Daikin DCH090, DCC060, DCH060, DCH072, DCH102 Service Instructions Manual

...

Ser vice Instr uctions

DCC Cooling/DCH Heat Pumps

Commercial Package Units

with R-410A Refrigerant

4 - 6 Tons & Accessories

Not for installation in the United S tates or Canada. This unit is for export only.

This manual is to be used by qualified, professionally trained HVAC

technicians only. Daikin does not assume any responsibility for property

damage or personal injury due to improper service procedures or services

performed by an unqualified person.

Copyright © 2015 - 2016

RSDX6412006r1

November 2016

T ABLE OF CONTENTS

IMPORTANT INFORMATION .................................2 - 3

PRODUCTION IDENTIFICATION ..........................4 - 6

PRODUCT DESIGN .............................................7 - 10

SYSTEM OPERATION.......................................11 - 16

SCHEDULED MAINTENANCE ................................. 17

TROUBLESHOOTING CHARTS ................................ 18

SERVICING TABLE OF CONTENTS ........................ 19

SERVICING .......................................................20 - 39

UNIT WIRING DIAGRAMS ....................................... 40

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE

APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL

ADJUST, SERVICE OR REPAIR (HEREINAFTER

EQUIPMENT SPECIFIED IN THIS MANUAL SHOULD SERVICE THE

EQUIPMENT

FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

THIS UNIT, YOU ASSUME RESPONSIBILITY FOR ANY INJURY OR

PROPERTY DAMAGE WHICH MAY RESULT

JURISDICTIONS THAT REQUIRE ONE OR MORE LICENSES TO

SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

MPROPER INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR

I

OF THE EQUIPMENT SPECIFIED IN THIS MANUAL, OR ATTEMPTING

TO INSTALL, ADJUST, SERVICE OR REPAIR THE EQUIPMENT

SPECIFIED IN THIS MANUAL WITHOUT PROPER TRAINING MAY

RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

. THE

MANUFACTURER WILL NOT BE RESPONSIBLE

.

, “

. IN

ADDITION, IN

SERVICE

. IF

,

”)

THE

YOU SERVICE

.

Do not store combustible materials or use gasoline

or other flammable liquids or vapors in the vicinity

of this appliance as property damage or personal

injury could occur. Have your contractor point out

and identify the various cut-off devices, switches,

etc., that serves your comfort equipment.

HIGH VOLTAGE!

Disconnect ALL power before

servicing or installing this unit.

Multiple power sources may be

present. Failure to do so may cause

prop er t y dam a ge, pe r sonal injury or de a t h.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE - DAIKIN BRAND PRODUCTS

TOLL FREE 1-855-770-5678 (U.S. only)

email us at: customerservice@daikincomfort.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

2

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

Refrigerants are heavier than air. They can "push out"

the oxygen in your lungs or in any enclosed space.To

avoid possible difficulty in breathing or death:

•

Never purge refrigerant into an enclosed room or

space. By law, all refrigerants must be reclaimed.

•

If an indoor leak is suspected, thoroughly ventilate

the area before beginning work.

• Liquid refrigerant can be very cold. To avoid possible

frostbite or blindness, avoid contact with refrigerant

and wea r gloves and gog gles. If liquid r efrige rant

does cont act your sk in or eyes, seek medic al help

immediately.

WARNING

To avoid possible injury, explosion or death, practice

safe handling of refrigerants.

The compre ssor POE oil for R-410A units is

extremely susceptible to moisture absorption and

could cause compressor failu r e. Do not leave system

open to atmosphere any longer than necessary

for insta llat i o n .

To avoid possible e xplosio n, use only returnabl e (n ot

disposable) service cylinders when removing refrigerant from a system.

• Ensure the cylinde r is f ree of damage which could

lead to a leak or explosio n .

• Ensure the hydrostatic test date does not exceed

5 years.

• Ensure the pressure rating meets or exceeds 400

lbs.

When in doubt, do not use cylinder.

WARNING

System contamina nts, improper se rvice procedure

and/or physical abuse affecting hermetic com pressor

electrical terminals may cause dangerous s ystem

venting.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes

associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the

compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the

hermetic compressor. The terminals and their dielectric

embedment are strongly constructed, but are vulnerable to

careless compressor installation or maintenance procedures and equally vulnerable to internal electrical short

circuits caused by excessive system contaminants.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the

compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a ) hot lubricating oil and refrigerant

(b ) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in the

vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be

electrically energized and/or operated without having the

terminal protective cover properly in place.

See Service Section S-17 for proper servicing.

3

PRODUCT IDENTIFICA TION

r

y

y

The model number is used for positive identification of component parts used in manufacturing. Please use this number when

requesting service or parts information.

DCC090045 5 D***

1 2 3 4, 5, 6 7, 8, 9 10 11 12 13 14

Brand

DDaikin

Configuration

C Standard Efficiency XNo Options

Application

C Cooling X Standard Aluminized Heat Exchange

HHeat Pump S Stainle ss Steel Gas Heat Exchanger

Nominal Gross Cooling Capacit

036 3 Tons 102 8½ Ton s

048 4 Tons 120 10 Tons

060 5 Tons 180 15 Tons

072 6 Tons 240 20 Tons BBelt Drive

090 7½ T on s D Direct Dr ive

Nominal Heating Capacit

Gas/Electric A/C H/P Factory-Installed Electric Heat

180 180,000 BTU/h X XX No Heat 030 30 kW 1 208-230/1/60 ( Unit ed St ates) 4 460/ 3/60 (United Stat es)

300 300,00 0 BTU/h 016 15 kW 045 44 kW 3 208-230/3/60 (Un ited States) 5 400/3/50 (Russia Daikin B rand)

350 350,00 0 BTU/h 6 400/3/ 60 ( Saudi Ar ab ia) A 400/3 /50 (Russia Goodman Bran d)

B 400/3/50 (Kuwait) E 400/3/50 (Argentina)

See product specifications for heat size(s) available for each c apacit y.

A *

15 16

Revision Levels

Major & Minor

Factory-Install ed Optio ns

Factory-Install ed Optio ns

Factory-Install ed Optio ns

XNo Options

Supply Fan/Drive Type/Motors

Voltage

4

PRODUCT IDENTIFICA TION

Daikin Commer cial Multiposition Package Heat Pumps

Models Description

DCH[048-060]XXX6DXXXAA

DCH072XX X6BX XXAA

DCH048XXX6 DXXXAD

DCH060XXX6 DXXXAC

DCH072XX X6BX XXAC

Daikin Commercial Package Heat Pump, Multiposition heat pump units, 400V 3 Phase, 60 Hz Di rect Dr ive. Initial release

of Daikin branded models.

Daikin Commercial Package Heat Pump, Multiposition heat pump units, 400V 3 Phase, 60 Hz Di rect Dr ive. Initial release

of Daikin branded models.

Daikin Commercial Package Heat Pump, Multiposition heat pump units, 400V 3 Phase, 60 Hz Di rect Drive with Phase

Monitor.

Daikin Commercial Package Heat Pump, Multiposition heat pump units, 400V 3 Phase, 60 Hz Di rect Drive with Phase

Monitor.

DCH***XXX**XXX

These units have R410A refrigerant

5

PRODUCT IDENTIFICA TION

Daikin Co mmercia l M ultip o s it io n Pa c k a g e C oo le rs

Models Description

DCC[048-060]XXX6DXXXAA

DCC072XXX6BXXXAA

DCC[048-060]XXXBDXXXAA

DCC[048-060]XXX6DXXXAC Daikin Commercial Package Cooler, Multiposition cooling, 400V 3 Phase, 50 Hz Direct Drive with Phase Monitor.

DCC072XXX6BXXXAC Daikin Commercial Package Cooler, Multiposition cooling, 400V 3 Phase, 50 Hz Direct Drive with Phase Monitor.

Daikin Commercial Package Cooler, Multiposition cooling, 400V 3 Phase, 60 Hz Direct Drive. Initial release of 4-5 Ton

Daikin branded models.

Daikin Commercial Package Cooler, Multiposition cooling, 400V 3 Phase, 60 Hz Direct Drive. Initial release of 4-5 Ton

Daikin branded models.

Daikin Commercial Package Cooler, Multiposition cooling, 400V 3 Phase, 60 Hz Direct Drive. Initial release of Daikin

branded models with SASO level 2 regulations.

DCC***XXX**XXX

6

These units have R410A refrigerant

PRODUCT DESIGN

UNIT LOCATION

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FOLLOWING BULLET P OINTS MUST BE OBSERVED

WHEN INSTALLING THE UNIT.

IMPORTANT NOTE: Remove wood shipping rails prior to

installation of the unit.

ALL INSTALLATIONS:

NOTE: Appliance is shipped from factory for vertical duct

application.

Proper installation of the unit ensures trouble-free operation.

Improper installation can result in problems ranging from

noisy operation to property or equipment damages, dangerous conditions that could result in injury or personal property

damage. Give this booklet to the user and explain it’s

provisions. The user should retain these instructions for future

reference.

• For proper flame pattern within the heat exchanger and

proper condensate drainage, the unit must be mounted

level.

• The flue outlet must be at least 12 inches from any

opening through which flue gases could enter a building,

and at least three feet above any forced air inlet located

within ten feet. The economizer/manual fresh air intake/

motorized fresh air intake and combustion air inlet

mounted on the unit are not affected by this restriction.

• To avoid possible corrosion of the heat exchanger, do not

locate the unit in an area where the outdoor air (i.e.

combustion air for the unit) will be frequently contaminated by compounds containing chlorine or fluorine.

