Daikin EKHHP300AA2V3, EKHHP500AA2V3 Installation manuals

Installation and operating

instructions

Hot water heat pump

(indoor unit)

Installation and operating instructions

Hot water heat pump

(indoor unit)

English

EKHHP300AA2V3

EKHHP500AA2V3

List of contents

1 Particular instructions for safe operation . 3

1.1 Particular safety instructions . . . . . . . . . . . . . . . 3

1.2 Observing instructions . . . . . . . . . . . . . . . . . . . . 3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Warning signs and explanation of symbols . . . . 4

2.1.1 Meaning of the warnings. . . . . . . . . . . . . . . . . . . . .4

2.1.2 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1.3 Handling instructions. . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Avoid danger . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Instructions for operating safety. . . . . . . . . . . . . 5

2.4.1 Before working on the hydraulic system . . . . . . . . .5

2.4.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.3 Working on cooling systems (heat pump). . . . . . . .5

2.4.4 Site of installation . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.5 Sanitary connection. . . . . . . . . . . . . . . . . . . . . . . . .6

2.4.6 Requirements for the depressurised storage tank

water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4.7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4.8 Instructing the user/owner. . . . . . . . . . . . . . . . . . . .6

3 Product description. . . . . . . . . . . . . . . . . . . 7

4 Set-up and installation . . . . . . . . . . . . . . . . 9

4.1 Tightening torque . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Hydraulic connection . . . . . . . . . . . . . . . . . . . . 11

4.4.1 Optional: Connection of an external heat generator12

4.5 Laying coolant lines . . . . . . . . . . . . . . . . . . . . . 13

4.6 Pressure test and filling the coolant circuit. . . . 13

4.7 Filling the system with water . . . . . . . . . . . . . . 14

4.7.1 Filling the hot water heat exchanger . . . . . . . . . . .14

4.7.2 Filling the storage tank . . . . . . . . . . . . . . . . . . . . .14

4.8 Electrical connection . . . . . . . . . . . . . . . . . . . . 14

4.8.1 Connection EKHHP on heat pump external unit, mains

connection Booster-Heater (BSH). . . . . . . . . . . . .15

4.8.2 High/low tariff mains connection (HT/NT) . . . . . . .15

4.8.3 Connection EVU receiver (intelligent regulator

Smart Grid - SG) . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.8.4 Optional: Connection of an external heat generator16

7.3.3 Low Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.4 High Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 Setting the timer programme. . . . . . . . . . . . . . 25

7.4.1 Display switching times . . . . . . . . . . . . . . . . . . . . 25

7.4.2 Programming switching times . . . . . . . . . . . . . . . 25

7.4.3 Delete switching time . . . . . . . . . . . . . . . . . . . . . 25

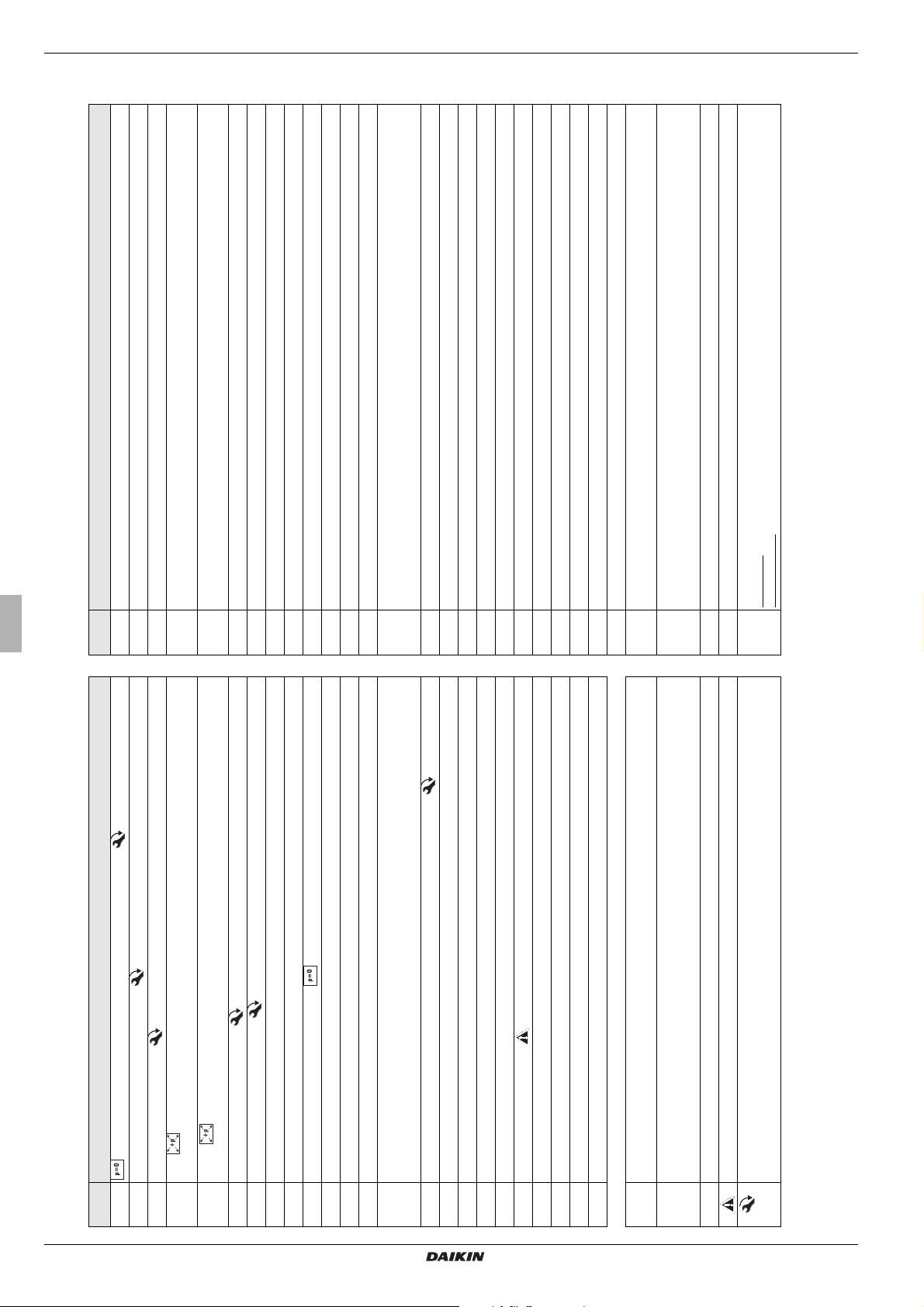

7.5 Parameter settings . . . . . . . . . . . . . . . . . . . . . 27

7.5.1 Setting parameters . . . . . . . . . . . . . . . . . . . . . . . 27

7.5.2 Parameter description . . . . . . . . . . . . . . . . . . . . . 27

7.5.3 Parameter factory settings. . . . . . . . . . . . . . . . . . 30

7.5.4 Individual parameter settings. . . . . . . . . . . . . . . . 31

7.5.5 Individual switching time settings . . . . . . . . . . . . 31

8 Malfunctions and fault codes . . . . . . . . . . 32

8.1 Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.2 Fault code . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9 Service and maintenance . . . . . . . . . . . . . 35

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.2 Periodic Checks . . . . . . . . . . . . . . . . . . . . . . . 35

9.2.1 Filling, topping up storage tank - without installed solar

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.2.2 Filling, topping up storage tank - with optional

KFEKFE filling connection or with installed DrainBack

solar system DrainBack. . . . . . . . . . . . . . . . . . . . 36

10 Technical data . . . . . . . . . . . . . . . . . . . . . . 37

11 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12 List of keywords . . . . . . . . . . . . . . . . . . . . 42

5 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Requirements:. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.1.2 Start the system . . . . . . . . . . . . . . . . . . . . . . . . . .17

6 Decommissioning . . . . . . . . . . . . . . . . . . . 19

6.1 Temporary shutdown . . . . . . . . . . . . . . . . . . . . 19

6.1.1 Draining the storage tank . . . . . . . . . . . . . . . . . . .19

6.1.2 Draining the hot water circuit. . . . . . . . . . . . . . . . .20

6.2 Final shutdown. . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Operation, Parameters . . . . . . . . . . . . . . . 22

7.1 Displays and function of the operating elements22

7.2 Basic functions. . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.1 Switching the system on and off . . . . . . . . . . . . . .23

7.2.2 Setting the clock . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.2.3 Display of the current Temperature. . . . . . . . . . . .23

7.2.4 Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.3 Operating modes . . . . . . . . . . . . . . . . . . . . . . . 23

7.3.1 ECO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.3.2 AUTOMATIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Installation and operating instructions

2

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423449_05 – 08/2016

1 x Particular instructions for safe operation

1 Particular instructions for safe operation

1.1 Particular safety instructions

WARNING!

