Page 1

OPERATION MANUAL

CENTRAL REMOTE CONTROLLER

MODELS

DCS302C51

English

Deutsch

Français

Español

Italiano

ΕλληνικÜ

Nederlands

Portugues

Page 2

Read these instructions carefully before installation.

Keep this manual in a handy place for future reference.

This manual should be left with the equipment owner.

Lesen Sie diese Anleitungen vor der Installation sorgfältig durch.

Bewahren Sie dieses Handbuch zum späteren Nachschlagen auf.

Dieses Handbuch sollte immer im Besitz des Geräteeigentümers verbleiben.

Lisez attentivement ces instructions avant l’installation.

Rangez ce manuel dans un endroit pratique pour pouvoir vous y reporter par la suite.

Ce manuel doit être conservé par le propriétaire de l’appareil.

Lea las instrucciones atentamente antes de la iniciar la instalación.

Tenga el manual a mano para referencia futura.

Este manual debería entregarse al propietario del equipo.

Prima dell’installazione, leggere queste istruzioni con attenzione.

Tenere a portata di mano il presente manuale per potervi fare riferimento in futuro.

Il manuale deve sempre essere consegnato al proprietario dell’apparecchiatura.

Πριν απü την εγκατÜσταση διαβÜστε προσεκτικÜ αυτÝò τιò οδηγßεò.

ΦυλÜξτε αυτü το εγχειρßδιο σε βολικü ìÝροò για ìελλοντικÞ αναφορÜ.

Το εγχειρßδιο αυτü πρÝπει να δοθεß στον ιδιοκτÞτη του εξοπλισìοý.

Lees deze instructies aandachtig door voordat u het product installeert.

Bewaar deze handleiding goed zodat u deze later opnieuw kunt doorlezen.

Overhandig deze handleiding aan de eigenaar van de apparatuur.

Antes da instalação, leia atentamente as presentes instruções.

Guarde o presente manual num local acessível para consulta futura.

O presente manual deve ser deixado com o proprietário do equipamento.

Page 3

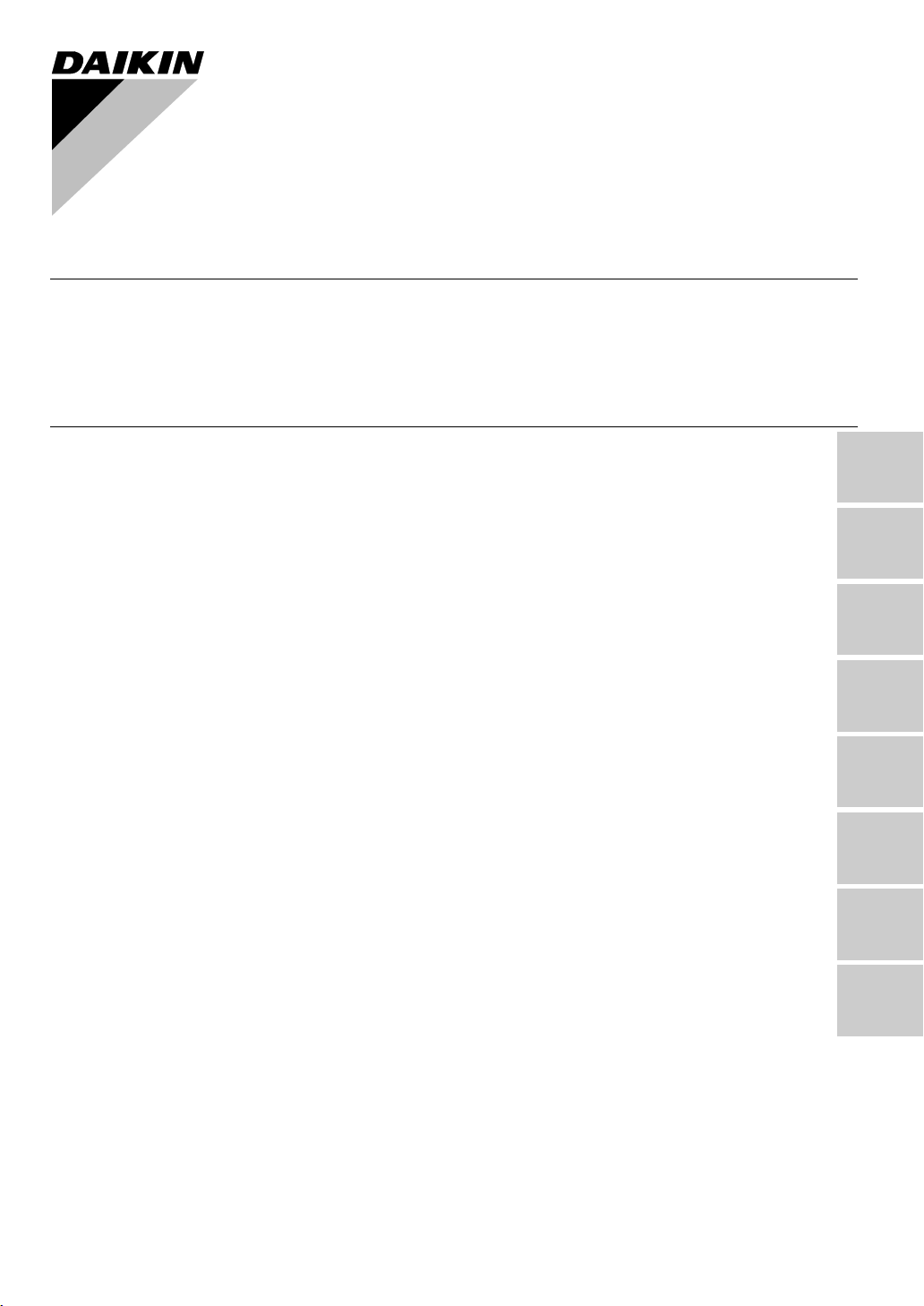

( 5 ) ( 6 ) ( 7 )

( 4 )

( 1 ) (11)( 3 )( 9 )(10)

( 2 )

(12)

( 8 )

1

(23)

(37)

(24)

ALL

INDIVIDUALLY

F

SET

NOT

AVAILABLE

C

L

FRESH UP

H

(16) (17) (15) (19)

(25)

(26) (28) (29) (30) (31)

OPTION

TEST

HH

12

No.

CODE

UNIT No.

(18) (22)

(13)

(14)

(20)

(21)

(36) (35) (27) (34) (33) (32)

2

2

INDIVIDUALLY

C

L

1

3

4

ALL

4

3

5

1

2

7

6

[1]

Page 4

4

2

INDIVIDUALLY

C

L

5

1

3

7

6

8

5

2

9

5

1

6

3

4

7

8

6

2

C

4

1

3

6

5

7

7

[2]