Common sources of such compounds include swimming

pool chemicals and chlorine bleaches, paint stripper,

adhesives, paints, varnishes, sealers, waxes (which are

not yet dried) and solvents used during construction and

remodeling. Various commercial and industrial processes

may also be sources of chlorine/fluorine compounds.

• To avoid possible illness or death of the building occu-

pants, do NOT locate outside air intake device (economizer, manual fresh air intake, motorized fresh air intake)

too close to an exhaust outlet, gas vent termination, or

plumbing vent outlet. For specific distances required,

consult local codes.

• Allow minimum clearances from the enclosure for fire

protection, proper operation, and service access (see

unit clearances). These clearances must be permanently maintained.

• The combustion air inlet and flue outlet on the unit must

never be obstructed. If used, do not allow the economizer/manual fresh air damper/ motorized fresh air damper

to become blocked by snow or debris. In some climates

or locations, it may be necessary to elevate the unit to

avoid these problems.

• When the unit is heating, the temperature of the return air

entering the unit must be a minimum of 55° F.

GROUND LEVEL INSTALLATIONS ONLY:

• When the unit is installed on the ground adjacent to the

building, a level concrete (or equal) base is recommended. Prepare a base that is 3” larger than the

package unit footprint and a minimum of 3” thick.

• The base should also be located where no runoff of water

from higher ground can collect in the unit.

ROOF TOP INSTALLATIONS ONLY:

• To avoid possible property damage or personal injury, the

roof must have sufficient structural strength to carry the

weight of the unit(s) and snow or water loads as required

by local codes. Consult a structural engineer to determine the weight capabilities of the roof.

• The unit may be installed directly on wood floors or on

Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, a safe, flat surface for

service personnel should be provided.

• As indicated on the unit data plate, a minimum clearance

of 36” to any combustible material is required on the

furnace access side of the unit. All combustible materials must be kept out of this area.

• This 36” clearance must also be maintained to insure

proper combustion air and flue gas flow. The combustion

air intake and furnace flue discharge must not be blocked

for any reason, including blockage by snow.

• Adequate clearances from the furnace flue discharge to

any adjacent public walkways, adjacent buildings, building openings or openable windows must be maintained in

accordance with the latest edition of the National Fuel

Gas Code (ANSI Z223.1)

• Minimum horizontal clearance of 48” from the furnace flue

discharge to any electric meters, gas meters, regulators

and relief equipment is required.

UNIT PRECAUTIONS

• Do not stand or walk on the unit.

• Do not drill holes anywhere in panels or in the base

frame of the unit except where indicated. Unit access

panels provide structural support.

• Do not remove any access panels until unit has been

installed on roof curb or field supplied structure.

• Do not roll unit across finished roof without prior

approval of owner or architect.

• Do not skid or slide on any surface as this may damage

unit base. The unit must be stored on a flat, level

surface. Protect the condenser coil because it is

easily damaged.

7

PRODUCT DESIGN

ROOF CURB INSTALLATIONS ONLY:

Curb installations must comply with local codes and should

be done in accordance with the established guidelines of the

National Roofing Contractors Association.

Proper unit installation requires that the roof curb be firmly

and permanently attached to the roof structure. Check for

adequate fastening method prior to setting the unit on the

curb.

Full perimeter roof curbs are available from the factory and are

shipped unassembled. Field assembly, squaring, leveling

and mounting on the roof structure are the responsibility of the

installing contractor. All required hardware necessary for the

assembly of the sheet metal curb is included in the curb

accessory.

WARNING

O PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL

T

INJURY OR DEATH, THE FOLLOWING BULLET POINTS MUST BE OBSERVED

WHEN INSTALLING THE UNIT.

• Sufficient structural support must be determined prior to

locating and mounting the curb and package unit.

• Ductwork must be constructed using industry guide-

lines. The duct work must be placed into the roof curb

before mounting the package unit. Our full perimeter

curbs include duct connection frames to be assembled

with the curb. Cantilevered type curbs are not available

from the factory.

• Curb insulation, cant strips, flashing and general roofing

material are furnished by the contractor.

The curbs must be supported on parallel sides by roof

members. The roof members must not penetrate supply and

return duct opening areas as damage to the unit might occur.

CLEARANCES

24”

Min.*

36” Min.

*

24”

Min.*

Unit Clearances

*In situations that have multiple units, a 48” minimum clearance

is required between the condenser coils.

Adequate clearance around the unit should be kept for safety,

service, maintenance, and proper unit operation. A total

clearance of 75” on the main control panel side of the unit is

recommended to facilitate possible fan shaft, coil, electric

heat and gas furnace removal. A clearance of 48” is

recommended on all other sides of the unit to facilitate

possible compressor removal, to allow service access and to

insure proper ventilation and condenser airflow. The unit must

not be installed beneath any obstruction. The unit should be

installed remote from all building exhausts to inhibit ingestion

of exhaust air into the unit fresh air intake.

NOTE: The unit and curb accessories are designed to

allow vertical duct installation before unit placement. Duct

installation after unit placement is not recommended.

CAUTION

ALL

CURBS LOOK SIMILAR

POSITIONING, CHECK JOB PLANS CAREFULLY AND VERIFY MARKINGS

ON CURB ASSEMBLY

SUPERSEDES INFORMATION SHOWN

. TO

AVOID INCORRECT CURB

. I

NSTRUCTIONS MAY VARY IN CURB STYLES AND

.

See the manual shipped with the roof curb for assembly and

installation instructions.

8

PROTRUSION

Inspect curb to ensure that none of the utility services

(electric) routed through the curb protrude above the curb.

ELECTRICAL WIRING

HIGH VOLTAGE!

D

ISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT

BE PRESENT

DAMAGE, PERSONAL INJURY OR DEATH

. F

. M

AILURE TO DO SO MAY CAUSE PROPERTY

W ARNING

ULTIPLE POWER SOURCES MAY

.

PRODUCT DESIGN

WARNING

HIGH VOLTAGE!

O AVOID PERSONAL INJURY OR DEATH DUE TO

T

ELECTRICAL SHOCK, DO NOT TAMPER WITH FACTORY

WIRING

. THE

OF THESE UNITS ARE FACTORY-INSTALLED AND HAVE

BEEN THOROUGHLY TESTED PRIOR TO SHIPMENT

ONTACT YOUR LOCAL REPRESENTATIVE IF

C

ASSISTANCE IS REQUIRED

INTERNAL POWER AND CONTROL WIRING

.

.

CAUTION

TO

PREVENT DAMAGE TO THE WIRING, PROTECT WIRING FROM

SHARP EDGES

LOCAL CODES AND ORDINANCES

REMOVABLE ACCESS PANELS

. F

OLLOW NATIONAL ELECTRICAL CODE AND ALL

. DO

NOT ROUTE WIRES THROUGH

.

CAUTION

C

ONDUIT AND FITTINGS MUST BE WEATHER-TIGHT TO PREVENT

WATER ENTRY INTO THE BUILDING

.

For unit protection, use a fuse or HACR circuit breaker that

is in excess of the circuit ampacity, but less than or equal to

the maximum overcurrent protection device. DO NOT EXCEED THE MAXIMUM OVERCURRENT DEVICE SIZE

SHOWN ON UNIT DATA PLATE.

All line voltage connections must be made through weatherproof fittings. All exterior power supply and ground wiring

must be in approved weatherproof conduit.

The main power supply wiring to the unit and low voltage

wiring to accessory controls must be done in accordance

with these instructions, the latest edition of the National

Electrical Code (ANSI/NFPA 70), and all local codes and

ordinances. All field wiring shall conform with the temperature limitations for Type T wire (63°F/35°C rise).

The unit is factory wired for the voltage shown on the unit’s

data plate. Refer to model nomenclature in Appendix B for

voltage requirement for your unit.

NOTE: If supply voltage is 208V, lead on primary of transformer must be moved from the 230V to the 208V tap. Refer

to wiring diagram on unit for details.

Main power wiring should be sized for the minimum wire

ampacity shown on the unit’s database. Size wires in

accordance with the ampacity tables in Article 310 of the

National Electrical Code. If long wires are required, it may be

necessary to increase the wire size to prevent excessive

voltage drop. Wires should be sized for a maximum of 3%

voltage drop.

CAUTION

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, USE

T

ONLY COPPER CONDUCTORS.

CAUTION

O PREVENT IMPROPER AND DANGEROUS OPERATION DUE TO WIRING ERRORS,

T

LABEL ALL WIRES PRI OR TO DISCONNECTION WH EN SERVICING CONTRO LS.

ERIFY PROPER OPERATION AFTER SERVICING.

V

NOTE: A weather-tight disconnect switch, properly sized

for the unit total load, must be field or factory installed. An

external field supplied disconnect may be mounted on the

exterior panel.

Ensure the data plate is not covered by the field-supplied

disconnect switch.

• Some disconnect switches are not fused. Protect the

power leads at the point of distribution in accordance with

the unit data plate.

• The unit must be electrically grounded in accordance

with local codes or, in the absence of local codes, with

the latest edition of the National Electrical Code (ANSINFPA 70). A ground lug is provided for this purpose. Size

grounding conductor in accordance with Table 250-95 of

the National Electrical Code. Do not use the ground lug

for connecting a neutral conductor.

• Connect power wiring to the compressor contactor closest to the entrance located within the main control box or

to electrical power block, if equipped.

