Daikin DCM014A51 Design Manual

DG_DCM014A51_02-17

Intelligent Touch Manager

BACnet® Server Gateway

DCM014A51

DESIGN GUIDE

Contents

Part 1. Overview .......................................................................................................................................... 6

1. DCM014A51 iTM BACnet® Server Gateway ......................................................................................... 6

1.1 Features ........................................................................................................................................ 6

1.2 BACnet® Compatibility .................................................................................................................. 7

1.3 System Outline .............................................................................................................................. 7

2. VRV System Overview ........................................................................................................................... 8

2.1 Types of Daikin VRV Systems ........................................................................................................ 8

2.2 DIII-Net System and Group Addresses ......................................................................................... 9

2.3 Remote Controller Group and Group Address ............................................................................. 9

2.4 Commanding Mode Change for Heat Recovery and Heat Pump Systems ................................. 11

2.5 Changeover Master and Secondary (Non-Master) Indoor Units................................................ 12

2.6 Indoor Unit Logic ........................................................................................................................ 12

3. iTM Overview ...................................................................................................................................... 14

3.1 Indoor Unit Management Point ................................................................................................. 14

3.2 Automatic Control ...................................................................................................................... 16

Part 2. Functional Specifications ............................................................................................................... 21

1. Introduction ........................................................................................................................................ 21

2. Network Topology .............................................................................................................................. 21

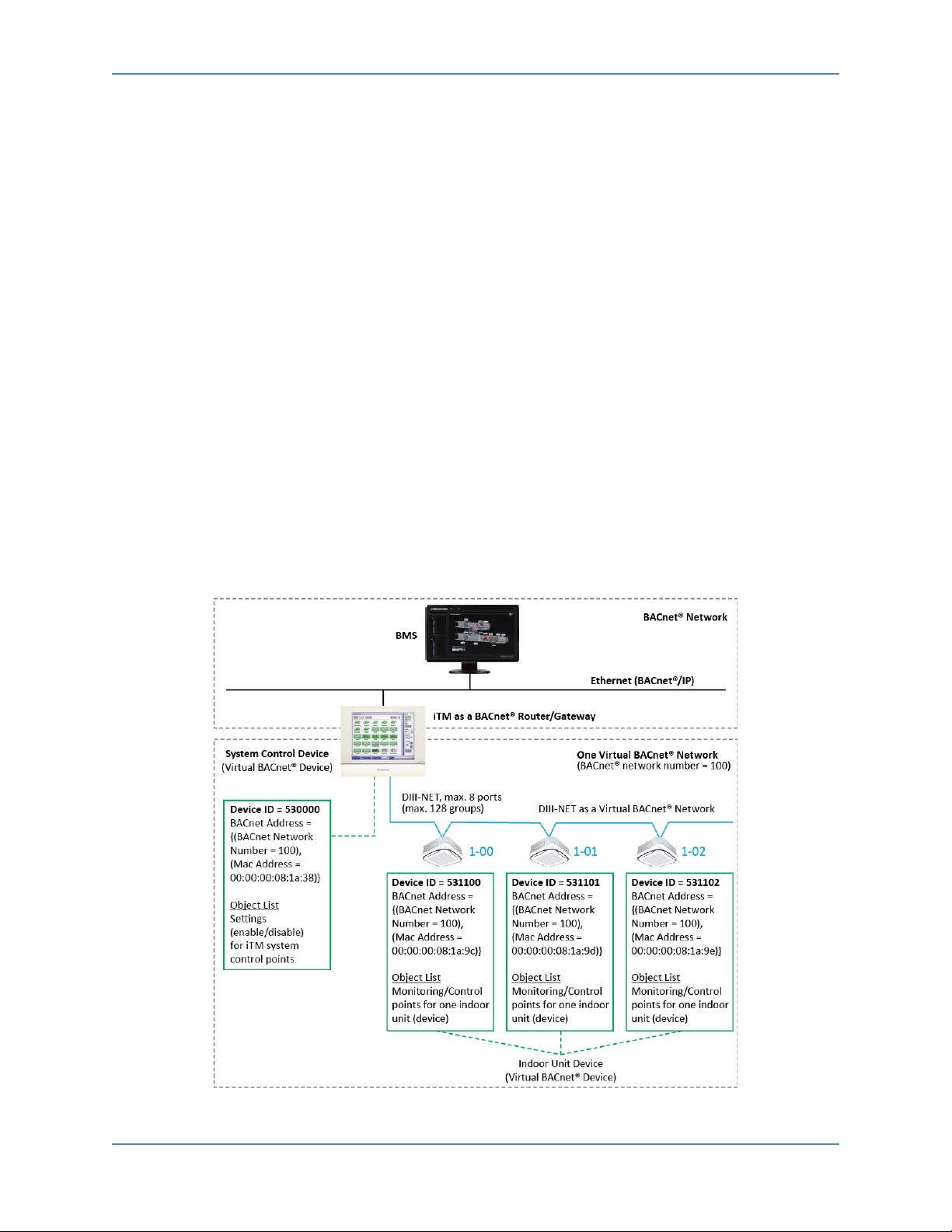

2.1 Visualization of Each Device on the BACnet® Network .............................................................. 21

2.2 BACnet® Network Number ......................................................................................................... 22

2.3 Device ID (Device Instance Number) .......................................................................................... 22

2.4 What is a MAC Address? ............................................................................................................. 22

2.5 MAC Address of a Virtual BACnet® Device ................................................................................. 22

3. iTM and BACnet® Server Gateway Logic ............................................................................................ 23

3.1 BACnet® Virtual Router Function ............................................................................................... 23

3.2 iTM BACnet® Server Gateway Point Logic in the iTM................................................................. 23

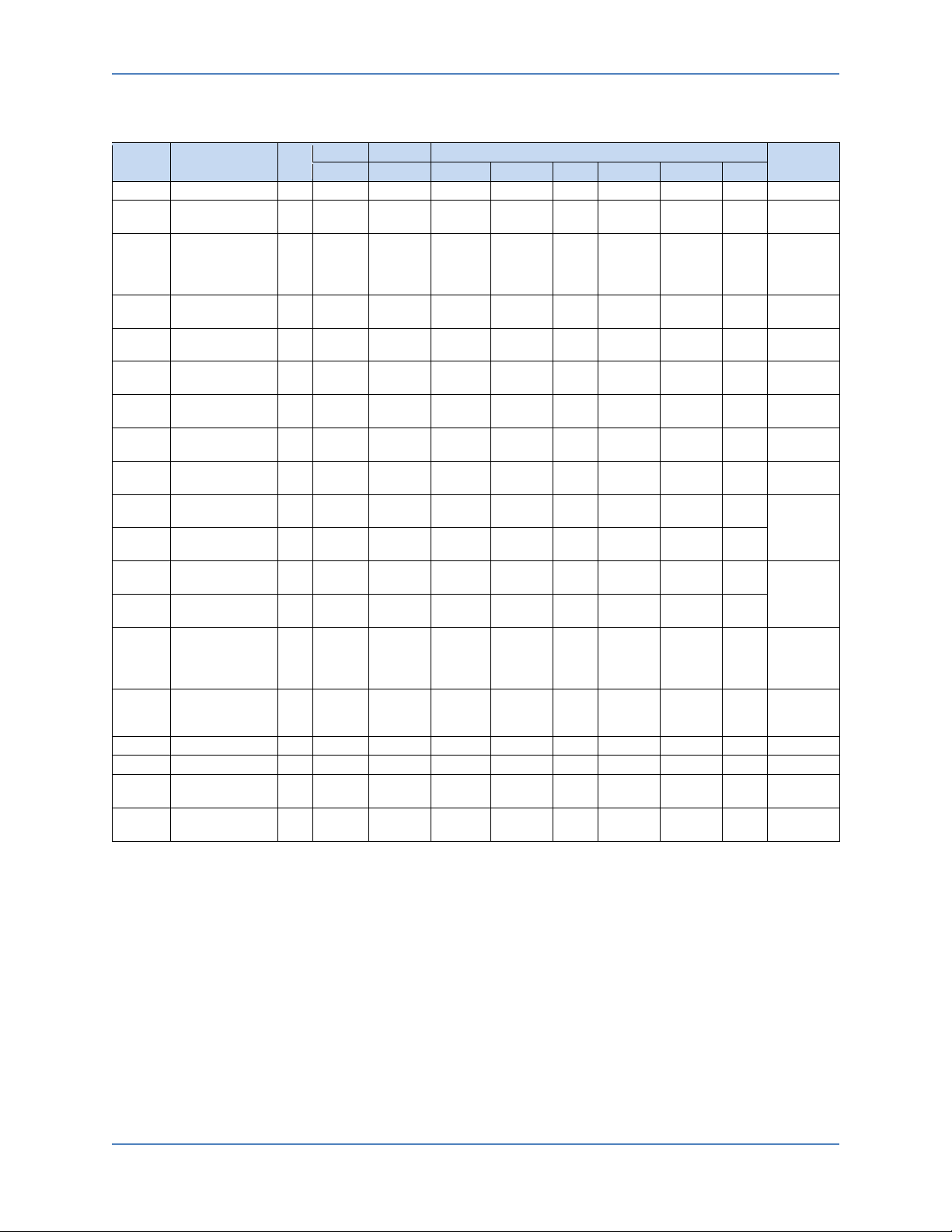

4. VRV System Monitor/Control Objects ................................................................................................ 24

4.1 Member Objects ......................................................................................................................... 24

4.2 Indoor Unit Device ...................................................................................................................... 24

4.3 System Control Device ................................................................................................................ 27

4.4 Restrictions ................................................................................................................................. 27

