Page 1

Operating Instructions

RoCon+ HP

ETSH(B)16P30D

ETSH(B)16P50D

ETSX(B)16P30D

ETSX(B)16P50D

Operating Instructions

Daikin controller RoCon+ HP1

Betriebsanleitung

Daikin Regelung RoCon+ HP1

Manuel d'utilisation

Régulation Daikin RoCon+ HP1

Gebruiksaanwijzing

Daikin regeling RoCon+ HP1

Istruzioni per l'uso

Regolazione Daikin RoCon+ HP1

Driftsvejledning

Daikin regulering RoCon+ HP1

Instruktionsbok

Daikin reglerenhet RoCon+ HP1

Brukerveiledning

Daikin Regulering RoCon+ HP1

English

Deutsch

Français

Nederlands

Italiano

Dansk

Svenska

Norsk

09/2019

Käyttöohje

Daikin-ohjaus RoCon+ HP1

Suomi

Page 2

List of contents

List of contents

1 General safety precaution 4

1.1 Particular safety instructions ..................................................... 4

1.1.1 Observing the instructions .......................................... 4

1.1.2 Meaning of warnings and symbols.............................. 5

1.2 Safety instructions for installation and operation....................... 5

1.2.1 General ....................................................................... 5

1.2.2 Intended use ............................................................... 5

2 Product description 6

2.1 Temporary shutdown................................................................. 6

3 Operation 7

3.1 General...................................................................................... 7

3.2 Display and operating elements ................................................ 7

3.2.1 Status display.............................................................. 7

3.2.2 Display ........................................................................ 7

3.2.3 Rotary button .............................................................. 7

3.2.4 Start screen................................................................. 7

3.3 Operating concept ..................................................................... 8

3.3.1 Navigating in the menu ............................................... 8

3.3.2 Help function............................................................... 9

3.3.3 Navigating in lists and selecting list entries................. 9

3.3.4 Setting setpoints ......................................................... 9

3.3.5 Setting the times ......................................................... 10

3.3.6 Calendar function........................................................ 10

3.3.7 Setting the time programs........................................... 10

3.3.8 External operation....................................................... 11

4 Function 12

4.1 Mode ......................................................................................... 12

4.2 User........................................................................................... 13

4.2.1 Room temperature setpoint setting............................. 13

4.2.2 Room temperature reduced setting ............................ 13

4.2.3 Room temperature absence setting............................ 13

4.2.4 Hot water temperature setpoint setting....................... 13

4.2.5 Unscheduled domestic hot water generation.............. 13

4.3 Time Program............................................................................ 13

4.3.1 Temporary time programs........................................... 13

4.3.2 Permanent time programs .......................................... 13

4.3.3 Time program reset..................................................... 14

4.4 Settings ..................................................................................... 14

4.4.1 Display settings........................................................... 15

4.4.2 System........................................................................ 15

4.4.3 Additional heat generators.......................................... 15

4.4.4 Inputs/Outputs............................................................. 15

4.4.5 Intelligent storage tank management.......................... 16

4.5 Configuration ............................................................................. 16

4.5.1 Access privileges (technician code)............................ 16

4.5.2 Sensors....................................................................... 17

4.5.3 HC configuration ......................................................... 17

4.5.4 Heating........................................................................ 17

4.5.5 Cooling........................................................................ 18

4.5.6 Domestic hot water ..................................................... 19

4.5.7 Additional program...................................................... 19

4.5.8 Configuration Wizard .................................................. 21

4.5.9 Parameter reset .......................................................... 21

4.6 Info ............................................................................................ 21

4.6.1 Current........................................................................ 21

4.6.2 Overview..................................................................... 22

4.6.3 Values......................................................................... 22

4.6.4 Water pressure ........................................................... 22

4.7 Error .......................................................................................... 22

4.8 Terminal .................................................................................... 22

4.8.1 Selecting the terminal address.................................... 23

4.8.2 Bus-Scan for terminal function.................................... 23

4.9 Statistics ..................................................................................... 24

4.9.1 Month........................................................................... 24

4.9.2 Total............................................................................. 24

5 Initial commissioning 25

5.1 Configuration Wizard.................................................................. 25

5.2 Menu navigation in the Configuration Wizard............................. 25

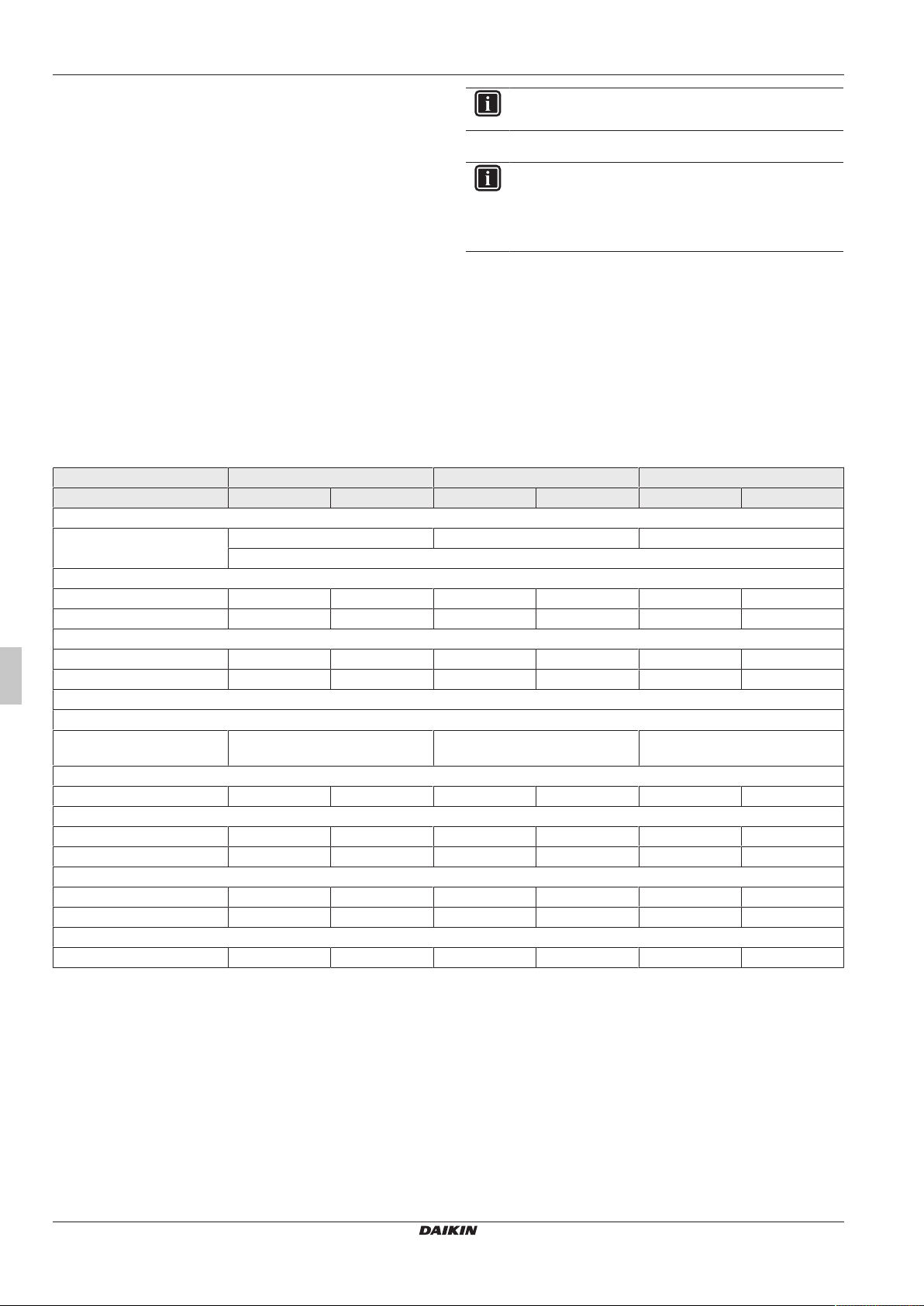

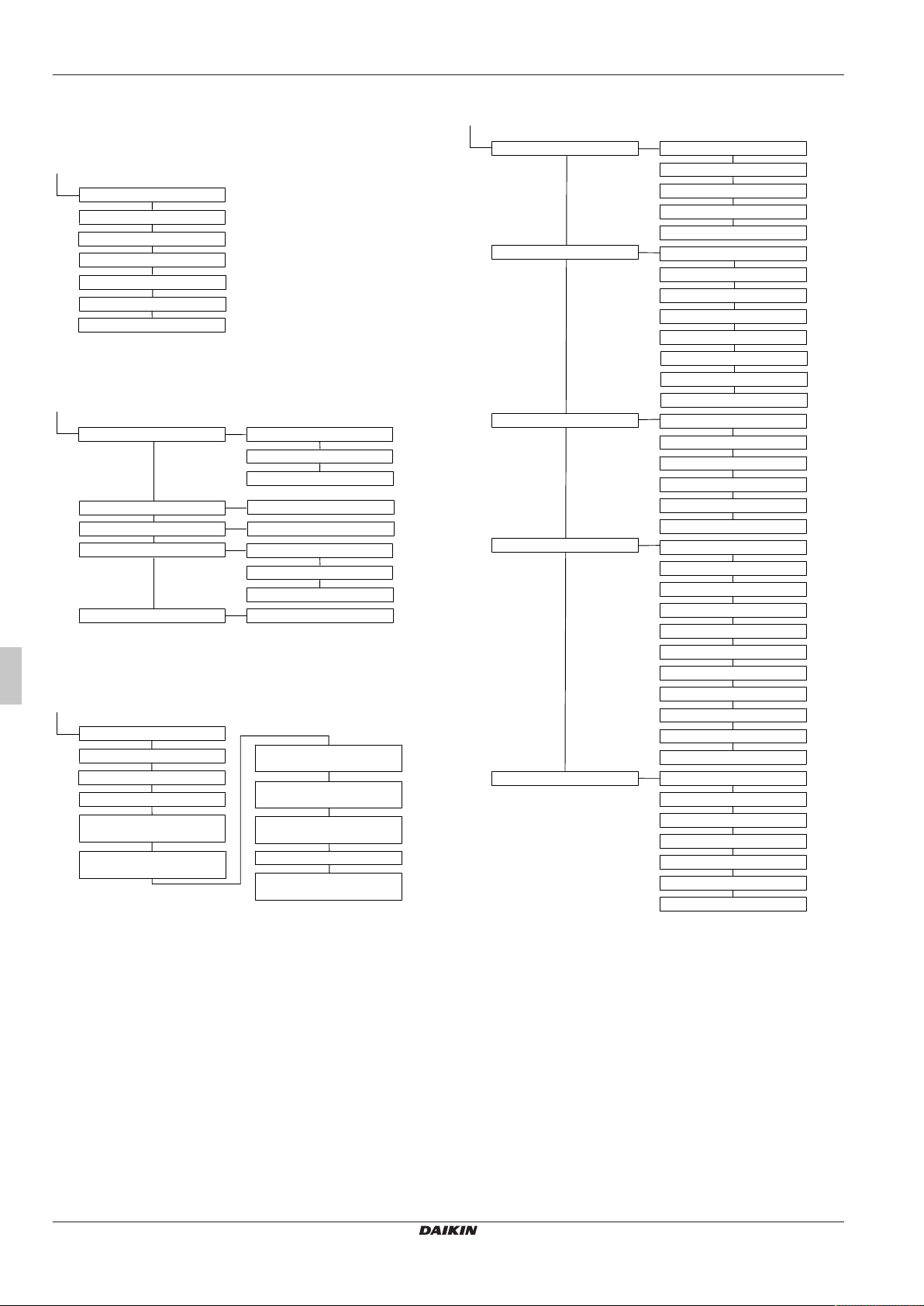

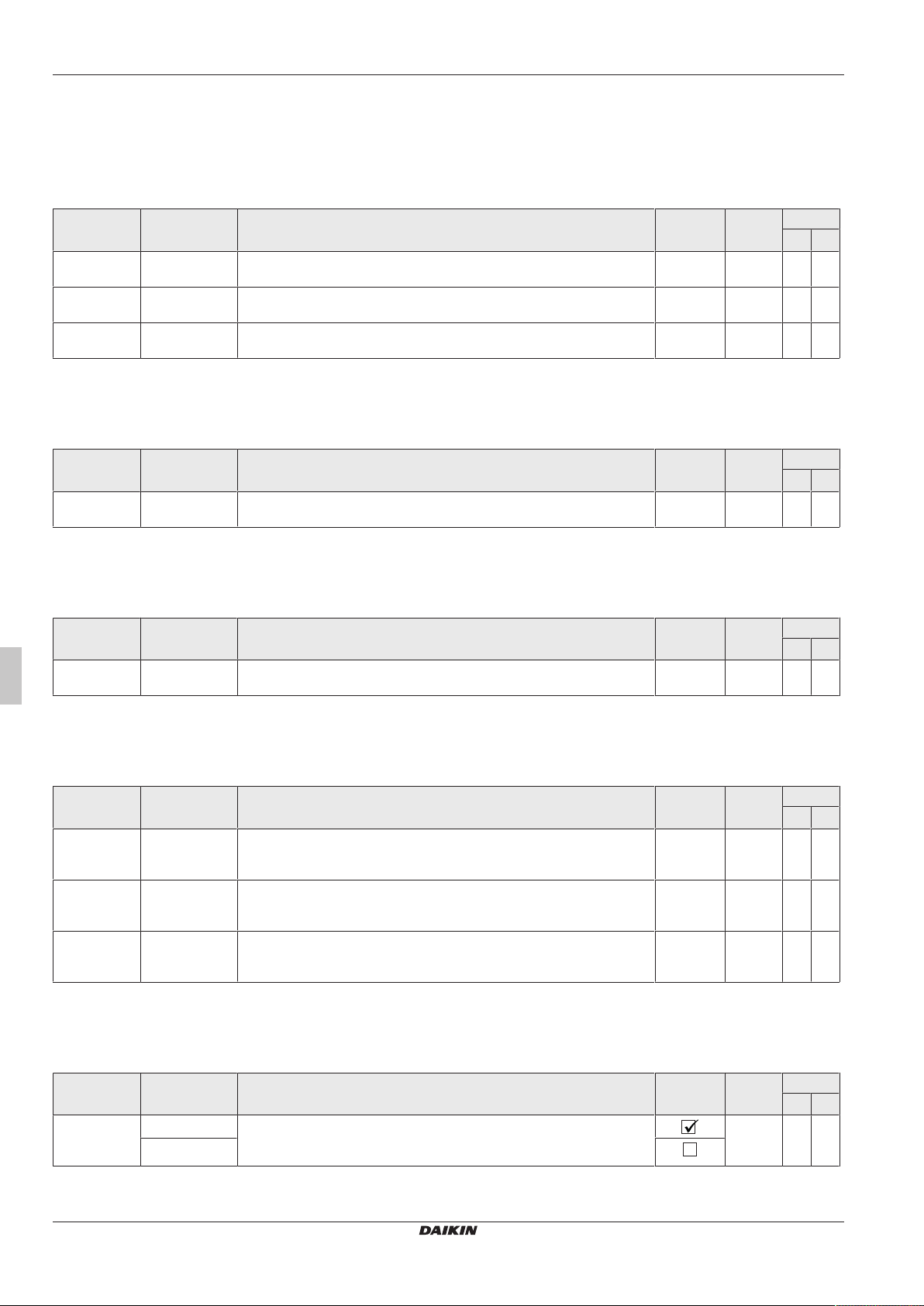

6 Parameter overview 26

6.1 Menu: Operating mode............................................................... 26

6.2 Menu: User................................................................................. 26

6.3 Menu: Time program .................................................................. 26

6.4 Menu: Settings ........................................................................... 26

6.5 Menu: Configuration ................................................................... 27

6.6 Menu: Information ...................................................................... 27

6.7 Menu: Error ................................................................................ 27

6.8 Menu: Terminal .......................................................................... 27

6.9 Menu: Statistics .......................................................................... 28

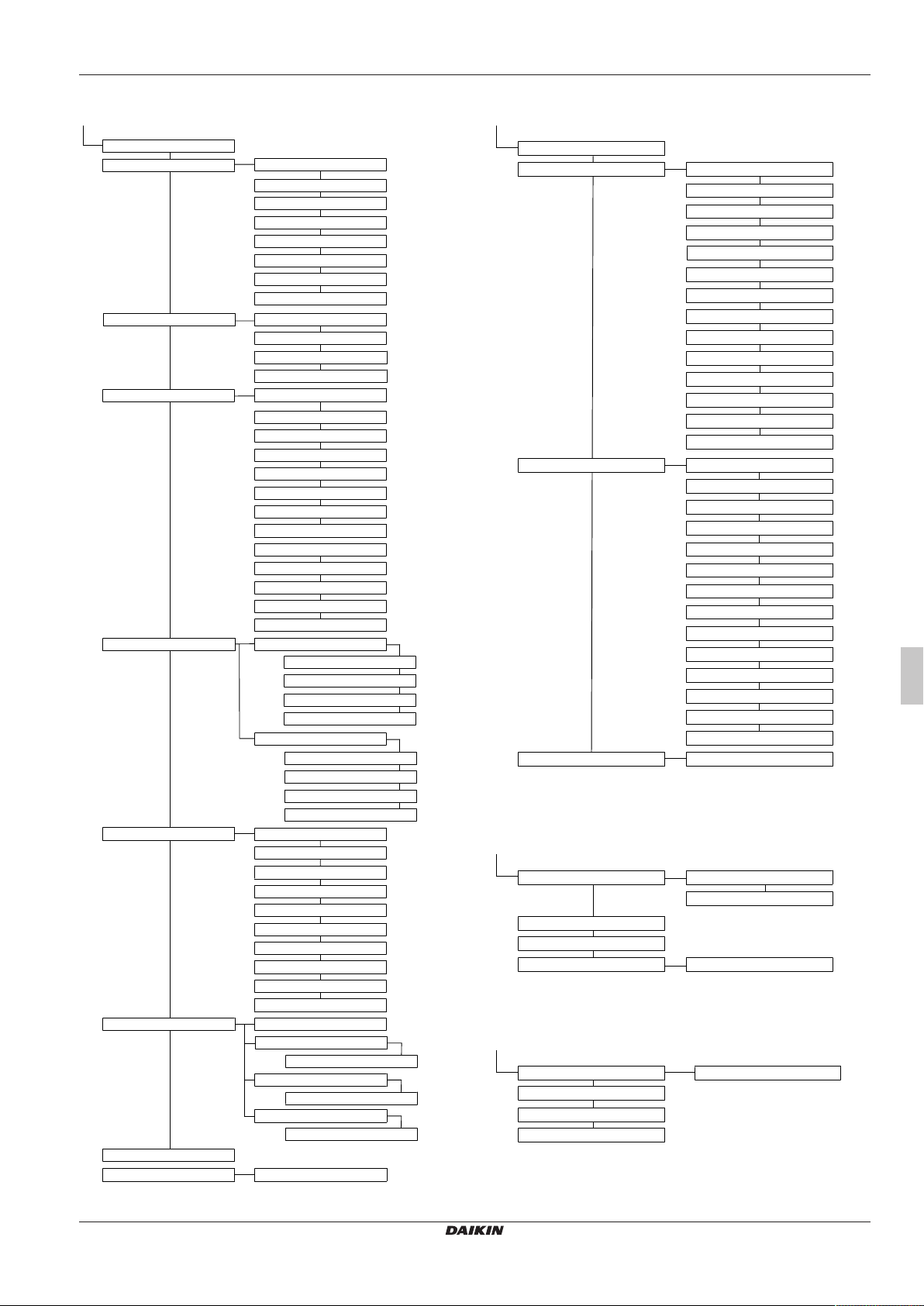

7 Parameter settings 29

7.1 Explanation of the parameter tables........................................... 29

7.2 Operating mode.......................................................................... 29

7.3 User............................................................................................ 30

7.3.1 Menu: Room temperature target.................................. 30