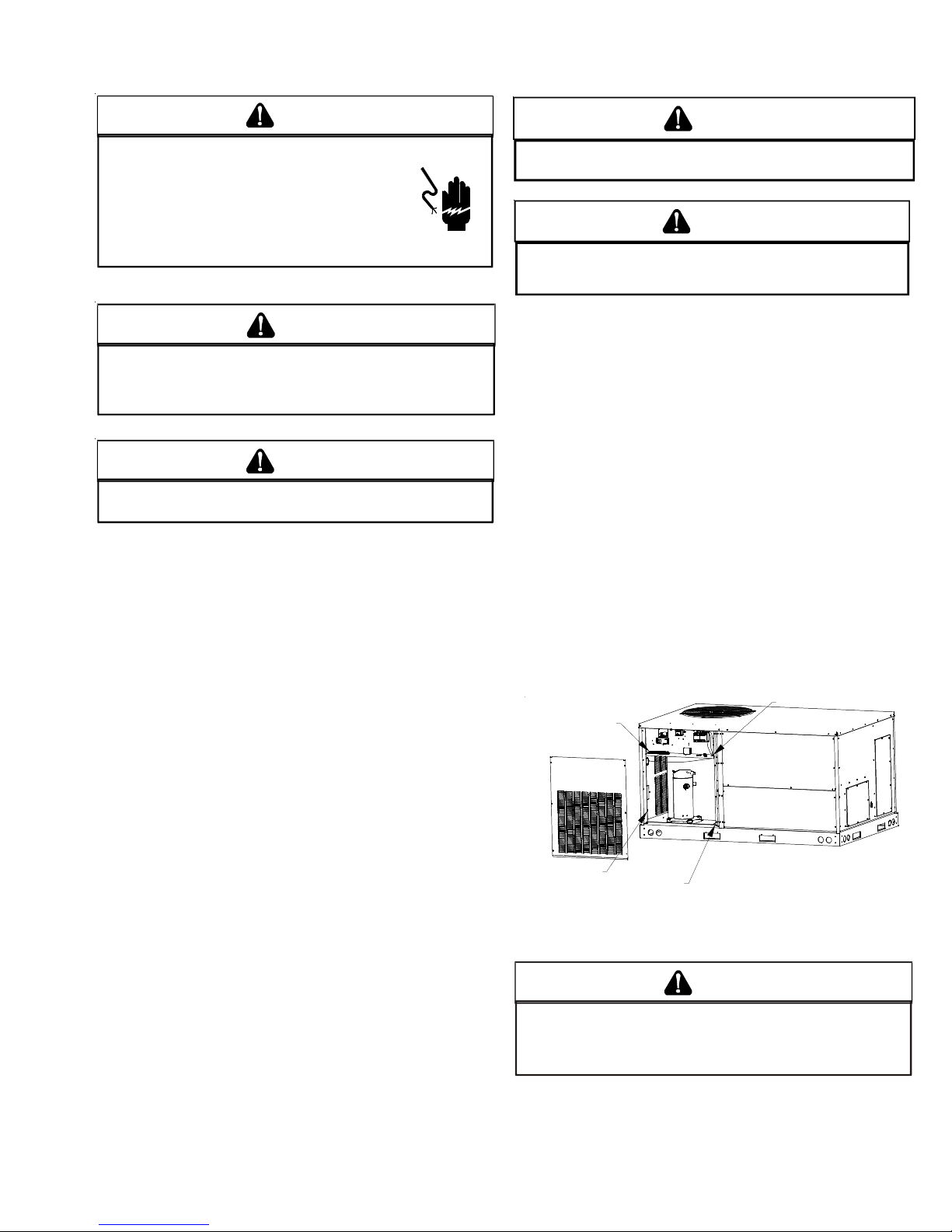

MAIN POWER

LOW VOLTAGE

BLOCK

LOW VOLTAGE

ENTRANCE

POWER THRU

THE CURB

Power and Low Voltage Block Connections

W ARNING

F

AILURE OF UNIT DUE TO OPERATION ON IMPROPER LINE VOLTAGE

OR WITH EXCESSIVE PHASE UNBALANCE CONSTITUTES PRODUCT

ABUSE AND MAY CAUSE SEVERE DAMAGE TO THE UNIT ELECTRICAL

COMPONENTS

.

9

PRODUCT DESIGN

AREAS WITHOUT CONVENIENCE OUTLET

It is recommended that an independent 115V power source

be brought to the vicinity of the roof top unit for portable lights

and tools used by the service mechanic.

NOTE: Refer to local codes for requirements. These outlets

can also be factory installed.

UNITS INSTALLED ON ROOF TOPS

Main power and low voltage wiring may enter the unit through

the condenser end of unit or through the roof curb. Install

conduit connectors at the desired entrance locations. External connectors must be weatherproof. All holes in the unit

base must be sealed (including those around conduit nuts) to

prevent water leakage into building. All required conduit and

fittings are to be field supplied.

Supply voltage to roof top unit must not vary by more than

10% of the value indicated on the unit data plate. Phase

voltage unbalance must not exceed 2%. Contact your local

power company for correction of improper voltage or phase

unbalance.

HIGH VOLTAGE ENTRANCE

(REMOVE PLUG)

12 3/8”

30 1/4”*

* (6 Ton - 34 1/4”)

1:4

LOW VOLTAGE ENTRANCE

3.5 DIA.

POWER THRU

THE CURB

4 1/2”

47 1/2”

7 1/2”

Electrical Entrance and Thru Curb

Unit is equipped with a Low Voltage Terminal Block and has

Single Point wiring to the contactor or power block, if

equipped.

LOW VOLTAGE CONTROL WIRING

1. A 24V thermostat must be installed for unit operation. It

may be purchased with the unit or field -supplied. Thermostats may be programmable or electromechanical as

required.

2. Locate thermostat or remote sensor in the conditioned

space where it will sense average temperature. Do not

locate the device where it may be directly exposed to

supply air, sunlight or other sources of heat. Follow

installation instructions packaged with the thermostat.

3. Use #18 AWG wire for 24V control wiring runs not

exceeding 75 feet. Use #16 AWG wire for 24V control

wiring runs not exceeding 125 feet. Use #14 AWG wire

for 24V control wiring runs not exceeding 200 feet. Low

voltage wiring may be National Electrical Code (NEC)

Class 2 where permitted by local codes.

4. Route thermostat wires from sub-base terminals to the

unit. Control wiring should enter through the condenser

panel opening or through curb indicated in “Electrical

Entrance” figure. Connect thermostat and any accessory

wiring to low voltage terminal block TB1 in the main

control box.

10

NOTE: Field-supplied conduit may need to be installed

depending on unit/curb configuration. Use #18 AWG solid

conductor wire whenever connecting thermostat wires to

terminals on sub-base. DO NOT use larger than #18 AWG

wire. A transition to #18 AWG wire may be required before

entering thermostat sub-base.

NOTE: Refer to unit wiring diagrams for thermostat

hookups.

SYSTEM OPERATION

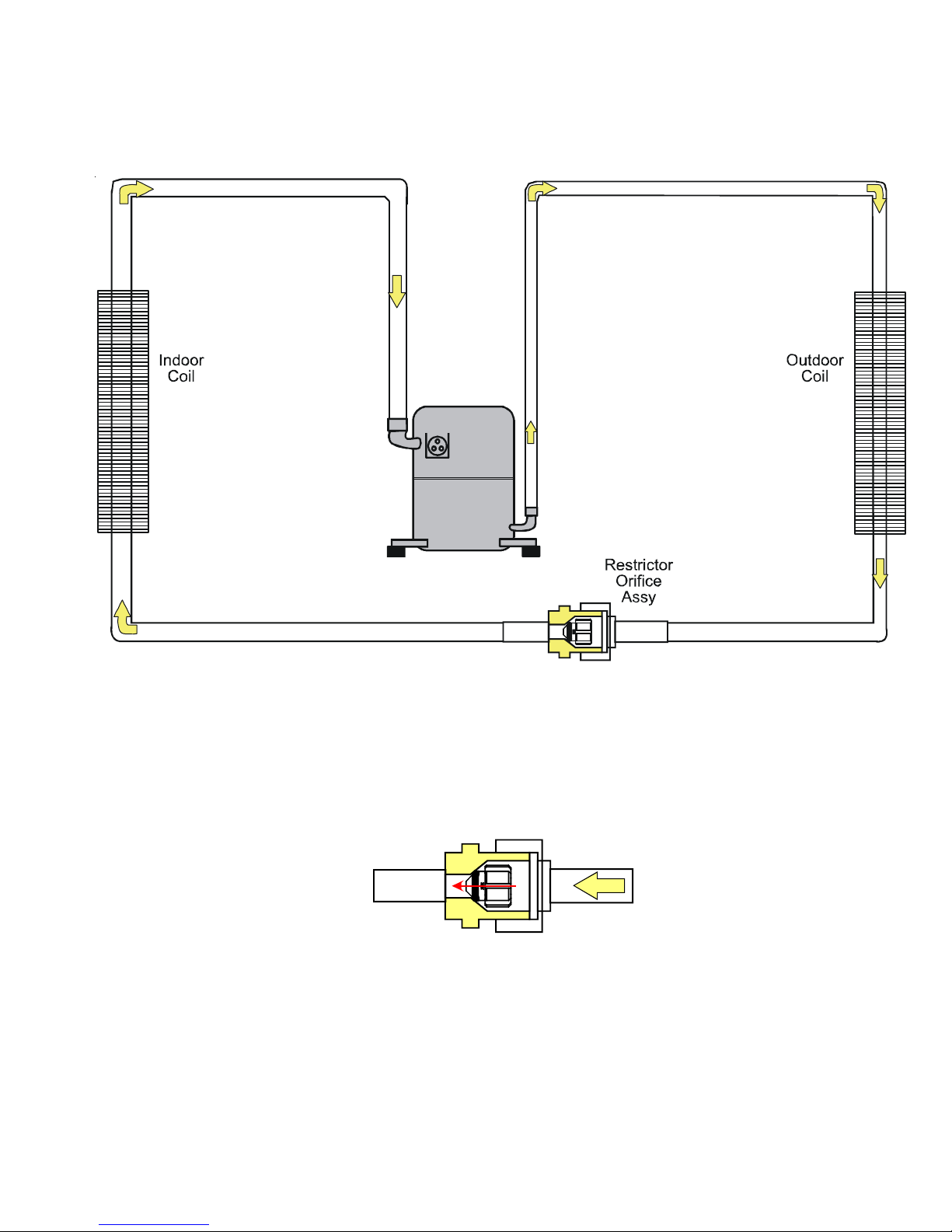

Typical Package Cooling or Package Gas

DCC***XXX**XXX

Restrictor Orifice Assembly in Cooling Operation

In the cooling mode the orifice is pushed into its seat forcing refrigerant to flow through the metered hole in the center of the

orifice.