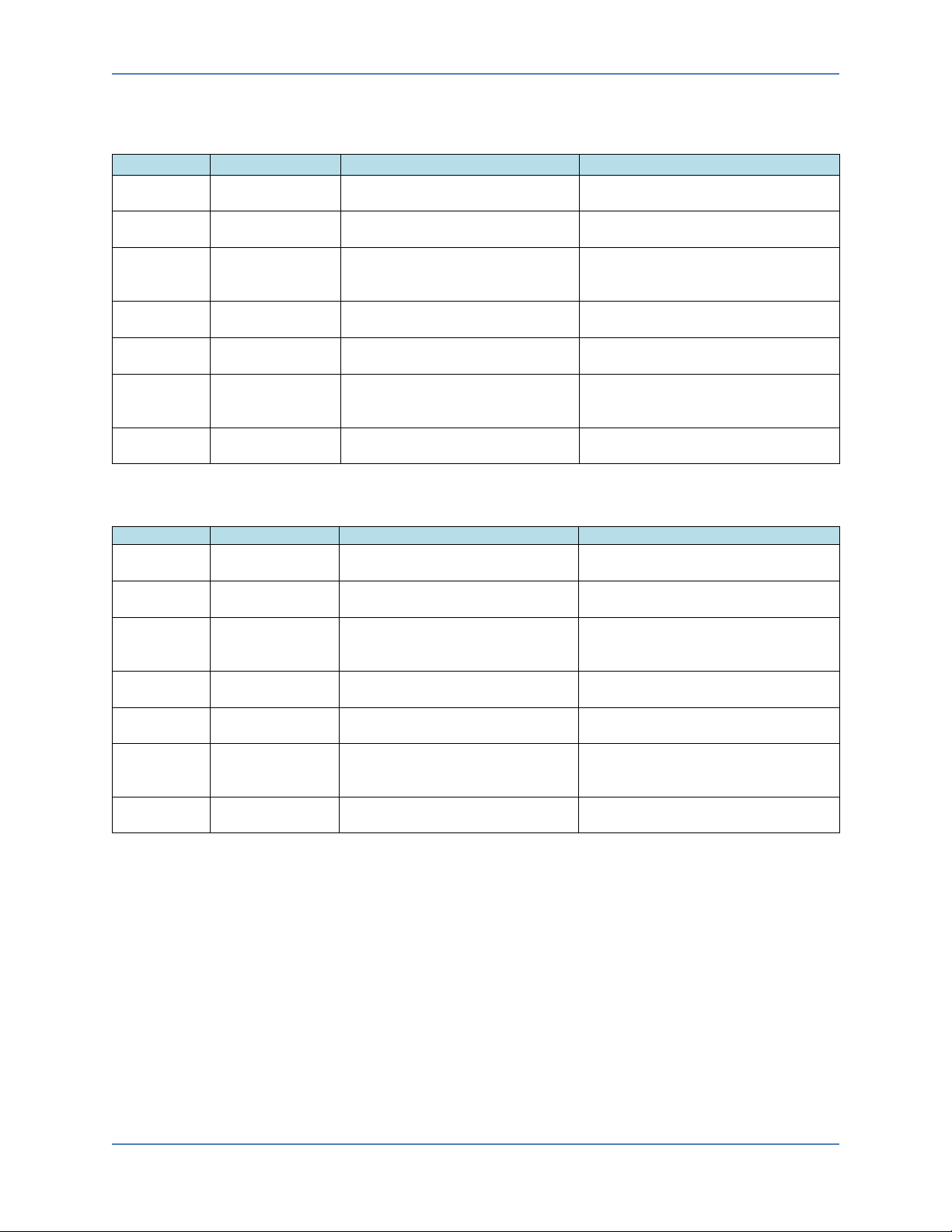

5. Properties ........................................................................................................................................... 30

5.1 Device Object Type ..................................................................................................................... 30

5.2 System Control Device ................................................................................................................ 32

5.3 Analog Input Object Type ........................................................................................................... 34

5.4 Analog Value Object Type ........................................................................................................... 35

5.5 Binary Input Object Typed .......................................................................................................... 36

5.6 Binary Output Object Type ......................................................................................................... 37

5.7 Binary Value Object Type ........................................................................................................... 38

5.8 Multi-State Input Object Type .................................................................................................... 39

5.9 Multi-State Output Object Type ................................................................................................. 40

5.10 Multi-State Value Object Type ................................................................................................... 41

6. Error Response in BACnet® Communication ...................................................................................... 42

7. Detailed Description of Objects .......................................................................................................... 43

7.1 Specifications Common to All Objects ........................................................................................ 43

7.2 Individual Object Specifications .................................................................................................. 44

7.3 Individual System Control Object Specifications ........................................................................ 61

8. Report Function .................................................................................................................................. 63

8.1 COV Notification ......................................................................................................................... 63

9. Error Codes ......................................................................................................................................... 64

10. PICS ................................................................................................................................................... 66

11. BACnet® Interoperability Building Blocks Supported (BIBBs) ........................................................... 70

Part 3. Commissioning Procedure ............................................................................................................. 74

1. Site Visit .............................................................................................................................................. 74

1.1 Obtaining Object Information .................................................................................................... 74

2. Foreign Device .................................................................................................................................... 79

2.1 Foreign Device Setting ................................................................................................................ 79

2.2 Typically Not Changed Unless Requested by the BMS ............................................................... 79

3. BACnet® Point List .............................................................................................................................. 80

What is a point list? ............................................................................................................................ 80

3.1 System Control (one per system) ............................................................................................... 80

3.2 Indoor Unit Points (for each indoor unit) ................................................................................... 81

4. Commissioning the BACnet® Server Gateway on the iTM ................................................................. 81

4.1 The iTM BACnet® Server Gateway Activation ............................................................................ 82

4.2 CSV Configuration ....................................................................................................................... 83

5. Connecting the test operation PC and iTM via the cross cable or the hub/switch

using 100BASE-TX straight cable ........................................................................................................ 89

5.1 Connecting a Test PC to the iTM ................................................................................................ 89

5.2 Configuring iTM Network Settings.............................................................................................. 89

5.3 How to configure PC Network Settings ...................................................................................... 89

5.4 Return the IP address of the Test PC to the Original Address After the Test Operation ........... 90

6. Reference ............................................................................................................................................ 91

6.1 Possible Causes for Unconnected iTM and Test Operation PC .................................................. 91

6.2 How to Execute PING .................................................................................................................. 91

7. Handover to BMS ................................................................................................................................ 92

7.1 CSV File ....................................................................................................................................... 92

7.2 Network Settings ........................................................................................................................ 92

7.3 Ask the BMS Integrator to Discover the BACnet® Points from the iTM. .................................... 92

7.4 Unable to Auto-Discover BACnet® Points .................................................................................. 92

7.5 Final Review ................................................................................................................................ 92

Part 4. Programming Guide ....................................................................................................................... 93

1. Typical Requirements ......................................................................................................................... 93

1.1 Typical Indoor Unit Schedule Set by BMS Master Schedule ....................................................... 93

2. How to Program .................................................................................................................................. 93

2.1 Setpoints ..................................................................................................................................... 93

2.2 Setpoint Range Limitation .......................................................................................................... 94

2.3 Auto-Changeover Configuration ................................................................................................. 94

2.4 Schedule ..................................................................................................................................... 94

2.5 Timed Override ........................................................................................................................... 94

2.6 Remote Controller Prohibits ....................................................................................................... 94

3. Notes ................................................................................................................................................... 95

3.1 Indoor Unit EEPROM .................................................................................................................. 95

3.2 Priority Array............................................................................................................................... 95

Part 5. Installation Manual ....................................................................................................................... 96

1. Installation .......................................................................................................................................... 96

1.1 Understanding theLocation of Terminals and Switches ............................................................. 96

1.2 Rear Face .................................................................................................................................... 96

1.3 Front Panel.................................................................................................................................. 97

1.4 Side Face ..................................................................................................................................... 98

1.5 Environmental Conditions .......................................................................................................... 98

2. Electrical Wiring .................................................................................................................................. 99

2.1 Removing Wiring Cover from Rear Face ..................................................................................... 99

2.2 Connecting DIII-Net-Compatible Air Conditioning Equipment ................................................... 99

2.3 Wiring Specifications ................................................................................................................ 100

3. Basic Setup of Intelligent Touch Manager ........................................................................................ 105

3.1 Setting Backup Battery to ON ................................................................................................... 105

3.2 Turning On Power Supply to iTM and Air Conditioners ........................................................... 106

Appendix A. BACnet® Gateway (DMS502B71) and iTM Protocol Comparison ................................... 107

1. Functions Removed from BACnet® Gateway............................................................................... 107

2. Changes from the BACnet® Gateway .......................................................................................... 108

Appendix B. Supported Models and Monitoring Control Items .......................................................... 111

Appendix C. iTM Specifications, Dimensions, and System Wiring ....................................................... 113

1. Specifications ............................................................................................................................... 113

2. Dimensions................................................................................................................................... 113

3. System Configuration and Wiring ................................................................................................ 115

Part 1. Overview

Part 1. Overview

1. DCM014A51 iTM BACnet® Server Gateway

The intelligent Touch Manager (iTM) is now capable of serving as a BACnet® interface for Building

Management System (BMS) integration. The iTM BACnet® Server Gateway option (DCM014A51) will

provide BMS integrators the ability to monitor and control VRV indoor units via the BACnet®/IP protocol.

The iTM BACnet® Server Gateway option eliminates the need for an additional hardware interface for

the BMS to monitor and control a VRV system. The iTM BACnet® Server Gateway option provides

seamless control-logic integration between the iTM and BMS.

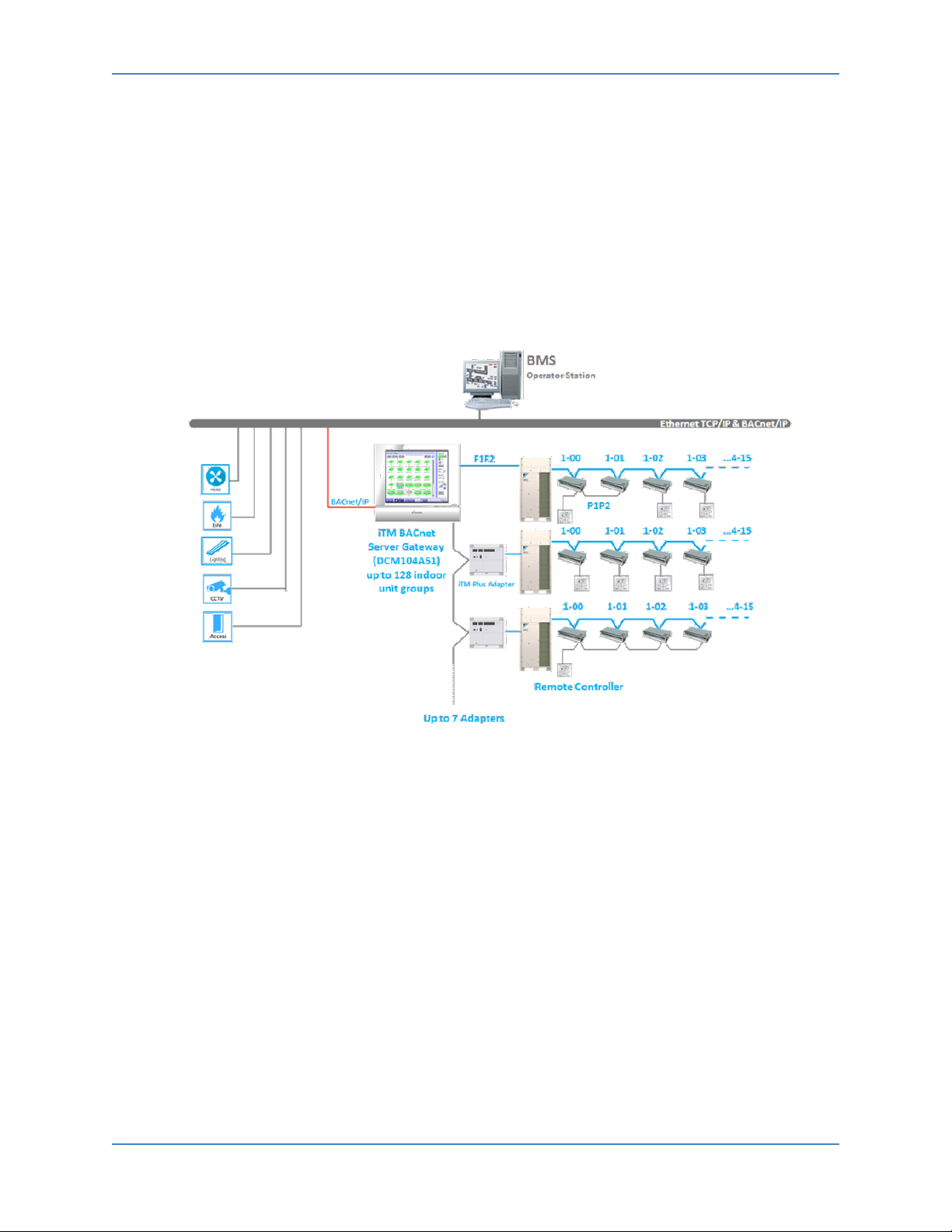

Figure 1. iTM BACnet® Server Gateway

1.1 Features:

• Direct connection on iTM using the BACnet®/IP Protocol.

