Page 1

MODELS

〈BS unit〉

BSVQ36PVJU

BSVQ60PVJU

INSTALLATION MANUAL

III SYSTEM Air Conditioners

English

Français

READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

Español

Page 2

BSVQ36PVJU

BSVQ60PVJU

VRVIII SYSTEM Air Conditioners

Installation manual

CONTENTS

1 SAFETY CONSIDERATIONS........................................................................................1

2 BEFORE INSTALLATION..............................................................................................3

3 SELECTING INSTALLATION SITE ............................................................................... 5

4 PREPARATIONS BEFORE INSTALLATION.................................................................5

5 BS UNIT INSTALLATION...............................................................................................6

6 REFRIGERANT PIPING WORK ....................................................................................7

7 ELECTRIC WIRING WORK.........................................................................................11

8 INITIAL SETTING.........................................................................................................15

9 TEST OPERATION......................................................................................................15

1. SAFETY CONSIDERATIONS

Please read these “SAFETY CONSIDERATIONS” carefully before installing air conditioning equipment and

be sure to install it correctly. After completing the installation, make sure that the unit operates properly during

the start-up operation.

Please instruct the customer on how to operate the unit and keep it maintained.

Also, inform customers that they should store this installation manual for future reference.

This air conditioner comes under the term “appliances not accessible to the general public”.

Meaning of danger, warning, caution and note symbols.

DANGER ..........Indicates an imminently hazardous situation which,if not avoided, will result in death

or serious injury.

WARNING ........Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION ......... Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be sued to alert against unsafe practices.

NOTE ................ Indicates situation that may result in equipment or property-damage-only accidents.

DANGER

• Refrigerant gas is heavier than air and replaces oxygen. A massive leak could led to oxygen depletion, especially in basements, and an asphyxiation hazard could occur leading to serious injury or

death.

• Do not install unit in an area where flammable materials are present due to the risk of explosion

resulting in serious injury or death.

• If the refrigerant gas leaks during installation, ventilate the area immediately.

Refrigerant gas may produce toxic gas if it comes into contact with fire such as from a fan, heater, stove or

cooking device. Exposure to this gas could cause severe injury or death.

• After completing the installation work, check that the refrigerant gas does not leak.

Refrigerant gas may produce toxic gas if it comes into contact with fire such as from a fan, heater, stove or

cooking device. Exposure to this gas could cause severe injury or death.

1 English

Page 3

• Do not ground units to water pipes, telephone wires or lightning rods because incomplete grounding could cause a severe shock hazard resulting in severe injury or death, and to gas pipes because

a gas leak could result in an explosion which could lead to severe injury or death.

• Safely dispose of the packing materials.

Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries.

Tear apart and throw away plastic packaging bags so that children will not play with them. Children playing

with plastic bags face the danger of death by suffocation.

WARNING

• Ask your dealer or qualified personnel to carry out installation work. Do not try to install the

machine by yourself.

Improper installation may result in water leakage, electric shocks or fire.

• Perform installation work in accordance with this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in water leakage, electric shocks, fire or the unit falling.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injuries.

• Carry out the specified installation work after taking into account strong winds, typhoons

or earthquakes.

Improper installation work may result in the equipment falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is

carried out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

• Make sure that all wiring is secured, the specified wires are used, and no external forces act on the

terminal connections or wires.

Improper connections or installation may result in fire.

• When wiring the power supply and connecting the remote controller wiring and transmission

wiring, position the wires so that the electric parts box lid can be securely fastened.

Improper positioning of the electric parts box lid may result in electric shocks, fire or the terminals overheating.

• Before touching electrical parts, turn off the unit.

• Be sure to establish an earth.

Do not earth the unit to a utility pipe, arrester, or telephone earth.

Incomplete earth may cause electrical shock, or fire.

A high surge current from lightning or other sources may cause damage to the air conditioner.

• Do not touch the switch with wet fingers.

Touching a switch with wet fingers can cause electric shock.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks, or fire.

• Do not install the air conditioner in the following locations:

(a) where a mineral oil mist or an oil spray or vapor is produced, for example in a kitchen. Plastic parts may

deteriorate and fall off or result in water leakage.

(b) where corrosive gas, such as sulfurous acid gas, is produced. Corroding copper pipes or soldered parts

may result in refrigerant leakage.

(c) near machinery emitting electromagnetic waves. Electromagnetic waves may disturb the operation of

the control system and result in a malfunction of the equipment.

CAUTION

• While following the instructions in this installation manual, insulate piping in order to prevent condensation.

Improper piping insulation may result in water leakage and property damage.

English 2

Page 4

• Be very careful about product transportation.

Some products use PP bands for packaging. Do not use any PP bands for a means of transportation.

It is dangerous.

• Make sure to provide for adequate measures in order to prevent that the outside unit be used as a

shelter by small animals.

Small animals making contact with electrical parts can cause malfunctions, smoke or fire. Please instruct

the customer to keep the area around the unit clean.

NOTE

• Install the indoor and outside units, power supply wiring and connecting wires at least 3.5ft. away

from televisions or radios in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 3.5ft. may not be sufficient enough to eliminate the noise.)

• Remote controller (wireless kit) transmitting distance can result shorter than expected in rooms

with electronic fluorescent lamps. (inverter or rapid start types)

Install the indoor unit as far away from fluorescent lamps as possible.

• This unit is a class A product.