Disregarding the following safety instructions may result in serious physical injury or death.

● This equipment must only be used by children aged 8 and above and by persons with restricted

physical, sensory or mental capabilities or with a lack of experience and knowledge, if they are

under supervision or if they have been instructed in the safe use of the equipment and understand the dangers arising therefrom. Children must not play with the equipment. Cleaning and

user maintenance must not be carried out by children without supervision.

● Make up the power supply in accordance with IEC 60335-1, via a separator device which exhibits

contact separation in all poles with a contact opening distance that provide full disconnection in

accordance with overvoltage category III.

● All the electrical work must only be carried out by electrically qualified experts and with consideration of the local and national regulations, and the instructions in this manual.

Check that a suitable electrical circuit is being used.

Inadequate capacity of the power circuit or improperly executed connections can cause electrocution or fire.

● The customer must install a pressure relief device with rated over-pressure less than 0.6 MPa

(6 bar). The connected drain line must have a continuous gradient and a free outlet in a frost-free

environment (see Section 2.4.1, 2.4.5 and 4.4 (Figure 4-5)).

● Water may drip out of the drain line of the pressure relief device. The drain opening must be left

free to atmosphere.

● The pressure relief device must be operated regularly in order to remove scale deposits and to

make sure it is not blocked.

● The storage tank and hot water circuit can be drained. The instructions in Sections 6.1.1 and

6.1.2 must be observed.

● All the work on the refrigerant circuit must only be carried out by refrigeration qualified experts

and with consideration of the local and national regulations, and the instructions in this manual.

● Improperly executed work on the refrigeration circuit of the heat pump can endanger life and

health of persons and can impair the function of the heat pump (see Section 6.2).

1.2 Observing instructions

These instructions are a >> translation of the original

version << in your language.

This manual describes all the necessary activities for installation,

start-up and maintenance, as well as for operation and settings.

All parameters needed for trouble-free operation have been configured at the factory. Please see the attached documents for a

detailed description of operation and control.

● Please read this manual carefully and thoroughly before

proceeding with the installation or modification of the heating

system, operation of the heating system and making settings.

● Make a note of the preset values before you make any

changes to the unit configuration.

● Comply strictly with warning instructions.

Relevant documents

– External unit for DAIKIN EKHHP: the associated installation

and operating instructions.

– When connecting to a DAIKIN solar system: the associated

installation and operating instructions.

The guides are included in the scope of supply for the individual

units.

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Installation and operating instructions

3

2 x Safety

2 Safety

2.1 Warning signs and explanation of symbols

2.1.1 Meaning of the warnings

Warnings in this manual are classified according

into their severity and probability of occurrence.

DANGER!

Draws attention to imminent danger.

Disregarding this warning can lead to serious

injury or death.

WARNING!

Indicates a potentially dangerous situation.

Disregarding this warning may result in serious

physical injury or death.

CAUTION!

Indicates a situation which may cause possible

damage.

Disregarding this warning can lead to damage

to property and the environment.

Heat pump indoor unit

Pay attention to the stipulated tightening

torque (see Section 4.1).

Applies only to the depressurised solar

system (DrainBack).

Applies only to the solar pressure system.

2.1.3 Handling instructions

● Instructions on actions are shown as a list.

Actions of which the sequential order must be

maintained are numbered.

Results of actions are identified with an

arrow.

2.2 Avoid danger

The DAIKIN EKHHP is state-of-the-art and is

built to meet all recognised technical requirements. However, improper use can lead to serious injuries or death, as well as causing material damage.

To prevent such risks, install and operate

DAIKIN EKHHP only:

– as stipulated and in perfect condition,

– with an awareness of the safety and hazards

involved.

This symbol identifies user tips and particularly useful information, but not

warnings or hazards.

Special warning signs

Some types of danger are represented by

special symbols:

Electric power

Risk of burning or scalding

Risk of environmental damage

2.1.2 Validity

Some information in this manual has limited validity. The validity is highlighted by a symbol.

Exterior heat pump unit

This assumes knowledge and use of the contents of this manual, the relevant accident prevention regulations and the recognised safetyrelated and occupational medical rules.

2.3 Intended use

The DAIKIN EKHHP system may only be used

for the generation of hot water and only set up,

connected and operated in accordance with the

specifications in this manual.

Only use of a suitable external unit approved by

DAIKIN is permitted. The following combinations

are permissible in this respect:

External unit Internal unit

EKHHP300AA2V3

ERWQ02AAV3

EKHHP500AA2V3

Tab. 2-1 Permissible combinations of DAIKIN EKHHP internal units and

DAIKIN heat pump external units

Installation and operating instructions

4

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

2 x Safety

Any other use outside the intended use is considered as improper. The operator alone shall

bear responsibility for any resulting damage.

Intended use also includes compliance with the

maintenance and service conditions. Spare

parts must at least satisfy the technical requirements defined by the manufacturer. This is the

case, for example, with original spare parts.

2.4 Instructions for operating safety

2.4.1 Before working on the hydraulic system

● Work on the DAIKIN EKHHP (such as setup,

servicing, connection and initial start-up) is

only to be carried out by persons who are

authorised and who have successfully

completed qualifying technical or vocational

training and who have taken part in advanced

training sessions recognised by the appropriate responsible authorities for the specific

activitiy. This, in particular, includes heating

specialists and climate control technicians

who have experience, as a result of their

technical training and their knowledge of the

subject, of proper and appropriate installation

and maintenance of heating, climate control

and cooling installations and heat pumps.

Switch off the external main switch before

starting any work on the DAIKIN EKHHP and

secure it against unintentional switch-on.

● Seals must not be damaged or removed.

● The domestic water connection must comply

with the requirements of EN 12897.

● Only original DAIKIN replacement parts may

be used.

2.4.2 Electrical installation

● Electrical installation must be carried out only

by qualified electrical experts and in

compliance with the valid electro-technical

guidelines as well as the regulations of the

relevant energy supply company (EVU).

● Make up the power supply in accordance with

IEC 60335-1, overvoltage category III. Means

with contact separation in all poles that

provide full disconnection must be incorporated in the fixed wiring in accordance with the

wiring rules.

● Compare the mains voltage (~230 V, 50 Hz)

indicated on the nameplate with the supply

voltage before connecting to the mains.

● Before beginning work on live parts,

disconnect all of the systems circuits from the

power supply (switch off main switch,

disconnect fuse) and secure against unintentional restart.

● Equipment covers and service panels must be

replaced as soon as the work is completed.

2.4.3 Working on cooling systems (heat

pump)

The DAIKIN EKHHP requires fluorinated greenhouse gas for its function.

For work on stationary refrigeration systems (heat pumps) and air conditioning

systems, proof of expertise is required in

the European Community according to

the F-Gases Directive (EC) No.

303/2008.

– up to 3 kg coolant fill quantity: Expert certifi-

cate category II

– 3 kg coolant fill quantity or over: Expert cer-

tificate category I

● Always wear safety goggles and protective

gloves.

● When working on the refrigerant circuit,

ensure that the workplace is well ventilated.

● Never carry out work on the refrigerant circuit

in closed rooms or work pits.

● Do not let coolant come into contact with open

fire, embers or hot objects.

● Never allow coolant to escape into the atmosphere (high pressure at the point of the leak).