• BACnet® virtual router function implemented:

» Individual BACnet® device ID assigned to each indoor unit group address.

» Indoor unit group names created in the iTM are visible on the BMS.

• Easy commissioning using CSV file.

» Available objects can be configured for each indoor unit.

• Support Change of Value (COV) notifications to BMS.

• Configurable as a BACnet® foreign device if BBMD exists on a different subnet within BACnet® network.

• Independent heating and cooling setpoints for occupied and unoccupied periods.

• Individual min/max Setpoint Range Limitation for heat and cool modes.

• The iTM’s auto-changeover, setpoint range limitation, setback, dual setpoint logic, and schedule can be accessed by the BMS.

The intelligent Touch Manager (hereinafter referred to as "iTM") supports the BACnet® 2004 protocol

(hereinafter referred to as "BACnet® specifications"). The iTM operates as a BACnet® server that

provides BACnet® objects to monitor/operate indoor units connected to the DIII network in response to

requests from a Building Management System (BMS), i.e., BACnet® client.

6 Design Guide DCM014A51

Part 1. Overview

This document describes the operation for the BACnet® Server Gateway option for the iTM.

1.2 BACnet® Compatibility

• Packaging of the VRV indoor unit objects:

» Compatible with BACnet® (ANSI / ASHRAE-135).

» Compatible with BACnet® / IP (ISO16484-5).

• Conforming to Safety and Electromagnetic Compatibility (EMC) rules and regulations.

1.3 System Outline

1. Typical BACnet® Server Gateway Application:

Figure 2. Typical Daikin VRV System

2. The iTM BACnet® Server Gateway (DCM014A51) software option provides communication between the VRV system and the BMS. The operation and monitoring of the VRV systems through BACnet® communication uses the BACnet®/IP protocol.

3. Up to 128 indoor unit management points can be controlled and monitored through the iTM BACnet® Server Gateway.

4. Up to 7 additional DIII-Net communication systems can be added with optional iTM Plus Adaptors. The iTM Plus Adaptor is intended for use with the iTM, and shall not be used independently.

DCM014A51 Design Guide 7

Part 1. Overview

2. VRV System Overview

The Daikin VRV system consists of outdoor units, indoor units, zone controllers, centralized controllers,

and BMS interfaces. The customizable Daikin control system is built around the VRV system, and does

not require advanced field engineering (i.e., programming) for the control of the VRV system, except for

field settings configurations. The iTM BACnet® Server Gateway can be used for monitoring, scheduling,

control, and interlock operation. A BMS can be used in conjunction with the Daikin controllers to share

operation workload to reduce project costs.

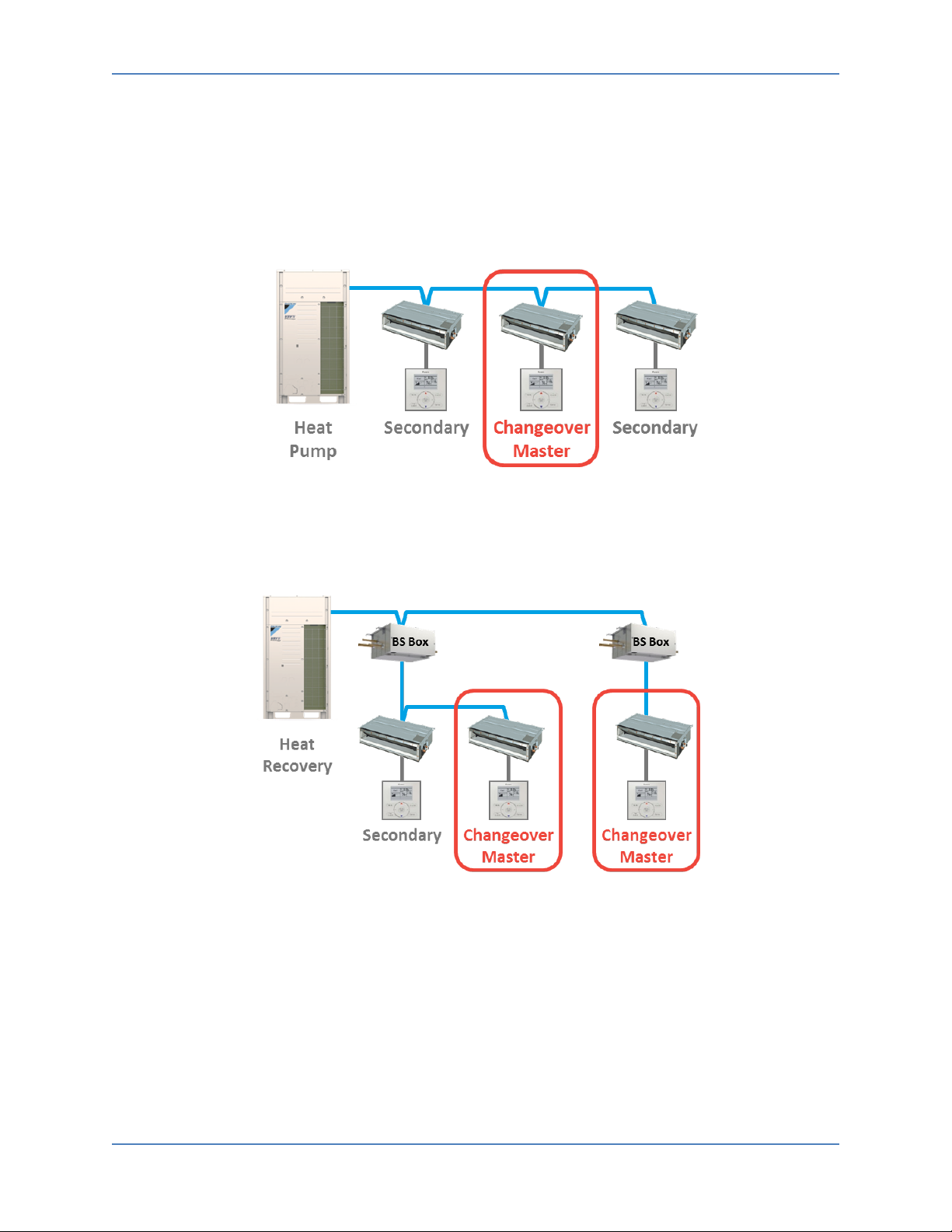

2.1 Types of Daikin VRV Systems

The VRV system can consist of either a Heat Recovery system, Heat Pump systems, or system that has a combination of both.

1. Heat Recovery systems can provide simultaneous cooling and heating to each indoor unit served by the same outdoor unit with use of Branch Selector Boxes (BS Box).

Figure 3. Heat Recovery System

2. Heat Pump systems only allow each outdoor unit and its connected indoor units to operate in either cooling or heating mode. Multiple Heat Pumps systems can be installed to operate independently in either cooling or heating mode.

Figure 4. Heat Pump System

8 Design Guide DCM014A51

Part 1. Overview

2.2 DIII-Net System and Group Addresses

1. The DIII-Net system consists of the following: a. Up to 10 VRV outdoor units (daisy chained). b. Up to 128 indoor units.

2. The iTM (central controller) and DIII-Net system consists of the following: a. Up to 10 VRV outdoor units (daisy chained). b. Up to 64 indoor unit groups (128 indoor units). c. Up to 7 iTM Plus Adapters can be connected to a single iTM. Each adapter can contain up to

64 group addresses and 10 outdoor units.

3. When a centralized controller is connected to the DIII-Net system, a unique group address must be created for each indoor unit to be monitored and controlled by the central controller.

4. Group Address: a. Indoor units are assigned unique group addresses (up to 64 per DIII-Net system) manually

during the VRV commissioning.

b. Addresses are as follows: 1-00 to 1-15, 2-00 to 2-15, 3-00 to 3-15, 4-00 to 4-15.

c. With the use of the iTM Plus Adapter, up to 8 DIII-Net systems can be connected to a single

iTM. Each DIII-Net system will be assigned a port number with the iTM being port 1. For

example, an indoor unit connected to the iTM will have the complete group address of 1:1-

00. Similarly, each additional system will be assigned a port number 2 to 8 (2:1-00, 3:1-00,

etc.).

2.3 Remote Controller Group and Group Address

1. A remote control group consists of 1 -16 indoor units connected (via P1P2 daisy chain) to the

same remote controller. The indoor unit group allows for a maximum of 2 remote controllers

to be connected to the same remote controller group. It is not required to have a remote

controller connected to an indoor unit. If no remote controllers are used there should be a

centralized method for monitoring and controlling the indoor units.

2. Assigning a group address to a single indoor unit (typical configuration):

* F1F2 = DIII-Net ** P1P2 = Remote Controller line

Figure 5. Assigning Group Address to a Single Indoor Unit

DCM014A51 Design Guide 9

Part 1. Overview

3. Assigning one group address to a remote controller group:

Figure 6. Assigning One Group Address to a Remote Controller Group

4. Assigning a group address to each indoor unit in a remote controller group:

Figure 7. Assigning a Group Address to Each Indoor Unit in a Remote Controller Group

Note: As shown in the figures above, a remote controller group consists of several

indoor units wired to the same remote controller. A remote controller group consists of

1-16 indoor units that can be started or stopped simultaneously. For units without a

remote controller, each unit is treated as a group.

10 Design Guide DCM014A51

Part 1. Overview

2.4 Commanding Mode Change for Heat Recovery and Heat Pump Systems

What is a Changeover Master?

1. When the VRV contractor has commissioned a Heat Pump system, an indoor unit can be nominated as the changeover master. This allows the nominated unit to change the mode of operation for all units connected to the same outdoor unit.

Figure 8. Heat Pump System

2. A Heat Recovery system can utilize BS Boxes to provide simultaneous heating and cooling for each zone.

Figure 9. Heat Recovery System

3. Every unit or group of units connected to a BS Box port can either be in cooling or heating mode, i.e., units connected to the same BS Box port operate as a mini Heat Pump system.

DCM014A51 Design Guide 11

Part 1. Overview

•

• •

• •

•

• •

•

2.5 Changeover Master and Secondary (Non-Master) Indoor Units

1. Cool and heat modes are only available for selection on the cool/heat changeover master

indoor unit. The following table indicates the available operating modes for secondary indoor

units in the system based on the selected mode of the master indoor unit.