In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

• Dismantling of the unit, treatment of the refrigerant, oil and eventual other parts, should be done in

accordance with the relevant local and national regulations.

NOTE

The refrigerant R410A requires strict cautions for keeping the system clean, dry and tight.

A. Clean and dry

Foreign materials (including mineral oils such as SUNISO oil or moisture) should be prevented from

getting mixed into the system.

B. Tight

R410A does not contain any chlorine, does not destroy the ozone layer, and does not reduce the

earth’s protection against harmful ultraviolet radiation.

R410A can contribute slightly to the greenhouse effect if it is released. Therefore we should take special attention to check the tightness of the installation.

Read the chapter “Refrigerant piping work” carefully and follow these procedures correctly.

2. BEFORE INSTALLATION

2-1 CAUTION CONCERNING NEW REFRIGERANT SERIES

• Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state. (If

the refrigerant is charged in a state of gas, its composition changes and the system will not work properly.)

The indoor/outside unit is for R410A. See the catalog for indoor/outside unit models which can be connected.

(Normal operation is not possible when connected to other units.)

2-2 PRECAUTIONS

• Hold the unit by the Hanging brackets (4 points) when opening the box and moving it, and do not lift it hold-

ing on to any other part especially the refrigerant piping.

• About installation of outside and indoor unit, refer to the installation manual provided with the outside and

the indoor unit.

• This unit, both indoor and outside, is suitable for installation in a commercial and light industrial environment.

If installed as a household appliance it could cause electromagnetic interference.

3 English

Page 5

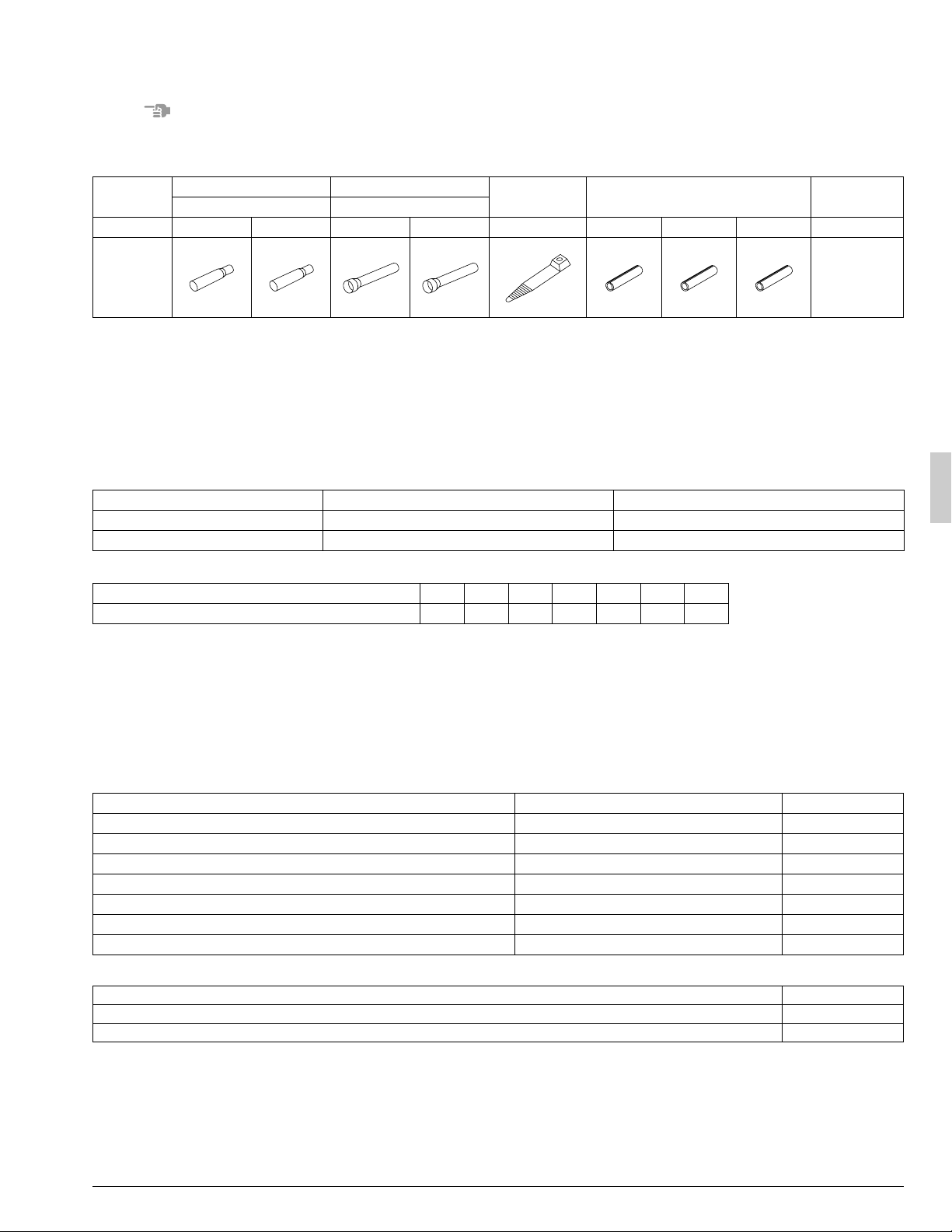

2-3 ACCESSORIES

Check the following accessories are included with your unit.

NOTE

• Do not throw away any of the accessories until installation is complete.