7.3.2 Menu: Reduce room temperature................................ 30

7.3.3 Menu: Room temperature absent ................................ 30

7.3.4 Menu: Hot water temperature, target........................... 30

7.3.5 Menu: 1 x hot water ..................................................... 30

7.4 Time Program............................................................................. 31

7.5 Settings ...................................................................................... 32

7.5.1 Menu: Display settings................................................. 32

7.5.2 Menu: System.............................................................. 32

7.5.3 Menu: External heat source......................................... 33

7.5.4 Menu: Inputs/Outputs................................................... 34

7.5.5 Menu: Intelligent Storage Mgmt................................... 36

7.6 Configuration .............................................................................. 37

7.6.1 Menu: Sensors............................................................. 37

7.6.2 Menu: Heating circuit config......................................... 38

7.6.3 Menu: Heating.............................................................. 38

7.6.4 Menu: Cooling.............................................................. 40

7.6.5 Menu: Hot water........................................................... 40

7.6.6 Menu: Additional programs.......................................... 42

7.7 Information ................................................................................. 43

7.7.1 Overview...................................................................... 43

7.7.2 Values.......................................................................... 44

7.7.3 Water pressure ............................................................ 44

7.8 Error ........................................................................................... 45

7.9 Terminal ..................................................................................... 45

7.10 Statistics ..................................................................................... 45

7.11 Configuration wizard................................................................... 46

8 Faults and malfunctions 47

8.1 Emergency operation ................................................................. 47

8.2 Manual Operation....................................................................... 47

8.3 Error protocol.............................................................................. 47

8.4 Error screen................................................................................ 47

8.5 Error codes................................................................................. 48

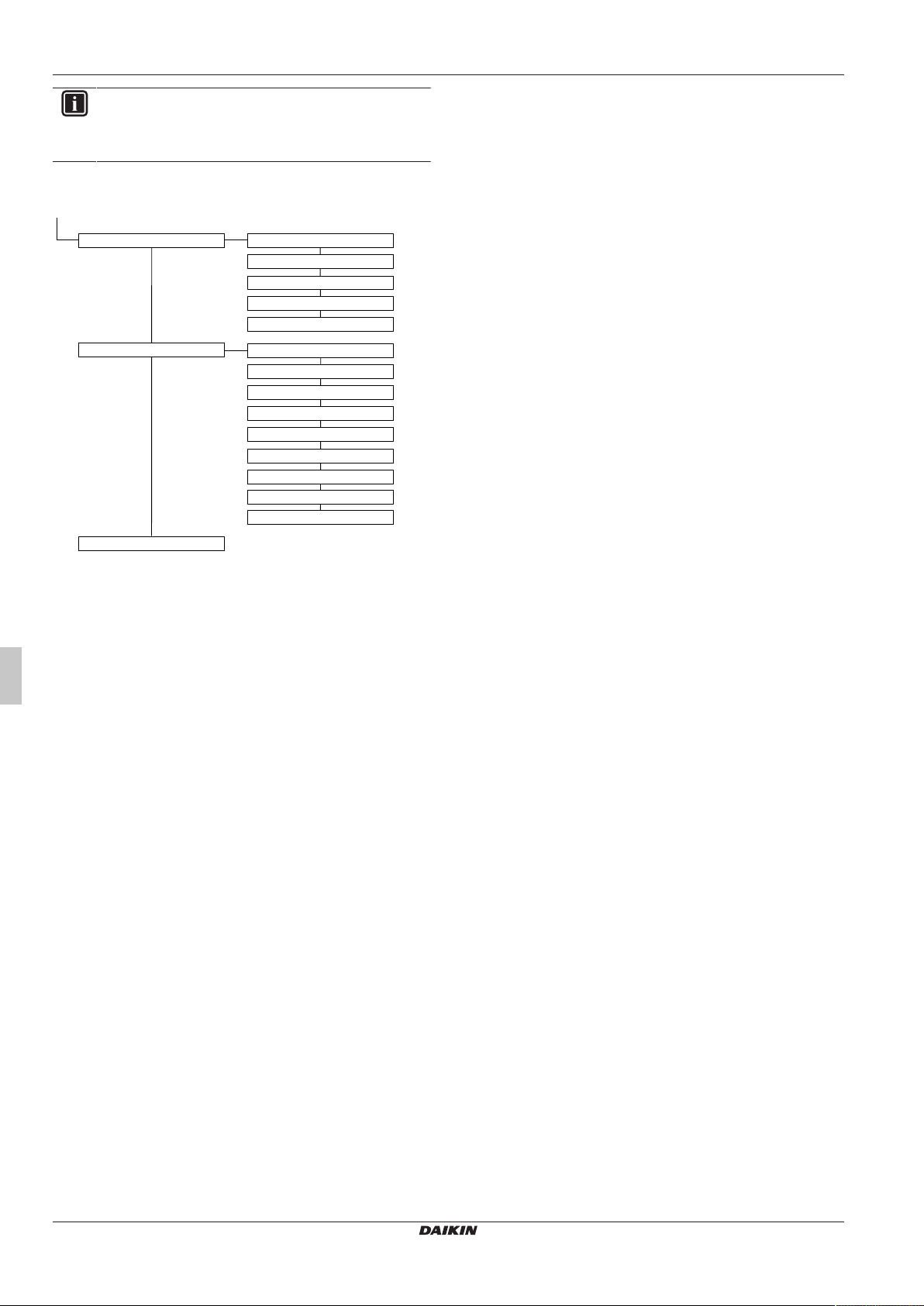

9 Mixer module 49

9.1 Mixer module start screen (terminal function) ............................ 49

9.2 Mixer valve parameter overview................................................. 49

9.3 Mixer module parameter settings ............................................... 51

10 Glossary 52

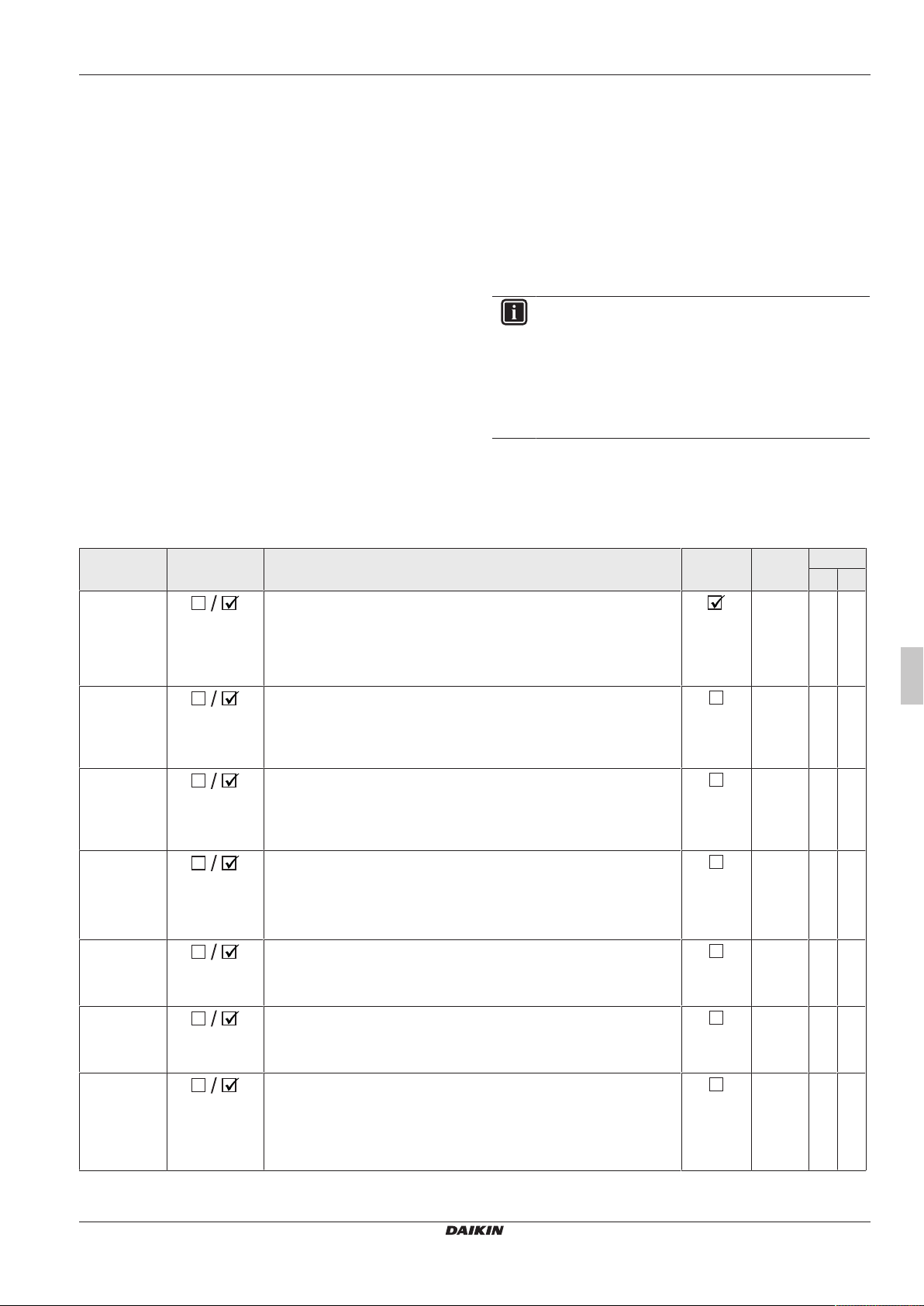

11 User-specific settings 53

11.1 Switching time program .............................................................. 53

11.2 Parameters ................................................................................. 54

11.3 Data bus addresses ................................................................... 54

12 Notes 55

Operating Instructions

2

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 3

List of keywords 56

List of contents

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

3

Page 4

1 General safety precaution

1 General safety precaution

1.1 Particular safety instructions

WARNING

Heating devices that are not set up and

installed correctly can impair the function of the heating device and/or cause

serious or fatal injury to the user.

▪ Work on the heat generator (such as

set-up, servicing, connection and initial commissioning) must only be

carried out by persons who are authorised and who have successfully

completed qualifying technical or vocational training and who have taken

part in advanced training sessions

recognised by the relevant responsible authorities for the specific activity. They include, in particular, certified heating engineers, qualified

electricians and HVAC specialists

who, because of their professional

training and their expert knowledge,

have experience in the professional

installation and maintenance of heating systems, oil and gas installations

and hot water storage systems.

▪ Only operate the heat generator

when it is in perfect condition with

the protective hood closed.

WARNING

Disregarding the following safety instructions may result in serious physical injury or death.

▪ This device may only be used by

children aged 8 and above and by

persons with restricted physical,

sensory or mental capabilities or with

a lack of experience and knowledge

if they are under supervision or if

they have been instructed in the safe

use of the equipment and understand the dangers arising from it.

Children must not play with the

device. Cleaning and user maintenance must not be carried out by children without supervision.

▪ Establish the power supply in ac-

cordance with IEC60335-1 via a

separator device which exhibits contact separation in all poles with a

contact opening distance that

provide full disconnection in accordance with overvoltage category III.

▪ All electrical work must only be car-

ried out by electrically qualified experts and with consideration of the

local and national regulations and

the instructions in this manual.

Ensure that a suitable electrical circuit is used.

Insufficient load capacity of the electrical circuit or improperly executed

connections can result in electric

shock or fire.

Operating Instructions

4

1.1.1 Observing the instructions

▪ The original documentation is written in German. All other lan-

guages are translations.

▪ Please read this manual carefully and thoroughly before proceed-

ing with the installation or modification of the heating system.

▪ The precautionary measures described in this document cover

very important topics. Follow them meticulously.

▪ The installation of the system and all activities described in this

manual and the applicable documents for the installer must be

carried out by an approved installer.

Documentation set

This document is part of a documentation set of other applicable

documents.The complete set comprises:

▪ Installation instructions for the indoor unit (format: paper – in-

cluded in the indoor unit scope of delivery)

▪ Operating instructions for the indoor unit (format: paper – included

in the indoor unit scope of delivery)

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Page 5

1 General safety precaution

▪ Operating manual for the heat pump (format: paper – included in

the indoor unit scope of delivery)

▪ Installation instructions for the outdoor unit (format: paper – in-

cluded in the outdoor unit scope of delivery)

▪ Installation instructions for optional components (format: paper –

included in the scope of delivery of the respective component)

▪ Reference manual for the installer of the indoor unit (format: di-

gital)

▪ Reference manual for the installer of the outdoor unit (format: di-

gital)

The reference manuals contain the complete set of technical data, a

detailed description of best practices and information on maintenance, troubleshooting and decommissioning.