4

2

INDIVIDUALLY

C

L

5

1

3

6

8

Page 5

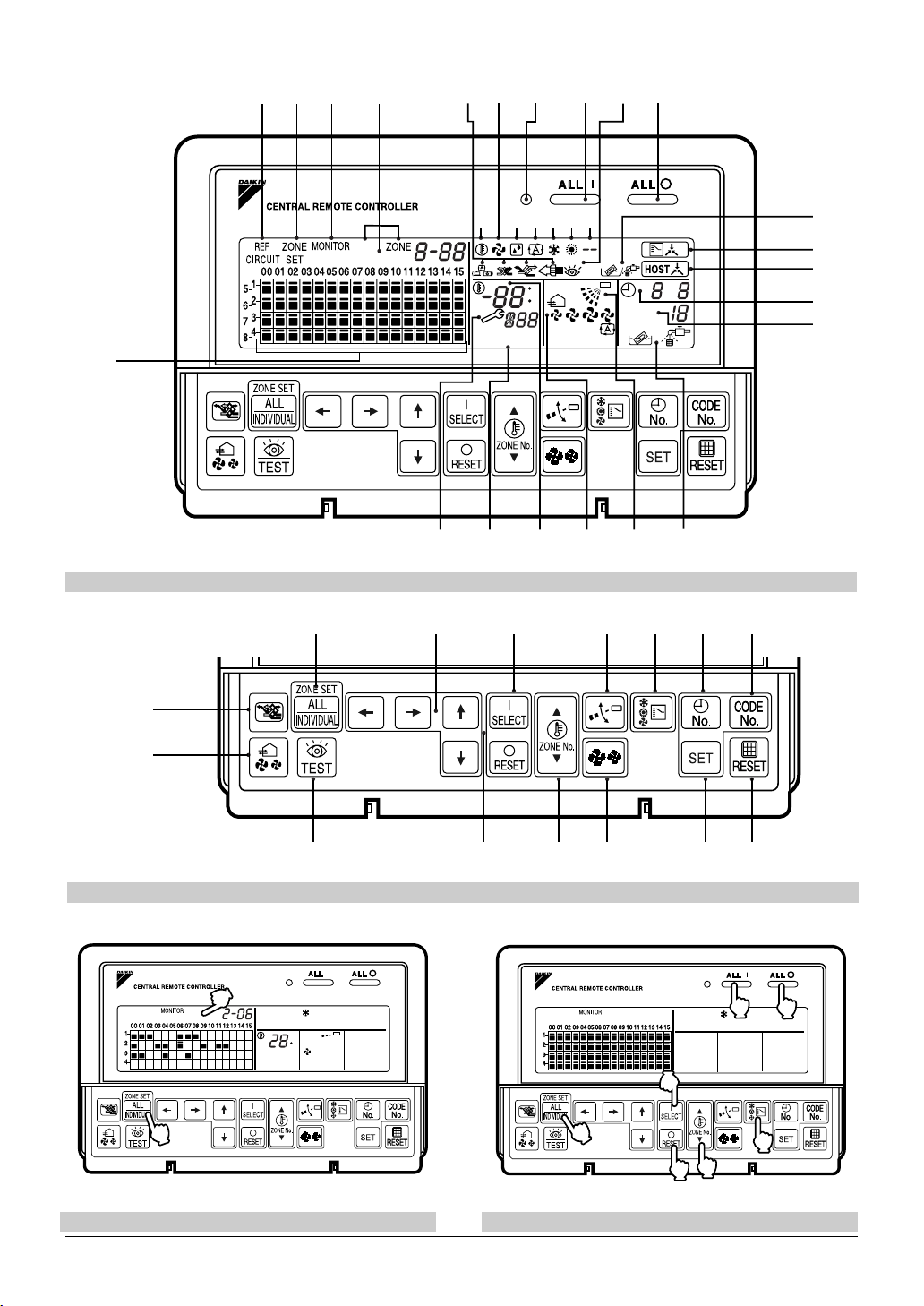

BEFORE USE

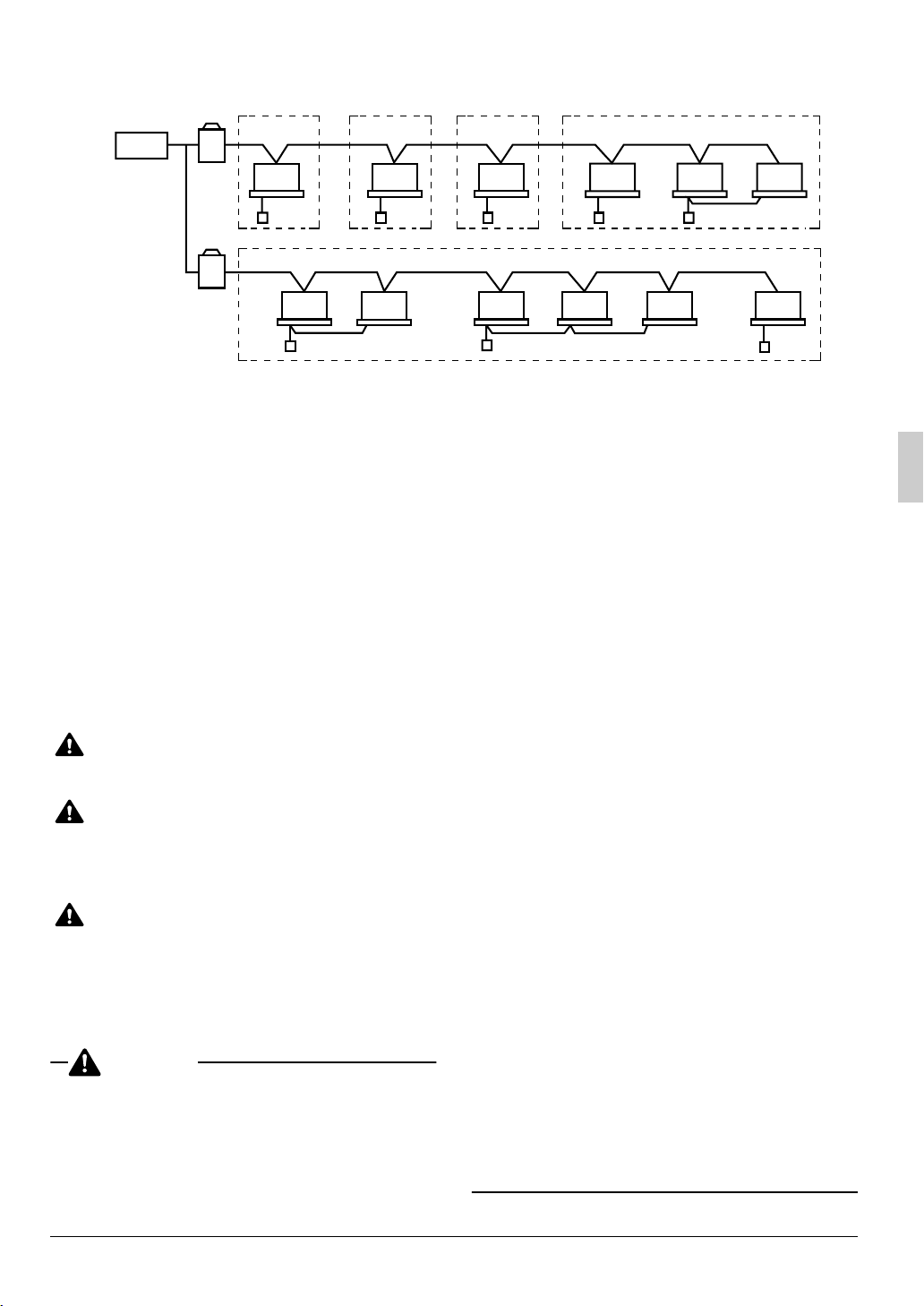

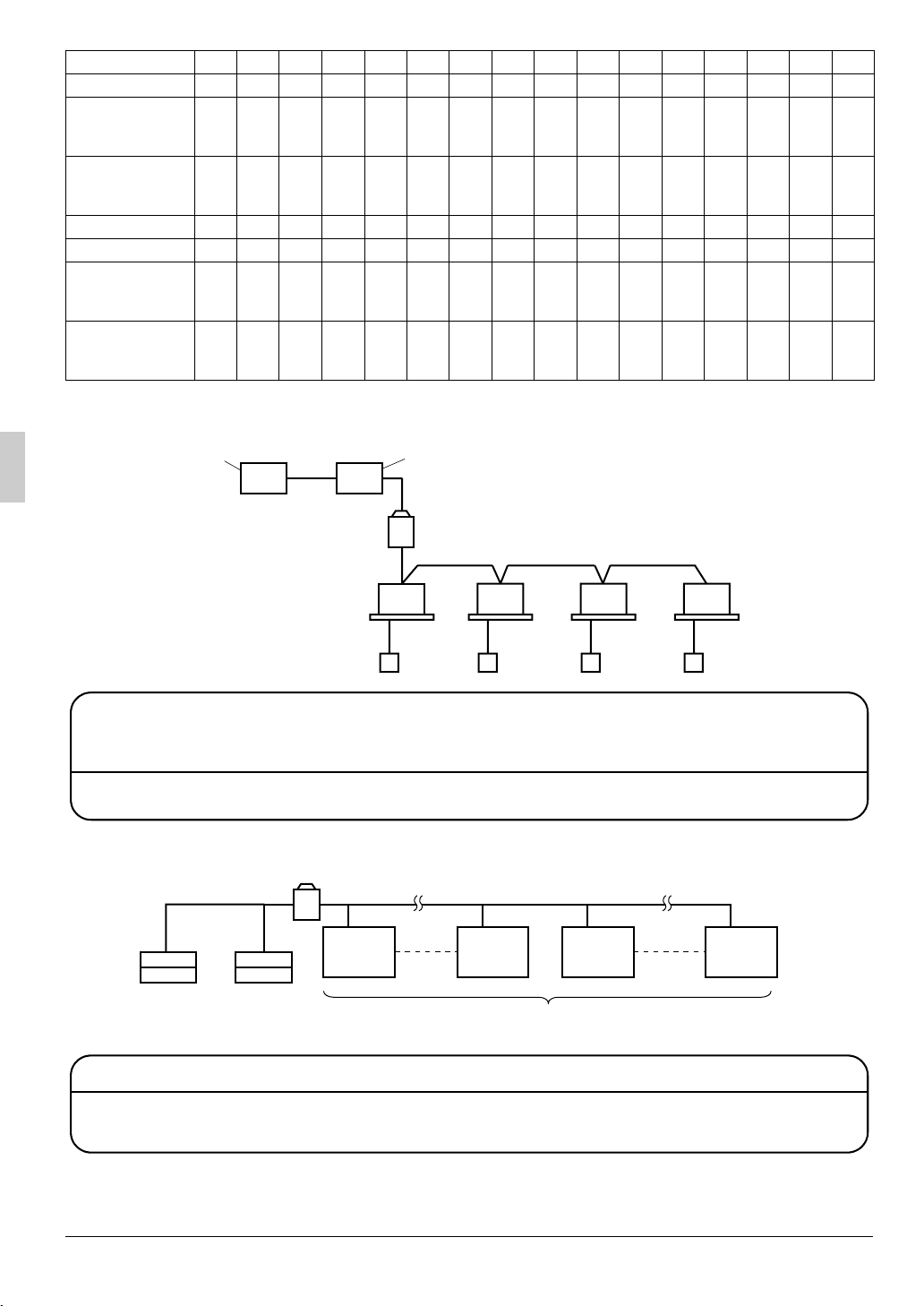

䡲䡲䡲䡲 GENERAL DESCRIPTION OF SYSTEM

This central remote controller can monitor and control up to 64 indoor unit groups.

Using two central remote controllers allows monitoring and controlling of up to 128 indoor unit groups.

Main Functions

Batch starting and stopping of indoor units connected to the central remote controller.

1.

Handling of operation settings such as start/stop, timer operation, remote controller prohibition/permission, etc.,

2.

and operation status settings such as temperature.

Operation status monitoring of operation mode, set temperature, etc.

3.

Can be connected to an external central monitor panel and key system using the forced stop input

4.

(non-voltage a connector).

• When using 1 central remote controller

Outdoor unit

Forced

Host computer

monitor panel,

etc.

• When using 2 central remote controllers

ON/OFF

command

Central remote

controller

Group No.

1–00

Outdoor unit

Group No.

A maximum of 64 groups

1–15

Group No.

2–00

Group No.

4–15

Host computer

monitor panel,

etc.

Central

remote

controller

Forced ON/OFF command

Forced ON/OFF command

should be connected

to one of the two units.

Group No.

1–00

Group No.

5–00

Group No.

Group No.

A maximum of 128 groups

1–15

5–15

Group No.

2–00

Group No.

6–00

Group No.

4–15

Group No.

8–15

(The central remote controller and the separately sold remote control adapter circuit board or group remote control adapter cannot be used together.)

∗ GROUP OF INDOOR UNIT refers to the below.

A single indoor unit without remote controller

1.

1. A single indoor unit without

remote controller

Indoor unit

Remote controller not used

2. A single indoor unit controlled by

one or two remote controllers

Remote

controller

Two remote

controllers

3. Maximum of 16 indoor units, group-controlled by one or two remote controllers

Remote

controller

A maximum of 16 units A maximum of 16 units

Two remote

controllers

1 English

Page 6

∗ Zone control from the central remote controller

Zone control is available from the central remote controller. With it, it is possible to make unified settings for multiple groups, so setting operations are greatly simplified.

Zone 1

Central

remote

controller

Zone 5

Outdoor

units

Zone 2 Zone 3 Zone 4

• Any setting you make within a given zone will apply to all groups in the said zone.

• A maximum of 64 zones can be set from a single central remote controller.

(Each zone contains a maximum of 64 groups.)

• Zones can be set randomly from the central remote controller.

SAFETY CONSIDERATIONS

Please read these “SAFETY CONSIDERATIONS”

carefully before installing air conditioning equipment

and be sure to install it correctly.

After completing the installation, make sure that the

unit operates properly during the start-up operation.

Please instruct the customer on how to operate the unit

and keep it maintained.

Also, inform customers that they should store this installation

manual along with the operation manual for future reference.

This air conditioner comes under the term “appliances

not accessible to the general public”.

Meaning of warning, caution and note symbols.

WARNING

CAUTION .... Indicates a potentially hazardous

NOTE........... Indicates situation that may result

Keep these warning sheets handy so that you can

refer to them if needed.

Also, if this equipment is transferred to a new user, make

sure to hand over this operation manual to the new user.

WARNING

In order to avoid electric shock, fire or injury, or if you

detect any abnormality such as smell of fire, turn off

power and call your dealer for instructions.