〈BSVQ36 · 60PVJU〉

Name

Quantity 1 pc. 1 pc. 1 pc. 2 pcs. 16 pcs. 2 pcs. 1 pc. 2 pcs. 1 copy

Shape

1) Accessory pipes 1) Accessory pipes

(BSVQ36 only) (BSVQ60 only)

1)-1

φ3/8

1)-2

φ5/8

1)-1

φ1/2

1)-2

φ5/8

2) Clamp 3) Insulation tube

3)-1

(Small)

3)-2

(Medium)

3)-3

(Large)

Explanation

Document

Installation

manual

2-4 COMBINATION

• This BS unit is only for systems for Models REYQ-P.

It cannot be connected to systems for Models REYQ-M.

• For series of applicable indoor units, refer to the catalog or other literature.

• Select the BS unit to fit the total capacity (sum of unit’s capacity) and max. number of the indoor units to be

connected downstream. About indoor unit’s capacity, refer to the Table 2.

Table 1

Model Total capacity of all downstreem indoor units Max. number of all downstreem indoor units

BSVQ36PVJU A ≤ 36 5

BSVQ60PVJU 36 < A ≤ 60 8

Table 2

Capacity expressed as indoor unit’s model No. 09 12 18 24 30 36 48

Indoor unit’s capacity (for use in computation) 9 12 18 24 30 36 48

<Example>

In case of the BS unit which connect two FXFQ12M and two FXSQ18M.

Total capacity = 12×2+18×2 = 60 → Select BSVQ60PVJU

2-5 CHECK ITEM

• For the following items, take special care during construction and check after installation is finished.

Completion check items

Check items Problems Check

Are the BS units installed securely? Falling, vibration, and operating noise

Have you performed a gas leak test? Does not cool or heat

Is the insulation complete? (Refrigerant piping and pipe connection part) Water leaking

Is the voltage the same as that listed on the unit’s nameplate? Does not operate/burnt out

Are all the wiring and piping correct? Does not operate/burnt out

Is the unit grounded? Dangers during electrical leak

Is the thickness of the power cord as specified? Does not operate/burnt out

Hand-over check items

Check items Check

Did you close the EL. COMPO. BOX lid?

Did you hand the operating manual and warranty card to the customer?

English 4

Page 6

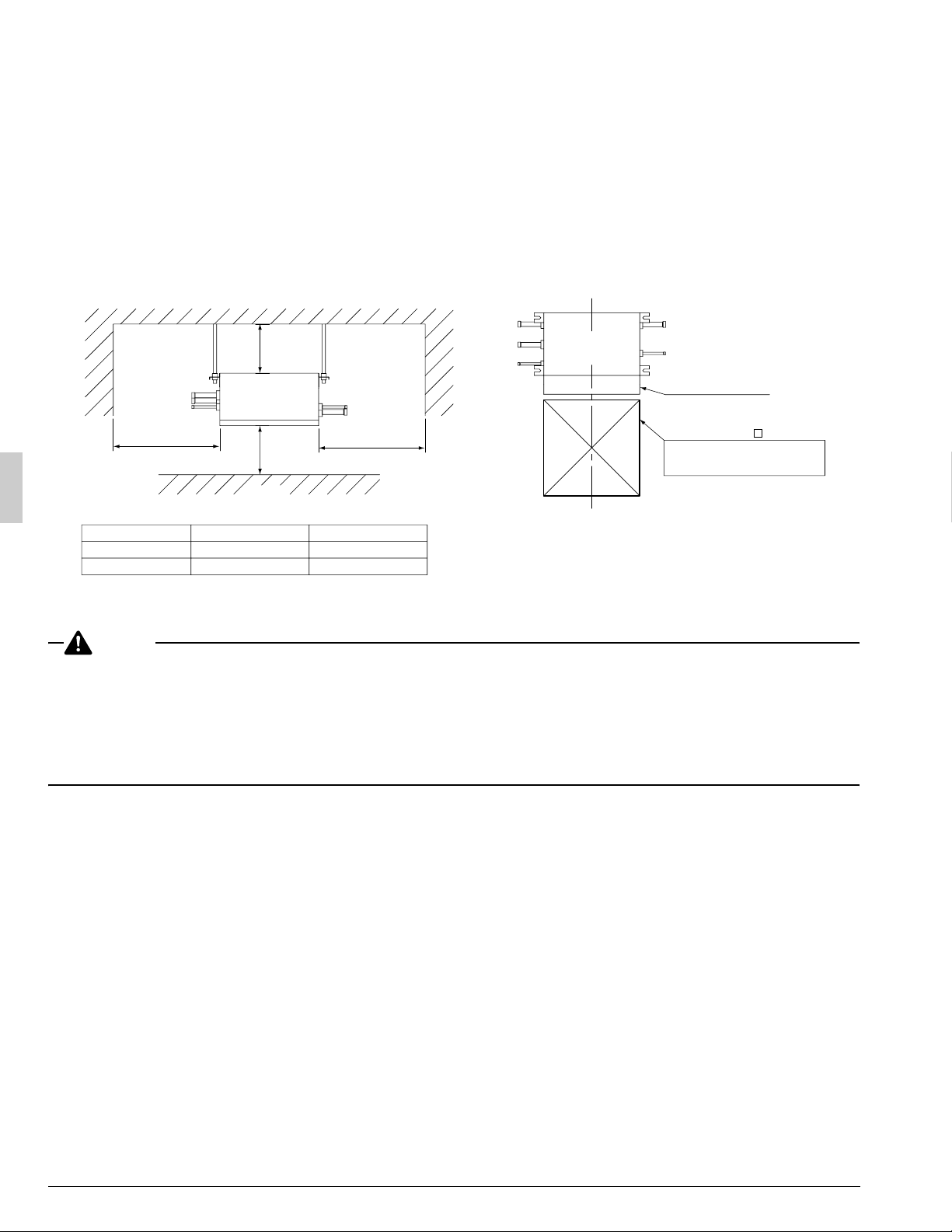

3. SELECTING INSTALLATION SITE

Select an installation site where the following conditions are satisfied and that meets with your customer’s approval.