The digital documents and the latest editions of the supplied documentation are available on the regional Daikin website or, on request, from your dealer. The Daikin website is easy to access using

the QR code on your device.

1.1.2 Meaning of warnings and symbols

Warnings in this manual are classified according to their severity and

probability of occurrence.

DANGER

Indicates an immediate danger.

Disregarding this warning can lead to serious injury or

death

WARNING

Indicates a potentially dangerous situation

Disregarding this warning may result in serious physical in-

jury or death.

CAUTION

Indicates a situation which may cause possible damage

Disregarding this warning can cause damage to property

and the environment and result in minor injuries.

Avoiding danger

The Daikin Altherma ETS(X/H) is state of the art and is built in accordance with all recognised technical regulations. However, improper use may result in serious physical injuries or death, as well as

property damage.

To avoid hazards, only operate the Daikin Altherma ETS(X/H):

▪ as stipulated and in perfect condition,

▪ with an awareness of safety and the dangers involved.

This assumes knowledge and use of the contents of this manual, all

applicable documents, the relevant accident prevention regulations

as well as the recognised safety-related and occupational health

rules.

Display of the RoCon+ controller

Certain screen displays or menu items may deviate from those

shown in these instructions depending on the national or equipment

variant of the Daikin Altherma ETS(X/H) or the user status logged

onto the controller.

1.2.2 Intended use

The RoCon+ HP controller must only be used in Daikin Altherma

ETS(X/H) heat pumps that are approved for the regulating system.

The RoCon+ HPcontroller must only be operated in accordance with

the specifications in these instructions.

Any other use outside the intended use is considered as improper.

The operator alone bears responsibility for any resulting damage.

For any work on the equipment that extends above and beyond the

operation of the regulating system, the details provided in the supplementary documents must be observed, particularly with regard to

safety instructions.

Documentation

The technical documentation included in the scope of supply is a

constituent part of the equipment. It must be stored in such a way

that it can be consulted at any time by the operator or technicians.

This symbol identifies user tips and particularly useful information, but not warnings or hazards

Special warning signs

Some types of danger are represented by special symbols.

Electric current

Risk of burns or scalds

General description

1 Handling instructions are shown as a list. Actions where the se-

quential order must be adhered to are numbered.

è Results of actions are identified with an arrow.

[Operating mode]: Parameters are shown in square brackets.

[→Main menu]: The position of menus and functions is shown in

square brackets with →.

1.2 Safety instructions for installation

and operation

1.2.1 General

▪ For any work on the equipment, which extends above and beyond

the operation of the regulating system, the details provided in the

supplementary documents must be observed, particularly with regard to safety instructions.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

5

Page 6

2 Product description

2 Product description

INFORMATION

The RoCon+ HP controller is part of the Daikin Altherma

ETS(X/H).

It consists of theswitching panel PCB RoCon BM2Cto

which the actuators and sensors as well as other components in the regulating system are connected and the operating unit RoCon+ B1.

These operating instructions only explain the functions and

possible settings of the controller. More detailed information on other device components can be found in the other

applicable documents.

The electronic, digital controller is able to automatically control all

heating and hot water functions for a direct heating circuit, a storage

loading circuit and also further heating circuits via optionally connectible mixer modules, depending on the heating device.

It undertakes all safety management for the Daikin Altherma ETS(X/

H). In the event of a water shortage or undefined operating states,

this executes a safety switch-off. A corresponding error message

shows the operator all the information regarding fault causes.

All function settings for the Daikin Altherma ETS(X/H) and the optional RoCon devices that are connected via the data bus are undertaken with the control elements of the integrated RoConB1 control

panel and shown on the plain text display with coloured backlighting.

The following additional, optional devices can be connected to the

Daikin Altherma ETS(X/H) via the controller data bus:

▪ Room controller EHS157034

▪ EHS157068 mixer module

In addition, the RoCon+ HP controller has a frost protection function

for the direct heating circuit and the storage tank charging circuit as

well as an automatic function for heating support (integration of an

additional heat source such as a wood-burning boiler or solar system).

The potential-free AUX switching contact can be used to carry out

different control functions in conjunction with external devices (request from an external heat generator, switching to bivalent operating mode, external status display, etc.).

In addition, it also has several inputs for assessing external control

contacts (external operating mode switching or heat request, Smart

Grid and low rate EVU functions

The optional outside temperature sensor installed on the north side

of the building can be used to further optimise the weather-compensated feed temperature controller.

If the optional EHS157056 gateway is installed and connected to the

Internet, the Daikin Altherma ETS(X/H) can be conveniently monitored and operated by remote control using a mobile phone (app).

Initial commissioning of the heating system is described in the installation instructions for the Daikin Altherma ETS(X/H).

Certain menu items of the RoCon+ HP controller are only accessible

to the heating expert. This security measure ensures that no undesirable malfunctions arise during operation of the system through

incorrect settings.

All settings for the allocated heating circuit can be carried out in the

same way as the operating unit. If the terminal function is activated,

all operating possibilities that are available on the integrated operating unit are available with the exception of certain special functions

(e.g. manual operation).

After appropriate assignment, a connected EHS157068 mixer module is also operated using the RoCon+ B1 control panel and/or the

EHS157034 room station.

(1)

).

2.1 Temporary shutdown

CAUTION

A heating system that is shut down can freeze in the event

of frost and may suffer damage.

▪ Drain the heating system that is shut down if there is

danger of frost.

▪ If the heating system is not drained, the power supply

must be ensured and the external main switch must remain switched on if there is a danger of frost.

If the indoor unit is not required for a lengthy period, it can be temporarily decommissioned.

However, we recommend not to disconnect the system from the

power supply but merely to switch it to "Standby mode" (see Controller operating instructions).

The system is then protected from frost. The pumps and valve protection functions are active.

If it is not possible to guarantee the power supply when there is

danger of frost,

▪ completely drain the indoor unit on the water side, or

▪ apply suitable antifreeze measures to the connected heating sys-

tem and hot water storage tank (e.g. draining).

INFORMATION

If there is a danger of frost for only a few days with uncertainly in the gas and power supply, the oes not need to be

drained because the heat insulation is very good as long

as the storage tank temperature is observed regularly and

does not fall below + 3°C.

However, this provides no frost protection for the connected heat distribution system.

(1)

The energy supply company (EVU) sends signals that are used for controlling the power mains loading and that have an influence on the cost

of the power and availability.

Operating Instructions

6

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 7

3 Operation

3 Operation

3.1 General

DANGER: RISK OF ELECTROCUTION

If electrical components come into contact with water, this

can cause an electric shock as well as cause potentially

fatal burns or injuries.

▪ The displays and keys of the control unit must be pro-

tected against the effects of moisture.

▪ To clean the control unit, use a dry cotton cloth. The

use of aggressive cleaning agents and other fluids can

cause damage to devices or lead to an electric shock.

INFORMATION

The Daikin Altherma ETS(X/H) makes the most effective

use of energy at the lowest possible return and hot water

target temperatures.

If an external heat generator (e.g. the optional backup

heater) is activated at feed target temperatures above

50°C, the efficiency (COP) of the Daikin Altherma ETS(X/

H) can deteriorate (depending on the outside temperature).

3.2 Display and operating elements

LED Mode Description

Flashes red Error A malfunction occurred. For fur-

ther details, see Chap. 8.

Tab.3-1 Status display

3.2.2 Display

During normal operation the display is deactivated (completely dark).

The activity of the system is indicated by the status display. Each

press of the rotary button (turn, press or hold) activates the display

with the start screen.

If the start screen is active and no user input is made for

60seconds, the display is deactivated. If no input is made by the

user at any other point in the menu for 120seconds, the system returns to the start screen.

3.2.3 Rotary button

CAUTION

Never operate the operating elements of the controller with

a hard, pointed object. This can cause damage and can

cause the controller to malfunction.

The rotary button can be used to navigate in the respective level, to

select or change the setting value and to accept this change with a

short key press.

Action Result

Turning Select menu, select setting, make setting

Press Confirm selection, accept setting, execute func-

tion.

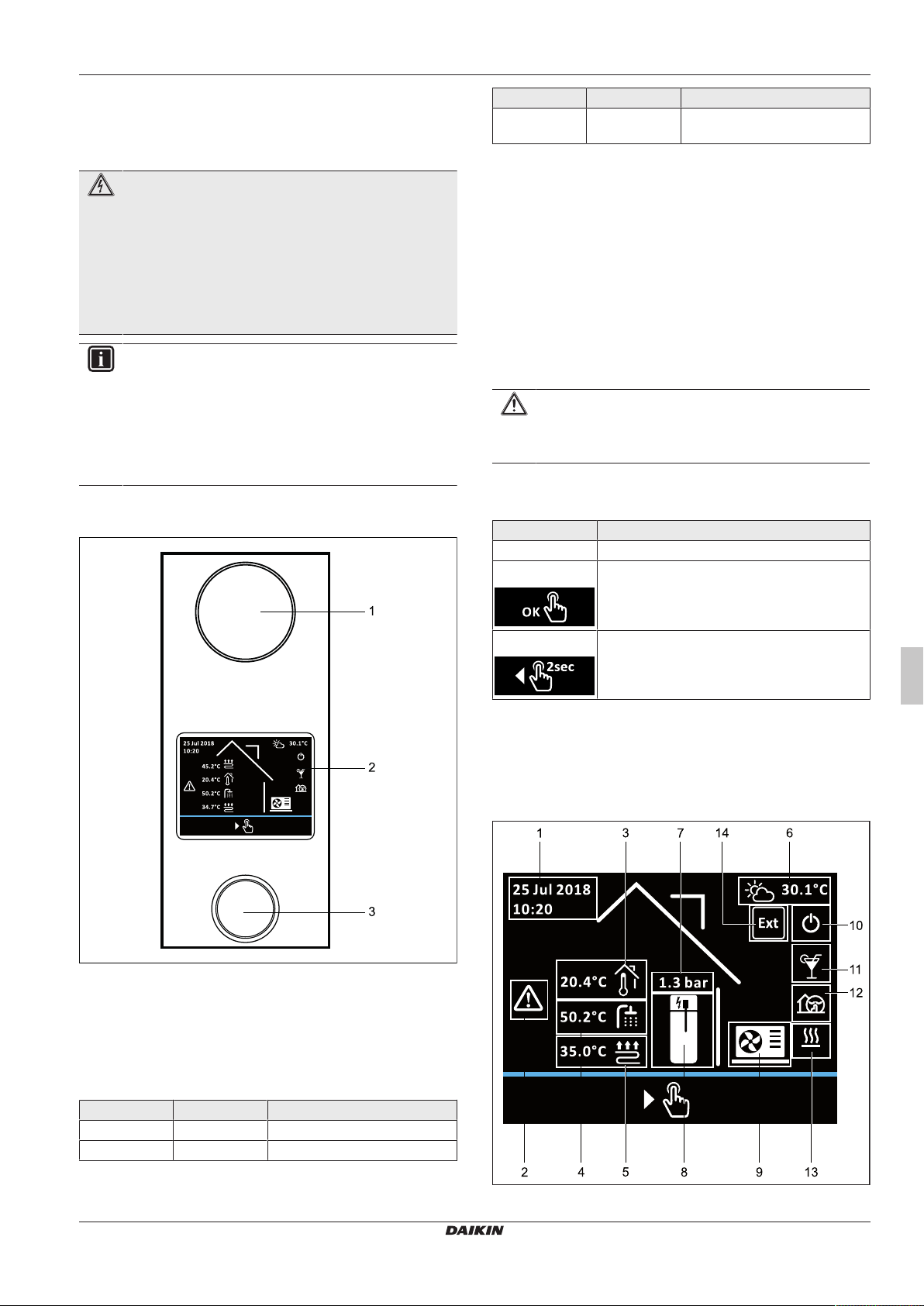

Fig.3-1 RoCon+ HP display and operating elements

1 Status display

2 Display

3 Rotary button

3.2.1 Status display

The LEDs of the status indicator light up or flash to indicate the operating mode of the device.

LED Mode Description

Flashes blue STANDBY The device is not in operation.

Lights up blue Operation The device is in operation.

Press for 2sec. Exit menu

Tab.3-2 Function of the rotary button

3.2.4 Start screen

The start screen provides an overview of the current operating status

of the system. From the start screen, any operation of the rotary

switch (turn, press or hold down) leads to the Main menu.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