11

SYSTEM OPERATION

Typical Heat Pump System in Cooling

DCH***XXX**XXX

Reversing Valve

(Energized)

Indoor

Coil

Outdoor

Coil

Accumulator

Indoor

Coil

Accumulator

12

Reversing Valve

(De-Energized)

Outdoor

Coil

SYSTEM OPERATION

CIRCULATING AIR AND FILTERS

DUCTWORK

The supply duct from the unit through a wall may be installed

without clearance. However, minimum unit clearances must

be maintained (see “Clearances” section). The supply duct

should be provided with an access panel large enough to

inspect the air chamber downstream of the heat exchanger.

A cover should be tightly attached to prevent air leaks.

Ductwork dimensions are shown in the roof curb installation

manual.

If desired, supply and return duct connections to the unit may

be made with flexible connections to reduce possible unit

operating sound transmission.

VENTING

NOTE: Venting is self-contained.

CONDENSATE DRAIN CONNECTION

CONDENSATE DRAIN CONNECTION

A 3/4” female NPT drain connection is supplied on the end of

the unit and bottom of the drain pan for condensate piping. An

external trap must be installed for proper condensate drainage.

DRAIN

CONNECTION

UNIT 2" MIN IMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

A POSIT IVE L I QUID

SEAL IS REQU IRE D

3" MINIMUM

Drain Connection

Install condensate drain trap as shown. Use 3/4" drain line

and fittings or larger. Do not operate without trap.

HORIZONTAL DRAIN

Drainage of condensate directly onto the roof may be acceptable; refer to local code. It is recommended that a small drip

pad of either stone, mortar, wood or metal be provided to

prevent any possible damage to the roof.

CLEANING

Due to the fact that drain pans in any air conditioning unit will

have some moisture in them, algae and fungus will grow due

to airborne bacteria and spores. Periodic cleaning is necessary to prevent this build-up from plugging the drain.

STARTUP, ADJUSTMENTS, AND CHECKS

WARNING

HIGH VOLTAGE!

O AVOID PERSONAL INJURY OR DEATH DUE TO

T

ELECTRICAL SHOCK, B

THE BUILDING ELECTRICAL GROUND BY USE OF THE

GROUNDING TERMINAL PROVIDED OR OTHER

ACCEPTABLE MEANS

SERVICING OR INSTALLING THIS UNIT

OND THE FRAME OF THIS UNIT TO

. D

ISCONNECT ALL POWER BEFORE

.

CAUTION

TO

PREVENT PROPERTY DAMAGE OR PERSONAL INJURY

START THE UNIT UNTIL ALL NECESSARY PRE-CHECKS AND TESTS

HAVE BEEN PERFORMED

.

, DO

NOT

WARNING

MOVING MACHIN ERY HAZARD!

T

O PREVENT POSSIBLE PERSONAL INJURY OR DEATH, DISCONNECT

POWER TO THE UNIT AND PADLOCK IN THE

SERVICNG FANS

.

“OFF”

POSITION BEFORE

CONTRACTOR RESPONSIBILITY

The installing contractor must be certain that:

• All supply and return air ductwork is in place, properly

sealed, and corresponds with installation instructions.

• All thermostats are mounted and wired in accordance

with installation instructions.

• All electric power, all gas, hot water or steam line

connections, and the condensate drain installation

have been made to each unit on the job. These main

supply lines must be functional and capable of operating all units simultaneously.

• Requirements are met for venting and combustion air.

• Air filters are in place.

• Input rate and temperature rise are adjusted per rating

plate.

• Return air temperature is maintained between 55°F

(13°C) and 80°F (27°C).

ROOF CURB INSTALLATION CHECK

Inspect the roof curb for correct installation. The unit and curb

assembly should be level. Inspect the flashing of the roof

mounting curb to the roof, especially at the corners, for good

workmanship. Also check for leaks around gaskets. Note

any deficiencies in a separate report and forward to the

contractor.

13

SYSTEM OPERATION

OBSTRUCTIONS, FAN CLEARANCE AND WIRING

Remove any extraneous construction and shipping materials

that may be found during this procedure. Rotate all fans

manually to check for proper clearances and that they rotate

freely. Check for bolts and screws that may have jarred loose

during shipment to the job site. Retighten if necessary. Retighten all electrical connections.

FIELD DUCT CONNECTIONS

Verify that all duct connections are tight and that there is no

air bypass between supply and return.

FILTER SECTION CHECK

Remove filter section access panels and check that filters are

properly installed. Note airflow arrows on filter frames.

AIR FLOW ADJUSTMENTS

When the final adjustments are complete, the current draw of

the motor should be checked and compared to the full load

current rating of the motor. The amperage must not exceed

the service factor stamped on the motor nameplate. The total

airflow must not be less than that required for operation of the

electric heaters or the furnace.

If an economizer is installed, check the unit operating

balance with the economizer at full outside air and at

minimum outside air.

NOTE: Airflow setting below 350 CFM/Ton is not

recommended, as evaporator freezing or poor unit

performance is possible.

PSC MOTOR

Adjust the CFM for the unit by changing the speed tap of the

indoor blower motor at the heat or cool tap on the control

board connection with the one of the speed taps on “M1” or

“M2” (Black-High Speed, Blue-Medium Speed, Red-Low

Speed).

EEM Motor

Adjust the CFM for the unit by changing the position of the low

voltage leads on the motor terminal block. Green is for Fan

Only. Yellow is for Cooling and Heat Pump Heating.NOTE: If

more than one lead is energized simultaneously, the motor

will run at the higher speed.

SET EVAPORATOR FAN RPM

Actual RPM’s must be set and verified with a tachometer or

strobe light. Refer to Appendices A and B for basic unit fan

RPM. Refer also to “Airflow” section of this manual. With

disconnect switch open, disconnect thermostat wires from

terminals Y and W. This will prevent heating and mechanical

cooling from coming on. Place a jumper wire across terminals

R and G at TB1 terminal block. Close disconnect switch;

evaporator fan motor will operate so RPM can be checked.

For gas heat units, the airflow must be adjusted so that the

air temperature rise falls within the ranges given stated on

Data Plate.

14

EVAPORATOR FAN ROTATION CHECK (THREE PHASE MODELS

ONLY)

Check that fan rotates clockwise when viewed from the drive

side of unit and in accordance with rotation arrow shown on

blower housing. If it does not, reverse any two incoming power

cables at Single Point Power Block. In this case, repeat

bearing check.

Do not attempt to change load side wiring. Internal wiring

assures all motors and compressors will rotate in correct

direction once evaporator fan motor rotation check has been

made.

ELECTRICAL INPUT CHECK

Make preliminary check of evaporator fan ampere draw and

verify that motor nameplate amps are not exceeded. A final

check of amp draw should be made upon completion of air

balancing of the duct system.

BELT DRIVE MODELS ONLY

The drive on the supply fan is typically set in the middle of the

RPM range. The drive motor sheave pitch diameter is field

adjustable for the required airflow.

Upon completion of the air flow balancing, we recommend

replacing the variable pitched motor sheave with a properlysized fixed sheave. A matching fixed sheave will provide

longer belt and bearing life and vibration free operation.

Initially, it is best to have a variable pitched motor sheave for

the purpose of airflow balancing, but once the balance has

been achieved, fixed sheaves maintain alignment and minimize vibration more effectively. For direct drive units, move fan

speed wire.

BEARING CHECK

Prior to energizing any fans, check and make sure that all

setscrews are tight so that bearings are properly secured to

shafts.

NORMAL SEQUENCE OF OPERATION

COOLING

Begin with power turned off at all disconnects.

1. Turn thermostat system switch to “Cool,” and fan switch

to “Auto” and turn temperature setting as high as it will go.

2. Inspect all registers and set them to the normal open

position.

3. Turn on the electrical supply at the disconnect.

4. Turn the fan switch to the “ON” position. The blower

should operate after a 7 second delay.

5. Turn the fan switch to “Auto” position. The blower should

stop after a 65 second delay.

SYSTEM OPERATION

6. Slowly lower the cooling temperature until the unit starts.

The compressor, blower and fan should now be operating. Allow the unit to run 10 minutes, make sure cool air

is being supplied by the unit.

