Daikin DP 13, DP 14 User Manual

Service Instructions

DP 13 and 14 SEER PACKAGE HEA T PUMPS

DP 13 and 14 PACKAGE COOLING

HORIZONTAL MODELS

WITH R-410A

This manual is to be used by qualified, professionally trained HVAC technicians only. Daikin does

not assume any responsibility for property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

Copyright © 2013 - 2016

RSD6300011r3

April 2016

1

INDEX

IMPORT ANT INFORMA TION ......................................................................................................... 4 - 5

PRODUCT IDENTIFICATION - DP[13-14]C/HH**41** ................................................................. 6 - 7

ACCESSORIES................................................................................................................................... 8

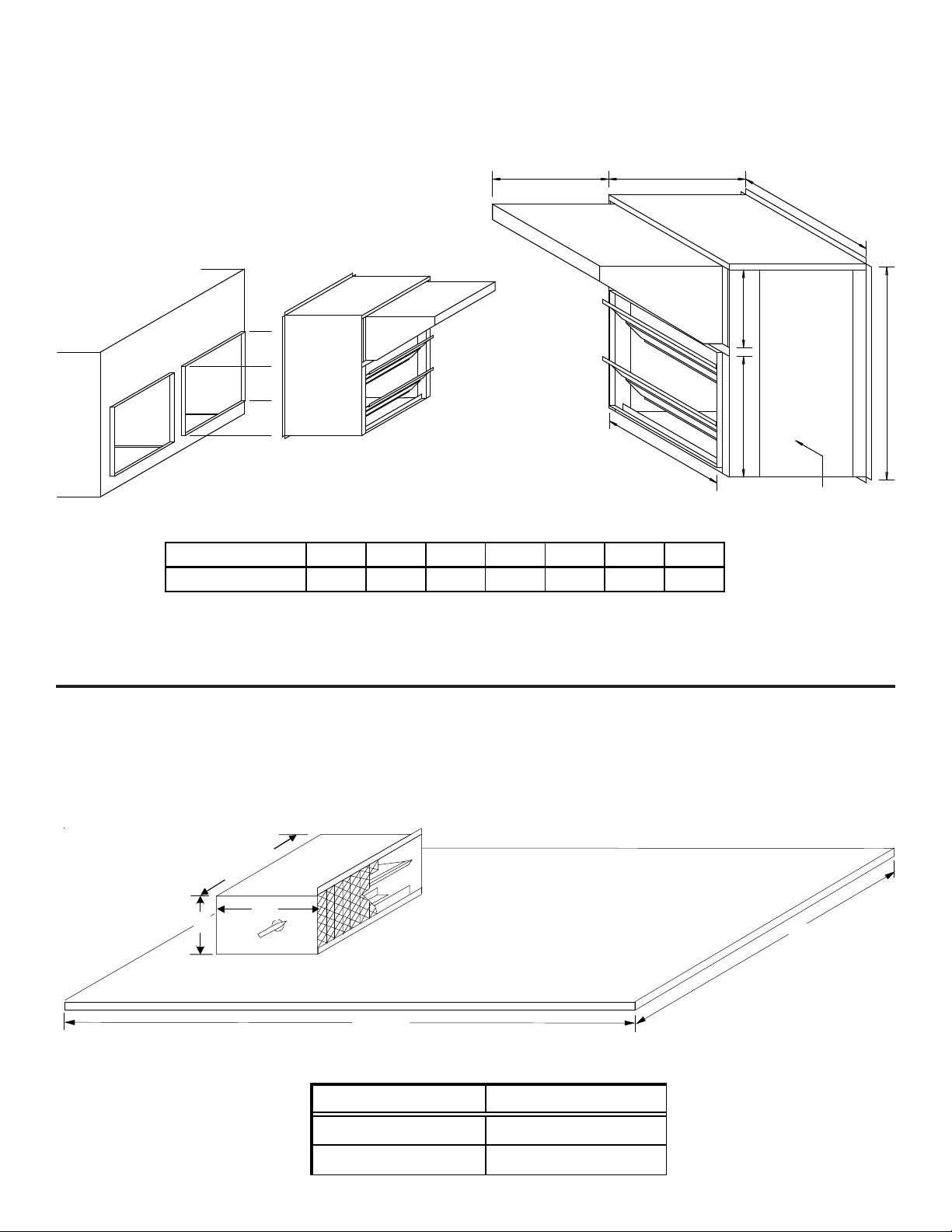

PCCP101-103 ROOF CURB .......................................................................................................................................... 9

PCP101-103 DOWNFLOW PLENUM ............................................................................................................................ 9

PCEF101-103 ELBOW AND FLASHING KIT ............................................................................................................... 10

DDNECNJPCHHA ECONOMIZER ................................................................................................................................10

PCMD101-103 DOWNFLOW MANUAL DAMPER ........................................................................................................11

GPHMD101-103 HORIZONTAL MOTORIZED DAMPER WITH DUCT FLANGE ............................................................11

SQRPC SQUARE TO ROUND CONVERTER............................................................................................................... 12

SQRPCH SQUARE TO ROUND CONVERTER ............................................................................................................ 12

DPHRFA EXTERNAL FIL TER KIT ............................................................................................................................... 13

PRODUCT DESIGN .......................................................................................................................... 14

ELECTRICAL WIRING ................................................................................................................................................. 15

LINE VOL T AGE WIRING.............................................................................................................................................. 16

SYSTEM OPERATION ...................................................................................................................... 17

DP[13-14]C/HH**41**

COOLING.................................................................................................................................................................... 17

COOLING CYCLE........................................................................................................................................................ 17

HEA TING CYCLE......................................................................................................................................................... 17

DEFROST CYCLE ....................................................................................................................................................... 18

FAN OPERA TION ........................................................................................................................................................ 18

SCHEDULED MAINTENANCE ......................................................................................................... 21

ONCE A MONTH ......................................................................................................................................................... 21

ONCE A YEAR............................................................................................................................................................. 21

TEST EQUIPMENT...................................................................................................................................................... 21

SERVICING ....................................................................................................................................... 22

COOLING/HEA T PUMP- SERVICE ANALYSIS GUIDE ................................................................................................ 22

S-1 CHECKING VOL TAGE ........................................................................................................................................... 23

S-2 CHECKING WIRING .............................................................................................................................................. 23

S-3 CHECKING THERMOSTAT , WIRING , AND ANTICIP A TOR.................................................................................... 23

S-3A Thermostat and Wiring ..................................................................................................................................... 23

S-3B Cooling Anticipator ........................................................................................................................................... 24

S-3C Heating Anticipator ........................................................................................................................................... 24

S-4 CHECKING TRANSFORMER AND CONTROL CIRCUIT ....................................................................................... 24

S-7 CHECKING CONT ACTOR AND/OR RELA YS........................................................................................................ 24

S-8 CHECKING CONT ACTOR CONTACTS.................................................................................................................. 25

S-9 CHECKING FAN RELA Y CONT ACTS..................................................................................................................... 25

S-11 CHECKING LOSS OF CHARGE PROTECT OR ................................................................................................... 26

S-15 CHECKING CAP ACITOR ..................................................................................................................................... 26

S-15A RESIST ANCE CHECK ....................................................................................................................................... 27