• Where is resistible against weight of BS unit.

• Locations where the wall is not significantly tilted.

• Where sufficient clearance for maintenance and service can be ensured. (Refer to Fig. 1)

• Locations where an inspection hole (Refer to Fig. 2) can be installed to EL. COMPO. BOX side (See Note).

• Where the total piping length involving indoor unit and outside unit is below the allowable piping length.

(See installation manual attached to outside unit.)

Note: The EL. COMPO. BOX mounting surface can be changed.

For information on how to change the mounting surface, refer to “5. BS UNIT INSTALLATION”.

(in.)

EL. COMPO. BOX

Inspection hole 18

Be sure to open this to the

EL. COMPO. BOX side.

Fig. 2

Outside unit

side (3 pipes)

AB

Fig. 1

BS Unit Name

BSVQ36P

BSVQ60P

Indoor unit

2-5/8

or more

2 or

more

AB

10 or more

10 or more (*2)

side (2 pipes)

10 or more (*1)

10 or more (*2)

(in.)

BS unit

proper top

(in.)

(*1) When using accessory pipes 1)-1, 2 (Refer to 6-5 PIPING

CONNECTION), provide a service space of at least 12 in..

(*2) When using accessory pipes 1)-1, 2 (Refer to 6-5 PIPING

CONNECTION), provide a service space of at least 14 in..

(*3) When using accessory pipes 1)-1, 2 (Refer to 6-5 PIPING

CONNECTION), provide a service space of at least 16 in..

NOTE

• Study if the installation location is strong enough to hold the weight of the unit, and if necessary reinforce

the area with a beam or other member and then install suspension bolts. Use the suspension bolts to install

the unit. (Refer to “4. PREPARATIONS BEFORE INSTALLATION”)

• Install the BS unit and its power supply wiring and transmission wiring at least 40 in. away from televisions

and radios to prevent image distortion and noise in those devices. Noise may still be introduced at this distance depending on the electromagnetic wave conditions.

4. PREPARATIONS BEFORE INSTALLATION

Refer the figure 3 and install the suspension bolts and hanging brackets.

〈Suspension bolts: For supporting the product〉

• Use M8-M10 suspension bolts.

• When holes are to be made anew, used embedded inserts and embedded foundation bolts. When holes

are already provided, use hole-in-anchors or the like.

Install the BS unit so that its weight can be withstood.

〈Hanging bracket: For supporting the connection pipe〉

• Be sure to support the connection piping around the unit using hanging brackets that are kept within

40 in. of the body side surface. Hanging excessive weight on the BS unit hanging bracket could cause the

unit to fall and injure someone.

5 English

Page 7

Anchor

16-7/8 8-5/8

Long nut or

turnbuckle

Suspension

bolt

>

<

Suspension bolt pitch

Hanging

bracket

40 in. or less 40 in. or less

Note: All the above parts are part to be procured in the field.

><

Fig. 3

Unit

proper

Example installation

5. BS UNIT INSTALLATION

Use only accessories and parts which are of the designated specification when installing.

(1) When necessary, use the following procedure to change the EL. COMPO. BOX mounting surface.

(Refer to Fig. 4)

1) Remove the EL. COMPO. BOX lid. (2 screws)

2) Remove the EL. COMPO. BOX. (2 screws)

3) Remove the top panel. (4 screws)

4) Remove the coil cover. (1 screw)

5) Change the pull out direction of the wire (motorized valve coil) between the body and the EL. COMPO. BOX.

6) Rotate the coil cover 180° and attach it.

7) Turn the top panel around 180° and attach it.

8) Attach the EL. COMPO. BOX.

9) Attach the EL. COMPO. BOX lid.

(2) Attach the hooks to the suspension bolts.

Be sure to use the nuts (M8 or M10: 3 pcs, 4 locations) and washers

(field supply) from both the top and bottom sides of the hanging

Washer

(Field supply)

Hanging

bracket

Nut

(Field supply)

bracket and make sure they are tightened correctly.

3/8 – 9/16 in.

Nut

(Double nut)

(Field supply)

Suspension bolt

(Field supply)

BS unit

proper

NOTES

• The BS unit has a top and a bottom, so install it so that the diagonal lines in the figure 4 are where the top is.

(Failing to do so may prevent the unit from operating properly and increase the volume of the operating noise.)

English 6

Page 8

3), 7)

3), 7)

(Rotate 180 degrees)

7)

[Before change 5)-1]

(Rotate 180 degrees)

1)

EL. COMPO. BOX lid

6)

2)

1)

4), 6)

Coil cover

4)

2)

2)

EL. COMPO. BOX

Fig. 4

Top Panel

3), 7)

3), 7)

8)

5)-2

(Move the

EL. COMPO. BOX)

9)

9)

8)

EL. COMPO. BOX

Remove the wire from the

wire clip.