Ask your dealer for installation of the air conditioner.

Incomplete installation performed by yourself may

result in a water leakage, electric shock, and fire.

....Indicates a potentially hazardous sit-

uation which, if not avoided, could

result in death or serious injury.

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

in equipment or property-damageonly accidents.

Ask your dealer for improvement, repair, and maintenance.

Incomplete improvement, repair, and maintenance may

result in a water leakage, electric shock, and fire.

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Be sure only

to use accessories made by Daikin which are specifically

designed for use with the equipment and have them

installed by a professional.

Ask your dealer to move and reinstall the air conditioner or the remote controller.

Incomplete installation may result in a water leakage,

electric shock, and fire.

Never let the indoor unit or the remote controller get wet.

It may cause an electric shock or a fire.

Never use flammable spray such as hair spray,

lacquer or paint near the unit.

It may cause a fire.

Never replace a fuse with that of wrong ampere

ratings or other wires when a fuse blows out.

Use of wire or copper wire may cause the unit to

break down or cause a fire.

Never inspect or service the unit by yourself.

Ask a qualified service person to perform this work.

Cut off all electric waves before maintenance.

Do not wash the air conditioner or the remote

controller with excessive water.

Electric shock or fire may result.

Do not install the air conditioner or the remote controller

at any place where flammable gas may leak out.

If the gas leaks out and stays around the air conditioner, a fire may break out.

Do not touch the switch with wet fingers.

Touching a switch with wet fingers can cause electric shock.

CISPR 22 Class A Warning:

This is a class A product. In a domestic environment this product may cause radio interference in which case the user may

be required to take adequate measures.

English 2

Page 7

CAUTION

After a long use, check the unit stand and fitting

for damage.

If they are left in a damaged condition, the unit may

fall and result in injury.

Do not allow a child to mount on the unit or avoid

placing any object on it.

Falling or tumbling may result in injury.

Do not let children play on and around the unit.

If they touch the unit carelessly, it may result in injury.

Do not place a flower vase and anything containing water.

Water may enter the unit, causing an electric shock or fire.

Never touch the internal parts of the controller.

Do not remove the front panel. Some parts inside are dangerous to touch, and a machine trouble may happen.

For checking and adjusting the internal parts, contact

your dealer.

Avoid placing the controller in a spot splashed

with water.

Water coming inside the machine may cause an electric

leak or may damage the internal electronic parts.

Do not operate the air conditioner when using a

room fumigation - type insecticide.

Failure to observe could cause the chemicals to become

deposited in the unit, which could endanger the health of

those who are hypersensitive to chemicals.

Safely dispose of the packing materials.

Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

Tear apart and throw away plastic packaging bags so

that children will not play with them. If children play

with a plastic bag which was not torn apart, they face

the risk of suffocation.

Do not turn off the power immediately after stopping operation.

Always wait at least five minutes before turning off the

power. Otherwise, water leakage and trouble may occur.

The appliance is not intended for use by young

children or infirm persons without supervision.

The remote controller should be installed in

such away that children cannot play with it.

NOTE

Never press the button of the remote controller

with a hard, pointed object.

The remote controller may be damaged.

Never pull or twist the electric wire of the remote

controller.

It may cause the unit to malfunction.

Do not place the controller exposed to direct sunlight.

The LCD display may get discolored, failing to display the data.

Do not wipe the controller operation panel with

benzine, thinner, chemical dustcloth, etc.

The panel may get discolored or the coating peeled

off. If it is heavily dirty, soak a cloth in water-diluted

neutral detergent, squeeze it well and wipe the panel

clean. And wipe it with another dry cloth.

Dismantling of the unit, treatment of the refrigerant, oil and eventual other parts, should be done

in accordance with the relevant local and

national regulations.

CONTENTS

BEFORE USE

GENERAL DESCRIPTION OF SYSTEM .............. 1

SAFETY CONSIDERATIONS

FEATURES AND FUNCTIONS

..................................................... 1

....................... 2

.................... 4

NAMES AND FUNCTIONS OF THE

OPERATING SECTION

OPERATION

Individual screen, all screen, zone screen ............. 6

Batch operation and stop method ........................ 7

Group operation and stop method ......................... 7

Registering zones................................................... 7

Zone operation and stop method .......................... 8

Changing the fan direction and fan strength .......... 9

Changing the ventilation mode and ventilation

strength .................................................................. 9

Timer Number Setting ............................................ 9

Setting the Operation Code.................................. 10

........................................................ 6

OPERATION MODE

3 English

................................... 5

....................................... 11

Setting operation mode .........................................14

Group monitoring .................................................14

Error diagnosing function ....................................15

Setting master remote controller ..........................18

Display of time to clean.........................................19

INSTALLATION TABLE

OPTIONAL ACCESSORIES

................................ 20

......................... 21

DOUBLE CENTRAL REMOTE

CONTROLLERS ............................................... 21

SPECIFICATIONS

Specifications .......................................................22

Outline drawings ..................................................22

Fig. 1, 2, 3, 4.............................................................[1]

Fig. 5, 6, 7, 8.............................................................[2]

Fig. 9, 10, 11, 12.......................................................[3]

Fig. 13, 14, 15, 16.....................................................[4]

............................................ 22

Page 8

FEATURES AND FUNCTIONS

n

Operation menu

This central remote controller can operate and stop machines by

either group or zone.

Batch operation and batch stop functions are also available. When

used in combination with the schedule timer (optional accessory),

timer operation and stop functions are available.

n

Various operation modes.

You can operate the system from both this unit and the remote

controller, so to enable various operation control patterns. Twenty

different operation modes are available including five operation

patterns:

1. Start/stop: remote controller prohibition, remote

controller stop-only permission, central

priority, after-press priority, remote controller

permission timer

2. Operation modes: remote controller prohibition, remote

controller permission

3. Set temperature: remote controller prohibition, remote

controller permission

n

Zone control for simpler setting procedures

You can control a maximum of 64 groups of indoor units by using

this central remote controller. You don’t have to repeat the same

setting operations by group because you can make each of the

following settings by zone.

A functions is available for setting all groups in one batch.

l

Operation mode

l

Control mode

l

Setting temperature

l

Programming time No. (Used in conjunction with the

schedule timer)

See page

6—10.

See page

11—13.

See page

6—14.

n

Monitoring all indoor unit information

The following information can be displayed by group.

l

Operation information such as operation mode, set

temperature, etc., for indoor units

l

Maintenance information such as cleaning signs for filters

or elements

l

Error codes and other malfunction diagnosis information

n

Function of refrigerant system display

This display helps you understand, at a glance, the indoor units

sharing the same outdoor unit and the particular indoor unit

among them that is set as the master remote controller.

• Room air conditioners and multi-purpose air conditioners may also be connected by using separately-sold

adapter boards.

This may limit functionality, so consult the manuals that come with each adapter board.

English 4

See page

14—19.

See page 18.

Page 9

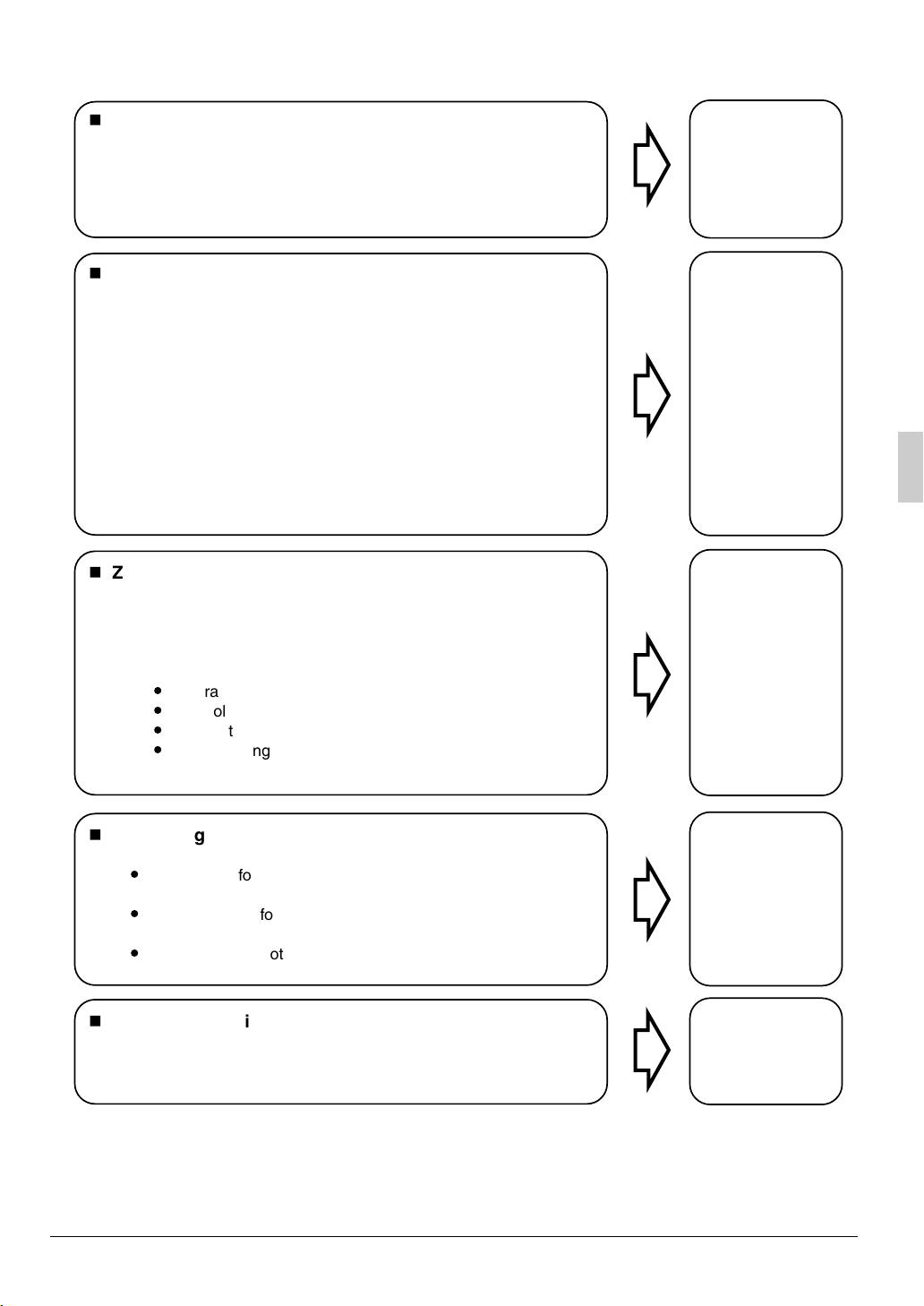

NAMES AND FUNCTIONS OF THE OPERATING SECTION (Fig. 1, 2)

H

UNIFIED OPERATION BUTTON

1

Press to operate all indoor units.

