﻧﺍ ﻭﺃ ﻲﻌﻴﺒﻃ ﺮﻴﻏ ﻞﻜﺸﺑ ﺓﺭﺍﺮﺤﻟﺍ ﻢﻛﺍﺮﺗ ﻰﻟﺇ ﺔﻨّﻣﺆﻤﻟﺍ ﺮﻴﻏ ﻙﻼﺳﻷﺍ ﻭﺃ ﺔﺤﻴﺤﺼﻟﺍ ﺮﻴﻏ ﺕﻼﻴﺻﻮﺘﻟﺍ ﻱﺩﺆﺗ ﺪﻘﻓ

.ﻦﻣﺁ ﻞﻜﺸﺑ

.ﺓﺪﺸﺑ ﺔﻴﻓﺮﻄﻟﺍ ﺕﻼﻴﺻﻮﺘﻟﺍ ﺓﺭﺍﺮﺣ ﺔﺟﺭﺩ ﻉﺎﻔﺗﺭﺍ ﻭﺃ ﻖﻳﺮﺣ ﺏﻮﺸﻧ ﻭﺃ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺕﺎﻣﺪﺼﻟ ﺽﺮﻌﺘﻟﺍ ﻰﻟﺇ ﺔﺒﺳﺎﻨﻣ ﺮﻴﻏ ﺔﻘﻳﺮﻄﺑ ﻢﻜﺤﺘﻟﺍ ﺔﺒﻠﻋ ﻊﺿﻭ ﻱﺩﺆﻳ ﺪﻗﻭ

.ﺭﺎﻨﻠﻟ ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻬﺟ ﺽﺮﻌﺗ ﺍﺫﺇ ﻡﺎﺴﻟﺍ ﺯﺎﻐﻟﺍ ﺭﺪﺼﻳ ﺪﻗ

.ﻥﺮﻓ ﻭﺃ ﺪﻗﻮﻣ ﻭﺃ ﺔﺣﻭﺮﻣ ﻥﺎﺨﺳ ﻞﺜﻣ ،ﺭﺎﻨﻟﺍ ﺭﺩﺎﺼﻣ ﻦﻣ ﺭﺪﺼﻣ ﻱﻷ ﻪﺘﺴﻣﻼﻣﻭ ﺔﻓﺮﻐﻟﺍ ﻲﻓ ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﺏﺮﺴﺗ ﺔﻟﺎﺣ ﻲﻓ ﻡﺎﺳ ﺯﺎﻏ ﺭﺪﺼﻳ ﺪﻘﻓ

.ﻊﻴﻘﺼﻟﺍ ﻰﻟﺇ ﻪﺴﻤﻟ ﻱﺩﺆﻳ ﺪﻘﻓ

ﺔﺛﺩﺎﺤﻟ ﺽﺮﻌﺘﻟﺍ ﻰﻟﺇ ﻚﻟﺫ ﻱﺩﺆﻳ ﺪﻘﻓ ﻻﺇﻭ .ﺏﺮﺴﺗ ﺙﻭﺪﺣ ﺔﻟﺎﺣ ﻲﻓ ﺰﻴﻛﺮﺘﻟﺍ ﺪﺣ ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﻦﻣ ﺏﺮﺴﺗ ﻱﺃ ﺔﻴﻤﻛ ﻰﻄﺨﺘﺗ ﻻ ﺚﻴﺤﺑ ﺔﺒﺳﺎﻨﻤﻟﺍ ﺮﻴﺑﺍﺪﺘﻟﺍ ﺫﺎﺨﺗﺍ

.ﻦﻴﺠﺴﻛﻷﺍ ﺺﻘﻧ ﺐﺒﺴﺑ

•.ﺓﺪﺣﻮﻟﺍ ﻥﺯﻭ ﻞﻤﺤﺘﻟ ﻲﻔﻜﻳ ﺎﻤﺑ ﺔﻳﻮﻗ ﺓﺪﻋﺎﻗ ﻰﻠﻋ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺐﻴﻛﺮﺘﺑ ﻢﻗ

•.ﻝﺯﻻﺰﻟﺍ ﻭﺃ ﺮﻴﺻﺎﻋﻷﺍ ﻭﺃ ﺔﻳﻮﻘﻟﺍ ﺡﺎﻳﺮﻟﺍ ﺭﺎﺒﺘﻋﻻﺍ ﻲﻓ ﺬﺧﻷﺍ ﺪﻌﺑ ﺓﺩﺪﺤﻤﻟﺍ ﺐﻴﻛﺮﺘﻟﺍ ﻝﺎﻤﻋﺃ ءﺍﺮﺟﺈﺑ ﻢﻗ