[After change 5)-3]

EL. COMPO. BOX

Pass the wire through the

wire clip.

6. REFRIGERANT PIPING WORK

• For instruction for installing piping between the outside unit and BS unit, selecting a refrigerant branch kit,

and installing piping between the refrigerant branch kit and the indoor unit, refer to the installation manual

and equipment design materials included with the outside unit.

• Before beginning the work, always check to make sure the type of refrigerant used is R410A. (The unit will

not operate correctly with a different type of refrigerant.)

• Insulate all of the piping including the liquid pipes, HP/LP gas pipes, suction gas pipes, gas pipes, equalizer

pipes (piping between outside units when an outside multi-unit system), and the pipe connections for these.

Not insulting these pipes could result in water leaks or burns. In particular, suction gas flows in the HP/LP

gas piping during full cooling operation, so the same amount of insulation as used for the suction gas piping

is required. In addition, high-pressure gas flows in the HP/LP gas piping and gas piping, so use insulation

that can withstand more than 250°F.

• Reinforce the insulation material when necessary for the installation environment. Refer to the following as

a guideline.

• For 86°F, RH75% to 80%: Thickness at least 5/8 in.

• For 86°F, over RH80%: Thickness at least 13/16 in.

If not reinforced, condensation could form on the surface of the insulation. For details, refer to the Engineering data book.

NOTES

• This product only uses the new refrigerant (R410A). Be sure to use the special pipe cutters for R410A, dur-

ing installation.

• Make sure that nothing besides the specified refrigerant, such as air, gets into the refrigerant piping.

• If refrigerant gas leaks during the work, ventilate the area. (The outside units are filled with refrigerant.)

6-1 PIPING MATERIAL SELECTION

• Use only pipes which are clean inside and outside and which do not accumulate harmful sulfur, oxidants,

dirt, cutting oils, moisture, or other contamination. (Foreign materials inside pipes including oils for fabrication must be 9 mg/10 ft or less.)

7 English

Page 9

• Use the following items for the refrigerant piping.

Material: Jointless phosphor-deoxidized copper pipe

Size: See “Example of connection” to determine the correct size.

Thickness: Select a thickness for the refrigerant piping which complies with national and local laws.

For R410A, the design pressure is 478 psi.

• For information regarding the piping allowable maximum length, allowable height difference, and allowable

length after a branch, refer to the installation manual that came with the outside unit or Engineering data book.

• The refrigerant branch kit (sold separately) is required for piping branches. For information on how to select a

refrigerant branch kit, refer to the Installation Manual that came with the outside unit or Engineering data book.

6-2 PROTECTION AGAINST CONTAMINATION WHEN INSTALLING PIPES

Protect the piping to prevent moisture, dirt, dust, etc. from entering the piping.

Place Installation period Protection method

Outdoor

Indoor Regardless of the period

More than a month Pinch the pipe

Less than a month

Pinch or tape the pipe

NOTE

Exercise special caution to prevent dirt or dust when passing piping through holes in walls and when passing

pipe edges to the exterior.

6-3 PIPING CONNECTION WORK PRECAUTIONS

• When brazing refrigerant piping, begin working after replacing the nitrogen (*1) or perform brazing while

nitrogen is flowing in the refrigerant piping (*2) (Refer to Fig. 5), and at the end made the indoor unit and

BS unit flare or flange connections.

(*1) For details on nitrogen replacement, see the “VRV Installation Manual” (available at any Daikin dealer).

(*2) The pressure regulator for the nitrogen released when doing the brazing should be set to about

2.9 psi (Enough to feel a slight breeze on your cheek).

Pressure-reducing valve

Part to be brazed

Nitrogen

Refrigerant piping

Fig. 5

Taping

Nitrogen

Valve

NOTES

• Do not use an anti-oxidizing agent when brazing the piping. Residual debris could clog the piping or cause

parts to malfunction.

• Do not use a flux when brazing the refrigerant pipe joints.

Using a chlorine flux may cause the pipes to corrode, and if it contains fluoride it may cause the refrigerant

lubricant to deteriorate, adversely affecting the refrigerant piping system.

Use phosphor copper brazing (B-Cu93P-710/795: ISO 3677) which does not require flux.

6-4 PIPING SIZE SELECTION

From Example of connection 1 and 2 below and Table 1, 2, select the piping size between the outside unit

(refrigerant branch kit) and BS unit, and between the BS unit and the indoor unit (refrigerant branch kit).

English 8

Page 10

Example of connection 1: When 1 indoor unit is connected downstream from the BS unit

Determine using Table 1 based

on the total capacity of the indoor

units connected downstream.

Select from Table 2 depending

on the capacity type of the

indoor unit.

To refrigerant branch

kit or outside unit

<Upstream> <Downstream>

Suction gas pipe

HP/LP gas pipe

Liquid pipe

BS

unit

*

Gas pipe

Liquid pipe

Indoor unit

Example of connection 2: When there is a branch downstream from the BS unit

To refrigerant branch

kit or outside unit

Determine using

on the total capacity of the indoor

units connected downstream.