● When removing the service pipes from the

filling connections, never hold the connections

in the direction of your body. Residual refrigerant could escape.

● If you suspect leaks in the refrigerant circuit:

Never pump the refrigerant back into the heat

pump external unit with the internal

compressor - always extract with a suitable

recycling unit and recycle it.

● Components and spare parts must at least

satisfy the technical requirements defined by

the manufacturer.

2.4.4 Site of installation

For safe and fault-free operation, it is necessary

that the installation location of the DAIKIN

EKHHP fulfils the safety-relevant criteria described exactly in Section 4.3.

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Installation and operating instructions

5

2 x Safety

Information on the installation site of other components can be found in the associated documentation supplied with them.

2.4.5 Sanitary connection

● You must comply with:

– EN 1717 - Protection of domestic water

from contamination in domestic water

installations and general requirements concerning safety equipment for the prevention

of domestic water contamination by backflow

– EN 806 - Technical regulations for domes-

tic water installations (TRWI)

– and, as a supplement, the country-specific

legal requirements.

A safety valve must be fitted in the domestic

water feed to the DAIKIN EKHHP. There should

be no isolating fitting between the safety valve

and the DAIKIN EKHHP.

Any steam or heating water which may escape

must be diverted by a suitable blow-off line with

constant gradient in a frost-protected, safe and

observable manner.

The storage tank temperature can exceed 60 °C

if you connect a solar system.

Using filling water and top-up water which does

not meet the stated quality requirements can

cause a considerably reduced service life of the

equipment. The responsibility for this lies solely

with the operator.

If an optional external heat generator is

connected via the corrugated pipe heat

exchanger of the EKHHP500AA2V3,

these minimum requirements also apply for the

filling and topping-up water of this heating

circuit.

2.4.7 Operation

The DAIKIN EKHHP

● Do not operate until all installation and

connection work is completed.

● Only operate with a completely full storage

tank (level indicator).

● Only connect with a pressure reducer on the

external water supply (supply line).

● Only operate the with the specified quantity of

coolant and the type of coolant specified.

● only operate if the protective cover is installed.

The specified servicing intervals should be adhered to and inspection work must be carried

out.

● For this reason you should fit scalding

protection (e.g. VTA32 + Verschraubungsset

1") during installation.

The domestic water quality must comply

with the EU Guideline 98/83 EC and the

regionaly-applicable regulations.

2.4.6 Requirements for the depressurised

storage tank water

Observe the current technological regulations to

prevent corrosion products and deposits.

Minimum requirements regarding the quality

of filling and supplementary water:

– Water hardness (calcium and magnesium,

calculated as calcium carbonate):

≤ 3 mmol/l

– Conductivity: ≤ 1500 (ideal: ≤ 100) μS/cm

– Chloride: ≤ 250 mg/l

– Sulphate: ≤ 250 mg/l

– pH value: 6,5 - 8,5

2.4.8 Instructing the user/owner

● Before you hand over the DAIKIN EKHHP,

explain to the user/owner how to operate and

check the system.

● Provide the operator with the technical

documentation (this documentation and all its

references) and indicate that these

documents must be available in the

immediate vicinity of the unit at all times.

● Document the hand-over.

Installation and operating instructions

6

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

3 Product description

3 x Product description

17

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

15

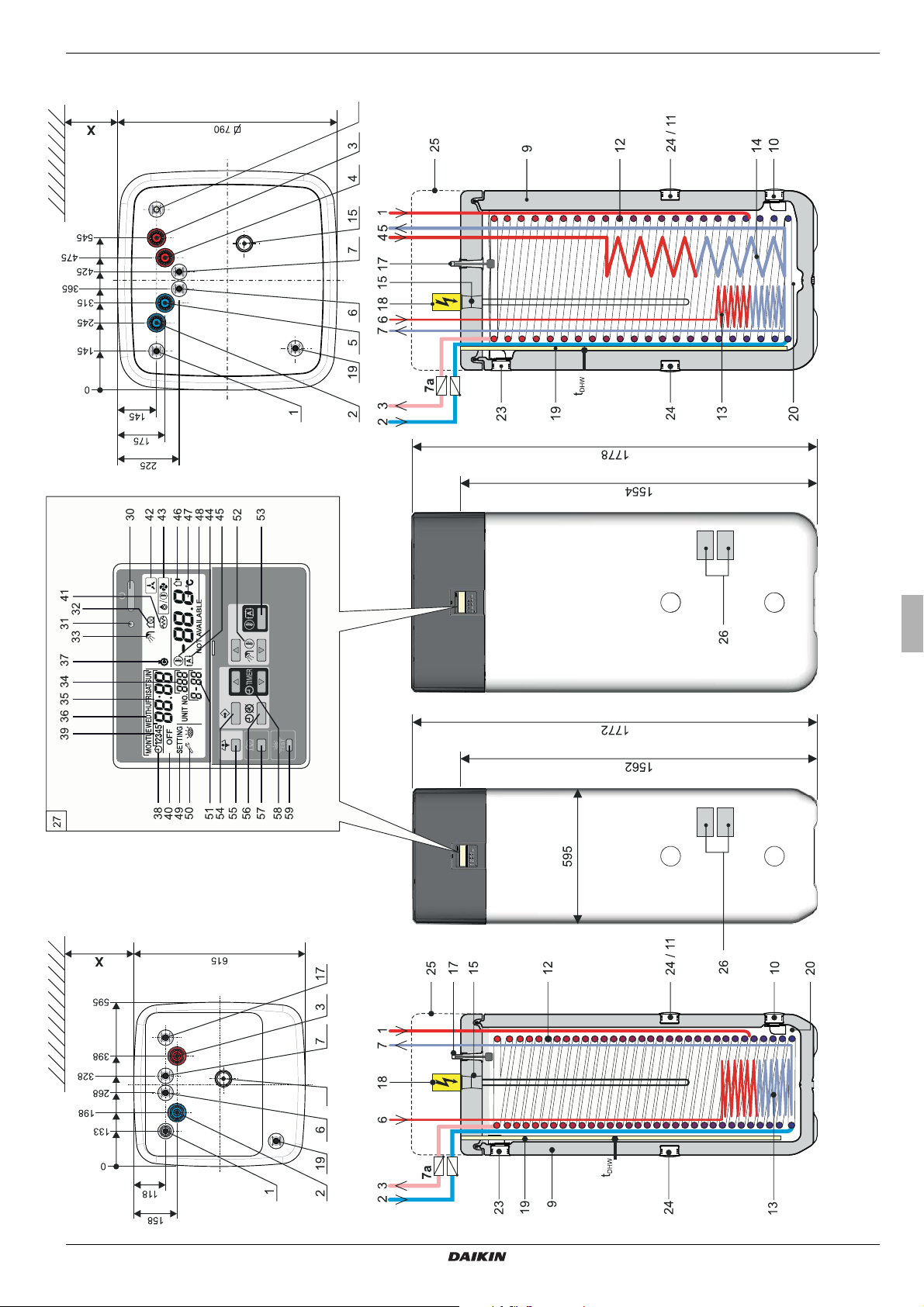

Fig. 3-1 Structure of the DAIKIN EKHHP – legend see Tab. 3-1

Installation and operating instructions

7

3 x Product description

33 Display operating mode "Hot Water Heating" active

34 Display of sensor number (see Tab. 7.1)

43 Display operating mode "Start-up", "Defrost Mode" active

Brief push: Display last error code

Push for 5 sec: Enter parameter settings

47 Display of hot water temperature or oher temperature values (in combination with Items 44 / 46)

DHW

54 Key programming

1 Flow Solar or flow for additional heat source (1" female thread) 30 Key "On / Off"

2 Cold water connection (1“ male thread) 31 Operating Display LED

3 Hot water (1“ male thread)* 32 Display operating mode "Low Noise Mode" active

Item Name (EKHHP) Item Name (Controller)

Installation and operating instructions

4 Flow Solar or for additional heat source (3/4" female thread + 1“ male thread) (only

8

EKHHP500AA2V3)