7. Turn the temperature setting to the highest position,

stopping the unit. The indoor blower will continue to run

for 65 seconds.

8. Turn the thermostat system switch to “OFF” and disconnect all power when servicing the unit.

WA RNING

HIGH VOLTAGE!

D

ISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT

BE PRESENT

DAMAGE, PERSONAL INJURY OR DEATH

. F

. M

AILURE TO DO SO MAY CAUSE PROPERTY

ULTIPLE POWER SOURCES MAY

.

HEAT PUMP

9. Check the cooling mode for the heat pump in the same

manner as above. The reversing valve is energized when

the thermostat is placed in the cooling position. A

clicking sound should be noticeable from the reversing

valve. By lowering the temperature setting to call for

cooling, the contractor is energized. The compressor,

blower and fan should then be running. After the cooling

mode is checked out, turn the thermostat system switch

to “OFF”.

10.Turn the thermostat system switch to “HEAT” and fan

switch to “AUTO”.

11.Slowly raise the heating temperature setting. When the

heating first stage makes contact, stop raising the

temperature setting.. The compressor, blower and fan

should now be running with the reversing valve in the deenergized (heating) position. After giving the unit time to

settle out, make sure the unit is supplying heated air.

12.If the outdoor ambient is above 80°F, the unit may trip on

its high pressure cut out when on heating. The compressor should stop. The heating cycle must be thoroughly

checked, so postpone the test to another day when

conditions are more suitable but-DO NOT FAIL TO TEST.

If the outdoor ambient is low and the unit operates

properly on the heating cycle, you may check the

pressure cutout operation by blocking off the indoor

return air until the unit trips.

13.If unit operates properly in the heating cycle, raise the

temperature setting until the heating second stage makes

contact. Supplemental resistance heat, if installed should

now come on. Make sure it operates properly.

NOTE: If outdoor thermostats are installed the outdoor

ambient must be below the set point of these thermostats for the heaters to operate. It may be necessary to

jumper these thermostats to check heater operation if

outdoor ambient is mild.

14.For thermostats with emergency heat switch, return to

step 11. The emergency heat switch is located at the

bottom of the thermostat. Move the switch to emergency

heat. The heat pump will stop, the blower will continue to

run, all heaters will come on and the thermostat emergency heat light will come on.

15.If checking the unit in the wintertime, when the outdoor

coil is cold enough to actuate the defrost control, observe

at least one defrost cycle to make sure the unit defrosts

completely.

HEAT PUMP OPERATION

COOLING CYCLE

When the heat pump is in the cooling cycle, it operates

exactly as a Summer Air Conditioner unit. In this mode, all the

charts and data for service that apply to summer air conditioning apply to the heat pump. Most apply on the heating cycle

except that “condenser” becomes “evaporator”, “evaporator”

becomes “condenser”, “cooling” becomes “heating”.

HEATING CYCLE

The heat pump operates in the heating cycle by redirecting

refrigerant flow through the refrigerant circuit external to the

compressor. This is accomplished with through the reversing

valve. Hot discharge vapor from the compressor is directed to

the indoor coil (evaporator on the cooling cycle) where the

heat is removed, and the vapor condenses to liquid. It then

goes through the expansion device to the outdoor coil

(condenser on the cooling cycle) where the liquid is evaporated, and the vapor goes to the compressor.

When the solenoid valve coil is operated either from heating

to cooling or vice versa, the piston in the reversing valve to the

low pressure (high pressure) reverse positions in the reversing valve.

The following figures show a schematic of a heat pump on the

cooling cycle and the heating cycle. In addition to a reversing

valve, a heat pump is equipped with an expansion device and

check valve for the indoor coil, and similar equipment for the

outdoor coil. It is also provided with a defrost control system.

The expansion devices are flowrator distributors and perform

the same function on the heating cycle as on the cooling

cycle. The flowrator distributors also act as check valves to

allow for the reverse of refrigerant flow.

15

SYSTEM OPERATION

DEFROST CONTROL

During operation the power to the circuit board is controlled

by a temperature sensor, which is clamped to a feeder tube

entering the outdoor coil. Defrost timing periods of 30,60 and

90 minutes may be selected by connecting the circuit board

jumper to 30, 60 and 90 respectively. Accumulation of time

for the timing period selected starts when the sensor closes

(approximately 31° F), and when the wall thermostat calls for

heat. At the end of the timing period, the unit’s defrost cycle

will be initiated provided the sensor remains closed. When

the sensor opens (approximately 75° F), the defrost cycle is

terminated and the timing period is reset. If the defrost cycle

is not terminated due to the sensor temperature, a ten minute

override interrupts the unit’s defrost period.

REFRIGERATION SYSTEM CHECKS

Ensure the hold-down bolts on the compressor are secure

and have not vibrated loose during shipment. Check that

vibration grommets have been installed. Visually check all

piping and clamps. The entire refrigeration system has been

factory charged and tested, making it unnecessary to field

charge. Factory charges are shown on the unit nameplate.

When the heat pump is on the heating cycle, the outdoor coil

is functioning as an evaporator. The temperature of the

refrigerant in the outdoor coil must be below the temperature

of the outdoor air in order to extract heat from the air. Thus,

the greater the difference in the outdoor temperature and the

outdoor coil temperature, the greater the heating capacity of

the heat pump. This phenomenon is a characteristic of a heat

pump. It is a good practice to provide supplementary heat for

all heat pump installations in areas where the temperature

drops below 45° F. It is also a good practice to provide

sufficient supplementary heat to handle the entire heating

requirement should there be a component failure of the heat

pump, such as a compressor, or refrigerant leak, etc.

Since the temperature of the refrigerant in the outdoor coil on

the heating cycle is generally below freezing point, frost forms

on the surfaces of the outdoor coil under certain weather

conditions of temperature and relative humidity. Therefore, it

is necessary to reverse the flow of the refrigerant to provide hot

gas in the outdoor coil to melt the frost accumulation. This is

accomplished by reversing the heat pump to the cooling

cycle. At the same time, the outdoor fan stops to hasten the

temperature rise of the outdoor coil and lessen the time

required for defrosting. The indoor blower continues to run and

the supplementary heaters are energized.

FINAL SYSTEM CHECKS

1. Check to see if all supply and return air grilles are

adjusted and the air distribution system is balanced for

the best compromise between heating and cooling.

2. Check for air leaks in the ductwork. See Sections on Air

Flow Adjustments.

3. Make sure the unit is free of “rattles”, and the tubing in the

unit is free from excessive vibration. Also make sure

tubes or lines are not rubbing against each other or sheet

metal surfaces or edges. If so, correct the trouble.

4. Set the thermostat at the appropriate setting for cooling

and heating or automatic changeover for normal use.

5. Be sure the Owner is instructed on the unit operation,

filter, servicing, correct thermostat operation, etc.

16

SCHEDULED MAINTENANCE

MAINTENANCE

WARNING

HIGH VOLTAGE!

D

ISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT

BE PRESENT

DAMAGE, PERSONAL INJURY OR DEATH

. F

. M

AILURE TO DO SO MAY CAUSE PROPERTY

ULTIPLE POWER SOURCES MAY

.

WARNING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER

INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE, REFER TO THIS MANUAL

ASSISTANCE OR INFORMATION, CONSULT A QUALIFIED INSTALLER

SERVICE AGENCY OR THE GAS SUPPLIER

. FOR

CAUTION

S

HEET METAL PARTS, SCREWS, CLIPS AND SIMILAR ITEMS INHERENTLY

HAVE SHARP EDGES, AND IT IS NECESSARY THAT THE INSTALLER AND

SERVICE PERSONNEL EXERCISE CAUTION

Preventive maintenance is the best way to avoid unnecessary

expense and inconvenience. Have this system inspected at

regular intervals by qualified service personnel, at least twice

a year. Routine maintenance should cover the following

items:

1. Tighten all belts, set screws, and wire connections.

2. Clean evaporator and condenser coils mechanically or

with cold water, if necessary. Usually any fouling is only

matted on the entering air face of the coil and can be

removed by brushing.

3. Lubricate motor bearings.

4. Align or replace belts as needed.

5. Replace filters as needed (see below).

6. Check for blockage of condensate drain.

7. Check power and control voltages.

8. Check running amperage.

9. Check operating temperatures and pressures.

10.Check and adjust temperature and pressure controls.

11.Check and adjust damper linkages.

12.Check operation of all safety controls.

13.Examine gas furnaces (see below and the User’s Information Manual).

14.Check condenser fans and tighten set screws.

.

.

ADDITIONAL

,

FILTERS

CAUTION

TO PREVENT PROPERTY DAMAGE DUE TO FIRE AND LOSS OF

EQUIPMENT EFFICIENCY OR EQUIPMENT DAMAGE DUE TO DUST AND LINT

BUILD UP ON INTERNAL PARTS, NEVER OPERATE UNIT WITHOUT AN AIR

FILTER INSTALLED IN THE RETURN AIR SYSTEM.

Every application may require a different frequency of replacement of dirty filters. Filters must be replaced at least every

three (3) months during operating seasons.

Dirty filters are the most common cause of inadequate

heating or cooling performance. Filter inspection should be

made at least every two months; more often if necessary

because of local conditions and usage.

Dirty throwaway filters should be discarded and replaced with

a new, clean filter.

Disposable return air filters are supplied with this unit. See the

unit Specification Sheet or the correct size and part number.

To remove the filters, remove the filter access panel on return

side of the unit.