UNIFIED STOP BUTTON

2

Press to stop all indoor units.

OPERATION LAMP (RED)

3

Lit white any of the indoor units under control is

in operation.

“” DISPLAY (REFRIGERANT

SYSTEM DISPLAY)

4

This indication in the square is lit while the

refrigerant system is being displayed.

“” DISPLAY (ZONE SETTING)

5

The lamp is lit while setting zones.

“” DISPLAY (OPERATION

6

MONITOR)

The lamp is lit while operation is being monitored.

ALL

“” “” “” DISPLAY

The status displays indicates either batch

7

functions or which zone or individual unit

(or group) are being used.

INDIVIDUALLY

OPERATION MONITOR

8

Each square displays the state corresponding to

each group.

“” “” “” “” “” “” “”

9

DISPLAY (OPERATION MODE)

Displays operating state.

“” “” “” “” DISPLAY

(VENTILATION CLEANING DISPLAY)

10

This is displayed when a Ventiair total enthalpy

heat exchanger unit or other such unit is

connected.

TEST

“”

Pressing the maintenance/test run button

11

(for service) displays this. This button should not

normally be used.

“”

12

It lights up when any individual unit (group) has

reached the time for the filter or element to be

cleaned.

DISPLAY (INSPECTION/TEST)

DISPLAY (TIME TO CLEAN)

“”

DISPLAY (COOLING/HEATING

SELECTION PRIVILEGE NOT SHOWN)

13

For zones or individual units (groups) for which

this is displayed, cooling and heating cannot be

selected.

“” DISPLAY (UNDER HOST

COMPUTER INTEGRATED CONTROL)

14

While this display is lit up, no settings can be

made. It lights up when the upper central

machines are present on the same air

conditioning network.

“” DISPLAY

SET

15

(PRESET TEMPERATURE)

Displays the preset temperature.

C

“” DISPLAY (MALFUNCTION

CODE)

16

This displays (flashes) the content of errors

when an error failure has occurred.

In maintenance mode, it displays the latest error

content.

“NOT AVAILABLE” DISPLAY

(NO FUNCTION DISPLAY)

17

If a function is not available in the indoor unit

even if the button is pressed, “NOT AVAILABLE”

is may be displayed for a few seconds.

“” DISPLAY

(FAN DIRECTION SWING DISPLAY)

18

This displays whether the fan direction is fixed

or set to swing.

“”

“” “” “” “” “”

DISPLAY (VENTILATION

19

STRENGTH/SET FAN STRENGTH

H

L

HH

FRESH UP

DISPLAY)

This displays the set fan strength.

“” DISPLAY (TIME NO.)

No.

20

Displays the operation timer No. when used in

conjunction with the schedule timer.

5 English

Page 10

CODE

UNIT No.

“” DISPLAY (OPERATION

CODE AND UNIT NUMBER DISPLAY)

The method of operation (remote controller

21

prohibited, central operation priority after-press

operation priority, etc.) is displayed by the

corresponding code.

This displays the numbers of any indoor units

which have stopped due to an error.

“” “” DISPLAY (TIME TO

CLEAN AIR CLEANER ELEMENT/

TIME TO CLEAN AIR FILTER)

22

Displayed to notify the user it is time to clean the

air filter or air cleaner element of the group

displayed.

VENTILATION MODE BUTTON

23

This is pressed to switch the ventilation mode of

the total enthalpy heat exchanger.

ALL/INDIVIDUAL BUTTON

24

Pressing this button scrolls through the “all

screen”, “zone screen”, and “individual screen”.

ARROW KEY BUTTON

25

This button is pressed when calling an individual

indoor unit or a zone.

ON/OFF BUTTON

26

Starts and stops ALL, ZONE, and INDIVIDUAL

units.

TEMPERATURE ADJUSTMENT

BUTTON (ZONE NUMBER BUTTON)

27

This button is pressed when setting the

temperature. Select the zone number if any

zones have been registered.

FAN DIRECTION ADJUSTMENT

BUTTON

28

This button is pressed when setting the fan

direction to “fixed” or “swing”.

OPERATION MODE SELECTOR

BUTTON

29

This sets the operation mode. The dry setting

cannot be done.

TIME NO. BUTTON

30

Selects time No. (Use in conjunction with the

schedule timer only).

CONTROL MODE BUTTON

31

Selects control mode.

FILTER SIGN RESET BUTTON

32

This button is pressed to erase the “clean filter”

display after cleaning or replacement.

SET BUTTON

33

Sets control mode and time No.

FAN STRENGTH ADJUSTMENT

BUTTON

34

Pressing this button scrolls through “weak”,

“strong”, and “fast”.

ZONE SETTING BUTTON

Zone registration mode can be turned on and off

35

by pressing the start and stop buttons simultaneously for at least four seconds.

INSPECTION/TEST RUN BUTTON

(FOR SERVICE)

36

Pressing this button scrolls through “inspection”,

“test run”, and “system display”.

This button is not normally used.

VENTILATION STRENGTH

ADJUSTMENT BUTTON

37

This button is pressed to switch the ventilation

strength (“fresh up”) of the total enthalpy heat

exchanger.

(Notes)

1. Please note that all the displays in the figure

appear for explanation purposes or when the

cover is open.

2. If the unit is used in conjunction with other optional

central controllers, the OPERATION LAMP of the

unit that is not under operation control may light

up and go out a few minutes behind schedule.

This shows that the signal is being exchanged,

and does not indicate any failure.