<Upstream> <Downstream>

Suction gas pipe

HP/LP gas pipe

Liquid pipe

Table 1 based

Gas pipe

BS

unit

Liquid pipe

For information on selecting the size of piping between

the refrigerant branch kits and between a refrigerant

branch kit and the indoor unit, refer to the Installation

Manual that came with the outside unit or Engineering

data book.

Refrigerant branch kit

Indoor unit Indoor unit Indoor unit

Table 1 Indoor unit total capacity and pipe size

Total capacity of indoor units

(Q)

Q < 54 φ3/5 φ1/2

54 ≤ Q < 60 φ3/4 φ5/8 φ3/4

Suction gas pipe HP/LP gas pipe Liquid pipe Gas pipe Liquid pipe

Upstream Downstream

Piping size (outer diameter)

φ3/5

φ3/5

(in.)

φ3/5

Table 2 Indoor unit connection pipe size

(in.)

Capacity type of indoor units

07 · 09 · 12 · 18 φ1/2 φ1/4

24 · 30 · 36 · 48 φ5/8 φ3/8

Gas pipe Liquid pipe

Piping size (outer diameter)

* The BS unit downstream connection pipe sizes are shown below. If the pipe diameter differs from that of the

indoor unit connection pipe size selected from Table 2, follow the instructions in “6-5 PIPING CONNECTION” and use the included pipe to make the connection.

Table 3 BS unit connection pipe size

(in.)

Piping size (outer diameter)

BSVQ36P

BSVQ60P

BS unit

Gas pipe Liquid pipe

φ5/8 φ3/8

9 English

Page 11

6-5 PIPING CONNECTION

Follow the connection example below and connect the site piping.

BSVQ36P type

When the downstream indoor unit total capacity is 36 or less and when one indoor unit with

a capacity of 24 to 36 is connected downstream.

Suction gas pipe (Site piping)

HP/LP gas pipe (Site piping)

Liquid pipe (Site piping)

BS unit

(Top)

Gas pipe (Site piping)

Liquid pipe (Site piping)

When one indoor unit with a capacity of 07 to 18 is connected downstream

Accessory pipes 1)-2

Suction gas pipe (Site piping)

HP/LP gas pipe (Site piping)

Liquid pipe (Site piping)

BS unit

(Top)

Gas pipe (Site piping)

Liquid pipe (Site piping)

Accessory pipes 1)-1

BSVQ60P type

When the downstream indoor unit total capacity is more than 36 but less than 54 and when one

indoor unit with a capacity of 48 is connected downstream.

Suction gas pipe (Site piping)

HP/LP gas pipe (Site piping)

Liquid pipe (Site piping)

BS unit

(Top)

Gas pipe (Site piping)

Liquid pipe (Site piping)

When the downstream indoor unit total capacity is 54 or more but 60 or less

Accessory pipes 1)-2

Suction gas pipe (Site piping)

HP/LP gas pipe (Site piping)

Liquid pipe (Site piping)

Accessory pipes 1)-1

BS unit

(Top)

Accessory pipes 1)-2

Gas pipe (Site piping)

Liquid pipe (Site piping)

6-6 PIPING INSULATION

• After the gas leak inspection is completed, refer to the following figures and use the included insulation tube

3) and clamps 2) to apply the insulation.

NOTES

• Insulate all of the piping including the liquid pipes, HP/LP gas pipes, suction gas pipes, gas pipes, and the

pipe connections for these. Not insulting these pipes could result in water leaks or burns. In particular, suction gas flows in the HP/LP gas pipes during full cooling operation, so the same amount of insulation as

used for the suction gas pipes is required. In addition, high-pressure gas flows in the HP/LP gas pipes and

gas pipes, so use insulation that can withstand more than 250°F.

• When reinforcing the insulation material for the installation environment, also reinforce the insulation on the

piping protruding from the unit and on the pipe connections. Locally purchase the insulation required for the

reinforcement work.

English 10

Page 12

BSVQ36 · 60P type

Insulation tube 3)-3

(Accessory)

Suction gas pipe

(Note 1)

HP/LP gas pipe

(Note 1)

Liquid pipe

Insulation tube 3)-2

(Accessory)

Insulation Attachment Instructions

(1) Attach the included

insulation.

Piping insulation

(Product piping side)

Main unit

(2) Seal (3) Use the clamps (accessory)

Clamp 2) (Accessory)

BS unit

Pipe connection

Piping insulation

(Site piping side)

to hold both ends.

Gas pipe

(Note 1)

Liquid pipe

Insulation tube 3)-1

(Accessory)

Note 1: For suction gas pipes, HP/LP gas

pipes, and gas pipes, after

attaching the included insulation

tube, wrap more insulation (field

supply) around the connections.

Insulation material

(Field supply)

Insulation Installation Precautions

1. Seal so that air cannot be in and out of the end.

2. Do not over tighten the clamp so as to maintain the insulation thickness.

3. Be sure to attach the insulation (field supply) with the seams facing up.

(See figure at right.)

Seam

Attach facing up

7. ELECTRIC WIRING WORK

7-1 GENERAL INSTRUCTIONS

• All wiring must be performed by an authorized electrician.

• All field supplied parts and materials, electric works must conform to local codes.

• Always ground wires. (In accordance with national regulations of the pertinent country.)

• Always turn off the power before performing the electric wire installation work.

• Follow the “WIRING DIAGRAM” attached to the unit body to wire the outside unit and indoor units.