CABINET FINISH MAINTENANCE

Use a fine grade automotive wax on the cabinet finish to

maintain the finish’s original high luster. This is especially

important in installations with extended periods of direct

sunlight.

CLEAN OUTSIDE COIL (QUALIFIED SERVICER ONLY)

The coil with the outside air flowing over it should be inspected

annually and cleaned as frequently as necessary to keep the

finned areas free of lint, hair and debris.

CONDENSER AND INDUCED DRAFT MOTORS

Bearings on the condenser fan motors and the combustion

fan motor are permanently lubricated. No additional oiling is

required.

LUBRICATION

The fan shaft bearings, the 1 to 2 HP supply fan motors, the

condenser fan motors and compressors are permanently

lubricated.

FUNCTIONAL PARTS

Refer to the unit Parts Catalog for a list of functional parts.

Parts are available from your distributor.

17

SERVICING

C

,

S-200,20

COOLING ANALYSIS CHART

Complaint

POSSIB LE CAUSE

DOTS IN ANALYSIS

GUIDE INDICATE

"POSSIBLE CAUSE"

Power F a i lure

Blown Fuse

Unbalanced Power, 3PH

Loose C o nne ct ion

Shorted or Broken Wires

Open Fan Overload

Faulty Thermostat

Faulty Transformer

Shorted or Open Capacitor

Inter n al Compr ess or O verload Open

Shorted or Grounded Compressor

Compressor Stuck

Faulty Compressor Contac tor

Faulty Fan Relay

Open Control Circuit

Low Voltage

Faulty Evap . Fan Motor

Shorted or Grounded Fan Motor

Im proper Cooling Anticipator

Shortage of Refrige r ant

Res tr i cted Liqu i d Line

Dirty Air Filter

Dirty Indoor Coil

Insuffic ient air a cross Indoor Coi l

Too mu ch air acros s Indoor Coil

Overcharge of Refrigerant

Dirty Outdoor Coil

Noncondensibles

Rec i rcul at ion of Condensing Ai r

Infi ltration of Outdoor Air

Im p ro perly Loc ated Therm osta t

Air F low Un balanc ed

Syst em U ndersized

Bro ken Internal P ar ts

Bro ken Val ves

Inef fic i ent Compresso r

E xpans i o n D e vice Re s tricted

Loose H o l d -down Bol ts

Flowrator Not Seating Properly

Compr ess or runs - goes of f on overload

Unsatisfactory

Compressor cycles on overload

Syst em runs continuo usly - little cooling

Cooling

No Cooling

SYMPTOM

System will not start

Compresso r will not start - fan runs

Com p. an d C on d. Fan wi ll no t st ar t

Evaporator fan will not start

Condenser fan will not start

•

•••

•••

•••

••••••

••

••• •

••

•••••

•

••

•••

•••

•

•

•••

••

••

••

•• •

•• • •

••••

••••

••••

•• • ••

••• • •

•• • •

•• • •

•••

••

••

••

•••

••

••• • • •

••

Cooling Cycle

•

System

Operating

Pressures

Test M et hod

Remedy

See Serv ic e Proced u re Re f.

To o c ool and the n too warm

Not coo l enough on w ar m days

Certain areas too cool, others too warm

Co m pr e s sor is no i s y

Low su ction pr essure

High suc ti on pres sure

High he ad pressure

Test Voltage S-1

Inspect Fus e Size & Type S-1

Test Voltage S-1

Inspect Connectio n - Ti gh te n S-2 , S- 3

Te st Ci rcu its Wi th Ohmmete r S-2 , S-3

Test Continuity of Overloa d S-17 A

Test Continuity of Thermostat & W iring S-3

Check Control Circuit with Volt meter S-4

Test C apa citor S- 15

Test Continuity of Overloa d S-17 A

Test Motor Windings S-17B

Use Test Cord S-17D

Test Continuit y of Coil & Contacts S-7, S-8

Test Continuit y of Coil And Contacts S-7

Test Control Circuit with Voltmeter S-4

Test Voltage S-1

Repair or Replace S-16

Test Motor Windings S-16

Check R esi st an ce of Anticipator S-3B

Test For Leaks, Add Refrigerant S-101,103

Remove Restriction, Replace Restricted Part S-112

In spec t Fil ter -Cle an or Replace

Inspect Coil - Clean

heck Blower Speed and Rotation, Belt, Pulleys

Reduc e Bl o wer Speed, C heck Pul ley Adjust m e nt S-205, 20 7

•

Recover Part of Charge S-113

Inspect Coil - Clean

Recove r C harge, Ev acua te, Re ch ar ge S-114

Remove Obstruction to Air Flow

Check Windows, Doors, V ent Fans, Etc.

Relocate Thermostat

Readjust Air Volume Dampers

Refigure Cooling Load

•

•

Repl ace Com pressor S-115

Test Compressor Efficiency

Test Compressor Efficiency S- 104

Remo ve Restric tion, Replace Expansi on Dev i ce 111

Ti ghten Bo lts

Check Flow ra to r & Se at or Replace F l owrator S-111

5,

S-104

18

SERVICING

Table of Contents

S-1 Checking Voltage.......................................... 2 0

S-2 Checking Wiring............................................ 21

S-3 Checking Thermostat, Wiring & Anticipator .. 21

S-3A Thermostat & Wiring ..................................... 21

S-3B Cooling Anticipator........................................ 21

S-4 Checking Transformer & Control Circuit ....... 21

S-7 Checking Contactor and/or Relays ................ 22

S-8 Checking Contactor Contacts .......................22

S-9 Checking Fan Relay Contact ........................ 23

S-11 Checking Loss of Charge Protection ............. 24

S-12 Checking High Pressure Control ................... 24

S-13 Checking Low Pressure Control .................... 24

S-15 Checking Capacitor......................................25

S-15A Resistance Check......................................... 25

S-15B Capacitance Check ...................................... 25

S-16 Checking Motors........................................... 26

S-16A Checking Fan & Blower Motor

Windings (PSC Motors) ............................... 26

S-16D Checking EEM Motors .................................. 26

S-17 Checking Compressor Windings .................. 27

S-17A Resistance Test ............................................27

S-17B Ground Test .................................................. 27

S-17D Operation Test ..............................................28

S-18 Testing Crankcase Heater (optional item).....28

S-18A Crankcase Heater Thermostat ...................... 28

S-21 Checking Reversing Valve & Solenoid.......... 28

S-24 Testing Defrost Control .................................29

S-25 Testing Defrost Thermostat ........................... 29

S-50 Checking Heater Limit Control(s).................. 30

S-100 Refrigeration Repair Practice ....................... 30

S-101 Leak Testing ................................................. 30

S-102 Evacuation .................................................... 31

S-103 Charging.......................................................32

S-104 Checking Compressor Efficiency ................. 33

S-106 Overfeeding .................................................. 33

S-108 Checking Superheat ..................................... 33

S-111 Fixed Orifice Restriction Devices.................. 36

S-112 Checking Restricted Liquid Line ................... 36

S-113 Refrigerant Overcharge ................................ 36

S-114 Non-condensables ........................................ 36

S-115 Compressor Burnout.....................................36

S-200 Checking External Static Pressure ...............37

S-201 Checking Temperature Rise .........................39

S-205 Checking Belt Tension .................................. 38

S-206 Indoor Fan Rotation Check ........................... 39

S-207 Motor Sheave Adjustment ............................. 39

HIGH VOLTAGE !

Disconnect ALL power before servicing or installing this unit. Multiple power sources

may be present. Failure to do so may cause property damage, person al inj ury or death.

19

SERVICING

S-1 CHECKING VOLTAGE

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g th is un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

1. Remove doors, control panel cover, etc. from unit being

tested.

With power ON:

WARNING

Line Voltage now present.

2. Using a voltmeter, measure the voltage across terminals

L1 and L2 of the contactor for single phase units, and L3,

for 3 phase units.

3. No reading - indicates open wiring, open fuse(s) no power

or etc. from unit to fused disconnect service. Repair as

needed.

4. With ample voltage at line voltage connectors, energize

the unit.

5. Measure the voltage with the unit starting and operating,

and determine the unit Locked Rotor Voltage.

Locked Rotor Voltage is the actual voltage available at

the compressor during starting, locked rotor, or a stalled

condition. Measured voltage should be above minimum

listed in chart below.

To measure Locked Rotor Voltage attach a voltmeter to

the run "R" and common "C" terminals of the compressor,

or to the T1 and T2 terminals of the contactor. Start the unit

and allow the compressor to run for several seconds, then

shut down the unit. Immediately attempt to restart the

unit while measuring the Locked Rotor Voltage.

6. Voltmeter should read within the voltage tabulation as

shown. If the voltage falls below the minimum voltage,

check the line wire size. Long runs of undersized wire can

cause low voltage. If wire size is adequate, notify the local

power company in regards to either low or high voltage.

Unit Supply Voltage

Voltage Min. Max.

208/230 198 253

400 360 440

460 437 506

575 546 604

Three phase units require a balanced 3 phase power supply

to operate. If the percentage of voltage imbalance exceeds

3% the unit must not be operated until the voltage condition

is corrected.

Max. Voltage Deviation

% Voltage = From Average Voltage X 100

Imbalance Average Voltage

To find the percentage of imbalance, measure the incoming

power supply.