EKHHP500AA2V3)

5 Return Solar for additional heat source (3/4" female thread + 1“ male thread) (only

6 Connection refrigerant gas line Cu Ø 3/8" (9.5 mm) 35 Display time

7 Connection refrigerant liquid line Cu Ø 1/4" (6.4 mm) 36 Display weekday

9 Storage tank ( polypropylene double walled jacket with PUR hard foam heat insulation) 38 Display switching timer programme switched on

10 Filling and draining connection or return Solar or return for additional heat source 39 Display active switching times

11 Mount for solar controller or handle 40 Display off status in timer programme

7a Recommended accessory:non-return valves(2 pcs.) 37 Display refrigerant compressor active

12 Heat exchanger (stainless steel) for domestic hot water heating 41 Display Booster-Heater (BSH) switched on

ator

(only EKHHP500AA2V3)

13 Heat exchanger (stainless steel) for storage tank charging by hot water heat pump (liquifier) 42 Display external signal (HT/NT / Smart Grid)

14 Heat exchanger (stainless steel) for storage tank charging by pressurised solar or alternative heat gener-

15 Connection for integrated electrical Booster-Heater BSH (R 1½" female thread) 44 Display external temperature or temperature in hot water storage tank

17 Fill level indicator (tank water) 45 Display operating mode "Automatic" active

20 Pressure-free storage tank water 48 Display "Function not available"

18 Integrated electrical Booster-Heater (BSH) 46 Display external temperature active

19 Sensor pocket for tank temperature sensor t

outer thread 55 Key "High Output" operating mode

internal thread 56 Key activation/deactivation of timer programme

23 Connection safety overflow 49 Display parameter setting mode active

24 Mount for handle 50 Display service technician required

25 Silencer hood 51 Display Parameter code or Fault code

26 Type plate 52 Keys setting hot water temperature

27 Regulator hot water heat pump 53 Key "Automatic" operating mode

outer

thread

inter-

nal

thread

Storage tank temperature sensor 57 Key "Low Noise" operating mode

Safety devices 58 Keys Time setting

Observe tightening torque! 59 Key error code / parameter setting

DHW

t

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

4 Set-up and installation

4 x Set-up and installation

4.1 Tightening torque

WARNING!

If you operate the DAIKIN EKHHP when the

storage tank is not completely full, damage to

the equipment may occur.

● Fill the DAIKIN EKHHP only after all the

hydraulic installation work has been

completed.

● Observe the sequence during the filling

process.

Commissioning only after all the installation

work has been completed and only after filling

the storage tank completely.

WARNING!

Cooling systems (heating pumps), climate

control systems and heating devices that have

been set up and installed incorrectly can both

endanger life and health of people and be impaired in their function.

Component Thread

size

Hydraulic line connections (water) 1" 25 to 30 Nm

Liquid line connections

(Coolant)

Gas line connections

(Coolant)

Booster-Heater 1.5" max. 10 Nm

Tab. 4-1 Tightening torque

1/4" 15 to 17 Nm

3/8" 33 to 40 Nm

Tightening

torque

(hand-tight)

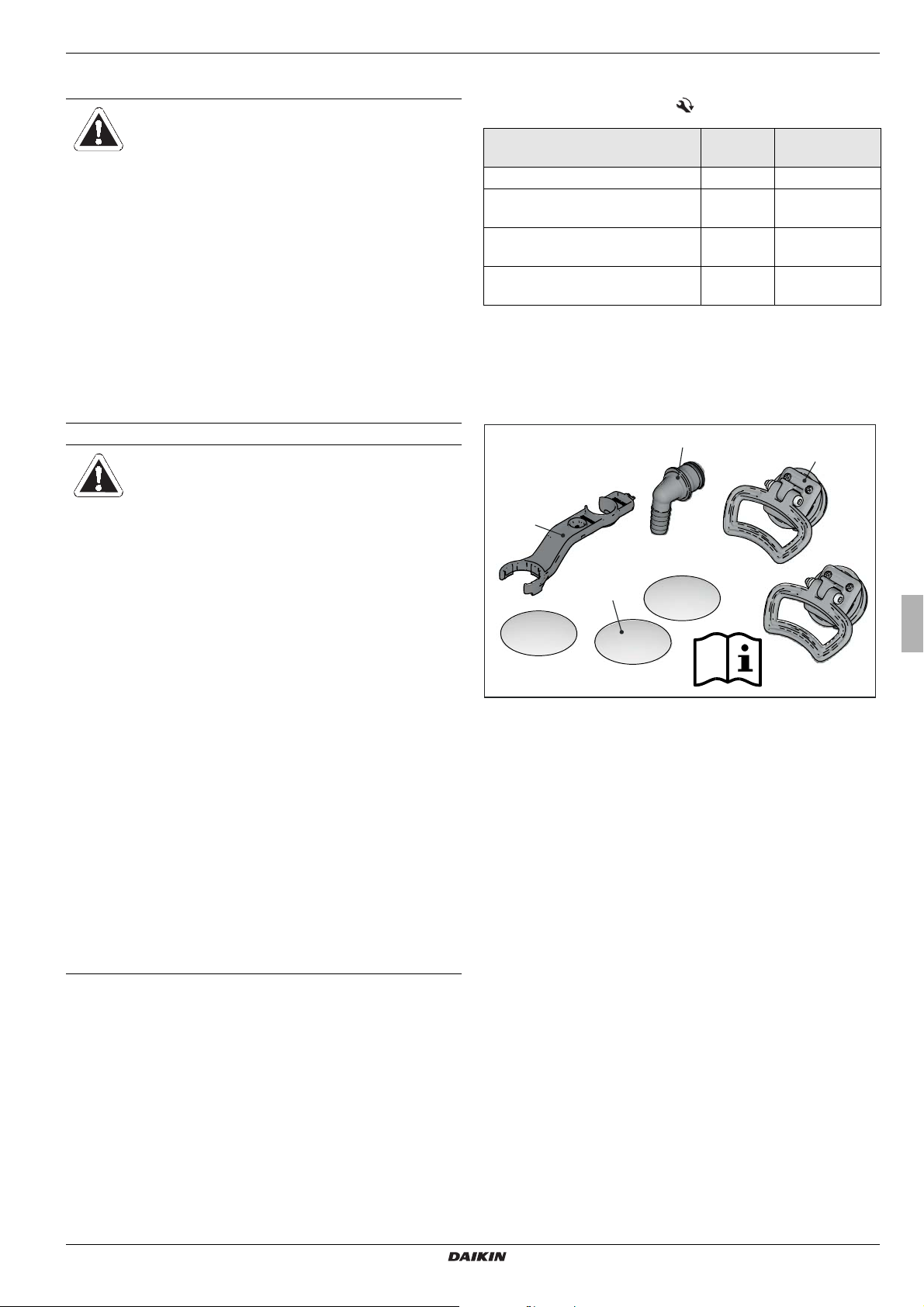

4.2 Scope of delivery

– DAIKIN EKHHP

– Bag of accessories (see Fig. 4-1)

C (1x)

D (1x)

A (2x)

B (3x)

● Work on the DAIKIN EKHHP (such as setup,

servicing, connection and initial start-up) is

only to be carried out by persons who are

authorised and who have successfully

completed qualifying technical or

vocational training and who have taken part

in advanced training sessions recognised by

the relevant responsible authorities for the

specific activity. These include in particular

certified heating engineers, qualified

electricians and HVAC specialists, who

because of their professional training and

expert knowledge, have experience in the

professional installation and maintenance of

heating, cooling and air conditioning systems

and heat pumps.