S-15B CAP ACITANCE CHECK ..................................................................................................................................... 27

S-16 CHECKING MOTORS .......................................................................................................................................... 28

S-16A CHECKING F AN AND BLOWER MOTOR WINDINGS (PSC MOT ORS) ............................................................ 28

S-16D CHECKING EEM MOTORS ............................................................................................................................... 28

S-17 CHECKING COMPRESSOR WINDINGS ............................................................................................................. 29

S-17A RESIST ANCE TEST .......................................................................................................................................... 29

S-17B GROUND TEST ................................................................................................................................................. 29

S-17D Operation T est ................................................................................................................................................. 30

S-18 TESTING CRANKCASE HEA TER ........................................................................................................................ 30

S-18A CHECKING CRANKCASE HEA TER THERMOST AT........................................................................................... 30

2

INDEX

S-21 CHECKING REVERSING V AL VE AND SOLENOID .............................................................................................. 30

S-24 TESTING DEFROST CONTROL .......................................................................................................................... 31

S-25 TESTING DEFROST THERMOSTA T.................................................................................................................... 31

S-50 CHECKING HEA TER LIMIT CONTROL(S) ........................................................................................................... 31

S-52 CHECKING HEA TER ELEMENTS ........................................................................................................................ 31

S-100 REFRIGERA TION REPAIR PRACTICE............................................................................................................... 32

S-101 LEAK TESTING ................................................................................................................................................. 32

S-102 EV ACUATION..................................................................................................................................................... 32

S-103 CHARGING ........................................................................................................................................................ 33

S-104 CHECKING COMPRESSOR EFFICIENCY ......................................................................................................... 34

S-108 SUPERHEA T ...................................................................................................................................................... 34

S-109 CHECKING SUBCOOLING ................................................................................................................................35

S-11 1 FIXED ORIFICE RESTRICTION DEVICES ......................................................................................................... 35

S-112 CHECKING RESTRICTED LIQUID LINE ............................................................................................................ 36

S-113 REFRIGERANT OVERCHARGE ......................................................................................................................... 36

S-114 NON-CONDENSABLES...................................................................................................................................... 36

S-115 COMPRESSOR BURNOUT................................................................................................................................39

S-122 REVERSING V ALVE REPLACEMENT................................................................................................................ 39

S-200 CHECKING EXTERNAL ST ATIC PRESSURE .................................................................................................... 40

S-201 CHECKING TEMPERA TURE RISE ..................................................................................................................... 40

WIRING DIAGRAMS.......................................................................................................................... 41

OT18-60A OUTDOOR THERMOST A T ......................................................................................................................... 41

OT18-60A OUTDOOR THERMOST A T ......................................................................................................................... 42

SINGLE PHASE HKR** HEAT KITS ............................................................................................................................ 43

PCE* ECONOMIZER .................................................................................................................................................... 44

SPK* - SINGLE POINT WIRING KIT ........................................................................................... ................................ 45

UNIT WIRING DIAGRAMS .......................................................................................................................................... 46

3

IMPORT ANT INFORMA TION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician who

is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORT ANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

This unit should not be connected to, or used in conjunction with, any devices that are not design certified for use with this

unit or have not been tested and approved by Daikin. Serious property damage or personal injury, reduced unit performance

and/or hazardous conditions may result from use of devices that have not been approved or certified by Daikin.

WARNING

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

MANUAL SHOULD SERVICE THE EQUIPMENT

BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

ASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT

. IN

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE OR

REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

, “

SERVICE

”)

THE EQUIPMENT SPECIFIED IN THIS

. THE

MANUFACTURER WILL NOT

. IF

YOU SERVICE THIS UNIT, YOU

ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORE

. I

MPROPER

.

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

T

DO NOT STORE COMBUSTIBLE MATERIALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS A PPLIANCE.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMA TION LINE - DAIKIN BRAND PRODUCTS

TOLL FREE 1-855-770-5648 (U.S. only)

email us at: customerservice@daikincomfort.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500

(Not a technical assistance line for dealers.)

Y our telephone company will bill you for the call.

4

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

EFRIGERANTS ARE HEAVIER THAN AIR. THEY CAN "P USH OUT" THE

R

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPAC E.

POSSIBL E DI FFI CULTY IN BR EAT HING O R DEA TH:

EVER PU RGE RE FRIG ERA NT INT O AN E NCLOS ED R OOM OR SPACE . BY

•

N

LAW, ALL REF RIGERANTS MUST BE RECLAIMED.

F AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTILATE THE AREA

•

I

BEFORE BEGINNING WORK.

•

IQUI D REFRIGE RANT CAN BE VERY COLD . TO AVOID POSSIBLE FROST-

L

BITE OR BLINDNESS, AVOID CONTACT WITH REFRIGERANT AND WEAR

GLOVES AND GOGGLES.

SKI N OR E YES, S EEK M EDI CA L HELP IMME DI AT ELY .

•

ALWAYS FOLLOW EPA REGULATI ONS. NEVER BUR N REFRIGERANT,

AS POISON OUS GAS WI LL BE PRODUC ED.

F LIQUID REFRIGERANT DOES CONTACT YOUR

I

O AVO ID

T

WARNING

TO AVOID POSSIBLE EXPLOSION:

• NEVER APPLY FLAME OR S TEAM TO A REFRIGERANT CYL INDER. IF YOU

MUST HEAT A CYLINDE R FOR FASTER CHARGING , PARTIALLY IMMERSE

IT IN WARM WATER.

• NE VER FILL A CYLINDER MO RE THAN 80% FULL OF LIQUID R EFRIGERANT.

• NE VER ADD ANYTHING O THER THAN R-22 TO AN R-22 CYLINDER OR

R-410A TO AN R-410A CYLINDER. THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIF IED FOR THE TYPE OF REFRIGE RANT USED.

• STORE CYLINDERS IN A CO OL, DRY PLACE. NEVER USE A CYLIND ER

AS A PLATFORM OR A ROLLER.

WARNING

O AVOI D P O SSIBL E E XP LOSI ON, US E ONLY R ETURN AB LE ( NOT DISPO SABL E)

T

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

•

NSURE T HE CYL INDER I S FREE O F DAMA GE WHIC H COULD LEAD TO A

E

LEAK OR EXPLOSION.

•

NSURE T HE HYDR OSTATI C TEST DATE DO ES NOT E XCEE D 5 YEARS .

E

•

NSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

E

HEN I N DOUB T, DO NOT U SE CYLI ND ER.

W

WARNING

WARNING

SYSTEM CONTAMINANT S, IMPROPER SERVICE PROCEDU RE AND/OR PHYSICAL

ABUSE AFFECTING HE RMETIC COMPRESSOR ELECTRI CAL TERMINALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the hermetic compressor. The terminals and their dielectric embedment are strongly constructed, but are vulnerable to careless compressor installation or maintenance procedures and

equally vulnerable to internal electrical short circuits caused

by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EXPLOSION OR DEATH, PRACTICE SAFE

HANDLING OF REFRIGERANTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a ) hot lubricating oil and refrigerant

(b ) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in

the vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be electrically energized and/or operated without having the terminal

protective cover properly in place.

See Service Section S-17 for proper servicing.