• Properly connect wire of the specified wire type and copper thickness. Also use the included clamp to avoid

applying excessive force to the terminal (field wire, ground wire).

• Do no let the ground wire should come in contact with gas pipes, water pipes, lighting rods, or telephone

ground wires.

• Gas pipes: gas leaks can cause explosions and fire.

• Water pipes: cannot be grounded if hard vinyl pipes are used.

• Telephone ground and lightning rods: the ground potential when struck by lightning gets extremely high.

• A circuit breaker capable of shutting down the power supply to the entire system must be installed.

• This system consists of multiple BS units. Mark each BS unit as unit A, unit B . . . , and be sure the terminal

board wiring to the outside unit and indoor unit are properly matched. If wiring and piping between the outside unit, BS unit and an indoor unit are mismatched, the system may cause a malfunction.

• Do not turn on the power supply (branch switches, overload interrupters) until all other work is done.

11 English

Page 13

7-2 EXAMPLE FOR THE WHOLE SYSTEM

Power supply

Main switch

Power supply

Main switch

BS unit

Indoor unit

Outside unit

Power supply wiring

Transmission wiring

Switch

Fuse

Remote controller

Cooling/Heating selectable indoor unit

Cooling-dedicated

indoor unit

7-3 POWER CIRCUIT, SAFETY DEVICE AND CABLE REQUIREMENTS

• A power circuit (Refer to Table 3) must be provided for connection of the unit. This circuit must be protected

with the required safety devices, i.e. a main switch, a slow blow fuse on each phase and an earth leakage

circuit breaker.

• When using residual current operated circuit breakers, be sure to use a high-speed type (0.1 second or

less) 30mA rated residual operating current.

• Use copper conductors only.

• Use insulated wire for the power cord.

• Select the power supply cable type and size in accordance with relevant local and national regulations.

• Use vinyl cord with sheath or cable (2 wire) of AWG 18-16 for transmission wiring.

Table 3

Units Power supply

Model Type Hz Voltage Min. Max. MCA MFA

BSVQ36P

BSVQ60P

MCA: Min. Circuit Amps (A); MFA: Max. Fuse Amps (A)

NOTES

• The above Table 3 of Electrical Characteristics refers to one BS unit.

• See the Engineering data book for other details.

VJ 60 208~230 187 253 0.1 15

7-4 WIRING EXAMPLE

• Here is shown a wiring example for one system transmission wiring.

• Connect terminals F1 and F2 (TO IN/D UNIT) on the control PCB (A1P) in the outside unit EL. COMPO.

BOX and terminals F1 and F2 (TO OUT/D UNIT) of the control PCB (A1P) of the first BS unit A.

English 12

Page 14

Outside unit

TO IN/D UNIT

TO OUT/D UNIT

F1F2

F1F2

(1)

F1

F2 F1 F2

TO IN/D UNIT

TO OUT/D UNIT

(1)

BS unit A BS unit B Final BS unit

(1) (1)

F1 F2 F1 F2 F1 F2 F1 F2

Absolutely do not

connect the power

supply wiring.

(1) (1) (1)

A

B

C/H SELECTOR

C

ABC ABC ABC

COOL/HEAT

SELECTOR

Cooling/Heating selectable indoor unit

Transmission wiring

Use 2-core wires.

(There is no polarity.)

A

F1 F2 F1 F2 F1 F2 F1 F2

TO IN/D UNIT

TO OUT/D UNIT

B

C/H SELECTOR

C

COOL/HEAT

SELECTOR

COOL/HEAT SELECTOR wiring

Use 3-core wires. (There is polarity.

Match the terminal numbers.)

A

B

(2)(2)(2)

C/H SELECTOR

C

COOL/HEAT

SELECTOR

(1)

TO IN/D UNIT

TO OUT/D UNIT

F1 F2

(1)

F1 F2

Cooling-dedicated

indoor unit

NOTE

1. Connect cooling-dedicated air conditioners to terminals F1 and F2 (TO OUT/D UNIT) of the final BS unit.

2. Use 2-core wire for the transmission wiring. Using a multi-core wire with 3 or more cores when two or more

indoor units are used at once could cause abnormal stoppage. (Only use 3-core wire in the COOL/HEAT

SELECTOR.)

3. Absolutely do not connect the power supply wiring to the transmission wiring terminal block. Doing so

could damage the entire system.

4. For the transmission wiring, use wire that is within the following ranges. Exceeding these limits could

cause a transmission error.

(1) Between an outside unit and BS unit,

Between a BS unit and indoor unit, and

branch

Sub-branching

Between a BS unit and BS unit

Maximum wiring length: 3280 ft or less

Total wiring length: 6560 ft or less

F1 F2 F1F2

F1F2

Branch point max: 16 branch points

(2) Between a BS unit and COOL/HEAT SELECTOR

Maximum wiring length: 1640 ft or less

F1F2

F1F2

7-5 WIRING CONNECTIONS

Remove the EL. COMPO. BOX lid on the side and follow the directions to connect the wires.

〈Transmission wiring〉

Remove the EL. COMPO. BOX lid and connect the wires to F1 and F2 (TO IN/D UNIT) and F1 and F2 (TO

OUT/D UNIT) transmission wiring terminals (control PCB (A1P)).

At this time, pass the wiring into the unit through the wiring through hole (left) and use the included clamps 2)

to securely hold the wires (in 2 places).