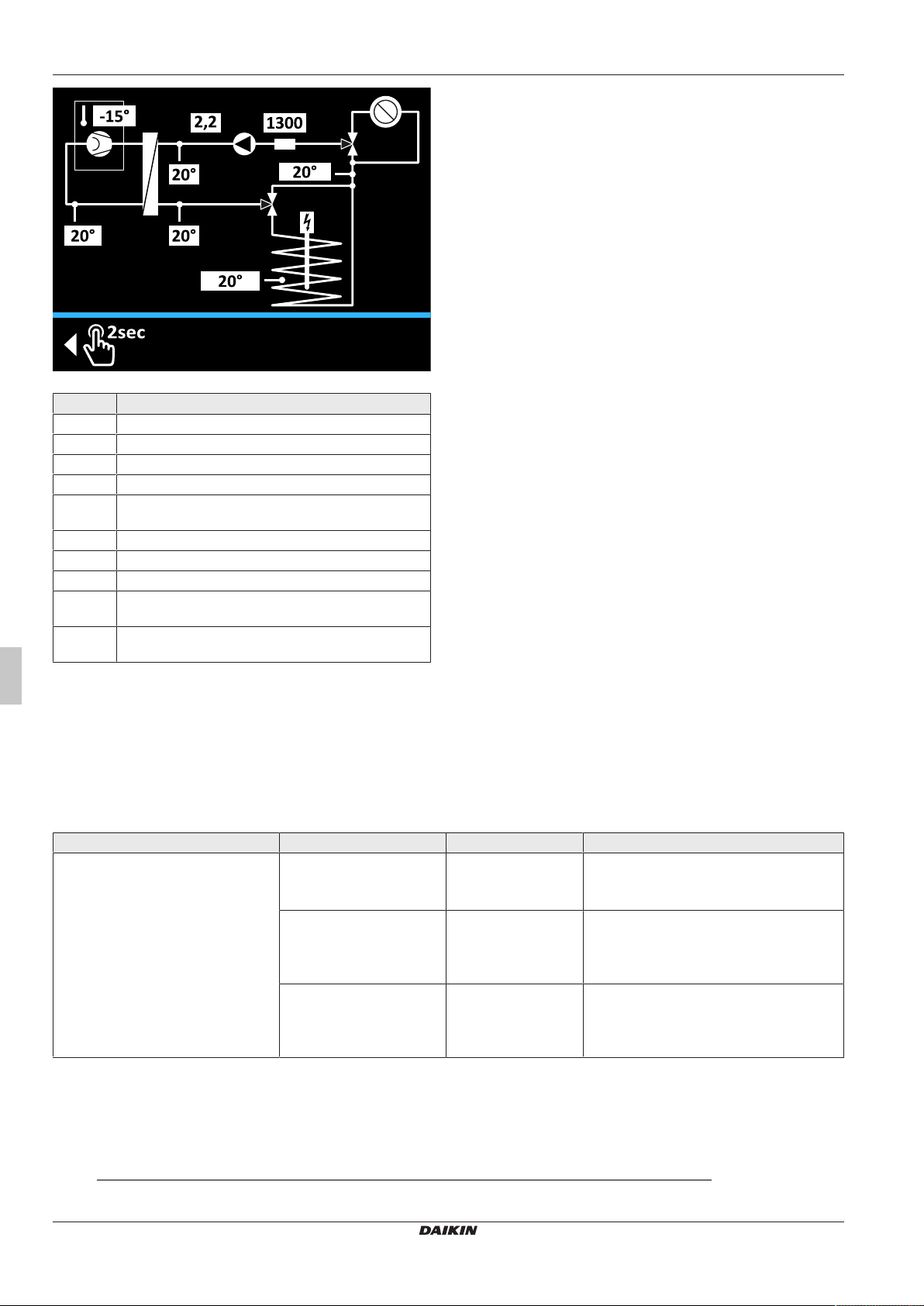

Fig.3-2 Display position on the start screen

Operating Instructions

7

Page 8

3 Operation

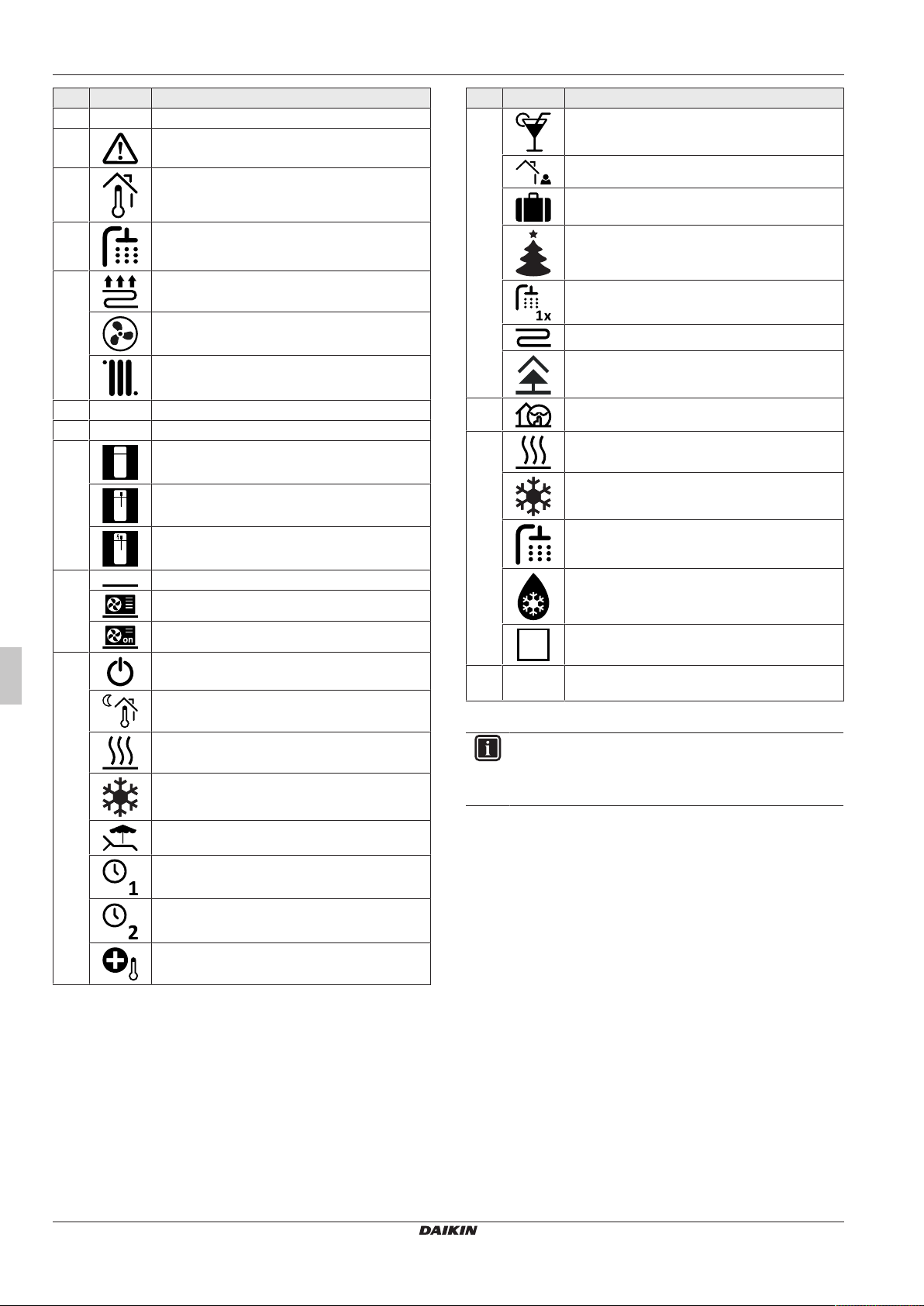

Item Icon Explanation

1 Date and time

2 Error message

3 Only with connected room unit: Room temperat-

ure

4 Hot water temperature

5 Floor heating feed temperature

Convector heating feed temperature

Radiator heating feed temperature

6 Outside temperature

7 Pressure in the heating circuit

8 Storage tank without heating rod

Storage tank with connected heating rod (off)

Storage tank with connected heating rod (on)

Item Icon Explanation

11 Special program: Party

Special program: Absent

Special program: Holiday

Special program: Public holiday

Special program: 1 x hot water

Special program: Screed

Special program: Ventilation

12 Quiet mode on

13 Operating mode: Heating

Operating mode: Cooling

Operating mode: Hot water

9 No outdoor unit detected

Outdoor unit present, compressor off

Outdoor unit present, compressor on

10 Operating mode: Standby

Operating mode: Reduce

Operating mode: Heating

Operating mode: Cooling

Operating mode: Summer

Operating mode: Automatic 1

Operating mode: Automatic 2

Operating mode: Emergency

Operating mode: Defrost

Operating mode: No request

14 Ext External operating mode switched (Burner block-

ing contact or Room thermostat)

Tab.3-3 Display icons on the start screen

INFORMATION

If the local control panel is used as a remote control for a

mixer module, both the standard screen and the menu

structure are changed (see Chap. 9).

3.3 Operating concept

The operating concept of the controller enables fast navigation in the

menu, clear display of information and convenient selection of parameters as well as the setting of setpoints and programs.

The basics of the operating concept are described in detail below using a few examples. The operation of special functions follows the

same principle and is described in the corresponding sections if required in Chap. 4.

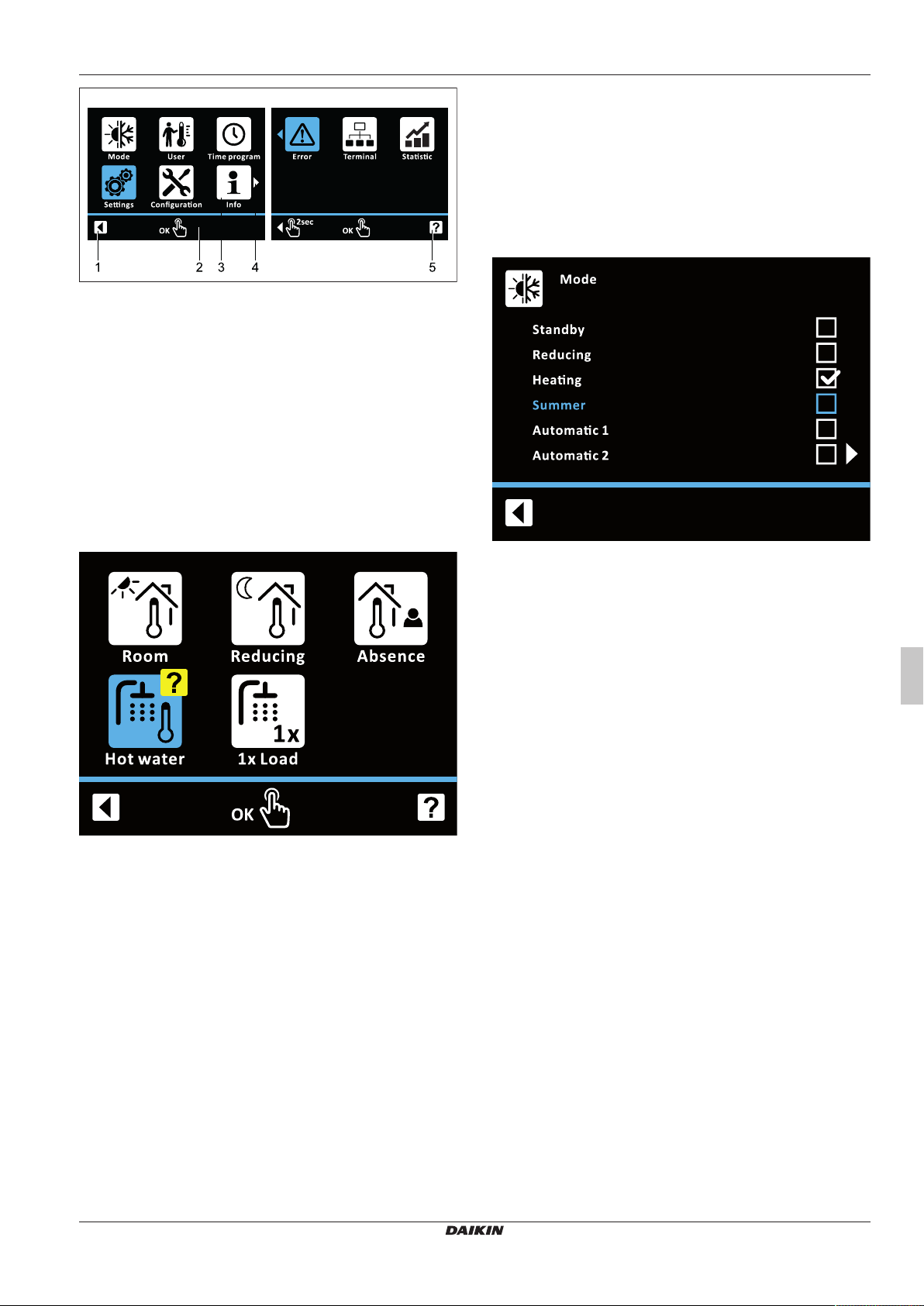

3.3.1 Navigating in the menu

From the start screen, any operation of the rotary switch (turn, press

or hold down) leads to the main menu. The menu view consists of an

upper area for the menu icons of the various submenus and the

lower menu bar. The Back and Help icons are displayed in the menu

bar. Use the rotary button to switch between the icons (including the

icons in the menu bar). Multi-page menus are indicated by the page

break arrow. Use the rotary button to switch between the menu icons

on the different menu pages.

Operating Instructions

8

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 9

3 Operation

3.3.3 Navigating in lists and selecting list entries

Lists exist as pure information lists or can be used to select a list

entry. Turning the rotary button switches between the list entries.

Multi-page lists are indicated by the page break arrow. Turn the

rotary button to switch between the list entries of the different pages.

In the case of selection lists, the currently selected list entry is indicated by a tick. Click "OK" to select another list entry. The corresponding setting is then accepted and the list is exited.

Fig.3-3 Example: Elements in a two-page menu

1 Back icon

2 Menu bar

3 Menu icon

4 Page change arrow (for multi-page menus)

5 Help icon

Example: In the "Statistics" menu, change [→Main menu]:

1 Turn the rotary button clockwise until the "Statistics" icon (on the

second menu page) turns blue.

2 Briefly press the rotary button to confirm ("OK").

è The "Statistics" submenu is called up

3.3.2 Help function

A help text is available for each menu icon.

Fig.3-5 List with selected list entry

Example: Switch the operating mode to "Summer" [→Main menu

→Operating mode]

1 Turn the rotary button clockwise until the "Summer" list entry is

displayed in blue.

2 Briefly press the rotary button to confirm ("OK").

è The box is ticked in the "Summer" list entry.

3 Turn the rotary button anticlockwise until the Back icon turns

blue.

4 Briefly press the rotary button to confirm ("OK").

è The setting is saved and the setting level is exited.

Fig.3-4 Help function

Example: Call up the help text for the "Hot water" menu and stop the

help function again [→Main menu →User]:

1 Turn the rotary button clockwise until the help icon in the menu

bar turns blue.

2 Briefly press the rotary button to confirm ("OK").

è The help function becomes active, the "?" symbol is dis-

played on the last menu icon.

3 Turn the rotary button anticlockwise until the "?" symbol appears

on the "Hot water" icon.

4 Briefly press the rotary button to confirm ("OK").

è The help text for the "Hot water" is displayed.

5 Briefly press the rotary button to confirm ("OK").

è Exits the help text level.

6 Turn the rotary button clockwise until the help icon in the menu

bar turns blue.

7 Briefly press the rotary button to confirm ("OK").

è The help function is terminated.

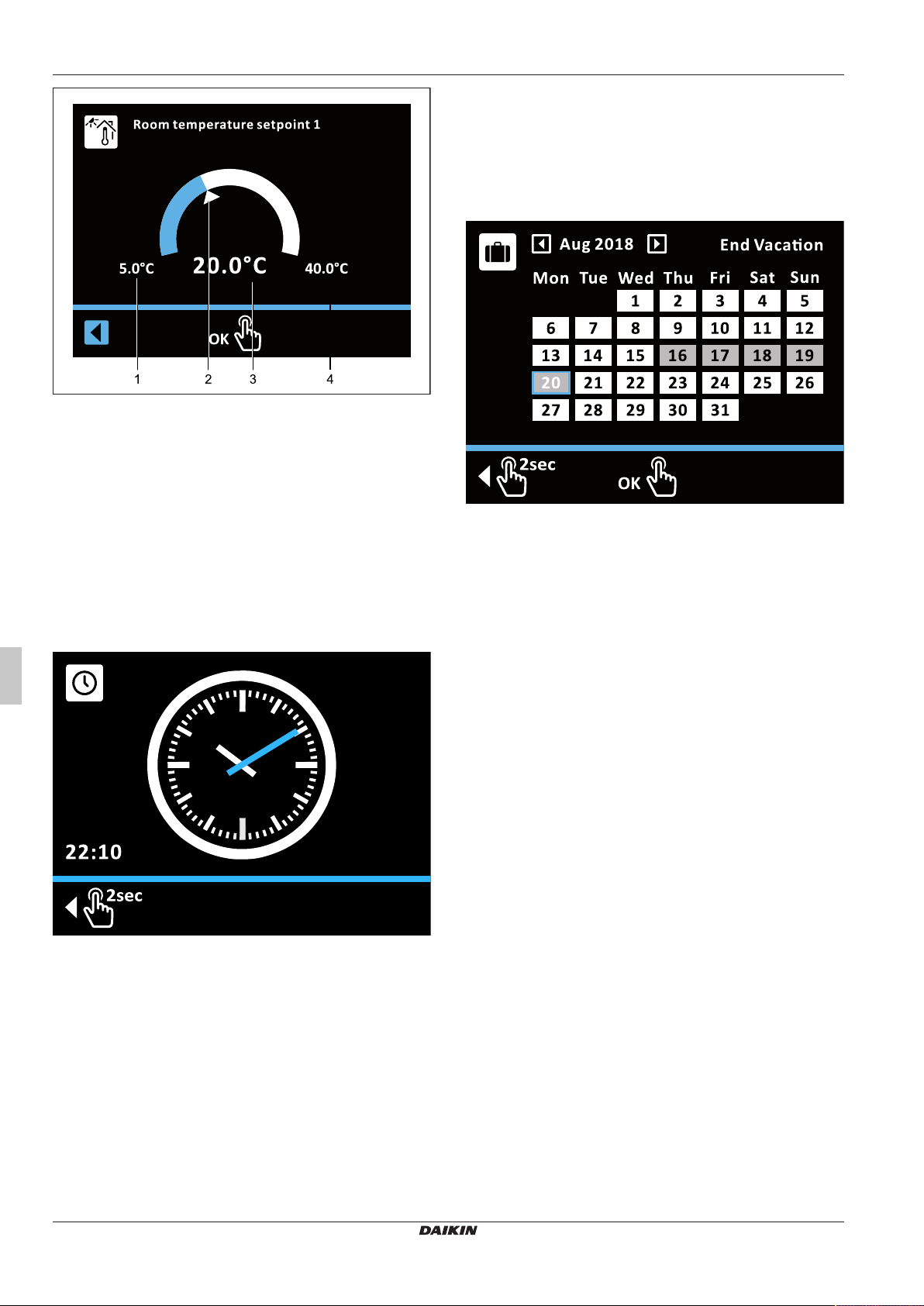

3.3.4 Setting setpoints

The setpoint of a parameter can be changed within the displayed

scale. Press "OK" to save the new value. Press and hold the rotary

button to exit the setting level without saving. For some parameters

there is an "Off" setting in addition to values on the scale. This setting can be selected by turning the rotary button anticlockwise after

the minimum value of the scale has been reached.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

9

Page 10

3 Operation

7 Briefly press the rotary button to confirm ("OK").

è The setting is saved and the setting level is exited.