5

PRODUCT IDENTIFICATION

yp

g

g

g

The model number is used for positive identification of component parts used in manufacturing. Please use this number when

requesting service or parts information.

D P13CH244 1AA

Brand Engineer ing

D - Daik in Minor revision

Product T

P - Packa

SEER 1 - 208/ 230 V single phase 60 Hz

13 - 13 SEER 2 - 220/240 V single phase 50 Hz

14 - Up to 1 4 SEER 3 - 208/230 V three phase 60 Hz

15 - Up to 1 5 SEER 4 - 460 V three phas e 60 Hz

Unit Type

H - Heat Pump Ref rigerant

C - Air Conditioner 4 - R-410A

Confi

M - Multi-position 24 - 2 to n 42 - 3.5 ton

H - Horizontal 30 - 2.5 ton 48 - 4.0 ton

eEn

ed Major revision

uration Tonnage Nominal

ineering

Voltage

5 - 380/415 V three phase 50 Hz

3 6 - 3 to n 6 0 - 5 t o n

6

PRODUCT IDENTIFICATION

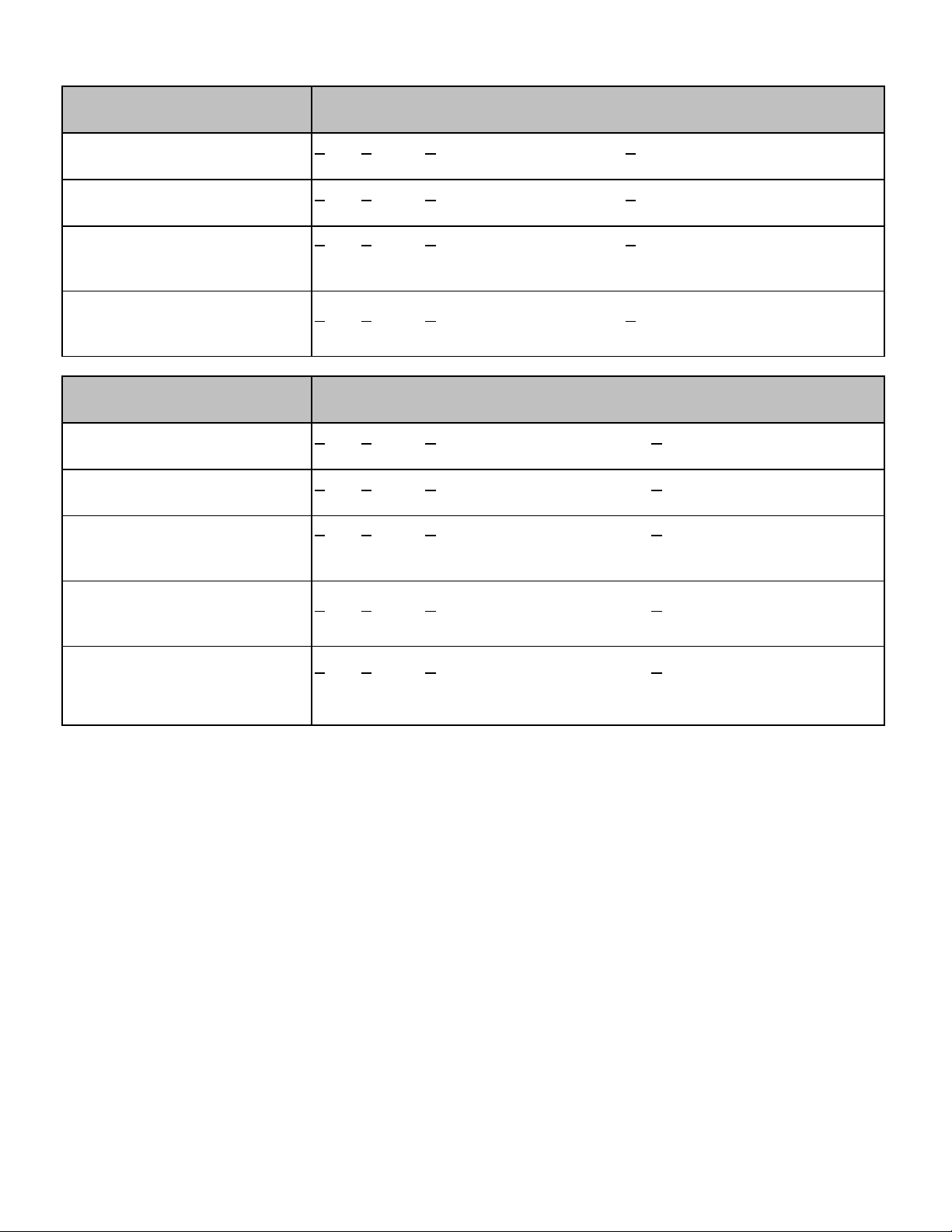

Model # Pa cka ge Cooling Description

aikin Package Cooling up to 13 Seer R410A Horizontal elec tric cooling unit.

DP13CH[24-60]41**

DP14CH[24-60]41**

DP14CH24-3041BB

DP14CH3641AC

DP14CH42-6041BB

DP14CH24-3041BC

DP14CH3641AD

DP14CH42-6041BC

Model # Package Heat Pump Description

DP13HH[24-60]41**

DP14HH[24-60]41**

DP14HH24-3641AC

DP14HH42-6041BB

D

Initial release of 208-230/1/60 s ingle phase m odel s.

aikin Package Cooling up to 14 Seer R410A Horizontal elec tric cooling unit.

D

Initial release of 208-230/1/60 s ingle phase m odel s.

aikin Package Cooling up to 14 Seer R410A Horizontal elec tric cooling unit,

D

208-230/1/60 single phase models. Converted Aluminum coils with 3/8" return

bends/ c ros s overs to Alum i num c oi ls us ing 9m m return bends / c ros s overs.

aikin Package Cooling up to 14 Seer R410A Horizontal elec tric cooling unit,

D

208-230/1/60 single phase models. Release of m odels with access box removed.

aikin Package Heat Pump up to 13 Seer R410A Horizontal heat pum p unit. Initial

D

releas e of 208-230/1/ 60 si ngl e phase models.

aikin Package Heat Pump up to 14 Seer R410A Horizontal heat pum p unit. Initial

D

releas e of 208-230/1/ 60 si ngl e phase models.

aikin Package Heat Pump up to 14 Seer R410A Horizontal heat pum p unit,

D

208-230/1/60 single phase models. Converted Aluminum coils with 3/8" return

bends/ c ros s overs to Alum i num c oi ls us ing 9m m return bends / c ros s overs.

DP14HH24-3641AD

DP14HH42-6041BC

DP14HH6041CA

aikin Package Heat Pump up to 14 Seer R410A Horizontal heat pum p unit,

D

208-230/1/60 single phase models. Release of m odels with access box removed.

D

aikin Package Heat Pump up to 14 Seer R410A Horizontal heat pum p unit,

208-230/1/60 single phase models. - Devel op and rel ease 14 SEER 5 Ton H model

heat pum p wi th new 7 mm condenser c oi l.