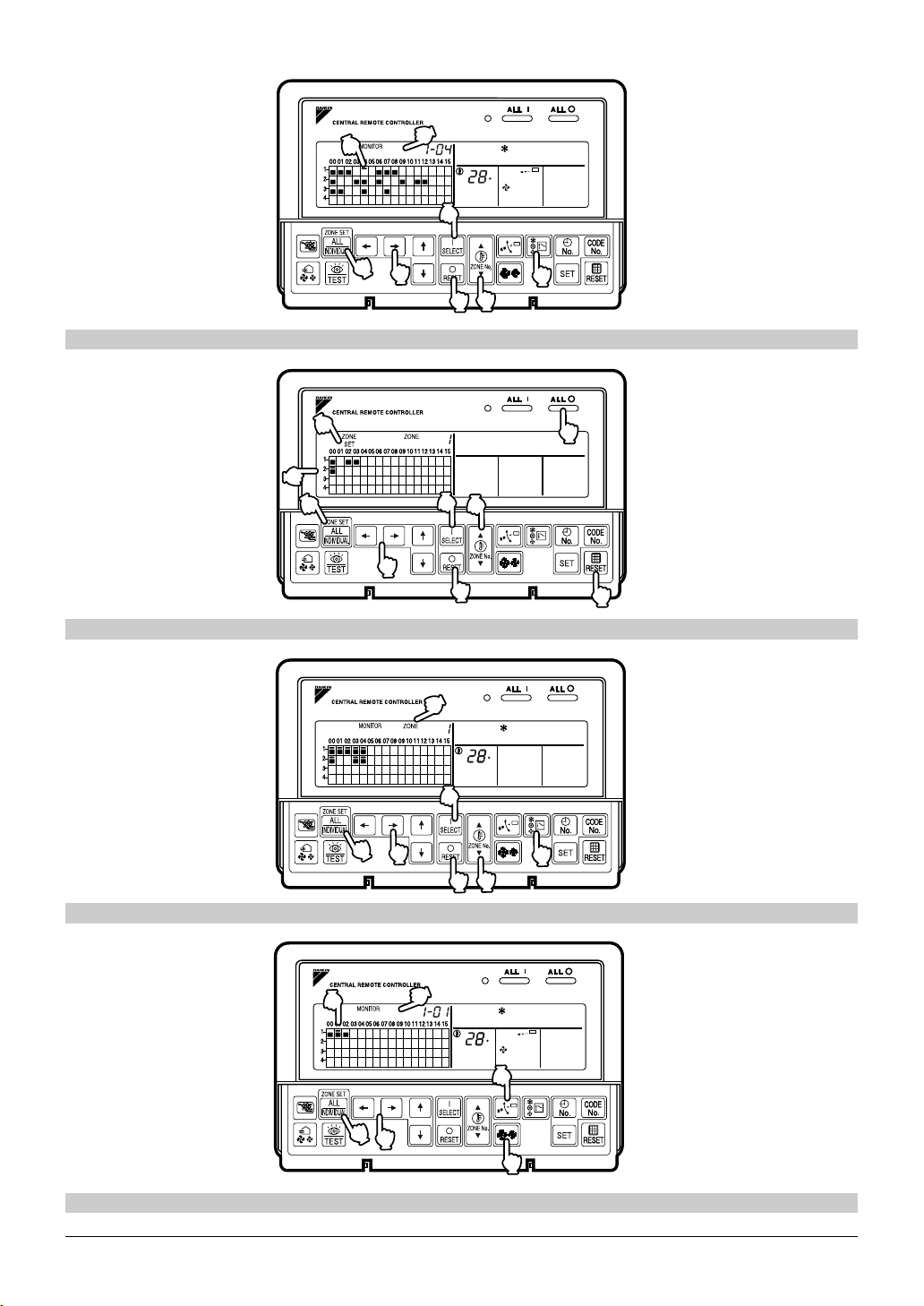

OPERATION

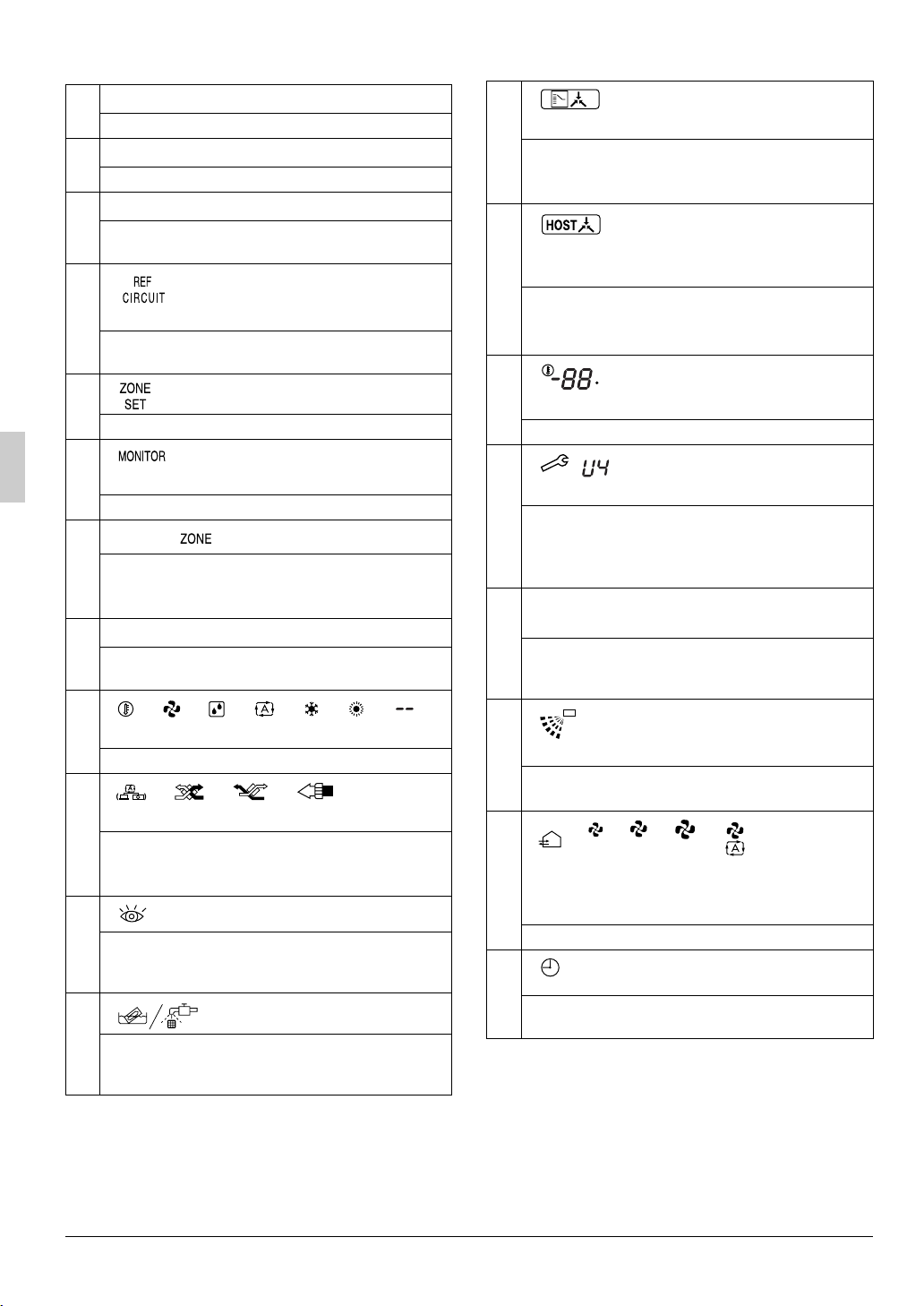

䡲䡲䡲䡲 Individual screen, all screen,

zone screen (Fig. 3)

This controller can perform operations in the individual

screen, all screen, or zone screen.

• Individual screen The individual screen is used

• All screen The all screen is used when per-

• Zone screen The zone screen is used when

1

1.

Select the screen by pressing the

“ALL/INDIVIDUAL” button.

2

Every time the “ALL/INDIVIDUAL” button is

pressed, the selection scrolls through INDIVIDUAL

→ ALL → ZONE.

If nothing is done in the all or zone screens for one

minute, it automatically goes to the individual

screen.

when performing group operations.

forming operations for all units at

once.

performing zone operations.

English 6

Page 11

• If the zone number in the zone screen is displayed as “---,” this indicates that no units are

registered in a zone.

Please perform zone registration before proceeding in the zone screen. (See page 7)

䡲䡲䡲䡲 Batch operation and stop method

(Fig. 4)

This is for operating or stopping all connected units at

once.

A. What to do when operating or stopping all

connected units at once.

1.

Press either “” or

2

“”.

• Operation can be performed from the individual screen, the all screen, or the zone

screen.

• The “TEMPERATURE ADJUSTMENT” and

“OPERATION MODE SELECTOR” buttons

cannot be used.

To set the temperature and operation mode,

use B. batch operation.

B. Batch Operation

3

1.

Press the “ALL/INDIVIDUAL button” to

enter the all screen.

The “” display lights up on all registered units.

4

2.

3.

Press the “SELECT” button.

The “” display lights up on all connected units.

5

Press the “RESET” button.

The “” display goes off on all connected units.

Operation and stop in the batch screen are done

the same as with the batch operation and batch

stop buttons.

6

Press the “TEMPERATURE ADJUST-

MENT” button.

The temperature rises 1° every time

the ( ) button is pressed.

The temperature drops 1° every time

the ( ) button is pressed.

Set to “” when you do not wish to use batch

setting for the temperature setting.

Setting to 1° above or below the temperature

setting range displays “”.

7

4.

Call up the desired mode by pressing

the “OPERATION MODE SELECTOR” button.

Set to “” when you do not wish to use batch set-

ting for the operation setting.

1

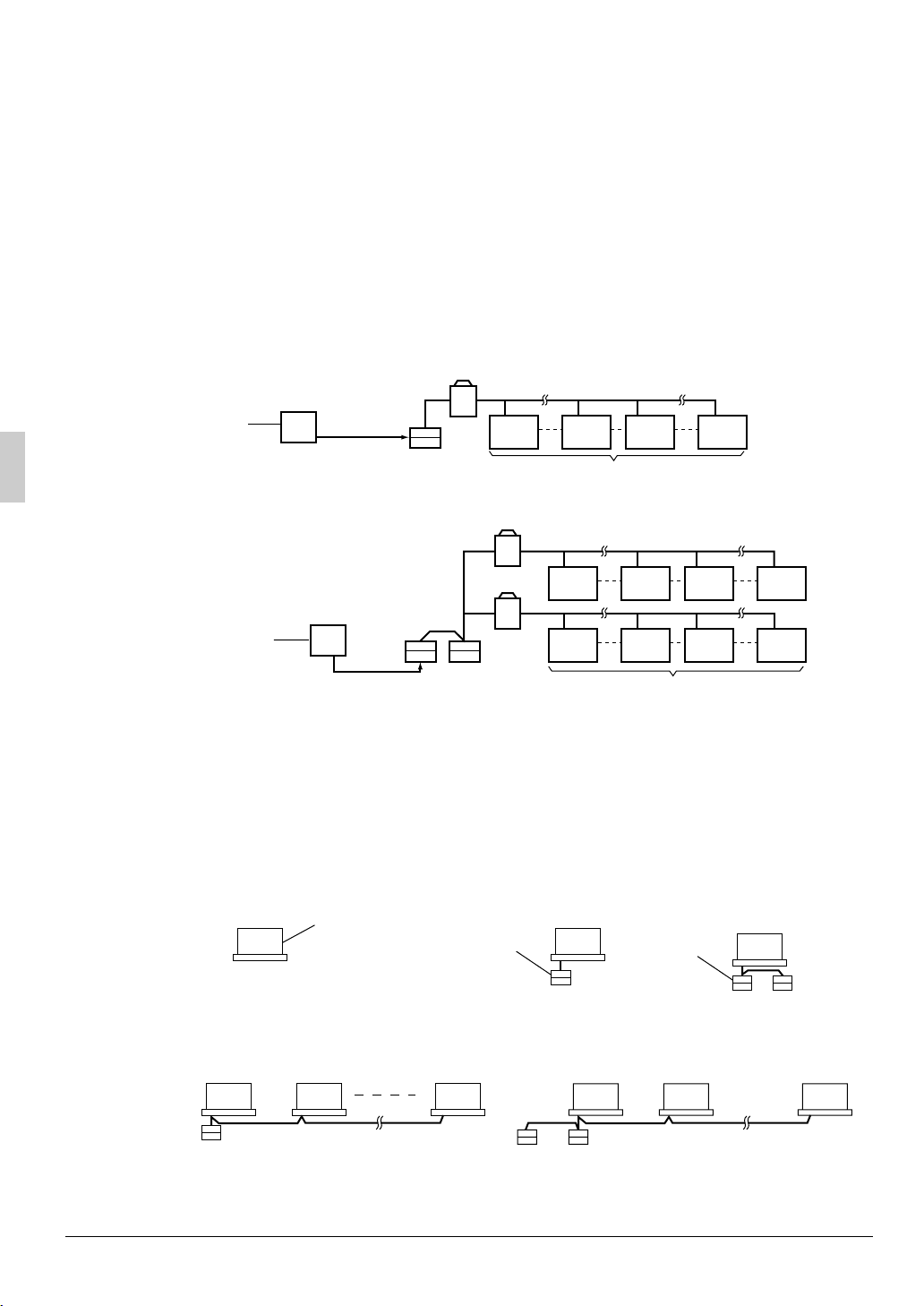

䡲䡲䡲䡲 Group operation and stop method

(Fig. 5)

This is for operating or stopping connected units in

groups.

[Group operation]

1.

Press the “ALL/INDIVIDUAL button”

to enter the individual screen.

The unit will enter the individual screen automatically if nothing is done for one minute.

3

2.

3.

4.

Using the arrow keys, move the

to select the units to operate or stop.

“”

Keeping the button pressed down will move it

rapidly.

The “” in this screen has selected unit 1-04.

5

Press the “SELECT” button.

The “” display lights up in the group.

6

Press the “RESET” button.

The “” display goes off in the group.

7

Press the “TEMPERATURE ADJUST-

1

2

4

MENT” button.

The temperature rises 1° every time the

( ) button is pressed.

The temperature drops 1° every time the

( ) button is pressed.

Temperature adjustment cannot be done if the

selected group’s air conditioners are in fan mode.

8

5.

Call up the desired mode by pressing

the “OPERATION MODE SELECTOR” button.

䡲䡲䡲䡲 Registering zones (Fig. 6)

It is possible to set multiple groups as one zone and

control each zone separately.

No zones are registered when the unit is shipped from

the factory.

Zone registration can be done in the individual screen,

all screen, or zone screen.

[Registration]

1

1.

Pressing the “ALL/INDIVIDUAL”

button for four seconds. Displays

2

ZONE SET.

Zone Number 1 will be displayed, and if there are

any groups already registered in the displayed

zone, a “” will light up on the operation monitor.

7 English

Page 12

3

2.

Select the Zone Number to be regis-

tered using the “ZONE NUMBER” button.

Keeping the button pressed down will move it

rapidly.

5

3.

to the group you wish to reg-

“”

ister using the arrow keys.

Keeping the button pressed down will move it

rapidly.

6

4.

Press the “SELECT” button to register

that group to the zone.

The “” display lights up on all the selected

units.

7

Pressing the “RESET” button removes

the group from that zone, and “” goes

off.

Repeat steps 3 and 4 until all the units you wish to

register to the zone have been added.

[Batch deletion of zone registration]

9

1.

Pressing the “” for at least

four seconds while pressing the “FIL-

8

TER SIGN RESET” button when

2

4

“ZONE SET” is displayed will delete all

zone registrations.

