Daikin DP13GM3604541A, DP13GM3007041A, DP13GM3607041A, DP13GM3609041A, DP13GM4207041A Technical Manual

...

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

DP 13 SEER

R-410A Single Phase

Package Gas Unit s

• Refer to Service Manual RSD6312004 for installation, operation, and troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• Models listed on page 3.

ALAL

AL

ALAL

This manual is to be used by qualified, professionally trained HVAC technicians only. Daikin does

not assume any responsibility for property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

Copyright © 2013 - 2014

RTD6312004r1

March 2014

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

D P 13 G M 24 070 4 1 A A

Brand Engineering

D - D aik in Minor revision

Product Type Engineering

P - Packaged Major revision

Voltage

SEER 1 - 208/230 V single phase 60 Hz

13 - 13 SEER 2 - 220/240 V single phase 50 Hz

14 - Up to 14 SEER 3 - 208/230 V three phase 60 Hz

15 - Up to 15 SEER 4 - 460 V three phas e 60 H z

5 - 380/415 V three phase 50 Hz

Unit Type

G - Gas/Electric R efrigerant

D - Dual Fuel 4 - R-410A

C onfiguration Nominal Heat Input

M - Multi-position 045 45 MBTU/H 115 115 MBTU /H

H - Horizonta l 070 70 MBTU/H 140 140 MBTU/H

090 90 MBTU/H

WARNING

WARNING

Tonnage Nominal

24 - 2 ton 42 - 3.5 ton

30 - 2.5 ton 48 - 4.0 ton

36 - 3 ton 60 - 5 ton

HIGH VOLTAGE!

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

WARNING

WARNING

vice procedures. If you install or perform service on this

unit, you assume responsibility for any personal injury or

property damage which may result. Many jurisdictions

require a license to install or service heating and air

conditioning equipment.

Daikin will not be responsible for

any injury or property damage arising from improper service or ser-

2

WARNING

WARNING

fied by the Air-Conditioning, Heating, and Refrigeration

Institute (AHRI) may use this information. Attempting to

install or repair this unit without such background may

result in product damage, personal injury, or death.

ONLY individuals meeting (at a

minimum) the requirements of an

"Entry Level Technician" as speci-

PRODUCT IDENTIFICATION

The model and manufacturing number are used for positive identification of component parts used in manufacturing.

Please use these numbers when requesting service or parts information.

DP13GM2404541A*

DP13GM2407041A*

DP13GM3004541A*

DP13GM3007041A*

DP13GM3604541A*

DP13GM3607041A*

DP13GM3609041A*

DP13GM4207041A*

DP13GM4209041A*

DP13GM4807041A*

DP13GM4809041A*

DP13GM4811541A*

DP13GM6009041A*

DP13GM6011541A*

DP13GM6014041A*

WARNING

WARNING

WARNING

WARNING

erty damage, personal injury, reduced unit performance

and/or hazardous conditions may result from the use of

such non-approved devices.

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow these

regulations may harm the environment and can lead to the imposition of substantial fines. These

regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by Daikin

for use with this unit. Serious prop-

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

To prevent the risk of property

damage, personal injury, or death,

3

PRODUCT DESIGN

DP13GM Package Gas Units are designed for outdoor installations only in either residential or light commercial applications and are available in 2 through 5 ton sizes. They are

designed for 208/230 volt single phase applications. (DP13GM

3, 4 and 5 ton models are also available for 230V 3 phase

applications. See Technical Manual RTD6312005.)

The connecting ductwork (Supply and Return) can be connected for either horizontal or vertical airflow. In the vertical

application, a matching Roof Curb is recommended.

A return air filter must be installed behind the return air grille(s)

or provision must be made for a filter in an accessible location within the return air duct. The minimum filter area should

not be less than those sizes listed in the Specification Section. Under no circumstances should the unit be operated

without return air filters.

A 3/4" pipe is provided for removal of condensate water from

the indoor coil. (Do not reduce the drain line size).

NOTE: Tighten drain to a maximum torque of 10 in-lbs.

Refrigerant flow control is achieved by use of restrictor orifices. DP13GM units use the FasTest Access Fitting System which consists of a saddle that is either soldered to the

suction and liquid lines or is fastened with a locking nut to

the access fitting box (core) and then screwed into the saddle.

NOTE: The core must not be removed from the saddle

until the refrigerant charge has been removed. Failure

to do so could result in property damage or personal

injury.

The single phase units use permanent split capacitors (PSC)

design compressors. Starting components are therefore not

required. A low MFD run capacitor assists the compressor

to start and remains in the circuit during operation.

The outdoor fan and indoor blower motors are single phase

permanent split capacitor type motors. DP13GM48***41**

and DP13GM60***41** models are equipped with EEM indoor blower motors. EEM motors are constant torque motors with very low power consumption and are energized by a

24V signal from the ignition control. The EEM features an

integrated control module.

Air for condensing (cooling cycle) is drawn through the outdoor coil by a propeller fan, and is discharged vertically out

the top of the unit. The outdoor coil is designed for .0 static.

No additional restriction (ductwork) shall be applied.

Conditioned air is drawn through the filter(s), field installed,

across the coil and back into the conditioned space by the

indoor blower.

Some models of the DP13GM series package units use the

Compliant Scroll compressor, there are a number of design

characteristics which are different from the traditional reciprocating compressor.

- Due to their design Scroll compressors are inherently more

tolerant of liquid refrigerant. NOTE: Even though the compressor section of a Scroll compressor is more tolerant

of liquid refrigerant, continued floodback or flooded start

conditions may wash oil from the bearing surfaces causing premature bearing failure.

- These Scroll compressors use "POE" or polyester oil

which is NOT compatible with mineral oil based lubricants

like 3GS. "POE" oil must be used if additional oil is

required.

- Compliant scroll compressors perform "quiet" shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart

even if the system has not equalized.

- Operating pressures and amp draws may differ from standard reciprocating compressors. This information may be

found in the "Cooling Performance Data" section.