L1 - L2 = 240V

L1 - L3 = 232V Avg. V =

L2 - L3 =

238V 3

710 = 236.7

Total 710V

To find Max. deviation: 240 - 236.7 = +3.3

232 - 236.7 = -4.7

238 - 236.7 = +1.3

Max deviation was 4.7V

% Voltage Imbalance = 4.7 = 1.99%

236.7

If the percentage of imbalance had exceeded 3%, it must be

determined if the imbalance is in the incoming power supply

or the equipment. To do this rotate the legs of the incoming

power and retest voltage as shown below.

L1 - L2 = 240V

L1 - L3 = 227V

L2 - L3 = 238V

L1 L2

L1

L3

L3L2

Ro tate all 3 incomin g

legs as shown.

L1 - L2 = 227V

L1 - L3 = 238V

L2 - L3 = 240V

By the voltage readings we see that the imbalance rotated or

traveled with the switching of the incoming legs. Therefore the

imbalance lies within the incoming power supply.

If the imbalance had not changed then the problem would lie

within the equipment. Check for current leakage, shorted

motors, etc.

20

SERVICING

S-2 CHECKING WIRING

HIGH VOL TAGE!

Disconnect ALL power before servicing

or insta llin g this uni t. M ultip le po wer

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

1. Check wiring visually for signs of overheating, damaged

insulation and loose connections.

2. Use an ohmmeter to check continuity of any suspected

open wires.

3. If any wires must be replaced, replace with comparable

gauge and insulation thickness.

S-3 CHECKING THERMOSTAT, WIRING, AND

ANTICIPATOR

THERMO ST AT WIRE SIZI NG CHART

LENGTH OF RUN

25 fe et 18

50 fe et 16

75 fe et 14

100 fe et 14

125 fe et 12

150 fe et 12

M IN. COPPER WI RE

GAUGE (AWG)

S-3A THERMOSTAT AND WIRING

4. Check the continuity of the thermostat and wiring. Repair

or replace as necessary.

S-3B COOLING ANTICIPATOR

The cooling anticipator is a small heater (resistor) in the

thermostat. During the "off" cycle, it heats the bimetal

element helping the thermostat call for the next cooling cycle.

This prevents the room temperature from rising too high

before the system is restarted. A properly sized anticipator

should maintain room temperature within 1 1/2 to 2 degree

range.

The anticipator is supplied in the thermostat and is not to be

replaced. If the anticipator should fail for any reason, the

thermostat must be changed.

S-4 CHECKING TRANSFORMER

AND CONTROL CIRCUIT

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g th is un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

A step-down transformer (either 208-240, 460 or 575 volt primary to 24 volt secondary) is provided with each unit. This

allows ample capacity for use with resistance heaters.

WARNING

Line Voltage now present.

With power ON, thermostat calling for cooling

1. Use a voltmeter to check for 24 volts at thermostat wires

C and Y in the unit control panel.

2. No voltage indicates trouble in the thermostat or wiring.

3. Check the continuity of the thermostat and wiring. Repair

or replace as necessary.

Indoor Blower Motor

With power ON:

WARNING

Line Voltage now present.

1. Set fan selector switch at thermostat to "ON" position.

2. With voltmeter, check for 24 volts at wires C and G.

3. No voltage indicates the trouble is in the thermostat or

wiring.

WARNING

Disconnect ALL power before servicing.

1. Remove control panel cover to gain access to transformer.

With power ON:

WARNING

Line Voltage now present.

2. Using a voltmeter, check voltage across secondary voltage side of transformer (R to C).

3. No voltage indicates faulty transformer, bad wiring, or bad

splices.

4. Check transformer primary voltage at incoming line voltage connections and/or splices.

5 If line voltage available at primary voltage side of trans-

former and wiring and splices good, transformer is inoperative. Replace.

21

SERVICING

S-7 CHECKING CONTACTOR AND/OR RELAYS

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g th is un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

The compressor contactor and other relay holding coils are

wired into the low or line voltage circuits. When the control

circuit is energized, the coil pulls in the normally open

contacts or opens the normally closed contacts. When the

coil is de-energized, springs return the contacts to their

normal position.

NOTE: Most single phase contactors break only one side of

the line (L1), leaving 115 volts to ground present at most

internal components.

1. Remove the leads from the holding coil.

2. Using an ohmmeter, test across the coil terminals.

If the coil does not test continuous, replace the relay or

contactor.

S-8 CHECKING CONTACTOR CONTACTS

SINGLE PHASE

HIGH VOL TAGE!

Disconnect ALL power before serv icing

or installing this unit. Multiple power

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

T2

T1

CC

VOLT/OHM

METER

L1L2

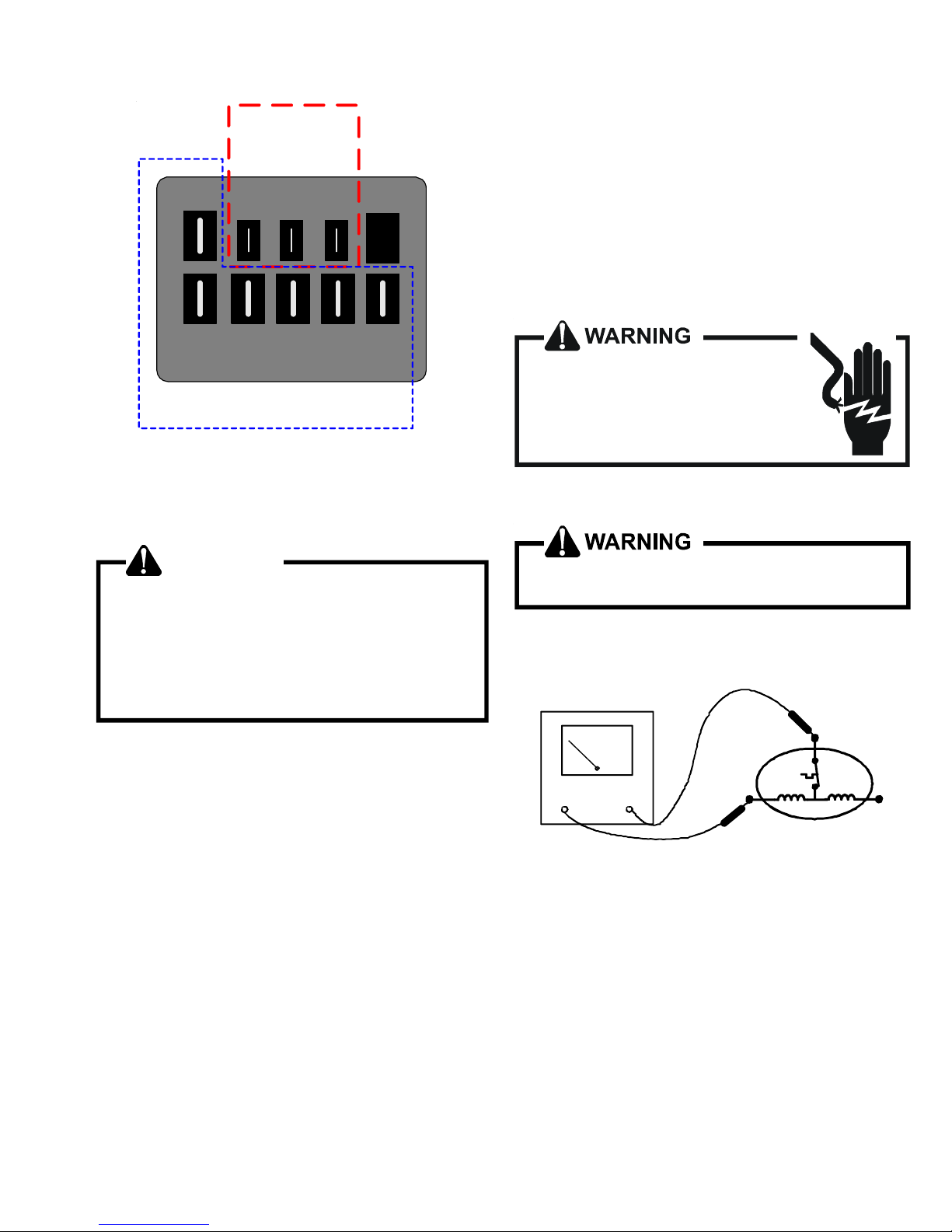

Ohmmete r fo r te st in g h oldi n g coil

Voltmeter for testing contacts

TESTING COMPRESSOR CONTACTOR

(Single Phase)

3. Using a voltmeter, test across terminals.

A. L1 - L2 - No voltage. Check breaker or fuses on main

power supply.

B. L2 - T1 - No voltage indicates CC1 contacts open.

If a no voltage reading is obtained - replace the contactor.

THREE PHASE

Using a voltmeter, test across terminals.

A. L1-L2, L1-L3, and L2-L3 - If voltage is present,

proceed to B. If voltage is not present, check breaker

or fuses on main power supply..

B. T1-T2, T1-T3, and T2-T3 - If voltage readings are not

the same as in "A", replace contactor.

T3L3T2

T1

1. Disconnect the wire leads from the terminal (T) side of the

contactor.

2. With power ON, energize the contactor.

22

CC

VOLT/OHM

METER

Ohmmeter for testing holding coil

Voltmeter for testing contacts

TESTING COMPRESSOR CONTACTOR

(ThreePhase)

L2

L1

SERVICING

S-9 CHECKING FAN RELAY CONTACTS

DCG:

The fan relays are incorporated into the control board. See

section S-313 for checking control board for single phase

gas models.

For 3 phase and belt drive models, the procedure for testing

the fan relay contacts will be the same as checking the

compressor contactor contacts (See section S-8).