• ﻞﻴﻟﺩﻭ ﺔﻴﻠﺤﻤﻟﺍ ﺢﺋﺍﻮﻠﻟﺍﻭ ﻦﻴﻧﺍﻮﻘﻠﻟ ﺎًﻘﻓﻭ ﻦﻴﻠﻫﺆﻣ ﻦﻴﻴﻨﻓ ﺔﻄﺳﺍﻮﺑ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﻝﺎﻤﻋﻷﺍ ﻊﻴﻤﺟ ﻢﺘﺗ ﻥﺃﻭ ﺓﺪﺣﻮﻟﺍ ﻩﺬﻬﻟ ﺔﻠﺼﻔﻨﻣ ﺔﻗﺎﻃ ﺩﺍﺪﻣﺇ ﺓﺮﺋﺍﺩ ﺮﻴﻓﻮﺗ ﻦﻣ ﺪﻛﺄﺗ

•.ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺾﻳﺭﺄﺗ ﻦﻣ ﺪﻛﺄﺗ

•.ﺭﺎﻴﺘﻠﻟ ﻲﺿﺭﻷﺍ ﺏﺮﺴﺘﻟﺍ ﻦﻣ ﺔﻳﺎﻤﺤﻟﺍ ﻊﻃﺍﻮﻗ ﺐﻴﻛﺮﺗ ﻦﻣ ﺪﻛﺄﺗ

•.ﺔﻴﺋﺎﺑﺮﻬﻛ ءﺍﺰﺟﺃ ﻱﺃ ﺲﻤﻟ ﻞﺒﻗ ﺓﺪﺣﻮﻟﺍ ﻞﻴﻐﺸﺗ ﻑﺎﻘﻳﺇ ﻦﻣ ﺪﻛﺄﺗ

•.ﻙﻼﺳﻷﺍ ﻭﺃ ﺔﻴﻓﺮﻄﻟﺍ ﺕﻼﺻﻮﻟﺍ ﻰﻠﻋ ﻂﻐﺿ ﻱﺃ ﺪﺟﻮﻳ ﻻ ﻪﻧﺃﻭ ﺔﻣﺪﺨﺘﺴﻤﻟﺍ ﻲﻫ ﺓﺩﺪﺤﻤﻟﺍ ﻙﻼﺳﻷﺍ ﻥﺃﻭ ﻙﻼﺳﻷﺍ ﺕﻼﻴﺻﻮﺗ ﻊﻴﻤﺟ ﻦﻴﻣﺄﺗ ﻦﻣ ﺪﻛﺄﺗ

• ﻢﻜﺤﺘﻟﺍ ﺔﺒﻠﻋ ءﺎﻄﻏ ﺖﻴﺒﺜﺗ ﻦﻜﻤﻳ ﺚﻴﺤﺑ ﻙﻼﺳﻷﺍ ﻊﺿﻮﺑ ﻢﻗ ،ﺔﻴﻠﺧﺍﺪﻟﺍﻭ ﺔﻴﺟﺭﺎﺨﻟﺍ ﺓﺪﺣﻮﻟﺍ ﻦﻴﺑ ﻙﻼﺳﻷﺍ ﻞﻴﺻﻮﺗﻭ ﺔﻗﺎﻄﻟﺍ ﺩﺍﺪﻣﺇ ﺭﺪﺼﻣ ﻙﻼﺳﺃ ﻞﻴﺻﻮﺗ ﺪﻨﻋ

•.ﺭﻮﻔﻟﺍ ﻰﻠﻋ ﺔﻘﻄﻨﻤﻟﺍ ﺔﻳﻮﻬﺘﺑ ﻢﻘﻓ ،ﺐﻴﻛﺮﺘﻟﺍ ءﺎﻨﺛﺃ ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﺏﺮﺴﺗ ﺍﺫﺇ

•.ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﻲﻓ ﺏﺮﺴﺗ ﺩﻮﺟﻭ ﻡﺪﻋ ﻦﻣ ﻖﻘﺤﺗ ،ﺐﻴﻛﺮﺘﻟﺍ ﻦﻣ ءﺎﻬﺘﻧﻻﺍ ﺪﻌﺑ