4

PRODUCT DESIGN

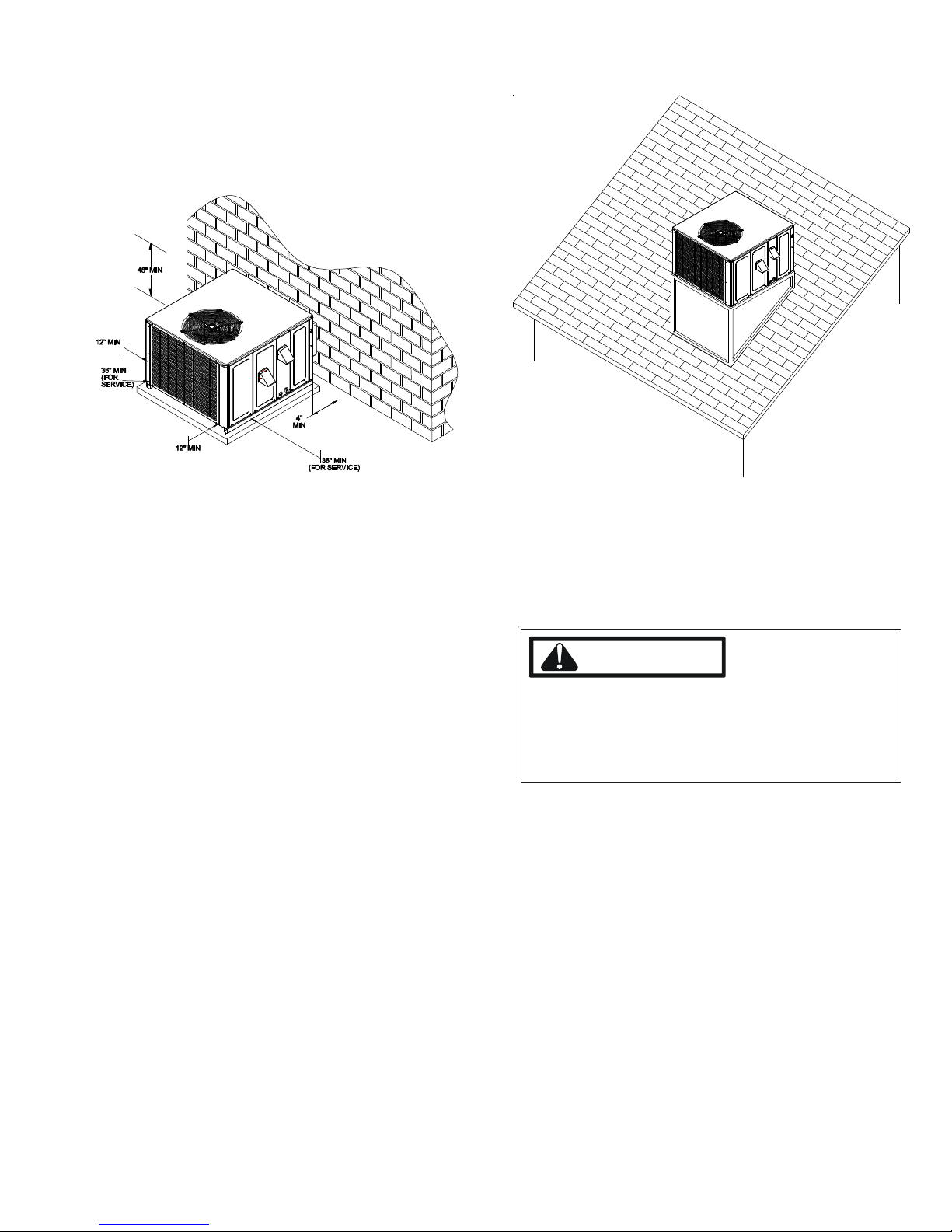

Location and Clearances

NOTE: To ensure proper condensate drainage, unit must be

installed in a level position.

Outside Slab Installation

NOTE: Roof overhang should be no more than 36" and pro-

vision made to deflect the warm discharge air out from the

overhang. Minimum clearances are required to avoid air

recirculation and keep the unit operating at peak efficiency.

Rooftop Installation

NOTE: To ensure proper condensate drainage, unit must

be installed in a level position.

WARNING

TO

PREVENT POSSIBLE PROPERTY DAMAGE, THE UNIT

SHOULD REMAIN IN AN UPRIGHT POSITION DURING ALL

RIGGING AND MOVING OPERATIONS

LIFTING AND MOVING IF A CRANE IS USED, PLACE THE UNIT

IN AN ADEQUATE CABLE SLING

IMPORTANT: If using bottom discharge with roof curb, duct-

work should be attached to the curb prior to installing the

unit.

Refer to Roof Curb Installation Instructions for proper curb

installation. Curbing must be installed in compliance with

the National Roofing Contractors Association Manual.

.