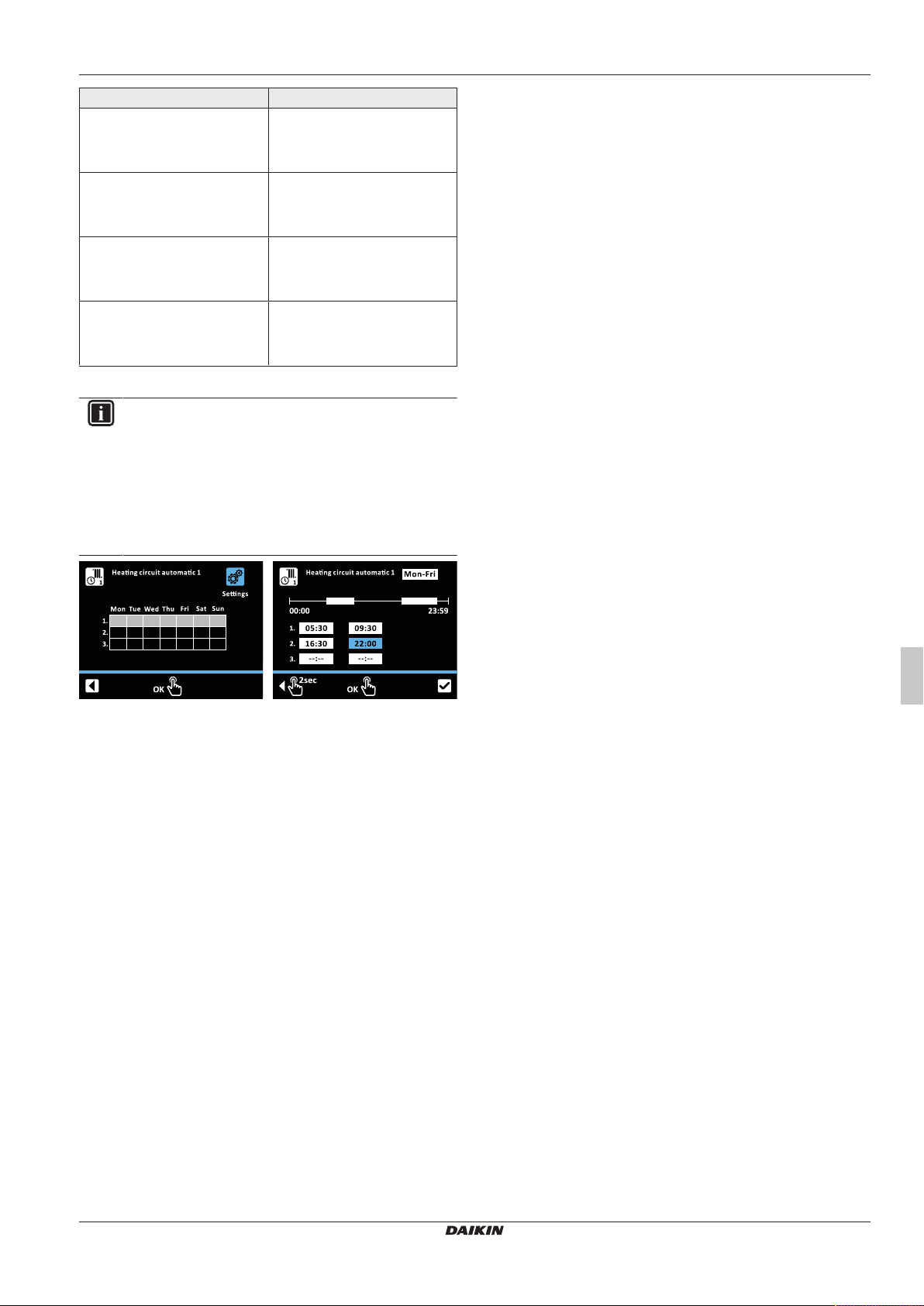

3.3.6 Calendar function

The calendar function is used to set the current date or the [Holiday]

and [Public holiday] time programs. The calendar function allows the

selection of a time period for the time programs.

Fig.3-6 Display of the parameter setting

1 Minimum value

2 Default value

3 Currently selected value

4 Maximum value

Example: Set [Room temperature target 1] to 22°C [→Main menu

→User →Room →Room temperature target 1]:

1 Turn the rotary button clockwise until 22°C is displayed.

2 Briefly press the rotary button to confirm ("OK").

è The setting is saved and the setting level is exited.

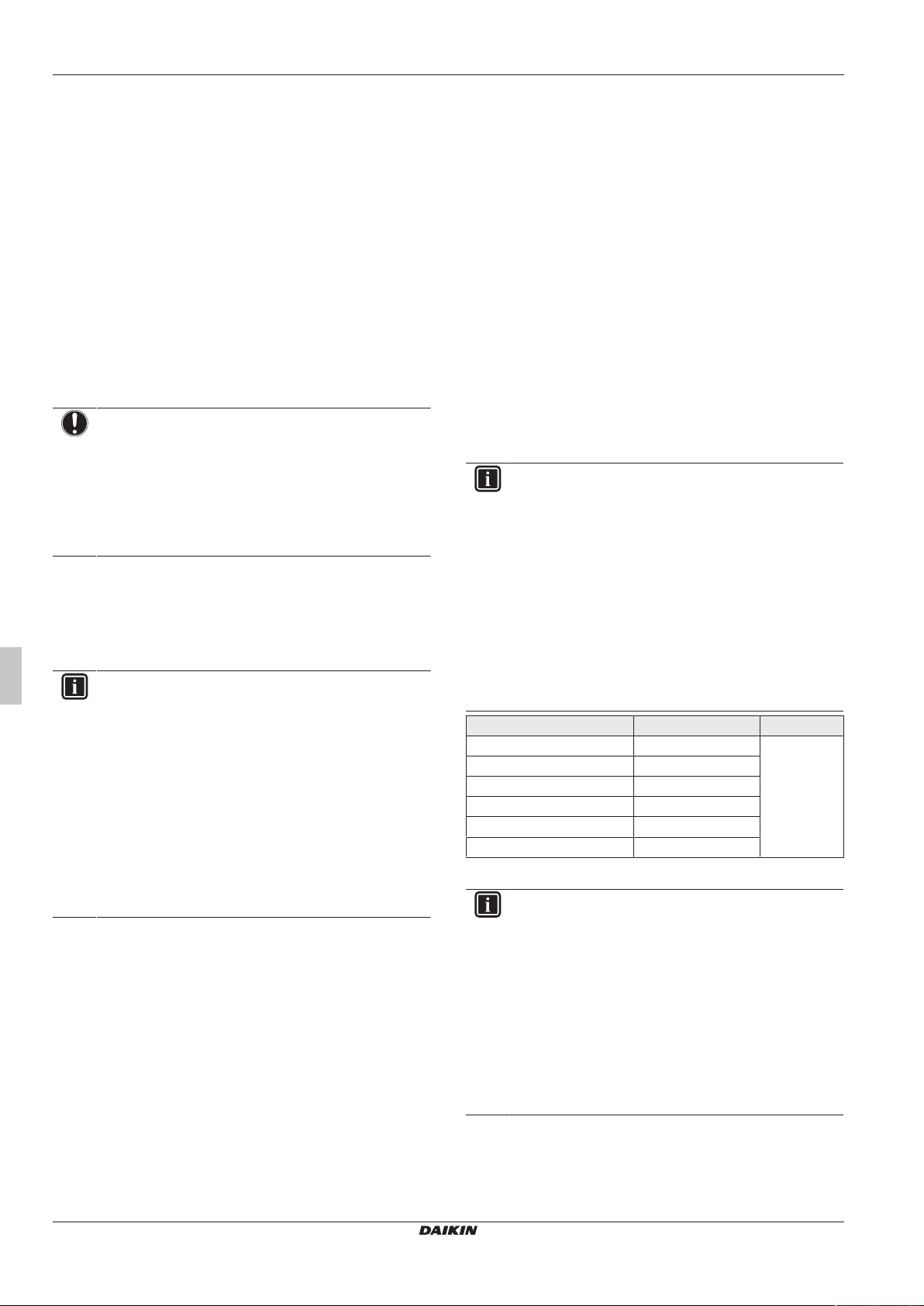

3.3.5 Setting the times

The clock function is used to set the current time.

Fig.3-7 Setting the times

Example: Set the time to 16:04 [→Main menu →Settings →Display →Time]:

1 Turn the rotary button clockwise until the circle is displayed in

blue.

2 Briefly press the rotary button to confirm ("OK").

è The hour hand is displayed in blue.

3 Turn the rotary button clockwise until 16:00 is displayed.

4 Briefly press the rotary button to confirm ("OK").

è The minute hand is displayed in blue.

5 Turn the rotary button clockwise until 16:04 is displayed.

6 Briefly press the rotary button to confirm ("OK").

è The Confirm icon in the menu bar is displayed in blue.

Fig.3-8 Setting the period with the calendar function

Example: Set [Holiday] from 25thAugust,2018 – 2ndSeptember,2018 [→Main menu → Time program →Holiday]:

1 Turn the rotary button clockwise until the month selection is

Aug2018.

2 Briefly press the rotary button to confirm ("OK").

è August 1 is shown with a blue border.

Turn the rotary button clockwise until 25th August is highlighted in

blue.

3 Briefly press the rotary button to confirm ("OK").

è August 25 is shown on a grey background.

4 Turn the rotary button clockwise until 2nd September is high-

lighted in blue.

5 Briefly press the rotary button to confirm ("OK").

è The setting is saved and the setting level is exited.

When a new holiday period is set, the previously set holiday period

is automatically deleted. Alternatively, the holiday setting can also be

reset.

Example: Reset the holiday setting [→Main menu → Time program

→Holiday]:

6 Turn the rotary button clockwise until the month selection is dis-

played in blue.

7 Briefly press the rotary button to confirm ("OK").

è The last selected day of the holiday is displayed with a blue

border.

8 Turn the rotary button anticlockwise until all days are shown in

white.

9 Briefly press the rotary button to confirm ("OK").

è The holiday setting is reset and the setting level is exited.

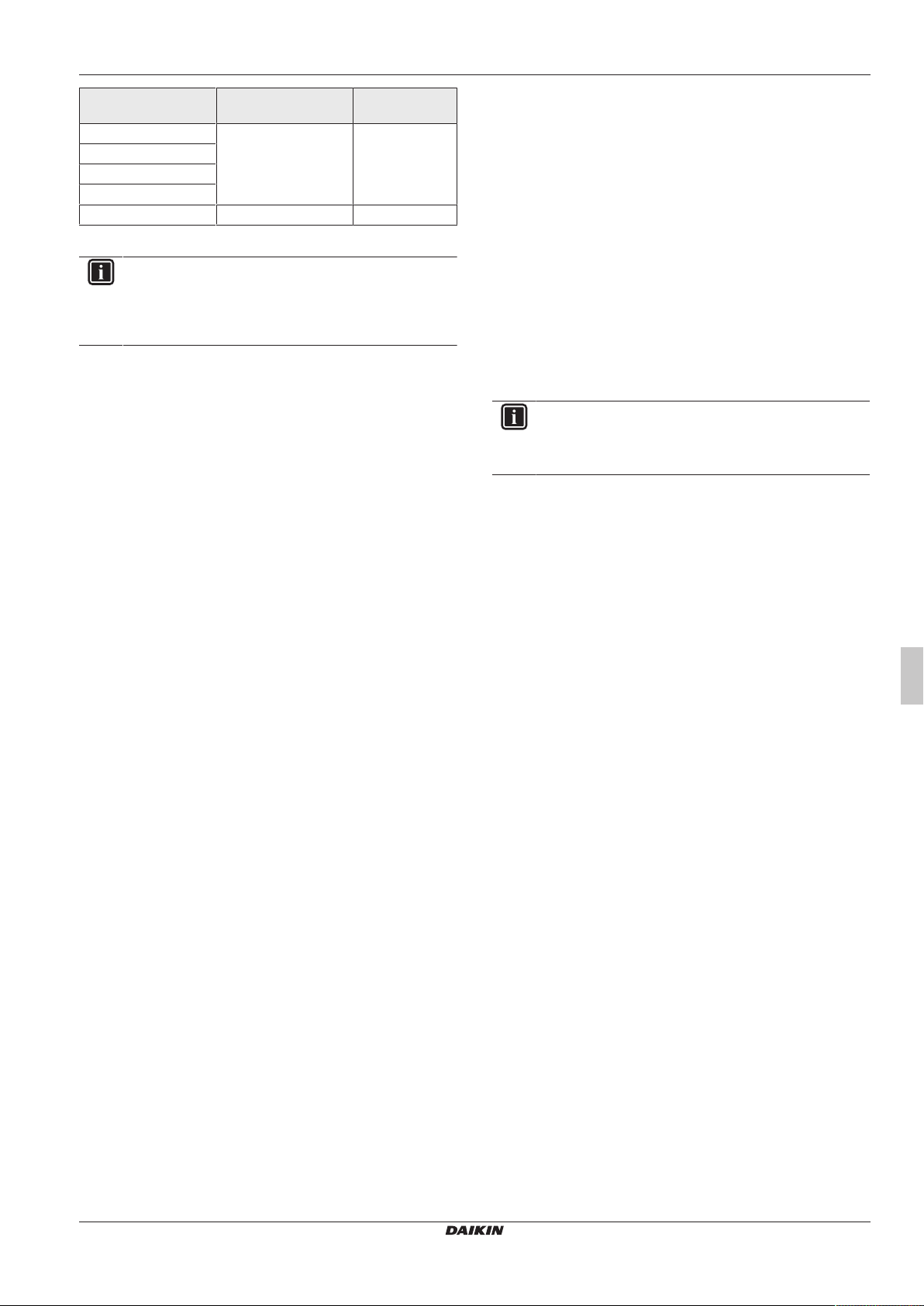

3.3.7 Setting the time programs

The time program function is used to set permanent time programs

(see Chap. 4.3.2). This allows the daily setting of 3 switching cycles.

The times can be entered separately for each individual weekday or

in blocks of "Monday to Friday", "Saturday to Sunday" and "Monday

to Sunday". The selected switching cycles are highlighted in grey

(Fig. 3-9) in the overview level of the respective program.