When the master

indoor unit is set to:

Cool Dry Heat Fan

Secondary indoor units in the

system can be set to:

Cool mode

Dry mode

Heat mode

Fan mode

2.6 Indoor Unit Logic

1. The indoor unit contains control logic to maintain room temperature by adjusting the

refrigerant flow and has the following data points:

a. Unit ON/OFF.

b. Operation Mode – Cool, Heat, Fan, Dry, Auto (Auto mode is not recommended as it can

create large temperature differentials between mode changes).

c. Setpoint – 60

o

F to 90oF, 1oF basis (16oC to 32oC, 0.1oC basis).

d. Room Temperature (read only).

e. Fan Speed – L, ML, M, MH, H, Auto (depends on indoor unit type).

f. Airflow Direction (if the indoor unit has louvers).

g. Alarm Status (read only).

h. Malfunction Code (read only).

2. Indoor Unit Sequence of Operation a. During the cooling thermo-on (call for cooling) period, the indoor unit fan will operate based

upon the fan setting from the local controller, iTM, or BMS.

b. During the cooling thermo-off (cooling satisfied) period, the fan will continue to operate

based on the setting from the local controller, iTM, or BMS fan speed setting. However, the

fan can be turned OFF during the thermo-off period with a field setting (depends on the

indoor unit type). Also, the fan should not be OFF when an indoor unit receives outside air.

c. During the heating thermo-on (call for heating) period, the indoor unit fan will operate

based on the fan setting from the local controller, iTM, or BMS.

d. During the heating thermo-off (heating satisfied) period, the fan will continue to operate in

LL (Low Low) speed (default). The fan can be set to ON (H, MH, M, ML, L), LL or completely

OFF with a field setting (depends on the indoor unit type). However, the fan should not be

OFF when an indoor unit receives outside air.

12 Design Guide DCM014A51

Part 1. Overview

3. Dry Mode a. When selected, the setpoint is based on the room temperature as not to over cool.

1. Setpoint = Return Air (when the Return Air ≤ 75°F).

2. Setpoint = Return Air – 1°F (when the Return Air > 76°F).

b. The current setpoint is not displayed on the local controller, iTM, or the BACnet® Server

setpoint present value during Dry mode.

c. In Dry mode (or Fan mode), the BMS can write the cooling and heating setpoints to the iTM,

and are set to the IDU management point in the iTM. However, the cooling and heating

setpoints are not sent to the indoor unit.

4. Room Temperature Sensing a. The room temperature can be measured by the following:

1. Indoor unit return air sensor (depending on indoor unit model).

2. Remote temperature sensor (KRCS01-1B/4B).

3. Sensor in the BRC1E73 (local remote controller). b. The sensing local method depends on the indoor unit configuration (field setting). c. The BMS cannot send the room temperature to the indoor unit due to the fact that the

room temperature is a read only point for the BMS.

DCM014A51 Design Guide 13

Part 1. Overview

3. iTM Overview

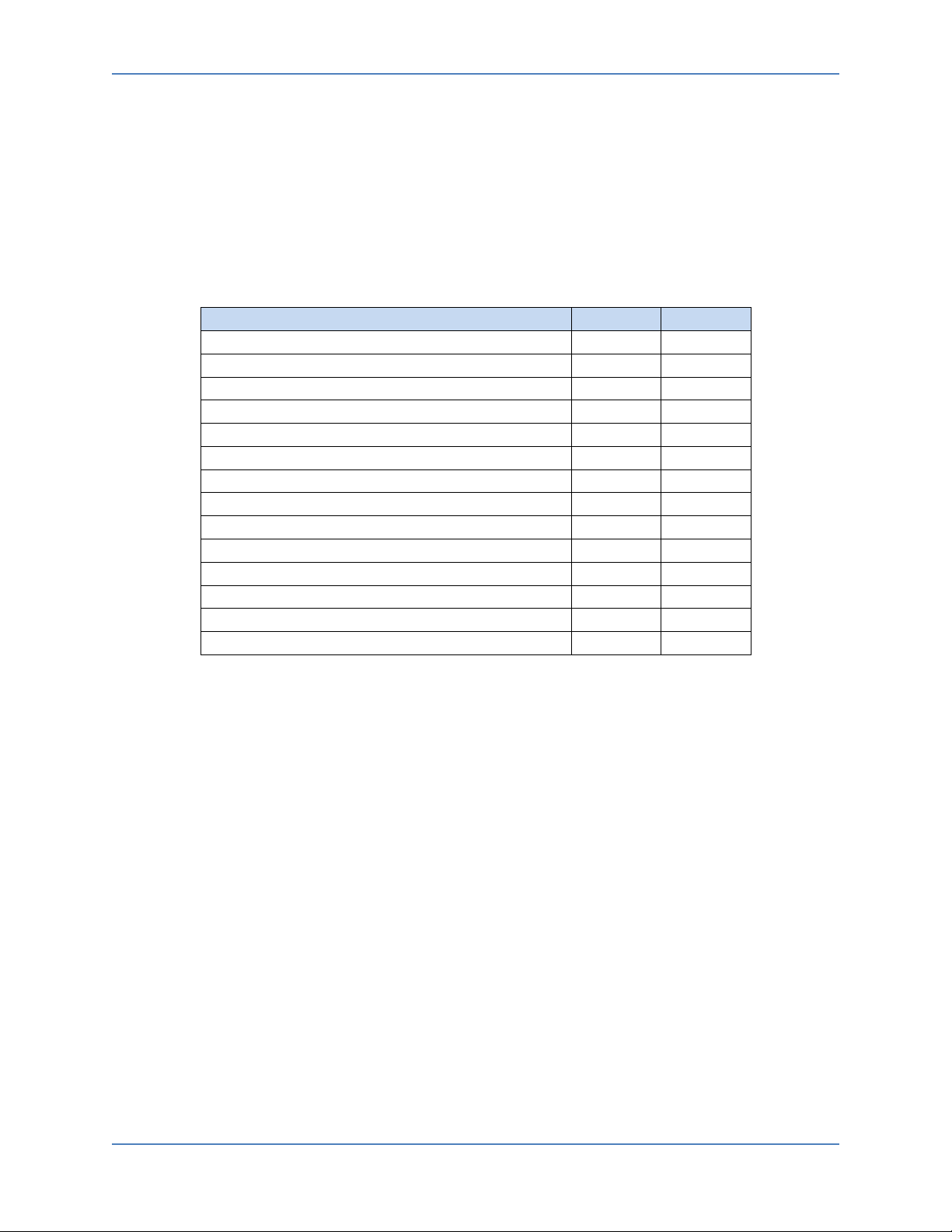

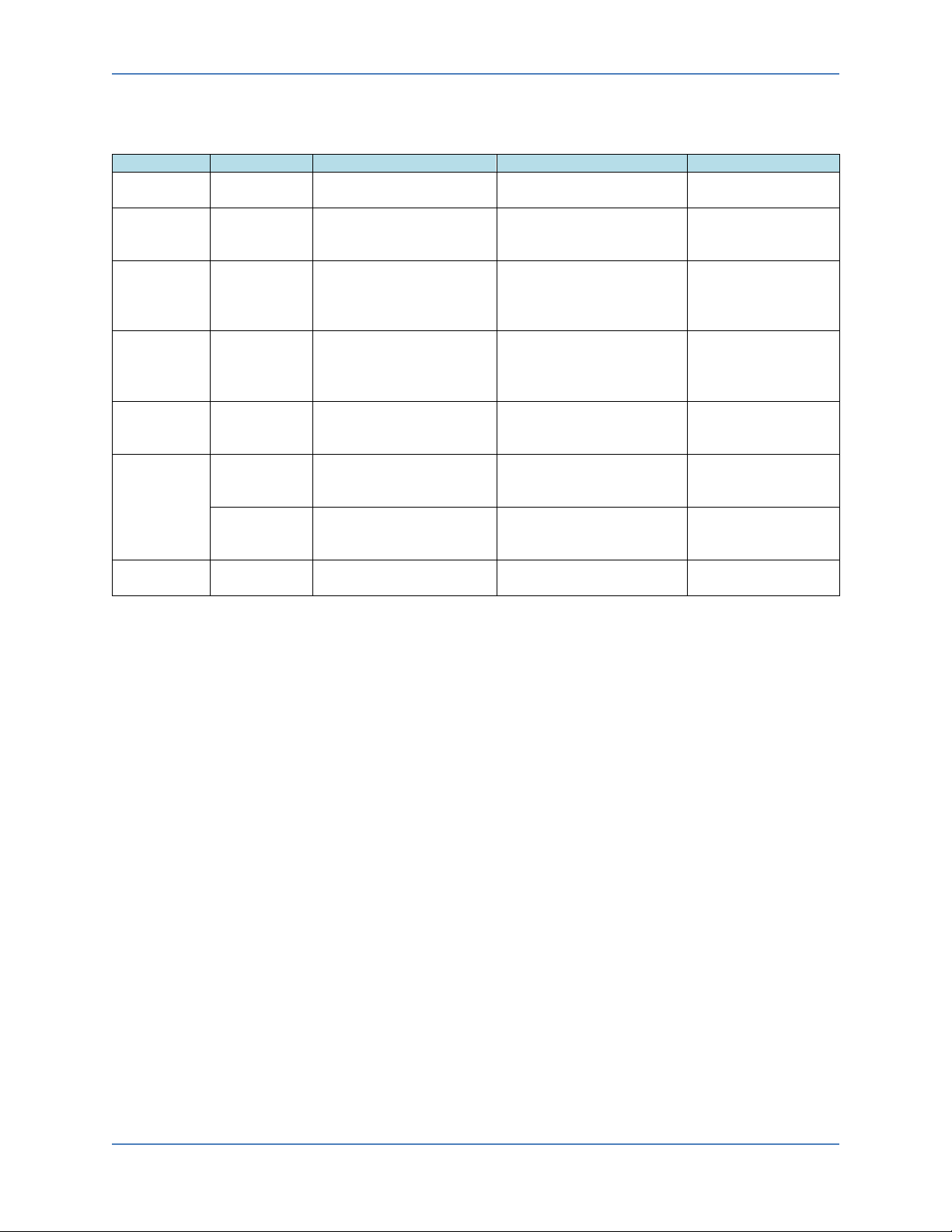

3.1 Indoor Unit Management Point

1. The iTM manages the indoor unit groups as an Indoor Unit Management Point only when a group address is assigned (see 2.3 Remote Controller Group and Group Address) to an indoor unit(s).