. TO

FACILITATE

5

PRODUCT DESIGN

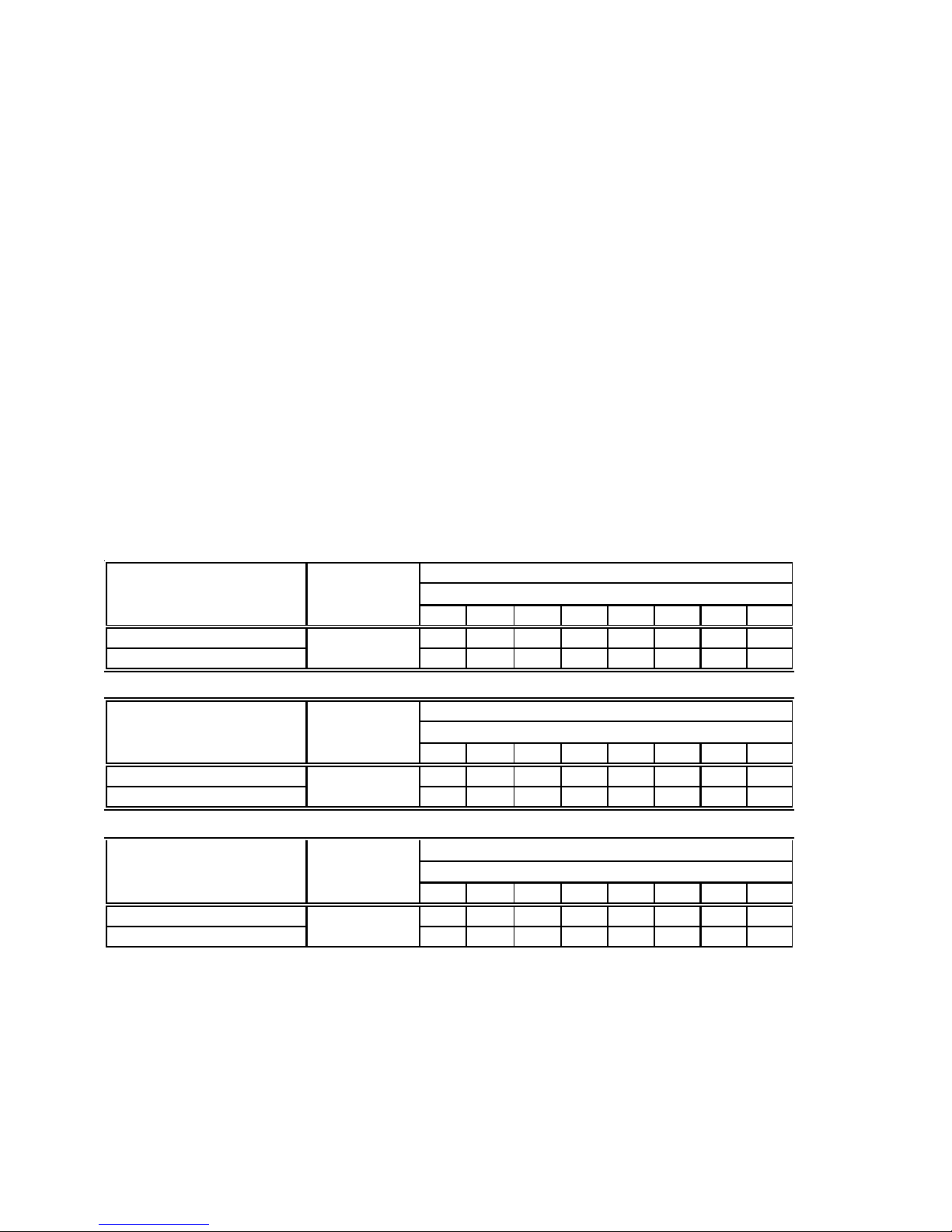

High Altitude Derate - U.S. Installations Only (Optional)

The gas/electric units naturally derate with altitude. High

Altitude Derate kit may be installed if desired.

IMPORTANT NOTE: The gas/electric units naturally derate

with altitude. Do not attempt to increase the firing rate by

changing orifices or increasing the manifold pressure. This

can cause poor combustion and equipment failure. At all

altitudes, the manifold pressure must be within 0.3 inches

W.C. of that listed on the nameplate for the fuel used. At all

altitudes and with either fuel, the air temperature rise must

be within the range listed on the unit nameplate. Refer to

the Installation Manual provided with the LP kit for conversion

from natural gas to propane gas and for altitude adjustments.

When this package unit is installed at high altitude, the appropriate High Altitude orifice kit may be installed. As altitude increases, there is a natural reduction in the density of

both the gas fuel and combustion air. This kit will provide the

proper design certified input rate within the specified altitude

range. High altitude kits are not approved for use in Canada.

For installations above 2,000 feet, use kit HA-02. The HA-02

kit is used for both Natural and LP gas at high altitudes.

Use LPT-03 propane conversion kit for propane conversions

at altitudes below 2000 feet. Natural gas installations below

2000 feet do not require a kit.

For propane conversion above 2000 feet, high altitude kit

HA-02 is required in addition to the LPT-03 propane conversion kit.

NATURAL GAS AND LP GAS INSTALLATIONS AT ALTITUDES > 2000 FT

INPUT/BURNER

U.S. BUR NER OR IFICE 45/55 47/55 47/56 - 47/56 48/57 48/58 49/58

CA NADA BURNE R O R I FIC E 45/55 - - 4 8 /5 7 - - - -

INPUT/BURNER

U.S. BUR NER OR IFICE 44/55 44/55 45/56 - 45/56 46/57 47/58 47/58

CA NADA BURNE R O R I FIC E 44/55 - - 4 7 /5 7 - - - -

INPUT/BURNER

U.S. BUR NER OR IFICE 43/55 43/55 44/56 - 44/56 44/56 45/57 45/57

CA NADA BURNE R O R I FIC E 43/55 - - 4 6 /5 7 - - - -

HI G H AL TI TUDE

KI T

HA-02

HI G H AL TI TUDE

KI T

HA-02

HI G H AL TI TUDE

KI T

HA-02

2000 3000 4000 4500 5000 6000 7000 8000

2000 3000 4000 4500 5000 6000 7000 8000

2000 3000 4000 4500 5000 6000 7000 8000

20,000 BTUH NAT/20,000 BTUH /L.P.

ELEVATION ABOVE SEA-LEVEL (FEET)

22,500 BTUH NAT/20,000 BTUH /L.P.

ELEVATION ABOVE SEA-LEVEL (FEET)

25,000 BTUH NAT/20,000 BTUH /L.P.

ELEVATION ABOVE SEA-LEVEL (FEET)