Operating Instructions

10

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 11

3 Operation

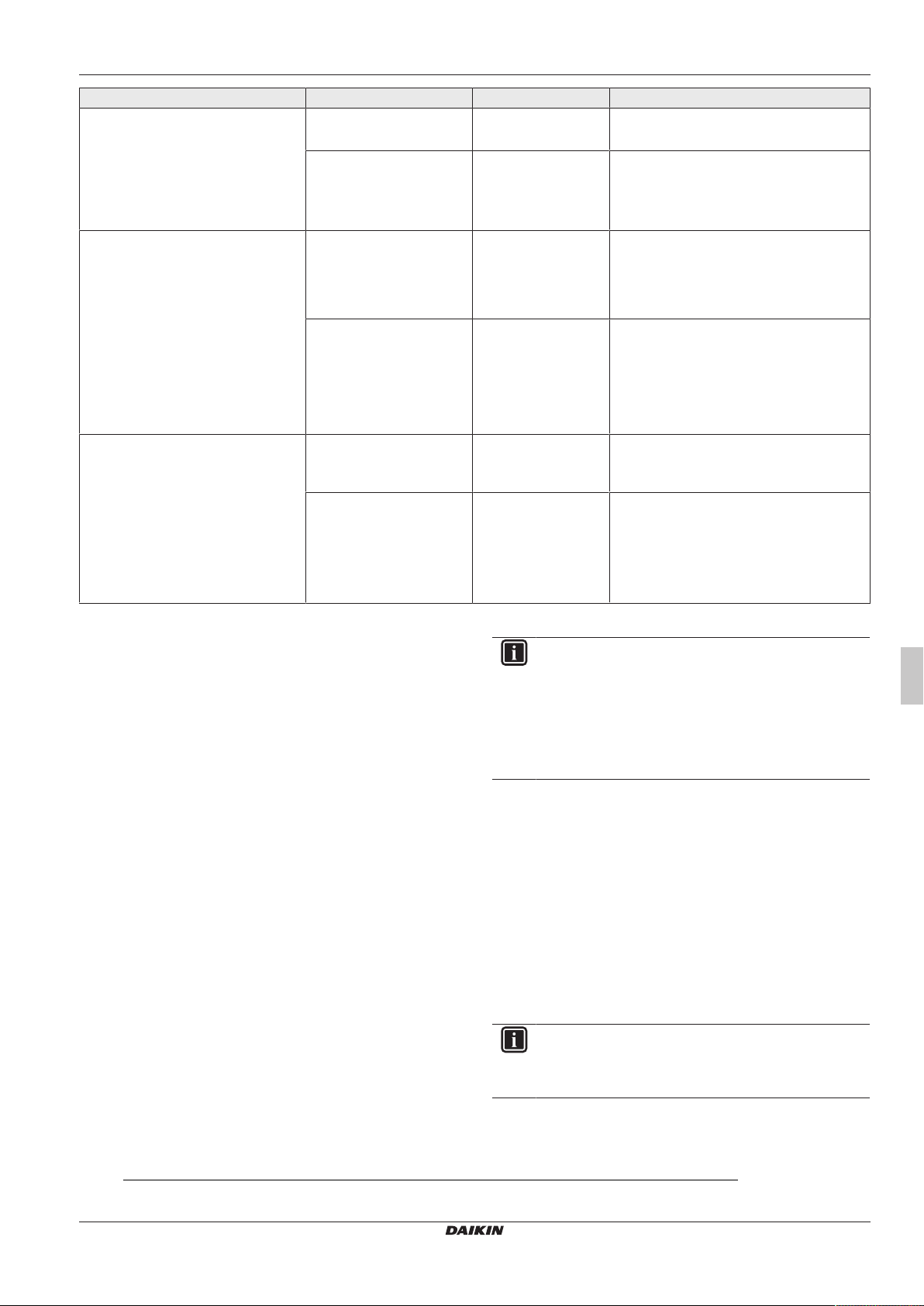

Time period Switching cycle

Single day of the week (Monday,

Tuesday ...)

Working week (Monday to Friday)

Weekend (Saturday to Sunday) 1. 06:00 to 22:00

Entire week (Monday to Sunday) 1. 06:00 to 22:00

Tab.3-4 Structure of the permanent time programs

INFORMATION

Time settings for a switching cycle in a weekday or block

program will also be accepted for other time periods as

long as they are for the same weekdays.

▪ The starting time in the first switching cycle is changed

from 06:00 am to 05:00 am for the individual weekday

"Monday". In the period " Monday to Friday" and

"Monday to Sunday", the first switching cycle is automatically changed from 06:00 to 05:00.

Fig.3-9 Time program function with overview level (left) and set-

ting level (right)

Example: For the [Heating circuit auto. 1] program, set switch cycles

1 and 2 for Monday to Friday [→Main menu →Time program →HC

auto 1]:

1 Turn the rotary button clockwise until the Setting icon turns blue.

2 Briefly press the rotary button to confirm ("OK").

è Display changes to setting level with blue flashing period se-

lection.

3 Turn the rotary switch clockwise until the required time period is

displayed.

4 Briefly press the rotary button to confirm ("OK").

è The display changes to the input window for the start time of

the first switching cycle.

5 Briefly press the rotary button to confirm ("OK").

è Input window for start time of the first switching cycle flashes

blue.

6 Turn the rotary button clockwise until the required start time is

displayed.

7 Briefly press the rotary button to confirm ("OK").

è The display changes to the input window for the end time of

the first switching cycle.

8 Turn the rotary button clockwise until the required end time is

displayed.

9 Briefly press the rotary button to confirm ("OK").

è The display changes to the input window for the start time of

the second switching cycle.

1. 06:00 to 22:00

2. xx:xx to xx:xx

3. xx:xx to xx:xx

1. 06:00 to 22:00

2. xx:xx to xx:xx

3. xx:xx to xx:xx

2. xx:xx to xx:xx

3. xx:xx to xx:xx

2. xx:xx to xx:xx

3. xx:xx to xx:xx

10 Briefly press the rotary button to confirm ("OK").

è Input window for the start time of the second switching cycle

flashes blue.

11 Turn the rotary button clockwise until the required start time is

displayed.

12 Briefly press the rotary button to confirm ("OK").

è The display changes to the input window for the end time of

the second switching cycle.

13 Turn the rotary button clockwise until the required end time is

displayed.

14 Briefly press the rotary button to confirm ("OK").

è The display changes to the input window for the start time of

the third switching cycle.

15 Turn the rotary button clockwise until the Confirm icon turns

blue.

è The display changes to the Confirm icon.

16 Briefly press the rotary button to confirm ("OK").

è The programming is saved.

è The setting level is exited.

è Selected switching cycles are highlighted in grey.

17 Turn the rotary button anticlockwise until the Back icon turns

blue.

18 Briefly press the rotary button to confirm ("OK").

è The menu is exited

3.3.8 External operation

In addition to operation via the integrated RoCon+ HP controller, the

system can also be adjusted and operated via external devices.

Operation via the Internet

An optional gateway (EHS157056) can be used to connect the RoCon+ HP controller to the Internet. This enables remote control of

the RoCon+ HP by mobile phone (using an app).

Operation via the room station

It can also be operated via the optional EHS157034 room controller.

For this purpose, observe the operating instructions enclosed with

the device.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

11

Page 12

4 Function

4 Function

The system fully automatically controls the operation of the room

heating, room cooling and domestic hot water preparation on the

sanitary side on the basis of the specifications set in the RoCon+ HP

controller. The functions that can influence system operation are described below.

Some of the functions and parameters described are restricted by

access rights and can only be set by a heating specialist (see

Chap. 4.5.1).

4.1 Mode

[→Main menu →Operating mode]

This menu is used to select the operating mode for operating the

device. The current operating mode is indicated by a corresponding

symbol on the start screen.

Standby operating mode (Standby)

NOTICE

A heating system that is not protected against frost can

freeze in the event of frost and thus be damaged.

▪ Drain the heating system on the water side if there is a

danger of frost.

▪ If the heating system is not drained, the power supply

must be ensured and the mains switch must remain

switched on if there is a risk of frost.

In this operating mode, the Daikin Altherma ETS(X/H) is switched to

standby mode. The frost protection function remains unchanged. In

order to maintain this function, the system must not be disconnected

from the mains.

All controllers integrated in the RoCon system via the CAN bus are

primarily also switched to the "Standby" operating mode.

INFORMATION

In the [Standby] operating mode, the heat pump and the

optionally connected backup heater are disconnected from

the power supply (energy-saving mode) if the following

conditions are met:

▪ the outside temperature sensor is connected and cor-

rectly parametrised in the system configuration

▪ the outside temperature is more than 8°C

▪ there is no heating request

▪ the frost protection function is not active in any connec-

ted HC and

▪ the Daikin Altherma ETS(X/H) has been switched on

for at least 5minutes.

Reduce operating mode

Reduced heating operation (lower room target temperature) according to the set reduction temperature in the [Reduce room temperature] parameter (see Chap. 4.2).

Domestic hot water preparation according to the feed target temperatures and switching cycles in the [Hot water auto. 1] hot water time

program (see Chap. 4.2).

Heating operating mode

Heating, cooling mode according to the room target temperature set

in the [Room temperature target 1] parameter (see Chap. 4.2).

A connected outside temperature sensor (weather-compensated

feed temperature control) or a connected room controller also influence the target temperature.

Domestic hot water preparation according to the feed target temperatures and switching cycles in the [Hot water auto. 1] hot water time

program (see Chap. 4.2).

Summer operating mode

Only domestic hot water preparation according to the set target temperatures and switching cycles is carried out in the [Hot water auto.

1] hot water time program (see Chap. 4.2).

All controllers integrated in the RoCon system via the CAN bus are

also switched to the higher-level [Summer] operating mode.

Automatic 1 operating mode (time program)

Automatic heating and setback mode according to the permanent

time programs (see Chap. 4.3):

▪ [Heating circuit auto. 1]

▪ [Hot water auto. 1]

Automatic 2 operating mode (time program)

Automatic heating and setback mode according to the permanent

time programs (see Chap. 4.3):

▪ [Heating circuit auto. 2]

▪ [Hot water auto. 2]

INFORMATION: SWITCHING CONTACT FOR EXTERNAL OPERATING MODE CHANGEOVER

Switching can also be performed from an external device

(e.g. modem, ...) via a floating switching contact connected

to terminal J8 of the Daikin Altherma ETS(X/H) to the "Ext"

terminals. See Tab. 4-1.

In this case, the switching contact functionality is dependent on the parameter [Func. burner blocking contact]:

▪ [Func. burner blocking contact] = Resistance values

(default setting): Evaluation of the resistance values.

▪ [Func. burner blocking contact] = Burner blocking con-

tact: Evaluation as a burner blocking contact. If the

switching contact is closed, the external heat generator

has priority.

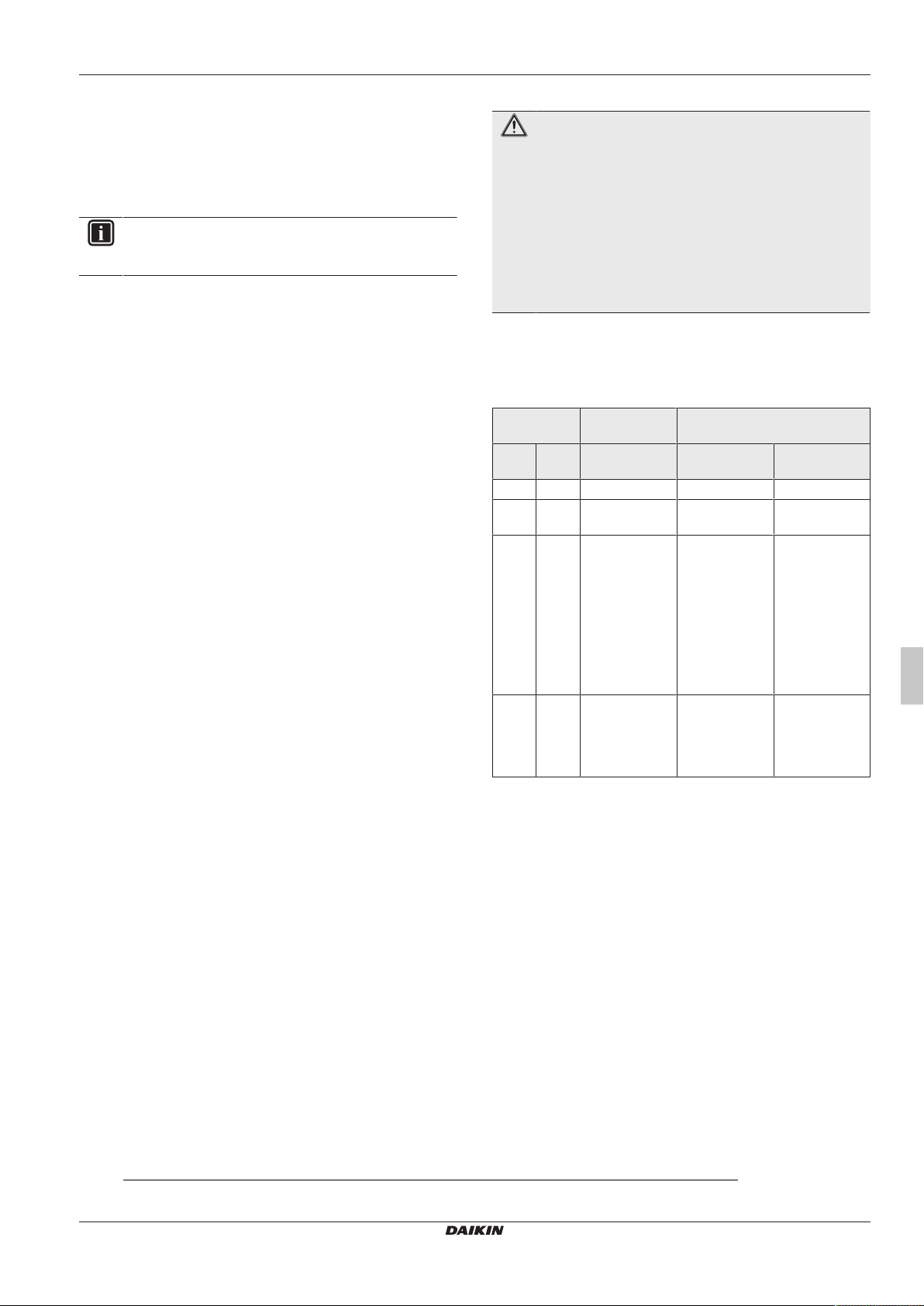

Operating mode Resistance Tolerance

Standby <680Ω ±5%

Heating 1200Ω

Reduce 1800Ω

Summer 2700Ω

Automatic 1 4700Ω

Automatic 2 8200Ω

Tab.4-1 Resistance values for evaluating the EXT signal

INFORMATION

The resistances specified in Tab. 4-1 in a tolerance field of

5%. Resistances outside this tolerance field are interpreted

as an open input. The heat generator switches back to the

previously active operating mode.

The input is not considered for resistance values greater

than the value for "Automatic 2".

If several switching contacts are connected to the Daikin

Altherma ETS(X/H) (e.g. smart grid, room thermostat), the

associated functions may have a higher priority than the

external mode switching. The operating mode requested

by the EXT switching contact is then possibly not activated

or is only activated later.

Besides these operating modes, different temporary time programs

(see Tab. 4-2) are available that are carried out with priority after activation.

Operating Instructions

12

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 13

4 Function

Temporary heating

program

Party Time program Chap. 4.3

Absent

Public holiday

Holiday

Screed Configuration Chap. 4.5.7

Tab.4-2 Overview of temporary time programs

INFORMATION

If a temporary heating program (Party, Absent, Public holiday, Holiday, Screed) is started during the selected operating mode, control is carried out primarily according to the

settings for this time program.

Setting/activation in

the menu

Information

4.2 User

[→Main menu →User]

The most important target temperatures and functions are set for the

user in this menu.

4.2.1 Room temperature setpoint setting

[→Main menu →User →Room]

The room target temperatures for room heating in Heating mode are

defined in this menu. The available setpoints (1-3) belong to the respective cycle (1-3) of the [Heating circuit auto. 1] and [Heating circuit auto. 2] time programs.

Further explanations and possible settings for this menu can be

found in Chap. 7.3.

4.2.2 Room temperature reduced setting

[→Main menu →User →Reduce]

The room target temperatures for room heating in Reduced mode

are defined in this menu. The reduced operation is carried out by the

"Reduce" operating mode or by the [Heating circuit auto. 1] and

[Heating circuit auto. 2] time programs.

Further explanations and possible settings for this menu can be

found in Chap. 7.3.

4.2.3 Room temperature absence setting

[→Main menu →User →Absent]

The room target temperature for room heating in Absence mode are

defined in this menu. The absence operation is carried out by the

[Absent] or [Holiday] time programs.

Further explanations and possible settings for this menu can be

found in Chap. 7.3.

4.2.4 Hot water temperature setpoint setting

[→Main menu →User →Hot water]

The hot water target temperatures for domestic hot water prepara-

tion are defined in this menu. The available setpoints (1-3) belong to

the respective cycle (1-3) of the [Hot water auto. 1] and [Hot water

auto. 2] time programs.

Further explanations and possible settings for this menu can be

found in Chap. 7.3.

4.2.5 Unscheduled domestic hot water generation

[→Main menu →User →1x load]

By starting this function, the hot water can be heated up to the [Hot

water temperature target 1] target temperature at any time. The

heating up is carried out with priority and independent of other heating programs. After this temporary function has elapsed, the control

unit automatically jumps back to the previously active operating

mode.

Possible settings for this menu can be found in Chap. 7.3.

4.3 Time Program

[→Main menu →Time program]

Various freely adjustable permanent time programs are available for

convenient and individual room and hot water temperature control.

Temporary time programs are also available, which override the permanent time programs or the currently set operating mode for the

duration of their validity.

4.3.1 Temporary time programs

INFORMATION

The following temporary time programs can be cancelled

at any time due to the manual changing of the operating

mode.