The zone registrations for all units will be lost.

䡲䡲䡲䡲 Zone operation and stop method

(Fig. 7)

This is for operating or stopping connected units in

zones.

[Zone operation]

1

1.

2.

Press the “ALL/INDIVIDUAL button” to

enter the zone screen.

3

Using the arrow keys, select the zone

number to operate or stop.

Pressing and reduces the zone number

2

In this example, a screen is shown with

units 1-00, 1-02, 1-03, and 2-00 registered

to Zone Number 1.

5.

Repeat steps 2 to 4 to register to the next

zone.

6.

Once zone registration is complete,

1

press the “ALL/INDIVIDUAL” button to

turn off “ZONE SET” display and return to

the individual screen.

The display returns to the normal screen if nothing

is done for one minute when in zone registration

mode.

(NOTE)

• It is impossible to register one group to several

different zones.

If this is done, the last zone registered to will be

valid.

while and raise the number.

Keeping the button pressed down will move it

rapidly.

• If the zone number is displayed as “---,” this

indicates that no units are registered in a

zone. Please perform zone registration

before using a zone. (See page 7)

4

3.

4.

Press the “SELECT” button.

The “” display lights up in the group.

5

Press the “RESET” button.

The “” display goes off in the group.

6

Press the “TEMPERATURE ADJUST-

MENT” button.

The temperature rises 1° every time the ( ) button is pressed.

The temperature drops 1° every time the ( ) button is pressed.

Set to “” when you do not wish to use zone

setting for the temperature setting.

Setting to 1° above or below the temperature

setting range displays “”.

7

5.

Call up the desired mode by pressing

the “OPERATION MODE SELECTOR” button.

Set to “” when you do not wish to use zone set-

ting for the operation mode.

English 8

Page 13

䡲䡲䡲䡲 Changing the fan direction and fan

L

strength (Fig. 8)

This changes the fan direction and strength settings in

the air conditioner.

Changing the fan direction and strength is done in the

individual screen.

[Registration]

1

1.

Press the “ALL/INDIVIDUAL button”

to enter the individual screen.

2

The unit will enter the individual screen automatically if nothing is done for one minute.

3 4

2.

Using the arrow keys, move the

to select the units to fan direction

“”

adjustment or fan strength adjustment.

Keeping the button pressed down will move it

rapidly.

5

3.

Press the “FAN DIRECTION ADJUST-

MENT” button.

This sets “fixed” or “swing” for the fan direction.

6

Press the “FAN STRENGTH ADJUST-

MENT” button.

Pressing this button scrolls through “”, “”,

and “”.

HH

Depending on the indoor unit, only “” and “”

may be available.

The functions included in the indoor units may vary.

Pressing a button for a function which is not available

will cause “NOT AVAILABLE” to be displayed.

H

L

L

H

䡲䡲䡲䡲 Changing the ventilation mode and

ventilation strength (Fig. 9)

This changes the ventilation mode and strength settings in the total enthalpy heat exchanger.

Changing the ventilation mode and strength is done in

the individual screen.

[Registration]

1

1.

2.

Press the “ALL/INDIVIDUAL button” to

enter the individual screen.

The unit will enter the individual screen automatically if nothing is done for one minute.

3 4

Using the arrow keys, move the

“”

2

to select the units to ventilation

mode or ventilation strength adjustment.

Keeping the button pressed down will move it

rapidly.

5

3.

Press the “VENTILATION MODE”

button.

It will scroll through “” → “” → “”

→ “”.

6

Press the “VENTILATION STRENGTH

ADJUSTMENT” button.

It will scroll through “” → “” → “” →

H

“” → “”.

FRESH UP

L

L

H

L

FRESH UP

The fresh up function may not be available

depending on the connected unit model.

The functions included in the indoor units may vary.

Pressing a button for a function which is not available

will cause “NOT AVAILABLE” to be displayed.

• Ventilation Mode and Amount

If these are changed using the remote controller

depending on the unit model, they cannot be displayed on the central remote controller.

To monitor the ventilation mode and amount, check

the values on the remote controller.

䡲䡲䡲䡲 Timer Number Setting (Fig. 10)

(Only when used with the schedule timer)

Using this together with the schedule timer makes it

possible to set on and off times four times a day.

[Registration]

1

1.

2.

Pressing the “TIMER NO.” button

causes the number set for timer number 1

to blink.

If no timer setting has been made

“” will be displayed.

Select the desired timer number

by pressing the “TIMER NO.”

1

12

No.

button.

2

Once the desired timer number is

displayed, press the “SET” button.

Press the “SET” button

within 10 seconds after the timer

number is displayed.

The display will return to how it

was after 10 seconds.

The display for timer number 1

will stop blinking and then timer number 2 will start

blinking.

2

12

No.

9 English

Page 14

1

3.

Select the desired timer number by

pressing the “TIMER NO.” button.

Once the desired timer number is

displayed, press the “SET”

2

button.

The display for timer number 2

will stop blinking.

The “” display will disappear

No.

after 3 seconds.

Select “” in the timer number when you do not

wish to set a timer number.

It is possible to set only one timer number.

(The times for turning the unit(s) on and off twice a

day can be set with a single timer number.)

• Timer Number Setting

Group control: select the unit in the individual

screen and set the timer number.

Batch control: set the timer numbers for all con-

nected units.

Zone control: set the timer numbers for all

zone-registered units.

Call up the zones which you wish

to set in the zone screen and set

the timer numbers.

• Since the timer number will be set to afterpress priority, the timer number in the last

screen set will be valid for the connected

units.

Example 1

Setting timer number 1 for unit 1-00 to “1” and

timer number 2 to “2” in the individual screen and

then setting timer number 1 to “3” and timer

number 2 to “4” in the batch screen causes the

timer numbers for all units to be set, so timer

number 1 for unit 1-00 will be “3” and timer number 2 will be “4”.

Example 2

To prevent leaving units on, timer number 1 is set

to “5” in the batch screen.

Setting timer number 1 in zone number 1 to “”

in the zone screen after that will change the

timer number for zone number 1, so the setting

to prevent leaving the units on will be lost for

zone number 1 only.

If a timer number is set incorrectly by accident,

redo the setting in the desired screen.

• What happens when the timer number on

time and off time are set to the same time

When the on time and off time are set to the

same time for the same timer number, operation

does not change.

When the on time and off time are set to the

same time for different timer numbers, the off

time is given priority.

12

No.

When using timer operation, make sure the

times do not overlap when setting the program of

the schedule timer.

䡲䡲䡲䡲 Setting the Operation Code (Fig. 11)

[Registration]

1

1.

2.

[The Operation Code Setting]

Group control: select the unit in the individual screen

Batch control: set the operation code for all con-

Zone control: set the operation code for all zone-reg-

Since the operation code will be set for after-press priority, setting the operation code in the zone and individual screens after setting the operation code in the

batch screen, will cause the operation codes set afterwards to be valid.

Pressing the “CONTROL MODE”

button causes the currently set operation

code to blink.

Call up the desired code number by pressing the

1

“CONTROL MODE” button.

Scroll through the code numbers.

2

Once the code number is displayed,

press the “SET” button.

The display will stop blinking.

The operation code display will disappear after

3 seconds.

and set the operation code.

nected units.

istered units.

Call up the zones which you wish to set

in the zone screen and set the operation code.

English 10

Page 15

OPERATION MODE

The following five operation control modes can be selected along with the temperature setting and operation mode

by remote controller, for a total of twenty different modes. These twenty modes are set and displayed with control

modes of 0 to 19. (For further details, see EXAMPLE OF OPERATION SCHEDULE on the next page.)

• ON/OFF control impossible by remote controller..... Use this mode when operating and stopping from the

central remote controller only. (ON/OFF control by the

remote controller is disabled.)

• Only OFF control possible by remote controller ...... Use this mode when executing the operation only by the

central remote controller, and executing only the stop by

remote controller.

• Centralized............................................................... Use this mode when executing the operation only by the

central remote controller, and executing start/stop freely

by remote controller during the preset hours.

• Individual ................................................................. Use this mode when executing start/stop both by central

remote controller and remote controller.

• Timer operation possible by remote controller......... Use this mode when executing start/stop by remote con-

troller during the preset hours, and not starting operation

by the central remote controller at the programmed time

of system start.

[HOW TO SELECT THE CONTROL MODE]

• Select whether to accept or to reject the operation from the remote controller regarding the operation, stop, temperature setting and operation mode setting, respectively, and determine the particular control mode from the

rightmost column of the table below.

Example

Operation by remote

controller (at time of

unified operation by

centralized control)

[

Rejection

][

Operation by remote

controller (at time of

unified operation by

centralized control)

Rejection

][

Stop by

remote

controller

Rejection

Temperature

control by

remote

controller

][

Acceptance

Operation

mode setting

by remote

controller

][

Acceptance

The control

mode is “ 1 ”.

]

11 English

Page 16

Control by remote controller

Operation

Operation

mode

Unified operation, individual operation by central

remote controller, or operation controlled by timer

ON/OFF control

impossible by

remote controller

Rejection

(Example)

Only OFF control

possible by

remote controller

Centralized

Acceptance

Individual Acceptance

Timer operation

possible by

remote controller

Note)

Do not select the timer operation possible without the remote controller. In this case, timer operation is disabled.

Acceptance

(During timer at

ON position only)

Unified stop, individual

stop by central remote

controller, or timer

stop

Rejection

(Example)

Rejection

(During timer at OFF

position)

Stop

Rejection

(Example)

Acceptance

Tempera-

ture control

Rejection

Acceptance

(Example)

Rejection

Acceptance

Rejection

Acceptance

Rejection

Acceptance

Rejection

Acceptance

Operation

mode setting

Acceptance 0

Rejection 10

Acceptance

(Example)

Rejection 11

Acceptance 2

Rejection 12

Acceptance 3

Rejection 13

Acceptance 4

Rejection 14

Acceptance 5

Rejection 15

Acceptance 6

Rejection 16

Acceptance 7

Rejection 17

Acceptance 8

Rejection 18

Acceptance 9

Rejection 19

Control

mode

1

(

Example

)

HOST

When the operation, stop, temperature

setting and operation mode setting by

remote controller are rejected, “ ”

is displayed on the remote controller.

EXAMPLE OF OPERATION SCHEDULE

Operation schedule is possible only in conjunction with the schedule timer (optional accessory).

Liquid crystal display of schedule timer

ON/OFF control impossible by remote controller

Stop

Stop controlled

by timer

Programmed

to stop at

5:00

- - - - - -

SET1

SET2

OFFON

OFFON

Centralized

PMAM

PMAM

Remote

controller

Centralized

Operation controlled

by timer

Programmed

to operate at

8:45

Start/stop by remote

controller cannot be made.