6

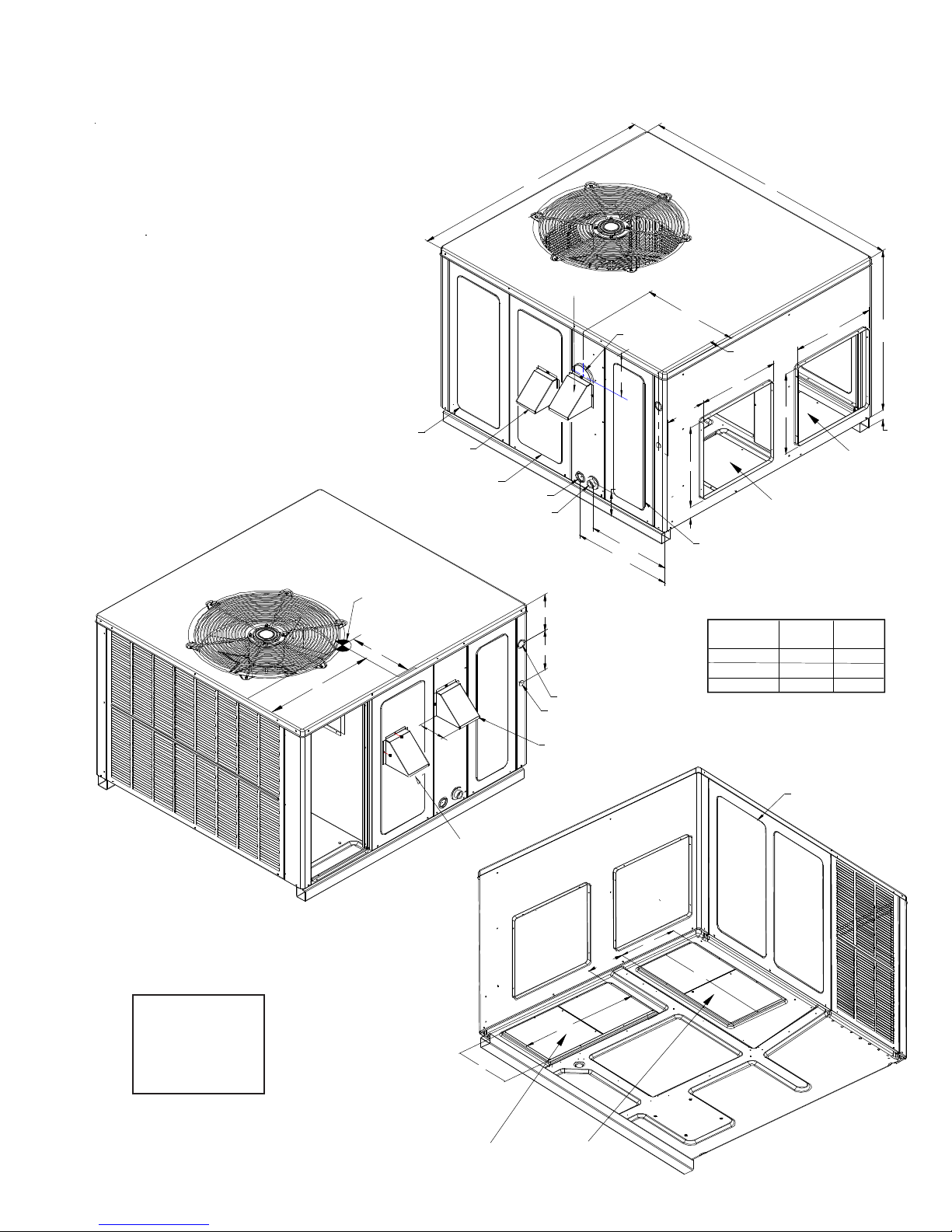

PRODUCT DIMENSIONS

UNIT DIMENSIONS

SUCTION/LIQUID PRESSURE PORTS

BEHIND COMPRESSOR ACCESS PANEL

COMBUSTION AIR INTAKE

HEAT EXCHANGE ACCESS PANEL

CONDE NSATE DRAIN CONNECTION

F

O

R

Y

E

T

T

I

N

V

E

A

C

R

G

20

24

47

GAS SUPPLY ENTRANCE

3/4" NPT FEMALE

FLUE E X HAUST

HOOD

FLUE EXHAUST

C

4 3/4

16 1/8

19 1/8

7 5/16

7 7/8

POW ER W IRE ENTRA NCE

CONTROL WIRE ENTRANCE

51

18 7/16

1 3/8

5 1/2

16

7 15/16

B

(INCHES)

SUPPLY

3

EVAPORATOR/CONTROL PANEL ACCESS PANEL

DIMENSION

B

MEDIUM

16

RETURN

A3240

B1618

C9 1/214

A

2 3/4

LARGE

MEDIUM CHASSIS

DP13GM24, 30, 36

LARGE CHASSIS

DP13GM42, 48, 60

5 1/4

COMBUSTION

AIR INTAKE

SUPPLY

EXHAUST FLUE HOOD

BLOWER ACCESS PANEL

11

5 3/4

22

11

RETURN

22

7

ACCESSORIES

DP13[C,G,H]M, DP14DM and DP15[G,H]M

Part Number Description

CDK36 3 Ton Concentric Duct Kit

CDK36515 3 Ton Flush Mount Concentric Duct Kit w/ F ilt er

CDK3 65 30 3 Ton St ep D own Co nc en tric Duct Kit

CDK3 65 35 3 Ton St ep D own Co nc en tric Duct Kit w/ Filter

CDK4 872 4 - 6 Ton Concen tric Du c t Kit

CDK4872515 4 - 6 Ton Flush Mount Concentric Duct Kit w/ F ilt er

CDK4 87 2530 4 - 6 Ton St e p Do wn Co ncentri c D uc t Kit

CDK4 87 2535 4 - 6 Ton St e p Do wn Co ncentri c D uc t Kit w / Filt er

D14CRBPGCHMA 14" Curb Daikin-M Series Package Unit A ll Chassis

DDN25FDPG CH MM Manual 25 % M-S er i es F r esh Air Damper D ownflow Application, Medium Chassis

DDN25FDPG CH ML Manual 25 % M-S er i es F r esh Air Damper D ownflow Application, La rg e C ha ssis

DDN25MFDPGCHMM Motorized 25% M-Series Fresh Air Damper Downflow Application, Medium Chassis

DDN25MFDPG CHML Motorized 25% M- Ser ies Fresh A ir Downflow A pplication, Large Chassis

DDNE CNJ P GM M Downflow Jade E c on omizer Da ik in M-Series Ga s Package Unit , M ed ium Cha ssis

DDNE CNJ P GM L Downflow Jade E c on omizer Da ik in M-Series Ga s Package Unit , Large Ch assis

DDNIFRPG A Downflow Internal Filter Rack for Daikin M- Series Gas Package Unit

DHZ25FDPGCHMS Manual 25% M-Series Fresh Air Damper Horizont al Application, Small Chassis

DHZ 2 5FDPG CH MM Manual 25 % M-S e ri es F r e sh Air Damper H or i zont a l Appl ic ation, Medium Chassis

DHZ25FDPGCHML Manual 25% M-Series Fresh Air Damper Horizont al Application, Large Chassis

DHZ25M F DPG CHMS Motoriz ed 25% M-Ser ies Fresh A ir Damper Horiz ontal Application, Small Chassis

DHZ25M F DPG CHMM Motorized 25% M- Ser ies Fresh A ir Damper Horiz ont al Application, Medium Chassis

DHZ25M F DPG CHML Motorized 25% M -Ser ies Fresh A ir Damper Horizontal Application, Large Chassis

DHZECNJPGCHM Horiz ontal Jade Economizer M-Ser ies Package Unit A ll F uels, Medium Chassis H-Series All Chassis

DHZECNJPGCHL Horiz ontal Jade Economizer M-Ser ies Package Unit All Fuels, Large Chassis

DPHFRA External Horizontal Filter Rack for Daikin M- and H-Series Package Units

HA-02 High Altitude Kit

LPT-03 Pr op an e Co nversion K it

SQRPG101/102

SQRPG103

SQRPGH101/102

SQRPGH103

Square to Round Adapter for M-Series Package Unit w/ 16" Round Downflow A pplication, Medium

Chassis

Square to Round Adapter for M-Series Package Unit w/ 18" Round Downflow A pplication, Large

Chassis

Square to Round Adapter f or M-Series Package Unit w/ 16" Round Horizontal Application, Small and

Medium Chassis

Square to Round Adapter f or M-Series Package Unit w/ 18" Round Horizontal Application, Large