Party

[→Main menu →Time program →Party]

The program runs from activation until the end of the set period. Dur-

ing this time, the HC is controlled to the temperature set in the

[Room temperature target 1] parameter. If the [Automatic 1] or [Automatic 2] time program is active, the heating cycle is extended or started prematurely. The domestic hot water preparation is not affected.

Absent

[→Main menu →Time program →Absent]

The program runs from activation until the end of the set period. Dur-

ing this time, the HC is controlled to the room target temperature in

the [Room temperature absent] parameter. The domestic hot water

preparation is not affected.

Holiday

[→Main menu →Time program →Holiday]

A calendar function can be used to enter a time period of absence.

During this time, the HC is continuously controlled (24h per day) to

the room target temperature set in the [Room temperature absent]

parameter. This program is not started if the [Standby] operating

mode is active on the set start date.

Public holiday

[→Main menu →Time program →Public holiday]

A calendar function can be used to enter a time period of presence.

During this time, regulation is carried out exclusively according to the

settings for "Sunday" in [Heating circuit auto. 1] and [Hot water auto.

1].

4.3.2 Permanent time programs

For the connected HCs and the storage tank charging circuit, time

programs control the HC and hot water temperatures or the operating times of the circulation pump according to the specified switching

cycles. The switching cycles are saved in time blocks for which different target temperatures can be set.

The saved time program can be changed at any time. For a better

overview, it is recommended to write down and safely store the programmed switching cycles (Chap. 11.1).

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

13

Page 14

4 Function

Heating circuit auto. 1 and Heating circuit auto. 2

[→Main menu →Time program →HC auto 1/HC auto 2]

The time programs for the HC can be parametrised in these menus.

Three switching cycles can be set per day, to which the [Room temperature target 1/2/3] parameters are assigned. Outside the switching cycles, it is controlled to the [Reduce room temperature] setpoint.

The entry can be made separately for each individual weekday or in

week segments.

Hot water auto. 1 and Hot water auto. 2

[→Main menu →Time program →DHW auto 1/DHW auto 2]

The time programs for the domestic hot water preparation can be

parametrised in these menus. Three switching cycles can be set per

day, to which the [Hot water temperature, target 1/2/3] parameters

are assigned.

Circulation program

[→Main menu →Time program →Circulation]

A time program for an optionally connected circulation pump can be

parametrised in this menu. 3 switching cycles per day can be set.

Switching cycle 1 Switching cycle 2 Switching cycle 3

Time period On Off On Off On Off

Room heating

Temperature setting [Room temperature target 1]: 20°C [Room temperature target 2]: 20°C [Room temperature target 3]: 20°C

[Reduce room temperature]: 10°C

"Heating circuit auto. 1"

Monday – Friday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

"Heating circuit auto. 2"

Monday – Friday 06:00 08:00 16:00 22:00 - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

INFORMATION

Use of circulation lines not permitted in France!

Sound program

INFORMATION

During quiet mode, the output in room heating and room

cooling mode decreases so that it may no longer be possible to achieve pre-set target temperature values.This program can therefore only be set by the installer.

In this menu, a time program can be parametrised for various stages

of the heat pump quiet mode. 3 switching cycles with a resolution of

15minutes can be set. A separate entry for each weekday is possible. Format: (on) hh:mm – hh:mm (off)

Also, the cycles from Monday to Friday, Saturday to Sunday and

Monday to Sunday can be parametrised.

A noise level can be assigned to each switching cycle (0 - no noise

reduction; 1 - min. noise reduction; 2 - med. noise reduction; 3 max. noise reduction).

Factory settings

The permanent time programs are preset according to .

Domestic hot water preparation

Temperature setting [Hot water temperature target 1]:

60°C

"Hot water auto. 1"

Monday – Sunday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

"Hot water auto. 2"

Monday – Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

"Circulation program"

Monday – Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Monday – Sunday - - : - - - - : - - - - : - - - - : - - - - : - - - - : - -

Tab.4-3 Factory setting of the permanent time programs

4.3.3 Time program reset

[→Main menu →Time program →TP reset]

This menu can be used to reset the time programs to factory set-

tings. To do this, select the respective time programs and then confirm the selection with the Confirm button on the second menu page.

[Hot water temperature target 2]:

60°C

"Sound program"

4.4 Settings

[→Main menu →Settings]

The basic settings of the controller and the system are made in this

menu. This includes the integration of optional and external components. Depending on the access authorisation (user or expert), different parameters are available.

[Hot water temperature target 3]:

60°C

Operating Instructions

14

Daikin controller RoCon+ HP1

Daikin RoCon+ HP

008.1447899_00 – 09/2019 – EN

Page 15

4 Function

4.4.1 Display settings

[→Main menu →Settings →Display]

This menu can be used to set the following parameters: Language,

date, time, LCD brightness and LCD illumination time.

Further explanations and possible settings for this menu can be

found in Chap. 7.5.

INFORMATION

Increasing the brightness of the LCD display beyond the

factory-set value will reduce the life of the display.

4.4.2 System

[→Main menu →Settings →System]

This menu combines basic parameters of the heating system.

Further explanations and possible settings for this menu can be

found in Chap. 7.5.2.

4.4.3 Additional heat generators

[→Main menu →Settings →Ext. source]

This menu can be used to configure the integration of an optional ex-

ternal heat source.

The heat supplied by an alternative WEZ must be fed to the unpres-

surised storage tank water in the Daikin Altherma ETS(X/H) hot water storage tank.

▪ On use of the optional EKBUxx backup heater, this is carried out

due to the design installation situation.

▪ If an alternative WEZ (e.g. gas- or oil-fired boiler) is used, this can

be hydraulically integrated

▪ unpressurised via the connections (solar feed and solar return)

of the hot water storage tank or

▪ in the case of Daikin Altherma ETS(X/H) ...B device types, via

the integrated pressurised solar system heat exchanger

The setting of the [Config. ext. heat source] parameter is used to

define if any additional heat generator (WEZ) is available for domestic hot water preparation and heating support, and which.

▪ No external heat source

▪ Optional backup heater

▪ Ext. heat sources HW and HZU: Alternative WEZ provide do-

mestic hot water preparation and backup heating. To request the

WEZ, relay K3 on PCB RTX-EHS is switched.

▪ Ext. heat source HW or HZU: Alternative WEZ 1 (optional backup

heater EKBUxx) undertakes domestic hot water preparation and

alternative WEZ2 undertakes heating support. To request WEZ 1,

relay K3, and to request WEZ 2, relay K1, on PCB RTX-EHS are

switched respectively. Heed warning notice! The operation of an

additional alternative WEZ is also influenced by the settings of the

[Bivalence function] and [Bivalence temperature] parameters.

Further explanations and possible settings for this menu can be

found in Chap. 7.5.3.

4.4.4 Inputs/Outputs

[→Main menu →Settings →Inputs/Outputs]

This menu can be used to adjust parameter for inputs and outputs of

the controller PCB to optimise the system controller individually.

Smart grid

WARNING

There is a danger of scalds at hot water target temperatures over 65°C. This is possible because the utility company (EVU) is entitled to control current draw optimised according to supply and demand in the definitions for Smart

Grid.

Due to such forced charging, the hot water target temperature in the hot water storage tank can exceed 65°C.

This storage tank charging is carried out even when the

[Standby] operating mode is set.

▪ Install scald protection in the hot water distribution line.

To use this function, a special electricity meter with SG receiver to

which the Daikin Altherma ETS(X/H) must be connected is required.

As soon as the function is activated by the [Smart grid] parameter,

the heat pump is set to an operating mode as per Tab. 4-4 depending on the utility company signal.

(1)

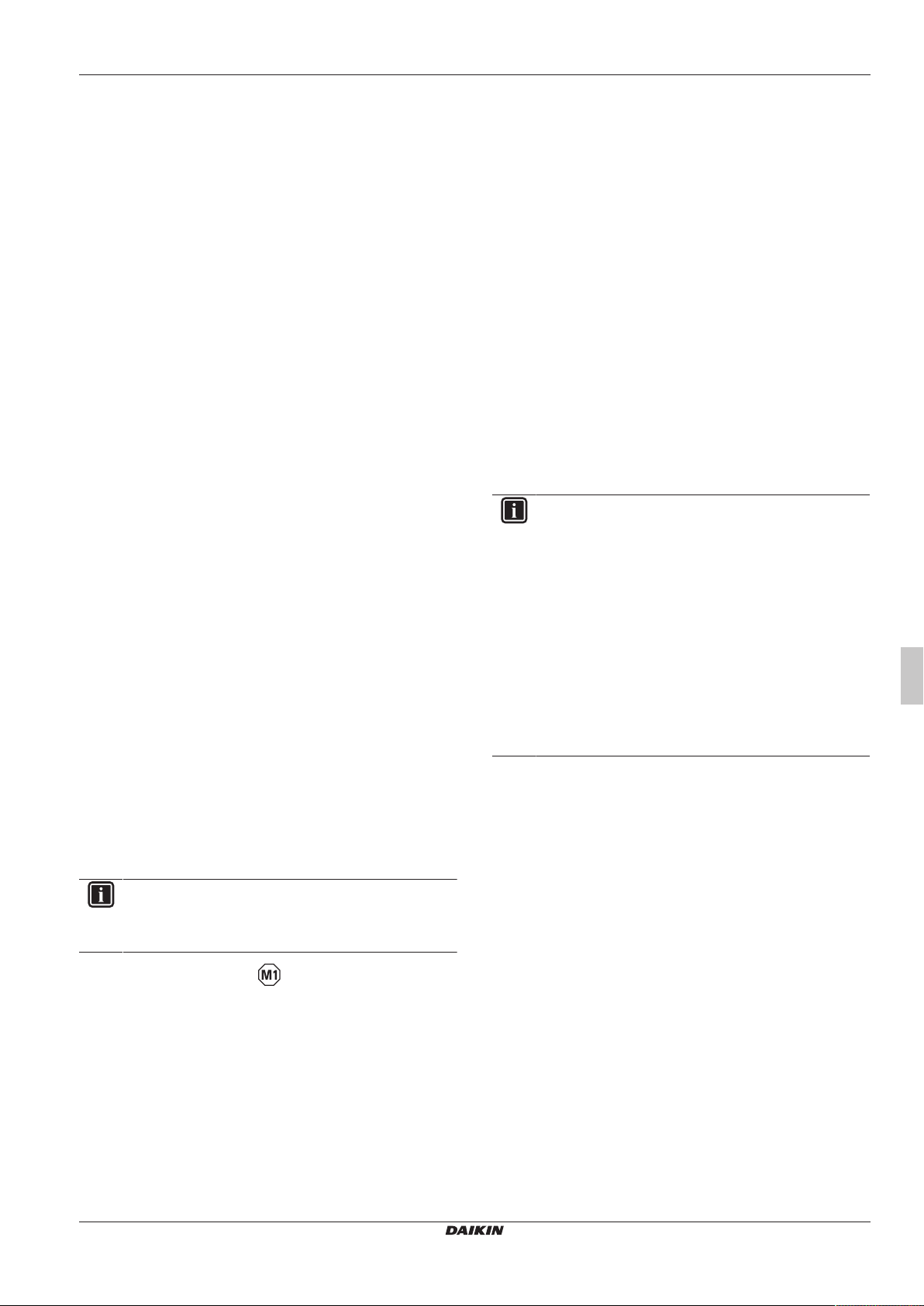

Signal

Electricity

Effect on

costs

EVU SG Hot water Heating install-

ations

1 0 --- No operation

0 0 Normal Normal opera-

tion

0 1 low Switch-on re-

commendation,

and target stor-

age tank tem-

perature value is

increased de-

pending on the

[Smart grid

mode] para-

(2)

No operation

Normal opera-

Switch-on recommendation,

and target feed

temperature is

increased de-

pending on the

[Smart grid

mode] para-

meter.

(2)

tion

meter.

1 1 Very low Switch-on com-

mand and storage tank target

temperature is

Switch-on com-

mand for stor-

age tank char-

ging.

set to 70°C.

Tab.4-4 Use of the SG signal

AUX switching function

Setting the [AUX switching function] parameter selects the switching

conditions for the potential-free AUX switching contact (toggle switch

output A). This switching contact can be used to control an external

heat generator, for example.

If one of the switching conditions is fulfilled, the potential-free switching contact is switched after the time set in the [AUX wait time] parameter.

AUX switching contact (toggle switch output A) is not switched if

setting is deactivated.

AUX switching contact (toggle switch output A) is switched, if setting

▪ Storage tank temperature (T

(AUX)] parameter value.

) ≥ [Switching threshold TDHW

dhw

▪ if an error is pending.

▪ Outside temperature < [Bivalence temperature] parameter value.

▪ Heat request for domestic hot water preparation.

▪ Heat request for room heating.

▪ Heat request for room heating or domestic hot water preparation.

(1)

Switching contacts at input J8 of the RoCon BM2C PCB closed(1) or open(0).

(2)

No frost protection function

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

15

Page 16

4 Function

Interlink function

Setting the [Interlink function] parameter = On offers the possibility

that the Daikin Altherma ETS(X/H) two different feed temperature

setpoints are included in the controller.

This applies to both weather-compensated control and control according to a fixed feed target temperature (see Chap. 4.5).

One possible application is, for example, the additional integration of

an HP convector in a surface heating and cooling system.

Prerequisite: 2 switching contacts are connected to Daikin Altherma

ETS(X/H) plug connection J16 (e.g. room thermostats).

▪ [Interlink function] parameter = Off: Deactivated

▪ [Interlink function] parameter = On: Evaluation of the heating and

cooling switching contacts at plug connection J16 on the RoCon

BM2C PCB. Activation of cooling mode only by switching the operating mode to [Cooling] (see Chap. 4.1). Setting of the [Room

thermostat] parameter is no longer evaluated.

▪ Open switching contacts: Only frost protection active

▪ [Heating] or [Automatic 1] / [Automatic 2] operating mode active

during daytime switching cycles.

▪ Closed switching contact Heating = IL1

▪ It is controlled to the normal feed target temperature according

to the parameter settings for [Heating].

▪ Closed switching contact Cooling = IL2

▪ It is controlled to the increased feed target temperature (normal

feed target temperature + value of the [Interlink temperature in-

crease ] parameter). Priority if both switching contacts are

closed!

▪ [Cooling] operating mode active.

▪ Closed switching contact Heating = IL1

▪ It is controlled to the normal feed target temperature according

to the parameter settings in level [Heating circuit config.] >

[Cooling].

▪ Closed switching contact Cooling = IL2

▪ The system is regulated to the reduced feed target temperature

(normal feed target temperature value of the [Interlink temperat-

ure increase ] parameter. Priority if both switching contacts are

closed!

Further explanations and possible settings for this menu can be

found in Chap. 7.5.

Tdhw > T

+ 4K and Tdhw > [Hot water temperature, target] in-

HZUmin

formation parameter + 1K

If the switch-on condition is fulfilled, heat is taken from the storage

tank and this is used to supply the heating system.

Switch-off condition:

Tdhw < T

or Tdhw < [Feed temperature, target] parameter (see

HZUmin

Chap. 4.5.3)

If the switch-off condition is fulfilled, the heating support from the hot

water storage tank is set and the burner takes over the heating operation.

The [Heating support power] parameter limits the maximum power

that can be taken. The [Heating support max. temp.] parameter limits

the maximum temperature that can enter the heating system.

Further explanations and possible settings for the parameters in this

menu can be found in Chap. 7.5.5.

4.5 Configuration

[→Main menu →Configuration]

This menu can be used to optimally adapt the operating characterist-

ics of the system to the system structure and the needs of the users.

Additional programs facilitate commissioning. Depending on the access authorisation (user or expert), different parameters are available.