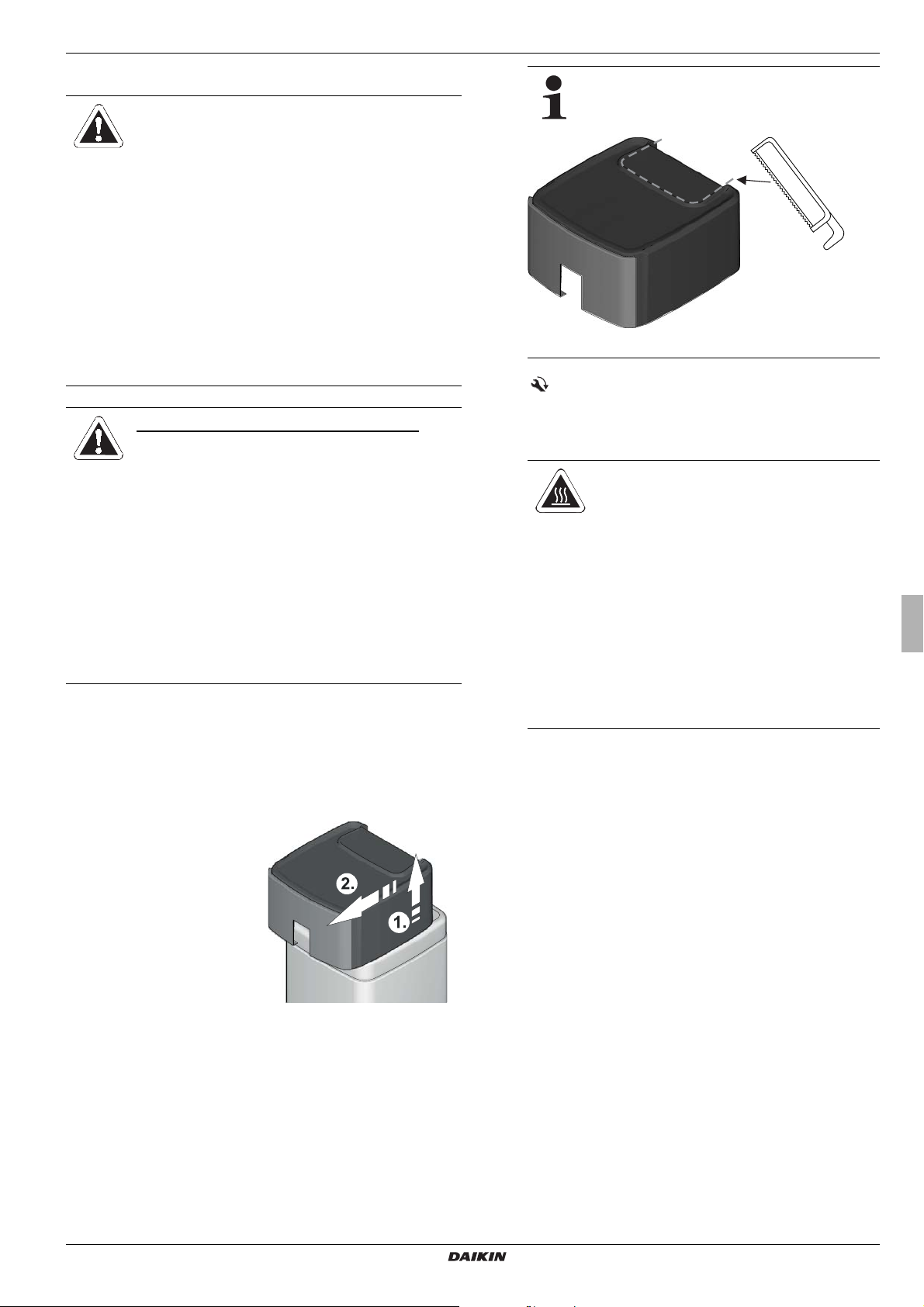

A Handles (only required for

transport)

B Cover screen

Fig. 4-1 Contents of bag of accessories

C Hose connection piece for

D Spanner

safety overflow

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Installation and operating instructions

9

4 x Set-up and installation

4.3 Set-up

CAUTION!

● Only erect the DAIKIN EKHHP when a sufficient ground load-bearing capacity, of

1050 kg/m² plus safety margin, has been

assured. The ground must be flat and level.

● Outdoor installation is not permitted.

● Erection in explosion-risk environments is

not permitted.

● The DAIKIN EKHHP must only be set up in

non-hermetically closed rooms.

● The electronic control system must not be

subjected to atmospheric factors under any

circumstances.

● The storage tank must not be exposed to

continuous direct sunlight, as the UV

radiation and the effects of the weather will

damage the plastic.

● The DAIKIN EKHHP must be installed in a

manner protected from frost.

● Make sure that the supply company does

not provide corrosive domestic water.

– Suitable water treatment may be

required.

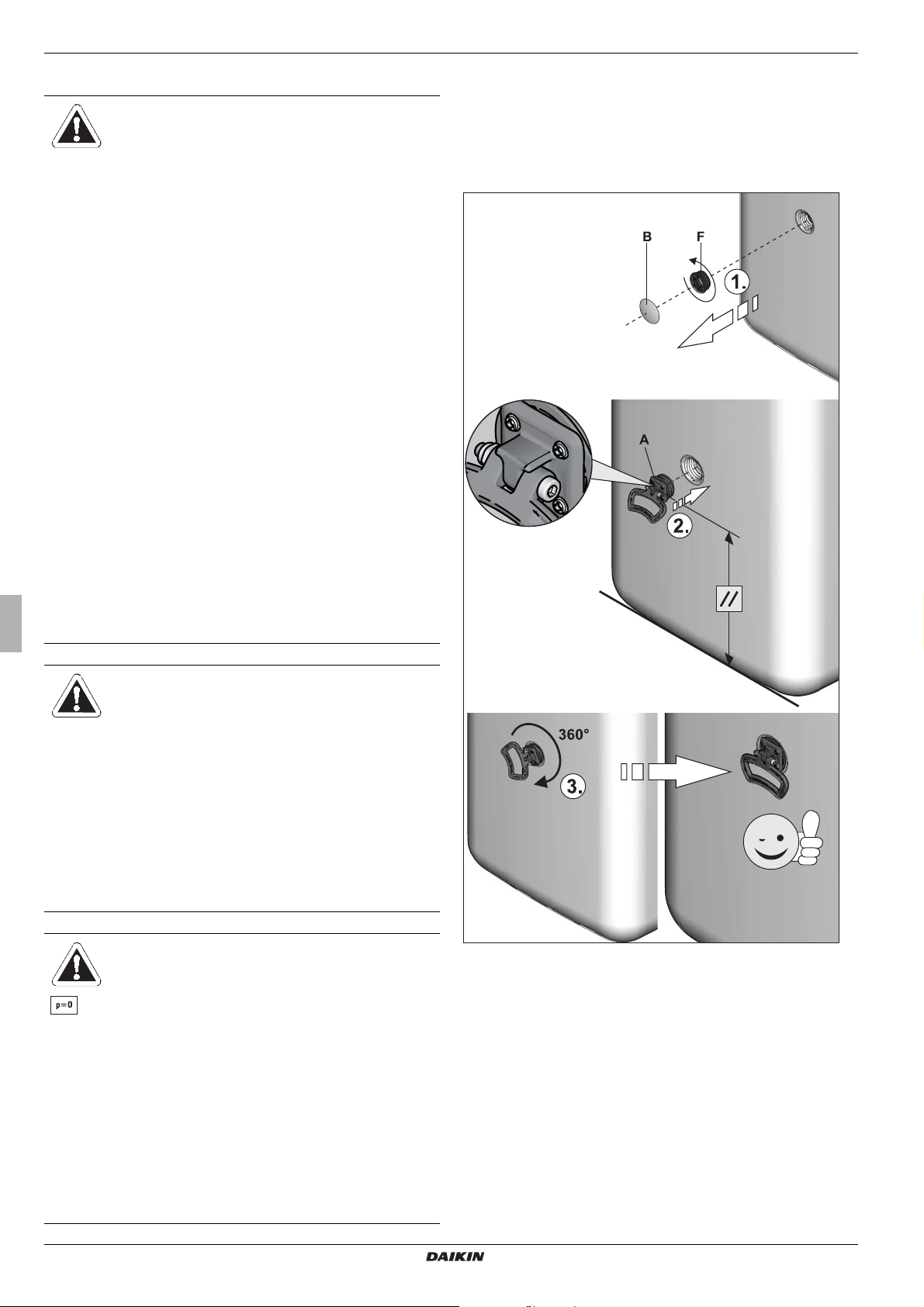

● Remove packing and dispose of it in an environment-friendly

manner.