Chassis

8

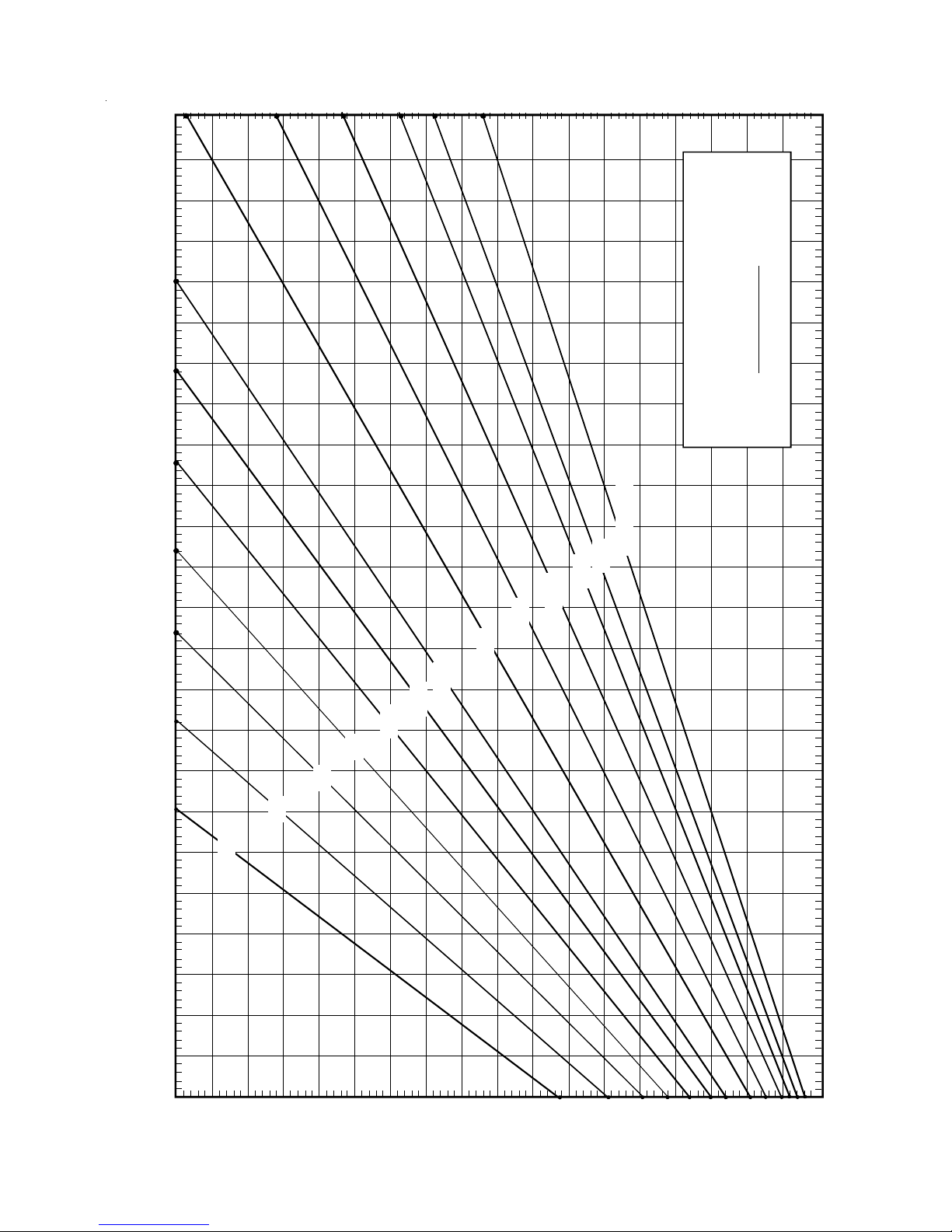

BLOWER PERFORMANCE DATA

÷ CFM

130 140 150

800

900

FORMULAS

BTU OUTPUT = CFM x 1. 08 x RISE

1.08

BTU OUTPUT

RISE =

100

2400 CFM

2200

2000

1800

1600

1400

1200

1100

1000

OUTPUT BTU/HR x 1000

BTU OUTPUT vs TEMPERATURE RISE CHART

600 CFM

100

700

90

80

70

60

50

30 40 50 60 70 80 90 110 120

40

30

20

10

TEMPERATURE RISE

9

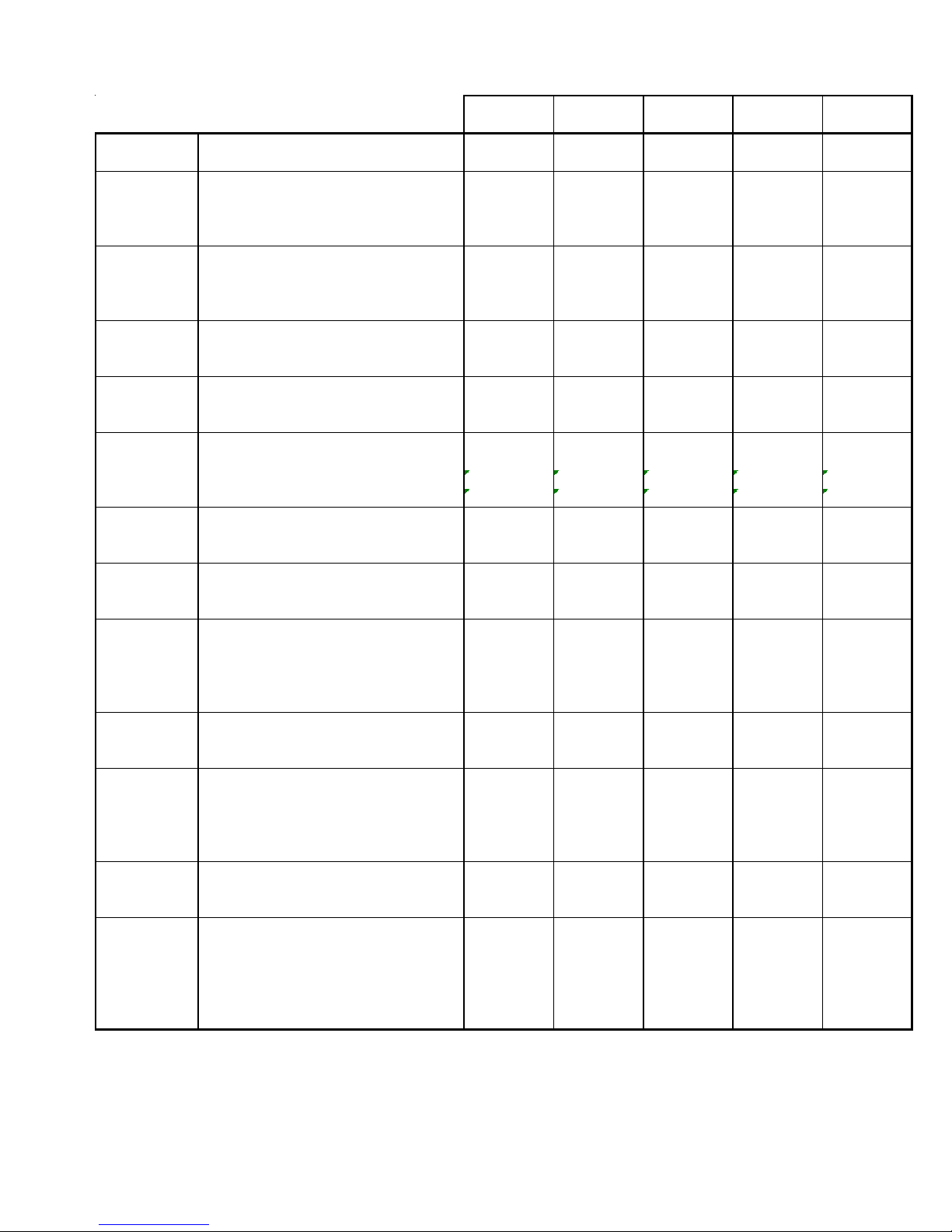

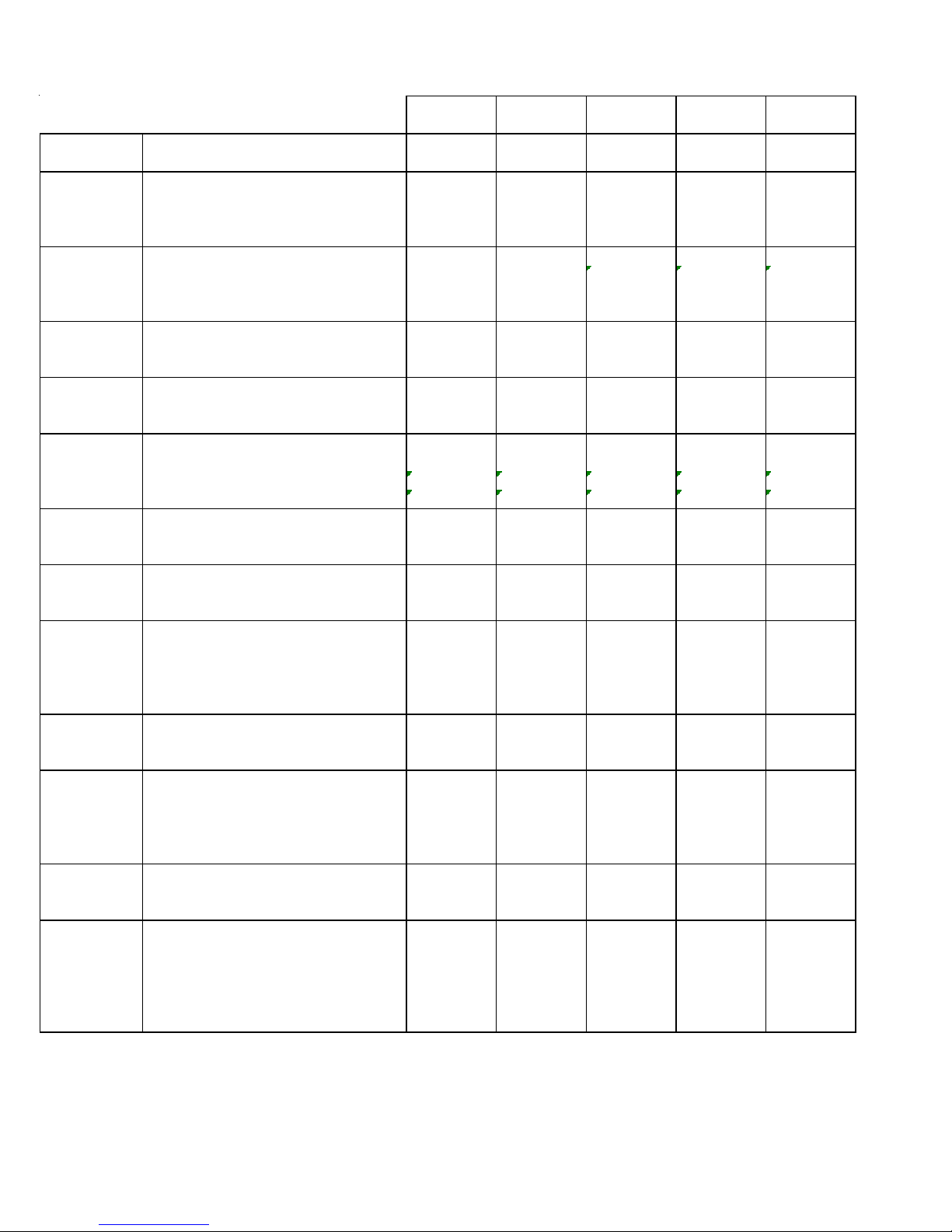

P ACKAGE GAS SPECIFICATIONS

DP13GM24045

41A*

COOLING

CAPACITY

HEATING

CAPACITY

UNIT

ELECTRICAL

SPECIFICATION

HEATING

SECTION

COMPRESSOR

CONDENSER

FAN M OT OR

CONDENSER

FAN

CONDENSER

COIL

EVAPORATOR

BLOWER

MOTOR

EVAPORATOR

BLOWER

EVAPORATOR

COIL

HEATING

LIMITS

GENERAL

INFORMATION

COOLING CAPACITY, BTUH 23,6 00 23,600 28,600 28,600 35,000

SEER / E E R 13. 0 / 11.0 13.0 / 11. 0 13.0 / 11.0 13.0 / 11.0 13. 0 / 11.0

HEA TING INPUT BTUH (U.S. & CA NA DIA N) 46 , 0 00 69,000 46,000 69, 000 46,000

HEA TING OUTPUT BTUH (U.S. & CANADIAN) 36, 7 00 55,000 36,700 55, 000 36,700

AFUE (%) 8080808080

TEMP E RA TURE RISE (°F ) 30 - 60 35 - 65 30 - 60 35 - 65 30 - 60

VOLTAG E (NA M E PLATE) 208/230 208/2 30 208/ 230 208/230 208/230

UNIT AMPS (TOTAL) 16. 1 16.1 17.5 17.5 21.2

MINIMUM CIRCUIT AM P ACITY 19. 5 19. 5 20. 9 20.9 25.4

MA XIMUM OV ERCURRE NT PROTECTION

NUMBER OF BURNERS 23232

ORIFICE SIZE NATURAL 4343434343

ORIFICE SIZE LP 55 55 55 55 55

TYPE Scroll Sc roll Scroll Scroll Scroll

RATED LOA D A M P S 13.5 13.5 14.1 14.1 16.7

LOCKE D RO TOR AMP S 58. 3 58.3 73.0 73.0 79.0

HORSEPOWER 1/6 1/6 1/4 1/4 1/4

RPM 830 830 1100 1100 830

FULL LOA D A M P S 1.1 1 . 1 1.4 1.4 1.5

LOCKED ROTOR AMPS 3.0 3.0 2.9 2.9 3.0

BLADE DIAMETER (INCHES) 22 22 22 22 22

NUMBER OF BLADES 33333