One (1) indoor unit management point consists of the following on the iTM:

Function Monitor Control

On/Off X X

Operation Mode X X

Occ Cooling/Heating Setpoint X X

Unocc Cool/Heat Setpoint X X

Fan Speed X X

Vane Position X X

Remote Controller Prohibit (On/Off, Mode, Setpoint) X

Room Temperature X

Setpoint Range Limitation (Cool/Heat Min/Max) X

Error Status X

Malfunction Code X

Override Timer X

Setpoint Tracking X

Minimum Setpoint Differential X

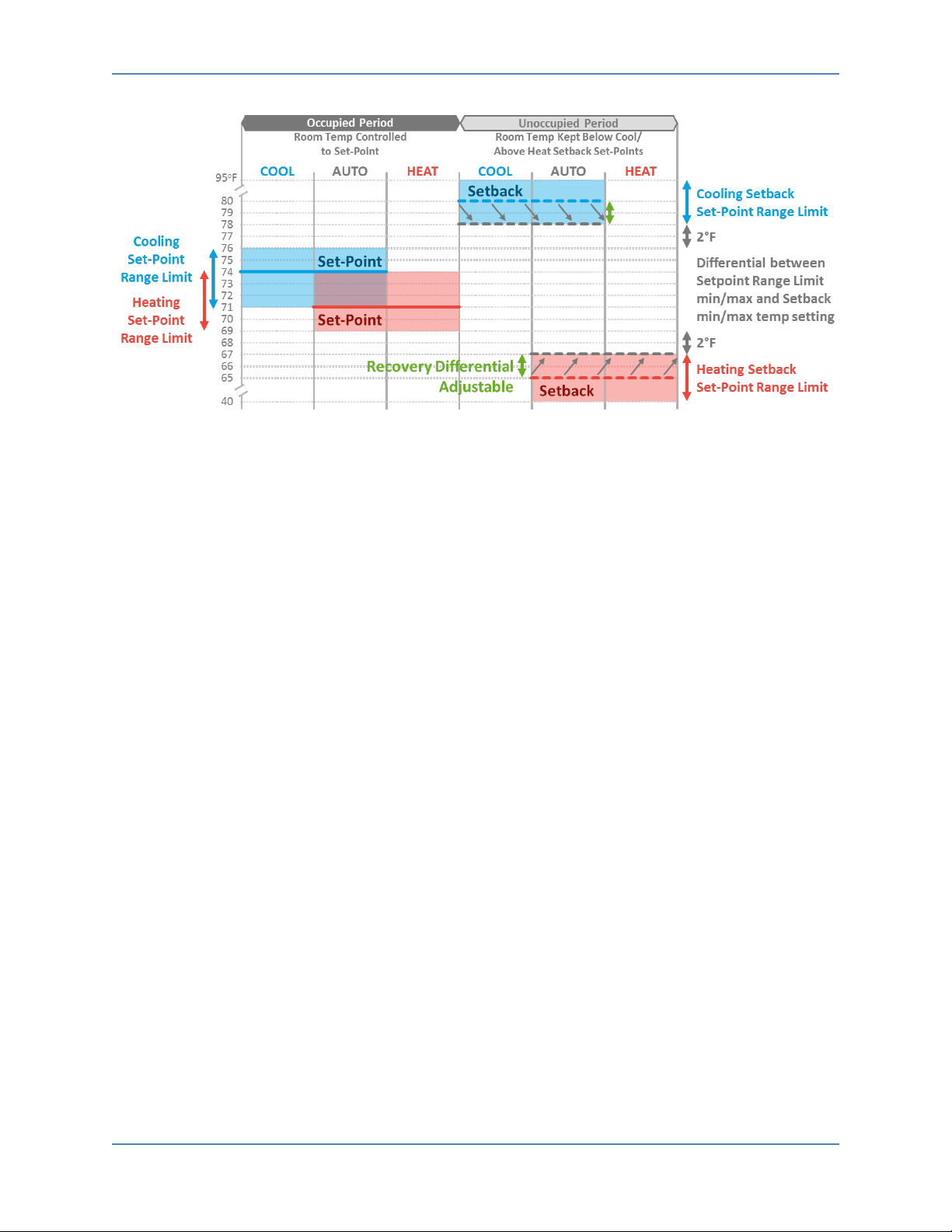

2. Setpoints a. Independent cool and heat dual setpoints in the occupied period. Single setpoint mode is

available with 0

b. Occupied setpoint range for cooling and heating are configurable by Setpoint Range

Limitation within 60

heating setpoint and the heating setpoint cannot be set higher than the cooling setpoint.

c. Minimum Cool/Heat Setpoint Differential refers to the difference between the cooling and

heating setpoint values. The differential can be set between 0

d. Setpoint tracking is used to lock in the Min. Setpoint Differential for cooling and heating to a

fixed value.

e. The setback setpoints (cooling and heating) in the unoccupied period are adjustable

between 50

f. The setback setpoints can only be set outside of the occupied setpoint range with a 2

differential. The setback (unoccupied) setpoint will reduce the occupied setpoint range

automatically to maintain a 2

(heating) possible occupied setpoints.

o

F min setpoint differential and setpoint tracking enabled.

o

F – 90oF as a default. The cooling setpoint cannot be set lower than the

o

F – 7oF.

o

F – 95oF.

o

F fixed differential from the highest (cooling) and lowest

o

F

14 Design Guide DCM014A51

Part 1. Overview

Figure 10. Relationship between Setpoints, Setback, and Setpoint Range Limitation

3. Setback a. The Setback function keeps the room temperature at a moderate level with the setback

setpoints when the indoor unit is off (when the room is unoccupied). The indoor unit only

turns on if the room temperature rises to meet the Cool Setback Setpoint in cooling mode,

or if the room temperature falls to meet the Heat Setback Setpoint in heating mode. Once

the room temperature has recovered and the guard timer has expired, the indoor unit is

turned off.

b. A guard timer keeps the indoor unit on for at least 30 minutes after the Setback function

turns on the indoor unit.

c. If the indoor unit is set to Fan or Dry mode, the setback function will not work.

d. The iTM setback provides independent setback setpoints for cooling and heating.

e. By default the setback setpoints are disabled and can be enabled by the schedule, interlock,

and setting features.

1. The default setback setpoint for cooling is 80

2. The default setback setpoint for heating is 64

3. Independent Setback Recovery Temp (hysteresis) for cooling (-4

o

(+4

F default). Configurable from 2oF to 10oF.

o

F (configurable).

o

F (configurable).

o

F default) and heating

f. Setback Control Logic

1. Room temperature and setback setpoint are evaluated every five minutes for each indoor unit.

2. If the indoor unit is turned on by the iTM manually (or by the Schedule function), the normal operation is maintained, i.e., the indoor unit maintains the room temperature from the setpoint.

3. When the Setback function turns on the indoor unit (unless it is turned off by the iTM manually, by the Schedule function, or by a remote controller), the Setback function maintains the room temperature below (or above) the setback setpoint.

DCM014A51 Design Guide 15

Part 1. Overview

4. Timer Extension a. The Timer Extension is used to turn the indoor unit off (after a specified time has expired)

when it is turned on manually by the iTM or remote controller during unoccupied hours. It

can be set for 30, 60, 90, 120 (default), 150, or 180 minutes. The Timer Extension must be

enabled to operate during the unoccupied period.

b. Timer Extension function will not turn off an indoor unit that was turned on by the Setback

function.

3.2 Automatic Control

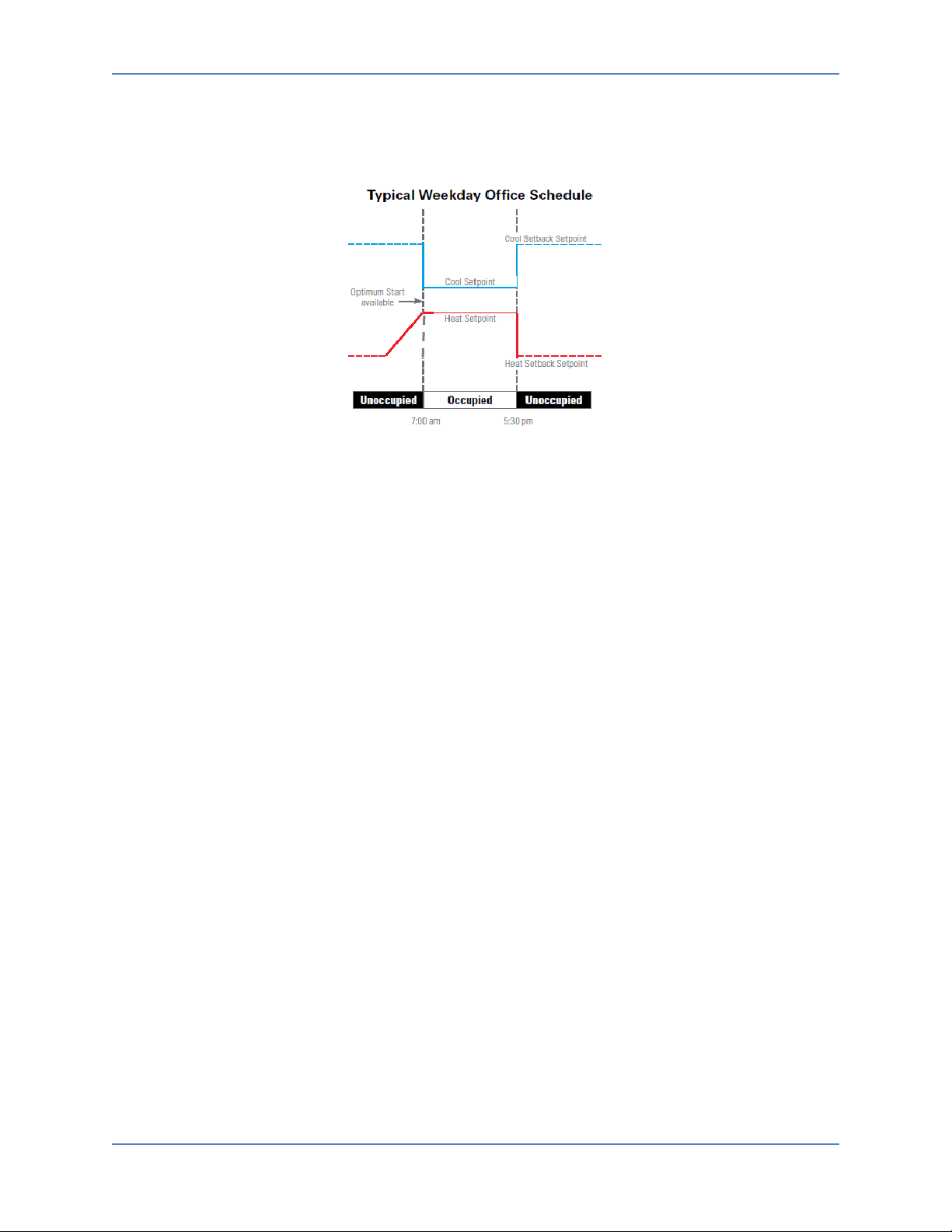

1. Scheduling a. Independent cool and heat setpoints and independent setback setpoints allow for one

schedule to be set to run year round.

Figure 11. Year round setpoint schedule

b. Up to 100 schedule programs can be created.

c. A 7 day, 5+2 (Weekday + Weekend), 5+1+1 (Weekday + Saturday + Sunday) and 1 (Everyday)

schedules can be created in the iTM.

d. Up to 20 events can be registered each day.

e. Special Day (such as holiday) events can be created:

1. Up to 5 special day patterns can be registered.

2. Up to 20 events can be registered each day.

3. Events can be set by calendar date or by week and day of the month (Ex. July 4

th

or 1st

Monday in September).

f. The iTM schedule can provide an Optimum Start function to insure the room temperature

achieves setpoint at the scheduled event time. Optimum Start calculates the time when the

target indoor units turn on, according to the room temperature and the setpoint for the

current operation mode. Optimum Start evaluates and adjusts the turn-on time

appropriately. The schedule and Optimum Start feature can only be set via the iTM schedule

function and cannot be configured by the BMS.

16 Design Guide DCM014A51

Part 1. Overview

g. The Daylight Savings Time (DST) setting automatically adjusts the iTM clock to insure

scheduled operation times are met.