● Remove the cover plates on the storage tank (Fig. 4-2,

Item B) and unscrew the threaded pieces (Fig. 4-2, Item F)

from the apertures on which the handles are to be mounted.

● Screw handles (Fig. 4-2, Item A) into the threaded holes that

are now free.

WARNING!

The plastic wall of the storage tank of the

DAIKIN EKHHP can melt under the effects of

external heat 80 °C) and, in the extreme case,

can catch fire.

● Erect the DAIKIN EKHHP only at a minimum

distance of 1 m to other heat sources

(>80 °C) (e.g. electric heater, gas heater,

chimney) and flammable materials.

CAUTION!

If the DAIKIN EKHHP is not erected ade-

quately lower the flat solar panels (the top

edge of the of the storage tank is higher than the

bottom edge of the solar panels), the unpressurised solar system in the outdoor area will be

unable to drain completely.

● Erect the DAIKIN EKHHP with a DrainBack

solar connection at a sufficient depth to the

flat solar panels (observe the minimum

gradient in the solar connecting lines).

A Handle

B Cover screen

Fig. 4-2 Attach handles

● Install the DAIKIN EKHHP at the installation site.

– Recommended distances:

To the wall (rear): ≥200 mm.

To the ceiling: ≥200 mm.

– Observe the tilt dimension (see Section 10).

– Carefully transport the DAIKIN EKHHP, use the handles.

– When setting up the unit in a cabinet, behind panels or in

other restricted conditions, sufficient ventilation (e.g.,

using ventilation gratings) must be ensured.

– To avoid a circulation line, install DAIKIN EKHHP close to

the draw-off location.

F Threaded piece

Installation and operating instructions

10

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

4 x Set-up and installation

4.4 Hydraulic connection

CAUTION!

If the DAIKIN EKHHP is connected to a cold

water line, where steel pipes are used, chips

can enter the special steel corrugated pipe heat

exchanger and remain there. This can lead to

contact corrosion damage and subsequently

to leakage.

● Flush the feed pipes before filling the heat

exchanger.

● Install contamination filter in the cold water

feed (see Section 2.4.5).

ONLY DAIKIN EKHHP500AA2V3

CAUTION!

If the heat exchanger for charging the pressurised solar system (see overview image on

Fig. 3-1, Items 4+5) has an external heating

unit (e.g. wood-burning boiler) connected to it,

an excessive flow temperature at these connections can damage or destroy the DAIKIN

EKHHP.

● The feed flow temperature of the external

heater should be limited to max. 95 °C.

Requirement: Optional accessories (e.g. Solar) mounted on the

DAIKIN EKHHP according to the specifications in the instructions

included with the delivery.

● Check the cold water connection pressure (maximum 6 bar).

– At higher pressure in the drinking water line, a pressure

reducer must be installed.

● Remove the cover on the

DAIKIN EKHHP.

If the installation conditions require the hydraulic

connection to be directly upwards, the cover

hood can be cut out along the broken line.

Fig. 4-4 Creating the hood cut-out

–

Pay attention to the stipulated tightening torque (see

Section 4.1).

– Design the lines as such that the sound attenuation cowl

can be applied without any problem following assembly.

WARNING!

There is a danger of scalding at hot water

temperatures over 60 °C. This is possible,

when solar energy is used, with a connected external heating device, when the

Legionella protection is activated or when

the domestic hot water target temperature

is set higher than 60 °C.

● Install scald protection (hot water mixer

(e.g. VTA32).

– Water shortage protection: The temperature monitoring

of the controller safely switches off the DAIKIN EKHHP in

the event of a water shortage. No additional water shortage protection is needed in the construction. Nevertheless, regular checking of the fill level is necessary in order

to ensure function as intended.

– Avoid damages caused by deposits and corrosion:

Observe the requirements for storage tank water (see

Section 2.4.6).

Fig. 4-3 Remove the protective

cover.

● When using circulation brakes, fit them into the pipe

connections on the DAIKIN EKHHP.

● Create hydraulic connections on the DAIKIN EKHHP (see

Fig. 4-5).

– Fig. 3-1 and Tab. 3-1 give the position and dimensions of

the connections.

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Installation and operating instructions

11

4 x Set-up and installation

● Connect the drain hose to the connector for the safety

overflow (Fig. 4-6 to Fig. 3-1, Item 23).

– Use transparent drain hose (draining water must be visi-

ble).

– Connect the drain hose to an adequately dimensioned

waste water installation.

– Drain should not be lockable.

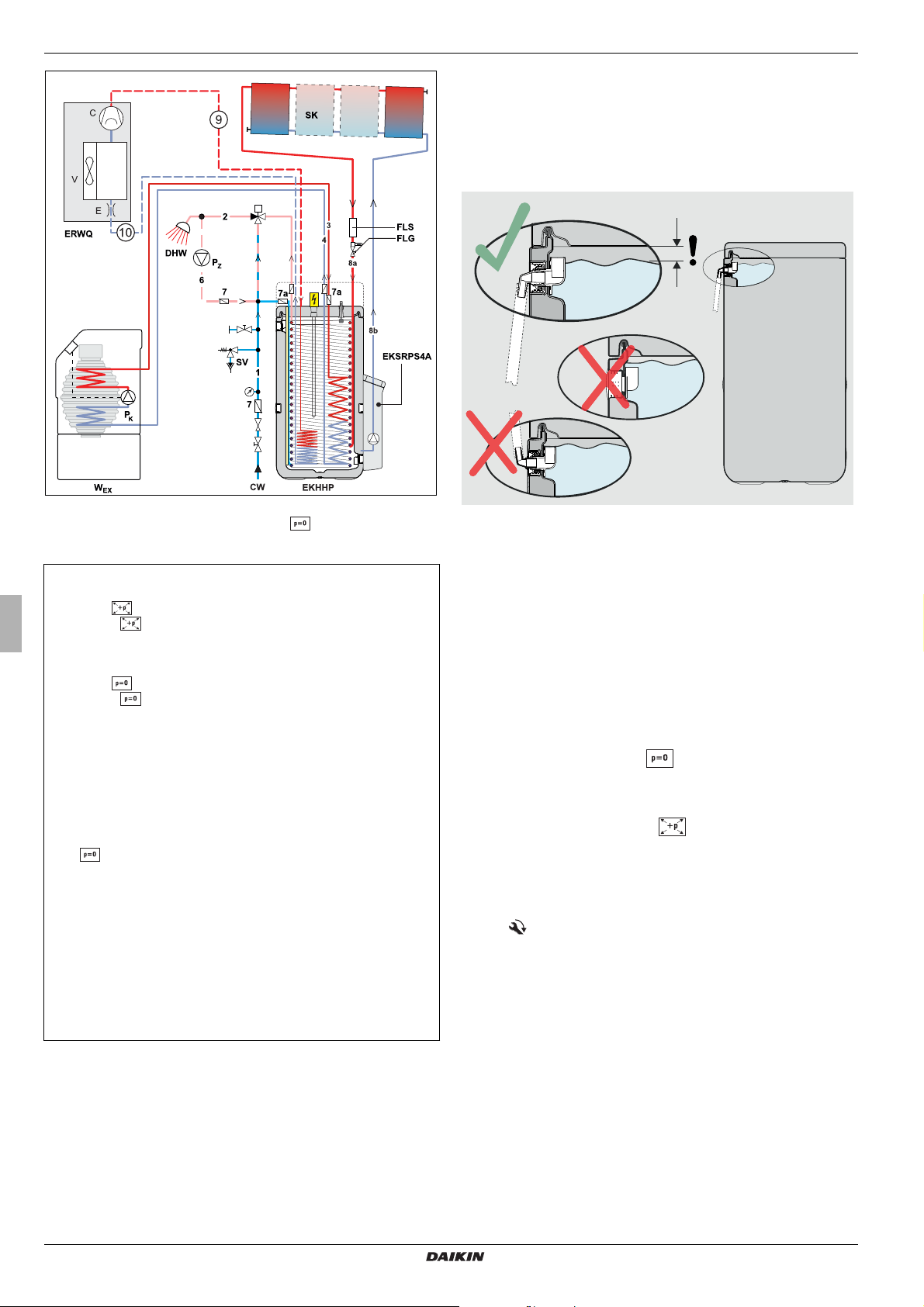

Fig. 4-5 Hydraulic connection - legend see Tab. 4-2

(Example EKHHP500AA2V3 with Solar and optional external heat generator)