Individual

stop

Stop

Forced and unified stop.

Power reminder stops.

- - - - - - - - -

HOST

Individual operation

except to the preset

hours

Operation

English 12

Page 17

Only OFF control possible by remote controller

Operation

SET1

OFFON

Centralized

PMAM

controlled

by timer

Timer stops even

if you forget to

turn off the unit.

Operation

controlled by

timer

SET2

Centralized

SET1

SET2

Individual

SET1

SET2

OFFON

PMPM

Remote

controller

Centralized

Remote

controller

OFFON

OFFON

OFFON

OFFON

PMAM

PMAM

PM

Centralized

Remote

controller

Centralized

Remote

controller

Centralized

Programmed to

operate at 8:45

Individual operation once

the unit is stopped.

Stop

- - -

Only stopping possible by the remote controller.

Operation

controlled

by timer

Programmed to

operate at 8:45

Operation

Start/stop is possible by the remote controller at any time

regardless of the hours programmed by the timer

Stops temporarily at the

timer-programmed stop time.

Stop

Only stopping possible by

the remote controller.

Operation

Stop

Start/stop is possible by the remote controller

during the hours programmed for timer operation.

Operation starts

without fail at the

timer-programmed

time.

Programmed to

operate at 9:00

- - -

Stop

- - -

Programmed to

stop at 5:00

Timer stops. Power reminder stops.

Programmed to

- - -

stop at 10:00

Operation

- - -

Operation

.

Stop

- - -

Stop

Programmed to

operate at 5:20

- - -

Timer stops.

Programmed to

stop at 7:00

Timer stops.

Remote

controller

- - -

Programmed to

stop at 5:00

Stop

Start/stop is possible by the remote controller at any time

regardless of the hours programmed by the timer.

- - -

Operation

Stop

- - -

Programmed to

stop at 10:00

Timer operation possible by remote controller

SET1

SET2

OFFON

OFFON

Centralized

PMAM

PMPM

Remote

controller

Centralized

Remote

controller

Air conditioner now operating.

- - - - -

Air conditioner now stopping.

Command by central remote controller

Command by remote controller

Timer operation possible

by remote controller at

preset times.

8:30

Operation

- - -

Startn/stop is possible by the remote controller

during the hours programmed for timer operation.

Stop

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Timer operation possible by remote controller

at preset times.

- - - - - - - - -

- - - - - -

Programmed to

operate at 5:20

Operation

- - -

Start/stop is possible by the remote controller

during the hours programmed for timer operation.

Stops for a time at

timer-programmed time.

Programmed to

- - -

stop at 5:00

Stop

- - -

- - - -

- - - - - - - -

Timer stops. Power

reminder stops.

Programmed to

stop at 10:00

13 English

Page 18

䡲䡲䡲䡲 Setting operation mode (Fig. 12)

[Registration]

1

1.

Press the OPERATION MODE SELECTOR BUTTON. Each time you press this

button, the display rotates as shown on

the below list.

• List of operations which can be set

In the below list, “ 䡬 ” refers to the acceptable setting, while “ × ” refers to the not acceptable setting.

A: Zones and groups with no

“ ” display.

Display Setting Contents of setting

×

¡

∗ 1

¡

¡

or or

Display Setting Contents of setting

∗ 1

∗ 1

¡

B: Zones and groups with a

“ ” display.

¡

¡

Can be set in individual

zones or groups

¡

Can be set in individual

zones or groups

Can be set in individual

zones or groups

Can be set in individual

zones or groups

Can be set in individual

¡

zones or groups ∗ 3

¡

Can be set in individual

zones or groups

Select this display if you

don’t wish to set by

zone.

To be set by zone

Can be set in individual

zones or groups

∗ 2

×

∗1: Setting may not be acceptable depending on the

type of indoor unit with which this unit is connected.

∗2: In zone control, the units run in temperature adjust-

ment mode (heating or cooling) for the outdoor system for the groups registered to those zones.

Heating or cooling selection is not available.

*3: or or

Changing the ventilation mode cannot be done in

the zone screen. Changing the ventilation mode

should be done in the individual screen.

∗4:

In group control, the units run in temperature adjustment mode (heating or cooling) for the group outdoor

system. Heating or cooling selection is not available.

• The Zone consists of the following two cases.

A. Zone without display“”

The group with master remote controller setting

exists in this zone.

Setting the master remote controller enables cool/

heat selection.

Operations other than cool/heat operations can also

be set for some operations. For further details, see

the list on the left.

B. Zone with display“”

No group with master remote controller setting

exists in this zone.

The cool/heat selection is not available because the

master remote controller has not been set.

Some operations other than cool/heat operations

can be set. For further details, see the list in the left.

See page 18 if the display“” is flashing.

• Fan operation can be performed for each zone using

the central remote controller even if there is no cooling/heating selection right during cooling or heating.

Also, if a Ventiair is connected in the zone, ventilation and ventilation cleaning operation is possible.

See the included operating manuals for details.

•

When the indoor unit is in heat operation, change the setting to FAN operation through the central remote controller; then, you can switch the fan speed to the extremely

low fan speed. Warm air may blow if any other indoor unit

belonging to the same system is in heat operation.

• The indoor fan stops during defrost/hot start.

•

DRY cannot be set from the central remote controller.

×

×

or or

English 14

¡

∗ 1

¡

∗ 1

¡

The displays are

shown by group ∗ 4

The displays are

shown by group ∗ 4

Can be set in individual

zones or groups ∗ 3

Can be set in individual

zones or groups

Select this display if you

don’t wish to set by zone.

䡲䡲䡲䡲 Group monitoring (Fig. 13)

Utilize the group monitor function in each of the following cases:

1. Check the malfunction code.

(See the next page.)

2. Check the group that requires cleaning of the air

filter and air cleaner element. (See page 19.)

3. Change the setting of the master remote controller. (See page 18.)

4. Check the group(s) sharing the same outdoor

unit. Or, check the particular group(s) with the

master remote controller setting. (See page 18.)

5. Check the conditions of other individual groups.

Page 19

When in zone screen

The zone screen will revert to the individual screen

automatically if nothing is done in it for one minute.

[Registration]

1

1.

2.

Press the “ALL/INDIVIDUAL” button to

switch to the “INDIVIDUAL” screen.

3

Using the arrow key, move the

“”

to select the unit to be monitored.

2

4

Keeping the button pressed down will move it

rapidly.

4

The “” lights up and the status of that unit

is displayed in the LCD. The cursor in the screen

Fig. 13 has selected unit 2-06.

䡲䡲䡲䡲 Error diagnosing function

(Fig. 14)

This central remote controller is provided with a diagnosing function, for when an indoor unit stops due to

malfunction. In case of actuation of a safety device,

disconnection in transmission wiring for control or failure of some parts, the operation lamp, inspection display and unit No. start to flash; then, the malfunction

code is displayed. Check the contents of the display,

and contact your DAIKIN dealer because the above

signs can give you the idea on the trouble area.

00 01 02 03

1

2

The display “ ” flashes under

the group No. where the indoor

unit that has stopped due to malfunction.

3

[Registration]

1

1.

Press the ARROW KEY BUTTON to call

up the group that has stopped due to malfunction.

2

The unit No. the malfunction code is

flashing because of an error failure.

3

C

L

UNIT No.

Operation

lamp

Maintenance

display

Unit No.

Malfunction

code

64

65

68

6A

6A Dumper system error + Thermistor error

6F

6H

94

A0 Indoor unit · external safety device error

A1

A1

A3 Indoor unit · Drain level error (33H)

A6 Indoor unit · Fan motor (51F) lock, overload

A7

A9 Indoor unit · BEV unit, electric expansion valve motor (20E) error

AF

Indoor air thermistor error

Outdoor air thermistor error

HVU error (Ventiair dust-collecting unit)

Dumper system error

Simple remote controller error

Door switch (Ventiair dust-collecting unit), relay harness fault

(Ventiair dust-collecting/humidifier unit)

Ventiair internal transmission error

(between total enthalpy – fan unit)

Indoor unit · BEV unit (Sky-Air connection unit) PC board

assembly fault

Indoor unit · PC board assembly fault

Indoor unit · Fan direction adjustment motor (MA) error

Indoor unit · Malfunctioning drain

Error content

AH

AJ Indoor unit · Insufficient capacity setting, address setting fault

Indoor unit · Dust-collector error

15 English

Page 20

C4

C5

C9

CA

CJ

E0 Outdoor unit · Safety device operation

E1 Outdoor unit · PC board assembly fault

E1

E3 Outdoor unit · High-pressure switch fault

E4 Outdoor unit · Low-pressure switch fault

E9 Outdoor unit · Electric expansion valve motor (20E) error

EC

EF Outdoor unit · Ice thermal storage unit error

F3 Outdoor unit · Discharge piping temperature error

Indoor unit · Liquid piping thermistor (Th2) Error (faulty connection, cut wire, short circuit, fault)

Indoor unit · BEV unit, gas piping thermistor (Th3) Error (faulty

connection, cut wire, short circuit, fault)

Indoor unit · Intake air thermistor (Th1) Error (faulty connection,

cut wire, short circuit, fault)

Indoor unit · Outlet air thermistor (Th4) Error (faulty connection,

cut wire, short circuit, fault)

Indoor unit · remote controller sensor error

Outdoor unit · PC board assembly fault

Heat source unit · Intake water temperature inter-lock operation

(fan operation)

H3

H4 Outdoor unit · Low-pressure switch operation

H9

H9

HC

HF

HJ Outdoor unit · water system fault

J1 Outdoor unit · pressure sensor error

J3

J3

J5

J6 Outdoor unit · Heat exchange thermistor (Th2) error

J6

J7 Outdoor unit · Header thermistor (Th6) error

JA Outdoor unit · Discharge piping pressure sensor error

JC Outdoor unit · Intake piping pressure sensor error

JF Outdoor unit · Oil temperature sensor (Th5) system error

Outdoor unit · High-pressure switch operation

Outdoor unit · Outdoor air thermistor (Th1)

Error (faulty connection, cut wire, short circuit, fault)

Outdoor unit · Outdoor air thermistor (Th1)

Error (faulty connection, cut wire, short circuit, fault)

Outdoor unit · Water temperature sensor system error

Ice thermal storage unit error, ice thermal storage controller error,

error in outdoor unit during ice thermal storage operation

Outdoor unit · Discharge piping thermistor (Th3)

Error (faulty connection, cut wire, short circuit, fault)

Outdoor unit · Discharge piping thermistor (Th3)

Error (faulty connection, cut wire, short circuit, fault)

Outdoor unit · Intake piping thermistor (Th4)

Error (faulty connection, cut wire, short circuit, fault)

Outdoor unit · Heat exchange thermistor (Th2) error

Error (faulty connection, cut wire, short circuit, fault)

JH

L0 Outdoor unit · Inverter system fault

L4 Outdoor unit · Inverter cooler fault

L5

Outdoor unit · Oil temperature sensor (Th5) system error

Outdoor unit · Ground circuit for compressor motor, short circuit,

or power unit short circuit

English 16

Page 21

or

or

or

or

L6 Outdoor unit · Ground circuit for compressor motor, short circuit

L8

L9 Outdoor unit · Compressor lock

LA Outdoor unit · Power unit error

LC

M1 Central controller: PC board fault

M8 Transmission error between central controllers

MA Central controller: Incorrect combination

MC Central controller: Address setting fault

P0

P1 Outdoor unit · Power voltage imbalance, phase loss

P4 Outdoor unit · Power unit temperature sensor error

U0

U1 Reversed or lost phase

U2 Power voltage error, momentary electrical stoppage

U4

U5

U5 Remote controller board fault or remote controller setting fault

U6 Transmission error between indoor units

U7

U7

U8

U9

UA

UC

Outdoor unit · Compressor overload, compressor motor wire

disconnection

Outdoor unit · Transmission error between inverter and outdoor

control unit

Insufficient gas (thermal storage)

Pressure drop due to insufficient refrigerant, electric expansion

valve fault, etc.