7

ACCESSORIES

DP[13-14]CH/HH**41**

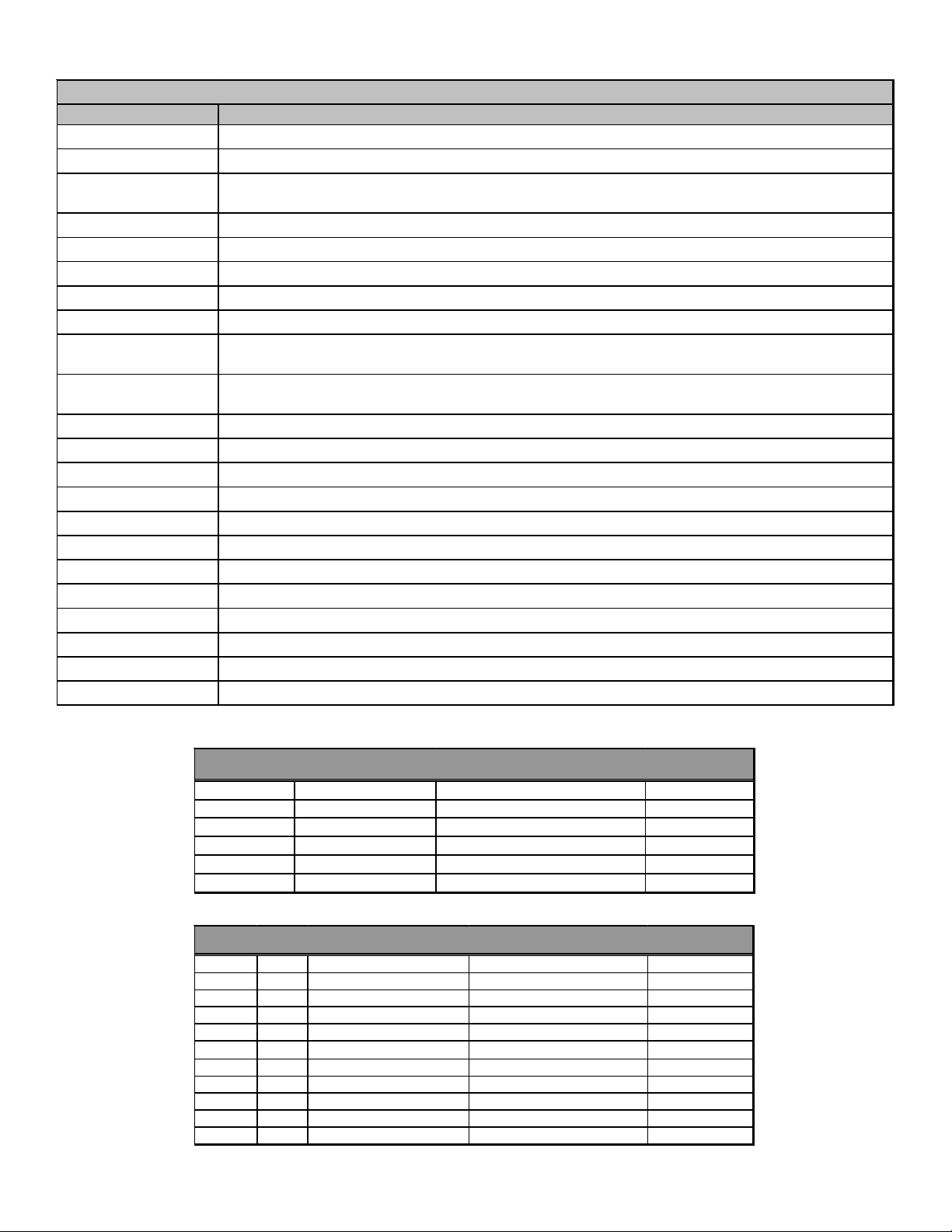

ACCESSORIES - DP**C/DP**H**** MODELS

Part Number Descriptio n

PCCP 101-103 14" Ro of Curb for Daik i n H - Series Package Un it A ll Chasis Requires PCP101 -103

PCP 101 -103 Downf lo w P lenu m Kit for Daik i n H - Ser i es Pac kage Units All Chassis. Requir es P CCP 1 01-103

PCP101-103R8

PCMD101-103 Manual Damper fo r D aikin H-Seri es Pac kage Units. Requi res PCP101-103

PCMDM101-103 Motorized Damper f or Daikin H- Ser ies Pac kage Units. Requires PCP 1 01- 103

GPHMD10 1- 103 Horizont al Manual Damper for Daik in H - Serie s Pac k a ge U ni t Horizontal Applications All Chassis

SQRPCH101 Horizont al Squar e to Round Adapters f or H- Series Pa c kage Unit 16"&14" Round .

SQRPCH102-103 Hor izontal Sq uar e t o Rou nd Adapter s f or H- Seri es Pac kage Unit 18"&14"

SQRPC101

SQRPC102-103

DPHFRA Exter na l H or izontal Filter Rack for Daikin M- and H- Series Pac k ag e Units

PCE F101-103 Elbow & Flashing w / R-8 Liner for Daiki n H- Ser i es Pa c kage Unit All Chassis

CDK36 3 T on Co nc e ntric Duc t Kit

CDK3651 5 3 T on Flush Mount Conc entric Duc t Kit w / Filt e r

CDK3653 0 3 T on Step Down Co nc e ntric Duc t Kit

CDK3653 5 3 T on St ep Do wn C oncentric D uct Kit w/ F ilter

CDK4872 4 - 6 Ton Concentric Duct Kit

CDK4872 515 4 - 6 To n Flush Mount Co nc e ntric Duc t Kit w / Filt er

CDK4872 530 4 - 6 To n Step Down Con c en tric Duct Kit

CDK4872 535 4 - 6 To n Step Down Con c en tric Duct Kit w/ Filter

DDNECNJPCHHA Downflow Economizer H-S eries Package Unit. Requires PCP 10 1-103.

DHZ E C NJPGCHM Economiz er H-Series Daikin Pa c kage Unit

Downf lo w P lenu m Kit for Daik i n H - Ser i es Pac kage Units w/ R-8 Insulation Lin er All C hassis.

Requires PCC P 101 -103

Downf lo w S quare to Round Adapt er for H- S eries Pa c kage Unit 16" Rounds.

Requires PCCP 101- 103 and P CP1 01-10 3

Downf lo w S quare to Round Adapt er for H- S eries Pa c kage Unit 18" Rounds.