1 Cold water connection

2 Hot water distribution network

3 Feed Solar or for other heat source*

4 Return Solar or for other heat source*

6 Circulation

7 Customer's side: Check valve, return valve

7a Circulation brakes (2 in number) Recommended accessory

8a Feed Solar or for other heat source*

8b Return Solar or for other heat source*

9 Gas line (refrigerant)

10 Liquid line (refrigerant)

CW cold water

DHW

hot water

EKHHP

DAIKIN heat pump internal unit

EKSRPS4A

DAIKIN solar regulation and pump unit*

FLG FlowGuard - solar regulating valve with flow indicator*

ERWQ

DAIKIN Heat pump external unit

FLS FlowSensor - solar flow and feed temperature measurement

PKBoiler circulation pump*

PZCirculation pump*

SK Solar panel field*

SV Customer's side: Safety over-pressure valve

WEXExternal heat generator*

Fig. 4-6 Installation of drain hose at safety overflow

4.4.1 Optional: Connection of an external heat generator

For support or as an alternative for heating by the heat pump you

can connect external heat generators (e.g. Solar, gas or oil boiler)

to the DAIKIN EKHHP.

The heat supplied by the external heat generator must be added

to the unpressurised storage tank water in the DAIKIN EKHHP

hot water storage tank.

● Carry out hydraulic connection in accordance with one of the

two following possibilities:

a) EKHHP(3/5)00AA2V3: unpressurised via

connections (solar infeed and solar return) of the hot

water tank

or

b) Only EKHHP500AA2V3:

pressurised solar heat exchanger.

– Fig. 3-1 and Tab. 3-1 give the position and dimensions of

the connections.

– CArry out hydraulic system incorporation in accordance

with Fig. 4-5.

–

Pay attention to the stipulated tightening torque (see

Section 4.1).

– Design the lines as such that the sound attenuation cowl

can be applied without any problem following assembly.

via the integrated

* Optional

Tab. 4-2 Legend for Fig. 4-5

● Carefully insulate pipe lines against heat loss and so as to

avoid the formation of condensation (insulation thickness at

least 20 mm).

Installation and operating instructions

12

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

4 x Set-up and installation

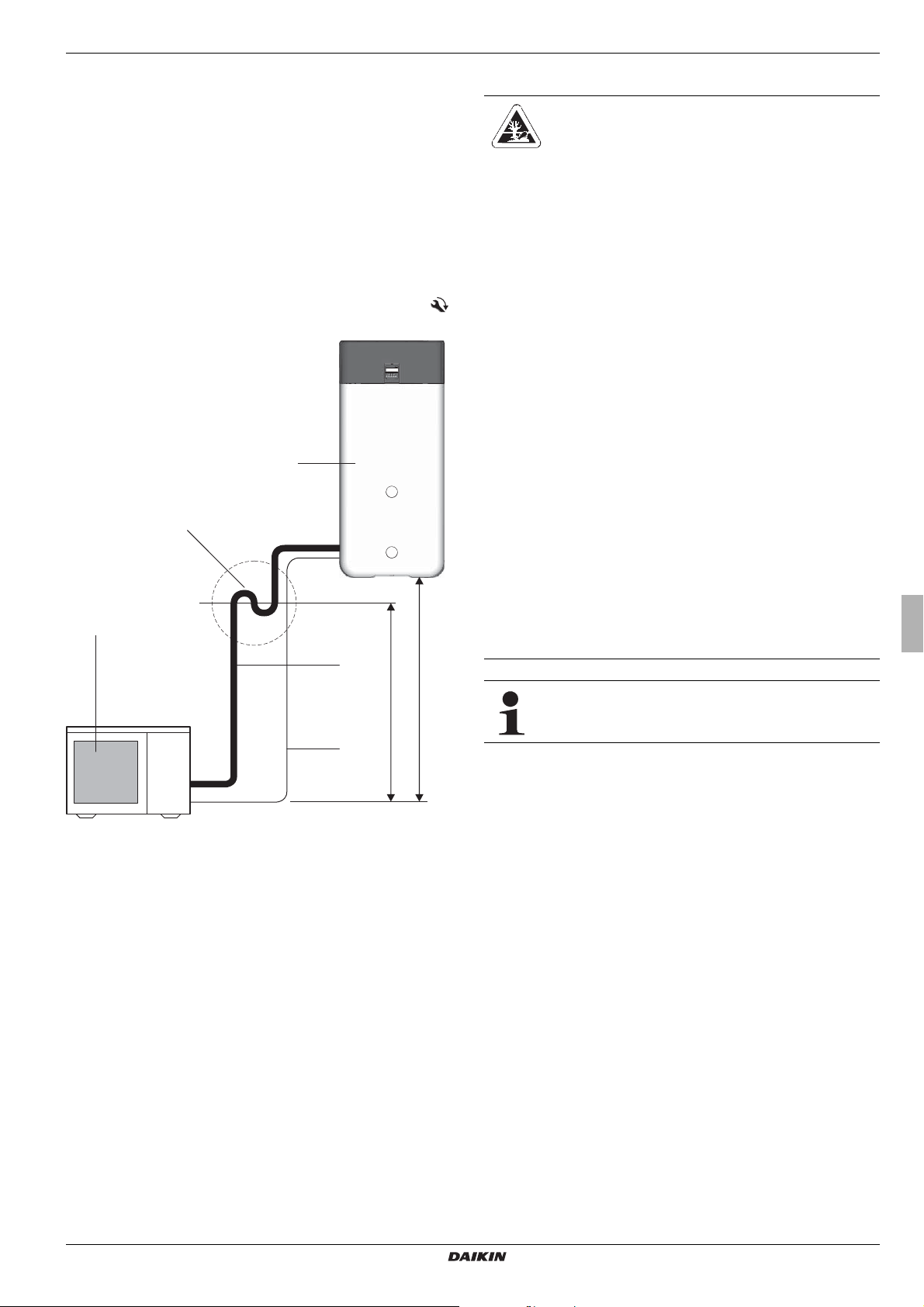

4.5 Laying coolant lines

● Check whether oil trap arc necessary.

– Required if DAIKIN EKHHP is not installed at ground level

with the heat pump exterior unit (Fig. 4-7, H

– At least one oil trap arc must be installed every 10 m dif-

ference in height (Fig. 4-7, H = clearance from oil trap arc

to oil trap arc).

– Oil trap arc only required in gas line.

● Install lines with bending unit and an adequate clearance to

electrical lines.

● Only solder with light nitrogen flow (hard soldering only).

● Do not apply heat insulation to joins until after start-up (for

purposes of leakage search).

● Establish flange connections and connect to the units. (

Pay attention to the tightening torque, see Section 4.1).

B

E

A

C

≥ 10 m).

O

4.6 Pressure test and filling the coolant circuit

RISK OF ENVIRONMENTAL

DAMAGE!

Important information regarding the coolant

used.

The complete heat pump system contains refrigerant with fluorinated greenhouse gases

which damage the environment if released.

Coolant type: R410A

GWP* value: 2087,5

* GWP = Global Warming Potential

● Work on fixed cooling systems (heat pumps)

and air-conditioning systems can only be

performed by persons who hold a certificate

of competence for the European Region, in

accordance with the F-Gas Regulation (Ec)

No. 303/2008.