Figure 12. Typical Weekday Office Schedule

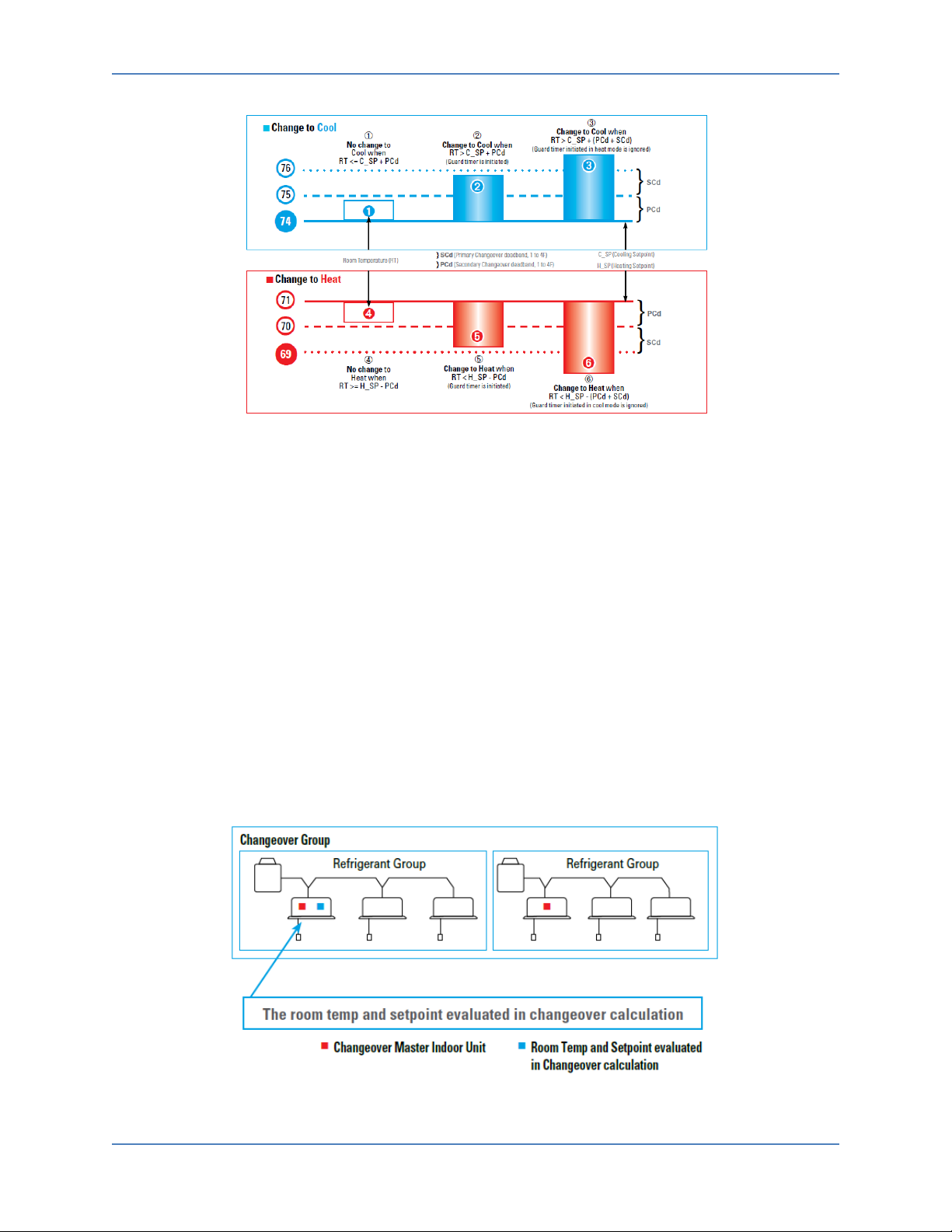

2. iTM Auto-Changeover a. Using the advanced auto-changeover functions in the iTM, the BMS programming time is

significantly reduced. Automatic changeover is available for both Heat Pump and Heat

Recovery systems. The changeover is automatically controlled to occur in the following two

cases:

Case 1: Changeover at the primary changeover temperature after the guard timer expires.

1. The changeover is evaluated by how much the room temperature has deviated from the

cooling or heating setpoint. For example, when the room temperature exceeds the

primary changeover deadband from the cooling setpoint, iTM initiates a change from

heating mode to cooling mode.

2. By default, the primary changeover setpoint is 1°F above the cooling setpoint or 1°F

below heating setpoint, which are configurable between 1°F – 4°F.

3. The guard timer can be set to 15, 30, or 60 (default) minutes. a. The initiation of the guard timer is built in to help prevent frequent changeovers

which may cause energy loss.

b. When the setpoint is changed manually or by the schedule, the guard timer is not

active.

DCM014A51 Design Guide 17

Part 1. Overview

Case 2: Changeover at the secondary changeover temperature.

1. By default, the secondary changeover temperature is 1°F above the primary changeover

2. Case 2 will happen while the guard time is active in Case 1.

3. The iTM auto-changeover is applicable to both Heat Pump and Heat Recovery systems.

Figure 13. Cool/Heat Changeover Logic

temperature for cooling, or 1°F below the primary changeover temperature for heating,

which is configurable between 1°F – 4°F.

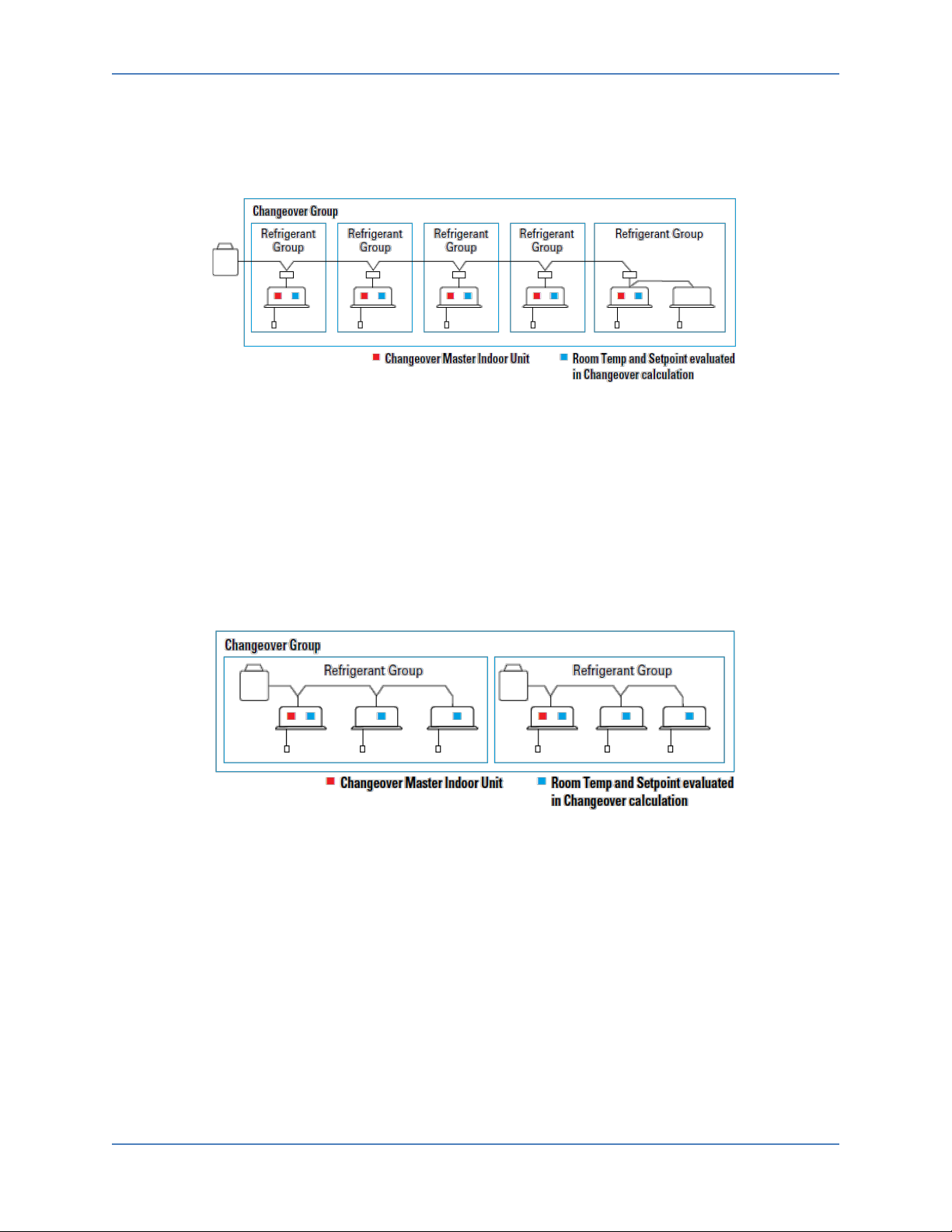

a. The iTM provides four changeover methods to meet a variety of expectations in a

project. Fixed, Individual, Average, or Vote methods can be specified in the

changeover group with targeted indoor units, as well as Primary/Secondary

Changeover deadbands.

1. Fixed Method: a. Changeover is evaluated with the representative indoor unit. b. Changeover affects all indoor units. c. Good method for prioritizing the representative indoor unit for the Heat Pump

system (or multiple units on the same port of the BS Box in Heat Recovery

system).

Figure 14. Fixed Method

18 Design Guide DCM014A51

Part 1. Overview

2. Individual Method: a. Changeover is evaluated by, and affects, each indoor unit individually. b. Used in application with the Heat Recovery system.

Figure 15. Individual Method

3. Average Method: a. Changeover is evaluated based on the average of the room temperature and

average setpoints in the changeover group.

b. A weight (0-3) can be added to each indoor unit demand in the changeover

group. The default is 1.

c. Changeover affects all indoor units in the changeover group.

d. Used in applications with Heat Pump systems (or multiple units on the same

port of the BS Box in the Heat Recovery system).

Figure 16. Average Method

4. Vote Method: a. Changeover is evaluated based on the total cooling demand and total heating

demand. If the total cooling demand is greater than the heating demand, the

iTM changes the indoor units in the changeover group to cool mode.

b. When the changeover group is in cooling mode, the total cooling demand will

decrease; at that point, the total heating demand may become greater than the

cooling demand and change the mode to heating (a guard timer applies).

DCM014A51 Design Guide 19

Part 1. Overview

c. The setpoints can be different in each indoor unit within the changeover group.

The demand is calculated based on the setpoints in comparison to room

temperature for each indoor unit. The demand within the Primary Changeover

deadband (PCd) is considered as no demand.

d. A good method for Heat Pump systems (or multiple units on the same port of

the BS Box in Heat Recovery system) as a pseudo-simultaneous cooling and

heating operation.

e. A weight (0-3) can be added to each indoor unit demand in the changeover

group. The default is 1.

f. An option for heating override can be applied if there is an indoor unit which

the heating demand exceeds [H_SP- (PCd + SCd)].

Figure 17. Vote Method

20 Design Guide DCM014A51

Part 2. Functional Specifications

Part 2. Functional Specifications

1. Introduction

The Daikin iTM BACnet® Server Gateway operates as a BACnet® interpreter using the services defined by

BACnet® to return the status of the indoor units connected to the DIII network. It also sends

configuration commands to the indoor units, in response to requests from the BMS (i.e., BACnet® Client)

which supports the BACnet® protocol (ISO16484-5, ANSI/ASHRAE135).