CFM 2400 2400 2700 2700 2400

FACE AREA - SQ. FT. 12.31 12.3 1 12.31 12. 31 8. 77

NUMBER OF ROWS 11112

FINS PER INCH 24 24 24 24 27

HORSEPOWER - NO. OF SPEEDS 1/4 - 3 1/4 - 3 1/3 - 3 1/3 - 3 1/3 - 3

FULL LOA D A M P S 1.5 1 . 5 1.9 1.9 3.1

LOCKED ROTOR AMPS 2.2 2.2 3.1 3.1 4.1

MOTOR SPEED TAP - COOLING Med Med Med Med High

RPM 952 952 1,015 1,015 910

DIAME TER X WIDTH (INCHES) 1 0” x 8” 10” x 8” 10” x 8” 10” x 8” 10” x 9”

RATED S CFM COOLING 800 800 1000 1000 1250

MAX EXTERNAL STATIC PRESS (" w.c.) 0.5 0.5 0.5 0.5 0.5

FACE AREA - SQ. FT. 4.33 4.33 4.33 4.33 4.33

NUMBER OF ROWS 33444

FINS PER INCH 14 14 14 14 14

FILTER SIZE - SQ. FT.

DRAIN S IZE (INCHES) 3/4 3/4 3/ 4 3/4 3/4

PRIMA RY LIMIT SE TTING (°F) 150 150 150 150 160

AUXILIARY LIMIT SETTING (°F) 150 150 150 150 150

ROLLOUT LIMIT SETTING (°F) 3 50 350 350 350 350

PISTON EXPANS ION DE V ICE Orific e (. 057) Ori fic e (.057) Orifice (.062) Orifice (.062) Orifi c e (. 0 68)

REF RIGERANT CHARG E R-4 10A (Oz.) 75 75 78 7 8 70

POWER SUPPLY ENTRANCE SIZE (INCHES) 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

LOW VOLTAGE ENTRANCE SIZE (INCHES) 7/8 7/8 7/8 7/8 7/8

SHIPPING WE IGHT LBS . 420 425 421 425 470

OPERATING WE IGHT LBS . 396 397 397 399 449

(2)

(3)

30 30 35 35 40

2.7 2.7 3.3 3.3 4.2

DP13GM24070

DP13GM[24-36]***41A*

41A*

DP13GM30045

41A*

DP13GM30070

41A*

(1 ) Units installed in Canada are certifed only to 4500 feet.

(2) Calculated external filter size based on air velocity of 300 ft/min. and applies to disposable filters only.

(3 ) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/

circuit breakers in accordance with the National Electrical Code and/or all local codes.

DP13GM36045

41A*

10

P ACKAGE GAS SPECIFICATIONS

DP13GM36070

41A*

COOLING COOLING CAPACITY, BTUH 35,000 35,000 40,500 40,500 46,000