〈Power supply wiring and ground wire〉

Remove the EL. COMPO. BOX lid and connect the power supply wiring to

the power terminal block (X1M).

Also connect the ground wire to the ground wire terminal. Pass both the

Ring-type crimp

style terminal

power supply wire and the ground wire together through the wire through

hole (right) and into the EL. COMPO. BOX and use the included clamps 2) to

securely hold the wires (in 2 places).

Be sure to wire the ground wire so that comes out of the slit in the cup washer.

(Not doing so could cause insufficient ground wire contact and causing the wire not to function as a ground.)

Cup washer

Cut out section

13 English

Page 15

Wire

Transmission wiring from the indoor unit

(To the TO IN/D UNIT F1, F2 terminals)

Clamp 2)

(Accessory)

Wiring through hole (left)

Transmission wiring from the outside unit

(To the TO OUT/D UNIT F1, F2 terminals)

Ground terminal Ground wire

A1P

TO IN/D UNIT TO OUT/D UNIT

F1 F2 F1 F2

Terminal block

Power supply wiring

(To the terminal block

L1, L2 terminals)

Wiring through

hole (right)

Wire fitting

Clamp 2)

(Accessory)

Clamp 2)

(Accessory)

NOTES

• Use ring-type crimp style terminal for connections to the

power terminal block. (Refer to Fig. 6)

Also, insulate the crimped area by attaching an insula-

Ring-type crimp

style terminal

Insulation sleeve

Electric wire

tion sleeve, etc.

If these are not available, see the following section.

(a) Wiring of different thicknesses cannot be connected

to the power terminal block.

(A loose connection could cause abnormal heating.)

Connect wires of the

same gauge to both

sides.

Fig. 6

Do not connect

wires of the same

gauge to one side.

Do not connect

wires of different

gauges.

(b) When connecting wire of the same diameter, make

the connection as shown in the figure 7.

• Use an appropriate screwdriver for tightening the terminal screw.

Using a screwdriver that is too small could damage the

screw head and prevent proper tightening.

• Over tightening the terminal screw could damage the

screw.

Refer to the Table 4 for the terminal screw tightening

torque.

• When fastening the wire, use the included clamp 2) so

Table 4

Terminal screw size

(COOL/HEAT SELECTOR/transmission

M3.5

wiring terminal block (A1P))

M4 (Power supply terminal block)

M4 (Ground terminal)

Fig. 7

Tightening torque (ft · lbf)

0.58-0.72

0.87-1.06

1.12-1.37

as not to apply tensile force to the wire connection and then securely fasten the wire. Also, after wiring is

completed, organize the wiring so that the EL. COMPO. BOX lid does not pop up and then properly replace

the EL. COMPO. BOX lid.

Make sure no wires are pinched when replacing the EL. COMPO. BOX lid.

Always use the wire through hole to protect the wires.

• Do not pass the transmission wiring and power supply wiring through the same locations and outside of the

unit keep them separated by at least 2 in..

Not doing so could cause the transmission wiring to pick up electric noise (external noise) and result in a

malfunction or breakdown.

• After the wiring working is complete, use sealer (field supply) to seal closed the wire through hole.

(Entry by small animals, etc., could cause a malfunction.)

English 14

Page 16

8. INITIAL SETTING

• When the refrigerant piping and wire installation work is completed, make the following settings as required.

1. Setting for when connecting the COOL/HEAT SELECTOR to the BS unit.

〈Setting description〉

Set the input signal from the COOL/HEAT SELECTOR (sold separately) to ON/OFF.

〈Setting method〉

Set the dip switches (DS1-1) on PCB (A1P) as shown at left before turning on the power to the BS unit.

Turn on DS1-1.

ON

OFF

DS1-1

ON

OFF

DS1-2

NOTES

This setting is read by the microcomputer when the BS unit power is turned on.

• Be sure to make the setting before turning on the power.

• Always close the EL. COMPO. BOX lid after making the setting.

2. Setting when changing the “Automatic mode differential” in the Cooling/Heating Automatic Operation Mode.

〈Setting description〉

• The “Automatic mode differential” can be changed within the range of 0°F to 12.6°F (0°F at factory ship-

ment).

• For details regarding the “Automatic mode differential” and indoor unit operation, refer to the “Engineering

data book”.

〈Setting method〉

The setting is made using the “Local Setting Mode” by the remote controller of indoor unit connected to the BS unit.

For information regarding the setting method, refer to “Engineering data book”.

The following table gives a list of the “MODE NO.,” “FIRST CODE NO.,” and “SECOND CODE NO.”

NOTES

This setting is operated by the operation remote controller while the indoor unit power is turned on.

• When the indoor unit, outside unit, and BS unit installation work is completed, confirm that it is safe even

with the power turned on before proceeding with the work.

MODE NO. FIRST CODE NO. SECOND CODE NO. Automatic mode differential (°F)

10← At factory shipment.

21.8

33.6

12 (22) 4

45.4

57.2

69.0

7 10.8

8 12.6

9. TEST OPERATION

(1) Check to make sure the EL. COMPO. BOX lid is closed.

(2) Refer to the Installation Manual included with the outside unit and conduct a test run.

• Clicking or humming sounds will continue for about 20 sec immediately after the power is turned on due

to the start of automatic initialization operation (closing) of the solenoid valve, but this is not a problem.

15 English

Page 17

3P194121-3D EM07A062

(0712) HTFS

Loading...

Loading...