Requires PCCP 101- 103 and P CP1 01-10 3

THERMOSTATS

CH70T G Manual Change over

CHSATG Manual Change over

CHT18-60 M anual Changeov er

CHT90-120 M anual Changeov er

CHT P 18 -6 0HD M anu al Chan ge over

CT18-60 Manual Changeover Mechanical, Nonprogrammable Cool Only

THERMOSTATS

1213401 White Manual Changeov e r

1213402 White Manual Changeov e r

1213403 White Manual Changeov e r

1213404 White Manual Changeov e r

1213406

1213407

1213408

1213410

1213411

1213412

1213431

Beige

White

White

White

White

White

White

Manual/Auto Changeover

Manual Changeov e r 5 + 2 Pr o gr amming Digital 2 Heat - 2 Cool

Manual/Auto Changeover

Manual Changeov e r

Manual Changeov e r

Manual/Auto Changeover

Manual/Auto Changeover 7 Day Programming Digital 3 Heat - 2 Cool

8

Digital, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable 1 Heat - 1 Cool

Mechanical, Nonprogrammable 2 Heat - 2 Cool

Digital, Nonprogrammable 2 Heat - 1 Cool

5 + 2 Pr o gr amming Digital 1 Heat - 1 Cool

Nonprogr a mmable Digital 1 Hea t - 1 Cool

7 Day Programming Digital 2 Heat - 1 Cool

Nonprogr a mmable Digital 2 Hea t - 1 Cool

5 + 2 Pr o gr amming Digital 3 Heat - 2 Cool

7 Day Programming Digital 1 Heat - 1 Cool

5 + 2 Pr o gr amming Digital 2 Heat - 1 Cool

Nonprogr a mmable Digital 2 Hea t - 2 Cool

7 Day Programming Digital 3 Heat - 2 Cool

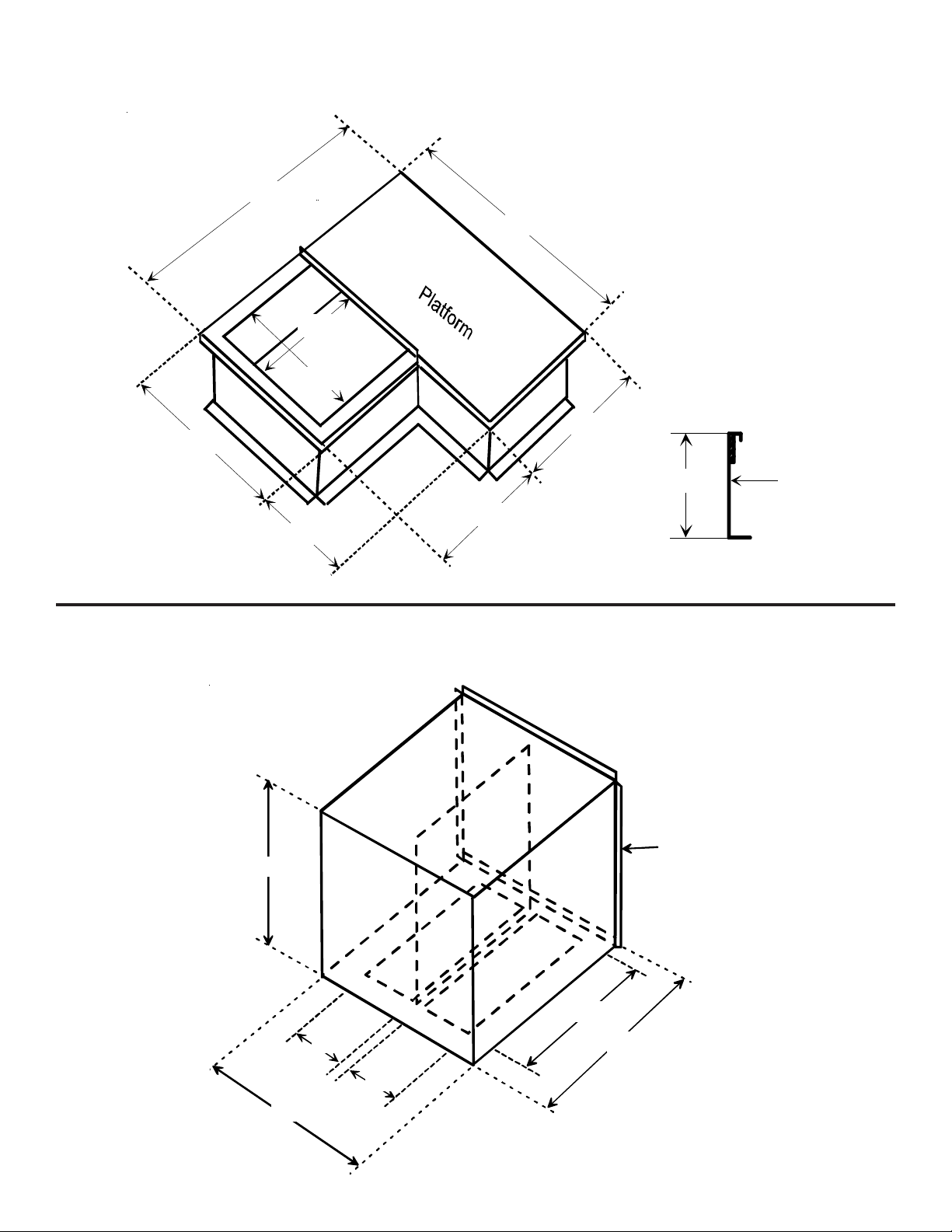

ACCESSORIES

33"

DP[13-14]CH/HH**41A*

PCCP101-103 ROOF CURB

64"

59"

29 3/8"

29 3/4"

33"

28 3/4"

31"

26"

PCP101-103 DOWNFLOW PLENUM

(Use with PCCP Roof Curb)

14"

1" Flange

Roof

Curb

37"

13"

25 1/2"

33"

13"