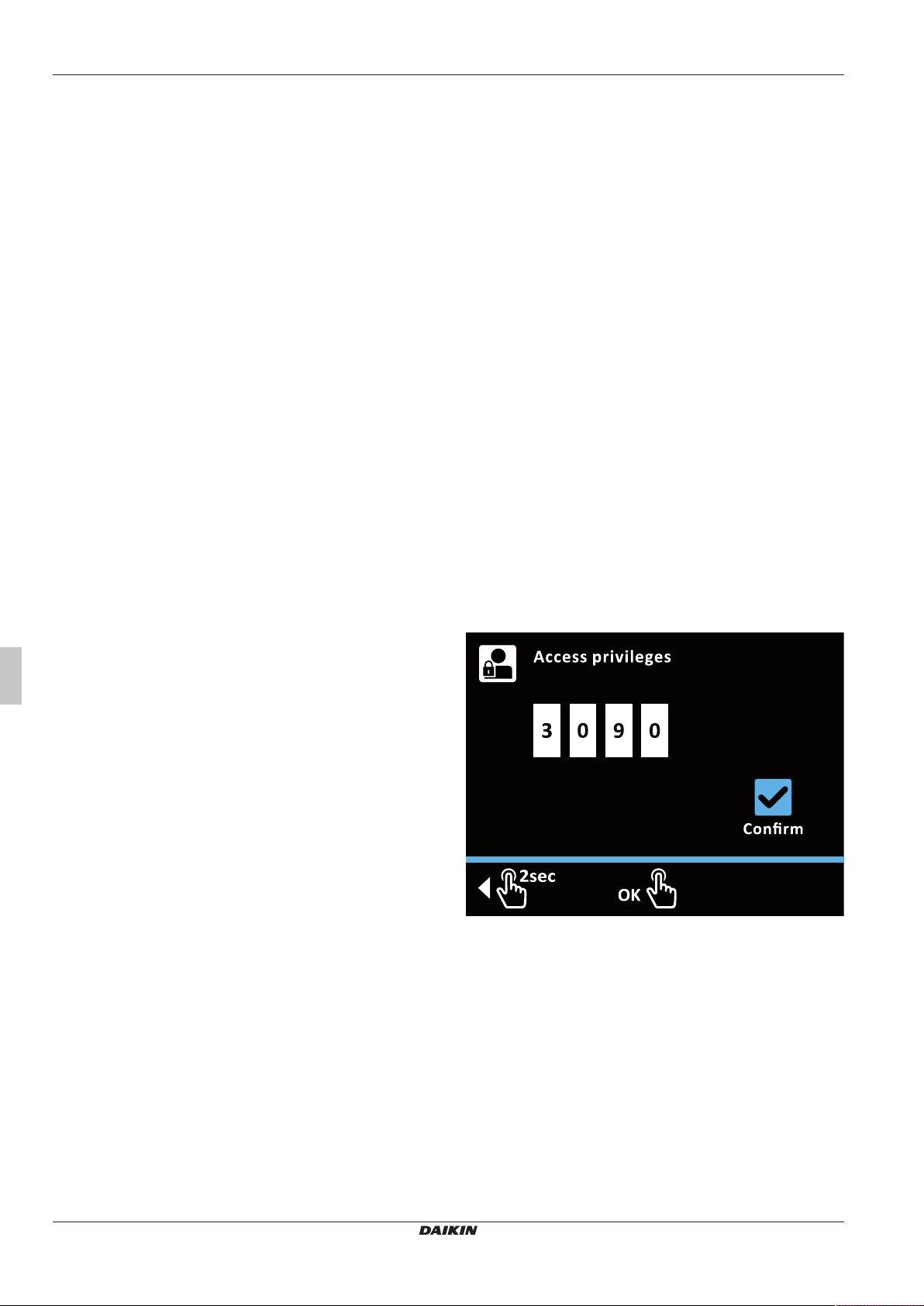

4.5.1 Access privileges (technician code)

[→Main menu →Configuration →Access]

Certain functions and parameters in the controller are restricted by

access rights and are not visible to the user. To gain access to it, the

specialist code must be entered.

4.4.5 Intelligent storage tank management

[→Main menu →Settings →ISM]

If the storage temperatures are high enough, the energy in the stor-

age tank can be used for room heating. This can either increase

comfort ([Continuous heating] function) or make it possible to use

energy from an external heat source, e.g. solar, when heating is required ([Heating support (HZU)] function).

Continuous heating

This function enables uninterrupted heating, even when the evaporator is being defrosted. This enables high comfort to be guaranteed,

even with rapidly reacting heating systems (e.g. convectors).

Heating support (HZU)

If the Heating support function ([Heating support (HZU)] parameter =

On) is activated, the energy in the Daikin Altherma ETS(X/H)'s integrated storage tank is used to undertake the heating function. If the

storage temperature is sufficiently high, the burner remains inactive.

The minimum value (T

) is calculated as follows: T

HZUmin

HZUmin

= currently active hot water target temperature [Hot water temperature,

target] + [Heating support hysteresis] parameter.

Switch-on condition:

Operating Instructions

16

Fig.4-1 Setting the access code

Example: Set code 3090 (example only, this is not a valid access

code) [→Main menu →Configuration →Access]:

1 Turn the rotary button clockwise until the first input field is dis-

played in blue.

2 Briefly press the rotary button to confirm ("OK").

è The first input field flashes blue.

3 Turn the rotary button clockwise until 3 is displayed.

4 Briefly press the rotary button to confirm ("OK").

è The second input field is displayed in blue.

5 Turn the rotary button clockwise until the third input field is dis-

played in blue.

6 Briefly press the rotary button to confirm ("OK").

è The third input field flashes blue.

7 Turn the rotary button clockwise until 9 is displayed.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Page 17

4 Function

8 Briefly press the rotary button to confirm ("OK").

è The fourth input field is displayed in blue.

9 Turn the rotary button clockwise until the Confirm icon turns

blue.

10 Briefly press the rotary button to confirm ("OK").

è The code is checked and the setting level is exited.

4.5.2 Sensors

[→Main menu →Configuration →Sensors]

Optional sensors are activated and configured in this menu. Pres-

sure setpoints for the water side can be defined.

Further explanations and possible settings for the parameters in this

menu can be found in Chap. 7.6.1.

4.5.3 HC configuration

[→Main menu →Configuration →HC config]

This menu is used to adjust the basic functionality of the heating cir-

cuit.

Further explanations and possible settings for the parameters in this

menu can be found in Chap. 7.6.2.

Weather-dependent feed temperature control

If the weather-compensated feed temperature control is active, the

feed temperature ([Feed temperature, target] parameter) is determined automatically according to the set heating/cooling curve depending on the outside temperature.

This function is activated in the delivery condition. It can only be deactivated (fixed value control) or reactivated with a technician code.

If the room controller is also connected (EHS157034) to the RoCon+

HP, the target temperatures are controlled according to the weather

and room temperature ([Room influence] parameter).

This function can only be configured using the technician code. Contact your heating expert in this regard.

This function is activated or deactivated via the [Weather-compensated] parameter in the "Configuration" menu.

▪ [Weather-compensated] parameter = Weather-compensated:

Weather-compensated feed temperature control

▪ [Weather-compensated] parameter = Feed temperature, fixed:

Control based on fixed target temperature

▪ For heating mode: [Feed temperature, heating mode] para-

meter or [Feed temperature, reducing mode] parameter

▪ For cooling mode: [Feed temperature, cooling mode] parameter

If the terminal function is activated, the mixer module can be operated and the settings for the assigned heating circuit undertaken via

the RoCon+ B1 control panel of the Daikin Altherma ETS(X/H).

In conjunction with the EHS157034 room control, the mixer module

can also control the assigned heating circuit completely autonomously and independently of the heat generator.

Further explanations and possible settings for this menu can be

found in Chap. 7.6.

Frost protection function

The integrated heating circulation pump is switched on at an external

temperature below the [Frost protection temperature] parameter

value in order to prevent the heating system from freezing.

In addition, the feed, storage and connected room temperature

sensors are also constantly monitored. If the temperature measured

by one of these sensors falls below 7°C (below 5°C at room temperature), the antifreeze function is also activated.

If the heating feed temperature falls below 7°C, the Daikin Altherma

ETS(X/H) heats until the heating feed temperature reaches at least

12°C.

The function is ended if the external temperature rises above the set

[Frost protection temperature] parameter value + 1K and also there

is no other activation condition.

INFORMATION

If low rate functions are activated,

[HT/NT function] parameter = Switch all off

or

[Smart grid] parameter = On

operation of the heat pump can be shut off completely for a

limited period of time by the utility company. In these

cases, regulation is not possible even in frost protection

conditions and the device's internal heating circulation

pump is not switched on.

These situations can be recognised if, in the [→Main

menu →Information →Overview] menu in the operating

data field: "Ext", the "High rate" value or "SG1" is displayed.

4.5.4 Heating

[→Main menu →Configuration →Heating]

This menu is used to configure heating times and target feed tem-

peratures for heating mode.

INFORMATION

The weather-compensated feed temperature control has

no influence on the feed target temperature in the case of

a hot water circuit request.

With connected Mixer module

The setting of the heating/cooling curves and the activation of the

weather-compensated feed temperature control for the assigned HC

are carried out in the same way as described above.

The assigned HC can be operated as a:

▪ Mixer add-on

The outside temperature of the outside temperature sensor connected to the Daikin Altherma ETS(X/H) external temperature

sensor is transmitted to the mixer module via the CAN bus.

or as a

▪ Mixer add-on with zone control

A separate outside temperature sensor must be connected to the

mixer module. The assigned HC is controlled according to the out-

side temperature relevant for this zone.

Daikin RoCon+ HP

Daikin controller RoCon+ HP1

008.1447899_00 – 09/2019 – EN

Operating Instructions

17

Page 18

4 Function

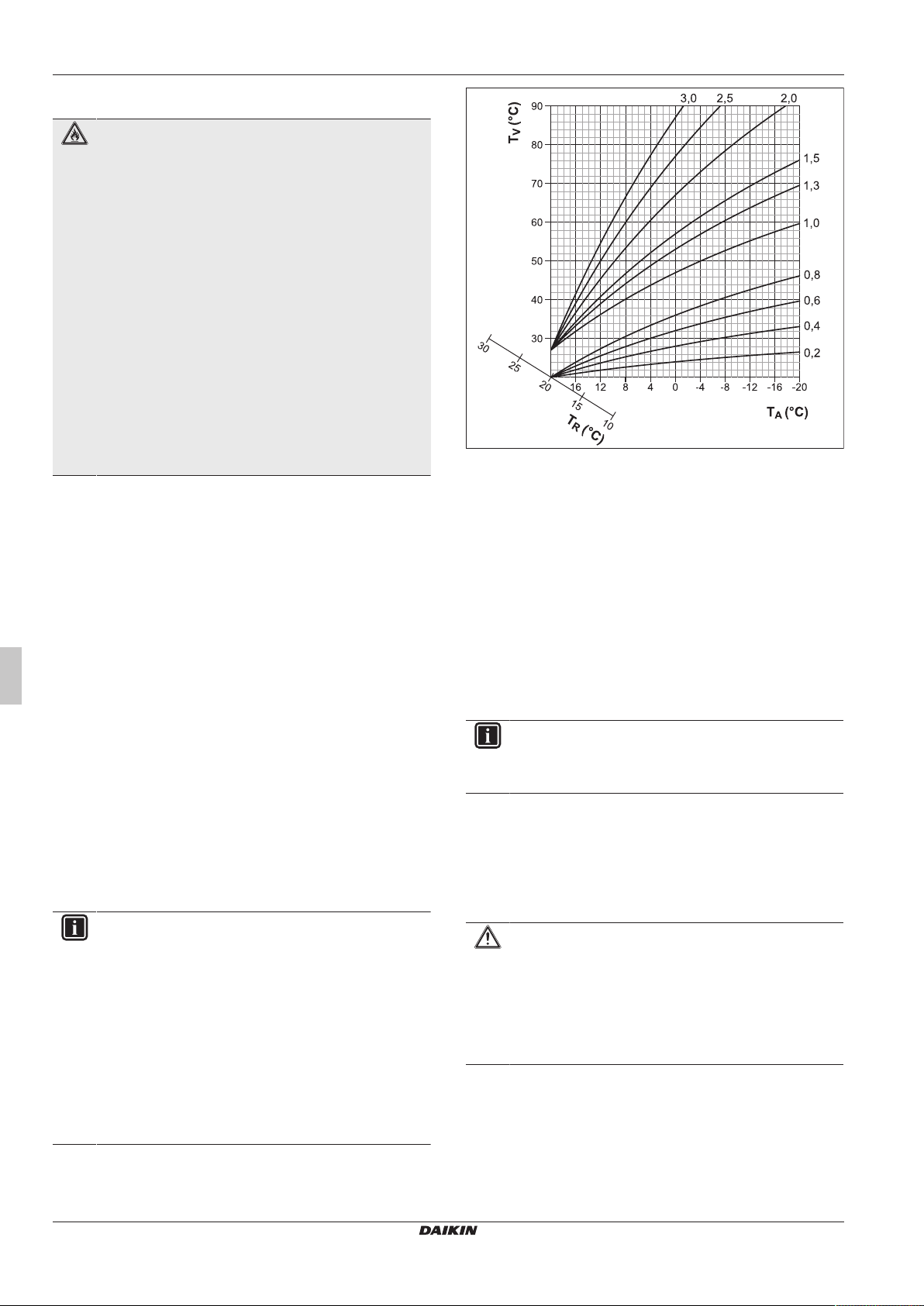

Heating curve

WARNING: FLAMMABLE MATERIAL

In the event of malfunction, the floor heating system, the

screed or the floor structure could be damaged due to

overheating.

▪ Prior to initial commissioning, set the maximum temper-

ature limit in the RoCon+ HP controller ([Max. feed

temperature] parameter) to the maximum permitted

system temperature prior to starting the emission

measurement.

▪ Connect an overheating protection switch (in the build-

ing) at the "Ext" plug connection for external operating

mode switch-over so that the Daikin Altherma ETS(X/

H) is switched to the "Standby" or "Summer" operating

mode. If the [Room thermostat] parameter = Yesor the

[Interlink function] parameter = On, the overheating

protection switch must be connected so that the room

thermostat's switching contact is interrupted.

▪ If the floor heating is also used for room cooling, the

connection notes in the above point also apply to the

connection of a moisture protection switch in the building.

The heating curve is used to adapt the feed temperature to the characteristics of the building independent of the respective outside temperature (weather-compensated feed temperature control, see

Chap. 4.5). Generally speaking, the slope of the heating curve de-

scribes the ratio of the feed temperature change to the external temperature change.

The heating curve is valid within the limits of the minimum and maximum temperatures set for the respective HC. The room temperature

measured in the occupied area may differ from the required room

temperature; these deviations can be kept to a minimum by installing

a room thermostat or a room control.

The controller is set at the factory in such a way that the heating

curve does not independently adjust itself during operation.

The automatic heating curve adjustment can be activated ([Heating curve adaptation] parameter) if the outside temperature sensor

and the room controller (EHS157034) are connected (see

Chap. 4.5).

Start conditions for automatic heating curve adjustment:

▪ Outside temperature <8°C

▪ Operating mode is [Automatic 1] or [Automatic 2]

▪ Duration of the setback period is at least 6h

If no automatic heating curve adjustment is activated, the heating

curve can be manually adjusted by adjusting the [Heating curve]

parameter).

INFORMATION: MANUALLY ADJUSTING THE HEATING CURVE

Do not make any corrections to the set values for 1 – 2

days, and then only make them in small increments.

▪ Deactivate the external heat sources (e.g. stoves, dir-

ect sunlight, open windows).

▪ Fully open any radiator thermostat valves or actuators.

▪ Activate "Heating" operating mode. Approximate setting

values:

Heating element: 1.4 to 1.6.

Floor heating: 0.5 to 0.9.

Fig.4-2 Heating curves

TAOutside temperature

TRRoom target temperature

TVT-HS

Comfort heating

If the heat pump cannot cover the heating demand when outside

temperatures are very low, heat is extracted from the storage tank

and used for room heating. In rare cases (in systems with high required feed temperatures and low required hot water temperatures),

the required feed temperature can be higher than the storage tank

target temperature. In order to avoid short-term loss of comfort in

heating mode for these systems, the [Comfort heating] parameter

can be set to "On". At corresponding outside temperatures, the storage tank temperature is raised above the storage tank temperature

set for the hot water requirement.

INFORMATION

If [Comfort heating] is set to "On", the power consumption

of the heat pump may increase. In the default setting,

[Comfort heating] is set to "Off".

Detailed explanations and possible setting values of this function can

be found in Chap. 7.6.

4.5.5 Cooling

[→Main menu →Configuration →Cooling]