•.ﺪﻳﺮﺒﺘﻟﺍ ﺐﻴﺑﺎﻧﺃ ﺕﻼﺻﻭ ﻦﻣ ﺏﺮﺴﺘﺗ ﺪﻳﺮﺒﺗ ﺓﺩﺎﻣ ﻱﺃ ﺲﻤﻠﺗ ﻻ

• ﻱﺭﻭﺮﻀﻟﺍ ﻦﻤﻓ ،ﺓﺮﻴﻐﺻ ﺔﻓﺮﻏ ﻲﻓ ءﺍﻮﻬﻟﺍ ﻒﻴﻴﻜﺗ ﺯﺎﻬﺟ ﺐﻴﻛﺮﺗ ﻢﺘﻳ ﺎﻣﺪﻨﻋ ،ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﺏﺮﺴﺗ ﺔﻟﺎﺣ ﻲﻓ ﻪﺑ ﻡﺎﻴﻘﻟﺍ ﺐﺠﻳ ﺎﻣ ﻥﺄﺸﺑ ﻲﻠﺤﻤﻟﺍ ﻞﻴﻛﻮﻟﺍ ﺮﺸﺘﺳﺍ

ﻪﻴﺒﻨﺗ

.ﺕﺎﻜﻠﺘﻤﻤﻟﺍ ﻒﻠﺗﻭ ﻞﺧﺍﺪﻟﺍ ﻲﻓ ءﺎﻤﻟﺍ ﺏﺮﺴﺗ ﻰﻟﺇ ﺔﺒﺳﺎﻨﻤﻟﺍ ﺮﻴﻏ ﻒﻳﺮﺼﺘﻟﺍ ﺐﻴﺑﺎﻧﺃ ﻱﺩﺆﺗ ﺪﻘﻓ

.ﺕﺎﺟﻮﻤﻟﺍ ﻞﺧﺍﺪﺗﻭ

(.ﺕﺎﺟﻮﻤﻟﺍ ﻞﺧﺍﺪﺗ ﻊﻨﻤﻟ ﺔﻴﻓﺎﻛ ﺮﺘﻣ ١ ﺔﻓﺎﺴﻣ ﻥﻮﻜﺗ ﻻ ﺪﻗ ،ﺓﺩﺭﺍﻮﻟﺍ ﺓﺭﺎﺷﻹﺍ ﺓﻮﻗ ﻰﻠﻋ ﺍًﺩﺎﻤﺘﻋﺍ)

ﻉﻮﻧ ﻦﻣ) ﺔﻴﻧﻭﺮﺘﻜﻟﺇ ﺖﻨﺳﺭﻮﻠﻓ ﺢﻴﺑﺎﺼﻣ ﺎﻬﺑ ﺪﺟﻮﻳ ﻲﺘﻟﺍ ﻑﺮﻐﻟﺍ ﻲﻓ ﺔﻌﻗﻮﺘﻤﻟﺍ ﻦﻣ ﺮﺼﻗﺃ (ﺔﻴﻜﻠﺳﻻ ﺔﻋﻮﻤﺠﻣ) ﺪﻌُﺑ ﻦﻋ ﻢﻜﺤﺘﻟﺍ ﺓﺪﺣﻮﻟ ﻝﺎﺳﺭﻹﺍ ﺔﻓﺎﺴﻣ ﻥﻮﻜﺗ ﺪﻗ

.(ﻊﻳﺮﺴﻟﺍ ءﺪﺒﻟﺍ ﻭﺃ ﺲﻛﺎﻌﻟﺍ

.ﺎﻬﻃﻮﻘﺳﻭ ﺓﺪﺣﻮﻟﺍ ءﺎﺨﺗﺭﺍ ﺔﻟﺎﺣ ﻲﻓ ﺔﺑﺎﺻﺇ ﺙﺪﺤﺗ ﺪﻗ

ﻰﻠﻋ ﺔﻈﻓﺎﺤﻤﻟﺍ ﻦﻋ ﻞﻴﻤﻌﻟﺍ ﺩﺎﺷﺭﺇ ﻰﺟﺮُﻳ .ﻖﻳﺮﺣ ﻭﺃ ﻥﺎﺧﺩ ﺭﻭﺪﺻ ﻭﺃ ﺓﺪﺣﻮﻟﺍ ﻞﻄﻌﺗ ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ءﺍﺰﺟﻷﺍ ﺲﻣﻼﺗ ﻲﺘﻟﺍ ﺓﺮﻴﻐﺼﻟﺍ ﺕﺎﻧﺍﻮﻴﺤﻟﺍ ﺐﺒﺴﺘﺗ ﺪﻘﻓ