9

ACCESSORIES

DP[13-14]CH/HH**41A*

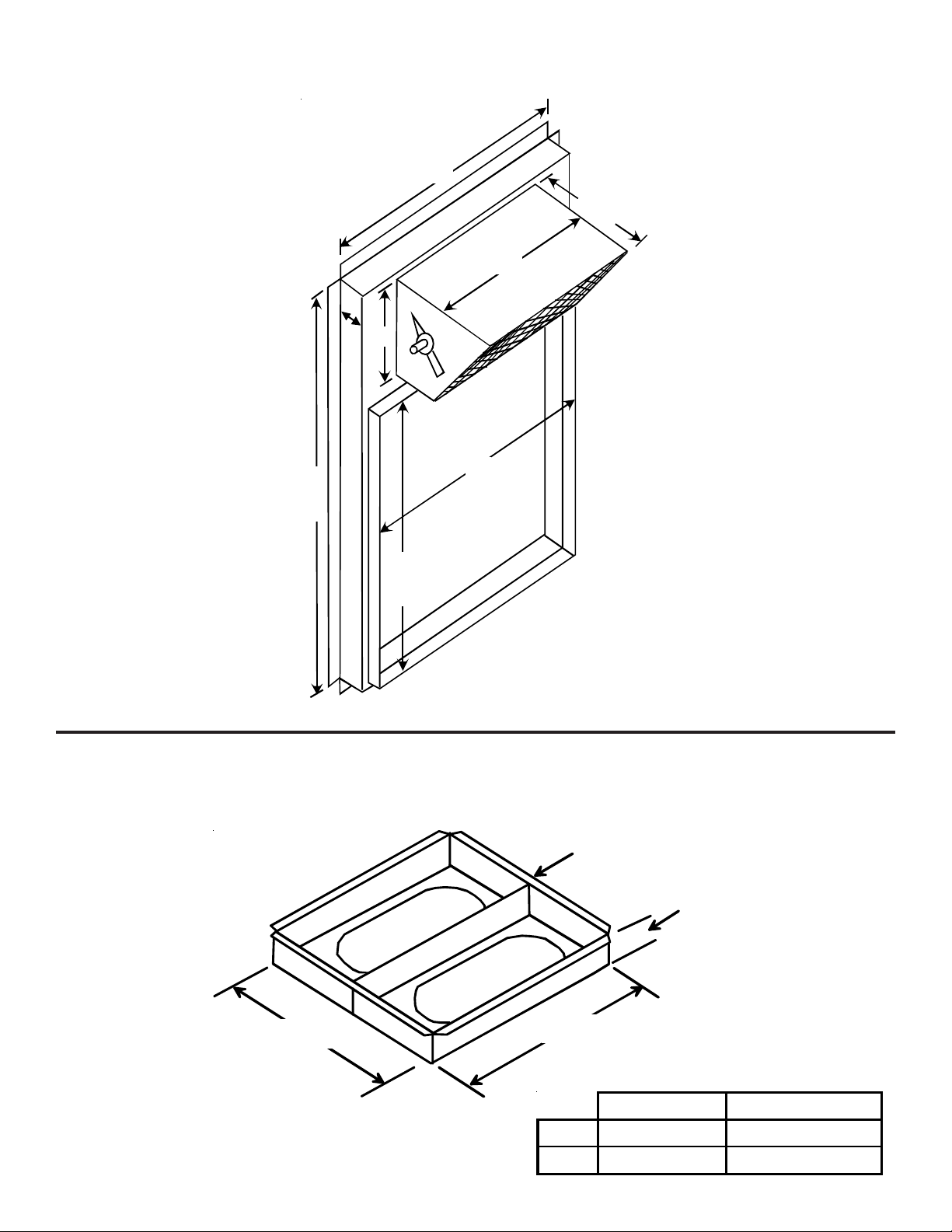

PCEF101-103 ELBOW AND FLASHING KIT

28"

35"

25"

33"

3"

4"

4"

25"

8"

DDNECNJPCHHA ECONOMIZER*

(DOWNFLOW APPLICATIONS)

C

E

D

Model Used With

DDNECNJPCHHA

10

B

H-SERIES DAI KI N

PACKAGE UNIT.