2. Network Topology

2.1 Visualization of Each Device on the BACnet® Network

1. iTM: Operates as a BACnet® router/gateway for the VRV indoor units.

2. Indoor unit device: One indoor unit management point is handled as one virtual BACnet®

device.

a. In the BACnet® specifications, the VRV communication line (DIII network) is handled as one

virtual BACnet® network.

(See Annex H.1 and H.2 in the BACnet® 2004 specifications.)

3. System control device: It is handled as a virtual BACnet® device to receive settings (i.e., enable/disable and the like) for the iTM system configuration points.

4. For a typical BACnet® network configuration, see chapters 4.2 and Annex J in the BACnet® 2004 specifications.

Figure 18. BACnet® Network

DCM014A51 Design Guide 21

Part 2. Functional Specifications

4bytes

2bytes

2.2 BACnet® Network Number

1. A BACnet® Client access the virtual BACnet® device of an indoor unit by specifying the BACnet® network number mapped to the virtual BACnet® network.

2. BACnet® network numbers are settable in the range defined in the BACnet® specifications (1 to

65534) default is 100.

2.3 Device ID (Device Instance Number)

1. The Device ID must be a unique number per indoor unit and on the BACnet® network. The setting range is 0 to 4194303.

2. The following Device ID calculation is recommended to be used as the default for each indoor

unit unless otherwise specified by the BMS integrator. The default Device ID should follow the

structure 53XXXX.

a. For the Device ID 531100:

1. 531100 → 53 represents Daikin’s BACnet® vendor ID.

2. 531100 → 1 represents the port number (1 = iTM, 2 – 8 = iTM Plus Adapter address).

3. 531100 → 100 represents the DIII-Net group address 1-00.

2.4 What is a MAC Address?

1. The MAC address is a unique physical address to identify a network device.

2. Each physical medium in a network has a MAC address whose length varies depending on the physical medium.

3. MAC addresses used for physical media are defined by the BACnet® specifications; see chapters 7 to 11 in the BACnet® 2004 specifications.

4. Furthermore, when using BACnet® IP, everything below the IP layer is considered the physical layer by definition so as to handle the 6 bytes composed of the IP address + UDP port number as the MAC address.

(See paragraph J.1.2 in the BACnet® 2004 specifications). Note that the MAC address of a virtual BACnet® device is expressed as described above.

5. In the BACnet® specifications, the address of the data source and destination are specified using the BACnet® network number and this MAC address.

For details, see paragraph 6.2.2.2 in the BACnet® 2004 specifications.

2.5 MAC Address of a Virtual BACnet® Device

1. The MAC address is a 6-byte long expression composed of the device instance number for the

indoor unit and system control device, as indicated below: The MAC address of each device is

represented by the hexadecimal conversion of the device Instance number.

(Ex. Device instance number = 531100 → 00:00:00:08:1a:9c = MAC Address)

Device Instance Number Not used (zero)

2. Settings related to the BACnet® Server Gateway functions such as the device instance number

can be done from the BACnet® Server Gateway configuration in the iTM Service Settings menu.

Refer to the iTM BACnet® Server Gateway Commissioning manual for more details.

22 Design Guide DCM014A51

Part 2. Functional Specifications

3. iTM and BACnet® Server Gateway Logic

3.1 BACnet® Virtual Router Function

1. The iTM BACnet® Server Gateway provides seamless control logic between the iTM and BMS.

2. The BACnet® virtual router function allows the BMS to see each Indoor Unit Management Point as a separate device. This allows for each Indoor Unit Management Point to have its own independent device ID.

3.2 iTM BACnet® Server Gateway Point Logic in the iTM

1. Each point exposed to the BMS from the iTM BACnet® Server Gateway is linked to the logic in

the iTM. This alleviates the need for the BMS integrator to create programming to control the

VRV system. The image below identifies which BACnet® points are linked to the iTM logic.

Figure 19. BACnet® Server Gateway Points

2. Each Indoor Unit Management Point can be assigned independent cooling and heating

occupied and unoccupied setpoints.

a. Setpoints set by the BMS are also updated in the iTM, and setpoints set at the iTM are

updated to the BMS.

b. The same logic applies to the setpoint range limitation as stated in Part 1., 3.1(2)(b) for the

minimum and maximum setpoint for cooling and heating.

c. To see how the occupancy mode is monitored and controlled, refer to 7.2.1.

3. Auto-changeover a. The iTM handles the cool/heat auto-changeover for the Changeover Group that consists of

all indoor units in Heat Pump systems, or under BS units in Heat Recovery system.

b. The Changeover Group is configured in the iTM.

c. The changeover method is configured from one of the following: Fixed, Average, Individual

and Vote which is selected in the iTM.

d. Different changeover options can be selected for each Changeover Group.

e. The Auto-changeover point (system point) allows the BMS to enable or disable all the

Changeover Groups simultaneously when the Changeover Groups are configured in the iTM.

DCM014A51 Design Guide 23

Part 2. Functional Specifications

bit: 31

22 21

0

f. The BMS Integrator should be provided with the Changeover Group configuration.

4. Scheduling a. The iTM can accommodate daily scheduling of the indoor unit groups. b. There are four types of schedules that can be set in the iTM 7 day, Weekday/Weekend,

Weekday/Saturday/Sunday, and Everyday.

c. The BMS can use the “Enable iTM Schedule” point to enable or disable the schedule in the

iTM. Typically the BMS Master Schedule is used to control the indoor units, and iTM

Schedule is not used.

5. Forced System Shutdown a. The “Forced System Shutdown” point can be used to turn off all indoor unit groups

connected to the iTM via the DIII-Net communication bus when an emergency signal has

been received by the BMS. Emergency Stop program should be configured and enabled in

advance.

b. Indoor unit groups cannot be restarted from the remote controller until the Forces System

Shutdown point is set to inactive.

4. VRV System Monitor/Control Objects

4.1 Member Objects

1. In BACnet®, a BACnet Object Identifier (hereinafter abbreviated as "ObjectID") is defined as follows:

BACnet Object Type Instance Number

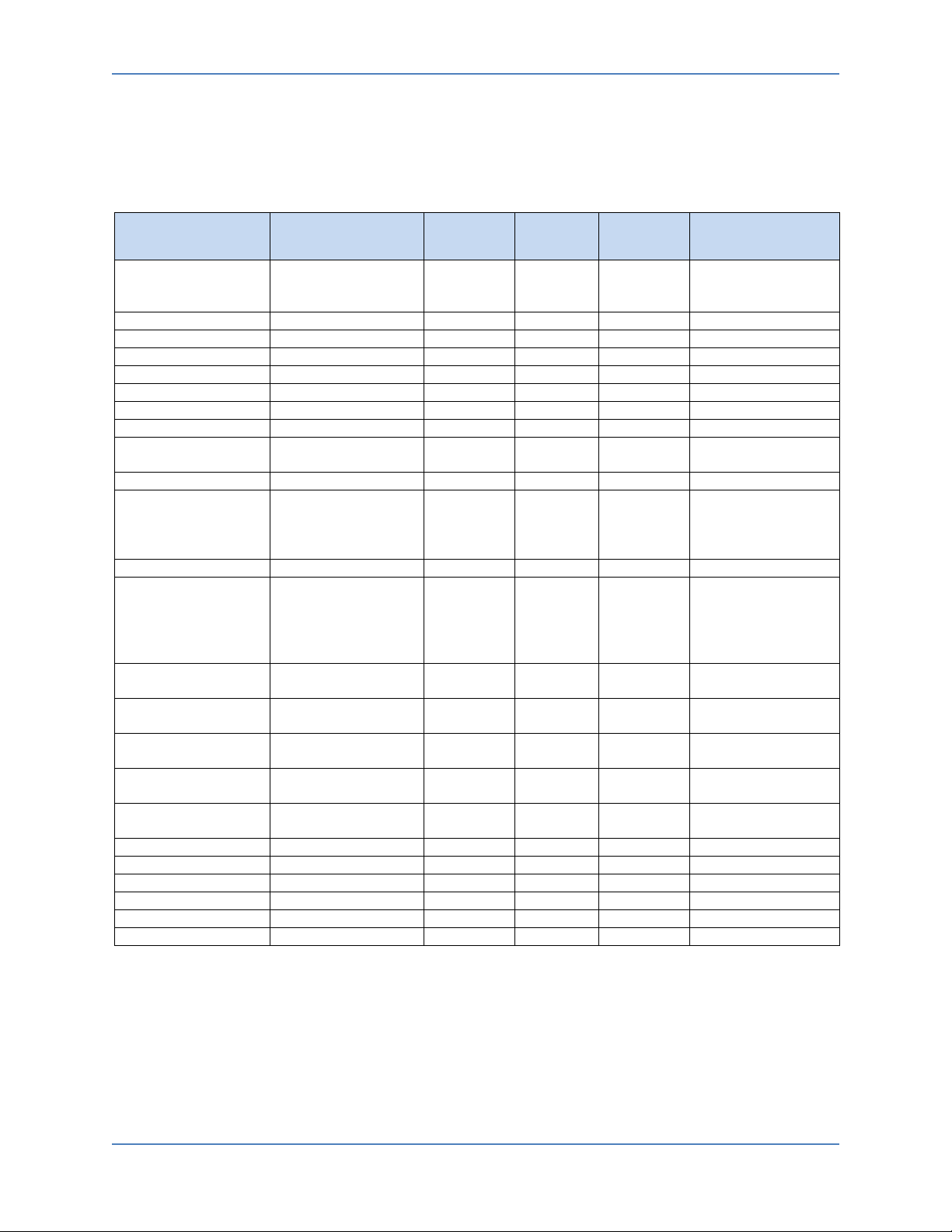

4.2 Indoor Unit Device

1. Each indoor unit monitoring/control item (called Member Object) is mapped to a BACnet® object (called indoor unit object) and to an ObjectID instance number, as indicated in the following table.

2. Each of the object types BI, BV, MI, MO, and MV sets the text shown in the following table in the Description Property in accordance with the value of the Present_Value.

3. The BMS cannot command an indoor unit from cool to heat (or from heat to cool) if the indoor unit is not designated as the changeover master.

4. When more than one indoor unit is connected to a single remote controller group, the BMS

should only send commands to the indoor unit that is designated to receive the command for

the remote controller group (unit #0). The BMS should not send commands to other indoor

units in the remote control group. If commands are sent to the other indoor units in the

remote controller group, the indoor unit that receives the command will decide if it should

follow the command.

5. During the iTM BACnet® Server Gateway commissioning, the BACnet® objects can be enabled and disabled. If an object is disabled, the object will not be available to be controlled and/or monitored by the BMS.

24 Design Guide DCM014A51

Part 2. Functional Specifications

Instance

Inactive

Active

Text-1

Text-2

Text-3

Text-4

Text-5

Text-6

Text-7

Text-8

1

Occupancy Mode

MO

Unocc

Occ

Standby

Unit On_Off

Status

Sets error

Description

property.

See (1)

below.