CAPACITY SEER / EE R 13.0 / 11.0 13.0 / 11.0 13.0 / 11.0 13.0 / 11.0 13.0 / 11.0

HEA TING INP UT B TUH (U. S. & C A N A D IA N) 69,000 92,000 6 9,000 92,000 69,000

HEATING HEA TING OUTPUT B TUH (U.S. & CA NA DIAN) 55, 000 73, 600 55, 000 73, 600 55,0 00

CAPACITY AFUE (%) 8080808080

TEMPERATURE RISE (°F) 35 - 65 45 - 75 35 - 65 45 - 75 35 - 65

UNIT VOLTAGE (NAMEPLATE) 208/230 208/230 208/230 208/230 208/230

ELECTRICAL UNIT AMPS (TOTAL) 21.2 21.2 22.3 22.3 27.1

SPECIFICATION MINIMUM CIRCUIT AMPACITY 25.4 25.4 26.8 26.8 32.1

MAXIMUM OVE RCURRENT PROTECTION 40 40 40 40 50

HEATING NUMBER OF BURNERS 34343

SECTION ORIFICE SIZE NATURAL 4343434343

ORIFICE S IZE LP 55 55 55 55 55

COMPRESSOR TYPE Scroll Scroll Scroll Scroll Scroll

RATED LOAD AMPS 16.7 16.7 17.9 17.9 19.9

LOCKED ROTOR AMPS 79.0 79.0 112.0 112. 0 109. 0

CONDE NSE R HORSEPOWER 1/4 1/4 1/4 1/4 1/4

FAN MOTOR RPM 830 830 1100 1100 1100

FULL LOAD AMPS 1.5 1.5 1.4 1.4 1.4

LOCKED ROTOR AMPS 3.0 3.0 2. 9 2.9 2.9

CONDENSER BLADE DIAMETER (INCHES) 22 22 22 22 22

FAN NUMBER OF BLADES 33333

CFM 2400 2400 3500 3500 3500

CONDENSER FACE AREA - SQ. FT. 8.77 8.77 15.3 15.3 15.3

COIL NUMBER OF ROWS 22111

FINS PER INCH 27 2 7 24 24 24

EVAPORATOR HORSEPOWER - NO. OF SPEEDS 1/3 - 3 1/3 - 3 1/3 - 3 1/3 - 3 3/4 - 5

BLOWER FULL LOAD AMPS 3.06 3.06 3.06 3.06 5.8

MOTOR LOCKED ROTOR AMPS 4.1 4.1 4. 1 4.1 --

MOTOR SPEED TAP - COOLING High High Medium Medium T4

RPM 910 910 910 910 1050

EVAPORATOR DIAM E TE R X WIDTH (INCHE S) 10” x 9” 10” x 9” 10” x 10” 10” x 10” 11” x 10”

BLOWER RATED SCF M COOLING 1200 12 00 1300 1300 155 0

MAX EXTERNAL STATIC PRESS ("w.c.) 0.5 0.5 0.5 0.5 0.5

EVAPORATOR FACE AREA - SQ. FT. 4.33 4.33 5.67 5.67 5.67

COIL NUMBER OF ROWS 44444

FINS PER INCH 14 1 4 14 14 14

FILTER SIZE - SQ. FT.