● Fill in the total coolant filling quantity on the

supplied lable on the heat pump exterior unit

(for information consult the installation

instructions for the heat pump exterior unit).

● Never allow coolant to be released into the

atmosphere - always suction it off and recycle

using a suitable recycling device.

Ho

H

D

A DAIKIN EWQ

B DAIKINEKHHP

C Gas line

D Liquid line

E Oil trap arc

H height to 1st oil trap (max. 10 m)

HOHeight difference between heat pump exterior unit and heat pump

interior unit.

Fig. 4-7 Oil trap arc coolant line

No additional coolant is required for the basic filling.

This is independent of the line length between the internal unit and external unit.

● Perform pressure test with nitrogen.

– Use nitrogen 4.0 or higher.

– Maximum 40 bar.

● After leak search is complete, completely drain.

● Evacuate the lines (see installation instructions of the heat

pump external unit).

● Open stop valve on exterior unit completely until the stop.

Tighten loosely.

● Reassemble valve caps.

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Installation and operating instructions

13

4 x Set-up and installation

4.7 Filling the system with water

WARNING!

If you operate the DAIKIN EKHHP when the

storage tank is not completely full, damage to

the equipment may occur.

● Fill the DAIKIN EKHHP only after all the

hydraulic installation work has been

completed.

● Observe the sequence during the filling

process.

● Commissioning only after all the installation

work has been completed and only after

filling the storage tank completely.

The corrugated pipe heat exchangers must be filled

before the storage tank.

The heat exchanger for connecting an optional heat

generator (Fig. 3-1, Item 14, only EKHHP500AA2V3) also

needs to be filled if no optional heat generator is connected to it.

This heat exchanger, and the heating circuit of the external heat

generator connected to it, should be filled first.

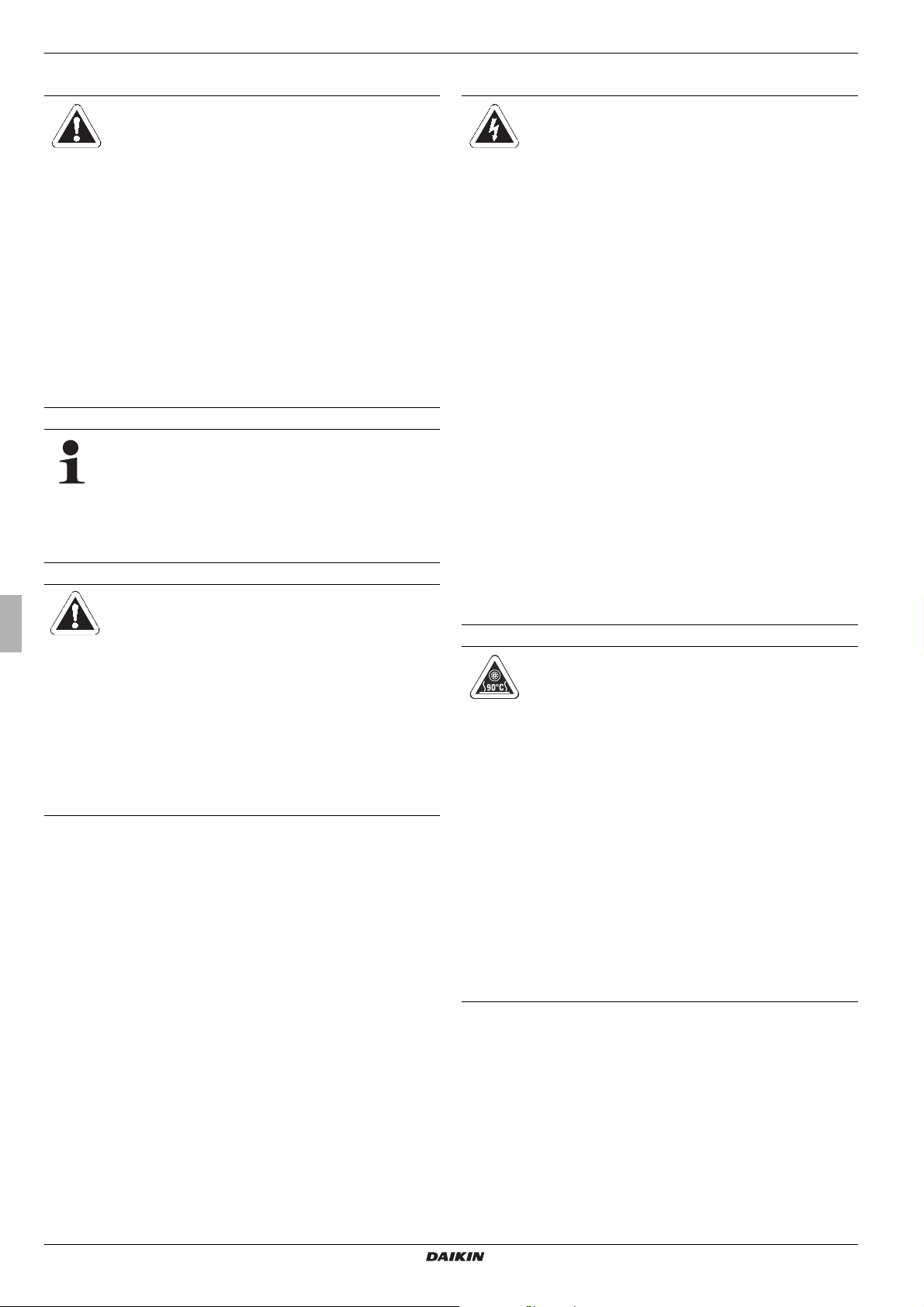

4.8 Electrical connection

WARNING!

Touching live parts can result in an electric

shock and lead to potentially fatal injuries and

burns.

● Before beginning work on live parts,

disconnect all of the systems circuits from

the power supply (switch off main switch,

disconnect fuse) and secure against unintentional restart.

● The electrical connection and working on the

electrical components should only be

performed by qualified electrical engineers

in compliance with valid standards and

guidelines as well as the specifications of the

energy supply company and the instructions

given in this manual.

● Never carry out any structural changes to

plug sockets or other electrical equipment

components.

● The equipment covers and maintenance

opening covers must be re-fitted immedi-

ately after completion of the work.

UK only!

CAUTION!

If filling or topping up the storage tank is done by

means of the boiler filling and drain valve, a

temporary filling loop must be used with the

appropriate backflow prevention device in

accordance with clause G24.2, Guidance to the

Water Supply (Water Fittings) Regulations

1999.

Observe the information on the water connection and water

quality in accordance with Chap. 2.4.5 and 4.4.

4.7.1 Filling the hot water heat exchanger

1. Open the shutoff valve for the cold water supply pipe.

2. Open the hot water tap connections so that the draw-off

volume can be set as high as possible.

3. Once water has been discharged from the tap connections,

do not interrupt the cold water flow; this will ensure that the

heat exchanger will be fully vented and that any impurities or

residue will be discharged.

4.7.2 Filling the storage tank

See Section 9.2.

CAUTION!

In the controller housing of the DAIKIN

EKHHP, in continuous running, elevated temperatures can be generated. This can result in

currently-carrying wires from reaching higher

temperatures during operation due to selfheating. For this reason, these lines need to

have a continuous use temperature of 90 °C.

● For the following connections, use only

cables with a long-term use temperature

≥90 °C:

– Exterior heat pump unit

– Voltage supplyBooster-Heater

– Contacts (connection HT/NT/Smart Grid)

– Network connections need to be executed as independent

power circuits.

– Ensure power cables, sensor cables and data bus cables are

laid separately from each other.

– Use only cable trunking with separate trays or cable trunking

with separators that ensure at least 2 cm spacing.

– Cable cross-overs are not permissible.

– For all the cables connected to the DAIKIN EKHHP effective

tension relief must be ensured in the controller housing using

cable ties (see Figures 4-8 to 4-10).

Installation and operating instructions

14

DAIKIN EKHHP(3/5)00AA2V3

DAIKIN Hot water heat pump

008.1423444_05 – 08/2016

Loading...

Loading...