Room

Temperature

Occ Cooling

Setpoint

Occ Heating

Setpoint

Unocc Cooling

Setpoint

Unocc Heating

Setpoint

Max Cooling

Setpoint

Min Cooling

Setpoint

Max Heating

Setpoint

Min Heating

Setpoint

Min Setpoint

Heating)

Cooling &

Tracking Mode

16

Fan Speed

MV

Low

Reserved

Medium

Reserved

High

Reserved

Reserved

Auto

17

Airflow Direction

MV

P0

P1

P2

P3

P4

Reserved

Reserved

P7

Timed Override

Operation

Current Unit

Operation

6. Indoor unit points list

No.

10

11

12

13

Object_Name Type

2

3 Alarm Status BI Normal Alarm

4 Operation Mode MV Cool Heat Fan Dry

5

6

7

8

9

BI Off On

AI

AV

AV

AV

AV

AV

AV

AV

AV

Remarks

code in the

*1, *2

*1, *2

*1, *2

*1, *2, *3

*1, *2, *3

*1, *2, *4

*1, *2, *4

Differential

14

(Cooling &

15

Heating Setpoint

18

19

AV

BV Disable Enable

BV Disable Enable

MI Off Normal Override Setback

*1, *2

Continued on next page.

DCM014A51 Design Guide 25

Part 2. Functional Specifications

Inactive

Active

Text-1

Text-2

Text-3

Text-4

Text-5

Text-6

Text-7

Text-8

Remote Controller

(On_Off)

Remote Controller

(Operation Mode)

Remote Controller

(Setpoint)

23

Filter Sign Status

BI

Normal

Alarm 24

Filter Sign Reset

BV

Reset

Alarm 25

Indoor Fan Status

BI

Off

On

Communication

Status

27

Thermo-on Status

BI

Off

On

Defrost/

Hot Start

29

Aux Heater Status

BI

Off

On 30

Forced Thermo-off

BV

Disable

Enable

Indoor Unit

Changeover Option

Not

Available

Instance

No.

20

21

22

26

28 Compressor Status MI Off On

31

Object_Name Type

Prohibit

Prohibit

Prohibit

MV Permit Prohibit Stop Only

BV Permit Prohibit

BV Permit Prohibit

BI Normal Alarm

BI

Remarks

Available

*1: The unit of temperature (Celsius or Fahrenheit) follows the iTM locale (regional settings).

*2: The number of valid digits for each object is shown in the table below.

If a value entered from BMS has a higher precision than the number of significant digits of an

object, the digits after the significant digits are rounded.

(For example, when Occ Cooling Setpoint is "75.55" in degrees Fahrenheit, round it to "76".)

Regarding values in commands sent from the BMS, the iTM rounds them off to the number of the

significant digits.

(For example, if the value in a command for Occ Cooling Setpoint is "75.55" in degrees Fahrenheit,

it is rounded to "76".)

Object Name

“Room Temperature” One decimal place One decimal place

"Occ Cooling Setpoint" "Occ Heating Setpoint"

"Unocc Cooling Setpoint" "Unocc Heating Setpoint"

"Max Cooling Setpoint" "Min Cooling Setpoint"

"Max Heating Setpoint" "Min Heating Setpoint"

"Min Setpoint Differential (Cooling & Heating)” Integer Integer

One decimal place Integer

Number of valid digits

Celsius Fahrenheit

*3: When the Out_Of_Service property is TRUE, the setting items (Setback Temperature (Cool/Heat),

Min Setpoint Differential (Cooling & Heating) that are mapped to the object are disabled.

Therefore, a value set on the indoor unit management point remains unchanged even if

Present_Value is changed.

26 Design Guide DCM014A51

Part 2. Functional Specifications

*4: The Out_Of_Service property of "Max Cooling Setpoint" and "Min Cooling Setpoint" indicates the

upper and lower limit of the Cool Setpoint change along with the Present_Value.

(When the Out_Of_Service property of either object is changed from FALSE → TRUE, the

Out_Of_Service property of the other object also changes from FALSE → TRUE.)

The "Max Heating Setpoint" and "Min Heating Setpoint" which indicates the upper and lower limit

of the Heat Setpoint also behaves in the same way.

When the Out_Of_Service property is TRUE, the setting items (Max and Min Setpoint) mapped to

an object are disabled, so a value set for the indoor unit management point remains unchanged

even when the Present_Value changes.

4.3 System Control Device

1. The instance numbers of the Object IDs are mapped to the system control settings on the iTM as shown in the table below.

2. Each of the BO and MV object types set the text shown in the table below for the Description Property in accordance with the value of Present_Value.

Instance

No.

1

2

3

4 System Forced Off BO Inactive Active

Object_Name Type

Enable iTM Schedule

Operation

Enable iTM

Auto-Changeover

Operation

Timed Override

Minutes

Inactive Active

Text-1 Text-2 Text-3 Text-4 Text-5 Text-6 Text-7

BO Disable Enable

BO Disable Enable

MV 30 60 90 120 150 180

4.4 Restrictions

1. When a Present Value (PV) is set by the BMS, the BACnet® Server in iTM updates the PV and keeps the previous PV.

2. The BACnet® Server in iTM sends the new PV to Management Point in iTM. The BACnet® Server in iTM then starts a 10 minute timer.

3. If the value in Management Point is changed (i.e., the indoor unit accepted the new value and

sent back the new status to iTM), the Management Point in iTM sends the new value to the

BACnet® Server in iTM. The BACnet® Server in iTM updates the PV and resets the 10 minute

timer.

4. If the value in Management Point is not changed (i.e., the indoor unit did not accept the new value and did not update the status to iTM) nothing happens. When the 10 minute timer expires, the BACnet® Server in iTM resets to the previous PV.

Remarks

DCM014A51 Design Guide 27

Part 2. Functional Specifications

•

• Cool SP range: 70-76°F

•

• Cool SP range: 70-76°F

• Sets Cool SP max

85°F

• PV: 85°F, previous PV: 76°F

Start 10-min timer

•

• Cool SP range: 70-78°F (Changed)

• PV 78°F

• Reset 10-min timer

•

85°F again

• PV: 85°F, previous PV: 78°F

Start 10-min timer

•

• Cool SP range: 70-78°F (No change)

• When 10-min timer expires, PV

back to 78°F

Step

BMS

BACnet® Server in iTM

Management Point in iTM

• Cool SP range: 70-78°F

• Cool SP: 72°F

• Cool SP range: 70-78°F

• Cool SP: 72°F

• PV: 68°F, previous PV: 72°F

• Start 10-min timer

• Cool SP 68°F is rounded to 70°F due to

Cool SP: 70°F (Changed)

•

• Reset 10-min timer

• Sets Cool SP 68°F

again

• PV: 68°F, previous PV: 70°F

Start 10-min timer

•

• Cool SP: 70°F (No change)

• When 10-min timer expires, PV

back to 70°F

EXAMPLE 1 – Cool SP Max

Step BMS BACnet® Server in iTM Management Point in iTM

Pre-condition

Unocc Cool SP: 80°F

Cool Setback SP: 80°F

#1

#2

#3

#1

#2

#4

Sets Cool SP max

EXAMPLE 2 – Cool SP

Pre-condition

#1

#2

#3

• Sets Cool SP 68°F

•

• Sends 85°F to Management Point

•

• Sends 85°F to Management Point

• Sends 68°F to Management Point

PV 70°F

Cool SP max 85°F is rounded to 78°F

due to Cool Setback SP 80°F.

• Updates 78°F to the BACnet® Server

Cool SP max 85°F is rounded to 78°F

due to Cool Setback SP 80°F

Cool SP range 70-78°F

•

• Sends 70°F to BACnet® Server

#1

#2

#4

•

• Sends 68°F to Management Point

Cool SP 68°F is rounded to 70°F due to

the Cool SP range 70-78°F

28 Design Guide DCM014A51

Part 2. Functional Specifications

Step

BMS

BACnet® Server in iTM

Management Point in iTM

Indoor Unit

•

Cool

•

mode Fan

•

mode Fan

• Operation mode: Fan

Server

• Sets

mode Heat

• Cannot accept Heat

slave unit

• Periodical status

Operation mode Fan

• When 10-min timer

expires, PV back to Fan

EXAMPLE 3 – Operation Mode to Changeover Slave Unit

Pre-condition

#1

#2

#3

#1

#2

#4

Sets

Operation

Operation

• Operation mode: Cool • Operation mode: Cool

• PV: Fan, previous PV: Cool

• Start 10-min timer

• Sends Fan mode to

Management Point

• PV Fan

• Reset 10-min timer

• PV: Heat, previous PV: Fan

• Start 10-min timer

• Sends Heat to

Management Point

• Send Fan mode to Indoor

Unit

(Changed)

• Send Fan to BACnet®

• Send Heat to Indoor Unit

• Operation mode: Fan (No

change)

Operation mode:

Accepts Fan mode

• Status update to

iTM as Operation

due to changeover

report to iTM as

DCM014A51 Design Guide 29

Part 2. Functional Specifications

Support

□ = No

Configurable with

Gateway Configuration

Object_Name

CharacterString

R ■ R

Indoor unit name*

Object_Type

BACnetObjectType

R ■ R

DEVICE

System_Status

BACnetDeviceStatus

R ■ R

Fixed to OPERATIONAL

Vendor_Name

CharacterString

R ■ R

DAIKIN Industries LTD

Vendor_Identifier

Unsigned16

R ■ R

Fixed to 53 (= DAIKIN)

Model_Name

CharacterString

R ■ R

Fixed to "Indoor Unit"

Firmware_Revision

CharacterString

R ■ R

Application_Software_

Version

Location

CharacterString

O

□

Port No. + Group

Ex: "1:1-00"

Protocol_Revision

Unsigned

R ■ R

RP, RPM, WP, WPM, I-

SubCOV

Protocol_Object_

Types_Supported

BACnetObjectTypesSupp

orted

AI, AV, BI, BV, MI, MO,

MV, Device

BACnetARRAY[N] of

BACnetObjectIdentifier

Max_APDU_Length_

Accepted

Segmentation_

Supported

Max_Segments_

Accepted

VT_Class_Supported

List of BACnetVTClass

O1

□

Active_VT_Sessions

List of BACnetVTSession

O2

□

Local_Time

Time

O3,4 ■ R

Follows the iTM clock

Local_Date

Date

O3,4 ■ R

Follows the iTM clock

UTC_Offset

Signed

O4 ■ R

Follows the iTM clock

Daylight_Saving_Status

Boolean

O4 ■ R

Follows the iTM clock

* The character code for indoor unit names is UTF-8

5. Properties

5.1 Device Object Type

1. Indoor Unit Device

Property Identifier Property Datatype

Object_Identifier BACnetObjectIdentifier R ■ R

CharacterString R ■ R

Description CharacterString O ■ R

Protocol_Services_

Supported

BACnetServiceSupported R

Compatible

Class

■ = Yes

■ R

R: Readable

W: Writable

-

Remarks

BACnet® Server/

Address connected to

DIII-NET

Am, I-Have, TimeSync,

Who-Is, Who-Has,

UTCTimeSync,

Object_List

R ■ R

R ■ R

Unsigned R ■ R 1024

BACnetSegmentation R ■ R SEGMENTED_BOTH

Unsigned O1 ■ R Fixed to 100

-

-

30 Design Guide DCM014A51

Loading...

Loading...