Transmission error between indoor unit/BEV unit and outdoor/BS

unit, Transmission error between outdoor unit and BS unit

Transmission error between remote controller and indoor

control unit

Transmission error between outdoor units

Transmission error between outdoor unit and ice thermal

storage unit

Transmission error between outdoor units

(cooling/heating batch, low-noise operation)

Transmission error between master remote controller and slave

remote controller (slave remote controller error)

Incorrect combination of indoor unit and remote controller within

a single system (model)

Transmission error between indoor unit/BEV unit and outdoor unit

within a single system

Transmission error between BS unit and indoor unit/BEV unit and

outdoor unit within a single system

Incorrect combination of indoor, BS, and outdoor units within a

single system (model, number of units, etc.)

Incorrect combination of indoor unit and remote controller

(remote controller in question) BS unit connection position fault

Central control group numbers overlap

UE Transmission error between indoor unit and central controller

UF

UH System fault

Unset system, incorrect settings between BEV unit and

indoor unit

error codes (in outline font) do not display “maintenance” and the system will run, but please check the content

of the display and contact your dealer.

17 English

Page 22

䡲䡲䡲䡲 Setting master remote controller

(Fig. 15)

You must set the master remote controller of the operation mode for one of the indoor units, if two or more

such indoor units with the remote controller are connected with the outdoor unit where the operation

modes such as cool/heat operation and FAN operation

can be set by remote controller and central remote controller.

1.

Preparations

When you want to fix settings

• Check the particular group with the master

remote controller setting for the refrigerant

system you wish to reset. (See the below.)

• Call up the group without the display

“” (See page 14.)

1

Hold the OPERATION MODE SELECTOR

BUTTON down for about four seconds while

the above group is being called up.

The display “” flashes on the liq-

uid crystal display of the remote controller

for all the groups sharing the same outdoor

unit or BS unit.

When you turn on the power switch for the first

time, the display“” flashes.

When switching operation

●●●● In case of operation switch

Call up the zone including the group with the

setting of master remote controller.

(Zone without the display

1

Press the OPERATION MODE SELECTOR

“”

)

BUTTON several times, and switch to the

desired operation mode.

Each time you press it, the display is switched

to “” “” “” and “” in sequence.

NOTE

• However, the displays “” “” and “VENTI-

LATION MODE” may appear in some zones,

depending on the type on indoor unit with which they

are connected.

(VENTILATION MODE)

or or

[System Display]

1.Test run mode is necessary to display the system

display.

2.In order to turn on test run mode, select the appropriate air conditioner on the individual screen with

the cursor and then set its operation mode to either

cooling or heating. (The air conditioner does not

need to be running. It doesn’t matter if it is, though.)

3.Press the “inspection/test run” button twice to put it

into test run mode.

4.Pressing the “inspection/test run” button for four or

more seconds in test run mode will display the

“REF CIRCUIT.”

1

1

2.

Setting selection right

Pall up the desired group to set the master

remote controller, and press the OPERATION MODE SELECTOR BUTTON. The master

remote controller is set for this group, and the

display “” goes out. The display

“” appears for the other groups.

Setting is finished now.

English 18

1

Page 23

Call the unit whose system you wish to look up using

the arrow keys.

The “” on all groups in the same system as the

displayed group will light up.

Of those, the “” display in all groups which have

cooling/heating selection privilege will blink.

In this example, individual units 1-00, 1-03, 1-05,

1-06, 1-07, 2-02, and 2-03 are in the same system,

and 1-05 has the cooling/heating selection privilege.

To look up other systems, call up all the units you wish

to look up using the arrow keys.

Pressing the inspection/test run button one more time

gets rid of the system display and ends it.

The unit will enter the individual screen automatically if

nothing is done for one minute in the system display

screen.

This function may not be available for all connected

outdoor units, in which case “REF CIRCUIT” will blink.

It will also not be correctly displayed if DIII-NET extension ADP is used.

2

2.

Press the FILTER SIGN RESET BUT-

TON, and the display “” disap-

pears. (Including all the groups where the

air filter has been cleaned.)

NOTE

Be sure to check the display “” has

disappeared at this point. The appearance of the

above display is a sign that the air filter or air cleaner

element of some group still needs cleaning.

3

䡲䡲䡲䡲 Display of time to clean (Fig. 16)

This central remote controller displays the time to clean

the air filter or air cleaner element for each group or any

given group by utilizing two types of signs. The display

“” tells the time to clean the air filter or the air

cleaner element of some group.

If a cleaning sign is displayed

A filter or element in some group is ready to be

cleaned.

1

1.

Press the ARROW KEY BUTTON, and

search the groups displaying “” or

“” (The group may be plural.)

Clean or change the air filter or air cleaner

element.

For further details, see the operation manual

attached to each indoor unit. (Clean or change the

air filter or air cleaner element of all the groups dis-

playing “” or “”.)

19 English

Page 24

INSTALLATION TABLE

When installing the equipment, mark the zone No. of each group and installation location in the below table.

Setting group No.

(Setting is not possible unless power is activated to

both the central remote controller and indoor unit.)

Operated by remote controller

1. Activate power to both the central remote controller

and indoor unit.

2. While in the normal mode, hold down the “” but-

TEST

ton for a minimum of 4 seconds. The unified ON/

OFF controller will enter the FIELD SET MODE.

3. Select the MODE No. “” with the “” button.

4. Use the “” button to select the group No. for each

group. (Group No. increases in the order of

1-00, 1-01 ... 1-15, 2-00, ... 8-15.)

5. Press “” to set the selected group No.

6. Press “” to return to the NORMAL MODE.

TEST

FIELD SET

MODE NO.

MODE

GROUP NO.

Operated by simplified remote controller

1. Activate power to both the central remote controller

and indoor unit.

2. Remove the upper part of the remote controller.

3. Press the BUTTON (field set) on the PC

BS6

board. The controller will enter the FIELD SET

MODE.

4. Select the MODE No. “” with the BUT-

TON and BUTTON (temperature setting).

5. Use the BUTTON (set A) and

BS3

BS9 BS10

BS2

BUTTON (set B) to select the group No. for each

group. (Group No. increases in the order of 1-00,

1-01 ... 1-15, 2-00, ... 8-15.)

6. Press BUTTON (set/cancel) to set the

BS7

selected group No.

7. Press BUTTON (field set) to return to the

BS6

NORMAL MODE.

BS1

MODE NO.

GROUP NO.

Zone No.

Group No.

Indoor unit

Quantity of units

Controlled by

Location

Zone No.

Group No.

Indoor unit

Quantity of units

Controlled by

Location

SETTING

TEST

3

2.6

–00 –01 –02 –03 –04 –05 –06 –07 –08 –09 –10 –11 –12 –13 –14 –15

–00 –01 –02 –03 –04 –05 –06 –07 –08 –09 –10 –11 –12 –13 –14 –15

45

UNIT

4

4

BS2

BS6 BS7 BS8 BS9 BS10

6

3.7

BS3

BS4

BS5

5

5

English 20

Page 25

Zone No.

Group No.

Indoor unit

Quantity of units

Controlled by

Location

Zone No.

Group No.

Indoor unit

Quantity of units

Controlled by

Location

–00 –01 –02 –03 –04 –05 –06 –07 –08 –09 –10 –11 –12 –13 –14 –15

–00 –01 –02 –03 –04 –05 –06 –07 –08 –09 –10 –11 –12 –13 –14 –15

OPTIONAL ACCESSORIES

(a)

(b)

You can perform the normal operation, take off the malfunction contact point and unified start/stop by contact

point, all by connecting this unit with the unification adaptor for computerized control. For further details, ask

your DAIKIN dealer.

(a) Unification adaptor for computerized control (b) Central remote controller

DOUBLE CENTRAL REMOTE CONTROLLERS

(b) (c) (d) (e)

(a)

-

(2)(a)-(1)

( f )

With two central remote controllers, centralized control (indoor units) is possible from different locations.

(a) Central remote controller (b) Group No. 1 – 00 (c) Group No. 1 – 15 (d) Group No. 2 – 00

(e) Group No. 4 – 15 ( f ) A maximum of 64 groups

Note)

• For control alignment and settings for double central remote controllers, contact your dealer.

21 English

Page 26

SPECIFICATIONS

INDIVIDU

ALL

䡲䡲䡲䡲 Specifications

Power supply 1 ~ 50/60Hz, 100V – 240V

Power consumption Max. 8W

Forced ON/OFF input

Size 180 (W) × 120 (H) × 64.5 (D)

Weight 420g

䡲䡲䡲䡲 Outline drawings

When using this unit an electric parts box of KJB311A is required.

For installation, a steel electric parts box to be embedded is mandatory.

Continuous “a” contact

Contact current: approximately 10mA

180 16 48.5

INDIVIDU

ALL

Y

C

120

71

English 22

Page 27

INDIVIDUALLY

3

2

H

FRESH UP

4

5

1

6

9

10

11

INDIVIDUALLY

INDIVIDUALLY

No.

12

C

L

1

2

C

CODE

L

1

2

12

INDIVIDUALLY

C

L

1

[3]

Page 28

13

2

INDIVIDUALLY

4

C

L

1

3

Operation lamp

14

15

INDIVIDUALLY

1

INDIVIDUALLY

C

L

2

UNIT No.

3

C

L

1

16

INDIVIDUALLY

3

C

L

1

2

[4]

Page 29

3P124623-2A EM03A107

(0401) HT

Loading...

Loading...