REQUIRES

PCP10 1- 103

F

A

A

20 16.25 16 23.5 12.5 45.75

B

C

D

E

F

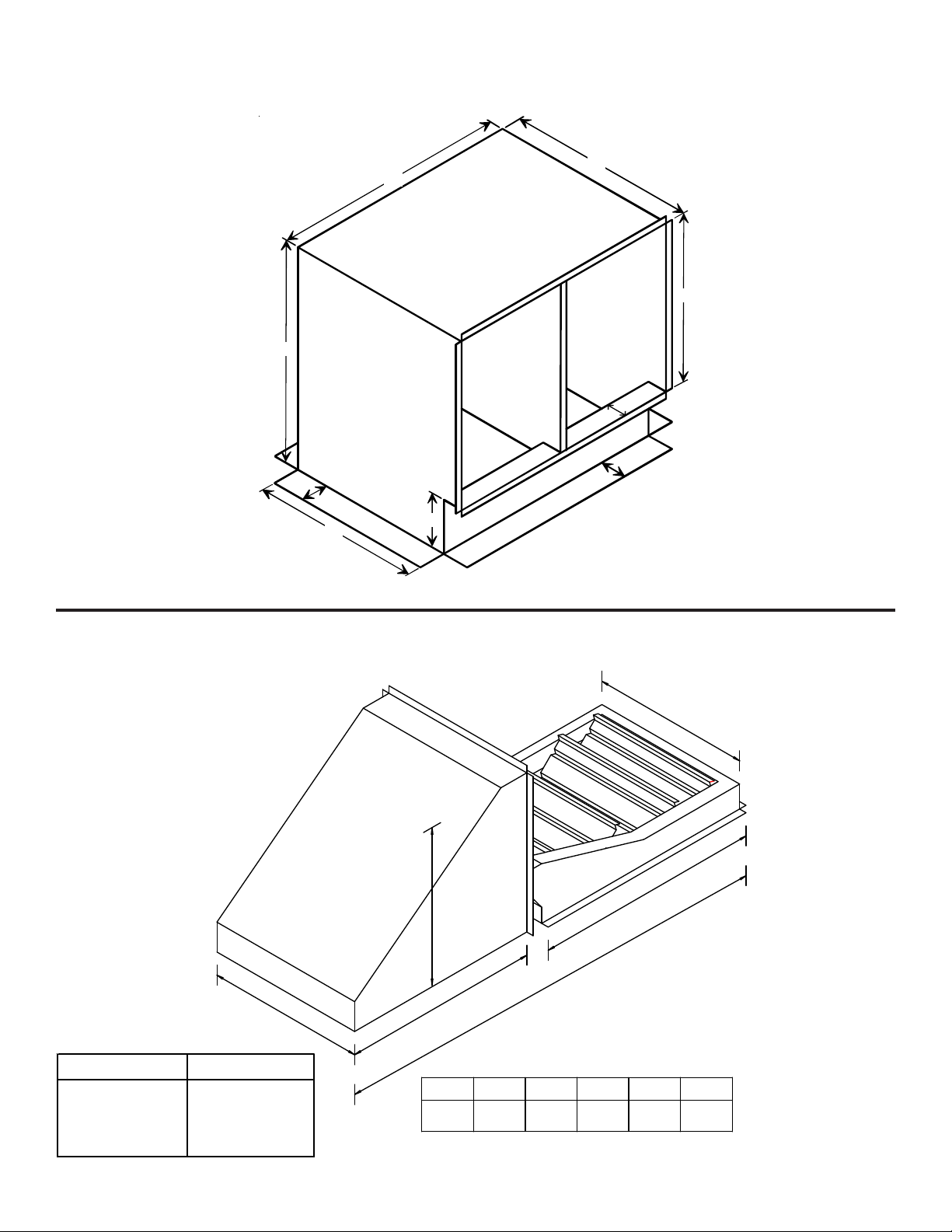

ACCESSORIES

DP[13-14]CH/HH**41A*

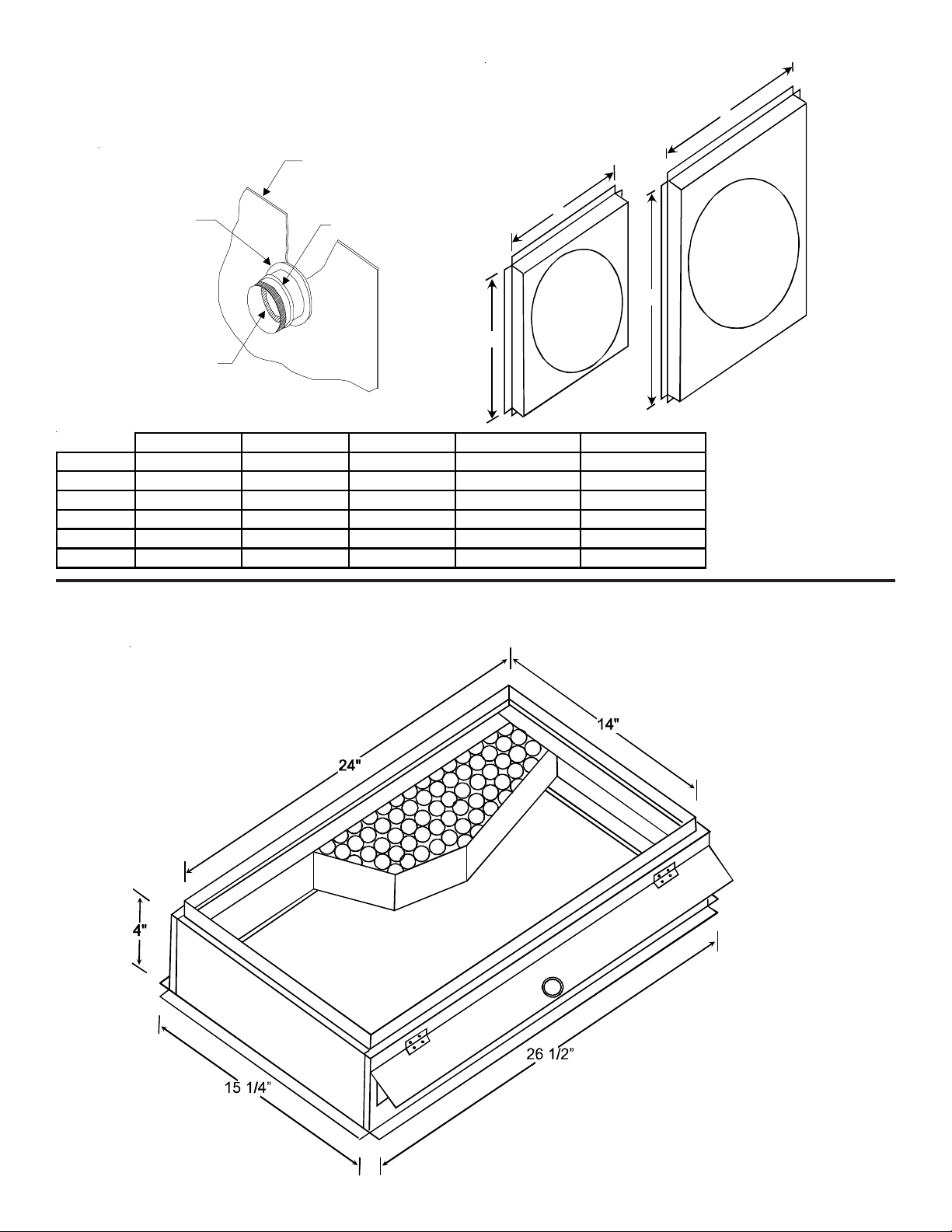

DHZECNJPGCHM ECONOMIZER*

(HORIZONTAL APPLICATIONS)

D C

B

E

A

F

SHIPPED WITH 16 X 25 X 1" FILTER AND

14.5 X 15.5 MIST ELIMINATOR INSTALLED

A B C D E F G

Shipped with 16 x 25 x 1" Filter and 14.5 x 15.5 Mist Eliminator Installed

PGEH101/102 25.25 18.125 18 16 10.375 13.75 16.125

PGEH103 35.25 18.125 18 16 15.875 18.25 16.125

ECONOMIZER ABCDEFG

DHZECNJPGCHM 25.25 18.125 18 16 10.375 13.75 16.125

G

PCMD101-103 DOWNFLOW MANUAL DAMPER*

PCMDM101-103 DOWNFLOW MOTORIZED DAMPER*

*USED WITH PCP101-103 DOWNFLOW PLENUM

"

8

/

1

2

1

FILTER ACCESS

PANEL

6"

10"

18"

29 3/4"

MODEL DESCRIPTION

PCMDH101-103 Manual Da mper

PCMDM101-1 03 M o torzie d Damper

11

ACCESSORIES

"

A

A

GPHMD101-103 HORIZONTAL MANUAL DAMPER WITH DUCT FLANGE

2"

6"

18"

17"

12"

DP[13-14]CH/HH**41A*

8

1

/

4

"

25 1/4"

17 1/4"

SQRPC SQUARE TO ROUND CONVERTER

(DOWNFLOW APPLICATIONS)

1" FLANGES

SA

1 1/2

12

29 1/2"

RA

29 1/4"

SQRPC101 SQRP102-103

S

R

16" 18"

16" 18"

ACCESSORIES

A

DP[13-14]CH/HH**41A*

SQRPCH SQUARE TO ROUND CONVERTER

(HORIZONTAL APPLICATIONS)

SQUARE TO ROUND

DUCT CONVERTER PANEL

2"

SUPPLY

A

OUTER FLANGE

STARTER FLANGE

SQRPCH-101 SQRPCH-102 SQRPCH-103 SQRPCH102-14 SQRPCH103-14

15" 17" 17" 15" 15"

B

C 17" 17" 19" 15" 15"

D 22 1/2" 24 1/2" 24 1/2" 24 1/2" 24 1/2"

SUPPLY

RETURN 16" 16" 18" 14" 14"

15" 17" 17" 15" 15"

14" 16" 16" 14" 14"

BEAD

B

C

2"

RETURN

D

DPHFRA EXTERNAL FILTER KIT

(HORIZONTAL APPLICATIONS)