DCC/DCH:

The Electronic Blower Time Delay Relay is used on PSC and

belt driven models.

HIGH VOL TAGE!

Disconnect ALL power before servicing

or inst all in g this u nit. M ult ip le po wer

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

Checking EBTDR High Voltage Contacts

1. With power off, remove wires from terminals NC, COM,

and NO.

2. Using a VOM, check for resistance from NO to COM.

Should read open. Next, check for resistance from NC to

COM. Should read closed.

3. If not as above, replace EBTDR.

PSC equipped, single phase model coolers and heat pumps

have an isolation relay with a 240 volt holding coil in addition

to the EBTDR.

WARNING

Disconnect ALL power before servicing.

Turn power off.

Testing relay holding coil

1. Remove the leads from the holding coil terminals 1 and

3.

2. Using an ohmmeter, test across the coil terminals 1 and

3. If the coil does not test continuous, replace the relay.

Testing relay contacts

WARNING

Disconnect ALL power before servicing.

Turn power off.

1. Using a VOM, test resistance across relay terminals 2

and 4. Should read open.

2. Turn power on.

Checking EBTDR Contact Operation

With power on:

1. Set the thermostat to the fan "on" position.

2. Check for 24 volts at the C and G terminals of the

EBTDR.

3. If no voltage present, check fan circuit from thermostat.

If 24 volts present, proceed to step 4.

4. Using a VOM, check for line voltage from the purple wire

at the transformer (terminal 3 on 240 volt units, terminal

2 on 208 volt units) to terminal NO on the EBTDR. Should

read line voltage. If no voltage present, check line voltage

wiring in unit. If line voltage present, proceed to step 5.

5. Using a VOM, check for line voltage from the purple wire

at the transformer (terminal 3 on 240 volt units, terminal

2 on 208 volt units) to the COM terminal on the EBTDR.

Should read line voltage. If not as above, replace EBTDR.

3. Apply 240 volts to coil terminals 1 and 3.

4. Using a VOM, check for 240 volts from terminals 3 and

1 of relay. Should read 240 volts. If voltage present,

proceed to step 5.

5. Using a VOM, check for 240 volts from L1 at contactor

to terminal 4 of relay. Should read 240 volts. Next check

from L1 at contactor to terminal 2 of relay. Should read

240 volts.

If not as above, replace relay.

On the 5 ton units with the EEM motor, a standard fan relay

is used.

WARNING

Disconnect ALL power before servicing.

Turn power off.

23

SERVICING

Testing relay holding coil

1. Remove the leads from the holding coil.

2. Using an ohmmeter, test across the coil terminals 1 and

3. If the coil does not test continuous, replace the relay.

Testing relay contacts

WARNING

Disconnect ALL power before servicing.

Turn power off.

1. Using a VOM, test resistance across relay terminals 2

and 4. Should read open.

2. Turn power on.

3. Apply 24 volts to coil terminals 1 and 3.

4. Using a VOM, check for 24 volts from terminals 3 and 2

of relay. Should read 24 volts. If no voltage, check low

voltage wiring from transformer to relay. If voltage present,

proceed to step 5.

5. Using a VOM, check for 24 volts from terminals 3 and 4

of relay. Should read 24 volts.

If not as above, replace relay.

S-11 CHECKING LOSS OF CHARGE PROTEC-

TOR

S-12 CHECKING HIGH PRESSURE CONTROL

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g th is un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

The high pressure control senses the pressure in the

discharge line. If abnormally high discharge pressures

develop, the contacts of the control open, breaking the

control circuit before the compressor motor overloads. This

control is automatically reset.

1. Using an ohmmeter, check across terminals of high

pressure control, with wire removed. If not continuous,

the contacts are open.

3. Attach a gauge to the access fitting on the liquid line.

With power ON:

4. Start the system and place a piece of cardboard in front

of the condenser coil, raising the condensing pressure.

5. Check pressure at which the high pressure control cutsout.

(Heat Pump Models)

The loss of charge protector senses the pressure in the liquid

line and will open its contacts on a drop in pressure. The low

pressure control will automatically reset itself with a rise in

pressure.

The low pressure control is designed to cut-out (open) at

approximately 22 PSIG. It will automatically cut-in (close) at

approximately 50 PSIG.

Test for continuity using a VOM and if not as above, replace

the control.

24

If it cuts-out at 660 PSIG ± 10 PSIG, it is operating normally

(See causes for high head pressure in Service Problem

Analysis Guide). If it cuts out below this pressure range,

replace the control. The control should reset at 420 PSIG ±

25 PSIG.

SERVICING

S-13 CHECKING LOW PRESSURE CONTROL

The low pressure control senses the pressure in the suction

line and will open its contacts on a drop in pressure. The low

pressure control will automatically reset itself with a rise in

pressure.

The low pressure control is designed to cut-out (open) at

approximately 22 PSIG ± 7 PSIG. It will automatically cut-in

(close) at approximately 50 PSIG ± 7 PSIG.

Test for continuity using a VOM and if not as above, replace

the control.

S-15 CHECKING CAPACITOR

CAPACITOR, RUN

A run capacitor is wired across the auxiliary and main

windings of a single phase permanent split capacitor motor.

The capacitors primary function is to reduce the line current

while greatly improving the torque characteristics of a motor.

This is accomplished by using the 90° phase relationship

between the capacitor current and voltage in conjunction with

the motor windings so that the motor will give two phase

operation when connected to a single phase circuit. The

capacitor also reduces the line current to the motor by

improving the power factor.

CAPACITOR, START

SCROLL COMPRESSOR MODELS

Hard start components are not required on Scroll compressor

equipped units due to a non-replaceable check valve located

in the discharge line of the compressor. However hard start

kits are available and may improve low voltage starting

characteristics.

This check valve closes off high side pressure to the compressor after shut down allowing equalization through the scroll

flanks. Equalization requires only about one or two seconds

during which time the compressor may turn backwards.

Your unit comes with a 180-second anti-short cycle to

prevent the compressor from starting and running backwards.

MODELS EQUIPPED WITH A HARD START DEVICE

A start capacitor is wired in parallel with the run capacitor to

increase the starting torque. The start capacitor is of the

electrolytic type, rather than metallized polypropylene as

used in the run capacitor.

A switching device must be wired in series with the capacitor

to remove it from the electrical circuit after the compressor

starts to run. Not removing the start capacitor will overheat

the capacitor and burn out the compressor windings.

These capacitors have a 15,000 ohm, 2 watt resistor wired

across its terminals. The object of the resistor is to discharge

the capacitor under certain operating conditions, rather than

having it discharge across the closing of the contacts within

the switching device such as the Start Relay, and to reduce

the chance of shock to the servicer. See the Servicing

Section for specific information concerning capacitors.

RELAY, START

A potential or voltage type relay is used to take the start

capacitor out of the circuit once the motor comes up to

speed. This type of relay is position sensitive. The normally

closed contacts are wired in series with the start capacitor

and the relay holding coil is wired parallel with the start

winding. As the motor starts and comes up to speed, the

increase in voltage across the start winding will energize the

start relay holding coil and open the contacts to the start

capacitor.

Two quick ways to test a capacitor are a resistance and a

capacitance check.

S-15A RESISTANCE CHECK

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g this un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

1. Discharge capacitor and remove wire leads.

WARNING

Discharge capacitor through a 20 to 30 OHM

resistor before handling.

OHMMETER

CAPACITOR

TESTING CAPACITOR RESISTANCE

2. Set an ohmmeter on its highest ohm scale and connect

the leads to the capacitor -

a. Good Condition - indicator swings to zero and

slowly returns to infinity. (Start capacitor with

bleed resistor will not return to infinity. It will still

read the resistance of the resistor).

b. Shorted - indicator swings to zero and stops there

-replace.

c. Open - no reading - replace. (Start capacitor

would read resistor resistance.)

25

SERVICING

S-15B CAPACITANCE CHECK

Using a hookup as shown below, take the amperage and

voltage readings and use them in the formula:

HIGH VOLTAGE!

Disconnect ALL power before servicing

or insta llin g th is un it. M ult iple powe r

sources may be present. Failure to do so

may cause property damage, personal injury

or death.

VOLTMETER

15 AMP

FUSE

AMMETER

CAPACITOR

TESTING CAPACITANCE

WARNING

Discharge capacitor through a 20 to 30 OHM

resistor before handling.

Capacitance (MFD) = 2650 X Amperage

Voltage

S-16 CHECKING MOTORS

S-16A CHECKING FAN AND BLOWER MOTOR

WINDINGS (PSC MOTORS)

1. Remove the motor leads from its respective connection

points and capacitor (if applicable).

2. Check the continuity between each of the motor leads.

3. Touch one probe of the ohmmeter to the motor frame

(ground) and the other probe in turn to each lead.

If the windings do not test continuous or a reading is obtained

from lead to ground, replace the motor.

S-16D CHECKING EEM (ENERGY EFFICIENT

MOTOR) MOTORS

Applies only to units with EEM Motors

The EEM Motor is a one piece, fully encapsulated, 3 phase

brushless DC (single phase AC input) motor with ball bearing

construction. Unlike the ECM 2.3/2.5 motors, the EEM

features an integral control module.

Note: The GE TECMate will not currently operate the GE EEM

motor.

1. Using a voltmeter, check for 230 volts to the motor

connections L and N. If 230 volts is present, proceed to

step 2. If 230 volts is not present, check the line voltage

circuit to the motor.

2. Using a voltmeter, check for 24 volts from terminal C to