.ﺔﻔﻴﻈﻧ ﺓﺪﺣﻮﻟﺎﺑ ﺔﻄﻴﺤﻤﻟﺍ ﺔﻘﻄﻨﻤﻟﺍ

.ﺔﻠﺼﻟﺍ ﺕﺍﺫ ﺔﻴﻨﻃﻮﻟﺍﻭ ﺔﻴﻠﺤﻤﻟﺍ ﺕﺎﻌﻳﺮﺸﺘﻠﻟ ﺎًﻘﻓﻭ ﻯﺮﺧﻷﺍ ءﺍﺰﺟﻷﺍﻭ ﺕﻮﻳﺰﻟﺍﻭ ﺪﻳﺮﺒﺘﻟﺍ ﺓﺩﺎﻣ ﻊﻣ ﻞﻣﺎﻌﺘﻟﺍﻭ ﺓﺪﺣﻮﻟﺍ ﻚﻴﻜﻔﺗ ﻢﺘﻳ ﻥﺃ ﺐﺠﻳ

•.ﻒﻴﺜﻜﺘﻟﺍ ﻊﻨﻤﻟ ﺐﻴﺑﺎﻧﻷﺍ ﻝﺰﻋﻭ ﻢﻴﻠﺴﻟﺍ ﻒﻳﺮﺼﺘﻟﺍ ﻥﺎﻤﻀﻟ ﻒﻳﺮﺼﺘﻟﺍ ﺐﻴﺑﺎﻧﺃ ﺐﻴﻛﺮﺘﺑ ﻢﻗ ،ﺍﺬﻫ ﺐﻴﻛﺮﺘﻟﺍ ﻞﻴﻟﺩ ﻲﻓ ﺓﺩﺭﺍﻮﻟﺍ ﺕﺍﺩﺎﺷﺭﻹﺍ ﻉﺎﺒﺗﺎﺑ ﻡﻮﻘﺗ ﺎﻣﺪﻨﻋ

• ﺓﺭﻮﺼﻟﺍ ﺶﻳﻮﺸﺗ ﻊﻨﻤﻟ ﻮﻳﺩﺍﺮﻟﺍ ﻭﺃ ﻥﻮﻳﺰﻔﻠﺘﻟﺍ ﺓﺰﻬﺟﺃ ﻦﻣ ﻞﻗﻷﺍ ﻰﻠﻋ ﺮﺘﻣ ١ ﺪﻌﺑ ﻰﻠﻋ ﻞﻴﺻﻮﺘﻟﺍ ﻙﻼﺳﺃﻭ ﺔﻗﺎﻄﻟﺍ ﻚﻠﺳﻭ ﺔﻴﺟﺭﺎﺨﻟﺍﻭ ﺔﻴﻠﺧﺍﺪﻟﺍ ﺓﺪﺣﻮﻟﺍ ﺐﻴﻛﺮﺘﺑ ﻢﻗ

•.ﻦﻜﻤﻣ ﺭﺪﻗ ﺮﺒﻛﺄﺑ ﺖﻨﺳﺭﻮﻠﻔﻟﺍ ﺢﻴﺑﺎﺼﻣ ﻦﻋ ﺍًﺪﻴﻌﺑ ﺔﻴﻠﺧﺍﺪﻟﺍ ﺓﺪﺣﻮﻟﺍ ﺐﻴﻛﺮﺘﺑ ﻢﻗ

•.ﺔﺒﺳﺎﻨﻣ ﺮﻴﺑﺍﺪﺗ ﺫﺎﺨﺗﺍ ﻰﻟﺇ ﻡﺪﺨﺘﺴﻤﻟﺍ ﺝﺎﺘﺤﻳ ﺪﻗ ﺔﻟﺎﺤﻟﺍ ﻩﺬﻫ ﻲﻓﻭ ﻮﻳﺩﺍﺮﻟﺍ ﺓﺰﻬﺟﺃ ﻰﻠﻋ ﺶﻳﻮﺸﺗ ﺙﻭﺪﺣ ﻲﻓ ﺞﺘﻨﻤﻟﺍ ﺍﺬﻫ ﺐﺒﺴﺘﻳ ﺪﻗ ،ﺔﻴﻨﻜﺴﻟﺍ ﺔﺌﻴﺒﻟﺍ ﻲﻓ