14" x 25" x 2" FILTER

13

PRODUCT DESIGN

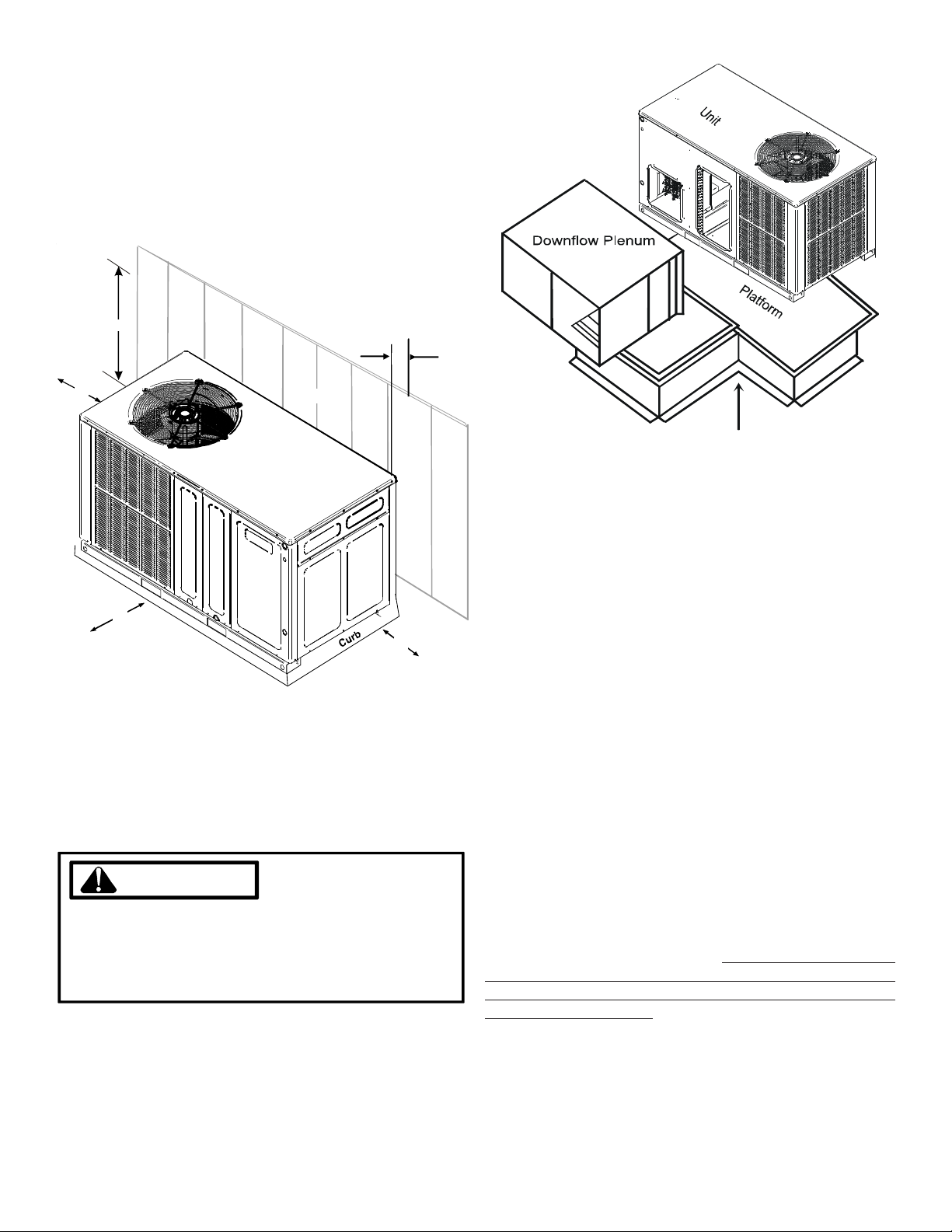

LOCATION & CLEARANCES

NOTE: To ensure proper condensate drainage, unit must be installed in a level position.

In installations where the unit is installed above ground level

and not serviceable from the ground (Example: Roof Top

installations) the installer must provide a service platform for

the service person with rails or guards in accordance with local

codes or ordinances.

48” MIN.

10"

36"

36"

DP[13-14]CH/DP[13-14]HH**41*

WALL

UNIT

36"

NOTE: Roof overhang should be no more than 36" and

provisions made to deflect the warm discharge air out from the

overhang.

Minimum clearances are required to avoid air recirculation and

keep the unit operating at peak efficiency.

WARNING

TO PREVENT PO SSIBLE DAMAG E, THE UNIT SHOUL D

REMAIN IN AN UPRIGHT POSITION DURING ALL

RIGGING AND MOVING OPERA TIONS. TO FACILIT A TE

LIFTING AND M OVING IF A CRANE IS USED, PLACE

THE UNIT IN AN ADEQUATE CABLE SLIDE.

Refer to Roof Curb Installation Instructions for proper curb

installation. Curbing must be installed in compliance with the

National Roofing Contractors Association Manual.

Lower unit carefully onto roof mounting curb. While rigging

unit, center of gravity will cause condenser end to be lower

than supply air end.

Roof Curb and Platform

DP[13-14]CH/DP[13-14]HH**41*

DPCH/DPHH Package Units are designed for outdoor installations only in either residential or light commercial applications.

NOTE: To ensure proper condensate drainage, unit must be

installed in a level position.

The connecting ductwork (Supply and Return) can be connected

for horizontal discharge airflow. In the down discharge applications, a matching Platform/Roof Curb (PCCP) and Downflow

Plenum (PCP101-103) is recommended for horizontal models

only.

A return air filter must be installed behind the return air grille(s)

or provision must be made for a filter in an accessible location

within the return air duct. The minimum filter area should not

be less than those sizes listed in the Specification Section.

Under no circumstances should the unit be operated without

return air filters.

A 3/4" - 14 NPT drain connector is provided for removal of condensate water from the indoor coil. In order to provide proper

condensate flow, do not reduce the drain line size.

Refrigerant flow control is achieved by use of restrictor orifices.

These models use the FasTest Access Fitting System, with a

saddle that is either soldered to the suction and liquid lines or

is fastened with a locking nut to the access fitting box (core)

and then screwed into the saddle. Do not remove the core

from the saddle until the refrigerant charge has been

removed. Failure to do so could result in property damage or personal injury.

The single phase units use permanent split capacitors (PSC)

design compressors. Starting components are therefore not

required. A low MFD run capacitor assists the compressor to

start and remains in the circuit during operation.

The outdoor fan motors are single phase capacitor type motors.

14

PRODUCT DESIGN

Air for condensing (cooling) is drawn through the outdoor coil

by a propeller fan, and is discharged vertically out the top of

the unit. The outdoor coil is designed for .0 static. No additional restriction (ductwork) shall be applied.

Conditioned air is drawn through the filter(s), field installed,

across the evaporator coil and back into the conditioned space

by the indoor blower.

COMPRESSORS

Some DPCH/DPHH series package units use the Compliant

Scroll compressor, instead of traditional reciprocating compressors. Still other models use reciprocating compressors.

A scroll is an involute spiral which, when matched with a mating scroll form as shown, generates a series of crescent shaped

gas pockets between the two members.

During compression, one scroll remains stationary (fixed scroll)

while the other form (orbiting scroll) is allowed to orbit (but not

rotate) around the first form.

NOTE: Operating pressures and amp draws may differ from

standard reciprocating compressors. This information can

be found in the unit's Technical Information Manual.

INDOOR BLOWER MOTOR

Some DPCH/DPHH model package units use a EEM blower

motor while others use the standard PSC type blower motor.

The EEM motor is a 3 Phase brushless DC (single phase AC

input), ball bearing construction motor with an integral control

module with an internal FCC B EMI filter.

The EEM motor is continuously powered with line voltage. The

switched 24 volt control signal is controlled by the thermostat

in the cooling and heat pump mode and the blower relay in the

electric heat mode.

ELECTRICAL WIRING

The units are designed for operation at the voltages and hertz

as shown on the rating plate. All internal wiring is complete.

Ensure the power supply to the compressor contactor is brought

to the unit as shown on the supplied unit wiring diagram. The

24V wiring must be connected between the unit control panel

and the room thermostat.

As this motion occurs, the pockets between the two forms are

slowly pushed to the center of the two scrolls while simultaneously being reduced in volume. When the pocket reaches

the center of the scroll form, the gas, which is now at a high

pressure, is discharged out of a port located at the center.

During compression, several pockets are being compressed

simultaneously, resulting in a very smooth process. Both the

suction process (outer portion of the scroll members) and the

discharge process (inner portion) are continuous.

Some design characteristics of the Compliant Scroll compressor are:

• Compliant Scroll compressors are more tolerant of liquid

refrigerant.

NOTE: Even though the compressor section of a Scroll

compressor is more tolerant of liquid refrigerant, continued

floodback or flooded start conditions may wash oil from the

bearing surfaces causing premature bearing failure.

• Compliant Scroll compressors use "POE" or polyolester

oil, which is NOT compatible with mineral oil based lubricant like 3GS. "POE" oil must be used if additional oil is

required.

• Compliant scroll compressors perform "quiet" shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart even

if the system has not equalized.

WARNING

TO AVOID PERSO NAL INJ UR Y OR DEA T H DUE TO

ELECTRI C SHOC K, WIRING TO THE UNIT MUST BE

PROPERLY POLA RIZ ED AN D GROUNDED.

WARNING

15

Loading...

Loading...