DRA IN SIZE (I NC HES) 3/4 3 /4 3/4 3/ 4 3/ 4

HEATING PRIMARY LIMIT SETTING (°F) 160 160 170 170 170

LIMITS AUXILIARY LIMIT SETTING (°F) 150 150 150 150 150

ROLLOUT LIMIT SETTING (°F) 350 350 350 350 350

GENERAL PISTON EXPANSION DEVICE Orifice (.068) Orifice (.068) Orifice (.072) Orifice (.072) Orifice (.076)

INFORMATION REFRIGERANT CHARGE R-410A (Oz.) 7070999987

POWER SUPPLY ENTRANCE SIZE (INCHES) 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

LOW VOLTAGE ENTRANCE SIZE (INCHES) 7/8 7/8 7/8 7/8 7/8

SHIP PING W EIGHT LBS . 4 75 480 515 520 540

OPERATING WEIGHT LB S. 453 4 58 493 496 51 8

(1 ) Units installed in Canada are certifed only to 4500 feet.

(2) Calculated external filter size based on air velocity of 300 ft/min. and applies to disposable filters only.

(3 ) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/

circuit breakers in accordance with the National Electrical Code and/or all local codes.

(2)

4.2 4.2 4.7 4.7 5.1

DP13GM36090

DP13GM[36-48]***41A*

41A*

DP13GM42070

41A*

DP13GM42090

41A*

DP13GM48070

41A*

11

P ACKAGE GAS SPECIFICATIONS

DP13GM48090

41A*

COOLING C OO L ING CAPA C ITY, BTUH 46, 0 00 46, 00 0 5 7 ,000 57,000 57,0 00

CAPACITY SEER / EER 13.0 / 11.0 13.0 / 11.0 13.0 / 10.75 13.0 / 10.75 13.0 / 10.75

HEATING INPUT BTUH (U.S. & CANADIAN) 92,000 115,000 92, 000 115,000 138,000

HEATING HE ATING OUTPUT BTUH (U.S. & CANADIAN) 73,600 92,000 73,600 92,000 110,400

CAPACITY AFUE (%) 8080808080

TEMPERATURE RIS E (°F) 45 - 75 45-75 45 - 75 45 - 75 45 - 75

UNIT VOLTAGE (NAMEPLATE) 208/230 208/230 208/230 208/ 230 208/ 230

ELECTRICAL UNIT AMP S (TOTAL) 27.1 27.1 35.4 35.4 35.4

SPECIFICATION MINIMUM CIRCUIT A MP ACITY 32. 1 32.1 42.0 42.0 42.0

MA XIMUM OVERCURRENT PROTECTION 50 50 60 60 60

HEATING NUMBER OF B URNERS 4 5 4 5 6

SECTION ORIFICE SIZE NATURAL 4343434343

ORIFICE SIZE LP 55 55 55 55 55

COMPRESSOR TYPE Scroll Scroll Scroll Scroll Scroll

RATED LOAD AMPS 19.9 19.9 26.4 26.4 26.4

LOCKED ROTOR AMPS 109.0 109.0 134.0 134.0 134.0

CONDENSER HORSEPOWER 1/4 1/4 1/4 1/4 1/4

FAN MOTOR RPM 11001100110011001100

FULL LOAD AMPS 1. 4 1.4 1. 4 1.4 1.4

LOCKED ROTOR AMPS 2.9 2.9 2.9 2.9 2.9

CONDENSER BLADE DIAM ETER (INCHES) 22 22 22 22 22

FAN NUMBER OF BLADES 3 3 3 3 3

CFM 35003500350035003500

CONDENSER FACE AREA - SQ. F T. 15.3 15.3 11.3 11.3 11.3

COIL NUMB E R OF ROWS 1 1 2 2 2

FINS PE R INCH 24 24 27 27 27

EVAPORATOR HOR S EPOWE R - NO. OF S P EEDS 3/4 - 5 3/4 - 5 1 - 5 1 - 5 1 - 5

BLOWER FULL LOAD AMP S 5.8 5. 8 7.6 7.6 7.6

MOTOR LOCK ED ROTOR AMPS -- -- -- -- --

MOTOR SPEED TAP - COOLING T4 T4 T4 T4 T4

RPM 10501050105010501050

EVAPORATOR DIAMETER X WIDTH (INCHES) 11” x 10” 11” x 10” 11” x 10” 11” x 10” 11” x 10”

BLOWER RATED SCFM COOLING 15501550175017501750

MAX EXTERNAL STATIC PRESS ("w.c.) 0.5 0.5 0.5 0.5 0.5

EVAPORATOR FACE AREA - SQ. FT. 5.67 5.67 5.67 5.67 5.67

COIL NUMB E R OF ROWS 4 4 4 4 4

FINS PE R INCH 14 14 14 14 14

FILTER SIZE - SQ. FT.

DRAIN SIZE (INCHES) 3/4 3/4 3/4 3/ 4 3/4

HEATING P RIMARY LIMIT SETTING (°F) 170 170 170 170 160

LIMITS AUXILIARY LIMIT SETTING (°F) 150 150 150 150 150

ROLLOUT LIMIT S E TTING (°F) 350 350 350 350 350

GENERAL PISTON EXPANSION DEVICE Orifice (.076) Orifice (.076) Orifice (.086) Orifice (.086) Orifice (.086)

INFORMATION REFRIGERANT CHARGE R-410A (Oz.) 8787919191

POW E R SUP PLY E NTRANCE SIZE (INCHES) 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

LOW VOLTAGE ENTRANCE SIZE (INCHES) 7/8 7/8 7/8 7/8 7/8

SHIPPING WEIGHT LB S . 545 550 555 560 565

OPERATING WEIGHT LB S. 523 528 533 538 543

(1 ) Units installed in Canada are certifed only to 4500 feet.

(2) Calculated external filter size based on air velocity of 300 ft/min. and applies to disposable filters only.

(3 ) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/

circuit breakers in accordance with the National Electrical Code and/or all local codes.

( 2)

5.1 5.1 6.3 6.3 6.3

DP13GM48115

DP13GM[48-60]***41A*

41A*

DP13GM60090

41A*

DP13GM60115

41A*

DP13GM60140

41A*

12

Loading...

Loading...