•.ﺓﺪﺣﻮﻟﺍ ﻰﻠﻋ ءﺎﻴﺷﻷﺍ ﻊﺿﻭ ﺐﻨﺠﺗﻭ ﺔﻴﺟﺭﺎﺨﻟﺍ ﺓﺪﺣﻮﻟﺍ ﻰﻠﻋ ﻖﻠﺴﺘﻟﺎﺑ ﻝﺎﻔﻃﻸﻟ ﺢﻤﺴﺗ ﻻ

•.ﺓﺮﻴﻐﺼﻟﺍ ﺕﺎﻧﺍﻮﻴﺤﻟﺍ ﻞﺒﻗ ﻦﻣ ﺄﺠﻠﻤﻛ ﺔﻴﺟﺭﺎﺨﻟﺍ ﺓﺪﺣﻮﻟﺍ ﻡﺍﺪﺨﺘﺳﺍ ﻊﻨﻤﻟ ﺔﺒﺳﺎﻨﻤﻟﺍ ﺮﻴﺑﺍﺪﺘﻟﺍ ﺫﺎﺨﺗﺍ ﻦﻣ ﺪﻛﺄﺗ

•.ﻲﻠﺧﺍﺪﻟﺍ ﻡﺍﺪﺨﺘﺳﻼﻟ ﺔﻤﻤﺼﻣ ﺓﺪﺣﻮﻟﺍ ﻩﺬﻬﻓ .ﺔﺑﻮﻃﺮﻟﺍ ﻦﻣ ﺔﻴﻟﺎﺧ ﺔﻓﺮﻏ ﻲﻓ ﺯﺎﻬﺠﻟﺍ ﺐﻴﻛﺮﺘﺑ ﻢﻗ

•ﺓﺪﺣﻮﻟﺍ ﻦﻣ ﺺﻠﺨﺘﻟﺍ ﺕﺎﺒﻠﻄﺘﻣ

٢ ﺔﻴﺑﺮﻌﻟﺍ

Page 33

.ﻩﺎﻴﻤﻟﺍ ﺏﺮﺴﺗ ﻰﻟﺇ ﻱﺩﺆﻳ ﺪﻗ ﺎﻤﻣ ءﺍﺰﺟﻷﺍ ﺾﻌﺑ ﻂﻘﺴﺗ ﺪﻗﻭ ،ﺔﻴﻜﻴﺘﺳﻼﺒﻟﺍ ءﺍﺰﺟﻷﺍ ﻒﻠﺘﺘﺴﻓ

.ﺪﻳﺮﺒﺘﻟﺍ ﺯﺎﻏ ﺏﺮﺴﺗ ﻰﻟﺇ ﺔﻣﻮﺤﻠﻤﻟﺍ ءﺍﺰﺟﻷﺍ ﻭﺃ ﺔﻴﺳﺎﺤﻨﻟﺍ ﺐﻴﺑﺎﻧﻷﺍ ﻞﻛﺂﺗ ﻱﺩﺆﻳ ﺪﻘﻓ

.ﺓﺪﺣﻮﻟﺍ ﻞﻄﻌﺗ ﻰﻟﺇ ﻱﺩﺆﻳ ﺎﻤﻣ ﻢﻜﺤﺘﻟﺍ ﻡﺎﻈﻧ ﻞﻴﻐﺸﺗ ﺔﻌﻃﺎﻘﻣ ﻰﻟﺇ ﺔﻴﺴﻴﻃﺎﻨﻐﻣﻭﺮﻬﻜﻟﺍ ﺔﻌﺷﻷﺍ ﻱﺩﺆﺗ ﺪﻘﻓ

.ﻦﻴﻟﻭﺯﺎﺠﻟﺍ ﻭﺃ ءﻼﻄﻟﺍ ﺮﻨﺗ ﻞﺜﻣ ﻝﺎﻌﺘﺷﻼﻟ ﺔﻠﺑﺎﻘﻟﺍ ﺓﺮﻳﺎﻄﺘﻤﻟﺍ ﻞﺋﺍﻮﺴﻟﺍ ﺔﺠﻟﺎﻌﻣ